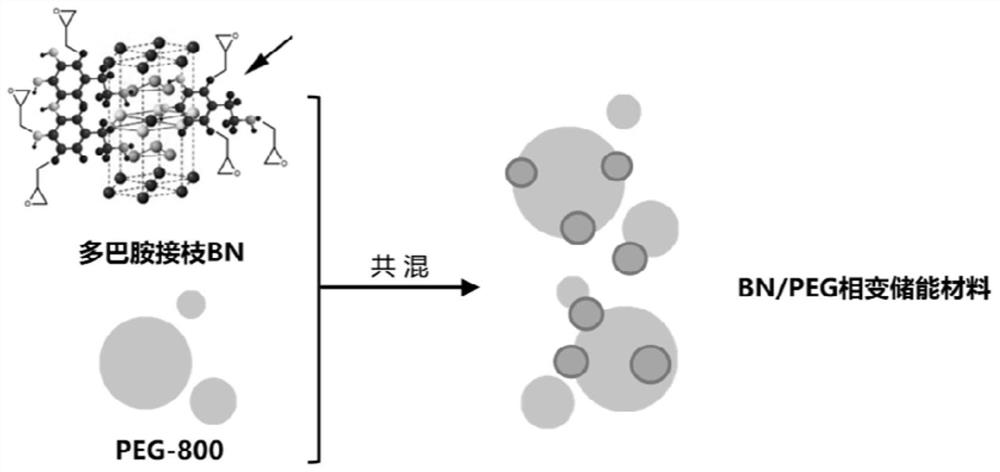

A kind of energy storage wood and semi-interpenetrating network regulation method using boron nitride as filler

A semi-interpenetrating network and boron nitride technology, applied in wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of poor encapsulation and low thermal conductivity, and achieve improved service life, mild reaction conditions, and short preparation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An energy storage wood and semi-interweepating network regulation method based on boron nitride as a filler, including the following steps:

[0024] (1) Decoche wood: Pick fast-growing poplar, select the mature sideworthy of the chest higher, with a specific standard for 20mm × width 20mm × thick 20mm, no cracking, decaying and discoloration. After weighing, the wood test piece is placed in deionized water (-0.1MPa, 1h), and the internal air is discharged.

[0025] (2) Organic solvent: 1 Pharained glycerol ester by the oxidal acrylate is passed to the cylinder, and the methacrylate of methacrylate 2 is mixed with 40 ml of methacrylate and 20 ml of polyethylene glycol 400 to obtain a mixture. , Then 30 ml of toluene and 1 g of triethylamine, mix well, poured into three bottles with stirring devices and reflow devices; 3 will be placed in an oil bath with stirring devices and reflow devices in 80 to 90 ° C In the middle, nitrogen gas is simultaneously introduced, stirred back...

Embodiment 2

[0030] An energy storage wood and semi-interweepating network regulation method based on boron nitride as a filler, including the following steps:

[0031] (1) Decocin wood: Picking the fir, select the mature sideworthy of the chest higher, with a length of 40 mm × width 40mm × thick 20mm, no cracking, decaying and discoloration. After weighing, the wood test piece is placed in deionized water (-0.1MPa, 1h), and the internal air is discharged.

[0032] (2) Organic solvent: 1 Methyl methacrylate is passed through the oxidation pan, which is purified to methacrylate 2 to mix 20 ml of methacrylate and 10 ml of polyethylene glycol 400 to obtain a mixture. , Then add 15 ml of toluene and 0.5 g of triethylamine, mix evenly, poured into three bottles with stirring devices and reflow devices; 3 will be placed in an oil bath with a stirred device and reflow device at 80 to 90 ° C In the pot, nitrogen gas is simultaneously introduced, stirred back, and the solution A is added to the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com