Supported ionic liquid catalyst and preparation method and application thereof

An ionic liquid and catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc. Selectivity and other issues, to achieve the effect of good mass transfer and heat transfer, firm connection, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

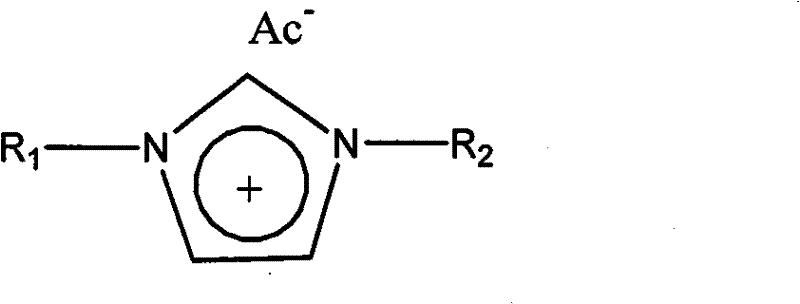

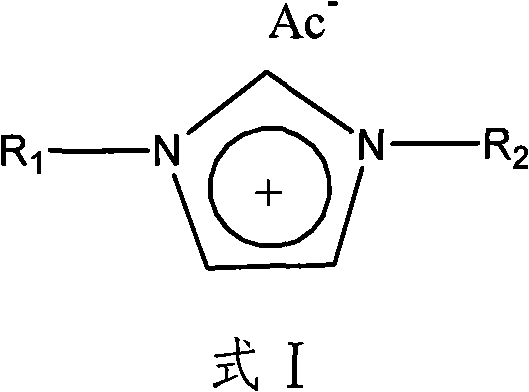

[0041]1) Preparation of imidazole acetate ionic liquid: Add 3.05g (0.025mol) ethyl chloroacetate and 2.7g (0.025mol) allyl imidazole to 50mL acetone, and stir the reaction for 24h at 25°C. Suction filtration, washing with acetone, and vacuum drying at a temperature of 80° C. to obtain 5.1 g (0.022 mol) of ethyl allyl acetate imidazole hydrochloride ionic liquid was used for future use. Dissolve 7.7g (0.1mol) of ammonium acetate in 100mL of glacial acetic acid, add the above hydrochloride ionic liquid, react at 30°C for 24h, filter with suction, wash with acetone, and vacuum dry at 80°C to obtain 4.5g ( 0.02mol) allyl ethyl acetate imidazole acetate ionic liquid.

[0042] 2) Preparation of mesoporous molecular sieves: Add 2g triblock copolymer P123 (Aloririch, template agent) and 4.4g (0.6mol) KCl to 130mL 2mol / L hydrochloric acid, stir until transparent, add 10mL tetraethyl orthosilicate (silicon source), after ultrasonication at 30°C for 10min, move it into a hydrothermal ke...

Embodiment 2

[0047] Replace 3.05g ethyl chloroacetate with 2g (0.025mol) chloroethanol, other reactant weight, reaction condition are identical with embodiment 1, make 7.6g supported ionic liquid catalyst.

Embodiment 3

[0049] Mesoporous molecular sieve MCM-48 was used instead of mesoporous molecular sieve SBA-15, and the weight of other reactants and reaction conditions were the same as in Example 1 to prepare 8.4 g of supported ionic liquid catalyst.

[0050] The preparation method of mesoporous molecular sieve MCM-48 is: in 170mL deionized water, add 9.6g (0.026mol) cetyltrimethylammonium bromide (CTAB, template agent, Beijing Chemical Reagent Company), 200mL absolute ethanol and 80mL of ammonia water (25%), stirred for 10min, then added dropwise 11.7mL of tetraethyl orthosilicate (silicon source) to react for 4h, then used a Soxhlet extractor to extract CTAB with ethanol for 24h, then filtered, dried, and calcined at 300°C for 4h. 3 g (0.048 mol) of mesoporous molecular sieve MCM-48 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com