Patents

Literature

120 results about "Ethyl chloroacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl chloroacetate is a chemical compound used primarily in the chemical industry. It is used as a solvent for organic synthesis and as an intermediate in the production of pesticides (such as sodium fluoroacetate).

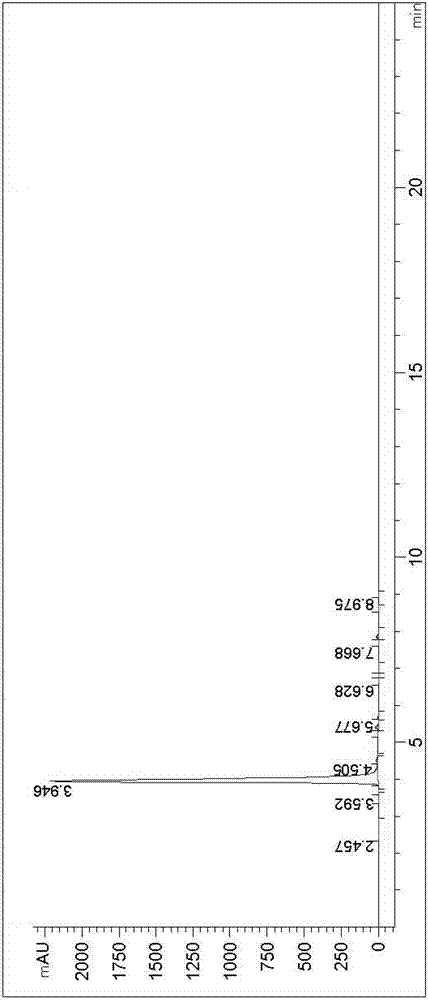

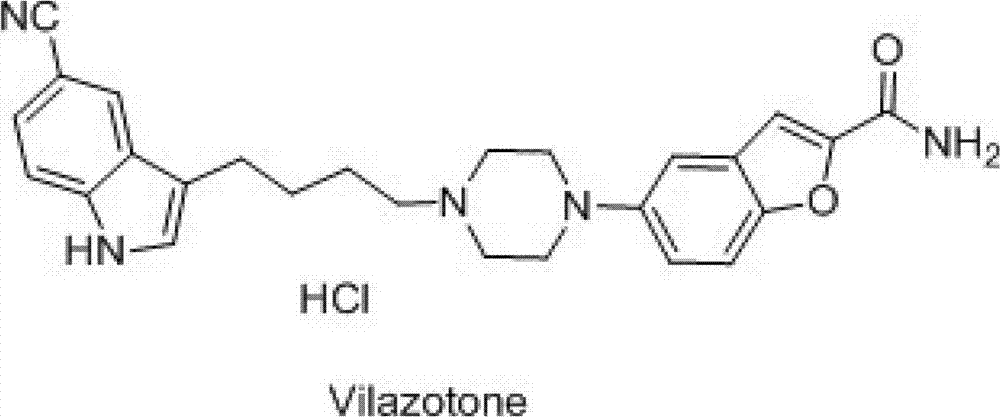

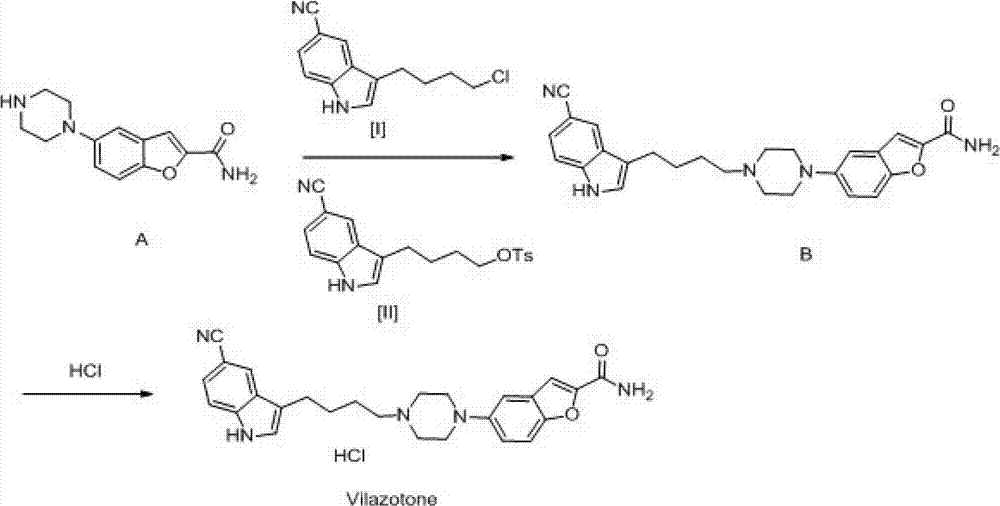

Synthesis method of 5-(piperazino-1-yl)benzofuryl-2-formamide

ActiveCN102964323ASolve environmental problemsLow costOrganic chemistryBulk chemical productionSynthesis methodsStructural formula

The invention relates to a synthesis method of a vilazodone hydrochloride intermediate 5-(piperazino-1-yl)benzofuryl-2-formamide, belonging to the technical field of medicine synthesis. The synthesis method comprises the following steps: reacting a compound disclosed as Formula (I) with polyformaldehyde under reflux for 3-10 hours, carrying out cyclization reaction with ethyl chloroacetate at 80-120 DEG C for 3-24 hours, dissolving in alcohol, introducing ammonia gas, and reacting at 10-80 DEG C under the pressure of 0.1-2.0 Mpa for 3-24 hours to obtain a compound disclosed as Formula (IV), wherein the structural formulae of the Formula (I) and Formula (IV) are disclosed in the specification: when R is H, the compound disclosed as Formula (IV) is the product 5-(piperazino-1-yl)benzofuryl-2-formamide, and when R is a nitrogen protecting group, the protecting group can be removed to obtain the target product 5-(piperazino-1-yl)benzofuryl-2-formamide. The synthesis method has the advantages of low cost, short production procedure, high product yield and purity, and good product quality.

Owner:SUZHOU UUGENE BIOPHARMA

Method for preparing 9-oxo-10(9H)-acridineacetic acid

ActiveCN103396362ASmooth responseResponse is smooth and easy to controlOrganic chemistryBenzoic acidPtru catalyst

The invention discloses a method for preparing 9-oxo-10(9H)-acridineacetic acid, and belongs to the field of organic synthesis. The method comprises the following steps: (1) under the effects of a metal carbonate, a catalyst and a solvent, performing a condensation reaction on o-chlorobenzoic acid (a) and aniline (b) to prepare an intermediate c; (2) under the effects of toluene and p-toluenesulfonic acid, performing a cyclization reaction on the intermediate c by refluxing and dehydrating to prepare an intermediate d; (3) dissolving the intermediate d in dimethyl formamide , successively adding 60% NaH, KI and ethyl chloroacetate, reacting at room temperature to obtain a wet intermediate e; and (4) hydrolyzing the wet intermediate d with NaOH to obtain a crude product f, and refining the crude product f to obtain the 9-oxo-10(9H)-acridineacetic acid product. The method has the advantages of low cost consumption, small pollution during reaction, smooth and easy-controlling reaction and high product yield, and has better industrial application value.

Owner:ZHENGZHOU SIGMA CHEM

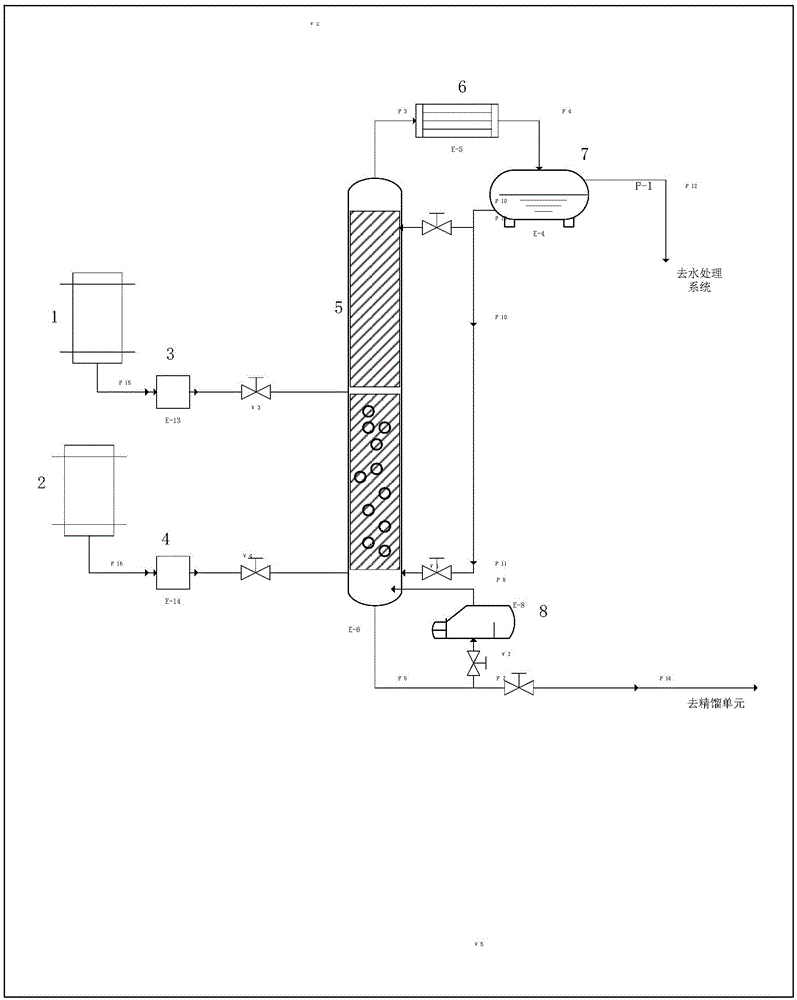

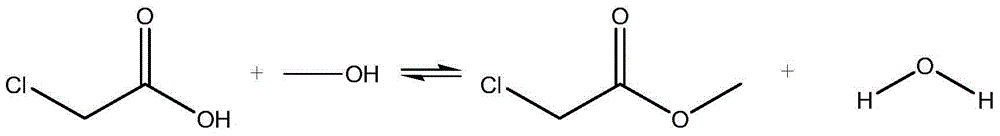

Reactive distillation method for preparing methyl chloroacetate

InactiveCN104592021AReduce dosageNo secondary pollutionOrganic compound preparationChemical industryTriflic acidReaction temperature

The invention relates to a new method for preparing methyl chloroacetate. The method is characterized in that chloroacetic acid and methanol are used as raw materials, a reactive distillation tower is adopted, and a pyridine trifluoromethanesulfonic acid polymeric ion liquid catalyst is used as mixed filler in a reaction section to perform gas-liquid-solid three-phase reaction. The reaction can be finished by adopting a one-section reactive distillation reactor, a water carrying agent does not need to be added in the process, the reaction temperature is low, the flow is simple, the investment cost is reduced, the energy consumption is low, the conversion rate is more than 99.5%, and the selectivity is 100%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Magnetic organic fertilizer containing sodium alginate and with excellent moisture-preservation and fertilizer-conservation performance and preparation method thereof

InactiveCN107337504APromote formationGood water solubilityMagnesium fertilisersAlkali orthophosphate fertiliserINCREASED EFFECTMoisture

Disclosed is magnetic organic fertilizer containing sodium alginate and with excellent moisture-preservation and fertilizer-conservation performance. The fertilizer is characterized in that firstly, a neutral mixed solution with sodium hydroxide, hydroxylammonium chloride and isopropyl alcohol is prepared; secondly, active hydroxyl in the sodium alginate reacts with ethyl chloroacetate to modify the sodium alginate; thirdly, magnetic particles are prepared, and ternary grafting is conducted on the magnetic particles with the sodium alginate, acrylic acid and starch; finally, the magnetic organic fertilizer containing the sodium alginate and with the excellent moisture-preservation and fertilizer-conservation performance is obtained through mixing and granulation. The organic fertilizer is excellent in moisture-preservation and fertilizer-conservation performance, comprehensive in nutrition and magnetic, the magnetism can increase the utilization rate of nutrients to achieve a significant yield-increasing effect, and the organic fertilizer is suitable for crops such as grains, vegetables, fruit and grass.

Owner:安徽奥利休闲农业发展有限公司

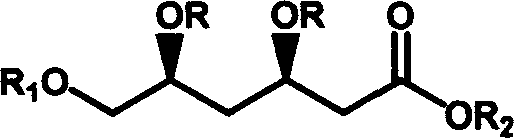

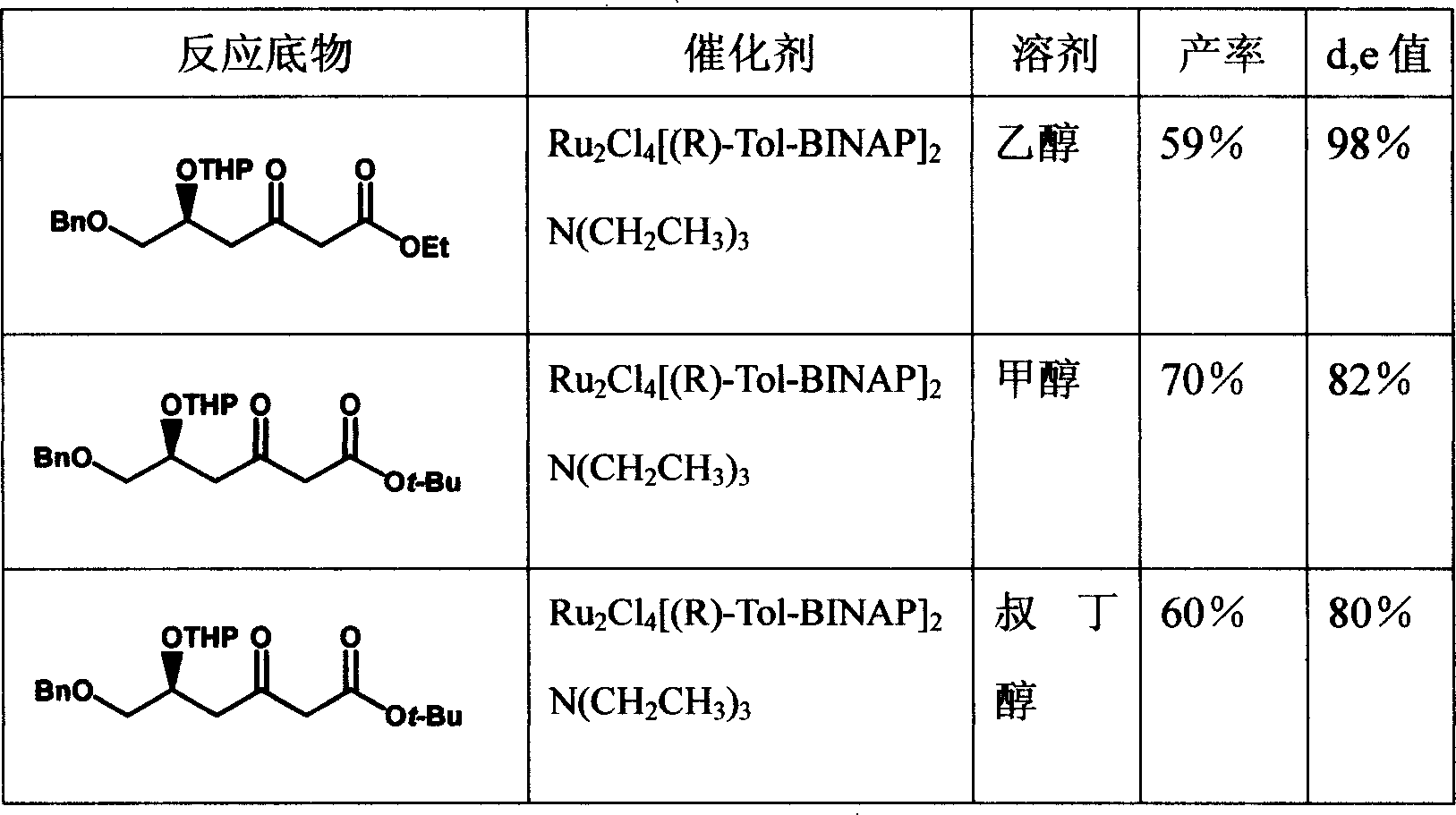

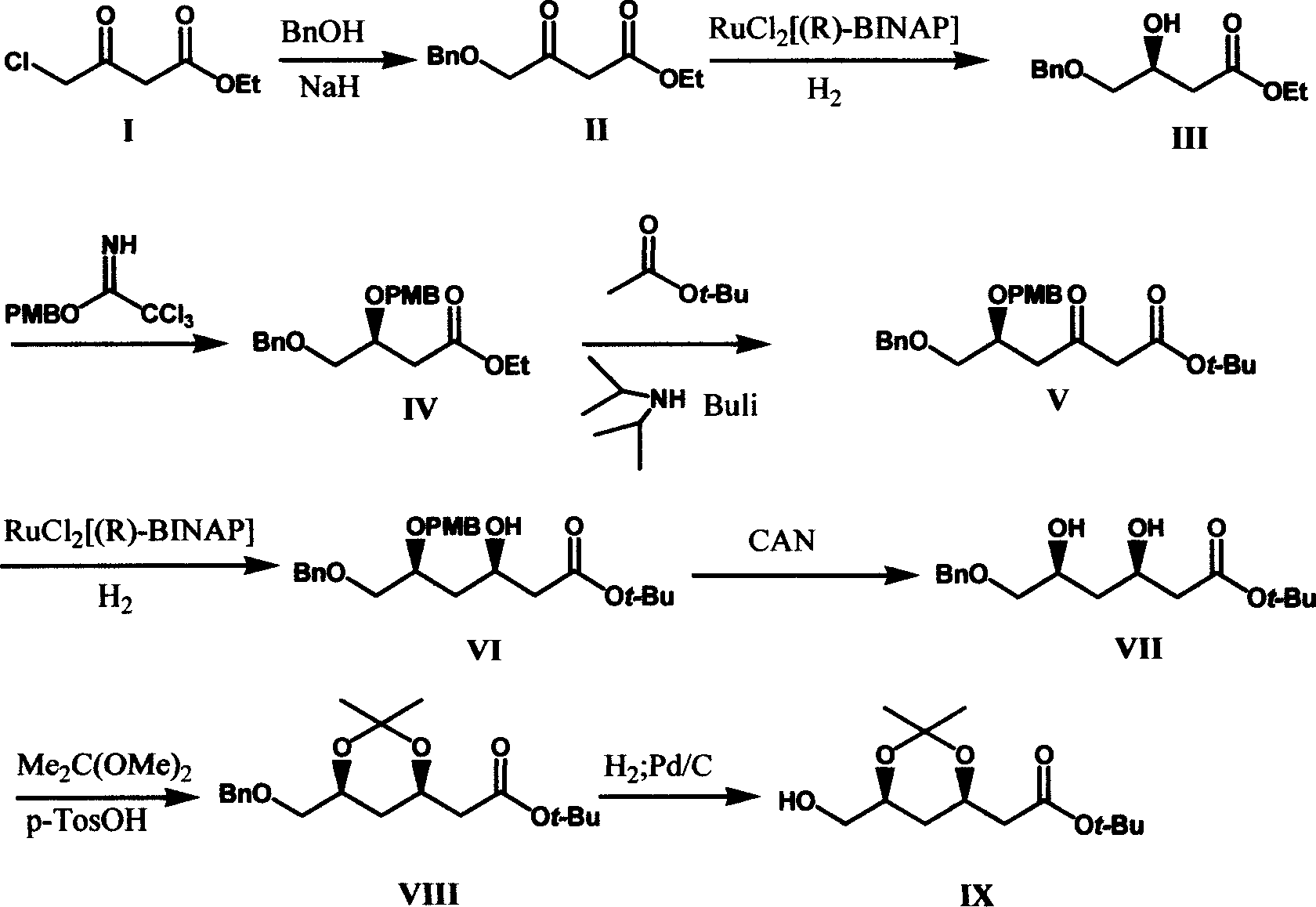

Method for preparing t-butyl (3R, 5S)-3,5,6-trihydroxy-hexanoate

The invention relates to a method for preparing (3R, 5S) - 3, 5, 6- trihydroxy- butylacetic acic tertbutyl ester, belonging to medical intermediate preparation technique. It comprises following steps: taking ethyl chloroacetate as raw material, oxides it with benzyl, catalyzing and hydrogenizing with RuCl2[(R)-BINAP] and getting(3S)- 3- hydroxy- 4- benzyloxy butyl acetate, employing methoxy benzyl to protect hydroxy, carryingout condensation reaction with Claisen ester to increase carbon chain, catalyzing and hydrogenizing the carbonyl at No. 3 carbon with RuCl2[(R)-BINAP] and getting (3R, 5S)- 5- p-methoxy benzyloxy- 6- benzyloxy- 3- hydroxy- butylacetic acic tertbutyl ester; removing p-methoxy benzyloxy with ammonium cerous nitrate, protecting with acetone, removing benzyl and getting (3R, 5S)- 6- hydroxy- 3, 5- 0- isopropylidene- 3, 5- dihydroxy butylacetic acic tertbutyl ester. The total productivity is 39.5%, d, e value is 99%. The cost is low and it is easy to industrialization.

Owner:SHANGHAI QINGSONG PHARMA

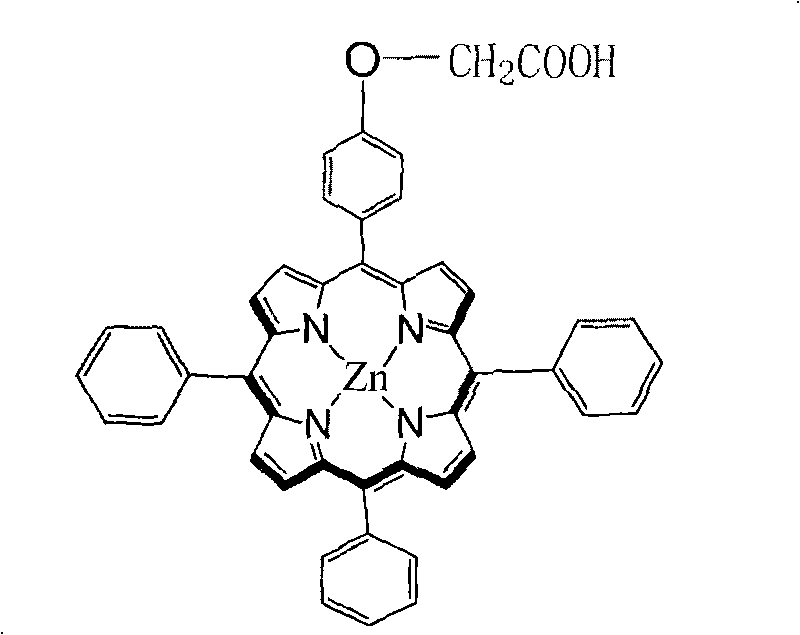

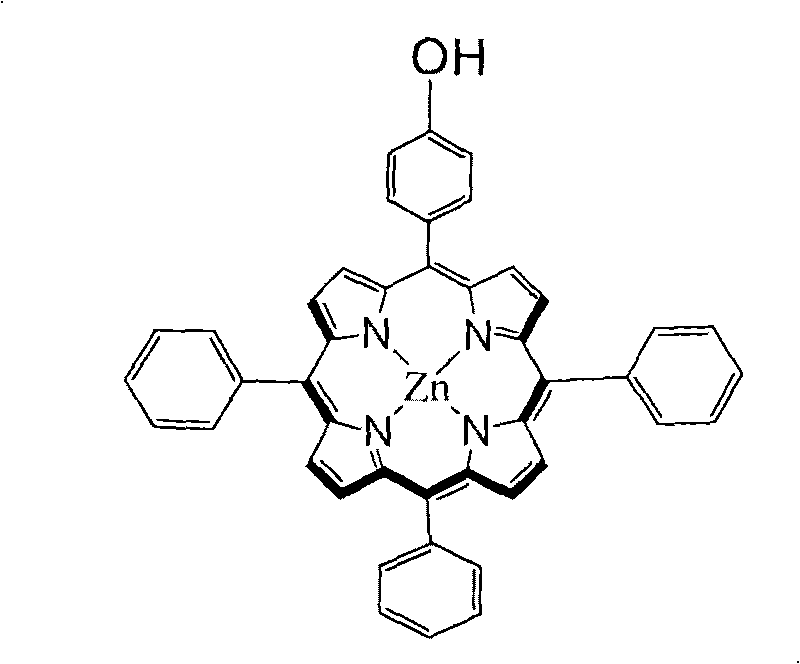

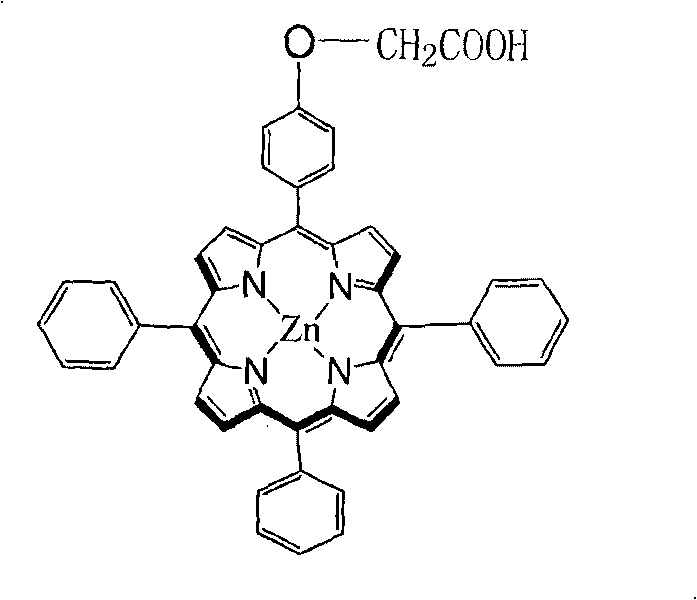

5-(4-phenoxyacetic acid)-10,15,20-triphenyl zinc porphyrin and preparation method thereof

The invention provides a novel water-insoluble porphyrin, namely 5-(4-phenoxyacetic acid)-10,15,20-triphenyl zinc porphyrin. The water-insoluble porphyrin is obtained by adopting 5-(4-hydroxyphenyl)-10,15,20-triphenyl zinc porphyrin as a raw material through coordination with zinc acetate, ethyl chloroacetate substitution reaction and acid neutralization reaction. Because the hydroxyl in the 5-(4-phenoxyacetic acid)-10,15,20-triphenyl zinc porphyrin is converted into soluble carboxyl, the 5-(4-phenoxyacetic acid)-10,15,20-triphenyl zinc porphyrin can be dissolved into water to a certain extent and particularly has favorable dissolubility under the alkaline condition. Compared with the hydroxyl, the carboxyl is better qualified for a task of electronic transmission, and the invention provides a good platform for further researching a photoelectronic functional material.

Owner:NORTHWEST NORMAL UNIVERSITY

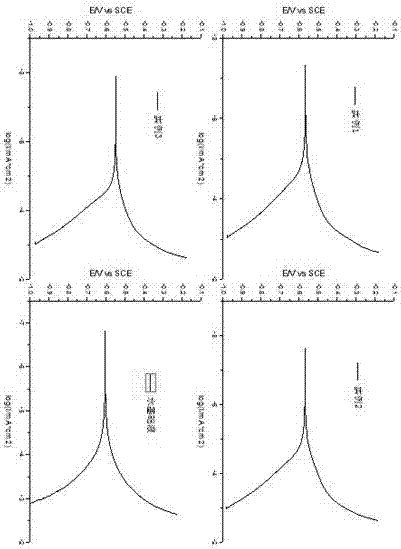

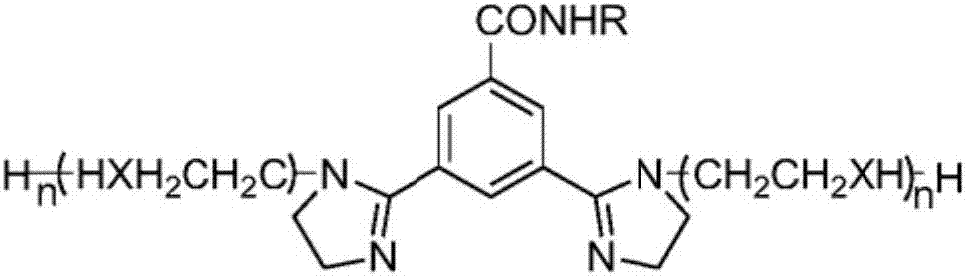

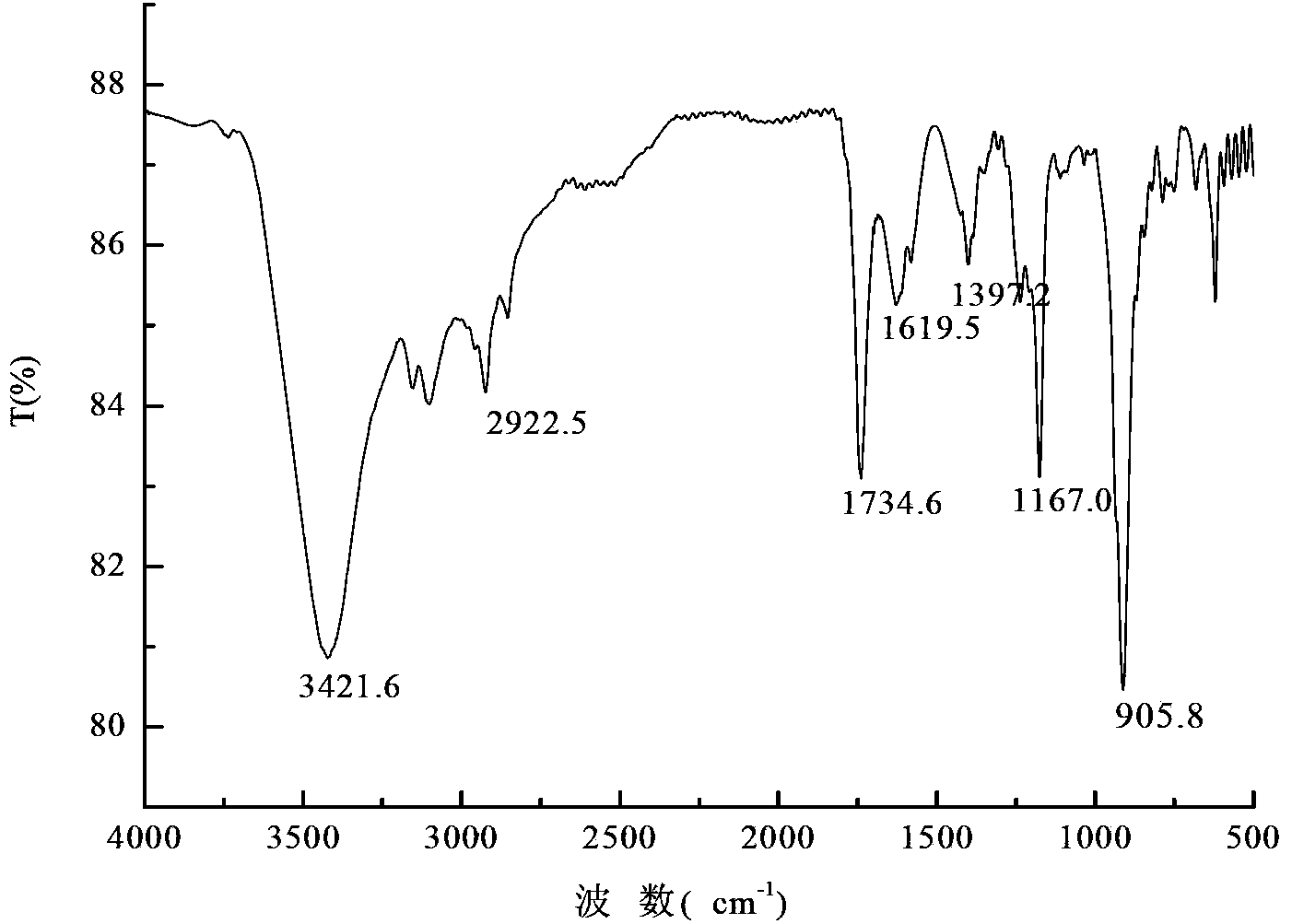

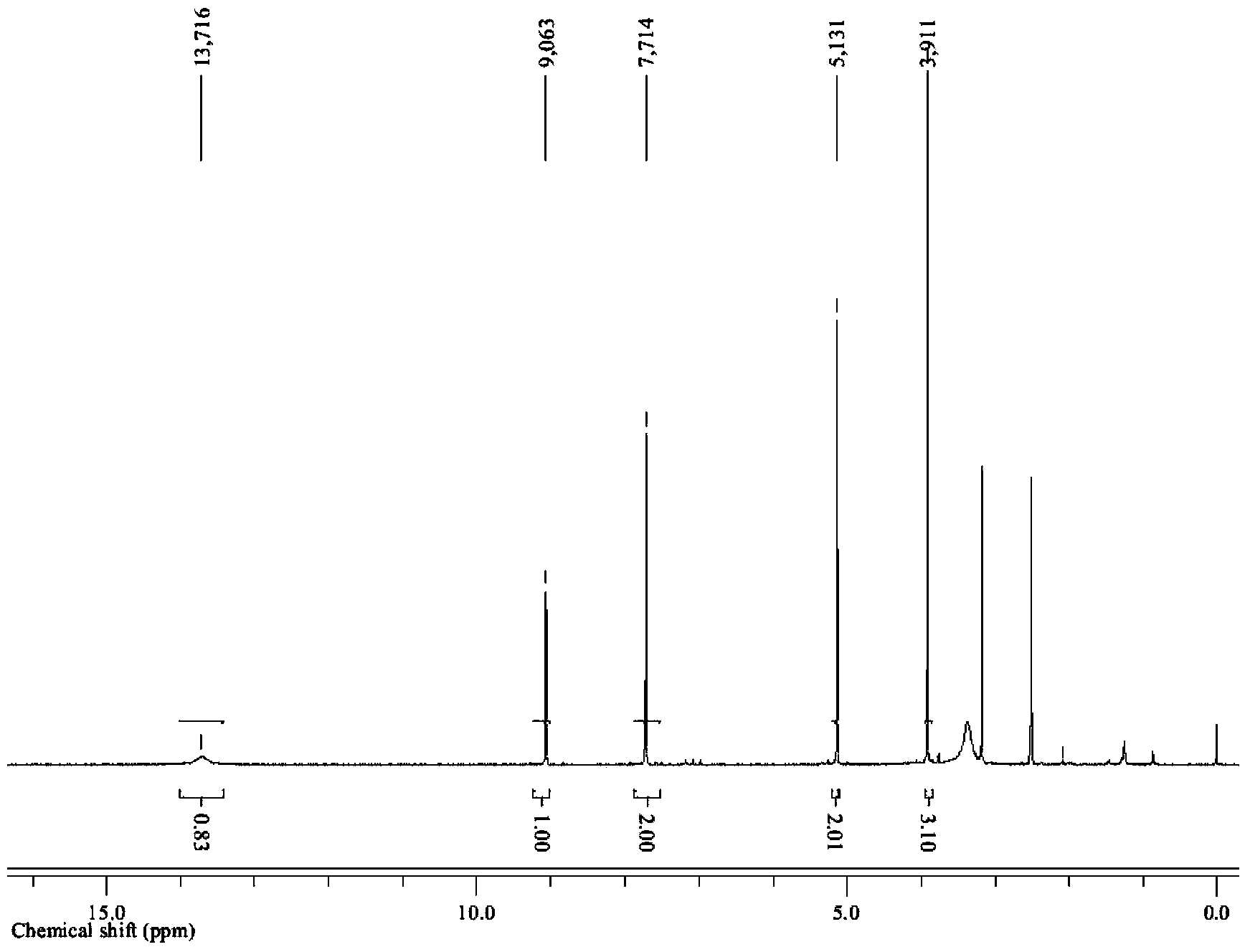

Benzotriazole imidazoline derivative, and preparation method and application thereof

InactiveCN107253945AHigh yieldReaction conditions are easy to controlOrganic chemistryAdditivesSodium chloroacetateDiethylenetriamine

The invention discloses an imidazoline group-containing benzotriazole derivative, and a synthesis process and application thereof. The synthesis process comprises the following steps: taking benzotriazole as a raw material, and reacting with sodium monochloroacetate / ethyl chloroacetate / ethyl bromoacetate (wherein the reacting yield of the sodium monochloroacetate is highest) to form benzotriazole acetic acid, and performing dehydration and cyclization reaction with diethylenetriamine / triethylenetetramine / tetraethylenepentamine to generate the benzotriazole imidazoline derivative. The reaction conditions are easy to control; and the yield is high. The benzotriazole imidazoline derivative has a good corrosion inhibiting effect on YG8 hard alloy and Q235 low-carbon steel in an acidic water environment.

Owner:EAST CHINA JIAOTONG UNIVERSITY

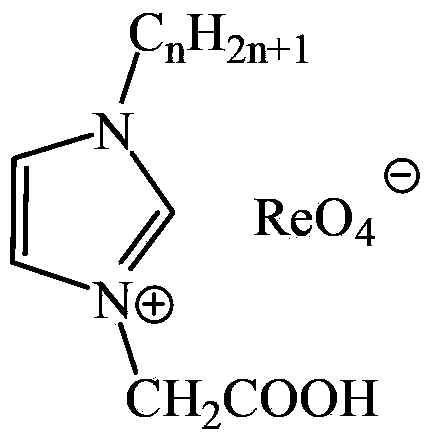

Novel carboxylic acid functional rhenium iron liquid and preparation method and application thereof

ActiveCN103467384ADoes not affect other quality indicatorsSimple processOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsRheniumOil phase

The invention relates to novel carboxylic acid functional rhenium iron liquid and a preparation method and application thereof. The preparation method of the ion liquid comprises the following steps: carrying out reaction between alkyl imidazole and ethyl chloroacetate to generate an ion liquid intermediate, acidifying the ion liquid intermediate by concentrated hydrochloric acid to decompose ester into carboxylic acid, and reacting the acidified ion liquid intermediate with silver perrhenate to obtain a product. The rhenium iron liquid is used for FCC gasoline oxidative desulfurization, the detected sulfur content of the oil phase is lower than 100ppm, and meanwhile, other performance indexes of the oil product do not significantly change, and the Euro V standard is reached basically.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

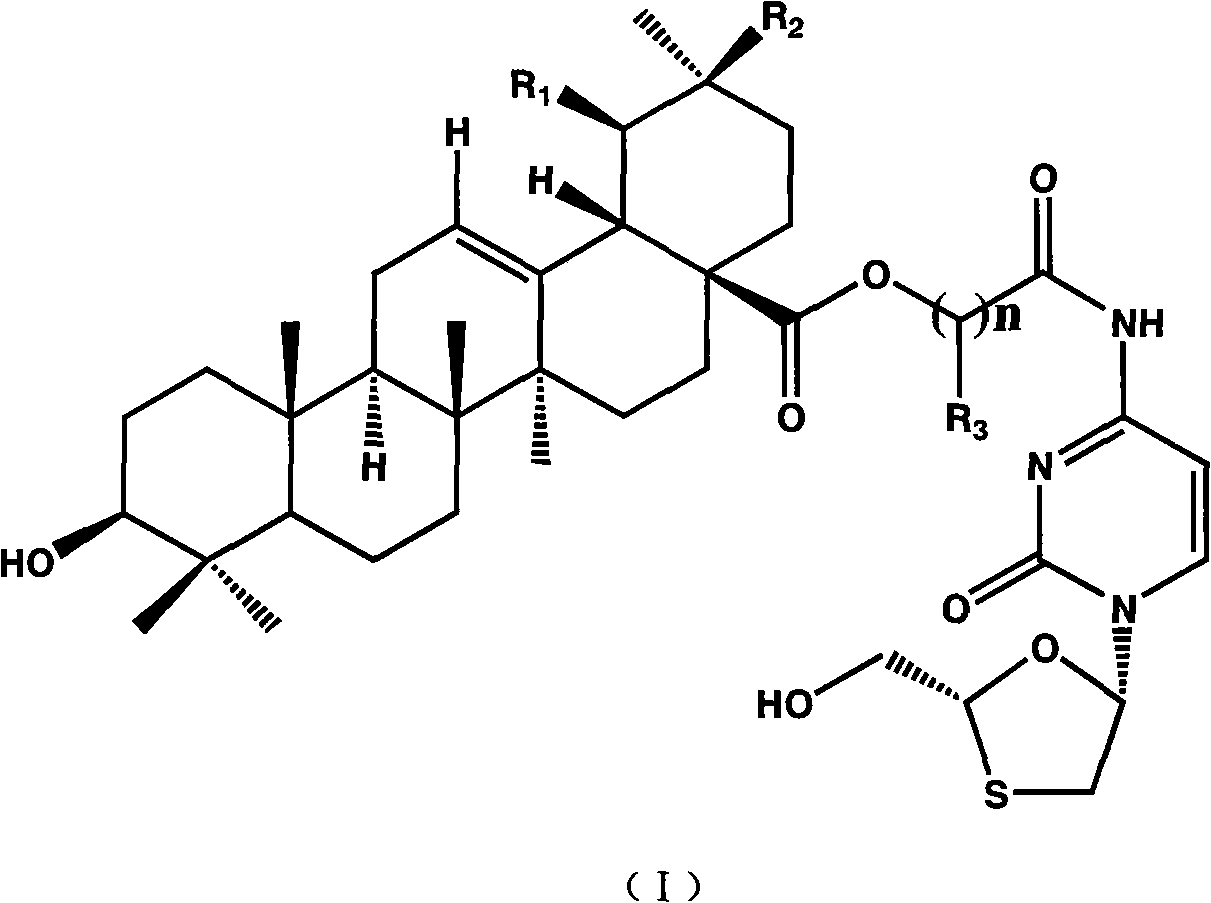

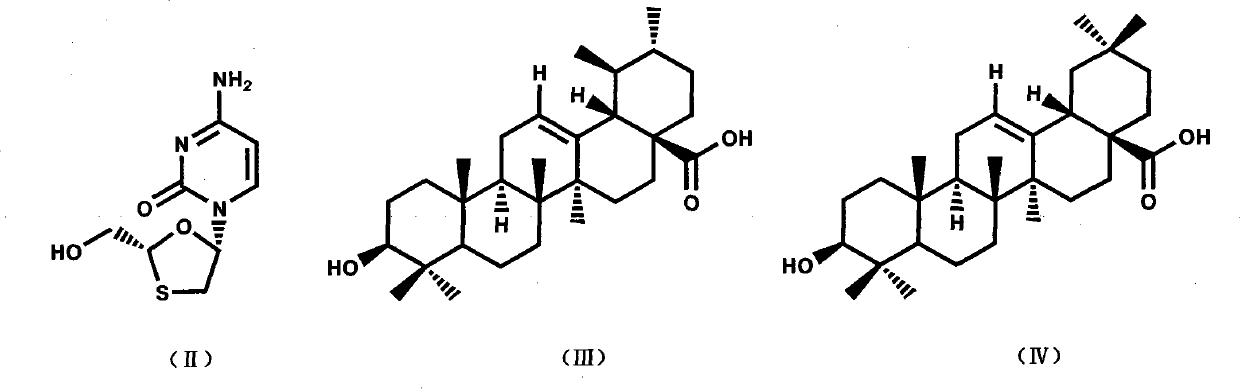

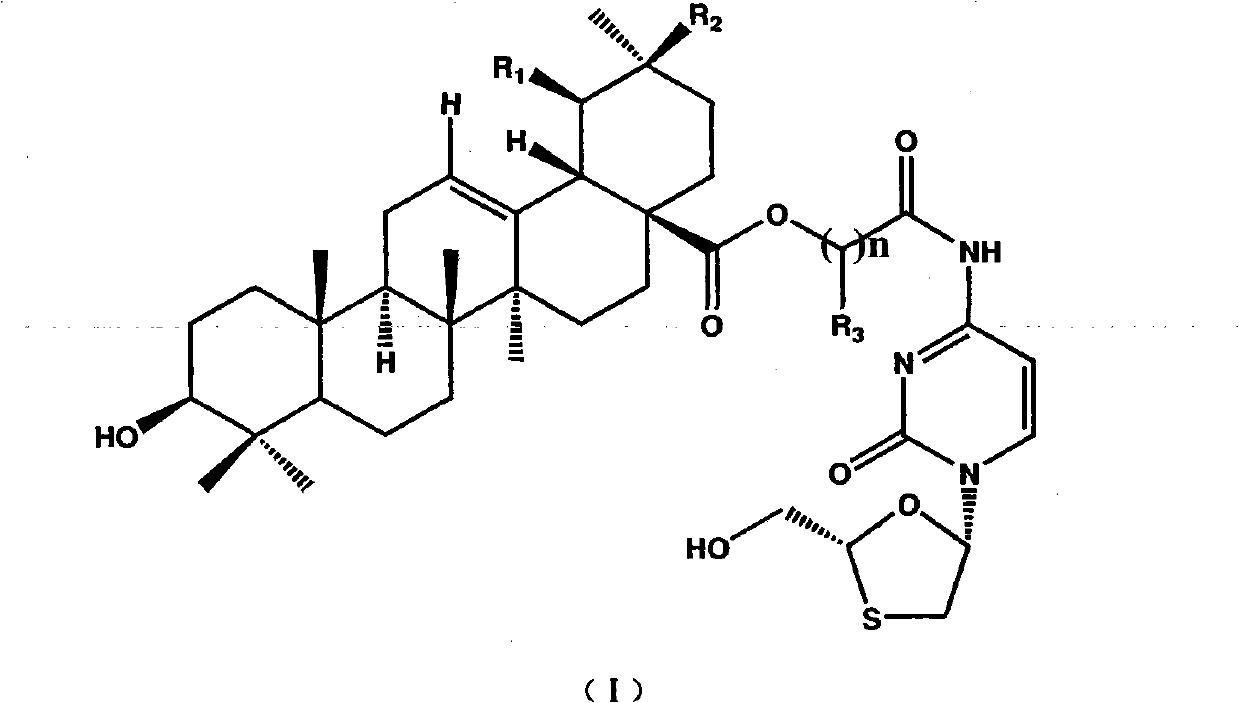

Preparation method and applications of lamivudine twin drug

InactiveCN101766632AHas antiviral effectImprove liver functionOrganic active ingredientsDigestive systemHepatic inflammationPropanoic acid

The invention provides a preparation method and applications of a lamivudine twin drug. Lamivudine, and ursolic acid or oleanolic acid are condensed into the lamivudine-ursolic acid or lamivudine-oleanolic acid twin drug at a low temperature by using ethyl chloroacetate (ethyl bromoacetate) or ethyl chloropropionate (ethyl bromopropionate) as the linking group. The twin drug possibly has a dual-action mechanism; and the twin drug has the action of antivirus, and also has the actions of resisting inflammations, protecting the liver cell membranes, improving the liver function and resisting fibrosis. Thus, the invention organically combines the antivirus therapy and the liver protection treatment and provides a new concept for the research and development of drugs for treating hepatitis.

Owner:CHINA PHARM UNIV

Biodegradable composite coating material for slow-release fertilizer and preparation method of coating material

InactiveCN107235767AGood water solubilityStrong ability to retain water and fertilizerLayered/coated fertilisersFertilizer mixturesCelluloseHydroxylamine Hydrochloride

The invention discloses a biodegradable composite coating material for a slow-release fertilizer. The biodegradable composite coating material is characterized in that firstly, neutral sodium hydroxide-hydroxylamine hydrochloride-isopropyl alcohol mixed liquid is prepared; secondly, active hydroxyl in sodium alga acid and ethyl chloroacetate react, and the sodium alga acid is modified; thirdly, the modified sodium alga acid, cellulose and octenyl succinic anhydride react; finally, the reactant and acrylic emulsion are compounded, and bentonite is filled to prepare the biodegradable composite coating material for the slow-release fertilizer. According to the composite coating material, the sodium alga acid, the cellulose and the acrylic emulsion serving as a main body of the material are nontoxic, the biodegradable material is low in cost and simple in preparation method, industrial production of the materials is easily achieved, and production and application of the material are environmentally friendly.

Owner:安徽奥利休闲农业发展有限公司

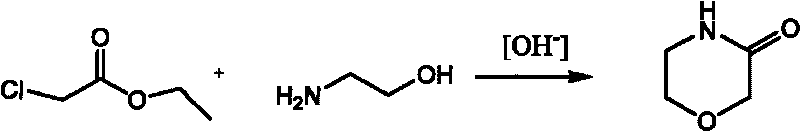

Preparation method of 3-morpholone

InactiveCN101735165ARaw materials are easy to getReduce contentOrganic chemistryOrganic solventNitrogen

The invention provides a preparation method of 3-morpholone, which comprises the steps of: firstly, under the protection of nitrogen, cooling ethanolamine and organic solvent or a mixed solvent to below 0--10 DEG C under the action of alkali or mixed alkali, dropwise adding ethyl chloroacetate, controlling the temperature below 0--6 DEG C; and secondly, raising the temperature to 30-80 DEG C, stirring for 0.2-2h, filtering, washing solid with a solvent, merging mother solutions, evaporating to remove the solvent, and recrystallizing to obtain the pure product of the 3-morpholone. The preparation method has the characteristics of easy obtaining of raw materials, simple process, low cost, high product purity, low content of side products and the like. The yield of the 3-morpholone is 20-80 percent. The invention is suitable for large-scale industrialized production.

Owner:SUZHOU TIANMA SPECIALTY CHEM

Method for preparing betaine hydrochloride

ActiveCN102267918AMild reaction conditionsSimple processOrganic compound preparationAmino-carboxyl compound preparationMeth-Ethyl group

The invention belongs to the technical field of feed additive and relates to a method for preparing betaine hydrochloride, which comprises the following steps: a, adding ethyl chloroacetate and methanol or isopropanol into the reactor, stirring uniformly and cooling the mixture; b, introducing trimethylamine anhydrous gas into the mixture, fully stirring after the trimethylamine anhydrous gas is introduced completely, filtering, recrystallizing collected solid product, drying under vacuum and obtaining 2-ethoxy-2-oxa-N,N,N-trimethyl-ethylammonium chloride; and c, adding 2-ethoxy-2-oxa-N,N,N-trimethyl-ethylammonium chloride and diluted hydrochloric acid into the reactor to obtain mixed solution, heating, reacting with stirring, distilling after reaction, filtering, drying collected solid product under vacuum, and thus, obtaining the refined betaine hydrochloride. In the invention, the reactions in the steps are normal operation, the safety of production is ensured, the need of using expensive raw material is obviated, the production cost is reduced, the final product does not contain sodium chloride, and the requirements of some special fields are met.

Owner:杭州海尔希畜牧科技有限公司

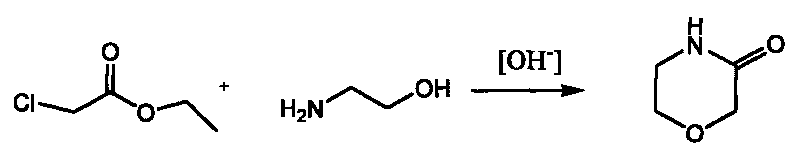

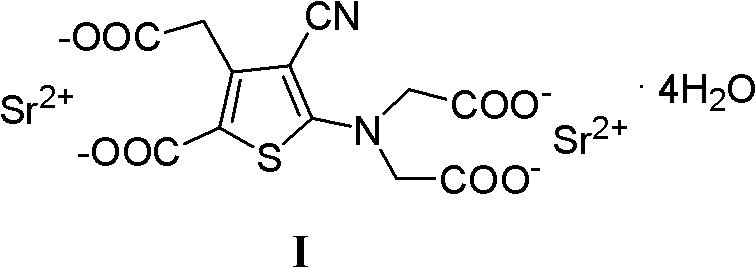

Preparation method of strontium ranelate

The invention relates to the field of pharmaceutical synthesis, in particular to a preparation method of strontium ranelate, which includes the following steps: reacting 5-amino-4-cyan-3-carbethoxy methyl-thiophene-2-carboxylic acid ethyl ester with a bifunctional alkylating agent in the presence of a catalyst to generate 5-[2-(carbomethoxy)amino]-4-cyan-3-carbethoxy methyl-thiophene-2-carboxylicacid ethyl ester, and then adding strontium chloride aqueous solution after hydrolysis of III in sodium hydroxide aqueous solution for salifying, thus obtaining the strontium ranelate. The preparation method is characterized in that the catalyst is polyethylene glycol, and the bifunctional alkylating agent is methyl chloroacetate or ethyl chloroacetate. In the preparation method, the low-price and environment-friendly catalyst and bifunctional alkylating agent are adopted, so as to be beneficial to industrial production.

Owner:CHINA PHARM UNIV +1

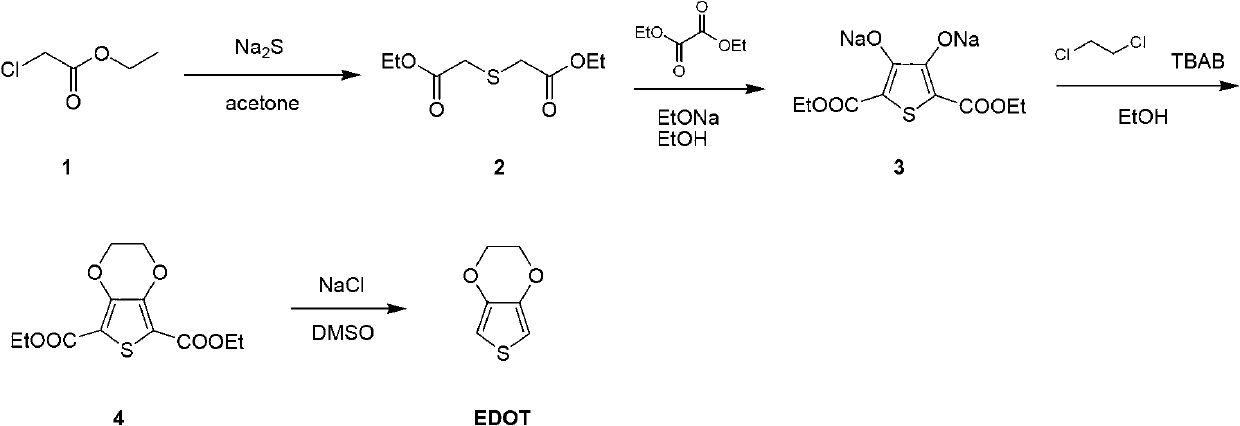

Method for preparing polymer monomer 3,4-ethylenedioxythiophene

ActiveCN102775423AShort routeShorten the production cycleOrganic chemistryPolymer scienceEthylenedioxy

The invention relates to a method for preparing polymer monomer 3,4-ethylenedioxythiophene. The method includes firstly dissolving ethyl chloroacetate and sodium sulphide in acetone to react to obtain diethyl thioglycolate; secondly, dissolving the diethyl thioglycolate to ethanol, adding sodium ethoxide and diethyl oxalate into the ethanol, heating and reflowing to obtain ethanol solution of 2,5-dioctyl phthalate ethyl ester-3,4-thiophene glycol sodium; thirdly, adding dichloroethane and tetrabutylammonium bromide into the ethanol solution of the 2,5-dioctyl phthalate ethyl ester-3,4-thiophene glycol sodium, heating and reflowing to obtain 3,4-ethylenedioxy-2,5-dioctyl phthalate ethyl ester thiophene; fourthly, dissolving the 3,4-ethylenedioxy-2,5-dioctyl phthalate ethyl ester thiophene in mixed solvent, adding sodium chloride, heating and reacting, and finally reducing pressure and rectifying. The method for preparing polymer monomer 3,4-ethylenedioxythiophene is few in procedures, low in cost, safe and reliable in technique, simple and fast in post-treatment method, and products are high in yield and purity.

Owner:TAISHAN MEDICAL UNIV

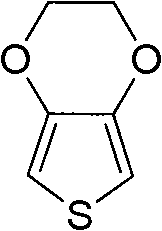

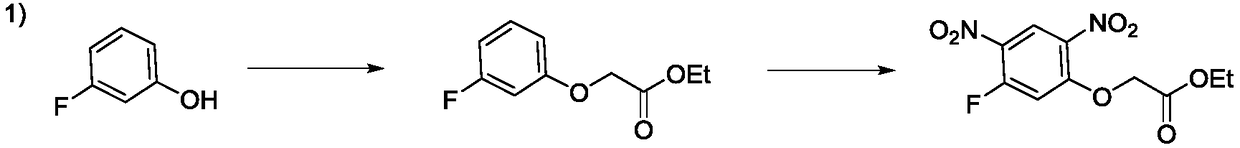

Method for preparing epoxiconazole intermediate

ActiveCN102304014AIncrease contentHigh yieldOrganic compound preparationHalogenated hydrocarbon preparationBenzaldehydeALUMINUM HYDRIDE

This invention discloses a method for preparing an epoxiconazole intermediate. The epoxiconazole intermediate is 2-(4-substituted phenyl)-3-(2-substituted phenyl)-propylene. The method comprises the following steps of: reacting para-substituted benzaldehyde with ethyl chloroacetate to generate the epoxiconazole intermediate in the presence of basic catalyst, then hydrolyzing and performing decarboxylation to the epoxyester intermediate with aqueous solution of sodium hydroxide and diluted sulfuric acid to generate para-substituted benzaldehyde; reacting the para-substituted benzaldehyde with ortho-substituted benzaldehyde to generate the epoxiconazole intermediate 2-(4-substituted phenyl)-3-(2-substituted phenyl)-acrolein, finally reducing the 2-(4-substituted phenyl)-3-(2-substituted phenyl)-acrolein by lithium aluminum hydride to generate the epoxiconazole intermediate. The process provided by the invention is simple in technology, and each reaction step can be finished under moderate conditions; the process is low in cost, and has little three wastes; in addition, the content and yield of the target product are higher and the process is suitable for industrial production.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

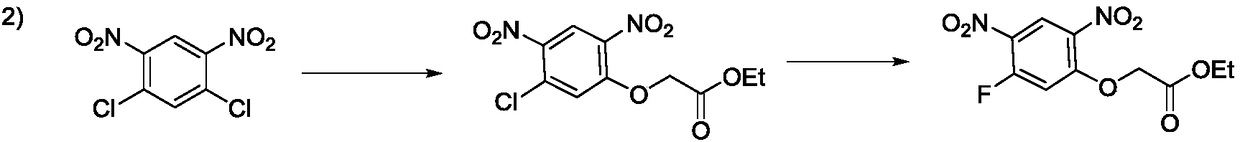

Preparation method of 2-(5-fluoro-2,4-dinitrophenoxy)acetate

ActiveCN108976129AHigh yieldImprove responseOrganic chemistryOrganic compound preparationDinitrophenolAcetic acid

The invention belongs to the technical field of organic synthesis, and in particular relates to a preparation method of 2-(5-fluoro-2,4-dinitrophenoxy)acetate. The preparation method comprises the following steps that: step 1, 2, 4-difluoronitrobenzene is used as a raw material, and is hydrolyzed by a base to form 5-fluoro-2,4-dinitrophenol; step 2, a catalyst A and a catalyst B are added into 5-fluoro-2,4-dinitrophenol and ethyl chloroacetate under the action of additives, and a nucleophilic substitution reaction is carried out to obtain the 2-(5-fluoro-2,4-dinitrophenoxy)acetate; the preparation method has the significant advantages of high yield, simple reaction, easy operation and low production costs.

Owner:安徽宁亿泰科技有限公司

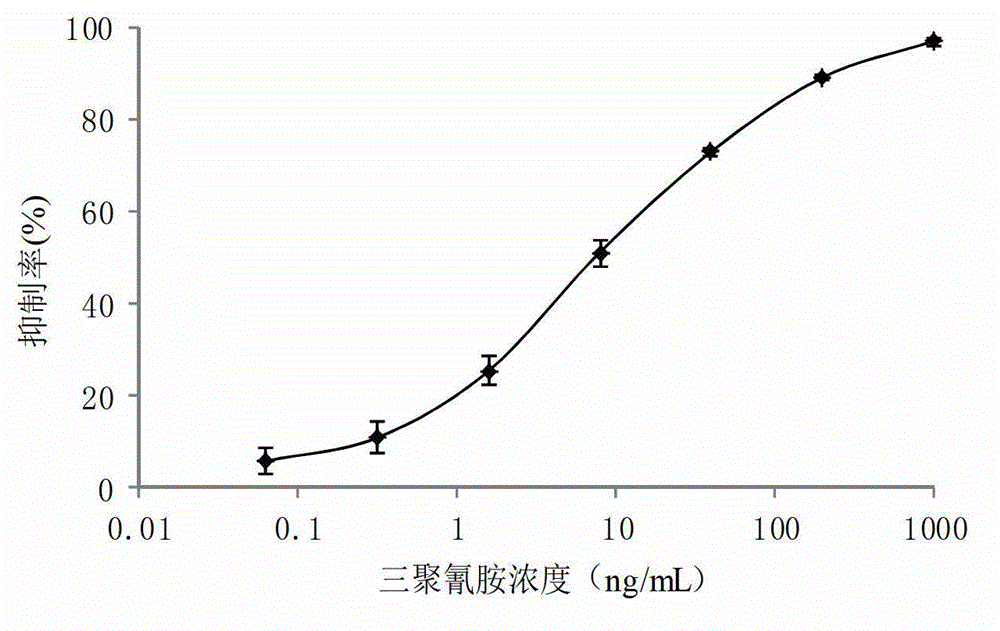

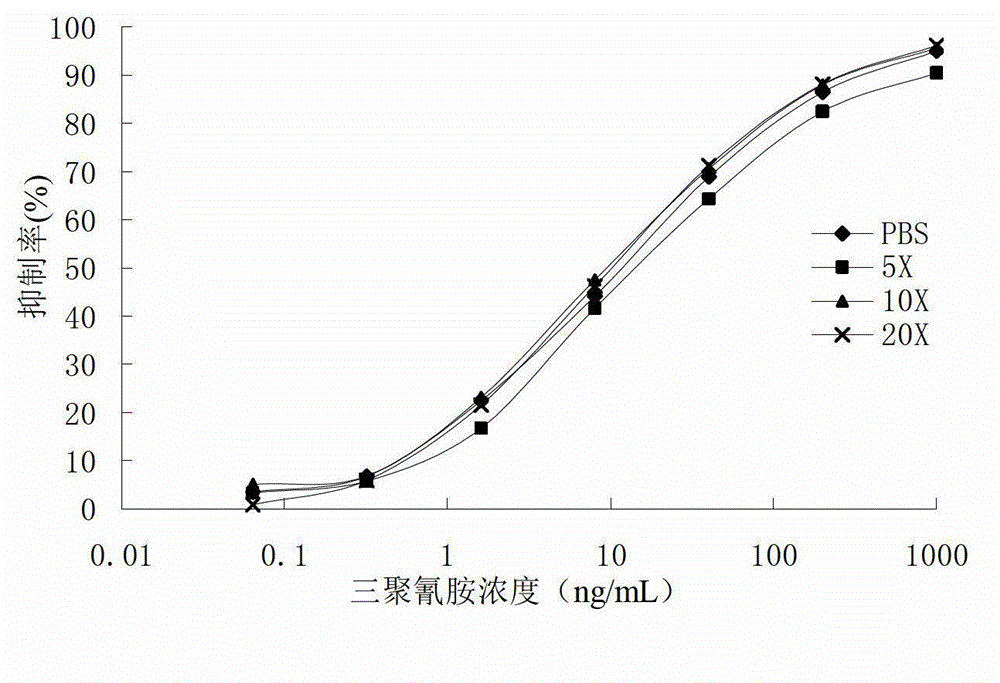

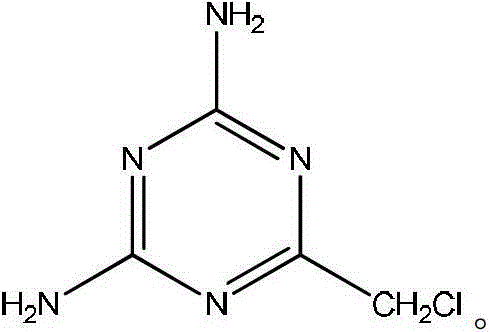

Novel melamine antigens and antibody as well as application

ActiveCN103145633AThe synthesis method is simpleImprove efficiencyOvalbuminImmunoglobulinsPropanoic acidSynthesis methods

The invention relates to novel melamine antigens and an antibody as well as application thereof. Biguanide and ethyl chloroacetate are employed to synthesize 6-chloromethyl-1, 3, 5-triazine-2, 4-diamino under the condition of sodium methylate, then the 6-chloromethyl-1, 3, 5-triazine-2, 4-diamino reacts with 3-mercaptopropionic acid so as to obtain a hapten 3-((4, 6-diamino-1, 3, 5-triazine-2-yl)-methylthio)propionic acid, which is coupled to a protein by an active ester technique so as to obtain an artificial antigen. After animal immunization, blood taking, antiserum separation and purification on the artificial antigen, the melamine antibody can be obtained. The synthesis method is reasonable, the route is simple, and the hapten is maximally consistent with the target object. The prepared melamine antibody has high sensitivity, and can fully meet the rapid detection need of melamine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

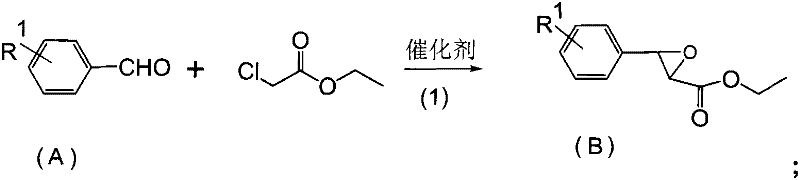

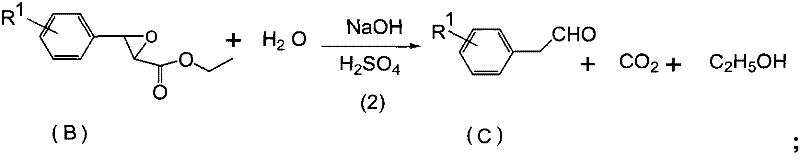

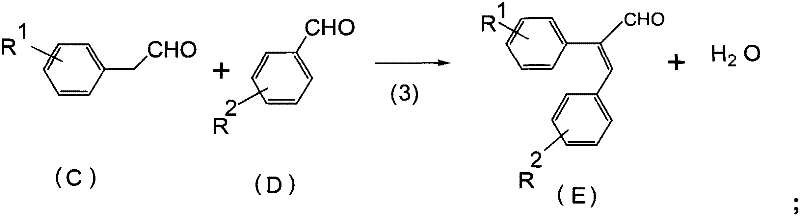

N-substituent-3-[3-(substituted phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound as well as preparation method and application thereof

ActiveCN104003924AEasy to synthesizeLow costBiocideOrganic chemistryNicotiana tabacumTobacco mosaic virus

The invention discloses an N-substituent-3-[3-(substituted phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound as well as a preparation method and application thereof, belonging to the technical field of organic synthesis and pesticides. The compound has a general structural formula (I). The N-substituent-3-[3-(substituent phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound is synthesized from substituted phenylamine, ethyl chloroacetate, ethyl acetoacetate and substituted benzaldehyde. The compound has good tobacco mosaic virus resistant living body treatment activity and can be used for preparing plant virus resistant pesticides.

Owner:GUIZHOU UNIV

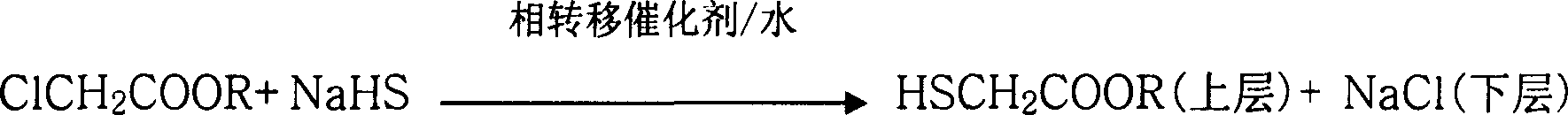

Method for preparing hydrosulfuryl acetate using phase transfer catalytic method

InactiveCN1807408ARaw materials are cheap and easy to getRaw materials are easy to getThiol preparationAcetic acidCatalytic method

The invention discloses a preparation method for thioglycollate ester by phase-transfer catalysis, which comprises: (1) dripping ethyl chloroacetate into the mixed liquid of NaHS, H2O and phase-transfer catalyst at room temperature, vigorous stirring and reacting for 1~12h; (2) keeping static for lamination; separating the lower water; cleaning the upper ester with water to neutrality; reducing pressure to distill and obtain the final product. This invention has high yield with low cost.

Owner:康富春

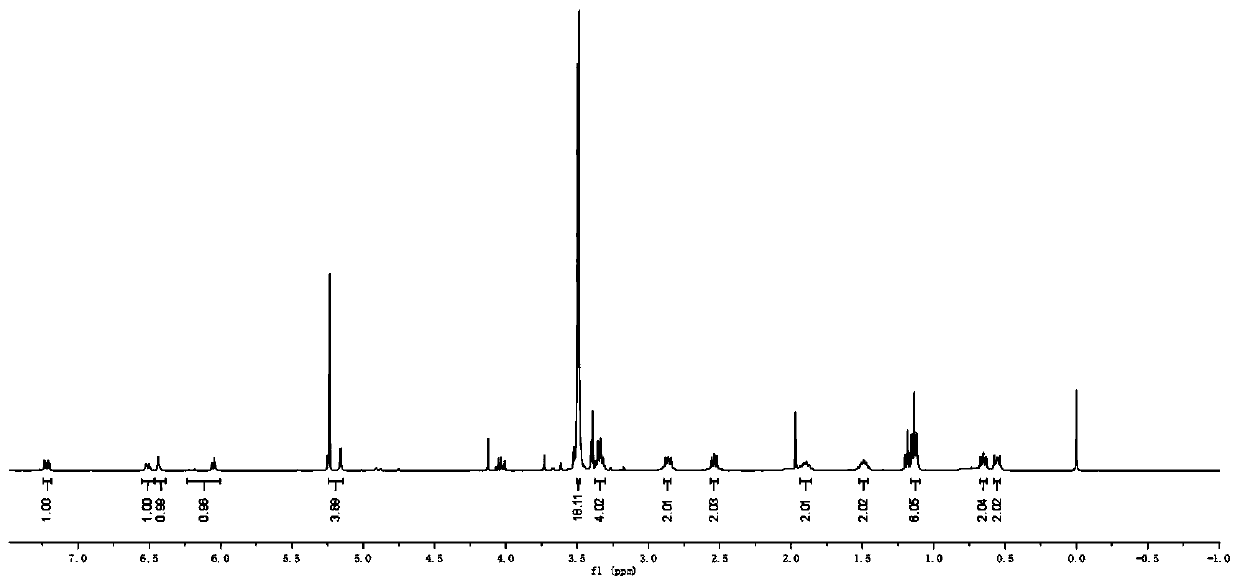

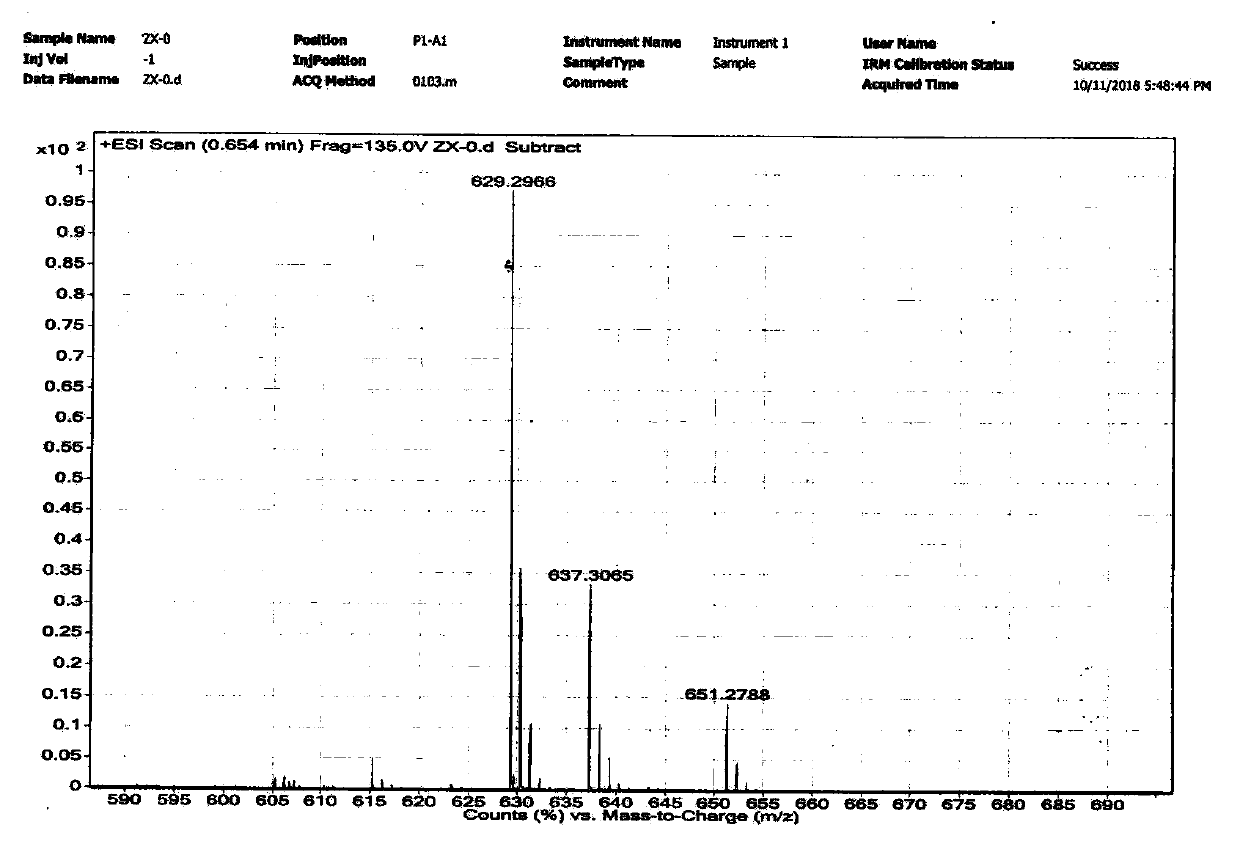

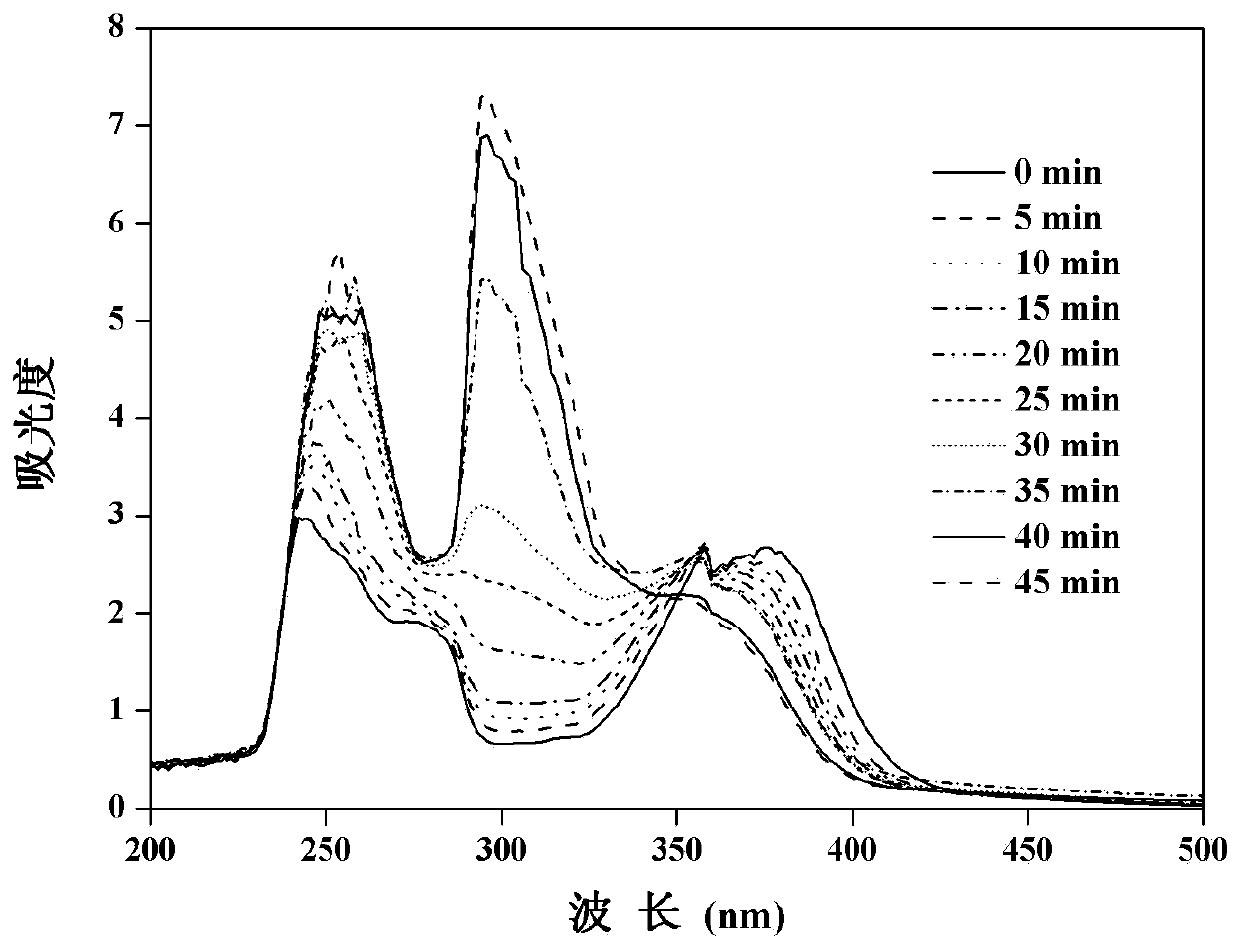

Coumarin-based bridged silane and preparation method thereof

ActiveCN110540549AFast photolysis ratePhotoresponsiveGroup 4/14 element organic compoundsSilanesEthyl chloroacetate

The invention relates to a coumarin-based bridged silane and a preparation method thereof. The coumarin-based bridged silane has a structure shown in formula I. 7-N,N-diethylamino-4-methyl coumarin isused as raw material, oxidized and reduced to obtain 7-N,N-diethylamino-4-hydroxymethyl coumarin, the 7-N,N-diethylamino-4-hydroxymethyl coumarin is acylated with chloroacetyl chloride to obtain 7-N,N-diethylamino-4-ethyl chloroacetate coumarin, last the coumarin-based bridged silane is obtained by substitution reaction between 7-N,N-diethylamino-4-ethyl chloroacetate coumarin and amine-containing bridged silane. The coumarin-based bridged silane obtained by the invention has good light response performance, can be used for designing and preparing light response performance materials, and hasimportant application value. The preparation method of the invention has the advantages of simple synthesis process, mild reaction conditions and strong operability.

Owner:SHANDONG UNIV

Rivaroxaban preparation method

The invention provides a rivaroxaban preparation method. 4-(4-aminophenyl)-3-molindone and (S)-N-glycidyl phthalimide are reacted to form 5-chloro-N-(((5S)-2-oxo-3-(4-(3-oxomorpholine-4-yl) phenyl)-1,3-oxazoline-5-yl) methyl) thiophene-2-formamide, wherein the rivaroxaban preparation method comprises the steps: adding ethylene oxide to phenylamine to generate hydroxyethyl aniline; adding ethyl chloroacetate and continuously reacting to obtain 4-phenyl-3-molindone; adding concentrated sulfuric acid, slowly adding concentrated nitric acid under an ice bath, wherein the volume ratio of the concentrated sulfuric acid and the concentrated nitric acid is (25-30): 1; reacting to obtain the 4-(4-aminophenyl)-3-molindone; adding palladium carbon to carry out reduction reaction, thereby obtaining rivaroxaban intermediates, i.e., 4-(4-aminophenyl)-3-molindone. The rivaroxaban preparation method provided by the invention has a simple processing route; after conditions are optimized, reaction is mild, cost of raw materials is low and yielding is high.

Owner:ZHEJIANG TIANSHUN BIOTECH

High-conversion-rate phenylacetaldehyde preparation method

InactiveCN106831373AThe synthetic route is simpleGentle processPreparation by hydrogenolysisPreparation from heterocyclic compoundsBenzaldehydeMethyl benzoate

The invention discloses a high-conversion-rate phenylacetaldehyde preparation method. The preparation method comprises the following steps: taking methyl benzoate as a raw material, enabling the methyl benzoate to be in contact with a catalyst, performing hydrogenation reaction to generate benzaldehyde, and adding diluter into the reaction system at the same time of the reaction; reacting the benzaldehyde and ethyl chloroacetate in the presence of alkali, the catalyst and organic solvent to generate epoxy acid ester; and hydrolyzing the epoxy acid ester under an alkaline condition, and decarboxylating to obtain phenylacetaldehyde. The method has mild process conditions and low requirements for equipment; and the product is easy to separate and high in synthesis ratio.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Chitosan-sodium alginate-crosslinking-coated biogas residue composite particles and preparation method thereof

InactiveCN107365223AComprehensive nutritionWide range of usesCalcareous fertilisersMagnesium fertilisersLand productivityHydroxylamine Hydrochloride

The invention relates to chitosan-sodium alginate-crosslinking-coated biogas residue composite particles. The preparation method is characterized by comprising the following steps: firstly, performing solid-liquid separation on biogas residues in a biogas tank, and performing solidification; performing uniform mixing with attapulgite and other nutrients, adding water, performing kneading, and performing granulation to obtain biogas residue composite particles; secondly, preparing a neutral sodium hydroxide-hydroxylamine hydrochloride-isopropanol mixed solution, performing a reaction on active hydroxyls in sodium alginate with ethyl chloroacetate to modify the sodium alginate; and finally, crosslinking the modified sodium alginate and chitosan to obtain a coating agent, uniformly spraying the coating agent on the surfaces of the biogas residue composite particles, and performing drying to obtain the chitosan-sodium alginate-crosslinking-coated biogas residue composite particles. The biogas residue composite particles are capable of effectively increasing the organic matter and nutrient contents in soil, loosening the hardened soil, accelerating the mellowing progress of raw soil and restoring the productivity of the raw soil, and have other favorable characteristics.

Owner:安徽奥利休闲农业发展有限公司

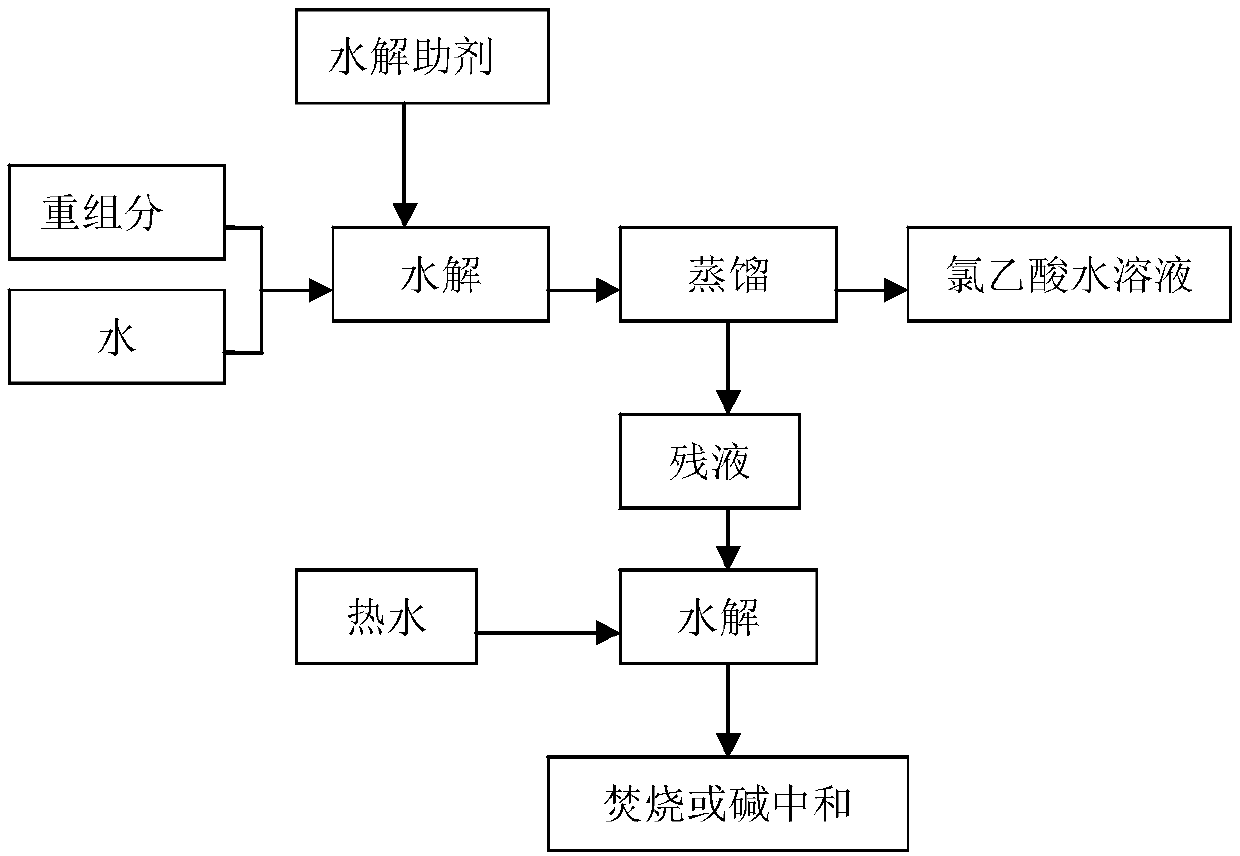

Method for treating chloroacetic acid heavy component based on chloroacetic acid recovery

ActiveCN107827728AFully hydrolyzedImprove solubilityPreparation from carboxylic acid esters/lactonesEnvironmental resistanceChemical industry

The invention belongs to the technical field of chemical industry, and in particular relates to a method for treating a chloroacetic acid heavy component based on chloroacetic acid recovery. The method comprises the following steps: adding water into the chloroacetic acid heavy component, heating, performing hydrolysis reaction, performing reduced-pressure distillation to obtain a chloroacetic acid aqueous solution, adding water into the residual liquid after reduced-pressure distillation to dissolve, and performing incineration or alkali neutralizing treatment. Ethyl chloroacetate in the chloroacetic acid heavy component is hydrolyzed into chloroacetic acid successfully by controlling the hydrolysis temperature and hydrolysis time and adding a hydrolysis aid, and reduced-pressure distillation is conducted to obtain the chloroacetic acid aqueous solution. The utilization rate of the raw materials is increased, three wastes are reduced, the environmental protection pressure of enterprises is reduced, and the production cost of products is reduced.

Owner:山东民基新材料科技有限公司

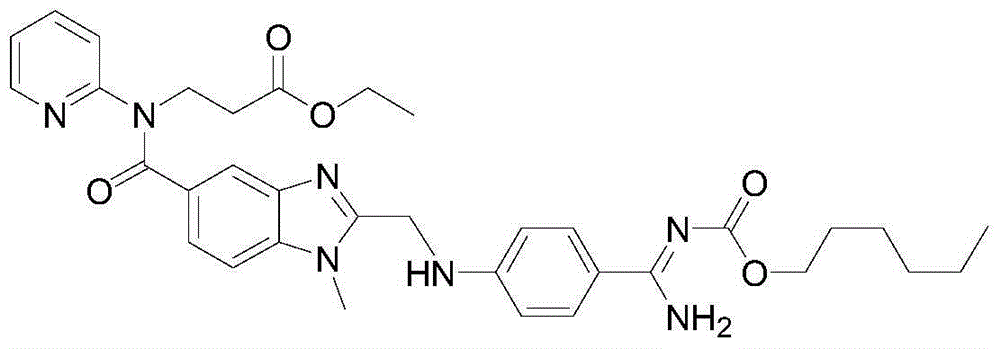

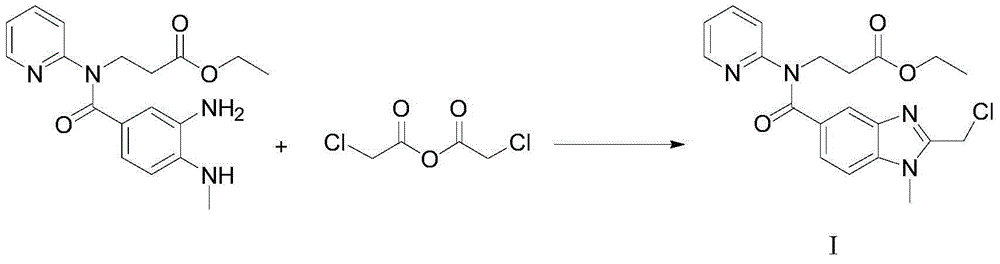

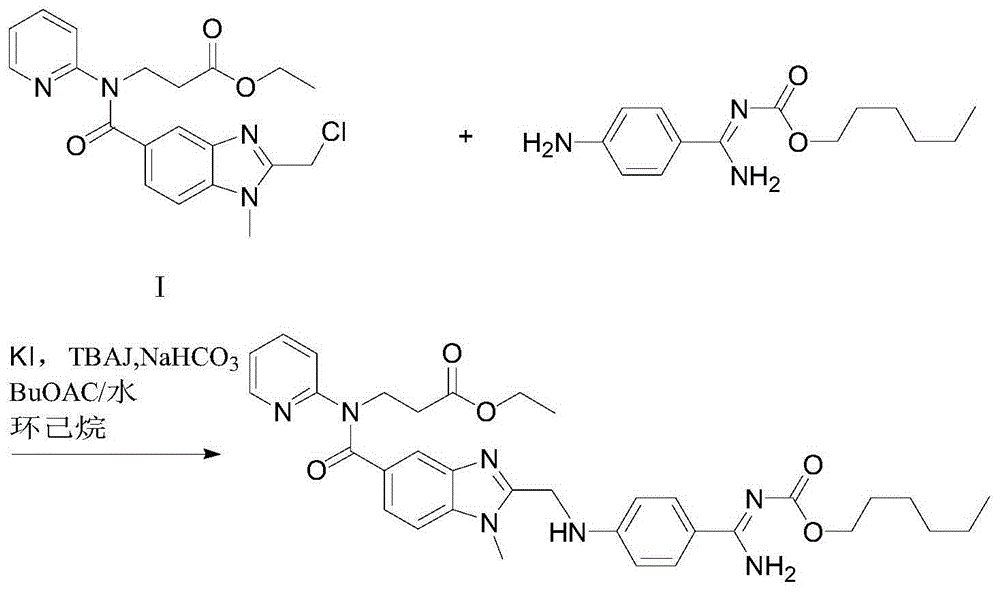

Preparation method of dabigatran etexilate intermediate

The invention discloses a preparation method of a dabigatran etexilate intermediate. The method comprises the major steps of (1) adding 3-[4-methylamino-3-amino-N-(2-pyridyl)-benzamido]-ethyl acrylate and ethyl chloroacetate to a reaction solution to mix and dissolve, and then adding immobilized enzyme to react; (2) removing immobilized enzyme after the reaction is finished to obtain organic layers; (3) distilling the organic layers to remove a reaction solvent so as to obtain an oily substance, and then adding acetic acid for reflux reacting; (4) distilling to remove glacial acetic acid after the reaction is finished, adding ethyl acetate and purified water, extracting, drying all obtained organic layers by distilling to obtain beta-alanine-N-[[1-methyl-1H-benzimidazole-2-chloromethyl]-5-carbonyl]-N-2-pyridine-ethyl ester. The method is simple to operate, mild under reaction conditions, easy to prepare a high-purity product, and high in product yield; in addition, the enzyme can be recycled, so that the preparation method has a good industrial application prospect.

Owner:BENGBU BBCA MEDICINE SCI DEV +1

New synthesis method of methyl fluoroacetate and ethyl fluoroacetate

ActiveCN112920050AImprove conversion efficiencySimple post-processingOrganic compound preparationCarboxylic acid esters preparationFluoroacetic acidPtru catalyst

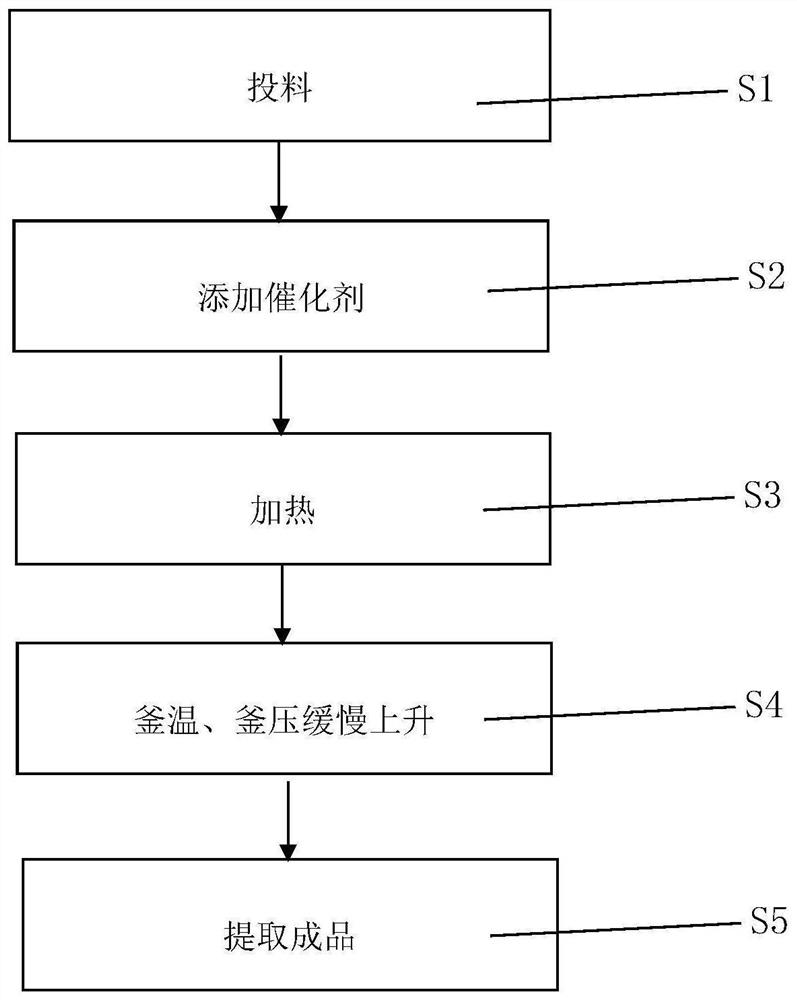

The invention discloses a novel synthesis method of methyl fluoroacetate and ethyl fluoroacetate. The method comprises the following specific steps: adding methyl chloroacetate or ethyl chloroacetate into a reaction kettle, and starting stirring; after uniformly stirring, sequentially adding potassium fluoride, a catalyst A and a catalyst B, and closing a charging hole; heating to 120 DEG C by using heat-conducting oil, starting reaction, stopping heating by the heat-conducting oil and starting heat preservation when the kettle temperature reaches 180 DEG C and the kettle pressure reaches 0.8 MPa after 1 hour; after keeping heat preservation for 3 hours and the kettle temperature reaches 220 DEG C and the kettle pressure reaches 1.5 MPa, continuously preserving heat for 5 hours; and cooling to 80 DEG C, discharging, carrying out filter pressing, rinsing, rectifying filtrate through a rectifying tower, and recovering chloroacetate to obtain the product methyl fluoroacetate or ethyl fluoroacetate, the product quality can reach 99.5% or above, and the molar yield (metered by potassium fluoride) reaches 96% or above. The method has the advantages of mild reaction conditions, simple operation, easy control, high fluoro conversion rate, high product yield, simple post-treatment process, realization of solvent-free reaction, and low energy consumption.

Owner:宁夏森萱药业有限公司

Method for synthesizing fluoro-ethyl acetate and fluoro-methyl acetate

InactiveCN102875370AReaction conditions are easy to controlEase of industrial productionOrganic compound preparationCarboxylic acid esters preparationEthyl acetateSolvent

The invention provides a method for synthesizing fluoro-ethyl acetate and fluoro-methyl acetate. The method includes: using chloro-alkyl imidazole ionic liquid and / or bromo-alkyl imidazole ionic liquid as catalysts, using ethyl chloroacetate or methyl chloroacetate and alkali metallic fluoride as raw materials, using polar non-proton solvent as reaction medium, reacting for a period of time at a set temperature, filtering, and removing inorganic salts to obtain the fluoro-ethyl acetate or fluoro-methyl acetate.

Owner:ANQING FULLTIME CHEM INDAL +1

Synthetic method for glycine betaine hydrochloride

PendingCN109942445ALess side effectsNo solid wasteOrganic compound preparationCarboxylic acid esters preparationEthyl monochloroacetateBetaine Hydrochloride

The invention relates to a synthetic method for glycine betaine hydrochloride. The synthetic method comprises the following steps: successively adding monochloro acetic acid, a catalyst and ethanol into a reaction bottle; then raising the temperature to 100-115 DEG C; dehydrating a molecular sieve in a reflux position; carrying out a reaction for 2-8 hours; washing a reaction liquid twice; distilling separated ethyl chloroacetate at a reduced pressure; adding ethyl monochloroacetate into the reaction bottle; adding a certain amount of water; introducing trimethylamine gas; keeping the temperature at 20-45 DEG C; carrying out a reaction for 2-6 hours; then adding hydrochloric acid to raise the temperature and hydrolyze to distill water and ethanol therein; and reducing the temperature by 10-15 DEG C and carrying out crystallization and centrifugalization to obtain the glycine betaine hydrochloride. By synthesizing ethyl monochloroacetate from monochloro acetic acid and ethanol, synthesizing ethyl glycine betaine hydrochloride from the obtained pure ethyl monochloroacetate and trimethylamine, raising the temperature to hydrolyze in the presence of hydrochloric acid to obtain ethanol,and cooling the concentrated liquor to separate out glycine betaine hydrochloride, the purity of the prepared glycine betaine hydrochlorid is over 99% and the yield reaches over 97%. Inorganic salt solid waste is avoided.

Owner:山东瑞弘生物科技股份有限公司

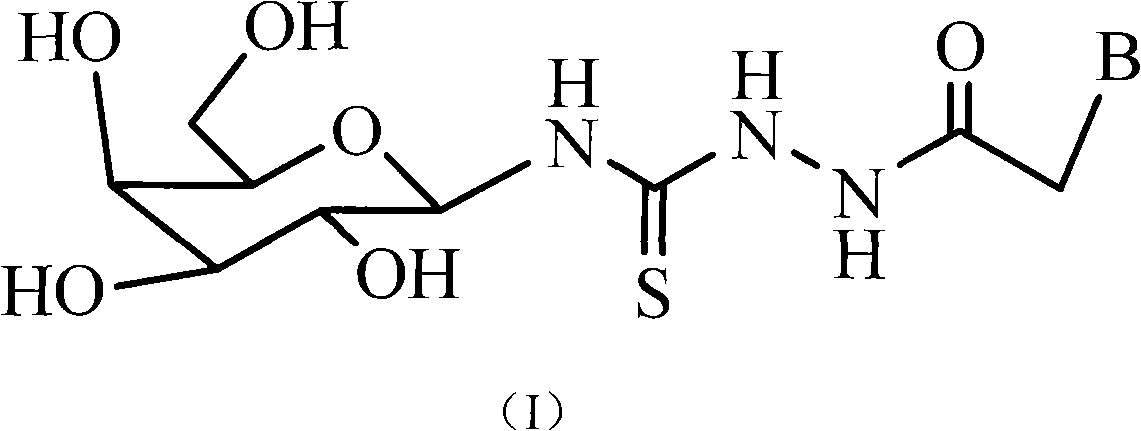

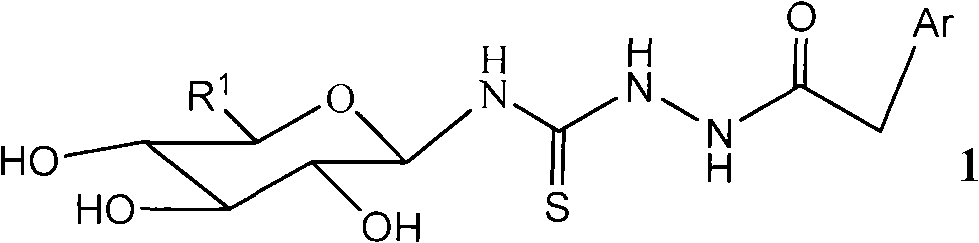

Galactosyl thiourea heterocyclic compounds, synthetic method thereof and antineoplastic applications

InactiveCN101307078AEsterified saccharide compoundsOrganic active ingredientsPotassium carbonateBromine water

The invention discloses a group of galactosyl thioureas heterocyclic compounds, a preparation method and biological activity thereof. The compounds are indicated by the following general formula. A B in the general formula is defined by an instruction book. The invention introduces a method for synthesizing the galactosyl thioureas heterocyclic compounds through six steps, which takes full acetic acid esterified galactosyl, bromine water, lead rhodanide, heterocyclic base, ethyl chloroacetate and hydrazine hydrate as raw materials, takes glacial acetic acid, trifluoroacetic acid, xylene, toluene, ethyl benzene, N,N- dimethyl formamide, dimethyl sulfoxide, dioxane, pyridine, methanol, ethanol, isopropyl alcohol, absolute methanol and absolute ethyl alcohol as solvents, and takes sodium hydride, anhydrous potassium carbonate and sodium methoxide as basic catalysts. The compounds have inhibiting effects on human body lung cancer cell strains and liver cancer cell strains.

Owner:QINGDAO UNIV OF SCI & TECH

Production method of 1-H benzotriazole acetate

ActiveCN103992285AImprove thermal stabilityGood oil solubilityOrganic chemistryRotary evaporatorPtru catalyst

The invention discloses a production method of 1-H benzotriazole acetate. The method comprises the steps of synthesizing ethyl chloroacetate and synthesizing 1-H benzotriazole ethyl acetate; firstly adding trichloromethane and a catalyst namely triethylamine, dropping a trichloromethane solution containing chloroacetyl chloride, removing triethylamine hydrochloride by filtration, and evaporating filtrate to dryness by using a rotary evaporator, thereby obtaining a residue namely ethyl chloroacetate; adding absolute ethyl alcohol, benzotriazole and sodium hydroxide, filtering an ethanol solution containing ethyl chloroacetate to obtain a generated inorganic salt, concentrating the filtrate, precipitating crystals, and filtering to obtain a product. Compared with conventional production methods, the method disclosed by the invention can be used for greatly shortening the production time and greatly improving the production efficiency; 1-H benzotriazole acetate produced by using the method has good thermal stability and oil solubility, can be used for significantly improving the extreme pressure property of liquid paraffin under an appropriate additive amount and improving the bearing capacity of liquid paraffin, and can reach a yield of more than 90%.

Owner:NANTONG BOTAO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![N-substituent-3-[3-(substituted phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound as well as preparation method and application thereof N-substituent-3-[3-(substituted phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ded1e93d-4058-473e-8d53-dcbce13d90b7/2014102304035100002DEST_PATH_IMAGE001.PNG)

![N-substituent-3-[3-(substituted phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound as well as preparation method and application thereof N-substituent-3-[3-(substituted phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ded1e93d-4058-473e-8d53-dcbce13d90b7/2014102304035100002DEST_PATH_IMAGE032.PNG)

![N-substituent-3-[3-(substituted phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound as well as preparation method and application thereof N-substituent-3-[3-(substituted phenyl)-2-allyl-1- ketone]-4-hydroxypyrroline-2-ketone compound as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/ded1e93d-4058-473e-8d53-dcbce13d90b7/2014102304035100002DEST_PATH_IMAGE033.PNG)