Preparation method of 3-morpholone

A technology of morpholinone and ethanolamine, applied in the field of preparation of 3-morpholinone, can solve the problems of many by-products, low yield, low industrialization value, etc., and achieves low cost, low content of by-products, and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

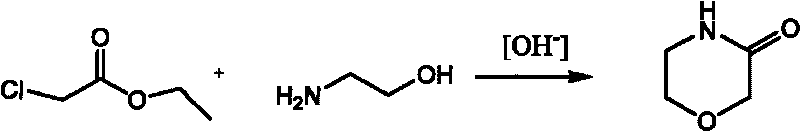

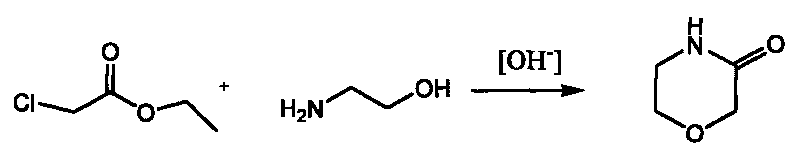

[0017] The preparation method of 3-morpholinone, such as figure 1 As shown, first nitrogen protection, under the action of alkali or mixed alkali, cool ethanolamine and organic solvent or mixed solvent to 0~-10°C, add ethyl chloride dropwise, and control the temperature at 0~-6°C, Then heat up to 30-80°C and stir for 0.2-2 hours, filter, wash the solid with solvent, combine the mother liquor, evaporate the solvent, and recrystallize to obtain pure 3-morpholinone.

[0018] Among them, the alkali is one of sodium metal, sodium hydride, potassium tert-butoxide, sodium tert-butoxide, and sodium isopropoxide, and the mixed alkali is sodium metal, sodium hydride, potassium tert-butoxide, sodium tert-butoxide, and isopropoxide. A mixture of several types of sodium alkoxide. The organic solvent is one of toluene, isopropanol, tert-butanol, ethanol, and methanol, and the mixed solvent is a mixed solvent of several kinds of toluene, isopropanol, tert-butanol, ethanol, and methanol. Th...

Embodiment 1

[0020] Under nitrogen protection, add 11.5g of metallic sodium in batches to a solution containing 30.5g of ethanolamine and 500ml of isopropanol, raise the temperature to 50°C, stir until the sodium dissolves, cool the reaction solution to 0~-10°C, and add dropwise 55.2 g of ethyl chloride, temperature controlled at 0~-6°C, then warmed up to 30~80°C and stirred for 0.2~2h, filtered, the solid was washed with a solvent, the mother liquor was combined, the solvent was evaporated, and ethyl acetate and iso Propanol was recrystallized to obtain 34.1 g of pure 3-morpholinone, with a yield of 75% and a GC purity of 99.5%.

[0021] Elemental Analysis: Theoretical: C, 47.52; H, 6.98, N, 13.85, O, 31.65. Found: C, 47.54; H, 6.99, N, 13.83, O, 31.64.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com