Patents

Literature

83results about How to "No solid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive utilization system and method for lignite upgrading and drying energy

InactiveCN103307891AHigh calorific valueImprove combustion efficiencyDrying solid materials with heatHearth type furnacesFluidized bed dryingBrick

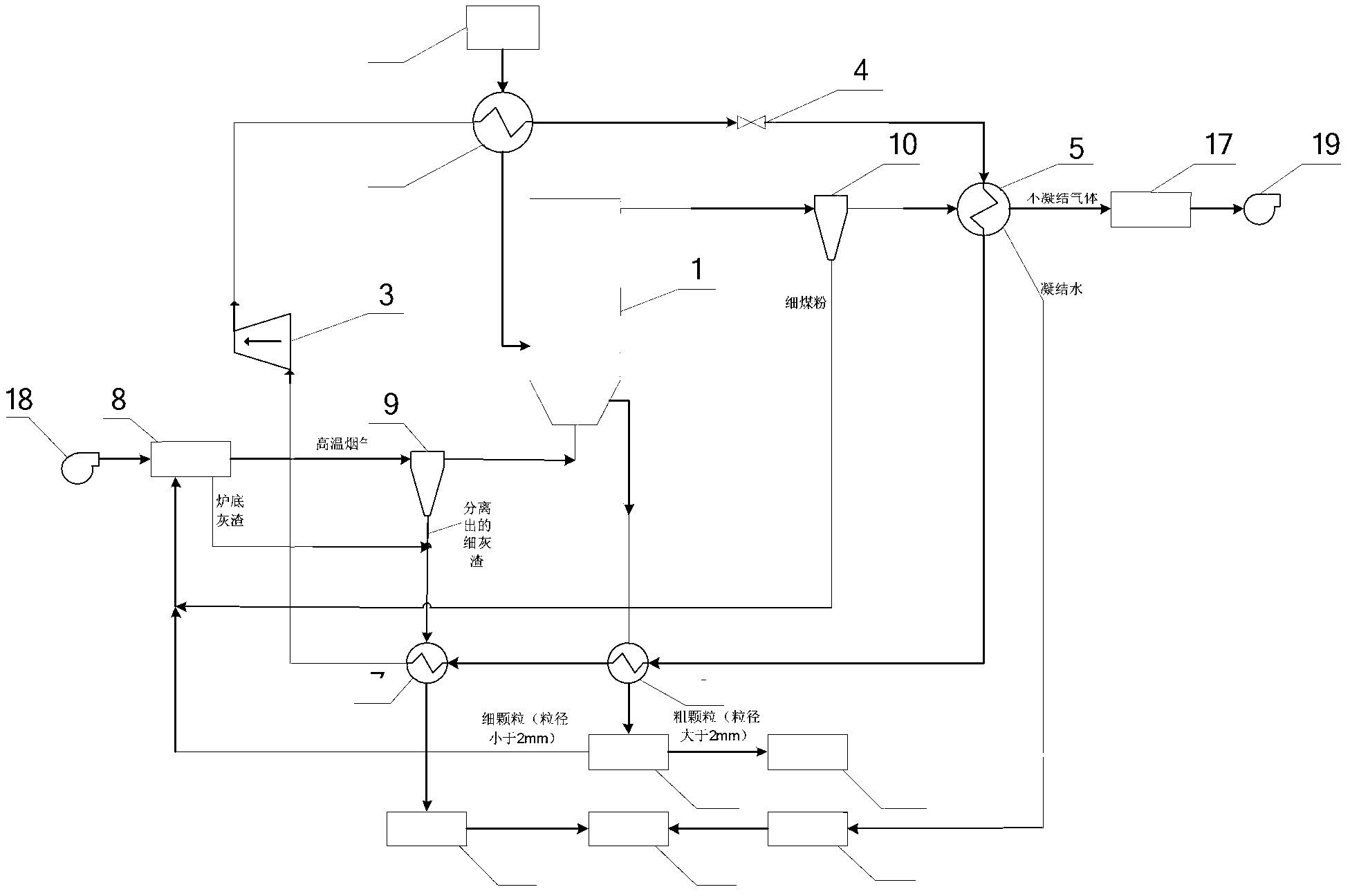

The invention discloses a comprehensive utilization system and method for lignite upgrading and drying energy. According to the system, a fume outlet of a hot blast stove (8) is connected with a fly ash separator (9); an ash residue outlet at the lower end of the fly ash separator (9) is connected with a high-temperature ash cooler (7); a clean fume outlet is connected with a dry wind inlet of a fluidized bed dryer (1); a fume outlet of the fluidized bed dryer (1) is connected with a cyclone separator (10); and a material outlet of the fluidized bed dryer (10) is sequentially connected with an inlet of a finished product coal temperature reduction device (6), and an inlet of a lignite screen separation device (12). The system makes the best of the heat generated during fine pulverized-coal combustion after the completion of lignite drying to dry the lignite, without an external heat; the heat pump technology is adopted to recover the exhaust heat generated by ready coal, high-temperature ash residue, exhaust steam and the like during the lignite drying process for predrying of the lignite; and meanwhile, the ash residue and solidified water are adopted to form ash residue slurry for industrial brick manufacturing raw materials, so as to achieve the purposes of energy conservation, emission reduction and waste utilization.

Owner:SOUTHEAST UNIV

Process method of synthesizing tenofovir alafenamide

InactiveCN106928277AEasy to handleNo solid wasteGroup 5/15 element organic compoundsChemistryPhosphate

The invention provides a process method of synthesizing tenofovir alafenamide. The tenofovir alafenamide is finally obtained through esterification, acylating chlorination, amidation and chiral splitting by taking (R)-9-(2-methoxyl propyl phosphate) adenine as an initial raw material. The process method provided by the invention is low in process cost, mild in reaction condition and simple and controllable in operating method, avoids use of a lot of toxic reagents, and is good in environment-friendly safety and stable in product quality.

Owner:JIANGSU CHENGXIN PHARMA

Device and method realizing synergic effects of waste heat utilization, desulfurization wastewater zero-emission and smoke plume removal

PendingCN108285188ASimple processUniversalAuxillary pretreatmentWaste water treatment from gaseous effluentsSmoke plumeZero emission

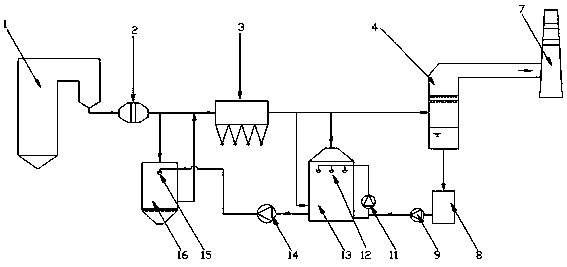

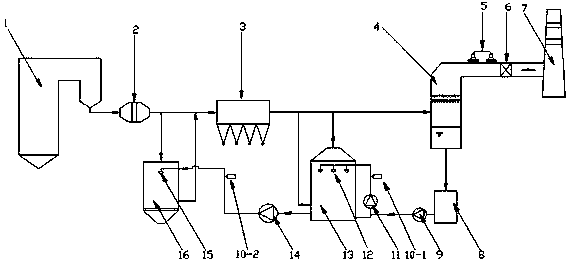

The invention discloses a device and a method realizing synergic effects of waste heat utilization, desulfurization wastewater zero-emission and smoke plume removal, the device comprises a boiler, anair preheater, a dust remover, a desulfurization tower and a chimney which are sequentially connected through a pipeline, a wastewater sedimentation tank, a wastewater concentration tower and a wastewater flashing tower simultaneously are connected to corresponding equipment in the device, a high-temperature gas required in the working process of the wastewater flashing tower and the wastewater concentration tower is taken from high-temperature flue gas during the operation of the device; and generated gases are sent into the dust remover for dust removal circulation. An acoustic wave agglomeration device and a demister are disposed in a connecting pipe between the desulfurization tower and the chimney. The method comprises the steps of concentrating and flashing the high temperature fluegas in the process of operation of the desulfurization wastewater utilization device, and finally feeding the concentrated and flashed gas to the device for circulation, thereby achieving zero emission, discharged smoke plume can be reduced by use of synergic effects of the reduced flue gas temperature, the acoustic wave agglomeration device and the demister, and the goal of energy saving and environmental protection, wastewater zero-emission and exhaust emission reduction can be comprehensively realized.

Owner:NANJING CHANGRONG ACOUSTIC INC +2

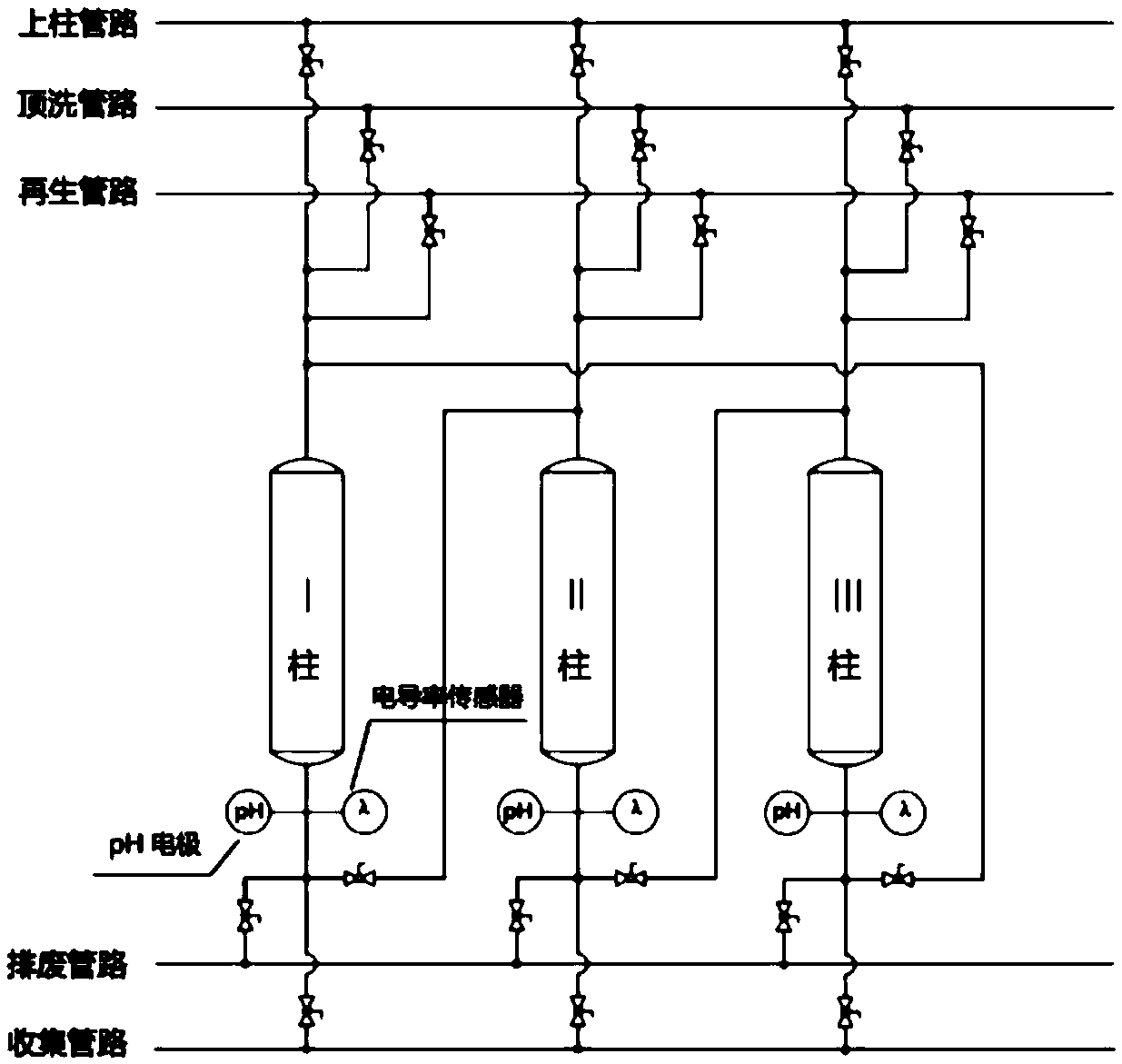

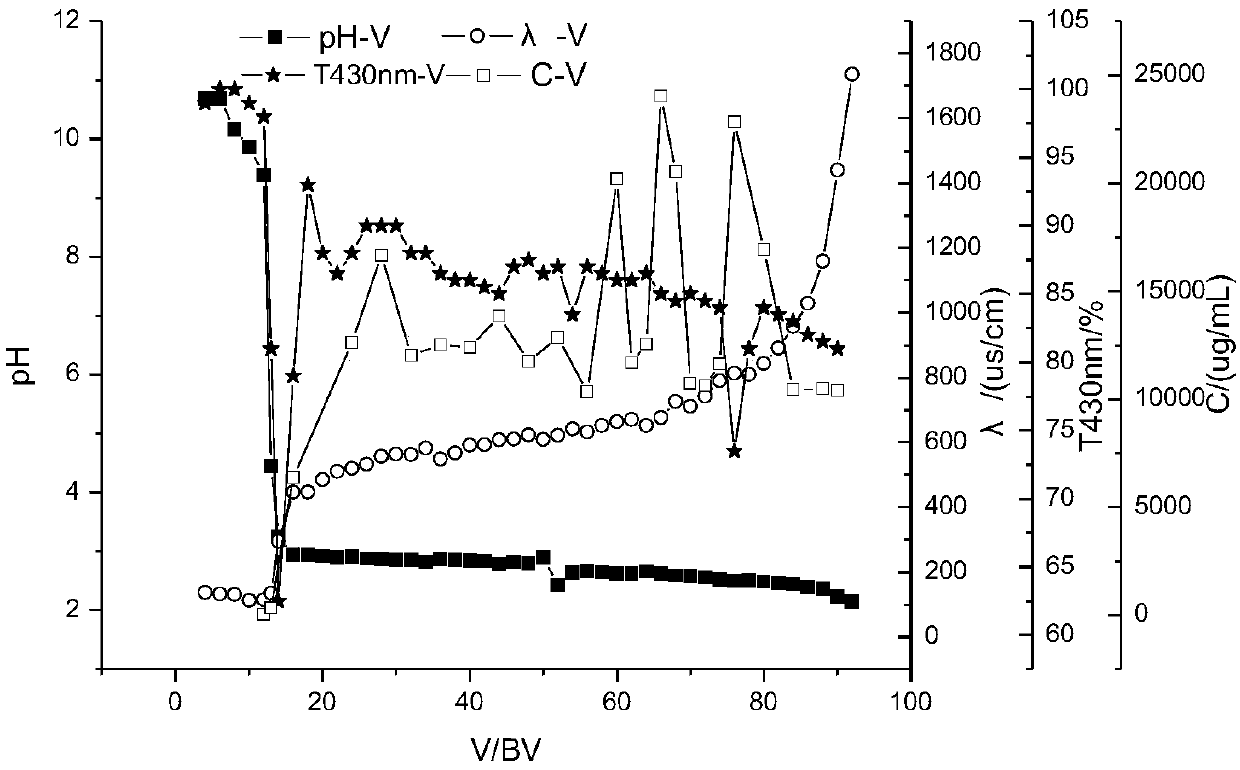

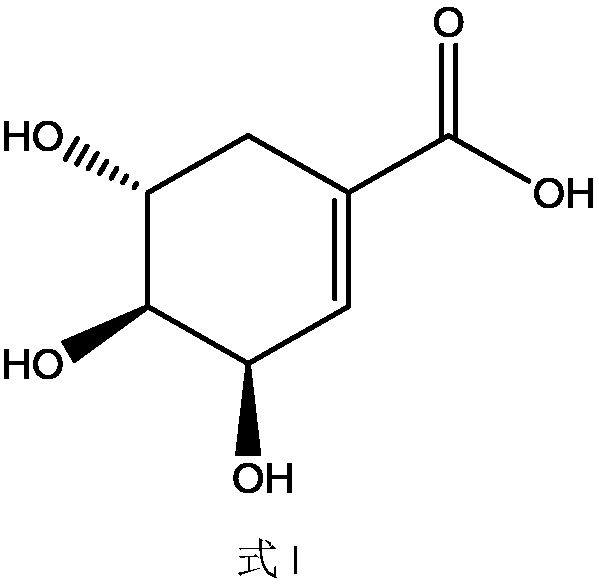

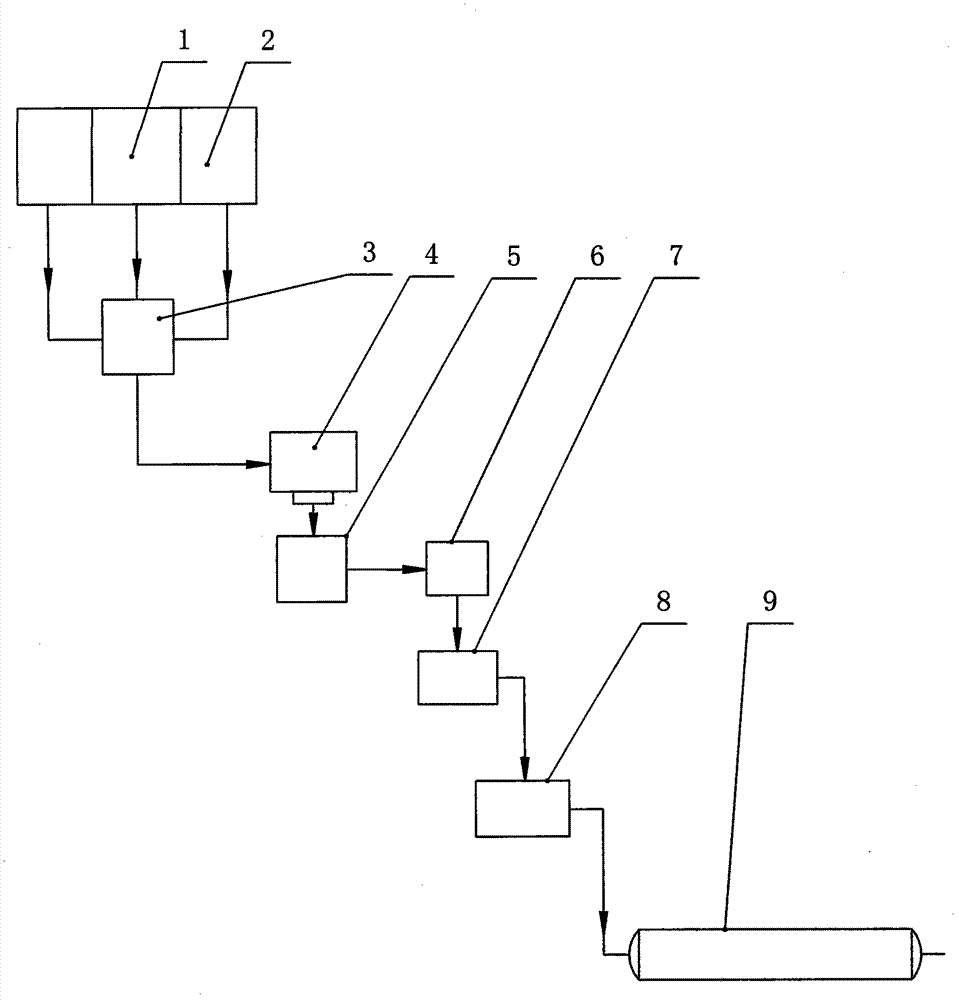

Process for efficiently purifying shikimic acid by utilizing continuous ion exchange technology

ActiveCN109721487AIncrease profitReduce usageCarboxylic compound separation/purificationShikimic acidIon exchange

The invention discloses a process for efficiently purifying shikimic acid by utilizing a continuous ion exchange technology, and the process comprises: carrying out solid-liquid separation to obtain afermentation filtrate, and carrying out pre-purification on the fermentation filtrate by virtue of cation exchange resin to obtain a pre-purified liquid a; and pre-purifying the pre-purified liquid athrough a continuous ion exchange system to obtain a pre-purified liquid b; and finally, carrying out fine purification and spray drying on the pre-purified liquid b to obtain the shikimic acid. Theprocess has the advantages that the process is simple and stable, continuous and automatic production can be realized, the chromatographic purity and the content of the prepared shikimic acid finishedproduct are both higher than 99%, the utilization rate of the resin is greatly improved, the total usage amount of the resin is reduced by about 80%, an eluent is not used in the pre-purification process, wastewater is greatly reduced, the production cost is greatly reduced, the market competitiveness of the product is enhanced, and the process is suitable for large-scale industrial production.

Owner:ZHEJIANG HISUN PHARMA CO LTD

Process for producing bricks by using saponification residual slag

ActiveCN102815880ASimple production processSimple processSolid waste managementCalcium silicateAluminate

The invention provides a process for producing bricks by using saponification residual slag. The process comprises processes of pretreatment of raw materials, batching, mixing and humidifying of materials and forming of adobe. During batching, materials comprise, by weight percentage, 20%-35% of the saponification residual slag, 15%-30% of aggregate and 35%-65% of fly ash and the batching is conducted through a batching machine. By the aid of the process, during steam curing process, calcium hydroxide and silicon dioxide and aluminium oxide in the fly ash are subjected to chemical reaction, hydrated calcium silicate and hydrated calcium aluminate are produced, a layer of hydration products is formed on surfaces of the fly ash and other mixing materials, so that the fly ash and other mixing materials are cemented together, a wall material with certain physical and mechanical properties is formed, and the strength of bricks is more than mu 10. The process is simple, a lot of residual slag can be processed, devices are simple, clay bricks can be replaced, land resources are saved, no environment pollution exists, wastewater cannot be produced and secondary solid waste cannot be produced.

Owner:山东滨化新型建材有限责任公司

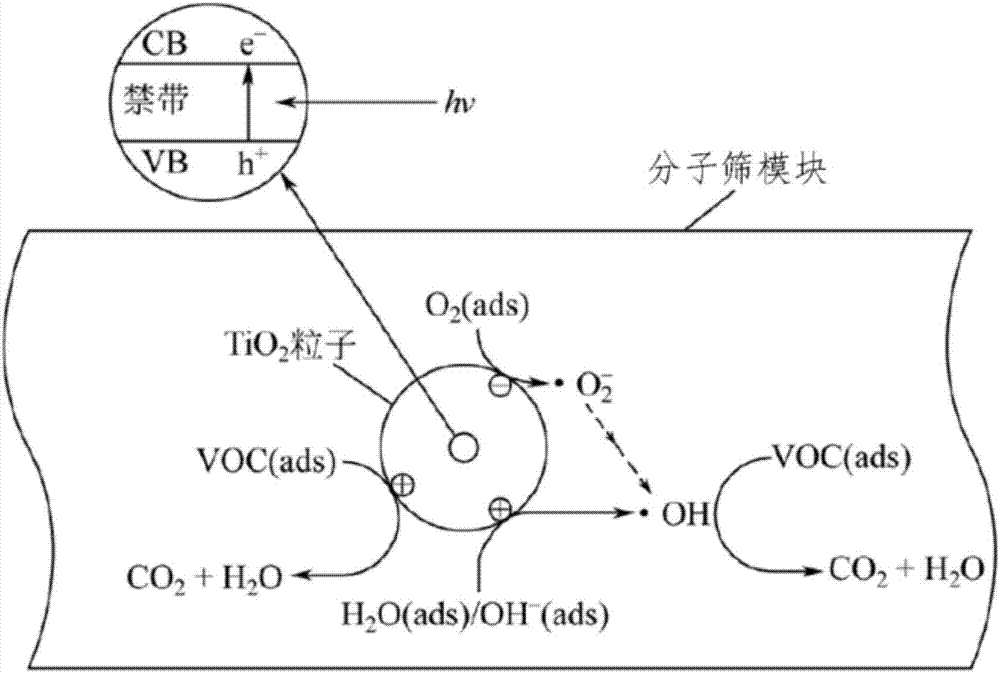

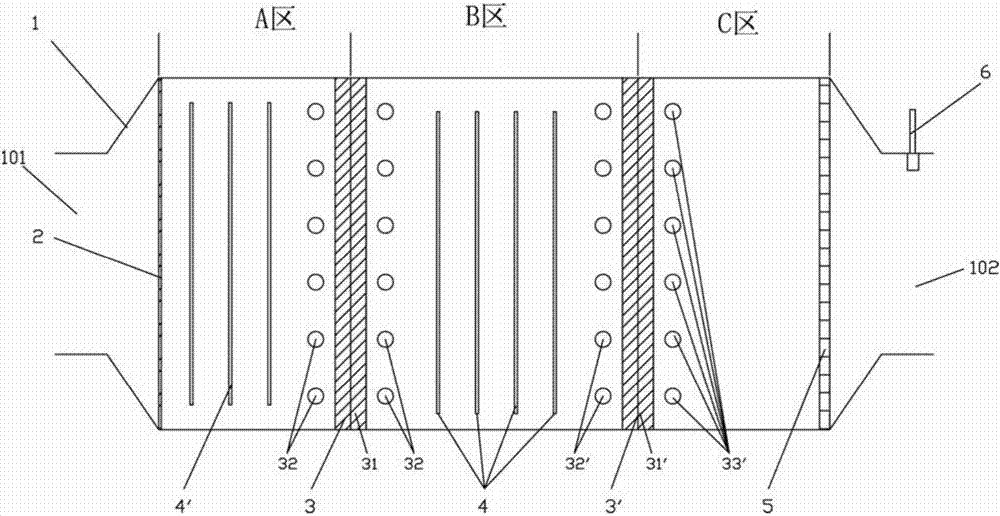

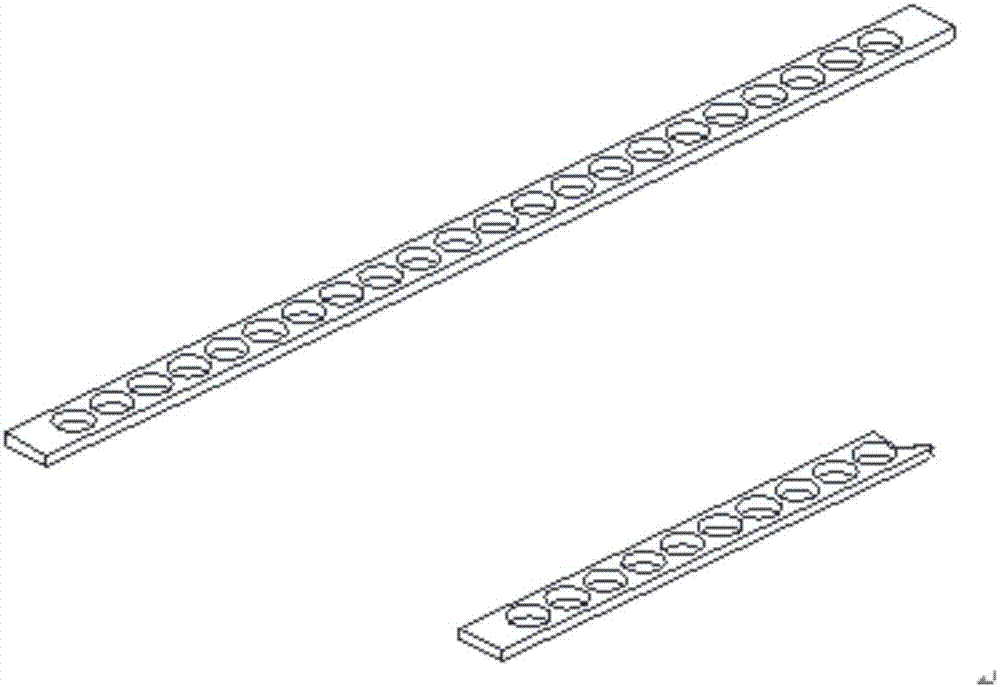

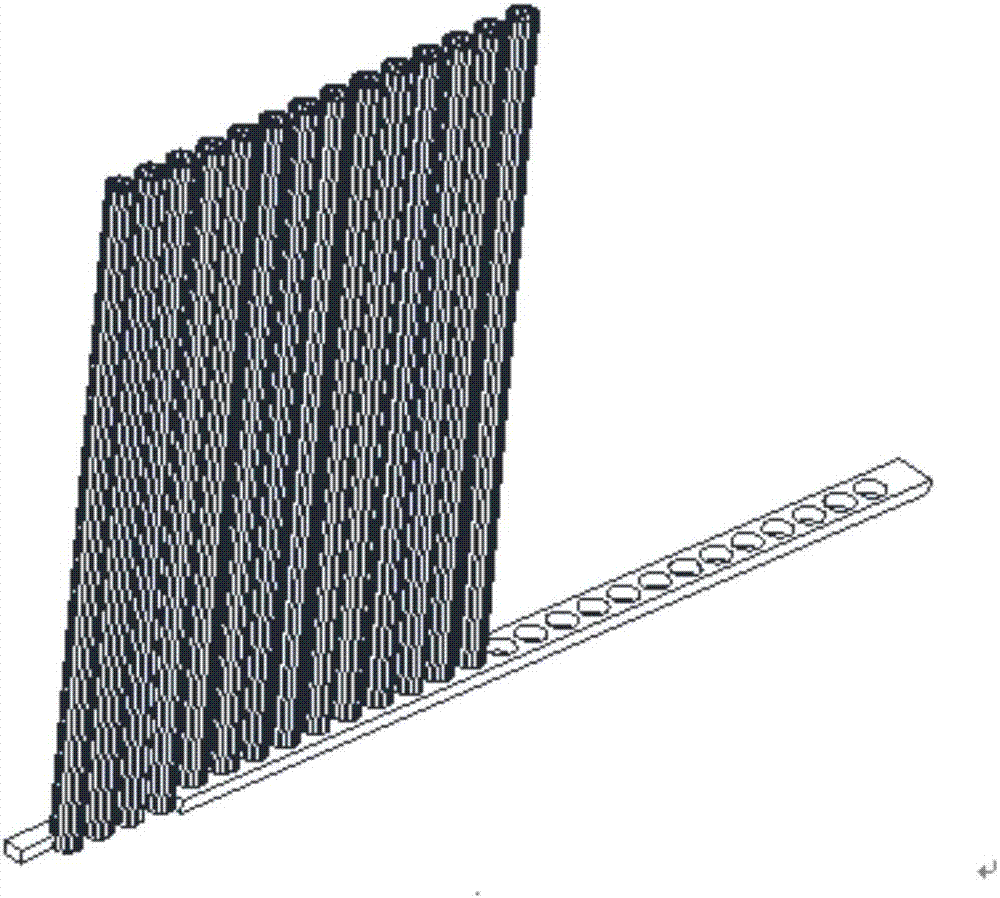

Method and device for treating volatile organic chemicals (VOCs) gas of medium or low concentration

PendingCN107569987AGood spatial dispersionRealize online desorptionDispersed particle filtrationAir quality improvementParticulatesDesorption

The invention relates to a method and a device for treating volatile organic chemicals (VOCs) gas of medium or low concentration. The method comprises the steps of filtering the VOCs gas of medium orlow concentration for removing particulate matters, then decomposing and oxidizing the VOCs gas by means of UVC photolysis, UVC photoexcited oxidation, ozone oxidation and TiO2 photocatalytic oxidation as well as molecular sieve adsorption and desorption so as to enable the VOCs gas to be converted into CO2 and water, filtering the obtained gas by using an ozone filtering device, and discharging the gas when the gas is proved to be qualified by means of detection. After the method and the device are adopted, on-line VOCs adsorption and desorption can be realized by means of a synergistic effect of a molecular sieve module and UVC light irradiation; in a treatment process, chemical additives and precious metal catalysts are not needed to be used, so that secondary pollutants are not produced, the efficiency is greatly increased, and a good treatment efficiency is further realized. After being treated, most of the VOCs gas is decomposed and oxidized, and extra energy consumption is not caused; furthermore, the operation and maintenance costs of the device are reduced.

Owner:彩融电光源技术(上海)有限公司

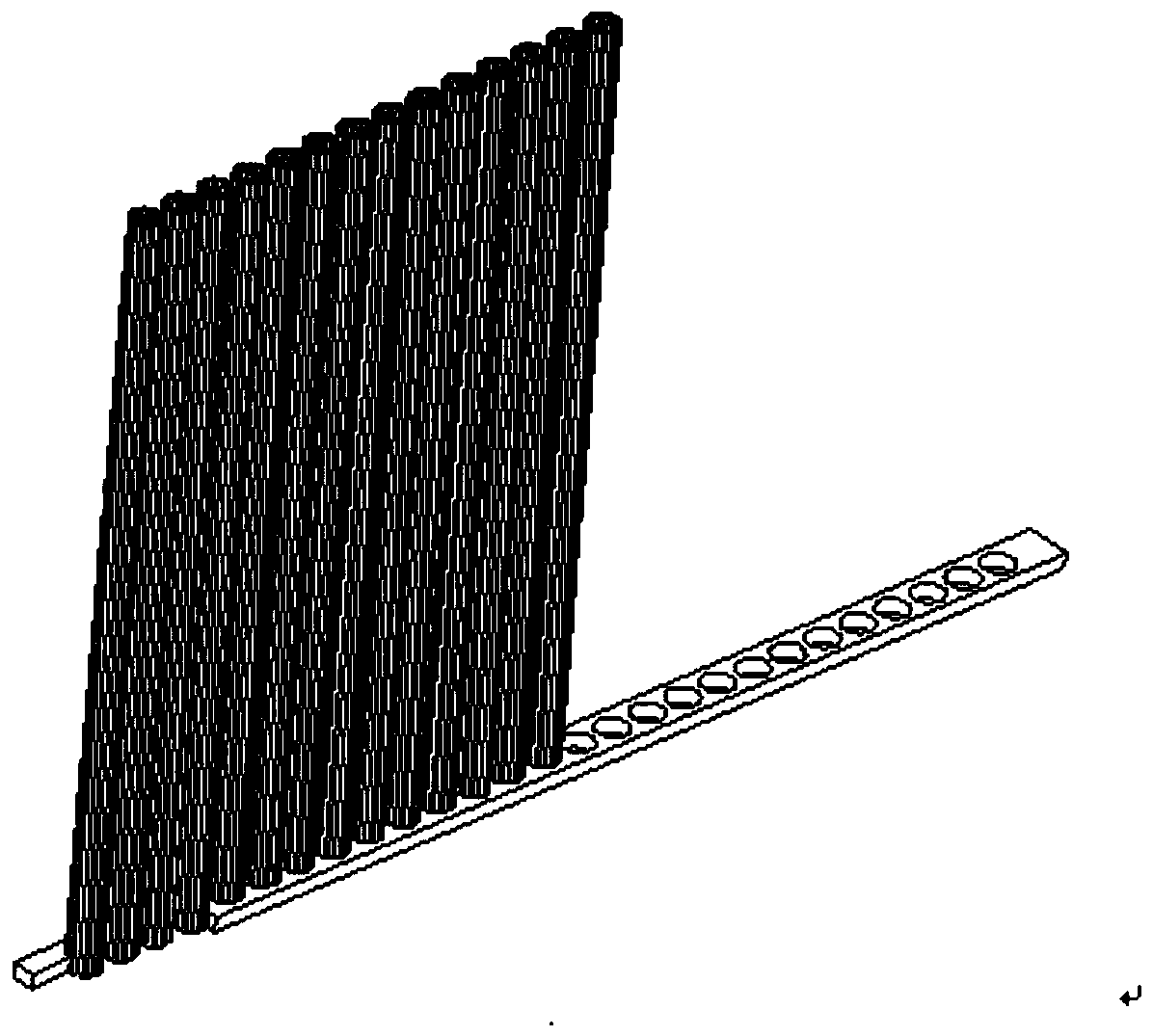

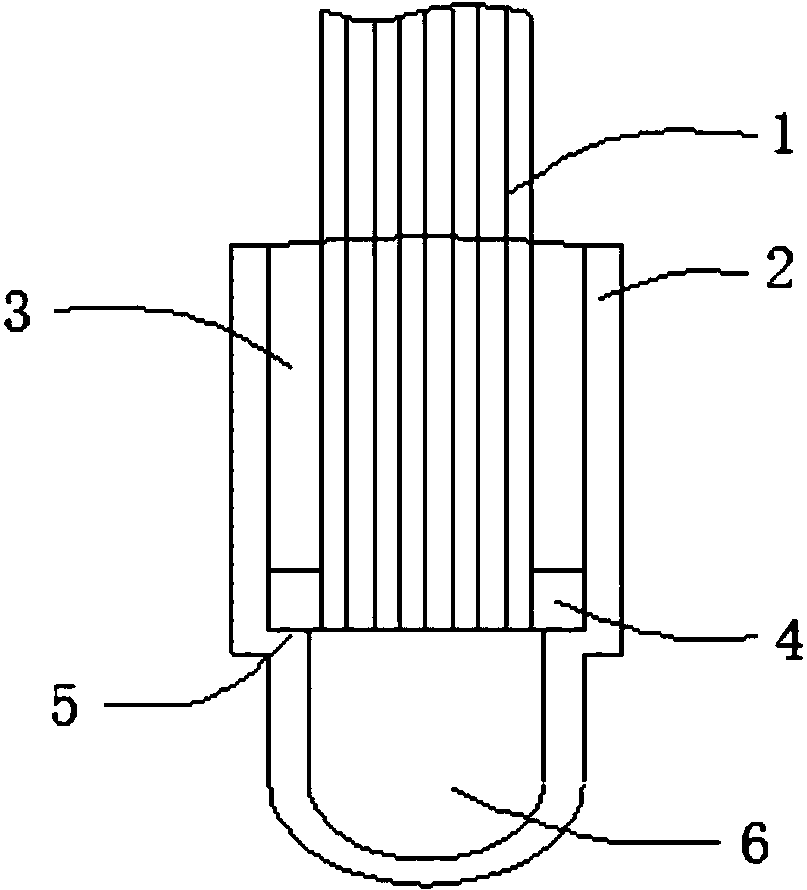

Sealing method for curtain type hollow fiber membrane

ActiveCN107398183AIncrease profitNo solid wasteSemi-permeable membranesBiological water/sewage treatmentEngineeringMechanical engineering

The invention relates to a sealing method for a curtain type hollow fiber membrane and belongs to the field of water treatment. The sealing method comprises the following steps: fastening one end of a hollow fiber membrane bundle; soaking the fastened end of the hollow fiber membrane bundle with a blocking matter, taking out the hollow fiber membrane bundle and curing the same; inserting one end of the cured hollow fiber membrane bundle into an MBR water collecting tube correspondingly, and bonding and fixing the two; and manufacturing the other end of the hollow fiber membrane. The method comprises the following steps: fastening two ends of the hollow fiber membrane bundle; soaking the two fastened ends of the hollow fiber membrane bundle with a blockage matter, taking out the hollow fiber membrane bundle and curing the same; and inserting two ends of the cured hollow fiber membrane bundle into MBR water collecting tubes correspondingly, and bonding and fixing the two. According to the sealing method provided by the invention, the tail end of the membrane silk does not need to extend into the water collecting tubes, so that the utilization ratio of the membrane silk is increased; the water yield end does not need to be cut, so that solid wastes are not generated; the packaging matter can be dissolved in water, and only needs to be dissolved out with water after the hollow fiber curtain type membrane is manufactured, and the dissolved-out package matter can be recycled.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

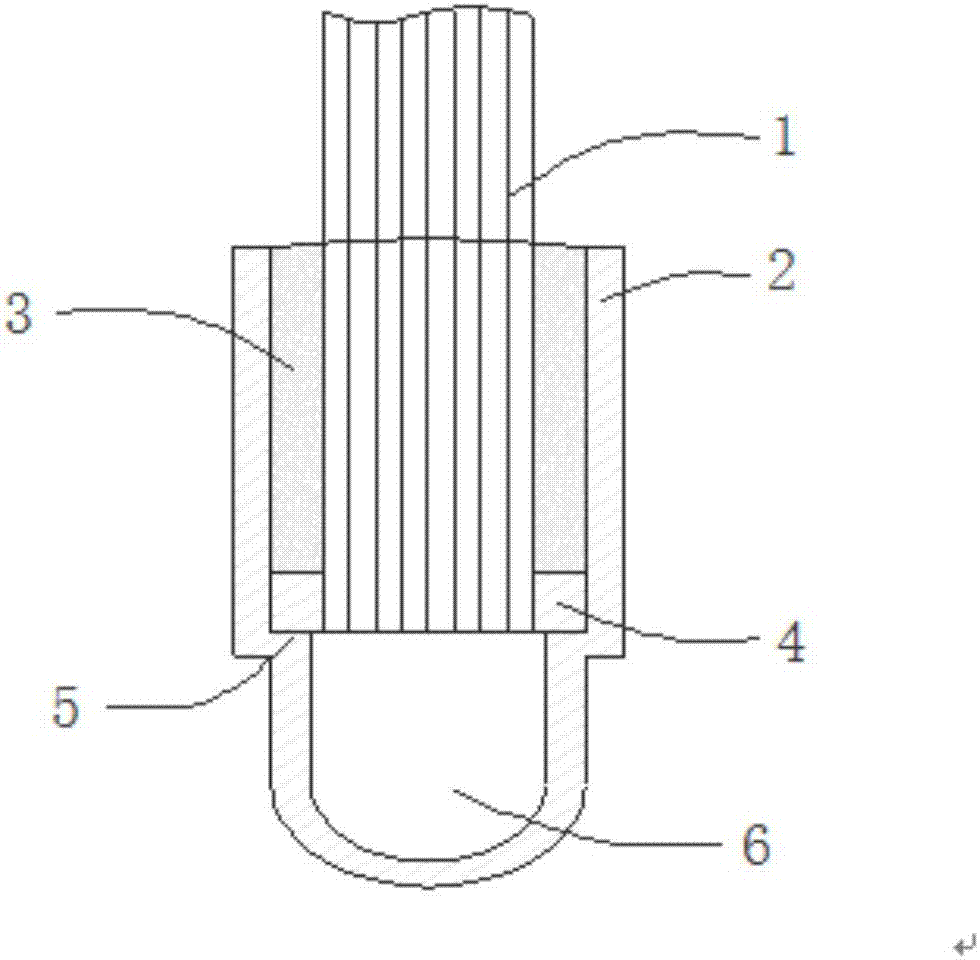

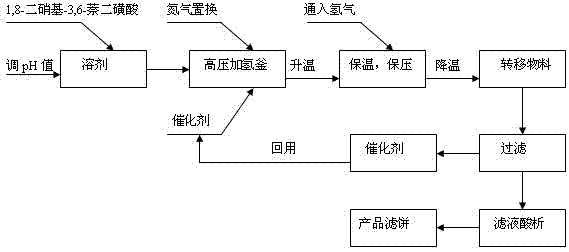

1,8-dinitro-3,6-naphthalene disulfonate hydrogenation reduction method

ActiveCN103113269ATake advantage of the economyNo solid wasteSulfonic acid preparationHydrogenation reactionAsymmetric hydrogenation

The invention relates to a 1,8-dinitro-3,6-naphthalene disulfonate hydrogenation reduction method belonging to the technical field of hydrogenation reaction of nitro-naphthalene disulfonic acid which contains and is connected to the same carbon skeleton. 1,8-dinitro-3,6-naphthalene disulfonate is reduced into 1,8-diamino-3,6-naphthalene disulfonate through catalytic hydrogenation, and is subjected to acidic hydrolysis to obtain an important intermediate compound H acid in dye industry. The method specifically comprises the following steps: dissolving 1,8-dinitro-3,6-naphthalene disulfonic acid, regulating the pH value to 7-10, and converting into corresponding salt; transferring the solution into a high-pressure hydrogenation kettle, adding a catalyst, heating and maintaining the pressure in a sealed environment, and reacting for 1-20 hours; and cooling to normal temperature, depressurizing, recovering the catalyst, performing acid precipitation on the reaction solution, filtering, and drying the filter cake to obtain 1,8-diamino-3,6-naphthalene disulfonic acid. The technical scheme of the invention has the advantages of no pollution in the preparation process, high product purity and the like.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Chloropentafluorobenzene preparation method

ActiveCN107188777AEasy to recycleIncrease productivityHalogenated hydrocarbon preparationLiquid wasteDistillation

The invention relates to a chloropentafluorobenzene preparation method, and belongs to the field of chemical production processes. According to the chloropentafluorobenzene preparation method, mixed gas obtained by mixing chlorine with reaction gas contacts with a catalyst to perform chlorination reaction, and pentafluorobenzene and ethyl alcohol are mixed and then gasified to obtain the reaction gas. The catalyst is prepared by a method including the steps: dissolving anhydrous ferric chloride and auxiliaries in absolute ethyl alcohol to obtain solution; adding coconut shell activated carbon or activated alumina particles into the solution, soaking the coconut shell activated carbon or activated alumina particles, and drying solvents by distillation to obtain the catalyst. The auxiliaries are one or more of manganese chloride, copper chloride and zinc chloride. Compared with the prior art, the chloropentafluorobenzene preparation method has the remarkable advantages that yield is high, solvents are omitted, reaction is continuous, no solid waste and liquid waste are generated, and the method is greener and more environment-friendly as compared with other methods.

Owner:DALIAN QIKAI MEDICAL TECH

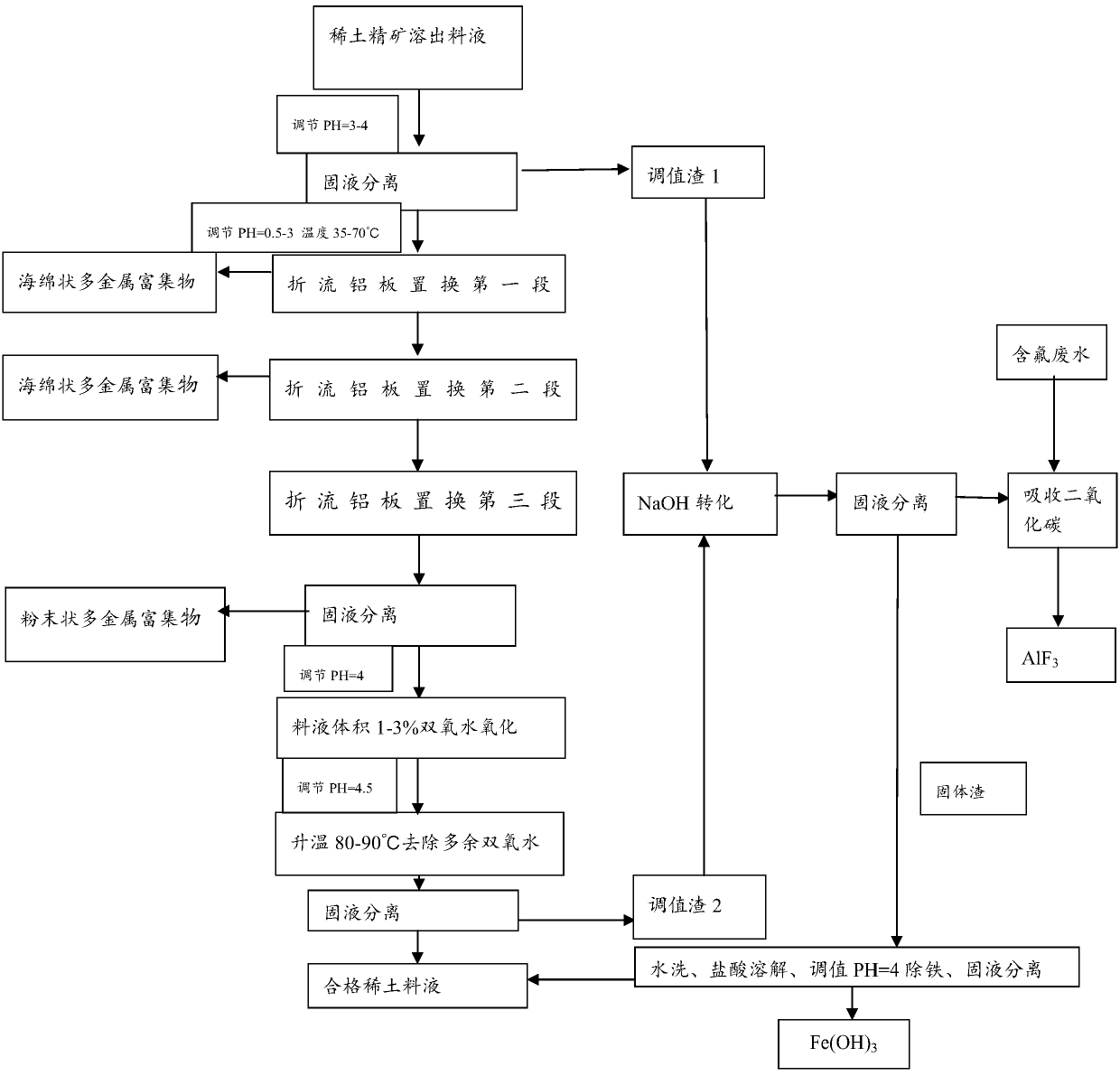

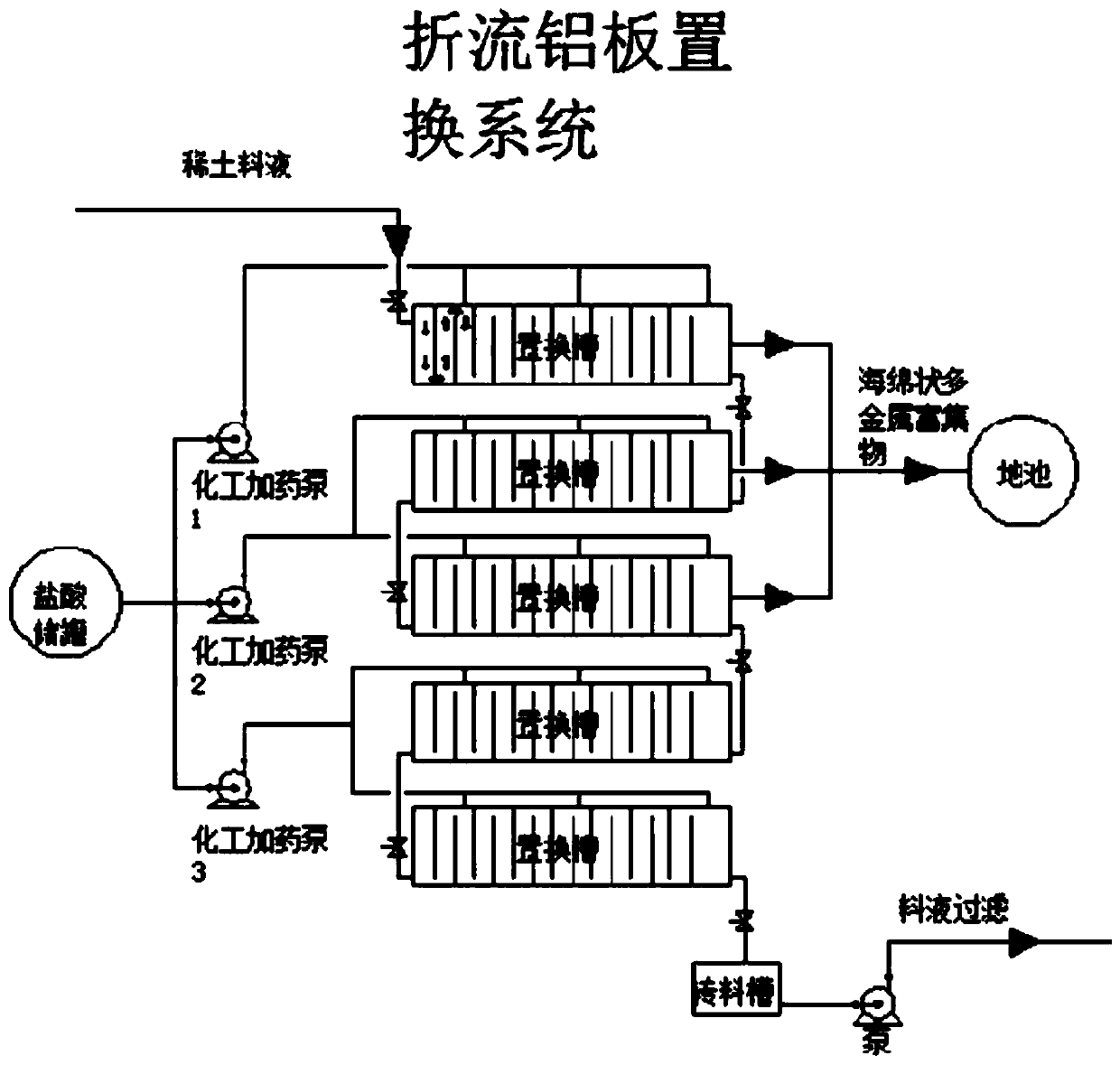

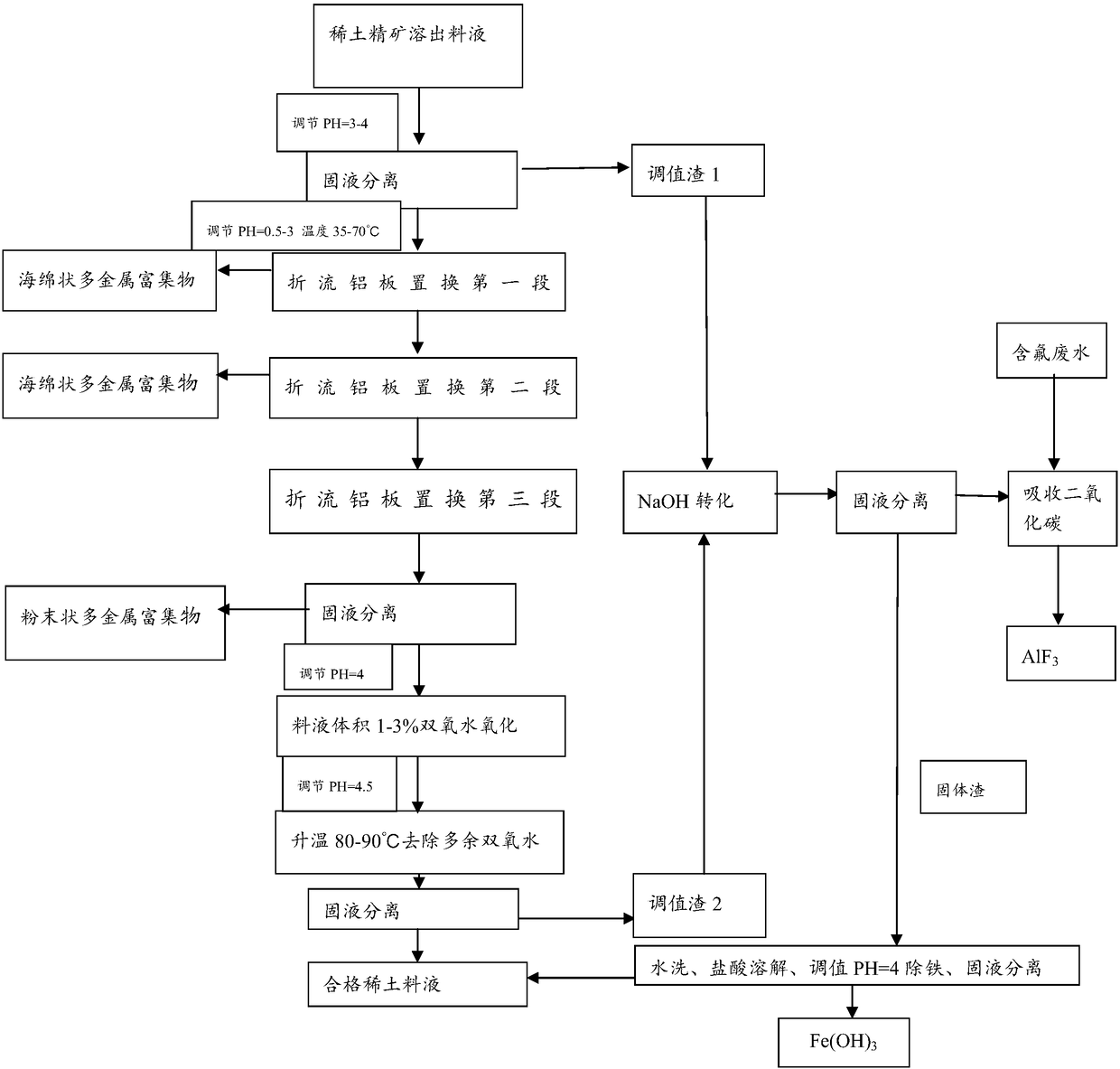

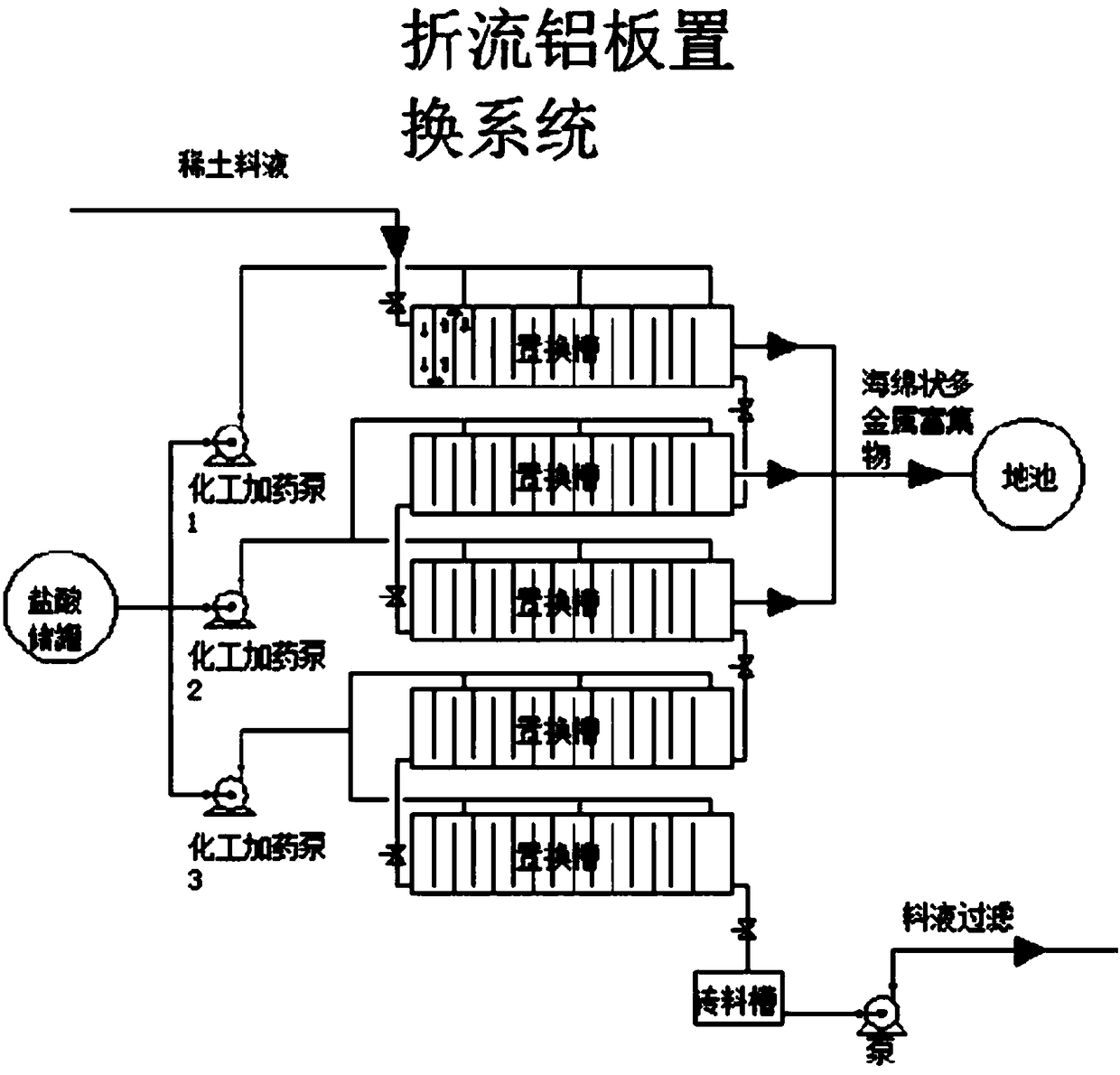

A rare earth material liquid impurity removal process

InactiveCN108411110BAchieve recyclingGreen and efficient impurity removalProcess efficiency improvementRare earthHydrometallurgy

The invention discloses an impurity removing process for rear earth feed liquid and belongs to the technical field of wet metallurgy. The impurity removing process for the rear earth feed liquid includes the following steps that (1) the rear earth feed liquid is preprocessed; (2) the rear earth feed liquid is subjected to three times of replacement in an independently controlled mode; (3) solid-liquid separation and collection of spongy multi-metal enriched products are carried out; (4) low-valence metal ions are subjected to oxidation treatment; and (5) an aluminum element and an iron elementin solid matter produced in the previous steps are solidified. The impurity removing process for the rear earth feed liquid has the beneficial effects that environment-friendly and high-efficiency impurity removing of the rear earth feed liquid is achieved, processing cost is low, higher safety is achieved, and the rear earth loss is less than 0.2% during displacement impurity removing of the rear earth feed liquid; and the lead content in the feed liquid is reduced to 0.005 g / L from 1-2 g / L, the iron content in the feed liquid is reduced to 0.004 g / L from 0.5-2 g / L, the copper content in thefeed liquid is less than 1 PPM after processing, silver, mercury and other trace metal elements capable of being replaced with metal aluminum in the feed liquid can be enriched, the content of sodiumions in the feed liquid is reduced, and the processing difficulty of waste water is reduced.

Owner:四川英创环保科技有限公司

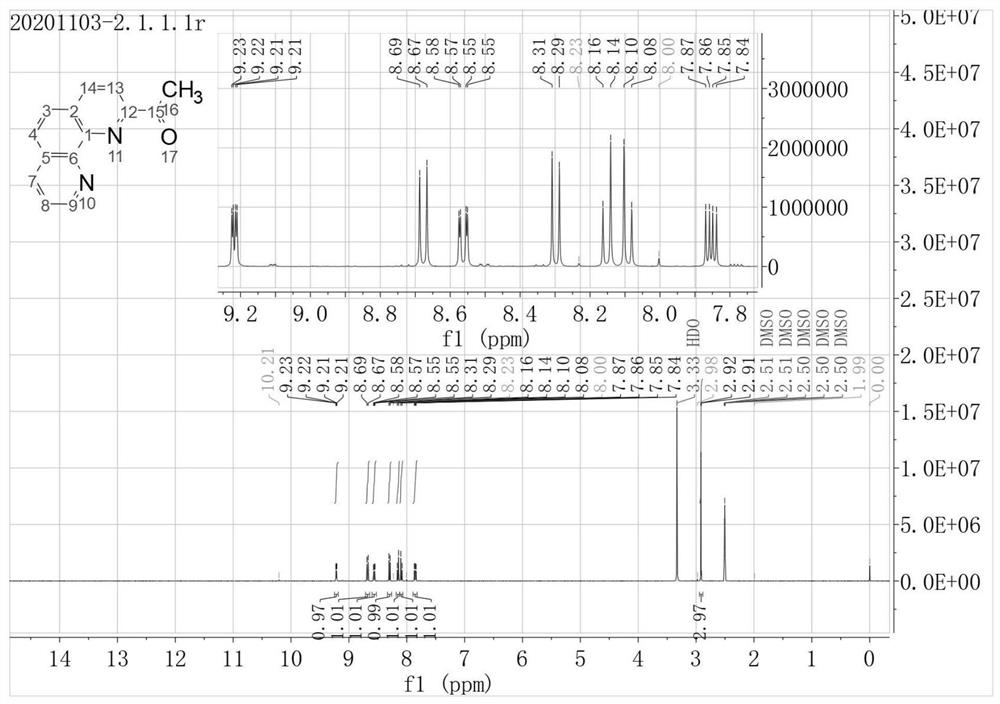

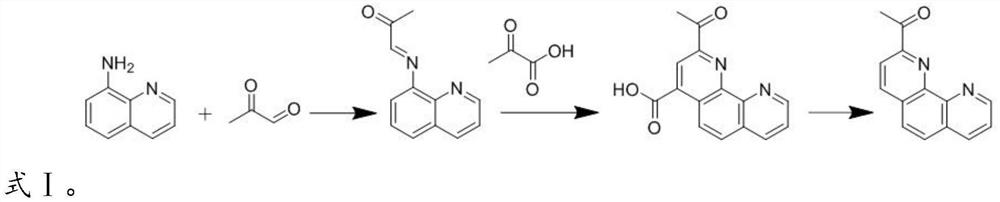

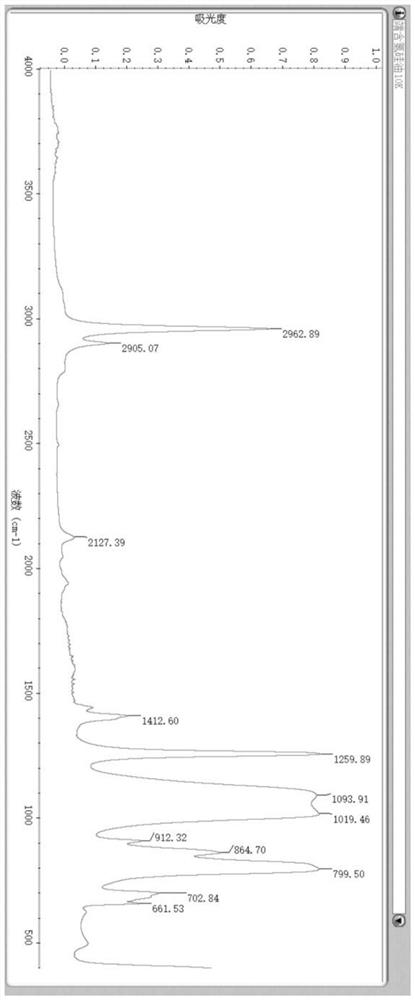

Preparation method of 2-acetyl-1, 10-phenanthroline

ActiveCN112939969AThe synthetic route is simpleRaw materials are easy to getOrganic chemistryPtru catalystOrganic synthesis

The invention relates to the technical field of organic synthesis, in particular to a preparation method of 2-acetyl-1, 10-phenanthroline. The preparation method provided by the invention comprises the following steps: mixing 8-aminoquinoline, pyruvic aldehyde and an alcohol organic solvent, and carrying out Schiff base reaction to obtain E-1-(quinoline-8-imino) propane-2-ketone; mixing the E-1-(quinoline-8-imino) propane-2-ketone and absolute ethyl alcohol, after moisture is removed, adding a catalyst and pyruvic acid, performing a doebner reaction, and obtaining 2-acetyl phenanthroline-4-formic acid; performing a decarboxylation reaction on the 2-acetyl phenanthroline-4-formic acid under the alkaline condition, and obtaining the 2-acetyl-1, 10-phenanthroline. The preparation method has the advantages of simple synthetic route, mild reaction conditions, easy industrial production, and green and friendly preparation raw materials.

Owner:TAIZHOU BIOMEDICAL & CHEM IND RES INST CO LTD

Preparation method of terminal hydrogen-containing silicone oil

The invention relates to a preparation method of terminal hydrogen-containing silicone oil, which is characterized in that the terminal hydrogen-containing silicone oil is prepared by adopting high-viscosity methyl silicone oil and tetramethyldisiloxane as raw materials, and under the action of a linear phosphonitrile chloride composite catalyst H, the catalyst has a degradation effect on siloxane chain segments in methyl silicone oil chain segments, so that macromolecular polysiloxane is degraded into many micromolecular polysiloxane; meanwhile, the micromolecular polysiloxane is quickly subjected to condensation polymerization, the tetramethyldisiloxane participates in reaction and is terminated in time, the linear polysiloxane is redistributed, and the high-activity terminated hydrogen-containing silicone oil is prepared. According to the method disclosed by the invention, no obvious cyclosiloxane is generated, the content of low-boiling-point substances is extremely low, and only extremely trace short-chain polysiloxane is generated. The problems that in a traditional acid equilibrium catalysis process, the prepared target product is low in activity, low in effective component and excessive in residual low-boiling-point substances and ring bodies are well solved, and particularly, the limitation of international regulations such as reaction on the residual quantity of organic silicon ring body components such as D3, D4 and D5 in the product can be met.

Owner:JIANDE BAISHA CHEM

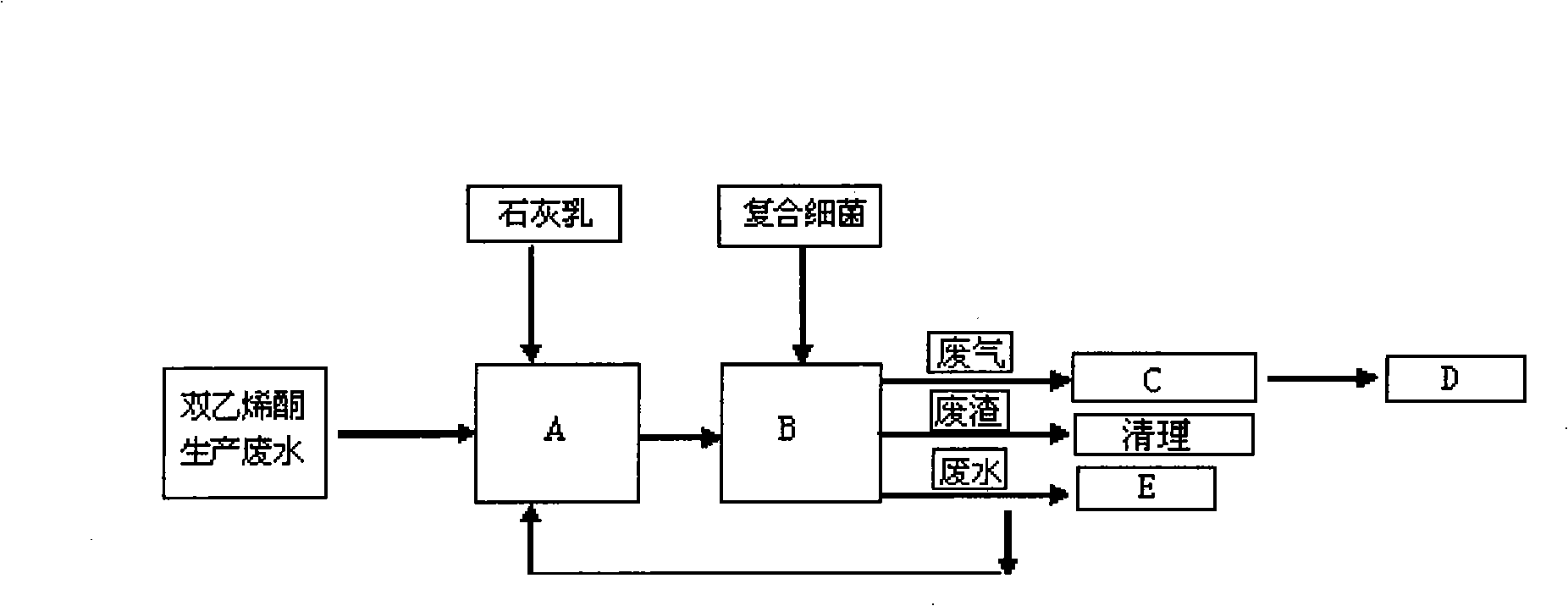

Method for processing production waste liquid of ketene dimer by composite bacteria

InactiveCN101337743AReduce CODNo solid wasteWaste based fuelTreatment with anaerobic digestion processesLiquid wasteChemical oxygen demand

The invention discloses a method for processing ketene dimmer industrial waste liquid by applying composite bacteria. The method comprises the following steps: adjusting the pH value of the ketene dimmer industrial waste liquid to 7 to 8 in a waste liquid adjusting tank by using lime milk; introducing the ketene dimmer industrial waste liquid into a UASB anaerobic reaction tank; processing the ketene dimmer industrial waste liquid by applying sludge in a domestic sewage treatment plant and methane bacteria used for sewage treatment in a citric acid plant, so that 96 percent of chemical oxygen demand (COD) in the ketene dimmer industrial waste liquid is eliminated; discharging exhaust gas from the top of the UASB tank; and enabling the exhaust gas to enter an exhaust gas collection device to be incinerated and discharged without pollution. A small quantity of residues in the waste liquid adjusting tank is cleaned periodically.

Owner:JIANGSU TIANCHENG BIOCHEM PROD

Method for preparing mullite-based light refractory material and synchronously purifying molybdenum calcine

ActiveCN111747759AHigh recovery rateHigh purityCeramicwareMolybdenum oxides/hydroxidesResource recoveryMullite

The invention discloses a method for preparing a mullite-based light refractory material and synchronously purifying molybdenum calcine. The invention belongs to the field of preparation of molybdenumchemicals and refractory materials. The method comprises the following steps: adding industrial molybdenum calcine which accounts for 100-500% of the mass of an aluminum-silicon raw material into thealuminum-silicon raw material, grinding and uniformly mixing the raw material, pressing the mixture into tablets, heating the tablet to 1000-1400 DEG C, and roasting the tablet for 0.5-3 hours, thereby obtaining the mullite-based light refractory material. In the roasting process, by collecting the condensed volatile matters at the same time, a pure molybdenum trioxide byproduct can be coproduced. The method integrates the preparation of the mullite-based light refractory material and the purification of molybdenum trioxide, wherein the production process is economic and environment-friendly,the added value of the product is high, the resource recovery rate is high, the equipment applicability is good, and the method is suitable for industrial application.

Owner:CENT SOUTH UNIV

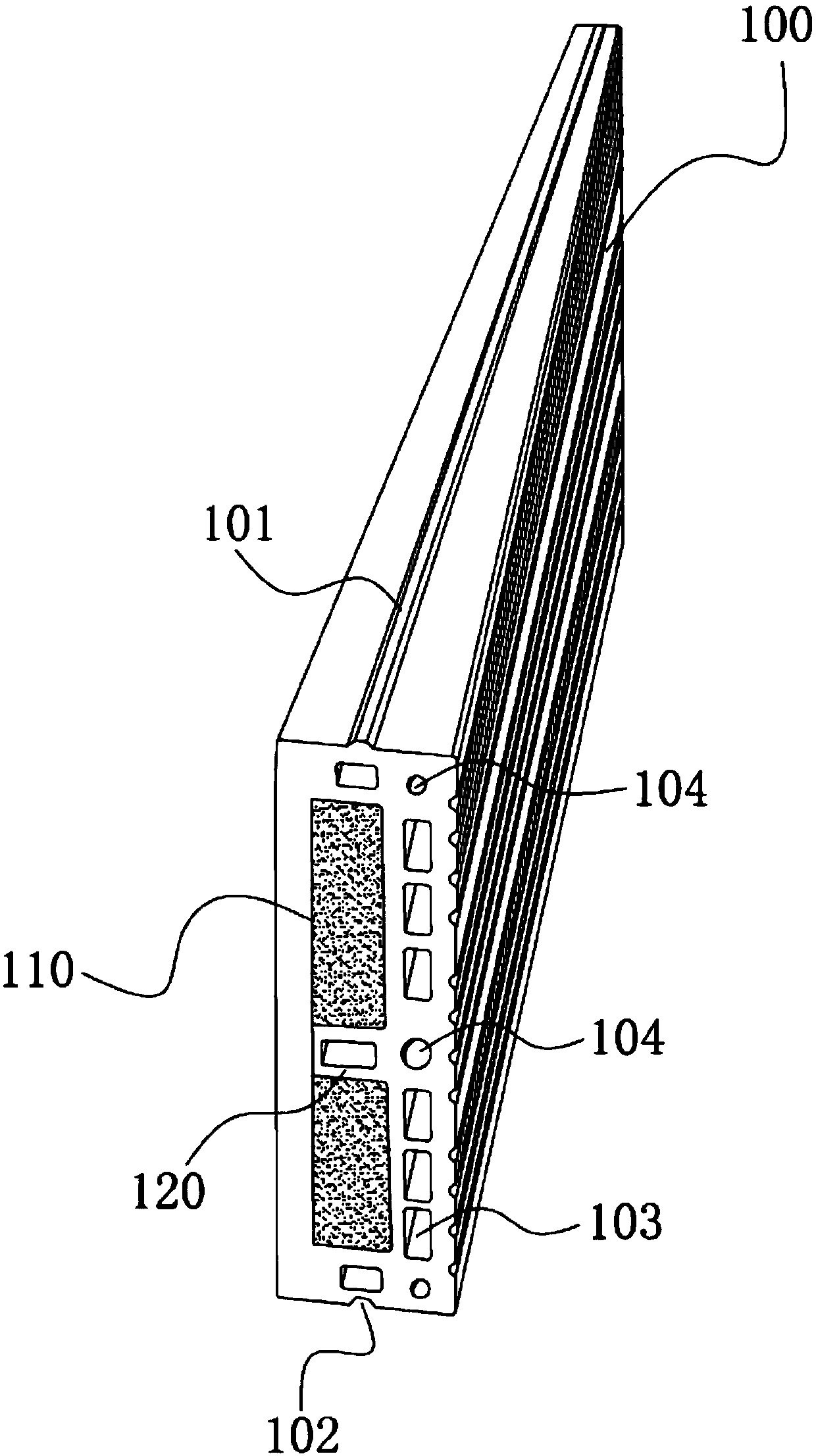

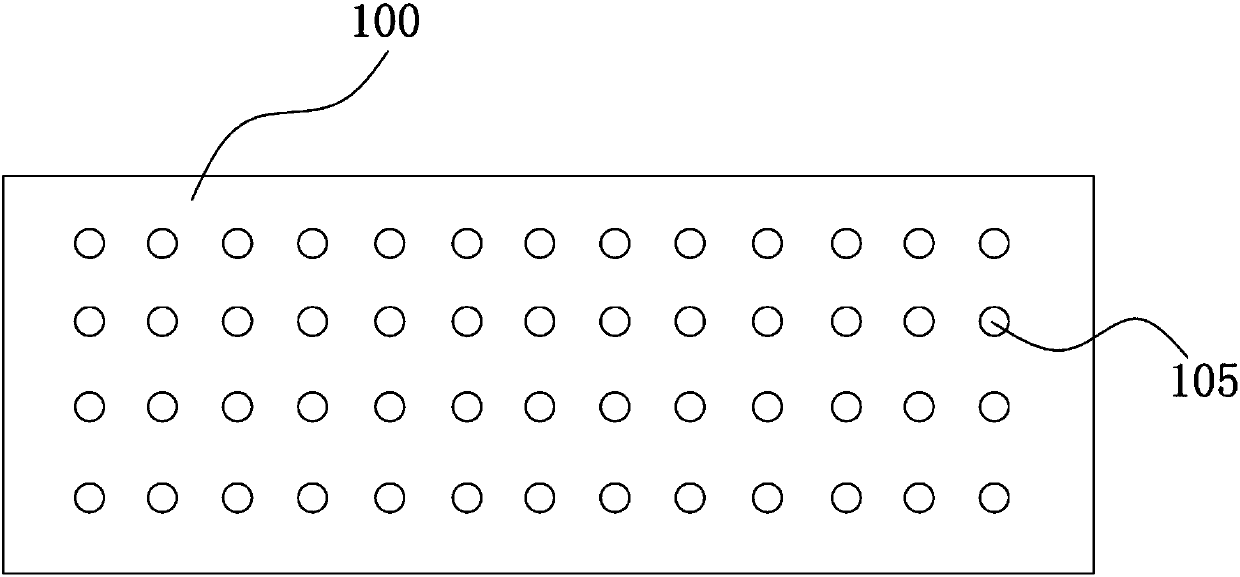

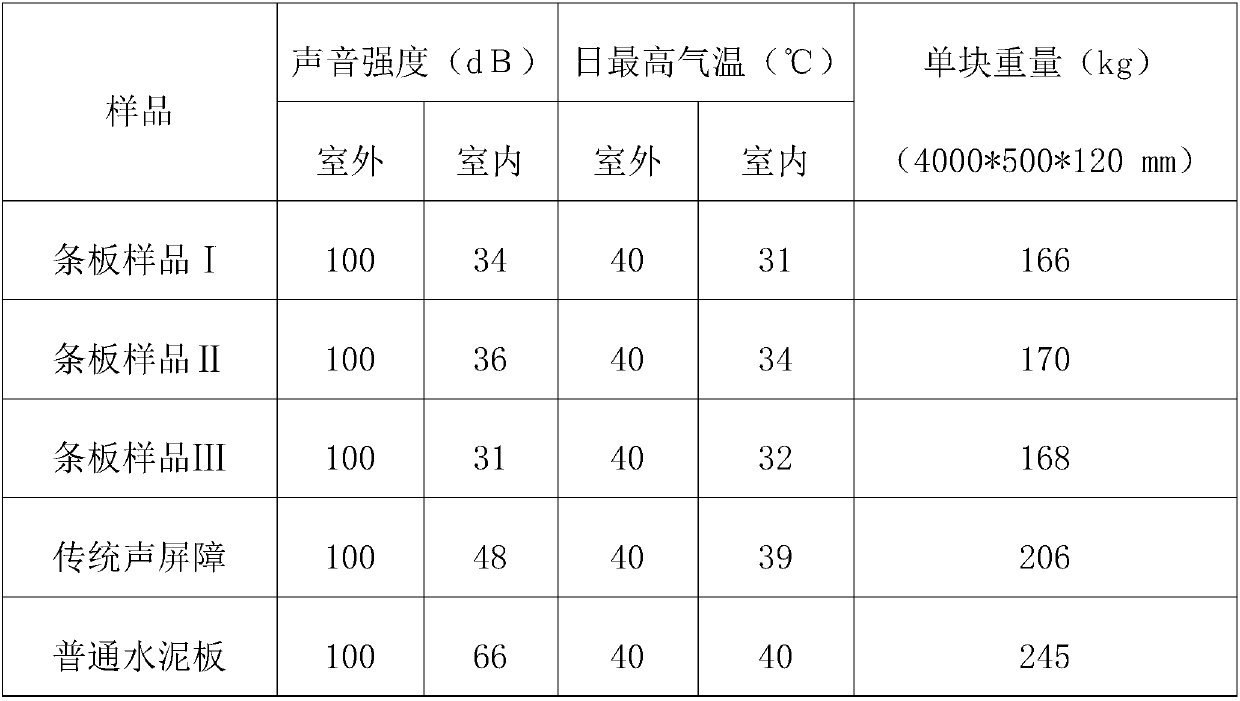

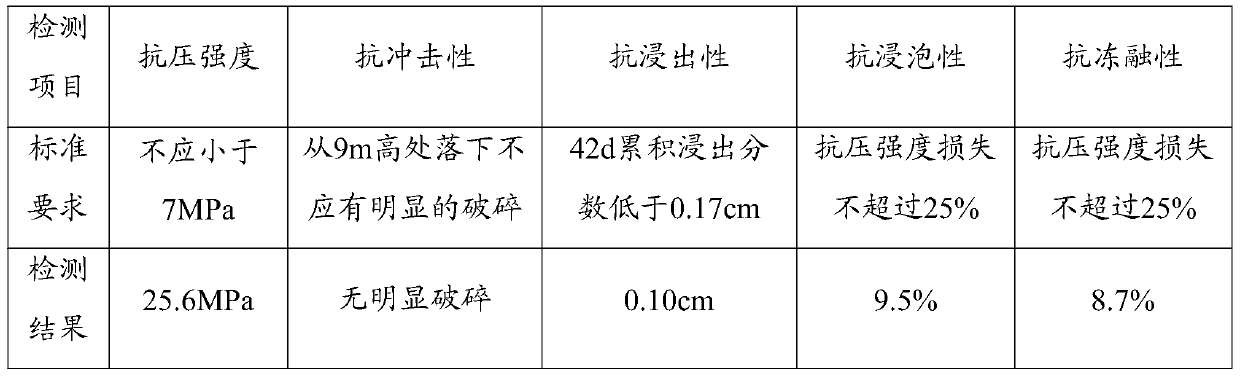

Light heat preservation and sound insulation batten and making method thereof

InactiveCN107869116AReduce workloadLow costNoise reduction constructionCeramic shaping apparatusSound barrierCeramic composite

The invention discloses a light heat preservation and sound insulation batten. The batten comprises a strip-shaped batten body (100), a male groove (101) is formed in the side wall of one side of thestrip-shaped batten body (100), a female groove (102) is formed in the side wall of the other side of the strip-shaped batten body (100), the shape of the male groove (101) is matched with that of thefemale groove (102), a sound insulation cavity (110) is formed in the strip-shaped batten body (100) in the length direction of the strip-shaped batten body (100), and the sound insulation cavity (110) is filled with ceramic composite materials. Accordingly, the sound insulation cavity of the strip-shaped batten body is filled with the sound insulation materials, in the production process, the strip-shaped batten body and a sound insulation part are combined into a whole, the workload and cost of construction are lowered, the laying efficiency is improved, and the application field is enlarged; the ceramic composite materials replace a traditional sound-absorbing plate, the sound insulation effect is better, the weight is lower, and meanwhile the manufacturing cost and environmental pollution of a sound barrier are lowered, and the market competitiveness of a production enterprise is improved.

Owner:SICHUAN SHUANGTIE TECH CO LTD

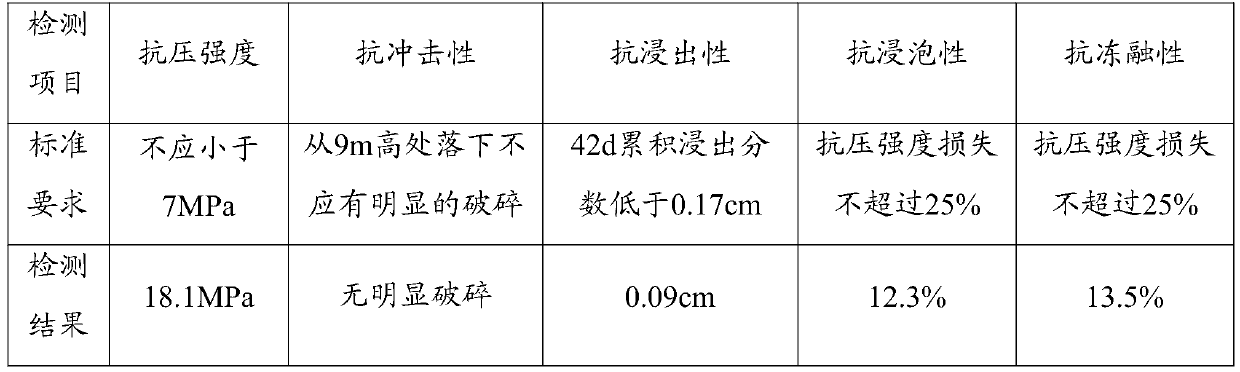

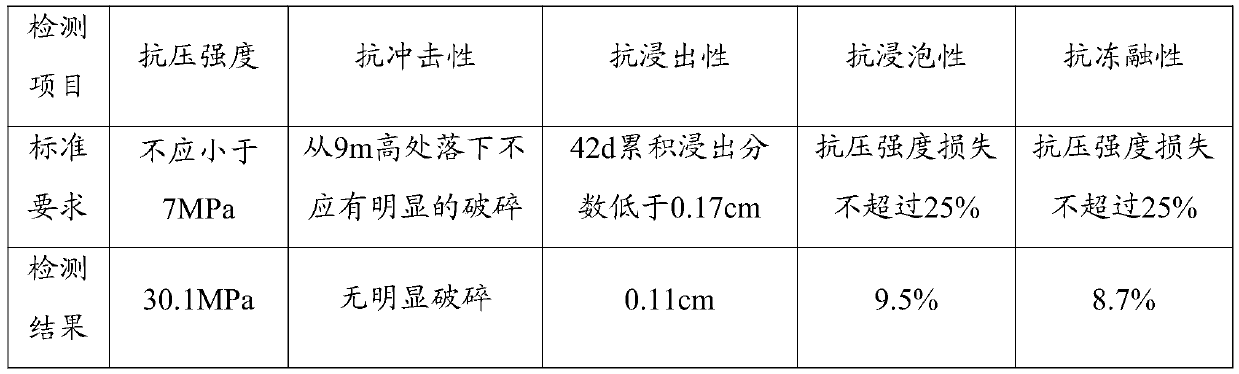

Treatment method of radioactive solid waste

ActiveCN111145931AHigh strengthImprove stabilityRadioactive decontaminationO-Phosphoric AcidExhaust fumes

The invention provides a radioactive solid waste treatment method which comprises the following steps: a) crushing radioactive solid waste to be treated, and mixing the crushed radioactive solid wastewith an admixture, sodium hydroxide and modified water glass to obtain a mixture; wherein the modified water glass is prepared by tempering water glass and inorganic mixed acid; and the inorganic mixed acid is prepared from sulfuric acid and phosphoric acid; and b) molding the mixture obtained in the step a) to obtain a solidified body. Compared with the prior art, the treatment method provided by the invention has the advantages of no need of moisturizing maintenance, no secondary pollution, no sewage discharge, no waste gas, no new solid waste, wide compatibility and strong applicability; the obtained solidified body has the characteristics of high strength and good stability, the requirements of GB 14569.1 Low and Medium Level Radioactive Solidified Body Performance Requirements-CementSolidified Body are met, and the solidified body solid waste package can meet the requirements of the near-surface disposal standard of radioactive solid waste in China.

Owner:NANHUA UNIV

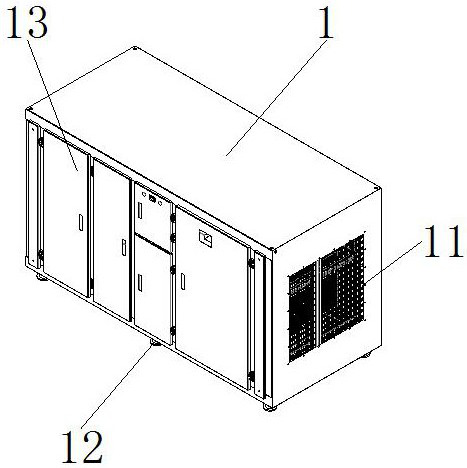

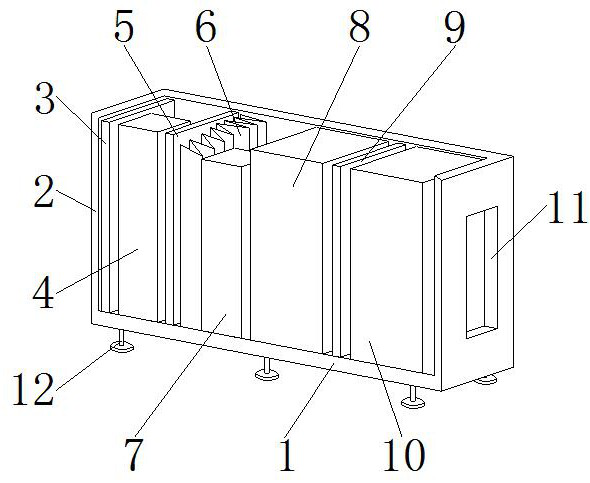

Negative ion and graphene combined waste gas purification equipment

PendingCN113877314ALow operation and maintenance costsImprove purification efficiencyDispersed particle filtrationActivated carbonFiltration

The invention discloses negative ion and graphene combined waste gas purification equipment which comprises a purification box, wherein the left side of the purification box is provided with a waste gas inlet pipeline connecting port, and primary filter screen cotton is fixedly mounted on the left side of an inner cavity of the purification box. Through mutual cooperation of the purification box, a waste gas inlet groove cavity, the primary filter screen cotton, a low-concentration ozone ion generator, a PM2.5 filter screen cotton, a filter screen bag, a negative oxygen ion generator, a graphene multilayer coating plate, high-grade filter screen cotton, a deodorization reaction module, a gas outlet pipeline connecting port, supporting legs and an access door, the advantage of high purification efficiency is achieved; and the multi-stage filtration and multi-stage combined purification design and the highly integrated structural design are adopted, the purification efficiency is high, power configuration is small, electricity is saved, solid waste (such as activated carbon) is not generated, sewage is not generated, secondary pollution is not generated, hazardous waste treatment cost is not generated, the application range is wide, the structure can be flexibly combined and adjusted according to different waste gas components, different concentrations and different air volumes, the installation occupied area is small, the operation is easy, and the operation and maintenance cost is low.

Owner:广州市福报环保科技有限公司

Synthetic method for glycine betaine hydrochloride

PendingCN109942445ALess side effectsNo solid wasteOrganic compound preparationCarboxylic acid esters preparationEthyl monochloroacetateBetaine Hydrochloride

The invention relates to a synthetic method for glycine betaine hydrochloride. The synthetic method comprises the following steps: successively adding monochloro acetic acid, a catalyst and ethanol into a reaction bottle; then raising the temperature to 100-115 DEG C; dehydrating a molecular sieve in a reflux position; carrying out a reaction for 2-8 hours; washing a reaction liquid twice; distilling separated ethyl chloroacetate at a reduced pressure; adding ethyl monochloroacetate into the reaction bottle; adding a certain amount of water; introducing trimethylamine gas; keeping the temperature at 20-45 DEG C; carrying out a reaction for 2-6 hours; then adding hydrochloric acid to raise the temperature and hydrolyze to distill water and ethanol therein; and reducing the temperature by 10-15 DEG C and carrying out crystallization and centrifugalization to obtain the glycine betaine hydrochloride. By synthesizing ethyl monochloroacetate from monochloro acetic acid and ethanol, synthesizing ethyl glycine betaine hydrochloride from the obtained pure ethyl monochloroacetate and trimethylamine, raising the temperature to hydrolyze in the presence of hydrochloric acid to obtain ethanol,and cooling the concentrated liquor to separate out glycine betaine hydrochloride, the purity of the prepared glycine betaine hydrochlorid is over 99% and the yield reaches over 97%. Inorganic salt solid waste is avoided.

Owner:山东瑞弘生物科技股份有限公司

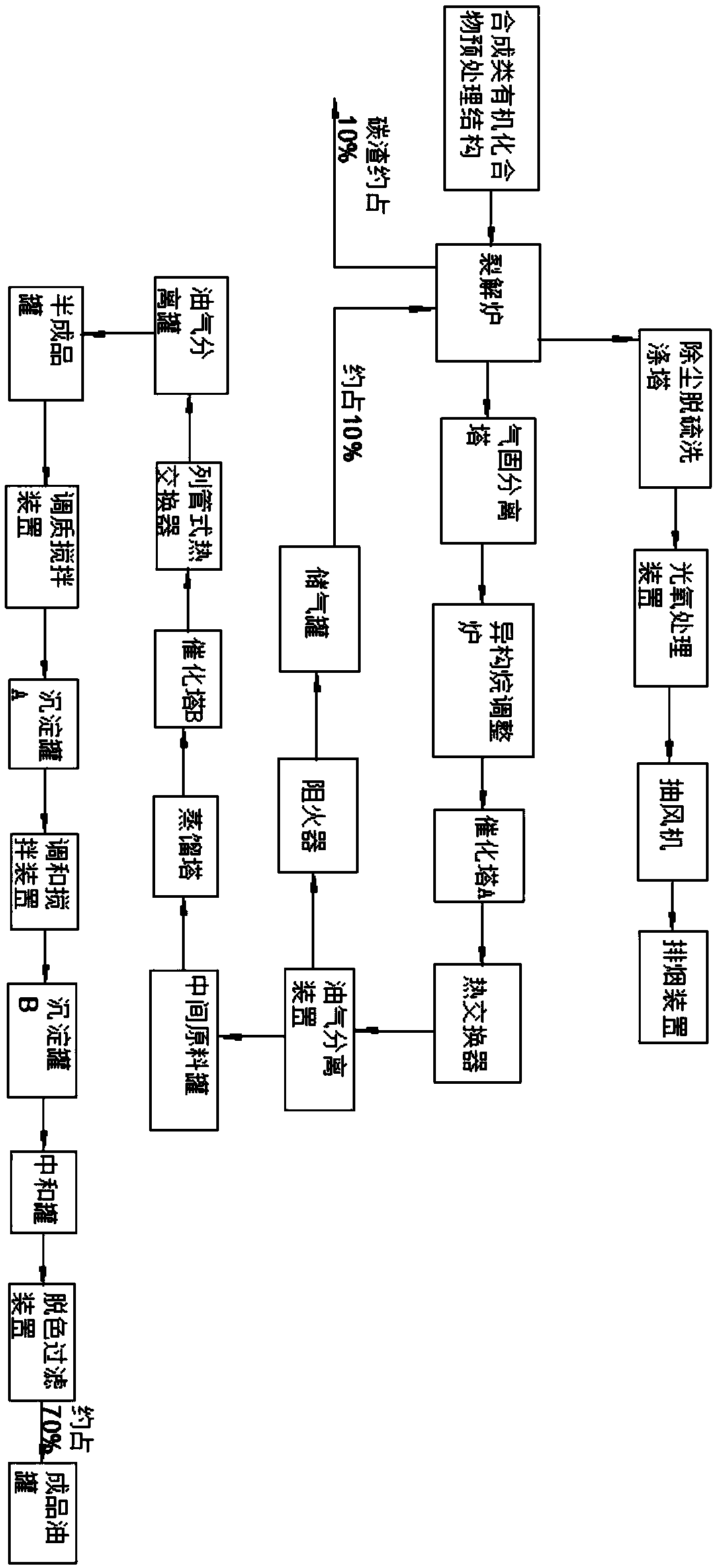

System and method for treating synthetic organic compounds in domestic waste

The invention discloses a system and a method for treating synthetic organic compounds in urban domestic waste. The system comprises a cracking system and an oil product purification system, wherein the cracking system comprises a synthetic organic compound pretreatment structure, the synthetic organic compound pretreatment structure is connected with a cracking furnace, the cracking furnace is connected with an exhaust gas treatment device, a gas-solid separation tower and a gas storage tank correspondingly, the gas-solid separation tower is sequentially connected with an isoalkane adjustingfurnace, a catalyzing tower A, a heat exchanger and an oil-gas separation device, the oil-gas separation device is further connected with the oil product purification system. By utilizing the system to crack the synthetic organic compounds in the domestic waste, the problem of pollution caused by toxic gases such as dioxin and heavy metals can be solved, regenerated energy prepared by the method is high in flash point and low in sulfur content, and is clean diesel, in the treatment process, the energy consumption is low, the emission is low, and zero pollution is achieved.

Owner:黑龙江九地生金科技有限公司

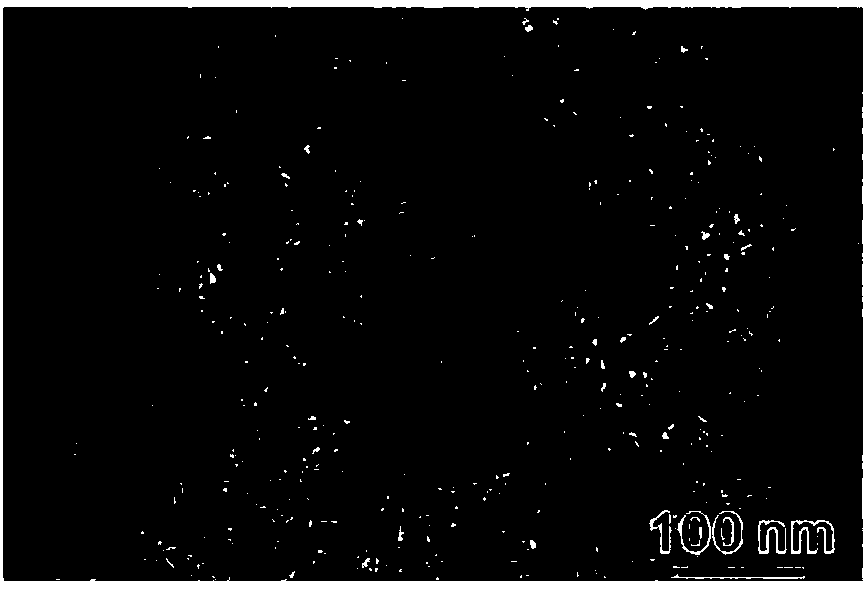

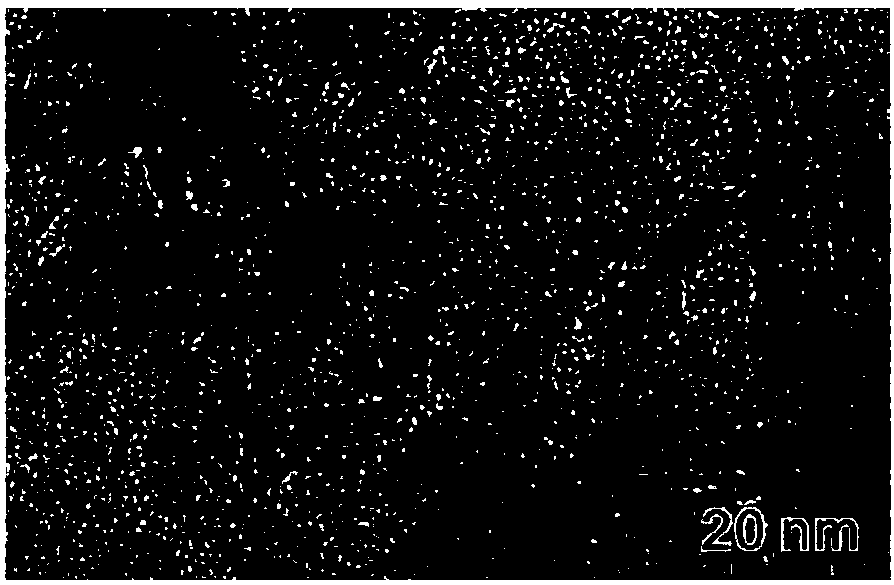

Green preparation method of two-dimensional hydroxide nano-sheets

InactiveCN108298600ALow costNo pollution in the processIron oxides/hydroxidesNickel oxides/hydroxidesChemical reactionSolvent

The invention provides a green preparation method of two-dimensional hydroxide nano-sheets, and relates to two-dimensional nano-materials. Metal salt is added into a solvent, and a settled solution isobtained after the metal salt is dissolved; an oxide medium is added into the prepared settled solution, ultrasonic dispersion is carried out, the material is stirred, and a product stands still; water for precipitation and ethyl alcohol are taken for repeated cleaning; after the product is dried, loose powder, namely the two-dimensional hydroxide nano-sheets, is obtained. A hydrolysis reaction of oxide particles can be used for replacing traditional soluble alkali at room temperature, specific metal cations are added, and by means of the chemical reaction between the metal cations and the surfaces of the oxide particles, the two-dimensional hydroxide nano-sheets corresponding to added metal are directly generated. In the solution, the oxide medium is used for replacing the traditional soluble alkali, and the two-dimensional hydroxide nano-sheets are prepared through interaction of the added transition metal cations and the surface of the oxide medium.

Owner:XIAMEN UNIV

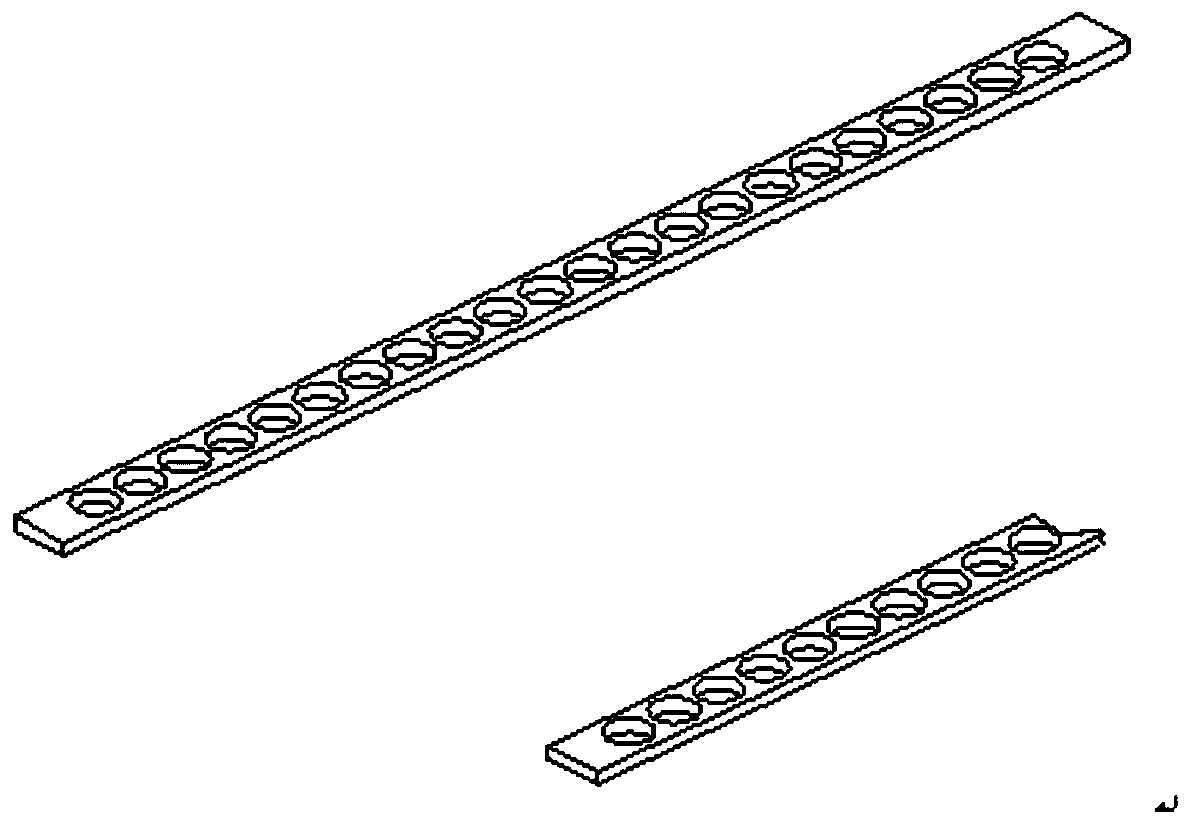

Climbing frame mesh sheet and production method thereof

PendingCN113123624AStrong resistance to deformationAchieve recyclabilityBuilding material handlingDomestic netsCompression moldingGlass fiber

The invention discloses a climbing frame mesh sheet and a production method thereof. The climbing frame mesh sheet comprises a frame and a mesh body, wherein the frame comprises two first supporting rods and two second supporting rods which are perpendicular to each other, wherein the first supporting rods and the second supporting rods form a rectangular structure, a mesh sheet is a rectangular sheet, the mesh sheet is fixedly connected to the surface of the frame, and the frame and the mesh sheet are both made of long glass fiber reinforced polypropylene. According to the climbing frame mesh sheet, the frame and the mesh sheet are made of long glass fiber reinforced polypropylene, so that a climbing frame has the characteristics of high strength, high deformation resistance and high recoverability, in addition, the frame and the mesh sheet are welded and fixed into an integral structure, the product material of the climbing frame mesh sheet is a material and is free of metal fasteners, the whole climbing frame mesh sheet can be crushed, recycled and reused, feeding, hot melting, mixing, spreading, compression molding and product taking can be automatically completed in the production process, intelligent manufacturing and green and environment-friendly for a factory is achieved, 100% recovery of products is achieved, and the environment-friendly policy is met.

Owner:HENGSHUI YOUJIETE PETROLEUM EQUIP TECH CO LTD

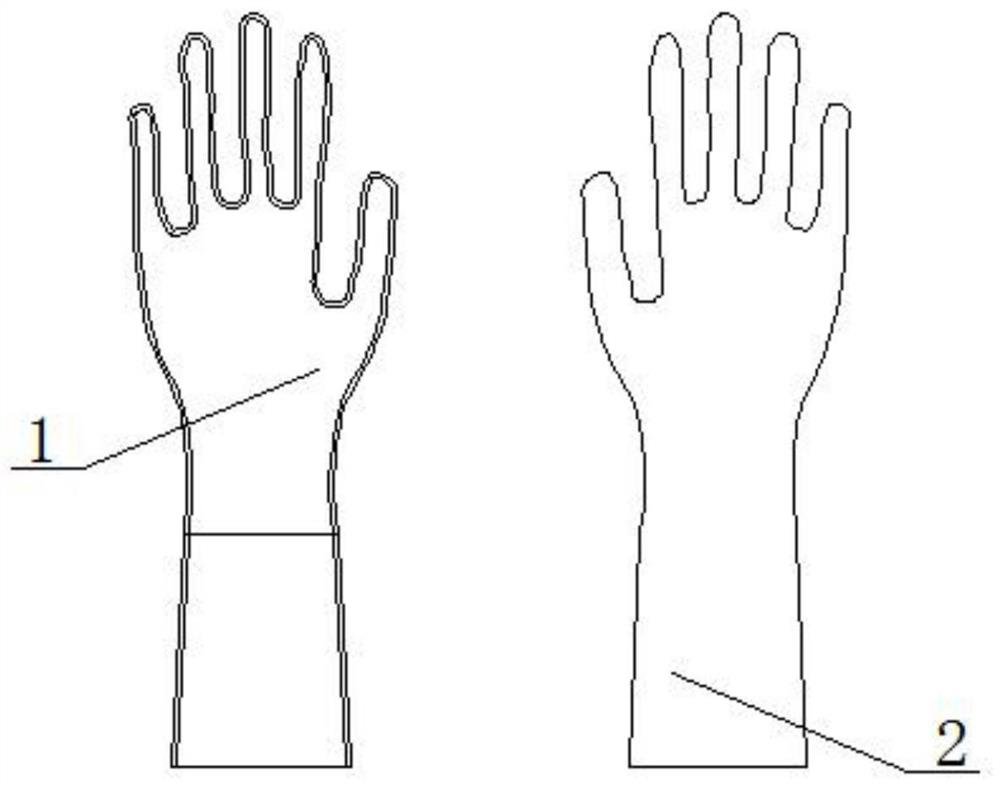

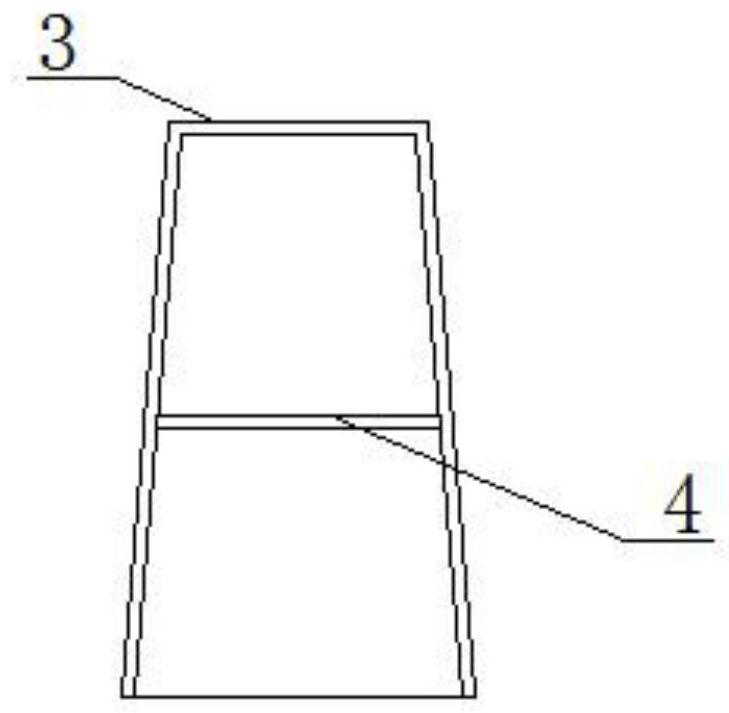

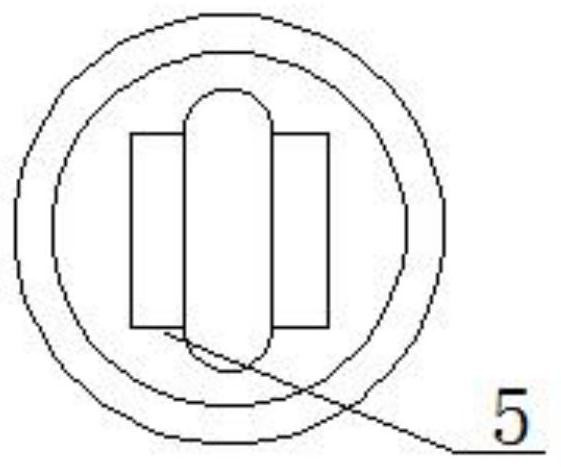

Metal hand mold applied to butyronitrile glove production line and production method thereof

InactiveCN112453839ANo solid wasteTo achieve the effect of repeated useAnodisationProduction lineProcess engineering

The invention discloses a metal hand mold applied to a butyronitrile glove production line. The metal hand mold comprises a first palm, a second palm is fixed to one side of the first palm, an arm module is arranged between the first palm and the second palm in a sleeving mode, and the upper end of the arm module extends to the position between the first palm and the second palm; and partition plates are jointly fixed to the peripheral side walls in the arm module. The invention further provides a production method of the metal hand mold applied to the butyronitrile glove production line, andthe production method comprises the following steps: S1, manufacturing a hand mold machine body: designing and manufacturing the butyronitrile metal hand mold, and according to design requirements, dividing the mold processes into two types, namely a stamping mold or a hydraulic mold. According to the metal hand mold and the production method, metal materials such as high-purity aluminum alloy / magnesium alloy can be used as material, the energy-saving effect can be effectively achieved, the material is not easy to break and wear, the service cycle is long, meanwhile, the material can be repeatedly used, solid wastes are avoided, the raw materials can be recycled, and the cost is reduced.

Owner:李国铭

A kind of sealing method of curtain hollow fiber membrane

ActiveCN107398183BIncrease profitNo solid wasteSemi-permeable membranesBiological water/sewage treatmentHollow fibrePolymer science

The invention relates to a sealing method for a curtain type hollow fiber membrane and belongs to the field of water treatment. The sealing method comprises the following steps: fastening one end of a hollow fiber membrane bundle; soaking the fastened end of the hollow fiber membrane bundle with a blocking matter, taking out the hollow fiber membrane bundle and curing the same; inserting one end of the cured hollow fiber membrane bundle into an MBR water collecting tube correspondingly, and bonding and fixing the two; and manufacturing the other end of the hollow fiber membrane. The method comprises the following steps: fastening two ends of the hollow fiber membrane bundle; soaking the two fastened ends of the hollow fiber membrane bundle with a blockage matter, taking out the hollow fiber membrane bundle and curing the same; and inserting two ends of the cured hollow fiber membrane bundle into MBR water collecting tubes correspondingly, and bonding and fixing the two. According to the sealing method provided by the invention, the tail end of the membrane silk does not need to extend into the water collecting tubes, so that the utilization ratio of the membrane silk is increased; the water yield end does not need to be cut, so that solid wastes are not generated; the packaging matter can be dissolved in water, and only needs to be dissolved out with water after the hollow fiber curtain type membrane is manufactured, and the dissolved-out package matter can be recycled.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

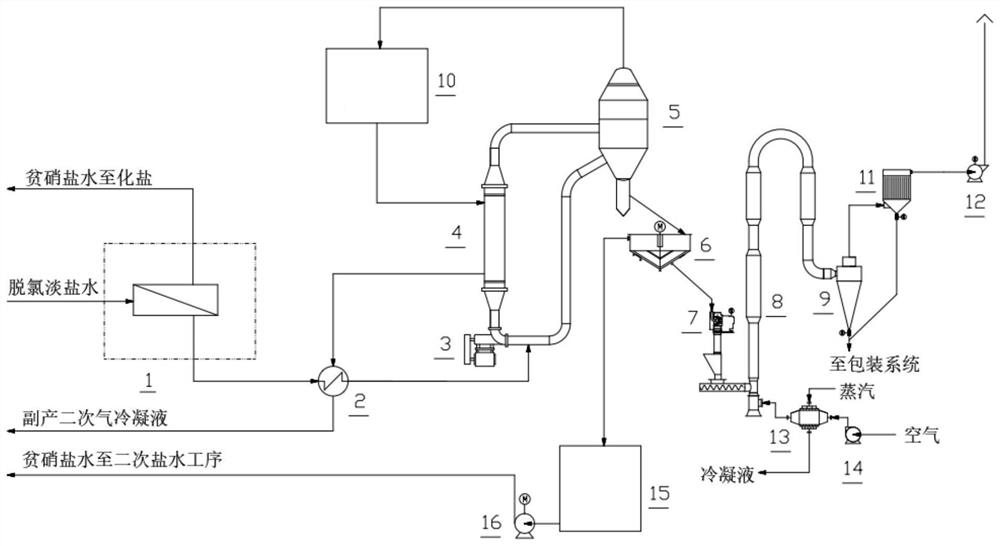

System and method for preparing byproduct potassium sulfate product through hydrothermal denitration of potassium chloride brine

PendingCN113184882ATo achieve the purpose of removing sulfateAvoid introducingAlkali metal sulfites/sulfates preparation formCalcium/strontium/barium chloridesPhysical chemistryPotassium sulfate

The invention relates to the technical field of chemical engineering, and discloses a system and method for preparing byproduct potassium sulfate product through hydrothermal denitration of potassium chloride brine, and the method comprises the following steps: a nanofiltration membrane unit receives dechlorinated light salt brine from an external potassium alkali device and conveys the dechlorinated light salt brine to a heat exchange unit for heat exchange; secondary gas condensate generated by an evaporative crystallization unit is conveyed to the heat exchange unit, in the heat exchange unit, the dechlorinated light salt brine exchanges heat with the secondary gas condensate, the dechlorinated light salt brine after heat exchange is conveyed to the evaporative crystallization unit to be evaporated and concentrated to obtain potassium sulfate crystals, and the secondary gas condensate after heat exchange is subjected to waste heat recovery treatment; and potassium sulfate crystals are treated by a centrifugal separating unit and then enter a drying unit to be dried, qualified potassium sulfate products are obtained, and centrifugal mother liquor obtained after centrifugal separating is output to a potassium alkali device to enter a secondary brine refining procedure. According to the method, the defects of a barium-method denitration process or a calcium-method denitration process used in current industrial production are effectively overcome, and the purposes of reducing cost and improving efficiency are achieved.

Owner:CHINA CHENGDA ENG

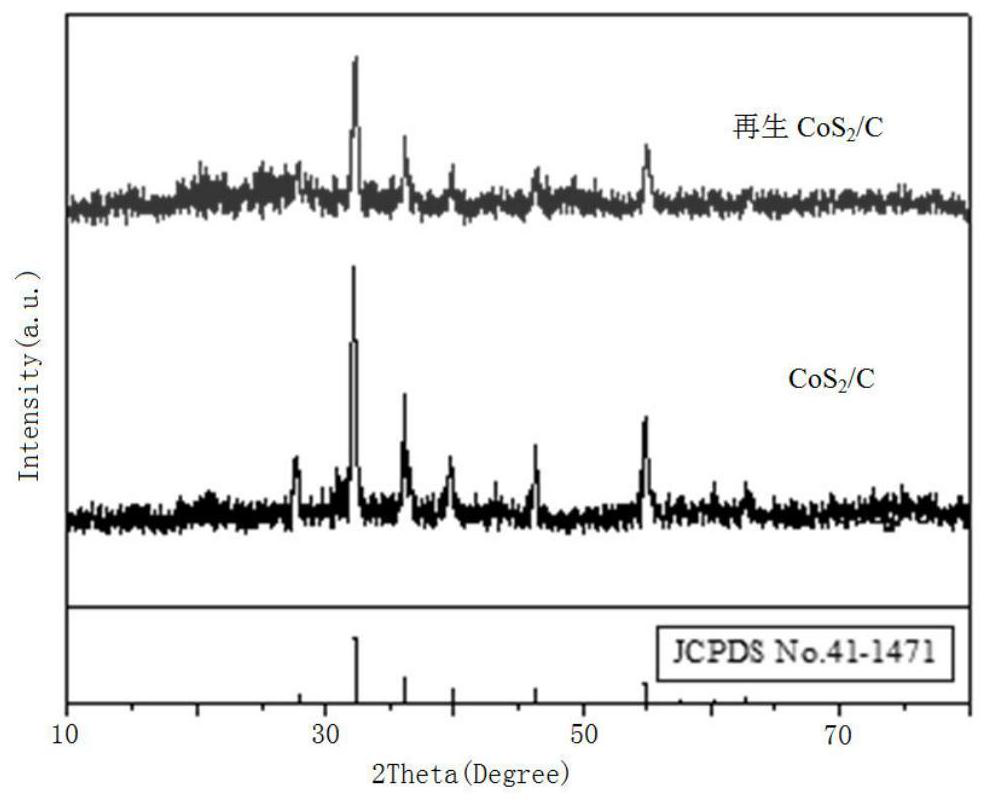

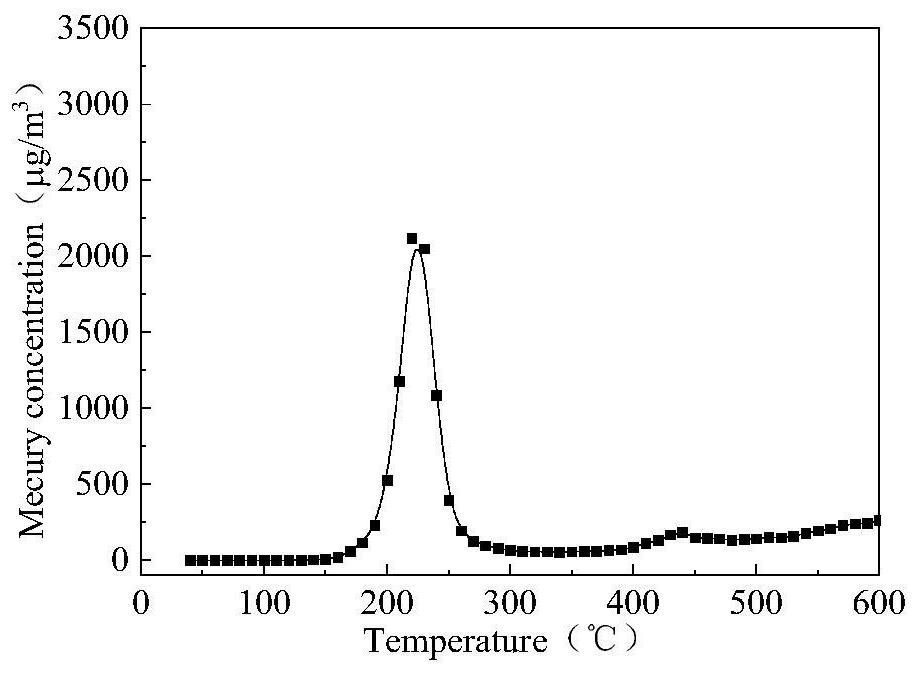

Method for regenerating flue gas demercuration material and recovering elemental mercury

ActiveCN114100592AImprove adsorption capacityEfficient recyclingGas treatmentDispersed particle separationEnvironmental engineeringMetallic sulfide

The invention discloses a method for regenerating a flue gas demercuration material and recovering elemental mercury. The method comprises the following steps: calcining a metal sulfide demercuration material which adsorbs elemental mercury to be saturated in a protective atmosphere I, recovering mercury vapor through condensation to obtain an inactivated metal sulfide demercuration material, and placing the inactivated metal sulfide demercuration material in a sulfur-containing vapor atmosphere to obtain the mercury-containing metal sulfide demercuration material. And calcining II in a mixed atmosphere containing hydrogen sulfide and / or sulfur vapor and sulfur dioxide, or in a mixed atmosphere containing hydrogen sulfide and / or sulfur vapor and sulfur dioxide, or in an atmosphere containing sulfur dioxide to obtain the regenerated metal sulfide demercuration material. According to the method, the desorption and recovery efficiency of elemental mercury adsorbed by the metal sulfide mercury removal material is high, the regenerated metal sulfide mercury removal material can keep high mercury removal activity and can be recycled for a long time, and the method is easy to operate, short in process, low in cost, environmentally friendly and beneficial to large-scale application and popularization.

Owner:CENT SOUTH UNIV

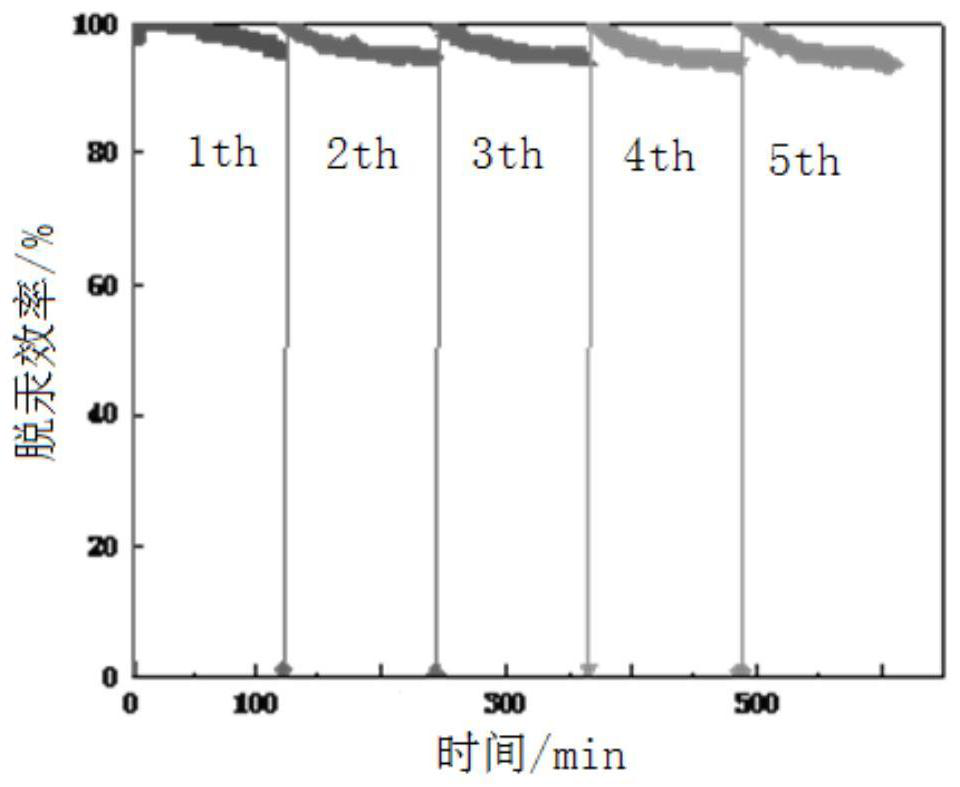

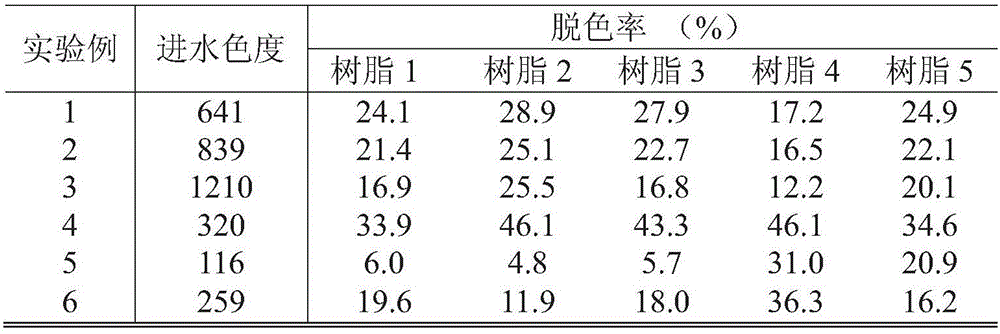

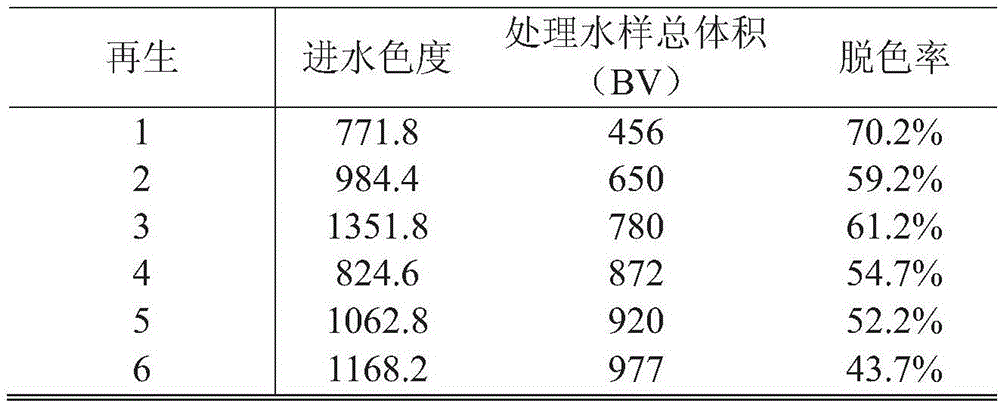

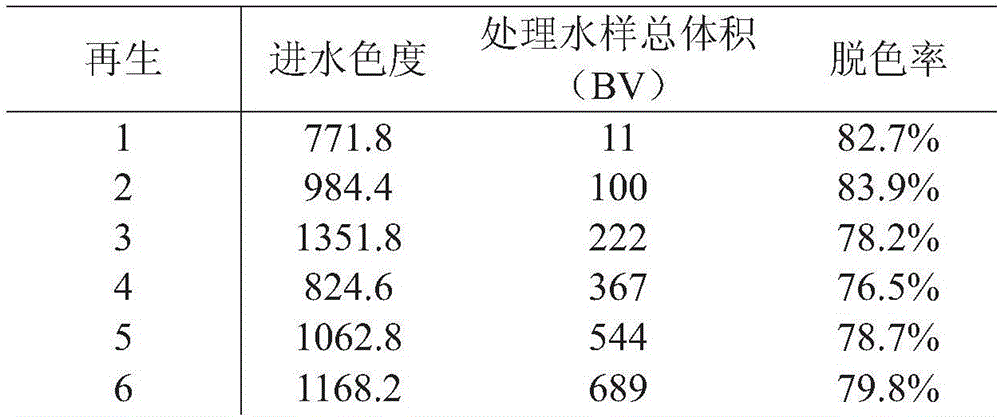

Regeneration method of adsorption medium and de-coloring treatment method of printing and dyeing wastewater

ActiveCN106365242AExtended service lifeIncrease the reuse ratioIon-exchanger regenerationWater/sewage treatment by ion-exchangeDyeing wastewaterIon-exchange resin

The invention discloses a regeneration method of an adsorption medium and a de-coloring treatment method of printing and dyeing wastewater. The regeneration method comprises: a regeneration solution flows through the adsorption medium; the adsorption medium is ion exchange resin or / and macro-porous adsorption resin; the regeneration solution is prepared from the following components: NaCl with the mass percent of 2 percent to 8 percent, NaOH with the mass percent of 2 percent to 8 percent and rhamnolipid with the concentration of 100ppm to 300ppm. According to the de-coloring treatment method provided by the invention, the adsorption medium is regenerated through adopting the regeneration method. According to the regeneration method of the adsorption medium, provided by the invention, the resin is rapidly regenerated in a short period through adopting the special regeneration solution and the service life of resin de-coloring is greatly prolonged; the wastewater de-coloring efficiency is improved and the operation cost is reduced; after 1500BV wastewater is treated through the resin, the adsorption performance basically has no changes and the de-coloring efficiency can reach 80 percent or above for a long period.

Owner:ZHEJIANG UNIV

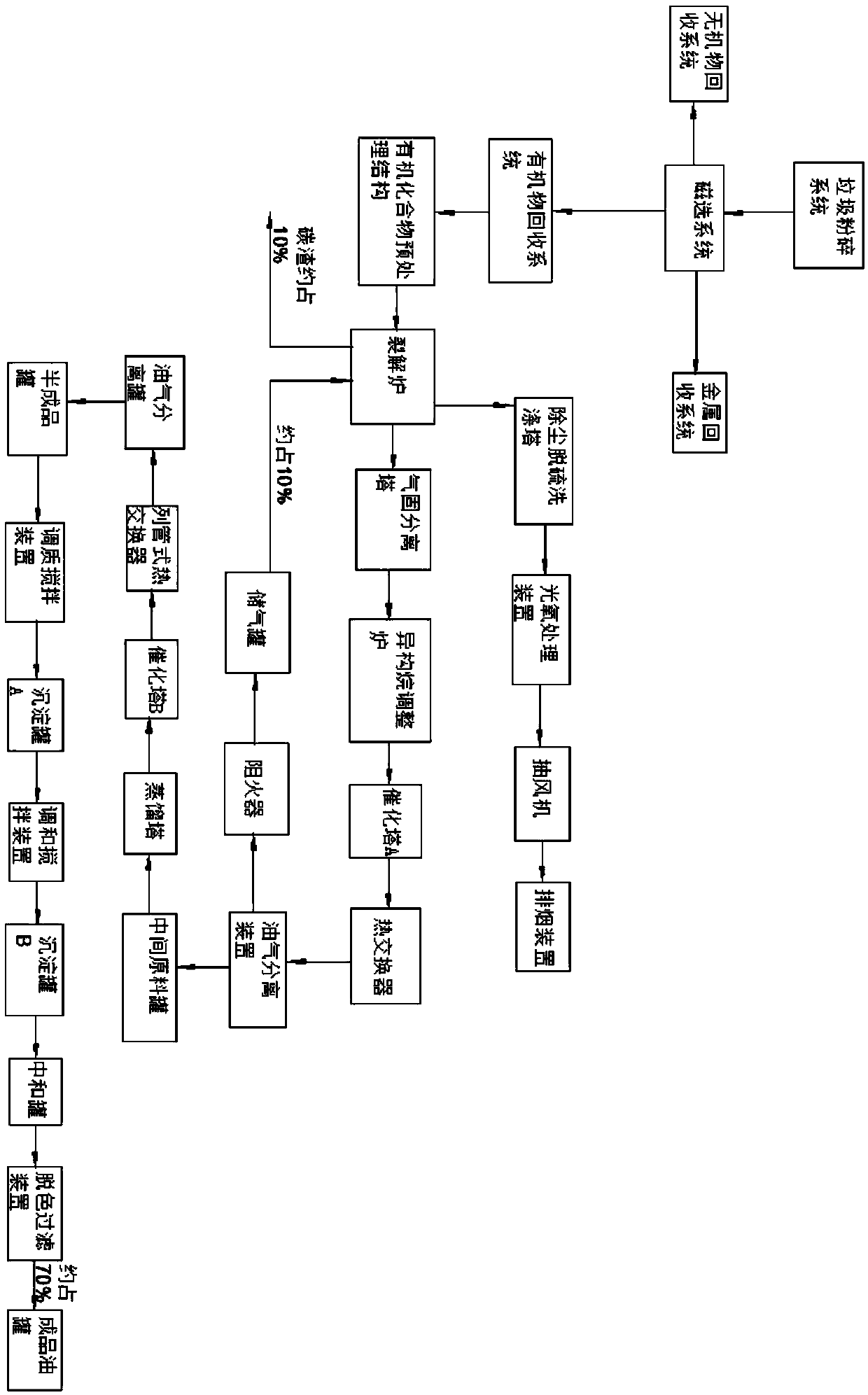

Urban domestic waste deep resource utilization system and method

PendingCN109536191AHigh flash pointHigh calorific valueLiquid hydrocarbon mixture productionResource utilizationOrganic matter

The invention discloses an urban domestic waste deep resource utilization system and method. The system comprises a waste classification system and a resource utilization system, wherein the waste classification system comprises a waste crushing system and a magnetic separation system in sequential connection; the magnetic separation system is respectively connected with a metal recovery system, an inorganic matter recovery system and an organic matter recovery system; the organic matter recovery system is connected with the resource utilization system. By using the system provided by the invention, the urban domestic waste is classified; various kinds of substances are sequentially classified and are sufficiently recovered and reused; the organic matters are subjected to cracking and purification treatment to obtain clean diesel oil, so that the pollution of the waste on atmosphere, water body and soil is reduced.

Owner:黑龙江九地生金科技有限公司

Impurity removing process for rear earth feed liquid

InactiveCN108411110AContinuous replacementAchieve serializationProcess efficiency improvementIonControl mode

The invention discloses an impurity removing process for rear earth feed liquid and belongs to the technical field of wet metallurgy. The impurity removing process for the rear earth feed liquid includes the following steps that (1) the rear earth feed liquid is preprocessed; (2) the rear earth feed liquid is subjected to three times of replacement in an independently controlled mode; (3) solid-liquid separation and collection of spongy multi-metal enriched products are carried out; (4) low-valence metal ions are subjected to oxidation treatment; and (5) an aluminum element and an iron elementin solid matter produced in the previous steps are solidified. The impurity removing process for the rear earth feed liquid has the beneficial effects that environment-friendly and high-efficiency impurity removing of the rear earth feed liquid is achieved, processing cost is low, higher safety is achieved, and the rear earth loss is less than 0.2% during displacement impurity removing of the rear earth feed liquid; and the lead content in the feed liquid is reduced to 0.005 g / L from 1-2 g / L, the iron content in the feed liquid is reduced to 0.004 g / L from 0.5-2 g / L, the copper content in thefeed liquid is less than 1 PPM after processing, silver, mercury and other trace metal elements capable of being replaced with metal aluminum in the feed liquid can be enriched, the content of sodiumions in the feed liquid is reduced, and the processing difficulty of waste water is reduced.

Owner:四川英创环保科技有限公司

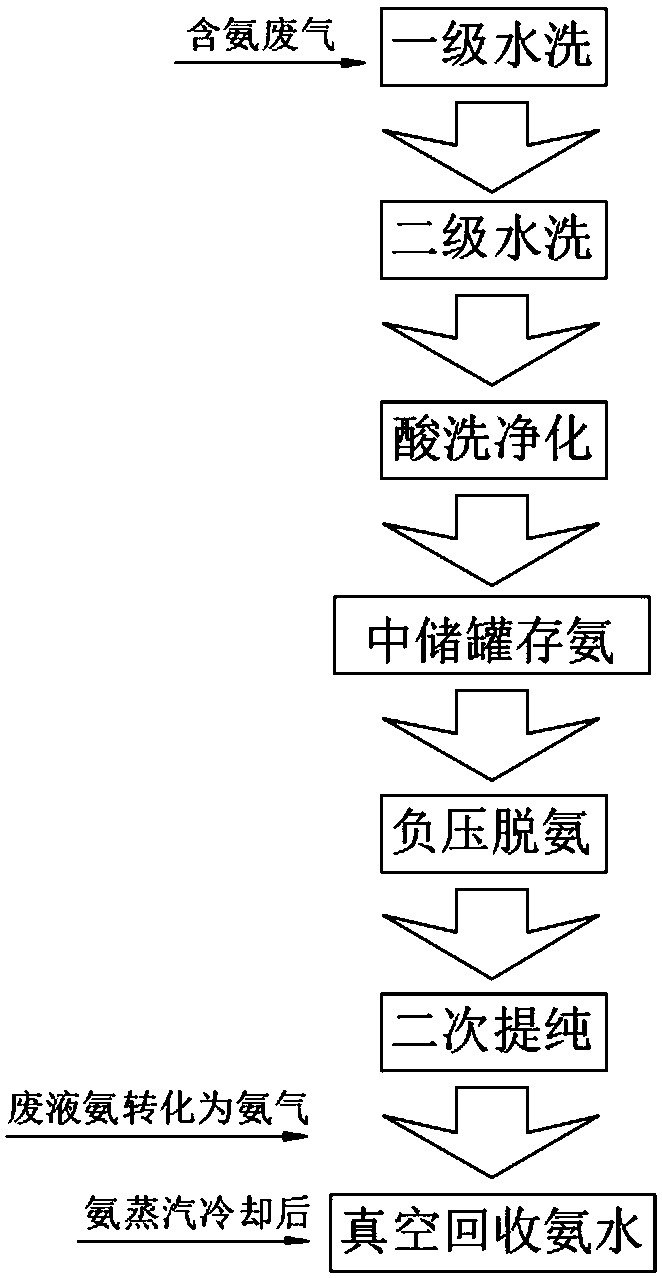

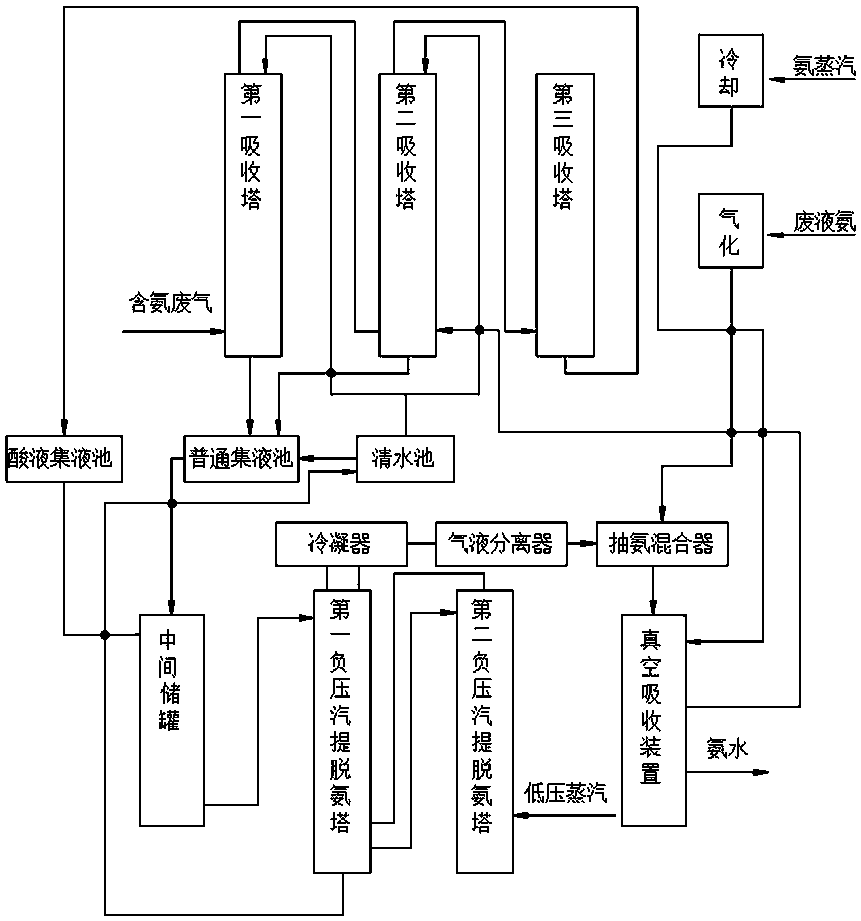

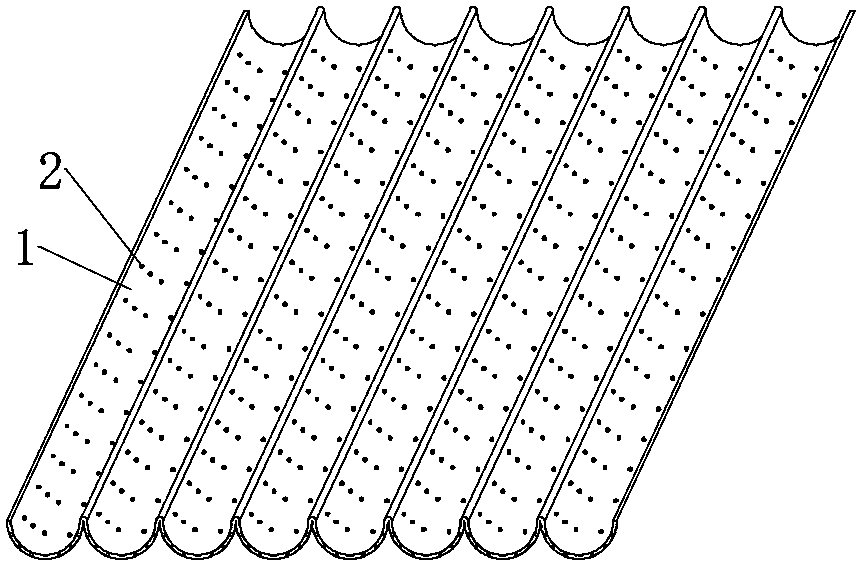

Special fabric ammonia-containing exhaust gas circulating purification and recovery technology

ActiveCN110575744AAchieving zero emissionsGood stripping effectDispersed particle separationAir quality improvementAcid washingWastewater

The invention discloses a special fabric ammonia-containing exhaust gas circulating purification and recovery technology. The special fabric ammonia-containing exhaust gas undergoes ammonia source classification, cooling, filtering and compression, then two-stage water washing and acid washing purification are carried out to form a circulating system in order to make the ammonia-containing exhaustgas absorbed into an absorption liquid with an ammonia nitrogen concentration of 6000-8000 mg / L and clean tail gas which can be discharged, the absorption liquid is deaminated by utilizing a deamination system, and purification and concentration are performed by combining ammonia-containing steam and exhaust liquid ammonia. A semi-bamboo-tube-shaped combined tower plate is innovatively adopted toimprove the steam stripping effect, so the ammonia nitrogen removal efficiency can reach 99% or above; ammonia steam is used as the absorption mother liquid, the exhaust liquid ammonia is directly absorbed, and ammonia nitrogen is recycled on the basis of the jet flow absorption principle to form ammonia water with a concentration being 20% or above, and the ammonia nitrogen concentration of theabsorption liquid is reduced to 15 mg / L or less; and the absorption liquid fully exchanges heat, is cooled, and then is reused for a washing section for recycling to form a closed ammonia-containing exhaust gas circulating purification and recovery system, so the recovery cost is reduced, and zero emission of wastewater is realized.

Owner:JIANGSU WODEKAI ENVIRONMENTAL PROTECTION TECH CO LTD

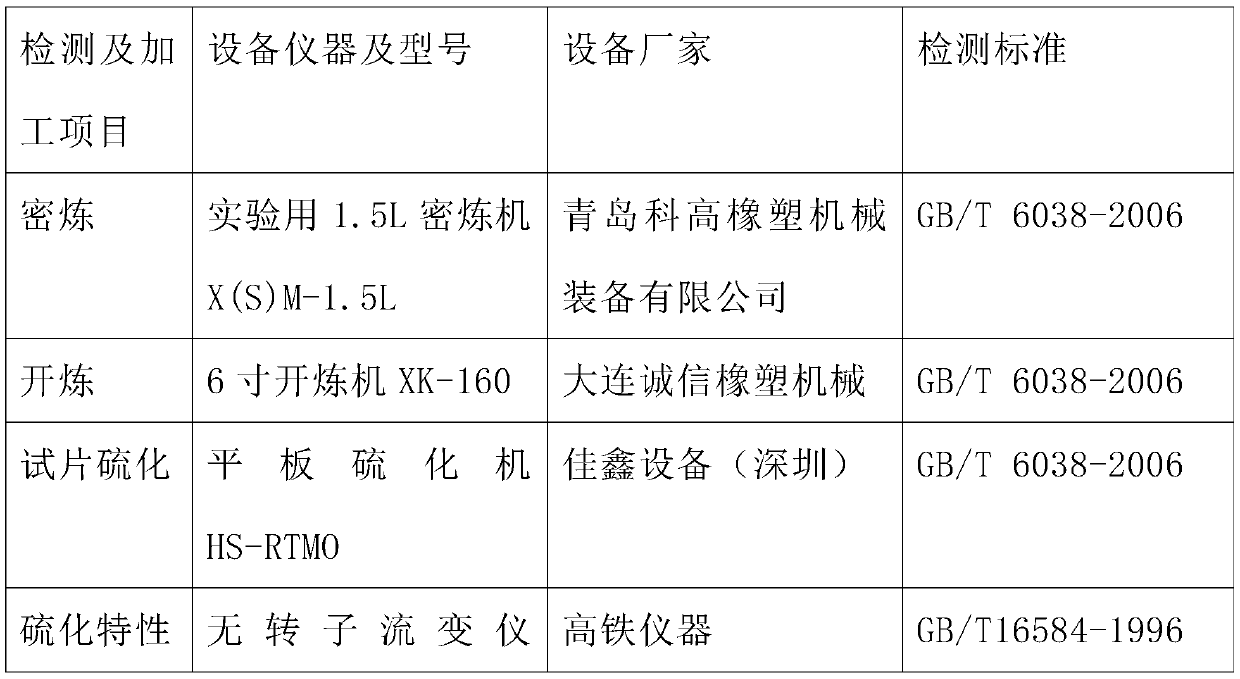

Maleimide modified p-tert-butyl phenol formaldehyde resin and synthesis method thereof

The invention provides a maleimide modified p-tert-butyl phenol formaldehyde resin and a synthesis method thereof. The synthesis method comprises the following steps: step 1, adding p-tert-butyl phenol, 4-maleimide phenol, formaldehyde and a catalyst into a reaction container, and carrying out a condensation reaction at the temperature of 80-100 DEG C; step 2, adding methylbenzene to extract the organic phase, adding alkali liquor to adjust reaction liquid to be neutral, discharging the water phase, and evaporating out water and solvents in the system; and step 3, heating to 160-190 DEG C, carrying out a polycondensation reaction, and carrying out reduced pressure distillation to remove water and unreacted monomers to obtain the maleimide modified p-tert-butyl phenol formaldehyde resin. Some R groups in the p-tert-butyl phenol-formaldehyde resin are substituted by maleimide groups, and double bonds can react with double bonds in rubber, so that migration of the resin in the rubber is reduced, heat generation is reduced, and the ageing resistance of the rubber is improved. Carbonyl of a modifying group has strong hydrogen-bond interaction, so that the interaction force between molecules can be effectively improved, and the lasting viscosity is improved.

Owner:SHANDONG YANGGU HUATAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com