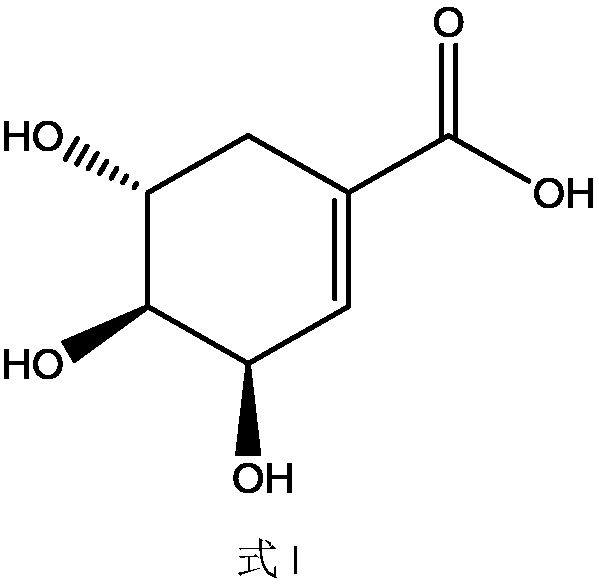

Process for efficiently purifying shikimic acid by utilizing continuous ion exchange technology

A technology of continuous ion exchange technology, applied in the field of efficient purification of shikimic acid using continuous ion exchange technology, can solve the problems of crossover of eluents, large fluctuations in operation between batches, large energy consumption for concentration, etc., and reduce the total amount of resin used. , the effect of enhancing market competitiveness and improving resin utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1: Construction of shikimic acid-producing genetically engineered bacteria E.coli HZ09-11 and preparation of shikimic acid fermentation broth

[0071] Construction and preservation of shikimic acid-producing genetically engineered bacteria E.coli HZ09-11:

[0072] Refer to the paper Shikimic Acid Production by a ModifiedStrain of E.coli (W3110.shik 1) Under Phosphate-Limited and Carbon-Limited Conditions. (Biotechnology and Bioengineering, 2005, 92 (5), 541-552.) by Louise Johansson et al. In the strain construction method disclosed, the host bacteria (strain number: CCTCC AB 209414, Escherichia coli derived from China Center for Type Culture Collection (CCTCC)) is genetically modified to obtain shikimic acid-producing genetically engineered bacteria E.coli HZ09-11 . Mix the bacterial suspension with 40% glycerol at a ratio of 1:1 and store at -20°C to obtain a glycerol tube of the working strain.

[0073] Preparation of shikimic acid fermentation broth:

[0...

Embodiment 2

[0083] Embodiment 2: the technique of extracting shikimic acid in fermented liquid

[0084] a) Solid-liquid separation: 70 L of the shikimic acid fermentation broth prepared in Example 1 was subjected to ceramic membrane microfiltration with a pore size of 50 nm. During the microfiltration process, frozen brine was used to cool down, and the feed liquid temperature was maintained at 30-35° C. Collect the fermentation filtrate. When the fermentation filtrate seeps out 36L, start to add deionized water continuously to the ceramic membrane raw material tank. unchanged), and finally collected a total of 174L of fermentation filtrate.

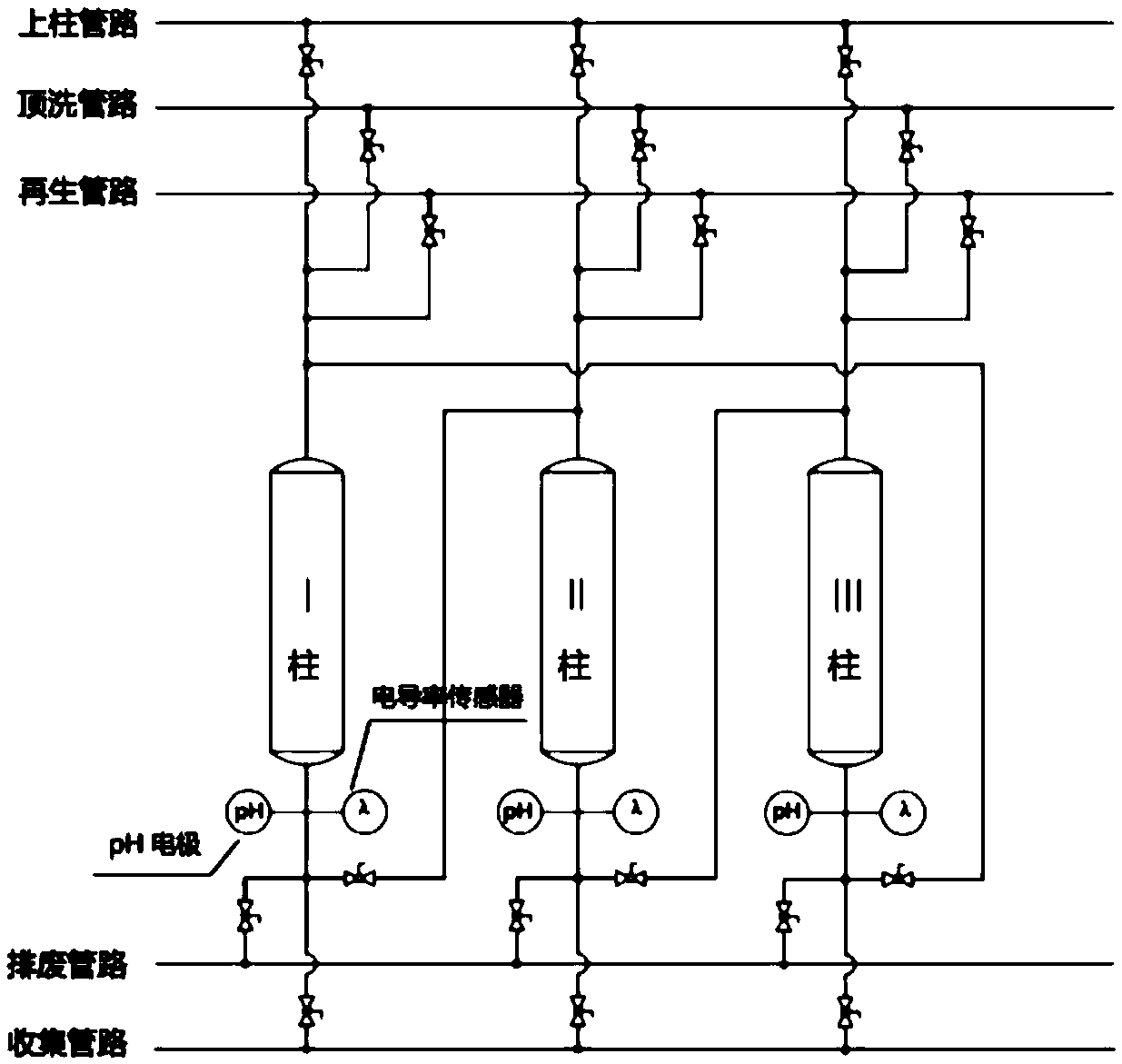

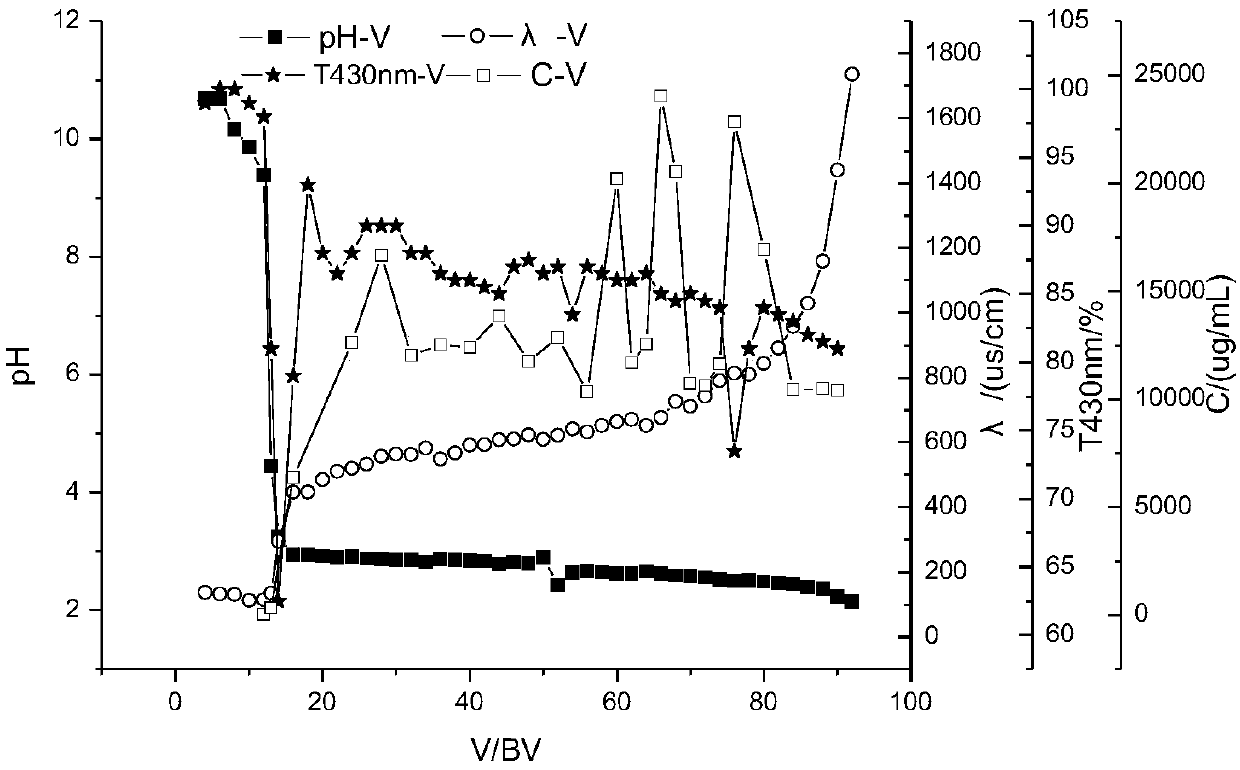

[0085] b) Put the 174L fermentation filtrate obtained in step a) on the column to a resin column filled with 10L of HZ001 cation exchange resin. The column effluent end is equipped with an online pH electrode and a conductivity sensor. The pH value of the liquid rises sharply until the slope of the pH value curve is > 1.5, stop loading the column, ...

Embodiment 3

[0091] Embodiment 3: the technique of extracting shikimic acid in fermented liquid

[0092]a) Solid-liquid separation: 70 L of shikimic acid fermentation broth prepared in Example 1 was subjected to ceramic membrane microfiltration with a pore size of 100 nm. During the microfiltration process, frozen brine was used to cool down, and the feed liquid temperature was maintained at 30-35° C. Collect the fermentation filtrate. When the fermentation filtrate seeps out 35L, start to add deionized water continuously to the ceramic membrane raw material tank. Collect ceramic membrane permeate 160L.

[0093] b) Put the 160L fermentation filtrate obtained in step a) on the column to a resin column filled with 13L of HZ016 cation exchange resin, the column effluent end is equipped with an online pH electrode and a conductivity sensor, and the column flow rate is 1.5BV / h. The pH value of the effluent rises sharply until the slope of the pH curve > 1.5, stop loading the column, then use 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com