Method for regenerating flue gas demercuration material and recovering elemental mercury

A technology for recovering single and elemental mercury, which is applied in chemical instruments and methods, separation methods, filter regeneration, etc., and can solve the problems of increasing impregnation, filtration, cleaning and drying processes, large resource and energy consumption, and difficulty in industrial application. , to achieve the effect of resource utilization, no secondary pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

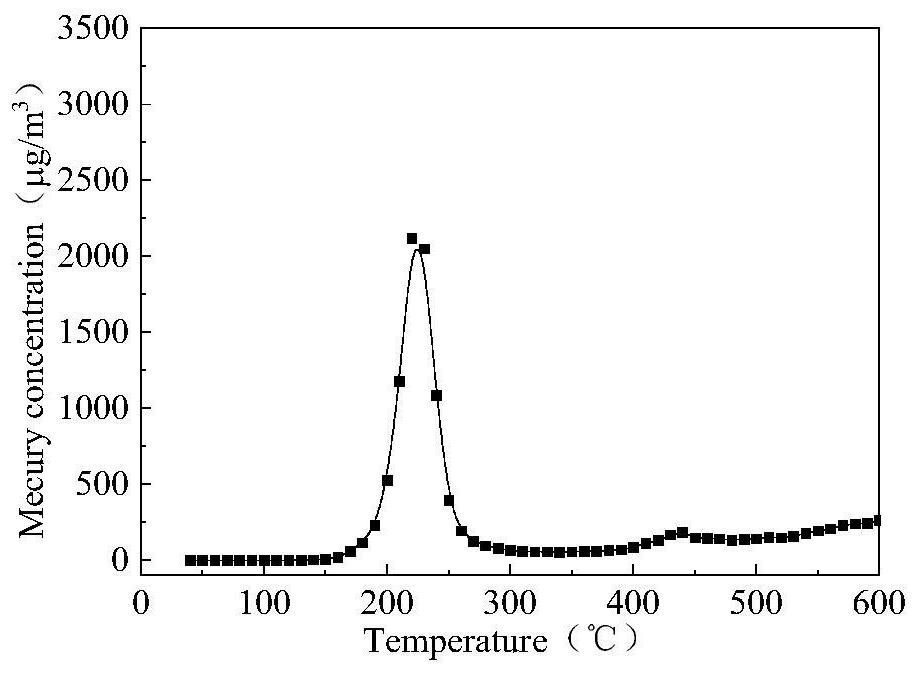

[0035] Using ZnS / C composite material (ZnS mass percentage content is about 30%) as the mercury removal material, the mercury-containing flue gas is demercurized, the temperature is 60°C, and the mercury-containing flue gas composition is SO 2 6% (volume percentage), O 2 6% (volume percentage), Hg 0 4000μg / m 3 , when the mercury concentration reaches 75% of the breakthrough concentration, the mercury-containing ZnS / C composite material is transferred to the mercury removal device, and the temperature is raised to 300°C under the protection of nitrogen, and the temperature is maintained until the mercury concentration in the outlet gas is lower than 10 μg / m 3 After that, the mercury removal composite material is regenerated by injecting S10% (volume percentage) and nitrogen mixed regenerating gas, the regenerating temperature is maintained at 300° C., and the regenerating time is 6 hours. Under the protection of nitrogen, the temperature was naturally lowered to 50°C, and t...

Embodiment 2

[0037] CuS / Al 2 o 3 The composite material (CuS mass percentage content is about 30%) is used as a mercury removal material to perform mercury removal treatment on mercury-containing flue gas. The temperature is 70°C, and the composition of mercury-containing flue gas is SO 2 6% (volume percentage), O 2 6% (volume percentage), Hg 0 4000μg / m 3 , when the mercury concentration reaches 75% of the breakthrough concentration, the mercury-containing CuS / Al 2 o 3 The composite material is transferred to the mercury removal device, and the temperature is raised to 400°C under the protection of nitrogen, and the temperature is maintained until the concentration of mercury in the gas is lower than 10 μg / m 3 After that, pass into SO 2 5% (volume percentage), H 2 S10% (volume percentage), nitrogen mixed regeneration gas to regenerate the mercury removal composite material, the regeneration temperature is maintained at 400°C, and the regeneration time is 3h. Under the protection...

Embodiment 3

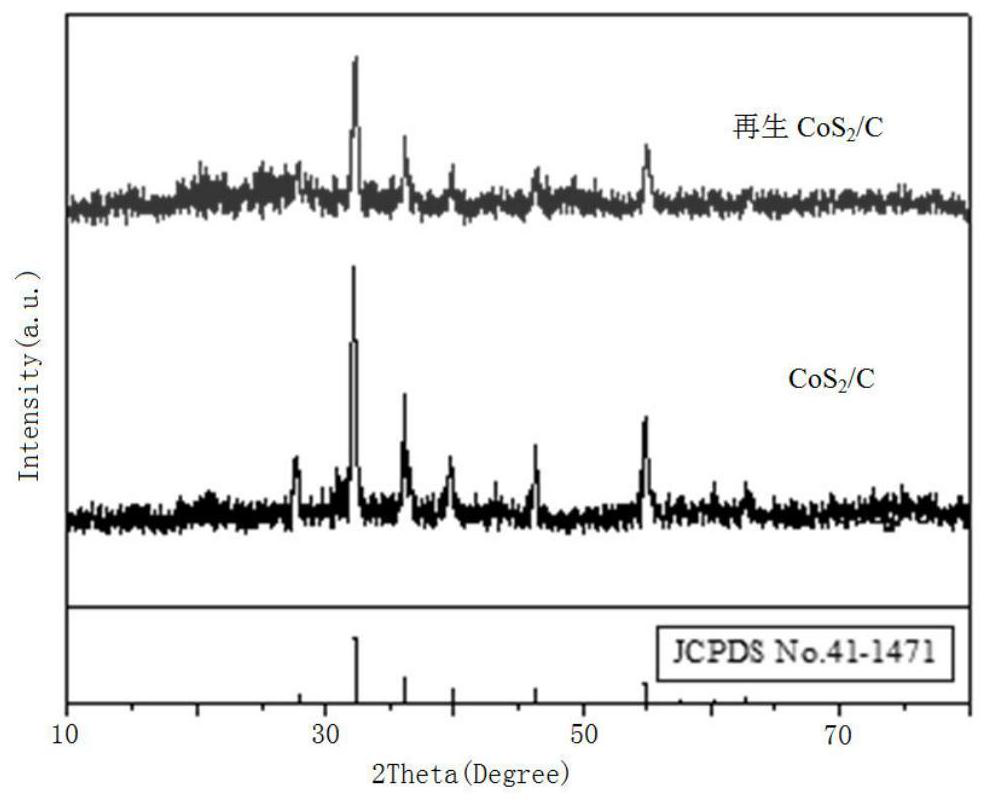

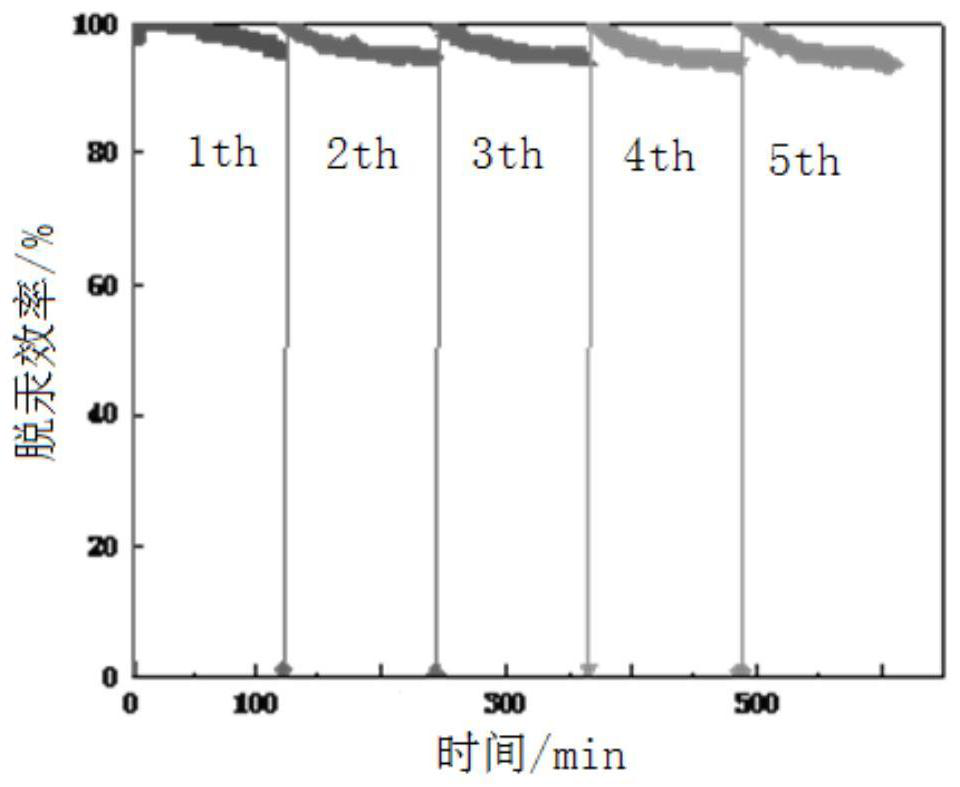

[0039] With Co 9 S 8 / C composite material (Co 9 S 8 The mass percentage content is about 30%) as a mercury removal material, and the mercury-containing flue gas is demercurized. The temperature is 50 ° C, and the mercury-containing flue gas composition is SO 2 6% (volume percentage), O 2 6% (volume percentage), Hg 0 4000μg / m 3 , when the mercury concentration reaches 75% of the breakthrough concentration, the mercury-containing Co 9 S 8 The / C composite material is transferred to the mercury removal device, and the temperature is raised to 350°C under the protection of nitrogen, and the temperature is maintained until the concentration of mercury in the gas is lower than 10 μg / m 3 Afterwards, the mercury removal composite material is regenerated by feeding S 5% (volume percentage) and nitrogen mixed regeneration gas, the regeneration temperature is maintained at 400°C, and the regeneration time is 3h. Under the protection of nitrogen, the temperature was naturally l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com