Method and device for treating volatile organic chemicals (VOCs) gas of medium or low concentration

A treatment method and gas treatment technology, which are applied in the field of medium and low concentration VOCs gas treatment, can solve the problems of unsatisfactory treatment effect, high cost, and reduced operation and maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

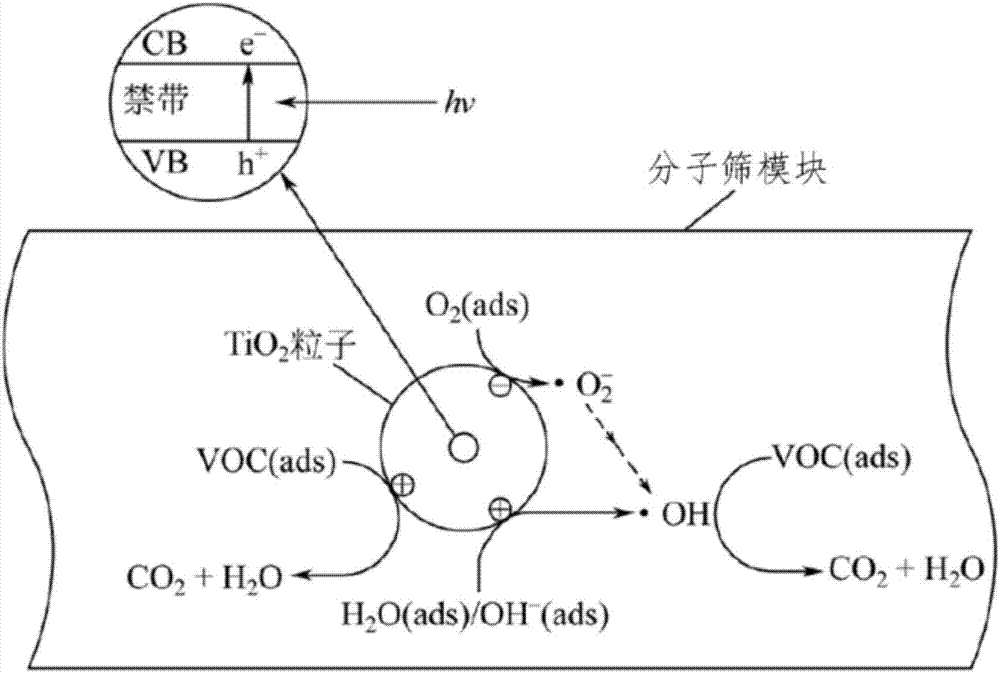

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with specific examples.

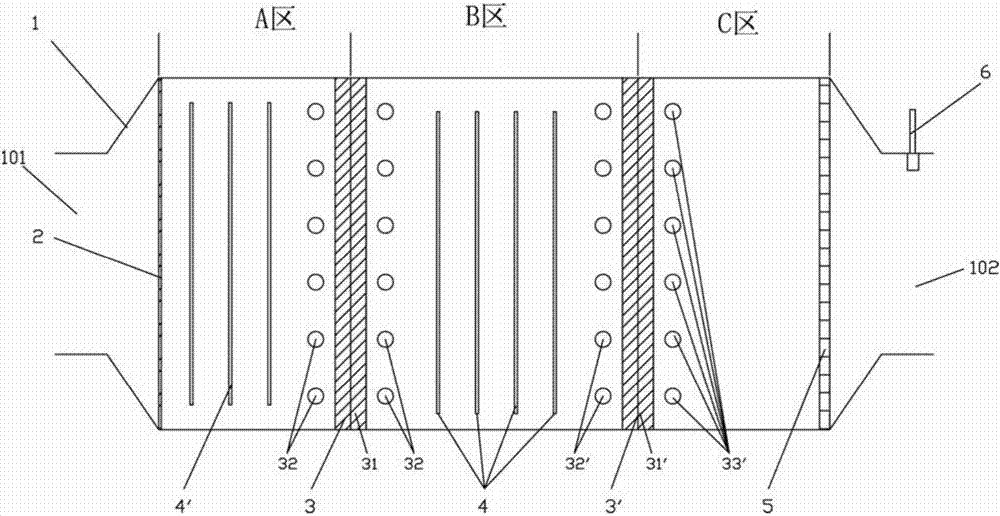

[0060] see figure 2 , a kind of medium and low concentration VOCs gas processing device of the present invention, comprises: box body 1, its two ends are respectively provided with air inlet 101 and exhaust port 102; A filter device 2 is provided, which is a filter screen or a filter membrane, and is located at the air inlet 101 in the box body 1; the first and second processing units 3, 3', the first processing unit 3 is illuminated by a molecular sieve module 31 and UVC module 32; the UVC illumination module 32 is composed of several low-pressure UVC lamps, which are respectively arranged on both sides of the molecular sieve module 31; the second processing unit 3' is composed of a molecular sieve module 31' and UVC illumination modules 32', 33' to dissipate heat The device 4 is arranged between the first and second processing units 3 and 3'; the ozone filter device 5 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com