Method for Improving Toner Point of High Gloss Polypropylene Composites

A technology of composite materials and polypropylene powder, which is applied in the field of modification of polypropylene composite materials and improvement of toner points of high-gloss polypropylene composite materials. Process and other issues, to achieve the effect of good stability, high gloss, uniform and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

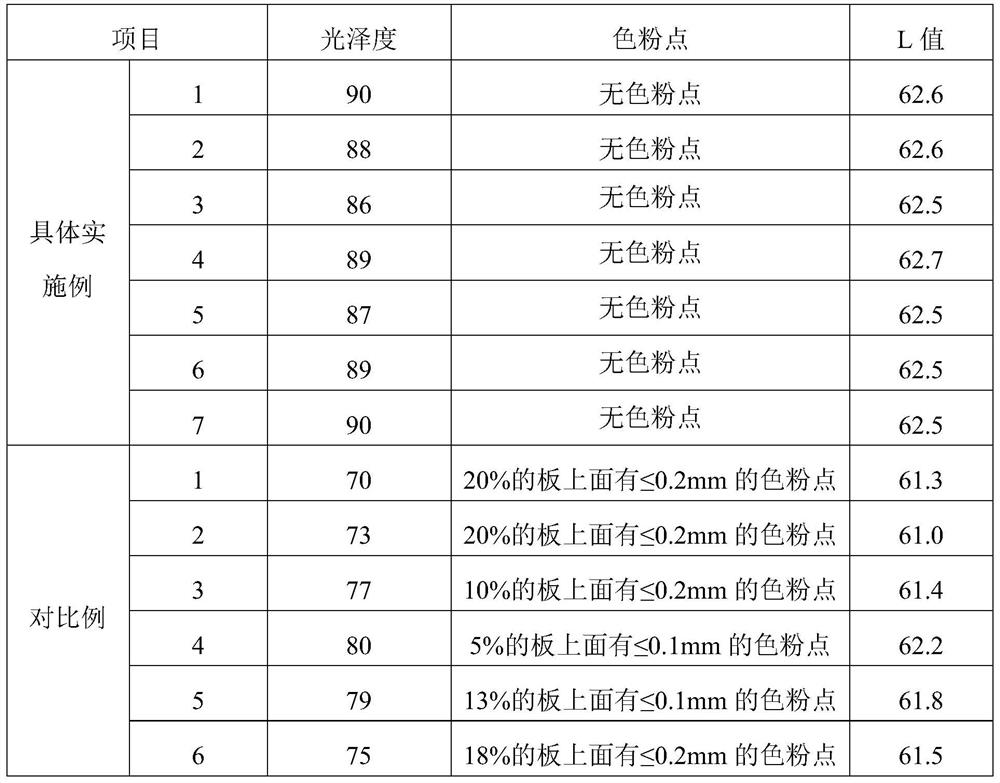

Examples

specific Embodiment 1

[0033] Raw material formula:

[0034] 40wt.% polypropylene pellets, 40wt.% polypropylene powder, 1.0wt.% toner, 18.5wt.% filler and 0.5wt.% nucleating agent.

[0035] Preparation Process:

[0036] (1) Take polypropylene pellets, polypropylene powder, toner, filler and nucleating agent by weighing according to the formula dosage for subsequent use;

[0037] (2) After putting 5wt.% polypropylene pellets and 20wt.% polypropylene powder into the high-speed mixer, start the high-speed mixer for high-speed mixing, and then put fillers and 20wt.% of the remaining polypropylene powder into it in turn. After mixing the material, toner and nucleating agent, continue to mix at a high speed to obtain a premix; wherein the speed of the high-speed mixer for high-speed mixing is 800-900r / min;

[0038] (3) The above-mentioned obtained premix and 35wt.% of the remaining polypropylene pellets are accurately fed into the main feeding port of the twin-screw extruder through a loss-in-weight fee...

specific Embodiment 2

[0040] Raw material formula:

[0041] With specific embodiment 1.

[0042] Preparation Process:

[0043] (1) Take polypropylene pellets, polypropylene powder, toner, filler and nucleating agent by weighing according to the formula dosage for subsequent use;

[0044] (2) After putting 20wt.% polypropylene pellets and 20wt.% polypropylene powder into the high-speed mixer, start the high-speed mixer for high-speed mixing, and then put fillers and 20wt.% of the remaining polypropylene powder into it in turn. After mixing the material, toner and nucleating agent, continue to mix at a high speed to obtain a premix; wherein the speed of the high-speed mixer for high-speed mixing is 800-900r / min;

[0045] (3) The above obtained premix and 20wt.% of the remaining polypropylene pellets are respectively accurately fed into the main feeding port of the twin-screw extruder through a loss-in-weight feeder, and melted, blended and extruded by the twin-screw extruder A high-gloss polypropy...

specific Embodiment 3

[0047] Raw material formula:

[0048] 60wt.% polypropylene pellets, 20wt.% polypropylene powder, 2.0wt.% toner, 17.5wt.% filler and 0.5wt.% nucleating agent.

[0049] Preparation Process:

[0050] (1) Take polypropylene pellets, polypropylene powder, toner, filler and nucleating agent by weighing according to the formula dosage for subsequent use;

[0051] (2) After putting 10wt.% polypropylene pellets and 10wt.% polypropylene powder into the high-speed mixer, start the high-speed mixer for high-speed mixing, and then put fillers and 10wt.% of the remaining polypropylene powder into it in turn After mixing the material, toner and nucleating agent, continue to mix at a high speed to obtain a premix; wherein the speed of the high-speed mixer for high-speed mixing is 800-900r / min;

[0052] (3) The above-mentioned obtained premix and 50wt.% of the remaining polypropylene pellets are accurately fed into the main feeding port of the twin-screw extruder through a loss-in-weight fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com