Patents

Literature

544results about How to "Play a stirring role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

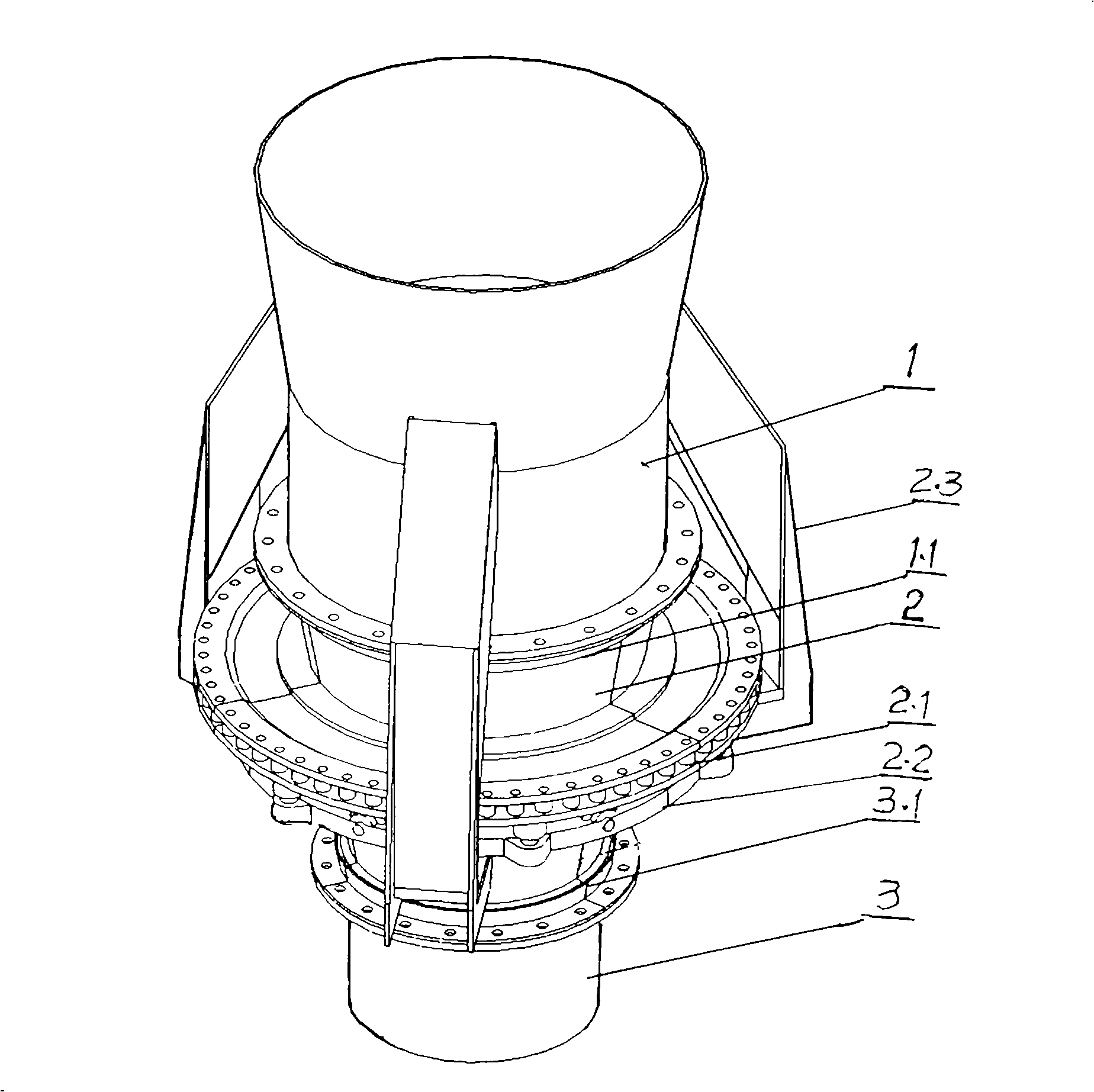

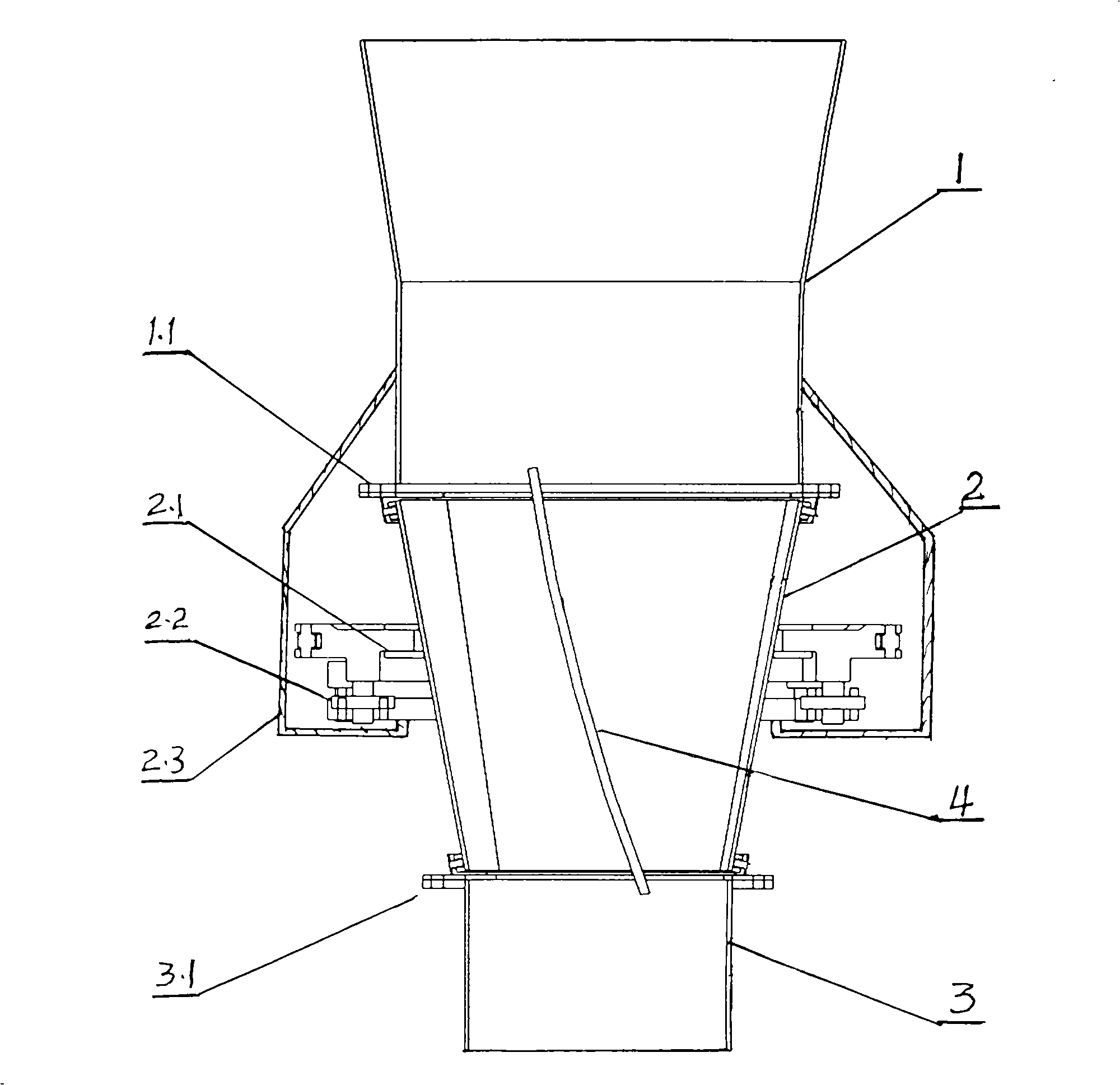

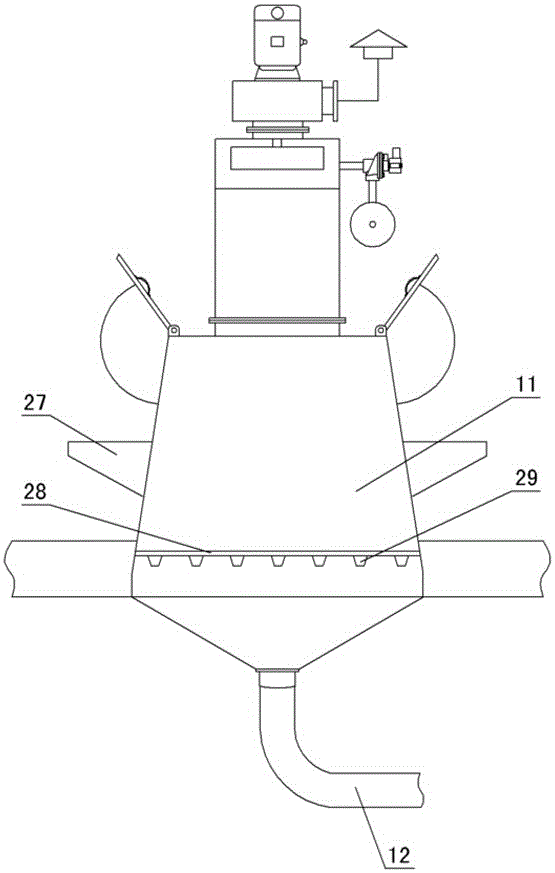

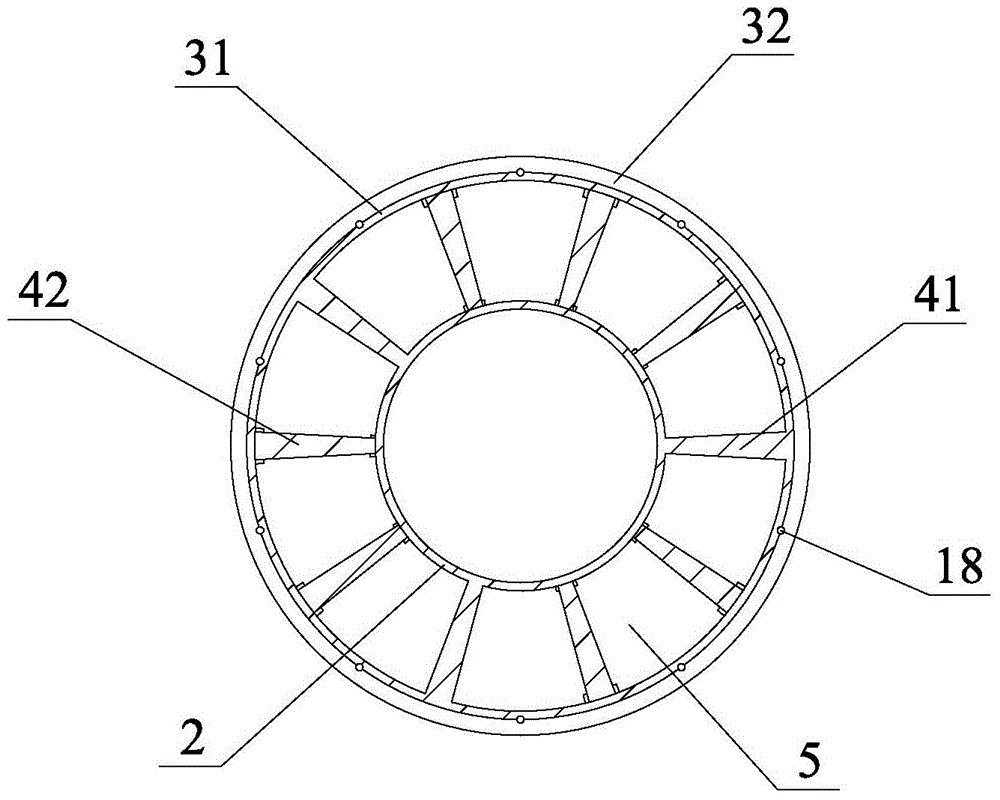

Rotary wall type anti-clogging material warehouse

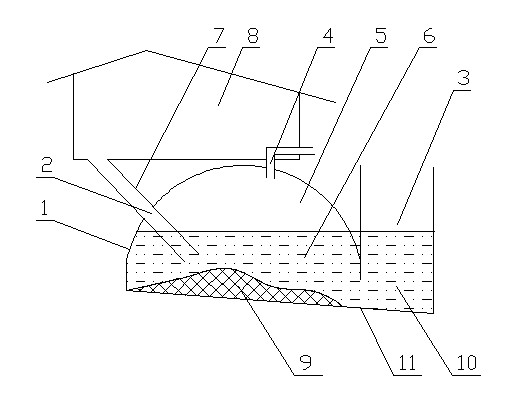

The invention provides a rotary wall type anti-jamming material bin which can effectively prevent material from being jammed in a discharging-bin-part during the discharging process of a grain material bin. The rotary wall type anti-jamming material bin is mainly characterized in that the original integrated bin body of the discharging-bin-part of the material bin is converted into a rotary bin body; and a relative movement system is formed by arc-breaking jam-removing vanes fixed in the wall of the rotary bin body and the rotary bin body, and then materials cannot form stable arc with the bin wall on the inner wall of the rotary bin body to destroy and break down the basic factor of jamming in time so as to better reach the aim of preventing material being jammed and dramatically enhance anti-jamming effect.

Owner:张玉伟

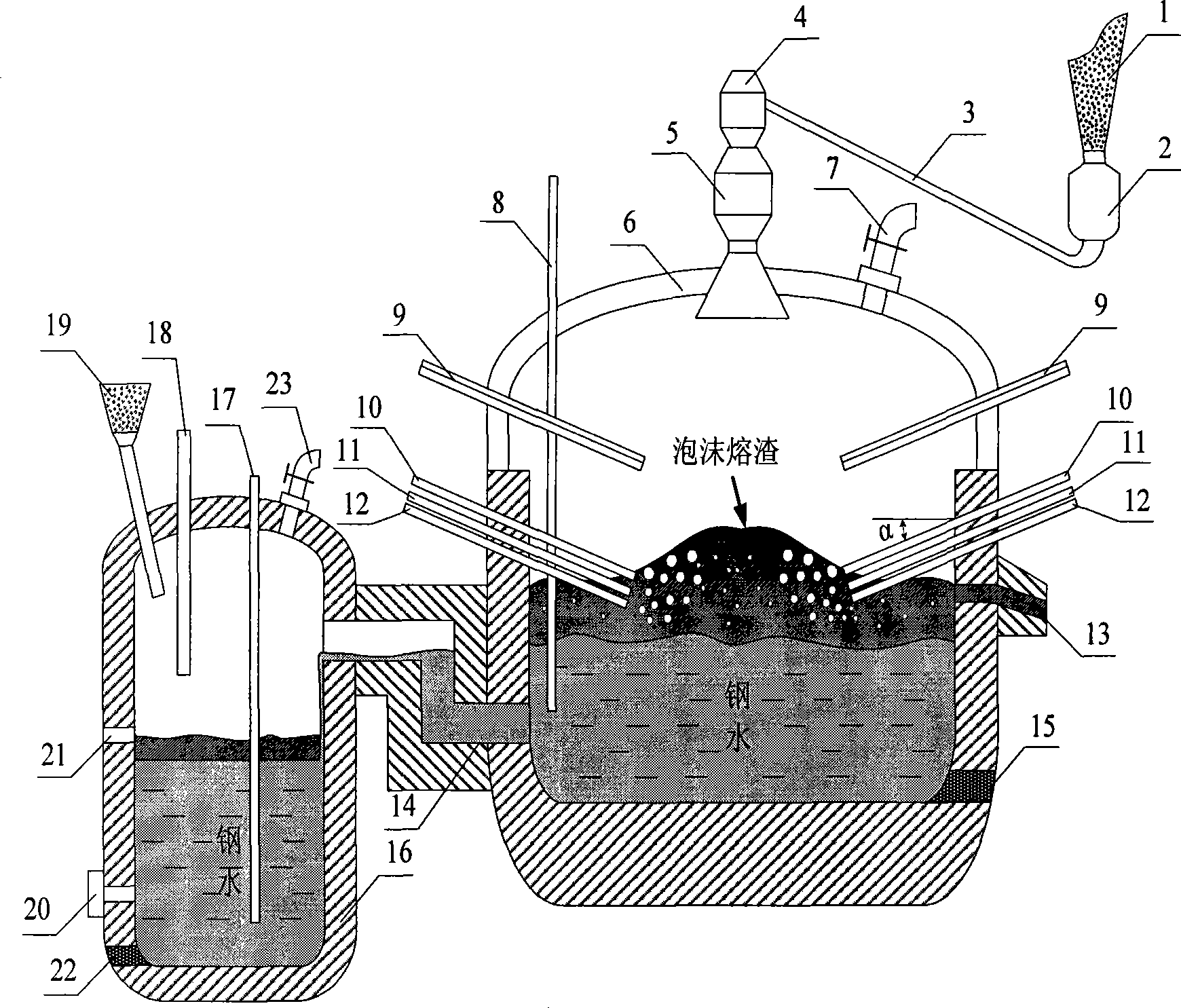

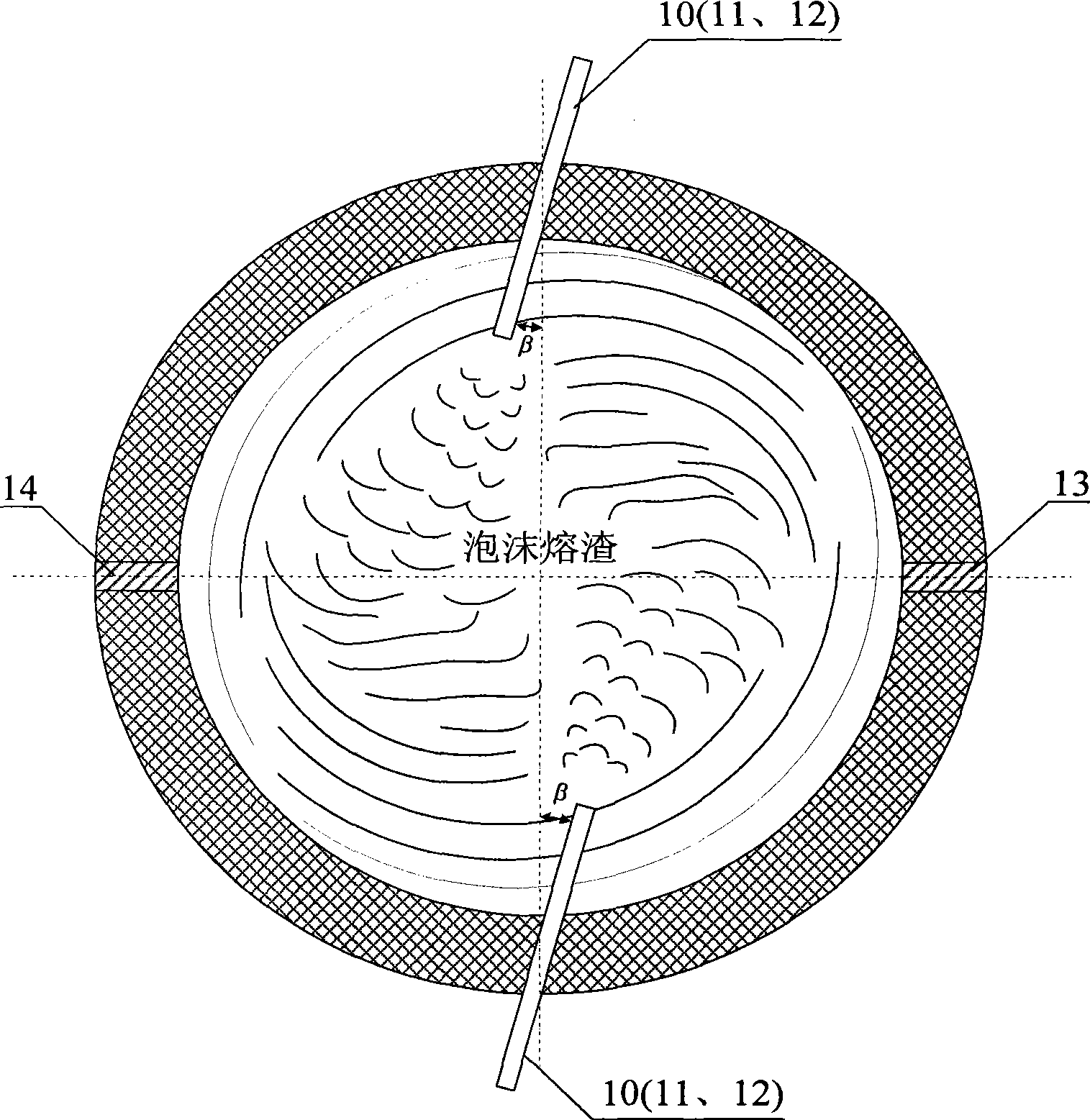

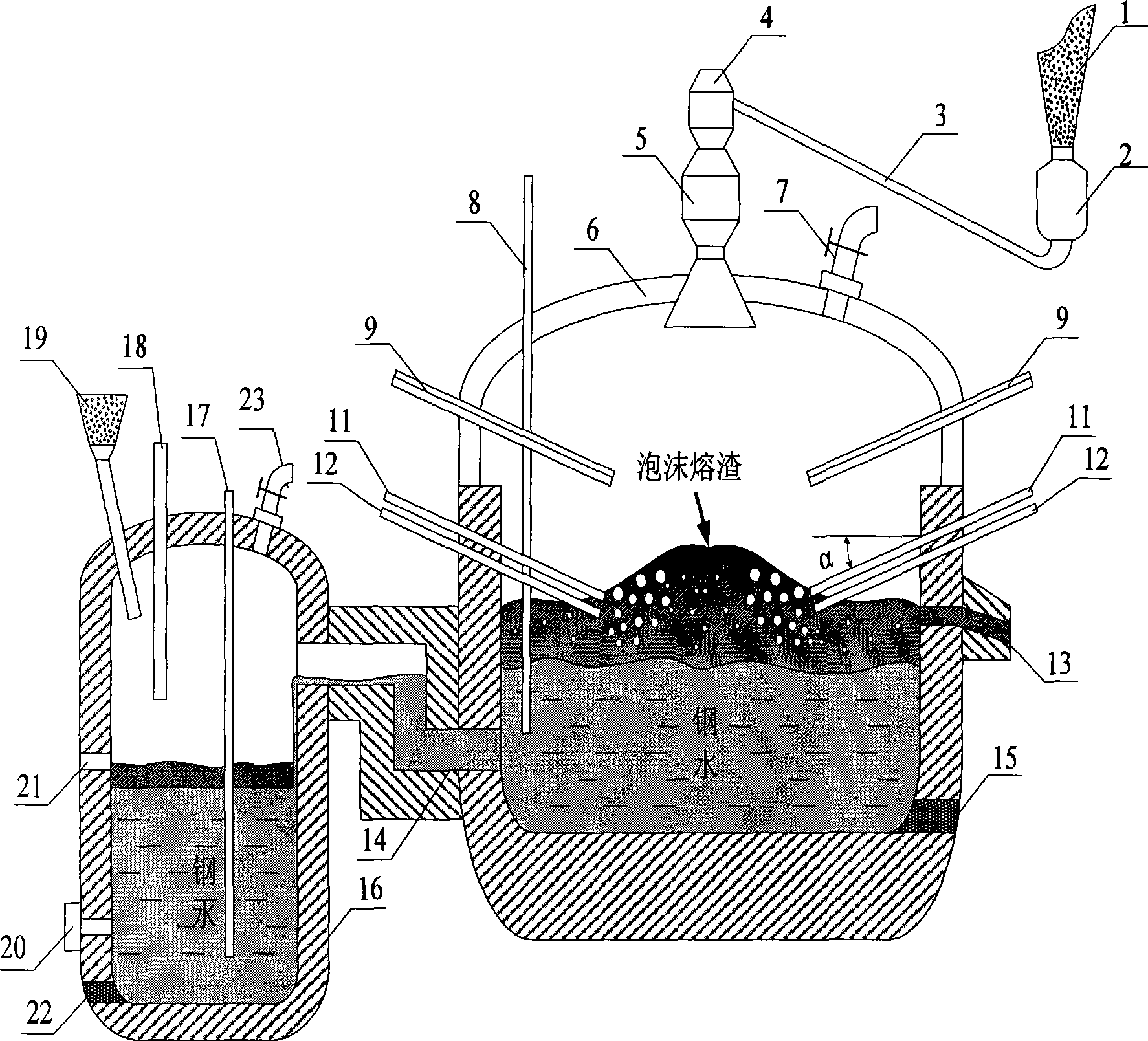

Process and device for continuous steelmaking from ferriferous material

ActiveCN101445848AReduce carbon contentIncrease temperatureFurnace typesProcess efficiency improvementSteelmakingMelting tank

The invention relates to a process for continuous steelmaking from a ferriferous material. A molten pool is formed in a steel-smelting furnace at first, and carbonic material and oxygen are insufflated to form foaming slag; the ferriferous material and a fluxing agent are added into the smelting furnace to be molten and reduced, oxygen is insufflated into the molten steel so as to reduce the carbon content in the molten steel, the temperature of the molten steel is risen, and the molten steel is stirred with the generated CO gas; high temperature oxygen or oxygen-enriched air is insufflated and burns with CO gas generated in the smelting furnace; and the molten steel continuously flows into an oxygen blowing furnace through a siphon nozzle, and a small quantity of the fluxing agent is added into the oxygen blowing furnace so that slag formation, desulfurization and dephosphorization are performed, the C content and the temperature in the molten steel are further adjusted through blowing oxygen by an insertion oxygen lance, therefore, the obtained molten steel is directly supplied for an LF refining furnace or an RH refining furnace. The invention has the advantages that the productivity equipment including a suspended pre-reduction furnace, the smelting furnace and the oxygen blowing furnace, the investment for devices and capital construction is saved, the land is saved, the physical distribution is simplified, and the continuous production and the automatic control are facilitated.

Owner:LAIWU IRON & STEEL GRP

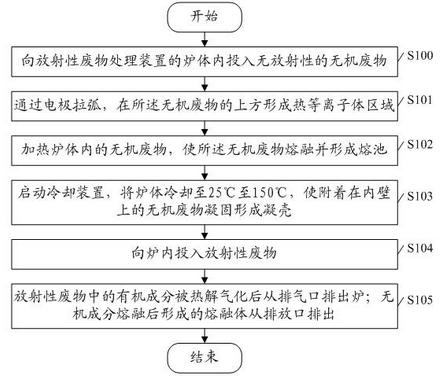

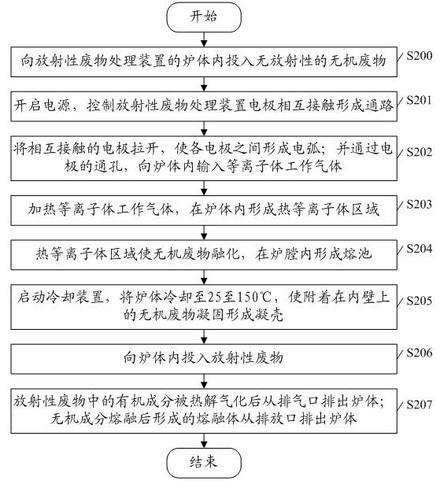

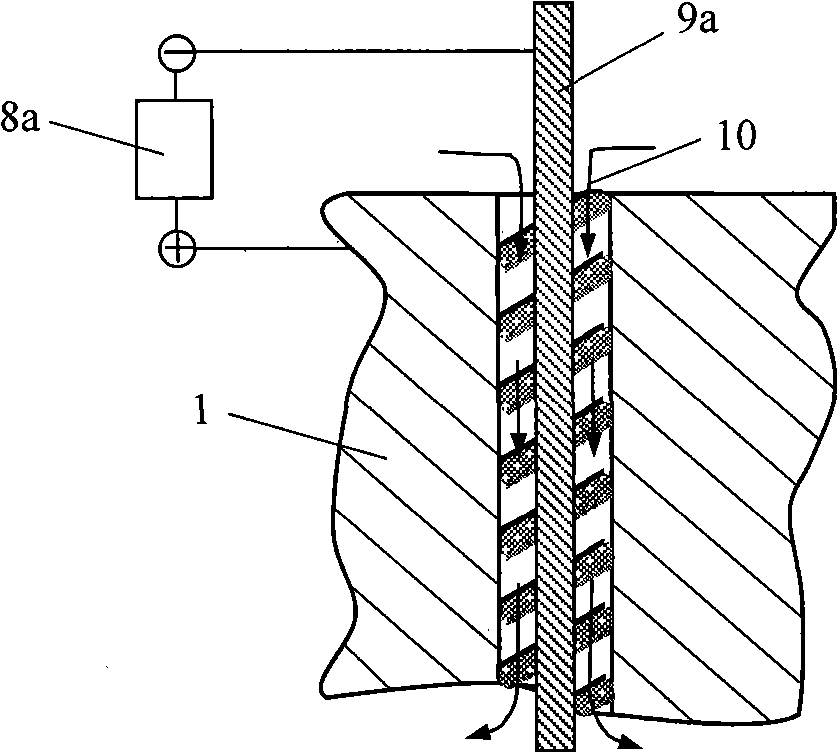

Method and device for treating radioactive wastes

ActiveCN102157215AAvoid pollutionImprove corrosion resistanceRadioactive decontaminationPlasma techniqueRefractoryRadioactive waste

The embodiment of the invention discloses a method and device for treating radioactive wastes. The method comprises the following steps of: putting nonradioactive inorganic wastes into a furnace body of a radioactive waste treatment device to form a thermal plasma area above the inorganic wastes by electrode arcing, and heating the putted inorganic wastes to form a molten pool; starting a coolingdevice to cool down the furnace body to a temperature of 25-150 DEG C so as to make the inorganic wastes attached to the inner wall of the furnace body be solidified to form a shell; putting radioactive wastes into the furnace body to pyrolyze organic elements of the radioactive wastes, and then exhausting the generated gas from the furnace body; and charging inorganic elements of the radioactivewastes into the molten pool to be molten, and discharging the molten inorganic elements out of the furnace body. During the implementation of the method and device disclosed by the invention, the furnace body does not need refractory materials, and the molten body is solidified in an area near the inner wall of the furnace to form the shell, thus the inner wall of the furnace does not directly contact with the molten body, radioactive nuclides are prevented from polluting the inner wall of the furnace, the device can be used for treating various wastes, the service life of the device is long and the amount of residual wastes is small.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD

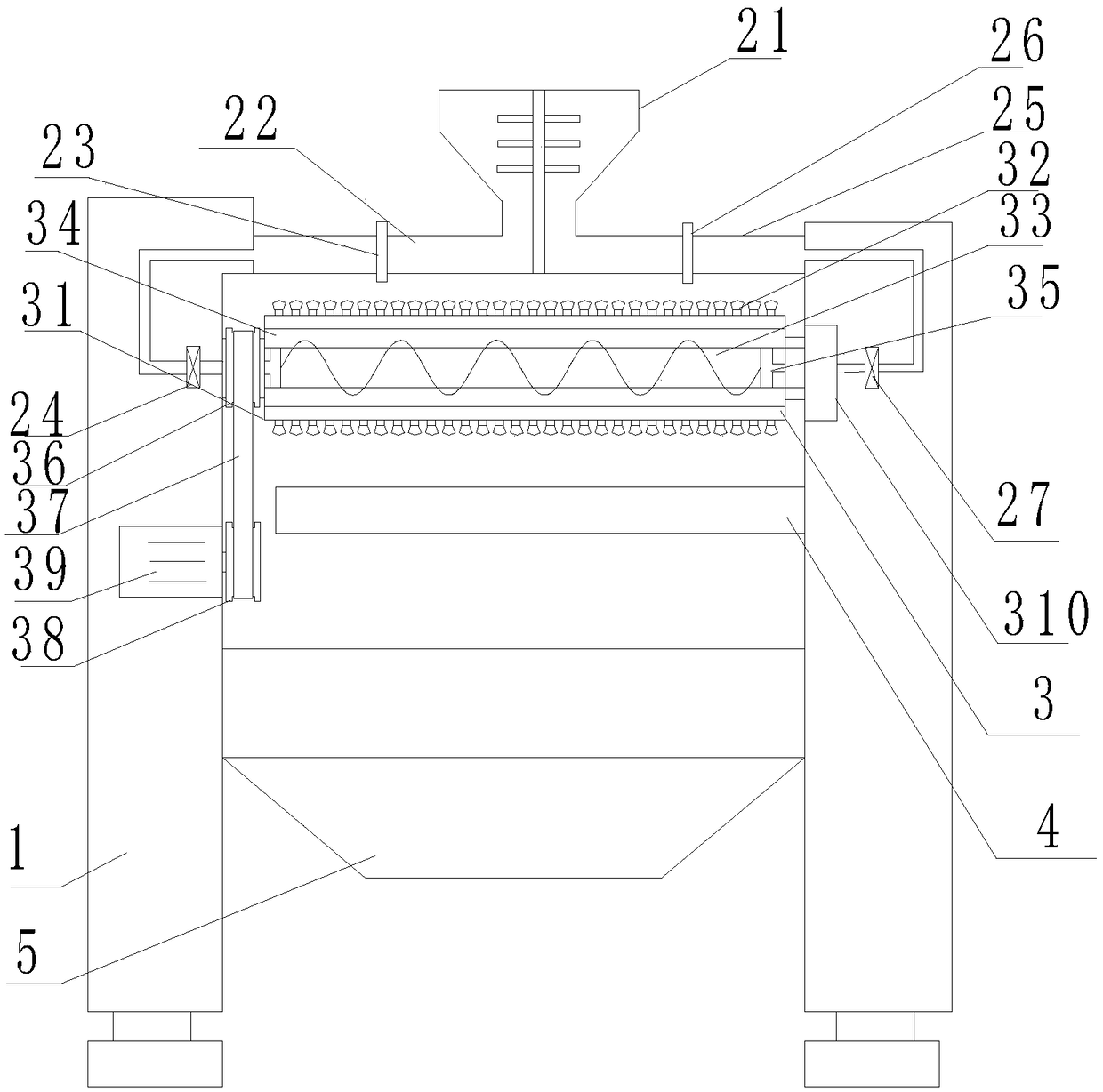

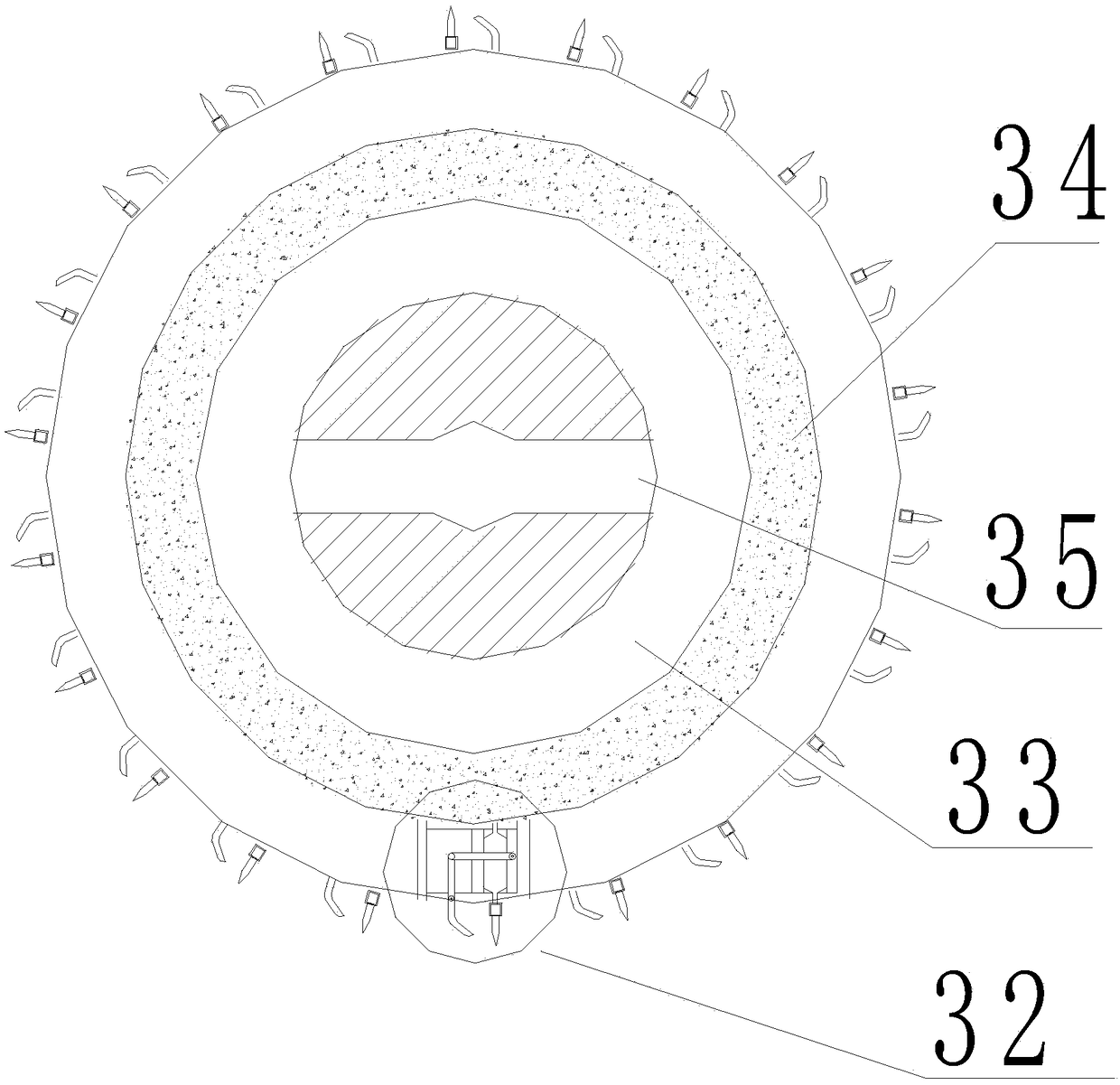

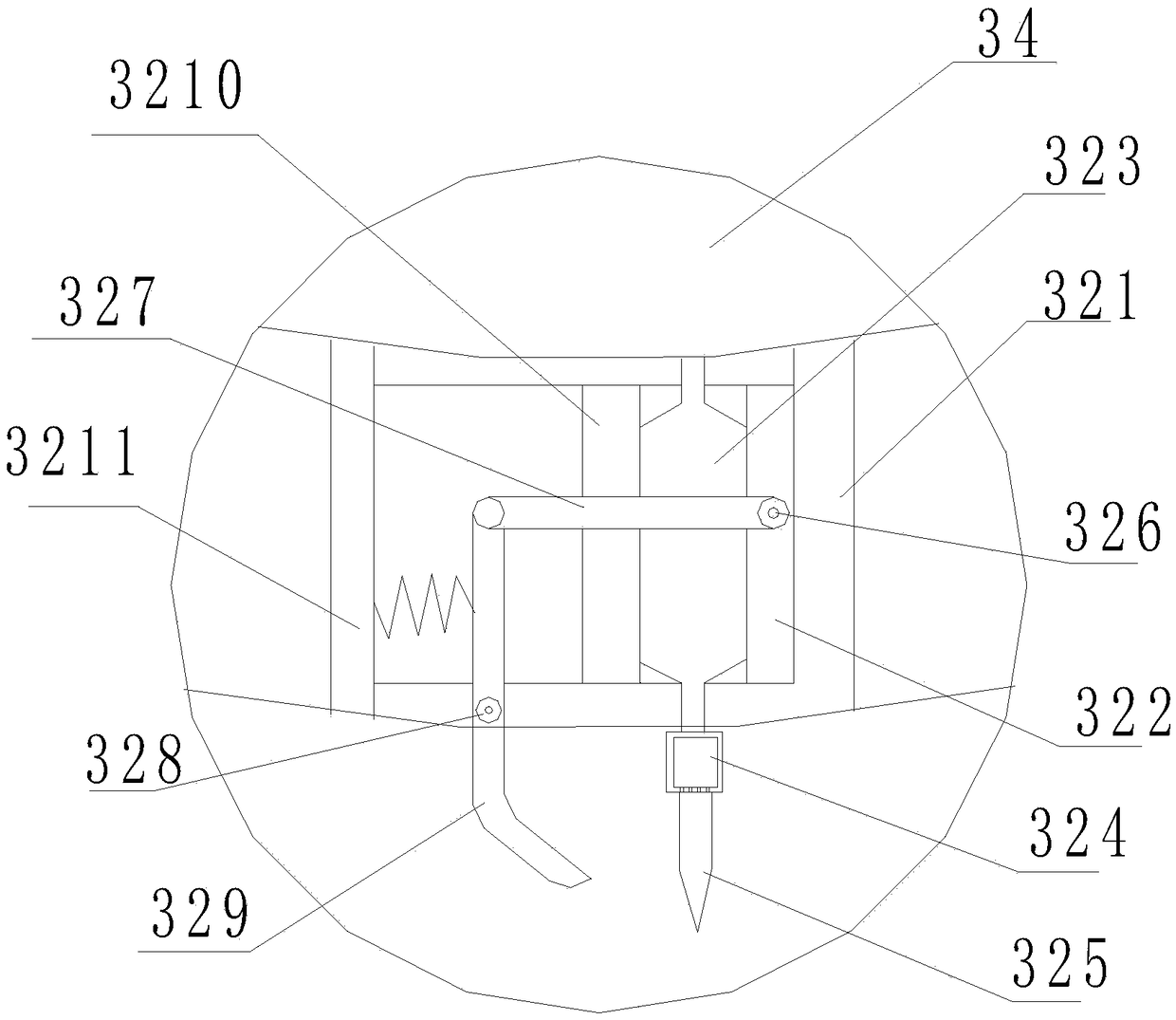

Plastic mixed-processing equipment

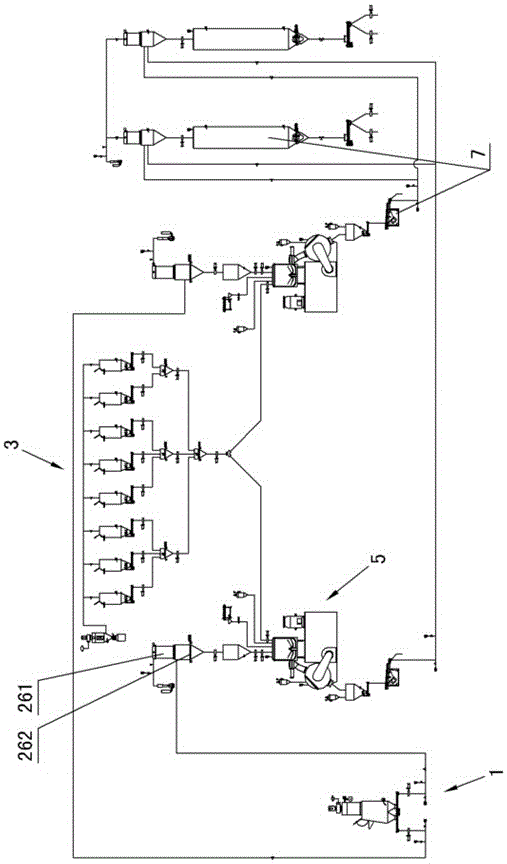

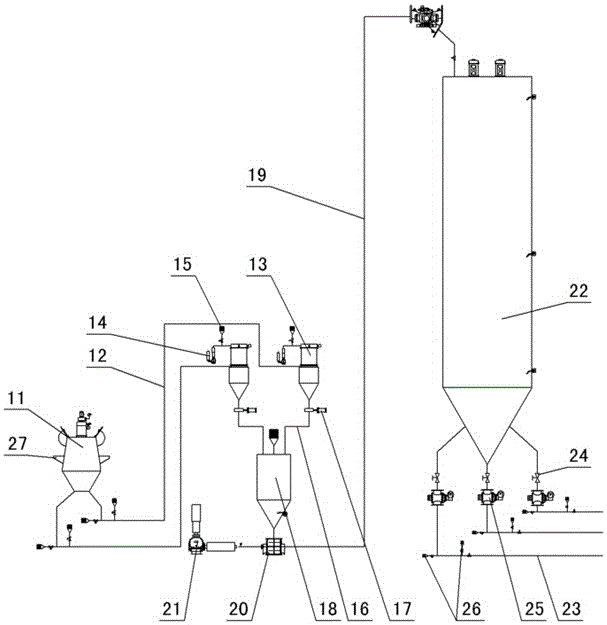

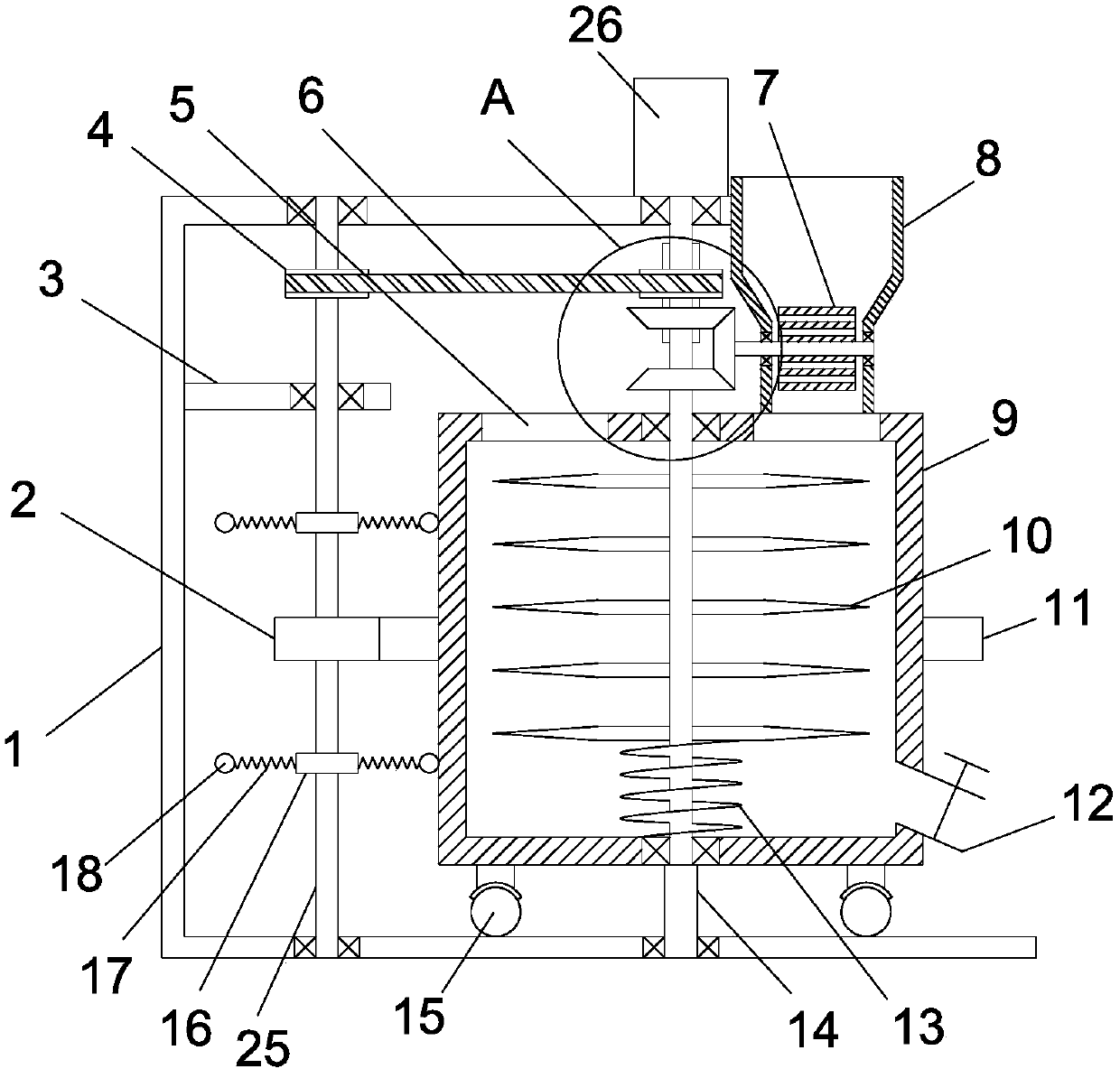

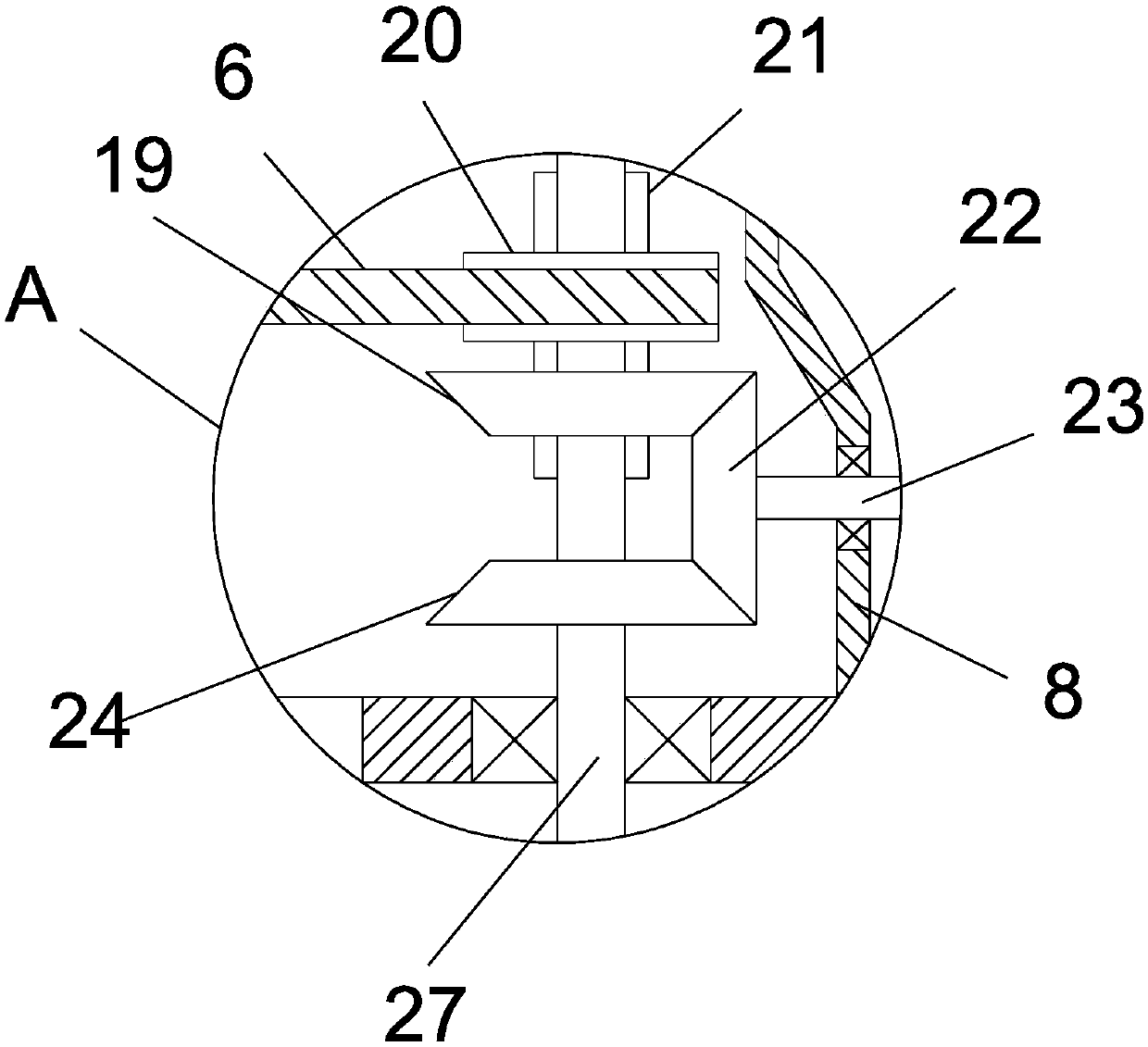

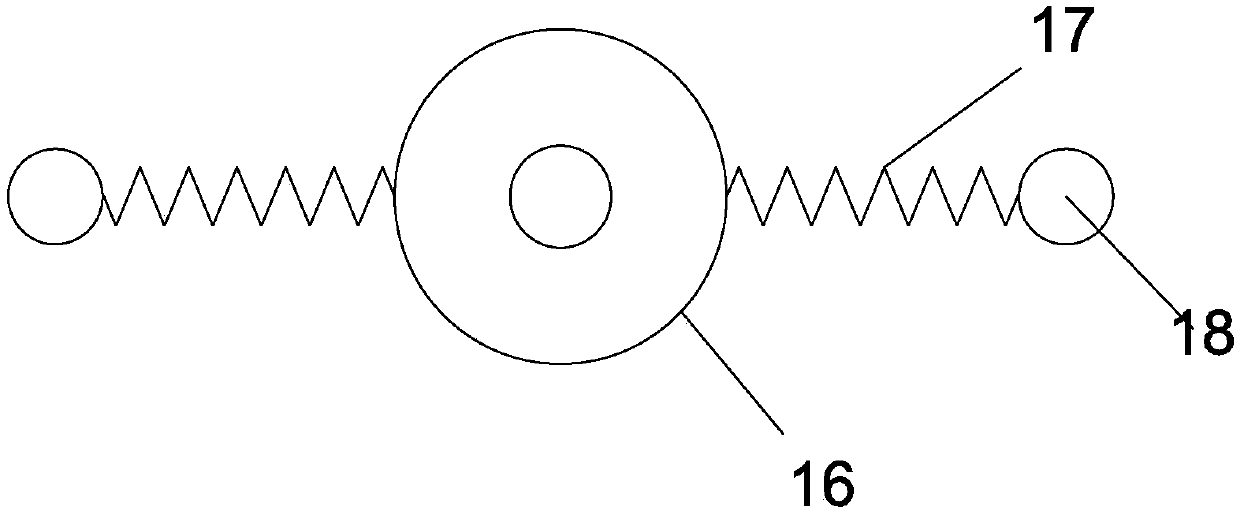

The invention relates to plastic mixed-processing equipment which comprises a main material conveying mechanism, an auxiliary material conveying mechanism, a mixed material stirring mechanism and a finished-product material screening and conveying mechanism. Workers only need to continuously pouring a main material and auxiliary materials into each batch bin, the main material is automatically conveyed to a storage bin, and various auxiliary materials are automatically conveyed; an electronic scale is controlled through a circuit to weigh the auxiliary materials in proportion, the auxiliary materials are mixed, and then the main material and the auxiliary materials are conveyed to the mixed material stirring mechanism; heat engine blades are utilized to carry out self-friction heating for the main material and the auxiliary materials, so that the main material and the auxiliary materials can be uniformly stirred and mixed, and the stirring efficiency is high; the heated and stirred mixed material is cooled through a cold mixer, and the cooled mixed material is more conductive to output and prevented from being stuck on the inner wall of a discharging pipe; finally, the mixed finished-product material is output to the finished-product material screening and conveying mechanism for screening, and then the finished-product material is stored to the storage bin. When needed, the finished-product material can be automatically conveyed to an injection molding machine. All operations can be controlled by the circuit, the labor intensity of workers is reduced, the production efficiency is improved, and the automatic continuous production is facilitated.

Owner:YONGGAO CO LTD

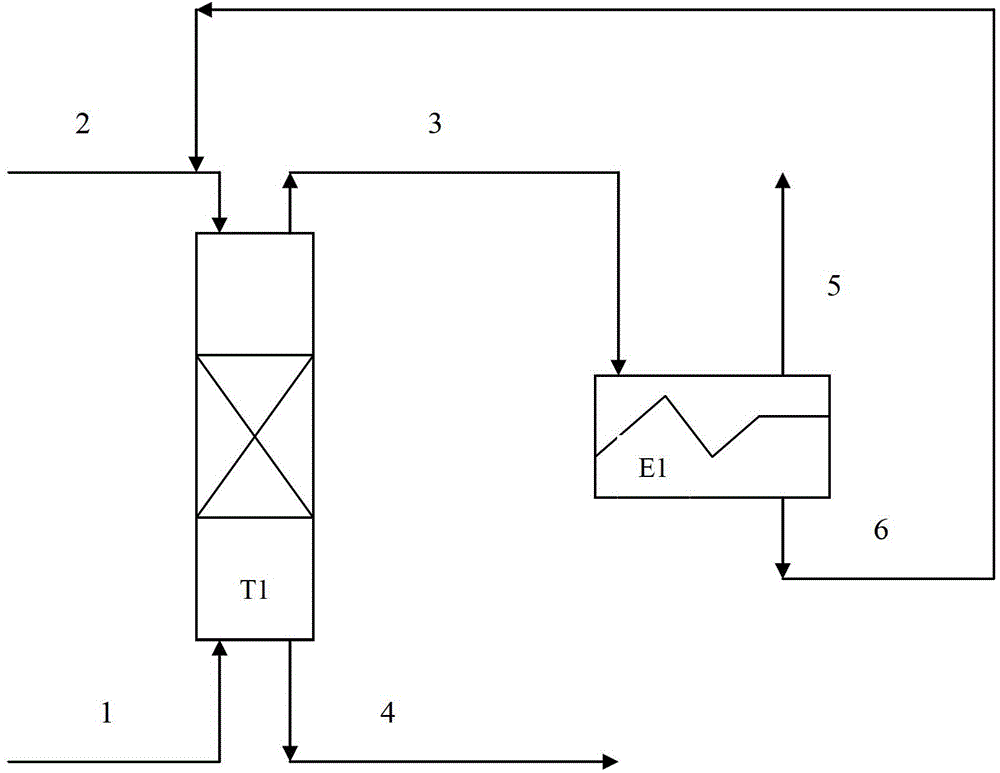

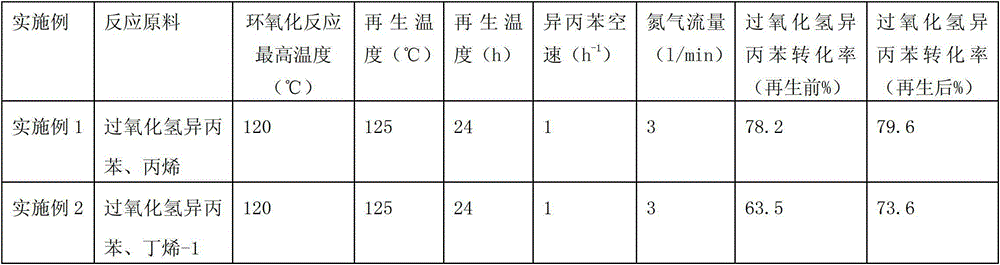

Regeneration method of titanium-silicon molecular sieve catalyst

InactiveCN102941117AShort cycleHigh activity recovery rateOrganic chemistryMolecular sieve catalystsMolecular sieveNitrogen

The invention relates to a regeneration method of a titanium-silicon molecular sieve catalyst. The catalyst is filled in a fixed bed reactor and applied to preparing an epoxy compound through epoxidation reaction of an organic peroxide and alkene. In the process of regeneration of a titanium-silicon molecular sieve, a liquid solvent enters the fixed bed reactor from top to bottom, at the same time, nitrogen enters the reactor in a reverse mode, and liquid solvent which is obtained through cooling and separating tail gas of the nitrogen from the top by a condensing system can return to a fixed bed to be recycled. According to the regeneration method, the period for regenerating the catalyst by the liquid solvent is shortened, the activity recovery rate of the catalyst is increased, and the regeneration method can be applied to industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

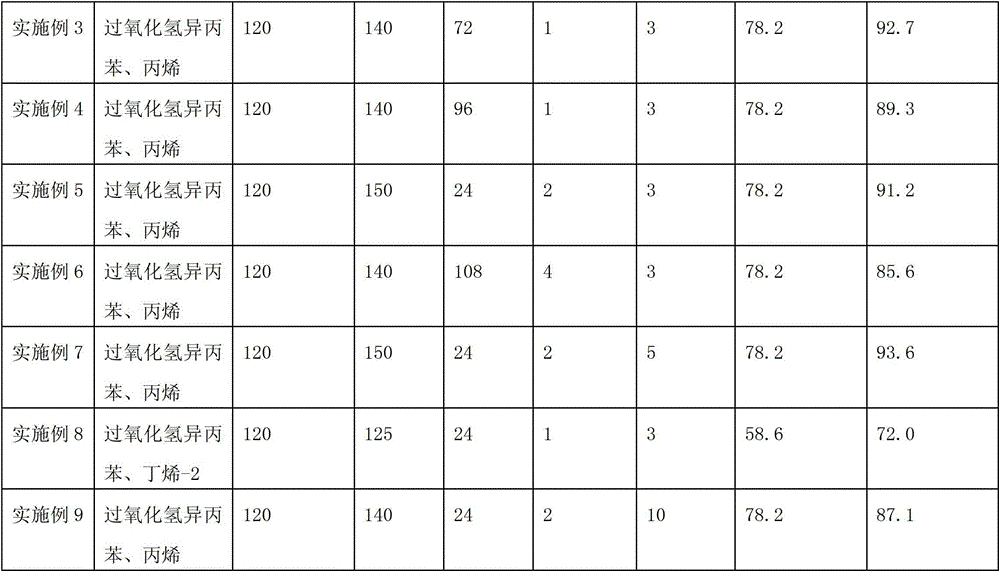

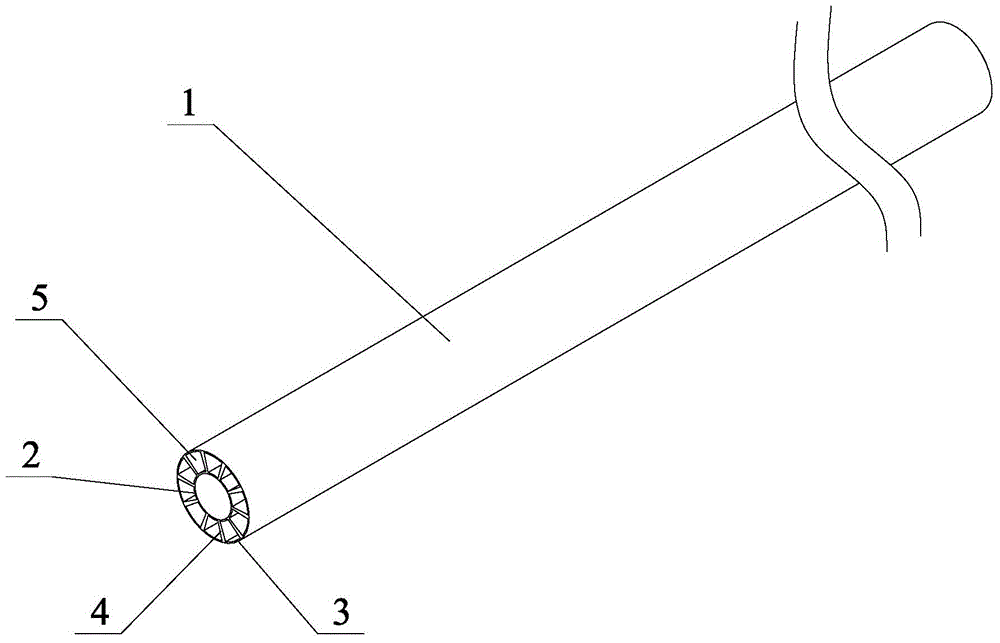

Double-layer straw

ActiveCN104433658AIncrease the pleasure of smokingImprove cooling effectTablewaresEngineeringMechanical engineering

The invention provides a double-layer straw. The double-layer straw comprises a straw body. The straw body comprises an inner layer straw wall and an outer layer straw wall. Longitudinal partition plates distributed in the radial direction of the straw body are arranged between the inner layer straw wall and the outer layer straw wall, space between the inner layer straw wall and the outer layer straw wall is divided into multiple cavities through the longitudinal partition plates, the longitudinal partition plates comprise the fixed partition plates and the movable partition plates, the fixed partition plates are fixedly connected to the inner layer straw wall and the outer layer straw wall, and the movable partition plates are connected with the inner layer straw wall and the outer layer straw wall in an inserted mode and can be pulled out in the length direction of the straw body. Through double-layer design, the multiple cavities through which liquid flows are formed in the straw, the inner layer straw wall allows liquid and particles with the large diameter to pass through, the cavities allow liquid and particles with the small diameter to pass through, the longitudinal partition plates can be movably arranged, a user can adjust the number of the longitudinal partition plates according to requirements so as to adjust the volume of the cavities, the flow speed of sucked liquid is adjusted, the interior of the straw is divided into the multiple cavities, heat dissipation of liquid drinks is facilitated, and the user is prevented from being scalded.

Owner:MENGTE COMMODITY CO LTD

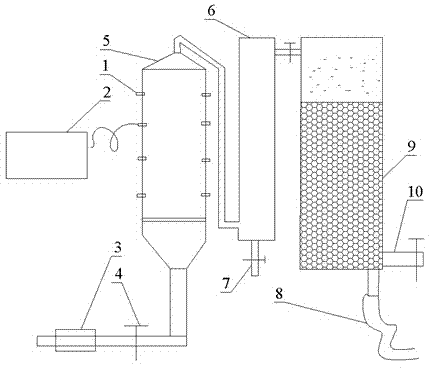

Rural drinking water integrated water purification method and device

InactiveCN104496090AReduce pollutionSolve the purification problemTreatment involving filtrationMultistage water/sewage treatmentAluminum IonElectrolysis

The invention discloses a rural drinking water integrated water purification method and device. The method comprises the steps of integral coagulation, precipitation and filtration. The integral coagulation comprises the following steps: coagulating in an electrocoagulation mode, and sending into a static pipeline flocculation plant to carry out mixed flocculation. In the electrocoagulation process, an aluminum sheet is used as the electrode, an up-flow electrocoagulation device reacts with aluminum ions generated by the aluminum sheet, and then the mixed flocculation is carried out. In the mixed flocculation process, water is precipitated and subjected to clearance drainage, and is filtered through activated carbon. The electrocoagulation water purification method can complete the process of electrocoagulation, electric flotation, electrolytic oxidation, electrolytic reduction and the like in one facility, has the functions of condensation, adsorption, upward flotation, redox and the like, comprehensively considers the economic cost, and has the characteristics incomparable with other techniques when being used in a minitype integrated facility. The method and device have favorable removal effect on turbidity, and have certain removal effect on chroma and COD (chemical oxygen demand).

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

System and method for landscape fishpond purification treatment

ActiveCN106082533AExpand the range of suctionImprove water quality treatment effectWater cleaningTreatment using aerobic processesWater qualityEnvironmental engineering

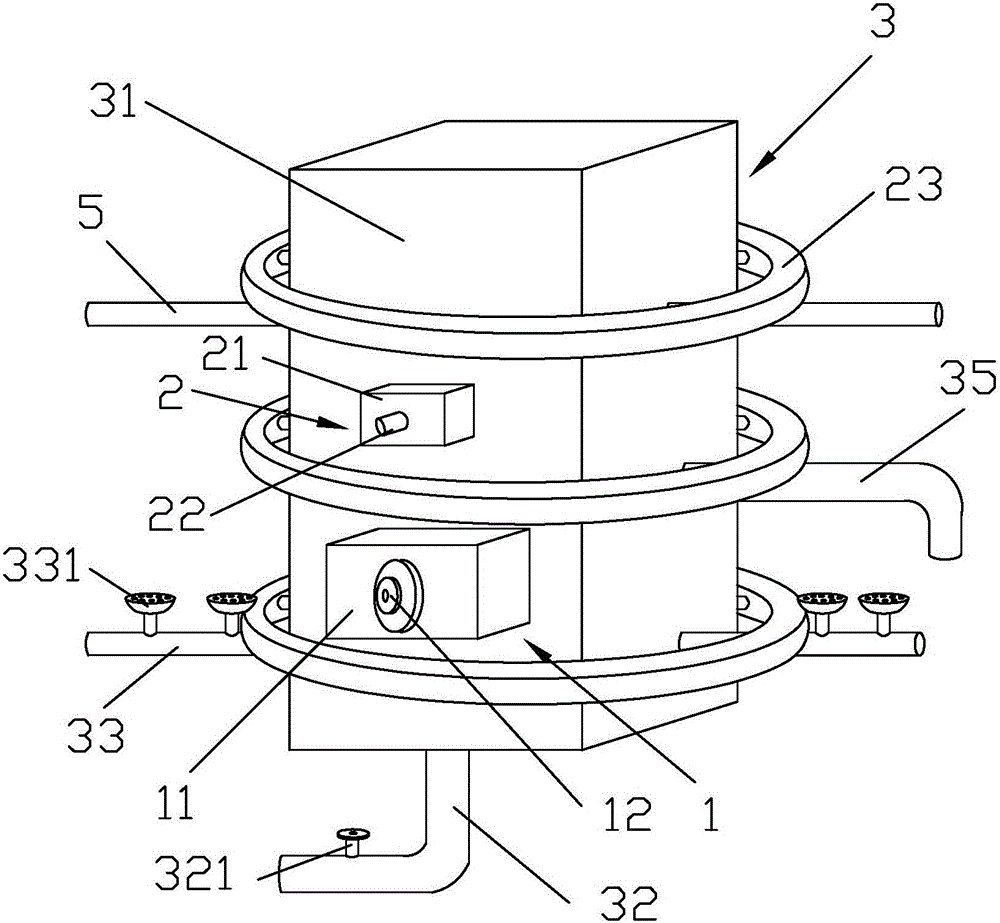

The invention mainly discloses a system and method for landscape fishpond purification treatment. According to the technical scheme, the system comprises a water quality monitoring device, a water purification device and a water surface decontamination device, the water purification device comprises a shell, a water inlet pipe, an aerator pipe, a blowdown pipe and a water outlet pipe, a filtering area, an active mud area and a sterilization area are arranged in the shell from inside to outside in sequence in a nested mode, and both the water inlet pipe and the blowdown pipe are connected with the filtering area; the water outlet pipe is connected with the sterilization area, the two ends of the aerator pipe are located outside the active mud area and the shell respectively, and the water surface decontamination device comprises a collection box, a stain adsorption head and a stain adsorption pipe. The method comprises the steps of 1, installing the water purification device; 2, installing the water surface decontamination device; 3; conducting water quality detection; 4, conducting water purification; 5, conducting water surface purification; 6, conducting detection again; 7, cleaning the devices. The system is reliable in performance, water purification can be conducted automatically, water quality purification efficiency is high, treatment time and period are short, and normal operation of a fishpond system is guaranteed.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

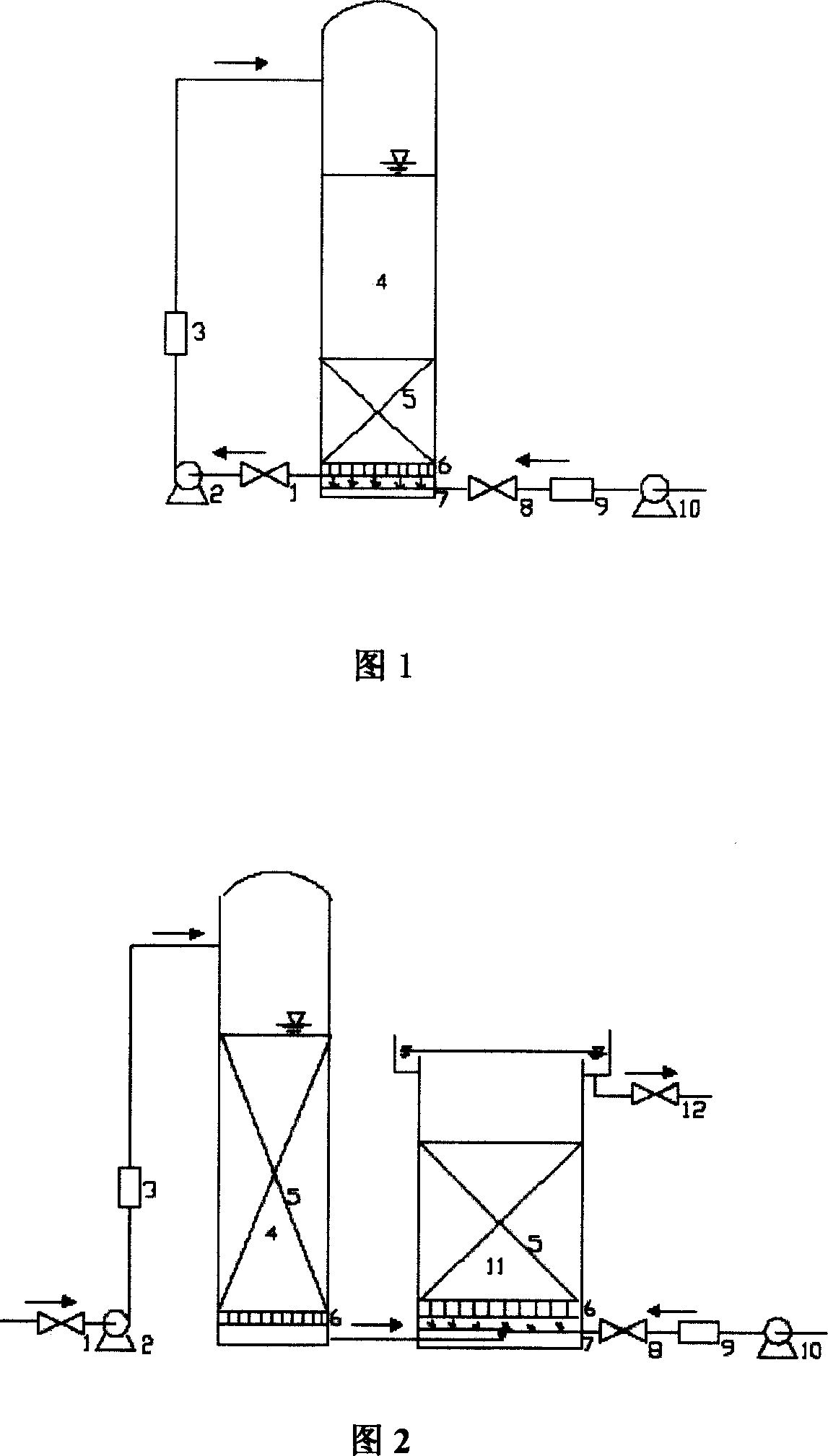

Anoxybiotic/aerobic two-section internal electrolysis organic waste water treating method

InactiveCN1935681AReduce concentrationImprove hydrophobicityWater/sewage treatmentTreatment with aerobic and anaerobic processesActivated carbonElectrolysis

The invention relates to an anoxic / aerobic, two-stage, internal- electrolysis organic waste water treating method, fully mixing iron chips and activated carbon / copper chips in a certain mass ratio, and placing their mixture into a reactor, regulating waste water pH value and then adding the waste water into the reactor in the fixed solid-liquid ratio, firstly making anoxic internal electrolysis reation for a certain period of time and then making aerobic reaction for a certain period of time, adding alkali in the effluent water to make mixing coagulation settlement and discharging supernatant. And the treating mode can adopt a single- groove static flow mode or double-groove continous flow mode. And it fully uses redox reaction to degrade organic matters, and has stronger ability to degreade organic matters difficult to degrade and more remarkable decoloring effect.

Owner:SHANGHAI JIAO TONG UNIV

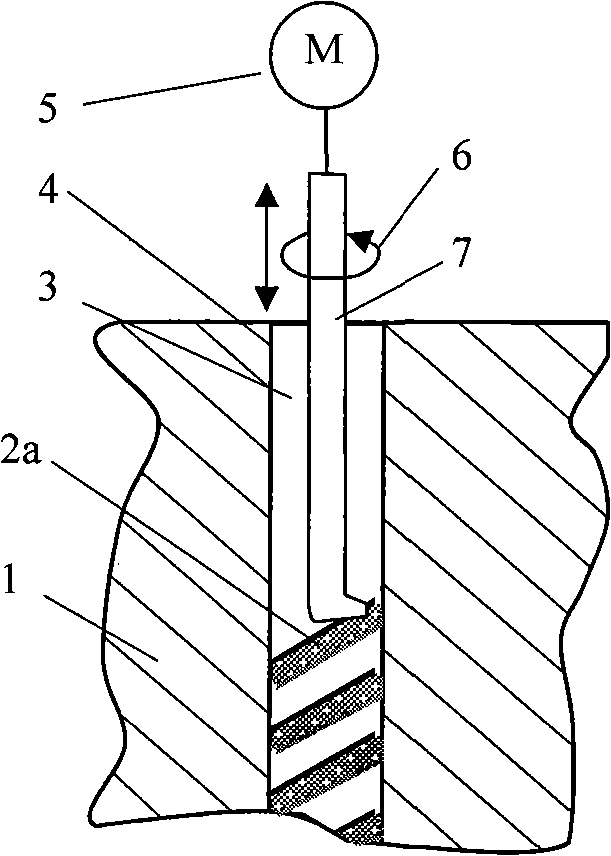

Electro-chemical machining technology of inner hole wall turbulence structure of metal parts

InactiveCN101491851ASkip the manufacturing processShielding electric fieldElectrochemical machining apparatusElectrolysisEngineering

The invention discloses an electrochemical machining process for an inner hole wall surface turbulent flow structure of a meal part. The machining process comprises: firstly, processing a smooth circular hole with an aperture of more than or equal to 2 millimeters on a position to be processed of the metal part, using a glue spreading spray head to coat a layer of insulating glue on the hole wall of the circular hole according to a set shape, and arranging a metal wire on a central axial line of the circular hole after the insulating glue of the hole wall is cured; and obtaining the turbulent flow structure by processing on the hole wall through electrolysis or electroforming, and finally using an insulating glue detergent to remove the prior cured insulating glue. The electrochemical machining process adopts special equipment and directly coats the insulating glue on the inner hole wall surface of the part as required, can effectively shield the influence of an electric field during electrochemical machining, save preparation of tool electrodes during electrochemical machining, and reduce the production period and the production cost; and simultaneously the electrochemical machining process can coat graphs with complex structures by controlling the motion track of the glue spreading head so as to be capable of processing different turbulent flow structures.

Owner:ZHEJIANG UNIV OF TECH

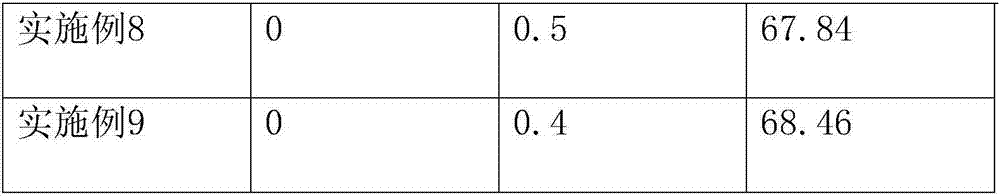

Environmental-friendly energy-saving veneer plywood glue coating device

InactiveCN108855768AReduce pollutionPlay a stirring roleLiquid surface applicatorsTransportation and packagingTransmission beltPulp and paper industry

The invention provides an environmental-friendly energy-saving veneer plywood glue coating device, which comprises a machine frame, wherein the top of the machine frame is fixedly provided with a feeding mechanism; a glue coating mechanism is connected under the feeding mechanism; a plate transmission belt is arranged under the glue coating mechanism; a waste glue collector is also fixedly arranged under the plate transmission belt; a glue accommodating air bag is arranged inside the glue coating mechanism; through the contraction and expansion of a glue accommodating air bag, the spraying andsuction on glue water is realized, so that the condition that residue glue water is thrown away by centrifugal force is effectively reduced; the glue material is effectively saved; meanwhile, the glue material pollution is reduced; meanwhile, the circulation spray suction of the material accumulation air bag also achieves the stirring effects on the glue materials in a material storage cavity, sothat the glue materials are more uniform; the glue coating quality is higher; during the cleaning, cleaning liquid is injected into the device; when a glue coating round tube rotates, the inside gluematerials can be cleanly cleaned through the spray washing by the glue accommodating air bag; convenience and high speed are realized; the waste glue collector recovers and treats the waste glue; green and environmental-friendly effects are achieved.

Owner:临泉县荣兴木业有限公司

Monophyletic solid disinfectant of chlorine dioxide and preparation method thereof

InactiveCN1969633AImprove stabilityPromote productionBiocideDisinfectantsSodium bicarbonateCITRATE ESTER

The invention discloses a monobasic solid chlorine dioxide sanitizer and making method, which comprises the following steps: a. weighing raw material with 16-19% sodium chlorite, 3-4% sodium percarbonate, 35-38% sodium bisulfate, 25-31% sodium tartrate, 5-6.2% citrate and / or amidosulfonic acid and 8.6-10.2% sodium bicarbonate; adding sodium percarbonate, sodium bisulfate, sodium tartrate and sodium bicarbonate in the drier to dry at 100-140 deg.c; b. blending sodium chlorite, sodium tartrate, sodium percarbonate and sodium bicarbonate in the sealed container evenly; c. adding sodium bisulfate, citrate and / or amidosulfonic acid to mix evenly; d. packing composition bag by bag.

Owner:刘桂发

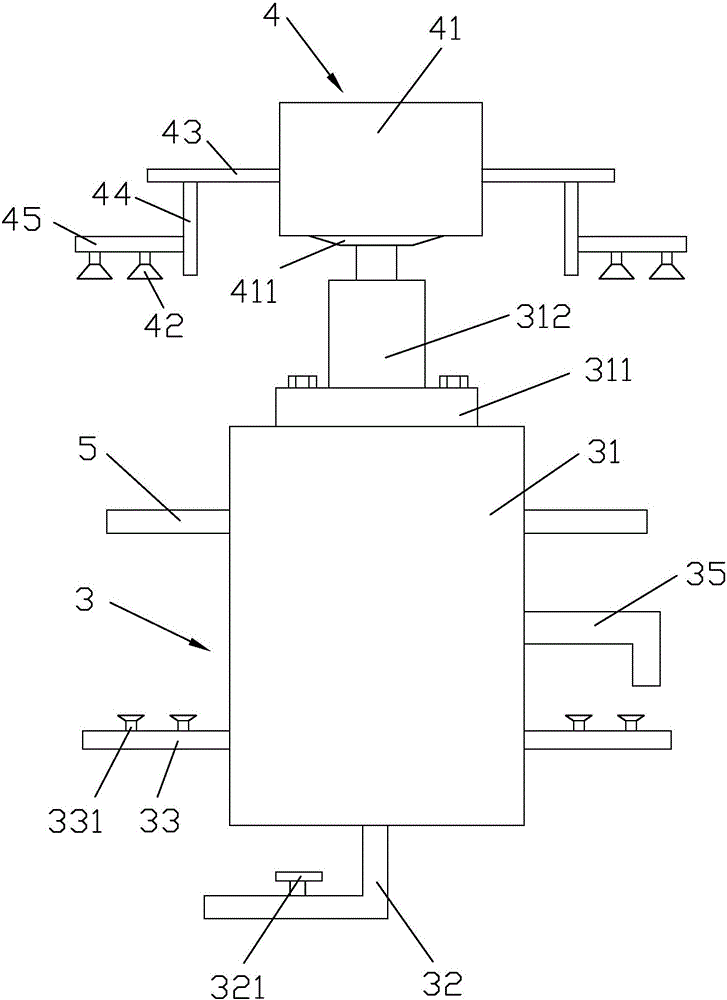

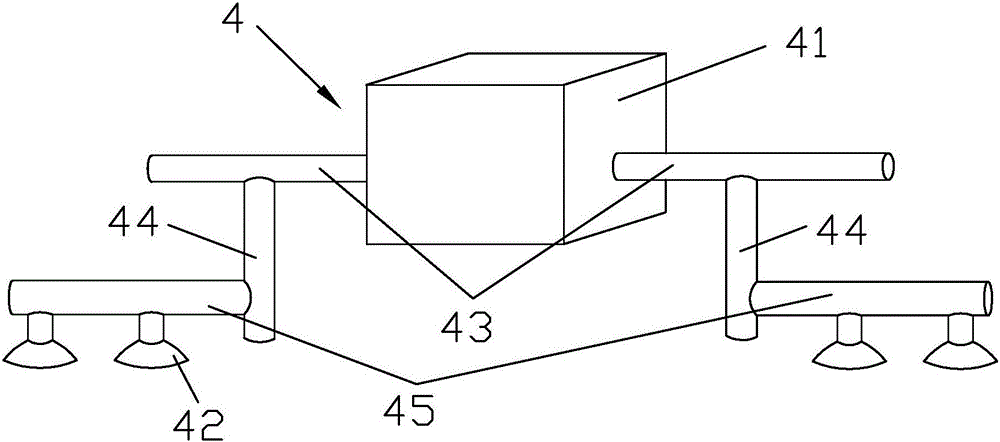

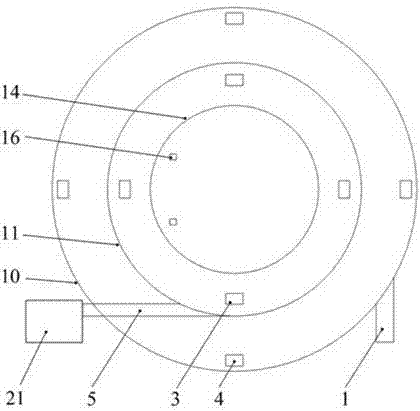

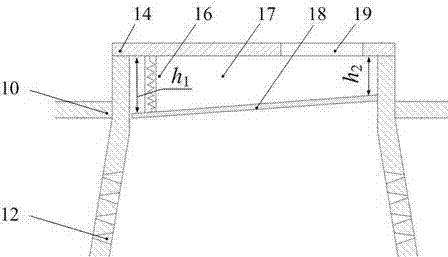

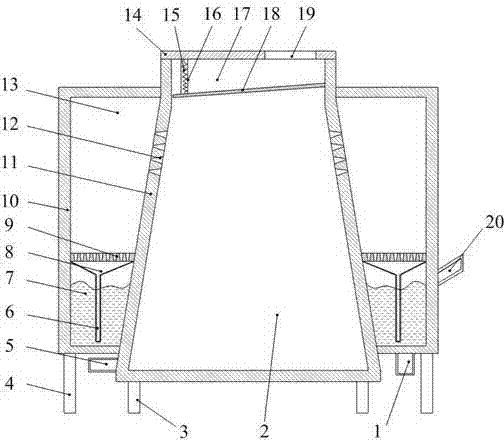

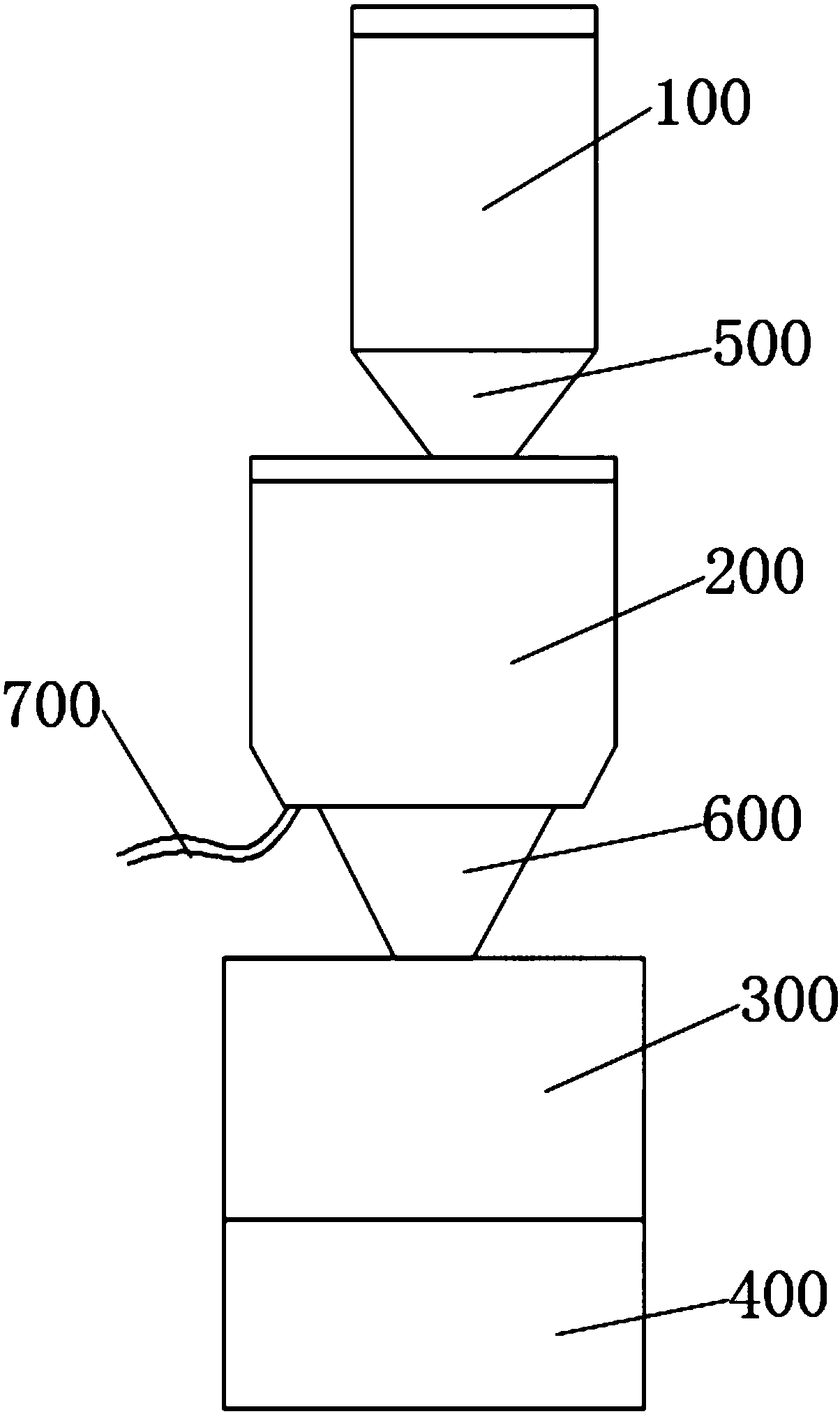

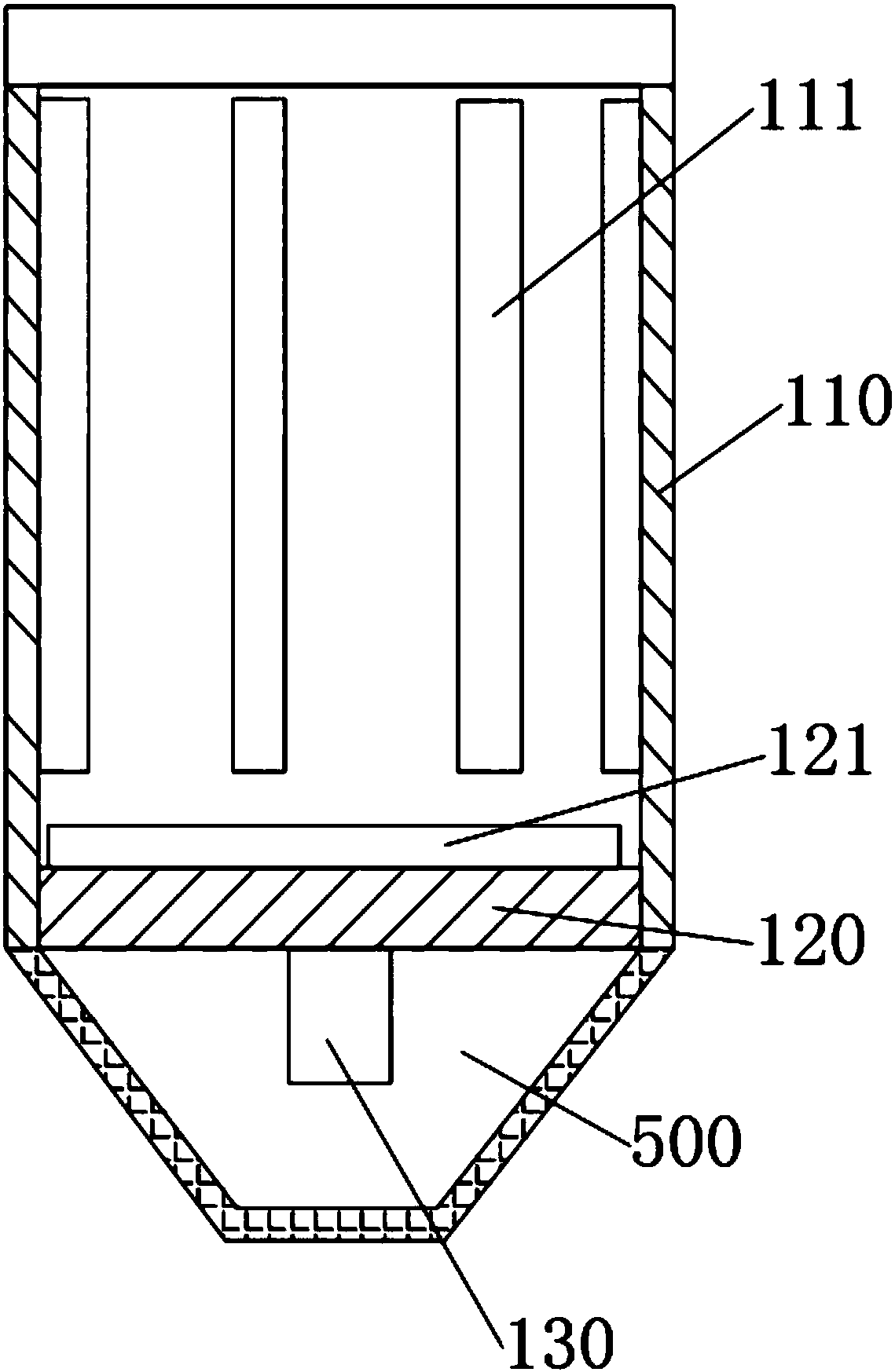

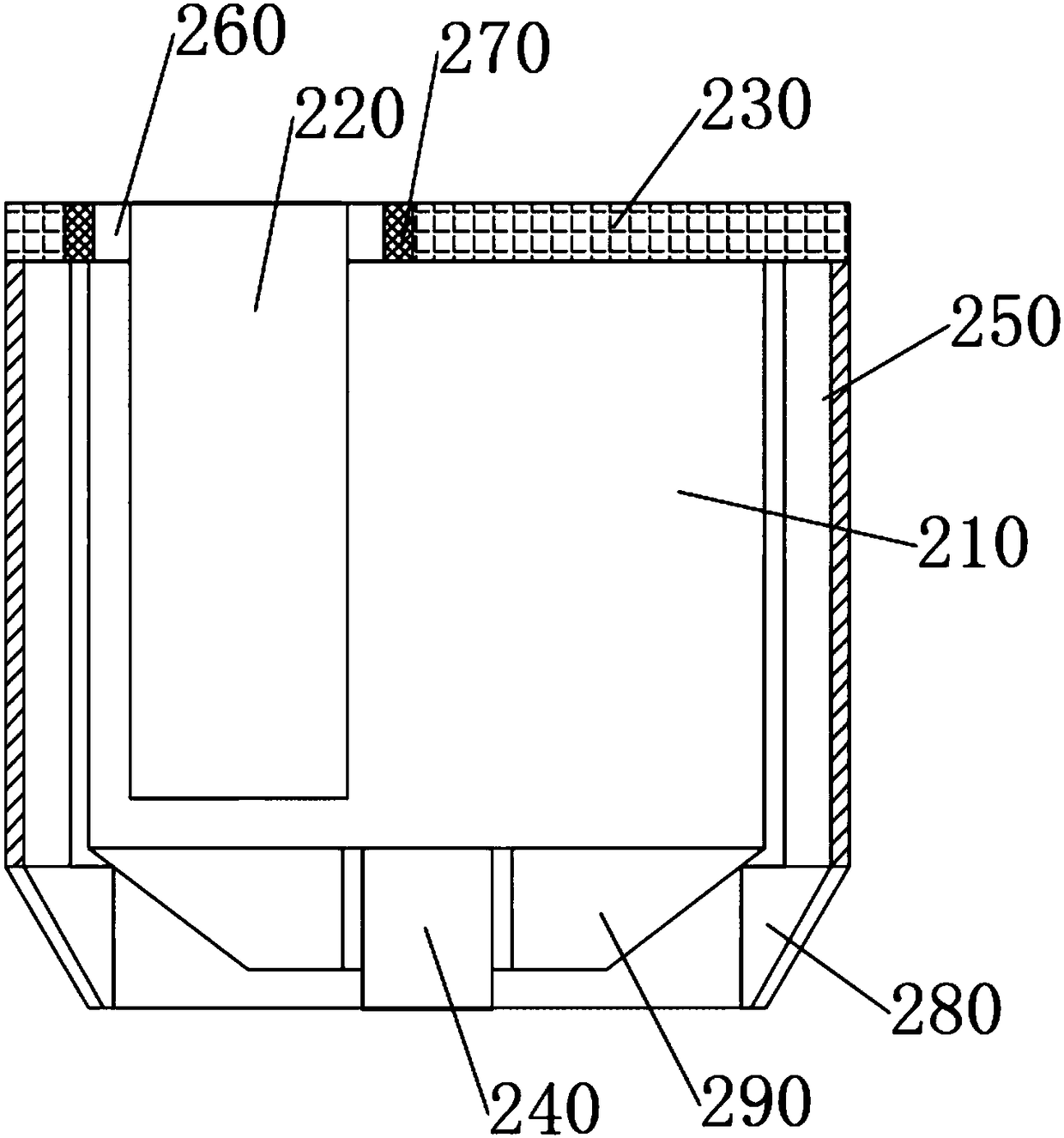

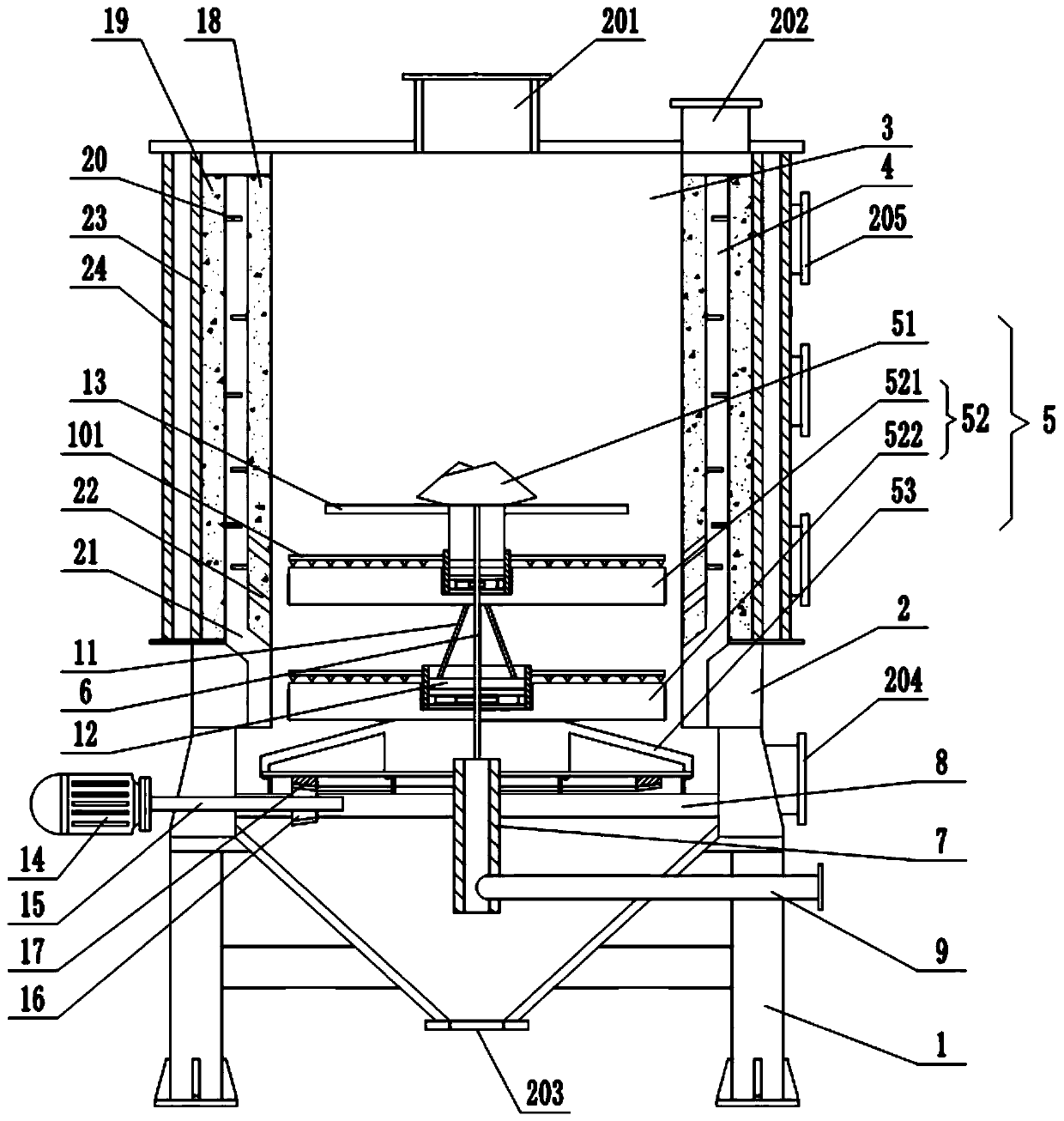

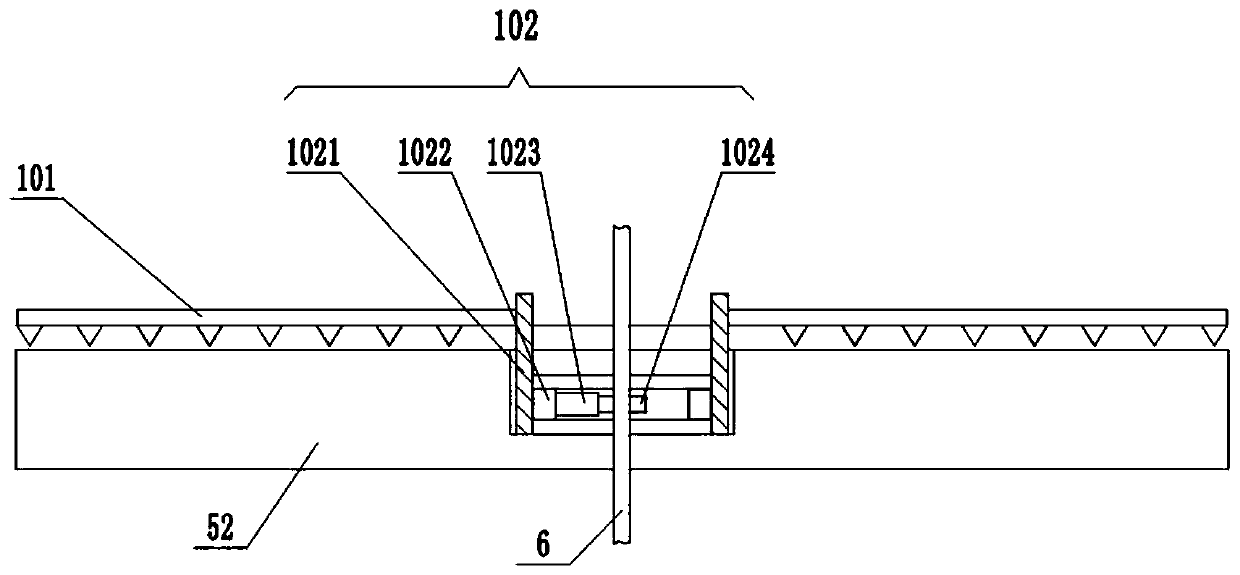

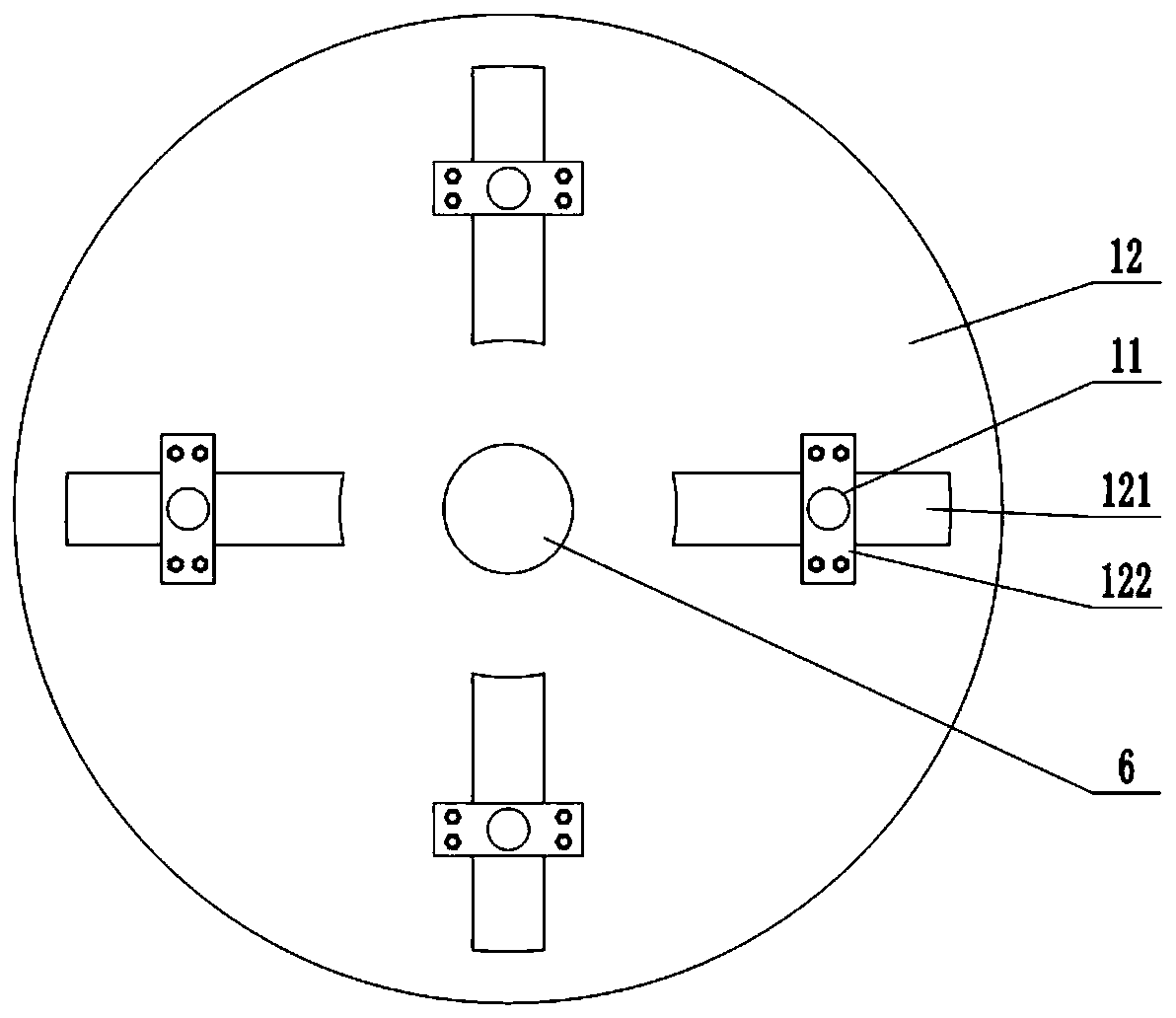

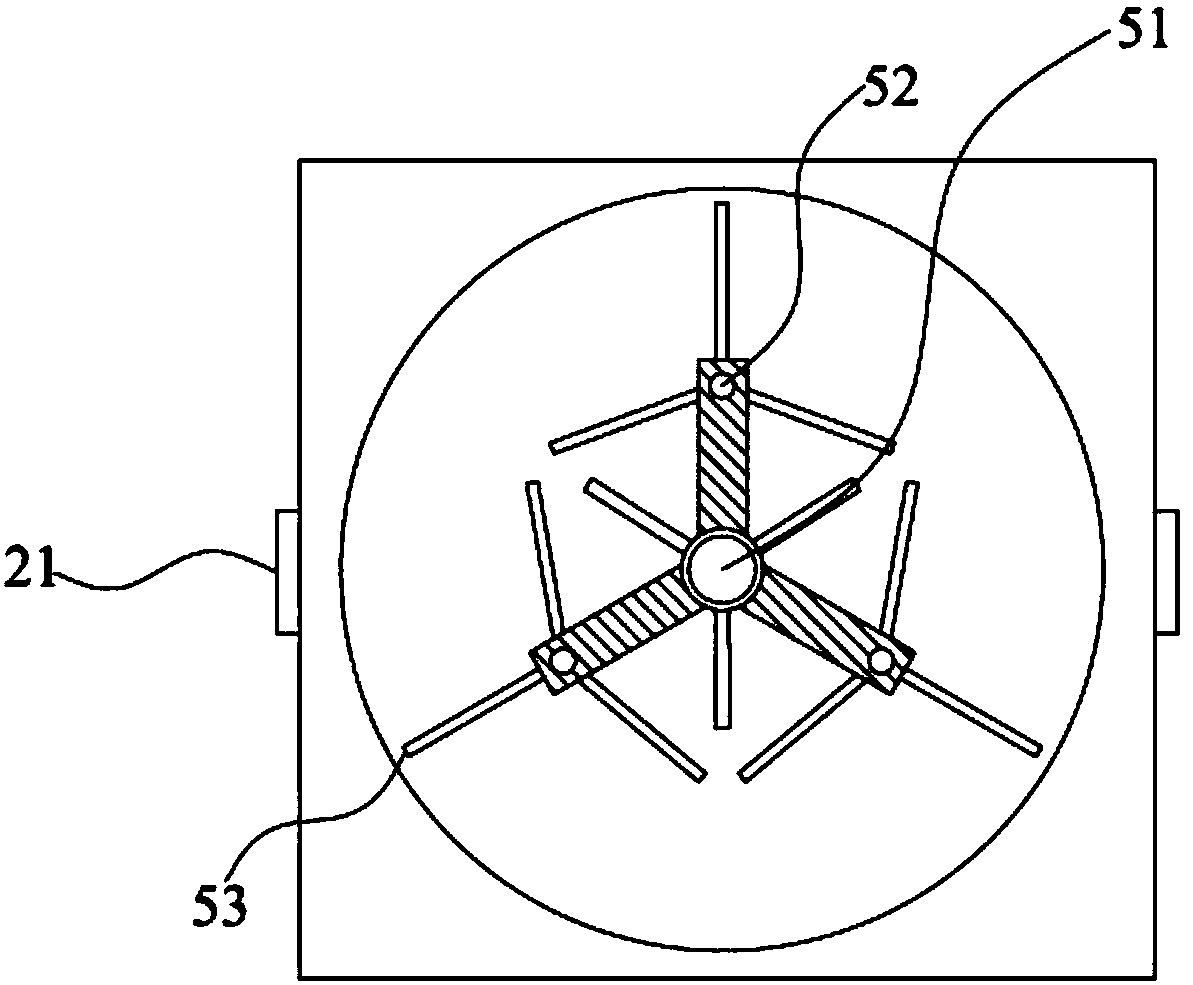

Pulping device capable of achieving solid-liquid separation and secondary air vortex breakdown

InactiveCN104727173AGuaranteed stabilityEliminate shakingRaw material divisionLiquid stateLiquid water

The invention provides a pulping device capable of achieving solid-liquid separation and secondary air vortex breakdown. The pulping device mainly comprises a feeding device, a vortex breakdown device and a liquid pulp generating device and is characterized in that solid and liquid are separated, air vortex breakdown is conducted firstly, and then broken materials are mixed with liquid water to form pulp. According to the pulping device, feeding amount control and sealing are achieved through a buffering and sealing plate and a spring, tangential feeding of air is achieved and loop current is formed through an air inlet tangent to the outer edge of the bottom of an inner conical cylinder, rotational flow is accelerated twice through a tapered primary vortex breakdown area and an oblique secondary vortex breakdown area, the broken materials are screened twice and blockage prevention is achieved through circular truncated cone-shaped holes in a primary filtering device and a secondary filtering device, and mixing and stirring of solid and liquid are achieved through a broken material delivery pipe.

Owner:UNIV OF JINAN

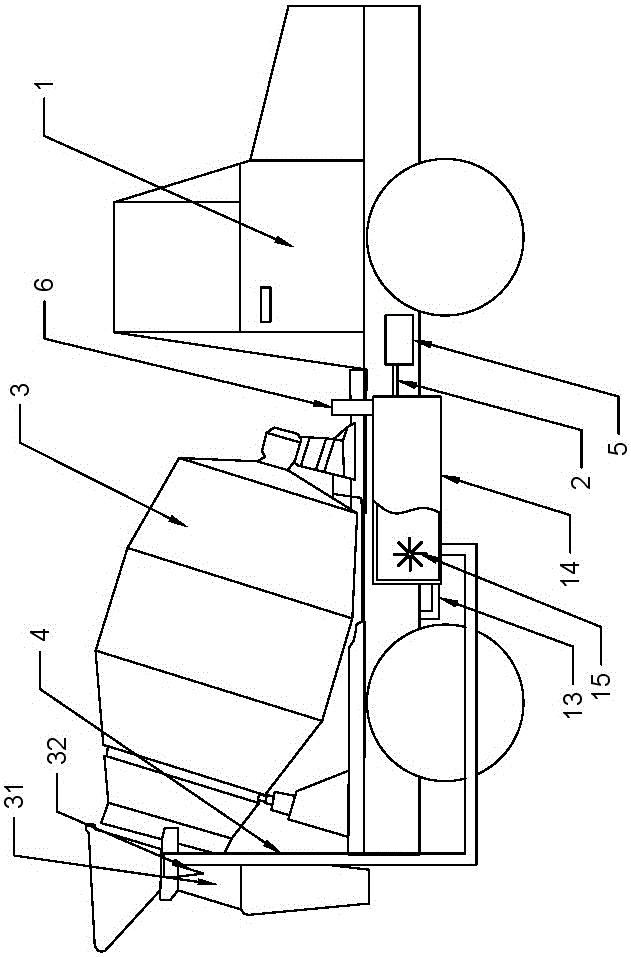

Kitchen waste treatment equipment

PendingCN108356051ASmooth rotationDoes not affect grinding actionTransportation and packagingSolid waste disposalElectricityEngineering

The invention relates to kitchen waste treatment equipment. The kitchen waste treatment equipment comprises a support, a crushing and grinding device, a solid-liquid separation device, a drying and deodorizing device, a first stock bin and a control device, wherein the crushing and grinding device, the solid-liquid separation device, the drying and deodorizing device, the first stock bin and the control device are arranged in the support and are sequentially arranged from top to bottom; the solid-liquid separation device is provided with a first discharge port and a second discharge port; thefirst discharge port is connected to a liquid discharge pipe; the second discharge port is connected to a feed port of the drying and deodorizing device; and the control device is electrically connected to the crushing and grinding device, the drying and deodorizing device and the solid-liquid separation device. The kitchen waste treatment equipment has the advantages that the structure is simple,the full-automatic operation is realized, the use is convenient, the environmental pollution caused by kitchen waste can be avoided from the source, and the kitchen waste can be conveniently recycled.

Owner:深圳市富利臻环保科技有限公司

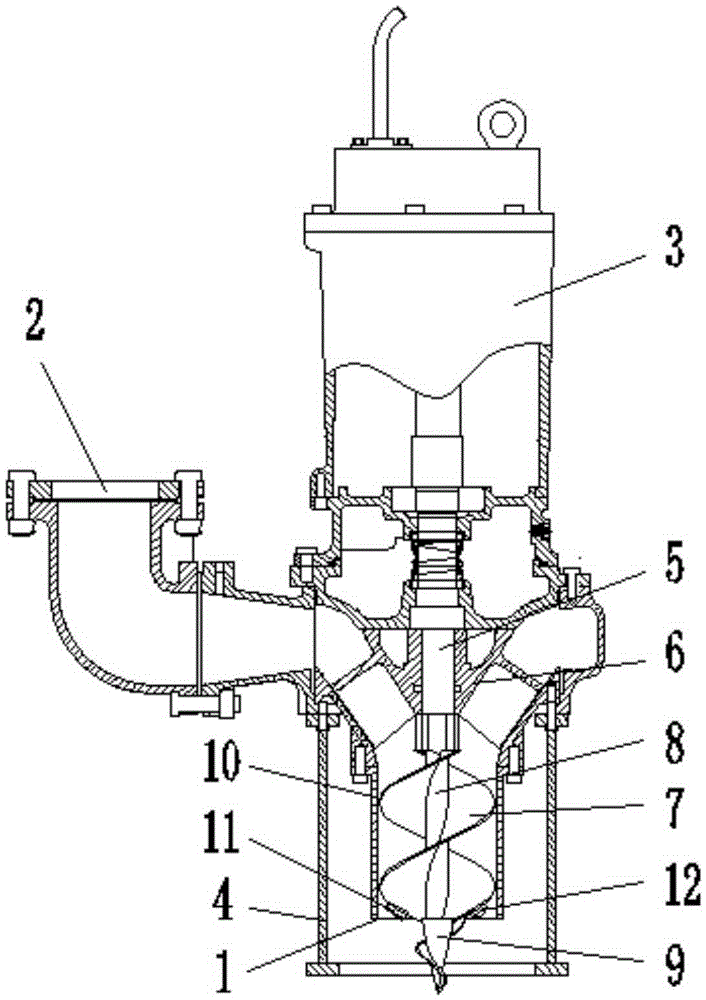

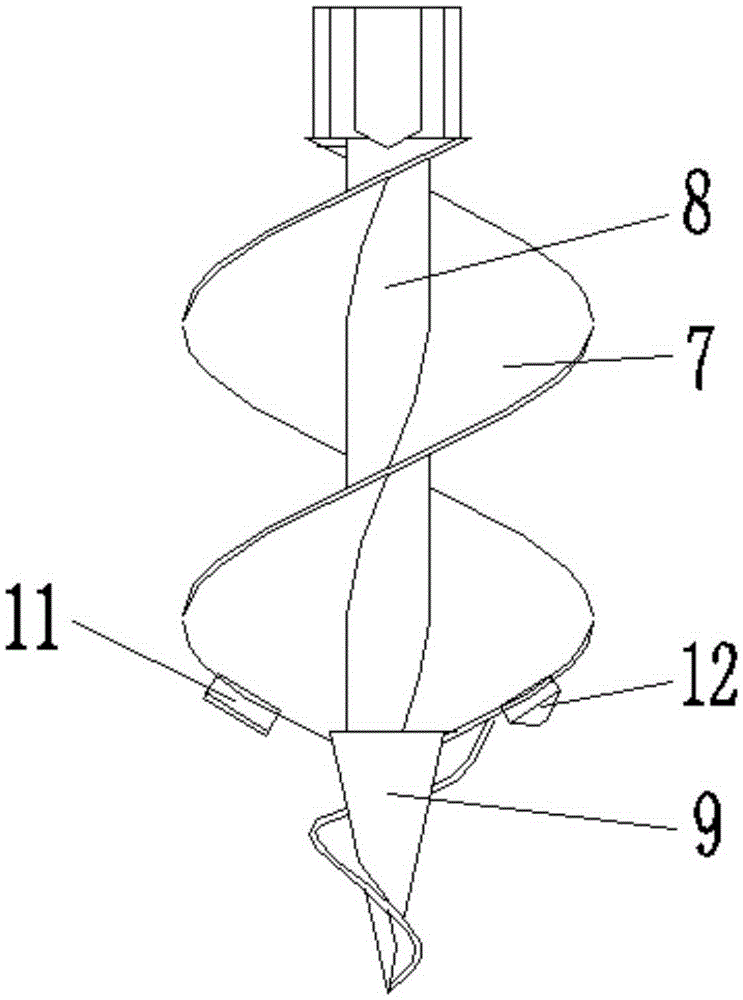

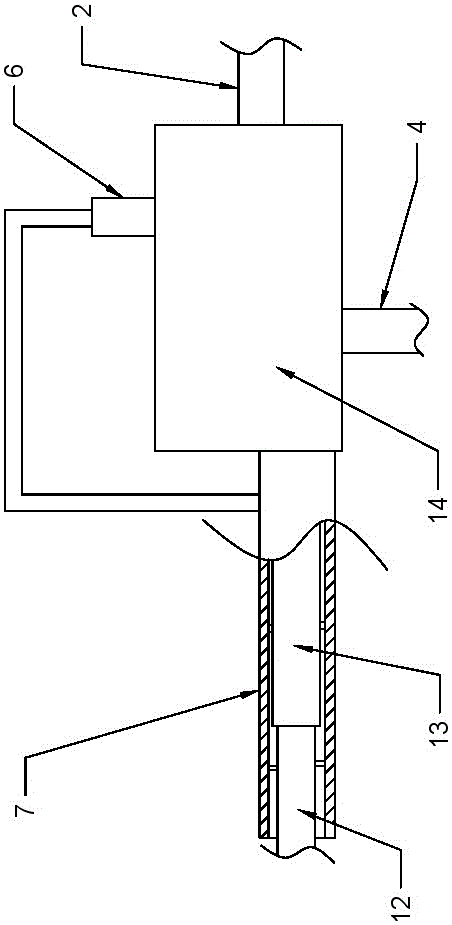

Feeding packing auger type submersible mud pump

InactiveCN105351210AImprove extraction efficiencyImproved extraction and dischargeSpecific fluid pumpsPump componentsImpellerSpiral blade

The invention relates to a feeding packing auger type submersible mud pump, and belongs to the technical field of electric pumps. The mud pump comprises a pump body with a water inlet and a water outlet, wherein a vertical type packing auger assembly driven by a motor is arranged in the pump body; the vertical type packing auger assembly comprises an impeller shaft and an impeller; the impeller rotates for throwing mud to the water outlet; the tail end of the impeller shaft is connected with a reamer shaft with a spiral blade; a drill bit is arranged at the tail end of the reamer shaft; the periphery of the spiral blade is provided with a guide pipeline; the end opening of the guide pipeline is used as the water inlet of the submersible pump; and the drill bit is exposed out of the end opening of the guide pipeline. The drill bit is used for drilling, pushing and lifting mud; the spiral blade not only can generate pushing effect, but also can generate stirring effect; a cutting-off tool bit and a crushing tool bit can be used for crushing large particles; the guide pipeline and the spiral blade jointly act, so that upward pushing force can be increased; and the submersible pump can increase discharge amount of mud, thereby avoiding large amount of surplus of mud, saving a manual clearing process, and achieving higher working efficiency and better discharge effect.

Owner:HEBEI QIANDA SPECIAL PUMP IND

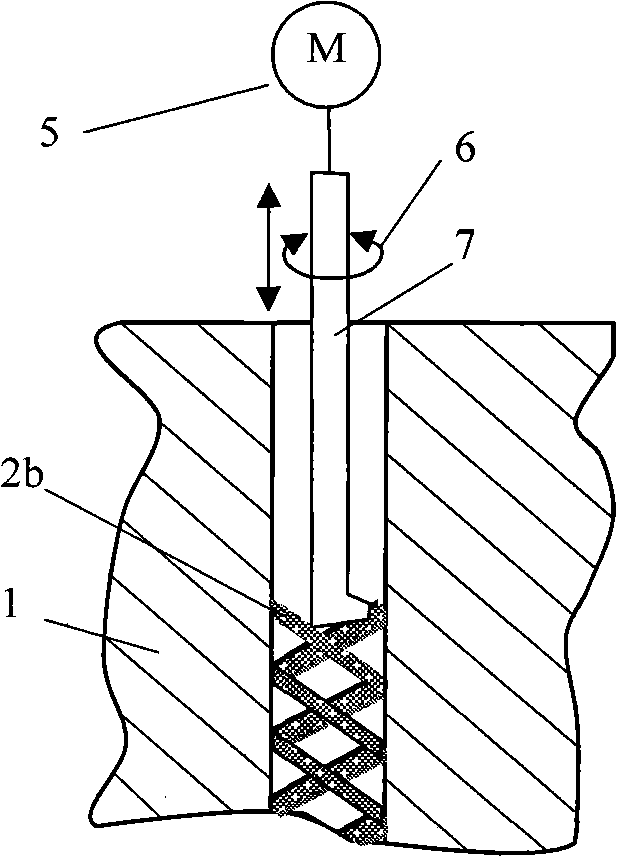

Methane tank capable of facilitating slag removal

InactiveCN102212464AEasy to ship outPlay a stirring roleGas production bioreactorsWaste based fuelPoisoning riskSlag

The invention discloses a methane tank capable of facilitating slag removal. The methane tank comprises a methane tank body, wherein a feed port, a discharge port and a methane outlet are formed on the methane tank body; a gas storage chamber is arranged on the upper part in the methane tank body; a fermenting chamber is arranged on the lower part in the methane tank body; the bottom surface of the methane tank body is inclined; the feed port corresponds to the higher part of the inclined surface; and the discharge port corresponds to the lower part of the inclined surface. The bottom surface of the methane tank body is set to be the inclined surface, so when removing methane slag, a user only needs to draw out one part of methane liquid and return the methane liquid from the feed port (a feed pipe) to impact the bottom surface of the methane tank body to push the methane slag into the discharge port (a water pressure room) along with the inclined surface, and then can take out the methane slag conveniently from the discharge port (the water pressure room), so the user does not need to enter the fermenting chamber to remove the slag under a poisoning risk, and time and labor are saved; and in addition, the tank is stirred by the impact of the methane liquid, so that methane bacteria completely contact with fermenting materials newly entering the tank and yield of the methane is increased.

Owner:金海

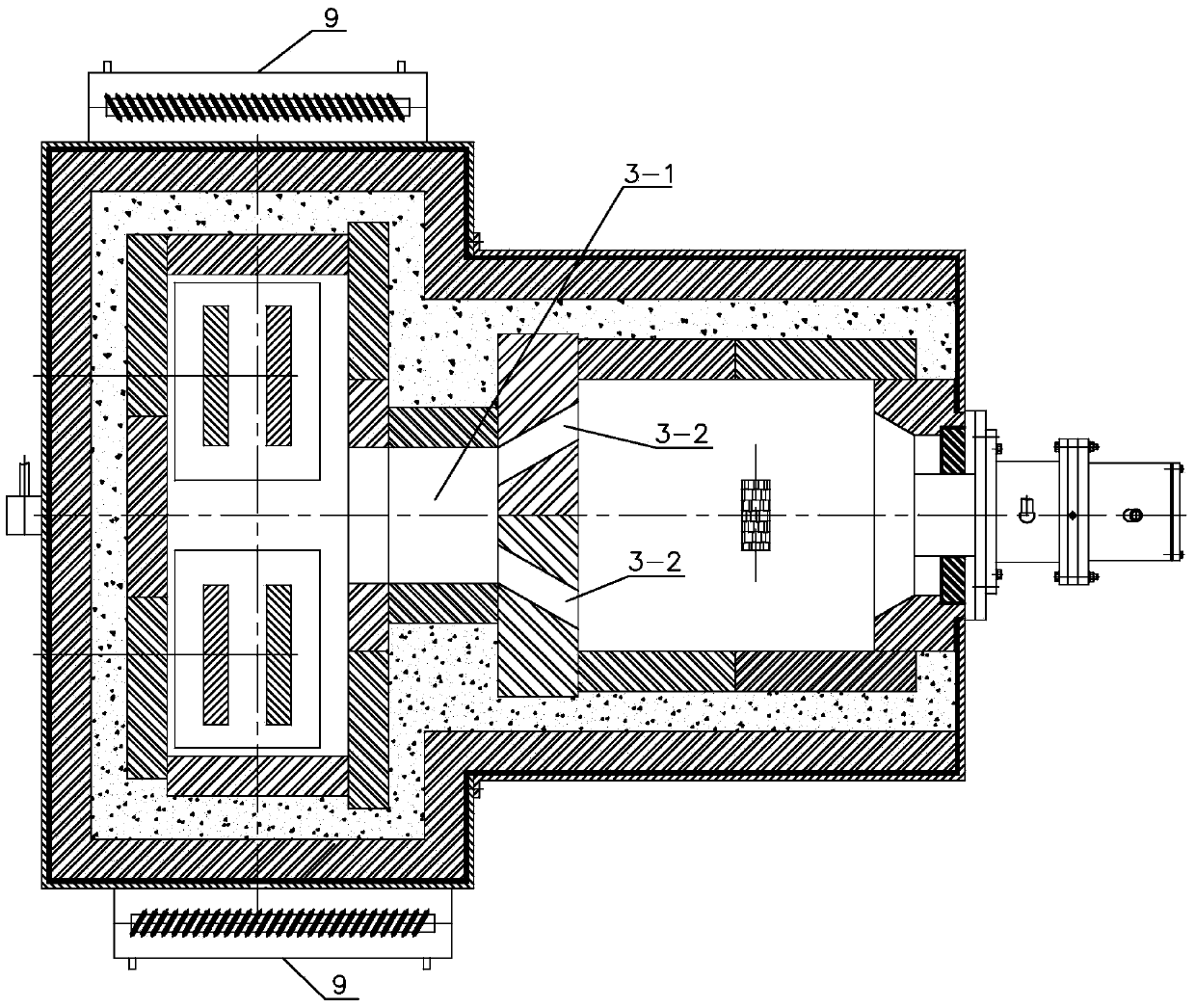

Large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process and connected furnace

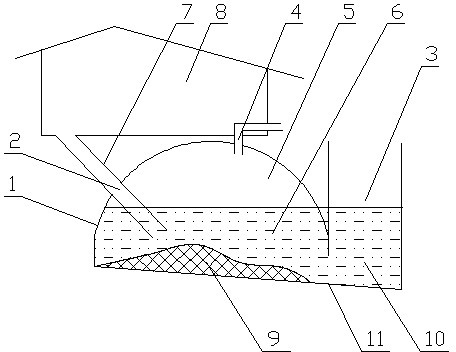

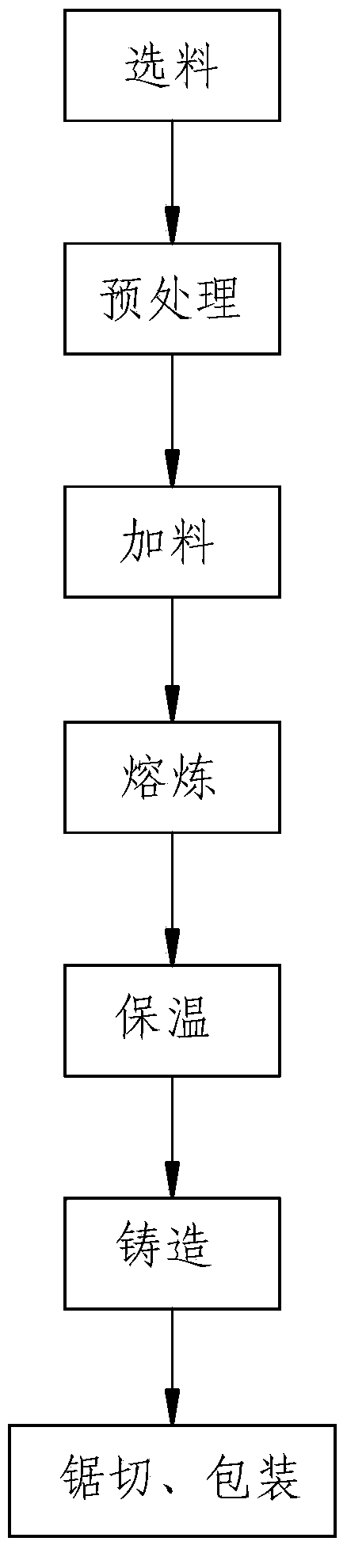

The invention relates to a large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process. An oxide layer and particles are removed from the standby cathode copper surface, in addition, preheating treatment is carried out, and the preheating temperature is controlled to be 280 DEG C to 300 DEG C; pretreated cathode copper is placed into a smelting furnace to be smelted, the smelting temperature is controlled to be 1180 to 1230 DEG C, inert gas is introduced into the bottom of the smelting furnace, a calcined charcoal layer floats above molten copper to be used as the coverage, and the molten copper is stirred through electromagnetic stirring; then, the smelted molten copper flows into a heat insulation furnace, inert gas is introduced into the bottom of the heat insulation furnace, the calcined charcoal layer floats above molten copper to be used as the coverage, and the temperature inside the heat insulation furnace is controlled to be 1180 to 1230 DEG C; the molten copper in the heat insulation furnace is guided out, a graphite crystallizer is subjected to water cooling, and high-purity oxygen-free copper cast blanks are obtained. The process has the advantages that the oxygen content of the cast blanks can be effectively controlled, the production cost is reduced, products can completely reach TU1 standards, and the yield can reach more than 90 percent.

Owner:JIANGSU XINGRONG MEILE COPPER IND

Pyrolysis gasification furnace

ActiveCN109780548AAvoid lostUtilize concentration and fullIncinerator apparatusCombustion chamberFlue gas

The invention belongs to the technical field of garbage disposal equipment, and particularly discloses a pyrolysis gasification furnace. The pyrolysis gasification furnace comprises a rack, a furnacebody, a furnace hearth, a secondary combustion chamber and a driving unit; the top of the furnace body is provided with a feeding port and a flue gas outlet, the bottom of the furnace body is providedwith a slag outlet, and the side wall of the furnace body is provided with a plurality of furnace doors and a plurality of observation holes; a rotatable furnace grate unit is arranged in the furnacehearth and comprises a garbage dispersing cap, a plurality layers of garbage distributing grates and a garbage furnace grate body which are sequentially connected from top to bottom; the side wall ofthe furnace body comprises an inner-side refractory layer, an outer-side refractory layer and a heat preservation layer, and the secondary combustion chamber is arranged between the inner-side refractory layer and the outer-side refractory layer; and a decoking unit is arranged in the furnace hearth and comprises a plurality of scraper blades and a power mechanism used for driving the scraper blades to do rotating motion, and the scraper blades are circumferentially distributed along the central axis and attached to the upper surface of the garbage furnace grate body. According to the pyrolysis gasification furnace, the scraper blades are arranged to remove coked materials on the furnace grate, furnace grate blocking is prevented, normal working and running of the furnace grate are guaranteed, and garbage can be fully combusted.

Owner:重庆管利仪器仪表有限公司

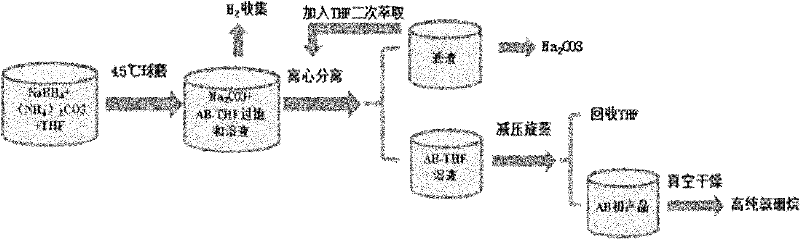

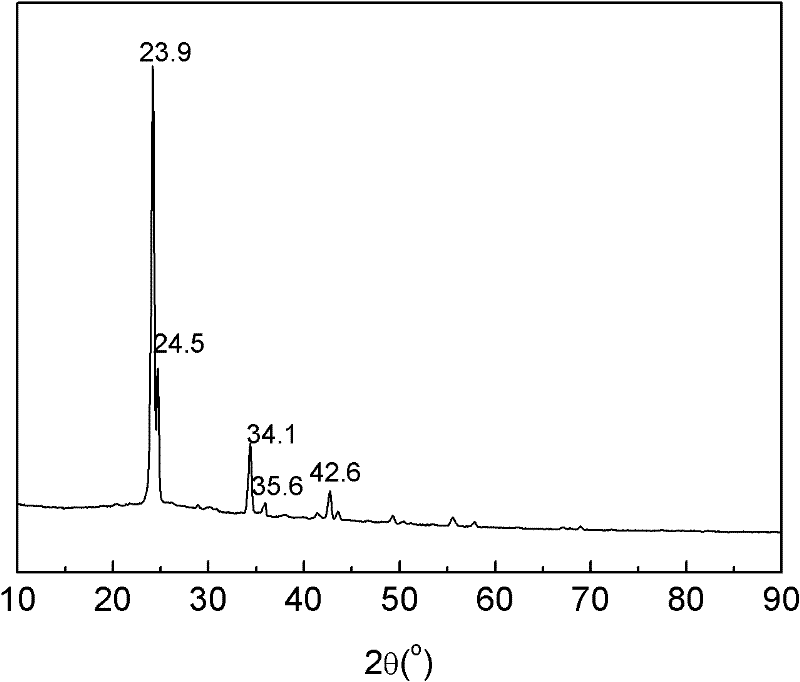

Method for preparing ammonia borane by wet chemical process

InactiveCN102530870ASmall particle sizeLarge reaction interfaceMetal hydridesChemical reactionDistillation

The invention provides a new method for preparing ammonia borane, which synthesizes ammonia borane with high efficiency by using an ammonium salt and a boron hydride as raw materials and an organic solvent as a reaction medium and by a wet chemical process. The method is characterized in that the chemical reaction between the starting raw materials is directly promoted by wet-process heating ball milling to form ammonia borane. Subsequently, ball milled pulp is subjected to centrifugal separation and reduced-pressure distillation, the clear liquid is obtained, and thus, high-purity ammonia borane crystal is obtained. The centrifugally separated and ball milled solid is subjected to multiple times of solvent extraction to achieve high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

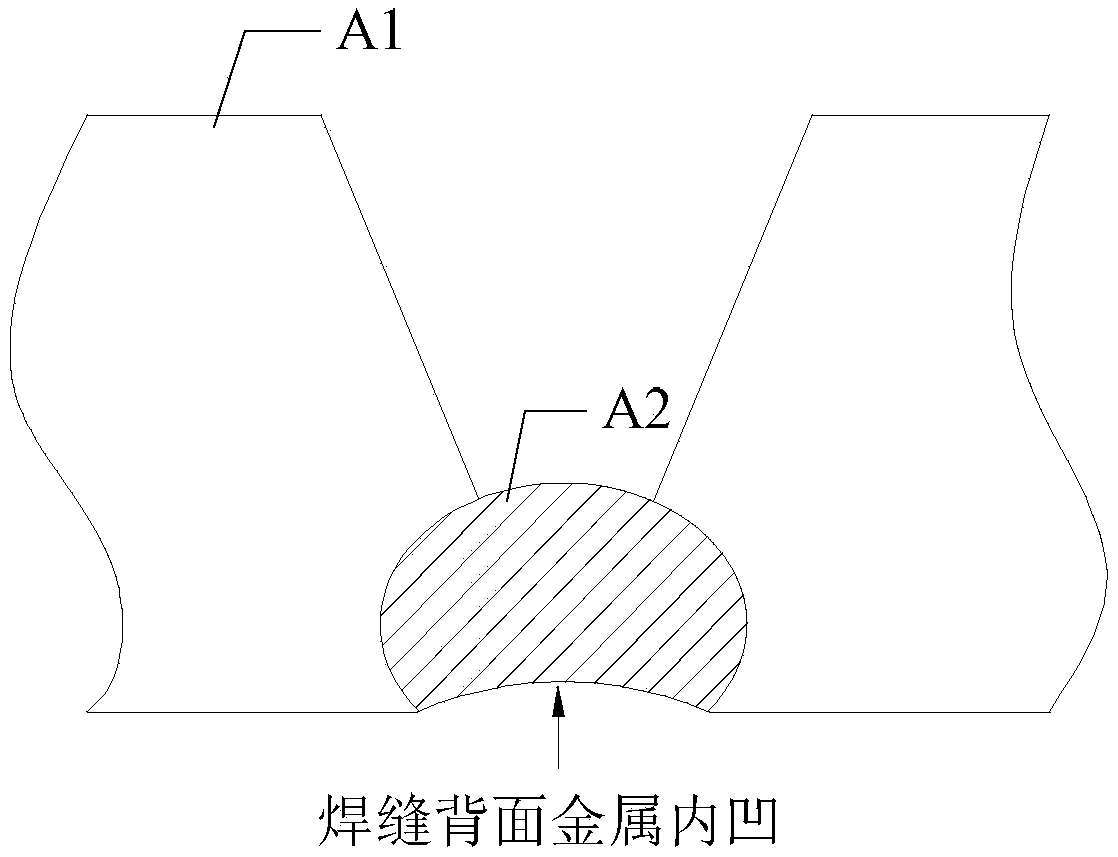

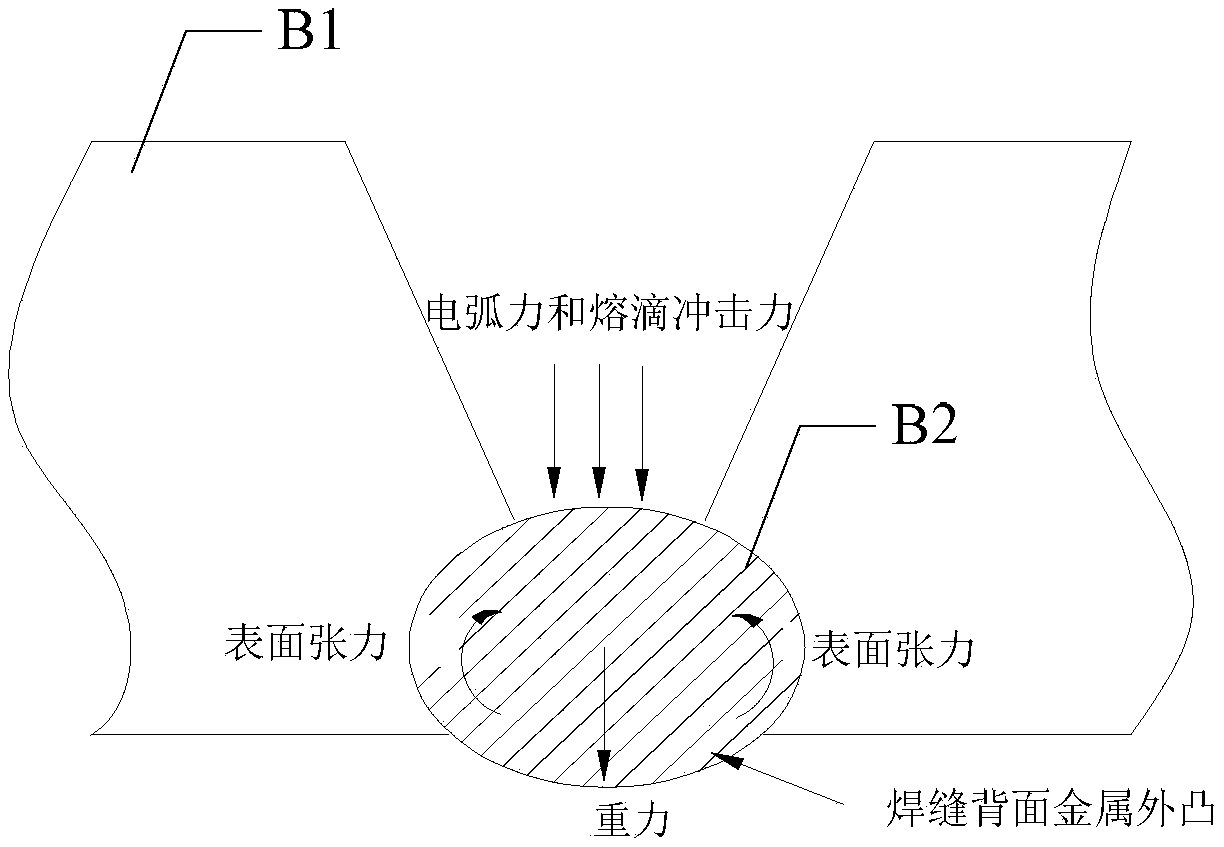

Bottoming welding method of laser-hot wire MIG composite based on light beam scanning

InactiveCN108971758APlay a stirring roleChange the state of stressLaser beam welding apparatusLaser scanningLight beam

The invention provides a bottoming welding method of laser-hot wire MIG composite based on light beam scanning, relates to the field of laser-hot wire MIG composite welding, and solves the problem that liquid metal welding joint back surface is prone to forming an indent when an existing laser-hot wire MIG welding performs bottoming welding. Bottoming welding is carried out on laser beam and hot wire MIG electric arc composite, wherein the laser beam scans along a certain track, and the hot wire MIG electric arc composite is protected by insert gas. The laser beam and the electric arc act in awelding pool, the power, scanning frequency and laser swing of the laser beam are matched reasonably to achieve a certain stirring action for the welding pool, the stress state of the welding pool ischanged, and the bottoming welding of welded workpieces is completed. The bottoming welding method of the laser-hot wire MIG composite based on the light beam scanning has the beneficial effects thatthe stirring action is achieved for the laser scanning, the stress state of the welding pool is changed, the resistance of the liquid metal flowing to a groove root portion is reduced, the forming effect of the welding joint back surface is improved, and the forming of the welding joint back surface is quite attractive and the spread-ability of the welding joint is good.

Owner:HARBIN IRT INTELLIGENT ROBOT TECH CO LTD

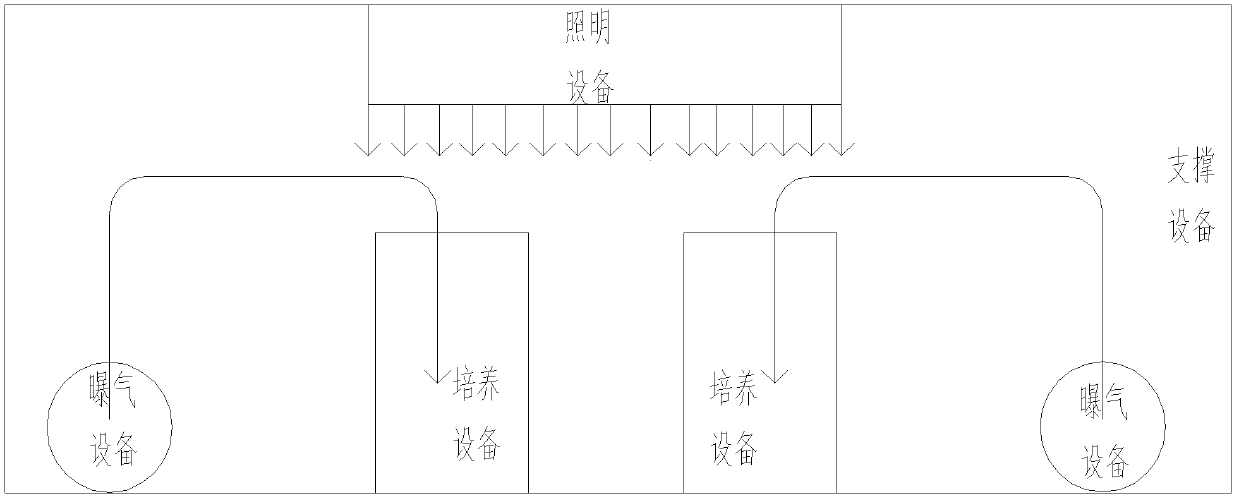

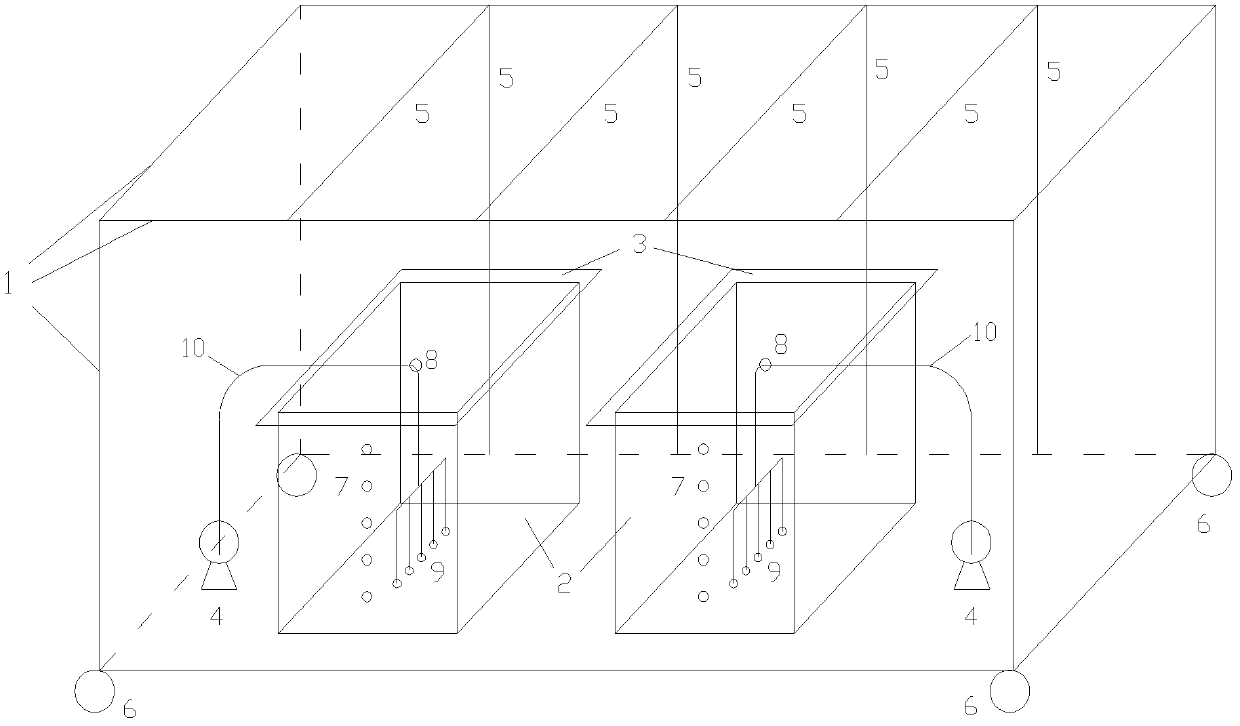

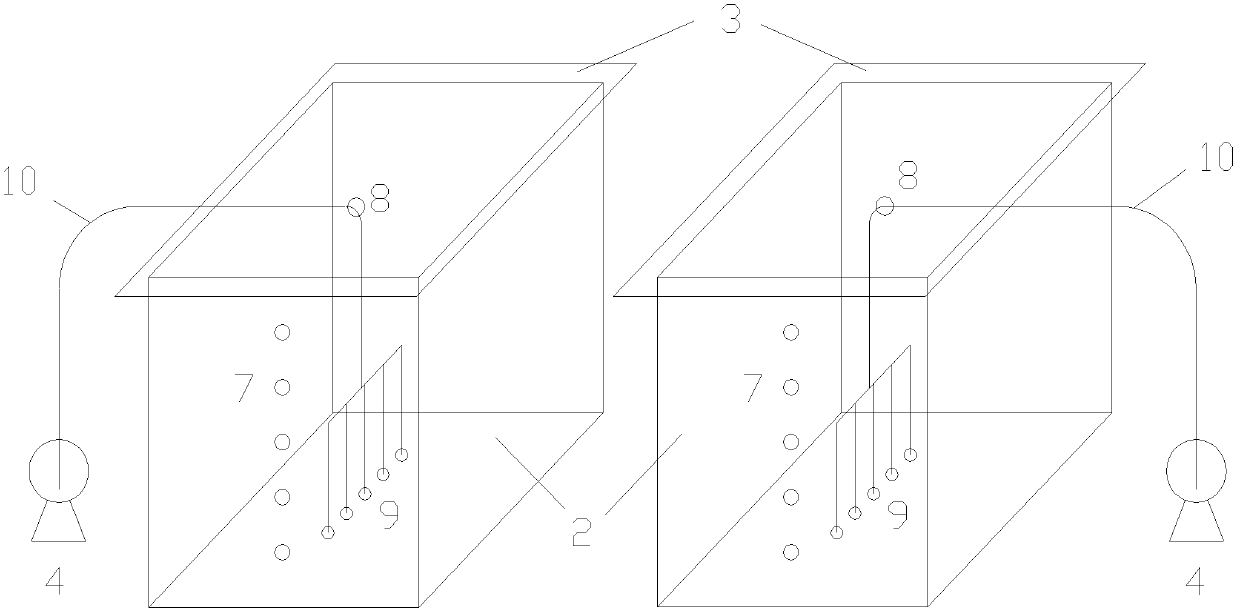

Submerged plant and algae coculture equipment

InactiveCN102577922AEasy to installFlexible moving processClimate change adaptationCultivating equipmentsLight equipmentSteel frame

The invention relates to submerged plant and algae coculture equipment, belonging to the field of water treatment. The submerged plant and algae coculture equipment is an experimental apparatus for simulating the living environment of submerged plants and algae and testing the condition of influence of the submerged plants on the growth metabolism of the algae. The submerged plant and algae coculture equipment comprises supporting equipment, culture equipment, lighting equipment and aeration equipment, wherein for the supporting equipment, a steel frame (1) of which the bottom is provided with four universal wheels (6) is used for placing other three sets of equipment; for the culture equipment, a water tank (2) with a tank cover (3) is used for simulating a river body to ensure the submerged plants and the algae to live, an air vent (8) on the cover can be communicated with the aeration equipment, and one side of the water tank is provided with sampling holes (7) so that samples at different water heights can be extracted; for the lighting equipment, a lamp tube (5) fixed on the steel frame provides light for the submerged plants and the algae and the lighting time and the strength can be regulated; and for the aeration equipment, an inflator pump (4) supplies oxygen to the submerged plants and the algae the oxygen supply can be regulated by regulating the operation time of the pump. The equipment occupies a small area, is convenient to move and has stable operation environment.

Owner:BEIJING UNIV OF TECH

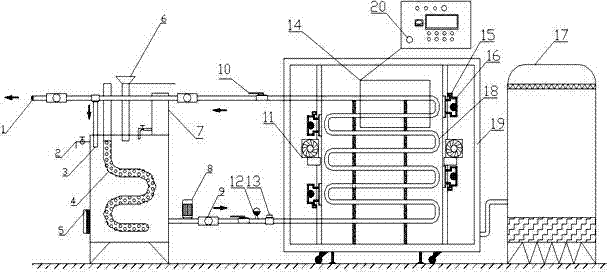

Microwave catalytic oxidation apparatus for landfill leachate treatment

InactiveCN103880229AImprove cooling efficiencyExtended service lifeWater/sewage treatment by irradiationMultistage water/sewage treatmentAutomatic controlTransformer

The invention discloses a microwave catalytic oxidation apparatus for landfill leachate treatment. The microwave catalytic oxidation apparatus mainly comprises a mixed water tank, a microwave reactor, a water cooling device, a circulating system and an automatic control system, wherein an overflow valve, a water inlet and a dosing tank are arranged on the upper part of the mixed water tank, and a water level indicator and an aeration pipe are arranged in the mixed water tank; the microwave reactor is surrounded by a housing, an outer wire, a magnetron, a transformer and a coil pipe are arranged in the microwave reactor, and the microwave reactor is connected with a cooling system; the circulating system is provided with a forward connecting pipe and a backward connecting pipe, the two of which are connected with the mixed water tank and the microwave reactor, and the connecting pipes are connected to the lower end of the coil pipe of the microwave reactor; the backward connecting pipe is provided with a water outlet and a circulating water pipe, and the circulating water pipe is communicated with the mixed water tank; and the microwave reactor and the water cooling device are connected with the automatic control system. The microwave catalytic oxidation apparatus is applied to landfill leachate treatment, and is high in microwave utilization rate, long in service life of the magnetron, good in leachate treatment effect, and also can be automatically controlled.

Owner:GUANGDONG UNIV OF TECH +2

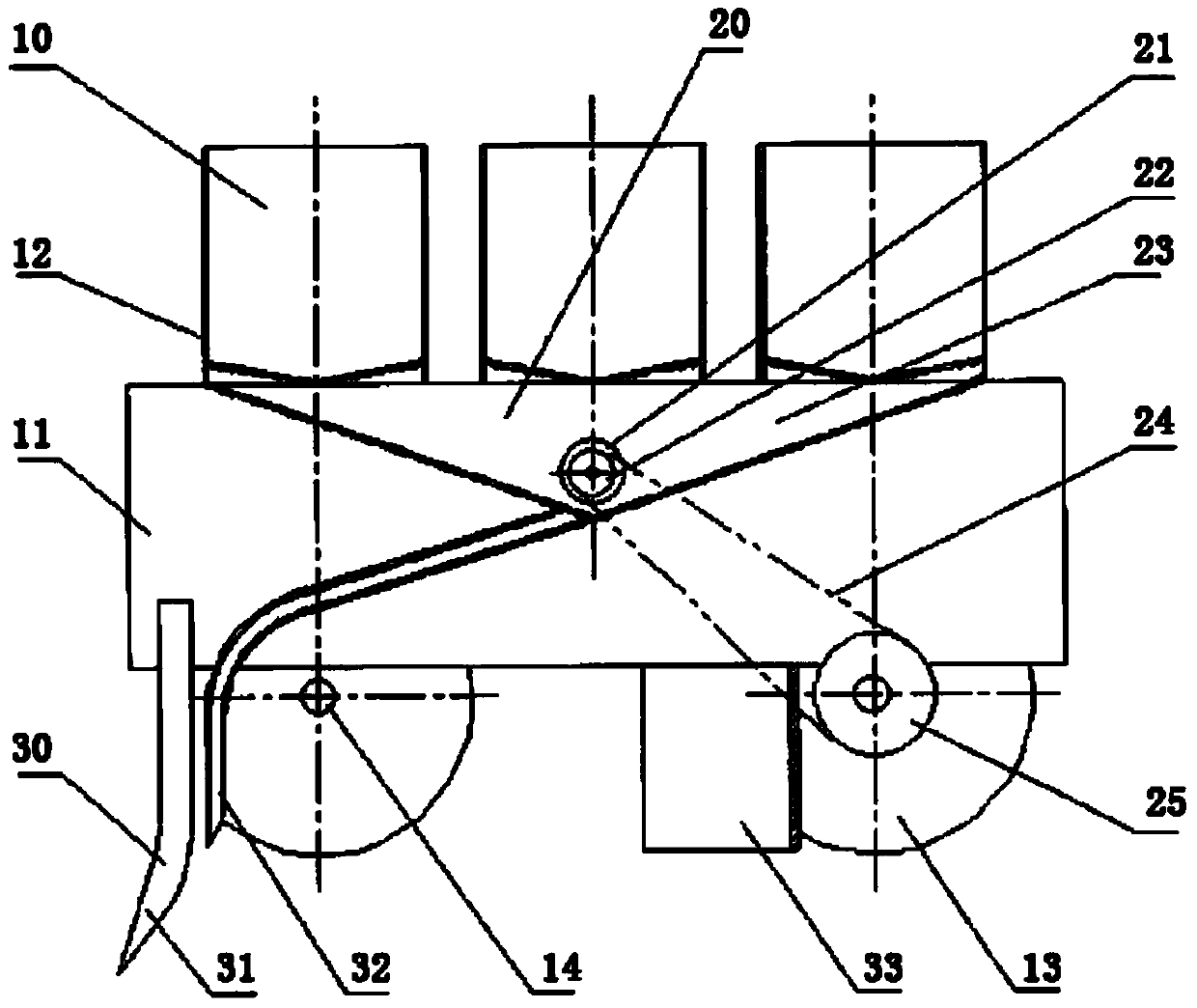

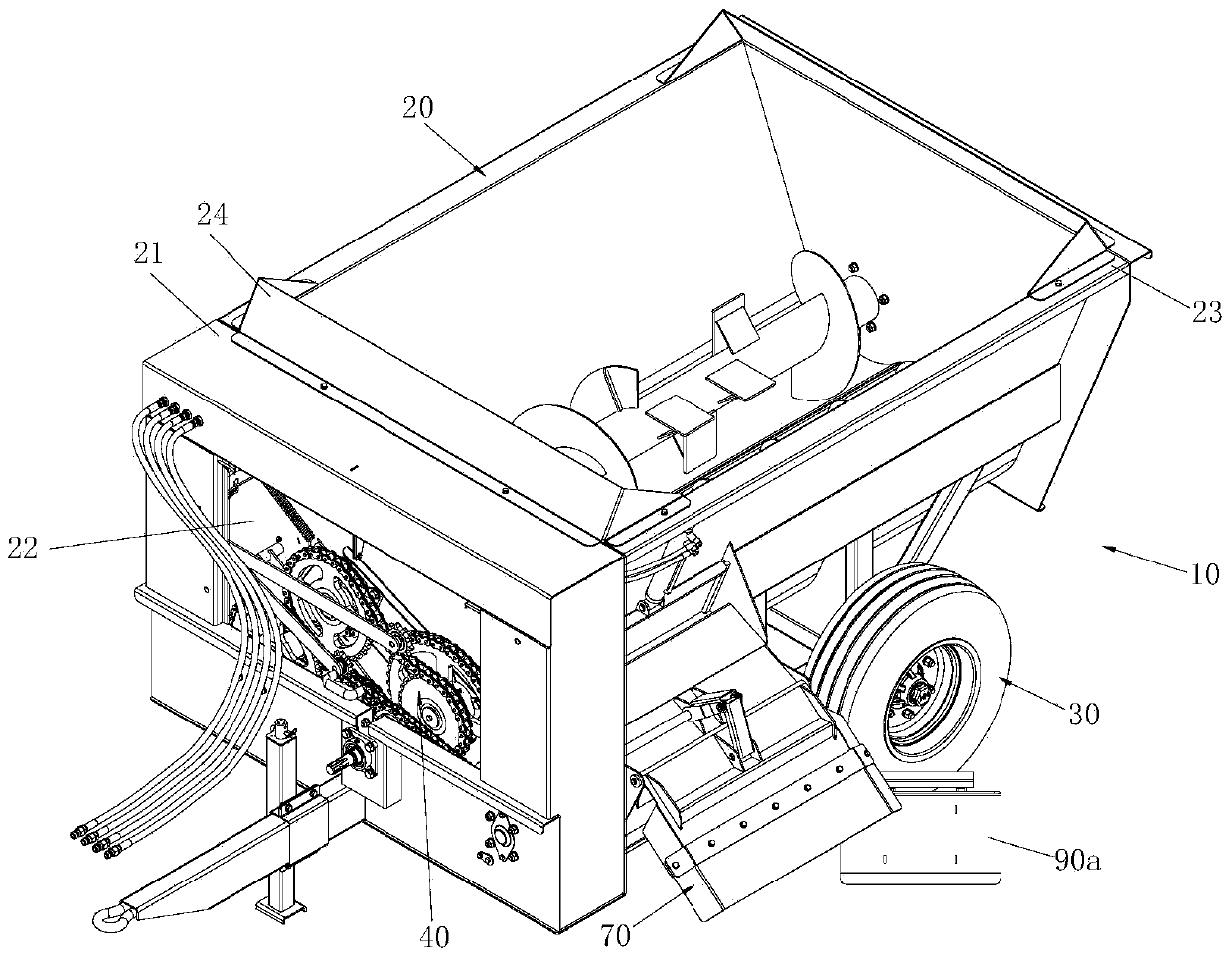

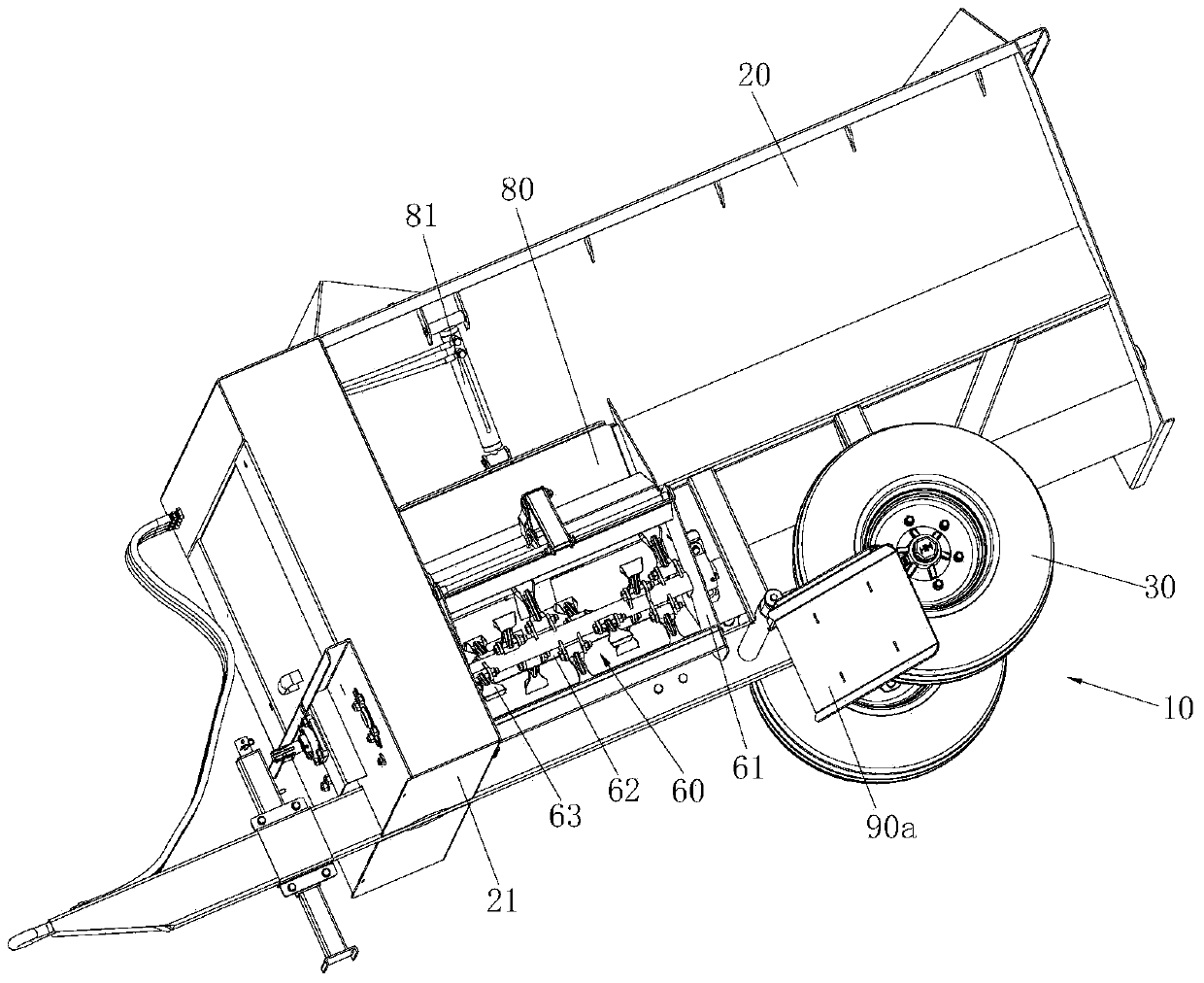

Fertilizer distributor

ActiveCN104206088AImprove backfill efficiencyNo damageFertiliser distributersAgricultural engineeringDistributor

The invention discloses a fertilizer distributor. A transmission chamber with an accommodating cavity is arranged at the front end of a feed box, a transmission mechanism is arranged in the accommodating cavity of the transmission chamber, one end of a feeding packing auger is rotatably supported at the rear end of the feed box, the other end of the feeding packing auger is rotatably arranged at the front end of the feed box and then extends into the transmission chamber and is connected with the transmission mechanism; a fertilizer distributing mechanism is arranged at a discharging hole, the fertilizer distributing mechanism comprises a housing with openings in two ends, a rotating shaft and a fertilizer distributing plate, the housing is fixed on the side wall surface of the feed box, one end of the rotating shaft is rotatably supported on the housing, the other end of the rotating shaft extends into the transmission chamber and is rotatably supported on the inner wall surface of the transmission chamber, and then is connected with the transmission mechanism, one end of the fertilizer distributing plate is fixed on the circumferential surface of the rotating shaft, and the other end of the fertilizer distributing plate extends along the radial direction of the rotating shaft. The fertilizer distributor disclosed by the invention has the advantages of high fertilizer distributing efficiency and no blockage in a fertilizer distributing process.

Owner:常州汉森机械股份有限公司

Method for reserving, conserving and culturing daphnia magna

InactiveCN102138542AEasy to operateLow costClimate change adaptationPisciculture and aquariaDaphnia magnaEcosystem

The invention belongs to the field of culturing of zooplanktons and relates to an ecological method for reserving, conserving and culturing daphnia magna. In the method for reserving, conserving and culturing daphnia magna, a simple daphnia magna-alga-spiral-fish aquatic ecosystem needs to be established, the daphnia magna stably grows and is reproduced in the ecosystem, a small amount of culturing water is replaced periodically and a small amount of bait is added, so that the daphnia magna is stabilized in the system permanently. Along with wide application of toxicological testing of daphnia magna, daphnia magna needs to be provided at any time to serve as a testing material. A method for establishing a simple aquatic ecosystem is adopted, so that the operation is simple, the cost is low, the daphnia magna can stably grow and be reproduced, frequent field seed collecting is not needed, the troubles of frequency manual water change, bait feeding and clearing of impurities and waste during ordinary culturing are eliminated, and the aim of easily and conveniently preserving in a laboratory for a long time is fulfilled.

Owner:SUN YAT SEN UNIV

Wood conditioning method

ActiveCN107116643AIdeal elastic strengthIdeal compressive strengthImpregnation spraying apparatusWood treatment detailsCell wallHigh-temperature corrosion

The invention discloses a wood conditioning method. The method comprises following steps of immersion treatment, primary heating and humidifying treatment, primary drying, primary cooling, secondary heating and humidifying treatment, secondary drying, secondary cooling and ventilation drying. According to the wood conditioning method, the high-temperature and low-temperature alternative drying manner is adopted to reduce the wood water containing rate, through immersion treatment, ammonium bicarbonate is guided into the wood, due to alkalescence of an ammonium bicarbonate solution, cellulose on the wood cell wall can be swelled up, introduction of subsequent heat and water flowing can be facilitated, according to high-temperature and high-humidity treatment, overheat water steam is used for forming partial pressure so as to move water out of the wood, through cooling, temperature gradient is used for diffusing water to the outer portion, the high temperature drying and the low temperature drying are alternatively carried out, the water containing rate of the wood is reduced to the proper range, the anti-mildew anti-corrosion property of the wood can be increased, consumed time is short, and energy consumption is small.

Owner:浙江润格木业科技有限公司

Granulator waste gas treating device

InactiveCN106039923APlay a stirring roleImprove purification effectUsing liquid separation agentActivated carbonProduct gas

The invention discloses a waste gas treatment device of a granulator, which comprises a box body, a partition, a fan, a waste gas inlet, a pipe box, a ventilation pipe, an air guide plate, a windmill, a perspective plate, a purification plate, an air outlet pipe, a gas sampling port, Coarse filter screen and activated carbon adsorption layer, a fan is arranged above the box, and the right end of the fan is provided with an exhaust gas inlet. An air guide plate is provided, a windmill is provided on the left side of the air guide pipe, a partition is provided in the box, a see-through board is provided on the right side of the partition, an activated carbon adsorption layer is provided above the see-through board, and an activated carbon adsorption layer is provided on the left side of the partition. Purification plate, the left side of the box body is provided with an air outlet pipe, and the air outlet pipe is provided with a gas sampling port. The present invention is provided with a pipe box on the right side of the device, and several air pipes are provided at the bottom of the pipe box to pass waste into the liquid surface. Next, the solid impurities in the exhaust gas are further removed, which solves the problems of too slow gas flow and low purification efficiency of the existing device.

Owner:SUQIAN HUAIHAI TECH SERVICES

Efficient concrete stirring device for water conservancy project

InactiveCN110154239AReduce workloadEfficient mixingDischarging apparatusMixing operation control apparatusDrive shaftEngineering

Owner:ZHAOQING SHENGSHANG INTPROP SERVICE CO LTD

Mixer truck for concrete transport

InactiveCN106626073AHigh bonding strengthTightly boundConcrete transportationExhaust apparatusEnvironmental engineeringAtmospheric pressure

The invention belongs to the field of concrete transporters and particularly discloses a mixer truck for concrete transport, comprising a truck body and a stirring barrel; the truck body comprises an exhaust pipe, a pneumatic brake system and a water tank holding water, a discharge pipe is arranged between the exhaust pipe and the water tank, one end of the discharge pipe is fixedly connected to the exhaust pipe, the other end of the exhaust pipe is immersed in the water tank below the water level, the discharge pipe is provided with a one-way valve, a pressure pipe is arranged between the pneumatic brake system and the water tank and is provided with a pressure valve, the stirring barrel comprises a discharge port, the discharge port is provided with a nozzle, a water spray pipe is arranged between the nozzle and the water tank, one end of the water spray pipe is fixedly connected to the nozzle, the other end of the water spray pipe is immersed in the water tank below the water level, the water spray pipe is provided with a water spray valve, and the water tank is provided with a gas discharge pipe which is provided with a gas discharge valve. The mixer truck for concrete transport is provided to solve the technical problem that an existing mixer truck is limited to the improvement of aggregate and cement bonding strength.

Owner:重庆健杰科技有限公司

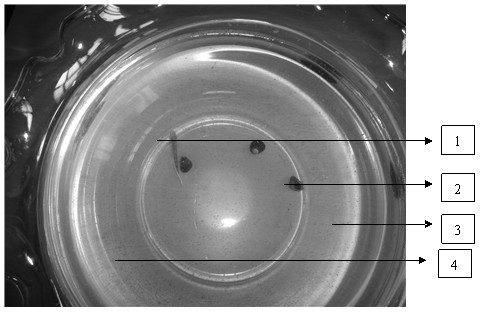

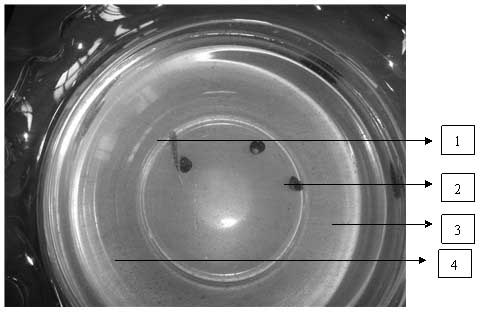

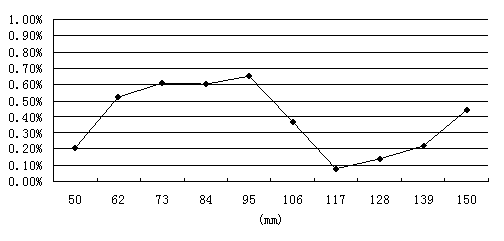

Processing method for single-cut corrosion slices of monocrystalline silicon wafer

The invention relates to a processing method for single-cut corrosion slices of a monocrystalline silicon wafer. The processing method comprises the following steps: 1, controlling the double-sided removal rate of the silicon wafer to be 20 plus (minus) 2 microns; 2, preparing acid corrosion resistant liquid consisting of the following components in percentage by weight: 9.03-12.41% of hydrofluoric acid, 39.9-42.0% of nitric acid, 19.2-23.1% of acetic acid, which are mixed by adding deionized water; 3, adding ammonia water to the acid corrosion resistant liquid as the additive, wherein the adding amount of the ammonia water is 1.08-2.48% of the total amount of the acid corrosion resistant liquid; 4, controlling the surface gloss of the corroded silicon wafer to 2-4Gs; 5, blowing nitrogen gas at the nitrogen gas position of 50-150 mm in an acid corrosion process, wherein the flow rate of the nitrogen gas is 100-300L / min, the pressure of the nitrogen gas is 80-300Pa, and the nitrogen gas blowing lasts in the whole process; 6, enabling the circulation volume of the acid corrosion resistant liquid to 300L, and enabling the discharge volume of the acid corrosion resistant liquid to 1-2L and the compensation amount of the acid corrosion resistant liquid to 0.3-1L after corroding 50 slices every time. The processing method is adopted to replace slice grinding and corroding to prepare the single-cut corrosion slices of the monocrystalline silicon wafer, so that the processing processes from the chamfering to the grinding are saved, the yield is increased, and the cost is greatly reduced. Therefore, the processing method achieves the purpose of replacing slice grinding and corroding to prepare the single-cut corrosion slices of monocrystalline silicon wafer.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

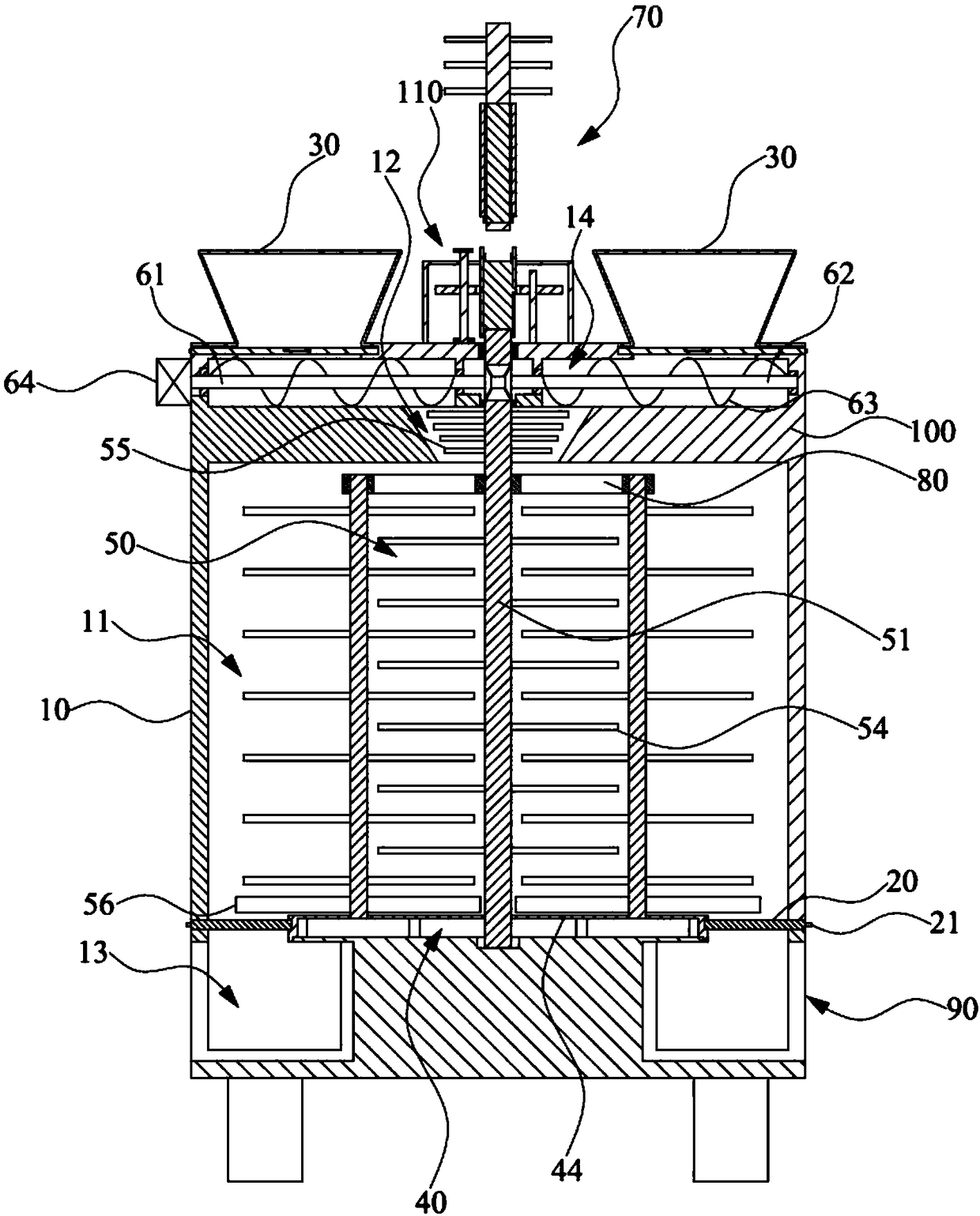

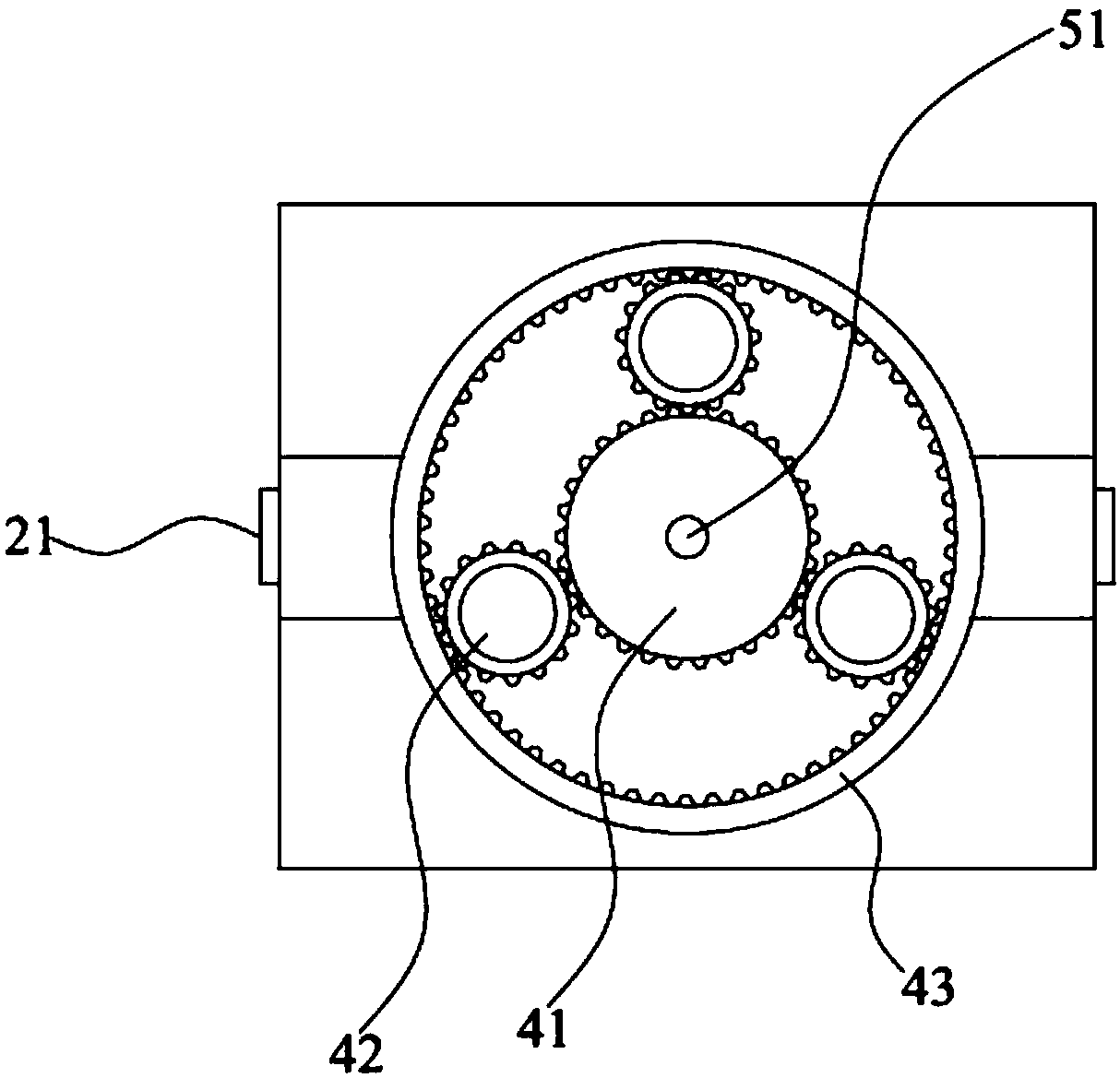

Energy-saving food stirring device

InactiveCN108339460AStir wellAvoid energy consumptionRotary stirring mixersTransportation and packagingEngineeringEnergy consumption

The invention discloses an energy-saving food stirring device. The device comprises an outer casing, a main stirring chamber, and a auxiliary stirring chamber, a discharging chamber and a feeding chamber are formed in the outer casing; two feeding funnels are arranged on the left and right sides of the feeding chamber; a planetary gear assembly is mounted at the bottom of the main stirring chamber; a stirring assembly penetrates through the planetary gear assembly, and a stirring main shaft of the stirring assembly penetrates from the main stirring chamber through the auxiliary stirring chamber to the feeding chamber; a left rotating shaft and a right rotating shaft is disposed in the feeding chamber and respectively located on both sides of a stirring main shaft, spiral blades are disposed on the left rotating shaft and the right rotating shaft, a motor is mounted on the outer casing to drive the left rotating shaft, and the left rotating shaft and the right rotating shaft mesh with the stirring main shaft through bevel gears. The device drives the rotating shafts through the motor, and spirally conveys the food into the stirring chamber, the rotating shaft drives the main stirring shaft and then drives the stirring assembly through the planetary gear assembly to achieve the stirring of the food, finally the food is discharged from the discharging cavity, the device is convenient and energy-saving, stirring is uniform, and troubles that energy consumption and poor practical performance in past are avoided.

Owner:NINGBO FEICHAI ROBOT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com