Patents

Literature

83results about How to "Skip the manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

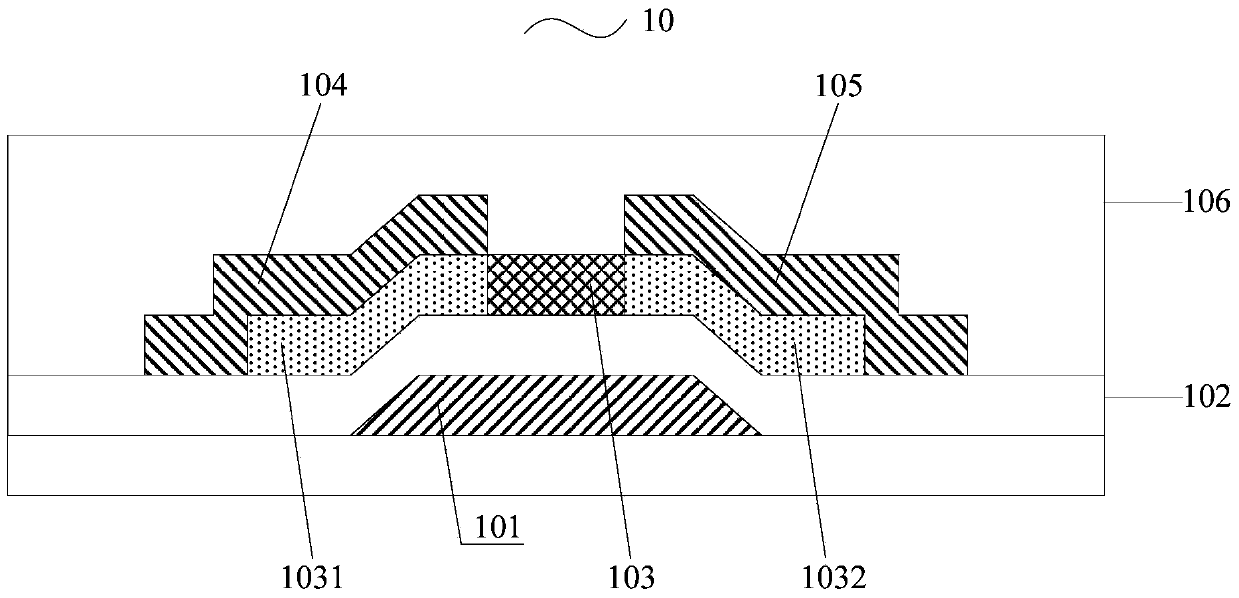

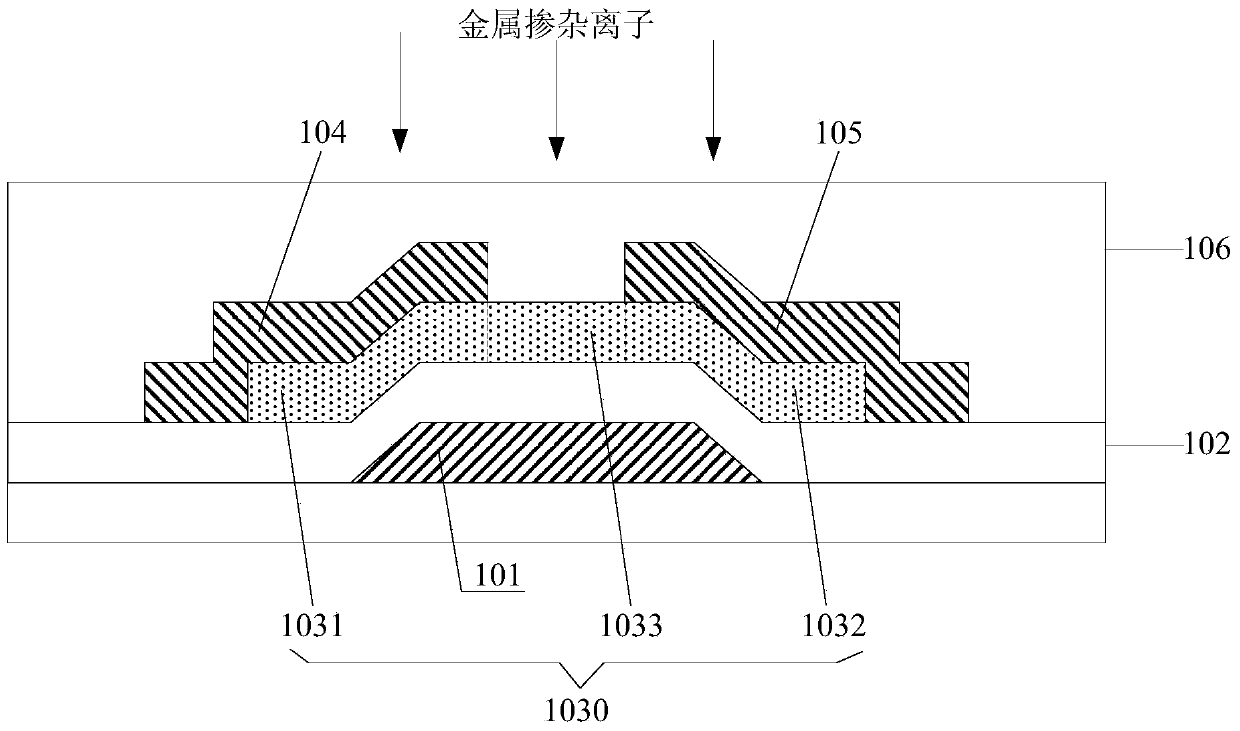

Thin film transistor and manufacturing method thereof, array substrate and display device

ActiveCN103730346ASolve the problem of contact resistanceSkip the manufacturing processTransistorSolid-state devicesIndiumDisplay device

The embodiment of the invention provides a thin film transistor and a manufacturing method of the thin film transistor, an array substrate and a display device, and relates to the technical field of display. The thin film transistor can solve the problem that the contact resistance exists between a source electrode and a semiconductor active layer and exists between a drain electrode and the semiconductor active layer, reduce the number of times of the picture composition technology and reduce the cost. The manufacturing method comprises the steps of forming a grid electrode, a grid insulating layer, the metal-oxide semiconductor active layer, the source electrode and the drain electrode on a substrate, wherein the formed metal-oxide semiconductor active layer comprises an indium-oxide series binary metal-oxide pattern layer making direct contact with the source electrode and the drain electrode, and a first pattern, a second pattern and a third pattern are included in the indium-oxide series binary metal-oxide pattern layer; using the insulating layer formed above the source electrode and the drain electrode as a barrier layer, adopting the ion implantation technology to implanting metal doping ions into the indium-oxide series binary metal-oxide pattern layer, conducting annealing treatment, converting the binary metal oxide of the third pattern into a polybasic metal-oxide semiconductor, and forming the metal-oxide semiconductor active layer. The thin film transistor is used for manufacturing the display device.

Owner:BOE TECH GRP CO LTD

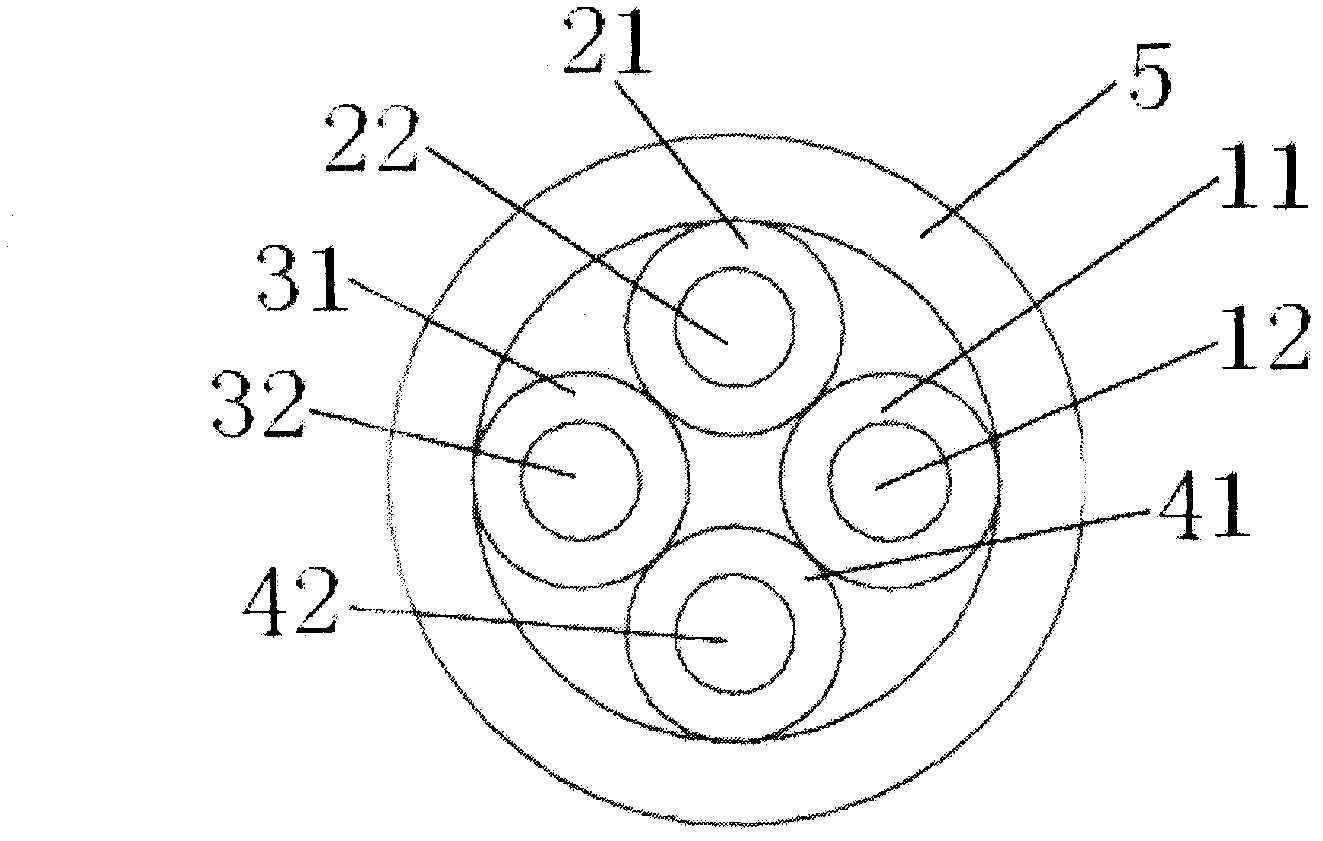

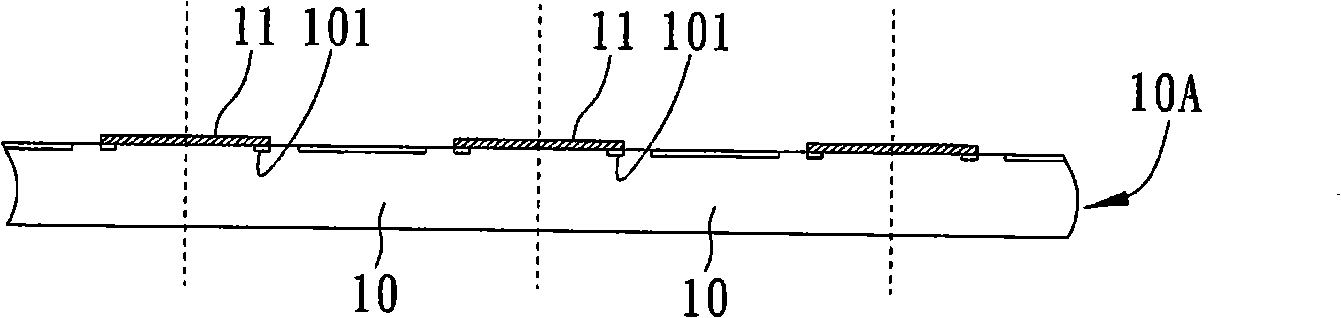

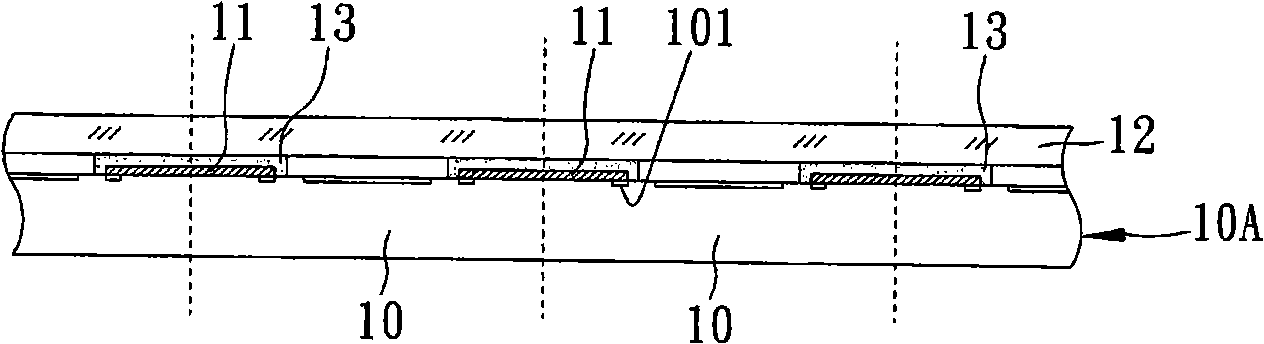

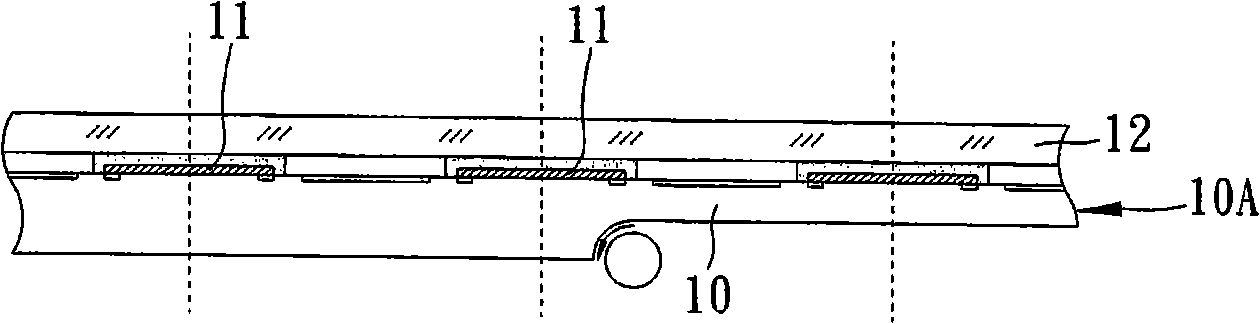

Four-core cable and its manufacturing method

ActiveCN102280172AReduce consumptionSkip the manufacturing processNon-insulated conductorsInsulated cablesEngineeringElectrical conductor

The invention belongs to the technical field of electric wires and cables and particularly relates to a four-core cable. The four-core cable comprises four conductors and a sheath layer and is characterized by also comprising a filling body positioned in the center and four isolating bars, wherein the four conductors and the four isolating bars are tightly attached to the filling body and are distributed along the outer circumference of the filling body; a first isolating bar is positioned between a first conductor and a second conductor; a second isolating bar is positioned between the second conductor and a third conductor; a third isolating bar is positioned between the third conductor and a fourth conductor; a fourth isolating bar is positioned between the fourth conductor and the first conductor; the four isolating bars and the sheath layer are integrally molded; the four isolating bars are protruded from the inner wall of the sheath layer to the filling body; on any cross section, the curvatures of the surfaces on which the isolating bars and the conductors are attached to the outer surface of the filling body are equal; and the sheath layer is used for covering the four isolating bars and the four conductors. The four-core cable has the advantages of low consumption of the sheath layer, thinner outer diameter, lower cost in various aspects, simpler production process, higher speed, simple production method and the like.

Owner:YUNNAN JULI CABLE MFG CO LTD

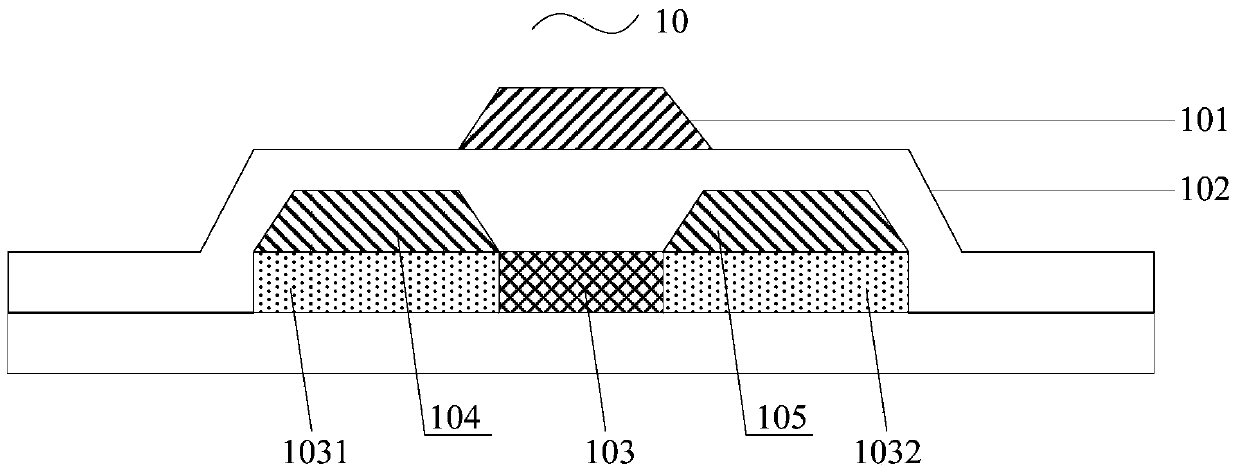

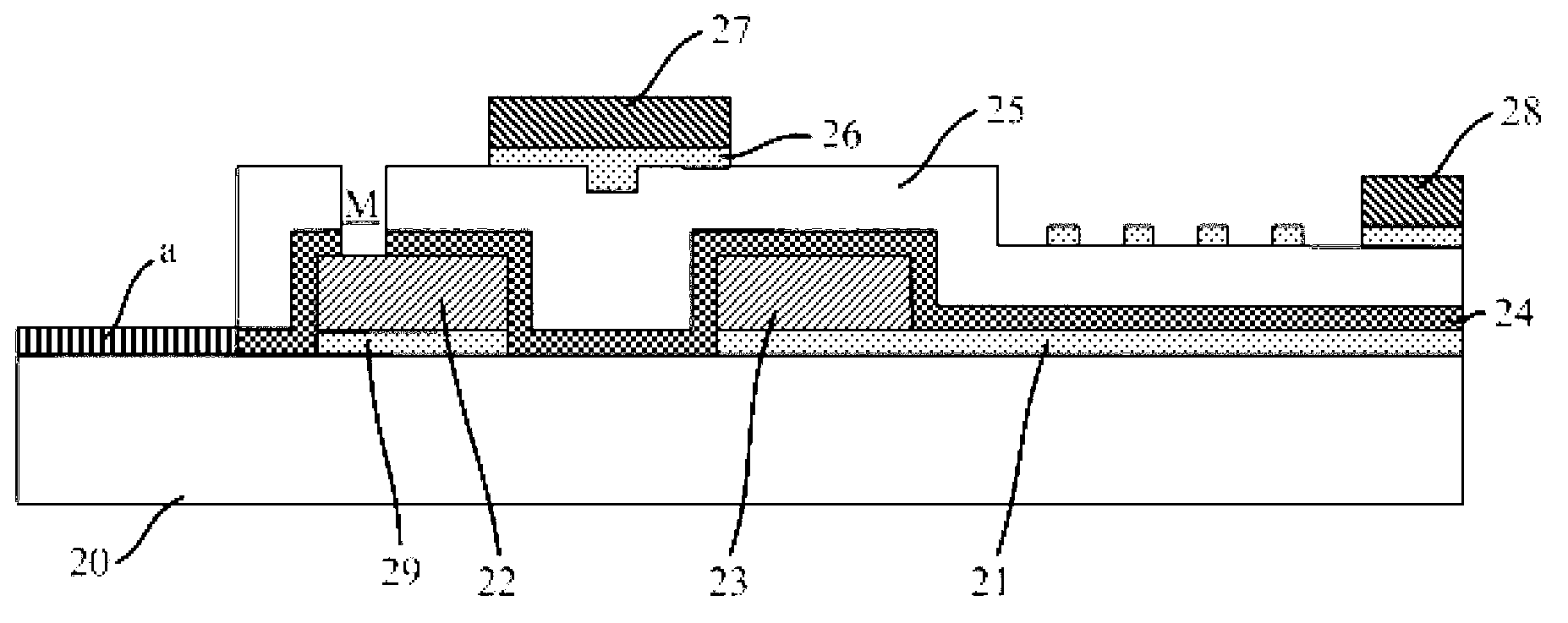

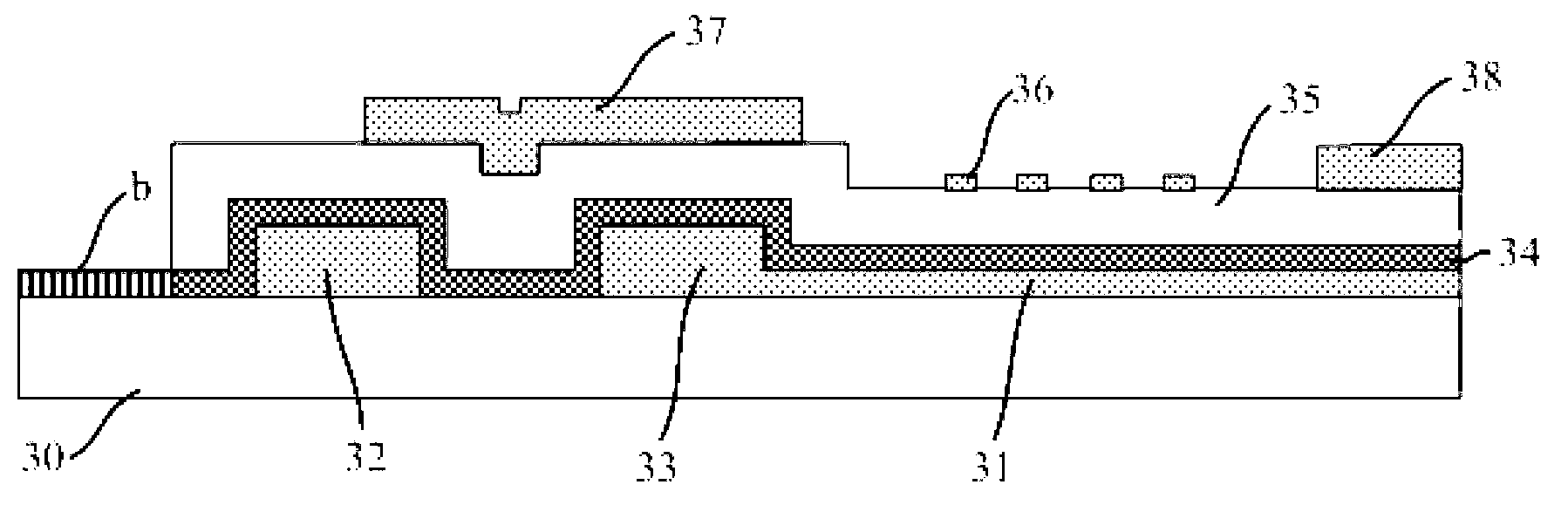

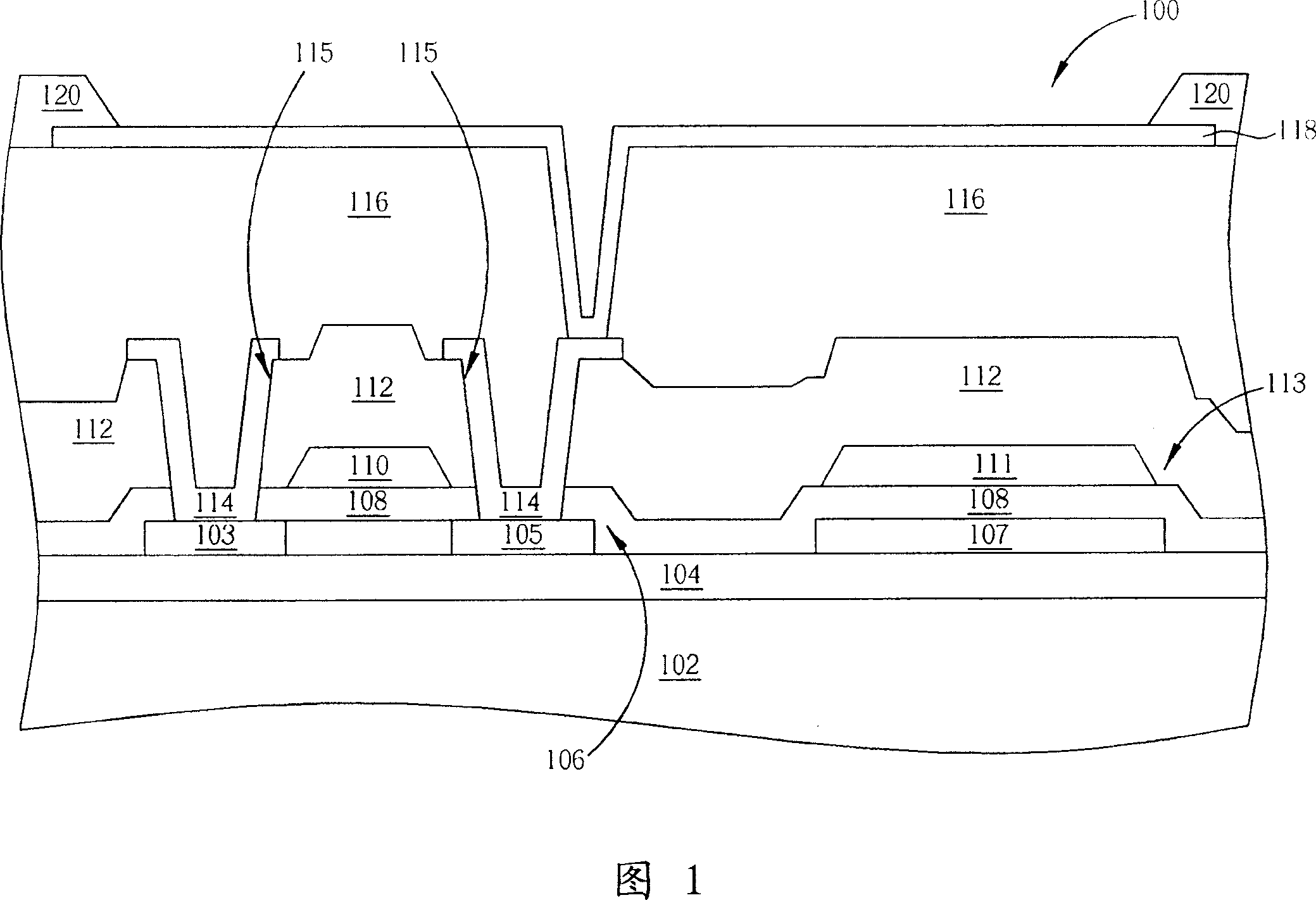

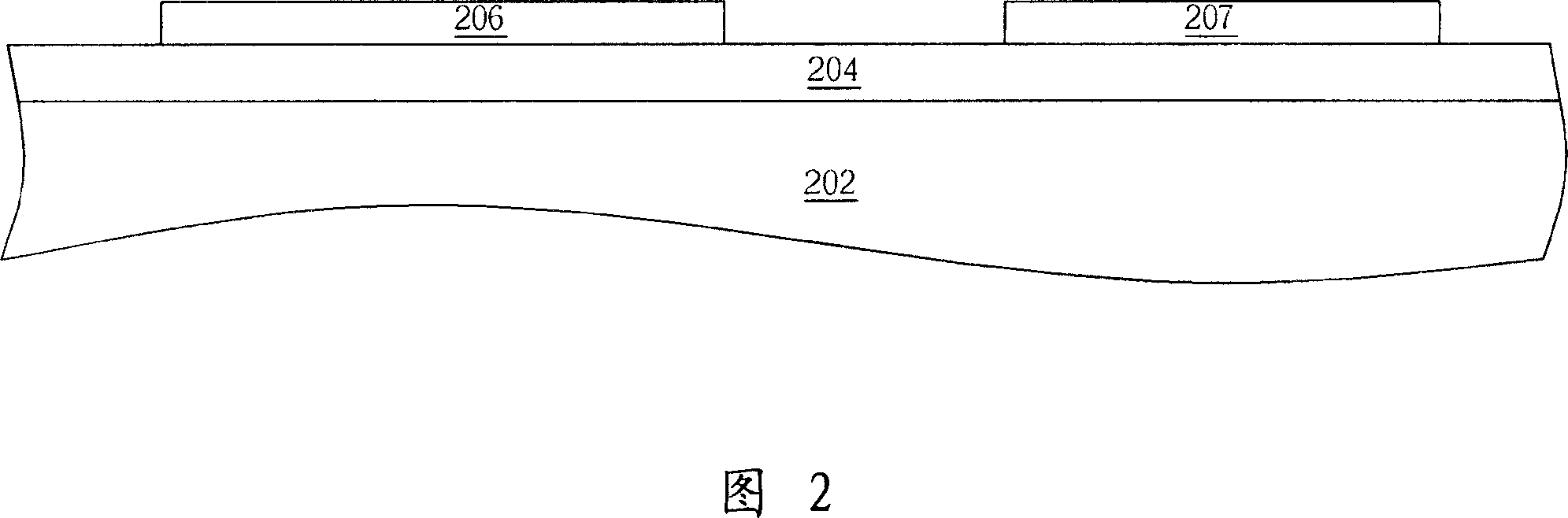

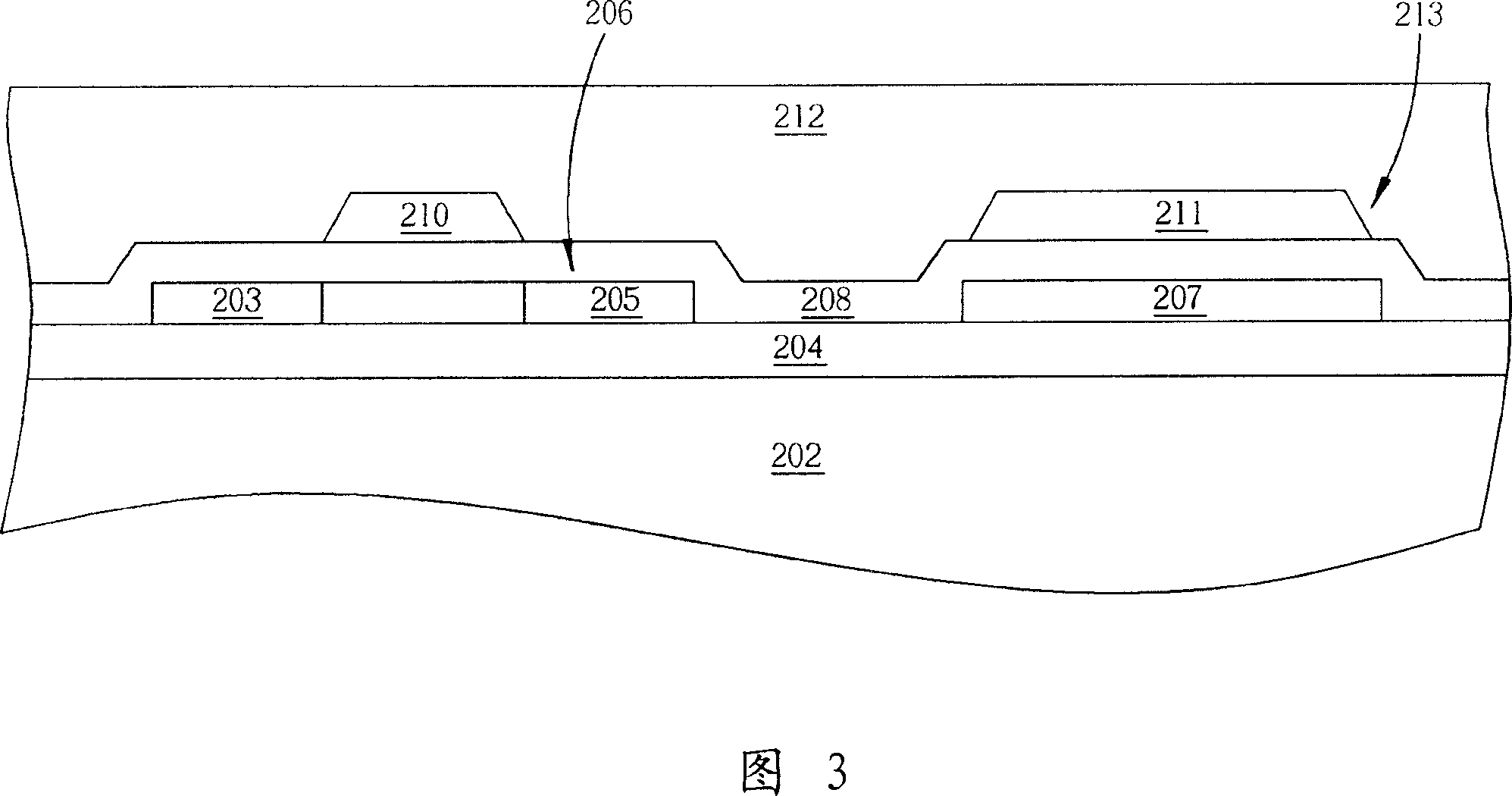

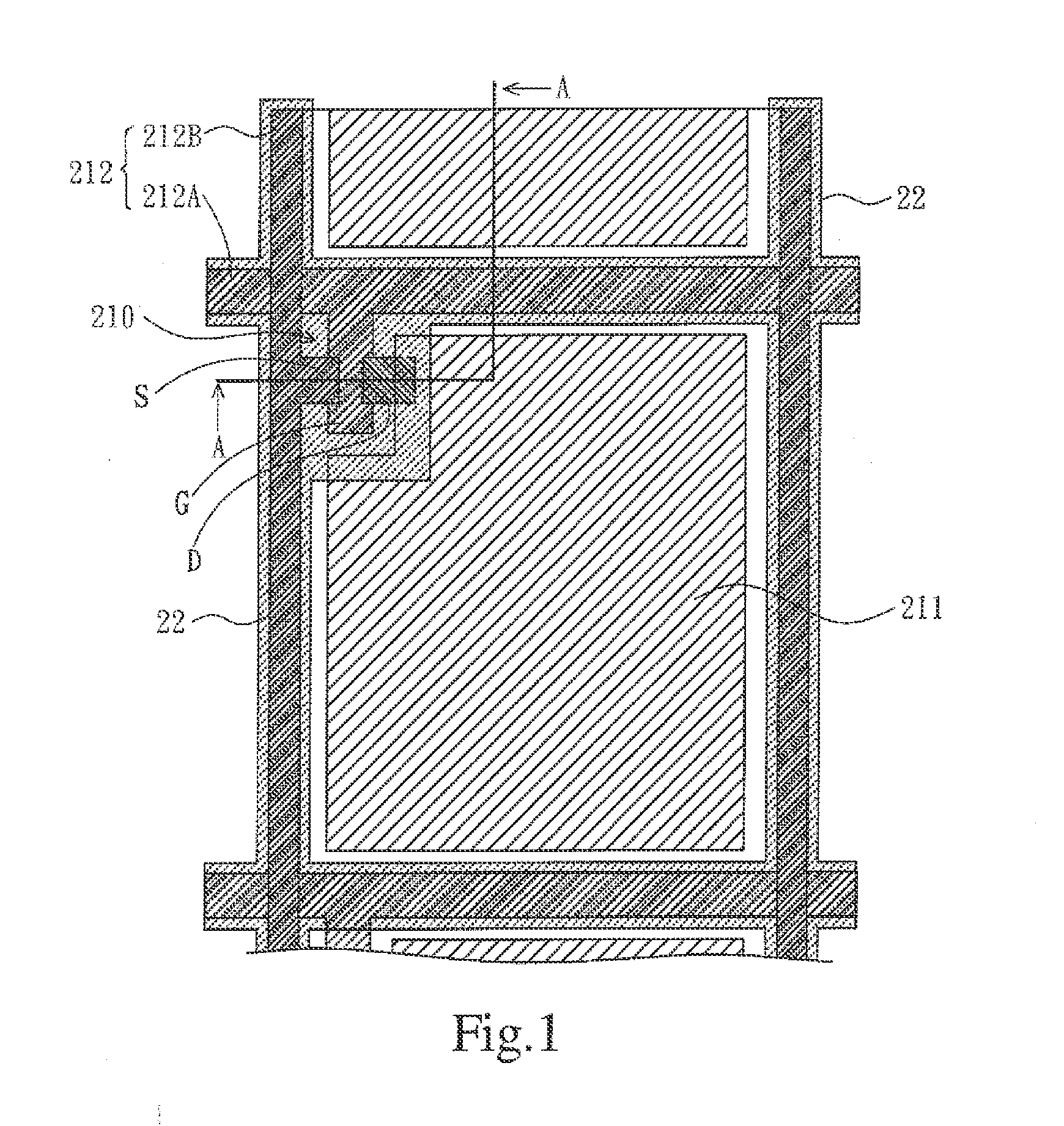

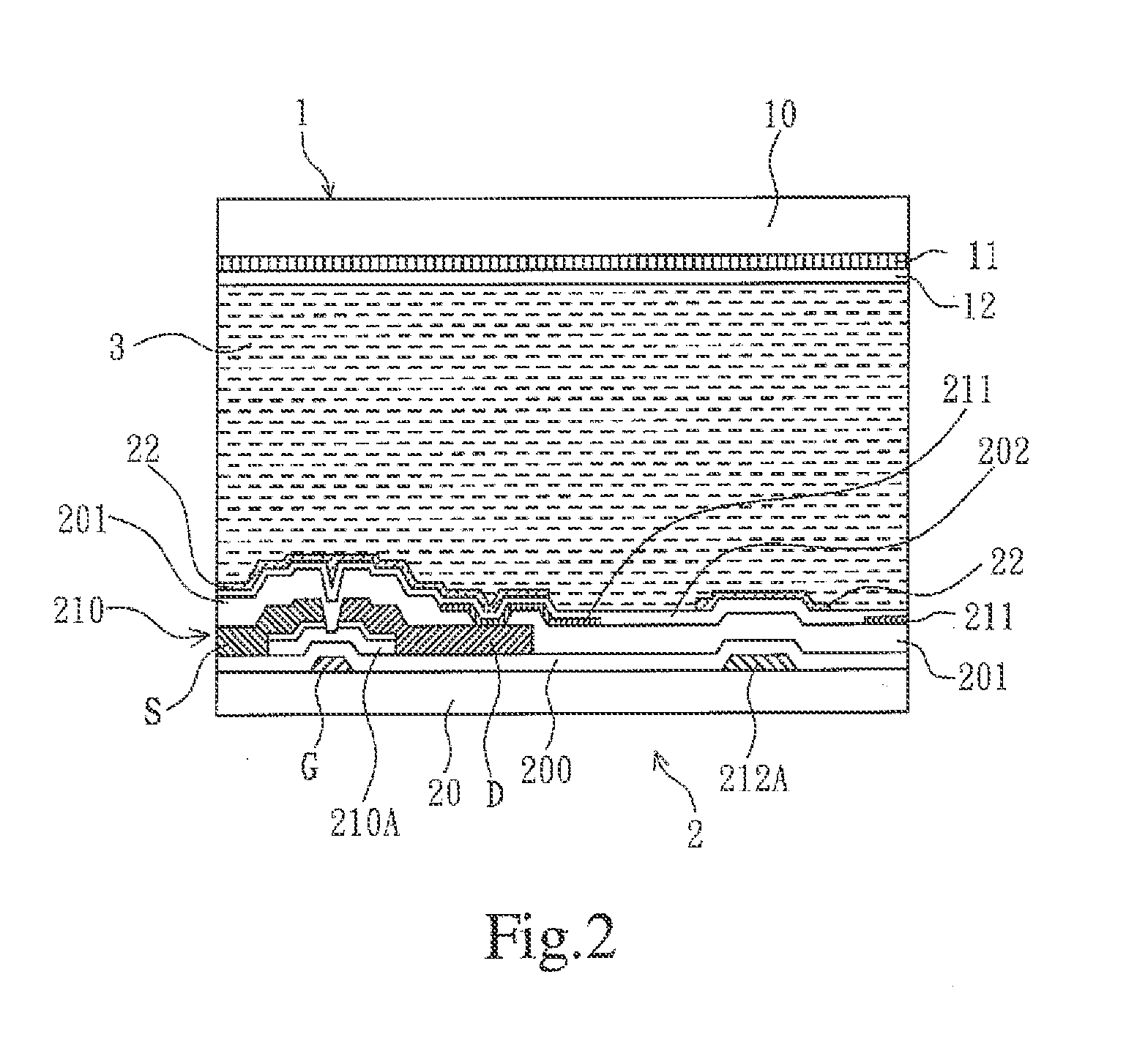

Array substrate and manufacture method thereof

ActiveCN103018977ASkip the manufacturing processSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayLap joint

The invention relates to the field of manufacture of liquid crystal display devices, in particular to an array substrate and a manufacture method thereof, aiming to solve the problem that the traditional manufacture process of a TFT-LCD (Thin Film Transistor Liquid Crystal Display) based on an ADS (Advanced Super Dimension Switch) structure is complex and is low in efficiency. According to the embodiment of the invention, each pixel region of the array substrate comprises a drain electrode, a source electrode, a pixel electrode in lap joint with the drain electrode, an active layer located on the drain electrode, the source electrode and the pixel electrode, a grid insulating layer located on the active layer, a grid electrode and a public electrode, wherein the drain electrode and the source electrode are located on an underlayer substrate, the pixel electrode is made of a single-walled carbon nanotube material, the grid electrode and the public electrode are located on the grid insulating layer, and the public electrode has a slit-shaped structure. According to the embodiment of the invention, the array substrate can be prepared by adopting layout processes three times, so that the manufacture process is simplified, the manufacture efficiency is improved and the manufacture cost is reduced.

Owner:BOE TECH GRP CO LTD

Method for producing high purity vanadium metal

The invention discloses a method for producing high purity vanadium metal, which comprises the following steps: using a ferrovanadium material as a soluble anode, using a corrosion-resistant metal conducting material as a cathode, using a molten salt system of a basic metal halide as an electrolyte, and adding a subhalide of vanadium into the electrolyte; electrolyzing the electrolyte at the temperature of 600-1000DEG C so that the vanadium in the anode can enter the molten salt system in the mode of low valence ions and deposit on the cathode to obtain the high purity vanadium metal. According to the method provided by the invention, not only high purity products can be obtained on the cathode, but also the process flow is shortened and the production cost is reduced by being compared with an existing process.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

Semiconductor device of sensing type and its manufacture

InactiveCN101308802AAvoid damageAvoid the problem of not being able to thin furtherSemiconductor/solid-state device detailsSolid-state devicesDielectric layerSemiconductor

A sensing semiconductor device and the fabrication method thereof are disclosed. A plurality of metal lines are developed on a light-transmitting carrier plate; a plurality of sensing chips which are processed with thickness reduction and chip probing in advance and are provided with conductive lug bosses on the solder pads are electrically connected to the metal lines on the light-transmitting carrier plate; a first dielectric layer is filled among the sensing chips to cover the metal lines and the areas around the sensing chips; a second dielectric layer and a groove exposed outside the metal lines are developed on the sensing chips and on the first dielectric layer; a plurality of leads electrically connected to the metal wires are arranged on the second dielectric layer; incision is carried out among the sensing chips so as to form a plurality of sensing semiconductor devices. In this way, problems of line rapture due to that the included angle at the joint of the lines is acute, poor electric connection of the lines and damage to the chips caused by contraposition error when incising from the backside of the wafer, and the increase of fabrication cost resulted from direct sputtering time after time when shaping the lines can be avoided.

Owner:SILICONWARE PRECISION IND CO LTD

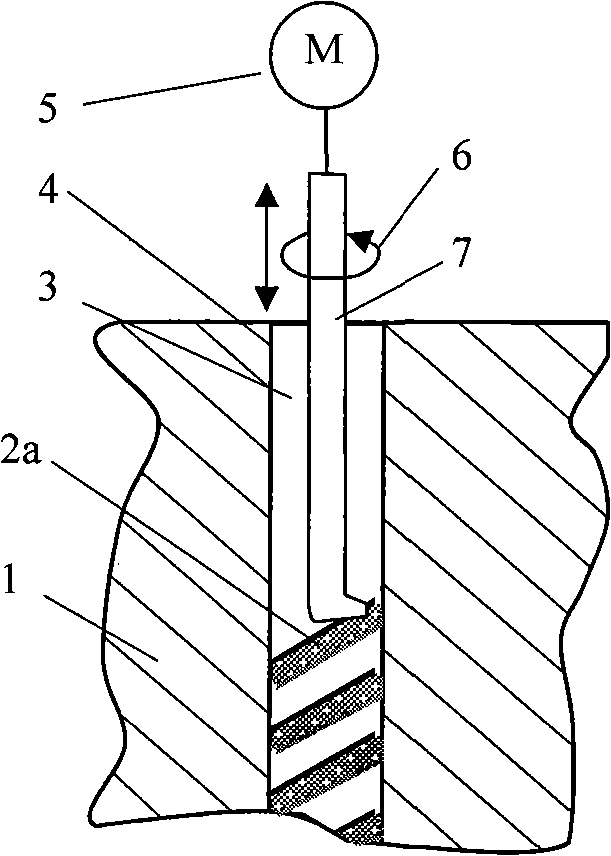

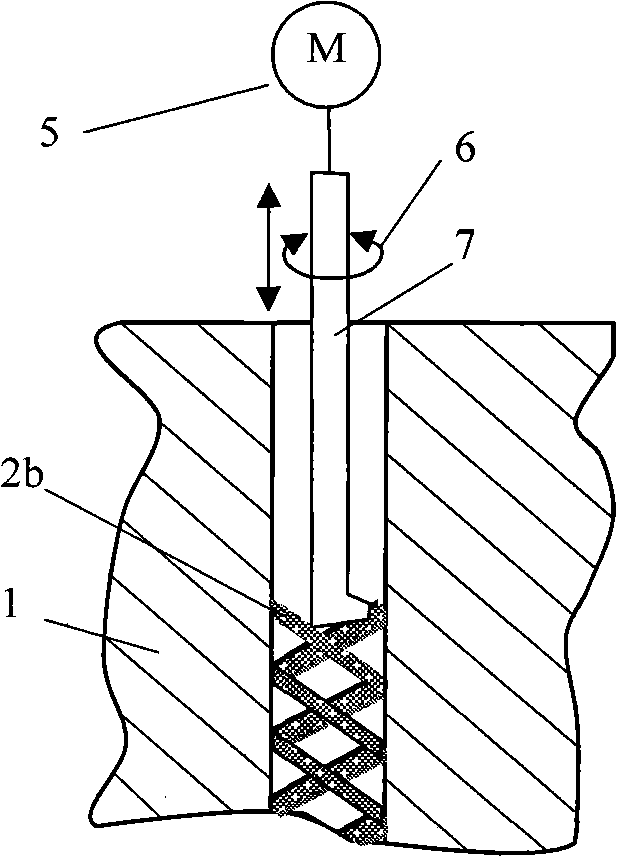

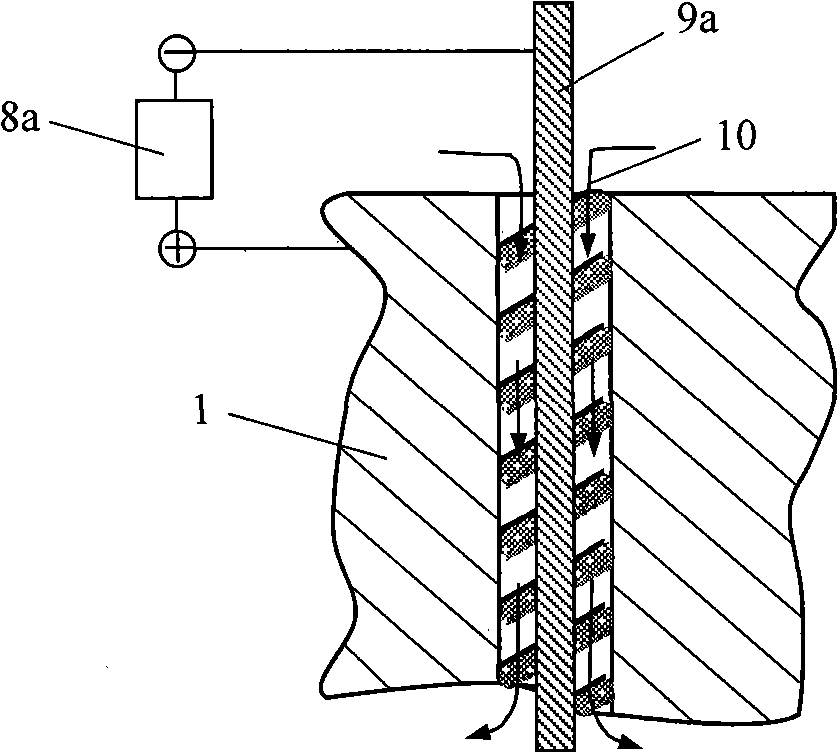

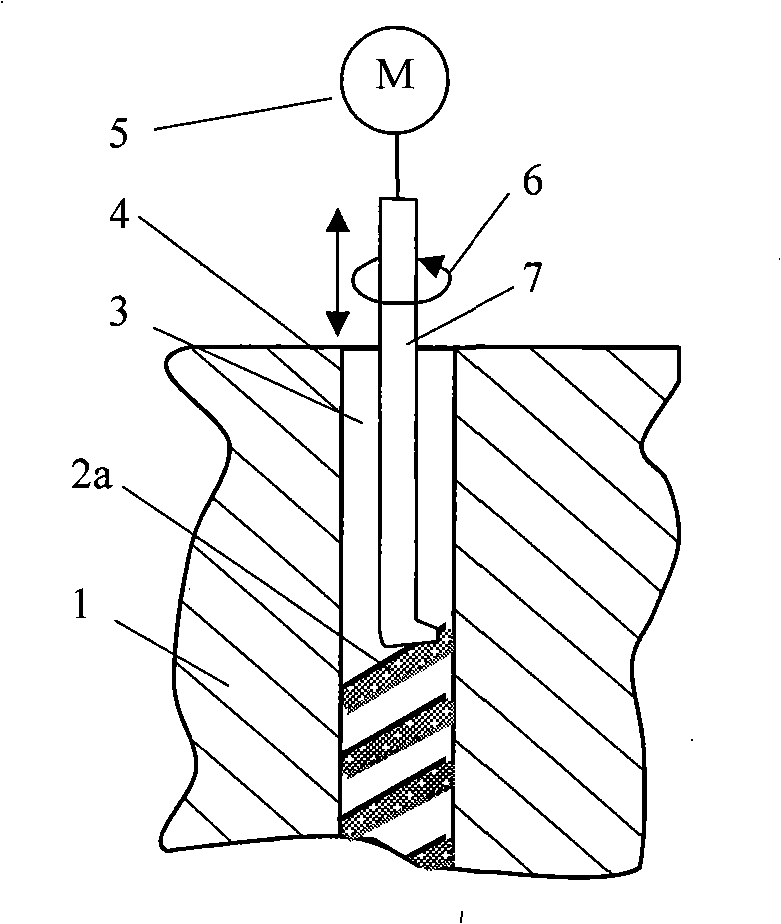

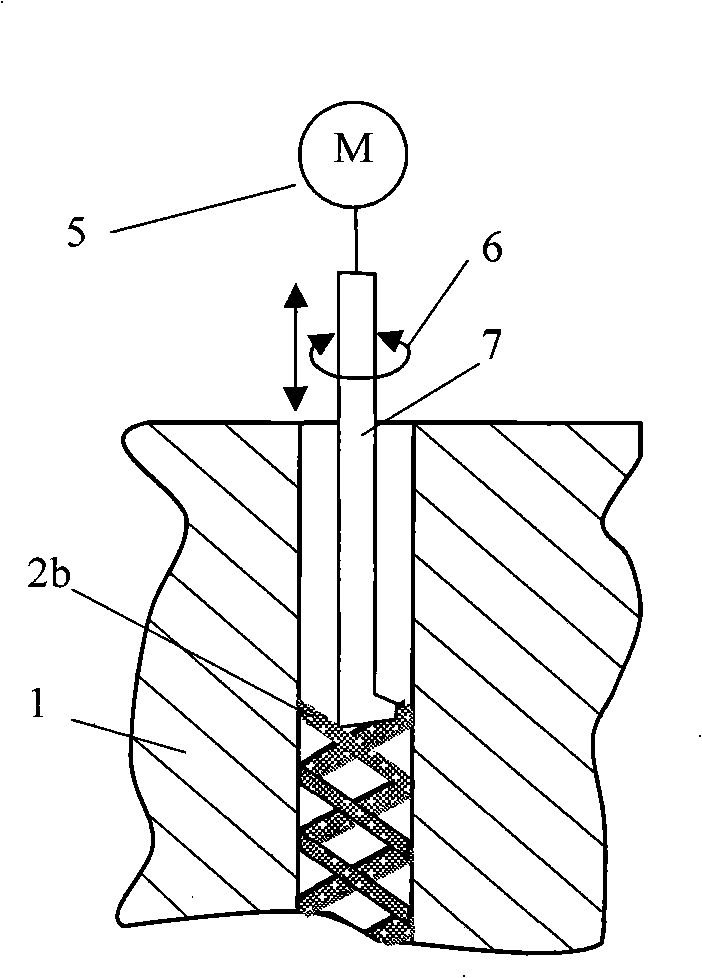

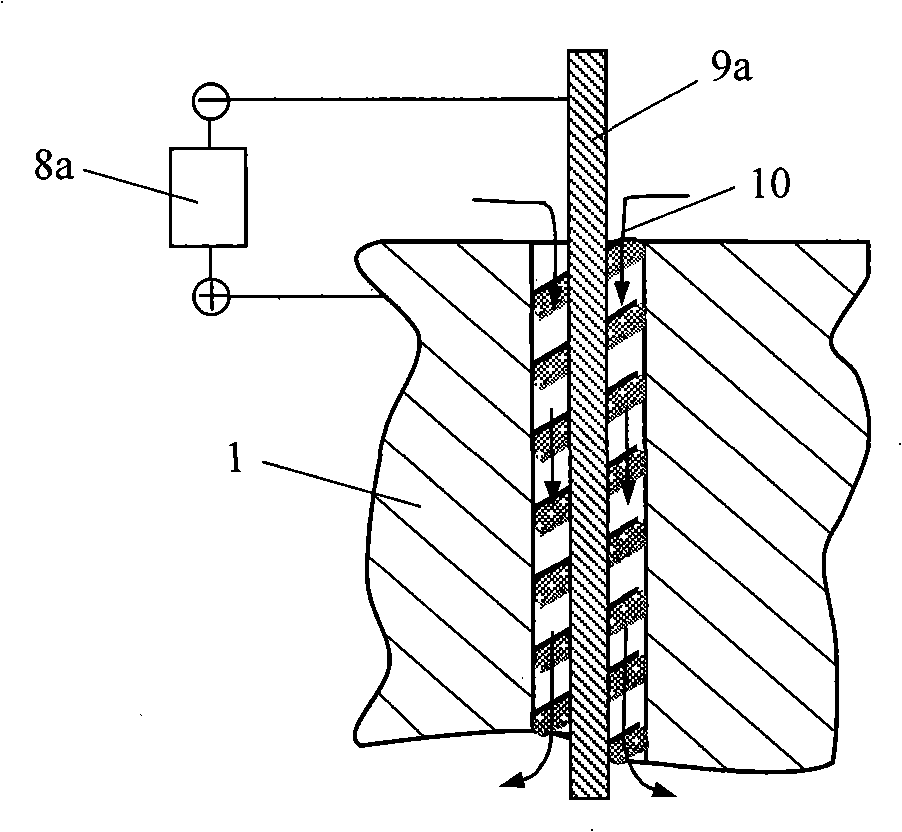

Electro-chemical machining technology of inner hole wall turbulence structure of metal parts

InactiveCN101491851ASkip the manufacturing processShielding electric fieldElectrochemical machining apparatusElectrolysisEngineering

The invention discloses an electrochemical machining process for an inner hole wall surface turbulent flow structure of a meal part. The machining process comprises: firstly, processing a smooth circular hole with an aperture of more than or equal to 2 millimeters on a position to be processed of the metal part, using a glue spreading spray head to coat a layer of insulating glue on the hole wall of the circular hole according to a set shape, and arranging a metal wire on a central axial line of the circular hole after the insulating glue of the hole wall is cured; and obtaining the turbulent flow structure by processing on the hole wall through electrolysis or electroforming, and finally using an insulating glue detergent to remove the prior cured insulating glue. The electrochemical machining process adopts special equipment and directly coats the insulating glue on the inner hole wall surface of the part as required, can effectively shield the influence of an electric field during electrochemical machining, save preparation of tool electrodes during electrochemical machining, and reduce the production period and the production cost; and simultaneously the electrochemical machining process can coat graphs with complex structures by controlling the motion track of the glue spreading head so as to be capable of processing different turbulent flow structures.

Owner:ZHEJIANG UNIV OF TECH

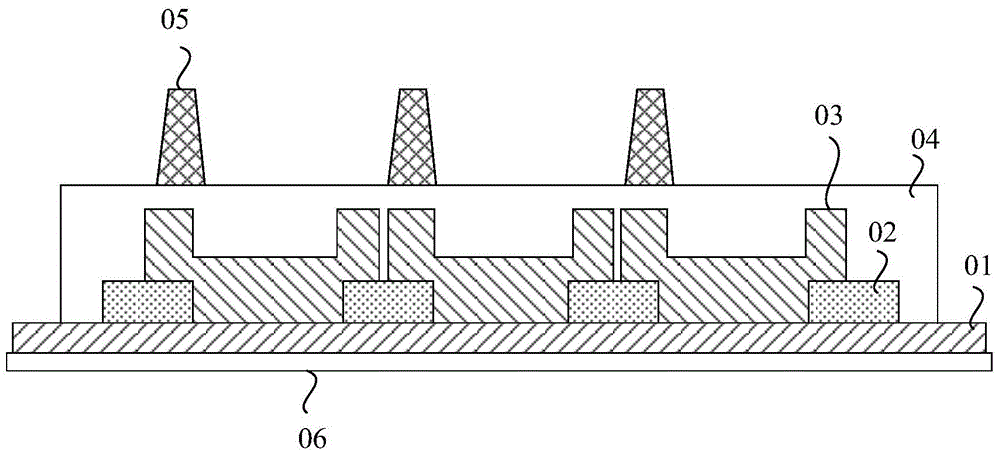

Method for producing active matrix organic LED panel

InactiveCN1945811ASkip the manufacturing processReduce the numberSemiconductor/solid-state device manufacturingInsulation layerActive matrix

This invention provides a manufacturing method for an organic LED panel of an active matrix including: providing a base plate, forming a film transistor on the base plate, forming an interlaminar insulation layer to cover the transistor and the base plate, forming multiple through holes to the surfaces of the source and drain of the transistor, forming metal layers in the through holes to be connected with the source and drain, forming transparent electrodes on the surfaces of the metal layers connected to the drain, forming pixel electrode insulation layers to the transparent electrode and the interlaminar insulation layer and forming a LED on the transparent electrode.

Owner:CHUNGHWA PICTURE TUBES LTD

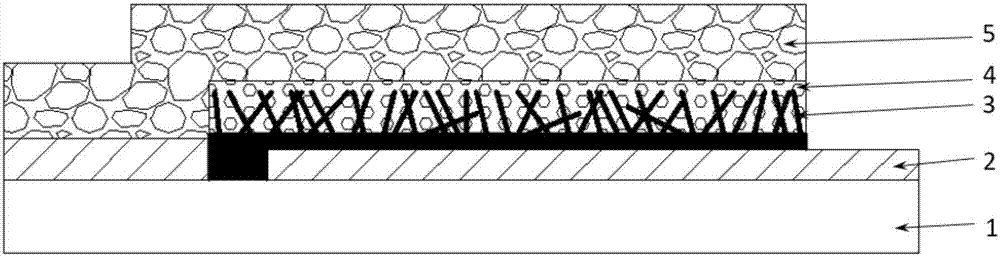

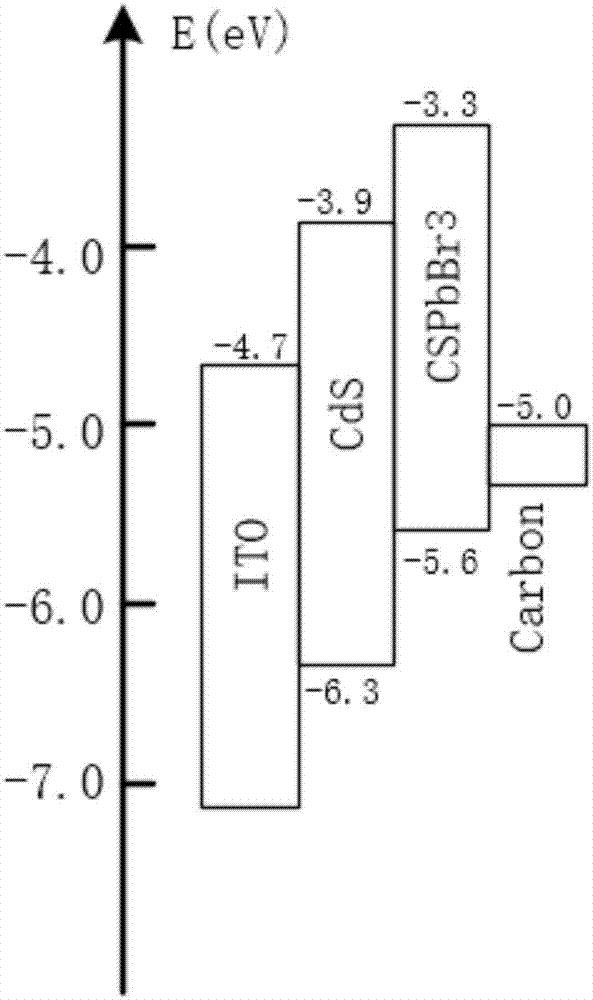

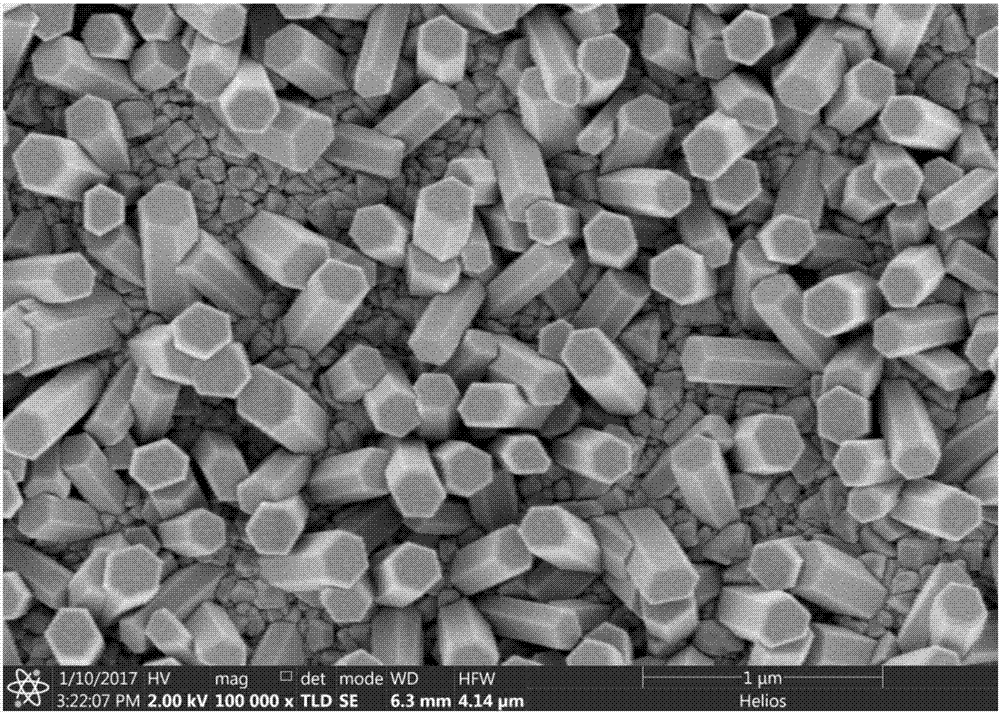

Full-inorganic perovskite solar energy cell and preparation method thereof

InactiveCN106960883AImprove transmission characteristicsReduce the density of defect statesFinal product manufacturePhotovoltaic energy generationMicro nanoManufacturing technology

The invention belongs to the micro nano manufacture technical field, and discloses a full-inorganic perovskite solar energy cell comprising a substrate glass, an ITO conductive layer and a photoanode, a luminous absorption layer and a carbon counter electrode layer; the photoanode is a CdS nanorod array structure having aperture structures; the luminous absorption layer is a CsPbBr3 inorganic perovskite layer embedded in the aperture structures of the photoanode, thus tightly contacting with the photoanode; the carbon counter electrode layer is paved on the top surface of the ITO conductive layer and the top surface of the luminous absorption layer, and formed by screen printing films. The contact areas between the perovskite layer and an electron transmission layer can be obviously improved, thus increasing the charge transmission channels; UV ozone processing is carried out for the grown CdS nanorod array, thus obviously improving the CdS film interface characteristics, reducing crystal grain boundaries, reducing electron defect density of states, reducing unfavorable charge recombination, and improving the electron transmission characteristics.

Owner:HUAZHONG UNIV OF SCI & TECH

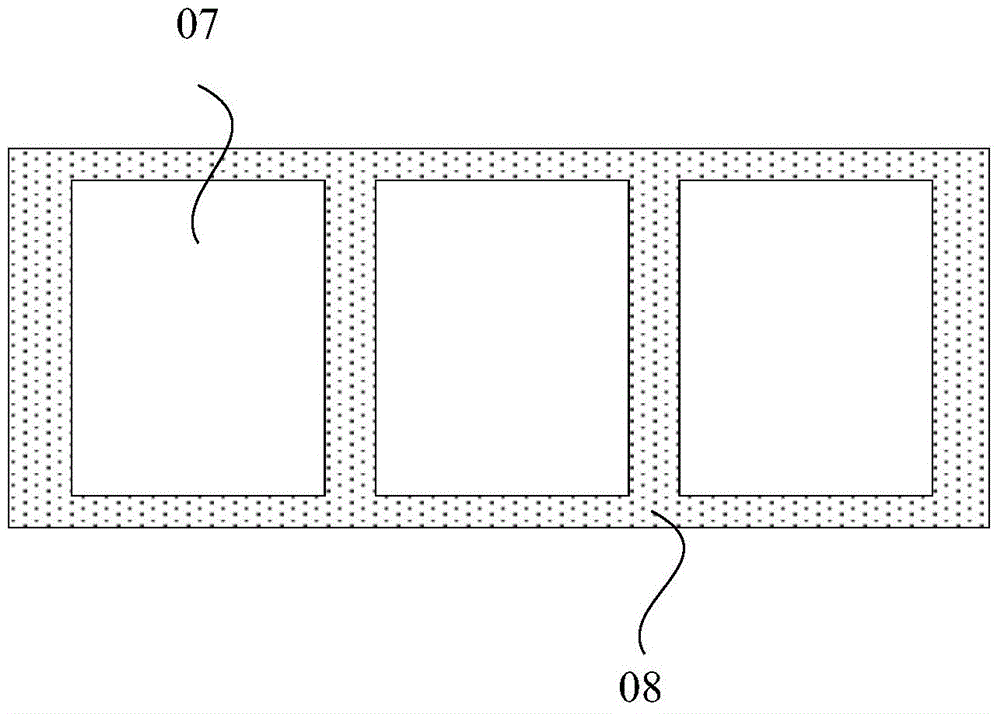

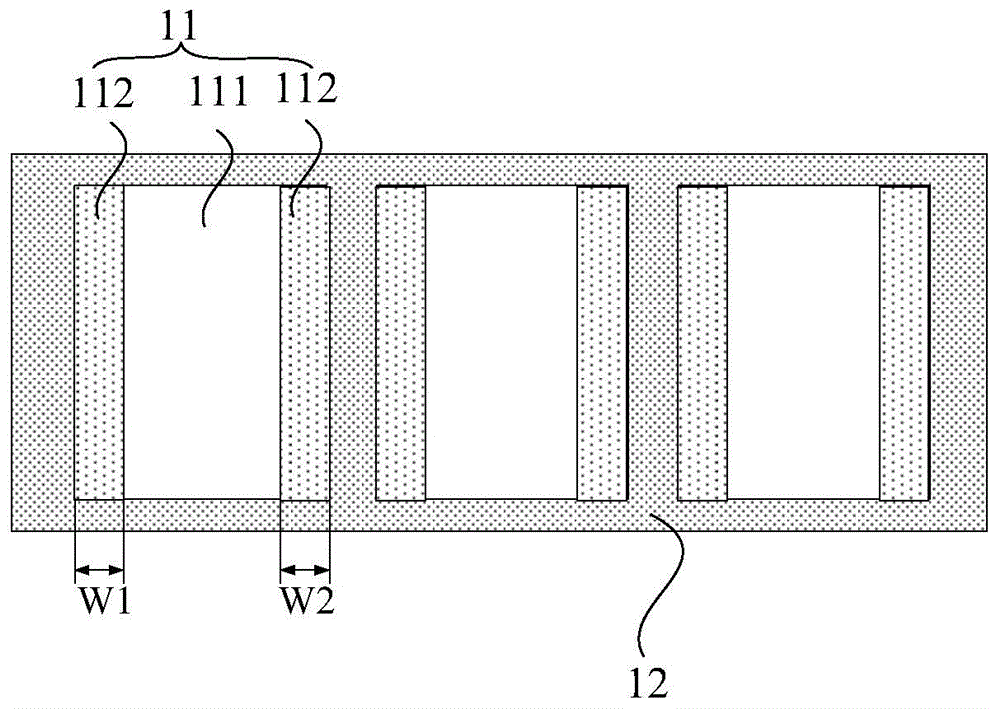

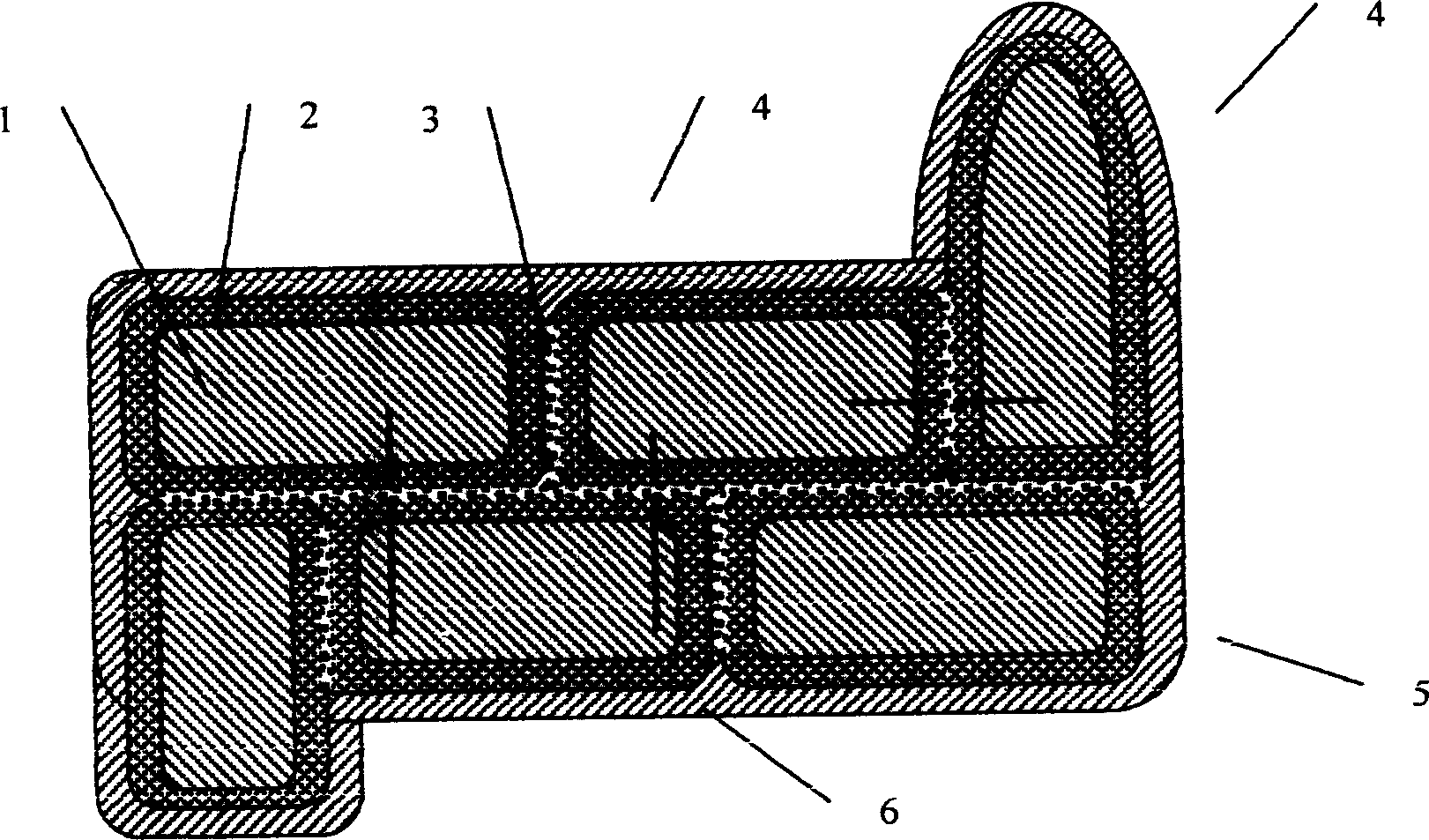

Mask plate, method for manufacturing color film substrate, and color film substrate

InactiveCN104614931AReduce the differenceSkip the manufacturing processPhotomechanical apparatusOriginals for photomechanical treatmentColor filmTransmittance

The invention discloses a mask plate, a method for manufacturing a color film substrate, and the color film substrate. The mask plate is used for reducing range difference of a color filter layer and improving transmittance of the color film substrate so as to improve a display effect of a display substrate. The mask plate comprises first regions and second regions, wherein each first region corresponds to each sub pixel unit; each second region is positioned between every two adjacent first regions; each first region is respectively provided with a first sub region for forming a color filter layer pattern positioned in an open region of a black matrix layer and two second sub regions for forming color filter layer patterns positioned in non-open regions of the black matrix layer; each first sub region is positioned between every two corresponding second sub regions; transmittance of each second sub region is gradually decreased or increased along the set length in the direction far away from the corresponding first sub region.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

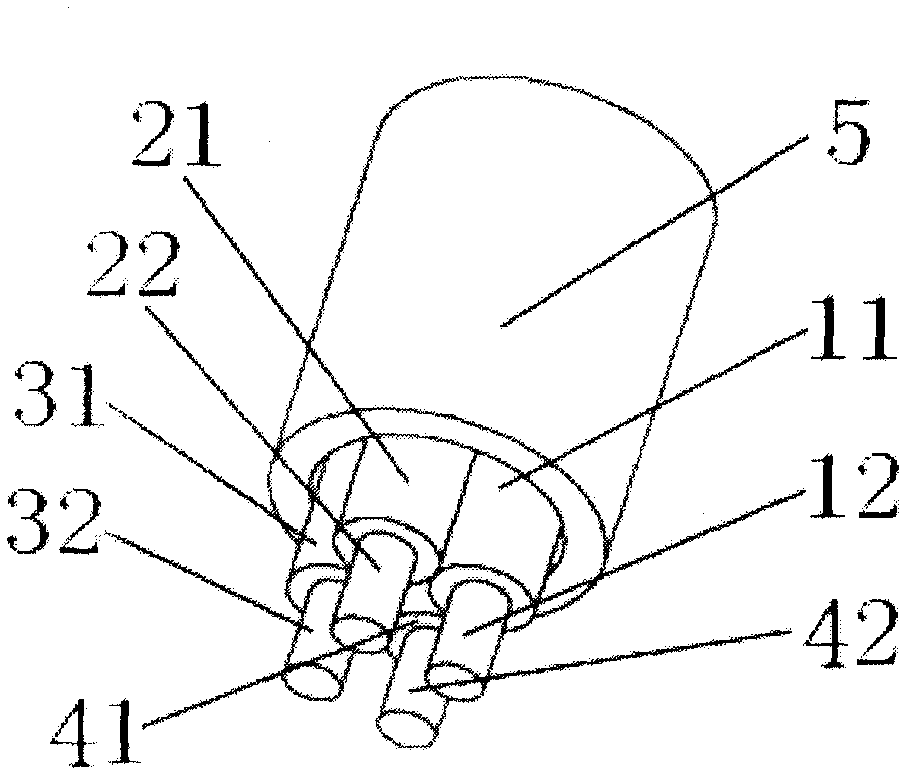

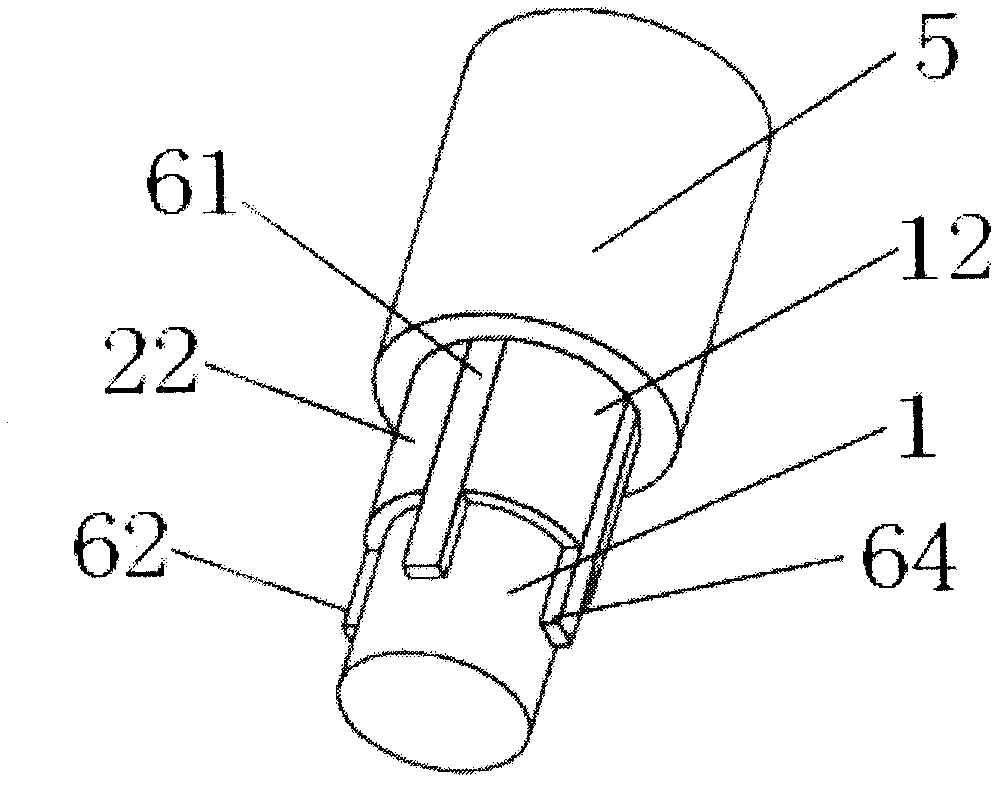

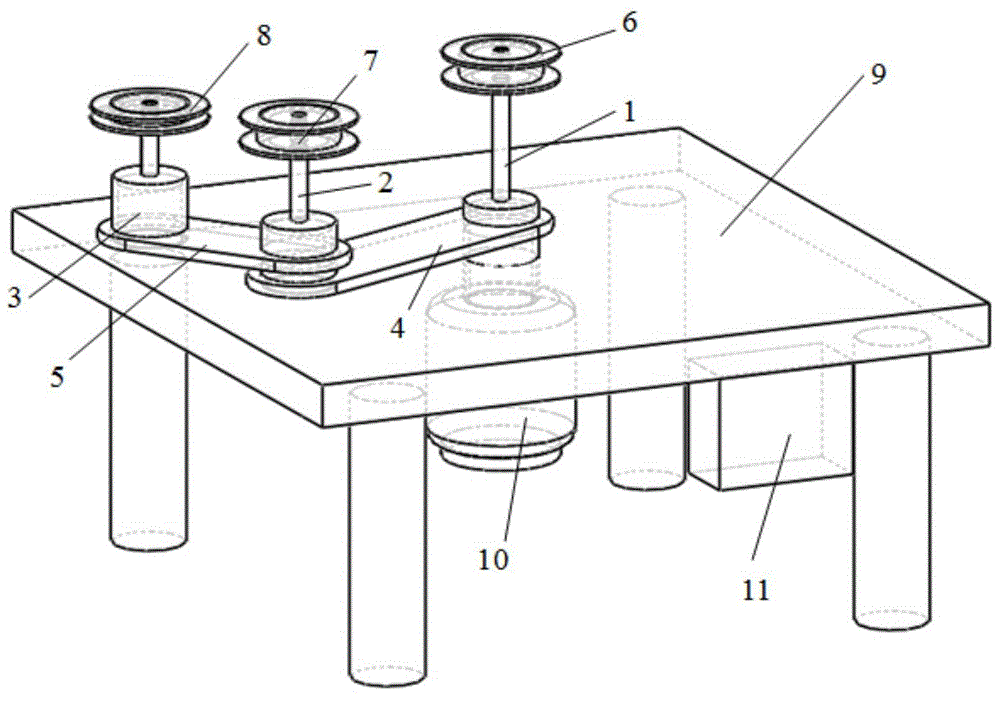

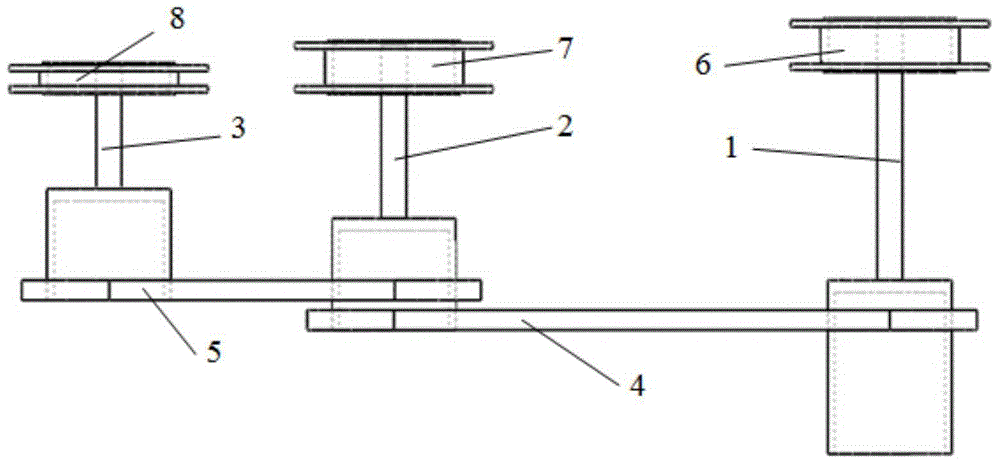

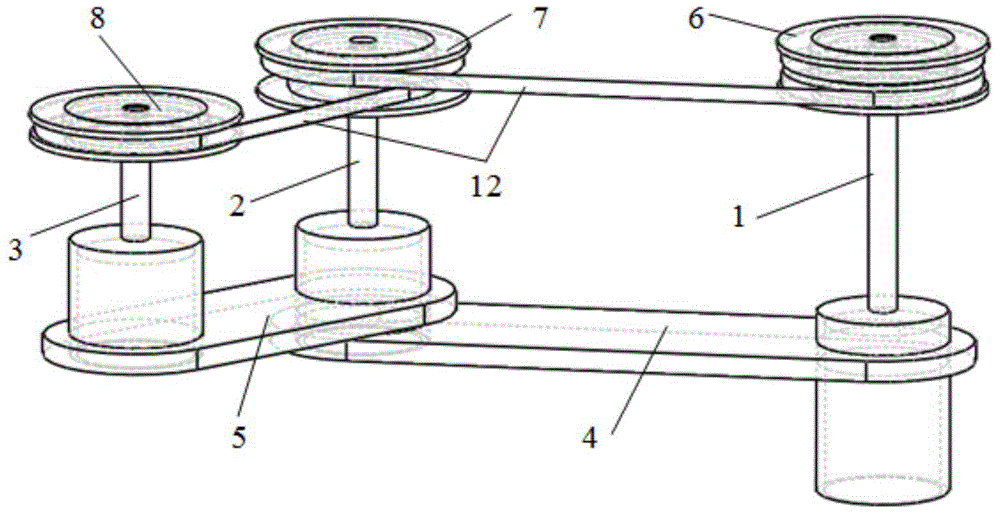

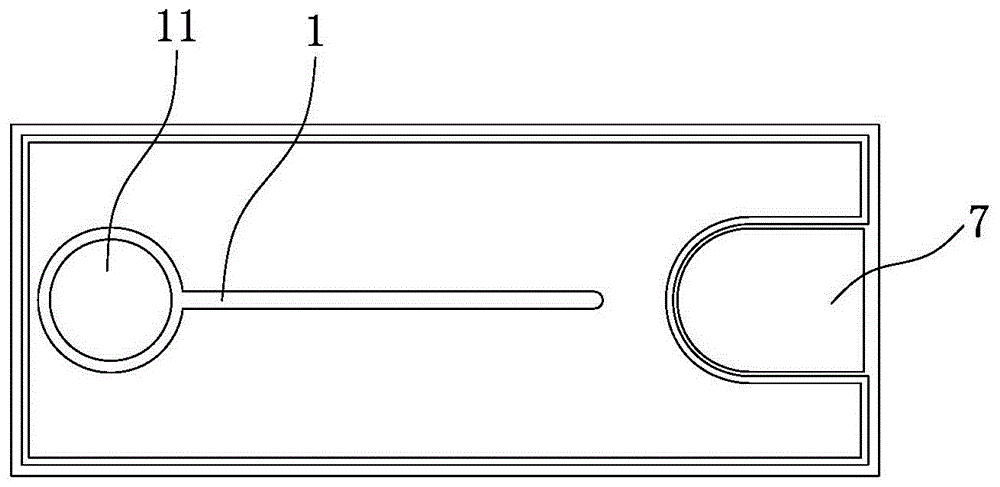

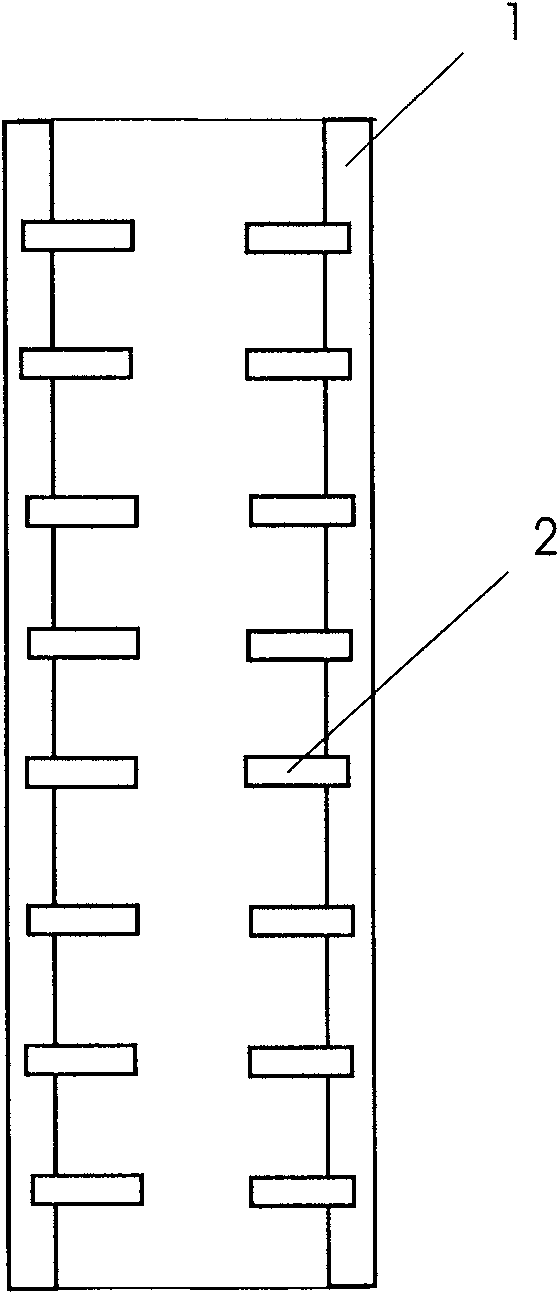

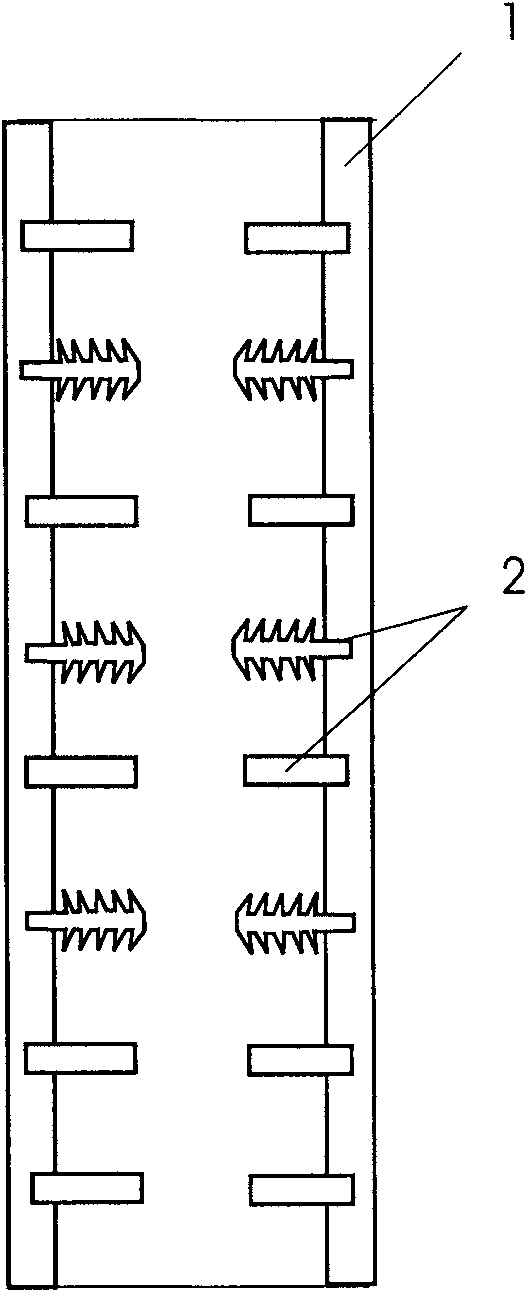

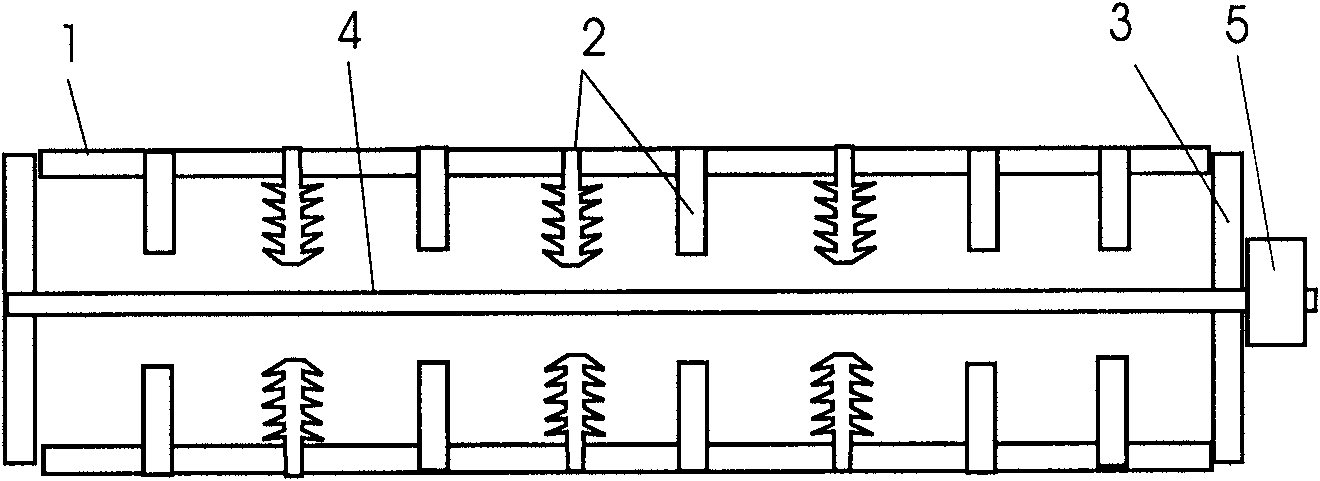

Planetary no-superconducting joint multi-bread coil winding machine

ActiveCN104952609AReduce energy lossSkip the manufacturing processFilament handlingSuperconducting magnets/coilsWinding machineHigh temperature superconducting

The invention discloses a planetary no-superconducting joint multi-bread coil winding machine, wherein a fixed star winding shaft (1) is arranged on a fixed table frame (9), one end of a planet driver (4) is arranged on below the fixed star winding shaft (1), and is connected with an adjustable-speed motor (10) and is driven by the adjustable-speed motor (10), a planetary winding shaft (2) is arranged on the other end of the planet driver (4), one end of a satellite transmission (5) is arranged on the lower end of the planetary winding shaft (2), is driven by a motor which is arranged on the planetary winding shaft (2), a satellite winding shaft (3) is arranged on the other end of the satellite transmission (5), a fixed star winding skeleton (6), a planet winding skeleton (7) and a satellite winding skeleton (8) are respectively arranged on the upper ends of the fixed star winding shaft (1), the planetary winding shaft (2) and the satellite winding shaft (3), and the adjustable-speed motor (10) and a controller (11) are fixed on the fixed table frame (9). The planetary no-superconducting joint multi-bread coil winding machine can wind a high temperature superconducting multi-bread coil of a no-superconducting joint.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Novel vaccine of tumor antigen, its preparation method and vaccine composition

InactiveCN1481899AThe method is simpleStrong immune responseAntibody mimetics/scaffoldsAntibody ingredientsTumour-associated antigenAmino acid

The new tumor antigen vaccine includes sequence with seven or more amino acids from tumor antigen and CH3 part amino acid sequence of immune globulin, and the two sequences are connected mutually. The NDA sequence encoding the tumor antigen vaccine, its preparation process and the vaccine composition containing the tumor antigen vaccine are also disclosed. The vaccine of the present invention has molecular weight many times smaller than that of antigen-antibody composition, and is easy to be phagocytized by dendritic cell to produce powerful immunological effect.

Owner:李进

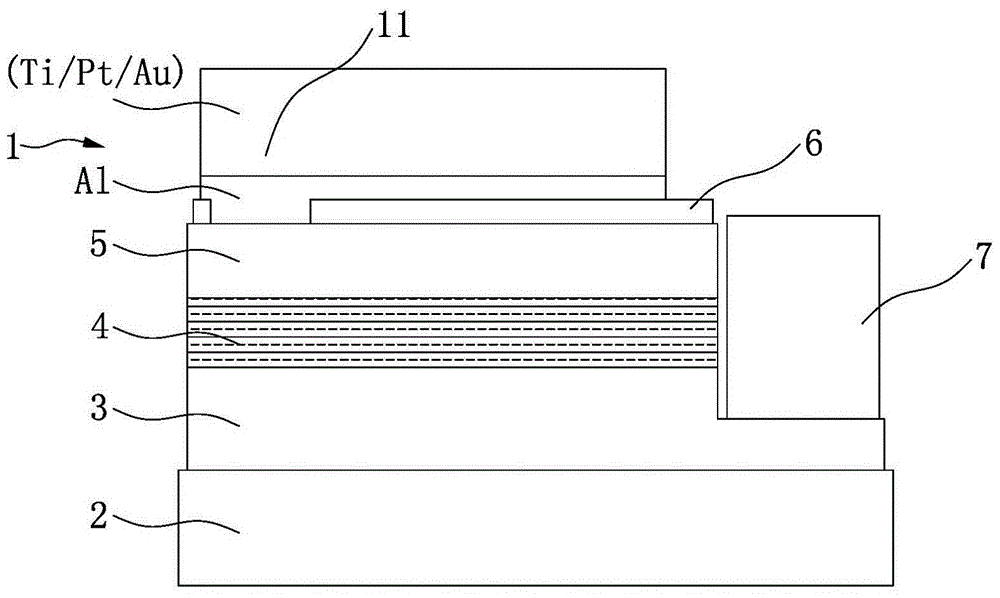

P electrode structure of LED chip, LED chip structure and manufacturing method therefor

ActiveCN106129214AIncrease brightnessSimple preparation processSemiconductor devicesEngineeringActive layer

The invention discloses a P electrode structure of an LED chip, an LED chip structure and a manufacturing method therefor. The P electrode is formed by multiple layers of metals, wherein Al is at the lowest layer; the LED chip structure comprises a substrate, an N type layer, an active layer, P type layer, an ITO transparent conductive layer, a P electrode and an N electrode; the N type layer, the active layer and the P type layer are formed on the substrate in sequence; the N type layer is connected with the N electrode; the ITO transparent conductive layer is formed on the P type layer; the P electrode is formed on the ITO transparent conductive layer, wherein the metal Al is arranged on the lowest layer of the P electrode; and Al is heated and permeated to the ITO transparent conductive layer, so that schottky contact is formed between the ITO transparent conductive layer and the P type layer. According to the P electrode structure of the LED chip, the LED chip structure and the manufacturing method therefor, the luminous reflectance of the electrode is improved; the luminance of the LED chip is improved; and the manufacturing process for the LED chip is simpler.

Owner:XIAMEN CHANGELIGHT CO LTD

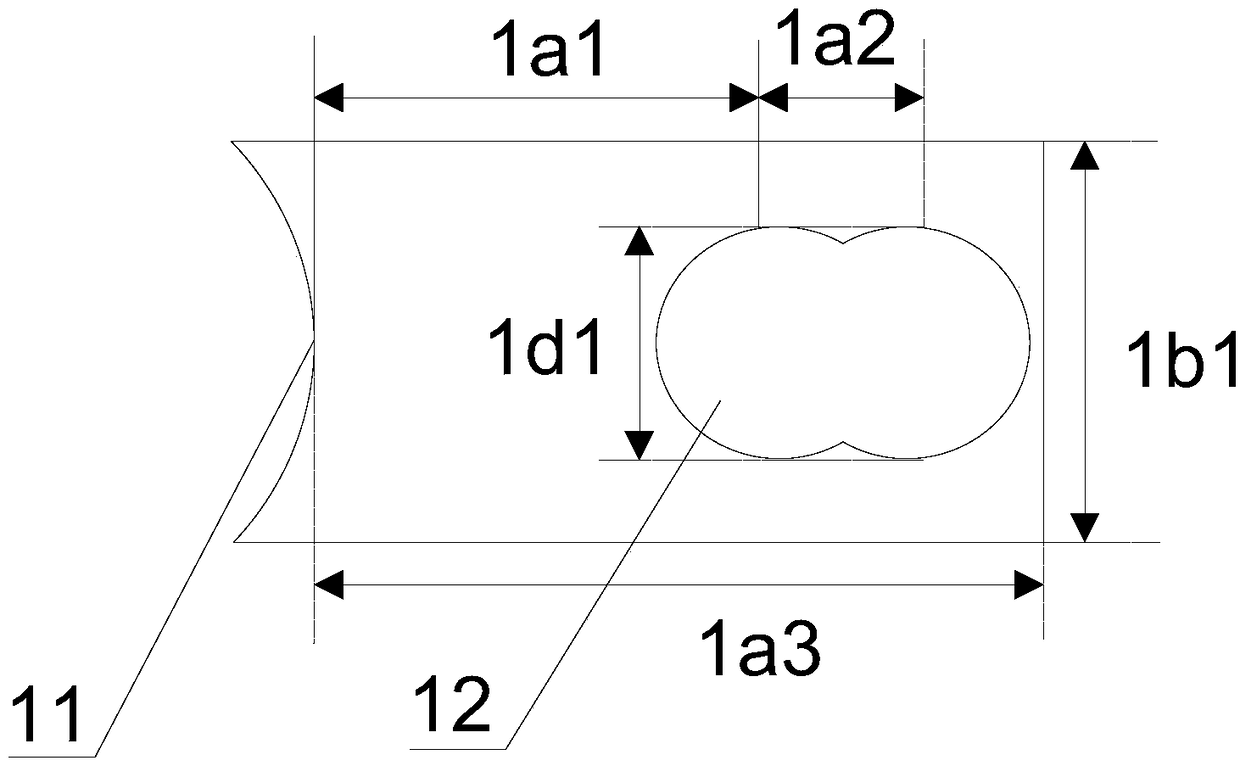

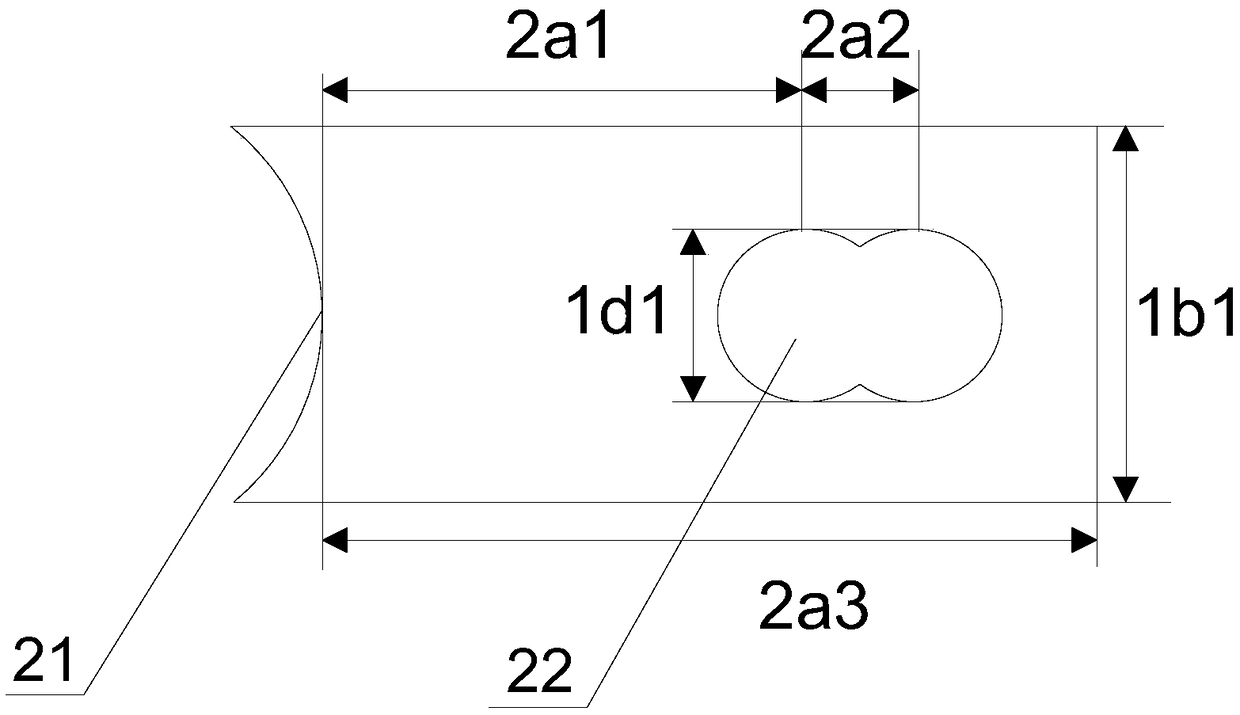

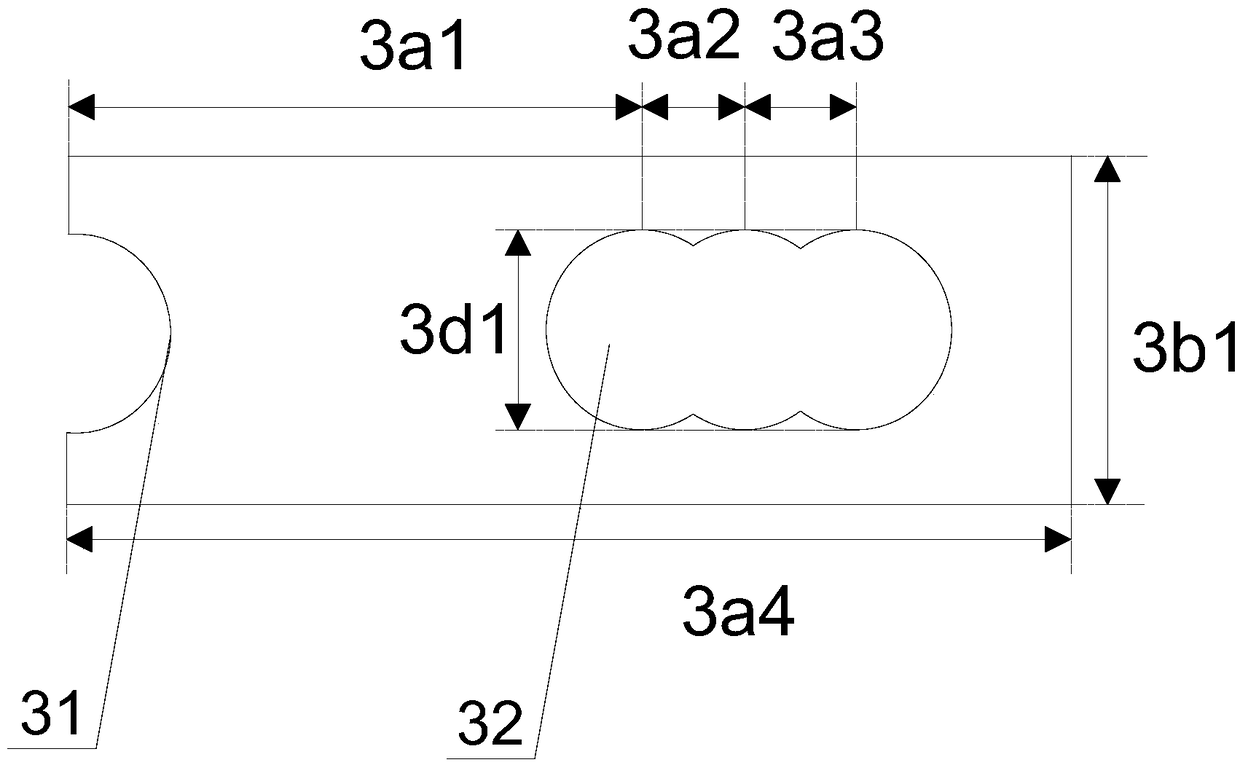

Measuring device and method for implantation site in dental implantation

The invention discloses a measuring device and method for the implantation site in dental implantation. The measuring device comprises a ruler I, a ruler II, a ruler III, a ruler IV, a ruler V and a ruler VI, wherein the ruler I is used for gap measurement and diagnosis and implant positioning when in loss of single premolar tooth; the ruler II is used for gap measurement and diagnosis and implantpositioning when in loss of single molar tooth; the ruler III is used for continuous implant positioning when in loss of continuous teeth; the ruler IV is used for gap measurement and diagnosis and implant positioning when in loss of continuous premolar teeth; the ruler V is used for gap measurement and diagnosis and implant positioning when in loss of continuous molar teeth; the ruler VI is usedfor gap measurement and diagnosis and implant positioning when in loss of continuous posterior teeth. The measuring device and method disclosed by the invention have the beneficial effects that by adoption of the measuring device provided by the invention, auxiliary positioning can be carried out on the conventional oral-cavity implantation surgery at the posterior-teeth area; the cost is low, the operation is simple, the use is convenient, the accuracy is high, the error is small, the ideal position of the implant can be more accurately and quickly positioned in the surgery.

Owner:SICHUAN UNIV

Method for preparing material special for polybutylene terephthalate (PBT) optical fiber loose tubes

ActiveCN102675608AQuality improvementAchieve high speedFibre mechanical structuresPolyethylene terephthalateReaction temperature

The invention provides a method for preparing a material special for polybutylene terephthalate (PBT) optical fiber loose tubes. The method comprises the following steps of: uniformly mixing a solid additive required by the production of the PBT optical fiber loose tubes and 1,4-butanediol, conveying and metering by using a gear pump, adding into a slurry preparation tank in a proportion, allowing the obtained slurry and slurry which is prepared from 1,4-butanediol and terephthalic acid to enter an esterification reaction kettle, and thus obtaining a PBT base material for optical fiber loose tubes by a direct esterification and continuous condensation production technology; and ensuring that the PBT base material continuously enters a solid-phase system through metering, preheating and crystallizing, entering a solid-phase reactor for tackification at the temperature of 170 to 210 DEG C for 15 to 20 hours, cooling a product obtained after tackification, dedusting, conveying, and packaging to obtain the material special for the PBT optical fiber loose tubes. By the method, a color value of the product can be effectively controlled, the special additive is uniformly mixed in the product, the PBT product for the optical fiber loose tubes has relatively stable quality, and the high-speed development tendency of the machining process of the loose tubes is met.

Owner:CHINA PETROCHEMICAL CORP

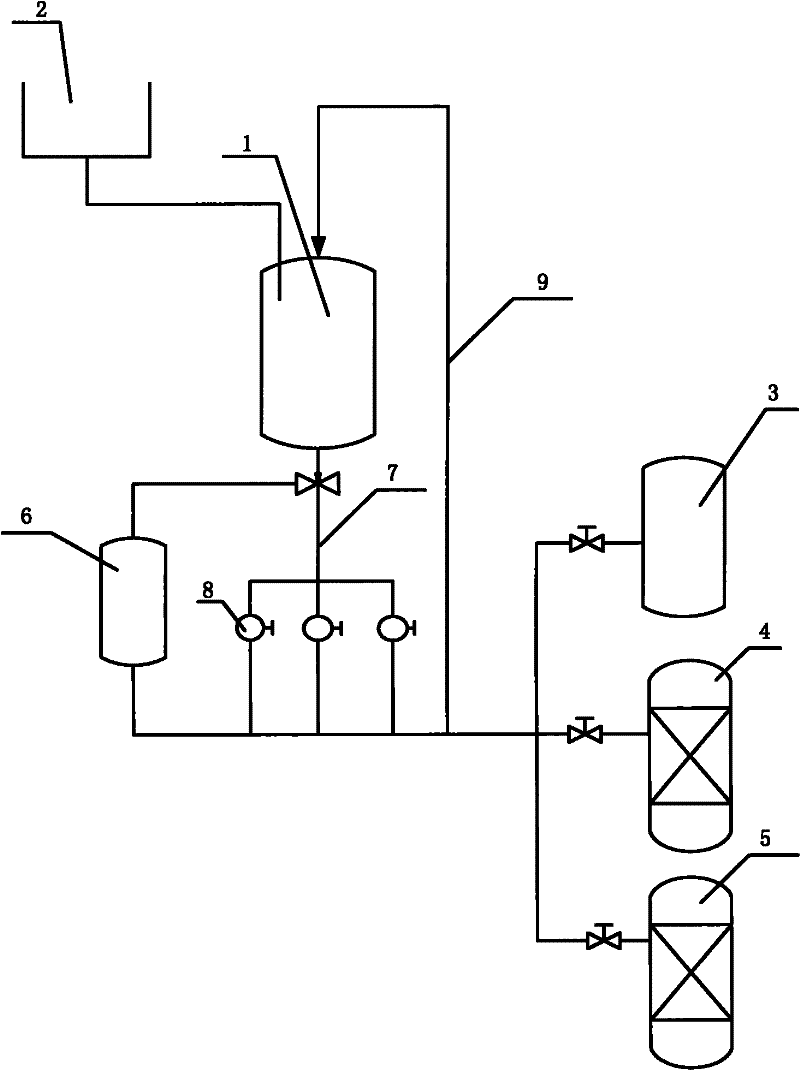

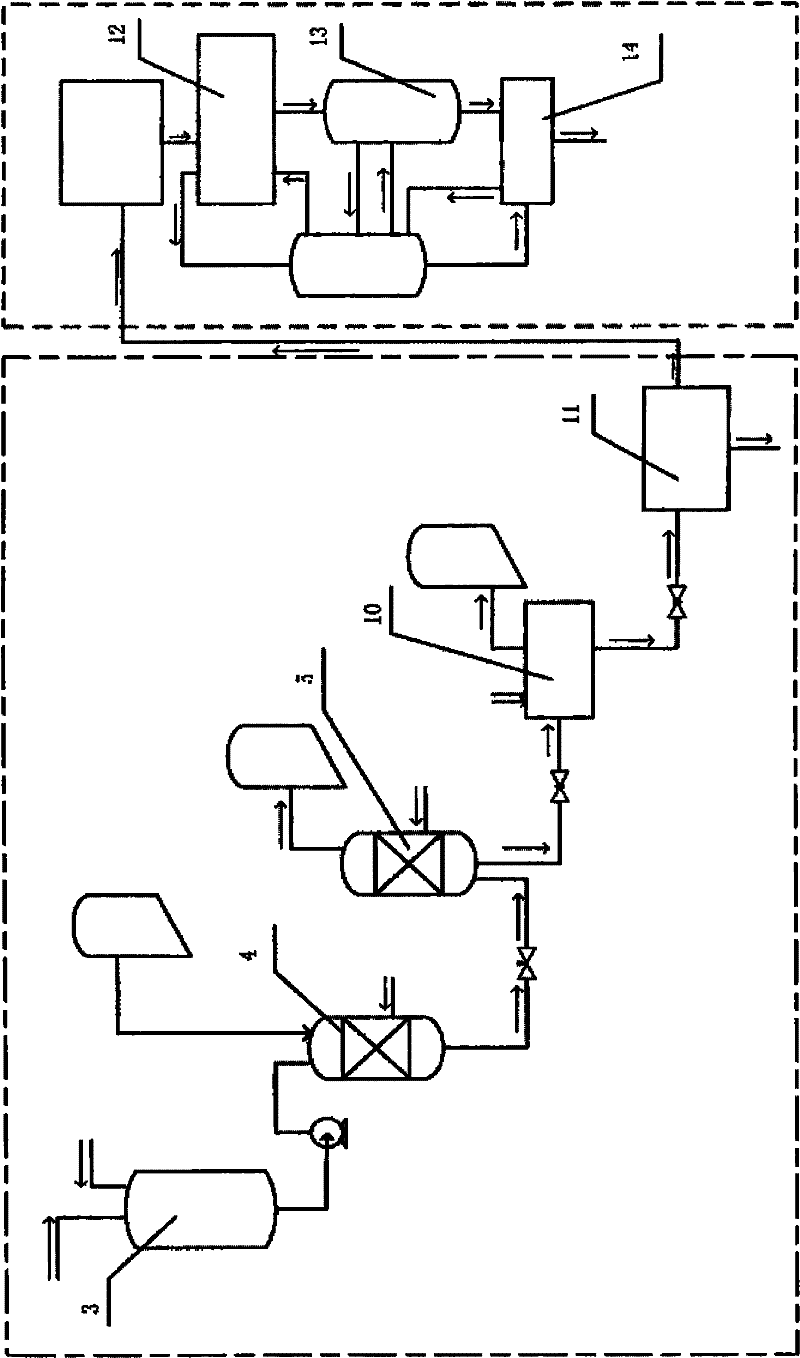

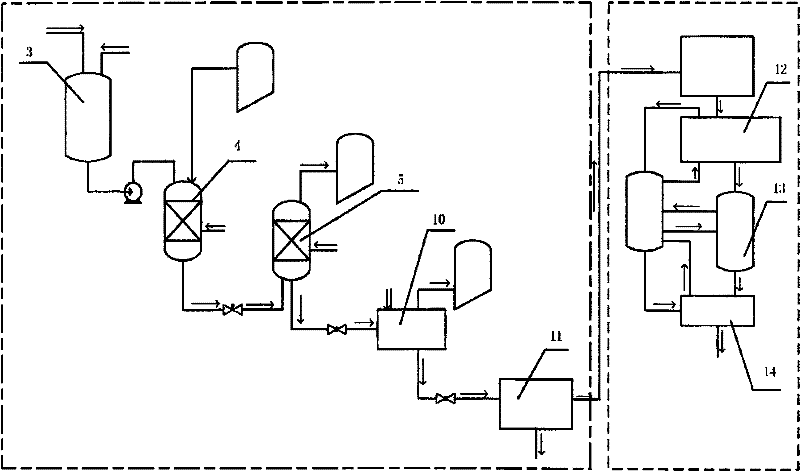

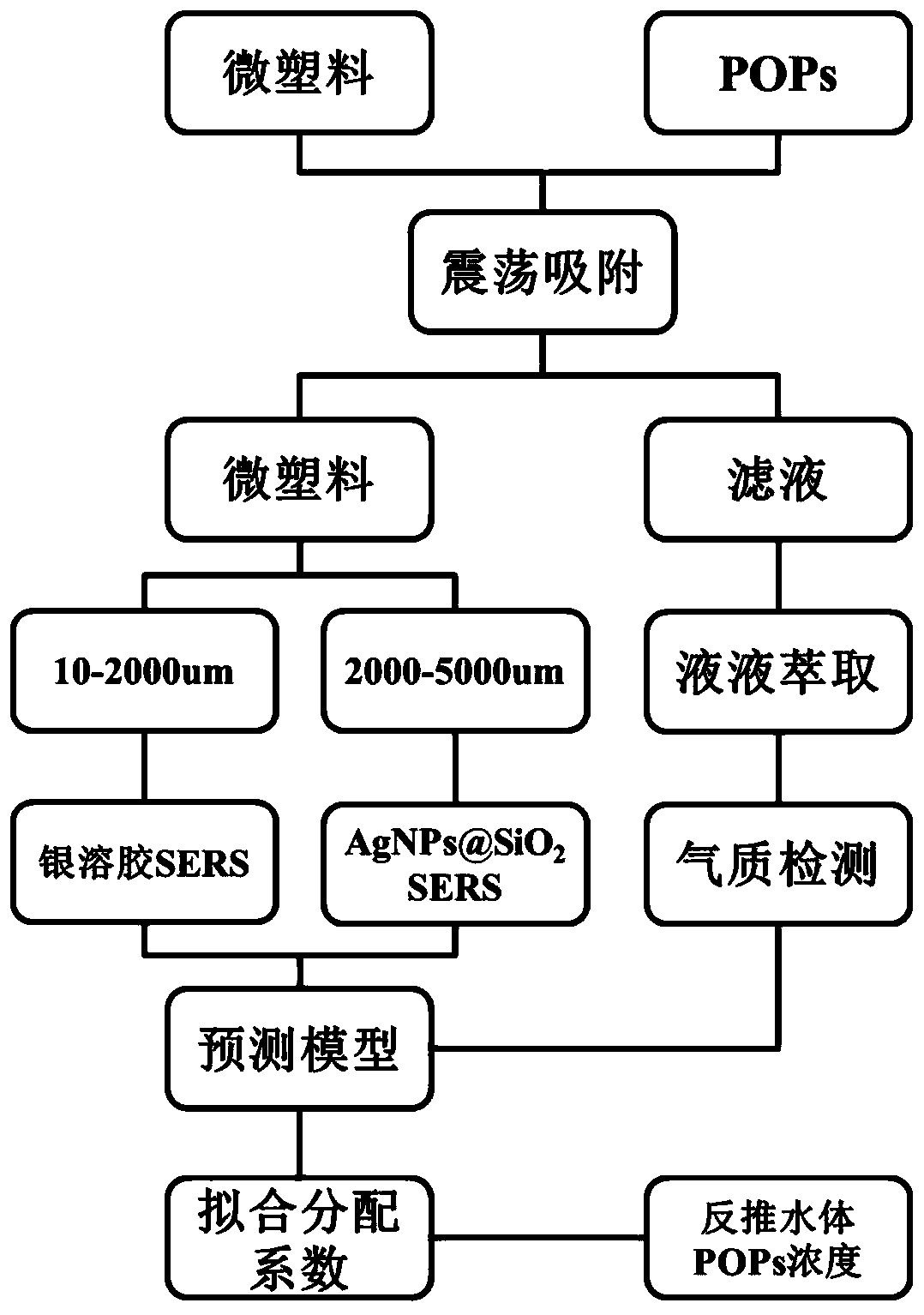

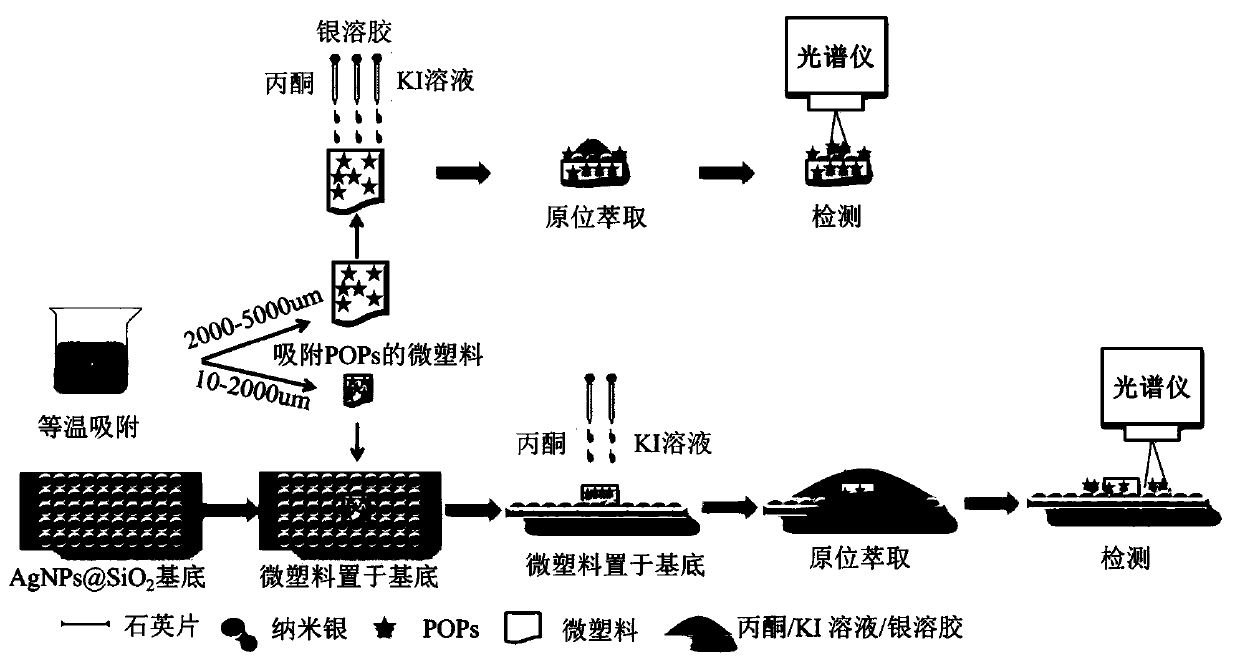

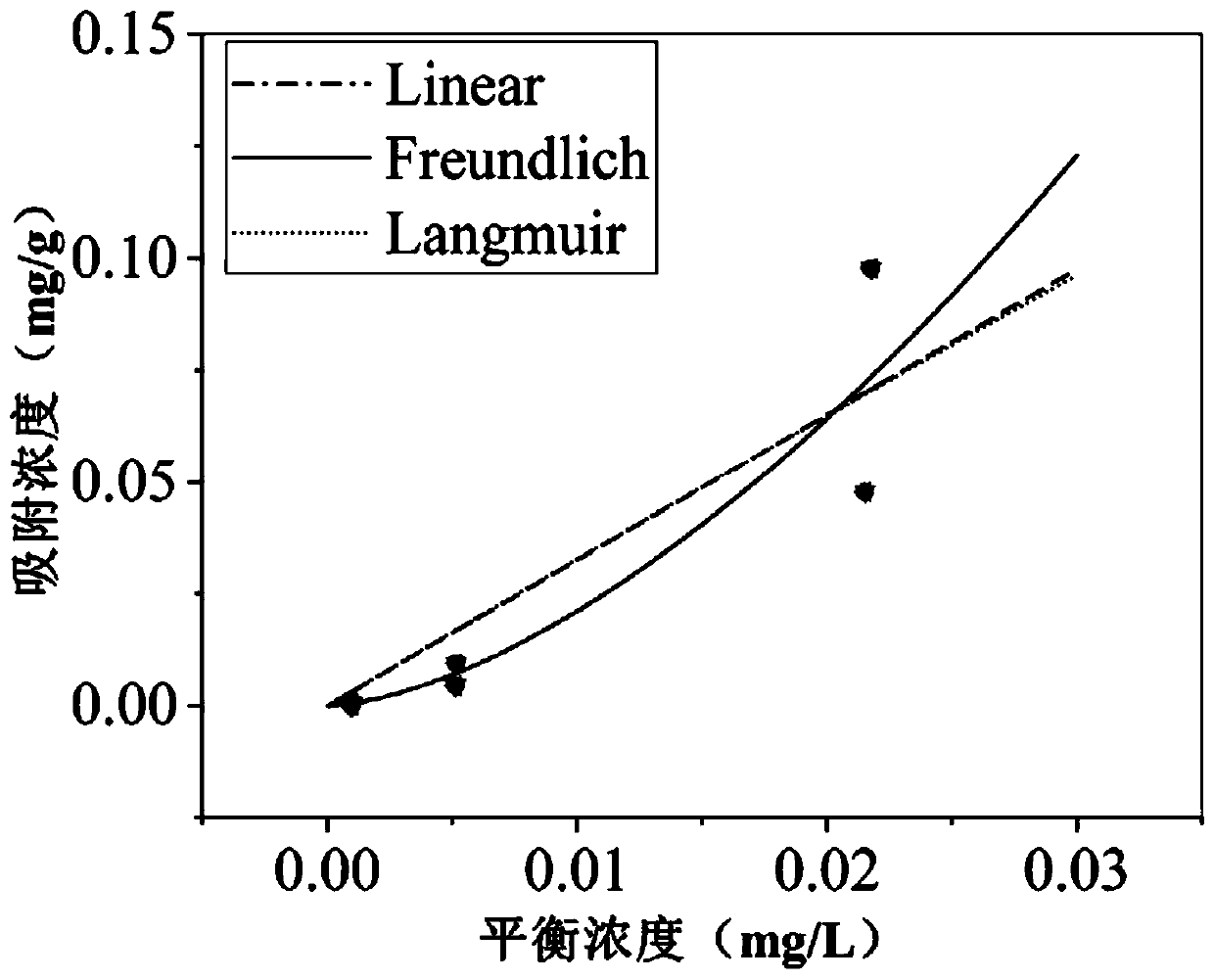

SERS detection method for persistent organic pollutants in water body based on microplastics

InactiveCN111220732AQuick checkSkip the manufacturing processComponent separationRaman scatteringSoil scienceRapid detection

The invention provides an SERS detection method for persistent organic pollutants in a water body based on microplastics. The SERS detection method comprises the following steps: (1) preparing silversol and an AgNPs-(at) SiO2 SERS substrate; (2) according to the particle size of the micro-plastic, respectively carrying out in-situ enhancement and detection on Raman signals of persistent organic pollutants adsorbed on the surface of the micro-plastic by using silver sol and an AgNPs-(at)SiO2 substrate; (3) establishing a prediction model for enriching persistent organic pollutants on the surface of the micro-plastic in combination with a chemometrics method; and (4) determining an optimal fitting model, calculating an equilibrium distribution coefficient / equilibrium adsorption constant ofthe persistent organic pollutants in the water phase and the solid phase, and estimating the concentration of the persistent organic pollutants in the water body. According to the method, micro-plastic is used as a passive sampler, rapid detection of the organic pollutants in the water body is realized, the steps are simple, the consumption of chemical reagents is low, the detection time is short,and a new thought and technical support are provided for rapid detection of the persistent organic pollutants in the water body.

Owner:DALIAN UNIV OF TECH

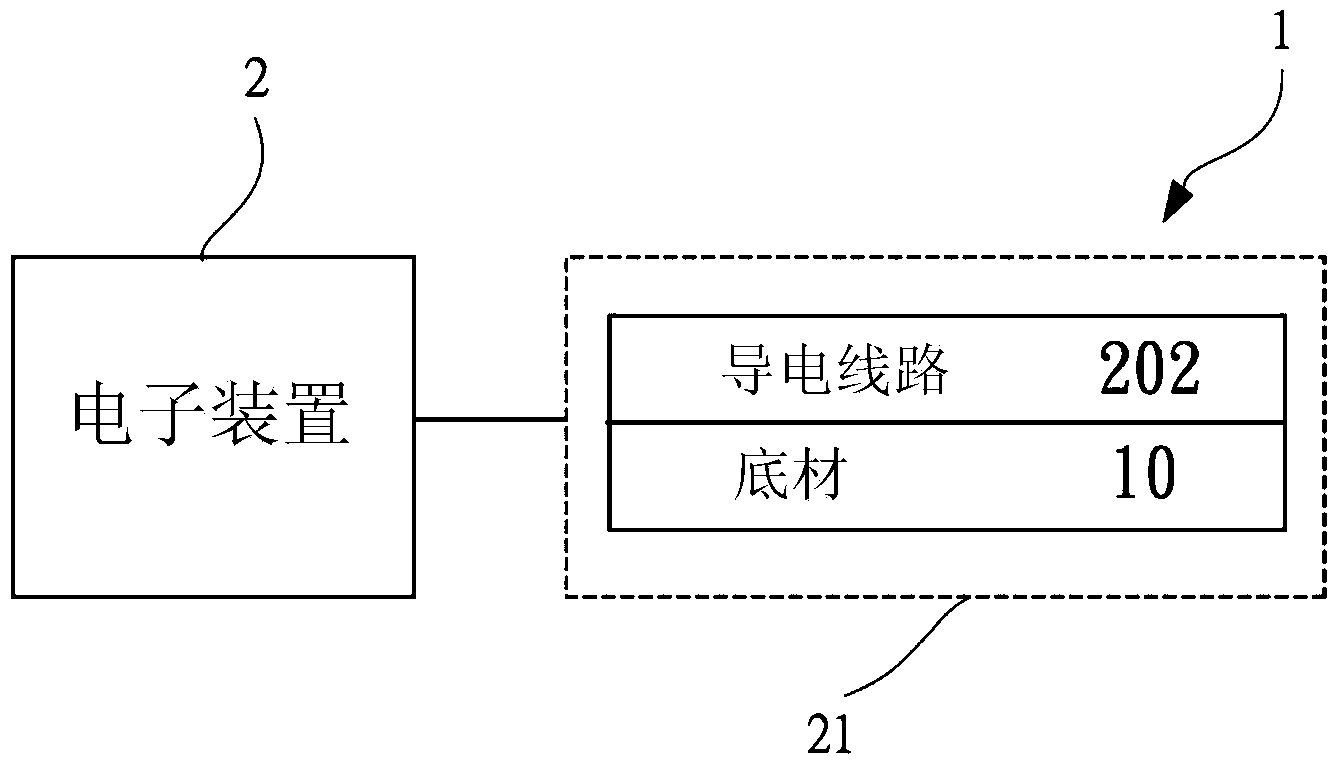

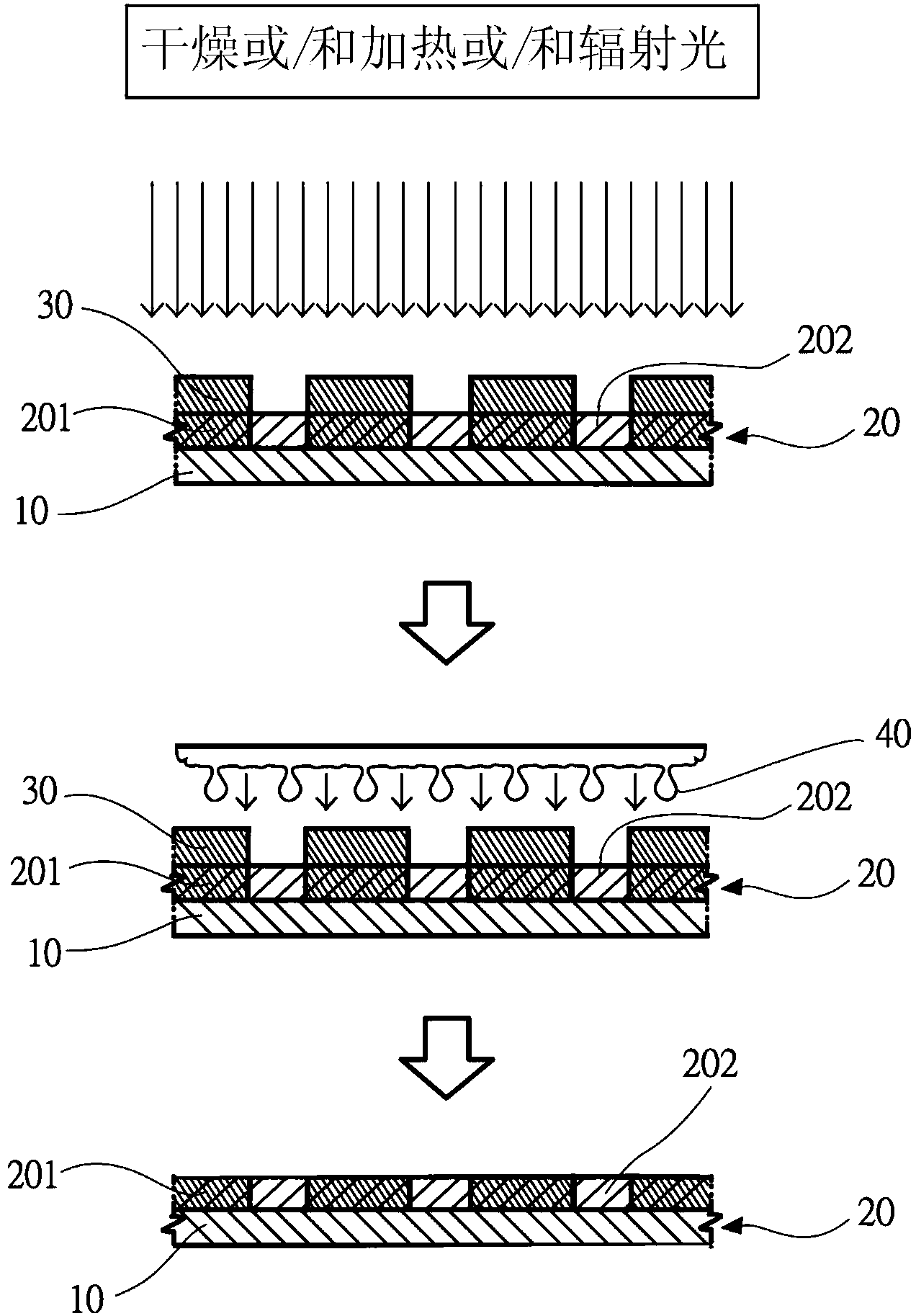

Composition Of An Aqueous Etchant Containing A Precursor Of Oxidant And Patterning Method For Conductive Circuit

InactiveCN104109859ANot easy to corrodeSkip the manufacturing processConductive material chemical/electrolytical removalSurface treatment compositionsEngineeringSolar cell

The present invention is primarily related to the composition of an aqueous etchant containing a precursor of oxidant and patterning methods for conductive circuits, in which the chemical structure of the precursor contains chlorine and can produce oxidants through various reactions. And, the patterned conductive circuits can be used for electronic devices, including printed electronics, sensors, displays, organic light emitting diodes (OLED), touch panels, electronic circuit boards, electrodes, electroluminescent (EL) films, antennas, and solar cells.

Owner:POLYCHEM UVEB INT CORP

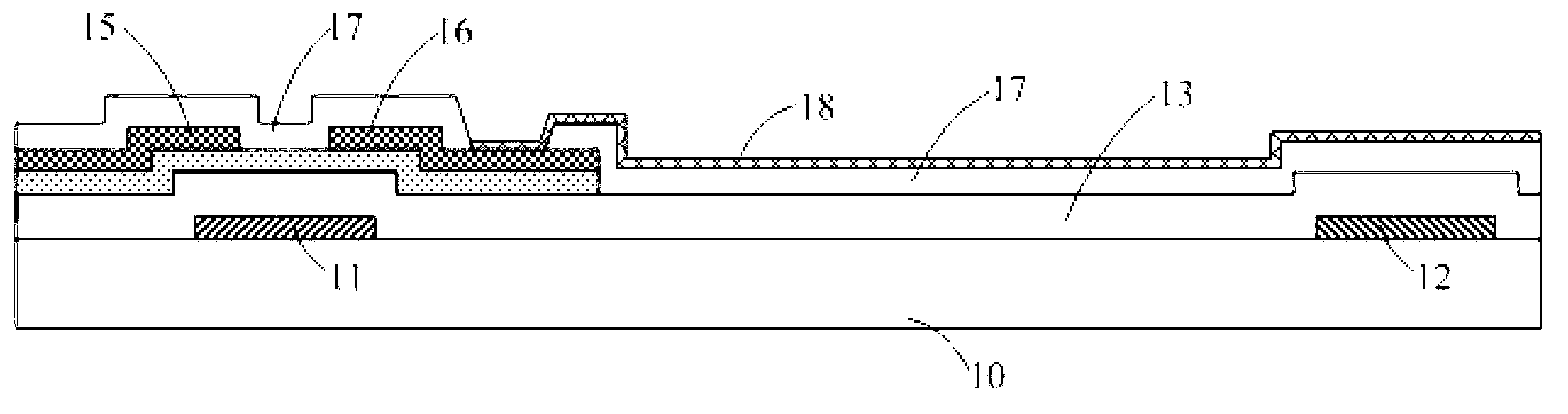

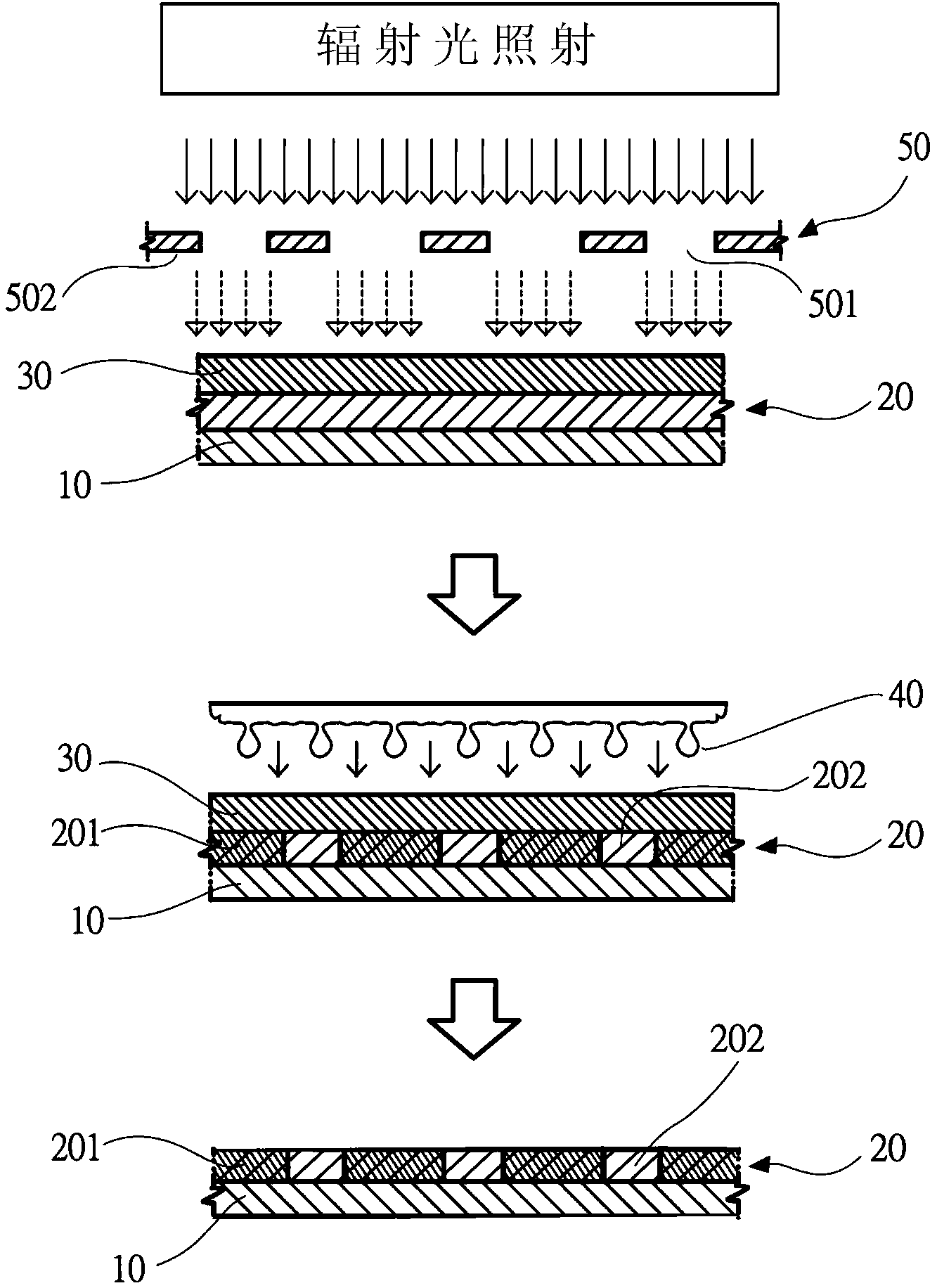

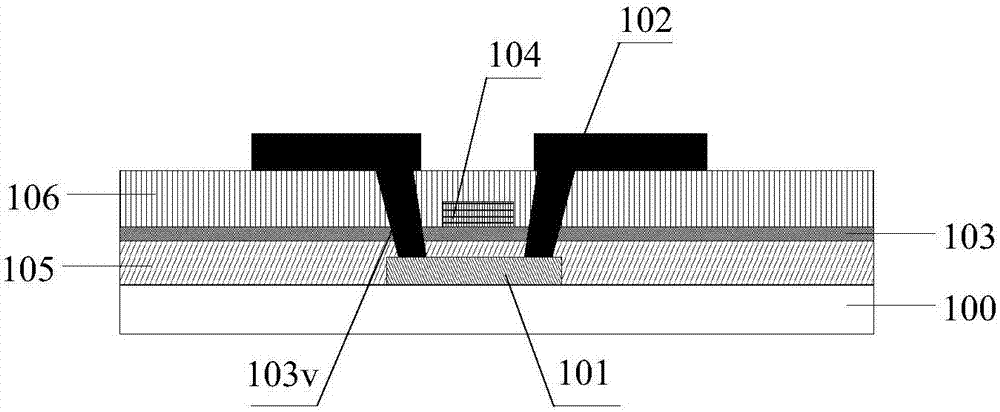

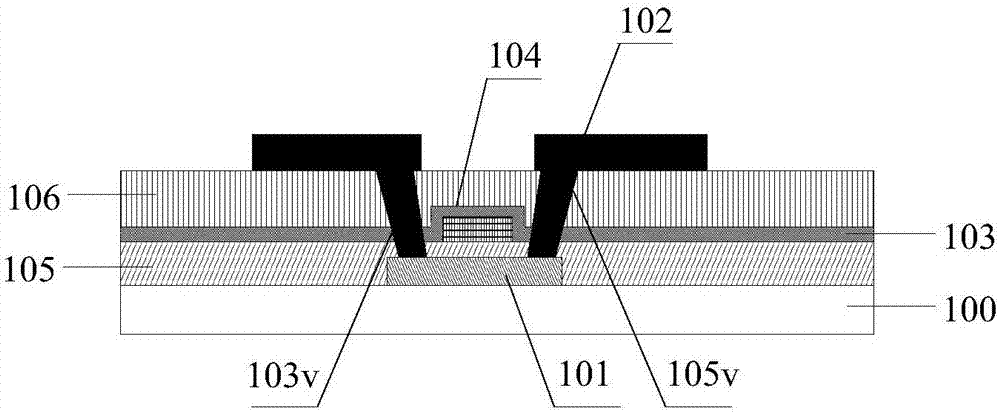

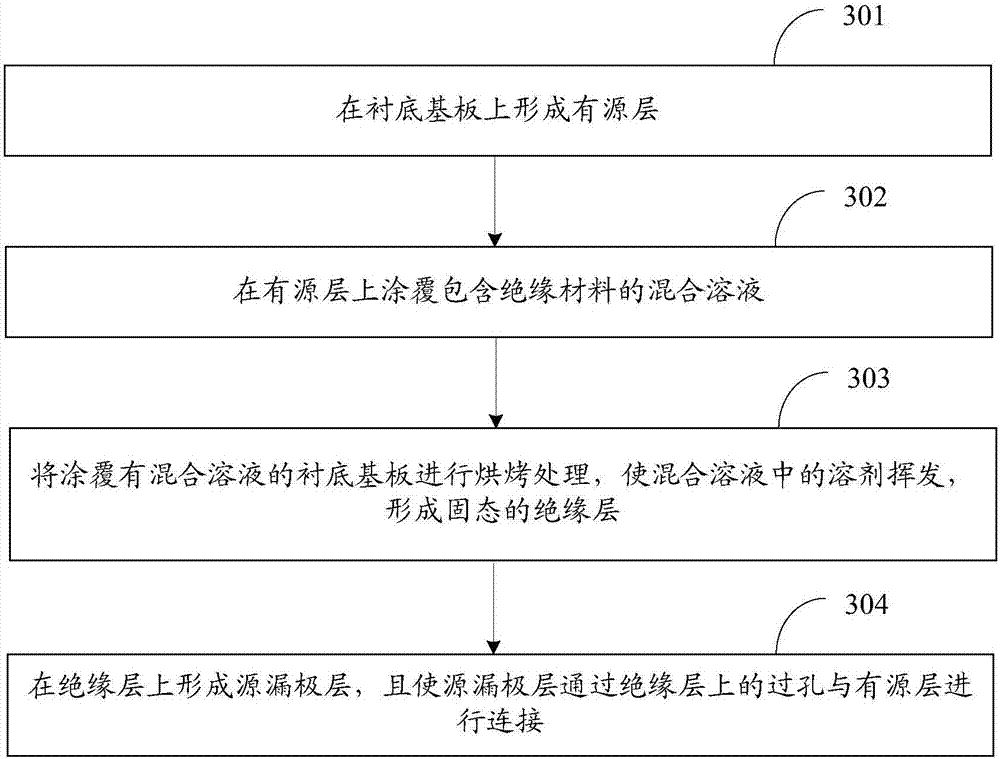

Thin film transistor and manufacturing method thereof and display device

ActiveCN107170830AStrong flexibilityNot easy to breakTransistorSolid-state devicesEngineeringDisplay device

The invention relates to a thin film transistor and a manufacturing method thereof and a display device, and is used for solving the problems in the present flexible display screen that the metal wires of the source and drain layer are broken because of fracturing in the bending process due to high thickness of the interlayer dielectric layer. The thin film transistor comprises an underlying substrate, an active layer and the source and drain layer which are arranged on the underlying substrate and an insulating layer which is arranged between the active layer and the source and drain layer. The source and drain layer is connected with the active layer through the through holes on the insulating layer. The material of the insulating layer includes hydrogen storage material. According to the thin film transistor, the insulating layer manufactured by the hydrogen storage material is arranged between the active layer and the source and drain layer, and the hydrogen atoms stored in the insulating layer can be provided for the active layer so that subsequent manufacturing of the interlayer dielectric layer can be omitted. Meanwhile, the flexible insulating layer has higher flexibility in comparison with the interlayer dielectric layer manufactured by inorganic material and is not liable to break in bending so that the yield rate of the product can be enhanced.

Owner:BOE TECH GRP CO LTD

Air-tight image chip packaging structure and manufacturing method thereof

InactiveCN107221516AImprove reliabilityAvoid mechanical stress build-upSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionThinning

The invention discloses an air-tight image chip packaging structure and a manufacturing method thereof. A conducting circuit is paved on the front side of a cofferdam, the functional surface of a thinned image chip faces a cavity of the cofferdam, so that a welding pad is attached onto the conducting circuit on the cofferdam for electrical connection, insulating layers are packaged on the side wall of the image chip and the non-functional surface of the image chip, an electric conductor is manufactured inside the insulating layer at the position of the side wall of the image chip, the conducting circuit on the front side of the cofferdam is leaded to the non-functional surface of the image chip, and electrical property is leaded out through a re-routing metal circuit on the non-functional surface insulating layer. According to the packaging technology in the invention, manufacture procedure is not set on the image chip, thinning of an image sensor can be realized, and the packaging reliability is improved. High-cost manufacture procedures such as manufacturing of silicon through holes and deep hole passivation are omitted, and the cost is greatly reduced.

Owner:BEIJING UNIV OF TECH

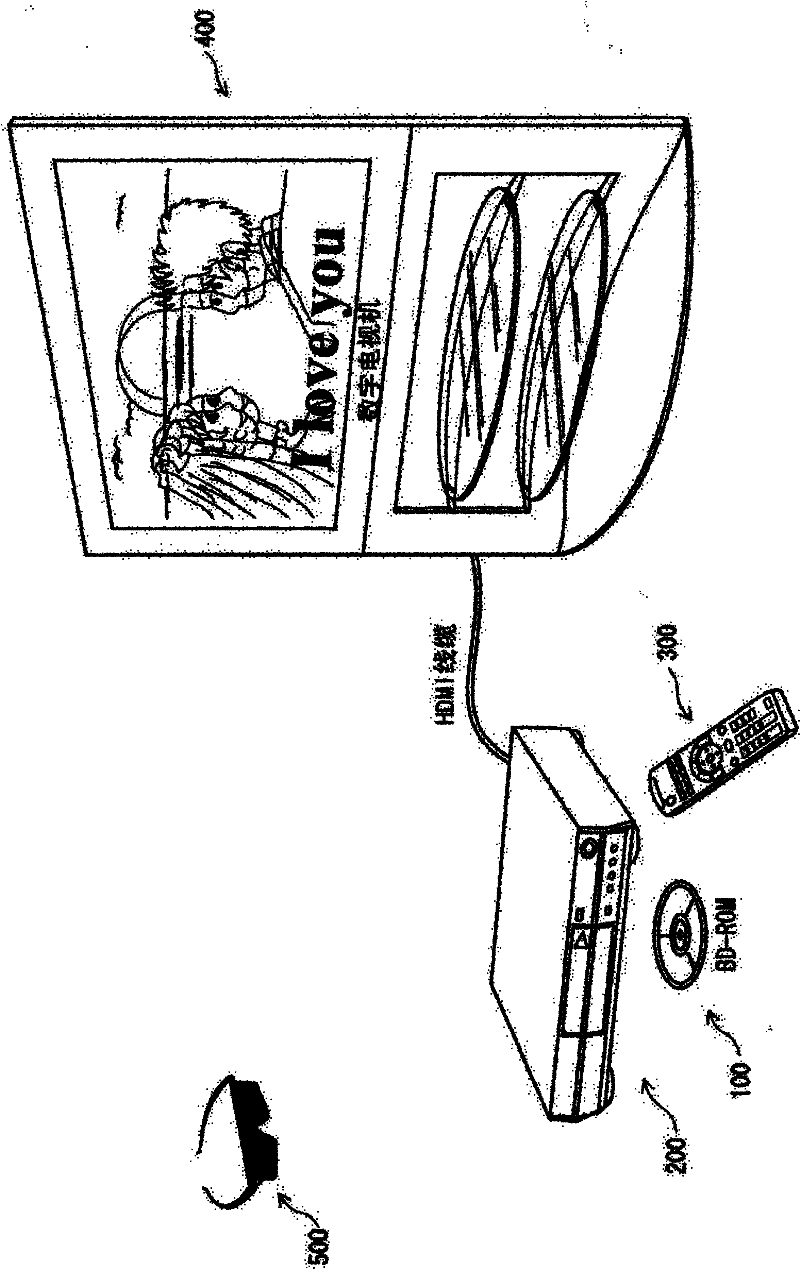

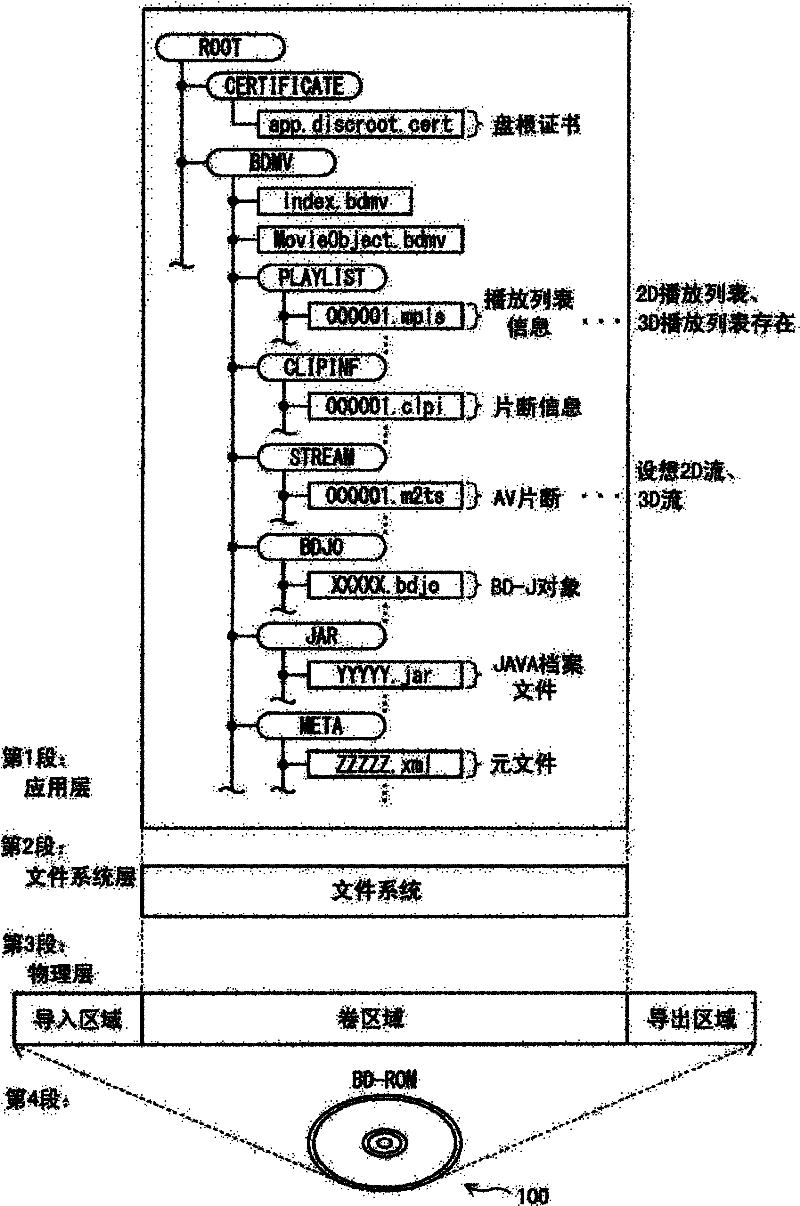

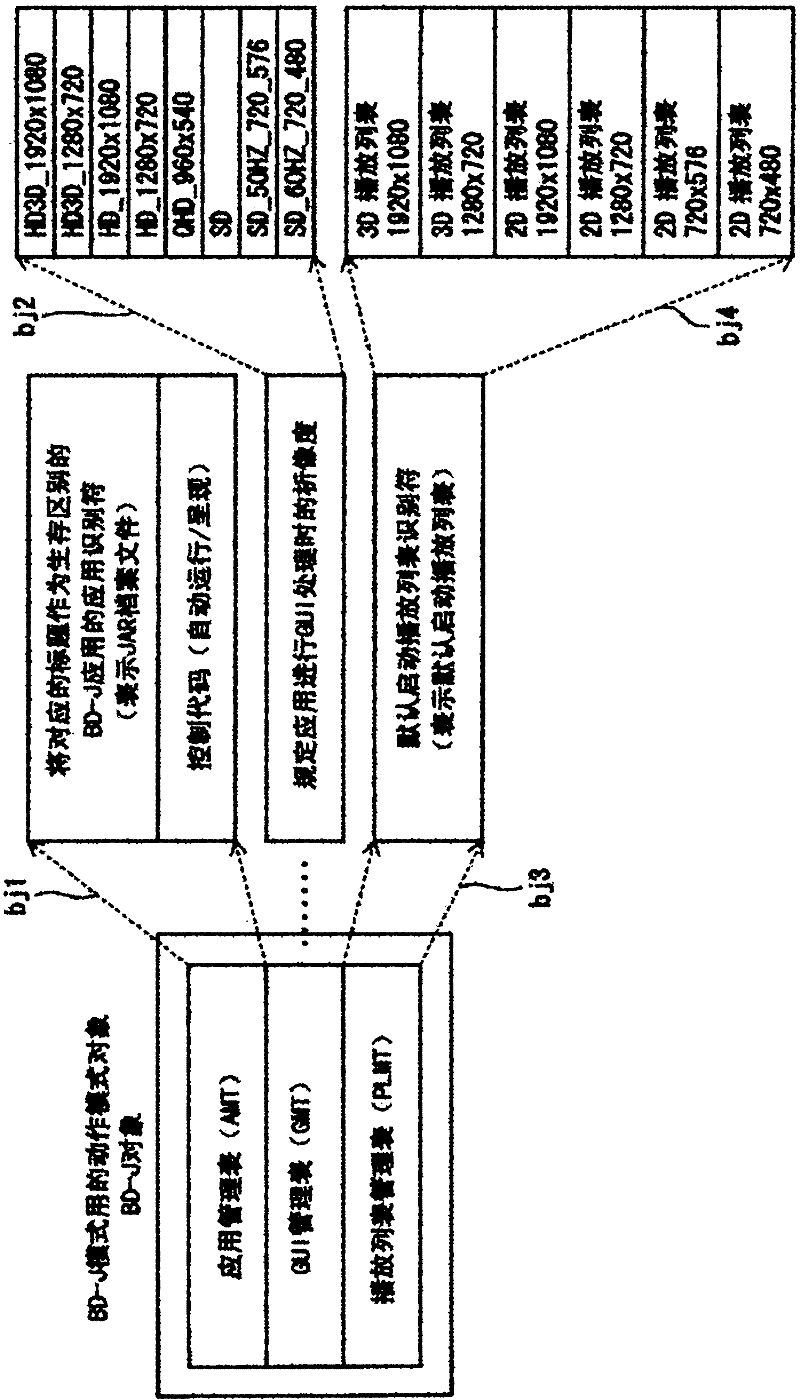

Playback device capable of stereoscopic playback, playback method, and program

InactiveCN102100076AProper stereopsis reproductionSkip the manufacturing processTelevision system detailsRecord information storageGraphicsLeft direction

Disclosed is a playback device that provides stereopsis by outputting each of a plurality of video frames stored in a video plane as a right-view video frame and a left-view video frame. A graphics plane stores image data with resolutions of 1920x1080 and 1280x720 as graphics data, and a shift engine shifts the coordinates of each item of image data in the graphics plane in either the right or left directions to execute left-view output while also shifting the coordinates of each item of image data in the graphics plane in the direction opposite from the left view to execute right-view output.

Owner:PANASONIC CORP

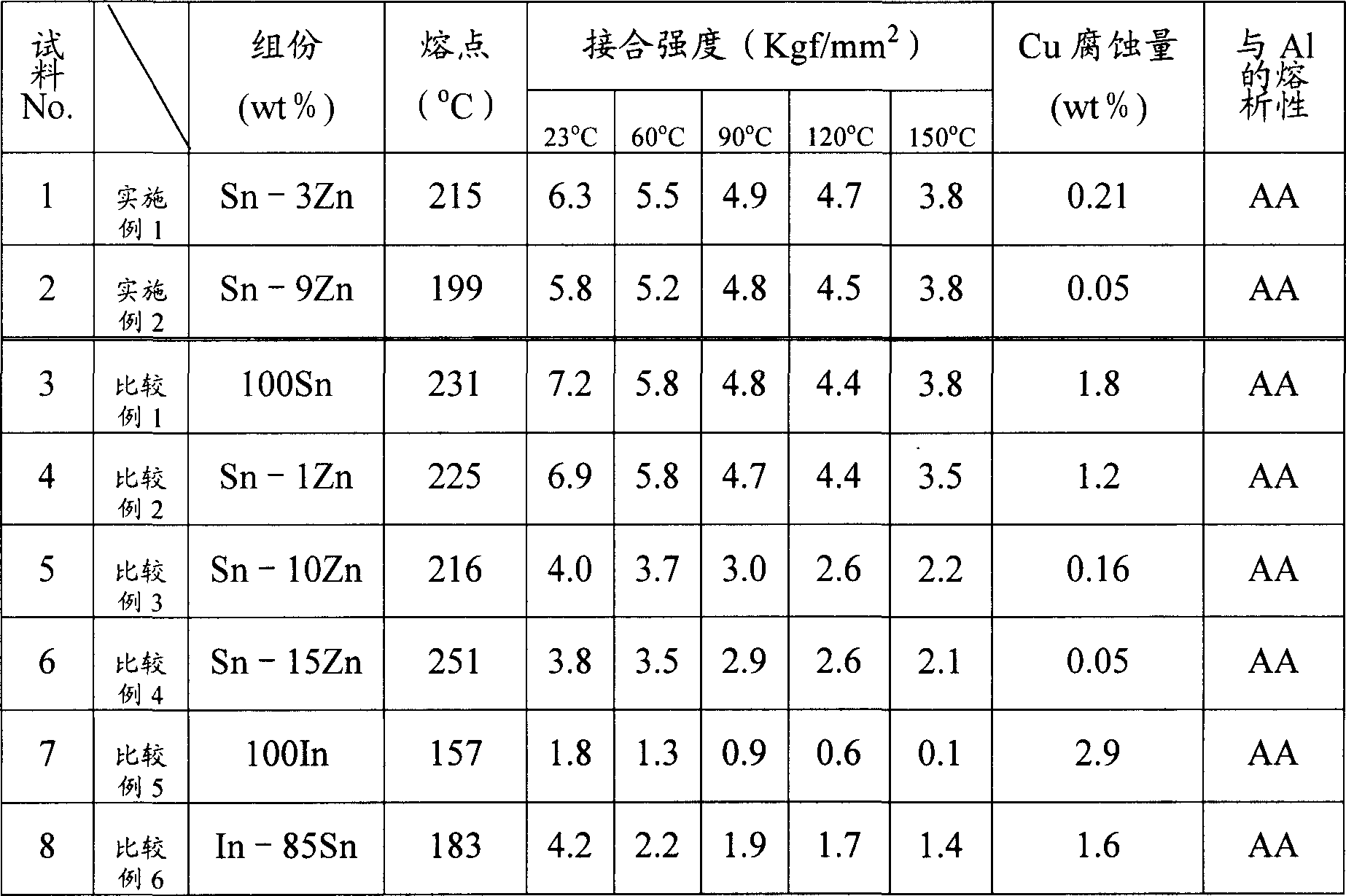

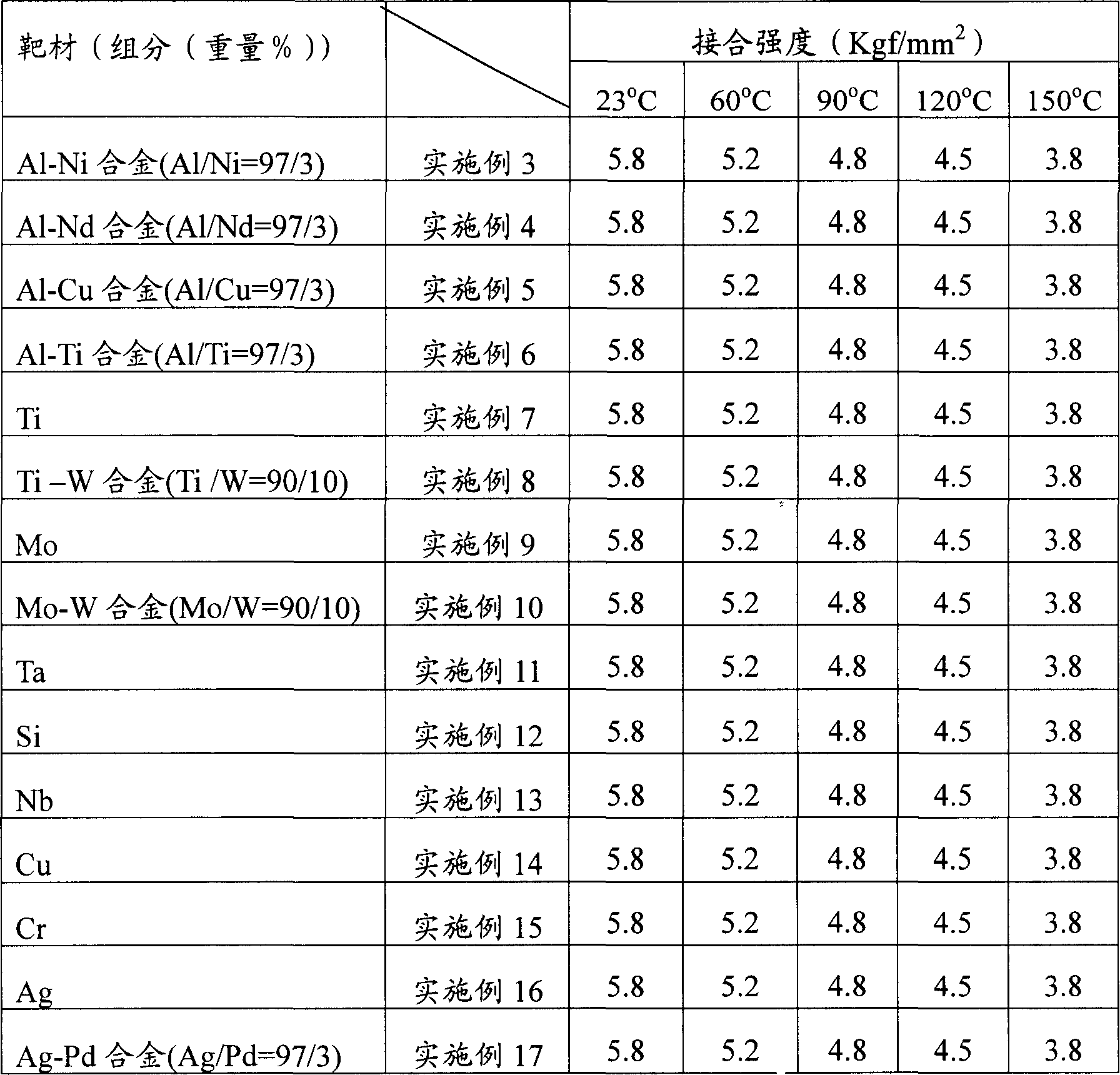

Welding alloy for sputtering target production and sputtering target

ActiveCN1880492APrevent peelingPrevent strength deteriorationVacuum evaporation coatingSputtering coatingAlloyRaw material

The present invention relates to a jointing alloy of two or more metallic elements for jointing butt and underprops whose raw materials include Cu or alloy of Cu and other metallic elements when making spatter butt. Characterized in that it contains 3 to 9 percent Zn, Sn and sundries that cannot be cleaned.

Owner:MITSUI MINING & SMELTING CO LTD

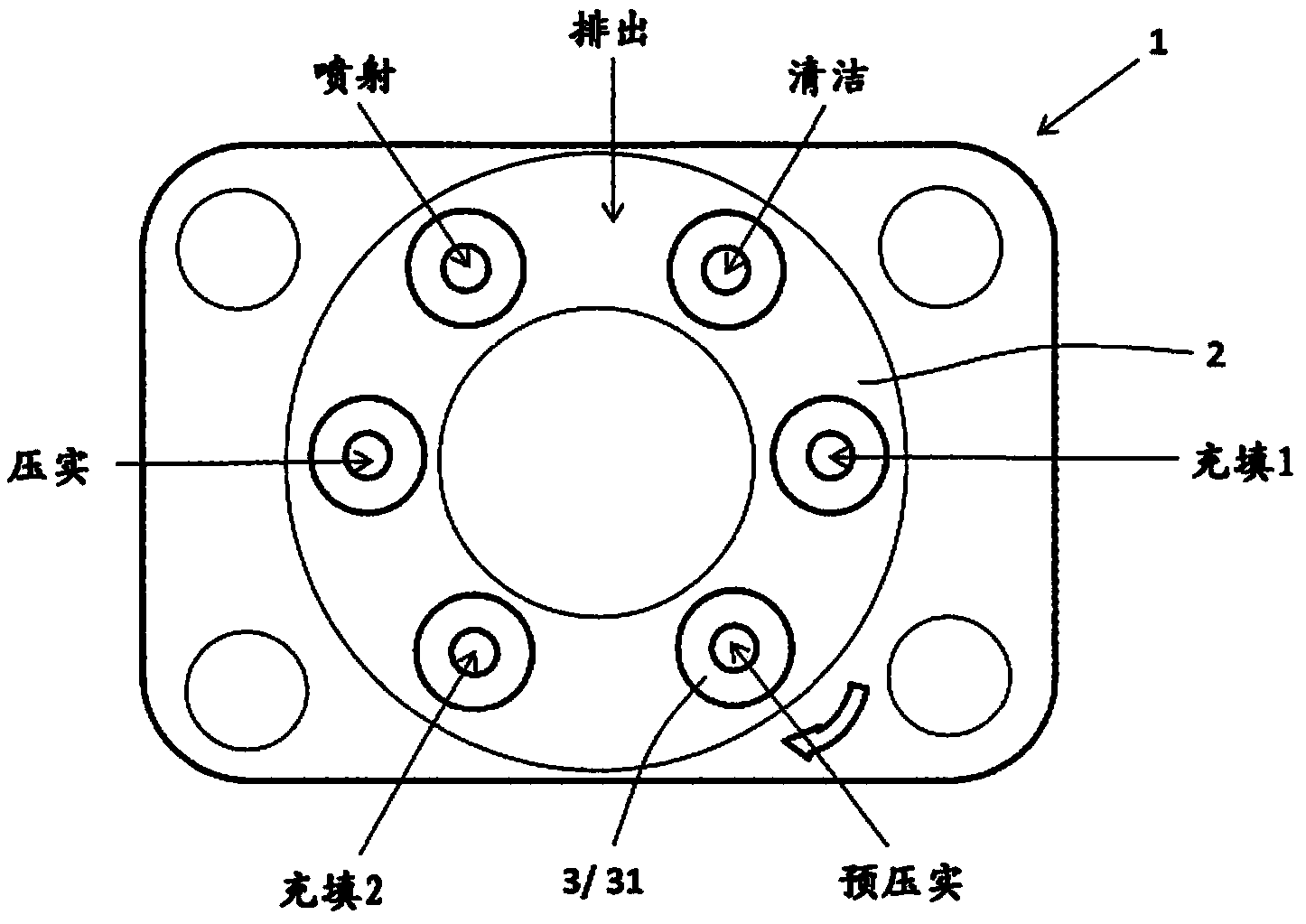

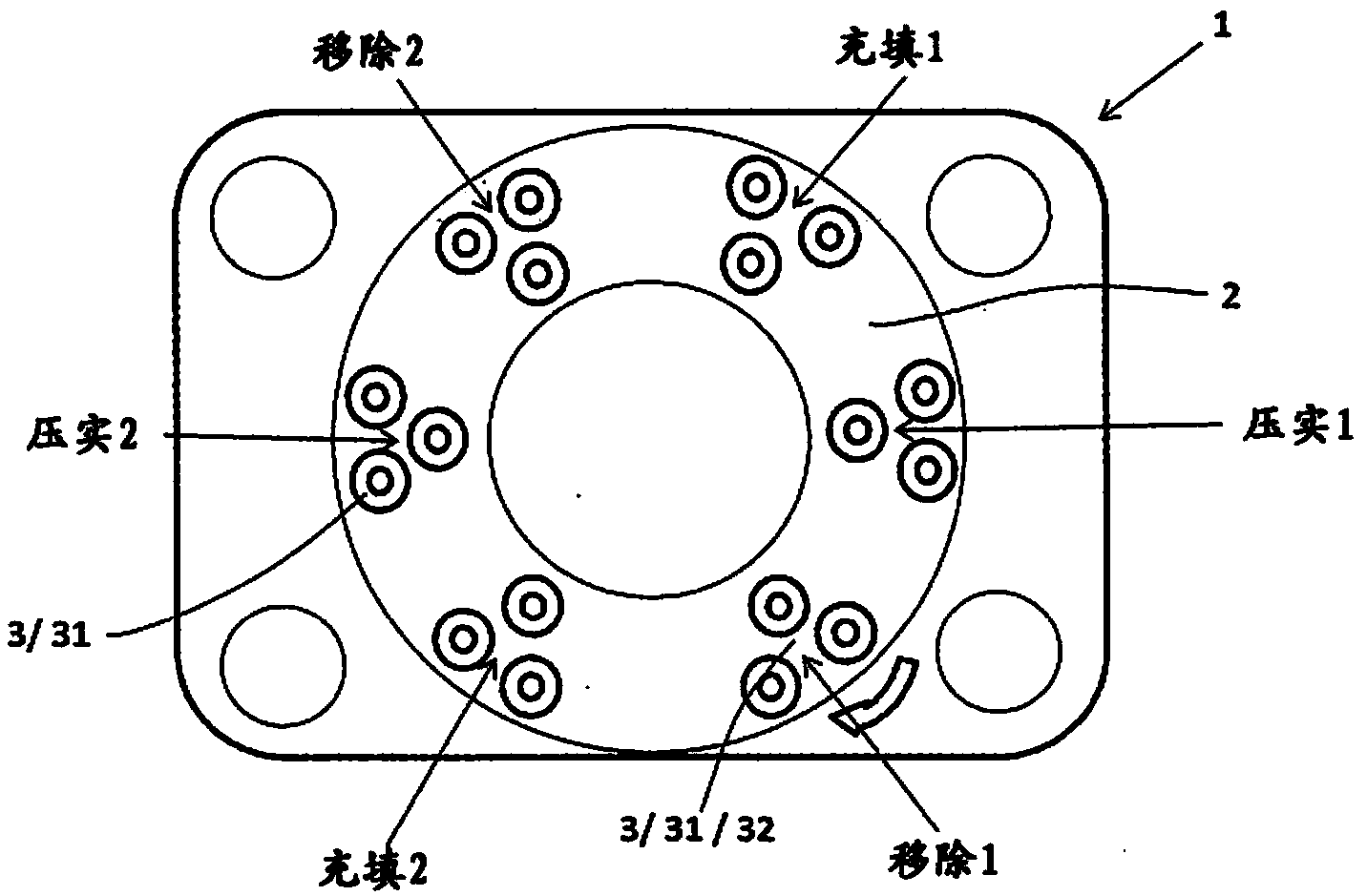

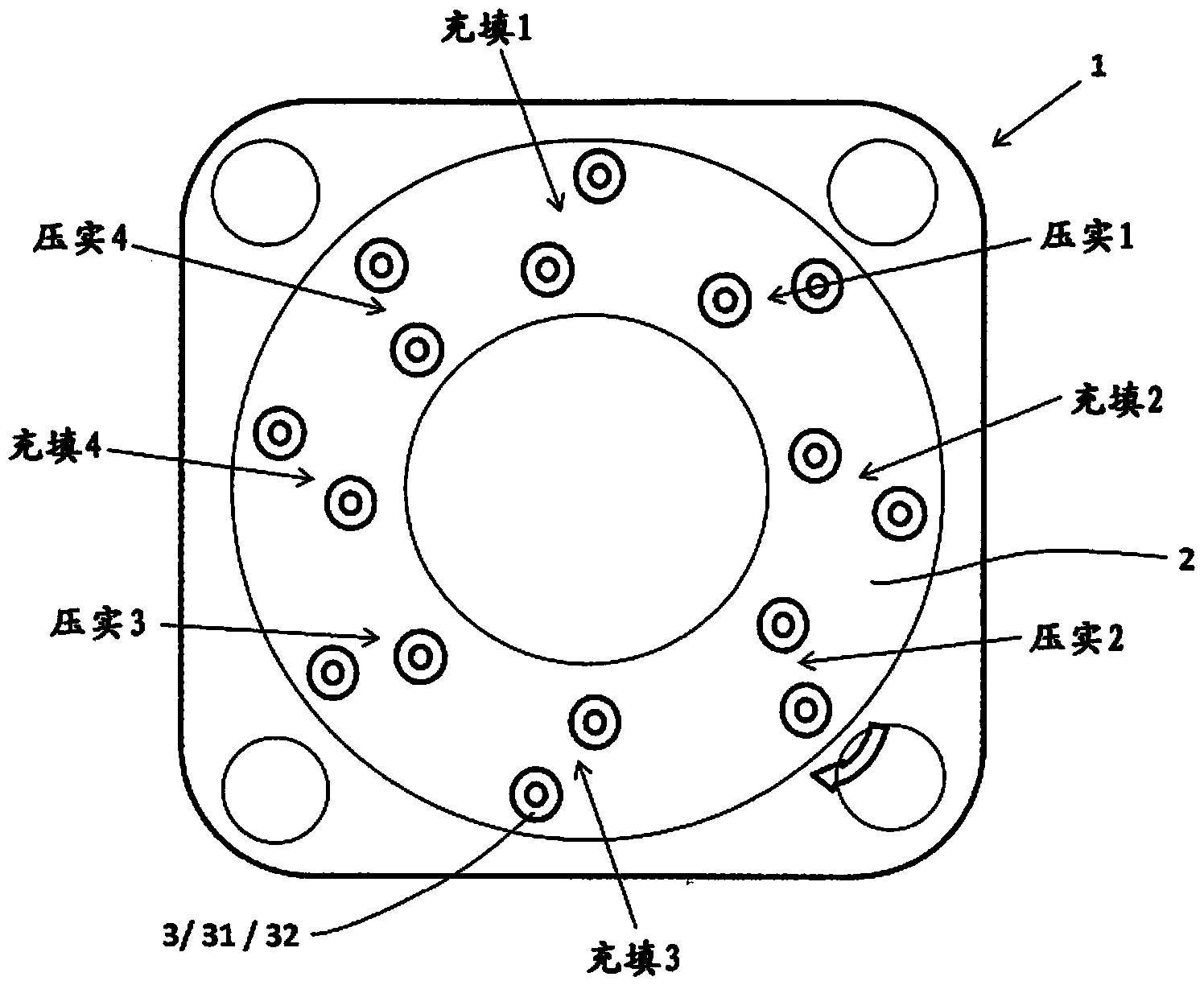

Rotary indexing press

InactiveCN104395063AIncrease variabilityExpand the scope of applicationDomestic articlesShaping pressEngineeringMechanical engineering

The invention relates to a rotary indexing press for producing green bodies from pulverulent materials. The rotary indexing press has an indexing plate which is equipped with a plurality of tool cavities which are assigned to a plurality of tool positions, wherein tool positions are provided at least for filling, compacting and ejecting workpieces, and each tool position is assigned at least one cavity, and wherein the indexing plate is connected to the machine body in a form- and / or force-fitting manner during compaction. The invention also relates to a method for producing green bodies from pulverulent materials on a rotary indexing press.

Owner:BLEISTAHL PRODN

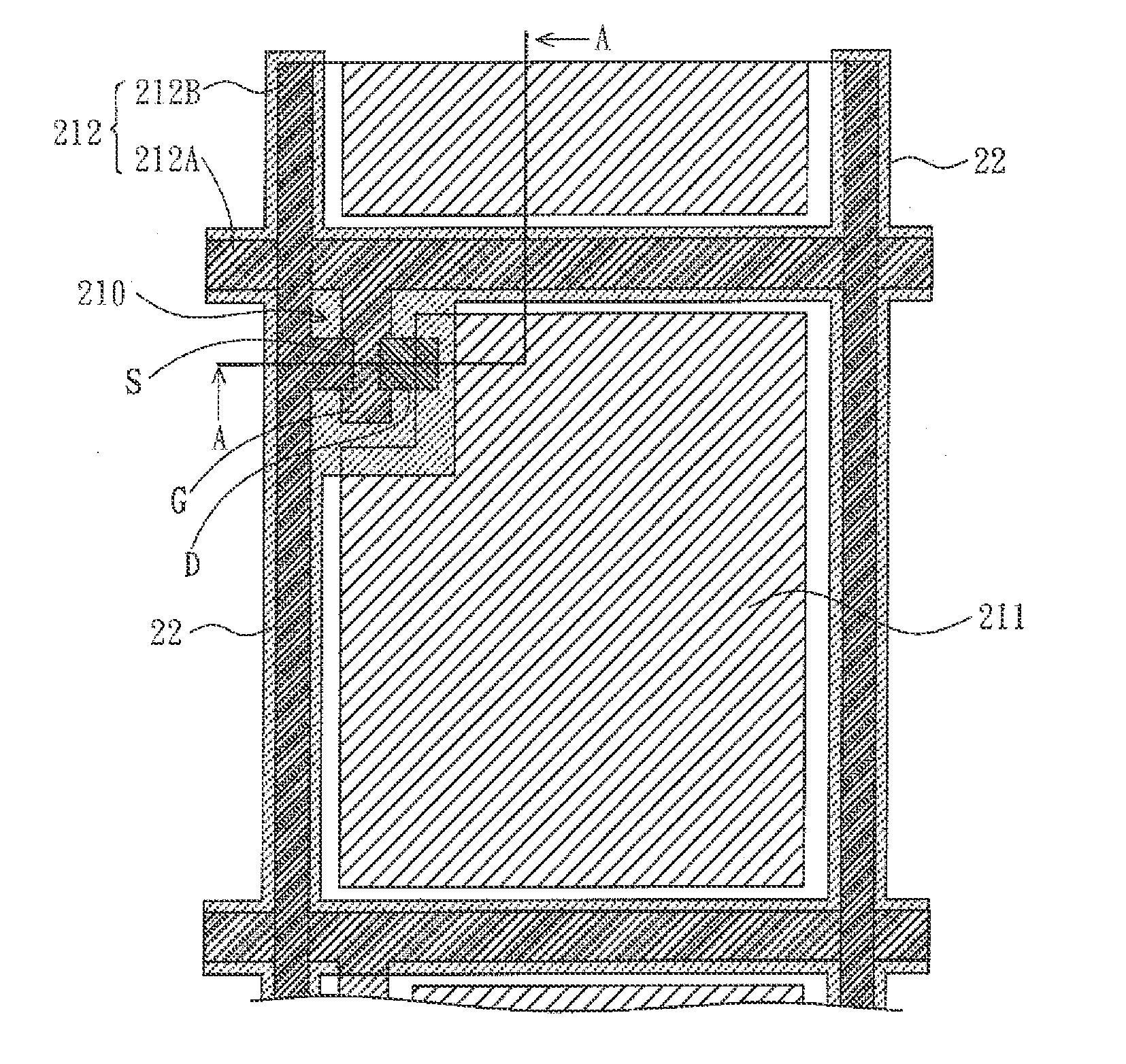

Liquid crystal display device, color-filter substrate, thin-film-transistor substrate and manufacturing method thereof

ActiveUS20120287363A1Save the processAvoid light leakageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringConductive materials

The present invention provides a liquid crystal display device, a color-filter substrate, a thin-film-transistor substrate and a manufacturing method thereof. The thin-film-transistor substrate has a pixel array and transparent conductive material. The pixel array has a plurality of thin-film-transistor units, pixel electrodes and metal signal lines. The transparent conductive material is mounted on the pixel array with an insulating layer placed therebetween, and correspondingly covers an area containing the thin-film-transistor units and the metal signal lines. And voltage difference between the transparent conductive layer and a common electrode of the color-filter substrate is smaller than a threshold voltage of liquid crystal cell. Therefore, without enough voltage difference for driving, the liquid crystal material between the transparent conductive material and the common electrode can maintain at a vertical status to block lights, so as to replace the function of traditional black matrix.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

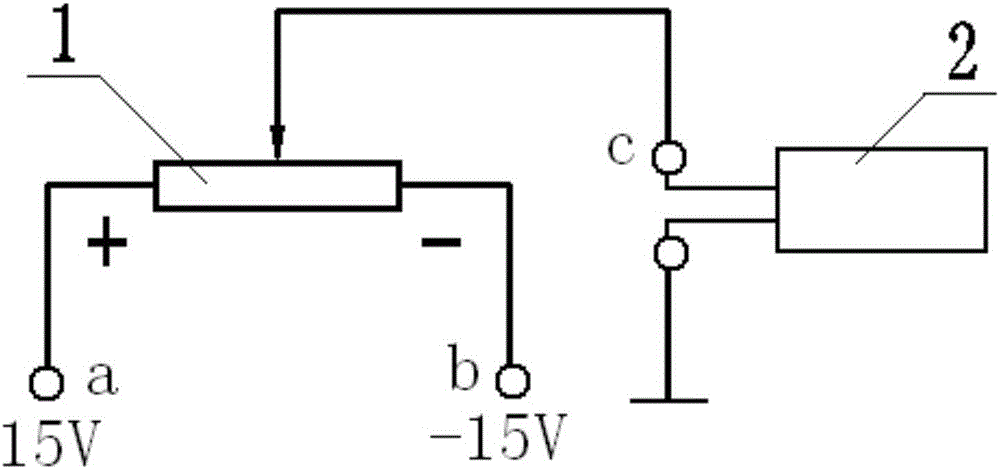

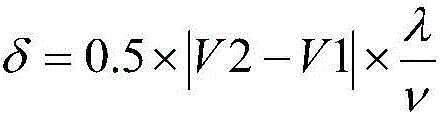

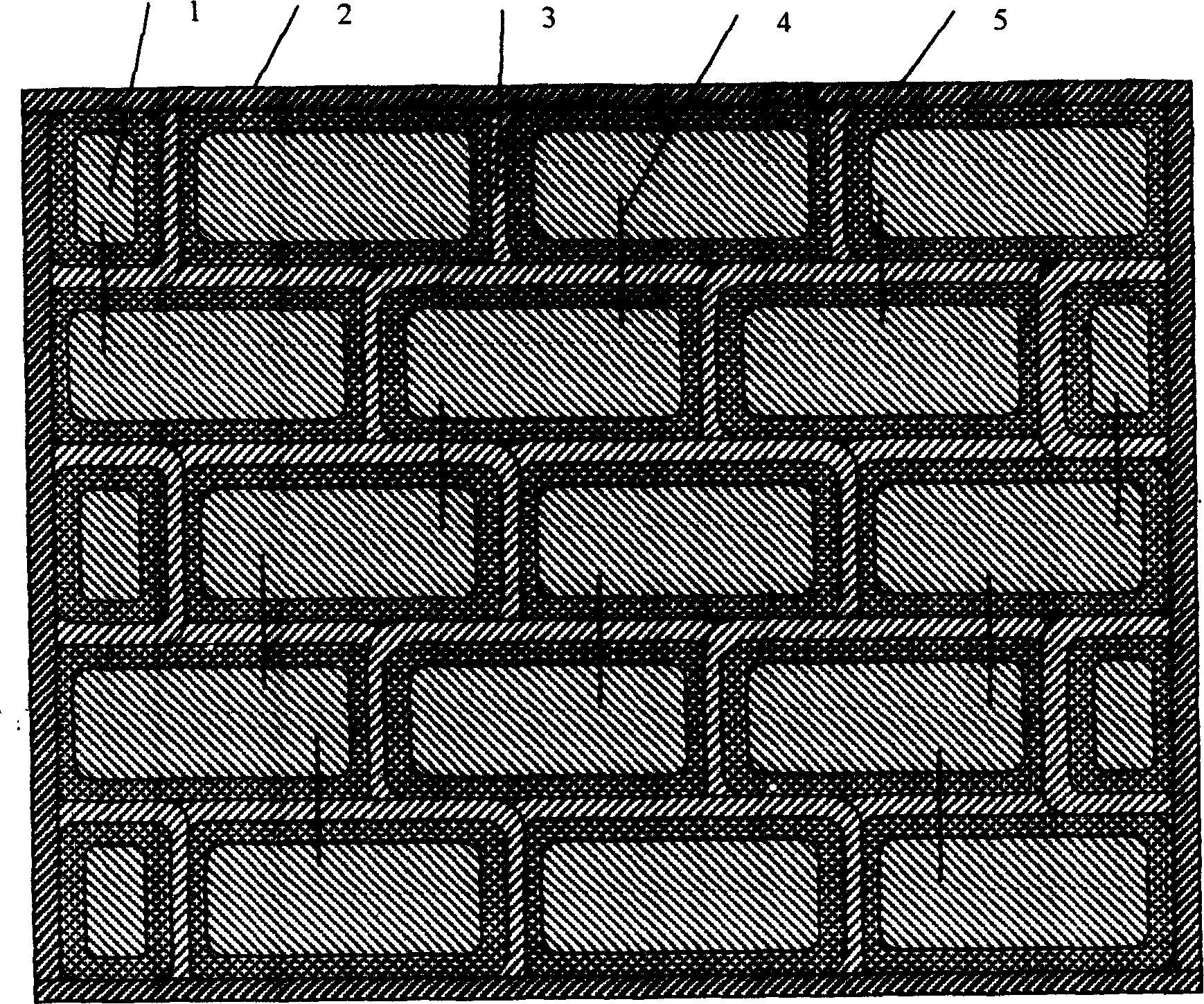

Mechanical transmission gap measuring method for angular displacement steering engine

InactiveCN106767373ASkip the manufacturing processMeet the test accuracy requirementsUsing electrical meansMaterial resourcesControl theory

The invention relates to the technical field of test, and relates to a mechanical transmission gap measuring method for an angular displacement steering engine. The mechanical transmission gap measuring method for the angular displacement steering engine comprises the steps that a measuring device is connected and mechanical transmission gap is measured. According to the mechanical transmission gap measuring method for the angular displacement steering engine, the manufacture of high precision test equipment is omitted, which saves manpower, financial resources, material resources and time; the measurement accuracy is improved; and the test precision requirement of a new developed angular displacement steering engine is met.

Owner:LANZHOU FLIGHT CONTROL

Manufacturing method of laying forming glass reinforced plastics construction

InactiveCN1544240ASkip the manufacturing processSimple preparation processGlass fiberFibre-reinforced plastic

The invention is a method of making glass fibre reinforced plastic structure by build-forming, mainly winding glass fiber material on the foam core material, coating glass fibre reinforced plastic resin with fillings on the combination surfaces of many foam core material with glass fibers, adopting locating nail, clamp, and master form, etc, to locate, building into component blanks, and polishing the dried blanks and then splicing many blanks into a whole blank, again coating the glass fibre reinforced plastic resin on the surface of the whole blank, and pasting on glass cloth, drying and then polishing so as to obtain the finished products. It has simple making technique, and convenient to construct; can largely reduce cost and shorten production cycle, and has high specific strength of the whole structure; can act as both mould and material; reduces making cost of glass fibre reinforced plastic products. It simplifies producing technique, can produce large-scale glass fibre reinforced plastic products, and can implement field design and construction, etc.

Owner:梅育华 +1

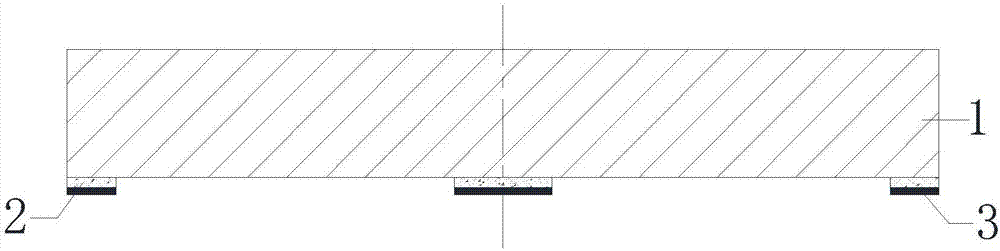

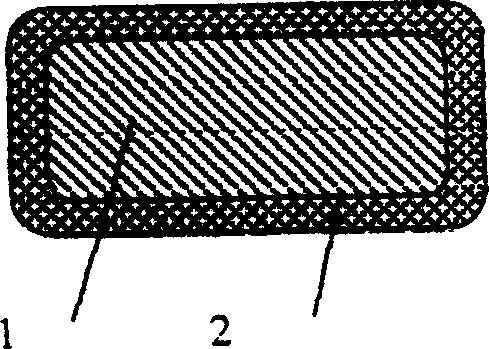

Core rod of insulator and manufacturing method thereof

InactiveCN101650995ASimple structureSkip the manufacturing processSupporting insulatorsEpoxyGlass fiber

The invention discloses a core rod of an insulator, comprising a hollow rod body and a plurality of partition blocks, wherein the hollow rod body is compounded by ethoxyline resins and glass fibres; the partition blocks are vertically embedded into the hollow rod body in the hollow rod body and can be all in a light disk shape, or the partition blocks close to both ends of the hollow rod body arein a light disk shape, and other partition blocks are in a light disk shape or a shape that both end surfaces of the light disk are provided with bevel teeth. A manufacturing method of the core rod comprises the following steps: (a) manufacturing the partition blocks, i.e. manufacturing the partition blocks according to the requirement of the core rod which needs to be manufactured; (b) manufacturing a base pipe, i.e. manufacturing the base pipe in a squeezing and pulling way; (c) cutting, i.e. cutting the base pipe on a position needing to install the partition blocks; (d) fixing, i.e. placing the partition blocks on the cutting position of the base pipe; (e) thickening, i.e. squeezing and pulling the core rod till the outer diameter of the core rod is equal to that of the code rod whichneeds to be manufactured. Because the plurality of partition blocks are embedded into the hollow rod body, the core rod of the insulator has the simple structures of the partition blocks and also saves materials consumed by a connection structure; and in addition, the technology is simple in a manufacturing method aspect.

Owner:浙江科成电气有限公司

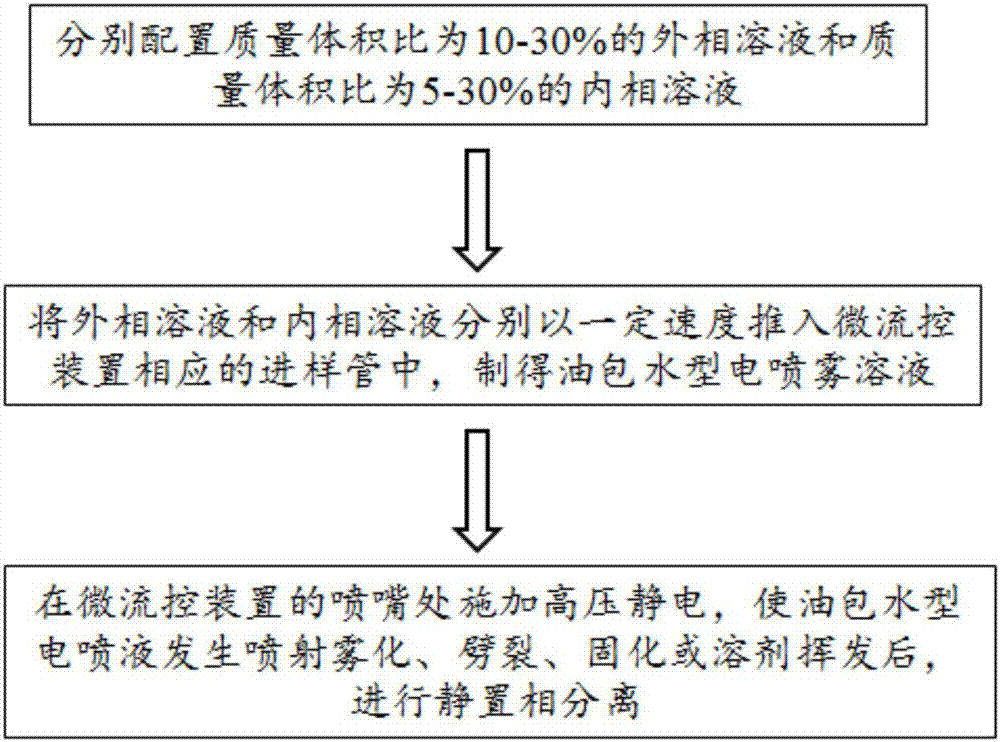

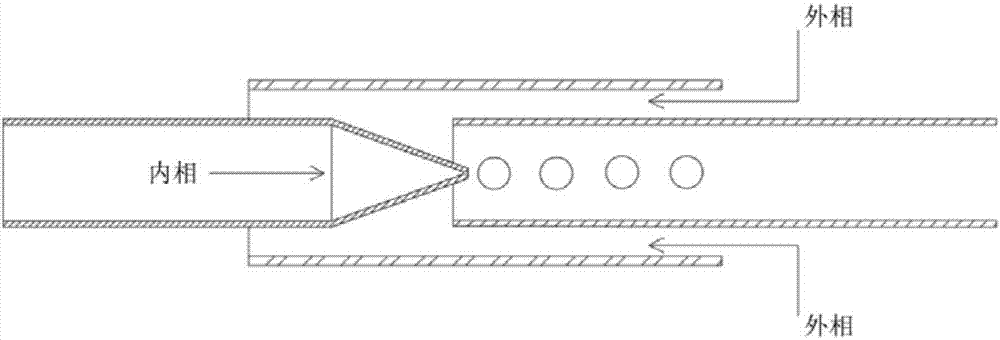

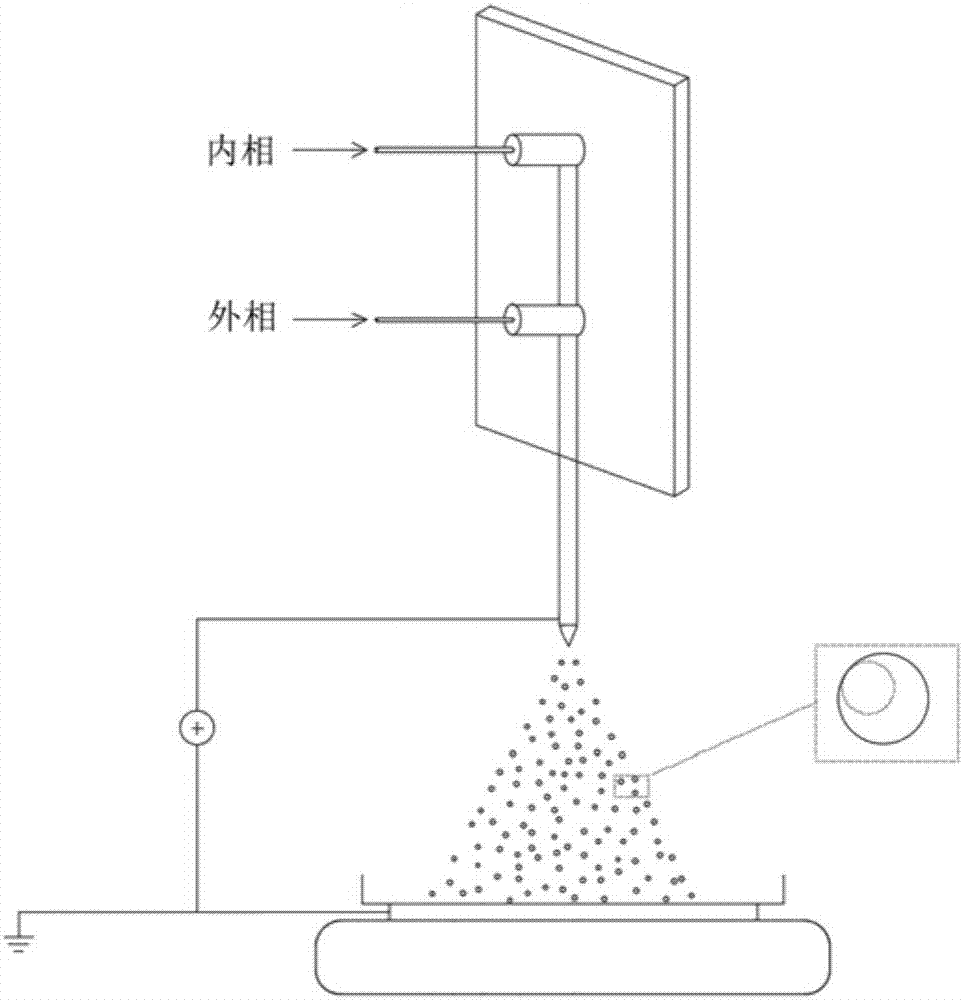

Eccentric structure polymer microsphere and preparation method thereof

The invention discloses an eccentric structure polymer microsphere and a preparation method thereof and mainly relates to the field of high polymer material processing. The method comprises the following steps that by organically combining a micro-fluidic control technology and an electrostatic spraying technology and by matching with proper internal-phase solution and external-phase solution, themonodisperse eccentric structure polymer microsphere with controllable size and morphology; and by regulating relevant parameters, relative regulation and control of shell thickness, eccentric area,eccentric degree and size of the microsphere are realized. Therefore, due to a unique structure and a controllable preparation method, the eccentric structure polymer microsphere has good biocompatibility, controlled drug release ability and ability of loading hydrophilic and hydrophobic materials and thus has important popularization and application values.

Owner:SOUTHWEST JIAOTONG UNIV

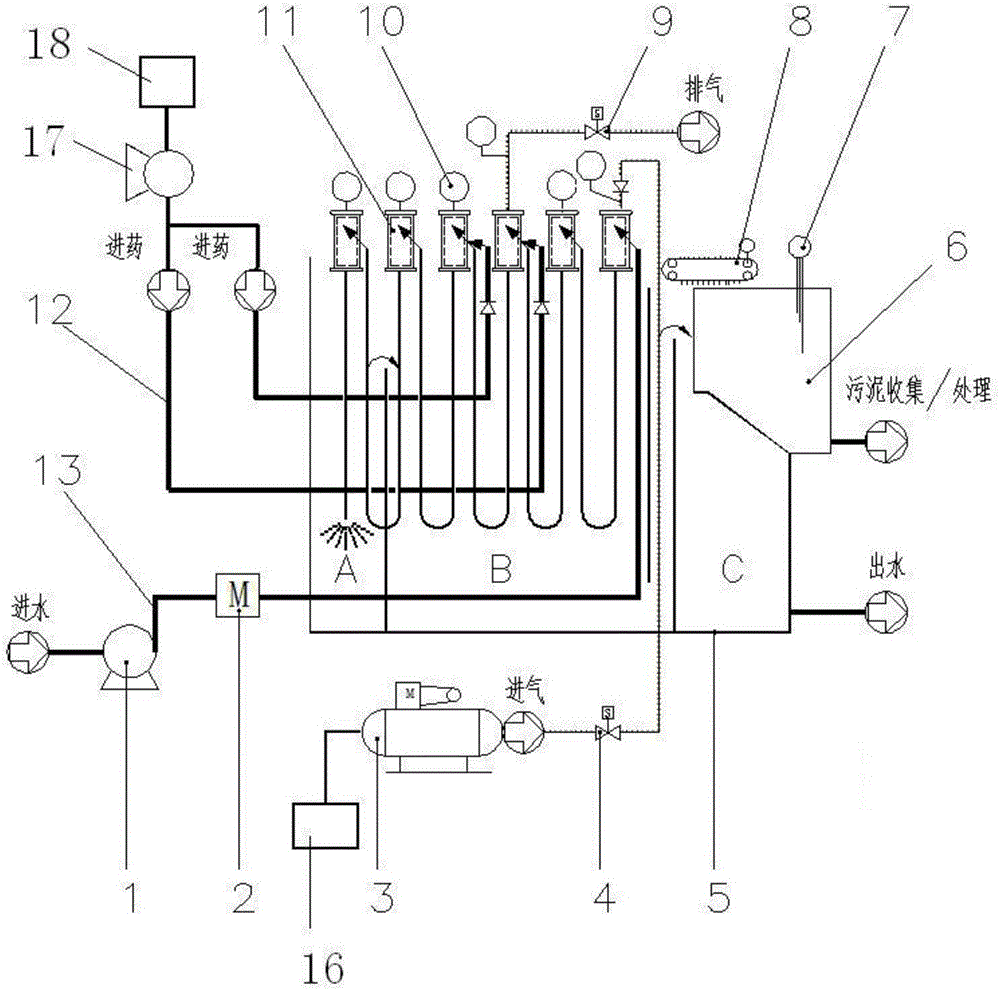

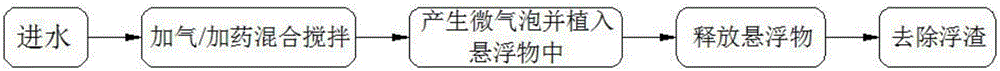

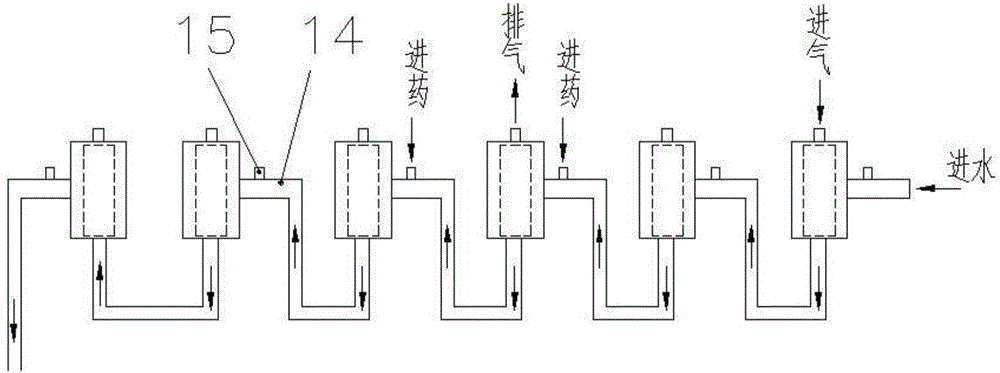

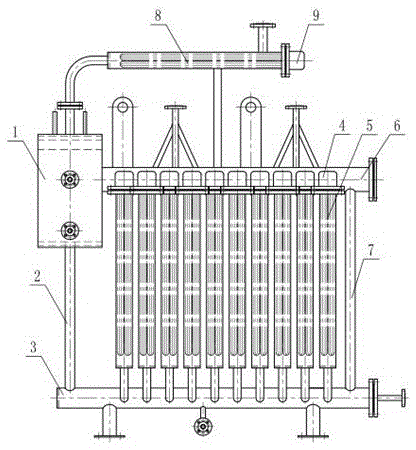

Ozone microbubble air floating concentration device and sludge conditioning and concentration method

InactiveCN105859076ARealization of quenching and temperingImprove dehydration effectSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSlagEnrichment methods

The invention discloses an ozone micro-bubble air flotation concentration device and a sludge conditioning and concentration method. The device includes a reaction tank, an ozone generator, a slag remover, and a slag collection tank, and 4 to 6 sets of series-connected vortex three-phase mixers are arranged side by side above the reaction tank. The sludge is sent into the multi-stage vortex three-phase mixer through the pressurized water pump to form a vortex; the ozone is sent into the first-stage vortex three-phase mixer through the gas booster pump or air compressor; the PAM agent is pumped through the agent dosing into the second-stage or third-stage vortex three-phase mixer; in the multi-stage vortex three-phase mixer, the agent is mixed with pollutant particles, water, and gas in three-phase contact, and the vortex generates microbubbles to form flocs; in the flocs Entrained air bubbles float to the surface of the liquid to form scum. The present invention realizes the sludge conditioning through the multi-stage vortex three-phase mixer and the enhanced oxidation of ozone, and at the same time can obtain air-floated scum with a moisture content of 90-95%, which is beneficial to the subsequent ultra-high pressure elastic press or plate-and-frame dehydrator dehydration.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

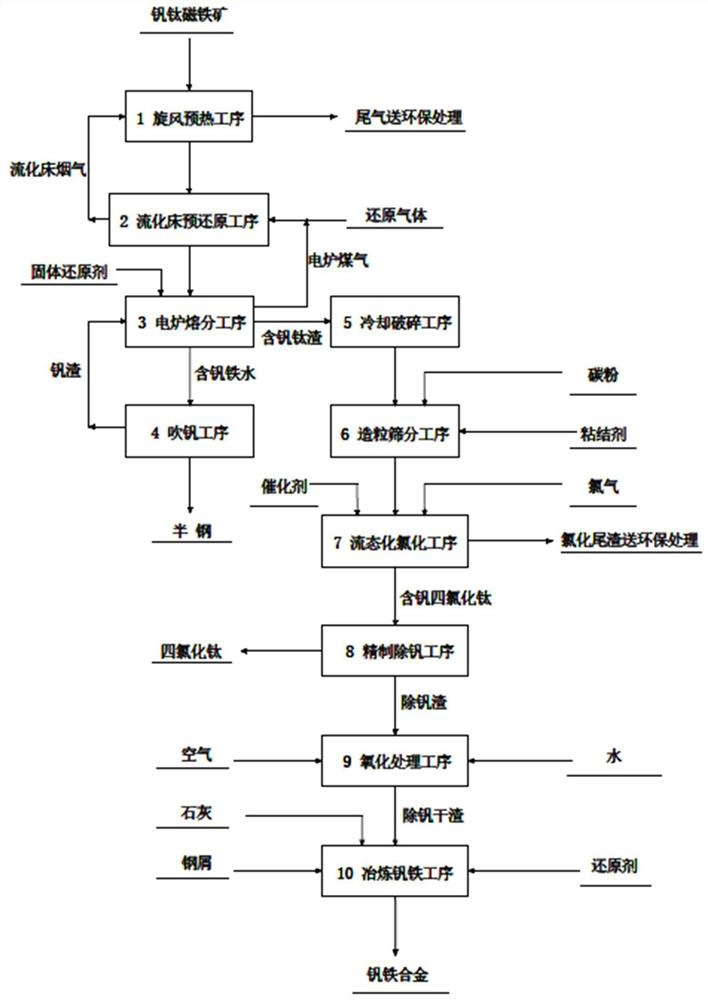

Method for comprehensively utilizing vanadium and titanium resources of vanadium titano-magnetite

ActiveCN112708783AEfficient use ofImprove utilization efficiencyProcess efficiency improvementElectric furnaceTitanium tetrachlorideFerrovanadium alloy

The invention belongs to the field of chemical engineering and metallurgy, and particularly discloses a method for comprehensively utilizing vanadium and titanium resources of vanadium titano-magnetite. Vanadium slag obtained in the vanadium blowing procedure is returned to the electric furnace melting separation procedure, vanadium is opened from titanium slag, the vanadium extraction path is changed, vanadium-titanium co-extraction is achieved, and the vanadium extraction tailing treatment problem is thoroughly solved. The crushing particle size of the vanadium-containing titanium slag is controlled, fine-particle carbon powder and a binder are added for granulation, ore / carbon contact is enhanced, catalytic chlorination is coupled, and therefore the chlorination reaction temperature is reduced, and the utilization problem of high-calcium magnesium and titanium resources is solved. A vanadium-iron alloy is directly smelted by adding a reducing agent and steel scraps into titanium tetrachloride vanadium removing dry slag, and therefore preparation of a vanadium pentoxide intermediate product is omitted, the process is greatly shortened, and the production cost is reduced. The method can realize comprehensive utilization of the vanadium and titanium resources in the vanadium titano-magnetite to respectively obtain titanium tetrachloride and ferrovanadium alloy products, and has the advantages of being high in resource utilization rate, capable of achieving energy conservation and consumption reduction, friendly to environment, high in product added value and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

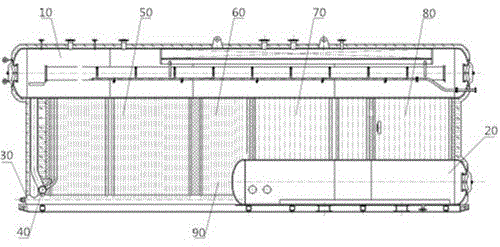

Electric-heating superheated steam boiler

InactiveCN105588099ALow costMeet needsSteam generation heating methodsSteam superheatersElectricityEngineering

The invention discloses an electric-heating superheated steam boiler. The electric-heating superheated steam boiler comprises a lower header, a saturated steam electric heater header, an upper header, a separation header and a superheated steam electric heater header. The upper header and the lower header are connected through a communication pipe I and a communication pipe II, to form an integrated structure. The saturated steam electric heater header is arranged between the upper header and the lower header. The separation header is connected with the upper header. The superheated steam electric heater header is arranged above the upper header and connected with the separation header through an elbow pipe. Saturated steam electric heaters of various specifications are arranged in the saturated steam electric heater header. A superheated steam electric heater is arranged in the superheated steam electric heater header. According to the electric-heating superheated steam boiler, the amount of generated saturated steam is stable, the temperature of superheated steam is stable, the investment cost is low, pollution is small, and the noise is low.

Owner:TAIJUNE BOILER IND KUSN

Electro-chemical machining technology of inner hole wall turbulence structure of metal parts

InactiveCN101491851BSkip the manufacturing processShielding electric fieldElectrochemical machining apparatusElectrolysisEngineering

The invention discloses an electrochemical machining process for an inner hole wall surface turbulent flow structure of a meal part. The machining process comprises: firstly, processing a smooth circular hole with an aperture of more than or equal to 2 millimeters on a position to be processed of the metal part, using a glue spreading spray head to coat a layer of insulating glue on the hole wallof the circular hole according to a set shape, and arranging a metal wire on a central axial line of the circular hole after the insulating glue of the hole wall is cured; and obtaining the turbulentflow structure by processing on the hole wall through electrolysis or electroforming, and finally using an insulating glue detergent to remove the prior cured insulating glue. The electrochemical machining process adopts special equipment and directly coats the insulating glue on the inner hole wall surface of the part as required, can effectively shield the influence of an electric field during electrochemical machining, save preparation of tool electrodes during electrochemical machining, and reduce the production period and the production cost; and simultaneously the electrochemical machining process can coat graphs with complex structures by controlling the motion track of the glue spreading head so as to be capable of processing different turbulent flow structures.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com