Semiconductor device of sensing type and its manufacture

A semiconductor and manufacturing technology, applied in the field of sensing semiconductor devices, can solve problems such as increased manufacturing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

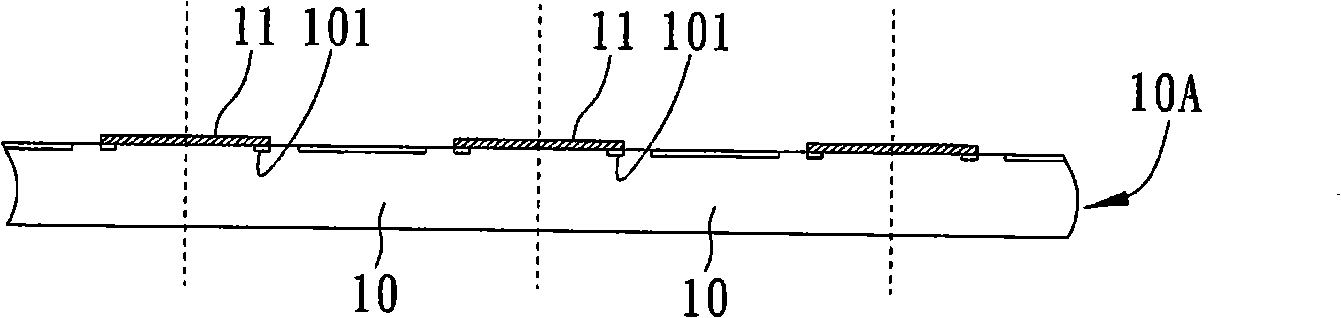

[0051] see Figure 2A to Figure 2K , is a schematic diagram of a first embodiment of the sensing semiconductor device and its manufacturing method of the present invention.

[0052] Such as Figure 2A and Figure 2B As shown, a transparent carrier 20 such as glass is provided, so as to form titanium tungsten / copper (TiW / Cu) or titanium / vanadium nickel on the transparent carrier 20 by sputtering (sputtering). (Ti / NiV) or the like thin conductive layer 21; then cover the resistance layer 22 on the thin conductive layer 21, and make the resistance layer 22 formed with an opening 220 to expose the part of the thin conductive layer 21; A metal line 23 is formed on the thin conductive layer 21 in the resistance layer opening 220, and the metal line 23 can be copper (Cu) / nickel (Ni) or copper (Cu) / tin (Sn) or copper (Cu) / nickel ( Ni) / Solder (Solder), the thickness is about 3-10μm.

[0053] Then the resistance layer 22 and the thin conductive layer 21 covered by the resistance lay...

no. 2 example

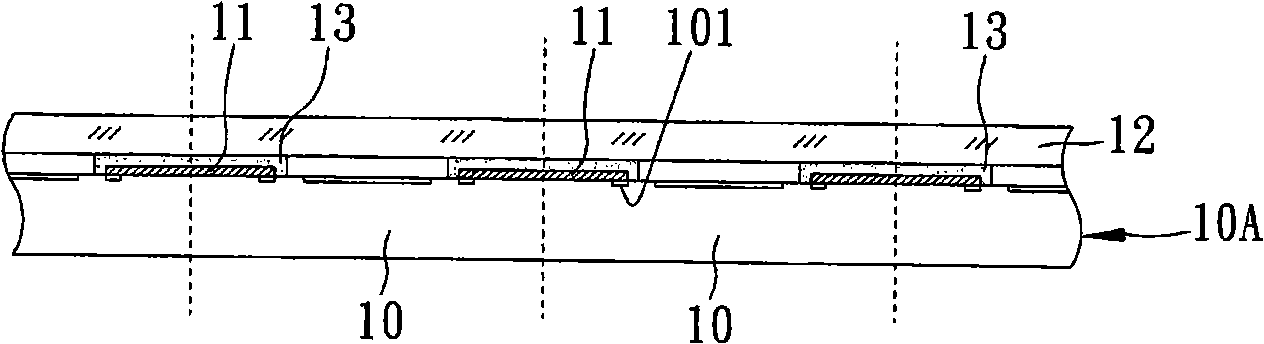

[0068] see Figure 3A to Figure 3D , is a schematic diagram of a second embodiment of the sensing semiconductor device and its manufacturing method of the present invention. In addition, to simplify description and drawings, the same or similar components corresponding to the above-mentioned embodiments are denoted by the same numbers.

[0069] This embodiment is substantially the same as the previous embodiment, the main difference is that a dielectric layer covering the sensing chip and metal lines and filling between the sensing chips is directly formed on the transparent carrier board, and the second dielectric layer is omitted. Manufacturing process.

[0070] Such as Figure 3A As shown, a light-transmitting carrier 20 with a plurality of metal lines 23 formed on the surface is provided, so that a thinned and good sensing chip 25 is connected to and electrically connected to the light-transmitting carrier 20 through its conductive bumps 255. on the metal line 23.

[007...

no. 3 example

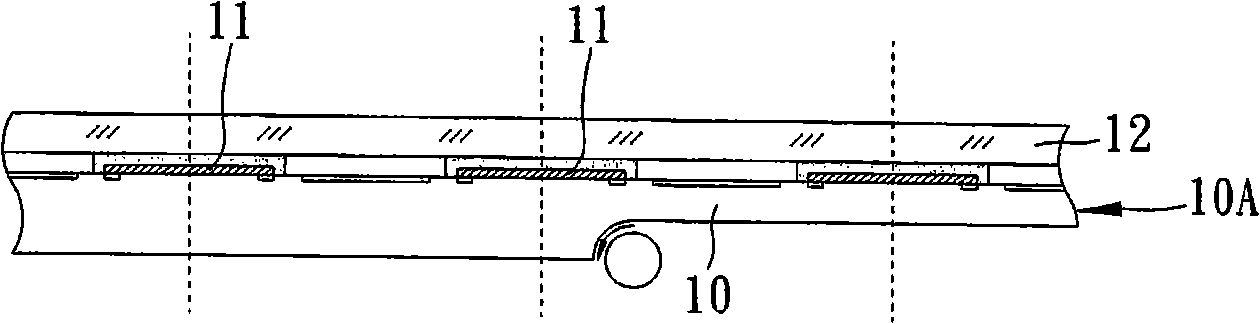

[0077] see Figure 4 , is a schematic diagram of a third embodiment of the sensing semiconductor device and its manufacturing method of the present invention. In addition, to simplify description and drawings, the same or similar components corresponding to the above-mentioned embodiments are denoted by the same numbers.

[0078] The sensing semiconductor device and its manufacturing method of this embodiment are substantially the same as those of the previous embodiments, the main difference is that a dam structure (dam) 201 is pre-set around the sensing area of the corresponding sensing chip on the light-transmitting carrier 20, For the sensing chip 25 to be connected to the metal circuit 23 through the conductive bump 255, and when the first dielectric layer 24 is filled between adjacent sensing chips 25, the first dielectric layer can be effectively controlled to avoid the 24 covers the sensing area 253 of the sensing chip 25 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com