Four-core cable and its manufacturing method

A four-core cable, the fourth technology, used in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problems of slow insulation core speed and restricting production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

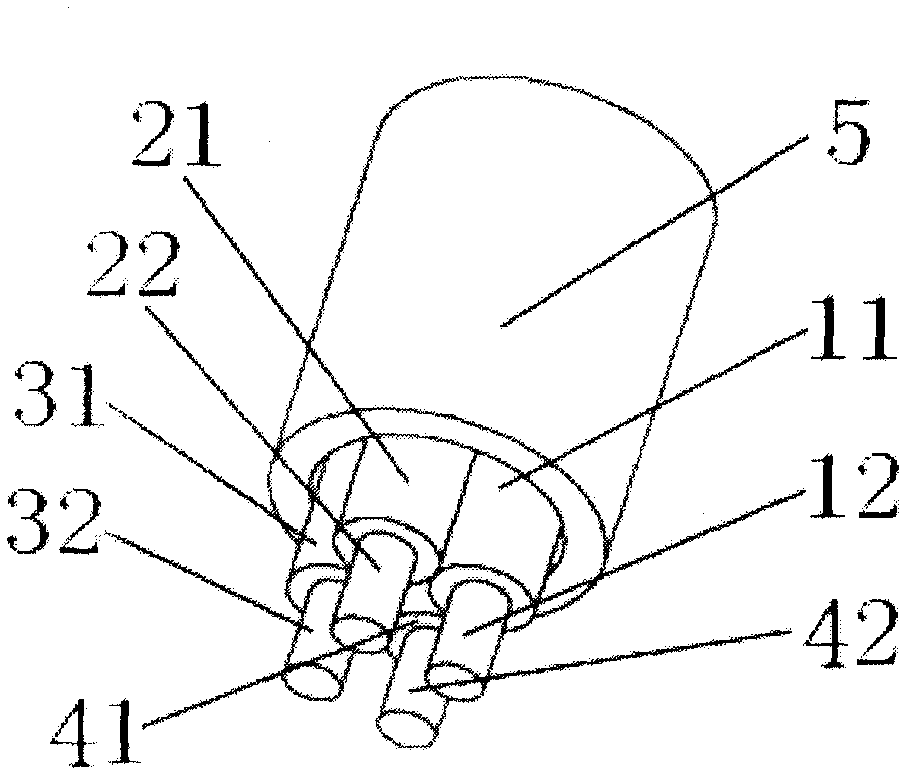

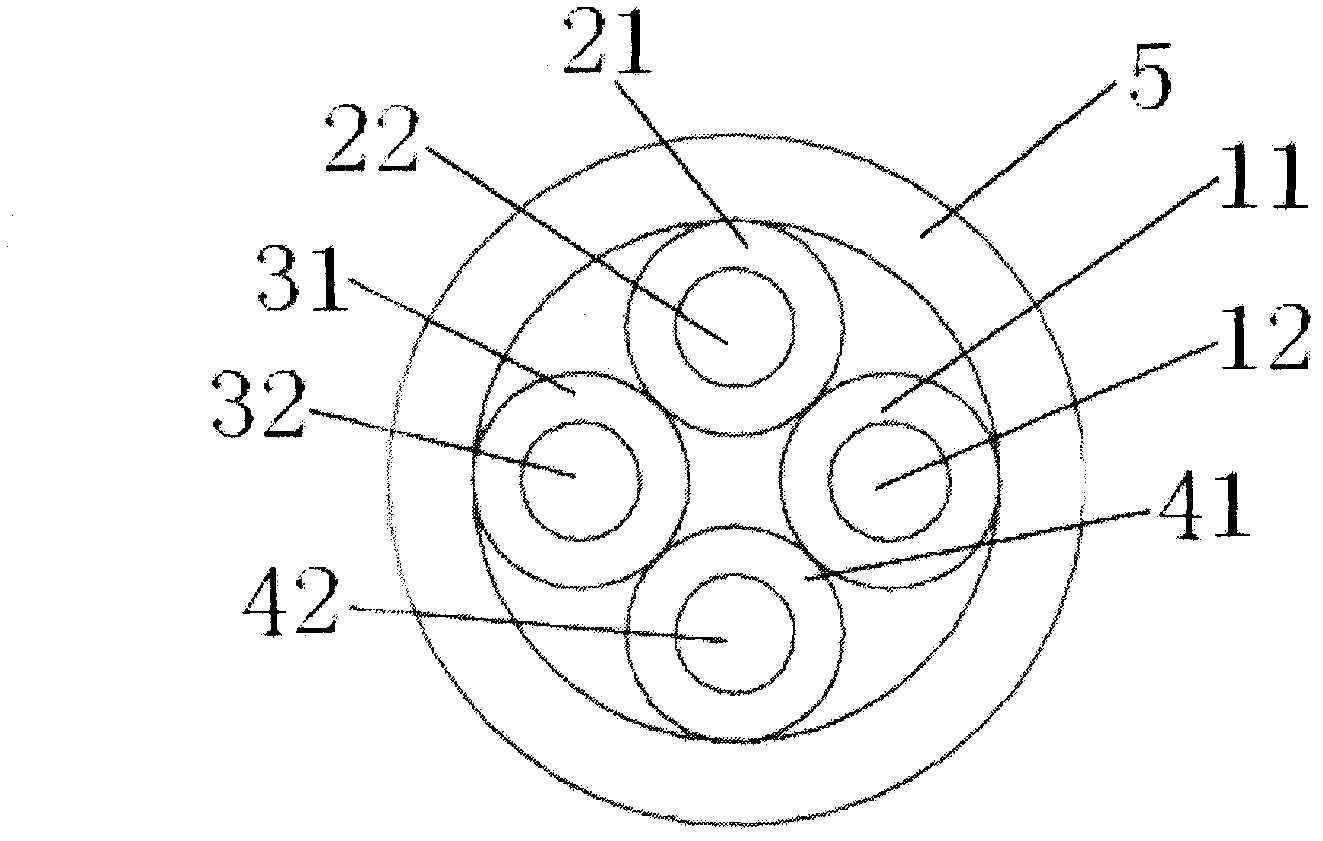

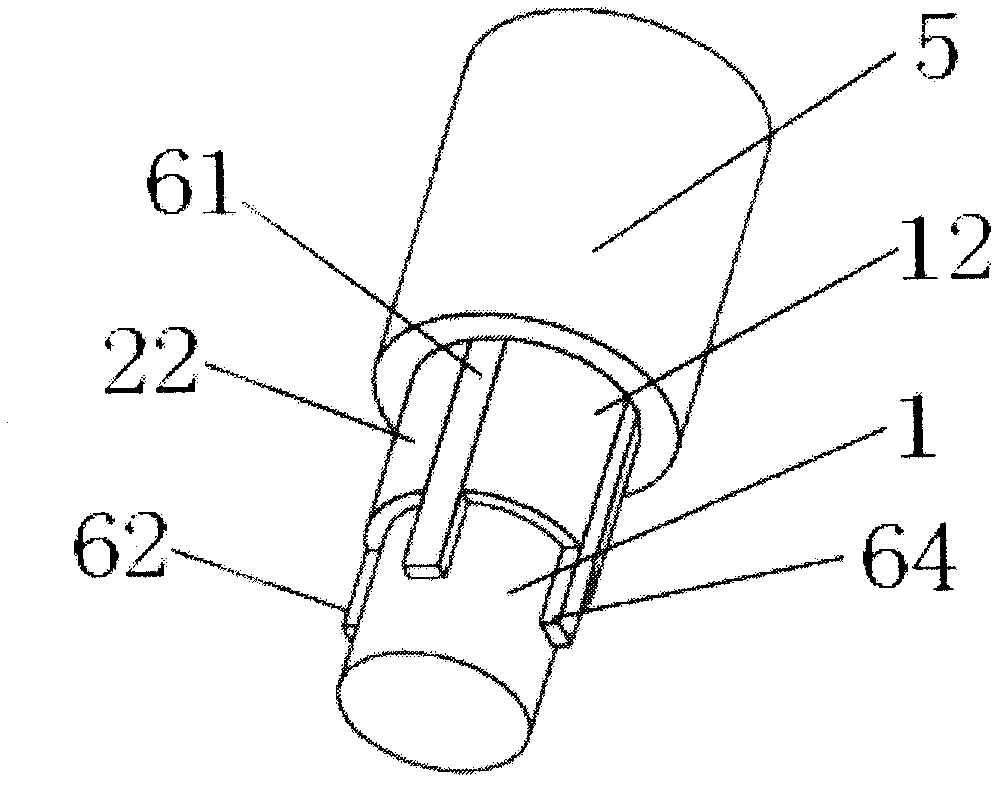

[0052] please see Figure 3 to Figure 6 , and combined with figure 1 and figure 2 , a four-core cable, including a first conductor 12, a second conductor 22, a third conductor 32, a fourth conductor 42, and a sheath layer 5; it is characterized in that it also includes a centrally located and cylindrical filler 1. A first spacer 61, a second spacer 62, a third spacer 63, and a fourth spacer 64; the four conductors and the four spacers are all close to the filling body and along the filling The outer circumference of the body is distributed; the upper surface 611 and the lower surface 612 of the first spacer 61 are arc-shaped; the first spacer is located between the first conductor and the second conductor and is adjacent to the first conductor and the second conductor ; The second spacer is located between the second conductor and the third conductor and is adjacent to the second conductor and the third conductor; the third spacer is located between the third conductor and ...

Embodiment 2

[0057] please see Figure 7 , and combined with Figure 1 to Figure 6 , a four-core cable, including a first conductor 12, a second conductor 22, a third conductor 32, a fourth conductor 42, and a sheath layer 5; it is characterized in that it also includes a centrally located and cylindrical filler 1. A first spacer 61, a second spacer 62, a third spacer 63, and a fourth spacer 64; the four conductors and the four spacers are all close to the filling body and along the filling Circumferential distribution on the outside of the body; the first spacer is located between the first conductor and the second conductor and is adjacent to the first conductor and the second conductor; the second spacer is located between the second conductor and the third conductor and is adjacent to the second conductor The second conductor and the third conductor are adjacent; the third spacer is located between the third conductor and the fourth conductor and is adjacent to the third conductor and...

Embodiment 3

[0076] A method of making a four-core cable, characterized in that it comprises the steps of:

[0077] Steps for forming four conductors: firstly twist and shape a plurality of metal wire bundles to form a first conductor, secondly twist and shape a plurality of metal wire bundles to form a second conductor, and twist and shape a plurality of metal wire bundles again Form the third conductor, and then form a fourth conductor by twisting a plurality of metal wire bundles; or form a conductor by twisting a plurality of metal wire bundles, and then cut and divide the conductor to form the first to second conductors. Four conductors; the first to fourth conductors are all coiled on the corresponding plates;

[0078] The step of forming the filling body through an extruder, extruding the filling body and winding it on a tray;

[0079] The step of forming four spacers: forming four spacers through an extruder, and installing them on different trays respectively to form the first to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com