Eccentric structure polymer microsphere and preparation method thereof

An eccentric structure and polymer technology, which is applied in the field of eccentric structure polymer microspheres and their preparation, can solve problems such as poor operability and controllability, complicated preparation process, and influence on the final microsphere structure and performance, so as to achieve Effects of improved operability and controllability, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

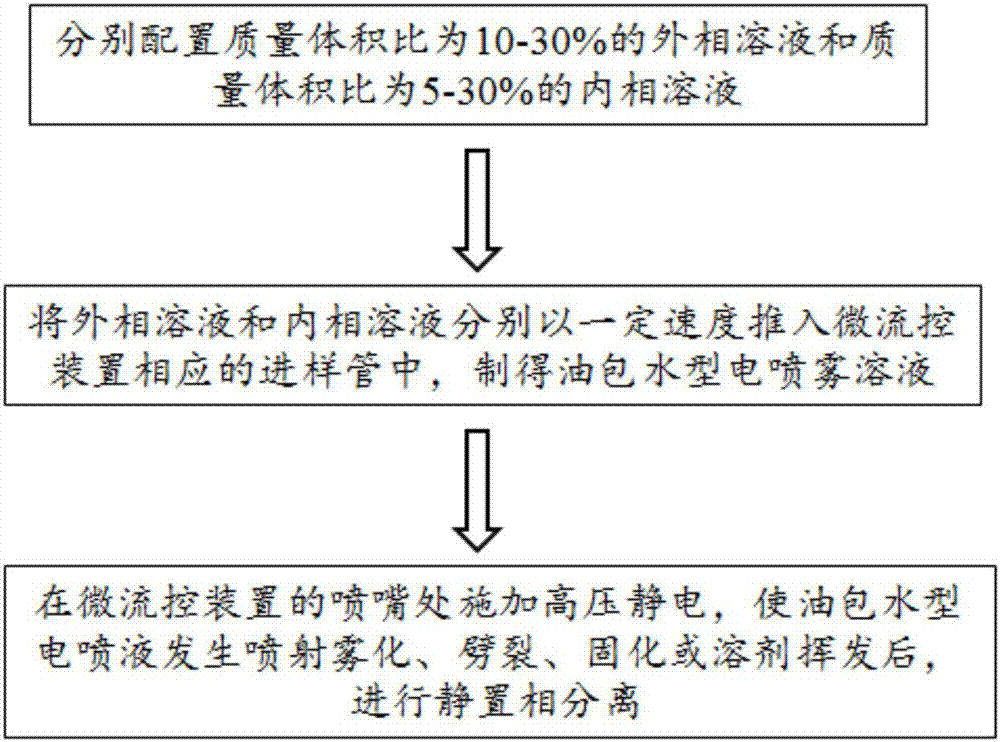

[0033] This embodiment provides a method for preparing polymer microspheres with an eccentric structure, and the preparation process is as follows:

[0034] First, 2 mL of glycerin was dissolved in 0.5 mL of deionized water, and magnetically stirred for 12 h to make it uniformly mixed to obtain an internal phase solution. Dissolve 2 g of polylactic acid-glycolic acid copolymer in 10 mL of dimethyl carbonate, and stir for 12 h to make it uniformly mixed to obtain an external phase solution.

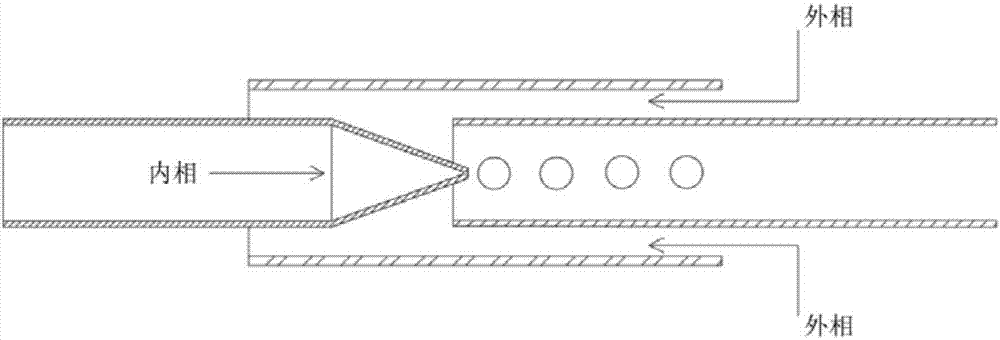

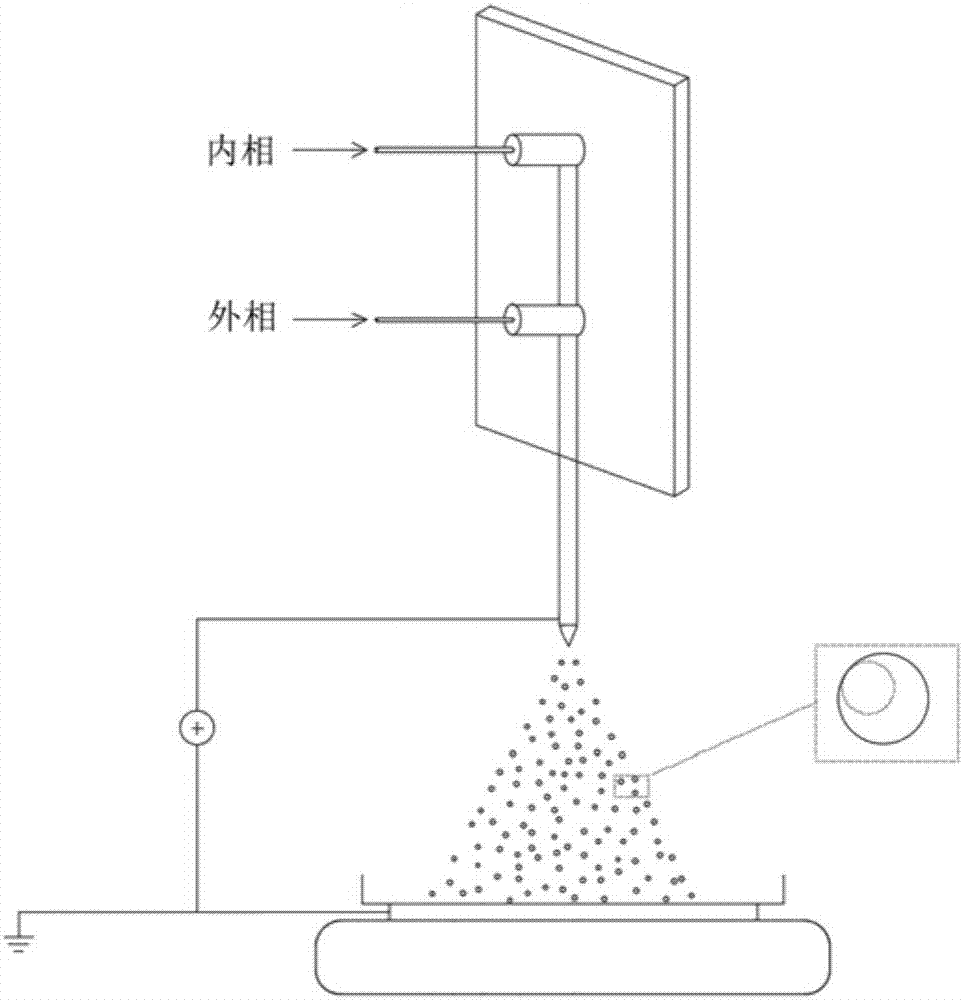

[0035] Then, the internal phase and the external phase are respectively pushed into the corresponding injection ports of the microfluidic device through the Teflon tube at the pushing speed of 0.2mL / h and 0.6mL / h, and the oil-packed phase is formed under the action of shear force. Water type EFI. Emulsion droplets with uniform size and equal spacing can be observed at the outlet tube of the microfluidic device. Among them, the size and spacing of milk droplets can be regulated by adjusti...

Embodiment 2

[0039] This example provides a method for preparing polymer microspheres with an eccentric structure, which is roughly the same as the method for preparing polymer microspheres with an eccentric structure provided in Example 1, except that 1 g of polylactic acid-glycolic acid is used in this example The copolymer was dissolved in 10 mL of dimethyl carbonate, and magnetically stirred for 12 hours for uniform mixing to obtain an external phase solution.

[0040] Further, different from Example 1, the pushing speeds of the internal phase solution and the external phase solution of this embodiment are 0.2mL / h and 0.8mL / h respectively. It should be noted that the rest of the parameters and the preparation process of this embodiment are the same as those of Embodiment 1.

[0041] This embodiment also provides a polymer microsphere with an eccentric structure, which is prepared by the method for preparing the polymer microsphere with an eccentric structure provided in this embodiment...

Embodiment 3

[0043] This example provides a method for preparing polymer microspheres with an eccentric structure, which is roughly the same as the method for preparing polymer microspheres with an eccentric structure provided in Example 1, except that this example uses 2 g of polylactic acid-polyethylene The diol copolymer was dissolved in 10 mL of dimethyl carbonate, and magnetically stirred for 12 hours for uniform mixing to obtain an external phase solution. It should be noted that the rest of the parameters and the preparation process of this embodiment are the same as those of Embodiment 1.

[0044] This embodiment also provides a polymer microsphere with an eccentric structure, which is prepared by the method for preparing the polymer microsphere with an eccentric structure provided in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com