Patents

Literature

205results about How to "Omit to use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

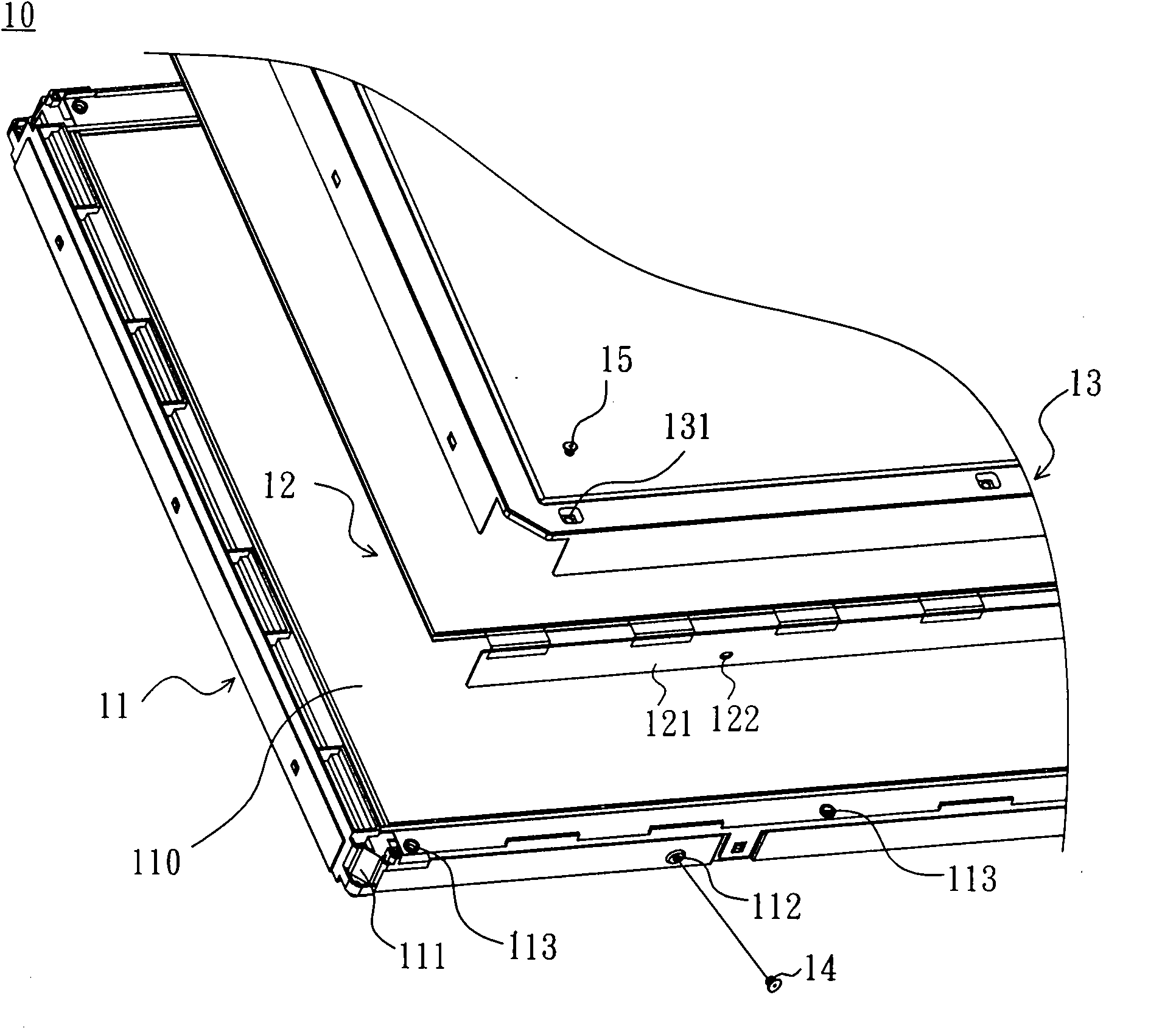

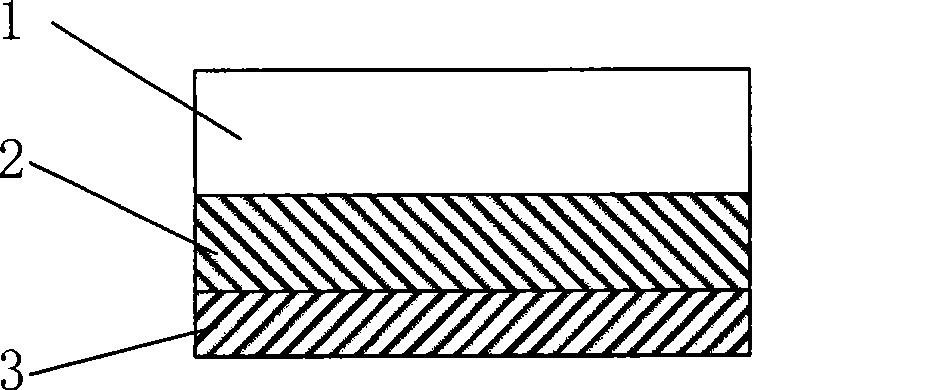

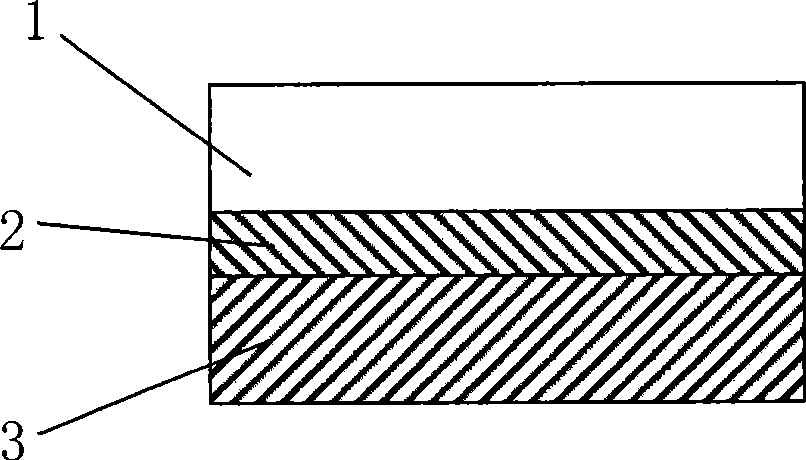

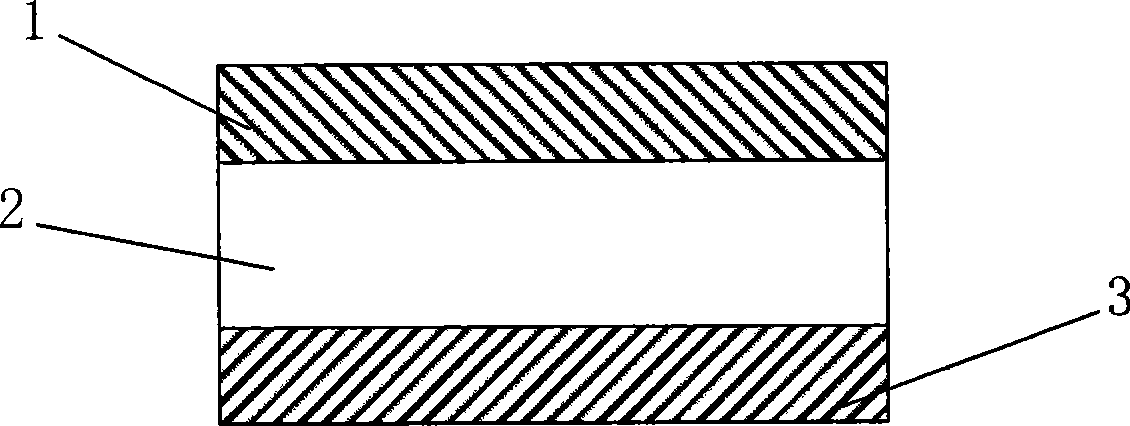

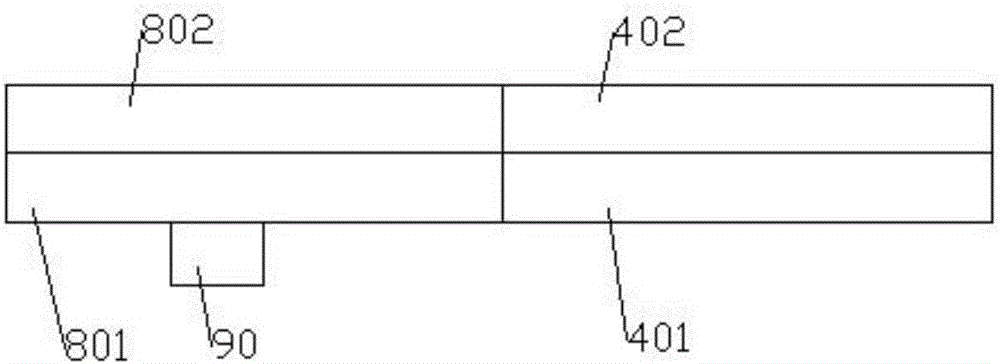

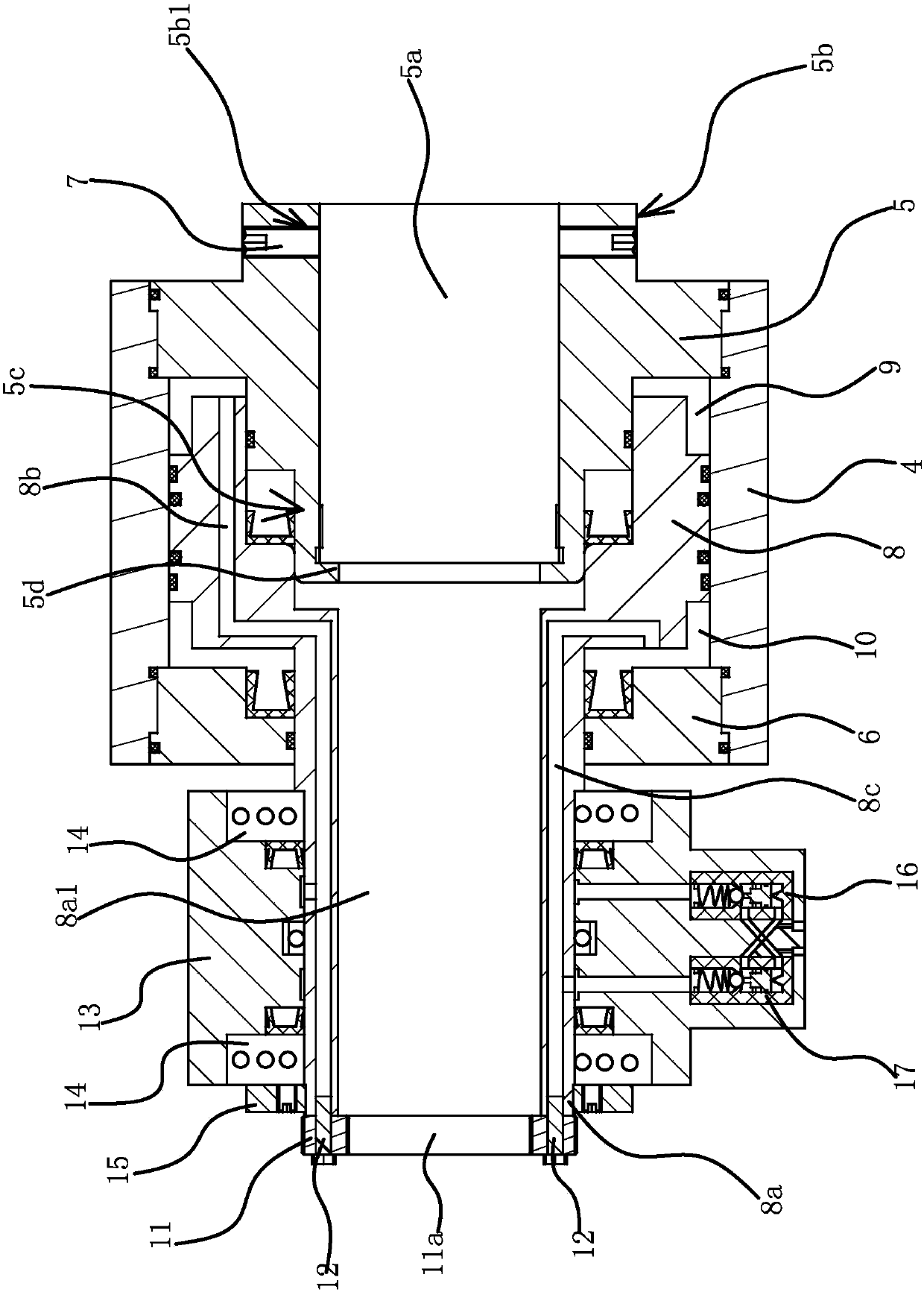

Liquid crystal display module and integrally-molded back plate thereof

The invention discloses a liquid crystal display module and an integrally-molded back plate thereof. The integrally-molded back plate of the liquid crystal display module comprises a plurality of first step parts, a plurality of second step parts and a plurality of fastening parts which are formed by extending and bending the bottom of the integrally-molded back plate in sequence, wherein an optical diaphragm group is supported and fixed by the first step parts; and a liquid crystal panel is supported and fixed by the second step parts. In the invention, by the design of the integrally-moldedback plate of the liquid crystal display module, a rubber frame and a front frame can be omitted, while the liquid crystal display panel is directly arranged on the integrally-molded back plate, so that the assembling mode is simple and fast relatively, the development cost can be reduced, the development period is shortened and the production cost is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

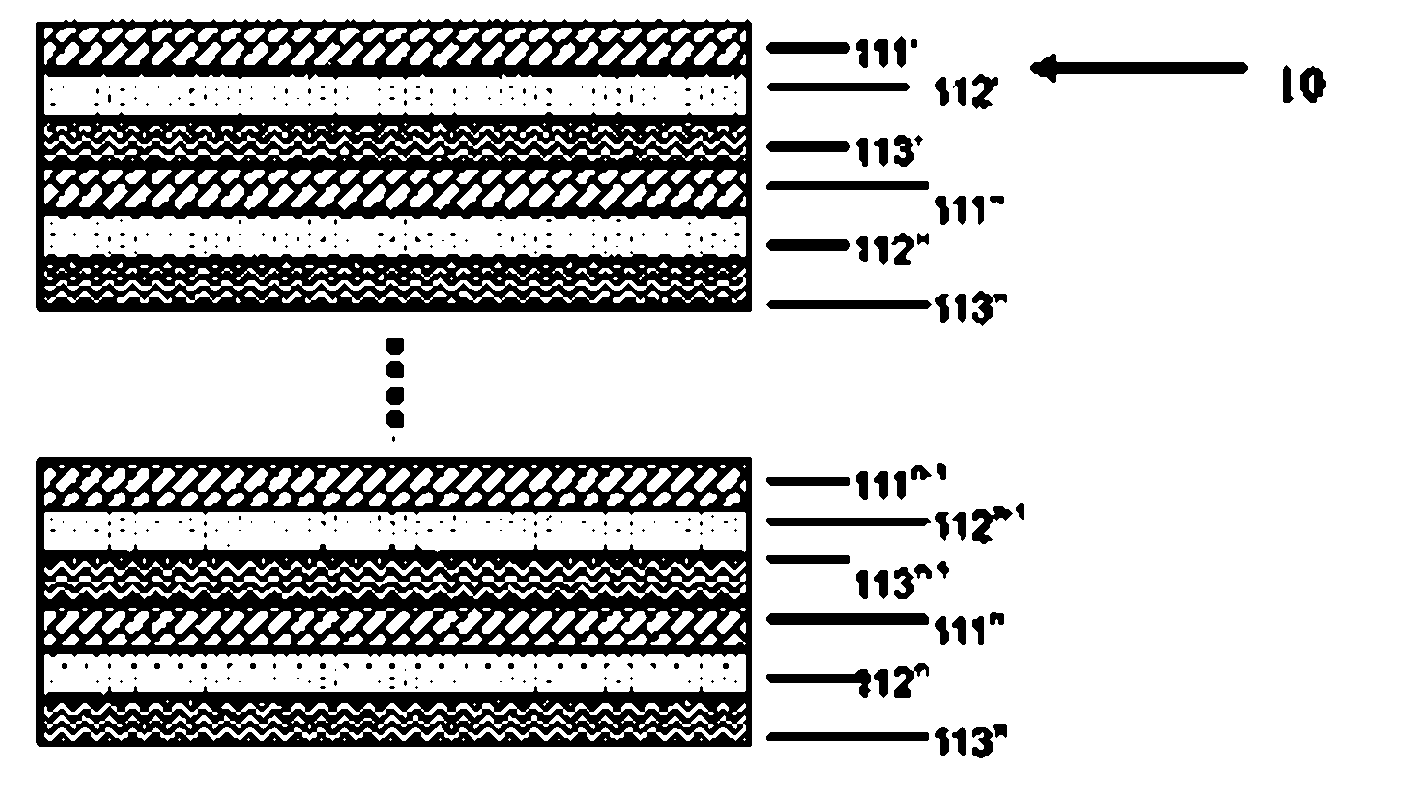

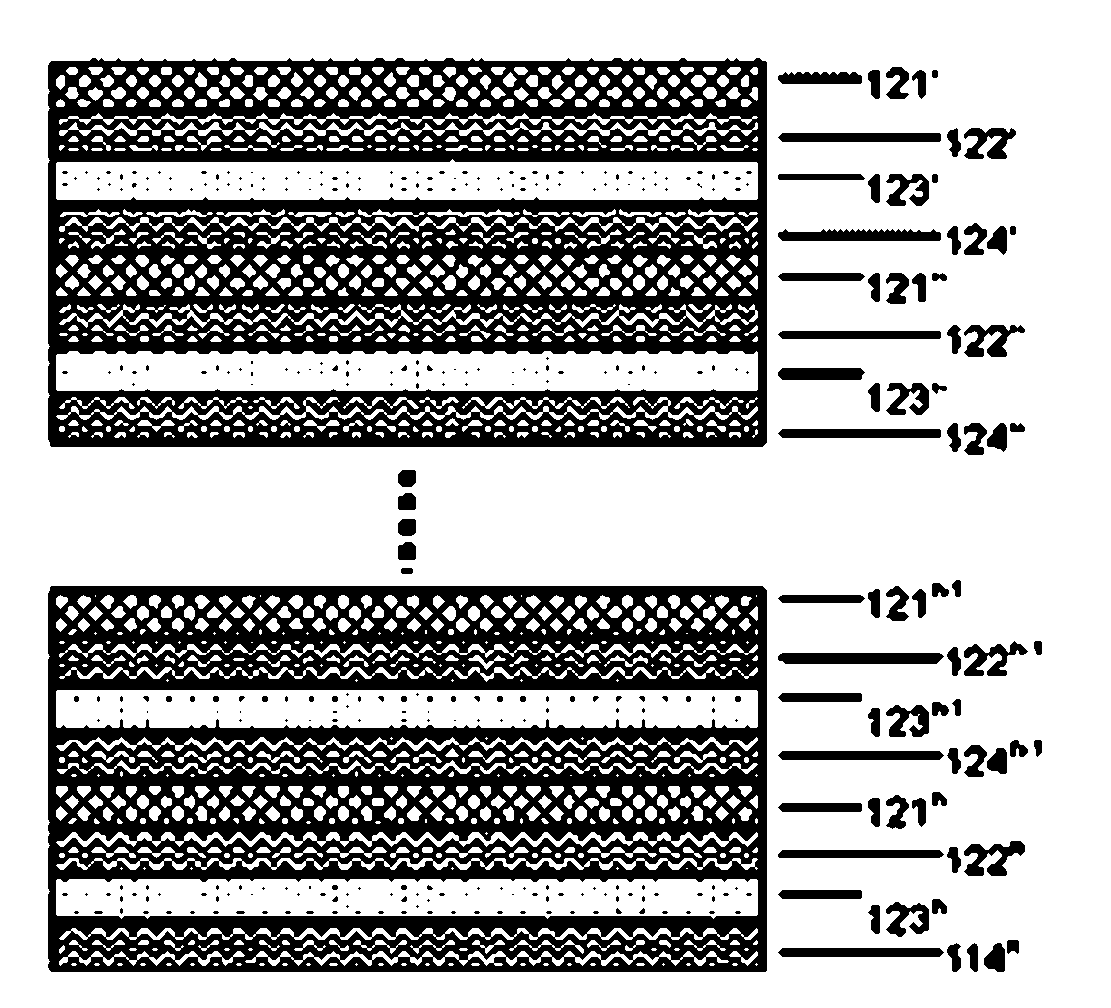

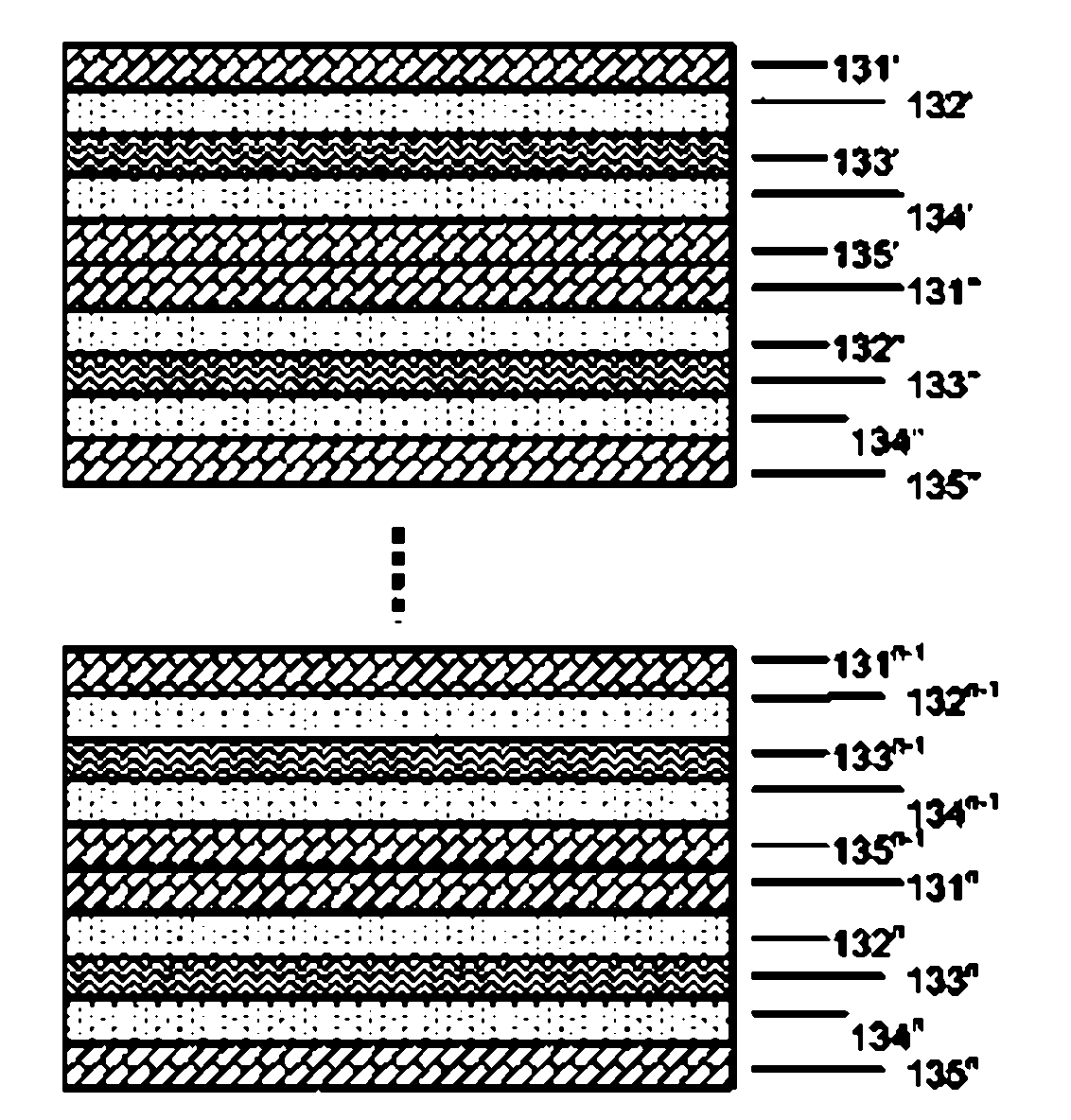

Barrier-property lapped polymer film packaging material

ActiveCN102001486AReduce dosageOne less contains at least dosageFlexible coversWrappersPolymer thin filmsEngineering

The invention discloses a barrier-property lapped polymer film packaging material comprising at least one layer-multiplied and coextruded lapped barrier compound layer. Each barrier compound layer comprises a plurality of repeating units which comprise at least two individual layers; each individual layer corresponds to one of two different polymers; at least one repeating unit of the lapped barrier compound layer at least comprises three individual layers; each of the individual layers corresponds to one of three different polymers; and at least one of the at least three polymers forms at least one barrier-property polymer part which can separate gas.

Owner:厦门天策材料科技有限公司

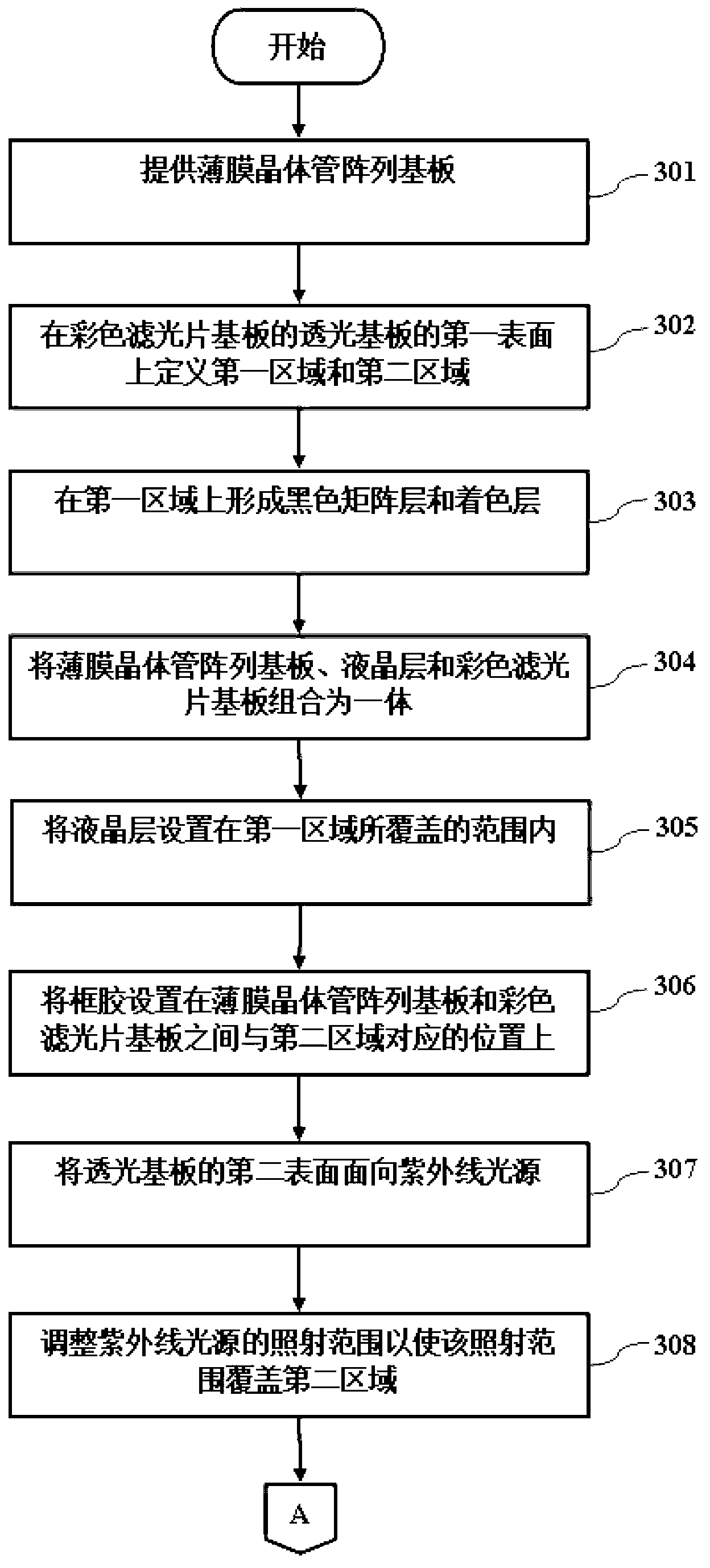

Liquid crystal display panel and manufacturing method thereof

InactiveCN102799018AAvoid exposureEffective protectionNon-linear opticsUltraviolet lightsLight filter

The invention discloses a liquid crystal display panel, which comprises a thin-film transistor array substrate, a color filter substrate, a liquid crystal layer and a frame, wherein the color filter substrate comprises a light transmission substrate, a black matrix layer and a colored layer, the light transmission substrate is provided with a first area and a second area, and the black matrix layer and the colored layer are arranged in the first area; the liquid crystal layer is arranged between the thin-film transistor array substrate and the color filter substrate; and the frame is arranged between the thin-film transistor array substrate and the color filter substrate and corresponds to the second area. The invention also discloses a manufacturing method of the liquid crystal display panel. An ultraviolet light source is shielded by the black matrix layer and the colored layer, so that in the process by utilizing the ultraviolet light source to solidify a rubber frame, an ultraviolet mask can be omitted.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

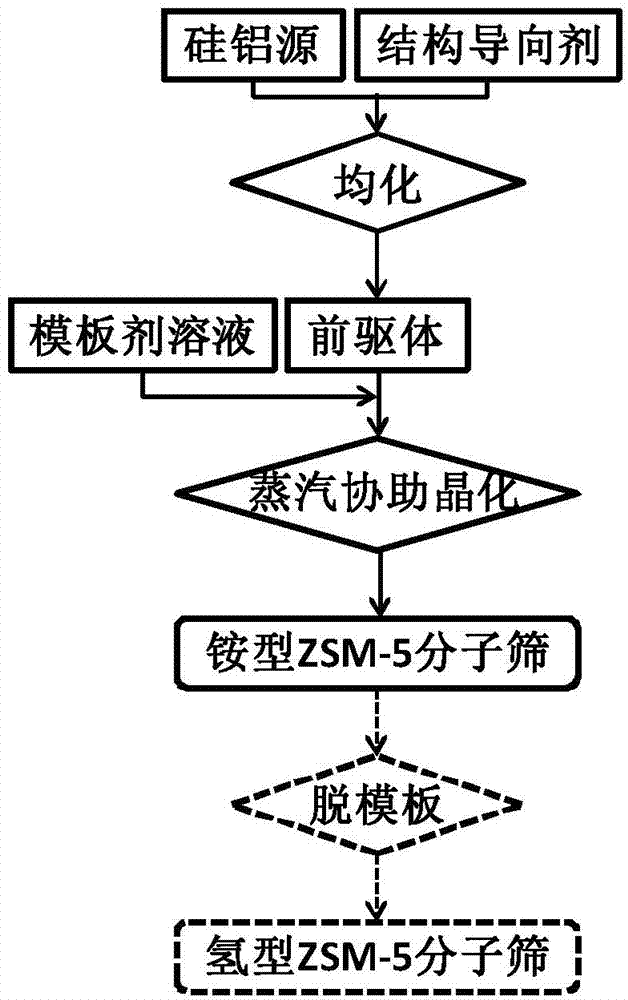

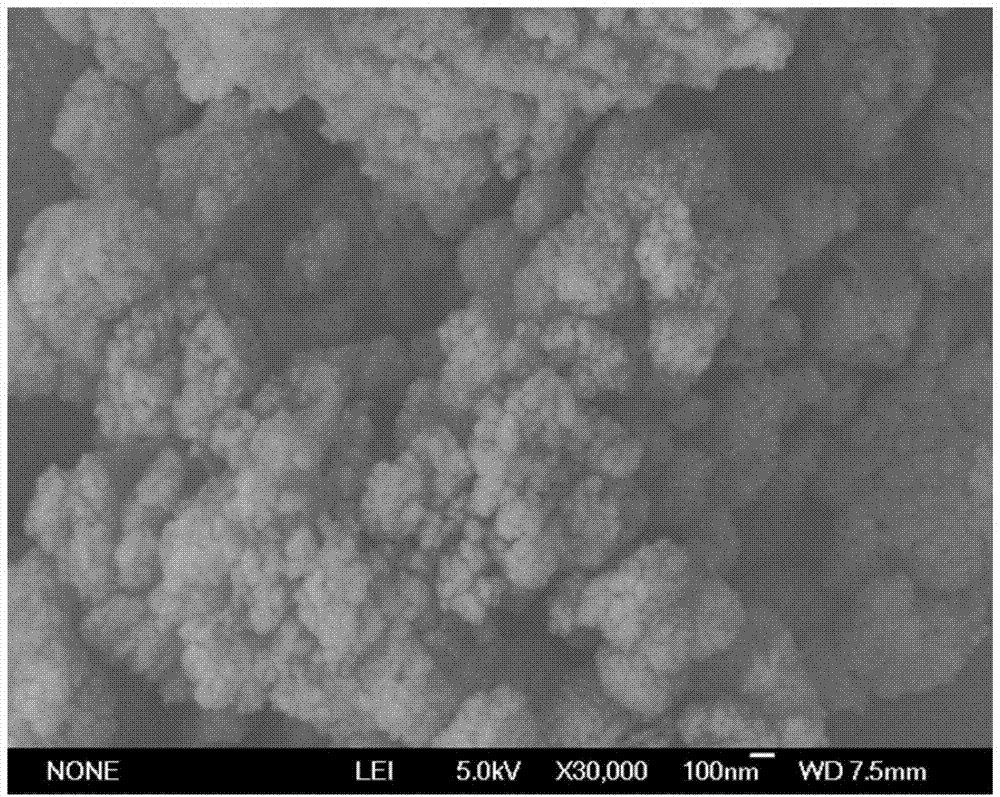

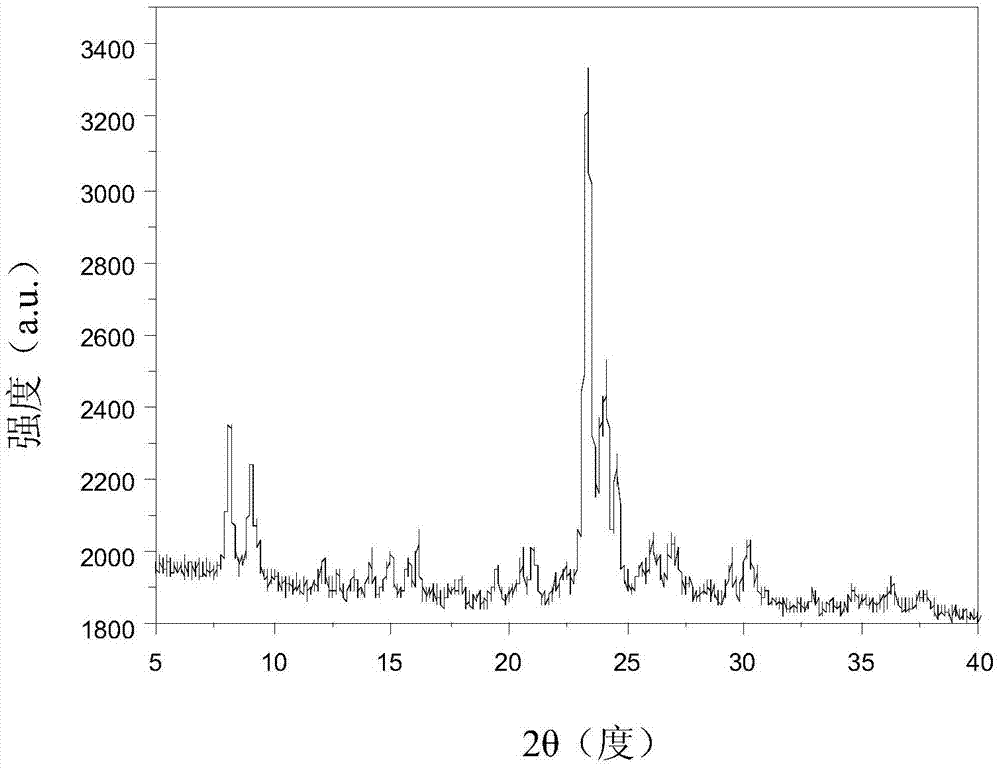

ZSM-5 molecular sieve and preparation method thereof

ActiveCN104843740ASynthesis fastEfficient synthesisMaterial nanotechnologyPentasil aluminosilicate zeoliteAlkaline earth metalHydrogen

The invention relates to a preparation method of a ZSM-5 molecular sieve. The method comprises performing assistant crystallization of a ZSM-5 molecular sieve precursor by utilizing steam of a template agent solution to obtain an ammonium-type ZSM-5 molecular sieve; and optionally, removing the template agent from the ammonium-type ZSM-5 molecular sieve to obtain a hydrogen-type ZSM-5 molecular sieve. According to the invention, the preparation method of the ZSM-5 molecular sieve abandons a conventional continuous medium in a crystallization process, and alkali metals or hydroxides of alkali metals, overcomes the technical prejudice in the prior art, and provides a novel synthesis idea for the field.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

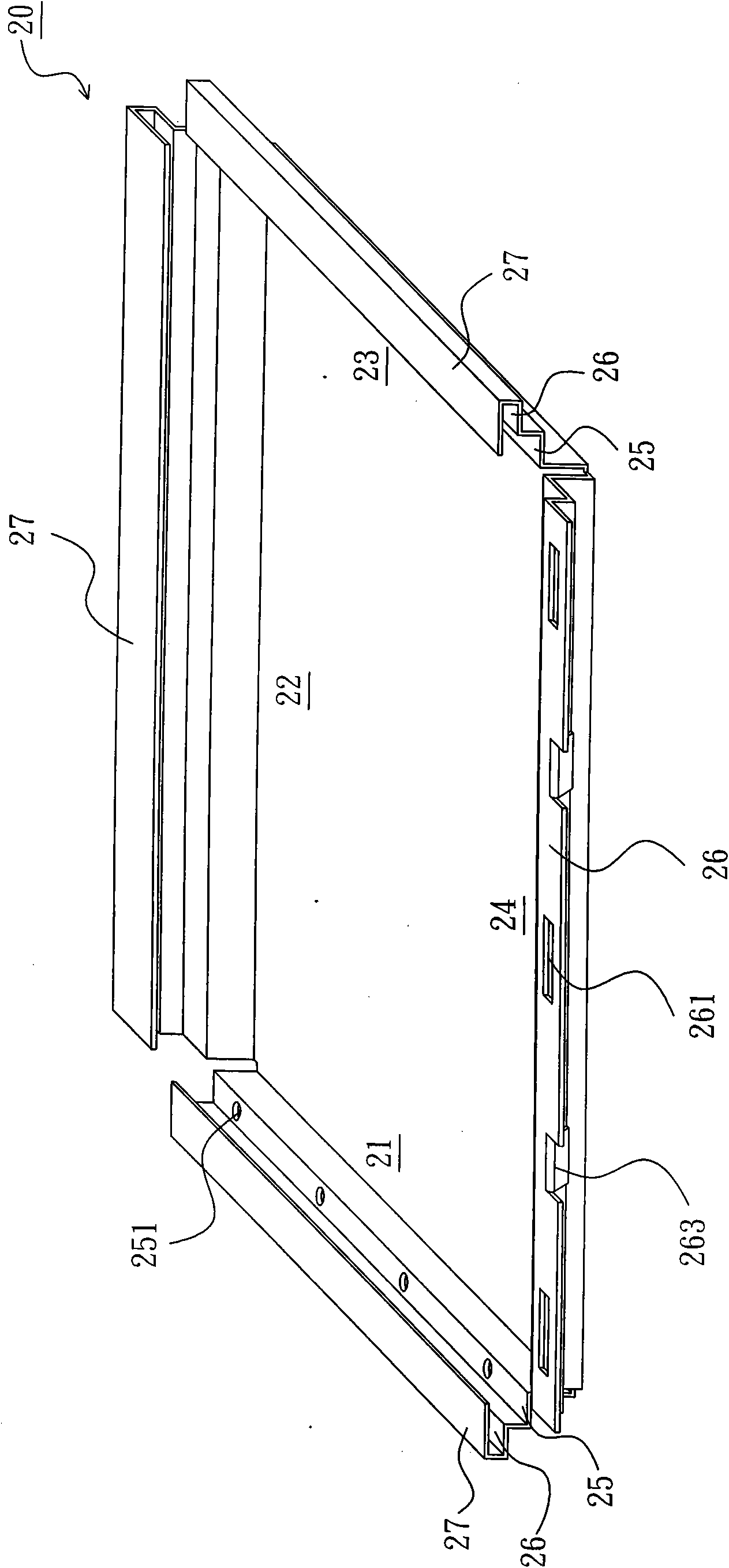

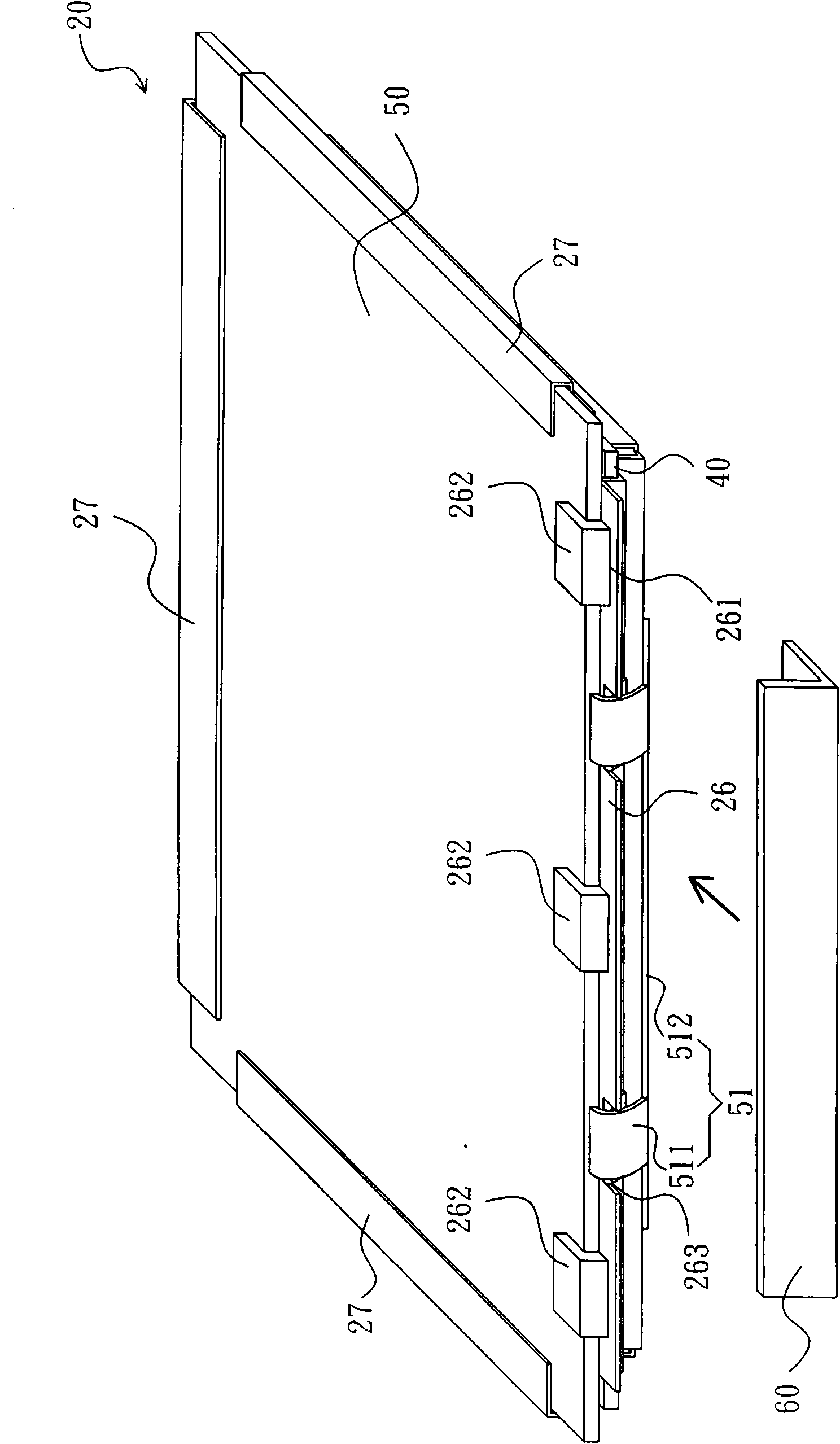

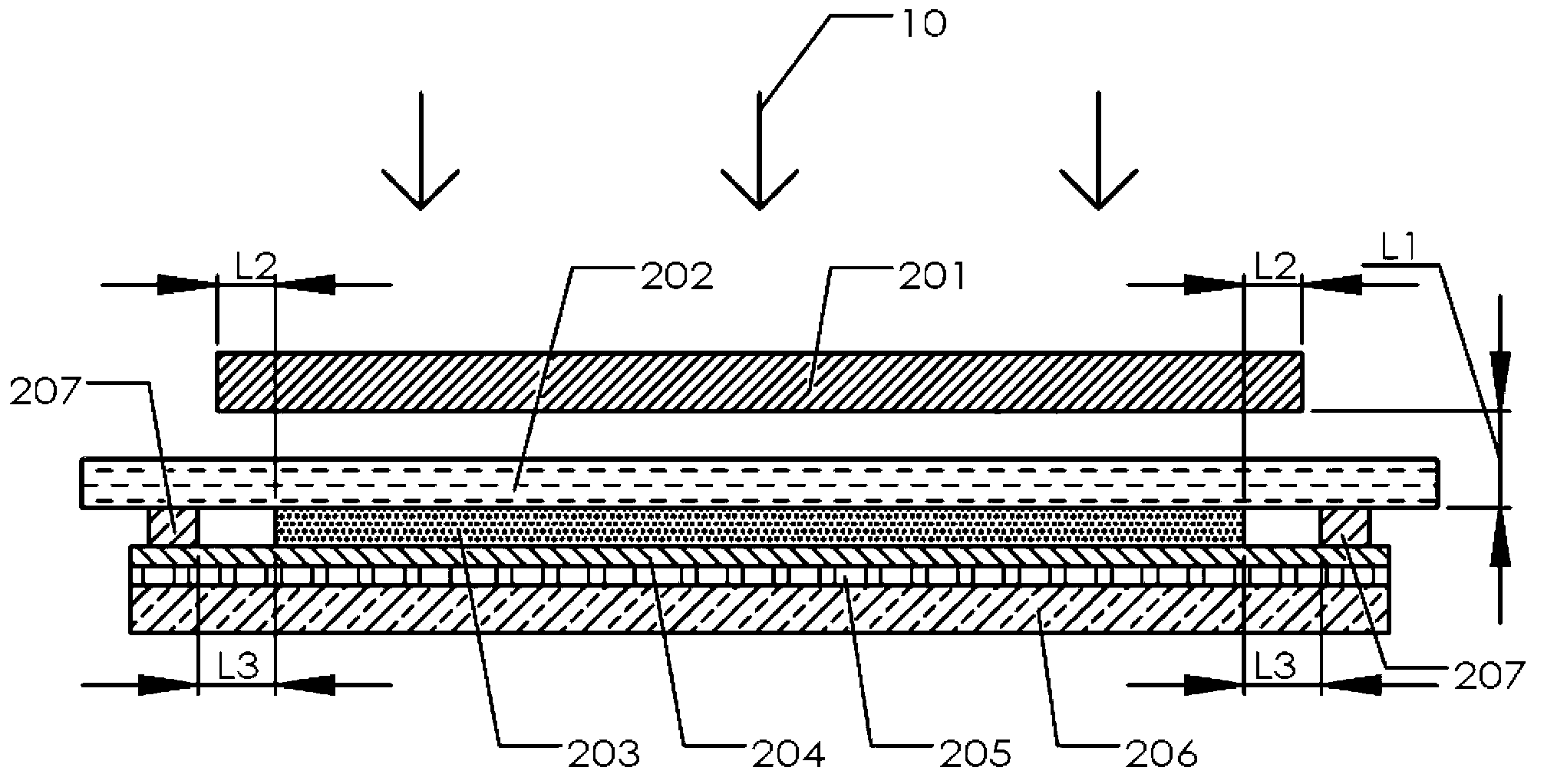

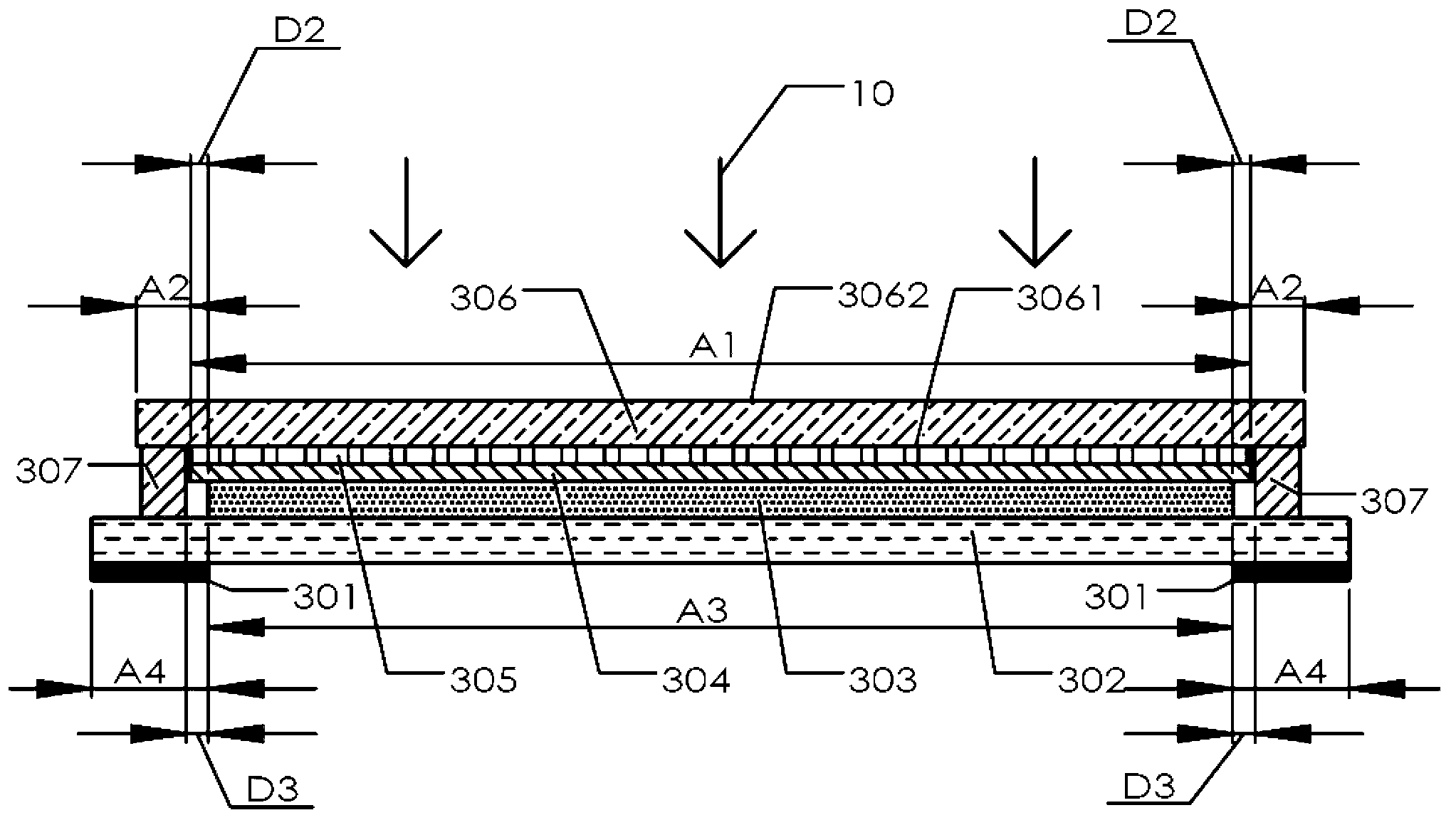

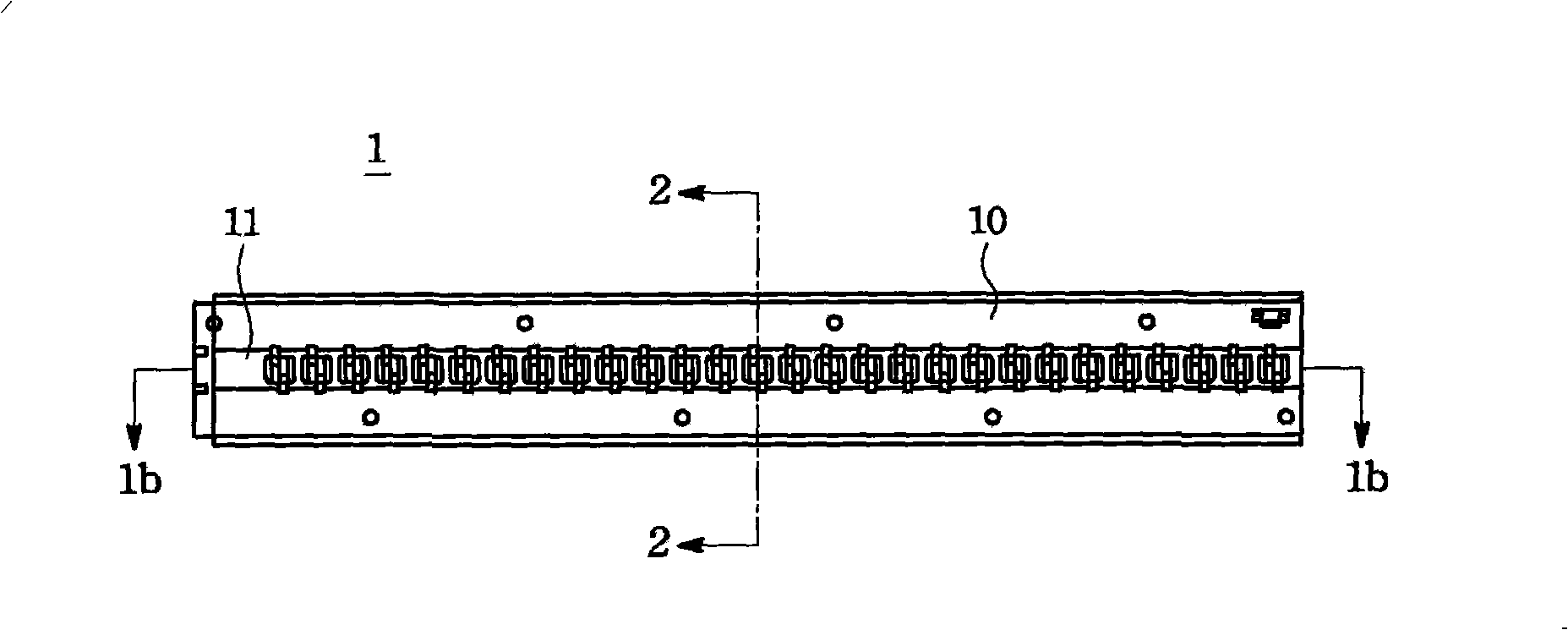

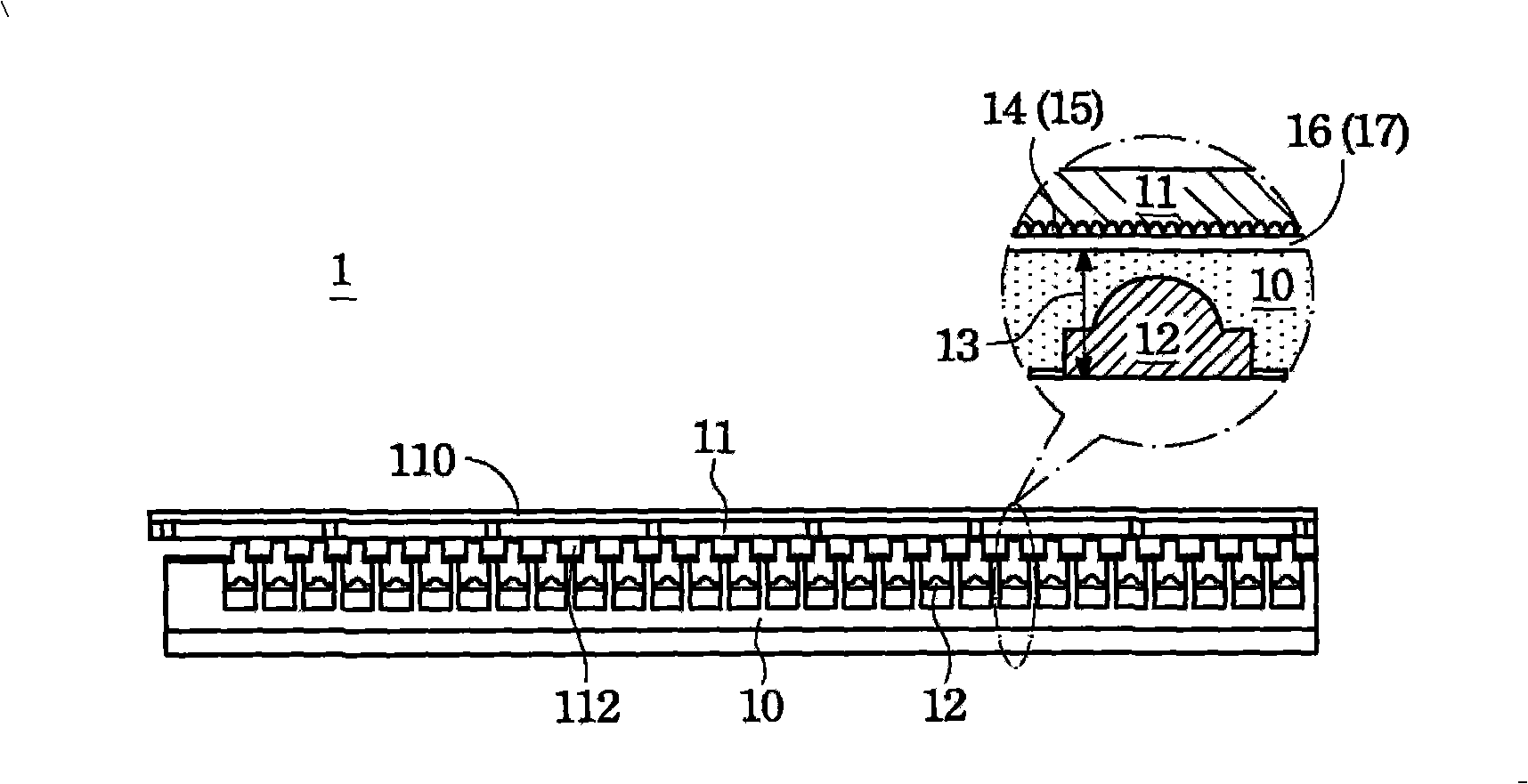

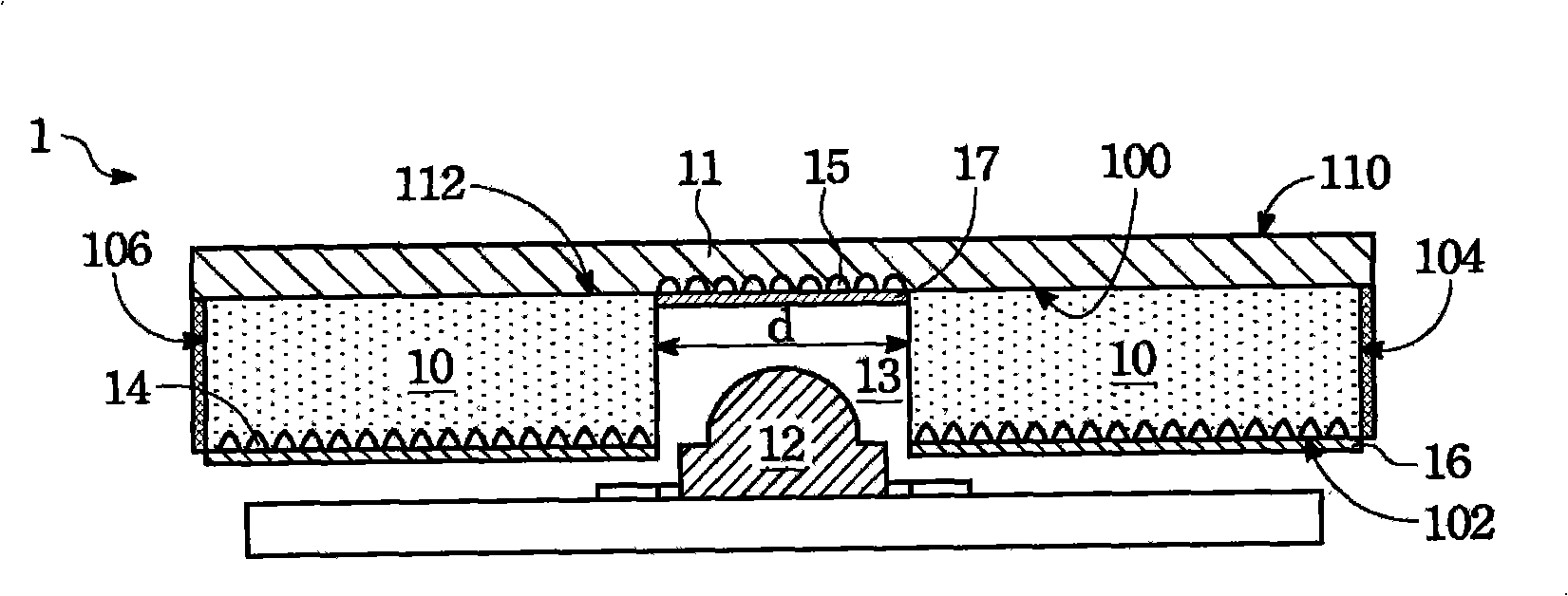

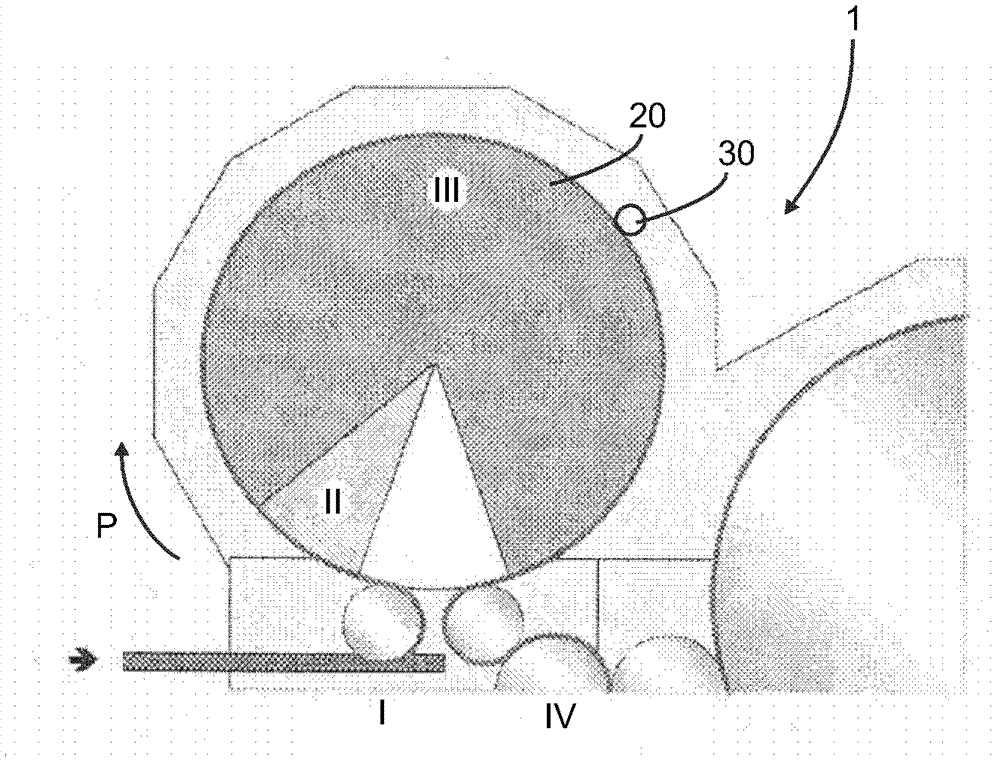

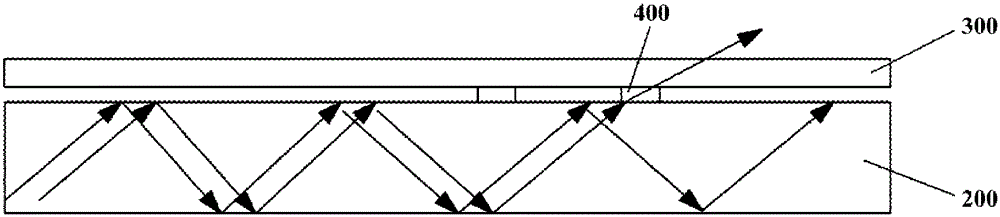

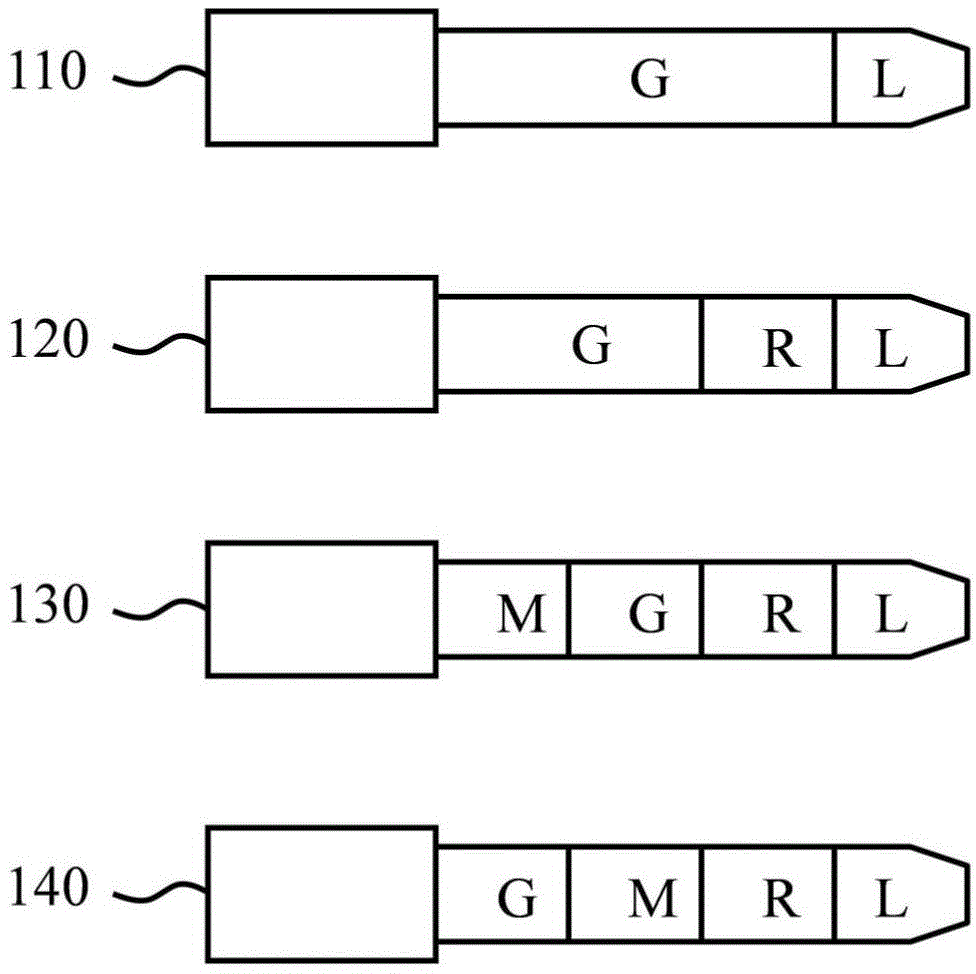

Illuminating device, backlight module with the illuminating device, lamp box module or digital electronic device and manufacturing method thereof

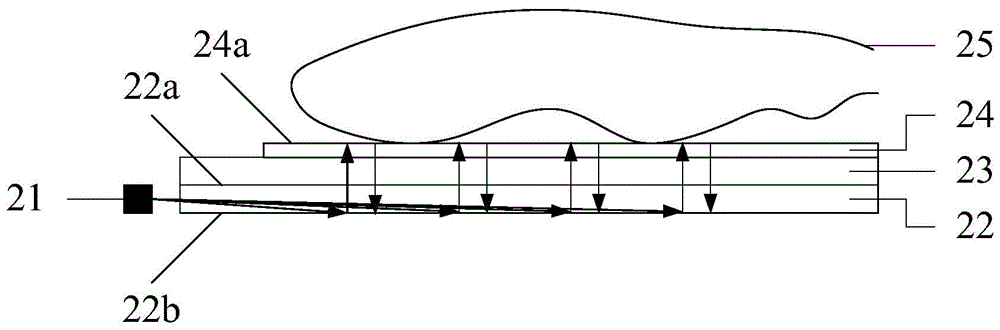

InactiveCN101329472AReduce thicknessShorten the mixing distanceOptical light guidesNon-linear opticsOptical reflectionDiffusion

The invention provides a light source light emitting device, a direct-type backlight module with the light-emitting device, a light box module, a planar light radiator, an LCD picture screen, a digital electronic device and a manufacturing method of the light-emitting device and the related products. The light emitting device comprises a plurality of long strip-shaped first light guide structures, a second light guide structure and a light source, the second light guide structure is adjacently spliced with two first light guide structures for receiving and containing the light source in a space which is combined by the two adjacent first light guide structures and the second light guide structure, wherein, patterned reflection layers are formed on the surfaces of the first light guide structures and the second light guide structure which are positioned at the same side of the light source and close to the periphery and the bottom part of the light source, at least optical reflection structures are additionally covered on the patterned reflection layers which are positioned at the bottom surfaces of the first light guide structures and the second light guide structure, thereby allowing light rays emitted by the light source to pass through the patterned reflection layers and the optical reflection structures for diffusion and reflection, improving the light uniformity, promoting the color mixing and reducing the occurrence of a dark band.

Owner:CHI LIN OPTOELECTRONICS CO LTD

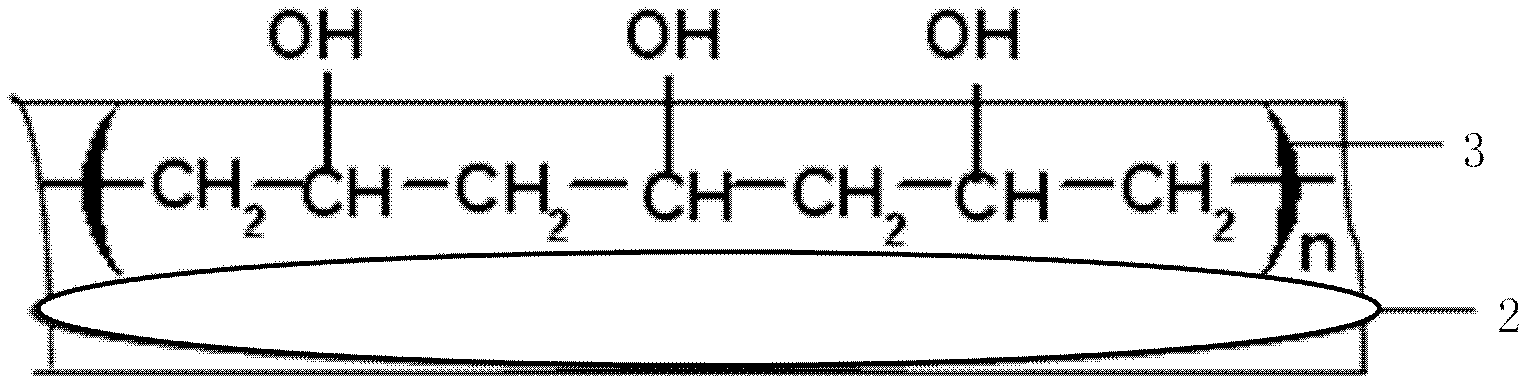

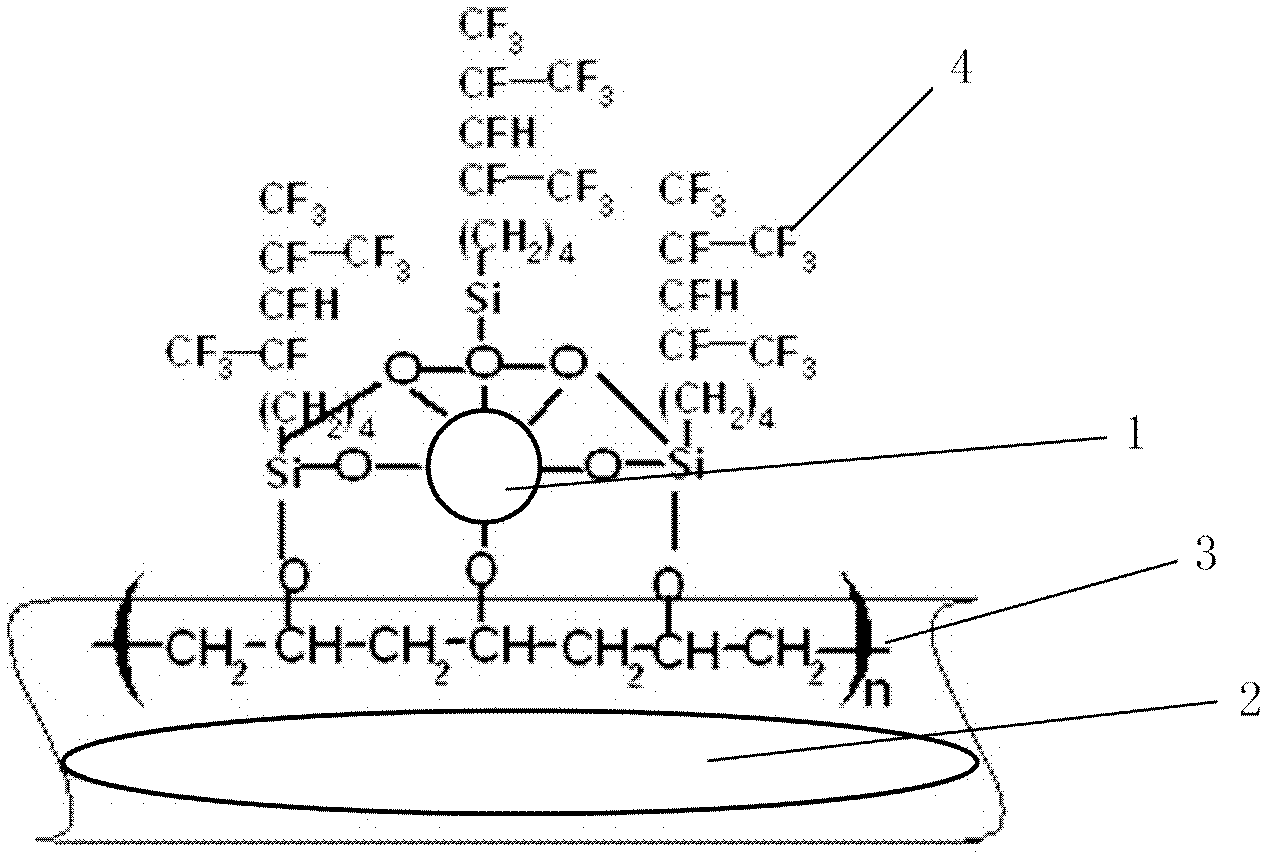

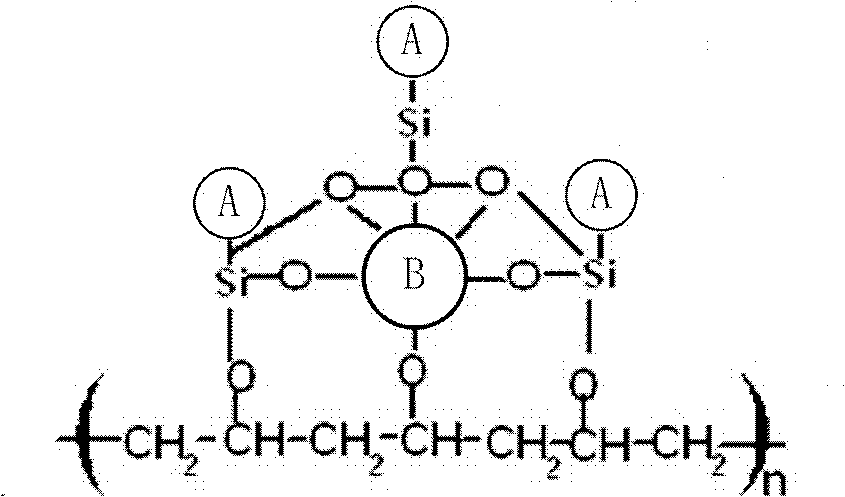

Modified polyvinylalcohol (PVA) base film, preparation method thereof and polarizer

InactiveCN102432899AImprove water resistanceAccelerated corrosionPolarising elementsCoatingsPolarizerMechanical property

The invention provides a modified polyvinylalcohol (PVA) base film, a preparation method thereof and a polarizer prepared by the modified PVA base film. The preparation method of the modified PVA base film comprises the following steps of: (1) adopting fluorosilane to carry out surface grafting modification on nano silicon dioxide so as to obtain modified nano silicon dioxide powder; (2) adding the modified nano silicon dioxide powder obtained in the step (1) into polyvinyl alcohol polymer aqueous solution so as to prepare polyvinyl alcohol polymer composite solution; and (3) casting the polyvinyl alcohol polymer composite solution prepared by the step (2) on the surface of a cast substrate so as to obtain the modified PVA base film. In the invention, nano silicone dioxide is modified by utilizing low-surface-energy fluorosilane, and further the PVA base film is modified in a crosslinking manner, so that the humidity-heat resistance and the stability of the PVA base film are improved and the mechanical performance and the stain resistance of the PVA base film are improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

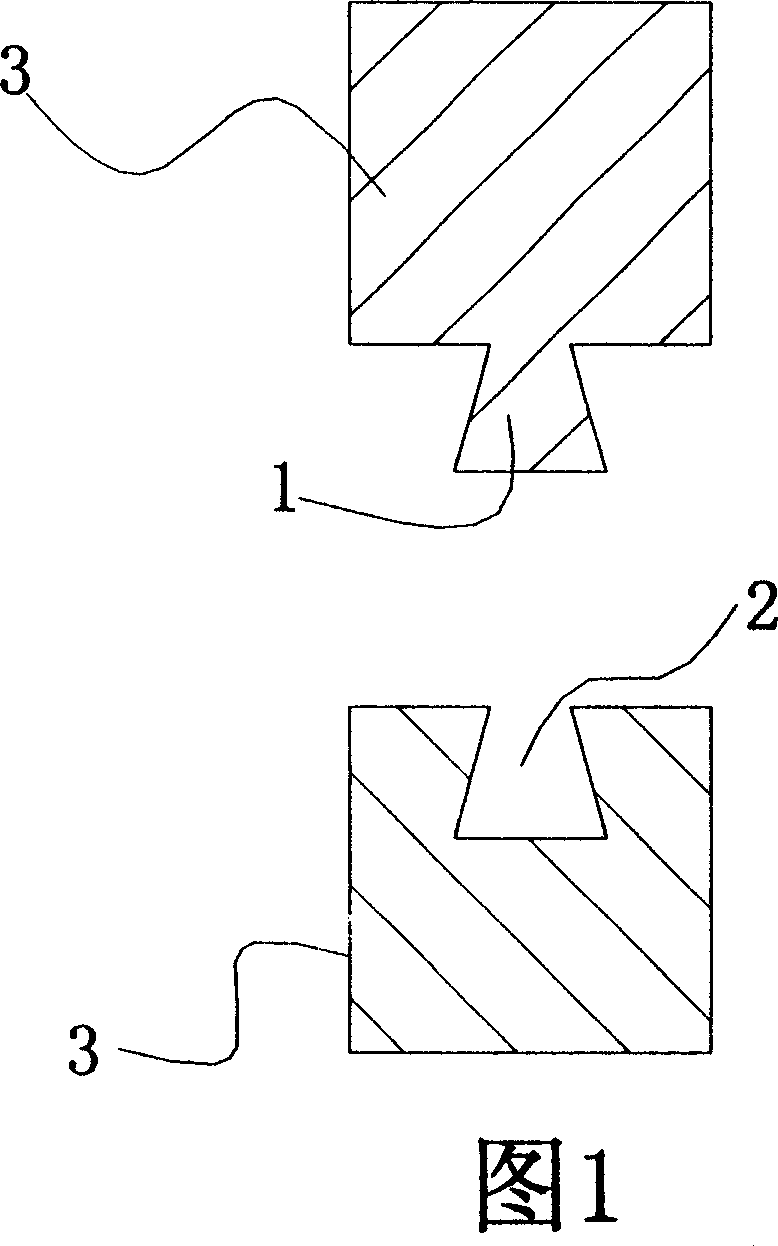

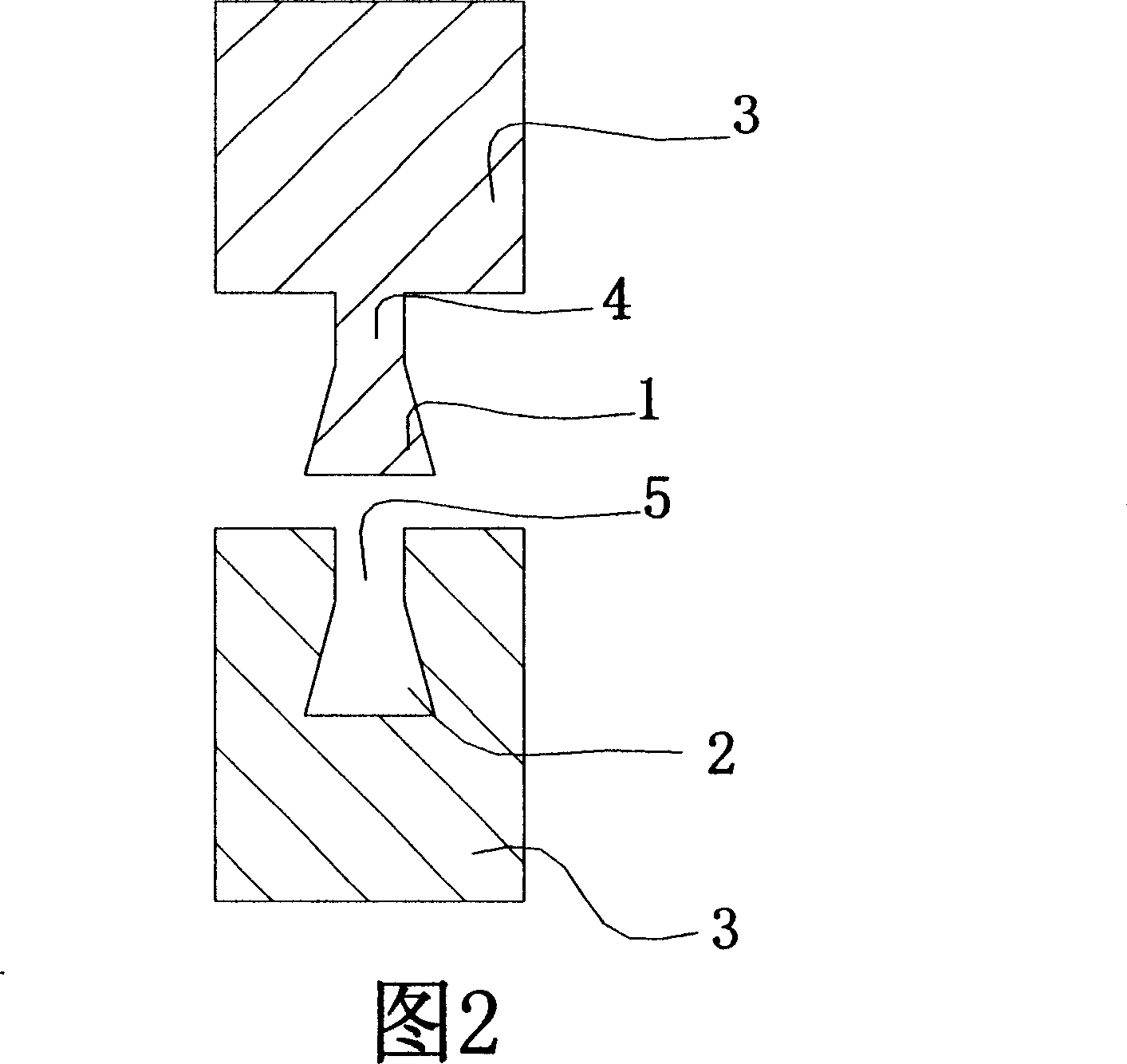

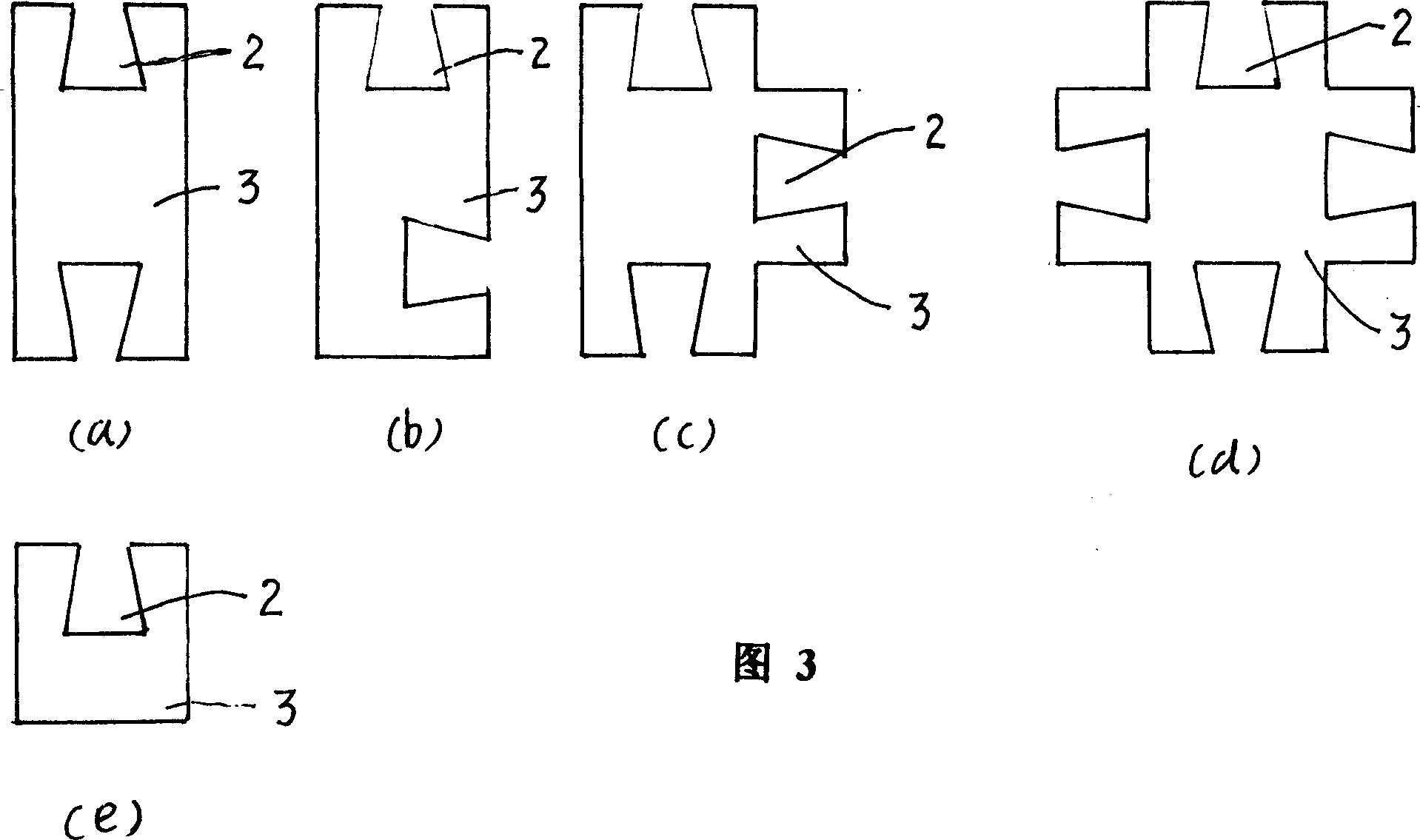

Fast tongue groove assembling sectional furniture

InactiveCN1948767ALow costEasy to assemble and disassembleSheet joiningSectional furnitureTongue and grooveEngineering

There is disclosed a rapid tongue and groove assembling and disassembling unit furniture, which includes each make-up member of the furniture. In the position of connecting two adjacent members are disposed a tongue and a groove capable of locking each other. There is also disclosed a furniture assembling method connected by using the tongue and the groove.

Owner:张金星

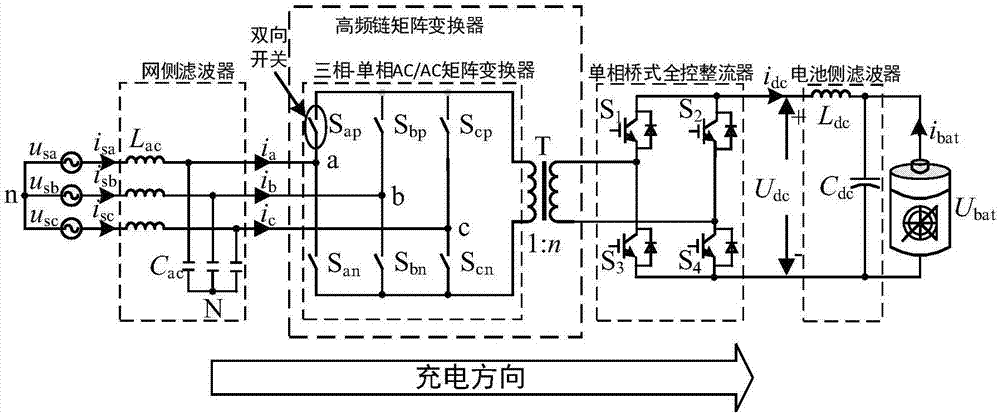

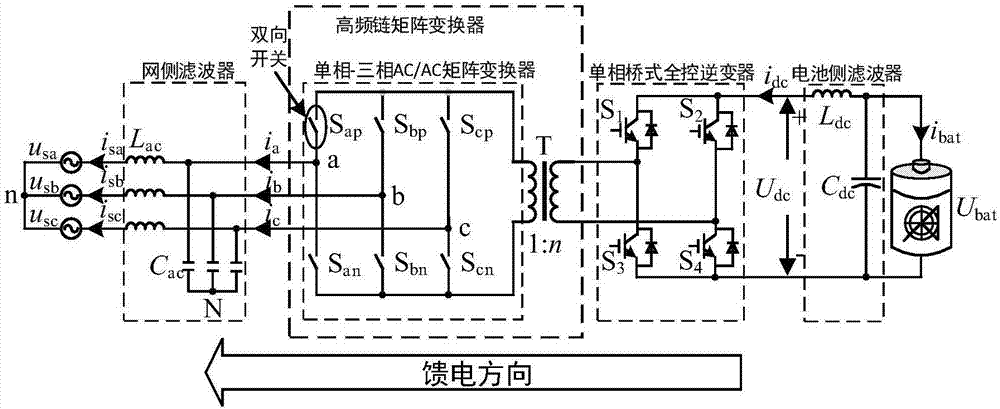

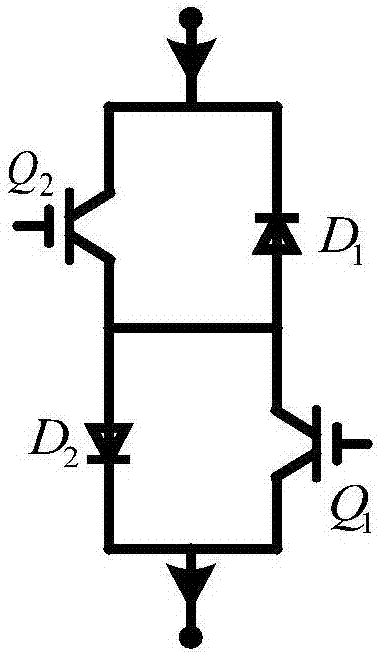

V2G charger adopting high-frequency chain matrix converter and control method thereof

ActiveCN106972603AOmit to useAvoid safety hazardsAc-dc conversionSingle network parallel feeding arrangementsMatrix convertersLoop control

The invention discloses a V2G charger adopting high-frequency chain matrix converter and a control method thereof. The V2G charger comprises a grid-side filter, a high-frequency chain matrix converter, a single-phase bridge-type full control rectifier, and a battery side filter, wherein the high-frequency chain matrix converter comprises a three phase-single phase AC / AC matrix converter and a high-frequency transformer T; and the grid-side filter, the three phase-single phase AC / AC matrix converter, the high-frequency transformer T, the single-phase bridge-type full control rectifier, and the battery side filter are sequentially connected. the V2G charger control method comprises steps of charging and feeding; and according to charging and feeding, outer loop switching control is adopted to generate an outer loop control quantity, the outer loop control quantity is subjected to inner loop decoupling control to obtain pulse signals, and the pulse signals are used for controlling the high-frequency chain matrix converter for realizing charging or feeding. The V2G charger adopting high-frequency chain matrix converter has the advantages of simplified structure, high conversion efficiency, small size and small weight, stable charging and feeding control, and good battery protection.

Owner:HUNAN UNIV

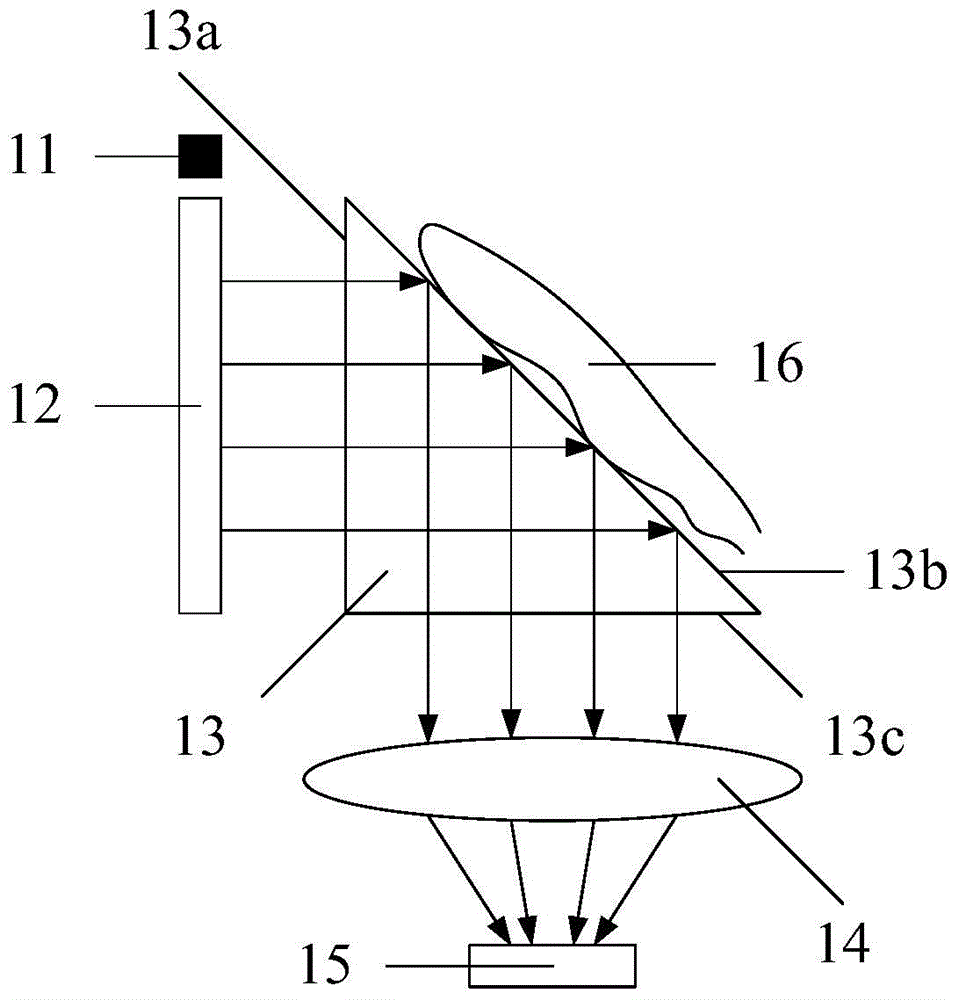

Motion analysis device and method

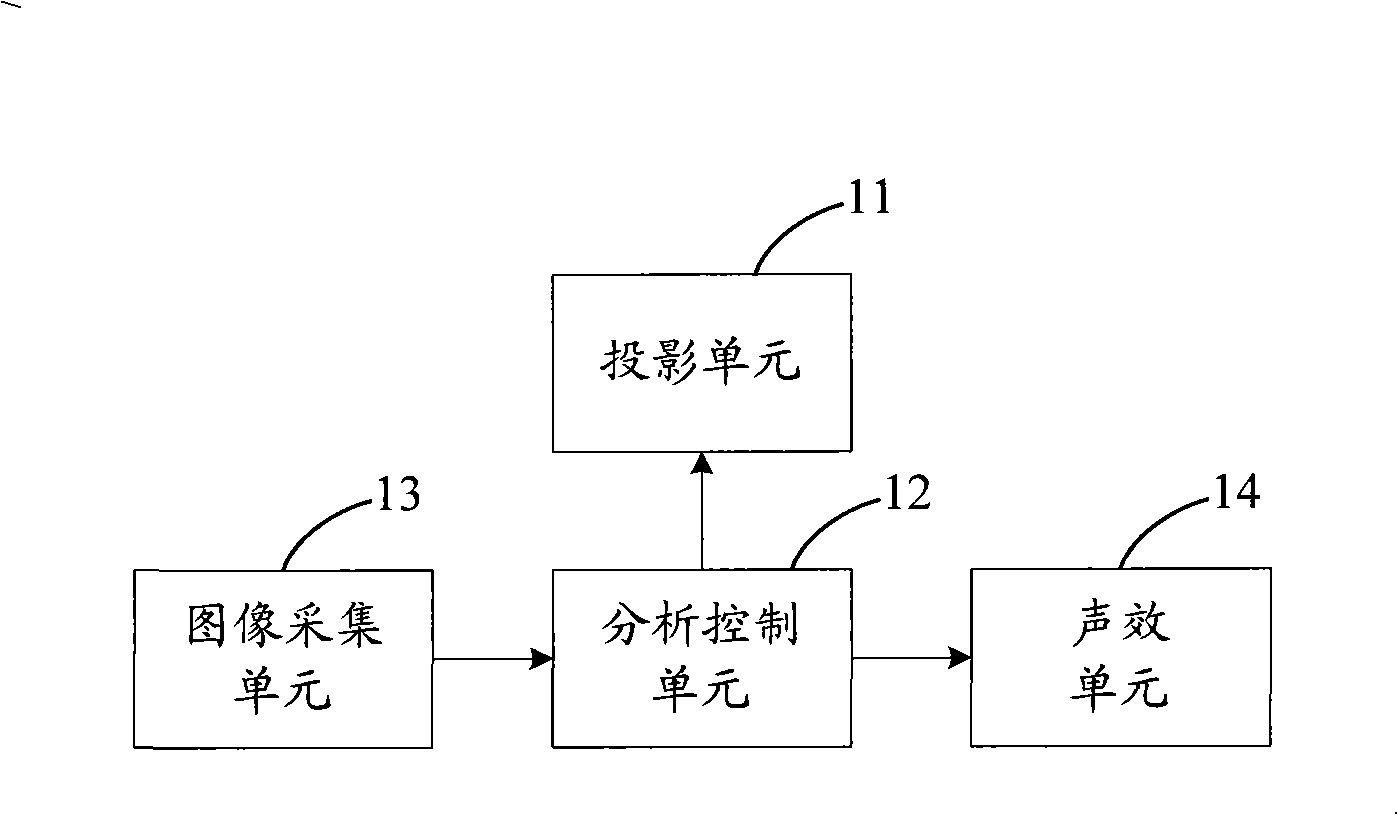

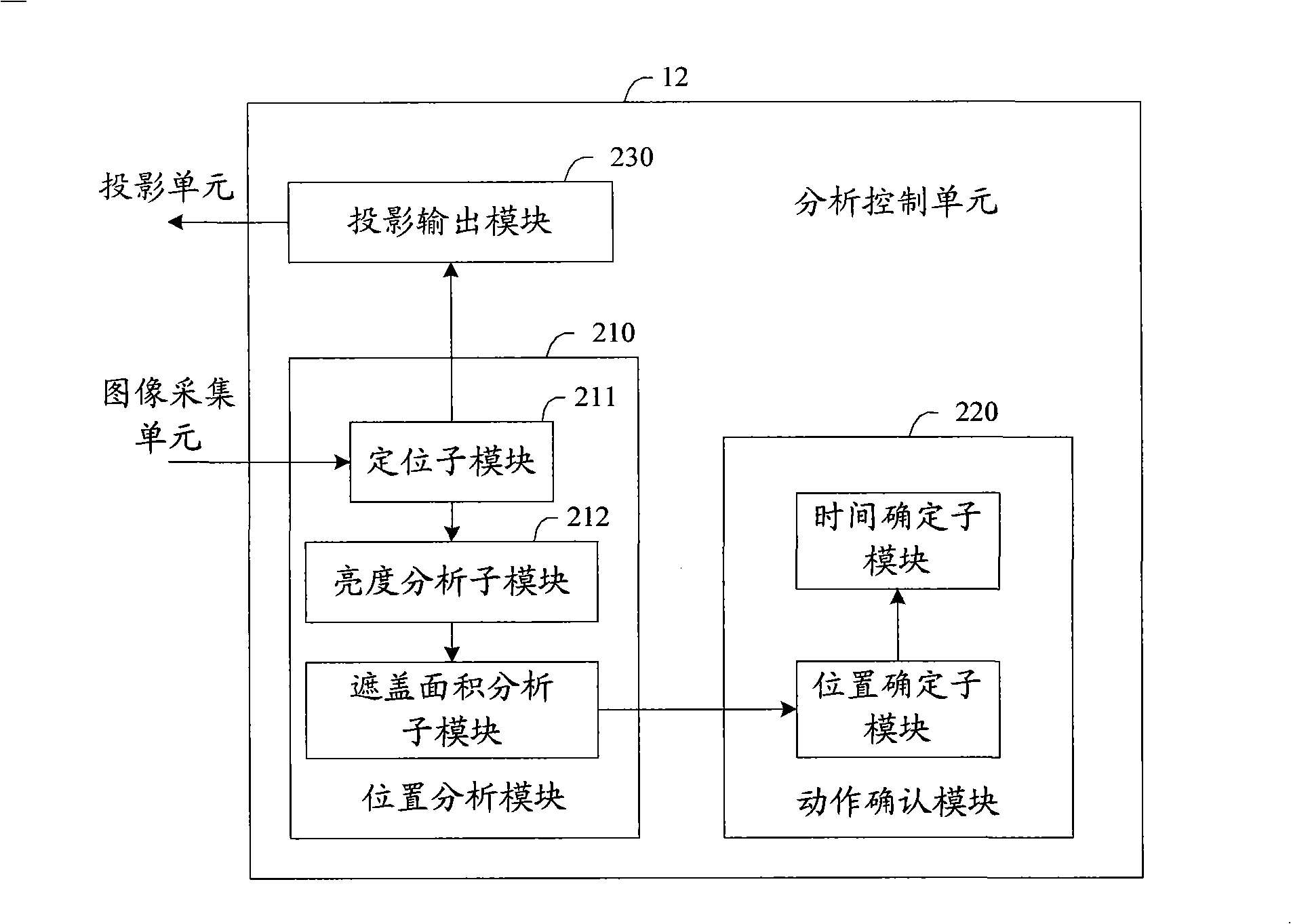

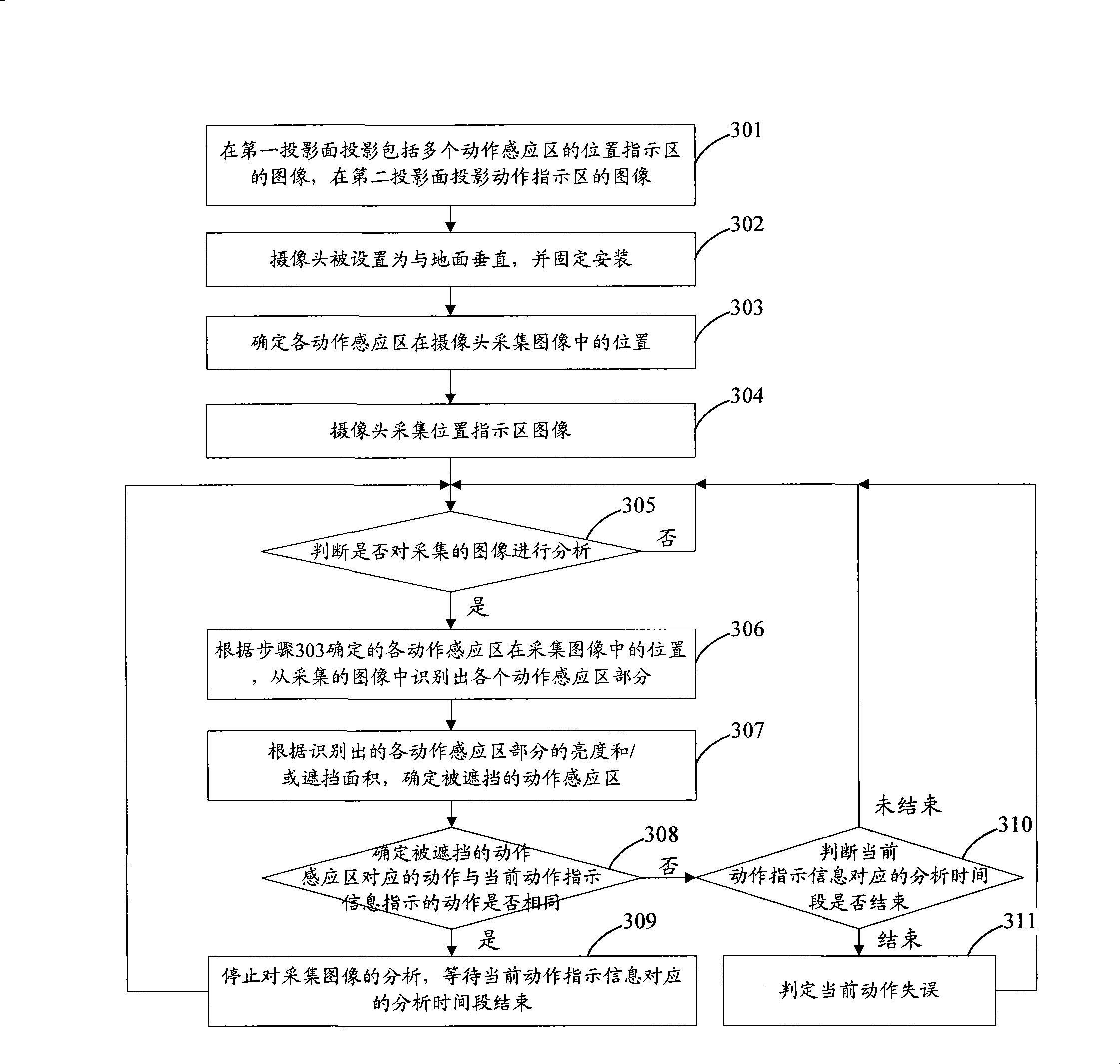

ActiveCN101306249AAvoid the defects of single function and incompatibilityOmit to useVideo gamesProjection planeAnalysis method

The invention discloses an action analysis device. The device comprises a projection unit, an image acquisition unit and an analysis and control unit; the projection unit is used for projecting an image of an action sensing area on a first projection plane and projecting action indicating information on a second projection plane under the control of the analysis and control unit; the image acquisition unit is used for acquiring the image of the action sensing area and sending the acquired image of the action sensing area to the analysis and control unit; the analysis and control unit is used for controlling the projection of the projection unit; when the image of the action sensing area indicated by the current action indicating information is judged to be blocked by an object by analyzing the image of the action sensing area received from the image acquisition unit, the current action is determined to be accurate. The invention further discloses an action analysis method. The use of the invention can avoid the limitations caused by the device shape and a sensor of the prior action analysis device.

Owner:BEIJING VIMICRO ARTIFICIAL INTELLIGENCE CHIP TECH CO LTD

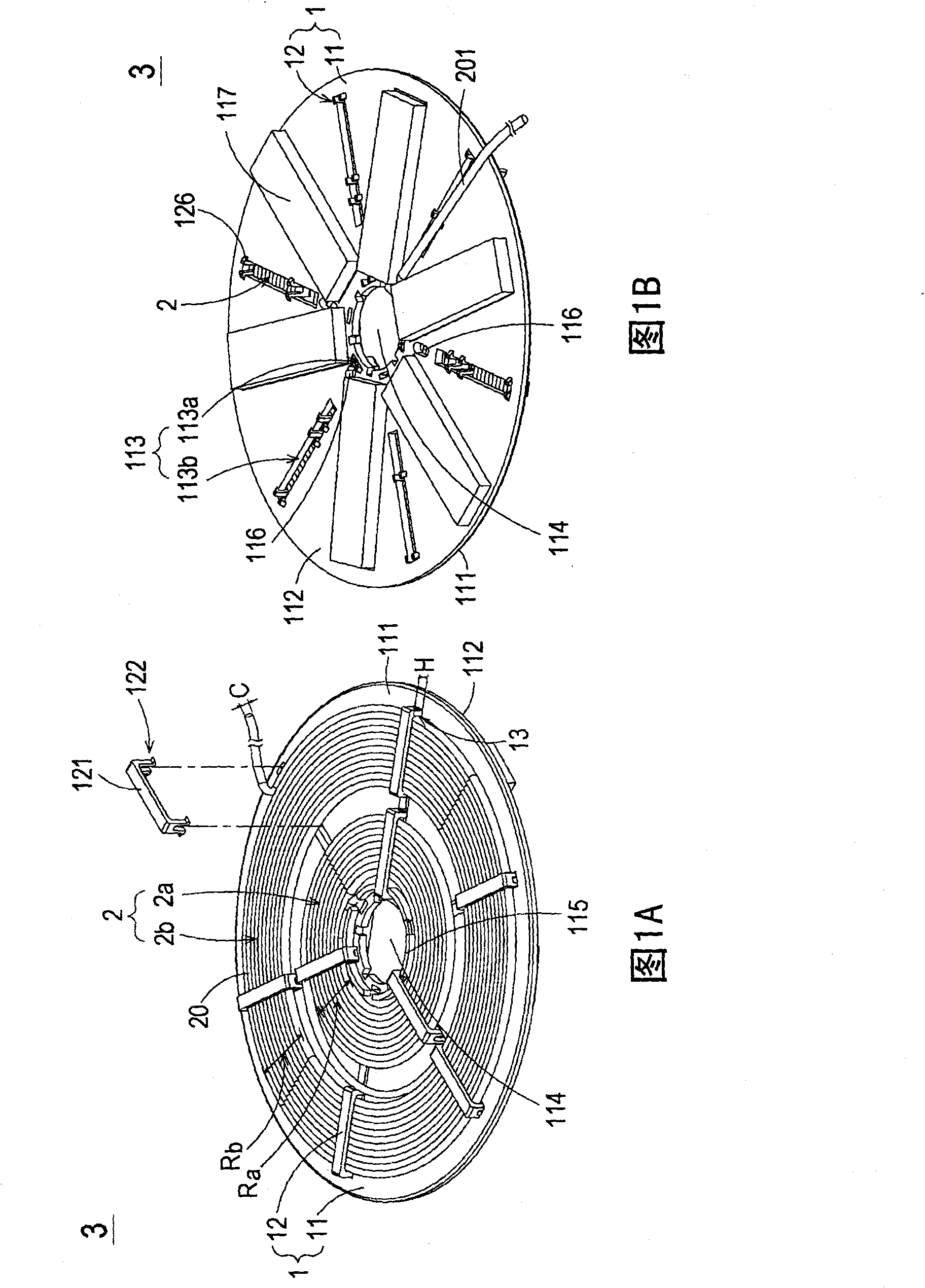

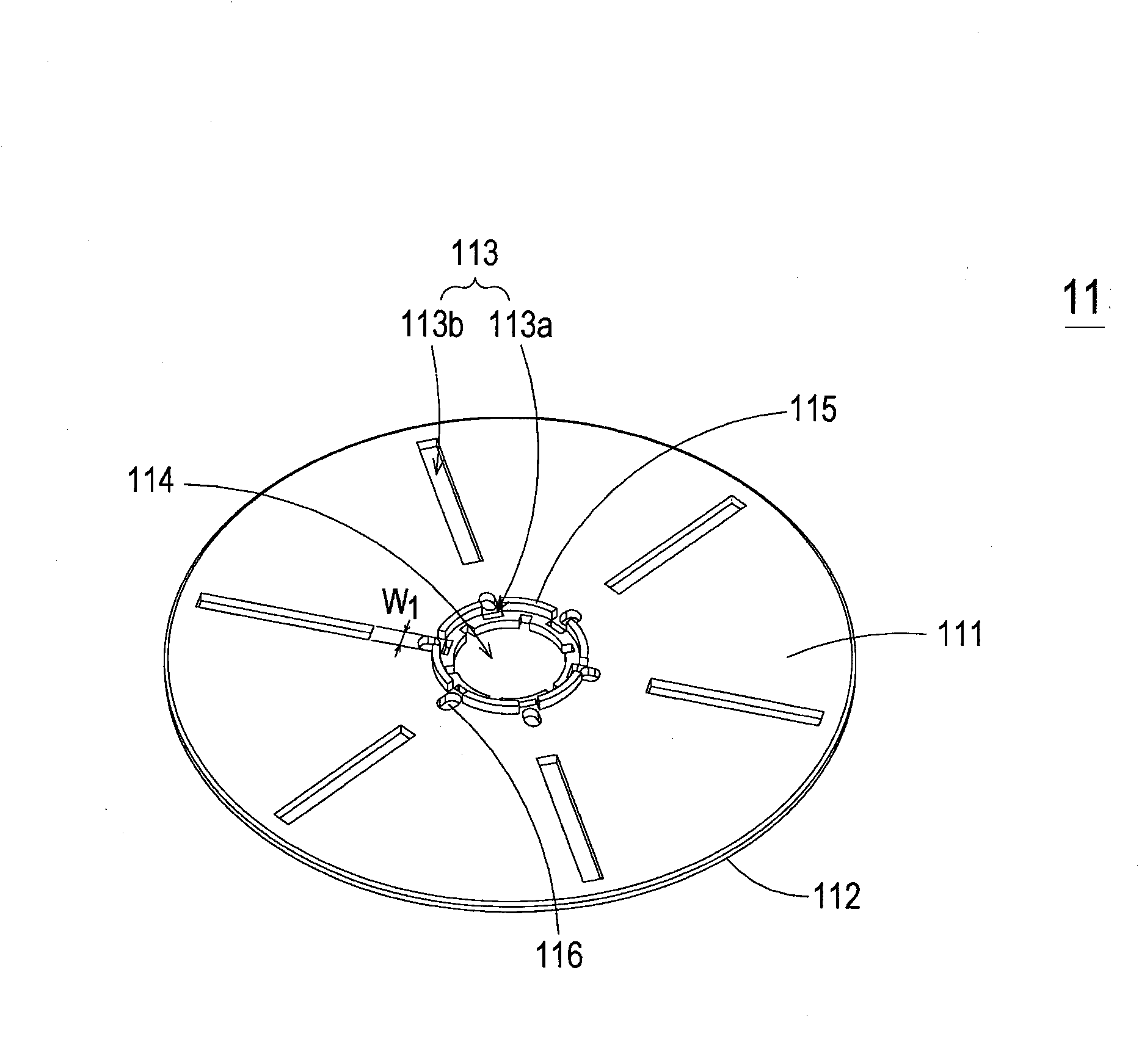

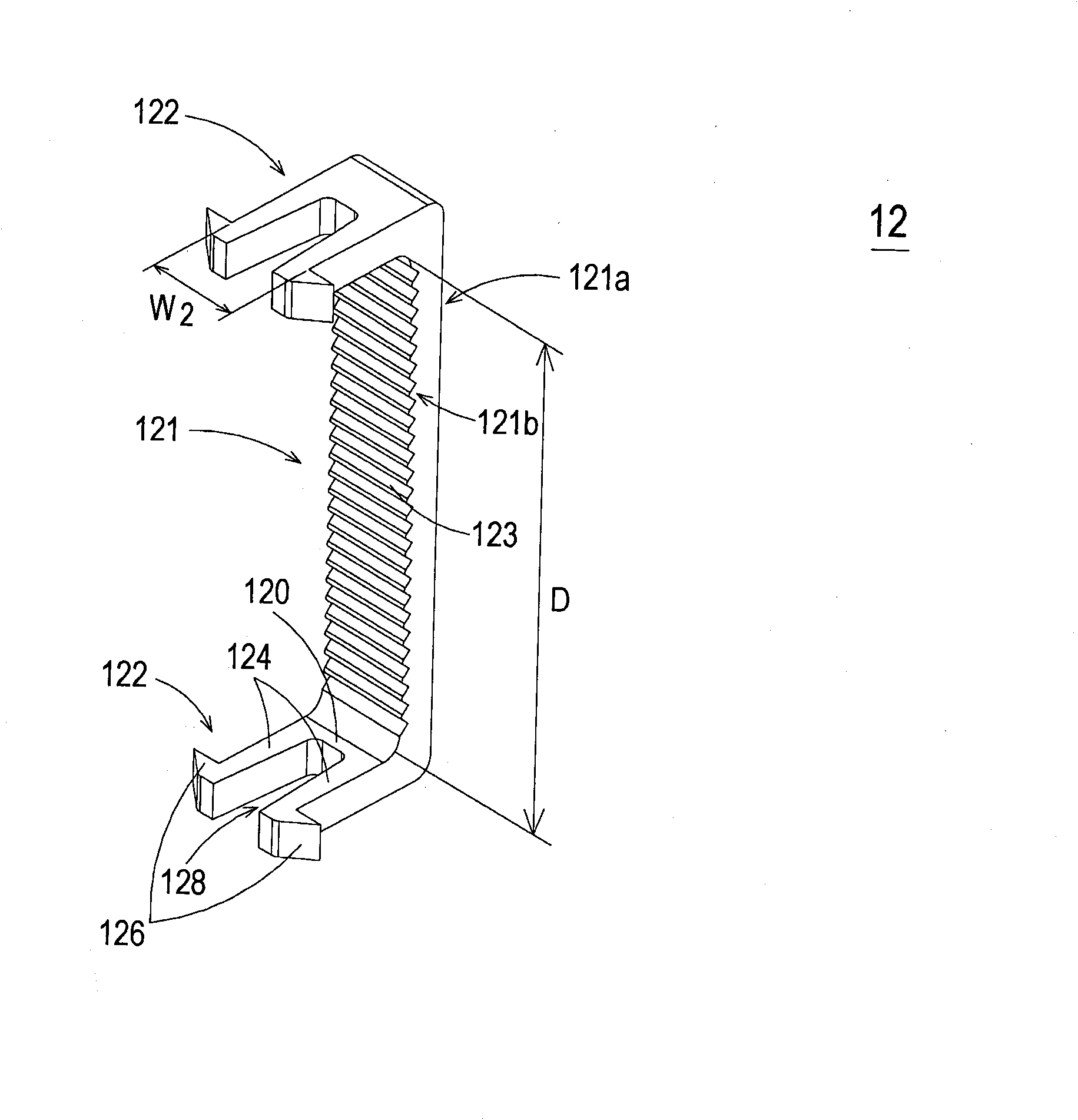

Coil fixing member and combined structure of coil fixing member and coil

InactiveCN102109187AClosely arrangedOmit to useDomestic stoves or rangesCoil arrangementsAdhesiveBiomedical engineering

The invention relates to a coil fixing member and a combined structure of the coil fixing member and a coil. The coil fixing member is a coil for fixing electromagnetic equipment and comprises a bearing element and a fixing element, wherein the coil and the fixing element are arranged on the bearing element; and the coil is sandwiched between the bearing element and the fixing element, so that the coil is fixed relative to the bearing element. An adhesive can be saved, equipment cost of dispensing and drying the adhesive can be saved, the negative effect possibly caused by the adhesive can be avoided, and the defect caused by improper coating of the adhesive is overcome.

Owner:DELTA ELECTRONICS INC

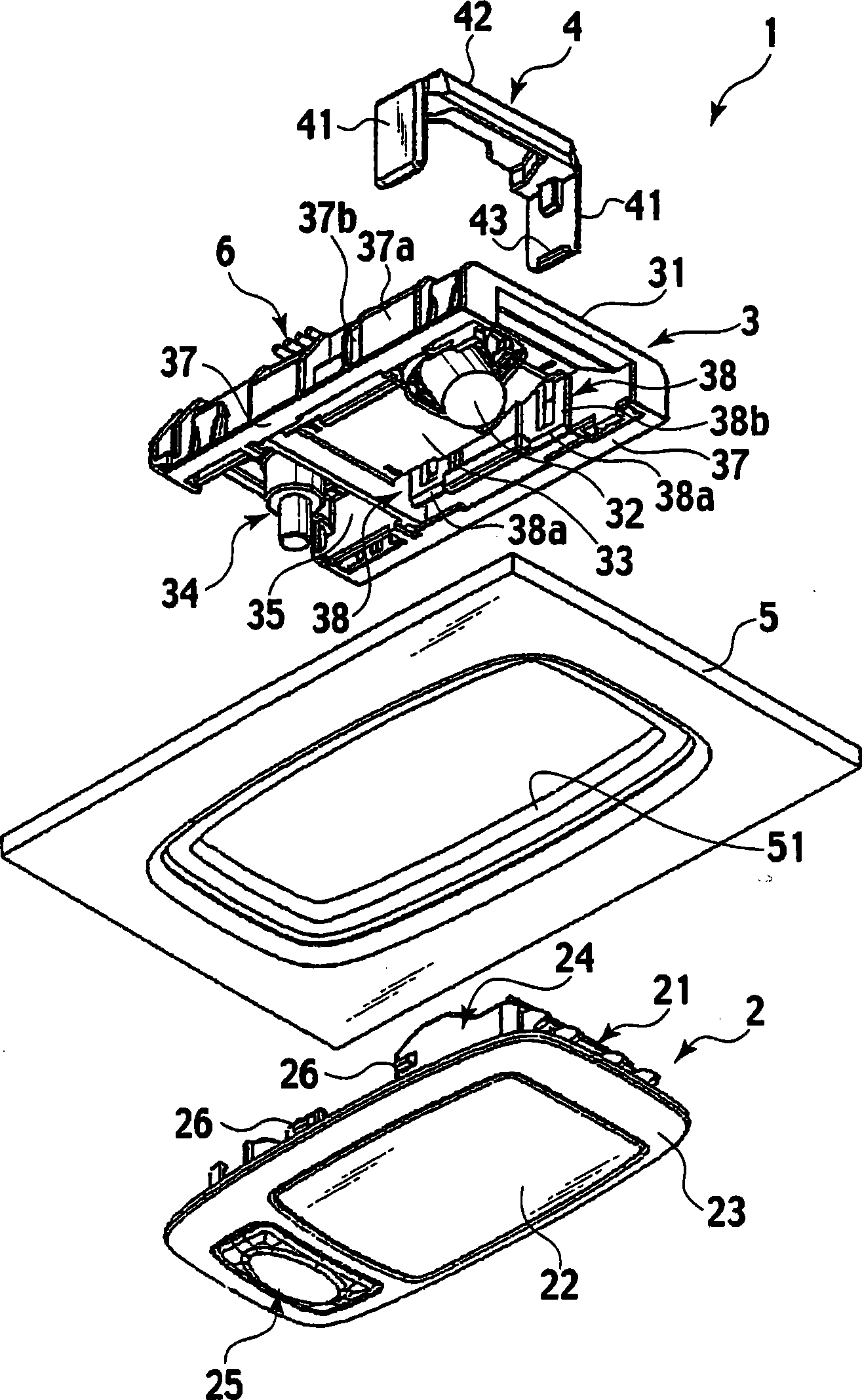

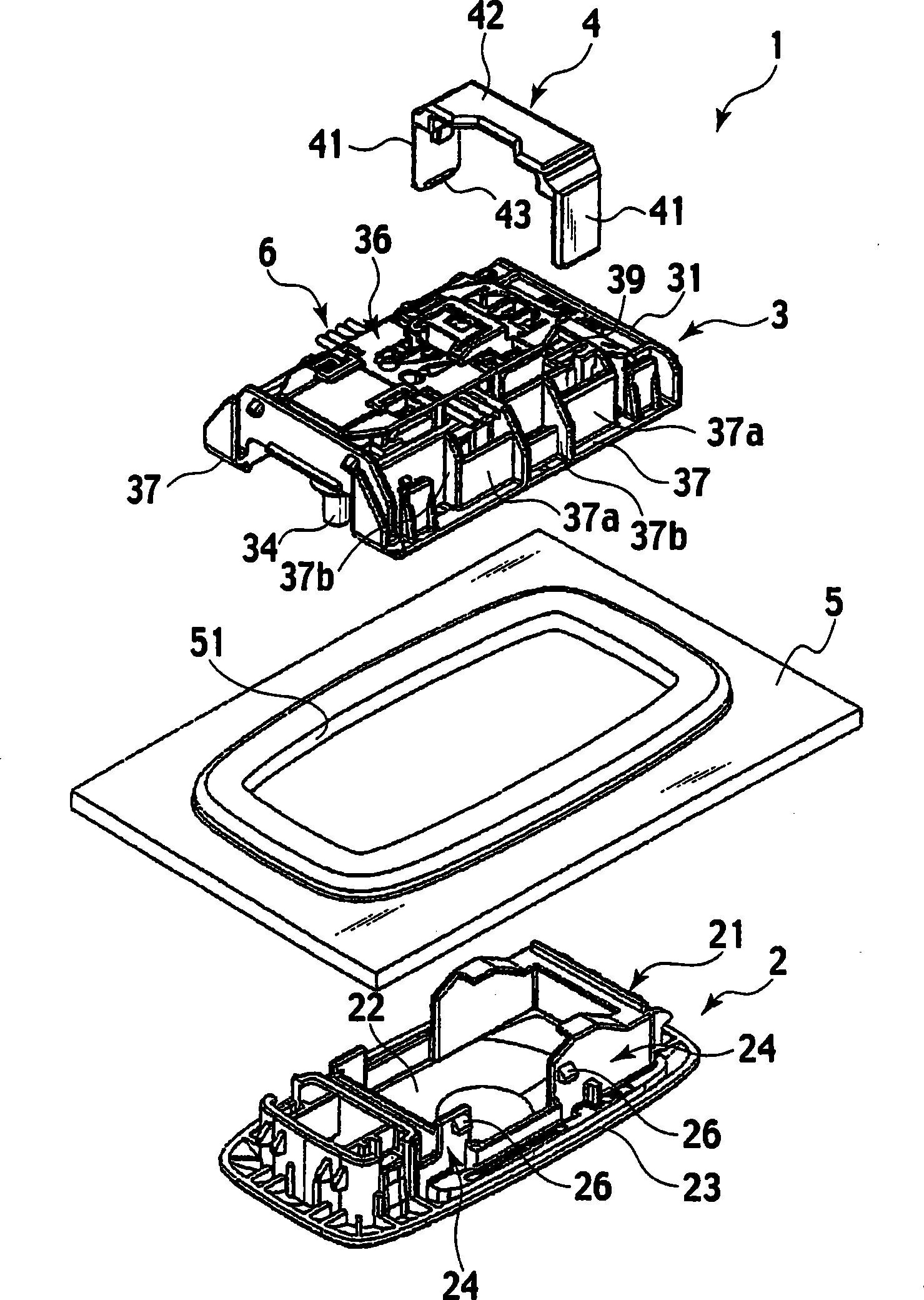

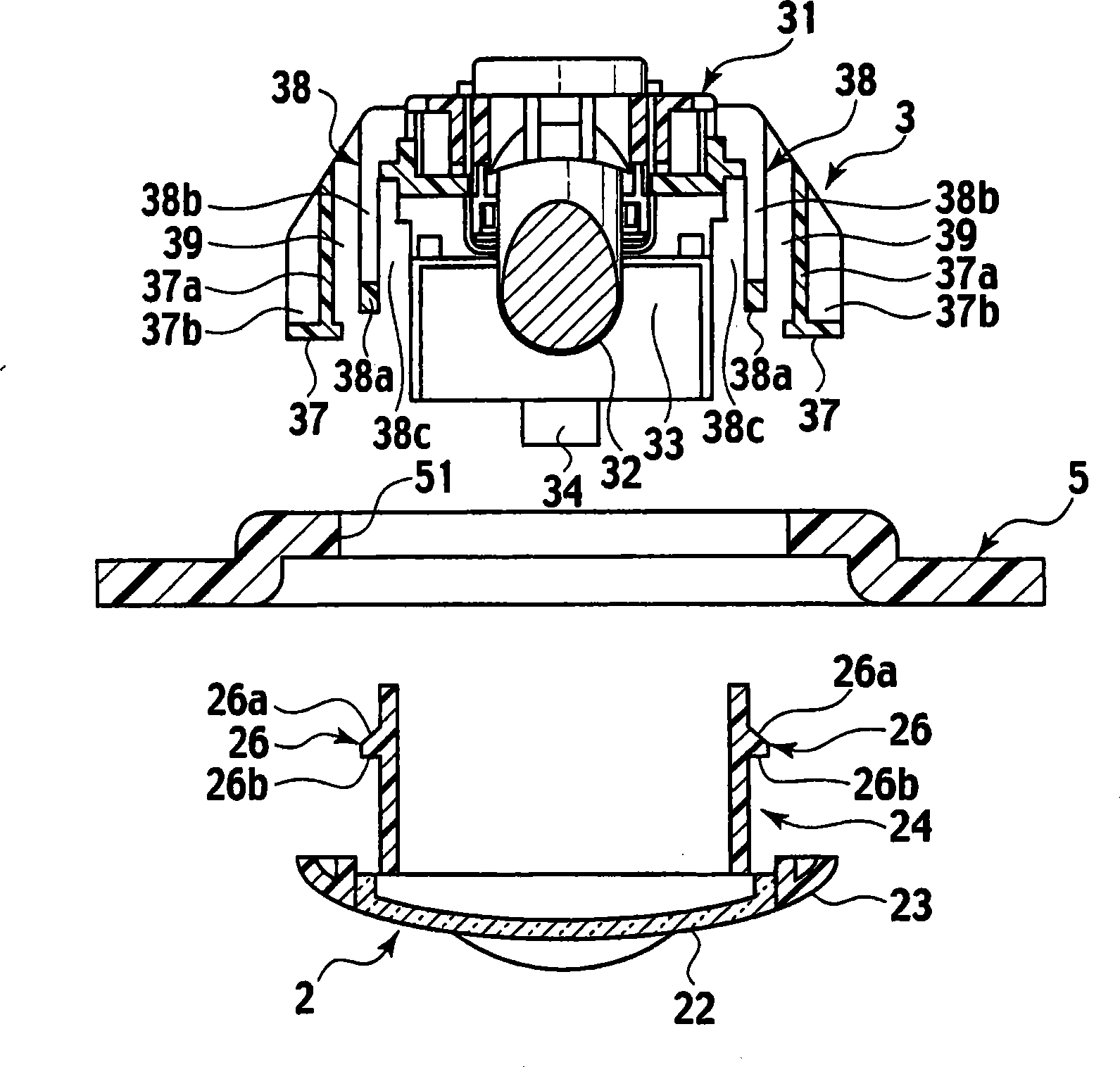

Vehicle interior illumination lamp unit

A vehicle interior illumination lamp unit includes: a designed unit disposed on a lower side of a ceiling plate of a vehicle; and a functional unit disposed on an upper side of the ceiling plate of the vehicle and coupled to the designed unit. A spacer insertion space is provided on an outside of an operation plate of the functional unit, and an insertion plate portion of the spacer is inserted into the spacer insertion space, whereby engagement between an engagement hook and an engaged portion is inhibited from being released by an impact.

Owner:YAZAKI CORP

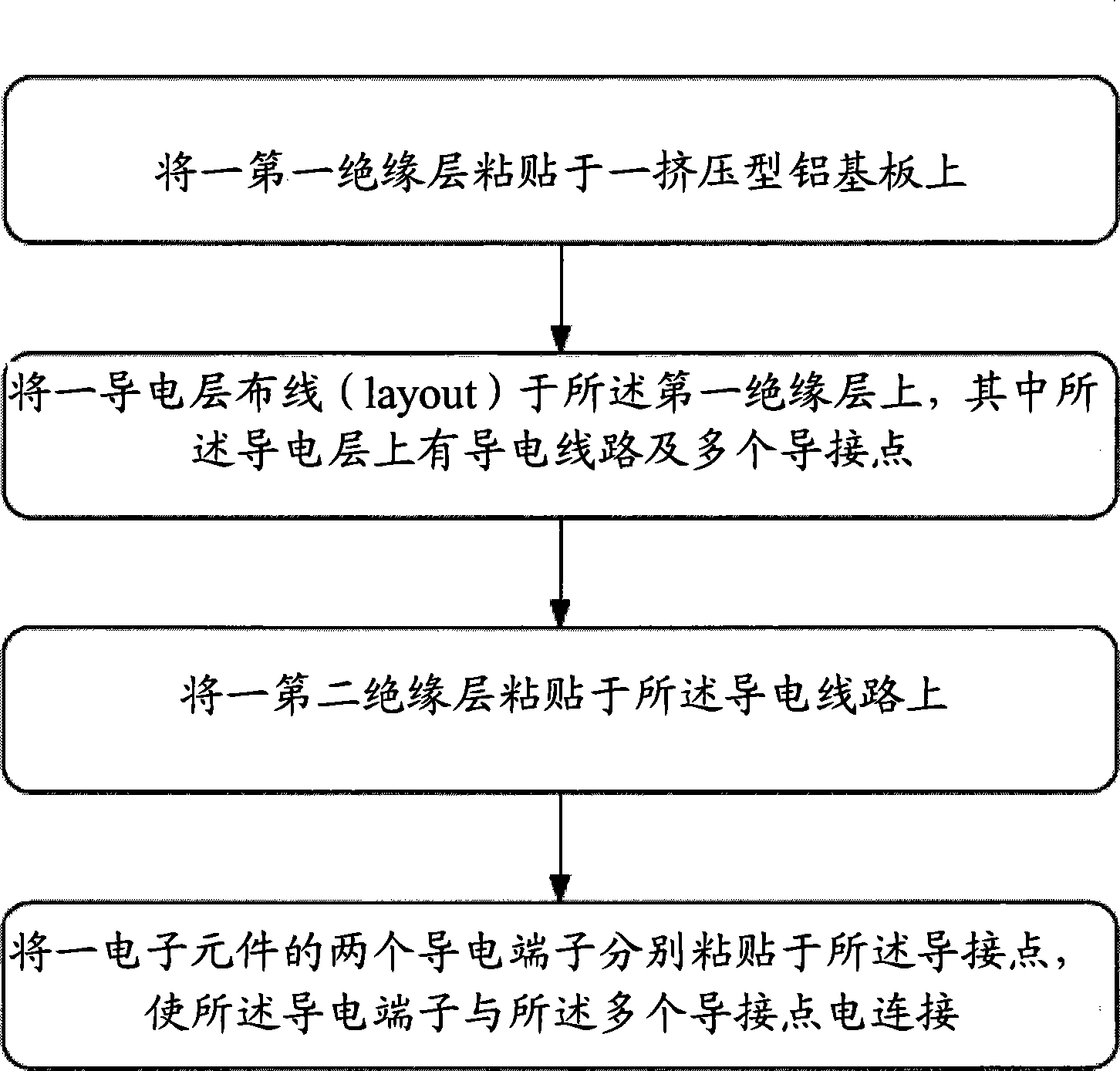

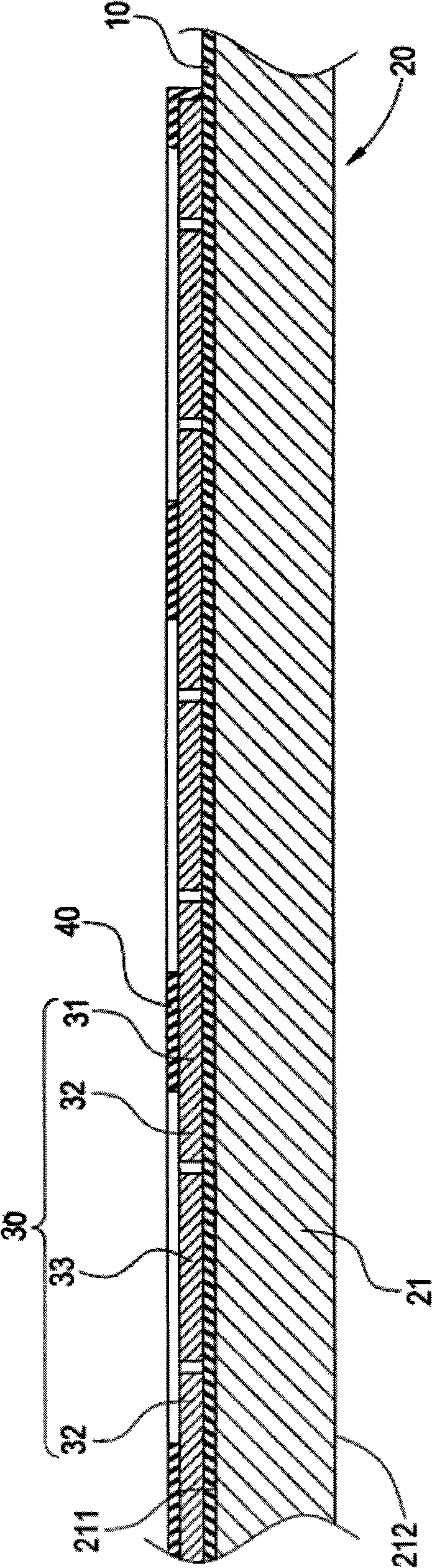

Combined structure and method of radiator and circuit

InactiveCN101472449ASolve the cooling problemImprove cooling efficiencySemiconductor/solid-state device detailsLighting heating/cooling arrangementsEngineeringElectronic component

The invention relates to a combination structure of a heat radiator and a circuit, as well as a combination method thereof. The structure comprises an extrusion-type aluminum-base plate, a first insulating layer, a conducting layer, a second insulating layer and an electronic element, wherein, the extrusion-type aluminum-base plate is covered with the first insulating layer; the conducting layer is wired on the first insulating layer and provided with a conducting wire and a plurality of guidance and connection points; the conducting wire is covered with the second insulating layer; the electronic element is provided with two conducting terminals; and the two conducting terminals are electrically connected with each guidance and connection point respectively. In addition, the invention further provides the method for combining the heat radiator and the circuit. Therefore, the invention can not only shorten process time and save the element consumption, thereby reducing the cost, but also increase the thermal conduction efficiency and improve the radiating efficiency.

Owner:AMA PRECISION INC

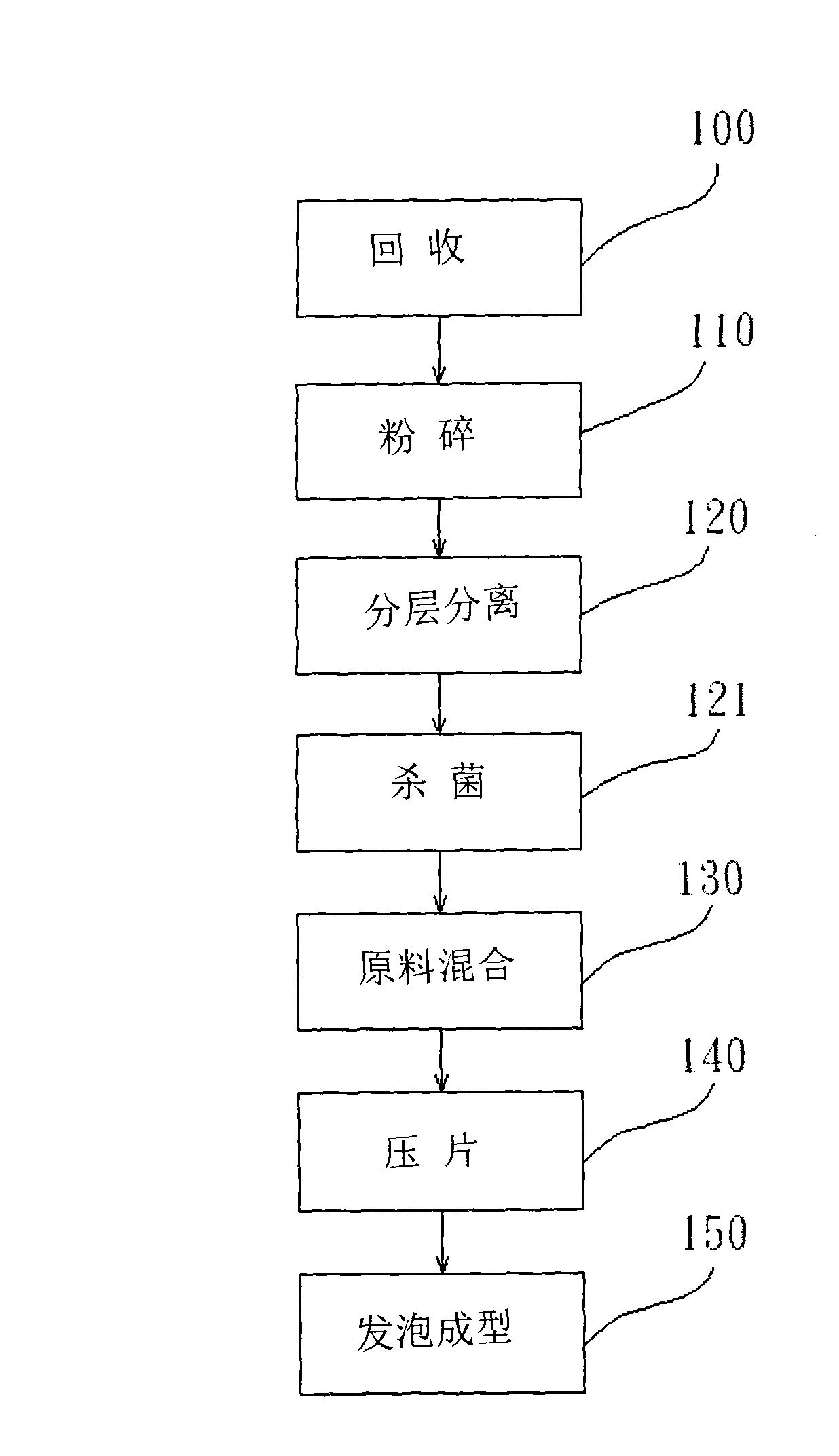

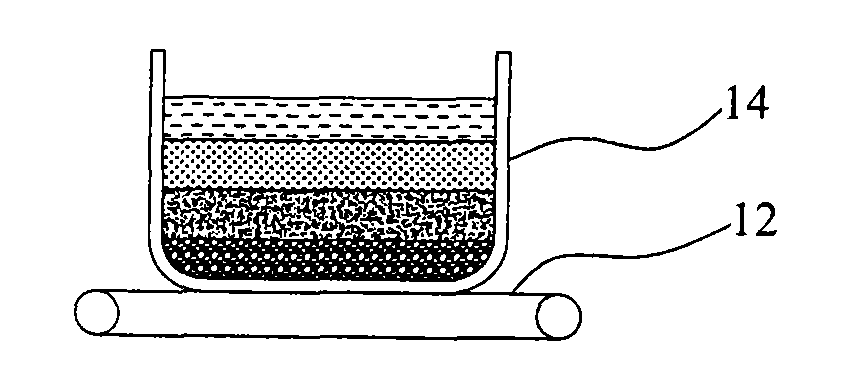

Method for manufacturing elastic foam by using reclaimed wastes as materials

InactiveCN101633218AOmit to useReduce wastePlastic recyclingMechanical material recoveryFiberFoaming agent

The invention discloses a method for manufacturing elastic foam by using reclaimed wastes as materials, which comprises the following steps: reclaiming, namely reclaiming metal wastes containing rubber, plastic, fiber, metal and the like; crushing, namely crushing the wastes into scraps; layering and separating, namely forming a layering and separating state of the waste scraps of different components according to a specific gravity difference; mixing raw materials, namely selecting the waste scraps of predetermined components and adding the waste scraps into the raw materials such as elastic material, foaming agent and the like, and mixing the whole; pressing, namely pressing the mixed raw materials into a sheet foaming material; and foaming and molding, namely foaming and molding the sheet foaming material into the elastic foam by adding sulfur. The reclaimed and treated waste scraps do not need to be fully separated into single materials and can be added into the foaming material as the elastic foam raw material, so the wastes can be fully reclaimed and reutilized, the rubbish amount is reduced, and the reclaiming and treating cost is effectively reduced; and the waste scraps and the elastic material are adhered together by utilizing the pressure of gas produced in the chemical change of the foaming agent, so the adhesive is saved, and the environment is protected.

Owner:SHIUN JIUG INDAL

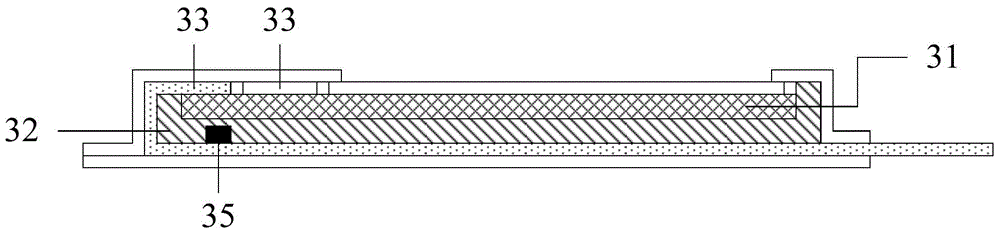

Fingerprint imaging unit and formation method thereof

A fingerprint imaging unit and a formation method thereof are disclosed. The fingerprint imaging unit comprises a light guide substrate, a plurality of net points and a sensitization device, wherein the light guide substrate includes a first surface, a second surface opposite to the first surface and a side surface located between the first surface and the second surface; the plurality of net points form on the second surface of the light guide substrate and are used for forming sensing light which is emergent from the first surface; and the sensitization device is arranged in the first surface. In the invention, through arranging the plurality of net points on the second surface of the light guide substrate, usage of a light guide plate is omitted so that the structure of the fingerprint imaging unit is simplified; thickness of the fingerprint imaging unit is reduced; an integration level of the fingerprint imaging unit is increased; and manufacturing cost and technology difficulty of the fingerprint imaging unit are reduced.

Owner:SHANGHAI OXI TECH

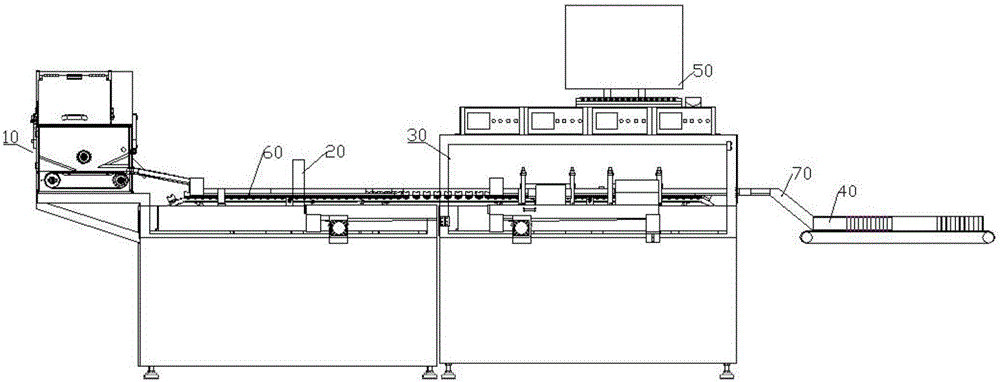

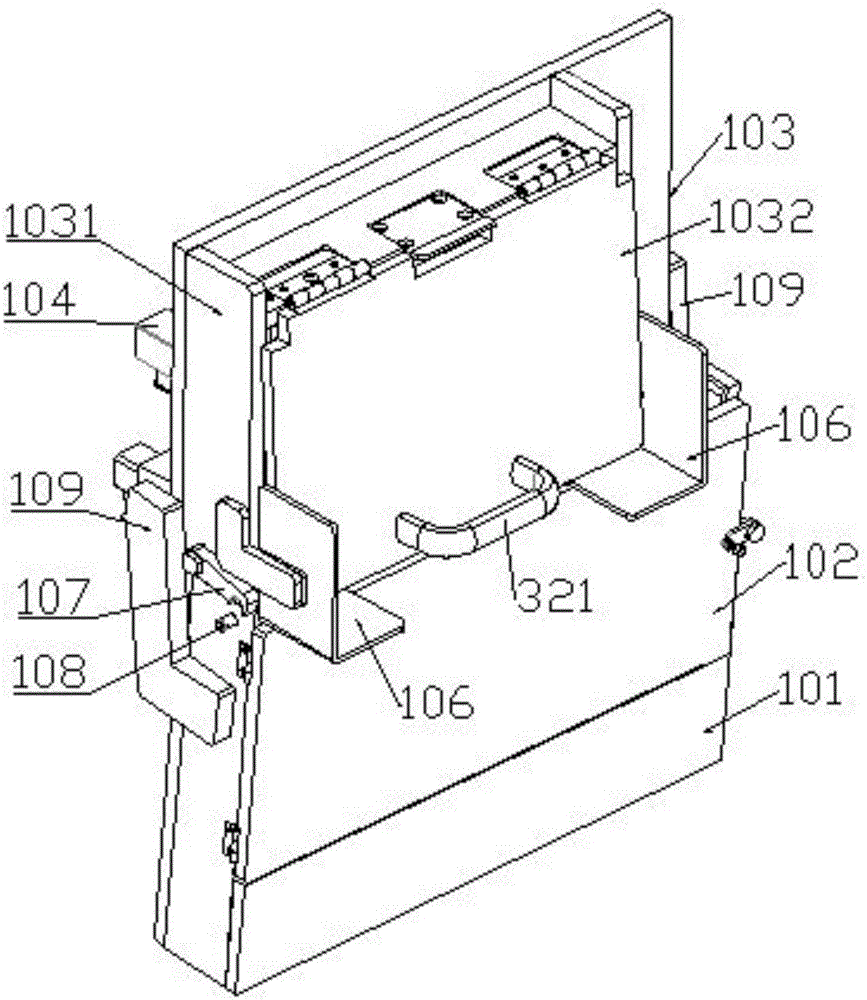

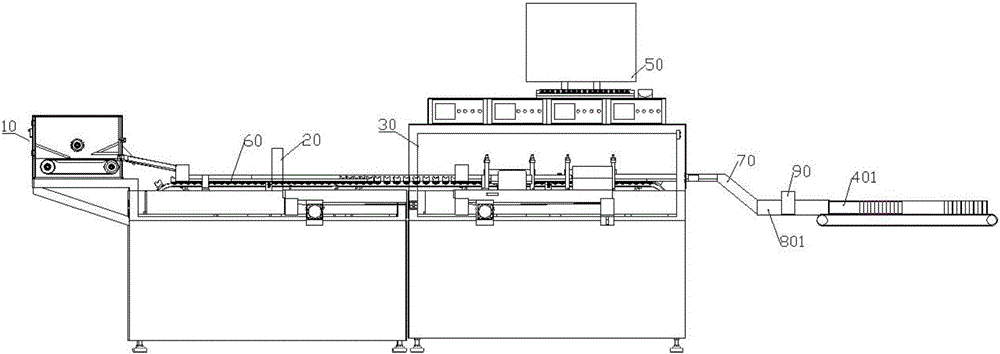

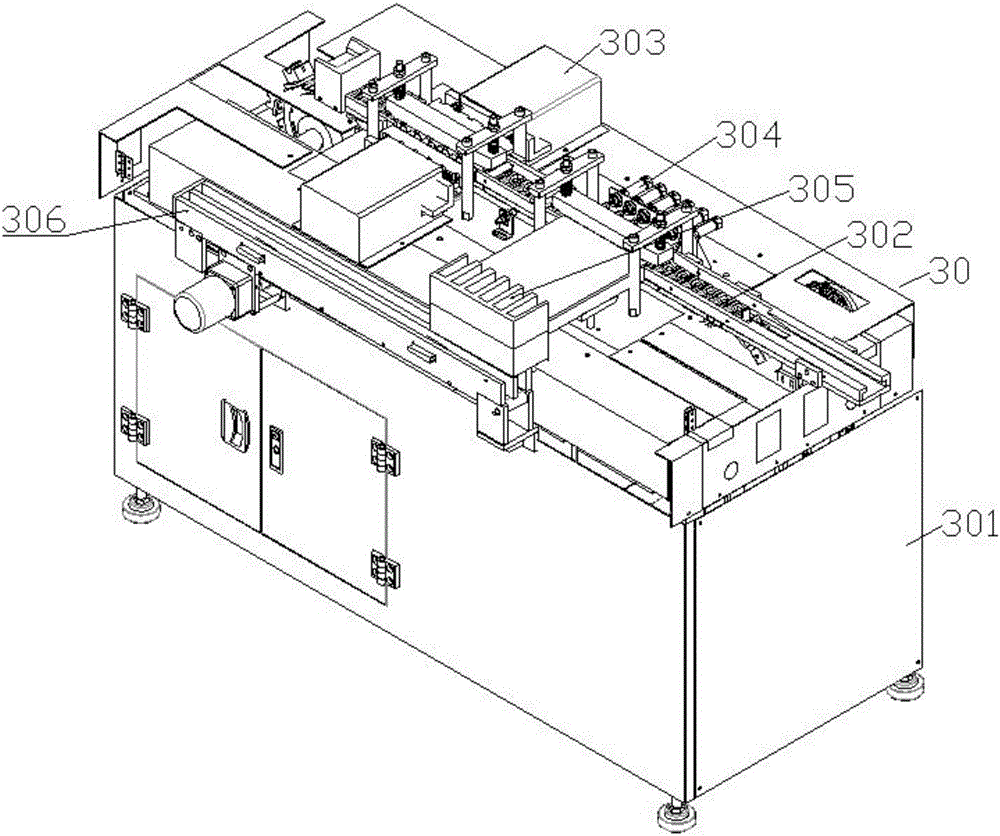

Automatic feeding, detecting and positioning system of batteries

PendingCN106694403AOvercoming the high processing and production costsLow processing and production costsElectrical testingSortingElectrical batteryElectrical and Electronics engineering

The invention discloses an automatic feeding, detecting and positioning system of batteries. A battery feeding mechanism is designed, a storage mechanism is arranged on a middle sorting box, a rotatable structure is arranged between the storage mechanism and the middle sorting box, and therefore when a battery feeding device is used, the storage mechanism is flatly put firstly, the purchased batteries in the whole box are completely buckled in the storage mechanism, a storage shell cover is closed, the storage mechanism is vertically put, and therefore it is ensured that positive electrode directions and the negative electrode directions of the batteries are consistent in the storage mechanism, and use of a mechanical arm for adjusting the directions of the positive electrodes and the negative electrodes of the batteries is avoided; in addition, an unqualified battery removing mechanism is designed and is provided with at least one air cylinder and at least one battery removing sliding groove matched with the air cylinder on the two sides of a conveying belt, and therefore use of the mechanical arm for picking out unqualified batteries is avoided, the machining and producing cost of a lithium battery module is saved, and meanwhile the machining efficiency of the lithium battery module is improved.

Owner:无锡福源自动化系统工程有限公司

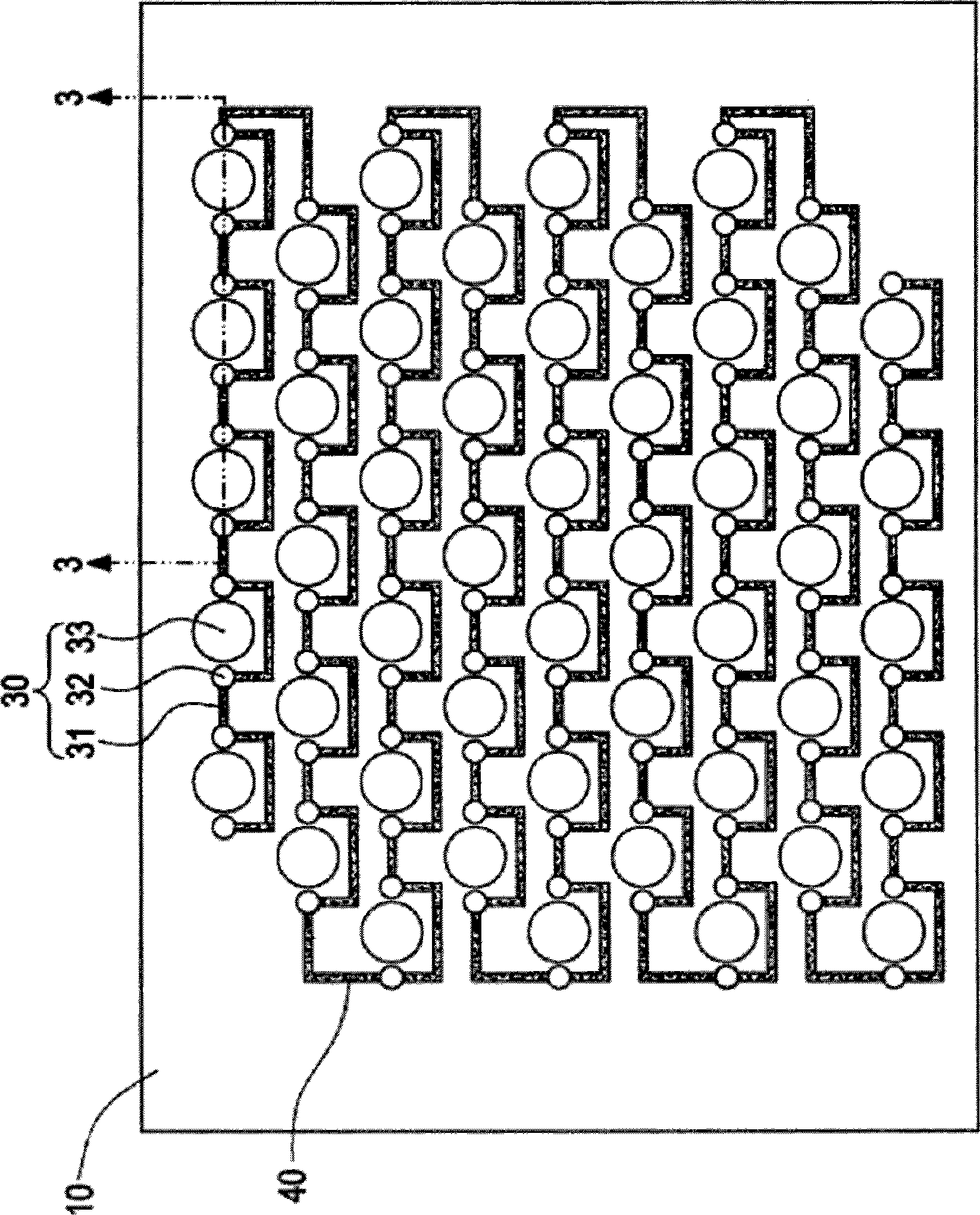

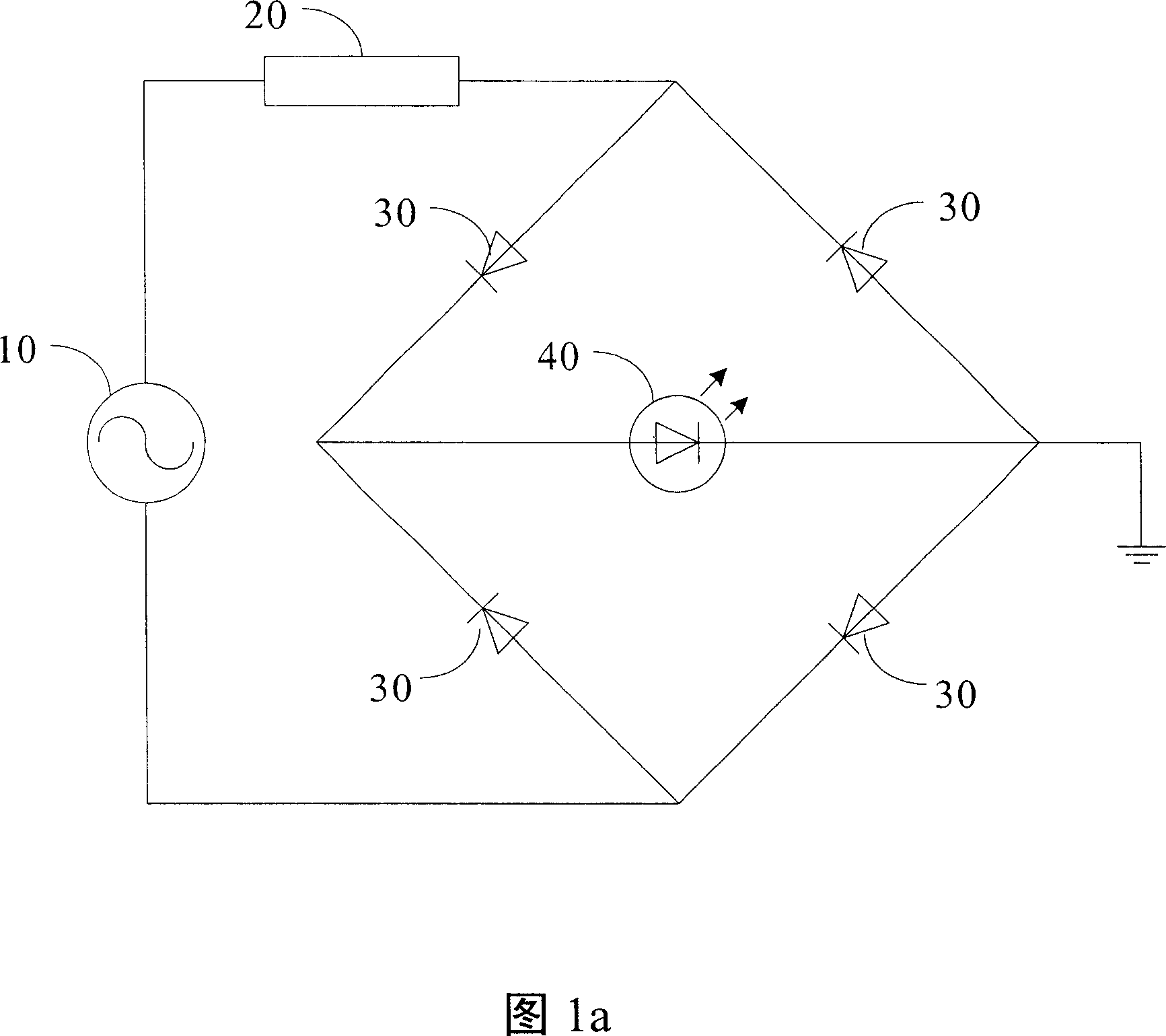

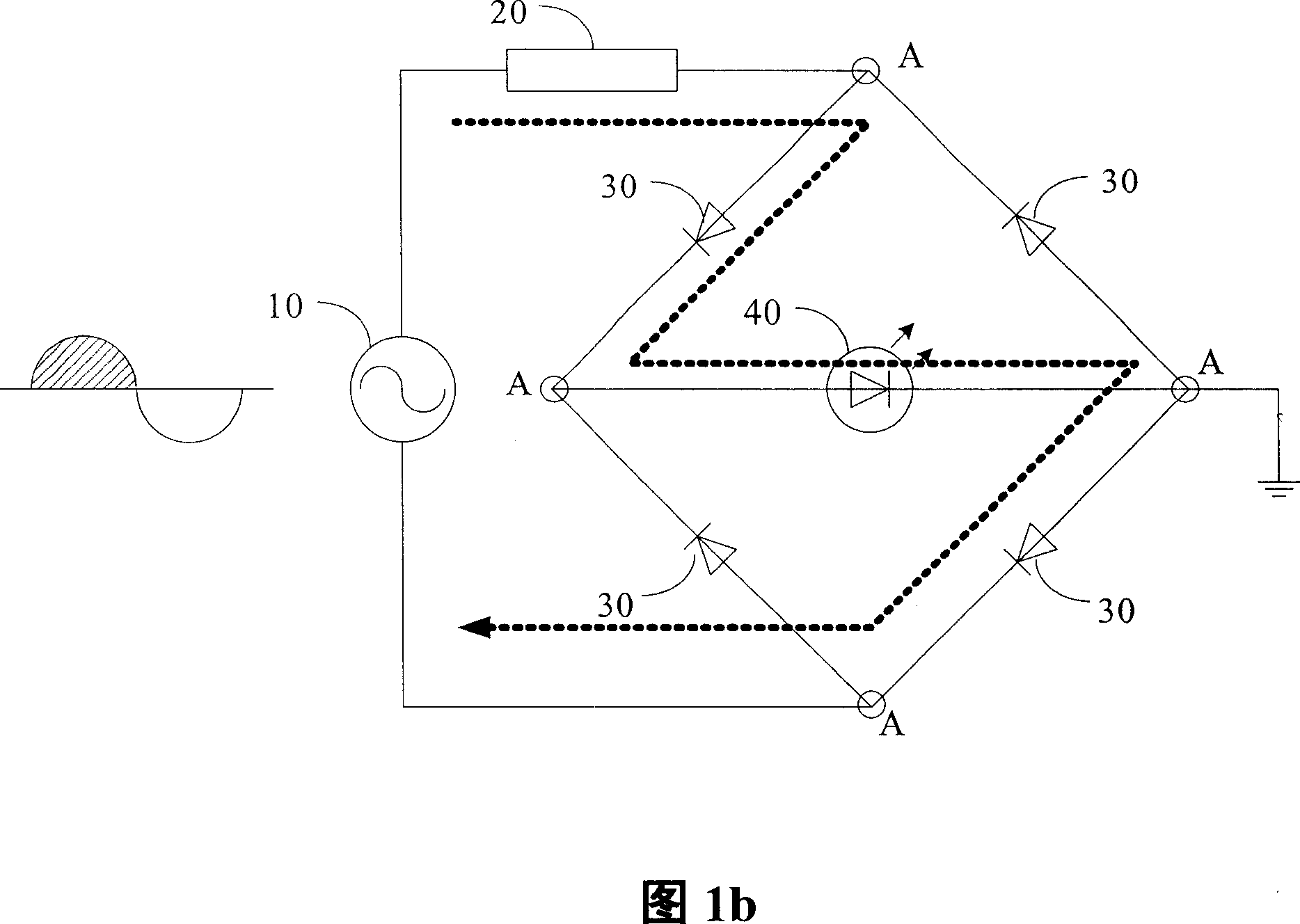

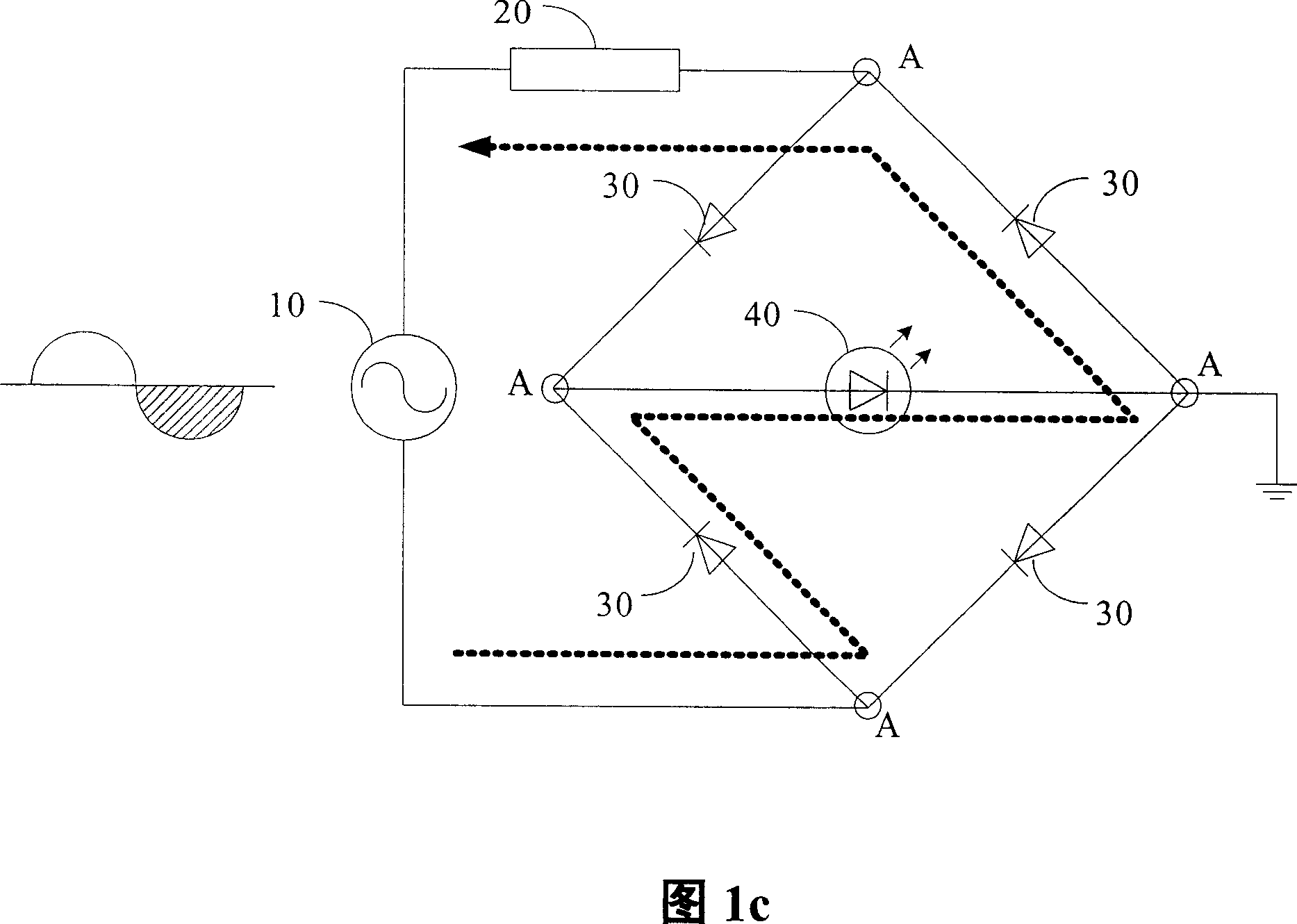

LED luminescent device combined with rectifying circuit on secondary carrier and its production

ActiveCN1983594AShorten process timeReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitMetal

The invention is concerned with the illumination equipment and the corresponding method for the alternating current direct drive, the conformity commutating circuit and the light-emitting diode (LED). The LED illumination equipment includes the base-board, the top base-board, and the bottom base-board. The bottom base-board uses the manufacture of the integrate circuit to implement the commutating circuit, and sets the fit electric point on the surface. The top base-board uses the manufacture of the integrate circuit to implement the several LED in it by the arrangement mode of insulating independent N*M matrix. Between the N*M of LED forms the fit circuit by the connection of the lead. The top base-board and the bottom base-board are opposite, and finish the electric connection between the commutating circuit and the LED by the metal protruding block.

Owner:TYNTEK

Wholly-degradable emulation empty aluminums plating or aluminum platinum composite paper

InactiveCN101377065ABeautiful appearanceNo pollution in the processPaper coatingCoatingsPlatinumWater soluble

The present invention relates to a fully degradable imitative vacuum-aluminized or aluminum foil composite paper, which not only can reduce the production cost of packing paper but also can avoid environment pollution. The composite paper comprises a lightweight coated paper or a lining paper, at least one side of which is provided with a water-soluble varnish coating. After being discarded, the imitative vacuum-aluminized or aluminum foil composite paper can be quickly and fully oxidated and degraded, so the environment cannot be polluted. Moreover, since the water-soluble varnish coating is adopted and the non-ferrous aluminum is not needed, a great deal of non-ferrous aluminum is saved, so the cost is remarkably reduced.

Owner:ANHUI SHUANGYONG PACKAGE & DECORATION MATERIAL

Automatic feeding, detecting and sorting system of batteries

PendingCN106697880AOmit to useOvercome the problem of high processing and production costsSortingConveyor partsProduction lineElectrical battery

The invention discloses an automatic feeding, detecting and sorting system of batteries, and belongs to the field of a battery machining production line. According to the automatic feeding, detecting and sorting system of the batteries, an unqualified battery removing mechanism is arranged behind a voltage and resistance detecting mechanism and is in the conveying direction of a conveying mechanism, and comprises at least one air cylinder arranged on one side of the conveying mechanism and at least one battery removing sliding groove which is matched with the air cylinder and formed in the other side of the conveying mechanism, and therefore use of a mechanical arm for picking out unqualified batteries is avoided, the problem that in the prior art, many mechanical arms are adopted, and the machining and producing cost of a lithium battery module is high is solved, the machining and producing cost of the lithium battery module is saved, and meanwhile the machining efficiency of the lithium battery module is improved.

Owner:无锡福源自动化系统工程有限公司

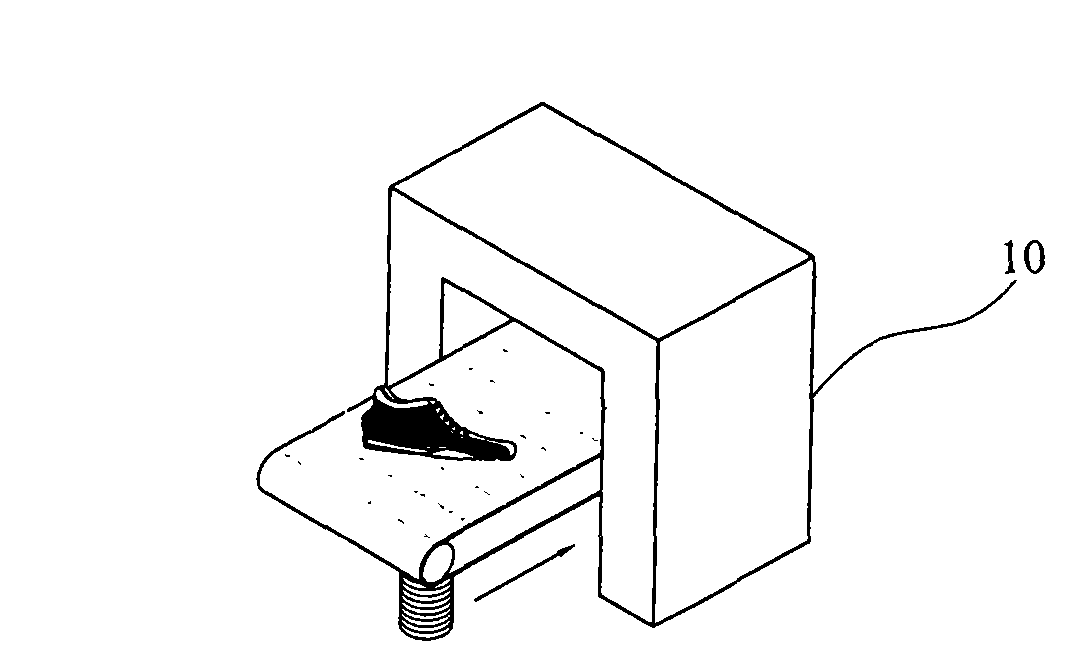

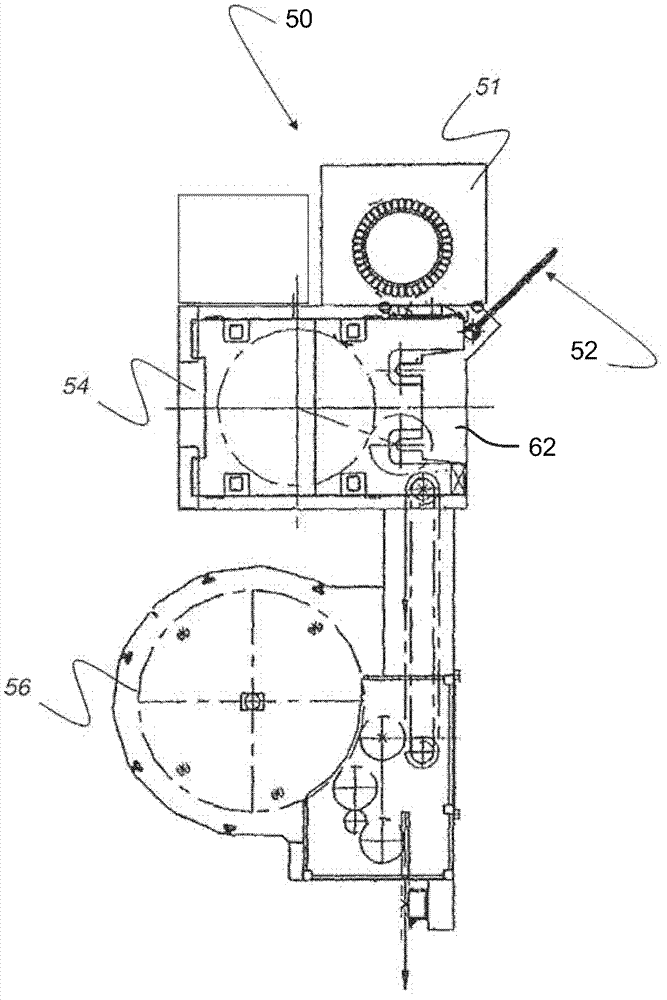

Device And Method For Sterilisation Packaging Items

InactiveCN103086021ASimplified mechanical technologyOmit to usePackage sterilisationPackaging machinesSinglet oxygenEngineering

A method of sterilizing packaging means (10) and, in particular, plastics material pre-forms (10), wherein the packaging means (10) are conveyed with a conveying device (2) and wherein at least one area of the packaging means (10) is acted upon with a flowable medium by a stressing device (4). According to the invention the medium applied to the area is subjected to irradiation with electromagnetic radiation in order to produce singlet oxygen, wherein this singlet oxygen is used to sterilize the packaging means (10).

Owner:KRONES AG

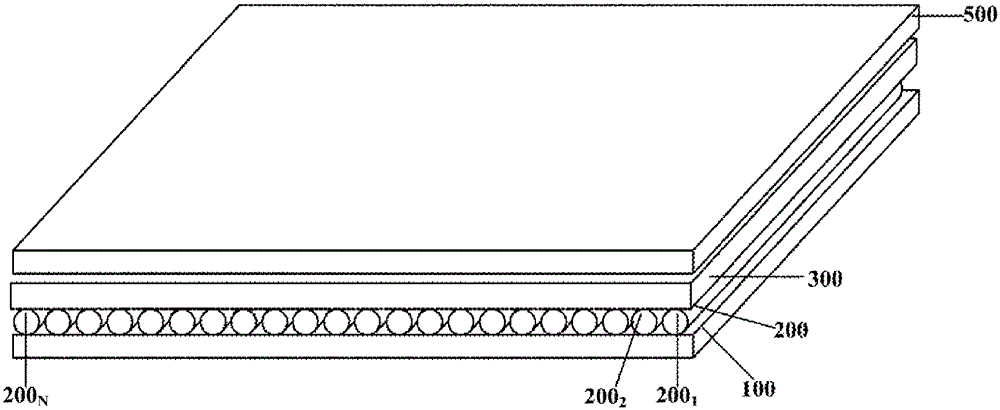

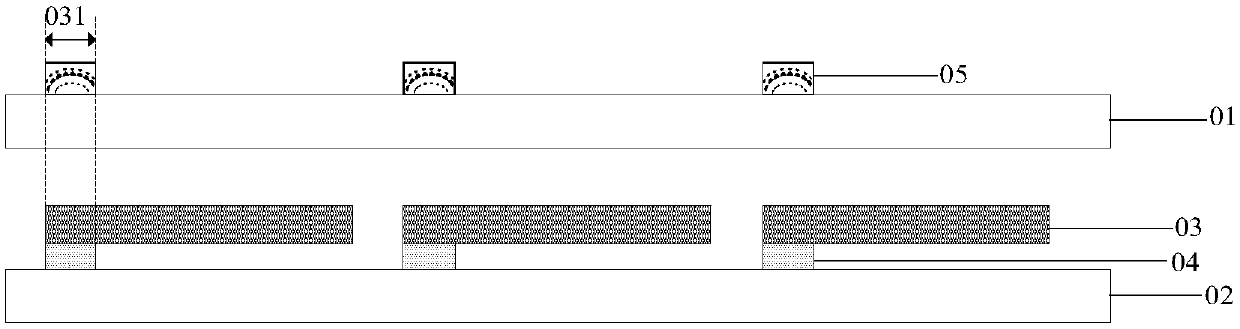

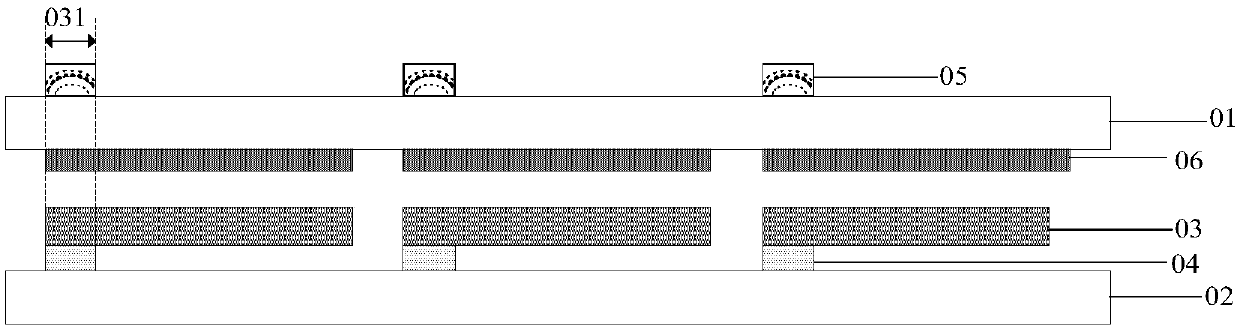

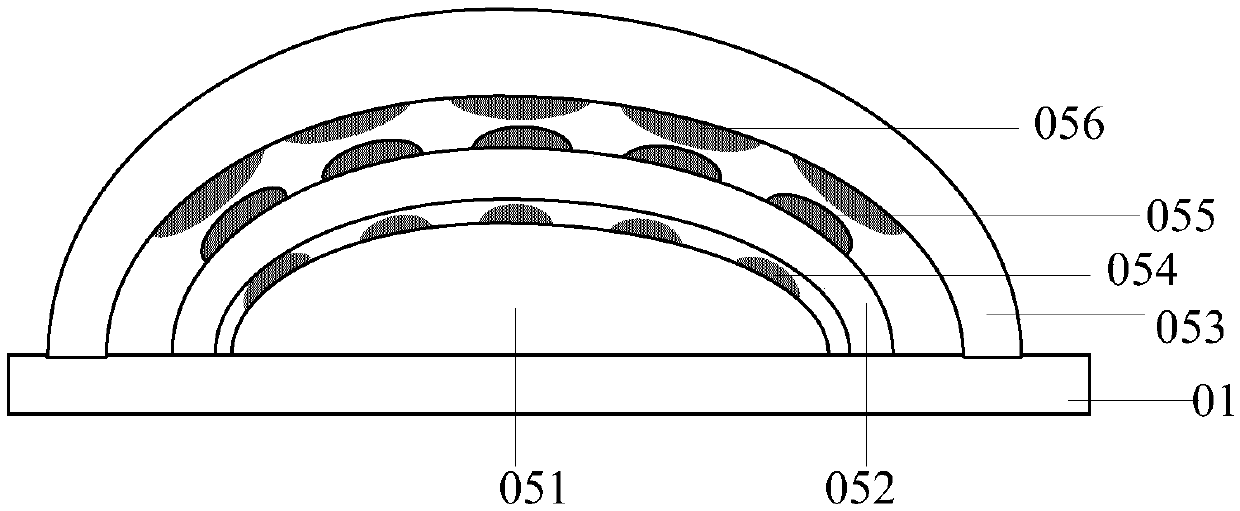

Optical module and liquid crystal display device using same

ActiveCN105158977AUniform emissionReduce crosstalkFibre light guidesBundled fibre light guideFiberOptical Module

The invention relates to an optical module and a liquid crystal display device formed by the same. The optical module comprises a first base material layer, a second base material layer and an optical fiber layer arranged between the first base material layer and the second base material layer, wherein the optical fiber layer comprises a single layer of multiple optical fibers which are closely arranged, at least one of the surface of the first base material layer and the surface of the second base material layer is provided with multiple adhesive points which make contact with the optical fibers, and the contact points on which the adhesive points make contact with the optical fibers destroy the total reflection happening in the optical fibers. In this way, by means of the optical module and the liquid crystal display device using the same, high color gamut display can be achieved.

Owner:BOE TECH GRP CO LTD +1

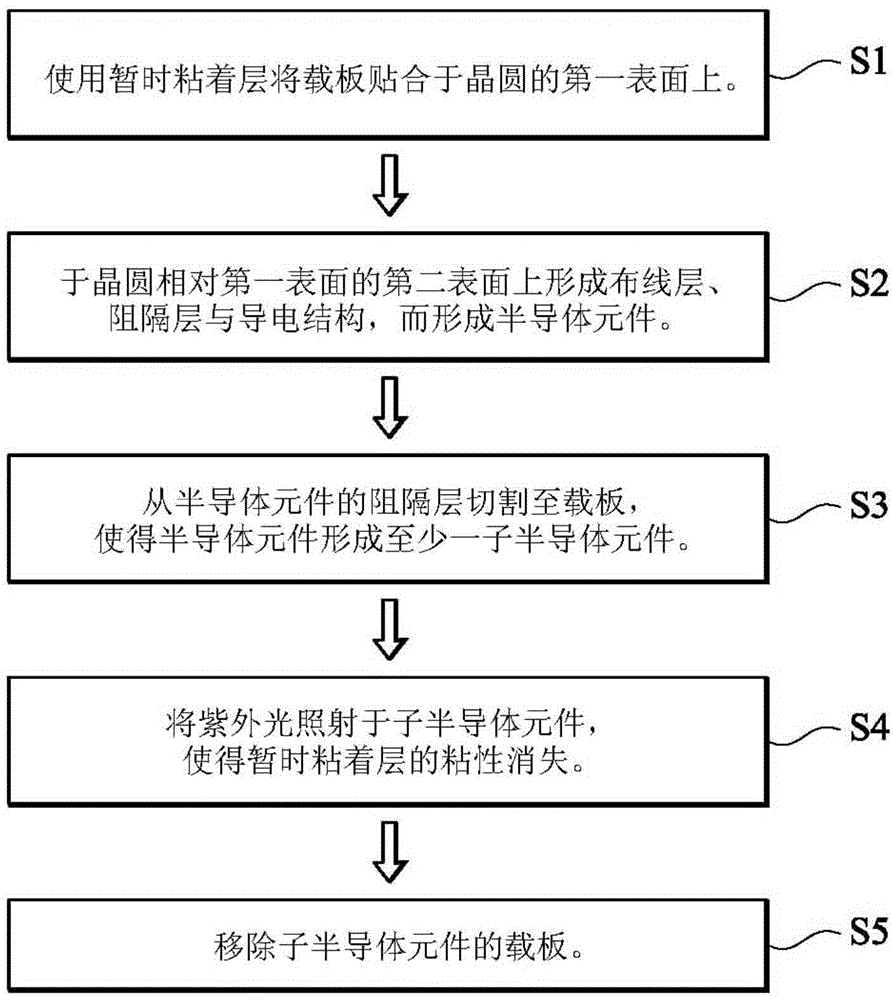

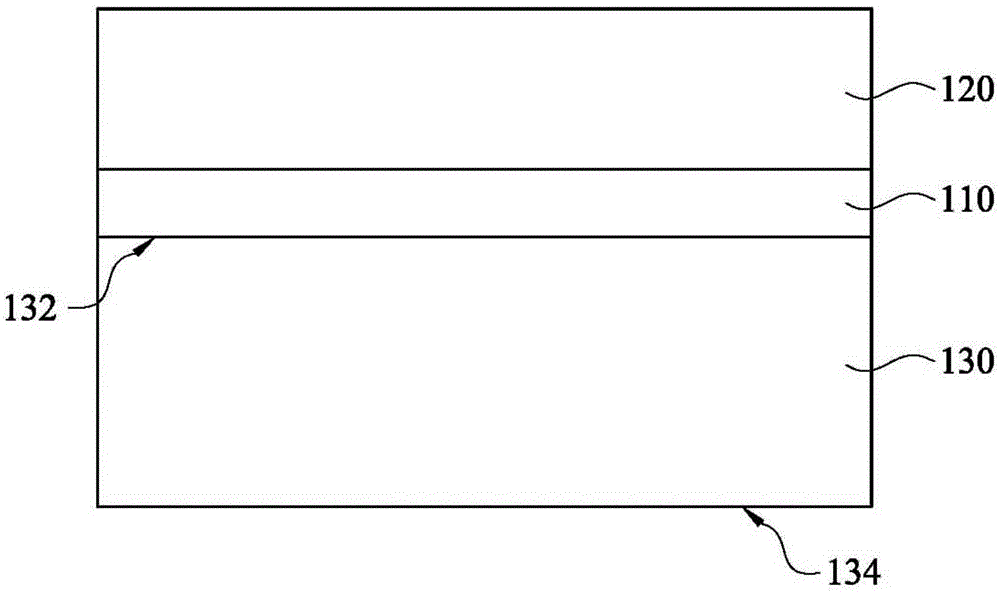

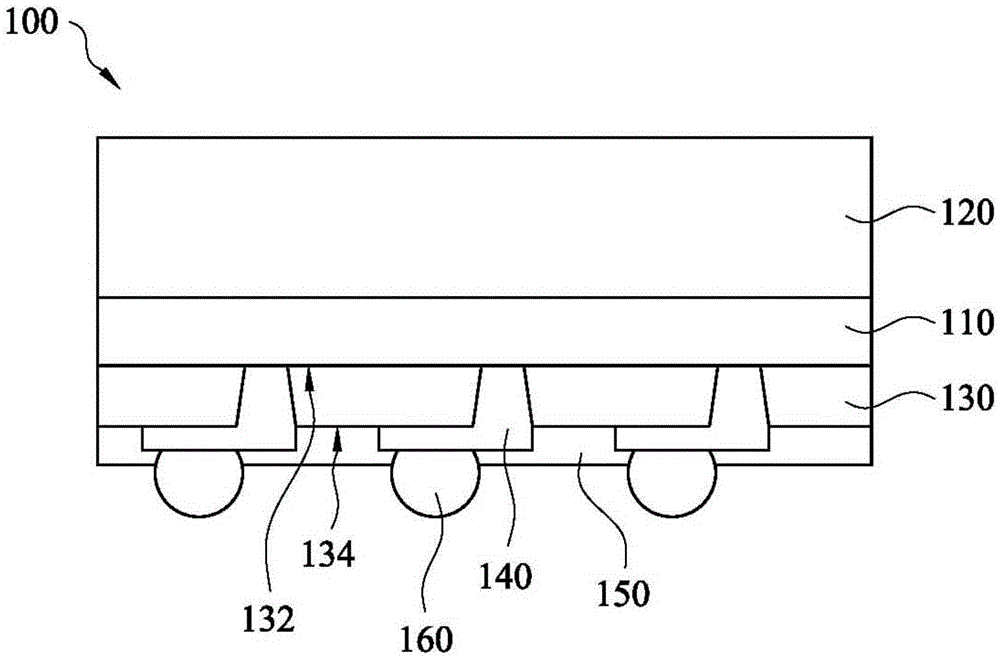

Semiconductor device and manufacturing method thereof

ActiveCN104795319ANot easy to polluteLow costSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing cost reductionRedistribution layer

A manufacturing method of a semiconductor device includes the following steps. A temporary bonding layer is used to adhere a carrier to a first surface of a wafer. A redistribution layer, an insulating layer, and a conductive structure are formed on a second surface of the wafer opposite to the first surface, such that a semiconductor element is formed. The semiconductor element is diced from the insulating layer to the carrier, such that the semiconductor element forms at least one sub-semiconductor element. UV light is used to irradiate the sub-semiconductor element, such that adhesion of the temporary bonding layer is eliminated. The carrier of the sub-semiconductor element is removed.

Owner:XINTEC INC

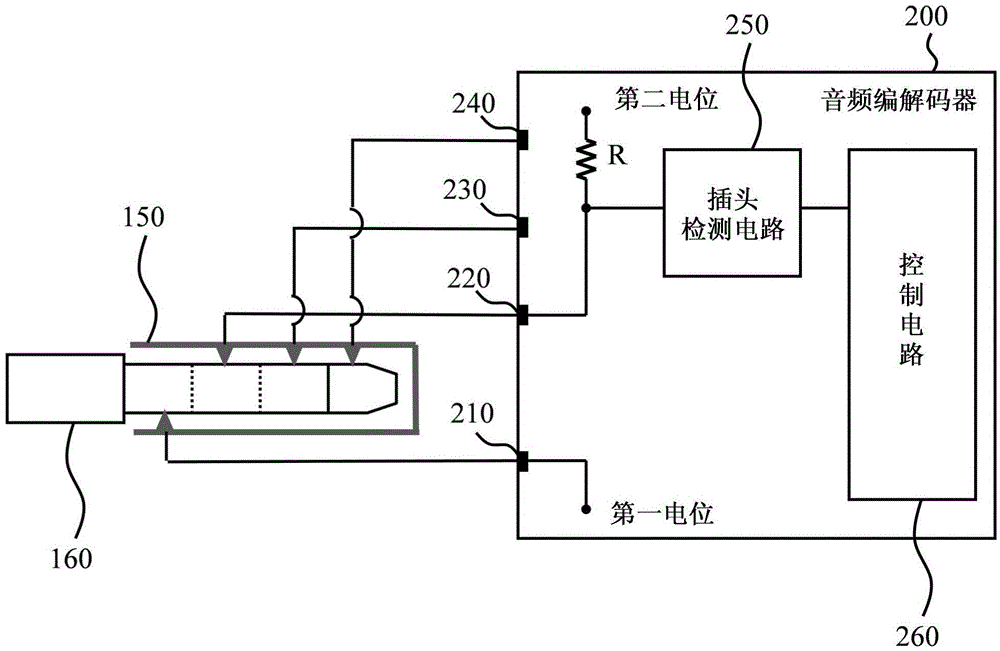

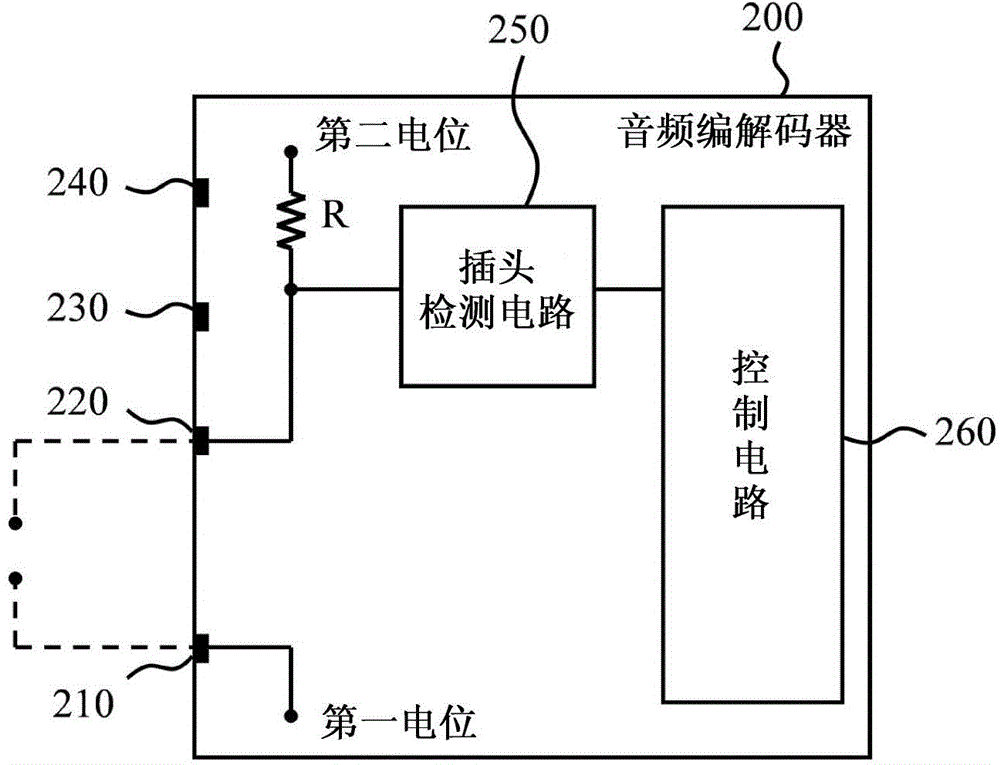

Audio encoder/decoder with audio insertion-connection detection capacity and audio insertion-connection detecting method

The invention discloses an audio encoder / decoder with audio insertion-connection detection capacity and an audio insertion-connection detecting method. The embodiment of the audio encoder / decoder includes a first contact signal input end, for being electrically connected with a sleeving-connecting point of a plug, and receiving a first contact signal; a second contact signal input end, for electrically connected with an annular connecting point or a sleeving-connecting point of the plug, and receiving a second contact signal; a plug detecting circuit, coupled with the first contact or second contact signal input end for detecting whether the voltage level of the first or second contact signal changes, and generate a plug detecting signal accordingly; and a control circuit, coupled with the plug detecting circuit, for judging whether the plug exists according to the plug detecting signal.

Owner:REALTEK SEMICON CORP

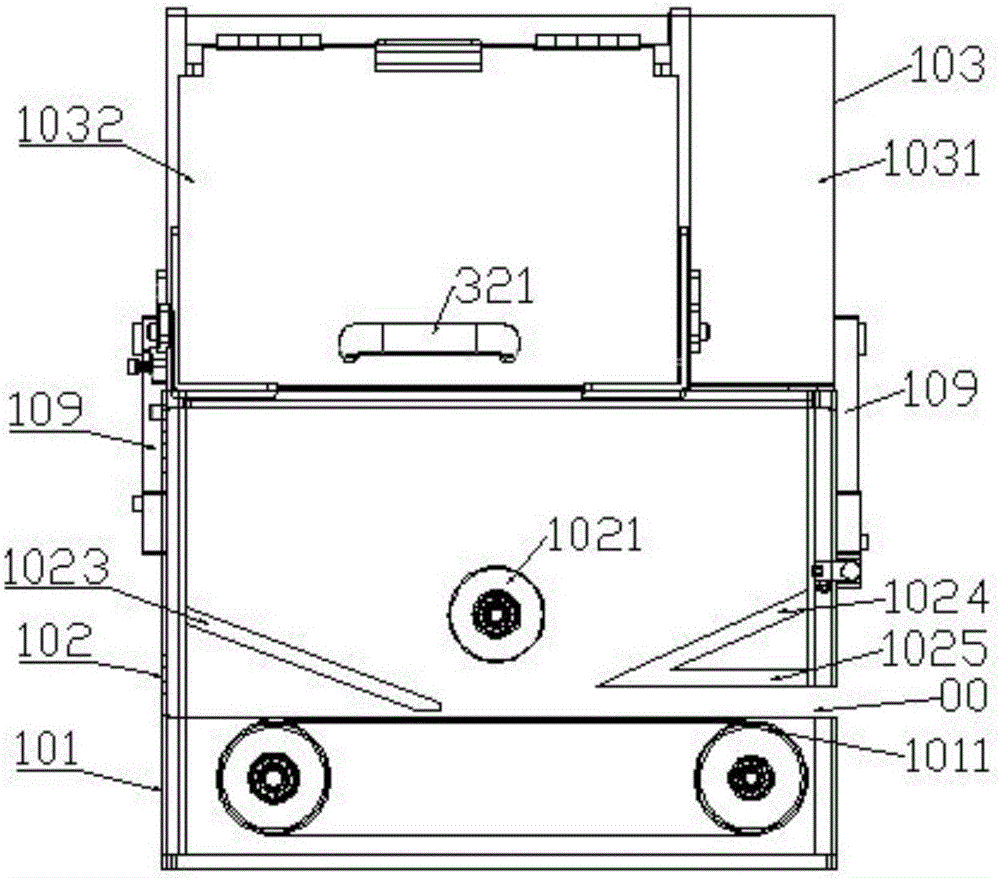

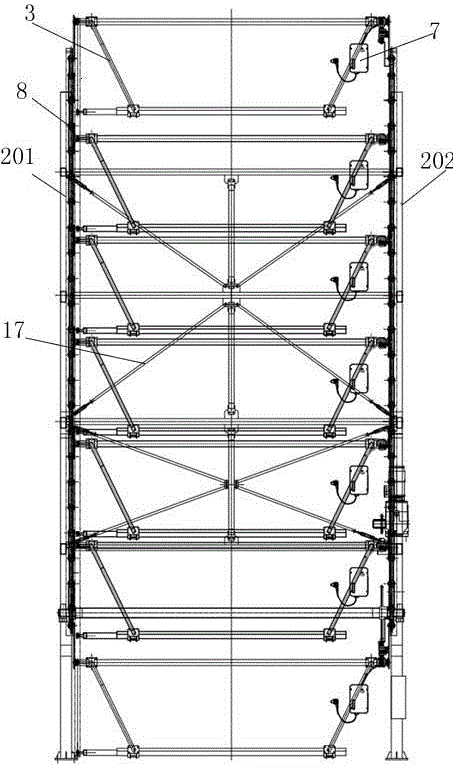

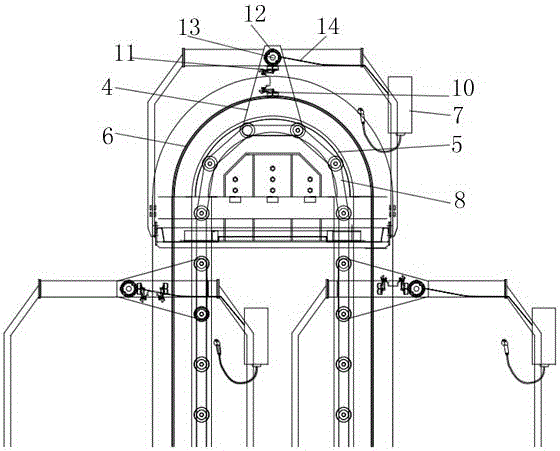

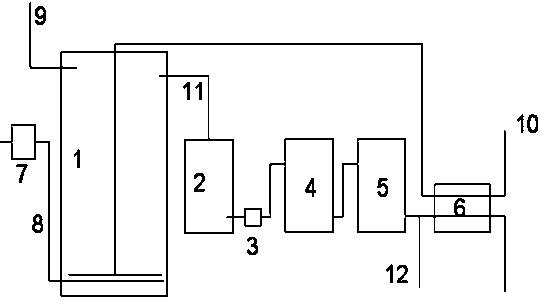

Vertical circular charging type three-dimensional parking garage

InactiveCN106168076AOmit to useSimple structureCharging stationsElectric vehicle charging technologyElectricityEngineering

Owner:SHANGHAI DOUYOU ELECTRIC EQUIP CO LTD

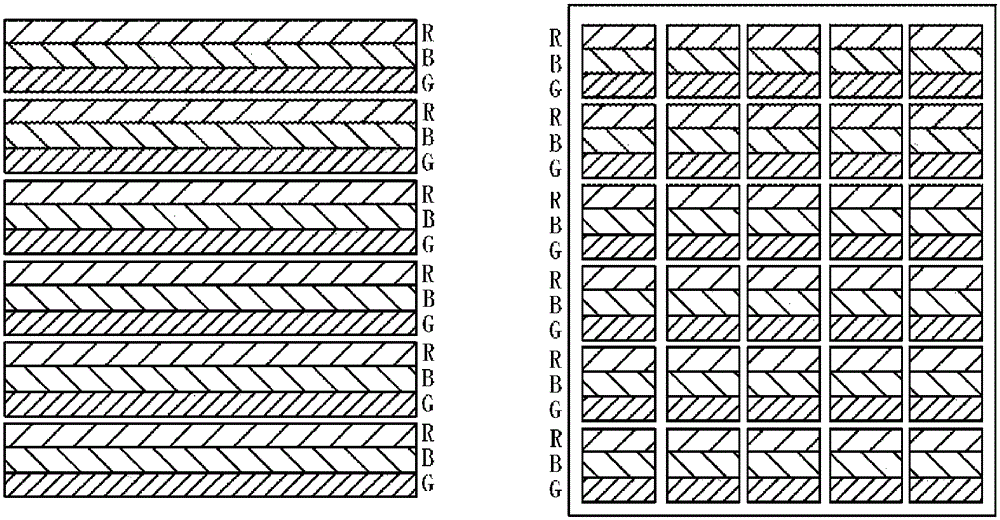

Display panel and display device

ActiveCN107592444AReduce crosstalk of lightImprove image qualityTelevision system detailsColor television detailsDisplay deviceImaging quality

The invention discloses a display panel and a display device. A lens imaging unit and a photosensitive element are integrated in a pixel unit of the display panel, thereby replacing the use of a camera, and reducing the cost of the display panel; through the imaging of the lens imaging unit, not only is the cross-talking of the light reduced, but also is the imaging quality of an edge visual fieldof the display panel greatly promoted; the display panel comprises a first substrate and a second substrate arranged in opposite, and multiple pixel units arranged in an array; the pixel unit comprises an imaging acquisition region; the display panel further comprises a photosensitive element arranged at one side of the second substrate facing to the first substrate and corresponding to the imaging acquisition region, and a lens imaging unit arranged at one side of the first substrate far away from the second substrate and in one-to-one correspondence to the photosensitive element.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

Energy saving and environment protecting electrolytic copper foil copper dissolving system and copper dissolving process

PendingCN109440170AReduce energy consumptionReduce heat lossCellsLiquid chemical processesCopper foilPollutant

The invention provides an energy saving and environment protecting electrolytic copper foil copper dissolving system and a copper dissolving process. A copper dissolving tank is included, and communicates with a liquid feeding pipeline and an overflow pipeline; the overflow pipeline communicates with the upper portion of the copper dissolving tank; the overflow pipeline is sequentially provided with an overflow liquid storing tank, a filter and a heat exchanger; the liquid feeding pipeline communicates with the top of the copper dissolving tank after passing through the heat exchanger; the upper portion of the copper dissolving tank communicates with an air draft pipeline; and the bottom of the copper dissolving tank communicates with an air blower. According to the energy saving and environment protecting electrolytic copper foil copper dissolving system and the copper dissolving process, due to energy transformation on the copper dissolving system, the copper dissolving reaction speed is effectively increased, the energy consumption is lowered, and various types of pollutants accompanied in the whole copper dissolving process are remarkably lowered.

Owner:LINGBAO WASON COPPER FOIL

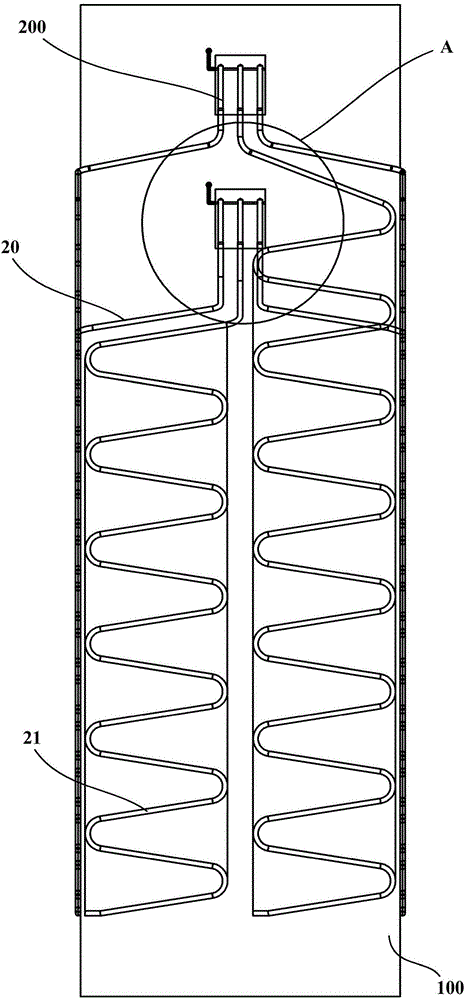

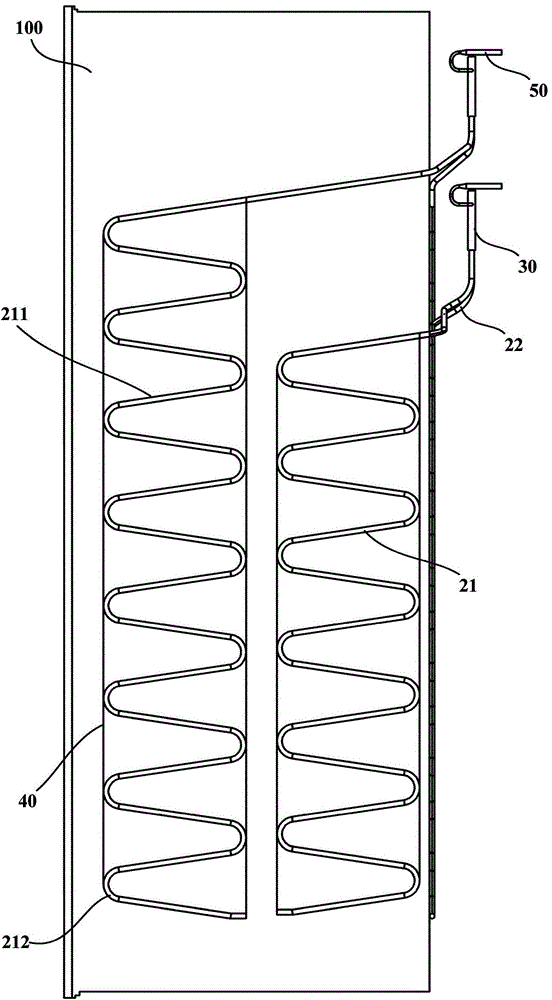

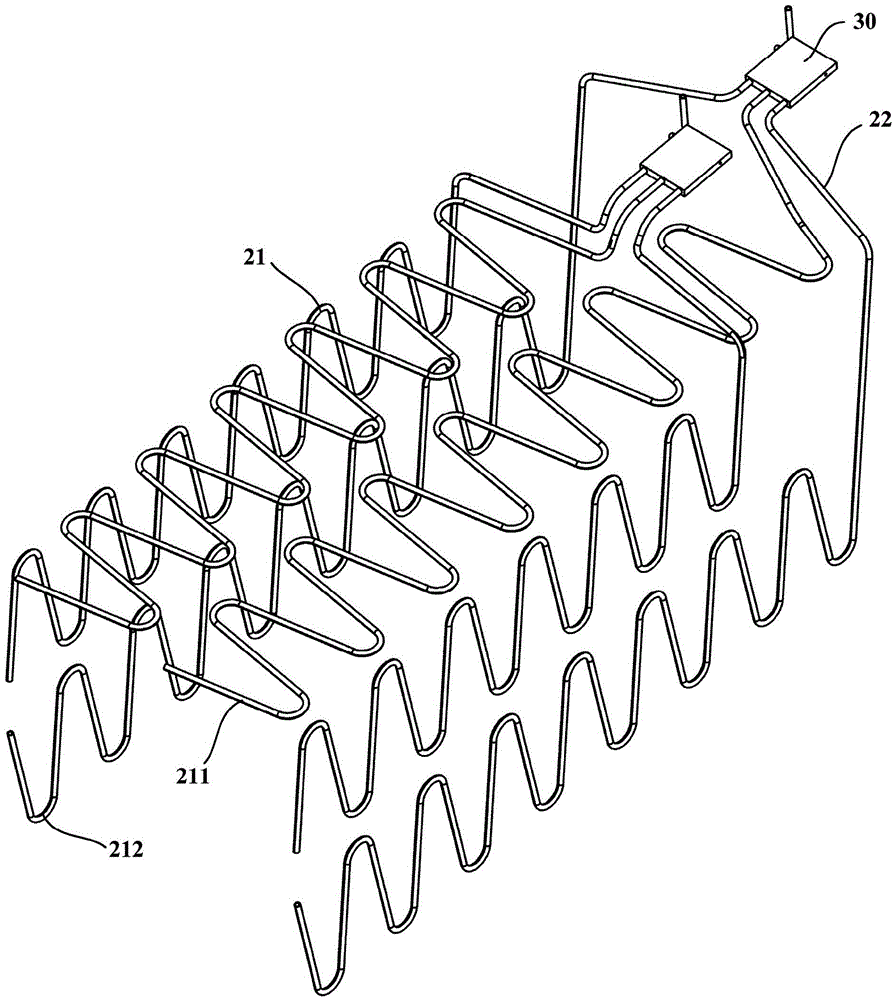

Semiconductor refrigeration refrigerator

ActiveCN104567175AImprove energy efficiencyIncrease the effective heat transfer areaDomestic refrigeratorsIndirect heat exchangersVertical planeEngineering

The invention provides a semiconductor refrigeration refrigerator. Specifically, the semiconductor refrigeration refrigerator provided by the invention comprises an inner container, at least one semiconductor refrigerating sheet and a plurality of cold-end heat exchanging devices, wherein each cold-end heat exchanging device is configured to exist a flow and a phase-change heat exchange of refrigerant in the cold-end heat exchanging device so as to transfer cold at an cold end of the at least one semiconductor refrigerating sheet to a storage chamber of the inner container. Specifically, each cold-end heat exchanging device is provided with three refrigerant pipelines, each refrigerant pipeline is provided with an evaporating segment with a closed end, the evaporating segment extends downwards in a vertical plane in a bent manner, and evaporating segments of the three refrigerant pipelines of each cold-end heat exchanging device are respectively connected to a rear wall and two side walls of the inner container in a thermal manner. According to the semiconductor-refrigerated refrigerator provided by the invention, as the plurality of cold-end heat exchanging devices are provided, effective heat exchange area in thermal connection with the inner container of the refrigerator is enlarged significantly, and therefore energy efficiency of the semiconductor refrigeration refrigerator is improved significantly.

Owner:HAIER SMART HOME CO LTD

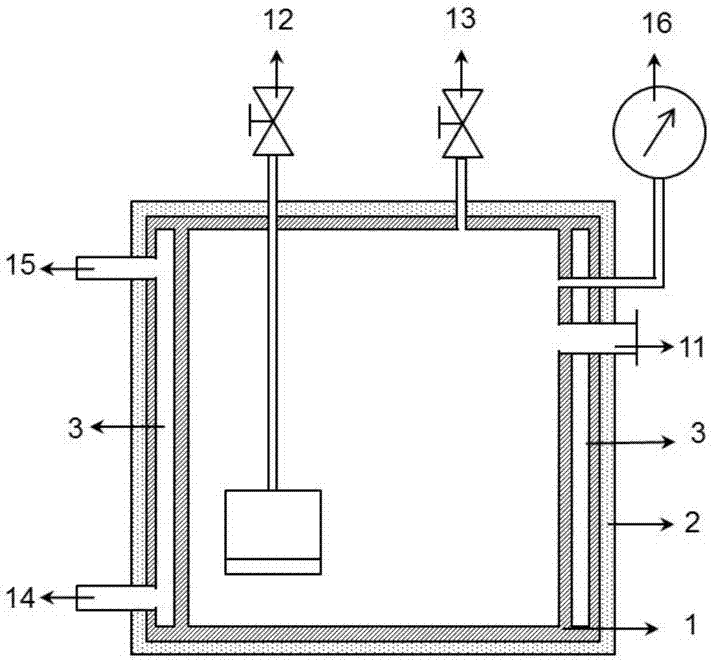

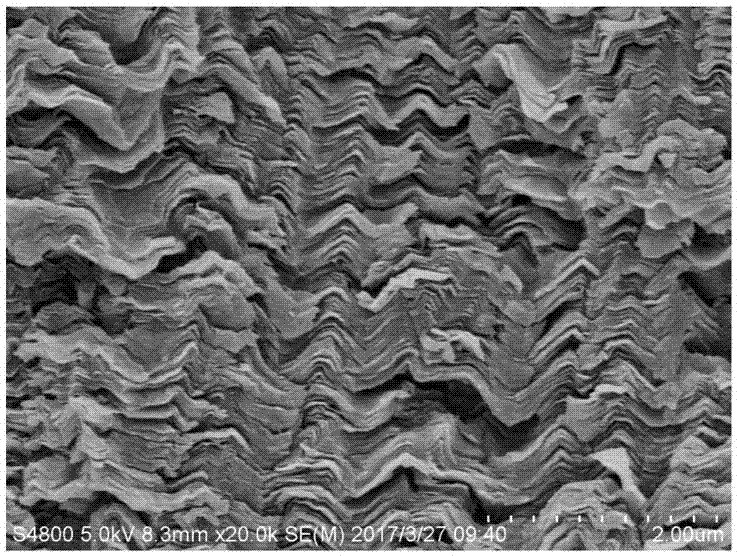

Method for preparing pyrolytic boron nitride material

InactiveCN107265416AIncrease productivityFast deposition growthNitrogen compoundsBoron nitrideChemical vapor deposition

The invention discloses a method for preparing a pyrolytic boron nitride material. The method comprises the following steps: putting a substrate mold in an air-carrying atmosphere carrying borazine vapor under a vacuum condition, and pyrolyzing borazine which constantly deposits on the depositing surface of the substrate mold by adopting a chemical vapor deposition method to form the pyrolytic boron nitride material. The preparation method of the pyrolytic boron nitride material has the advantages of simple and easily controlled process, low cost, low energy consumption, high yield, environmental friendliness and the like.

Owner:NAT UNIV OF DEFENSE TECH

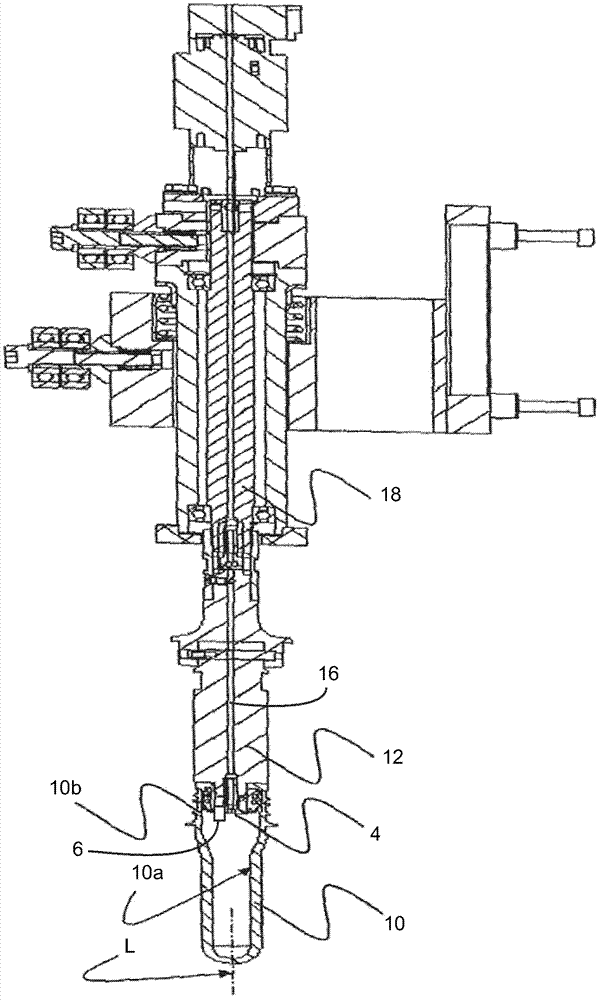

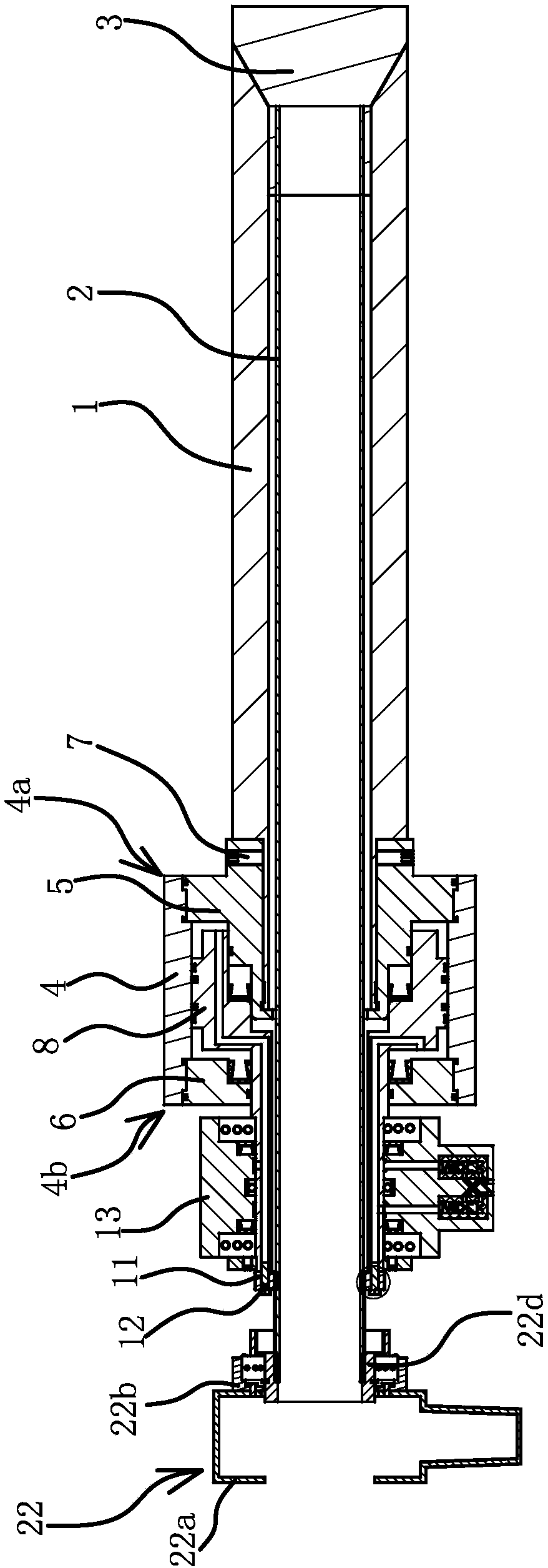

Rotary oil cylinder for lathe spindle box

PendingCN107695364AEasy to disassembleImprove the convenience of disassembly and assemblyLarge fixed membersPositioning apparatusCylinder blockHeadstock

The invention provides a rotary oil cylinder for a lathe spindle box and belongs to the technical field of machinery. By means of the rotary oil cylinder, the problem that existing rotary oil cylinders are inconvenient to dismount. The rotary oil cylinder for the lathe spindle box comprises a cylinder body. The cylinder body is provided with a fitting end and a mounting end, wherein the mounting end is used for being connected with a spindle of the lathe spindle box. The cylinder body is internally provided with a piston, wherein the piston can move. One end of the piston is provided with a protruding fitting portion. The fitting portion extends out of the fitting end of the cylinder body, and a mounting disc is detachably connected to the end of the fitting portion. A pull tube of the lathe spindle box can sequentially penetrate the fitting portion and the mounting disc, and detachable connection can be formed between the pull tube and the mounting disc. The rotary oil cylinder has the beneficial effects of being convenient to dismount, simple in structure and the like.

Owner:郭必龙

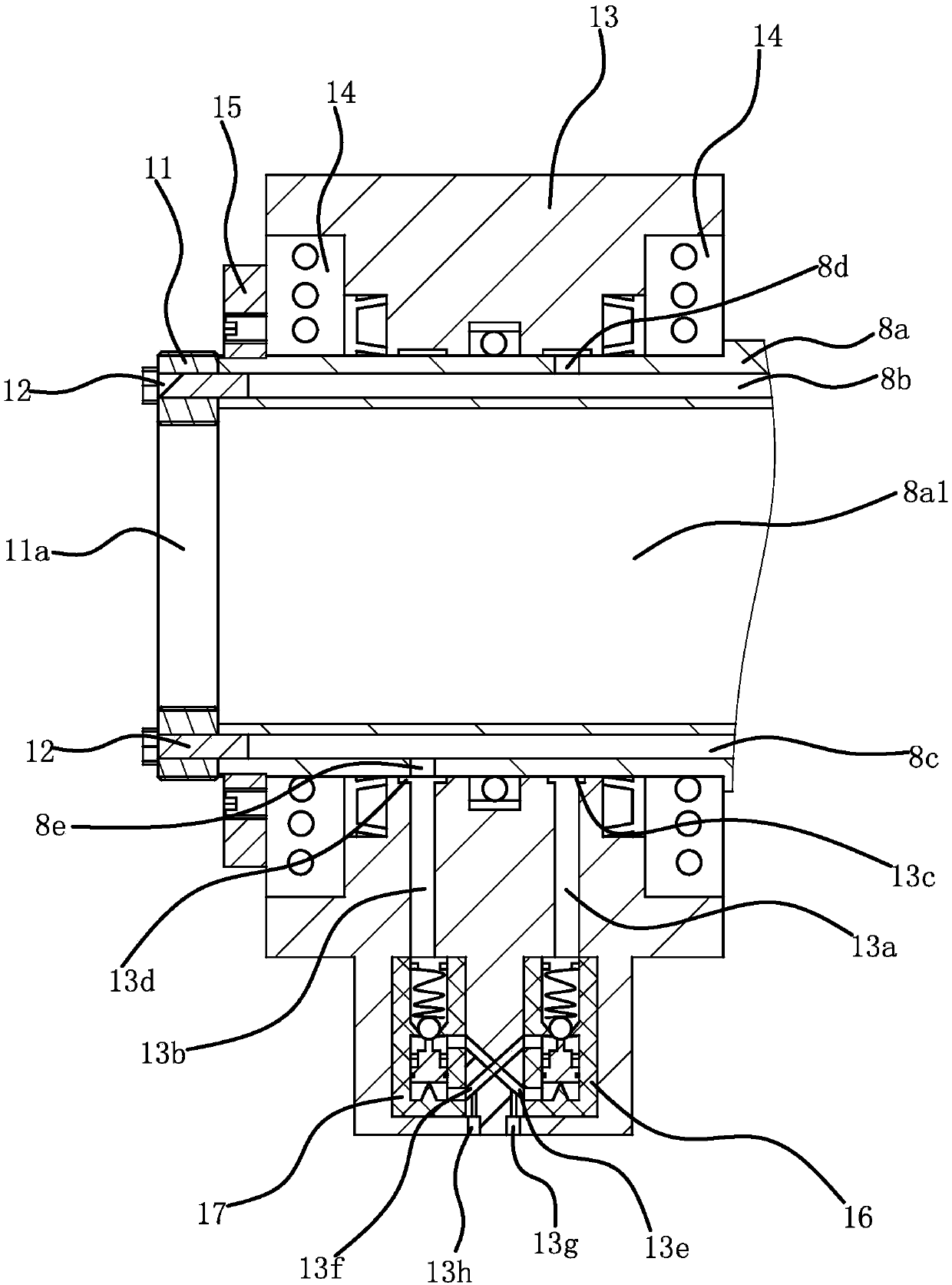

Two-stage dry mixing method for powder metallurgy iron-based mixed powder

The invention discloses a two-stage dry mixing method for powder metallurgy iron-based mixed powder. The two-stage dry mixing method includes steps of 1), weighing iron powder, alloyed powder, graphite powder, lubricating agent and binding agent according to requirements of the iron-based mixed powder; 2), adding the weighed iron powder, alloyed powder, graphite powder, lubricating agent and binding agent to a 1# blender to be mixed for 10-20mins; 3), placing the materials in the 1# blender into a 1# transit warehouse; 4), paving the materials evenly on a steel belt and keeping the same in a high-temperature zone of a heating furnace at the temperature of from 140 DEG C to 200 DEG C for 2-10mins; 5), transferring the materials out of a cooling zone of the heating furnace and the temperature of which is dropped below melting temperature of the lubricating agent into a 2# transit warehouse; 6), further transferring into a 2# blender and adding the lubricating agent into the same; 7), starting up the 2# blender and the same to operate for 15-30mins; 8), transferring the materials into a 3# transit warehouse; 9), sieving and packaging to obtain qualified iron-based mixed powder. The two-stage dry mixing method has the advantages of reasonable design, environmental friendliness, high production efficiency, capability of mass production, and the like.

Owner:LAIWU IRON & STEEL GRP

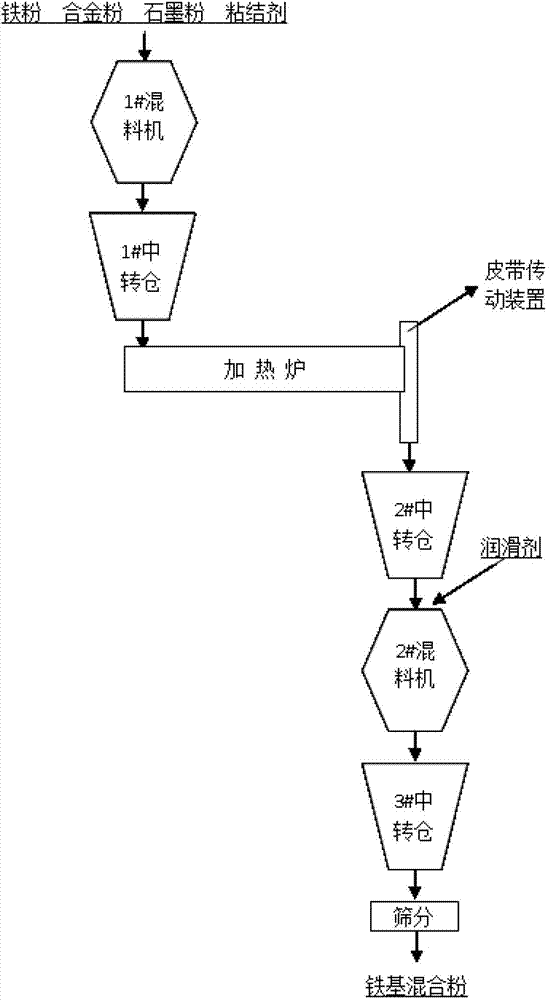

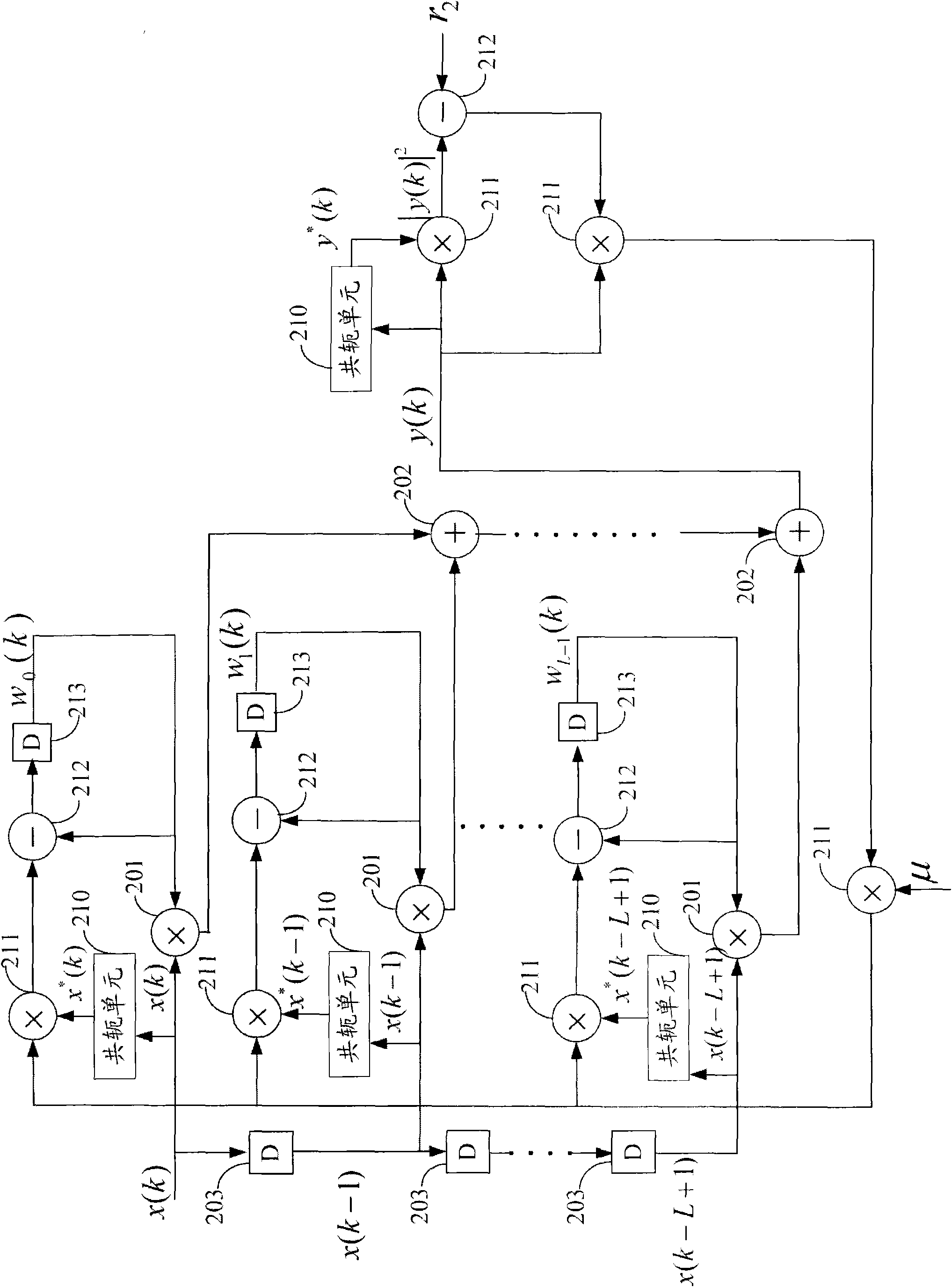

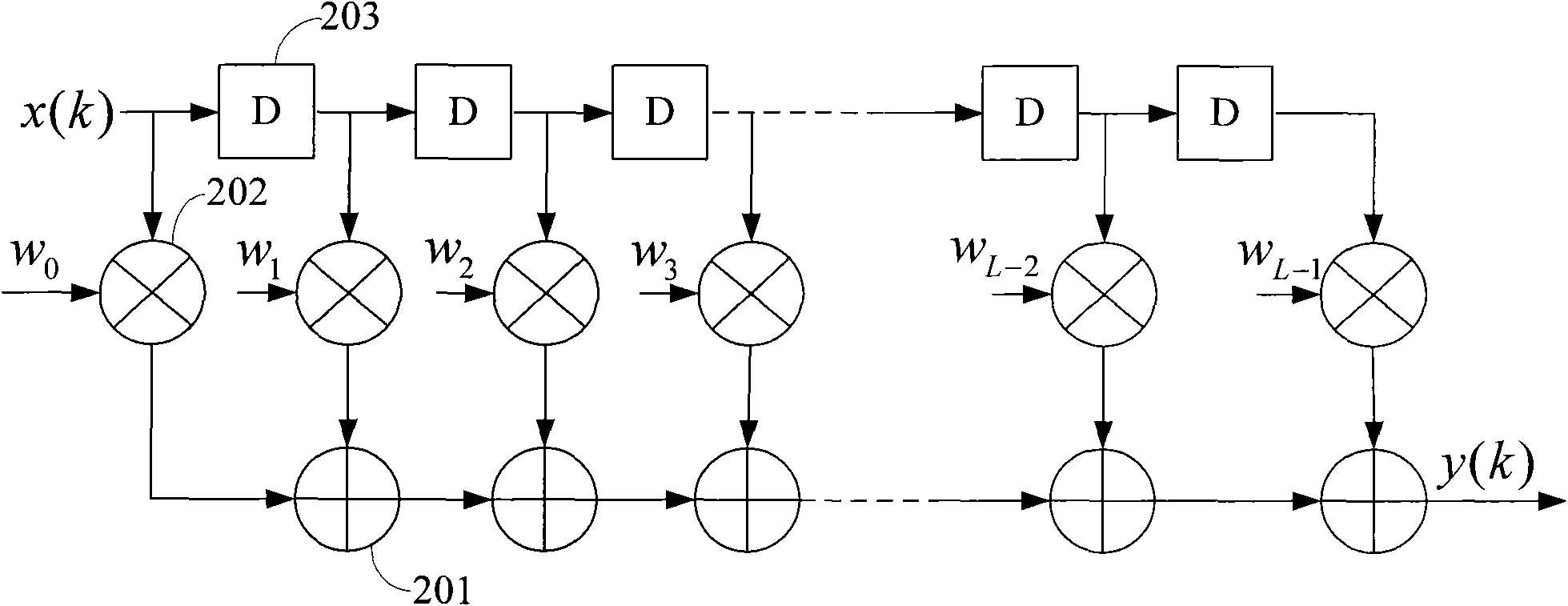

Blind equalization method and blind equalization device

InactiveCN101931596AImplement multiplicationOmit to useTransmitter/receiver shaping networksBlind equalizationRate of convergence

The invention provides a blind equalization method and a blind equalization device. A blind equalization module delays an external input signal to acquire L received signals, and a conjugate signal of the received signals are acquired according to the L received signals; an error signal is calculated according to a blind equalization output signals and an error correction signal output by a filter; the error signal is subjected to nonlinear quantization to form a quantization error signal serving as an enable signal, and a first adjustment subsystem is calculated according to the conjugate signal of the received signals; shifting places is calculated according to relationships and steps of the error signal, a first error signal threshold value and a second error signal threshold value and 0; and the first adjustment subsystem is shifted according to the shifting places; and a second adjustment subsystem updates a blind equalization coefficient, and outputs the updated blind equalization coefficient to the filter. The method and the device can reduce calculation amount, retain a large amount of information of the error signal and improve stability and convergence rate.

Owner:北京国科环宇科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com