Combined structure and method of radiator and circuit

A heat sink and circuit technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve problems such as heat dissipation of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It is known that in the combination of aluminum substrate and light-emitting diode, the aluminum substrate is stamped and cut in the form of pure aluminum A1100 or A1050, and the combination method is mostly made individually, and then locked and connected one by one with fixing elements such as screws. . Not only does it require a lot of manpower for assembly, but also there is a cost problem of fixing components such as screws, which greatly reduces its practicability and economic benefits.

[0028] The technical content of the present invention will be described in detail below in conjunction with the accompanying drawings, but the accompanying drawings are only for reference and description, and are not intended to limit the present invention.

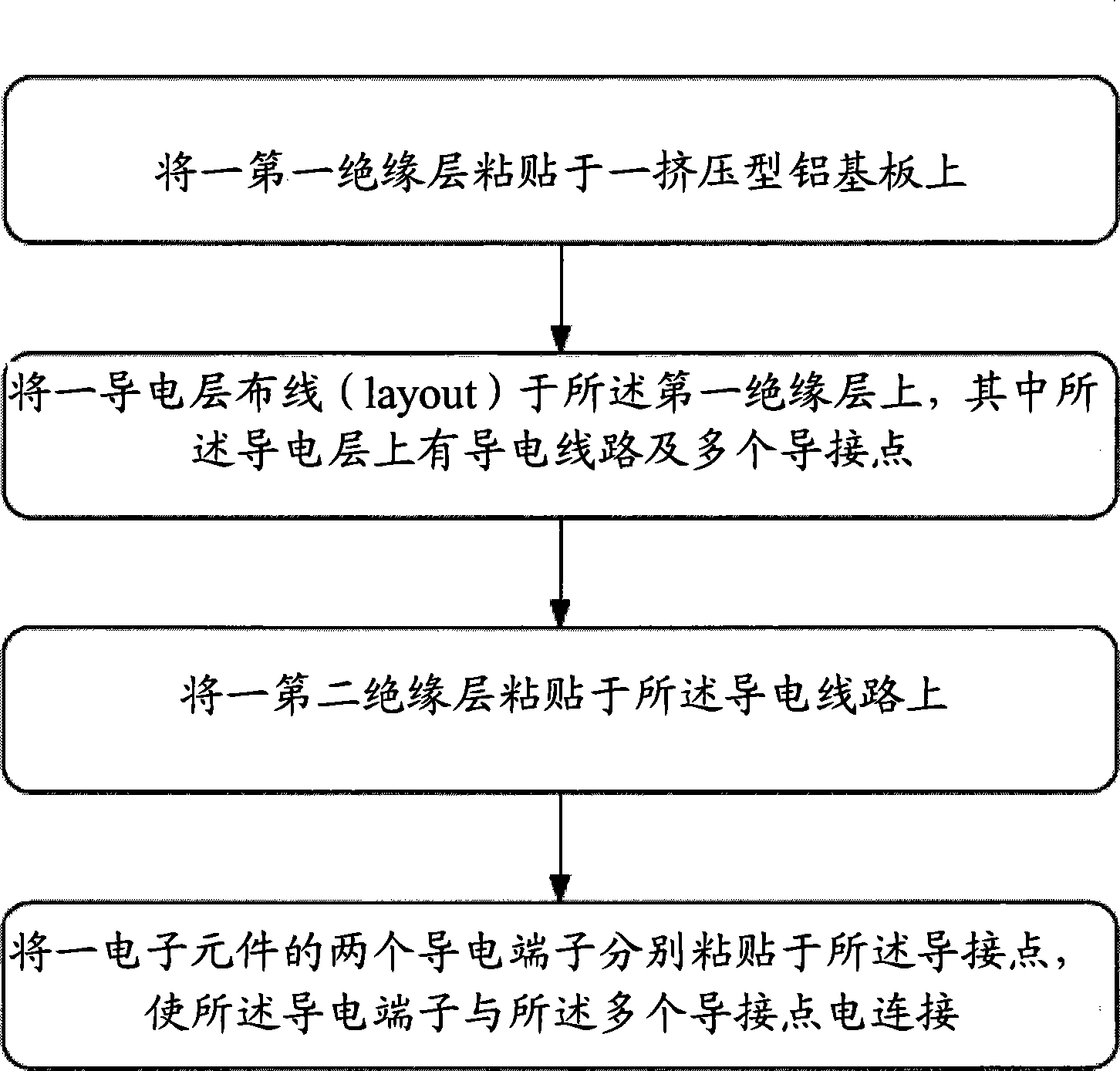

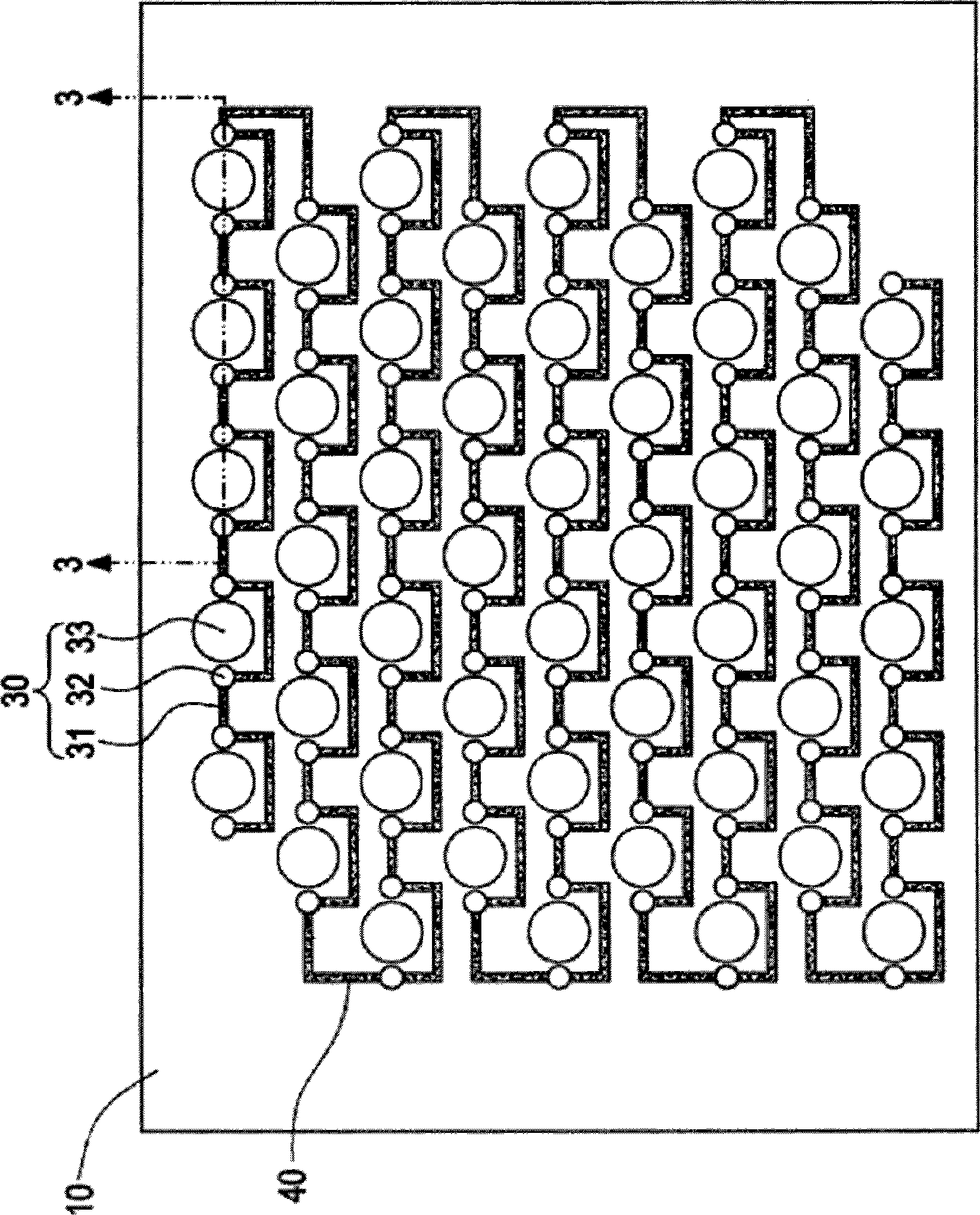

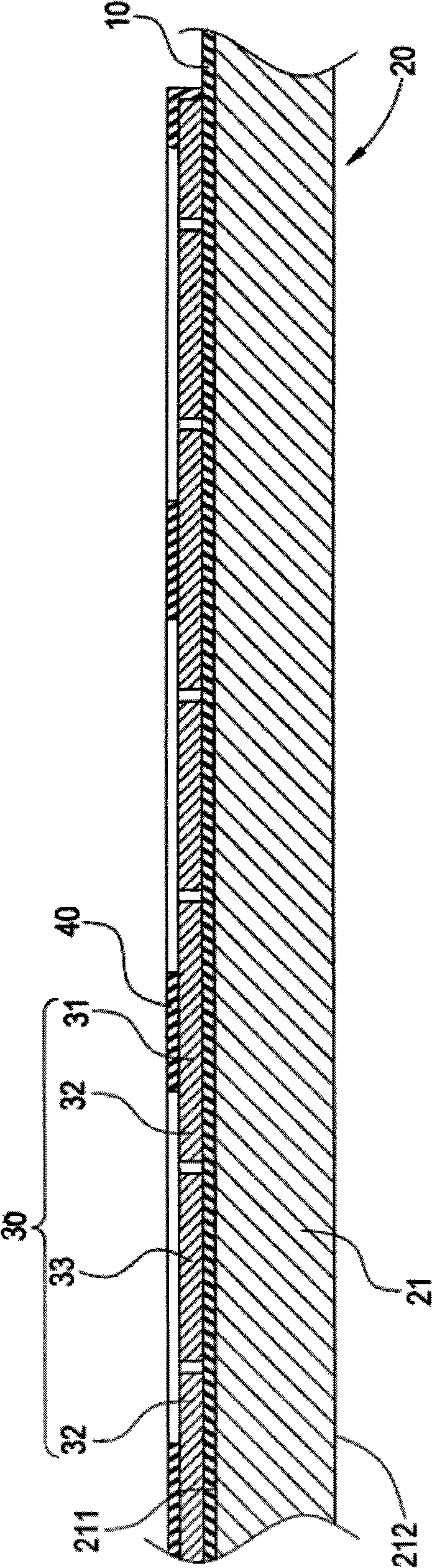

[0029] Please refer to Figure 1-4 As shown, according to a method for combining a heat sink and a circuit provided by the present invention, the method includes the following steps:

[0030] First, paste a first insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com