Liquid crystal display panel and manufacturing method thereof

A technology for a liquid crystal display panel and a manufacturing method, which is applied in the directions of nonlinear optics, instruments, optics, etc., can solve the problems of complicated liquid crystal display panel manufacturing process, inability to cure the sealant 207, high manufacturing cost of liquid crystal display panel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

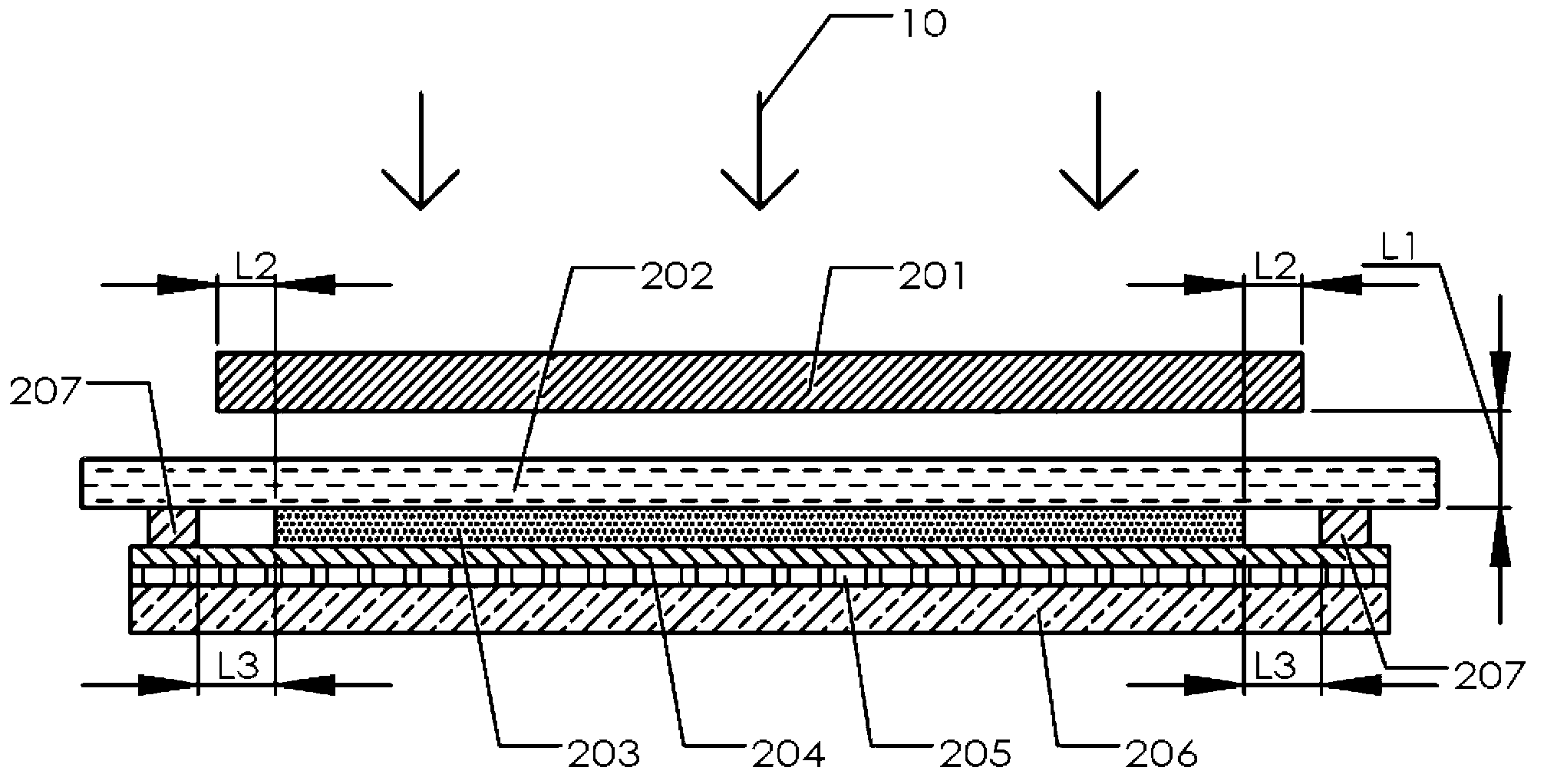

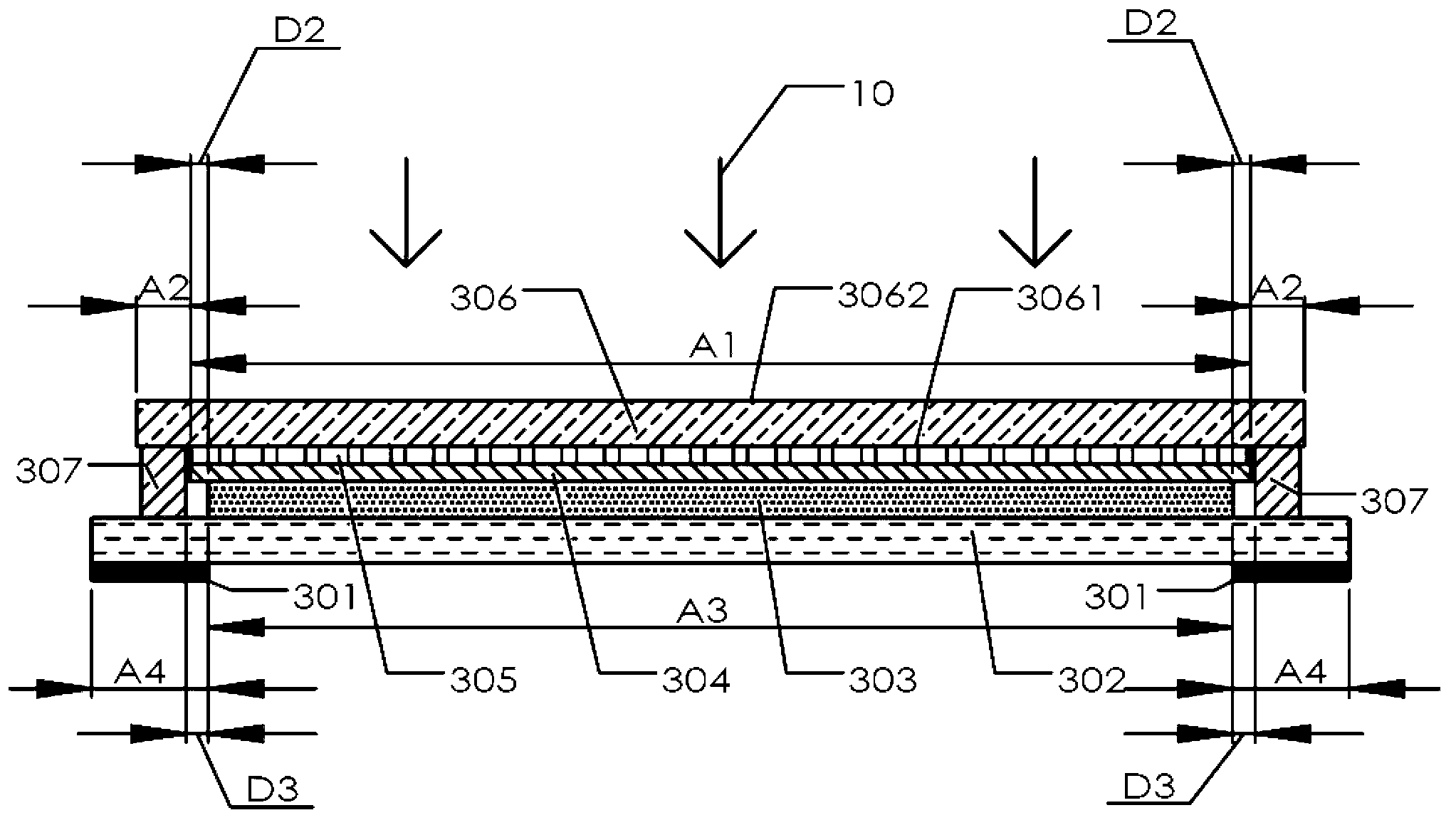

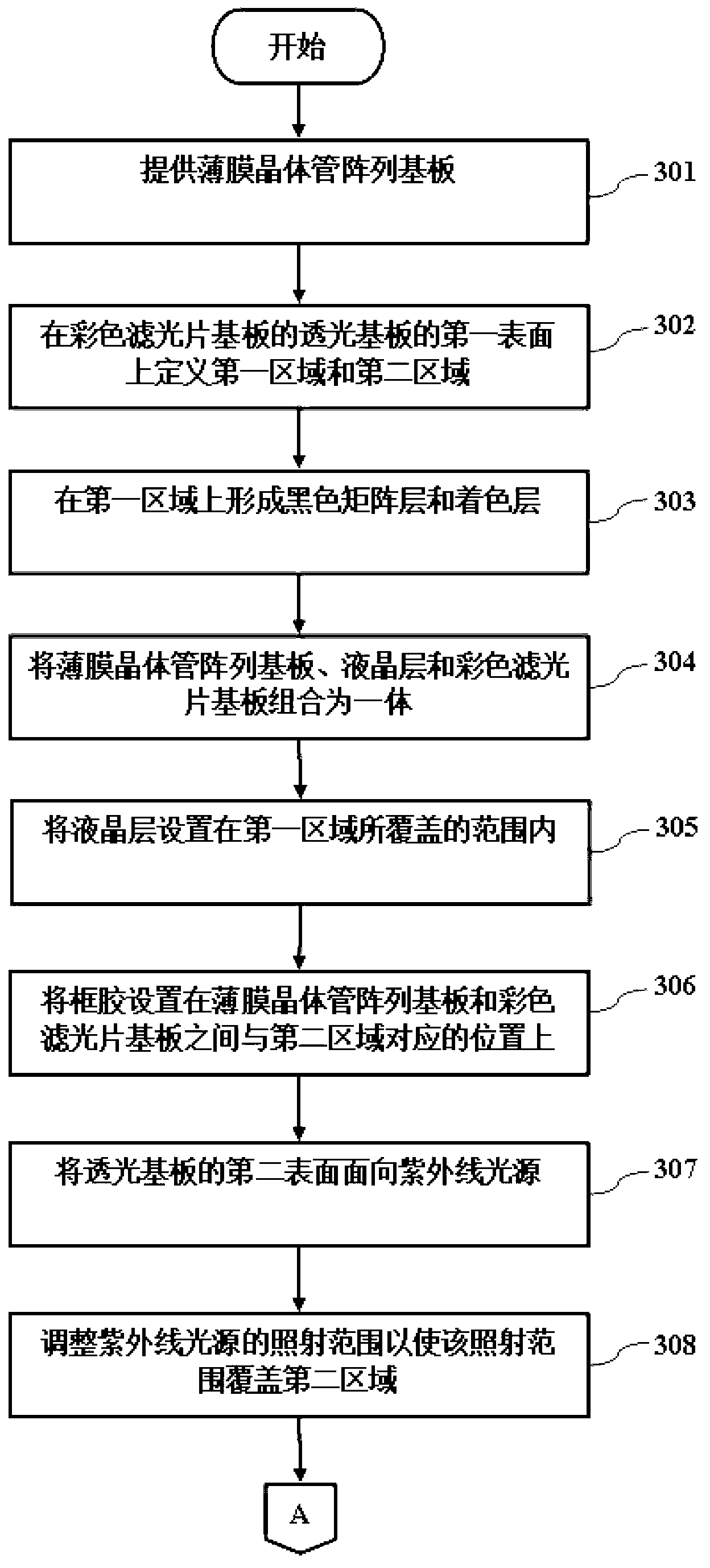

[0026] refer to figure 2 , figure 2It is a schematic diagram of the curing method of the sealant in the liquid crystal display panel of the present invention. The liquid crystal display panel of the present invention includes: a thin film transistor array substrate 302, a color filter substrate, a liquid crystal layer 303 and a frame. Wherein, the color filter substrate includes a transparent substrate 306 , a black matrix layer 305 and a colored layer 304 , and the transparent substrate 306 may be a glass substrate. The transparent substrate 306 has a first surface 3061 and a second surface 3062, the first surface 3061 is provided with a first area A1 and a second area A2, the second area A2 is located outside the first area A1, the black matrix layer 305 and the colored The layer 304 is disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com