ZSM-5 molecular sieve and preparation method thereof

A ZSM-5, molecular sieve technology, applied in nanotechnology, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of difficult separation of crystallization product and reaction medium liquid, single-pot yield limitation, crystallization Long time and other problems, to avoid emissions, save raw material costs, reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

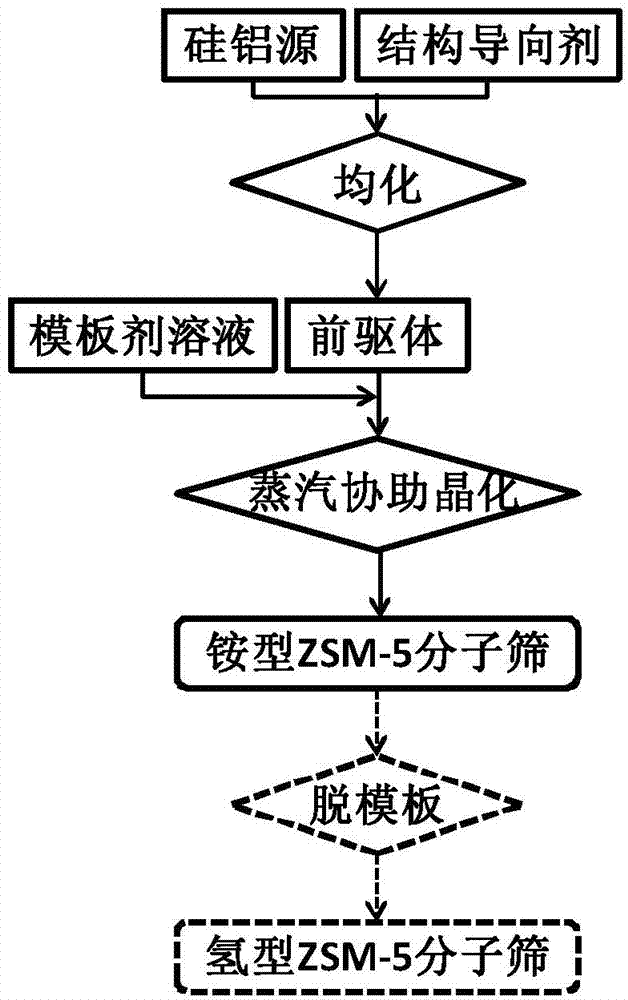

[0084] A kind of preparation method of ZSM-5 molecular sieve, described method is silicon-aluminum source with amorphous silicon dioxide and boehmite, specifically comprises the following steps:

[0085] (1) Homogenization of ingredients: mixing and homogenizing amorphous silica, boehmite and tetrapropylammonium hydroxide (TPAOH) to obtain a ZSM-5 molecular sieve precursor, in which SiO 2 :Al 2 o 3 :TPAOH (substance ratio) is 1:0.01:0.07;

[0086] (2) Assisted crystallization: place a TPAOH aqueous solution with a concentration of 10.5wt% at the bottom of the crystallization tank, place the ZSM-5 molecular sieve precursor obtained in step (1) in the crystallization tank without direct contact with the TPAOH aqueous solution; The mass ratio of the precursor to the TPAOH aqueous solution is 0.1, and the temperature is raised to 190°C for steam-assisted crystallization for 3 hours to obtain the crystallized product, namely ammonium ZSM-5 molecular sieve;

[0087] (3) The ammon...

Embodiment 2

[0090] A preparation method of ZSM-5 molecular sieve, said method uses fumed silica (white carbon black) and aluminum sulfate as silicon and aluminum sources, specifically comprising the following steps:

[0091] (1) Homogenization of ingredients: Mix and homogenize fumed silica (white carbon black), aluminum sulfate and diethylamine (DEN) to obtain a ZSM-5 molecular sieve precursor, in which SiO 2 :Al 2 o 3 :DEN (substance ratio) is 1:0.09:0.15;

[0092] (2) Assisted crystallization: place a DEN aqueous solution with a concentration of 30wt% at the bottom of the crystallization tank, and place the ZSM-5 molecular sieve precursor obtained in step (1) in the crystallization tank without direct contact with the DEN aqueous solution; The mass ratio of the precursor to the DEN aqueous solution was 0.3, and the temperature was raised to 190° C. for steam-assisted crystallization for 50 hours to obtain the crystallized product, namely ammonium ZSM-5 molecular sieve.

[0093] The ...

Embodiment 3

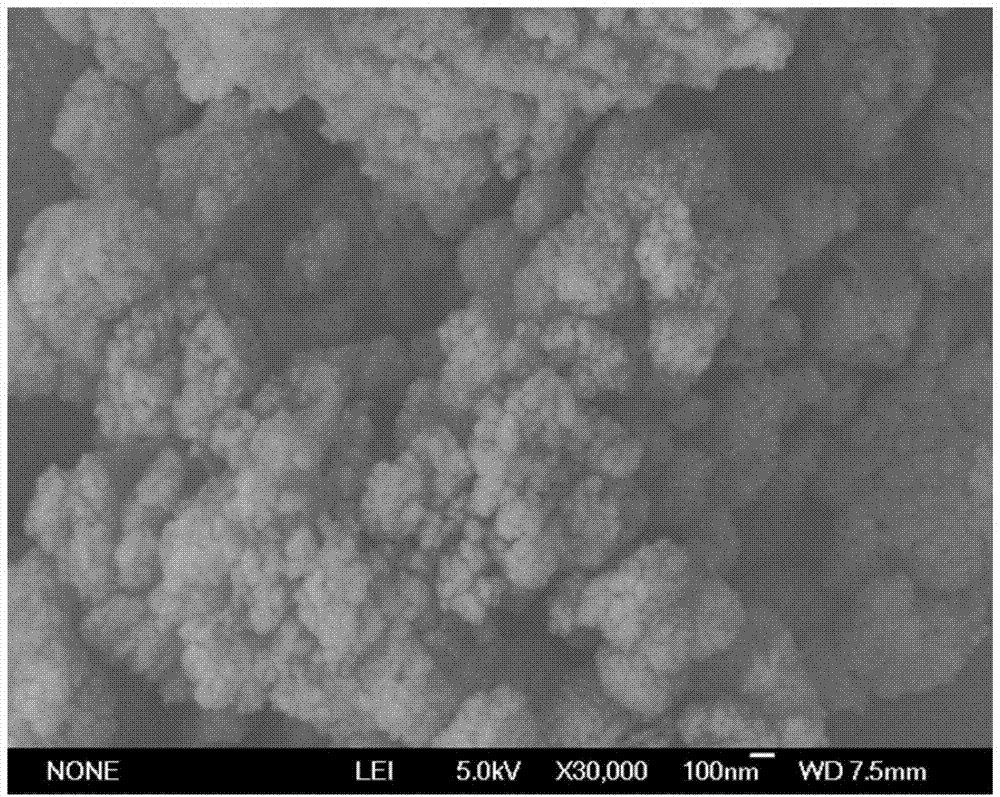

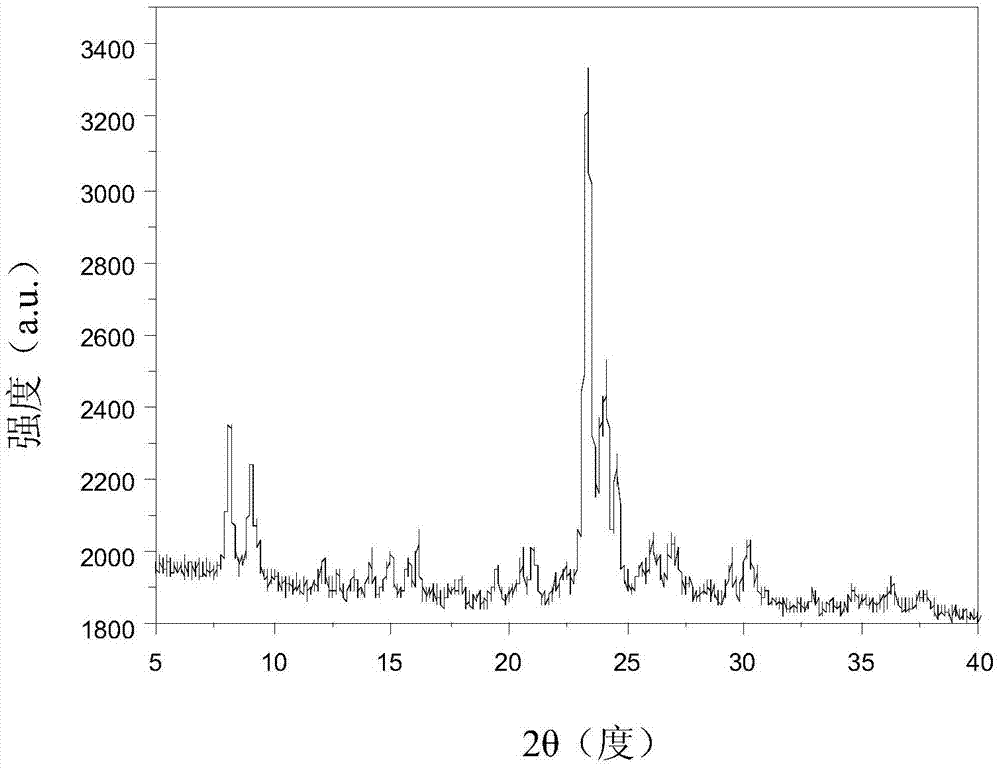

[0095] A kind of preparation method of ZSM-5 molecular sieve, described method is to use embodiment 2 to prepare the DEN solution after ZSM-5 molecular sieve, continue to put a new batch of ZSM-5 molecular sieve precursor (proportioning is the same as embodiment 2) in The crystallization kettle is not in direct contact with the DEN aqueous solution, and the mass ratio of the ZSM-5 molecular sieve precursor to the DEN aqueous solution is 0.5; the temperature is raised to 190°C for steam-assisted crystallization for 5 hours, and the crystallized product is obtained, which is the ammonium ZSM- 5 molecular sieves. The obtained hydrogen ZSM-5 molecular sieve has a particle size of about 40-60nm and a crystallinity of 94.0%.

[0096] Optionally, the templating agent solution can be removed and retained for continued recycling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com