Preparation method of rare earth hydrotalcite-like compound/polymer nanocomposite

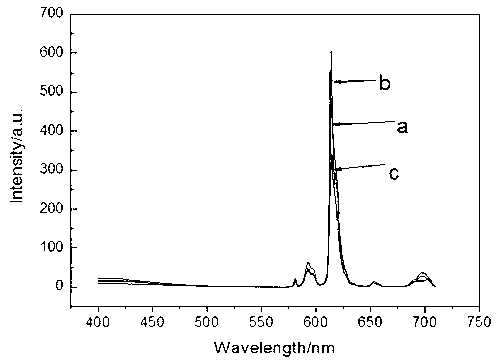

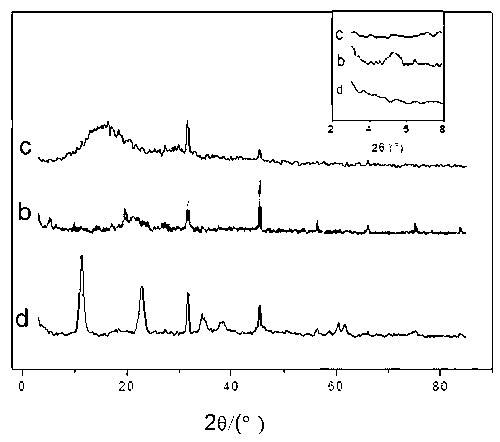

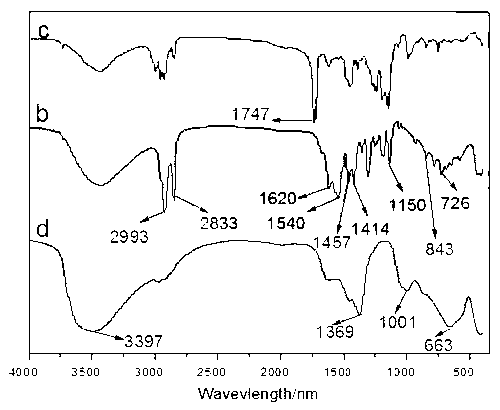

A nanocomposite material and technology of hydrotalcite, applied in the field of exfoliated fluorescent rare earth hydrotalcite/polymer nanocomposite material and its preparation, can solve the problem of concentration quenching, rare earth complex light, poor thermal stability, poor dispersibility, etc. problems, to achieve the effect of simple equipment, preventing fluorescence quenching, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Weigh 0.16g NaAlO 2 , 0.08 gram of NaOH are dissolved in deionized water together, this is solution A;

[0037] 2. Weigh 0.5 g of MgCl 2 Dissolved in deionized water, this is solution B;

[0038] 3. Weigh 0.011 grams of Eu 2 o 3 , dissolved in dilute hydrochloric acid and added to solution B, this is solution C;

[0039] 4. Weigh 0.035 grams of thienoyl trifluoroacetone and 0.01 grams of 1,10-phenanthroline respectively, dissolve them in absolute ethanol and pour them into an aqueous solution containing 0.28 grams of sodium stearate to prepare a mixed slurry d.

[0040] 5. Under strong stirring, simultaneously add solution A and solution C dropwise to mixed slurry D to prepare mixed slurry E, adjust mixed slurry E to pH = 12 with 20% sodium hydroxide aqueous solution, and age at 80°C After 6 hours, filter with suction and wash the filter cake with water until the pH of the filtrate = 7.5, soak with a small amount of absolute ethanol, wash the precipitate, and t...

Embodiment 2

[0046] 1. Weigh 0.05g NaAlO 2 , 0.025 gram of NaOH are dissolved in deionized water together, this is solution A;

[0047] 2. Weigh 0.14 g of MgCl 2 Dissolved in deionized water, this is solution B;

[0048] 3. Weigh 0.03 g of Tb 4 o 7 , dissolved in dilute hydrochloric acid and added to solution B, this is solution C;

[0049] 4. Weigh 0.05 g of acetylacetone and 0.02 g of 2,2-bipyridine respectively, dissolve them in absolute ethanol and pour them into an aqueous solution containing 0.15 g of sodium stearate to prepare a mixed slurry D.

[0050] 5. Under the action of continuous ultrasonic waves, add solution A and solution C dropwise to mixed slurry D to prepare mixed slurry E. Use 20% sodium hydroxide aqueous solution to adjust mixed slurry E to pH = 10, and age at 70°C After 6 hours, filter with suction and wash the filter cake with water until the pH of the filtrate = 7.5, soak it with a small amount of absolute ethanol, wash the precipitate and then filter with suc...

Embodiment 3

[0053] 1. Weigh 1.36 grams of NaAlO 2 , 0.68 gram of NaOH are dissolved in deionized water together, this is solution A;

[0054] 2. Weigh 4.75 grams of MgCl 2 Dissolved in deionized water, this is solution B;

[0055] 3. Weigh 0.18 grams of Sm 2 o 3 , dissolved in dilute hydrochloric acid and added to solution B, this is solution C;

[0056] 4. Weigh 0.8 g of naphthoyl trifluoroacetone and 0.16 g of 2,2-bipyridine respectively, dissolve them in absolute ethanol and pour them into an aqueous solution containing 3.2 g of sodium stearate to prepare a mixed slurry D.

[0057] 5. Under strong stirring, simultaneously add solution A and solution C dropwise to mixed slurry D to prepare mixed slurry E, adjust mixed slurry E to pH = 13 with 20% sodium hydroxide aqueous solution, and age at 60°C After 6 hours, filter with suction and wash the filter cake with water until the pH of the filtrate = 8, soak with a small amount of absolute ethanol, wash the precipitate and then filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com