Energy saving and environment protecting electrolytic copper foil copper dissolving system and copper dissolving process

An electrolytic copper foil, energy saving and environmental protection technology, applied in the electrolysis process, electrolysis components, electroforming and other directions, can solve the problems of high energy consumption and low copper melting efficiency, achieve continuous stability of liquid temperature, reduce power consumption, and reduce blasting effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

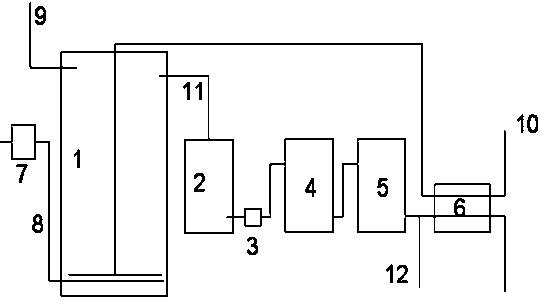

[0018] Such as figure 1 As shown, an energy-saving and environment-friendly electrolytic copper foil melting copper system includes a copper melting tank 1, and the copper melting tank 1 is connected with an upper liquid pipeline 10 and an overflow pipeline 11, and the overflow pipeline 11 is connected to The upper part of the copper melting tank 1, and the overflow pipeline 11 is provided with an overflow liquid storage tank 2, a frequency conversion pump 3, a primary filter 4, a secondary filter 5 and a heat exchanger 6, and a primary filter 4 The filter pore diameter is larger than the filter pore diameter of the secondary filter 5, the overflow liquid storage tank 2 is provided with a liquid level gauge, and a freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com