Patents

Literature

103results about How to "No oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

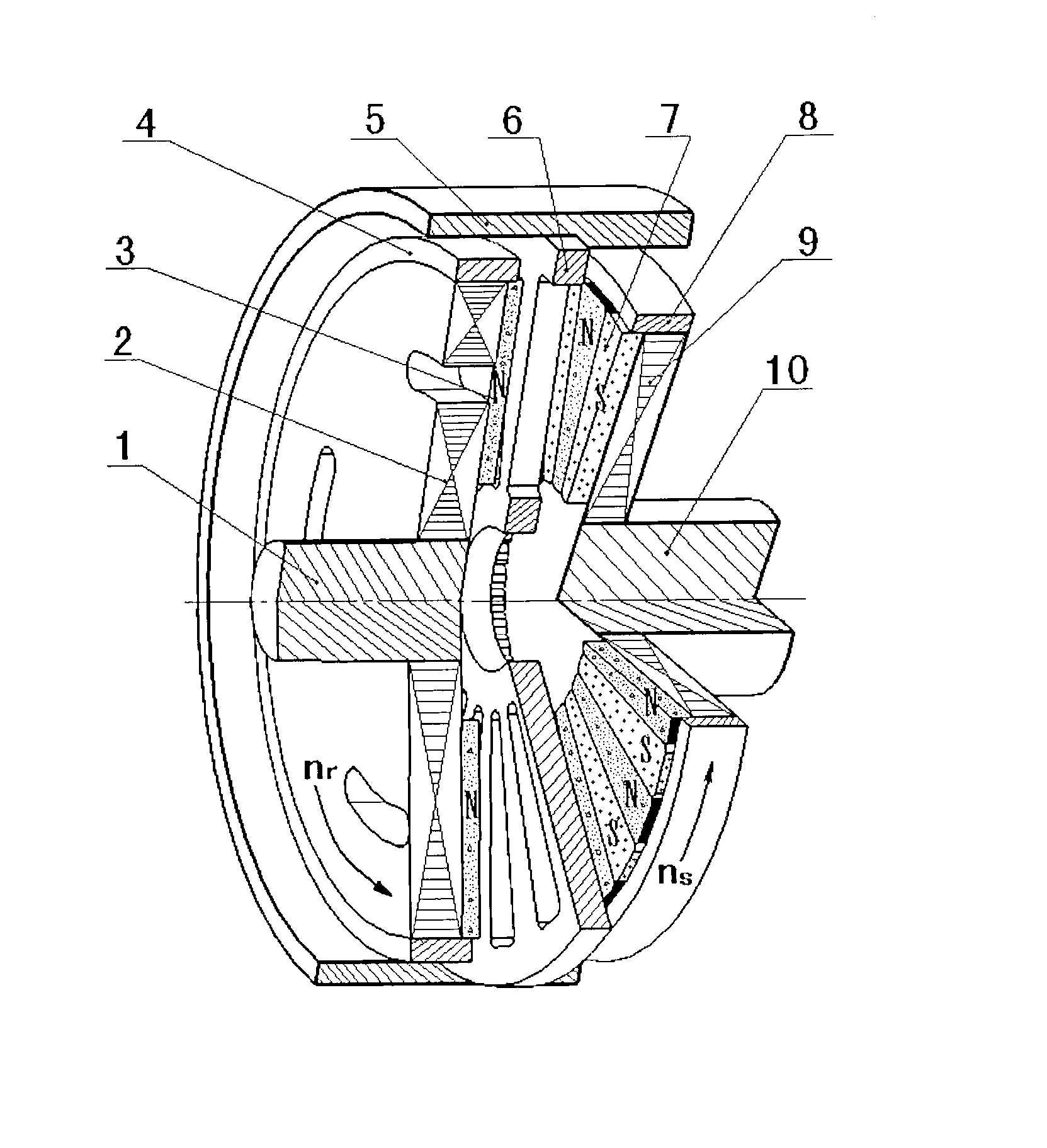

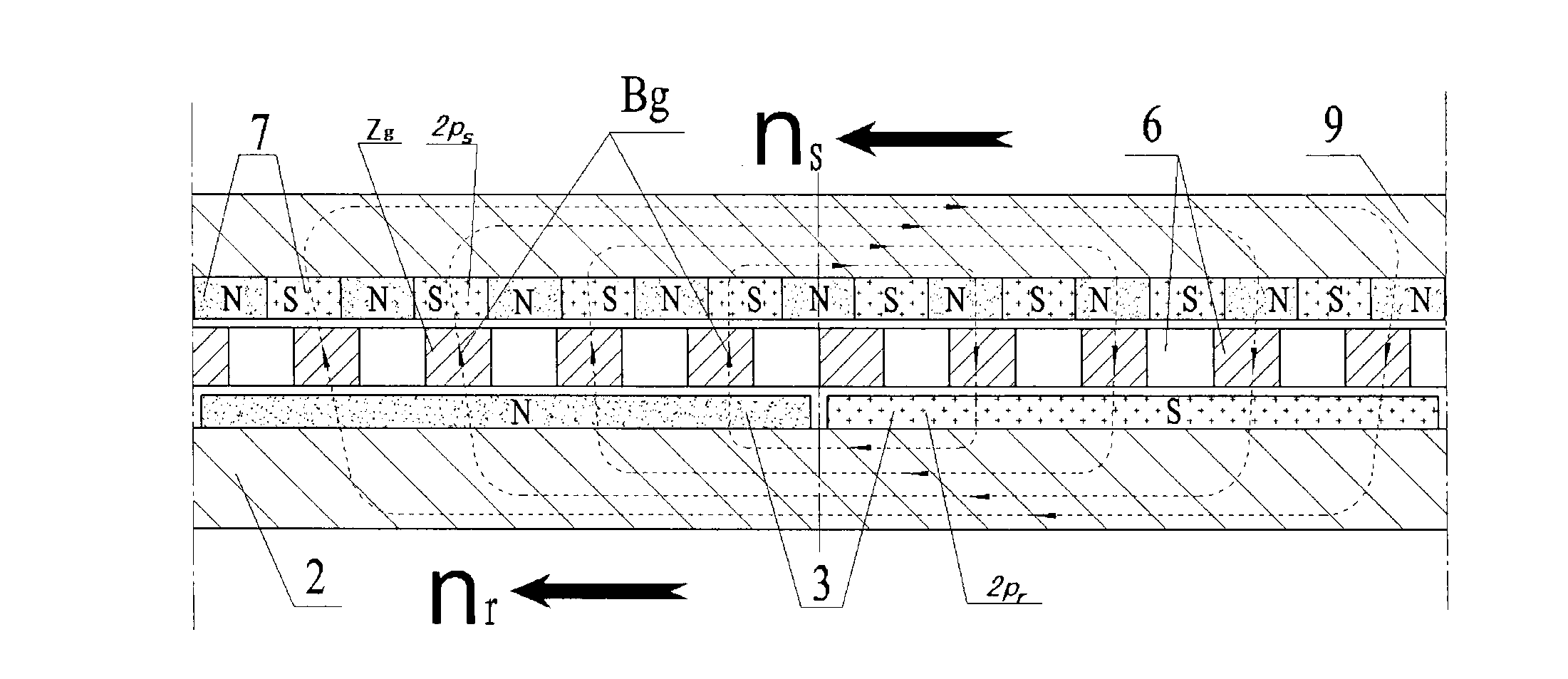

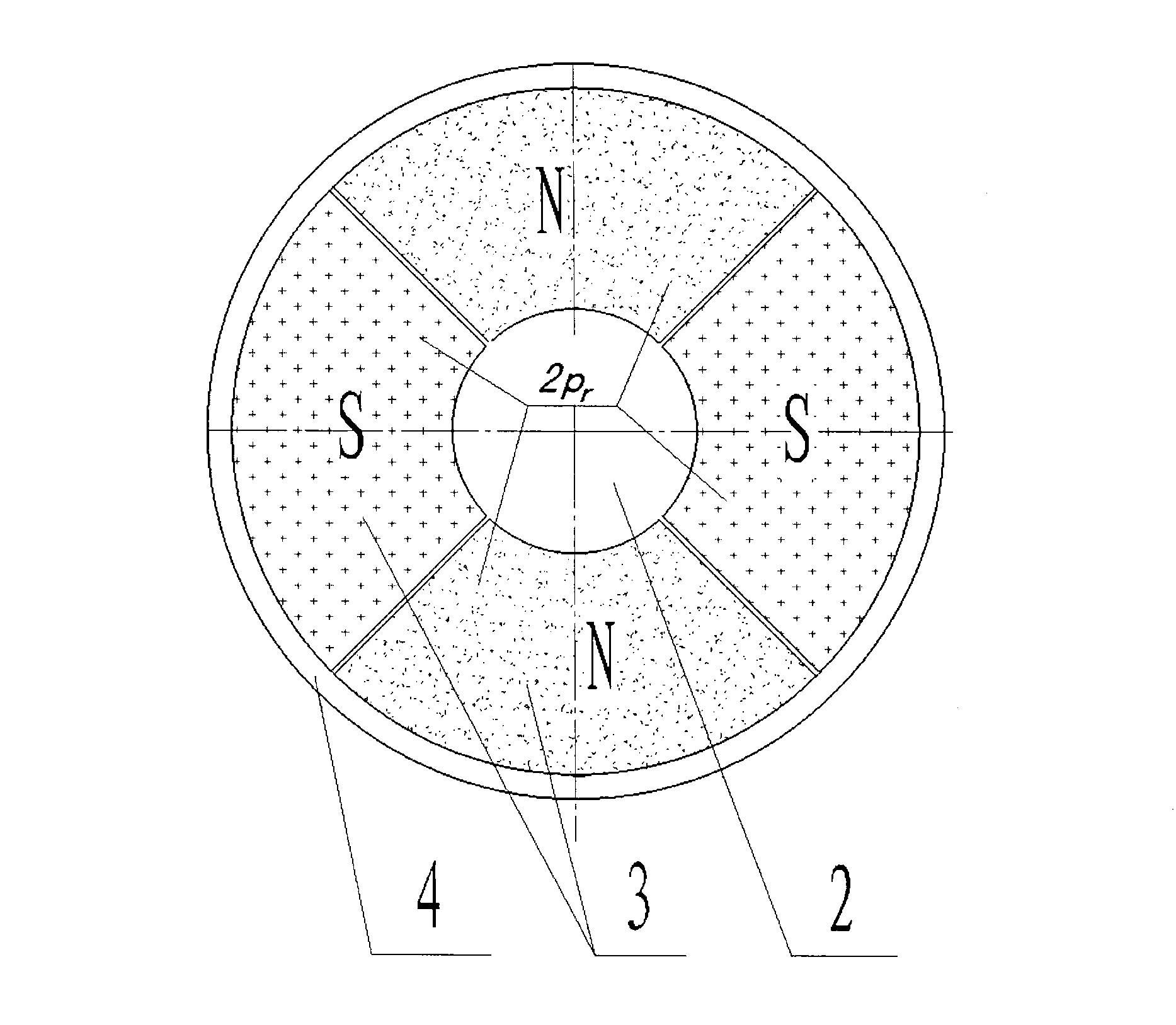

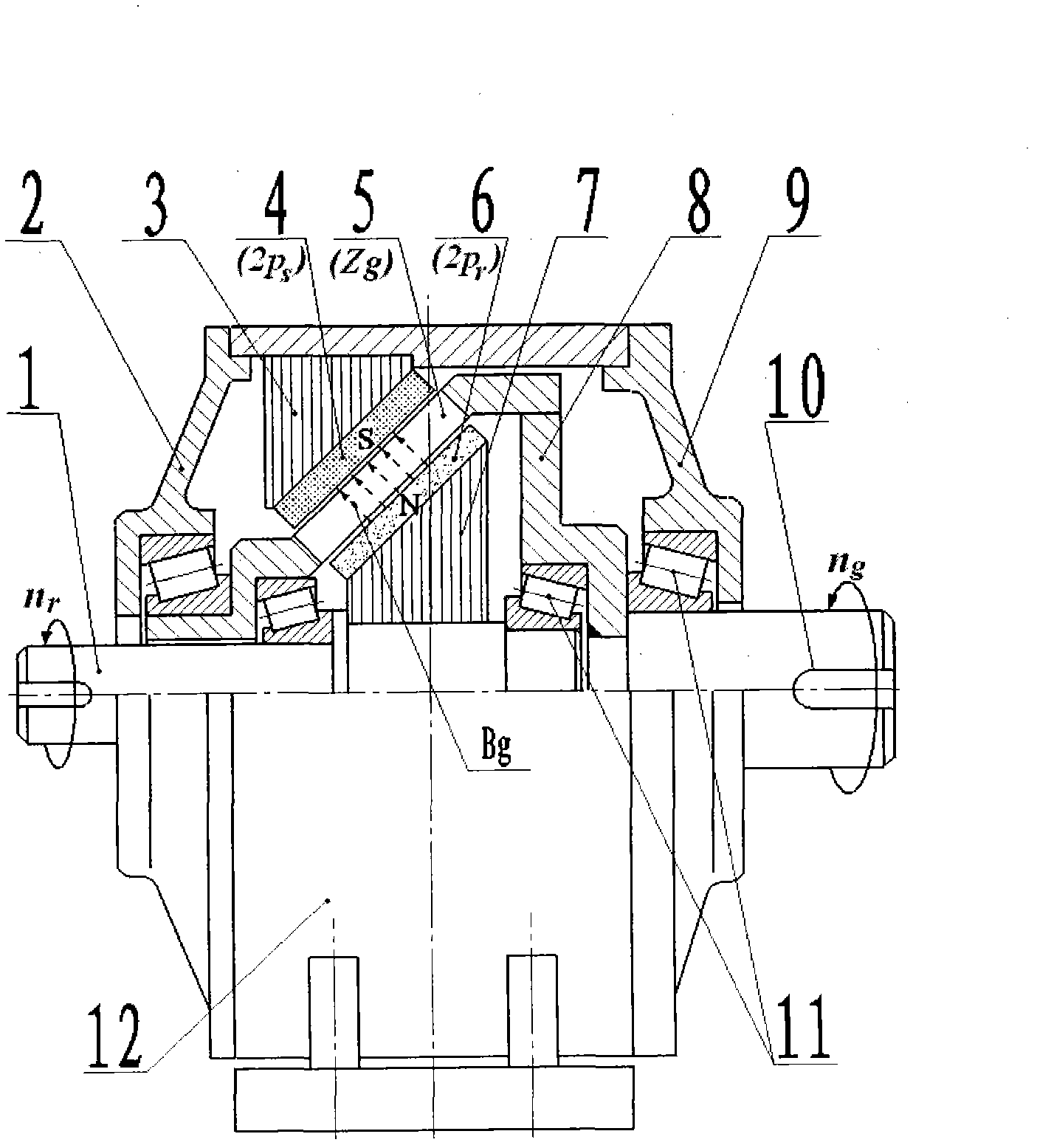

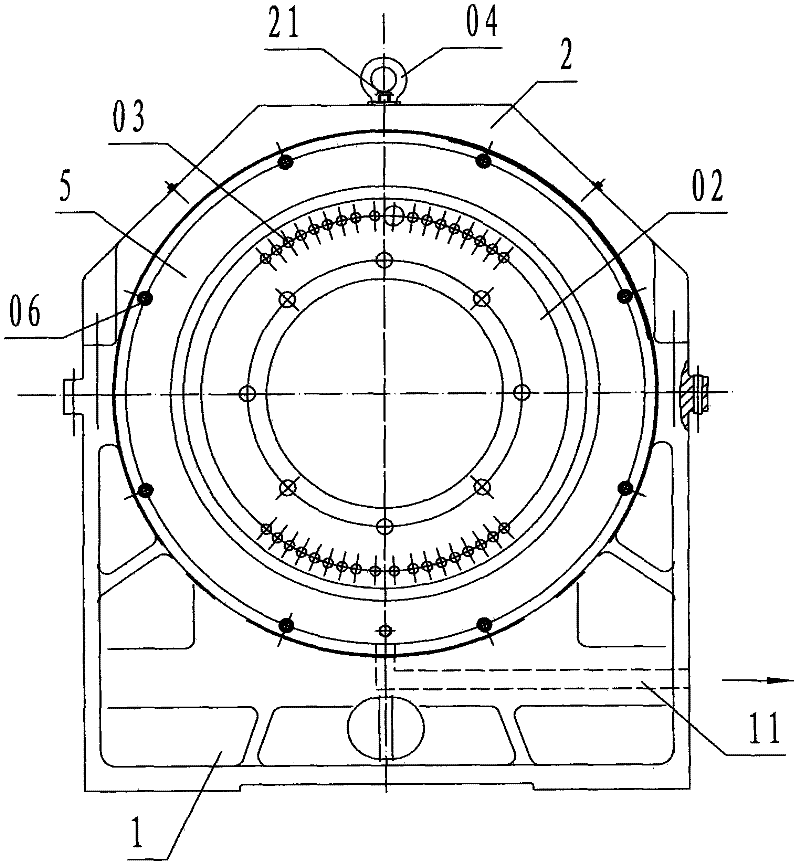

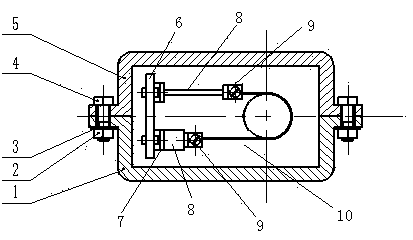

Magnetism transmission gear pair of novel transverse magnetic field

The invention relates to a magnetism transmission gear pair of a novel transverse magnetic field, which can be widely applied to wind power generation, electric cars, ship drive and other industrial transmission fields requiring direct drive. The magnetism transmission gear pair is characterized in that a driving wheel and a driven wheel of the magnetism transmission gear pair are of a flat disk shape, 2pr driving wheel permanent magnets 3 are distributed on the driving wheel, and 2ps driven wheel permanent magnets 7 are distributed on the driven wheel; a ferromagnetic magnetic modulation grid 6 playing a role of modulating an air-gap magnetic field is arranged between the driving wheel and the driven wheel, air gaps are reserved between the ferromagnetic magnetic modulation grid 6 and the end surfaces of the driving wheel and the driven wheel, and the ferromagnetic magnetic modulation grid 6, the driving wheel and the driven wheel have no mechanical contact and are distributed along the same axis; the air-gap magnetic field Bg passes through an air-gap plane along a route parallel to a rotation axis to form a transverse magnetic field of the magnetism transmission gear pair; and during working, power speed change transmission without mechanical contact and friction is realized by utilizing a principle of heteropolarity attraction of an N pole and an S pole of a permanent magnet material.

Owner:余虹锦

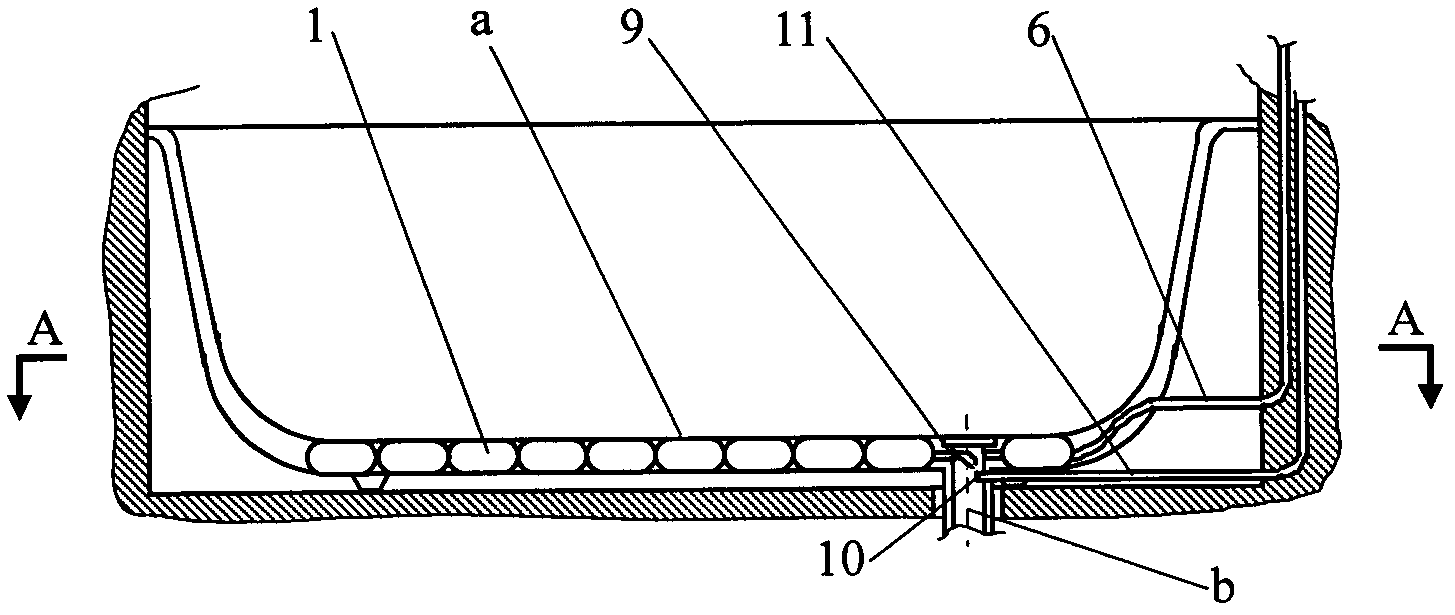

Filling oil-containing semi-solid composition for fibre-otpical composite overhead earth wire

A filling grease for composite fibre-optical overhead earth wire is prepared by mixing 36®|hydrogenated white oil and PAO-8 synthesized oil with PriCO-3002 polybasic alcohol ester and viscosity exponential improver Lc-212, adding into additive OB fluorescent brightening agent, grease-separating inhibitor BP2400 and G1702, raising temperature, stirring, adding into organic thickening agent gas-phase carbon white H20, raising temperature, thickening, adding into antioxidant AT-215 and inorganic thickening agent SEP1650, raising temperature, thickening, shearing, circulation feeding back, cooling to normal temperature, homogenizing, degassing, filtering and obtaining the grease. It achieves good hydrogen absorption and stable fibre-optical transmitting performance.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

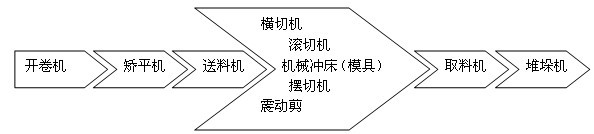

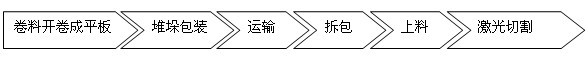

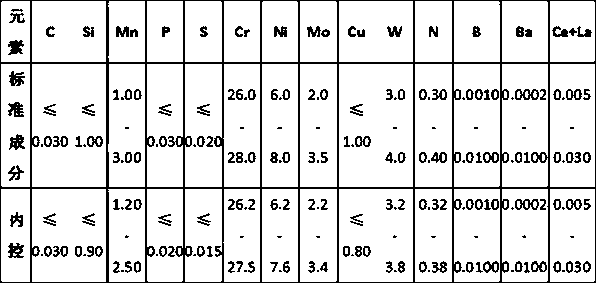

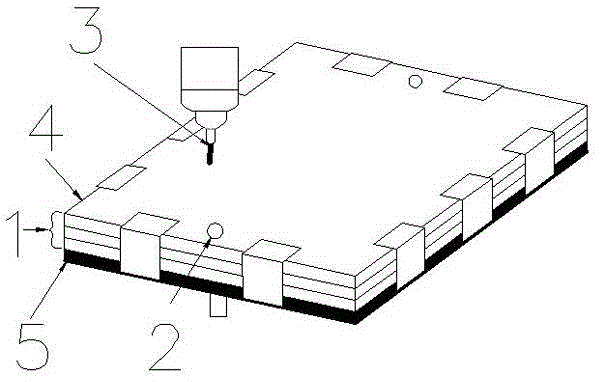

Processing method of automatic-feeding laser cutting

InactiveCN102490070ACancel noiseEliminate vibrationMetal working apparatusLaser beam welding apparatusLaser processingDevice material

The invention relates to the technical field of laser processing, in particular to a processing method of automatic-feeding laser cutting, which comprises the following steps of 1 uncoiling a coiled material into a flat plate through an uncoiler, and leveling the coiled material uncoiled into the flat plate through a leveler; and 2 pushing the coiled material leveled in the step 1 into a laser cutting work area through an automatic feeder, and cutting and processing the coiled material into a plurality of workpieces through laser. Therefore, the processing method of the automatic-feeding laser cutting has the advantages of 1 being free of noise, vibration and greasy dirt, safe and environment-friendly; 2 being capable of randomly being cut in a suit mode, and completely cutting the material in the suit mode theoretically to achieve zero waste material; 3 saving device materials and reducing problems of investment waste and environment pollution caused by casting of large-sized devices and corresponding moulds; 4 greatly improving production efficiency and rate of finished products of relevant industries; 5 being capable of obtaining high accuracy and good quality and being wide in application range; and 6 reducing operation and maintenance costs of the devices, energy consumption and invested operation cost of large-sized coil feed lines.

Owner:余小刚

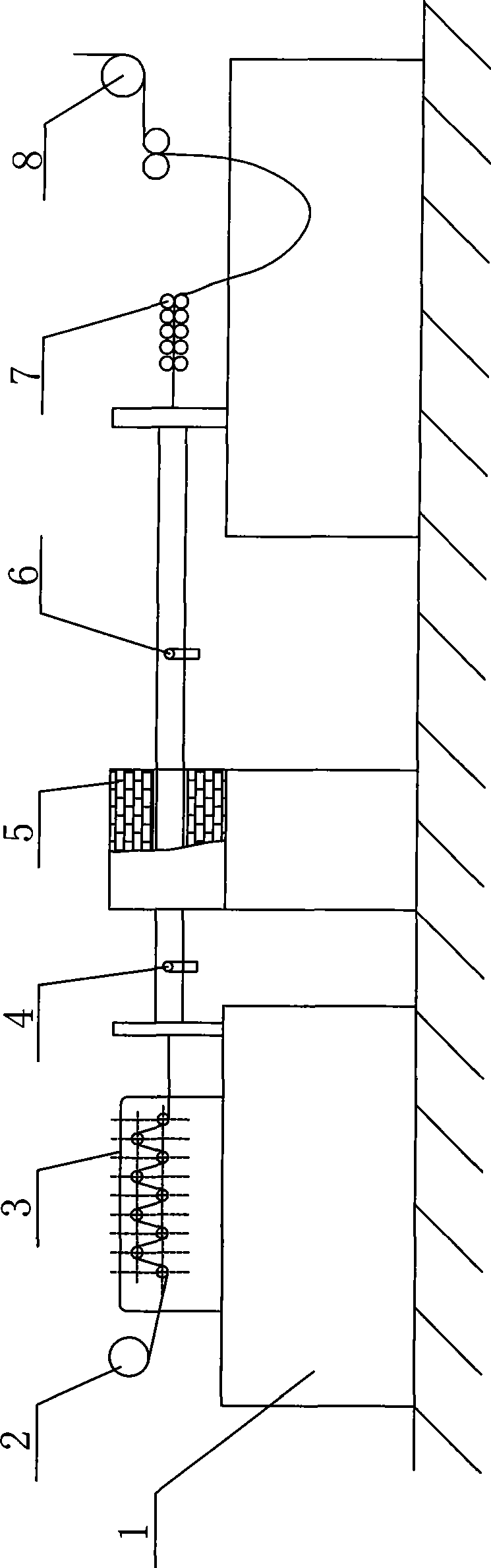

Production method of stainless steel belt for electronic film

The invention relates to a production method of a stainless steel belt for an electronic film. The production method comprises the following steps: (1) selecting and using a 12Cr17Ni7 stainless steel belt billet with the thickness of 0.7-1.0 mm; (2) rolling the stainless steel belt into a steel belt with the thickness of 0.16-0.18 mm by a 20-roll precision cold rolling machine set; (3) washing the steel belt for one time; (4) passing a continuous hydrogen-spraying bright annealing furnace by the steel belt; (5) rolling the steel belt into a steel belt with the thickness of 0.03-0.05 mm by the 20-roll precision cold rolling machine set; (6) passing a continuous degreasing washing machine set by the steel belt; (7) straightening the steel belt by a 23-roll precision stretch bending straightening machine; (8) passing the continuous hydrogen-spraying bright annealing furnace by a rusted steel belt; (9) straightening the steel belt in the direction opposite to the warping direction by the 23-roll precision stretch bending straightening machine; (10) cutting the steel belt into a steel belt with the required size so as to obtain the stainless steel belt for the electronic film. The stainless steel belt produced by the method is good in elasticity, high in strength and uniform in thickness.

Owner:WUXI BAOSHUN STAINLESS STEEL

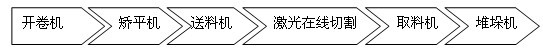

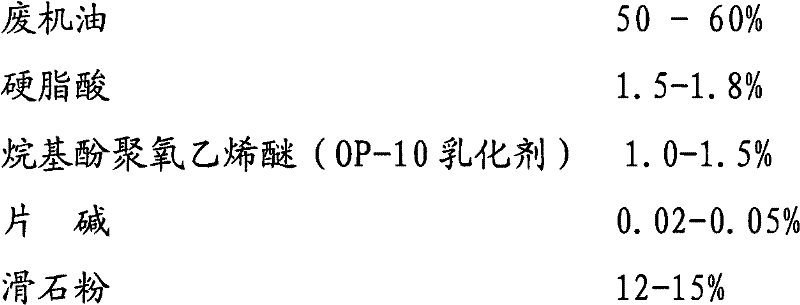

Foam concrete preform release agent and preparation method thereof

InactiveCN102191120ABroaden applicationFast film formationLubricant compositionFoam concretePhosphoric acid

The invention relates to a foam concrete preform release agent and a preparation method thereof. The foam concrete preform release agent comprises the following components by weight percent: 50-60% of waste oil, 1.5-1.8% of stearic acid, 1.0-1.5% of alkylphenol polyoxyethylene ether (OP-10 emulsifier), 0.02-0.05% of flake caustic soda, 12-15% of talc, 0.01-0.03% of phosphoric acid and 40-45% of water (60-80 DEG C). When the release agent prepared by adopting the formula is used for mould release, the foam concrete preform has no oil stain on the surface, no spallation and no edge defect and is good for second construction; and the preform has low dimensional deviation, the film-forming speed is high, the production cycle is short and the work efficiency is increased. In addition, the prepared release agent can be used to prevent the wooden mould from warping and deforming.

Owner:ZUNYI JIANTAI LIGHT ENERGY SAVING MATERIAL

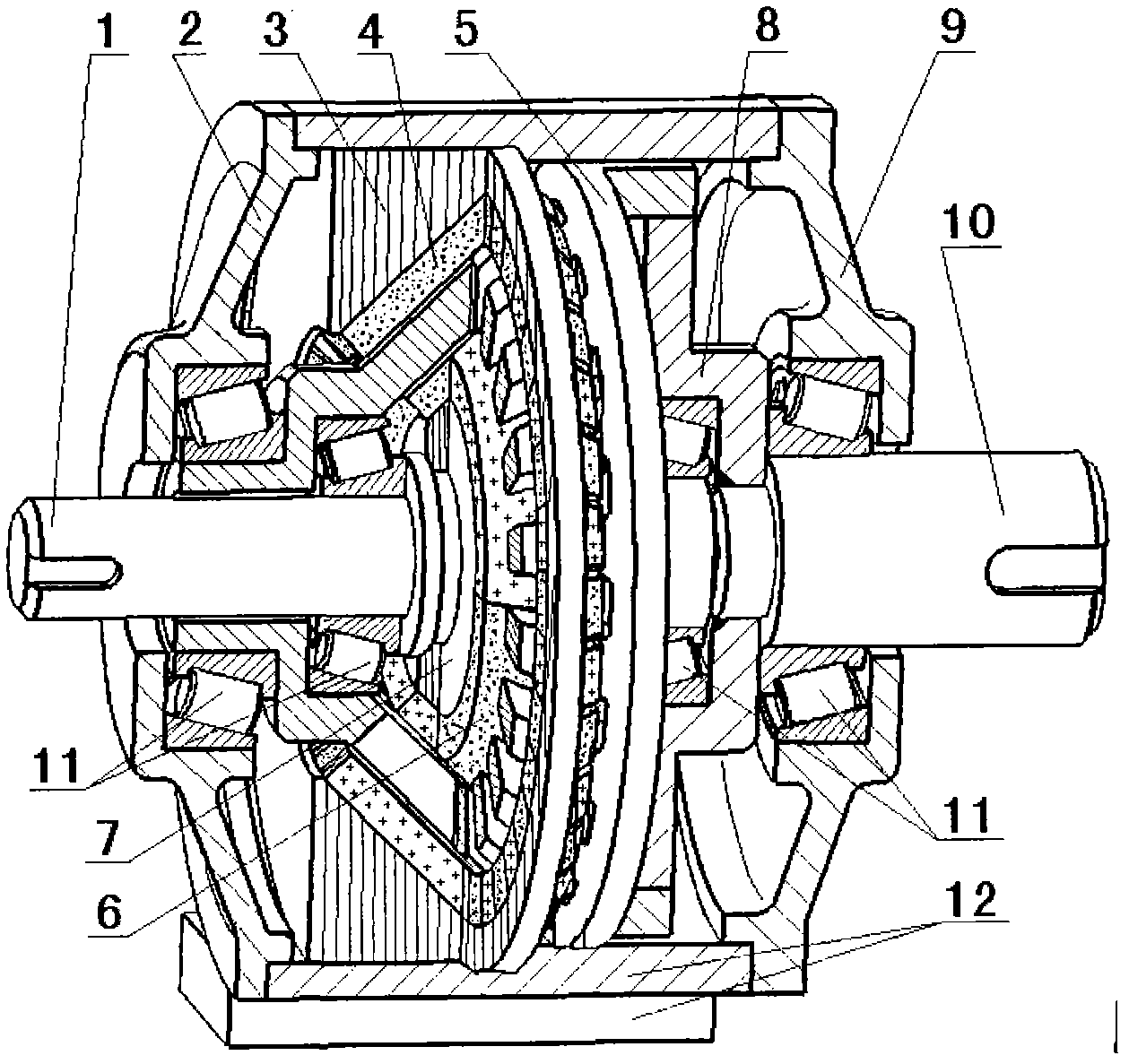

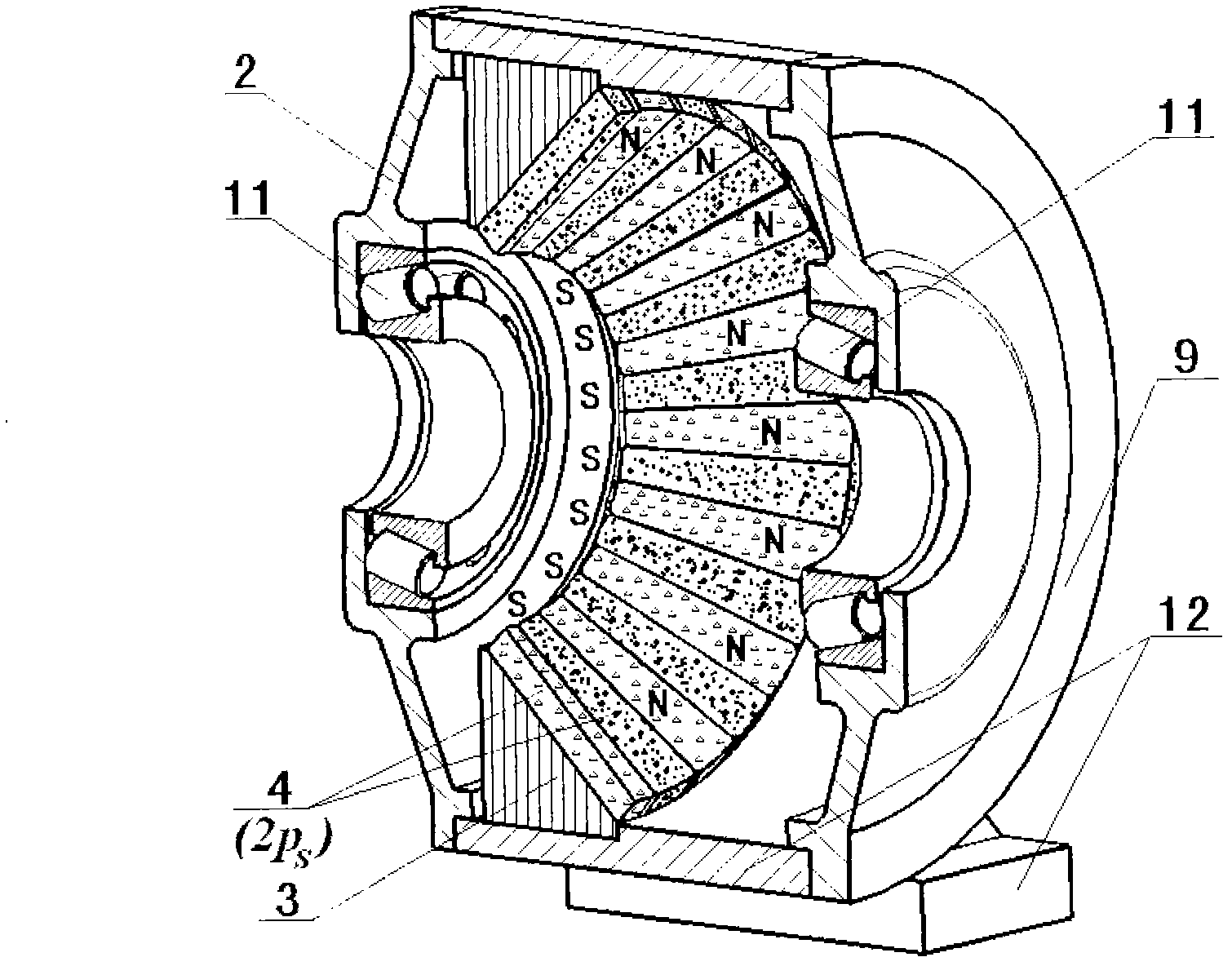

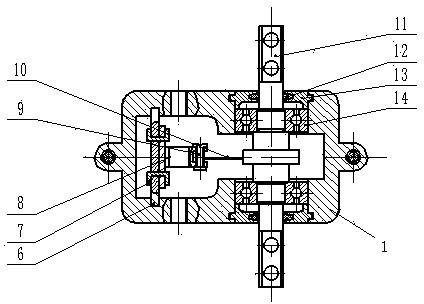

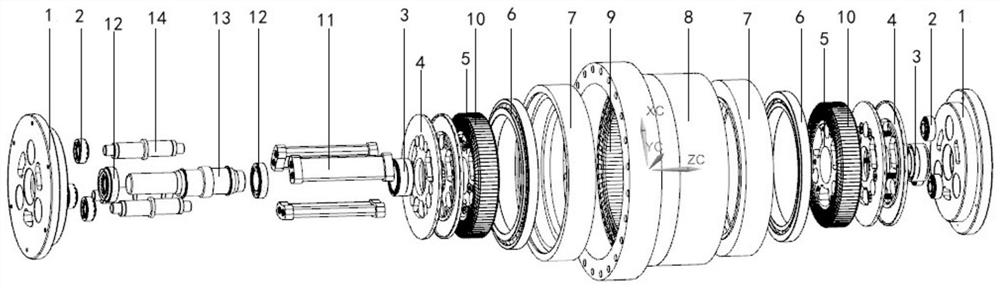

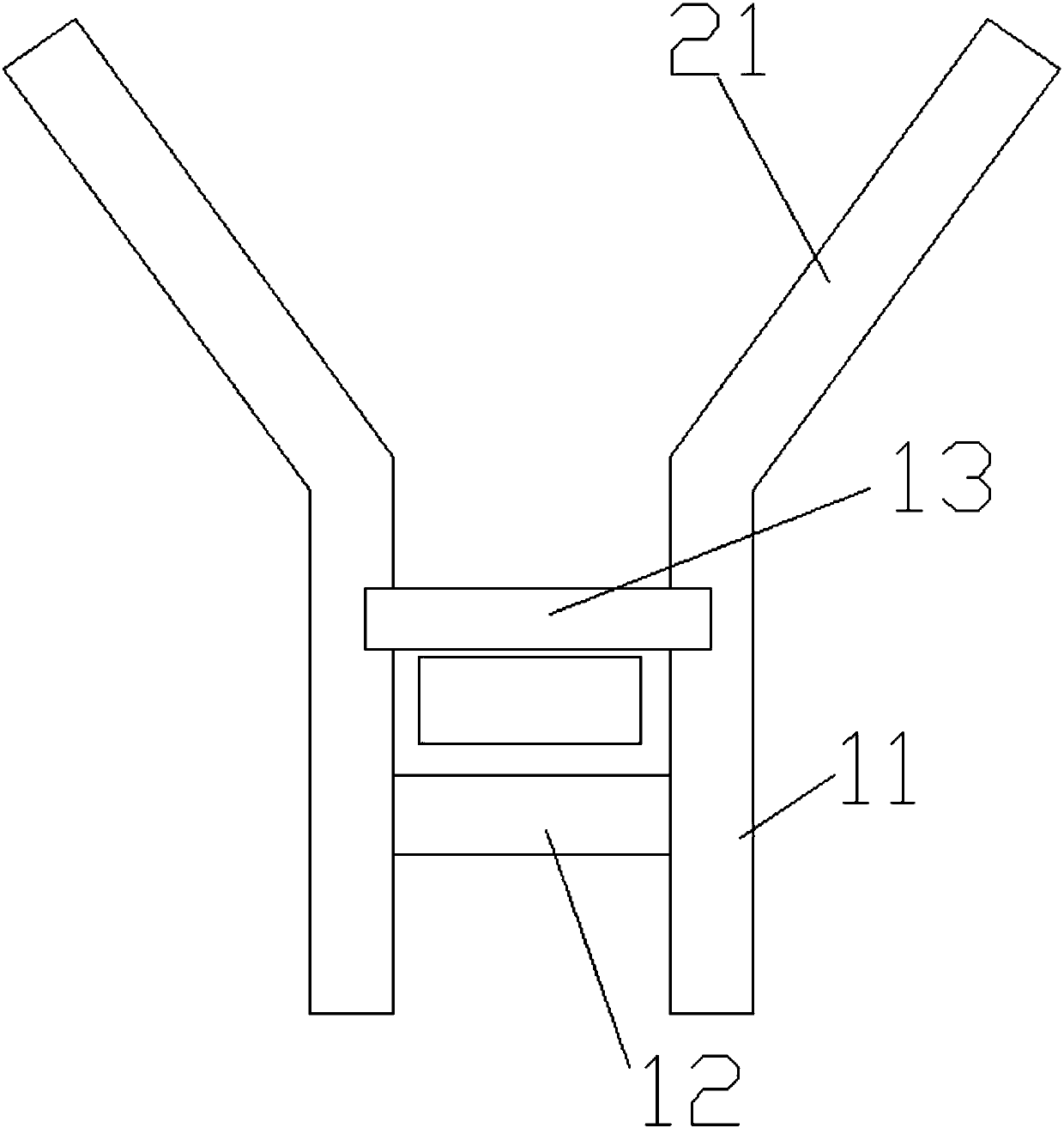

Novel magnetic drive oblique gear pair with oblique air-gap magnetic field

A novel magnetic drive oblique gear pair with an oblique air-gap magnetic field can be widely applied to the industrial drive field of wind power generation, electric cars, ship drive and the like with the requirement of direct driving. The novel magnetic drive oblique gear pair is characterized in that the inner hole of a stator of the magnetic drive oblique gear pair is conical internally; 2ps of stator permanent magnets 4 are distributed on an internally-conical stator iron core 3; a driving gear is conical externally; 2pr of driving gear permanent magnets 6 are distributed on an conical driving gear iron core 7; conical hollow driven gear ferromagnetic grids 5 for modulating the action of a space oblique air-gap magnetic field are mounted between the driving gear permanent magnets 6 and the stator permanent magnets 4; conical space oblique air gaps in coaxial distribution exist among the conical hollow driven gear ferromagnetic grids 5, the driving gear permanent magnets 6 and the stator permanent magnets 4 so as to form an air-gap magnetic field Bg of the magnetic drive oblique gear pair to pass along the conical space air gaps, thereby forming an oblique magnetic field of the magnetic drive oblique gear pair. During work, the power variable speed drive of the magnetic drive oblique gear pair is realized without mechanical contact and friction by utilizing the principle that N pole and S pole of a permanent magnetic material are attracted to each other based on different polarity.

Owner:余虹锦

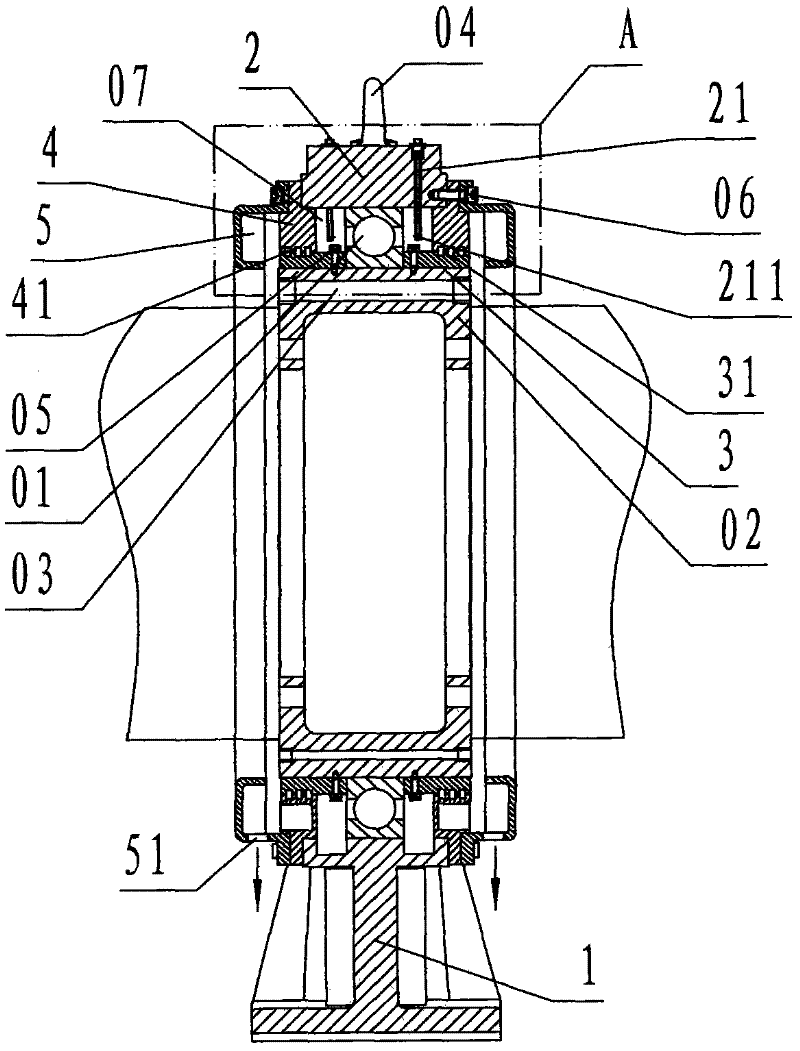

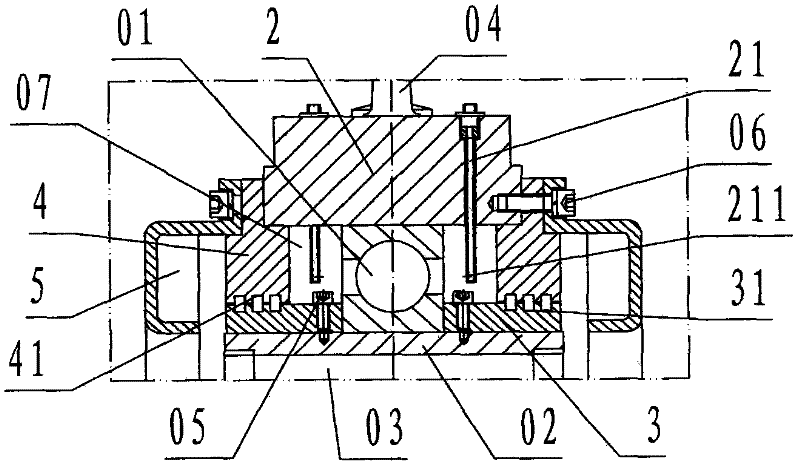

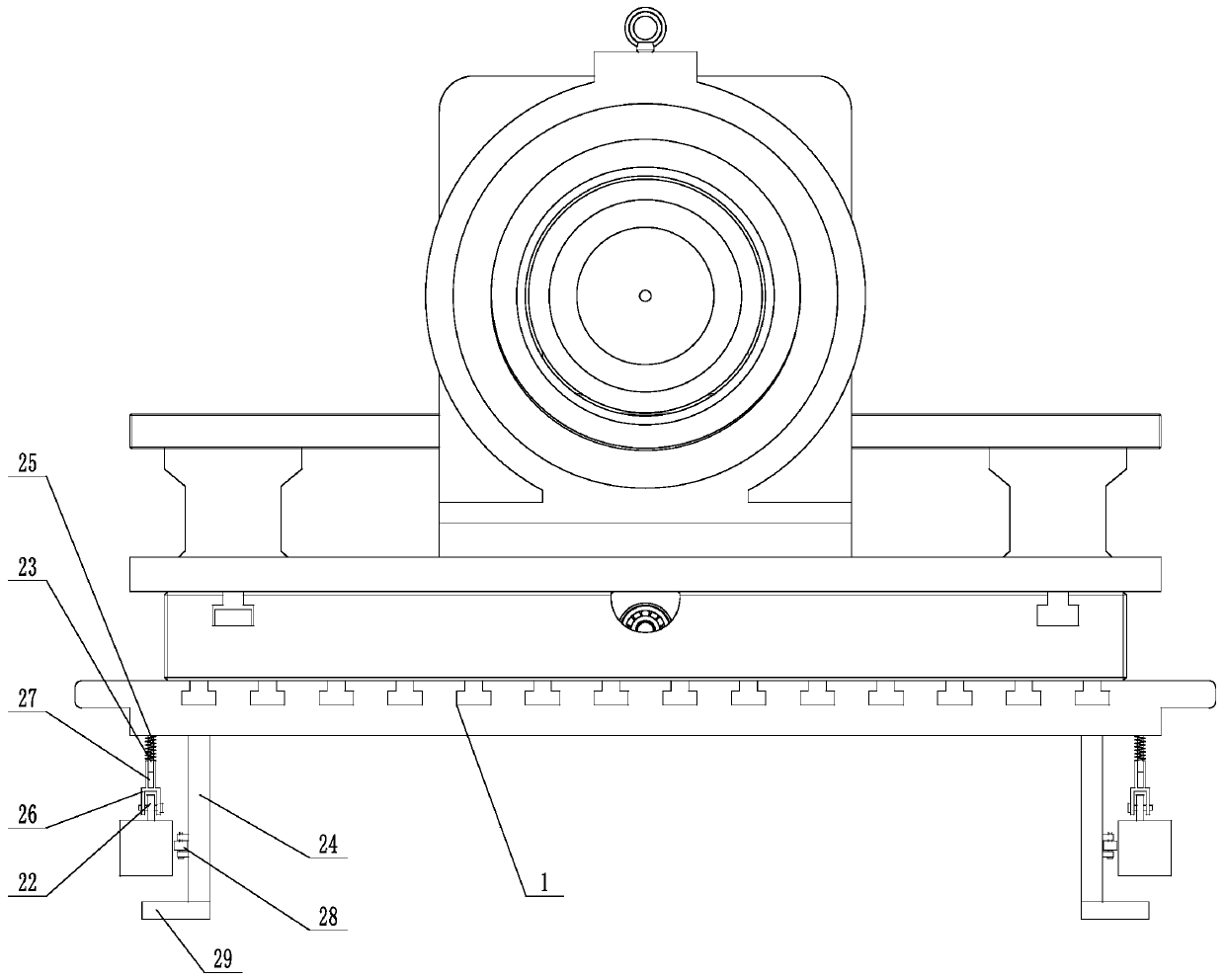

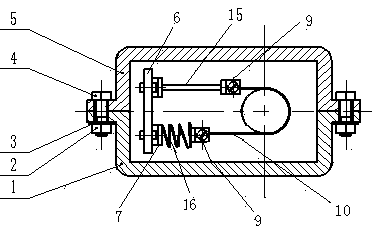

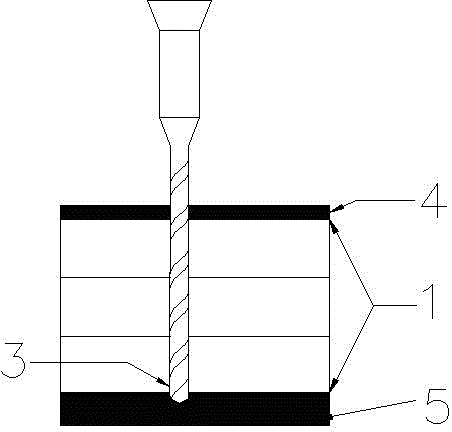

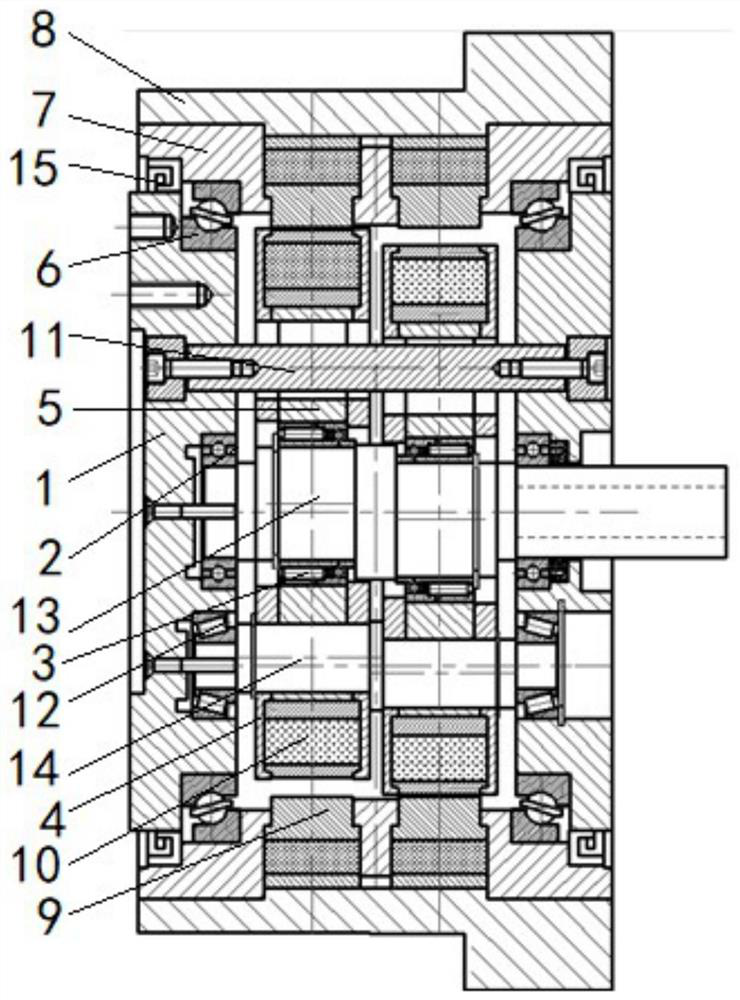

Bearing Block Device of Pulse Liquid Grease Circulation Lubrication Mode for Steel Wire Rope Stranding Machine

InactiveCN102297205AImprove running accuracyReduce noiseRope making machinesBearing coolingPulse injectionLubrication

The invention discloses a bearing seat device of pulse liquid grease circulation lubrication mode for a wire rope stranding machine, which is characterized in that it comprises a base (1), an upper cover (2), a thrust ring (3), an end cover (4), Anti-leakage cover (5). The present invention adopts the metal oil pipe that pulse-sprays lubricating oil to the rolling bearing on the upper cover; the main oil return passage is arranged on the base; the outer labyrinth groove is arranged on the thrust ring, and the inner labyrinth groove is arranged on the end cover; The lower part of the cover is provided with an auxiliary oil return channel; in application, it is collected and recovered through pulse jet oil injection, labyrinth dynamic damping seal and anti-leakage cover, which overcomes the difficulty in controlling the leakage and splash of liquid lubricating oil in the existing technology and recycles liquid lubrication The problem and shortage of oil make the wire rope stranding machine suitable for the pulse injection liquid lubricating oil circulation cooling lubrication method, which prevents the leakage and splashing of the liquid lubricating oil and recycles the lubricating oil, thereby further improving the operating speed of the tubular stranding machine the goal of.

Owner:NINGBO KAITE MACHINERY

High-precision ultrathin cold-rolled steel strip for electronic component and production method thereof

The invention discloses a high-precision ultrathin cold-rolled steel strip for an electronic component and a production method thereof. The thickness of the high-precision ultrathin cold-rolled steelstrip is 0.14 to 0.16mm; the high-precision ultrathin cold-rolled steel strip is prepared by carrying out acid washing of a hydrochloric acid acid-washing machine set, one-rolling-path rolling of a single-rack and six-roller HC rolling machine, unwinding and edge cutting of a slitting machine set, primary annealing of a bright cover type annealing furnace, flattening of a single-rack and four-roller flattening machine, and plate-shaped defect elimination of a bending and straightening machine set on a hot-rolled steel strip in sequence. The high-precision ultrathin cold-rolled steel strip disclosed by the invention has the advantages of short flow and high product rate, secondary rolling and secondary annealing procedures are omitted and the production cost is reduced; meanwhile, the high-precision ultrathin cold-rolled steel strip for the electronic component has the characteristics of low impurity content, ultrathin thickness, high size precision, flat and straight plate shape, highsurface reflection rate, high roughness uniformity, low yield ratio, uniform performance and good stamping performance, and is applicable to electronic basic components including a battery shell, a communication cable, a television color tube, a carbon membrane resistor and the like.

Owner:山东泰山轧钢有限公司

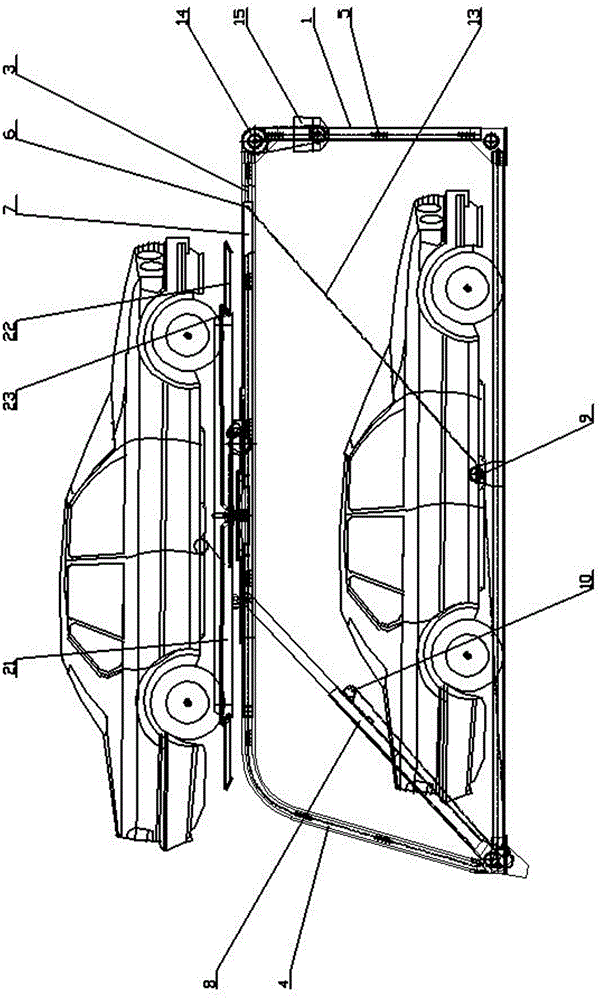

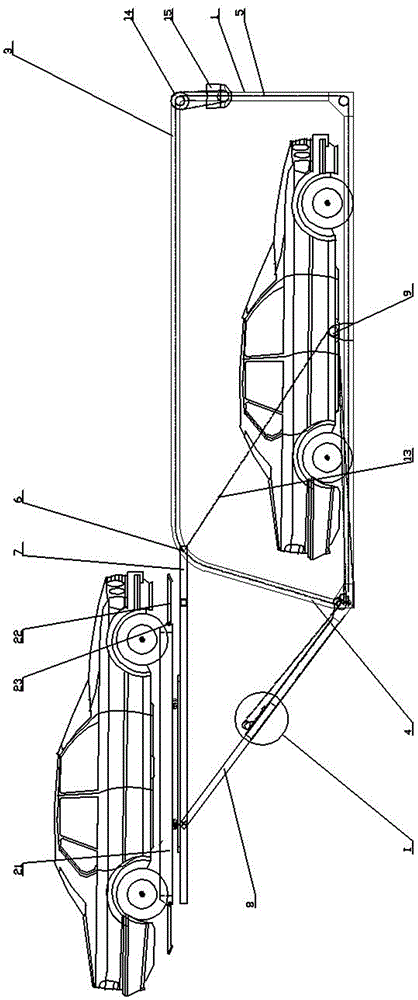

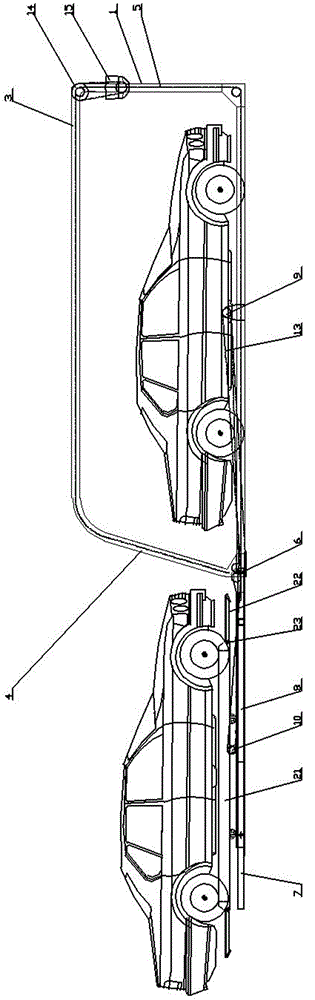

Two-layer longitudinal avoidance-free telescopic rod type three-dimensional garage

The invention provides a two-layer longitudinal avoidance-free telescopic rod type three-dimensional garage. The three-dimensional garage comprises two frames. The tops of the frames are each provided with a horizontal guide groove. The same sides of the frames are each provided with an inclined guide groove. The horizontal guide grooves communicate with the inclined guide grooves. Guide blocks are installed in the horizontal guide grooves and the inclined guide grooves. The guide blocks are connected with one ends of lifting trays. Circulation chains are arranged on the circumferential rings of the frames and can drive the guide blocks to move along the horizontal guide grooves and the inclined guide grooves. The lower ends of the inclined guide grooves are hinged to the fixed ends of telescopic rods. The movable ends of all the telescopic rods are all hinged to the other ends of the lifting trays. The three-dimensional garage has the advantages that the occupied space is small, independent installation can be conducted on the ground and an underground parking space, the effect that two vehicles are stored in a parking space is achieved, the two layers of vehicles do not need mutual avoidance, the stability of storing, lifting and falling of the upper layer vehicle is high, the equipment service life is long, the equipment and maintenance cost is low, oil contamination is avoided, and cleanness and tidiness of a parking area are kept well.

Owner:陈秀海

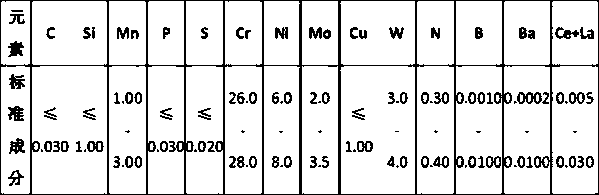

Super advanced double-phase stainless steel smelting process method of CD3MWN material

ActiveCN108823348AIncrease contentReduce precipitationProcess efficiency improvementHydrogenDouble phase

The invention relates to a super advanced double-phase stainless steel smelting process method of a CD3MWN material. According to the invention, internal control components during double-phase stainless steel smelting is designed, wherein C is less than or equal to 0.030 wt%, Si is less than or equal to 0.90 wt%, Mn is 1.20-2.50 wt%, P is less than or equal to 0.020 wt%, S is less than or equal to0.015 wt%, and Cr is 26.2-27.5 wt%, Ni is 6.2-7.6 wt%, Mo is 2.2-3.4 wt%, Cu is less than or equal to 0.80 wt%, W is less than or equal to 0.80 wt%, N is 0.32-0.38 wt%, B is 0.0010-0.0100 wt%, Ba is0.0002-0.0100 wt%, and Ce+La is 0.005- 0.030 wt%; and %Cr+3.3 (%Mo+0.5%W)+16%N is less than or equal to 45, the content of trace elements B, Ba, Ce, and La can be precisely controlled; the N content is increased to 0.30% or more, and at the same time, nitrogen holes in the casting can be avoided; and the content of harmful elements such as sulfur, oxygen, hydrogen and the like is minimized to improve the purity of the molten steel. The cast casting has high strength and excellent corrosion resistance. In the stainless steel, a ferrite phase and an austenite phase are close to 50%, the castinglife is prolonged. the production costs are greatly reduced, and purposes of energy saving and environmental protection can be realized.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Aqueous lubricating liquid for stamping, stretching and forming cell phone battery shell, preparation method and application method thereof

The invention discloses aqueous lubricating liquid for stamping, stretching and forming a cell phone battery shell, a preparation method and an application method thereof. The lubricating liquid comprises the following raw materials: 45# transformer oil, a non-ionic emulsifying agent, aqueous extreme-pressure lubricant, boric acid, an aluminum powder sinking agent, triethanolamine, isopropanolamine, synthetic petroleum sodium sulfonate, a branched chain phosphate aluminum protecting agent, a dicarboxylate based composite anti-rust agent, a butyl ether coupling agent, a hard water resistant agent, a defoaming agent and distilled water; the lubricating liquid is excellent in lubricating performance, anti-rust performance and settling performance, and the lubricating performance, the anti-corrosion performance and the cleaning performance are matched and stabilized for a long time, the antibacterial performance is good and the service life is long, the working liquid can be circularly added, the emission of the waste liquid is reduced, the environment cannot be polluted, and all indexes of 5% of diluent reach or exceed relative indexes of GB6144-2010.

Owner:AMER TECH CO LTD

Method for processing soft copper foil

InactiveCN101462228AThe unit area is largeEvenly heatedBase-materialsMetal rolling arrangementsMetal foilKerosene

The invention relates to a method for processing a soft copper foil. The copper foil manufactured by the method has the advantages of even hardness, clean surface, brightness, no oil pollution, and higher product qualification rate. The method comprises the following steps: smelting electrolytic copper and then casting the electrolytic copper into a cast ingot; milling the surface of the cast ingot; performing homogenization treatment on the cast ingot in a heating furnace; performing hot rolling on the cast ingot immediately after the treatment; performing acid cleaning on the cast ingot after finishing the hot rolling; blowing and drying the cast ingot after the acid cleaning and then annealing the cast ingot; and performing a cold rolling process after the annealing. The method is characterized in that the cold rolling process adopts four-roller cold rolling, a cold rolling liquid used in the cold rolling is prepared from coal oil, gasoline and rape oil through mixing, and the mixture ratios of the components comprise: 80 to 85 percent of the coal oil, 15 to 17 percent of the gasoline and 5 to 8 percent of the rape oil; after the cold rolling, the semi-automatic continuous annealing is performed directly; and a single layer of a metal foil is heated evenly in a heating body, the single layer at one end is used for uncoiling, the middle part is a furnace body for heating, while the single layer at the other end is used for coiling, and protective gas is kept between 0.3 and 0.5 Pma in the furnace during annealing.

Owner:朱元康

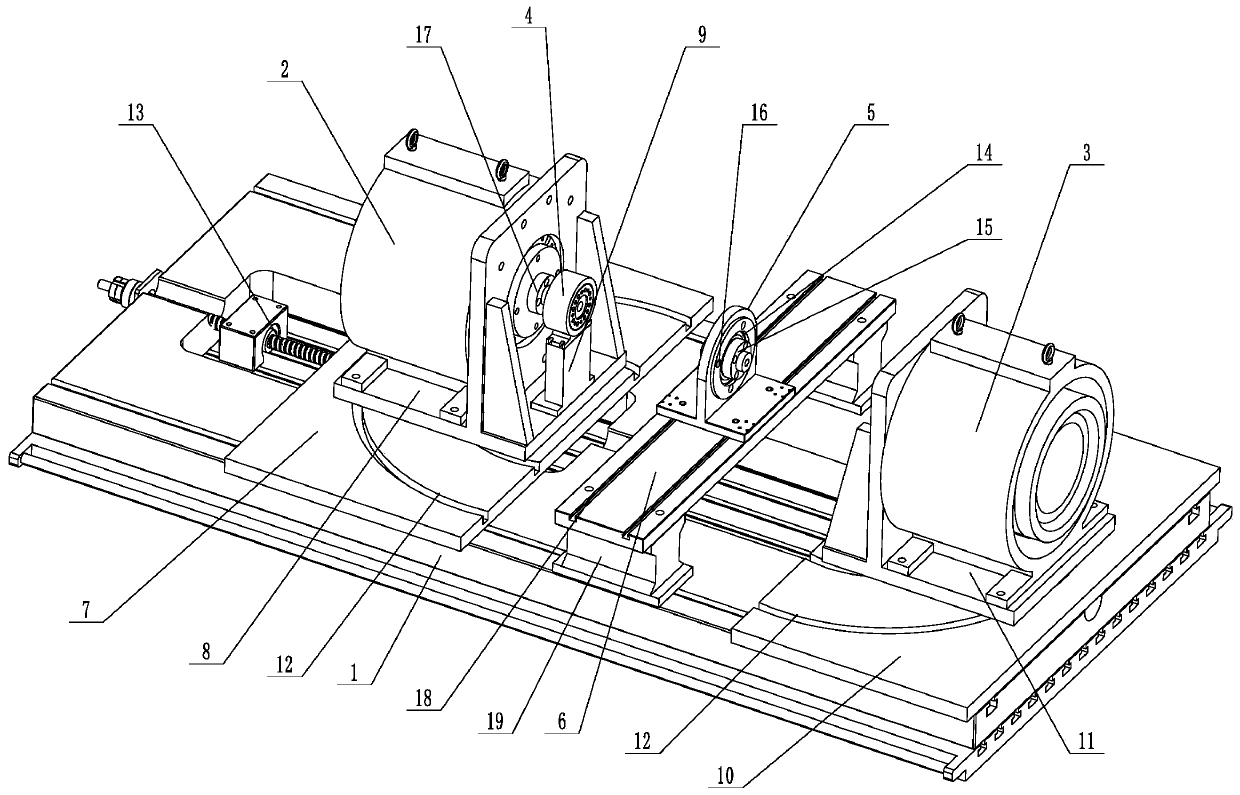

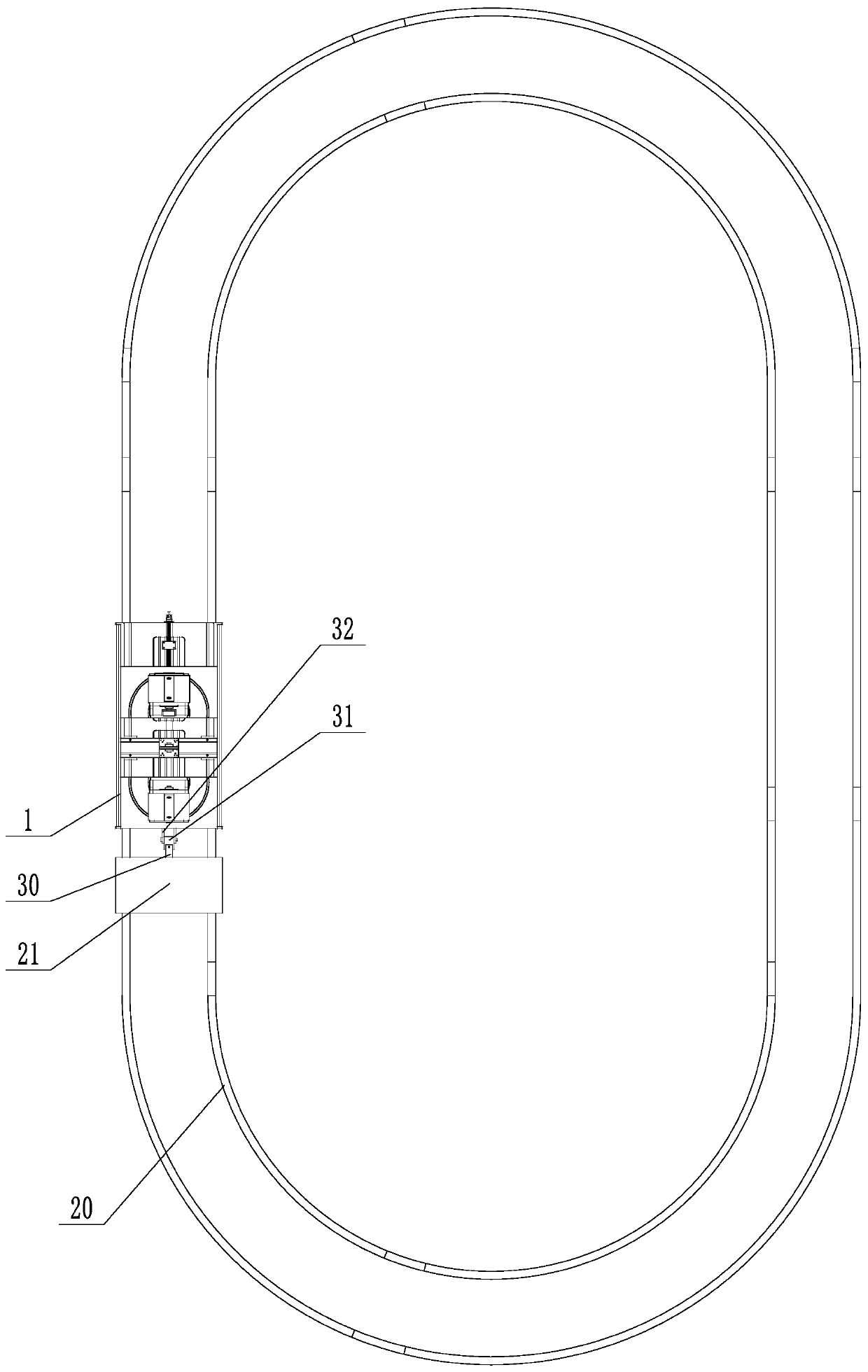

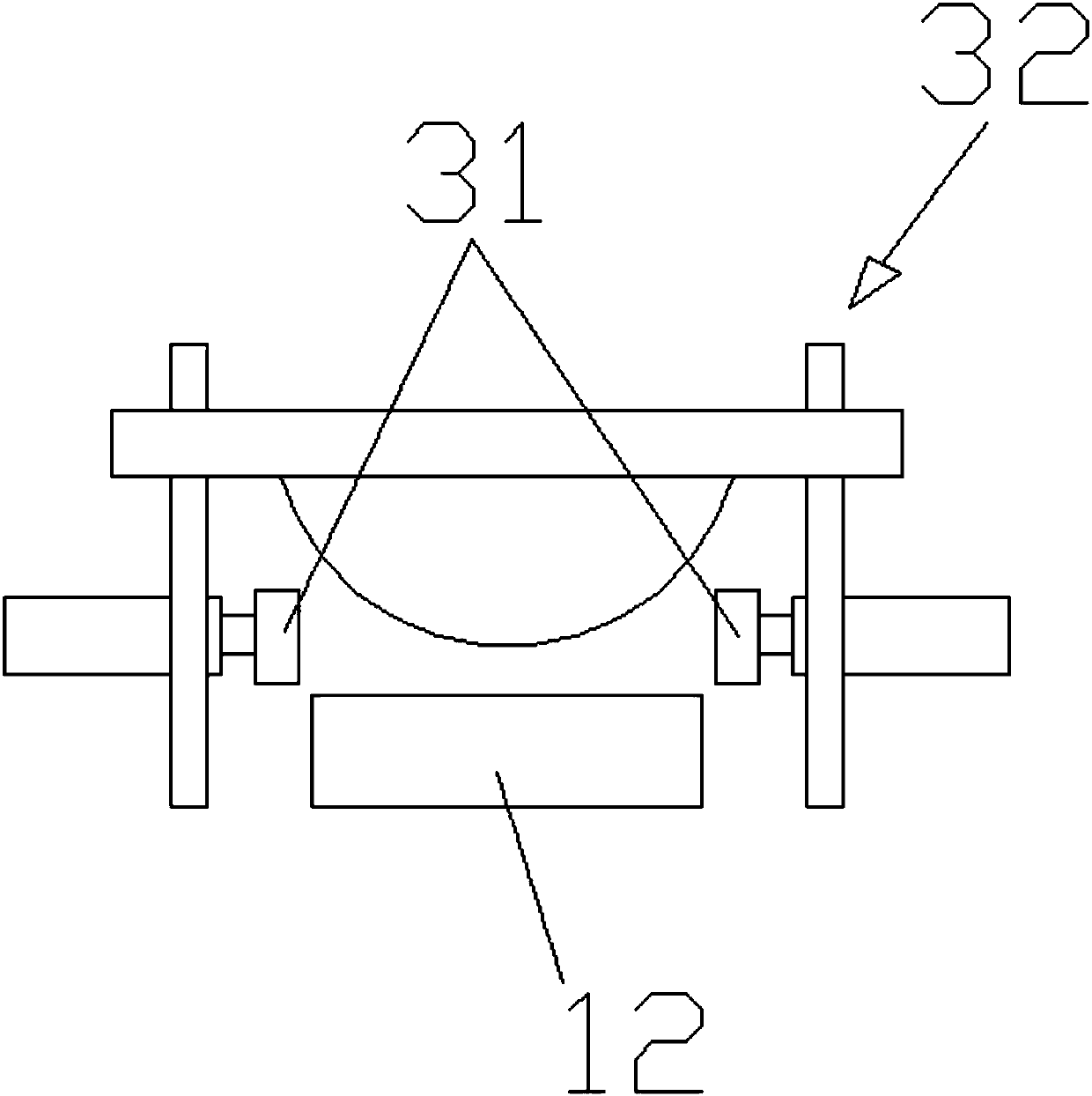

Electric direct-drive shaft torsional fatigue test device and method

ActiveCN111366357ASimple structureLow costMachine gearing/transmission testingTorsion fatigueElectric machine

The invention discloses an electric direct-drive shaft torsional fatigue test device and method, and aims to overcome defects of high cost, poor universality and oil leakage risk of an existing hydraulic fatigue test machine. The device comprises a mounting platform, a power direct-drive main motor, a power direct-drive auxiliary motor, a torque sensor and a connecting seat for clamping a test piece, wherein a movable sliding plate is mounted on the mounting platform, the power direct-drive main motor is rotatably mounted on the sliding plate, the power direct-drive auxiliary motor is rotatably mounted on the mounting platform, the connecting seat is movably mounted between the power direct-drive main motor and the power direct-drive auxiliary motor, the connecting seat is arranged betweenthe power direct-drive main motor and the power direct-drive auxiliary motor, and the torque sensor is arranged between the connecting seat and the power direct-drive main motor. The electric direct-drive shaft torsional fatigue test device is simple in structure, low in cost and good in universality, and the risk of oil leakage is avoided.

Owner:策仕(宁波)工业技术有限公司

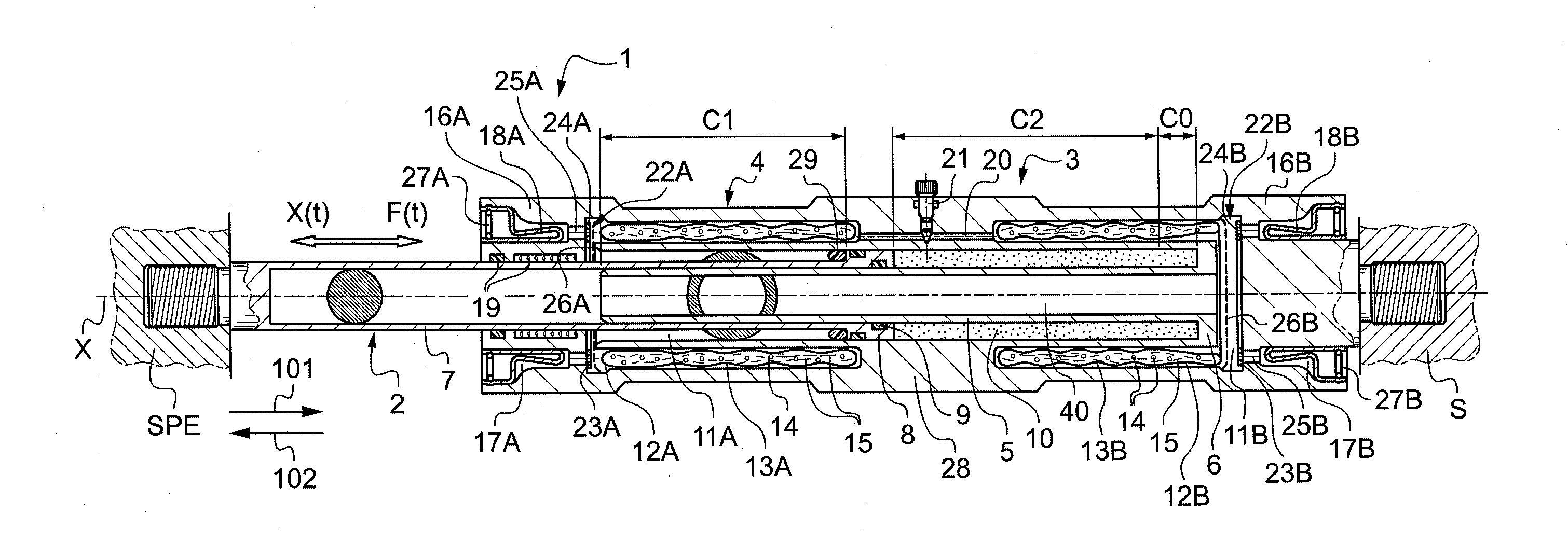

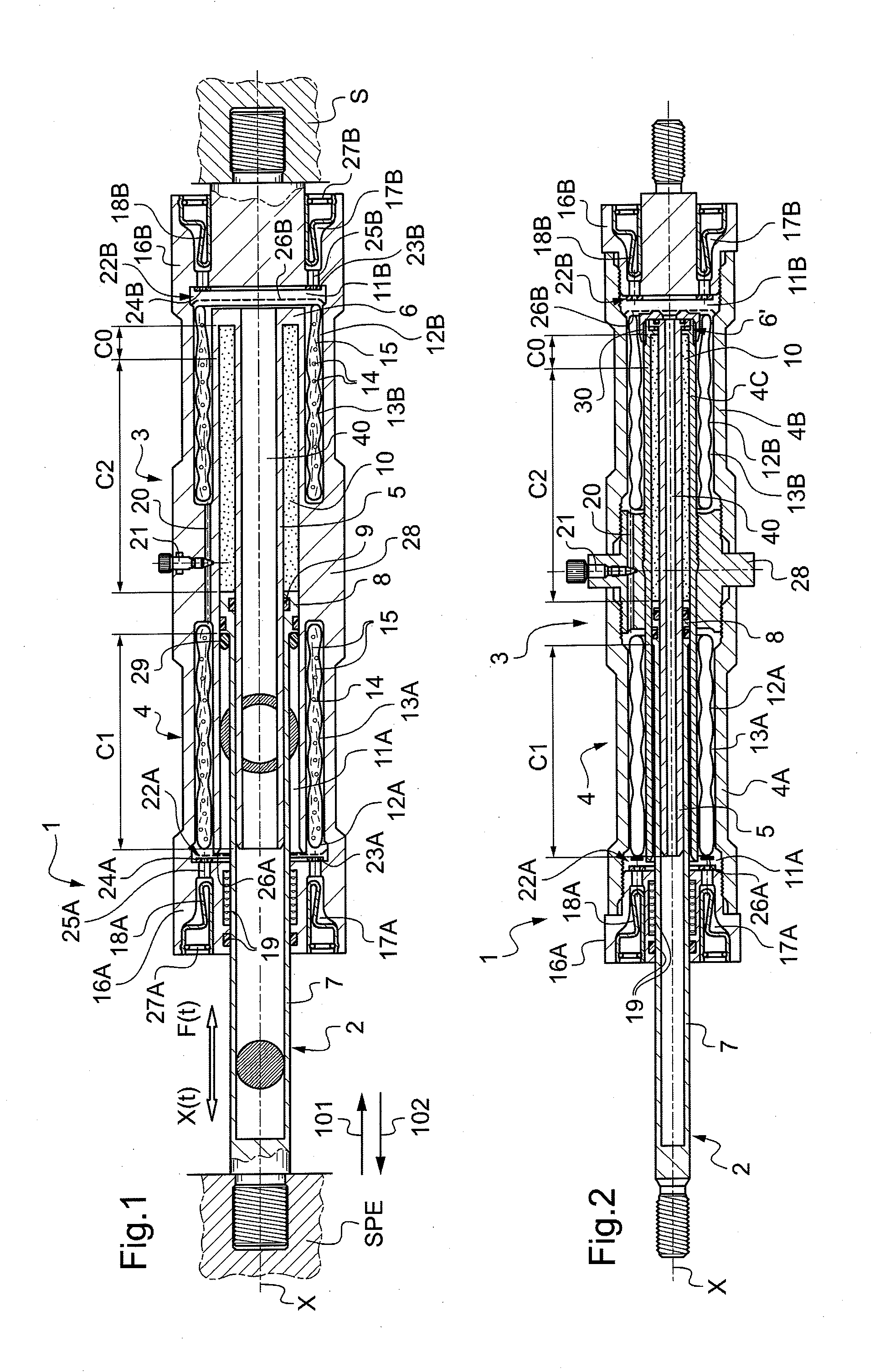

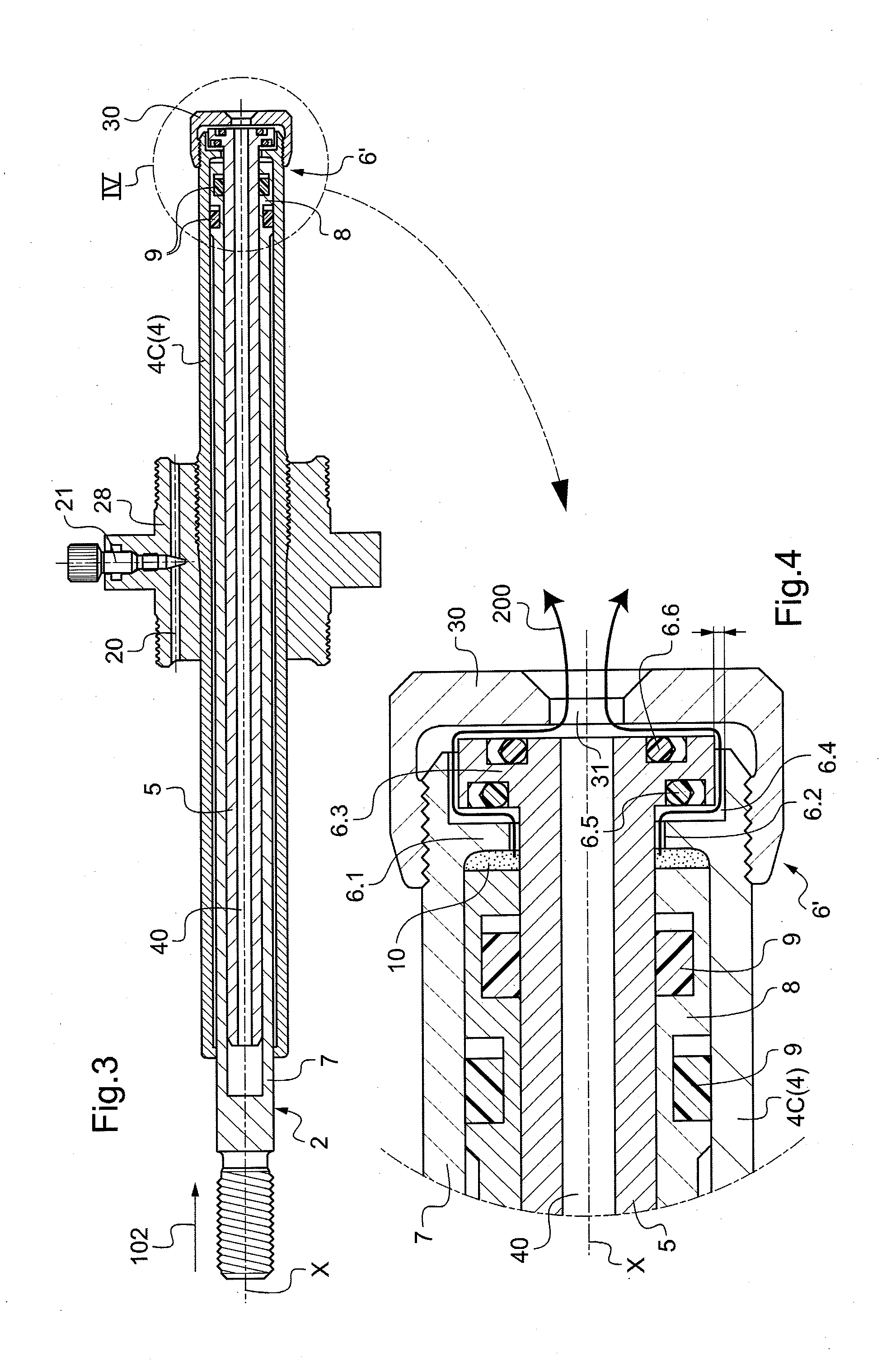

Virtually oil-free shock absorber having high dissipative capacity

InactiveUS20130189138A1Ensure continuityReduce inertiaSpringsGas based dampersEnergy absorptionOil free

A shock absorber has dissipation power and practically no oil. The shock absorber comprising a rod-and-piston assembly slidable in a tubular body. The rod-and-piston assembly co-operating with the tubular body to define two working chambers containing hydraulic fluid. Each working chamber being in permanent communication with an auxiliary chamber containing a heterogeneous energy absorption-dissipation structure with at least one porous capillary matrix and an associated liquid relative to which the matrix is lyophobic. The two auxiliary chambers are annular chambers formed in the wall of the tubular body on either side of central portion of the tubular body. Each of the annular auxiliary chambers houses a flexible bag containing the associated heterogeneous structure; and each of the two working chambers also communicates with an associated compensation chamber. The compensation chambers ensures hydraulic fluid continuity during movements of the rod-and-piston assembly in the tubular body.

Owner:WALDEN ASSOCS

Rotary device based on chain transmission and driven by shape memory effect

ActiveCN103352787AForward and reverseSimple structureHydro energy generationEndless-chain machinesMemory effectStrong acids

A rotary device based on chain transmission and driven by a shape memory effect mainly comprises a driving component, a sprocket shaft component, a shell body component, a chain and the like, and achieves forward and reverse rotation through the shape memory effect of a shape memory polymer driving body in the driving component. The rotary device based on chain transmission and driven by the shape memory effect has the advantages of being simple in structure, easy to control, light in weight, resistant against abrasion, good in shock-absorption effect and the like. All the exposed parts are made of polymer, so that the rotary device based on chain transmission and driven by the shape memory effect can be applied to a high-corrosion environment with strong acid, strong alkali or the like.

Owner:JIANGSU UNIV

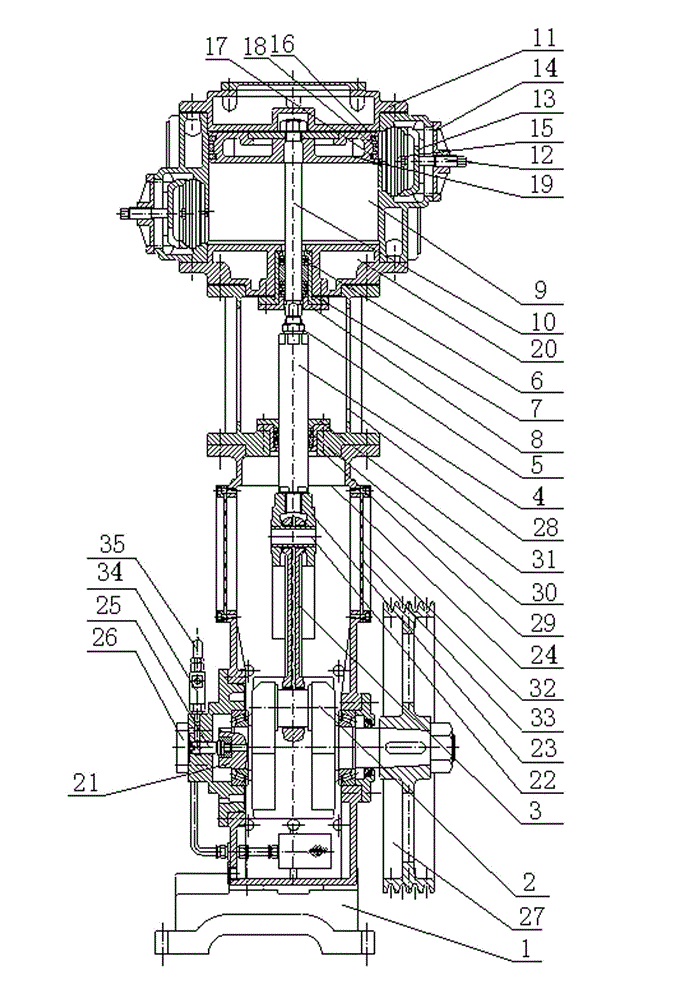

Novel oilless vertical vacuum pump

InactiveCN102913417AReliable lubricationRun smoothlyPumpsPositive-displacement liquid enginesFlywheelCrankshaft

The invention discloses a novel oilless vertical vacuum pump which comprises a base, a machine body, an air cylinder, an air cylinder cover and a flywheel, wherein the air cylinder is arranged above the machine body; a piston and a piston rod are arranged in the air cylinder; an upper packing chamber is formed between an air cylinder neck and the piston rod; an upper packing pressure cover is arranged under the upper packing chamber; a piston ring, a tension ring and a guide ring are arranged between the air cylinder and the piston; the piston rod penetrates through the air cylinder and the air cylinder neck downwards in sequence, and the lower end of the piston rod is in cap connection with a connecting rod through the piston rod; the bottom of the connecting rod is inserted into a cross head; the cross head is connected with an upper end hole of the connecting rod through a cross head pin; a lower end hole of the connecting rod is in circumferential sliding connection with crankshafts on the two sides; the crankshaft on one side is connected with the flywheel through a rotating shaft, and the crankshaft on the other side is connected with a machine oil pump through a machine oil pump joint in the rotating shaft. The novel oilless vertical vacuum pump has the advantages that the novel vertical pump is free from oil stain, is reliable to lubricate, is more stable to run and is convenient to filter, the long-term normal operation of an air valve and the piston is ensured, the service life is long, and the maintenance is convenient.

Owner:NANTONG CITY WEISHI VACUUM EQUIP

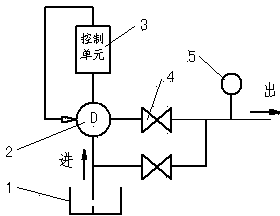

Sealing leakage test device for oil-immersed transformer

InactiveCN103528769AGuaranteed test pressure valueStable pressure valueMeasurement of fluid loss/gain rateInductances/transformers/magnets manufactureAutomatic controlTransformer

The invention discloses a sealing leakage test device for an oil-immersed transformer. The device comprises an oil pump, a control unit, a pressure gauge and a remote control switch, wherein an oil tank is connected with the oil pump of the sealing leakage test device through a pipeline; the control unit is arranged on the oil pump; valves are mounted at outlets of both the oil pump and the oil tank; the pressure gauge is arranged on the pipeline; the control unit comprises two outgoing lines, one of the outgoing lines is connected with a power supply, the other outgoing line is connected with an oil pump motor, and the control unit controls the working state of the oil pump according to a standard product leakage test pressure value or the pressure of a pressure relief valve; and the remote control switch is mounted at a power supply input end. The sealing leakage test device has the advantages of simplicity and flexibility in operation, high detection rate, adjustable test pressure, automation in control, remote power interruption and wide application range and is low in investment, applicable to products of all voltage classes and beneficial to the improvement on the product quality.

Owner:CEEG JIANGSU

Method for preparing PCB (Printed Circuit Board) aluminum foils by using cast-rolled slabs

ActiveCN104550235AImprove conduction efficiencyReduce the intermediate annealing processMetal rolling arrangementsPrinted circuit boardMechanical properties of carbon nanotubes

The invention discloses a method for preparing PCB (Printed Circuit Board) aluminum foils by using cast-rolled slabs. The method comprises the following steps: (1) smelting, casting and rolling 1050 or 1060 aluminum alloys; (2) roughly rolling, intermediately rolling, longitudinally shearing edges; (3) finely rolling; (4) washing and straightening; (5) cutting, checking and packing to obtain PCB electronic aluminum foils. The mechanical property control deltab of PCB electronic aluminum foils prepared by the method is 190-230MPa; the extension ratio of the PCB electronic aluminum foils is larger than or equal to 2%; the surface hardness value is smaller than 60HV.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

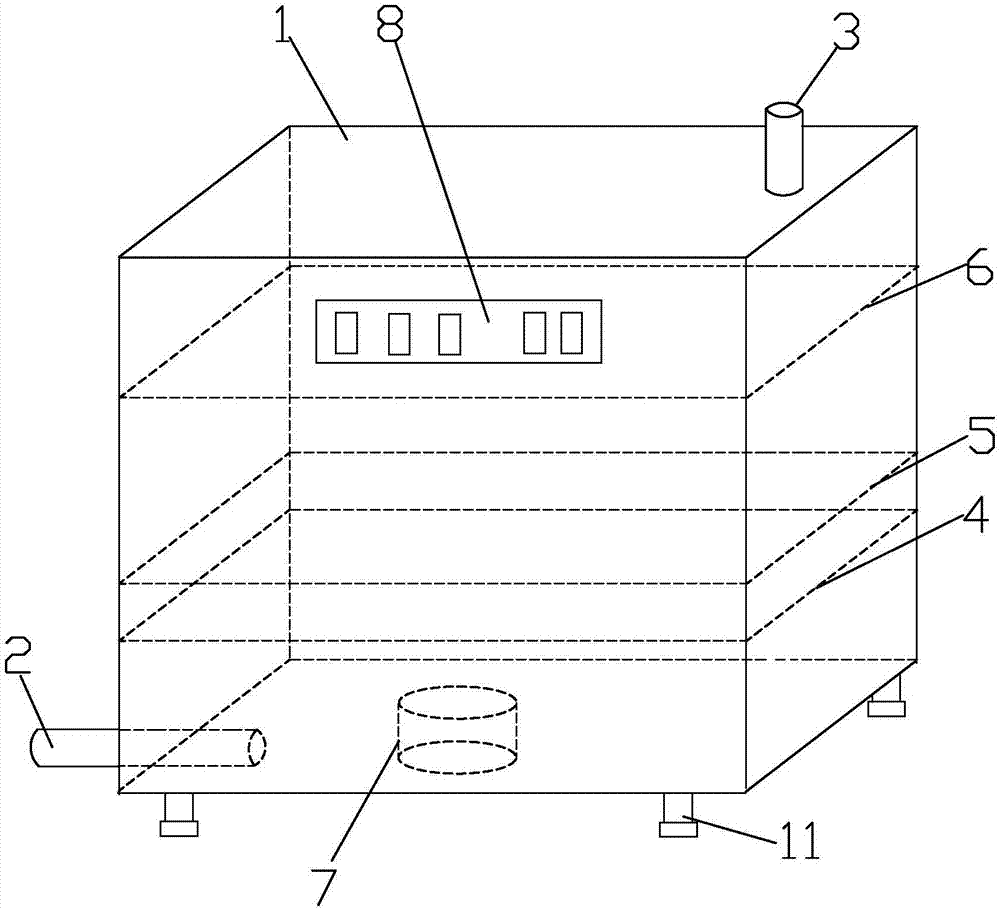

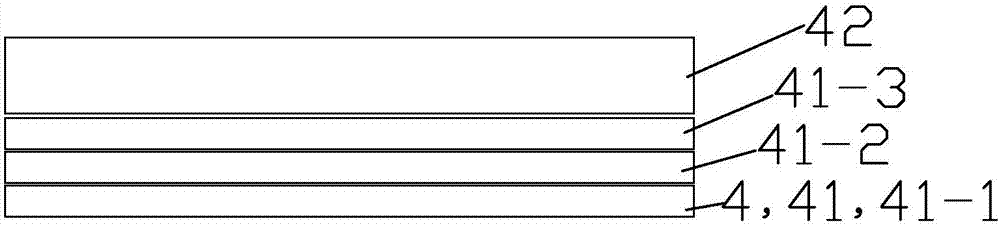

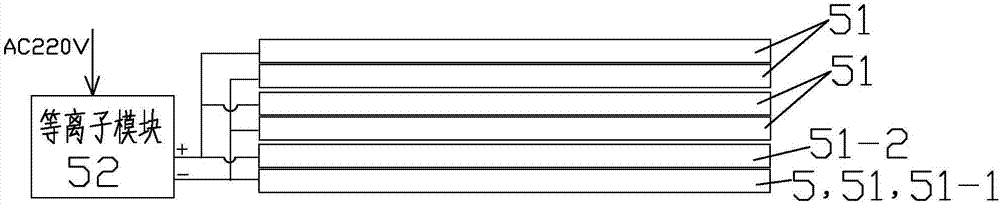

Moxibustion smoke processing device

PendingCN106974826ASolve processing problemsSimple structureCombination devicesDevices for heating/cooling reflex pointsSmoke EmissionMechanical engineering

The invention provides a moxibustion smoke processing device. The processing device comprises a box body, an air inlet pipe and an air outlet pipe which are arranged on the box body, and a blower arranged in the box body. The structure is characterized in that the box body further comprises an oil fume filtering unit, a plasma unit and a rear processing unit arranged in the box body sequentially, and a main control panel arranged on the box body; the plasma unit comprises 1-6 emission plate layers and plasma modules, wherein the plasma modules are electrically connected with the emission plate layers and provide working voltage for the emission plate layers; the emission plate layer comprises a negative emission plate and a positive emission plate which are oppositely arranged; the main control board is a circuit board for controlling the work of the plasma unit and the blower. The moxibustion smoke processing device in use has the advantages that the moxibustion smoke emitted by the front end moxibustion device is processed relatively thoroughly; after processing, the moxibustion smoke after can be directly emitted indoors, and indoor facilities are not polluted and breathing of people is not affected because the processed moxibustion smoke has no odor; the difficult problem of processing the moxibustion smoke produced by the moxibustion smoke device in the prior art is effectively solved.

Owner:常州普邦医疗设备有限公司

Environment-friendly 35KV special high-voltage cable filling strip and preparation method thereof

InactiveCN103214713APromote plasticizationExtrude evenlyPower cablesLow-density polyethyleneLinear low-density polyethylene

The invention discloses an environment-friendly 35KV special high-voltage cable filling strip and a preparation method thereof. The filling strip is composed of, by weight, 45-50 parts of low-density polyethylene, 40-45 parts of linear low-density polyethylene, 20-25 parts of metallocene linear low-density polyethylene resin, 38-42 parts of high-pressure polyethylene, 5-7 parts of modified white carbon black, 0.5-0.7 parts of a rheological agent PPA, 0.9-1.1 parts of stearic acid, 0.2-0.4 parts of an antioxidant B225, 2.8-3.2 parts of a PE toughening agent, 0.9-1.1 parts of asphalt, and 0.4-0.6 parts of an AC foaming agent. The 35KV special high-voltage cable filling strip provided by the invention has the advantages of good plasticization, uniform extrusion, no impurity, no oil stain, no water stain, smooth surface, uniform color, reduced cost, low density, reduced cable outer diameter, improved roundness, pressure resistance, temperature resistance, light specific weight, high tensile strength, and the like.

Owner:安徽双荣电器电缆有限公司

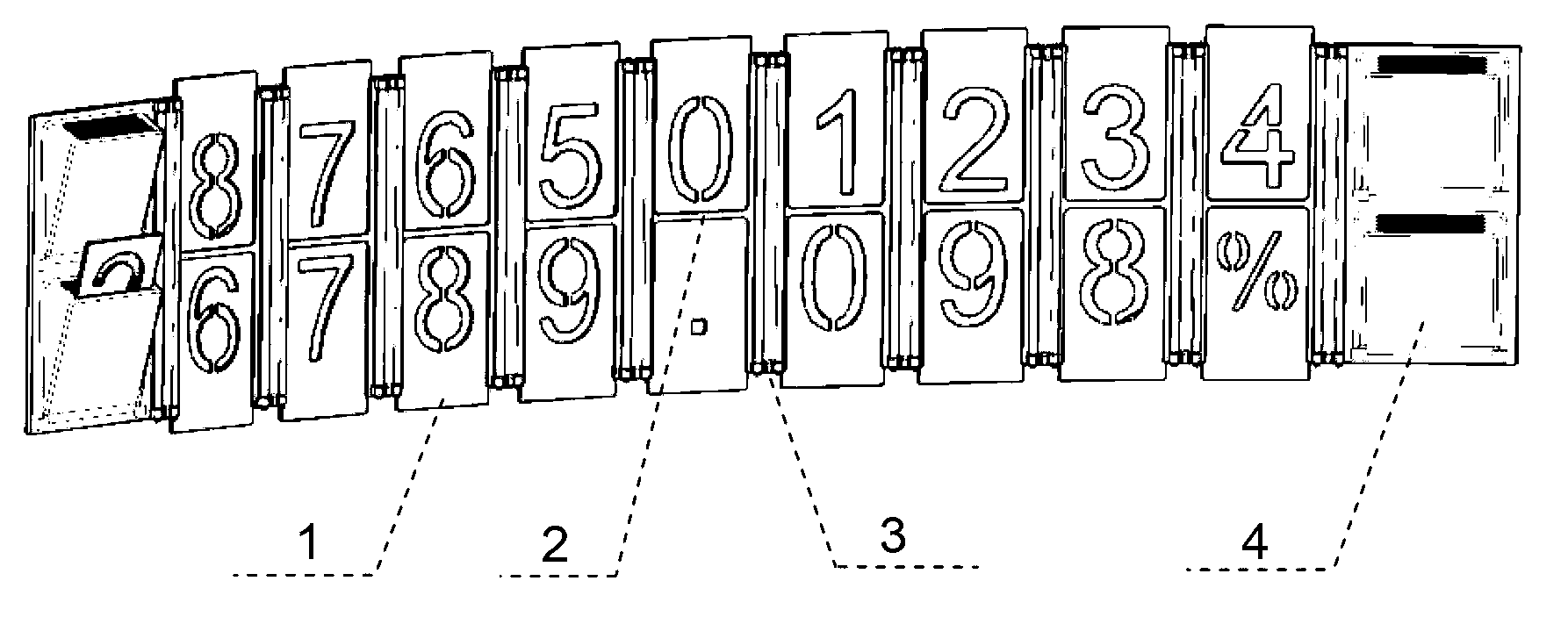

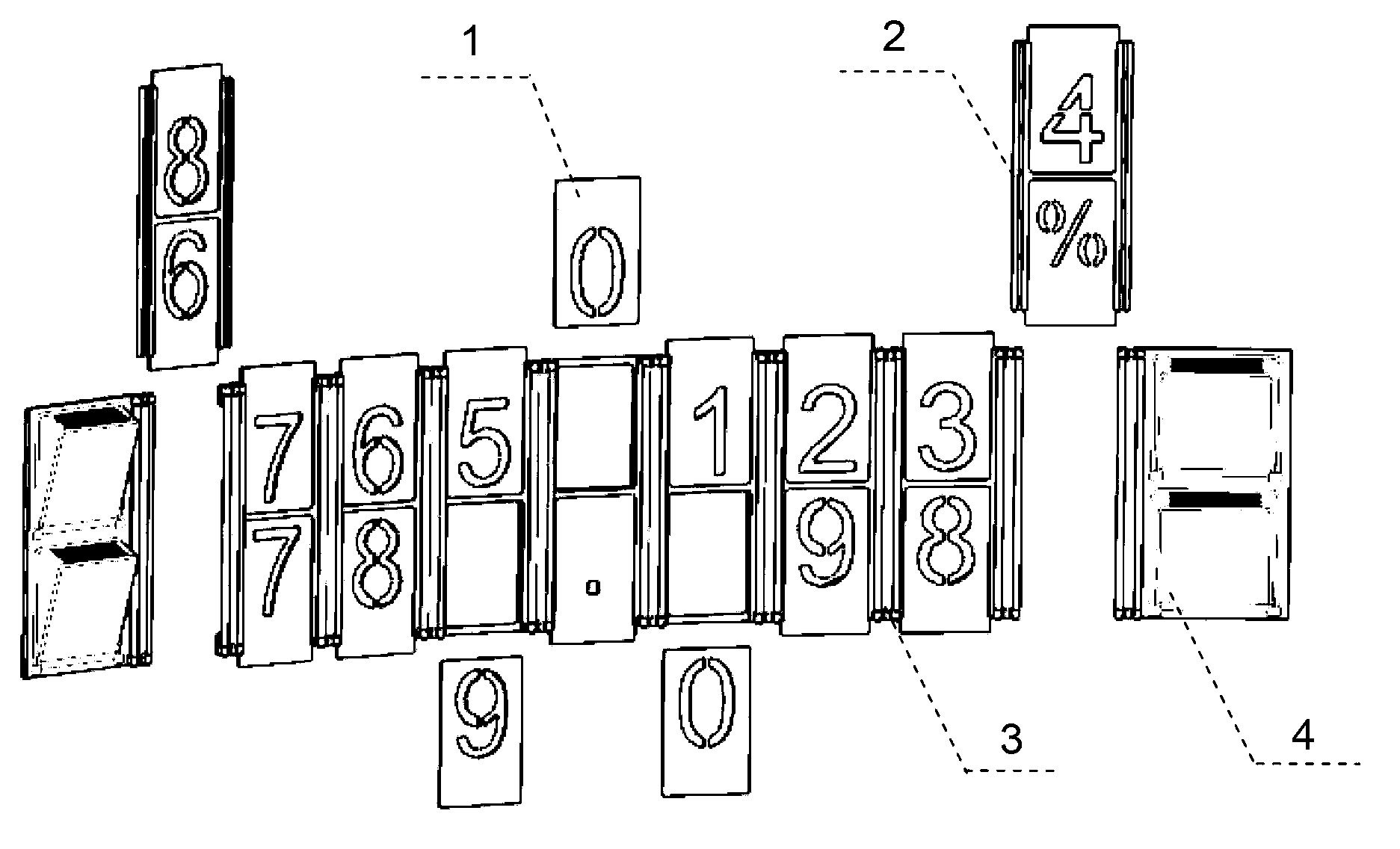

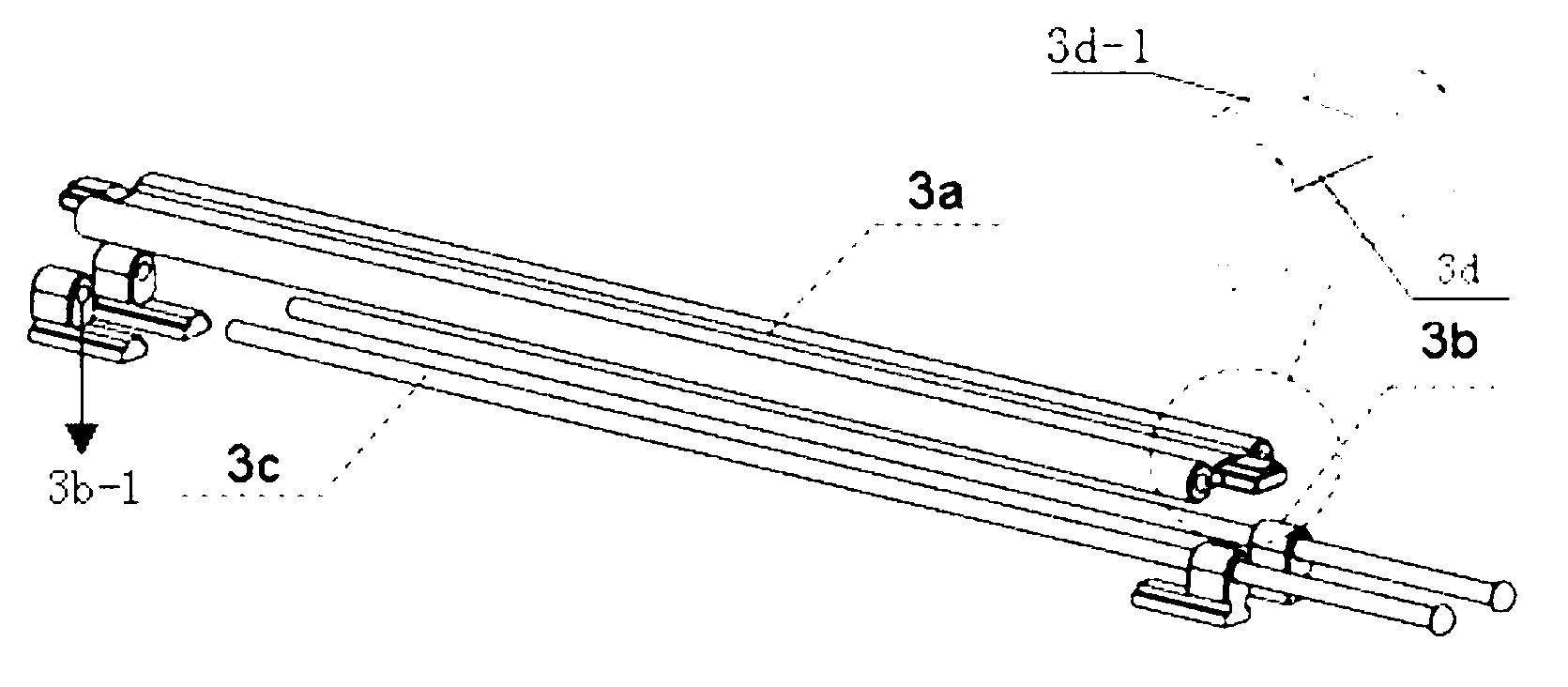

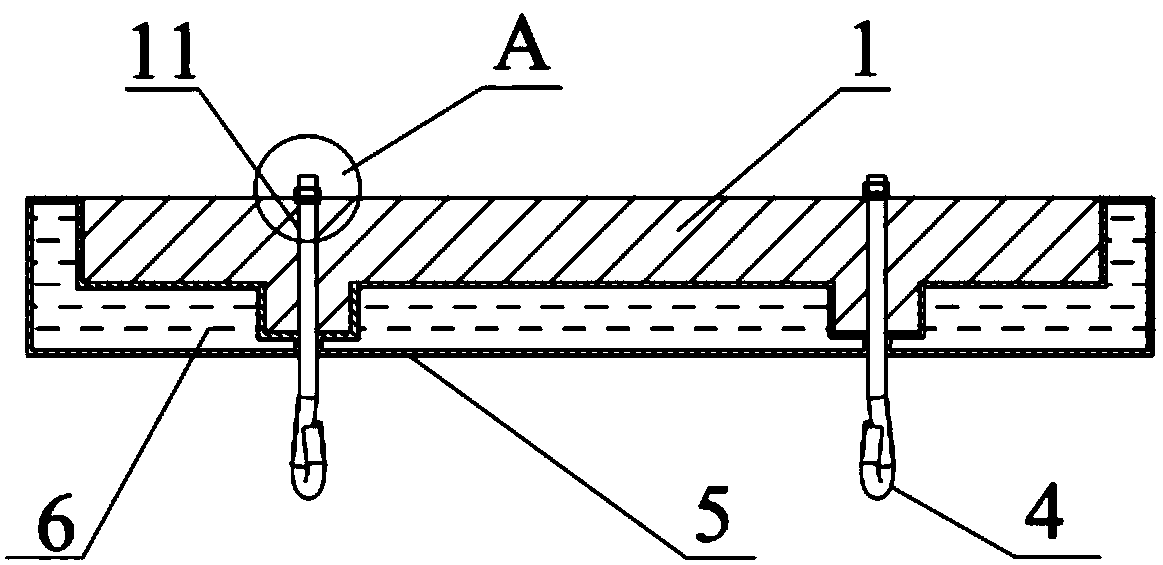

Metal spray marking plate special for cold and hot rolling

InactiveCN102974511AAchieve repeated useHigh reuse rateLiquid surface applicatorsCoatingsChinese charactersMetal

The invention relates to a metal spray marking plate special for cold and hot rolling. The metal spray marking plate special for the cold and hot rolling comprises a number plate engraved with numbers, base plates and chain shaft components used for connecting adjacent base plates. Each base plate is a frame shaped like a Chinese character 'ri'. Reverse T-shaped through grooves and inner grooves oppositely formed inwards are formed in the two sides of each frame. Two sides of the number plate is inserted in two groove openings of the base plate. The chain shaft components comprise a double-row connecting shaft, groove seats and a mandril. The double-row connecting shaft is provided with a connecting portion. The middle segment of the mandril penetrates through the double-row connecting shaft. Two ends of the mandril are respectively penetrate through circular holes of the groove seats. An end head of the mandril is riveted on one groove seat. The groove seats are arranged in the reverse T-shaped through grooves of the base plate. The shape of the lower portion of each groove seat is matched with that of each through groove. The groove seats are capable of rotating around the mandril. The metal spray marking plate special for the cold and hot rolling can be cleaned by organic solution so as to be reused after using and therefore cost is effectively saved. Due to the fact that the metal spray marking plate spares a number imprinting process, spraying and coating work efficiency is improved and optimized.

Owner:BAOSTEEL DEV CO LTD

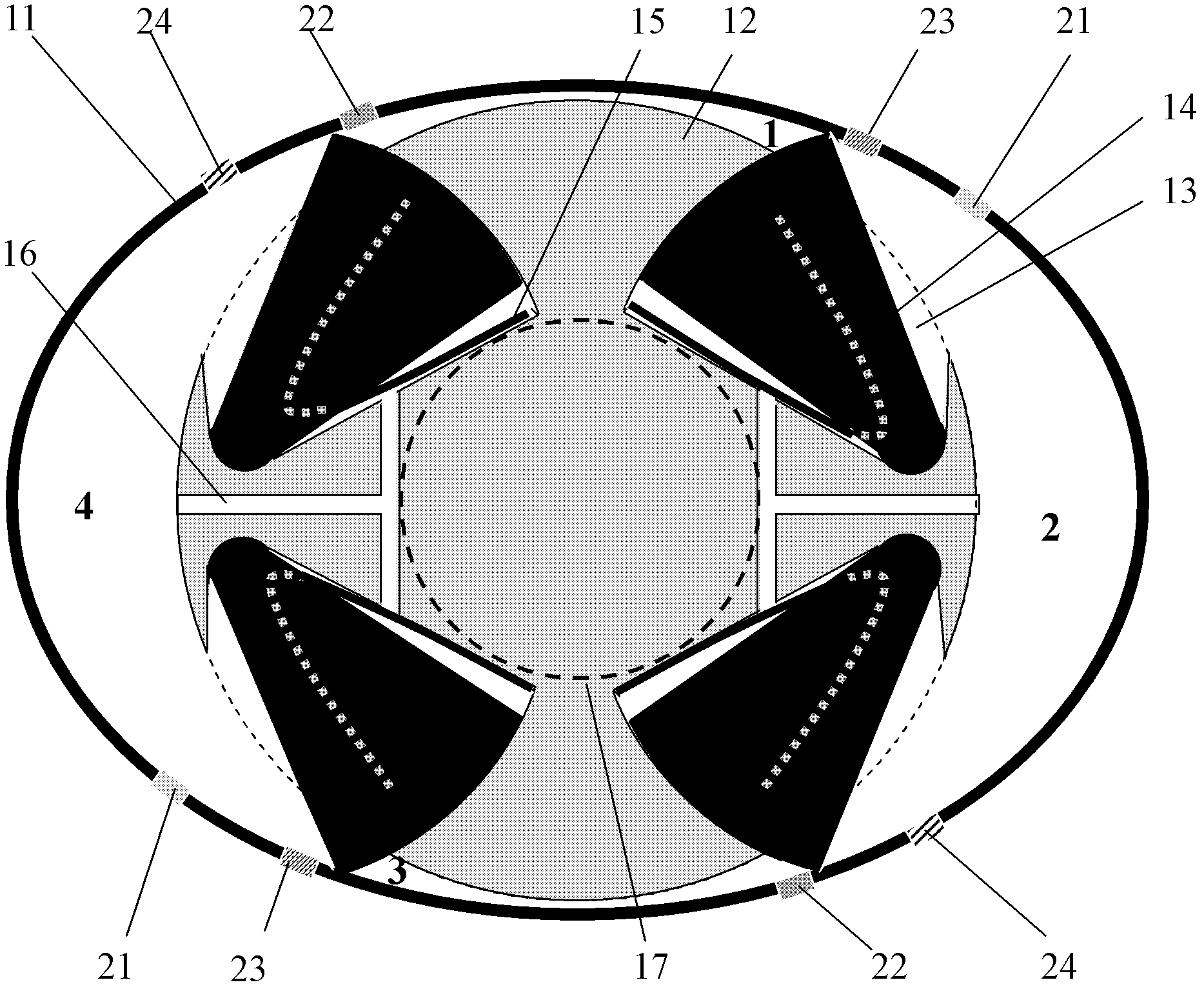

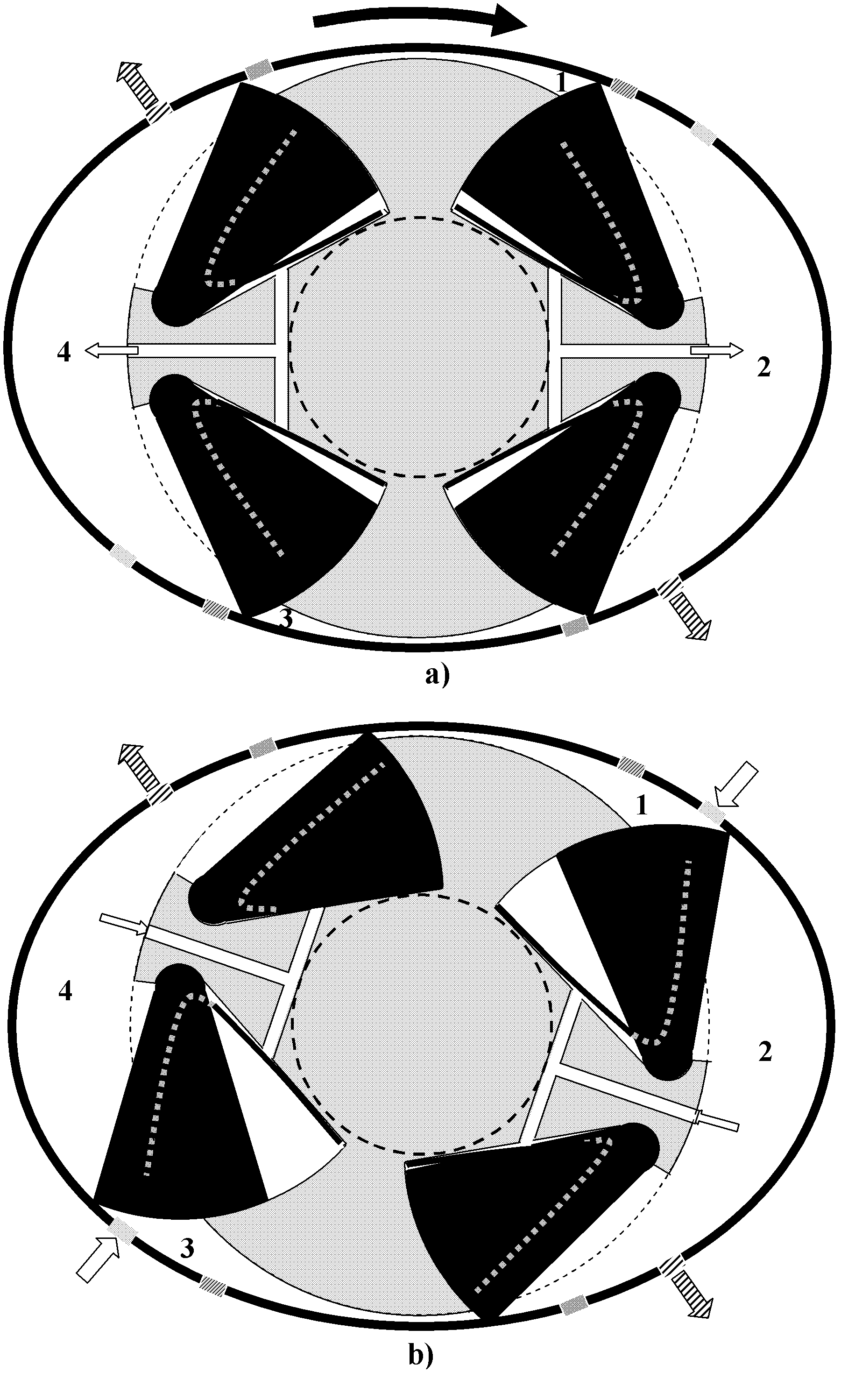

Rotary engine with homocentric arc trapezoid swivel plugs

A rotary engine with homocentric arc trapezoid swivel plugs belongs to the technical field of engine manufacture, energy conservation and emission reduction. An elliptic columnar cylinder cavity is enclosed by a cylinder body and end caps, a cylindrical rotor coaxial with the cylinder cavity is arranged in the cylinder cavity, four through grooves with homocentric arc trapezoid cross sections are axially arranged at the outer edge of the rotor along the axial direction of the rotor, and the homocentric arc trapezoid swivel plugs are placed in the through grooves and can rotate around the axes of the swivel plugs. The cylinder cavity is divided into two combustion cavities and two lubrication cavities by the swivel plugs, fuels are combusted in the combustion cavities to generate power, only engine oil and air are sprayed into the lubrication cavities to lubricate the cylinder body, the cylinder end caps and the swivel plugs, and the positions of the cavities are sequentially changed clockwise or anticlockwise along with rotation of the rotor. When the engine works, only pure torque is generated, so that the engine is low in vibration, noise and friction force, sufficient in combustion, low in tail gas pollution and high in overall efficiency, and has great popularization value.

Owner:李德杰

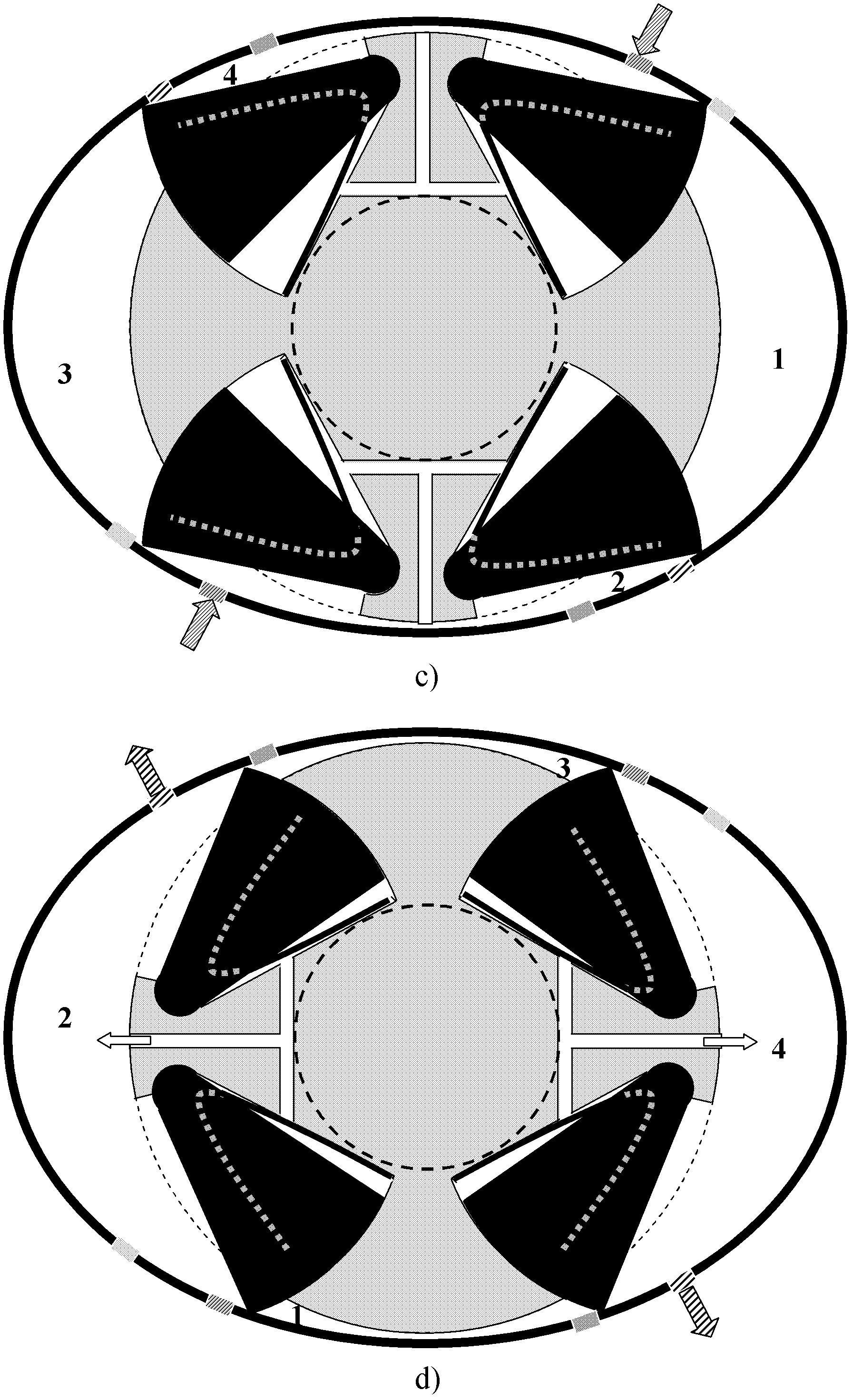

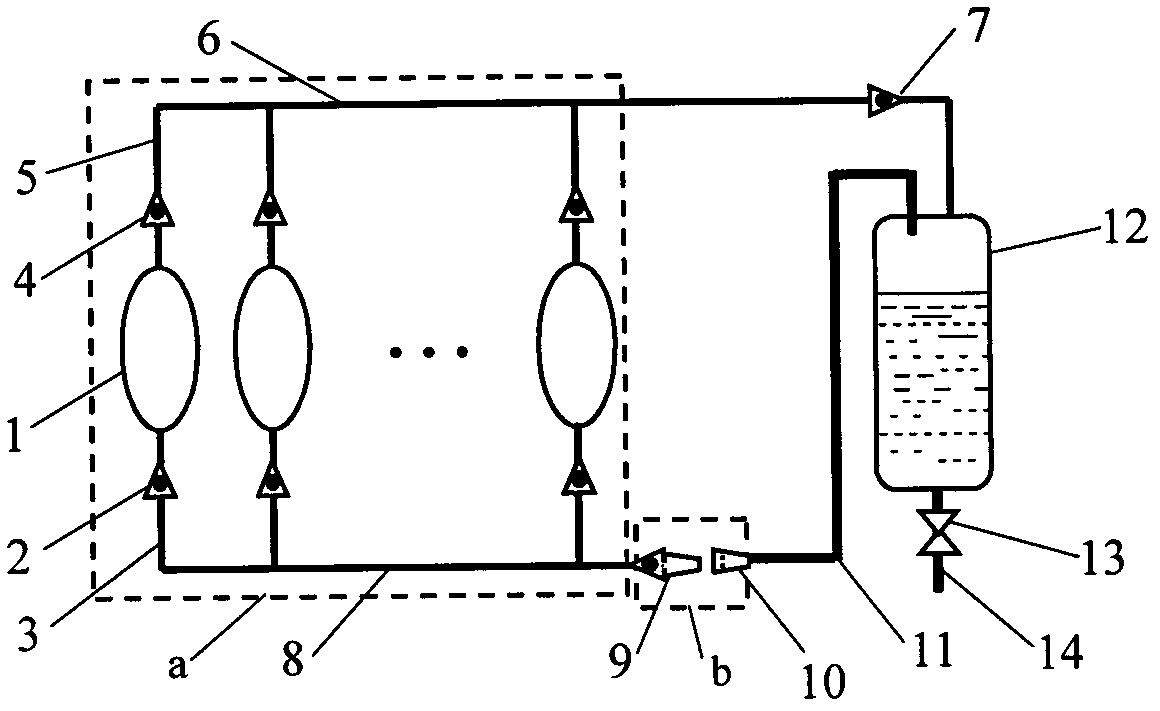

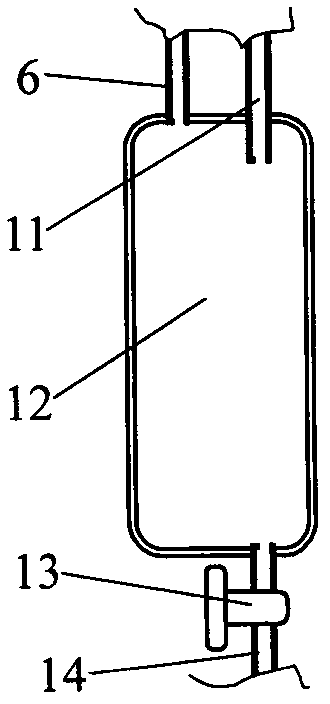

Automatic centralized circulating lubrication system for screw press

The invention discloses an automatic centralized circulating lubrication system for a screw press. The automatic centralized circulating lubrication system for the screw press comprises an oil tank, ahydraulic motor oil pump, a multi-lubricating-oil-passage distributor, multi-passage oil injecting branch pipes, a main oil returning pipe, a lower oil returning branch pipe and an upper oil returning branch pipe, wherein the hydraulic motor oil pump is installed on the oil tank, the multi-lubricating-oil-passage distributor is connected with the hydraulic motor oil pump, the multi-passage oil injecting branch pipes are connected between the multi-lubricating-oil-passage distributor and a plurality of lubricating points, the main oil returning pipe is connected with the oil tank, the lower oil returning branch pipe which is used for collecting dripping lubricating oil is connected between the bottom of a lower cavity of a sliding block and the main oil returning pipe, and the upper oil returning branch pipe for collecting the dripping lubricating oil is connected between the bottom of an upper cavity of the sliding block and the main oil returning pipe. According to the automatic centralized circulating lubrication system for the screw press, automatic centralized lubrication is achieved, recycling is achieved, the energy is saved, the consumption is reduced, oil pollution does not exist, clean environment and environmental protection are achieved, the abrasion of moving parts is reduced, the operation of equipment is reliable, the service life of the equipment is long, the production cost is reduced, the maintenance time is reduced, fully lubrication is achieved, the operation cost is reduced, cooling is achieved, the operation of the equipment is safe, sealing is used for preventing corrosion and rusting, damping and cushioning are achieved, and the automatic centralized circulating lubrication system for the screw press is widely used in the lubrication of the screwpress.

Owner:青岛浩源益友锻压机械有限公司

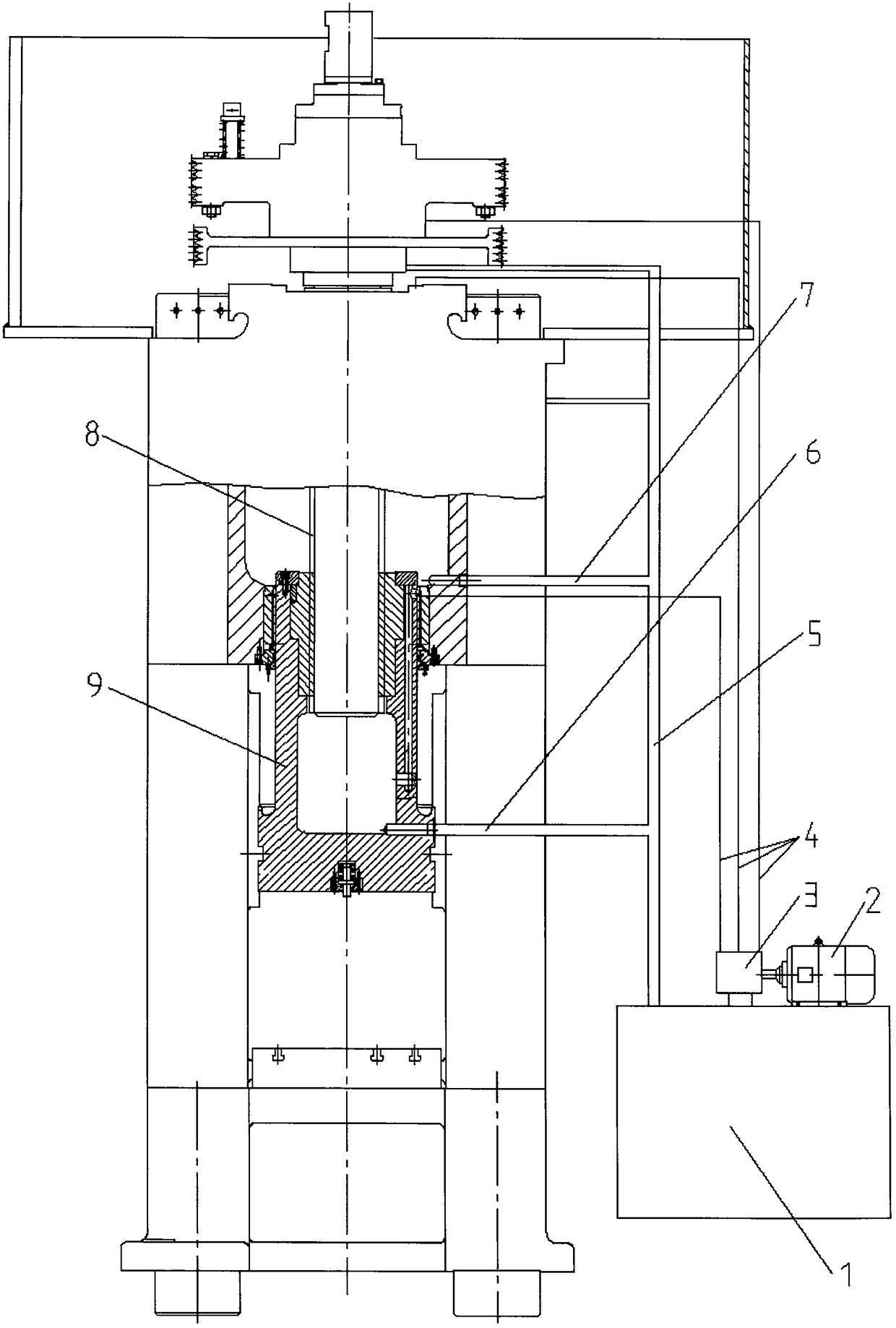

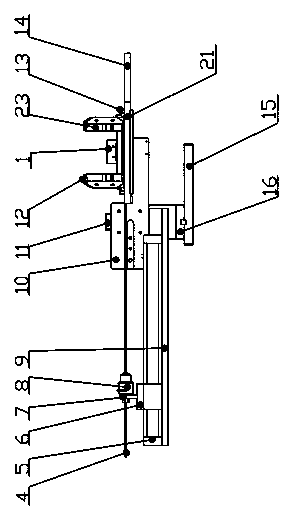

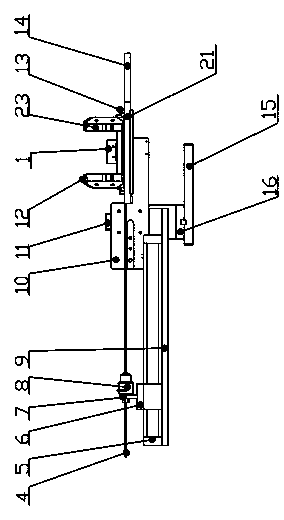

Automatic feeding device of high-precision numerical control groove grinding machine

InactiveCN103962880AFast feedingImprove efficiencyGrinding feedersMetal working apparatusNumerical controlSlide plate

The invention belongs to an automatic feeding device of a high-precision numerical control groove grinding machine. The automatic feeding device comprises a main board (2), a steel wire (4), a clamping head (8), a rodless air cylinder support plate (9), a hopper (12), a material tank (14), a slide board (17), an upper guide rail (18) and a lower guide rail (21). The automatic feeding device is characterized in that an air cylinder (1) is mounted on the lower guide rail (21) and between the hopper (12) and a hopper cover plate (23); a rodless air cylinder (5) is mounted on the rodless air cylinder support plate (9). The automatic feeding device is high in feeding speed and efficiency, simple in structure and low in cost; pneumatic power is adopted as a power source and is clean and free from oil stains.

Owner:大连远东机床有限公司

Dental plate surface nitriding technology

The invention discloses a dental plate surface nitriding technology, and relates to the technical field of workpiece nitriding treatment. The technology comprises the steps of 1) preparing before treatment, 2) vacuumizing, 3) heating, 4) reheating, 5) vacuumizing, 6) surface activating, 7) vacuumizing, 8) decomposing through ammonia gas, 9) nitriding, 10) vacuumizing, 11) blackening, and 12) cooling. The technology has the beneficial effects that the fatigue resistance of a workpiece is improved; high pressure stress is generated in a nitriding layer, so that the fatigue limit of the workpieceis high, and the sensitivity of the workpiece is low under the effect of alternating load; and moreover, the fatigue limit of the workpiece subjected to alternating load can be increased by 200%.

Owner:HAIYAN JINGBIN HARDWARE PROD CO LTD

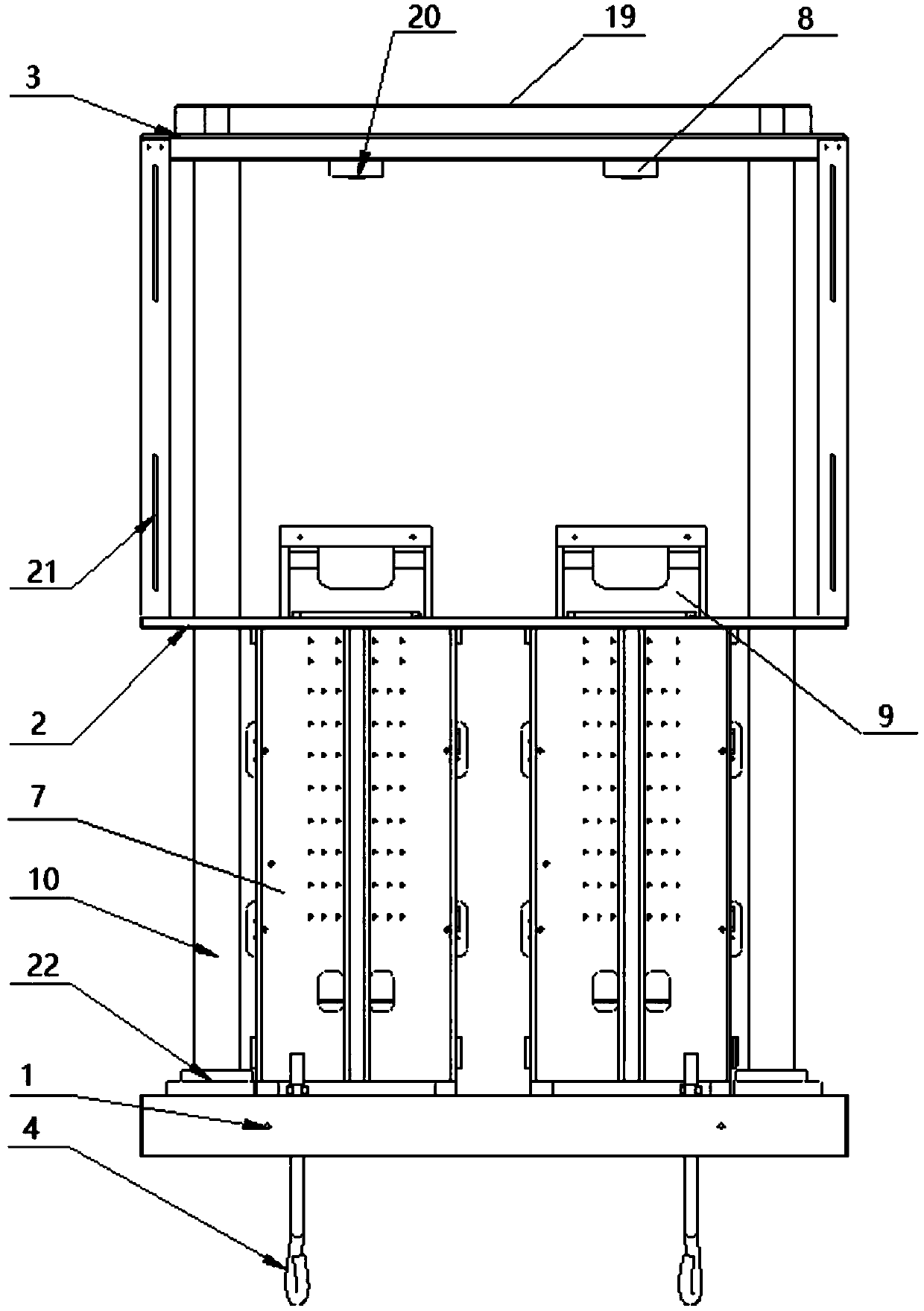

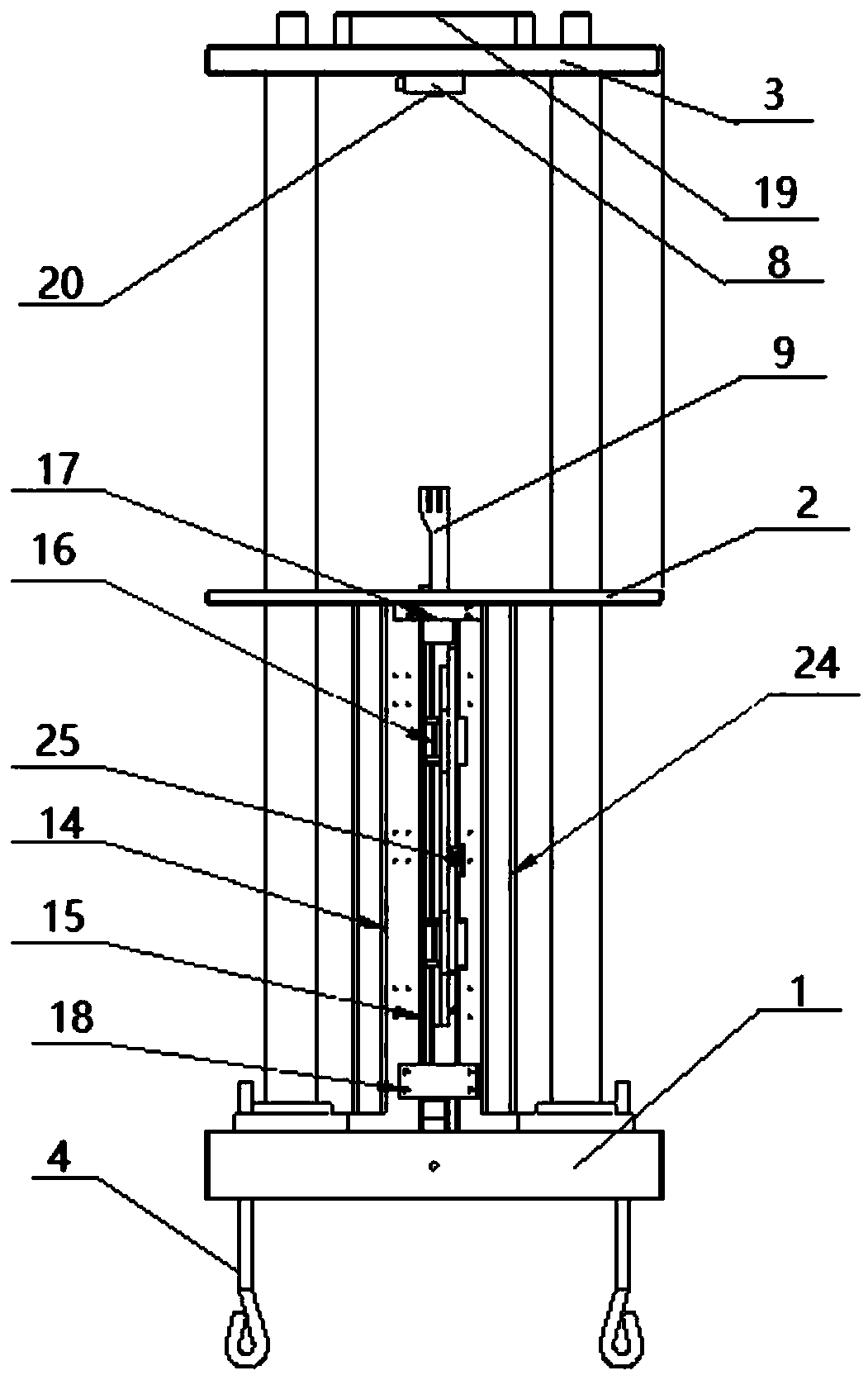

Damper fatigue test device driven by linear motors

InactiveCN109580204ASolution to short lifeNo collisionMachine part testingVehicle suspension/damping testingElectricityElectric machine

The invention relates to the technical field of automobile detecting equipment, in particular to a damper fatigue test device driven by linear motors. The damper fatigue test device comprises an outerframe, a driving mechanism and a functional accessory; the outer frame comprises a base, a middle partition plate and a top plate; the base is provided with a plurality of foundation bolts, and a buffer sleeve sleeves the bottom of the base, is of a hollow structure, and is filled with a buffer solution; the driving mechanism is mounted on the base and comprises two sets of motion modules in thevertical direction, wherein the two sets of motion modules are composed of the linear motors; and the functional accessory comprises a first clamp arranged on the top plate, and a second clamp mountedon the middle partition plate. According to the full-electric driving damper fatigue test device driven by the linear motors, no friction exists between motion parts, the life is long, collision is avoided, oil stains are avoided, noise is low, the working efficiency is high, the energy loss is less, the electric energy loss is lowered, and the damper fatigue test device can be widely suitable for testing indicator characteristics and speed characteristics of dampers of vehicles such as automobiles and motorcycles.

Owner:宁波亿文特自动化科技有限公司

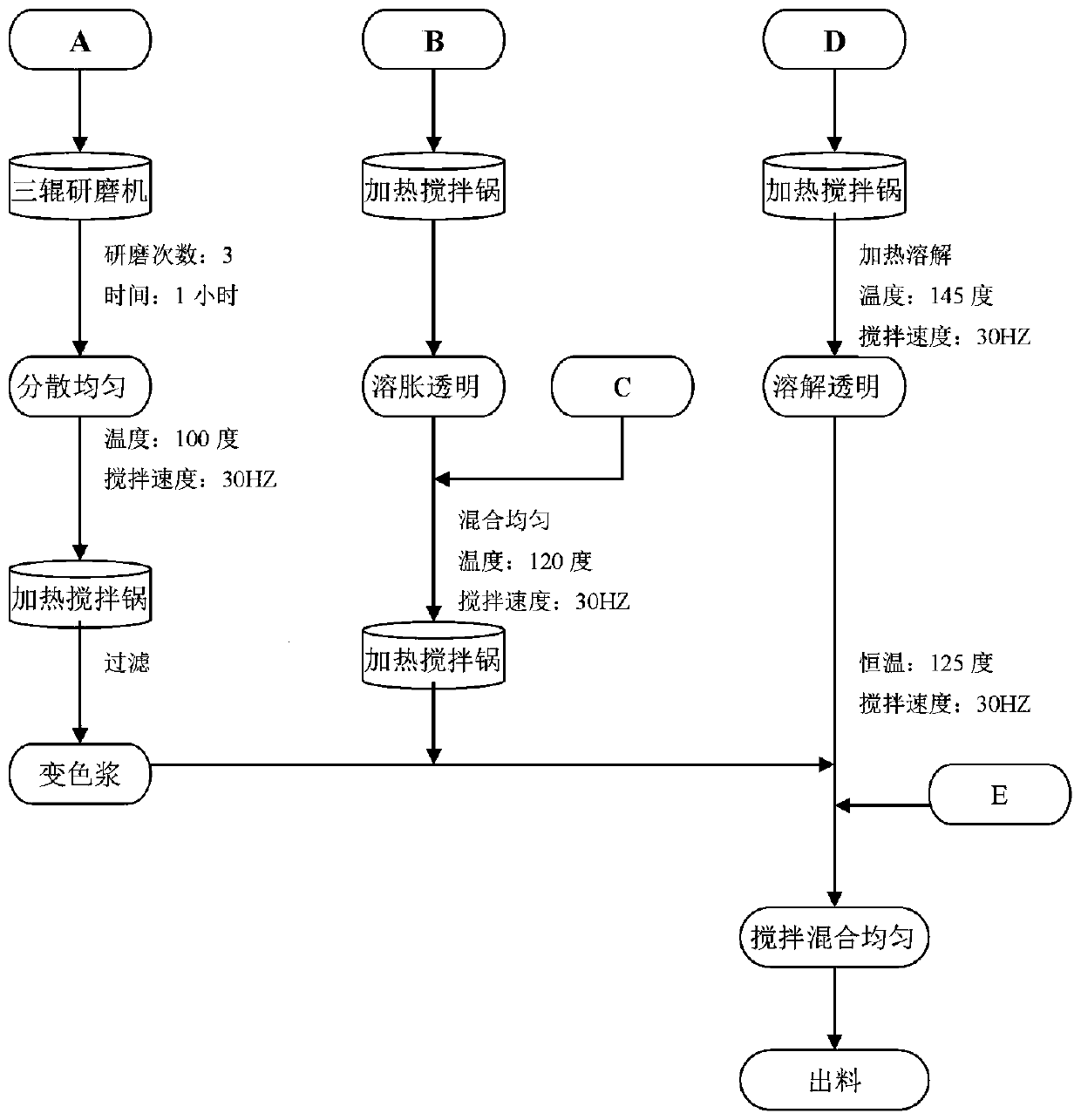

Lipstick color-developed based on pH value of human body and preparation method thereof

The invention discloses a lipstick color-developed based on the pH value of a human body, wherein the lipstick includes the following components in parts by mass: 3-5 parts of a high-effective gelling agent, 50-60 parts of skin-moisturizing oil, 8-10 parts of a film forming agent, 2-4 parts of a viscosity control agent, 0.1-0.4 part of acid and alkali discoloring toner, 0.05-0.1 part of an essence, 8-10 parts of a moisture-preserving ingredient, 5-10 parts of a solvent, 0.1-0.2 part of a preservative, 0.01-0.02 part of an antioxidant and 10-15 part of an acid regulator. With a discoloring and dyeing mechanism of tetrachlorotetrabromofluorescein under different acid and alkali conditions, the coloring is more durable, decoloration is not easy, and different skin textures show different lip color characteristics. With the moisture-preserving and skin-moisturizing oil, formation is performed by the high-effective gelling agent, wax ingredients are not added, high glossiness, good makeup effect, soft and moist texture, light and thin skin feeling, moisture preservation and water prevention, difficult fading, lasting makeup effect are achieved, and the lipstick has both nursing and decoration functions; the stability is good; at the same time, the lipstick has real moisture preservation and lasting makeup effect, has real moisturizing effect with long-term use, is lasting without makeup removal, and realizes the combination of lip caring and decoration.

Owner:GUANGDONG LEIQI COSMETIC CO LTD

Energy-consumption-free reclaimed water lifting method

The invention discloses an energy-consumption-free reclaimed water lifting method capable of matching with existing facilities in a bathroom, a toilet, a kitchen and the like. In the method, a layer of flexible air pump cushion is additionally paved on the floors of the bathroom, the toilet, the kitchen and the like or the bottom of a bathtub, water tanks with proper shapes are additionally arranged on proper positions in the bathroom, the toilet, the kitchen and the like, air pumps and the water tanks are combined into a machine-gas-liquid power system by means of gas, water pipes and valves, and discharged reclaimed water can be sucked and lifted to the water tanks by means of mechanical energy generated from motion changes of a human body and gas exhaust-gas suction-liquid suction functions realized by the system.

Owner:南通成平建设开发有限公司

Magnetic-gathering Halbach small-range magnetic gear reducer

ActiveCN112886789AImprove efficiencyIncreased torque densityPermanent-magnet clutches/brakesCrankCrankshaft

The invention belongs to the technical field of magnetic gear transmission, and particularly relates to a magnetic-gathering Halbach small-range magnetic gear reducer which comprises a machine shell, an end cover and an input shaft, two pieces of stator magnetic steel are arranged on the inner wall of the machine shell side by side in a spaced mode, two rotor discs are arranged on the input shaft side by side in a sleeved mode, and the space phase difference between the two rotor discs is 180 degrees. Rotor magnetic steel is respectively sleeved on the two rotor discs, the input shaft is respectively provided with non-magnetic baffle plates at two sides of the single rotor magnetic steel, the two rotor discs are also jointly provided with a crankshaft in series, two ends of the crankshaft are respectively connected with the two end covers, and the stator magnetic steel and the rotor magnetic steel are respectively of a magnetism gathering Halbach array arrangement structure. The magnetic gear reducer breaks through the bottleneck of friction clearance of a mechanical gear and the like, and compared with a mechanical reducer, the magnetic gear reducer has the advantages of being low in noise, free of friction, high in efficiency, high in durability and the like.

Owner:CHONGQING UNIV

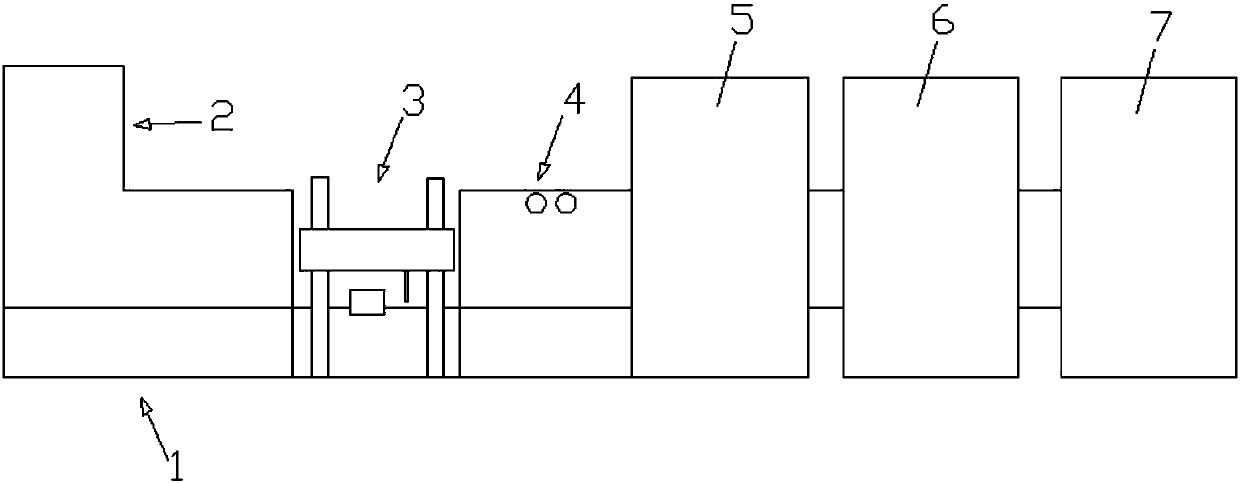

Steel pipe production line

The invention relates to a steel pipe production line, belonging to the technical field of steel pipe production. The steel pipe production line comprises a conveying track, wherein a discharging table is arranged on the conveying track; a cutting table is arranged at the right side of the discharging table; a cleaning device is connected with the right side of the cutting table; a deburring machine is connected with the right side of the cleaning device; an expanding machine is connected with the right side of the deburring machine; a cleaning machine is connected with the right side of the expanding machine. The production line provided by the invention has the advantages of convenient use, simple operation, good stability and high reliability.

Owner:芜湖德海机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com