Automatic feeding device of high-precision numerical control groove grinding machine

A technology of automatic feeding and groove grinding machine, which is applied in the direction of grinding feed movement, grinding machine tool parts, grinding/polishing equipment, etc. It can solve the problems of high cost, easy oil leakage, and affecting feeding stability. Achieve the effect of low cost, fast feeding speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

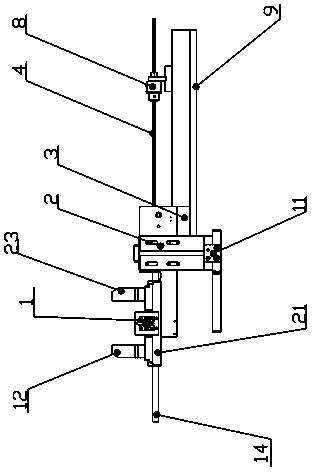

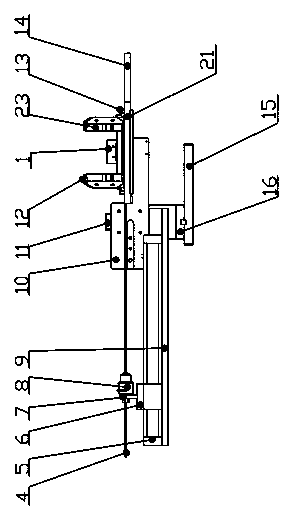

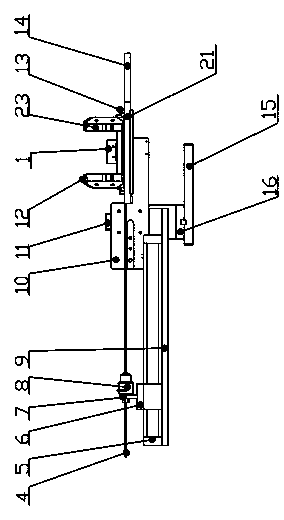

[0011] Embodiments, with reference to the accompanying drawings, an automatic feeding device for a high-precision numerically controlled groove grinding machine, including a main board 2, a steel wire 4, a chuck 8, a rodless cylinder support plate 9, a hopper 12, a trough 14, a slide plate 17, and an upper guide rail 18 And lower guide rail 21, it is characterized in that a cylinder 1 is adorned above the lower guide rail 21 and between the hopper 12 and the hopper cover plate 23, and a rodless cylinder 5 is adorned on the rodless cylinder supporting plate 9. Rodless cylinder support plate 9 (see attached image 3 ) The chuck base 6 is installed on the left end, the chuck frame 7 is installed on the chuck base 6, the chuck 8 is installed on the chuck frame 7, and the steel wire 4 passes through the chuck 8; above the right end of the rodless cylinder supporting plate 9 A feeder bracket 10 is installed, and an adjustment screw base plate 11 is installed on the feeder bracket 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com