Novel oilless vertical vacuum pump

A vacuum pump and vertical technology, applied in the field of new oil-free vertical vacuum pumps, can solve the problems of increasing maintenance costs, increasing manpower and material resources, and difficulty in dismantling, maintaining or replacing air valves, achieving long service life, convenient maintenance, and filtering. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

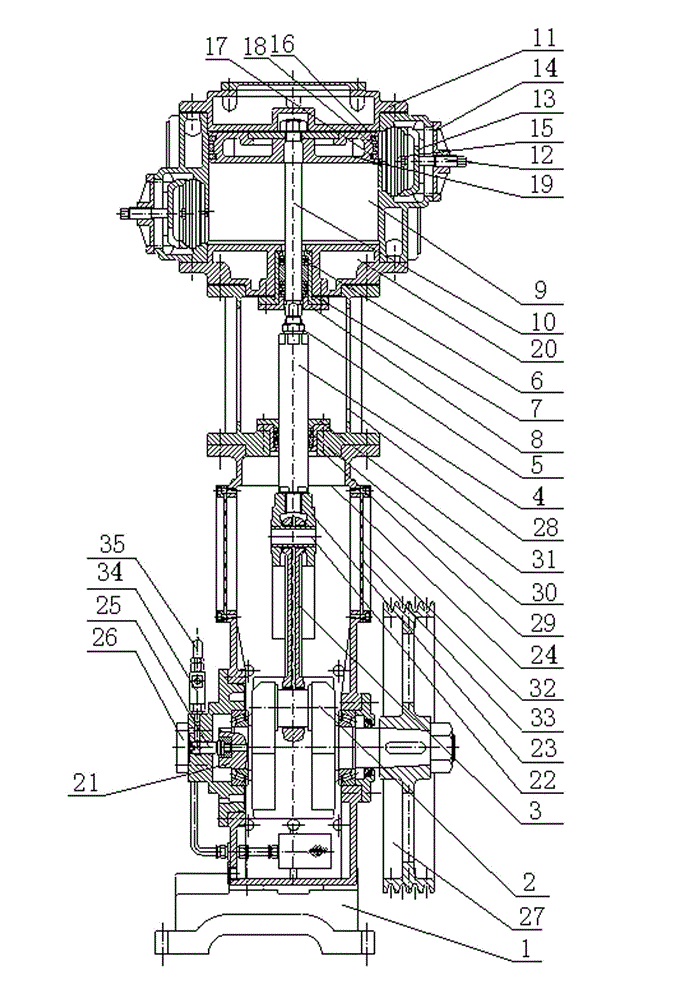

[0014] Such as figure 1 As shown, the novel oil-free vertical vacuum pump of the present invention comprises a base 1, a fuselage 24, a cylinder 9, a cylinder head 11 and a flywheel 27, the cylinder 9 is located above the fuselage 24, and a Cylinder neck 20, piston 19 and piston rod 10 are arranged in cylinder 9, upper packing chamber 7 is arranged between cylinder neck 20 and piston rod 10, upper packing gland 8 is arranged under upper packing chamber 7, upper packing chamber 7 and A sealing ring 6 is provided between the piston rods 10, a piston ring 16, a tension ring 17 and a guide ring 18 are provided between the cylinder 9 and the piston 19, and the piston rod 10 runs through the cylinder 9 and the cylinder neck 20 in sequence downwards, and the piston rod 10 The lower end of the connecting rod 4 is connected with the piston rod and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com