Vertical non-oil-contamination energy-saving vacuum pump

A kind of oil-free, vacuum pump technology, applied in the direction of variable displacement pump parts, pumps, pump components, etc., can solve the problems of unsightly appearance, stuck, severe wear, etc., to achieve the effect of huge market potential, reliable lubrication and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

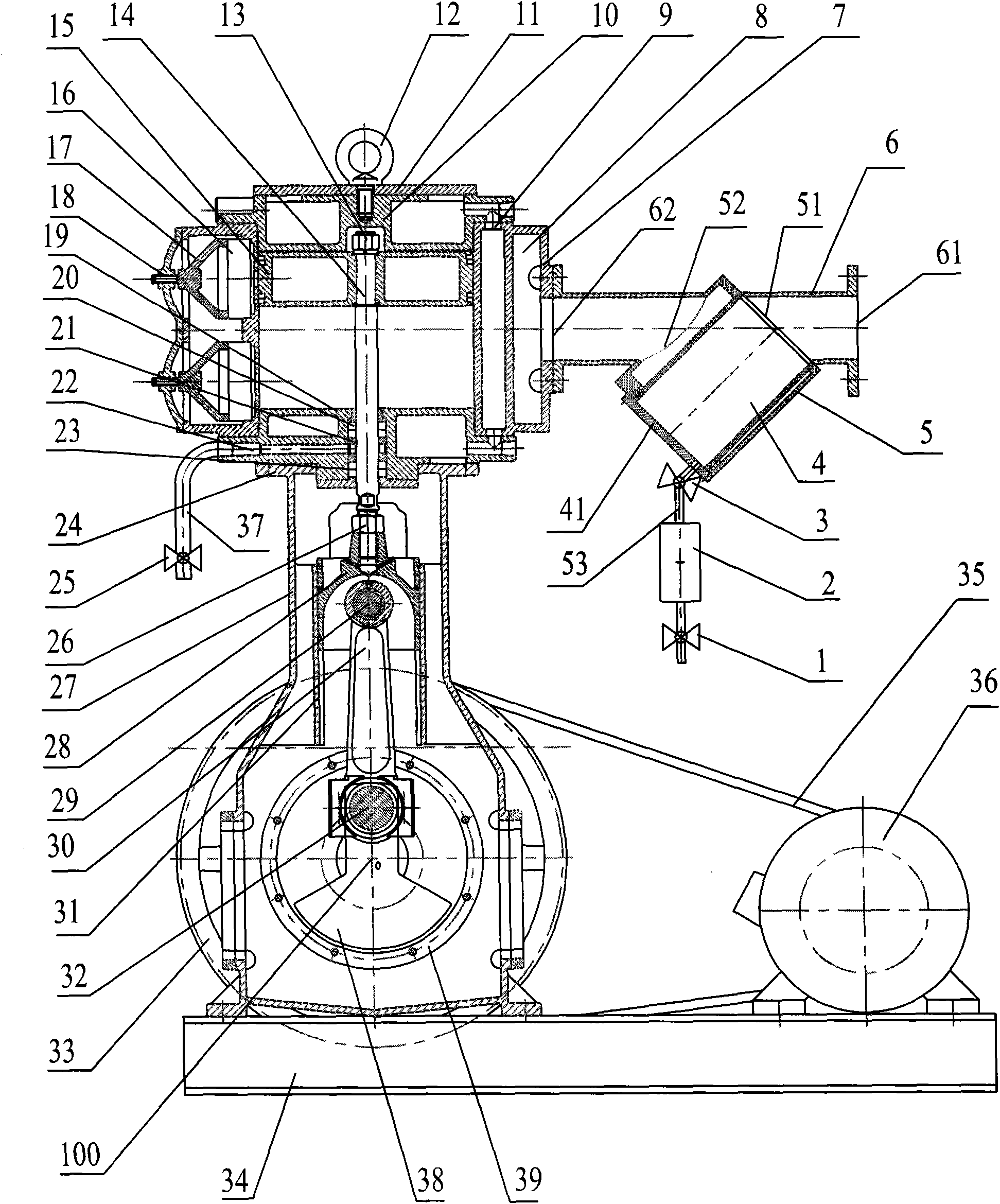

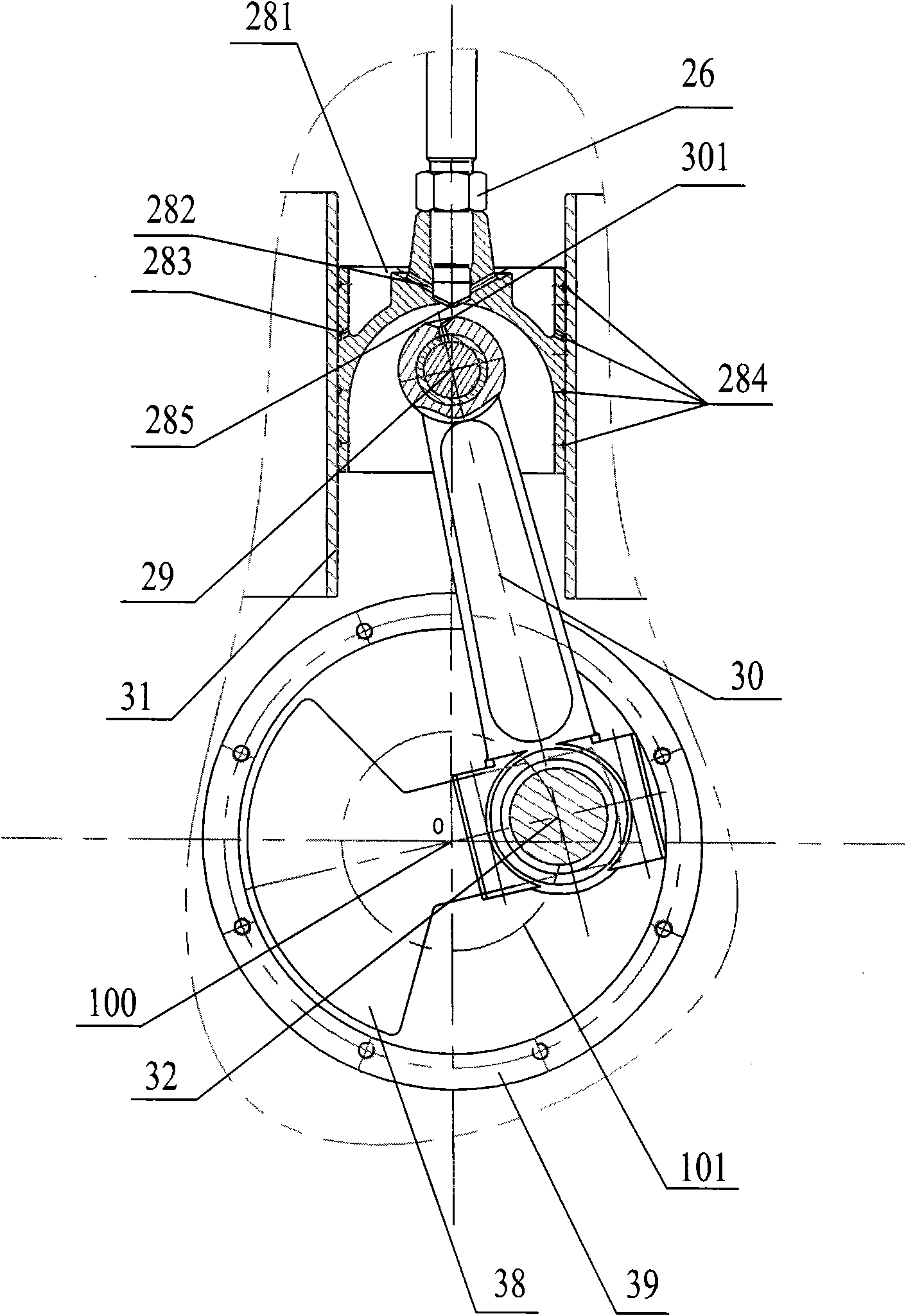

[0026] Figure 1 to Figure 4 In combination, a vertical oil-free energy-saving vacuum pump is provided, which includes an intake pipe 6, a cylinder 7, a cylinder neck 19, a pump body 27, a base 34, a motor 36, and the like.

[0027] A cylinder head 10 is arranged on the top of the cylinder 7, and the cylinder head 10 is fixedly connected with the side wall of the cylinder 7 so that the inner chamber of the cylinder 7 becomes a closed cavity. The technology stuffy cover 11 that is positioned at cylinder head 10 tops is fixedly connected with cylinder head 10, and hanger screw 12 is set on the technology stuffy cover 11, and hanger screw 12 is used for hoisting when installing.

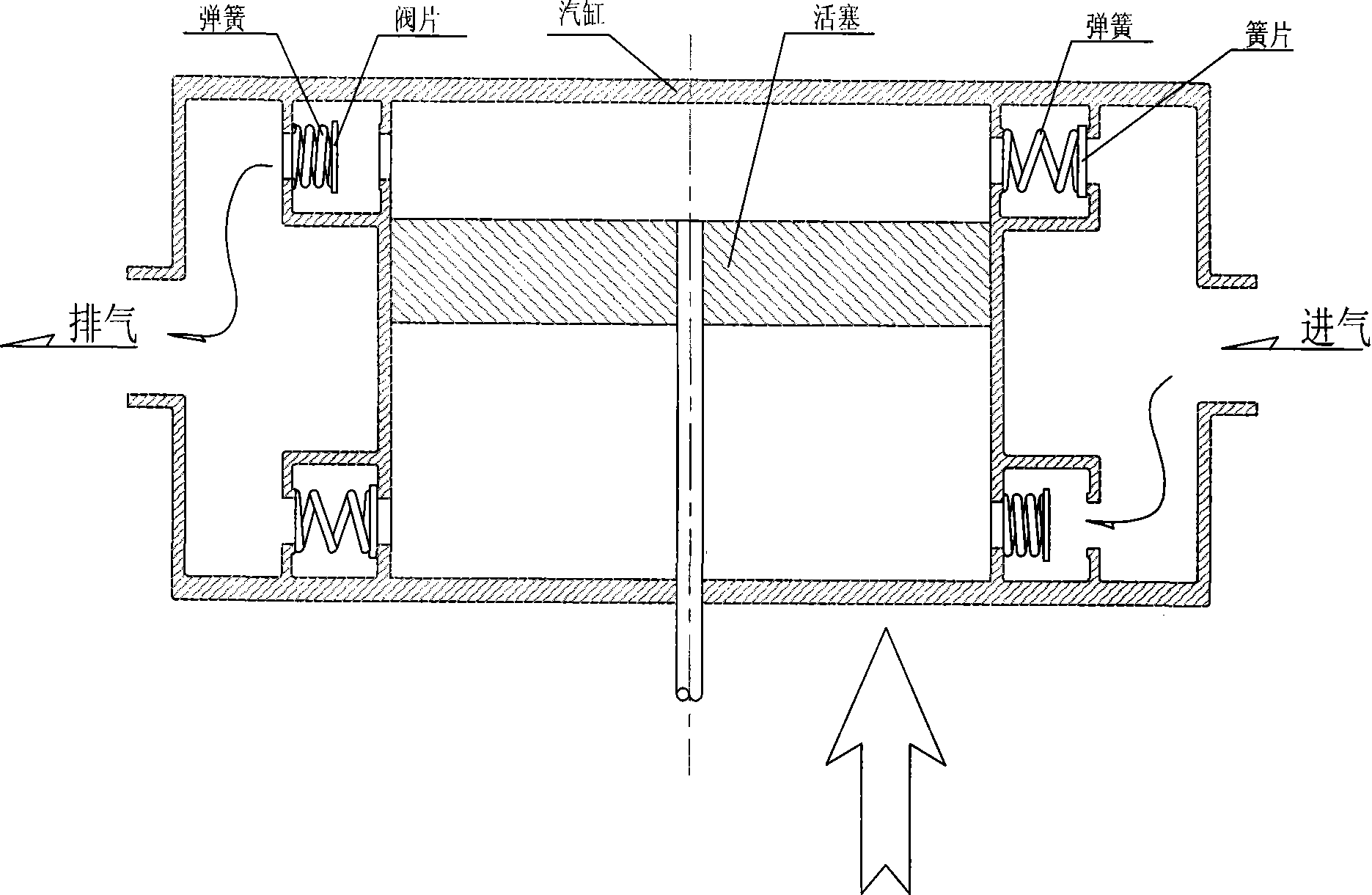

[0028] A piston 15 and a piston rod 14 are arranged in the inner cavity of the cylinder 7, and the piston 15 is slidably connected with the inner side wall of the cylinder 7 without clearance.

[0029] Both the guide ring and the piston ring in the piston 15 can be made of polytetrafluoroethylene, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com