Screw rotor end face tooth type

A rotor-end, face-tooth technology, used in rotary piston pumps, rotary piston machines, machines/engines, etc., can solve the problems of uneven screw meshing, low product volumetric efficiency, and short screw life, and achieve smooth operation. , space contact line and end face projection optimization, design flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

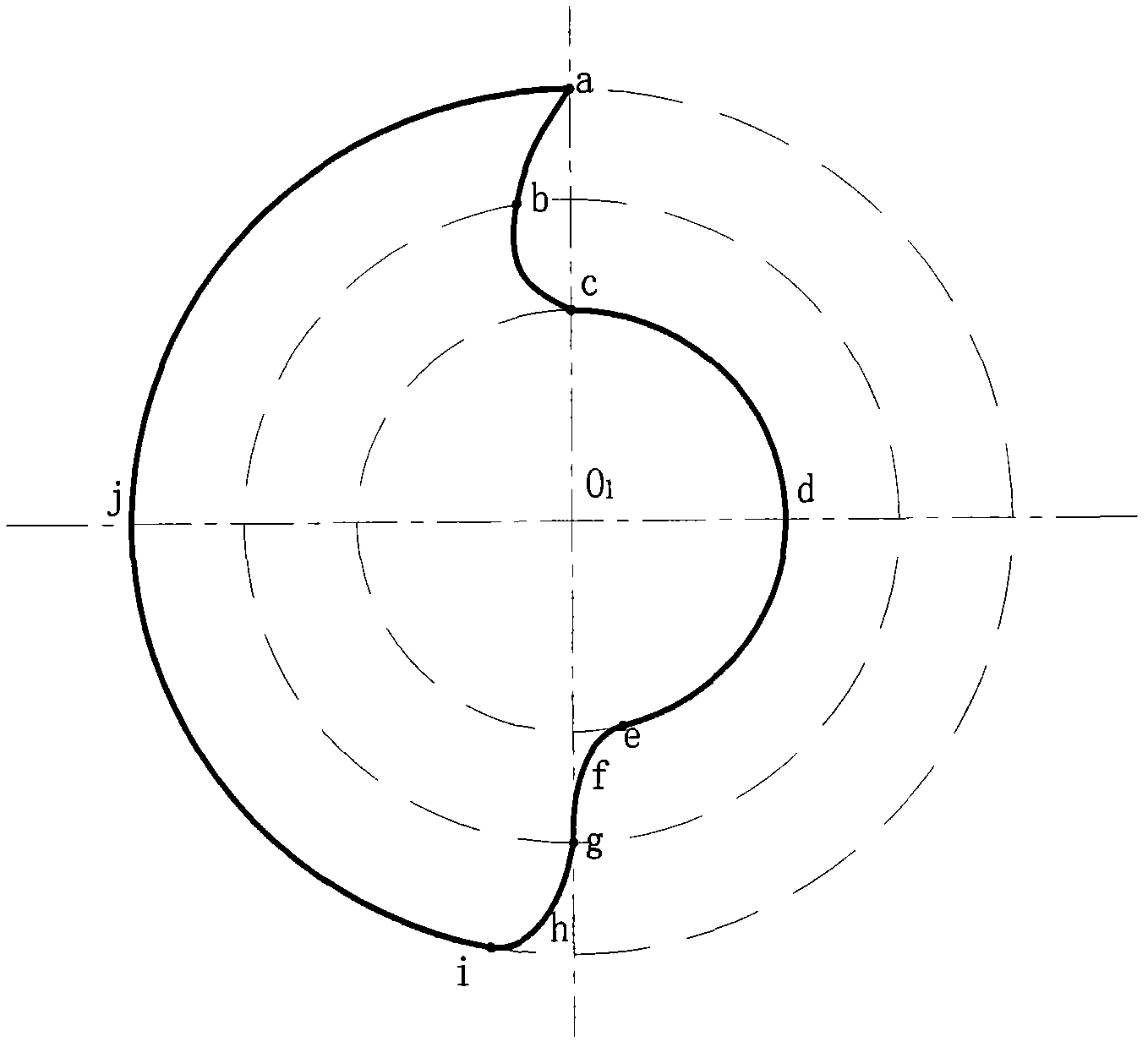

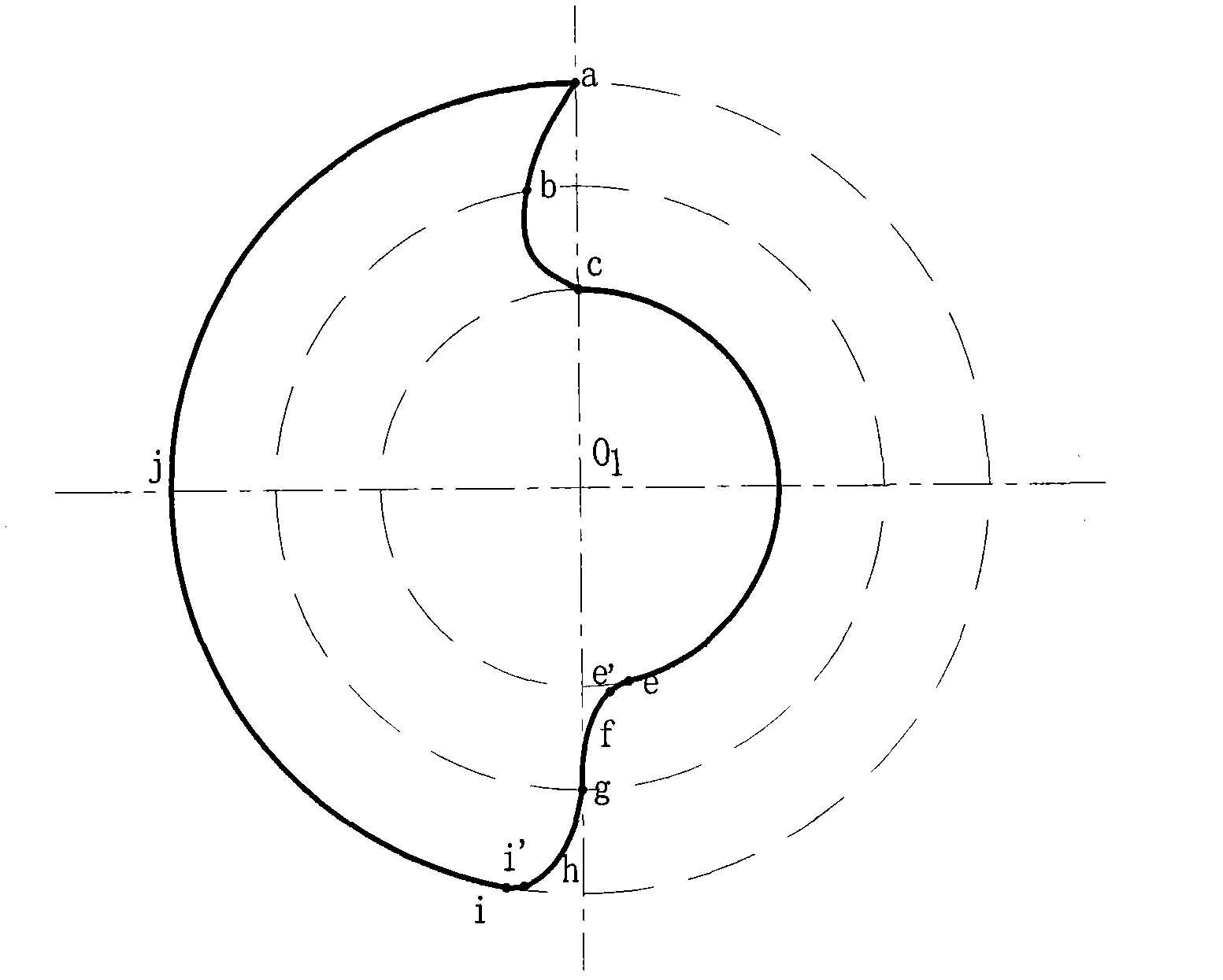

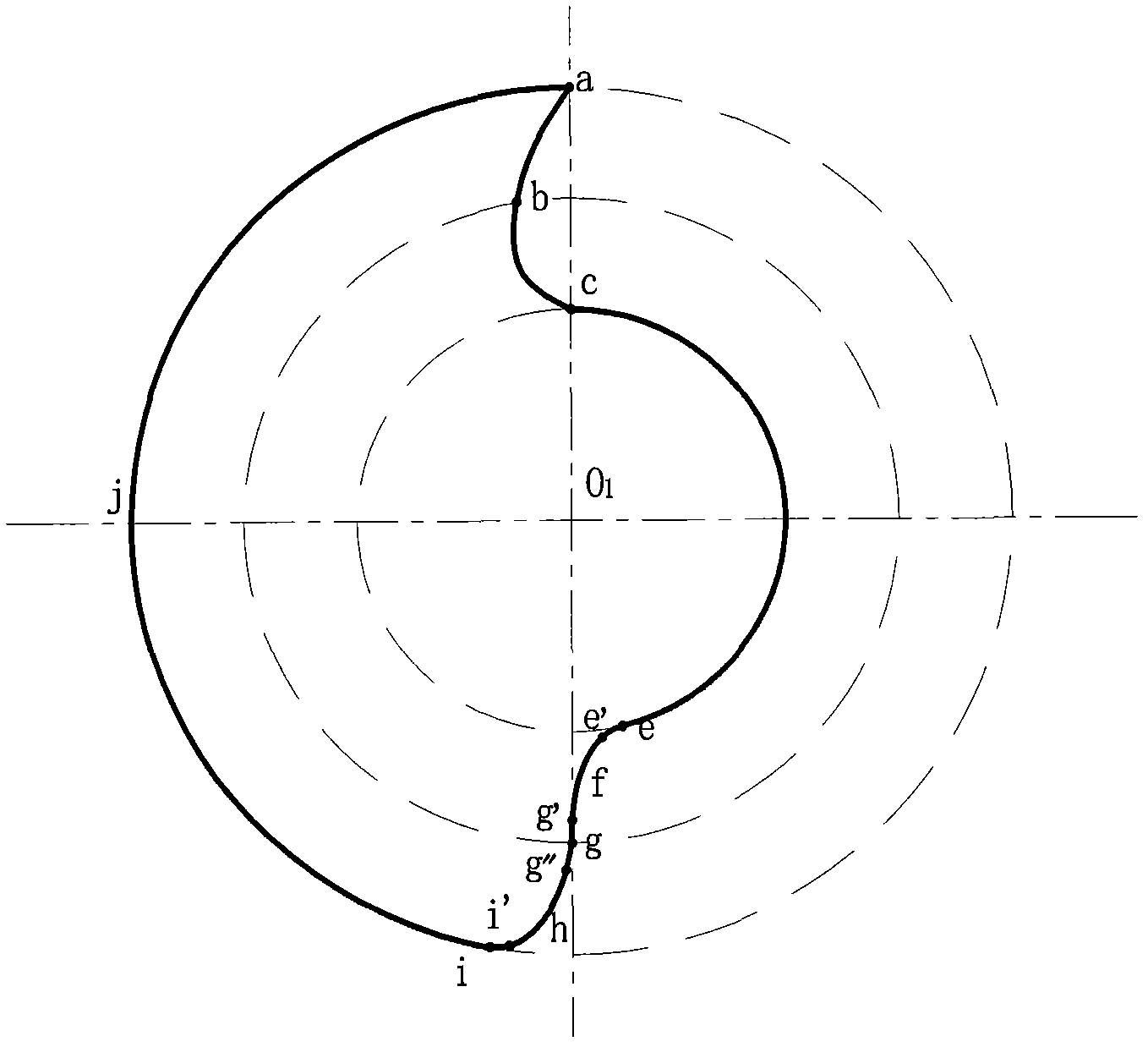

[0018] according to figure 1 The tooth profile of the end surface of the basic screw rotor shown, the tooth curve consists of cycloidal tooth curve abc, circular arc tooth curve cde, circular arc tooth curve ija, elliptic arc tooth curve efg and elliptic envelope tooth curve ghi composition.

[0019] Among them: the three points a, c, g are collinear and the connecting line passes through the center O1, point a is on the addendum circle Ld, points c, d, e are on the dedendum circle Lg, points i, j are on the addendum circle Ld , the tooth curve abc is a long epicycloid generated by the sharp point a on the addendum circle of another screw with the same tooth shape but in the opposite direction. We generally call the tooth curve abc the seal side tooth profile; The curve efg is an elliptical arc, and the tooth curve ghi is an elliptical envelope based on the elliptical arc tooth curve efg on another screw with the same tooth shape but in the opposite direction. We call the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com