Patents

Literature

162results about How to "Increase intake pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

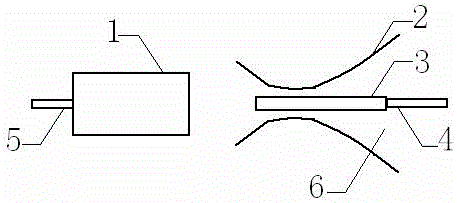

Intake air sound generation device

ActiveUS7975802B2Increased durabilityIncrease intake pressureSilencing apparatusMachines/enginesSound generationResonance

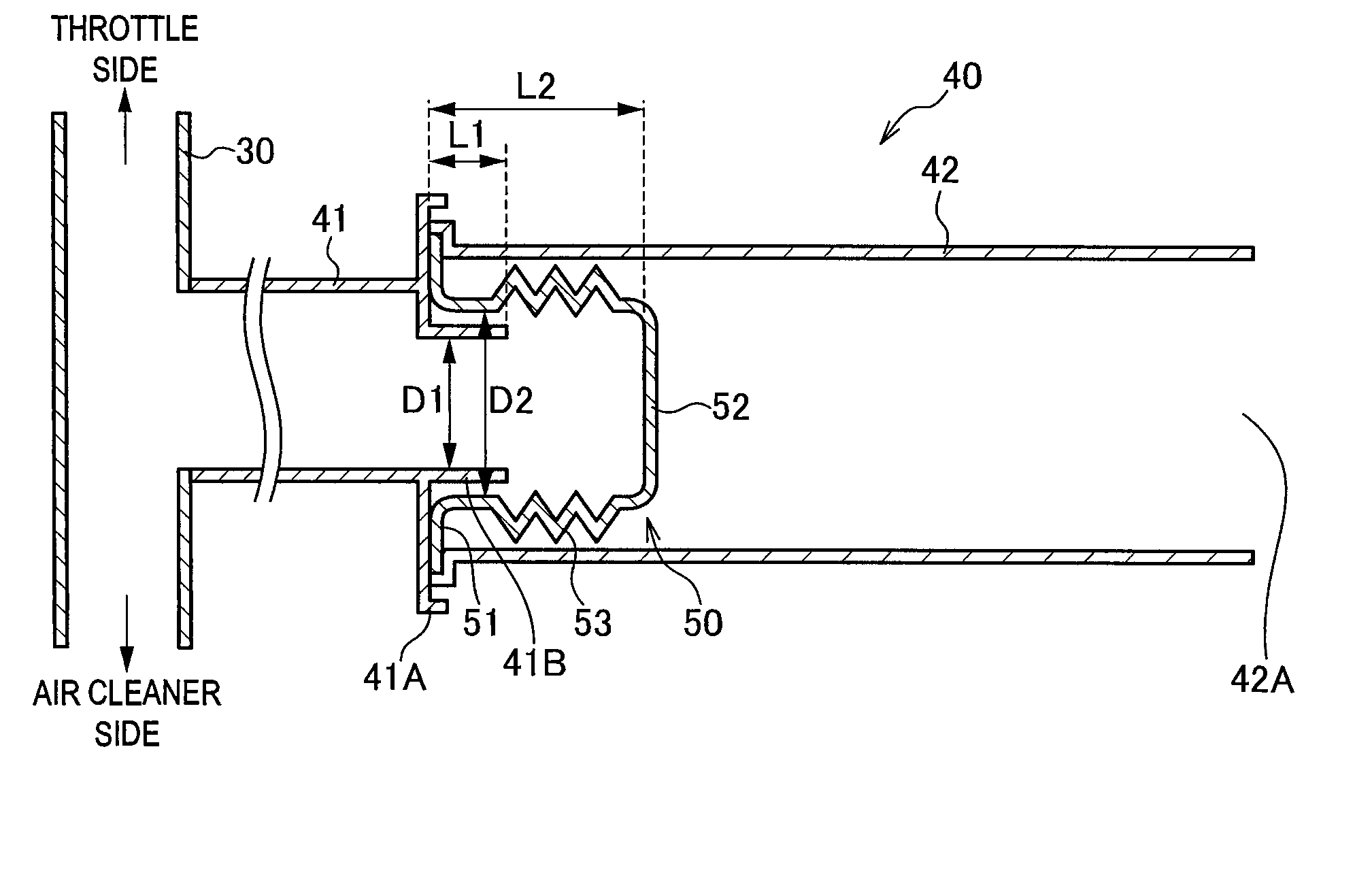

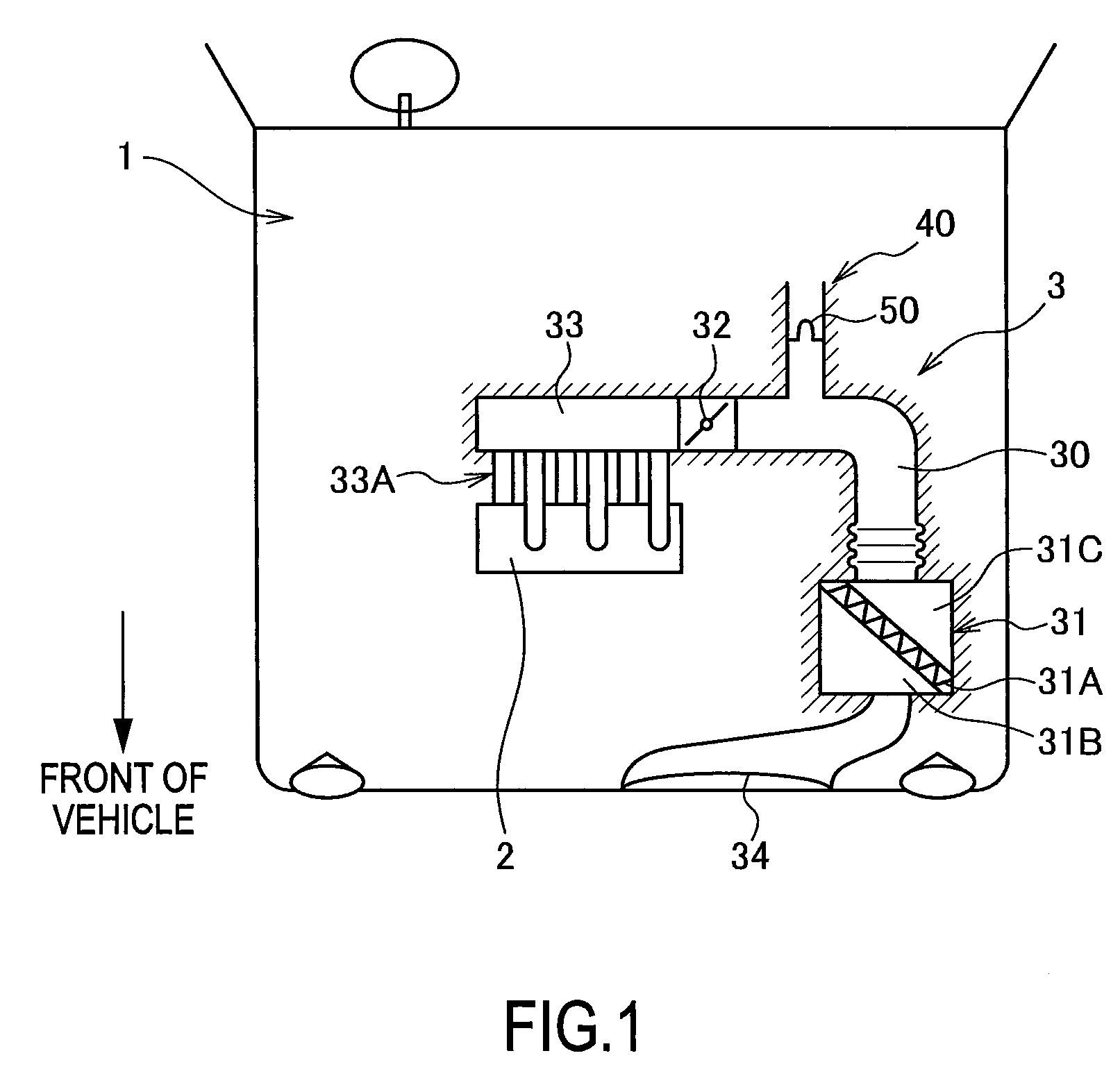

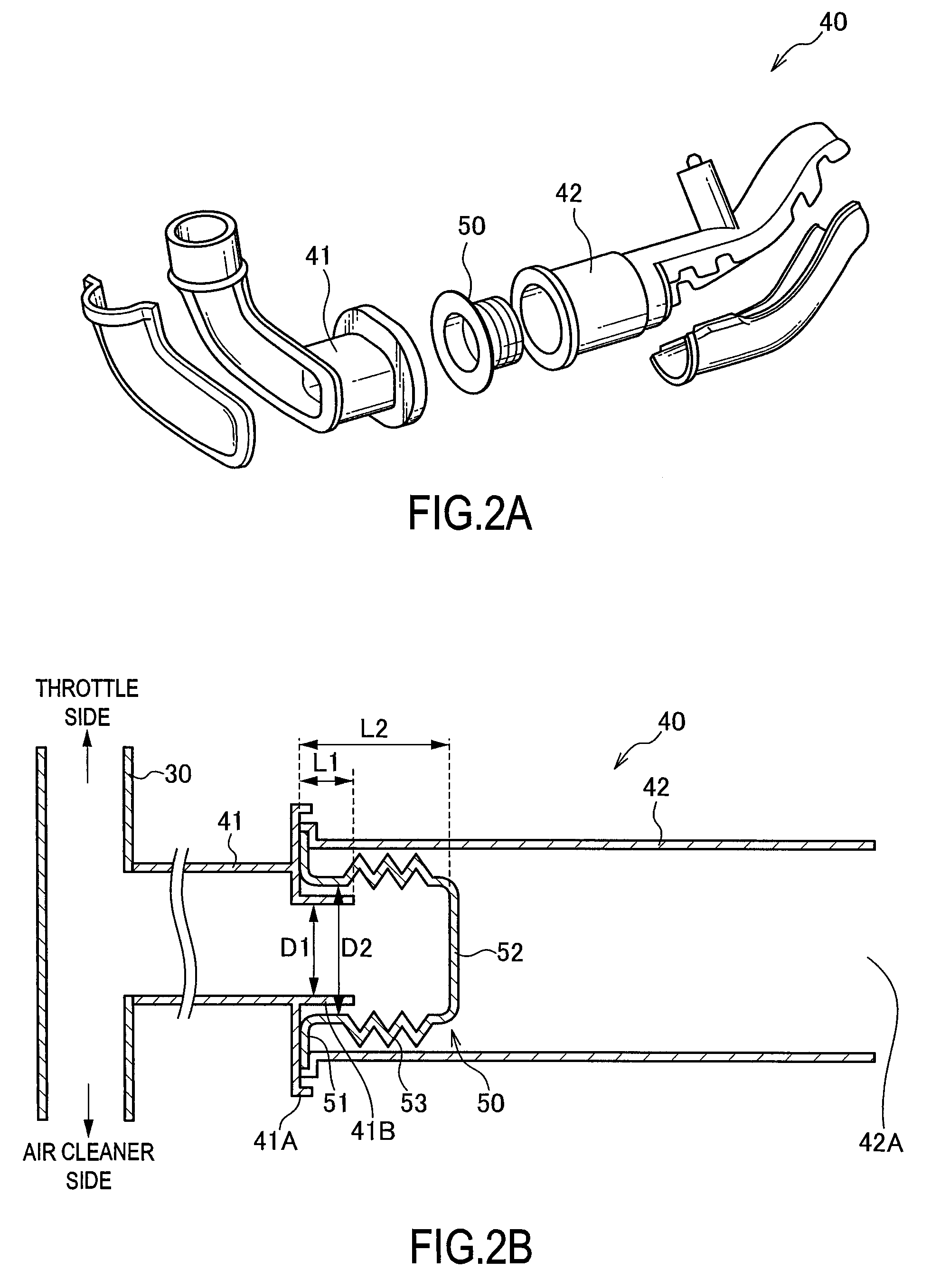

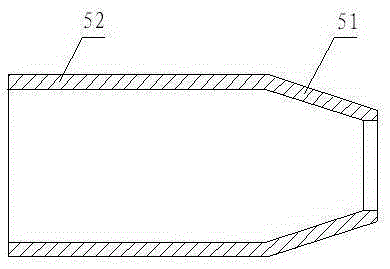

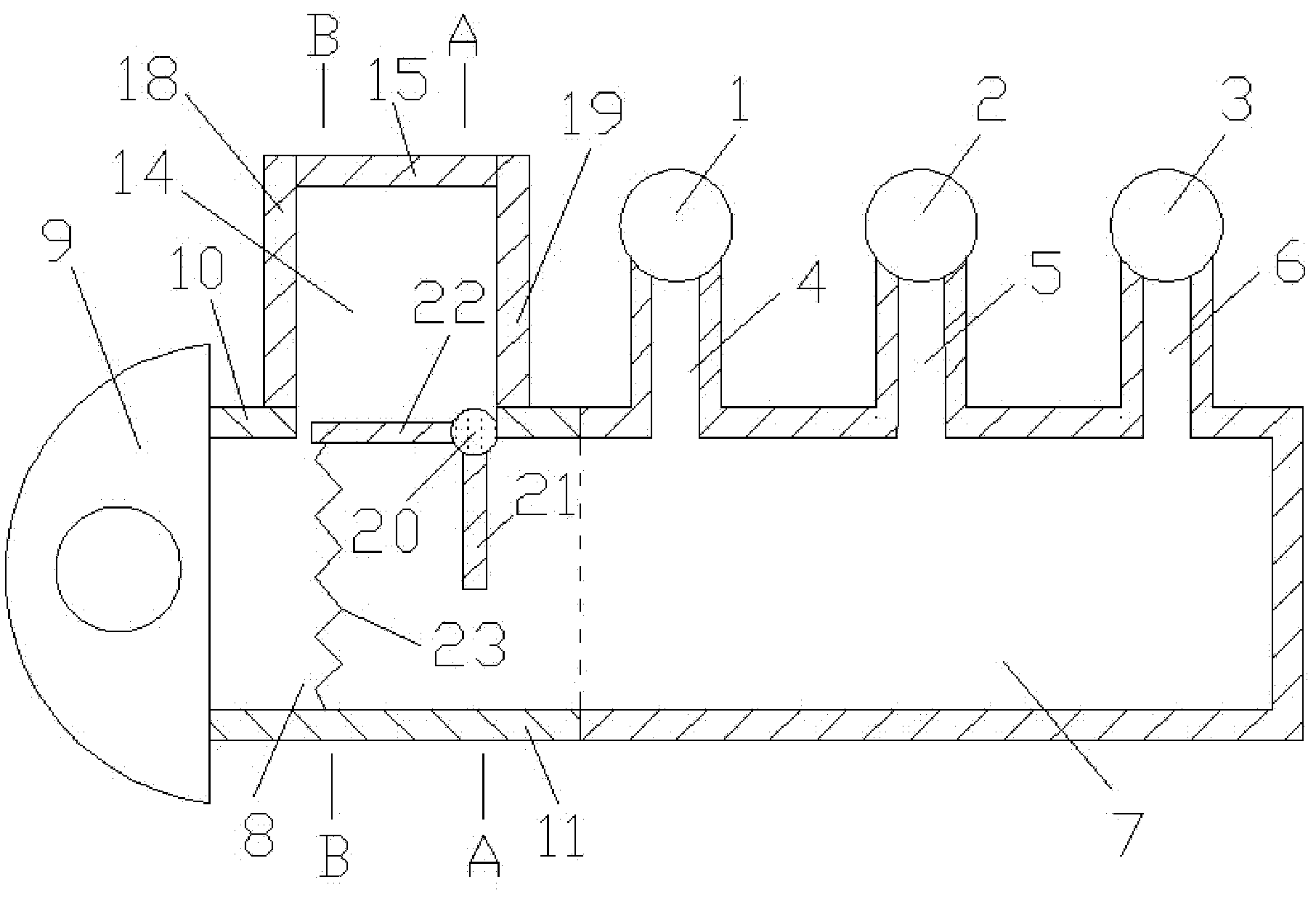

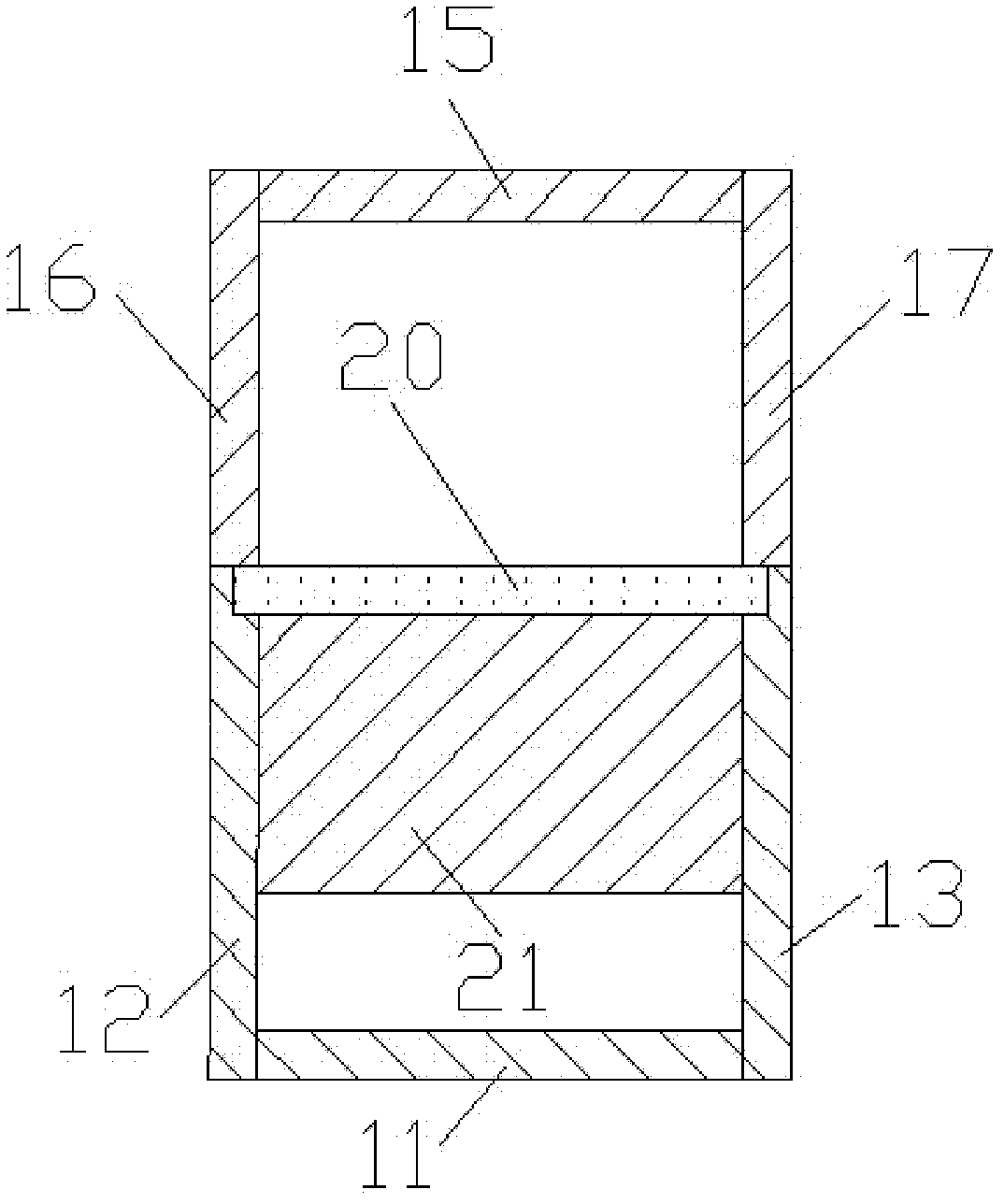

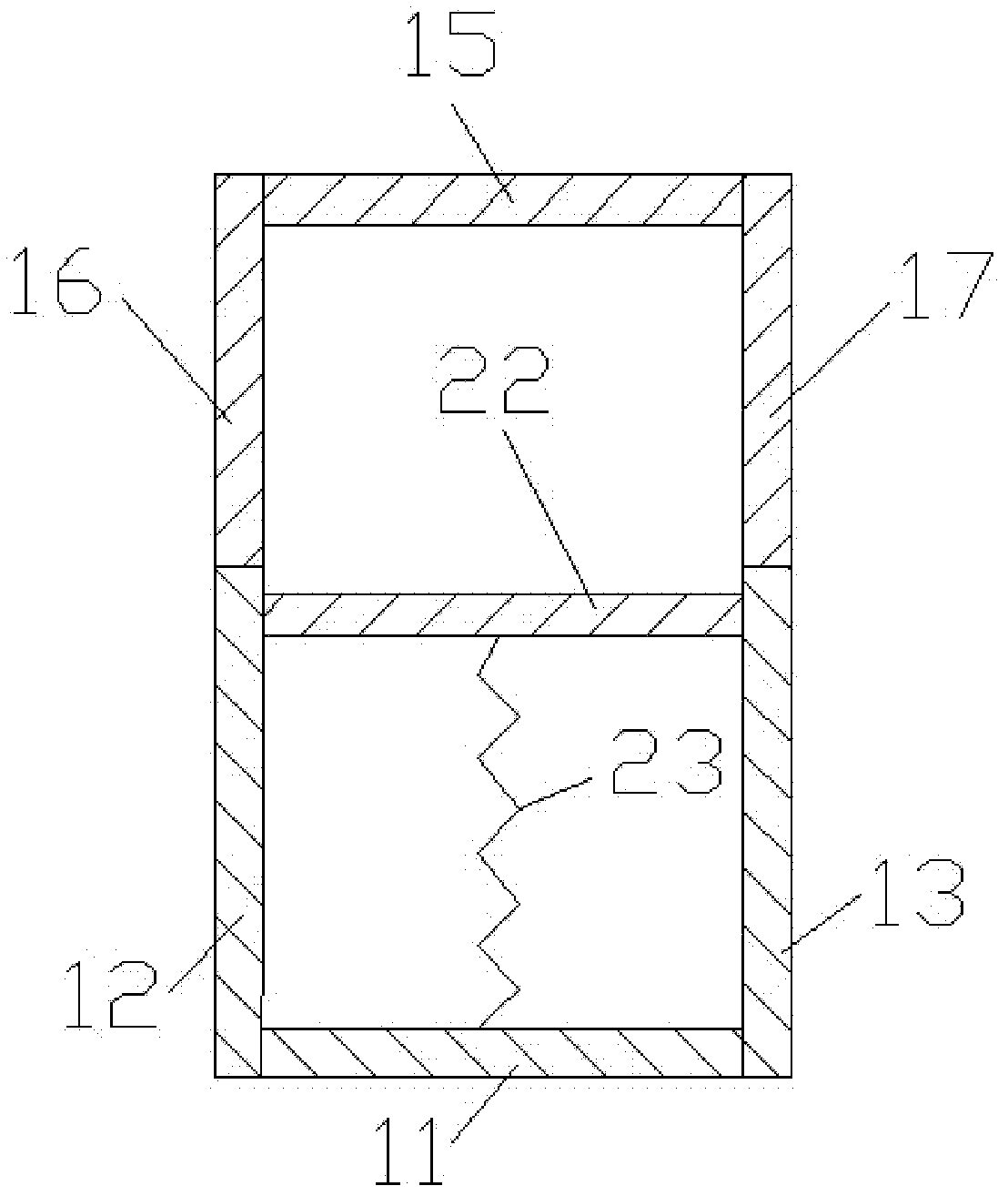

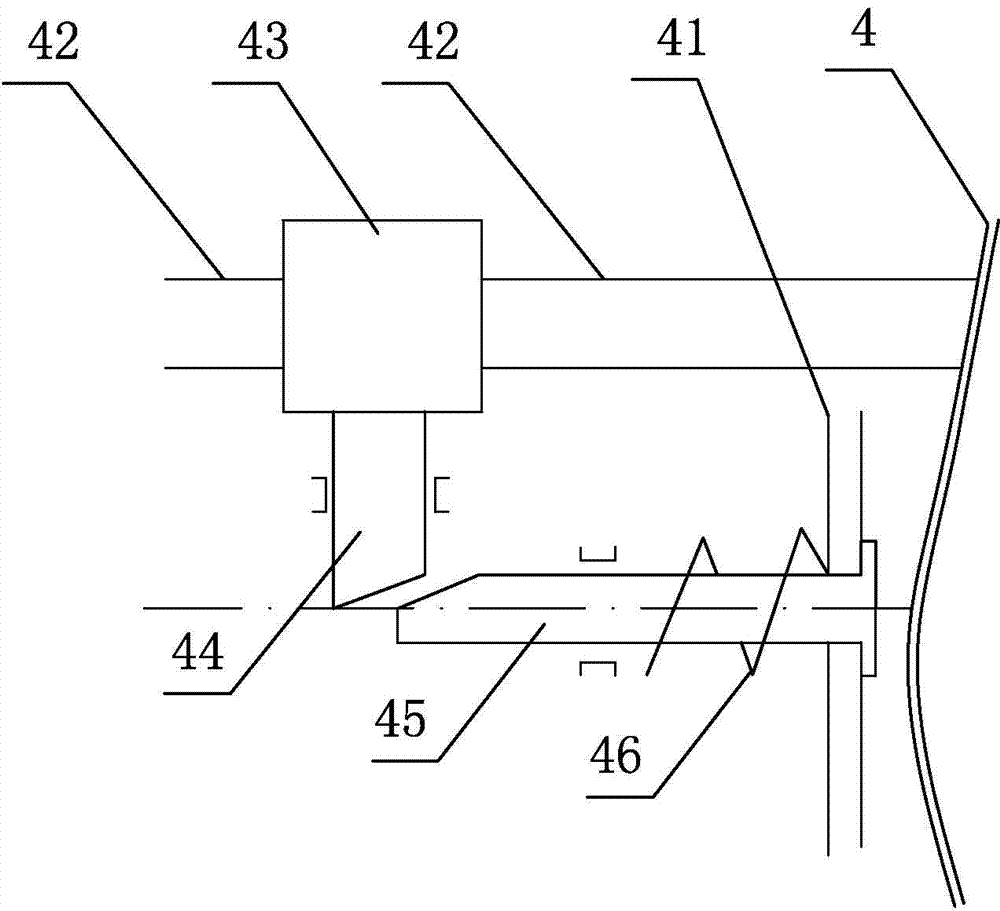

An intake air sound generation device 40 for an internal combustion engine 2, comprises an introduction tube 41 which is connected to an intake passage 30 of the internal combustion engine 2 to introduce an intake pulse of an intake system, a vibrating body 50 which has a vibration surface 52 that is vibrated by the intake pulse and an accordion portion 53 that promotes vibration of the vibration surface 52, and is provided to cover one end of the introduction tube 41, and a resonance tube 42 which is connected to the introduction tube 41 via the vibrating body 50 and increases a sound pressure in a predetermined frequency band of an intake air sound generated by the vibration of the vibration surface 52. Thus, the sound pressure of the intake air sound at the predetermined frequency can be increased, and the durability of the vibrating body 50 can be improved.

Owner:MAHLE JAPAN LTD +1

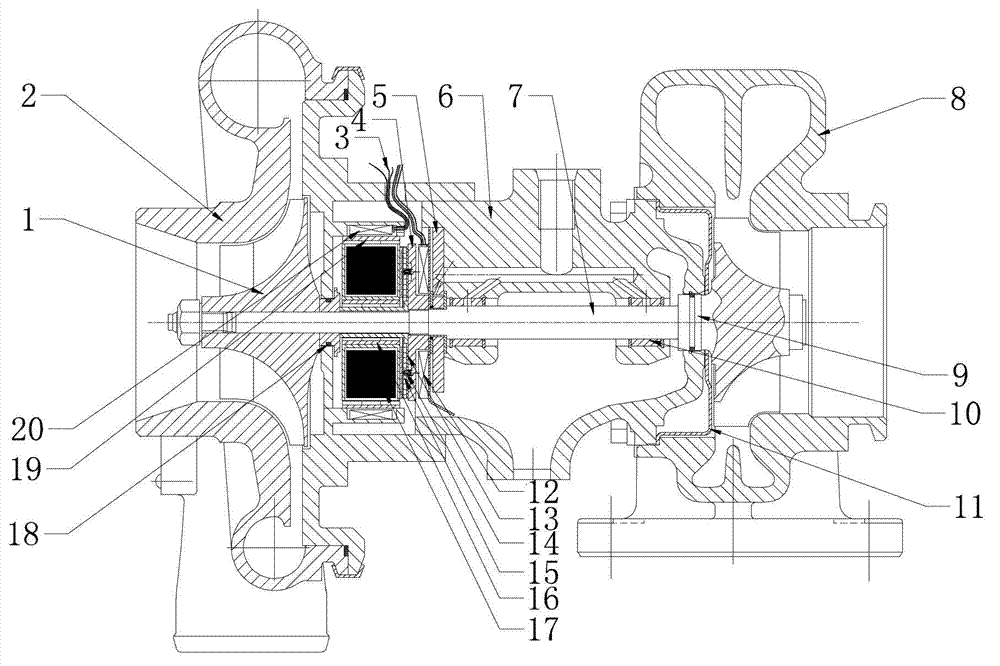

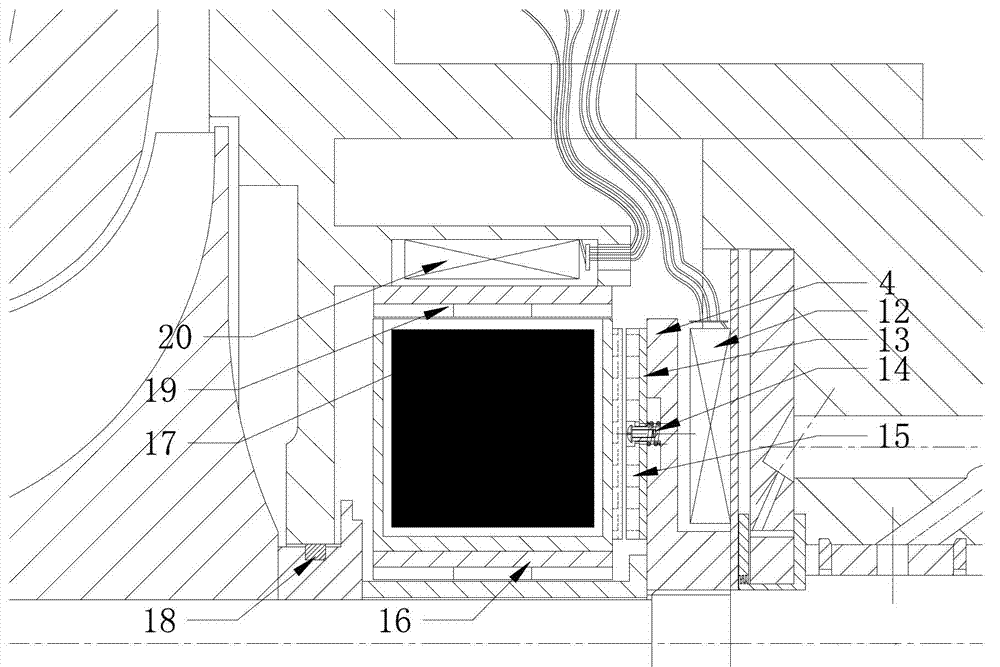

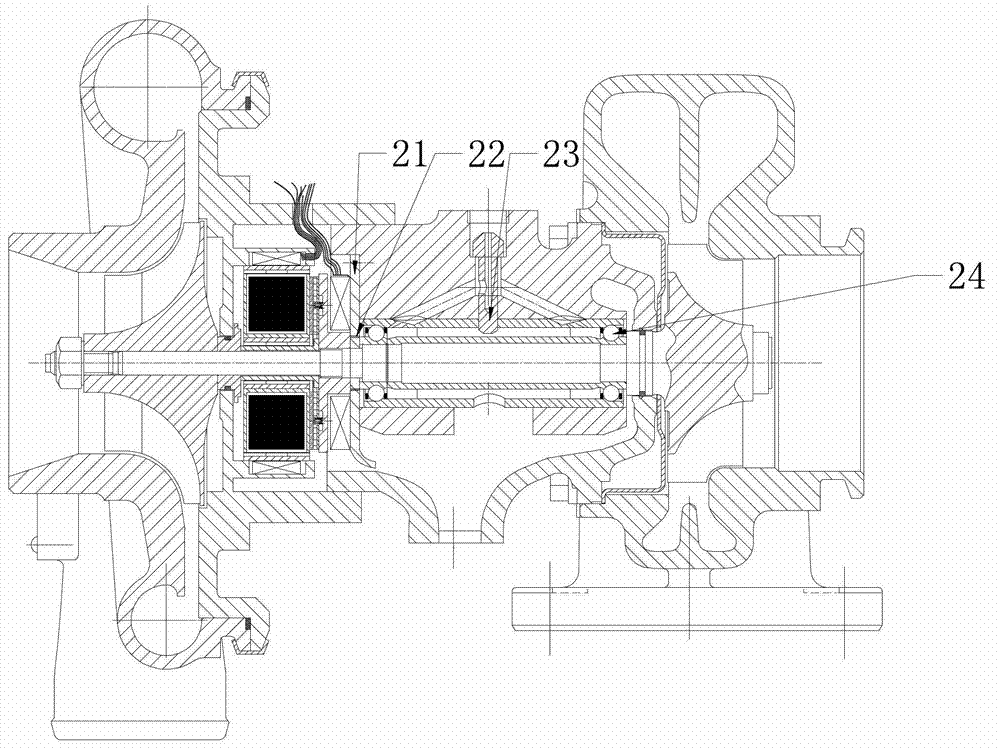

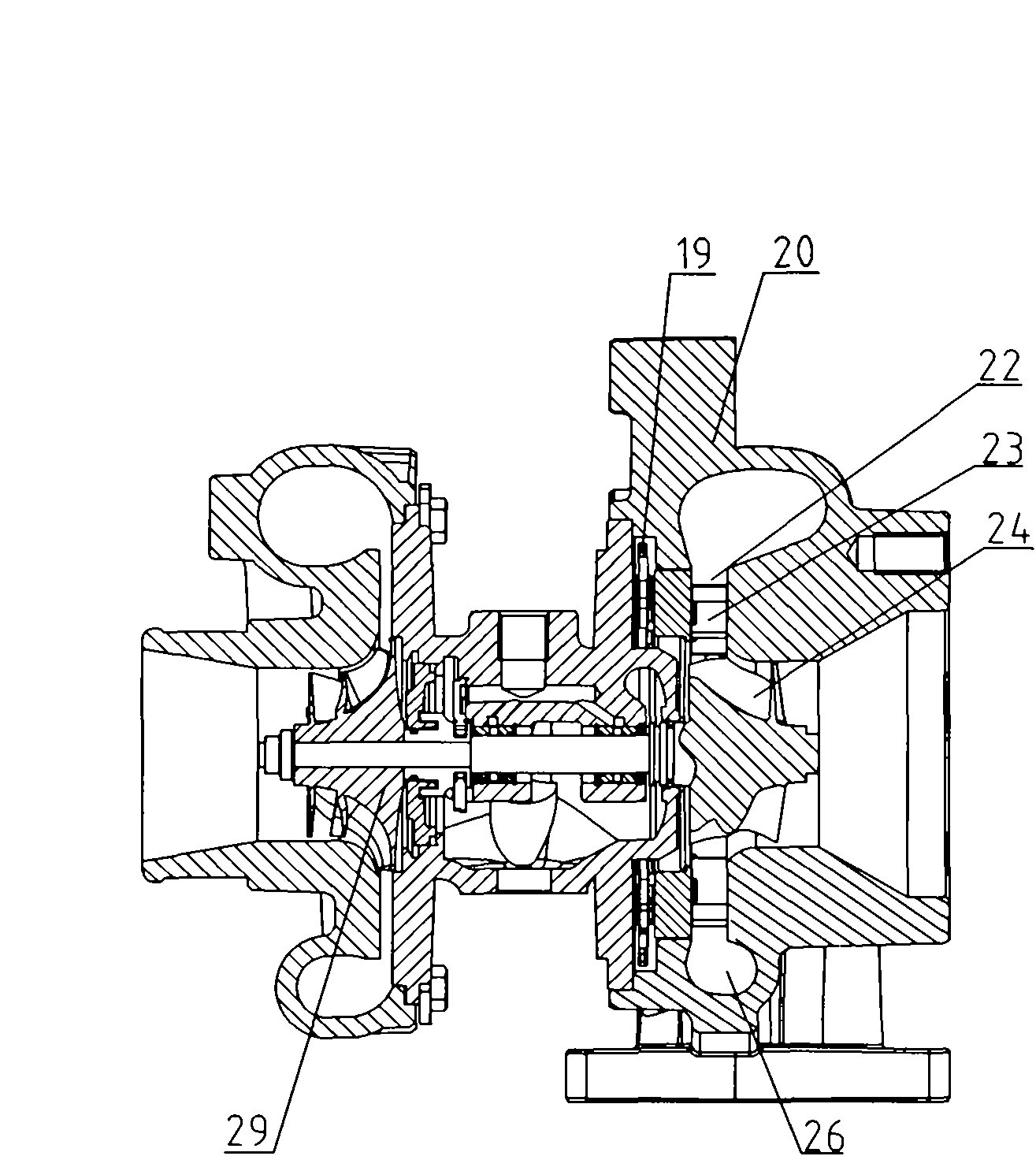

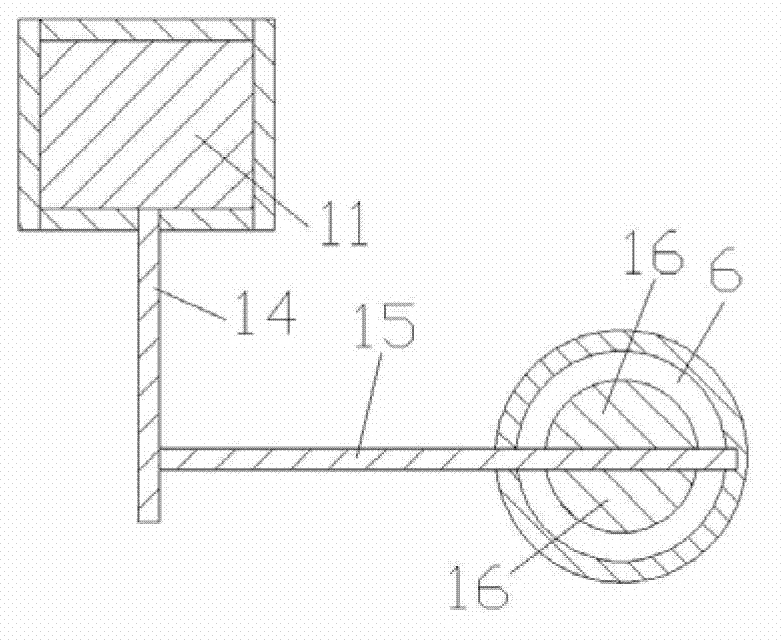

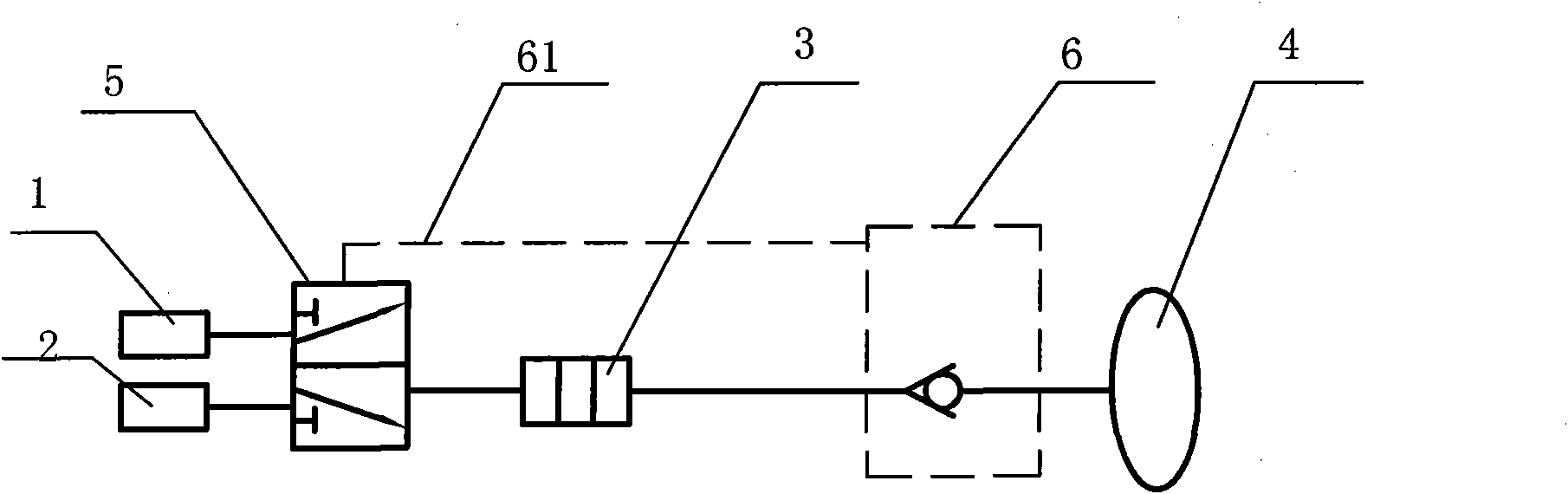

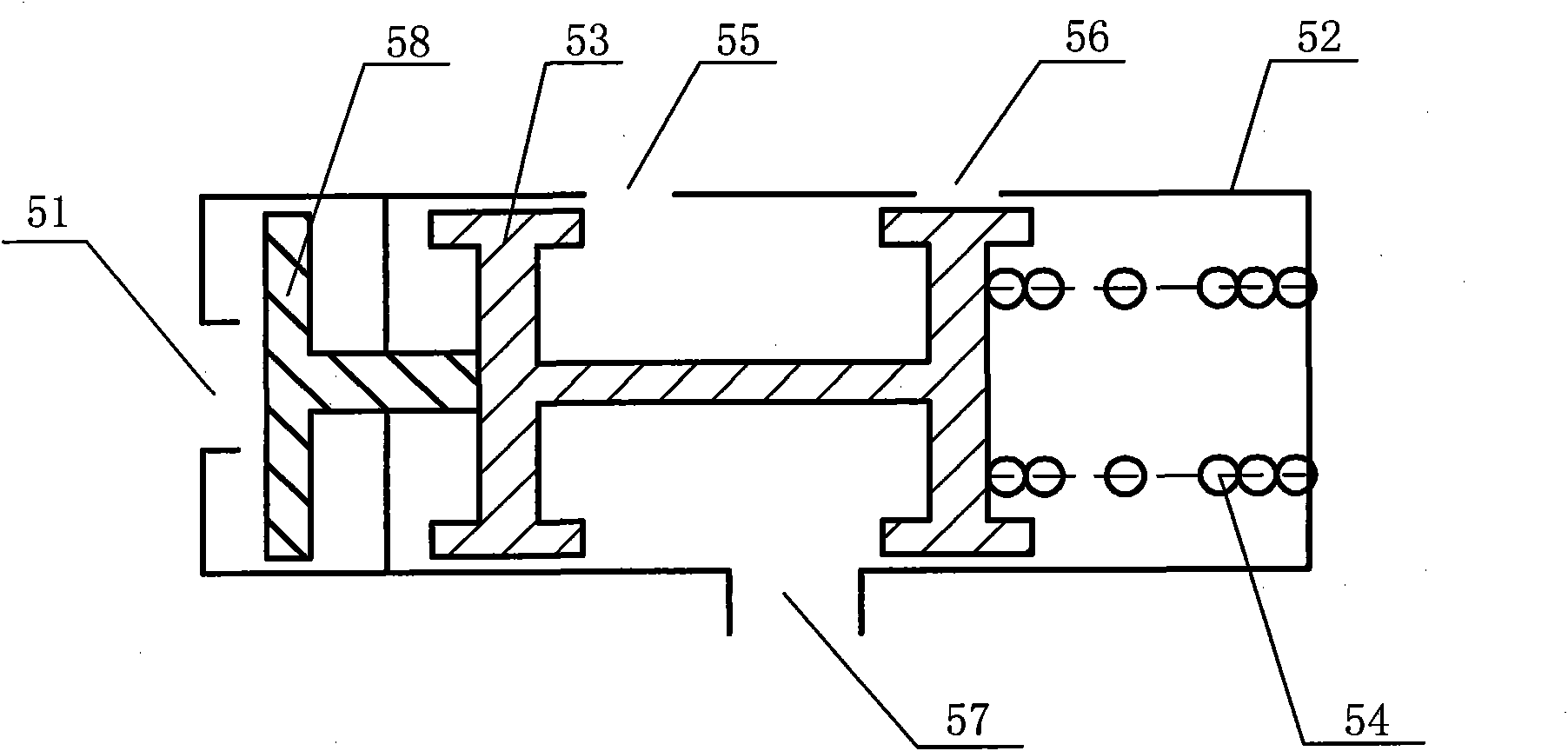

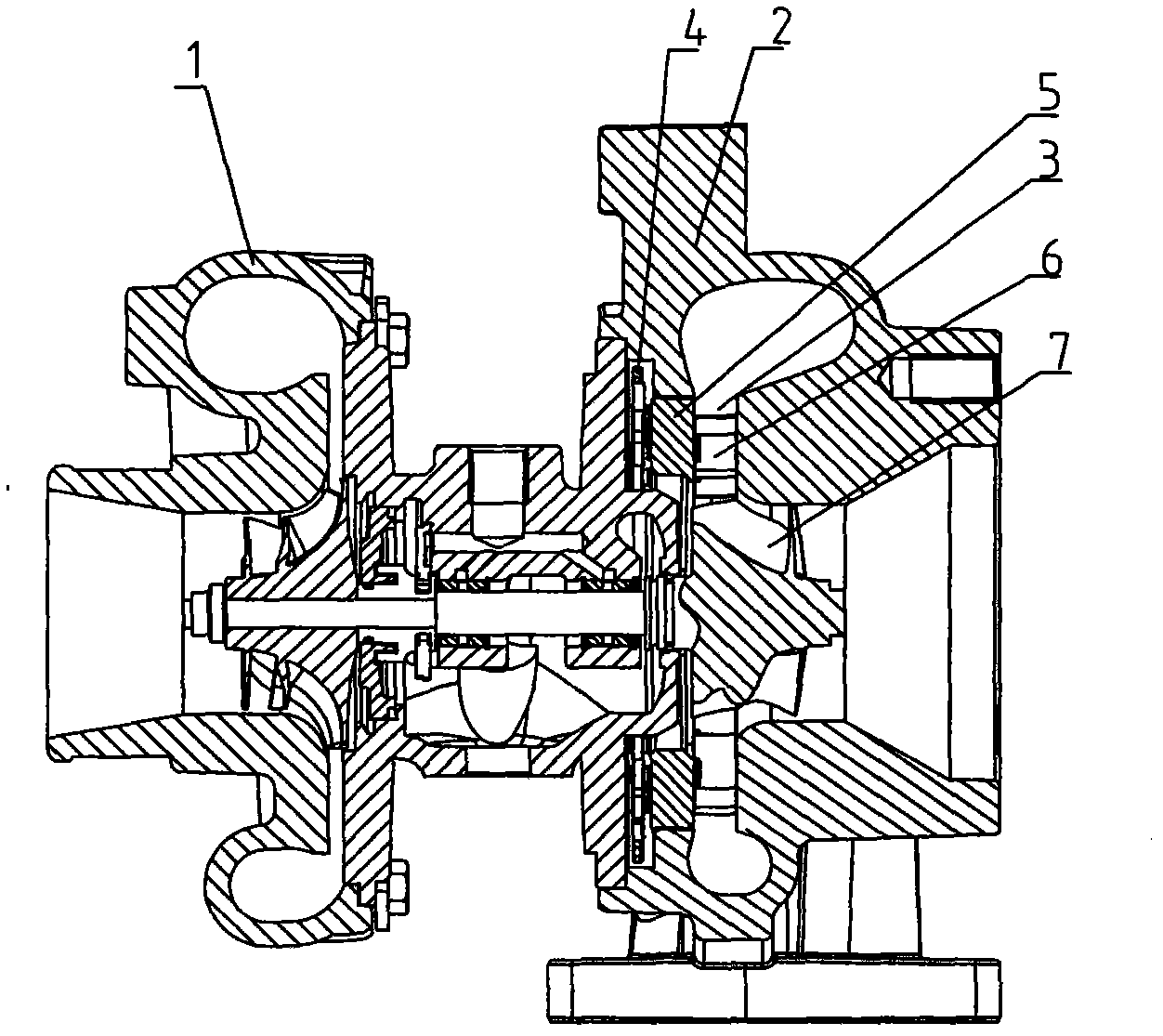

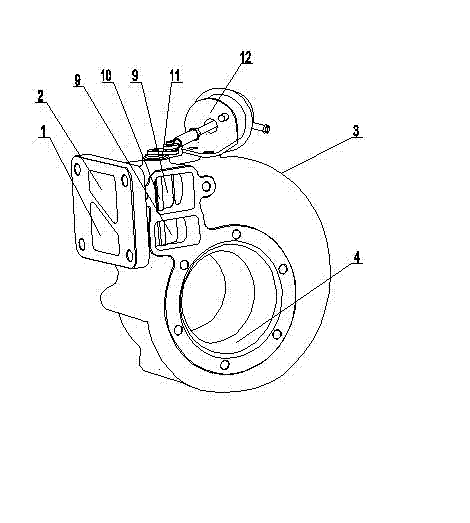

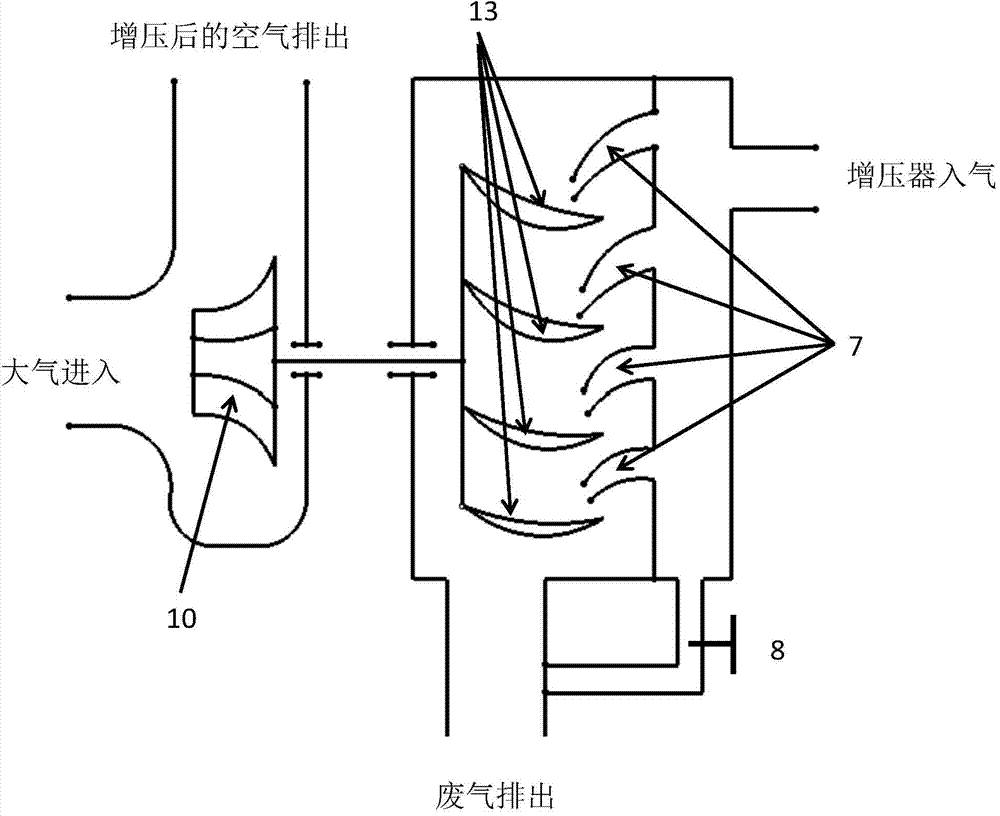

Rotor clutch type motor-driven power generation turbocharger and auxiliary control circuit and control method thereof

ActiveCN103089407ASmall moment of inertiaImprove stabilityInternal combustion piston enginesEngine componentsTurbochargerEngineering

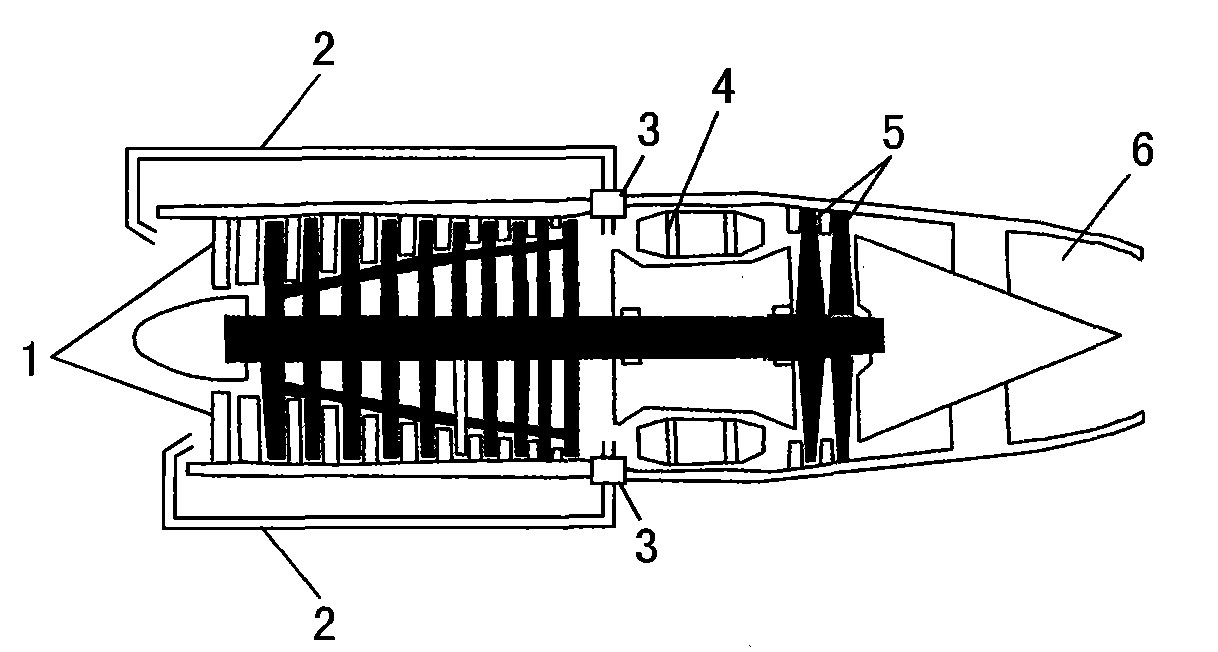

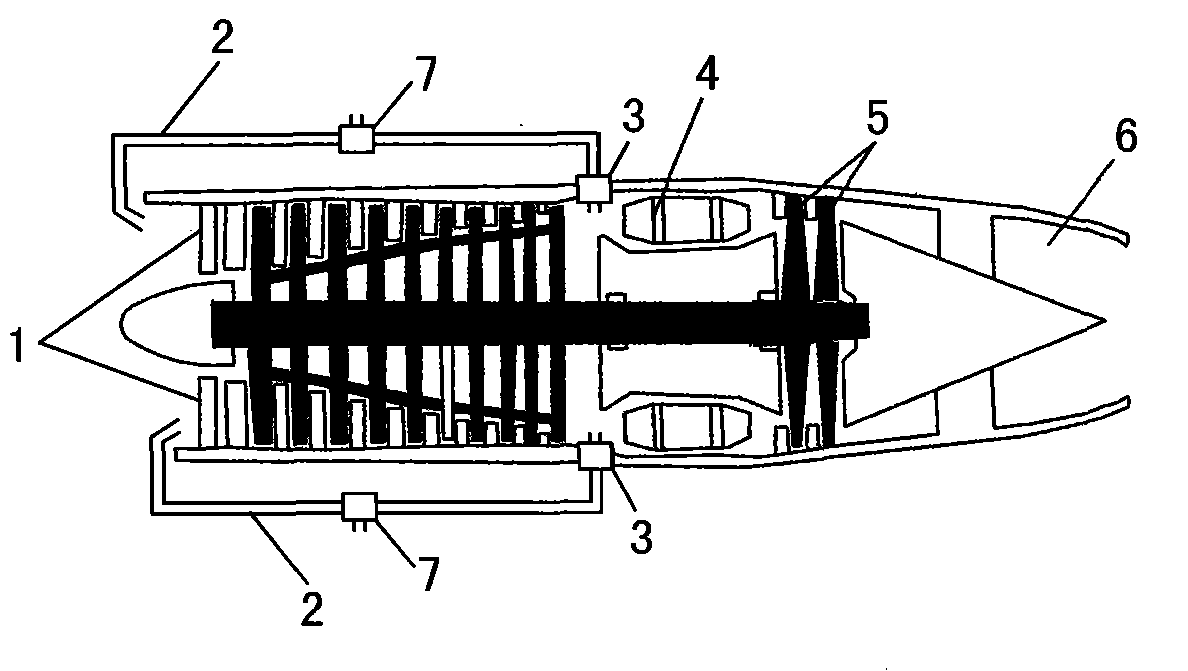

The invention relates to a rotor clutch type motor-driven power generation turbocharger and an auxiliary control circuit and a control method thereof. A motor-generator, an electromagnetic clutch device and the auxiliary control circuit are installed on a turbine rotor of the turbocharger, wherein the electromagnetic clutch device and the auxiliary control circuit can control combination and separation between the motor-generator and the turbine rotor, and the motor-generator and the electromagnetic clutch device are both connected with the auxiliary control circuit through conductive wires. Under the control of the auxiliary control circuit, the turbocharger is respectively in three working states of motor-driven auxiliary supercharging, outage no-load and power generation energy storage. The electromagnetic clutch device is installed to achieve timely combination or separation between the motor-generator and the turbine rotor of the turbocharger. Rotational inertia of the turbine rotor is reduced, energy loss is reduced, stability and reliability of operation of the turbocharger are improved, fuel energy is effectively utilized, and efficient distribution and utilization of energy of the turbocharger are achieved. The rotor clutch type motor-driven power generation turbocharger has the advantages of being flexible and accurate to control.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

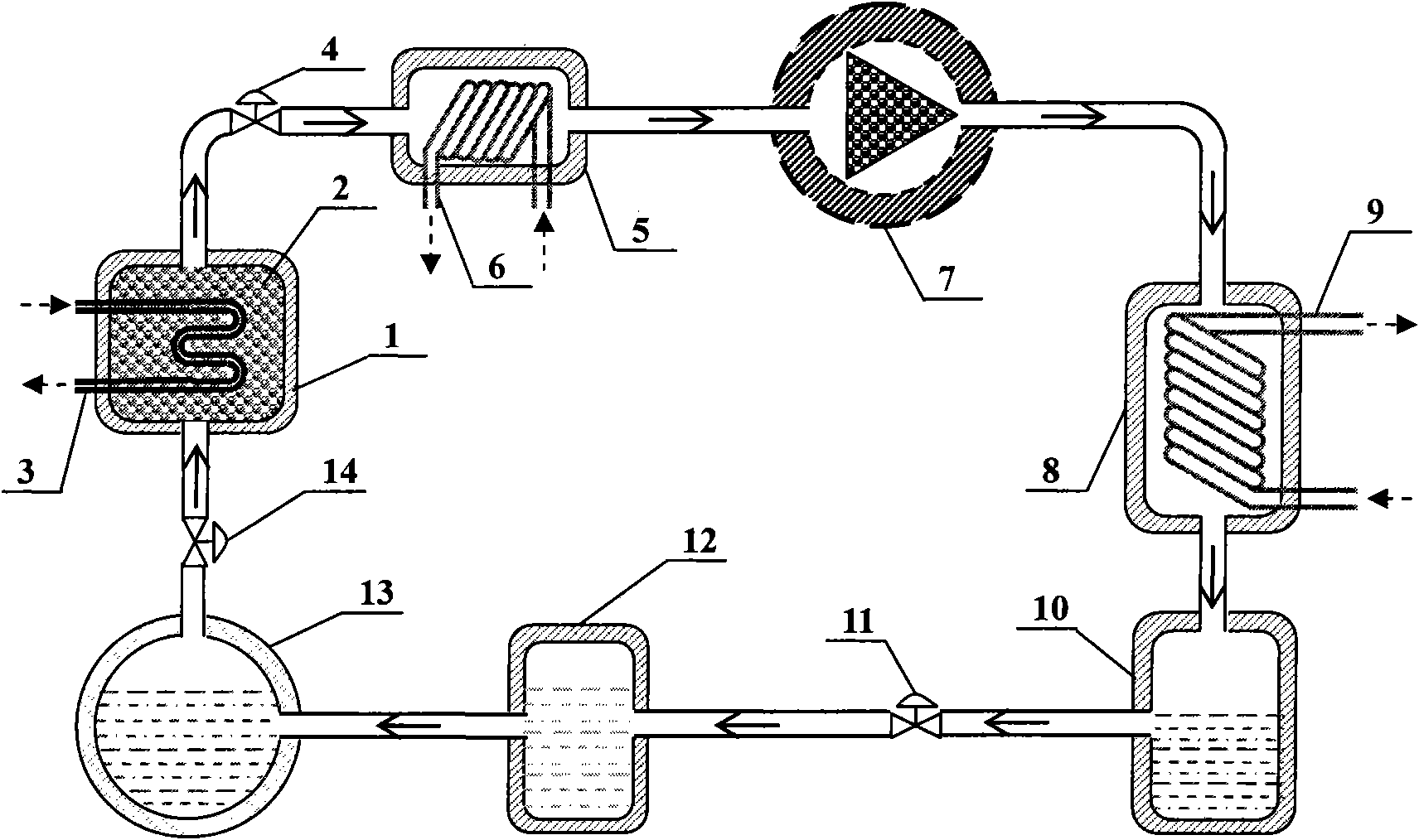

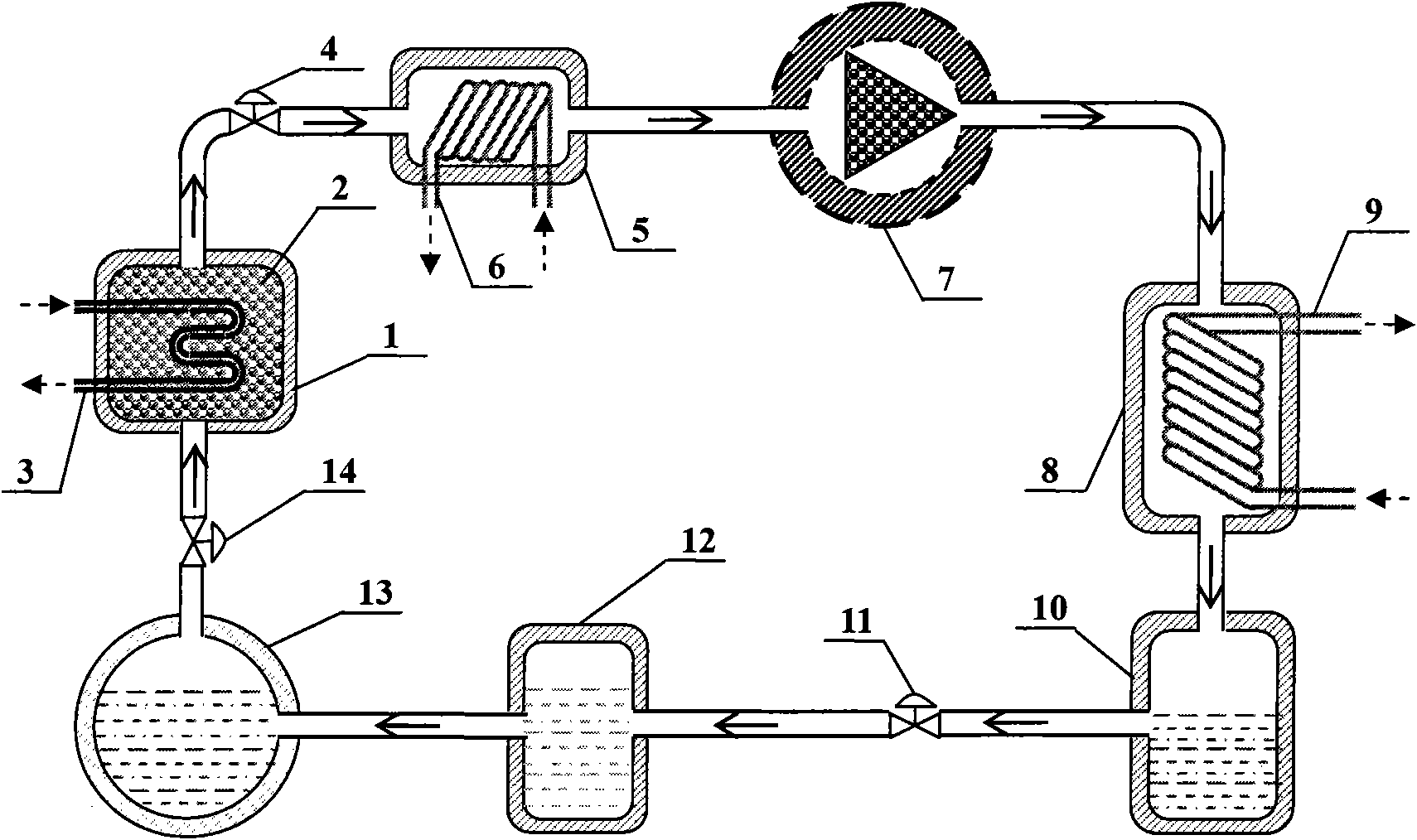

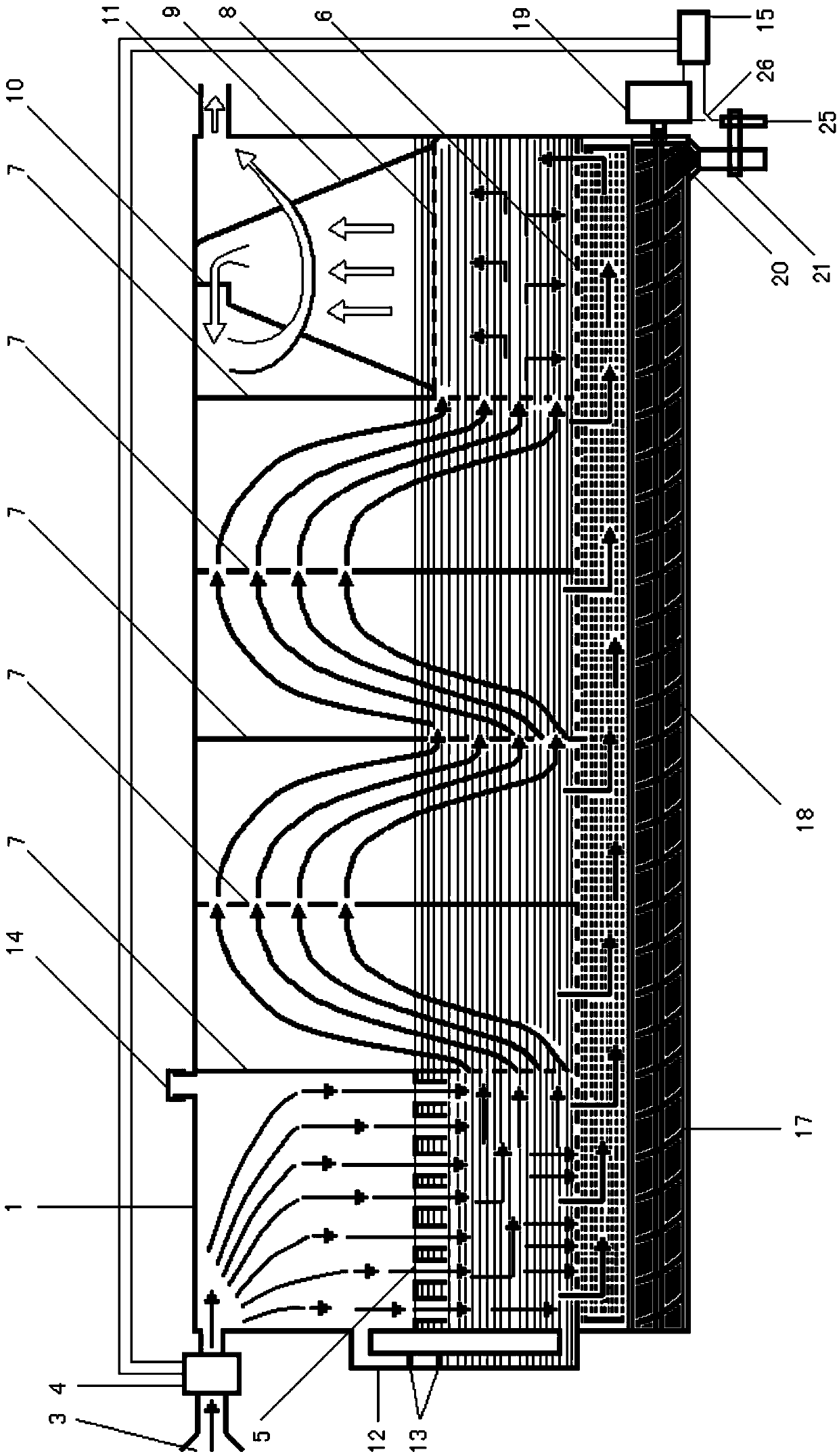

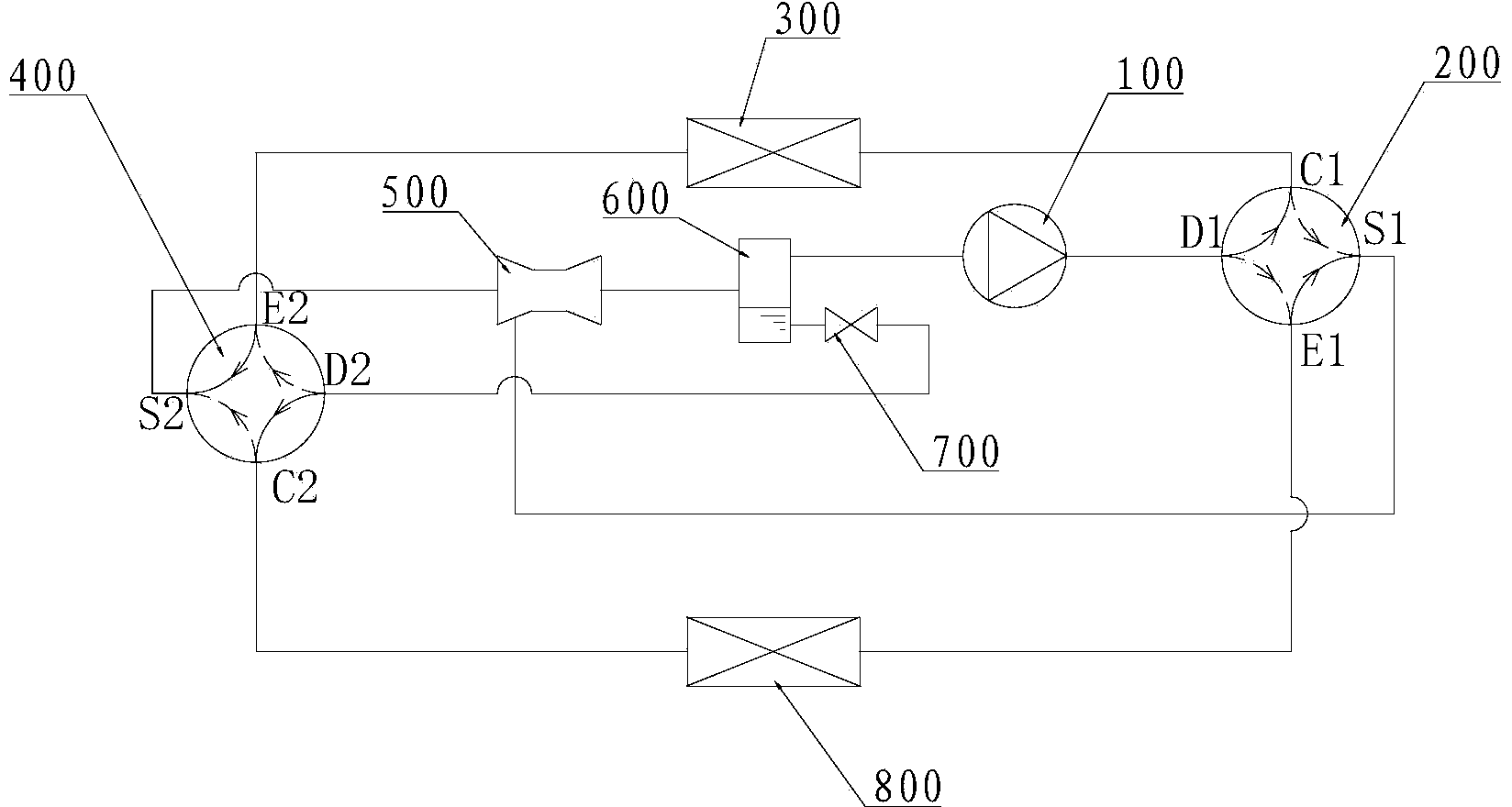

Absorption-mechanical compression coupling refrigeration and cold accumulation system

ActiveCN102141322ALow running costIncrease intake pressureFluid circulation arrangementLower gradeLiquid storage tank

The invention belongs to the technical field of refrigeration and cold accumulation, and discloses an absorption-mechanical compression coupling refrigeration and cold accumulation system. The absorption-mechanical compression coupling refrigeration and cold accumulation system comprises an absorption bed, a desorbing valve, a cooler, a compressor, a condenser, a high-pressure liquid-storage tank, a throttling valve, a low-pressure liquid-storage tank, an evaporator and an absorbing valve. An absorption bed heat exchanger is arranged in the absorption bed; an absorbing agent is filled in the absorption bed; the outlet of the absorption bed is connected with the inlet of the desorbing valve; the outlet of the desorbing valve is connected with the inlet of the cooler; the outlet of the cooler is connected with the inlet of the compressor; the outlet of the compressor is connected with the inlet of the condenser; the outlet of the condenser is connected with the inlet of the high-pressure liquid-storage tank; the outlet of the high-pressure liquid-storage tank is connected with the inlet of the throttling valve; the outlet of the throttling valve is connected with an inlet of the low-pressure liquid-storage tank; the outlet of the low-pressure liquid-storage tan is connected with the inlet of the evaporator; the outlet of the evaporator is connected with the inlet of the absorbing valve; and the outlet of the absorbing valve is connected with the inlet of the absorbing bed. With the adoption of the absorption-mechanical compression coupling refrigeration and cold accumulation system, low-grade heat source can be utilized to realize cold accumulation without cold lass, so that the power consumption of the system and the operation cost are obviously reduced.

Owner:SHANDONG UNIV

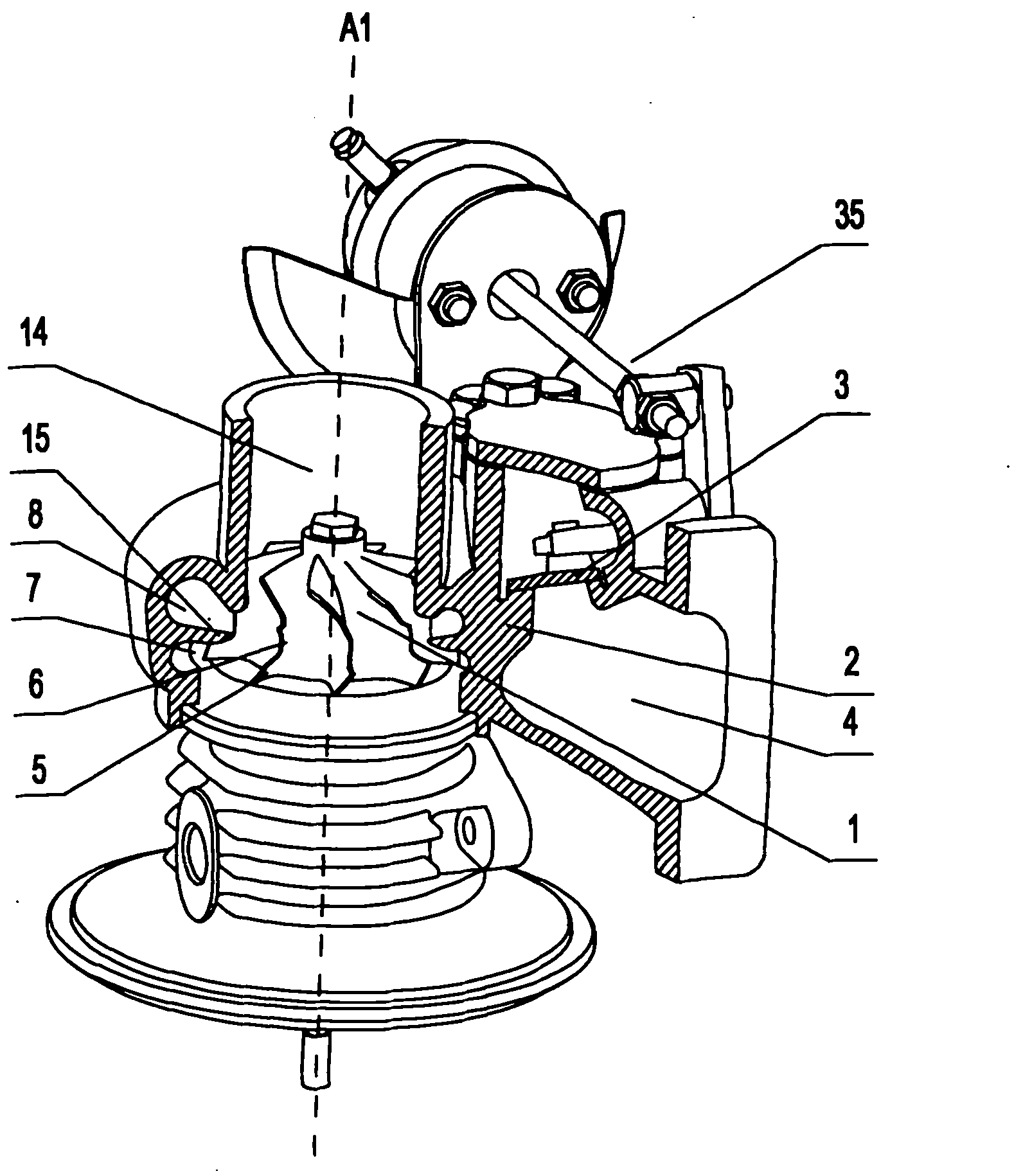

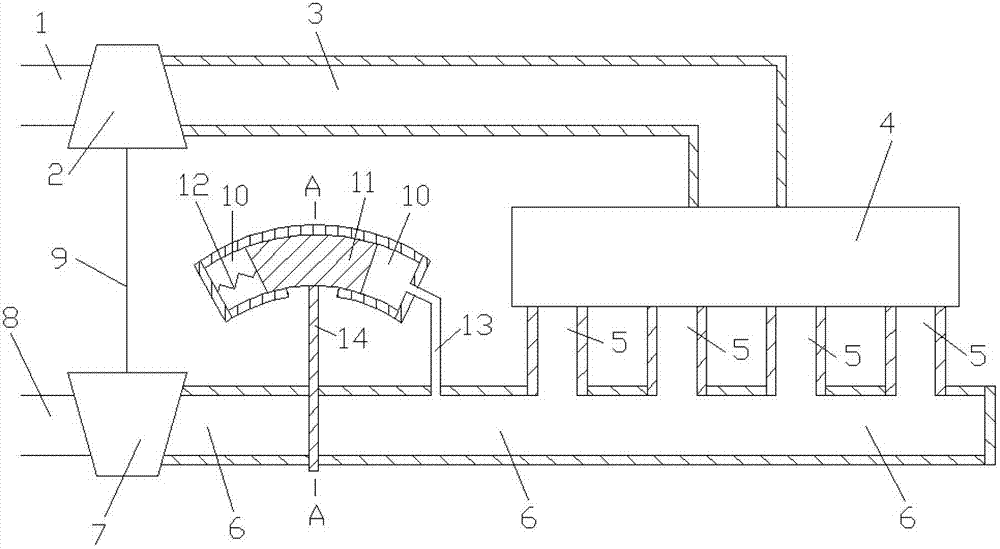

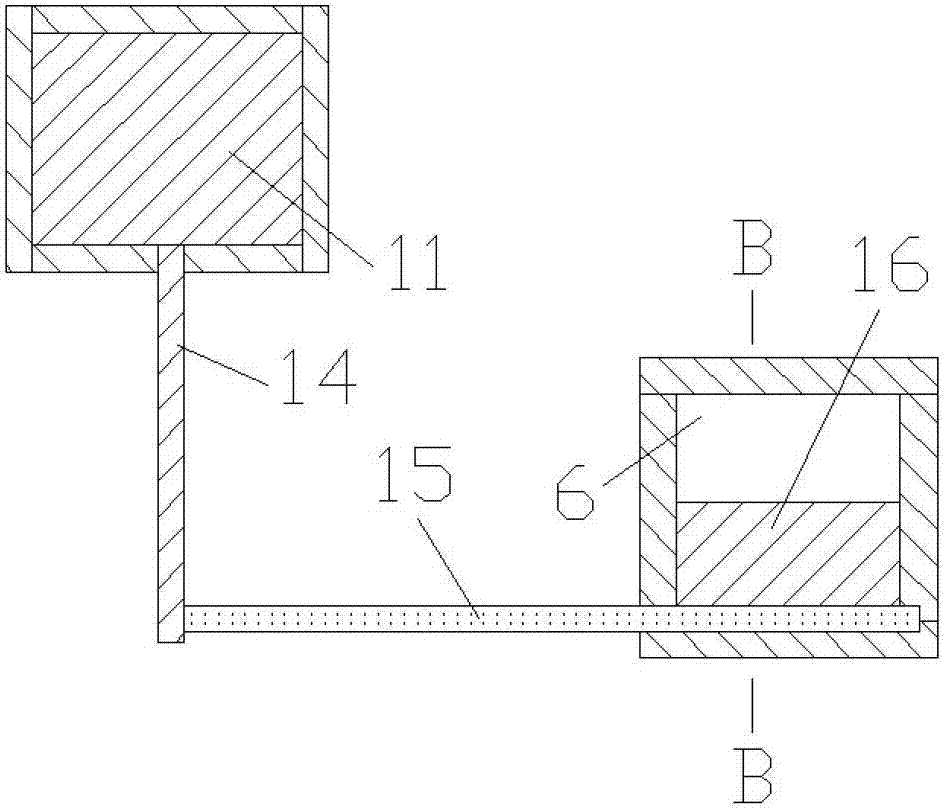

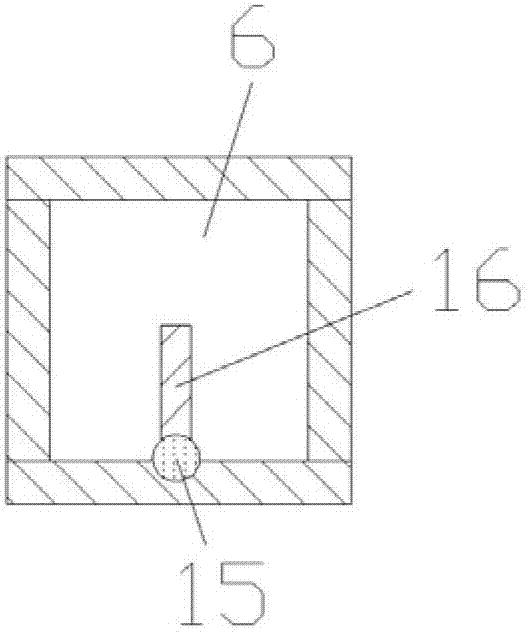

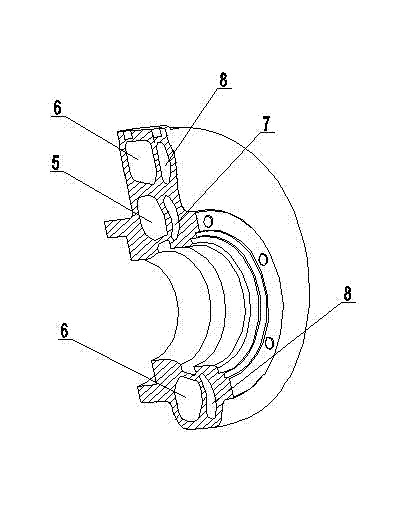

Complex turbine device with variable section

InactiveCN101985897AGuaranteed inflowAvoid enteringInternal combustion piston enginesBlade accessoriesImpellerLow speed

The invention discloses a complex turbine device with a variable section, comprising a double flow channel turbine volute, wherein the double flow channel turbine volute is provided with two air flow passageways; the double flow channel turbine volute is provided with a volute air outlet and a volute air inlet which are communicated with the air flow passageways; a complex turbine impeller is arranged in the double flow channel turbine volute; and the complex turbine impeller is formed by compounding two turbine impellers which correspond to the two air flow passageways one by one. In the invention, the variable section function can be achieved by design and development of the turbine of a turbocharger and by using the complex turbine device, thereby effectively solving the defects of poor reliability and high cost of a vane type turbocharger with the variable section, effectively improving the efficiency of the turbine of an engine in low speed and increasing the torque output of the turbine.

Owner:KANGYUE TECH

Variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for turbocharged engine

InactiveCN103089411ALarge throat areaIncrease intake pressureInternal combustion piston enginesInlet pressureAir compressor

A variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of a connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air exhaust pipe in front of the rotation plate is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air exhaust pipe in front of the rotation plate is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

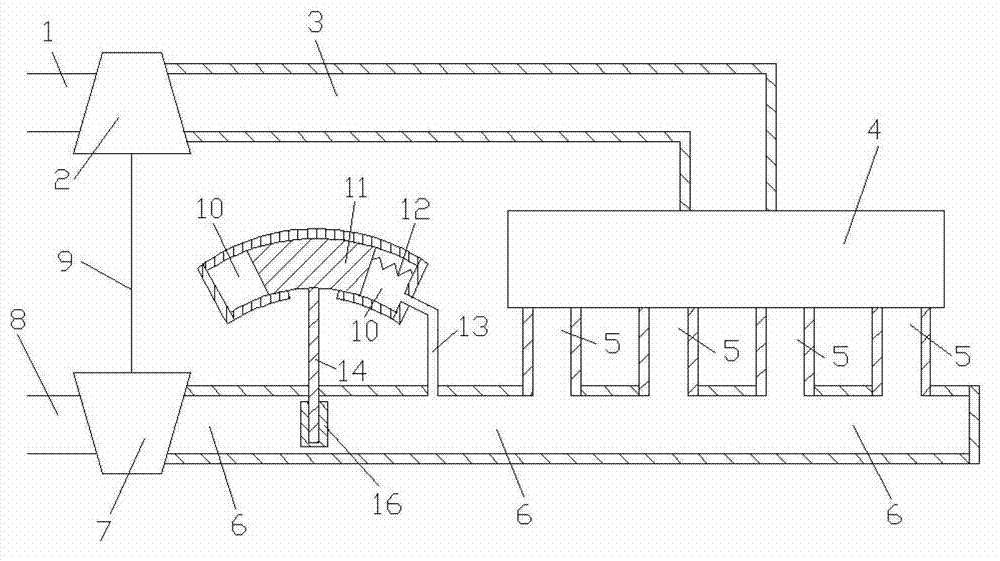

Air purification equipment using liquid reducing agent and working and applying method of air purification equipment

ActiveCN104174246AIncrease deflationPrevent deflagrationCombination devicesGas treatmentParticulatesEnvironmental engineering

The invention discloses air purification equipment using a liquid reducing agent. The air purification equipment is characterized by comprising a polluted gas suction opening, a polluted gas purification cavity and a clean gas discharging opening, wherein the polluted gas purification cavity is divided into a plurality of cavities by a plurality of half-surface multihole type pollution particle vertical baffles; pollution cleaning liquid is contained in the polluted gas purification cavity; one end of each half-surface multihole type pollution particle vertical baffle is closed, and the other end of each half-surface multihole type pollution particle vertical baffle is used for communicating two adjacent cavities through multiple holes; the polluted gas suction opening and the clean gas discharging opening are respectively formed in the two cavities at the head and the tail. The air purification equipment has the advantages that polluted air enters the pollution cleaning liquid, so that all particulate matters entering pollution cleaning equipment can be humidified to gain the weight and basically retained; by the adding of a feldspar aqueous solution component, carbon elements in carbon dioxide and other elements in the feldspar aqueous solution are combined to generate carbonate type substances, and sucked carbon dioxide components can be eliminated.

Owner:段洪池 +1

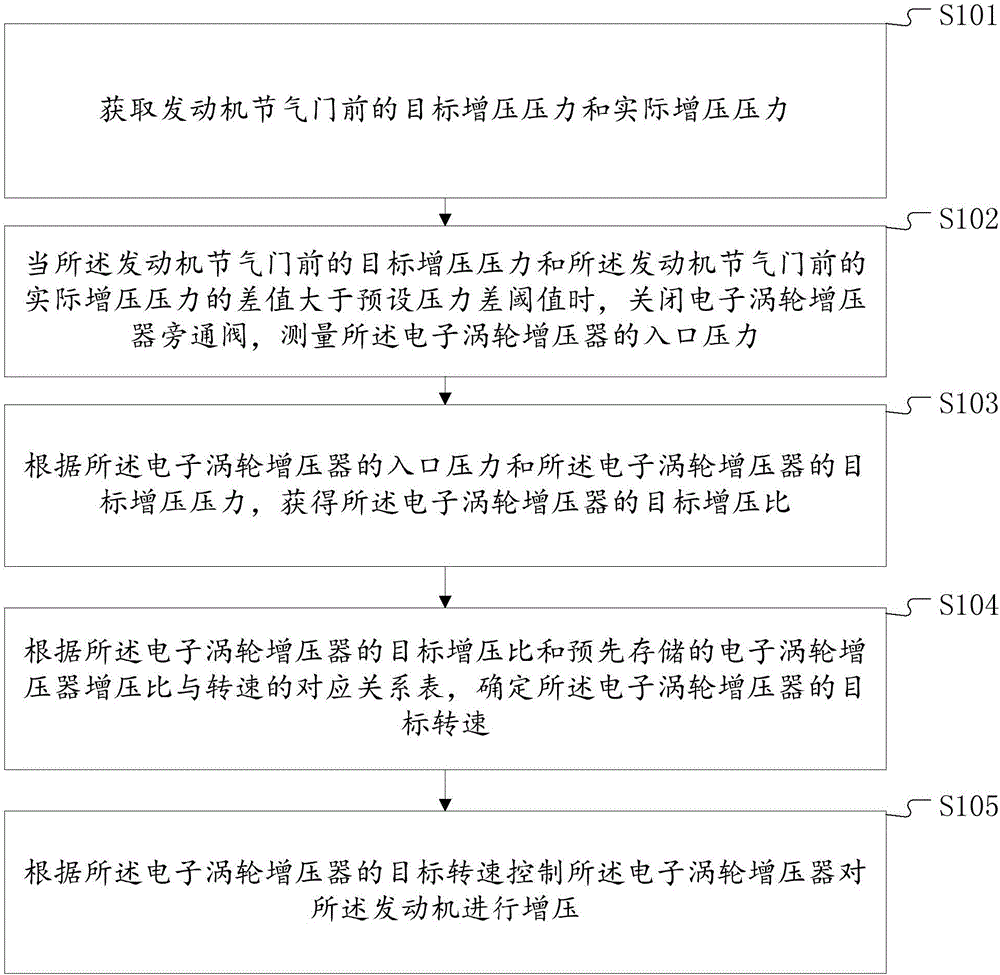

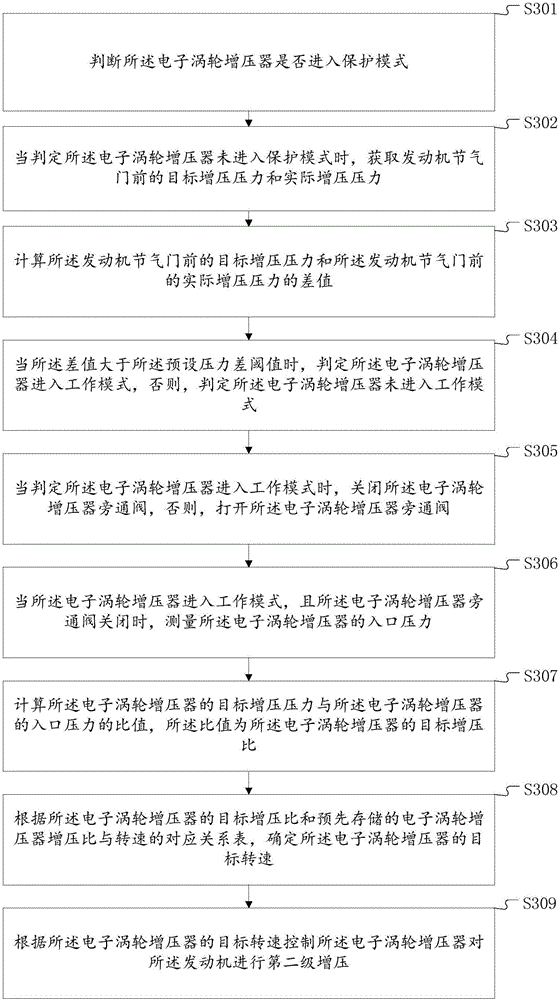

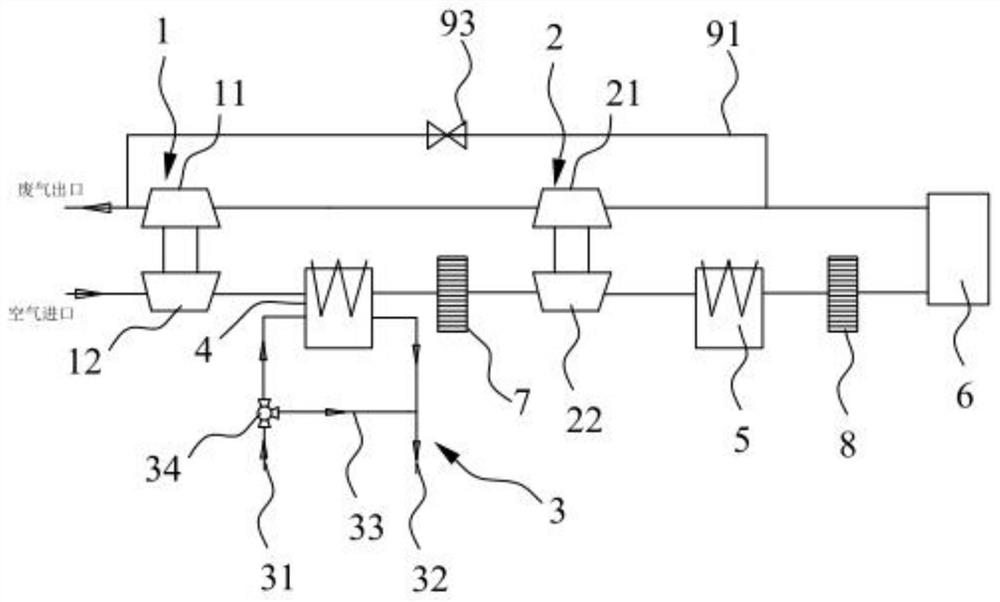

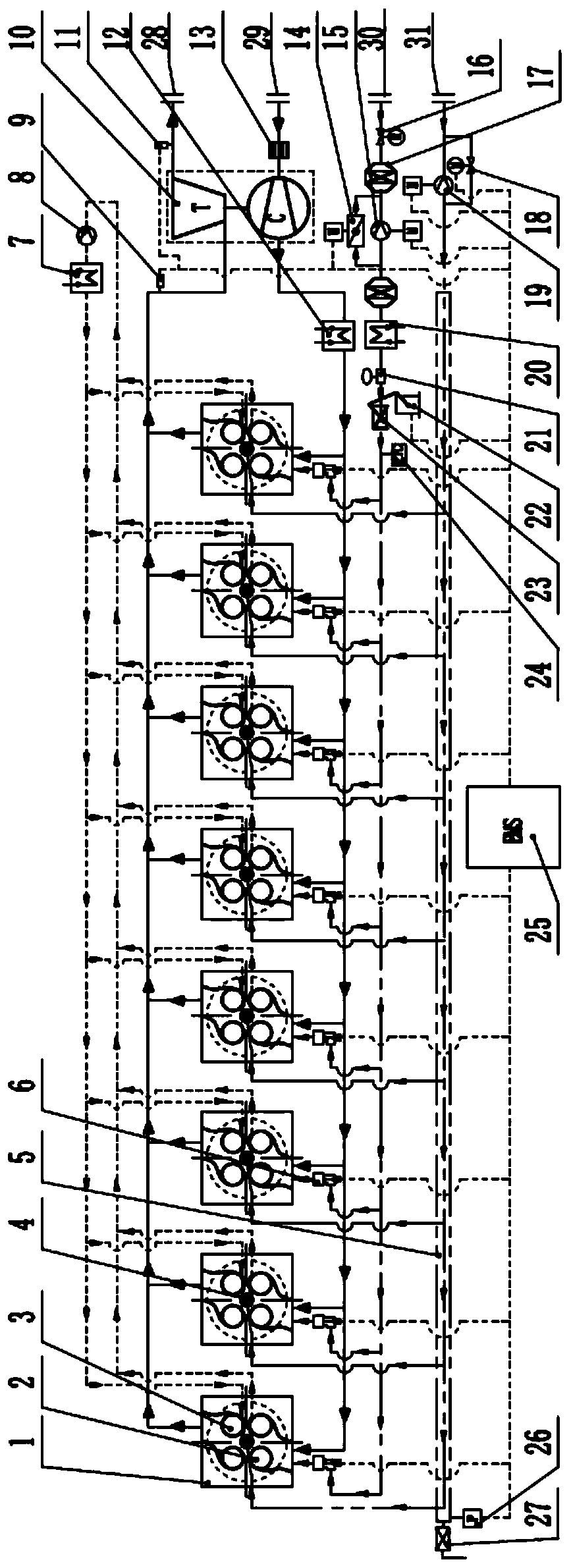

Pressurization method and system for engine

ActiveCN106368804AIncrease intake pressureHigh output torqueElectrical controlInternal combustion piston enginesHysteresisTurbocharger

The invention discloses a pressurization method and system for an engine. The method includes the steps of obtaining the target pressurization pressure and the actual pressurization pressure in front of a throttle valve of the engine; closing a bypass valve of an electronic turbocharger and measuring the inlet pressure of the electronic turbocharger when the difference value between the target pressurization pressure and the actual pressurization pressure in front of the throttle valve of the engine is greater than the preset pressure difference threshold value; according to the inlet pressure and the target pressurization pressure of the electronic turbocharger, obtaining the target pressurization ratio of the electronic turbocharger; according to the target pressurization ratio of the electronic turbocharger and a pre-stored corresponding relation table of the pressurization ratio and the rotation speed of the electronic turbocharger, determining the target rotation speed of the electronic turbocharger; and according to the target rotation speed, controlling the electronic turbocharger to pressurize the engine. According to the pressurization method and system, when the actual pressurization pressure cannot reach a target value fast, the electronic turbocharger can pressurize the engine, and therefore the power acceleration performance of vehicles can be improved, and turbine lag can be reduced.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

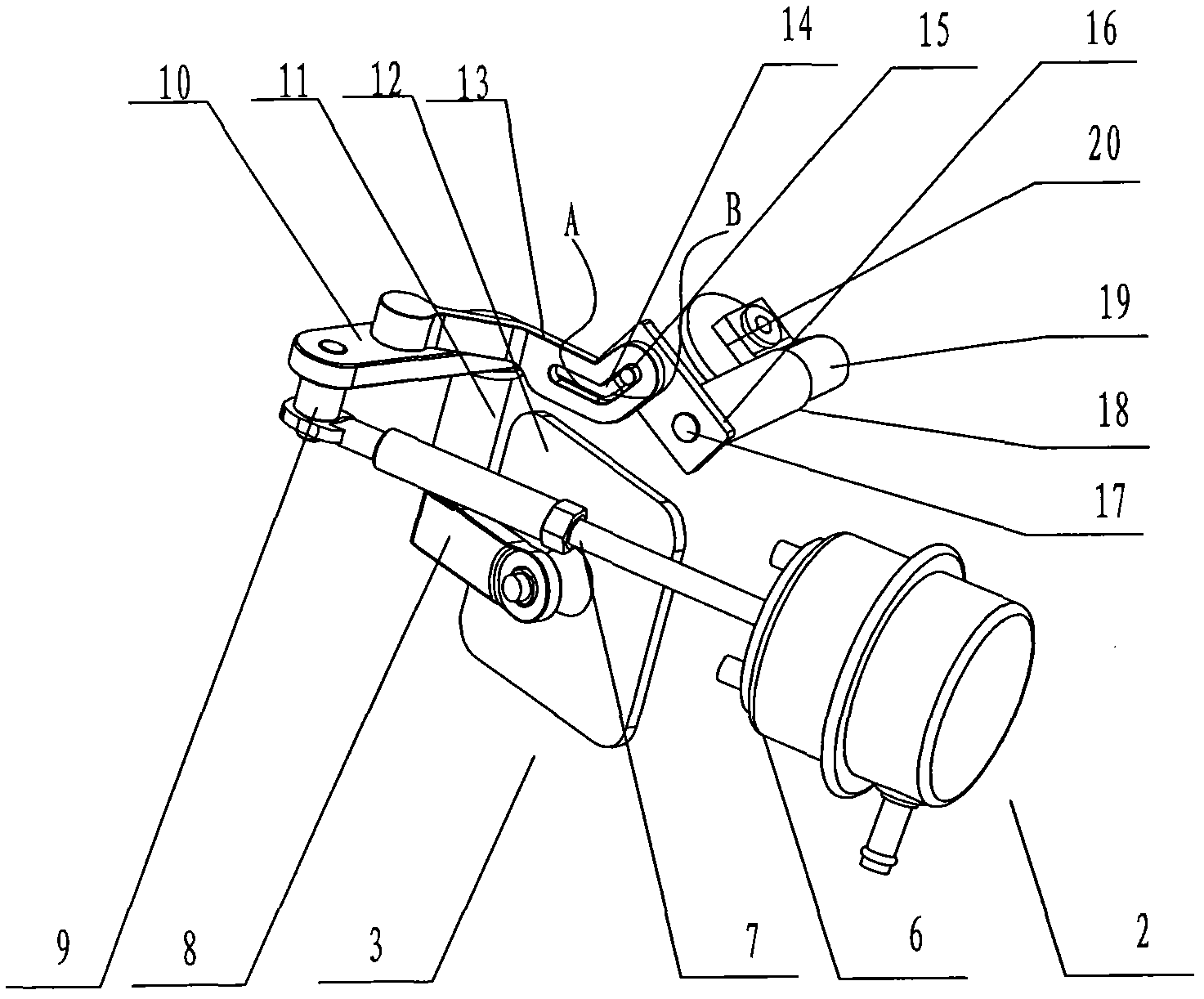

Rotation control type air exhaust pipe outlet area variable device

ActiveCN103089412AReasonable designSimple structureInternal combustion piston enginesIntake pressureMechanical design

A rotation control type air exhaust pipe outlet area variable device belongs to the technical field of mechanical design and comprises an air compressor, an engine, an air exhaust pipe, a turbine, a volume cavity, a rotation body, a spring, a connection pipe, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in the air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air exhaust pipe in front of the rotation plate is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air exhaust pipe in front of the rotation plate is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The rotation control type air exhaust pipe outlet area variable device is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

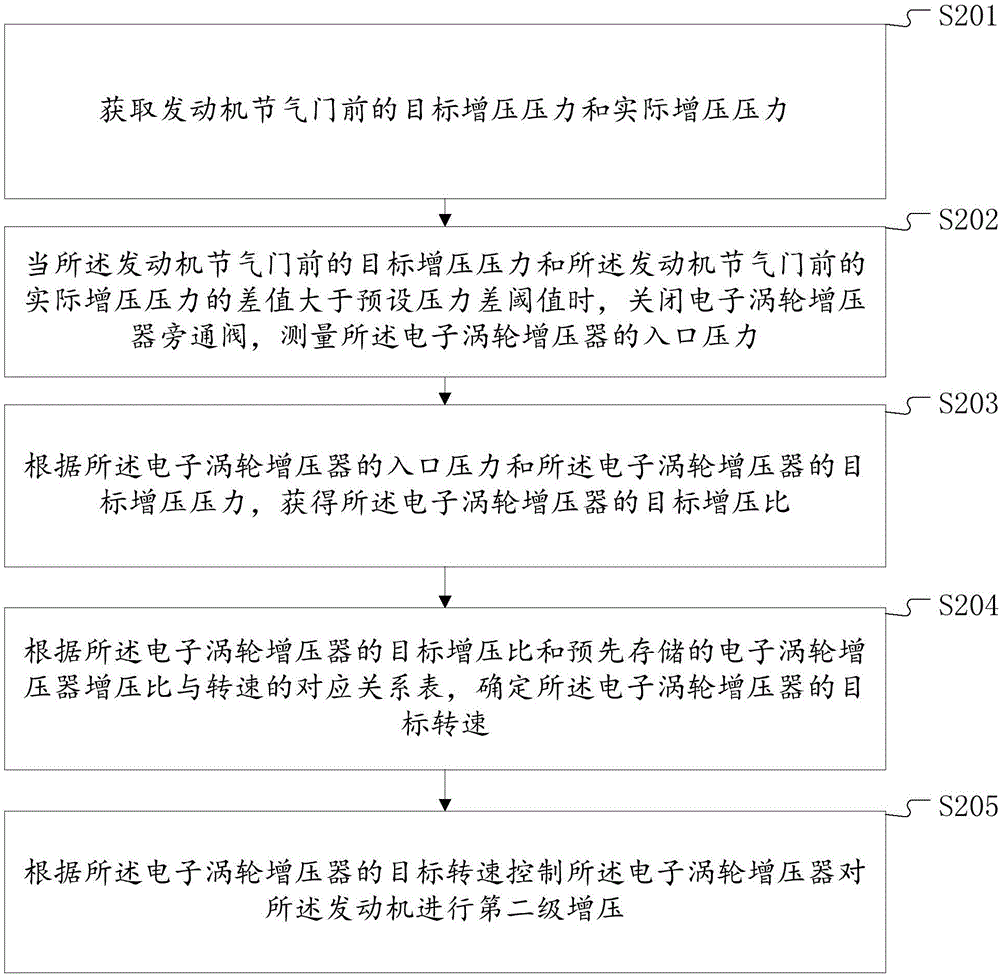

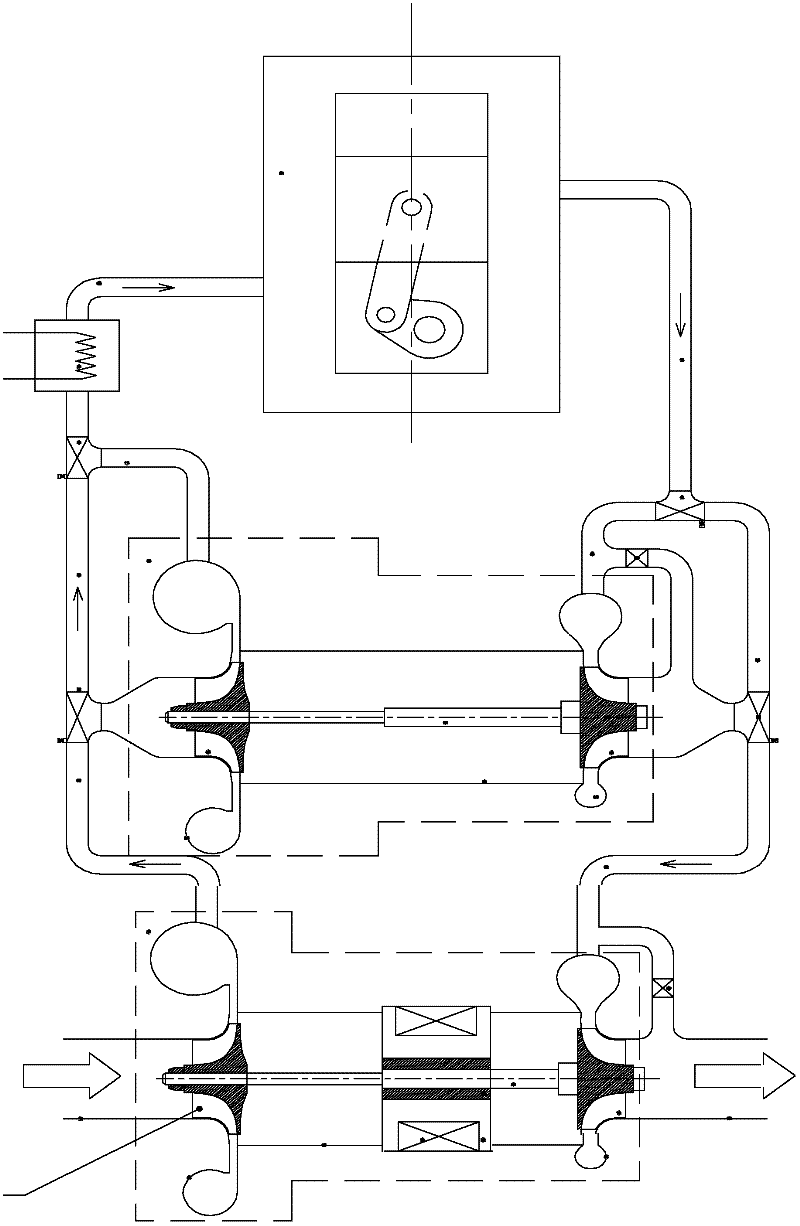

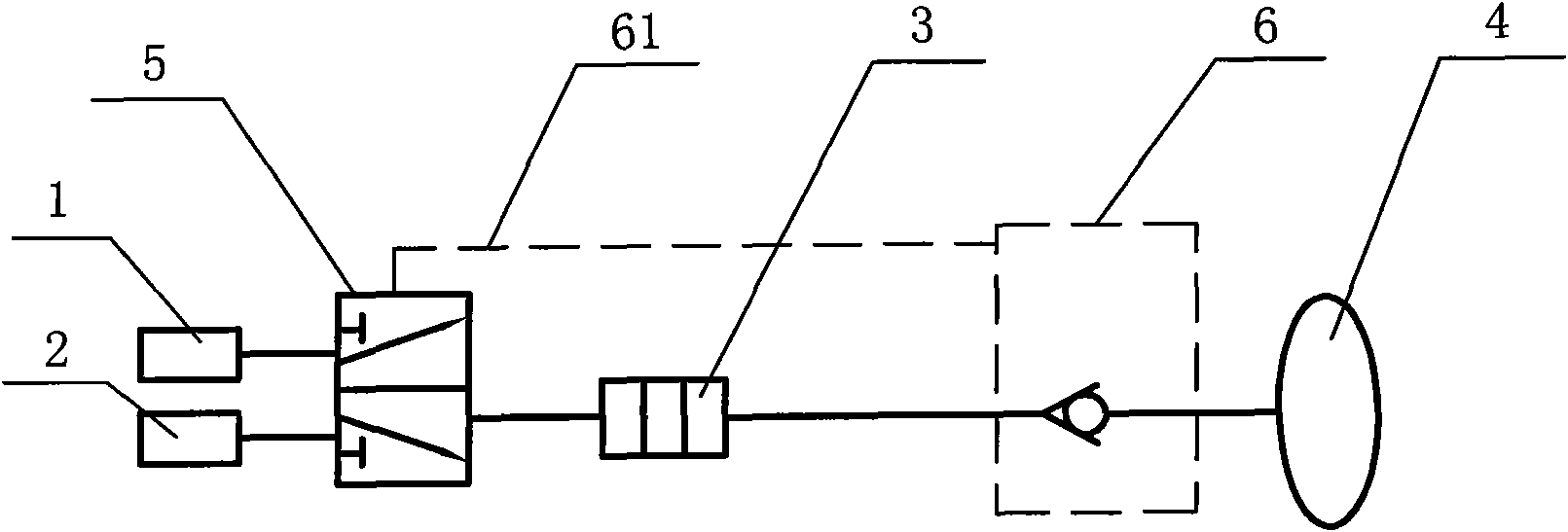

Electricity-auxiliary two-stage supercharging system capable of reusing exhaust gas

ActiveCN102230418AImprove acceleration performanceIncrease motivationInternal combustion piston enginesElectricityTurbocharger

The invention relates to an electricity-auxiliary two-stage supercharging system capable of reusing exhaust gas, belonging to the technical field of waste gas turbine supercharging. The electricity-auxiliary two-stage supercharging system specifically comprises the first-stage booster of an electricity-auxiliary turbine, the second-stage booster of a waste gas turbine, an electromagnetic three-way valve, an inlet and outlet pipeline system, a supercharging control circuit and an engine system. In the electricity-auxiliary two-stage supercharging system, the flexible control of opening and closing the three-way electromagnetic valve is used for further improving engine intake pressure by a second-stage supercharging system while solving the problem of waste gas turbine supercharging delaying, thereby realizing the high-pressure ratio of the engine supercharging, and improving the power and the emission performance of the engine under the whole working condition; the waste gas applying work in the second-stage booster of a waste gas turbine can be further utilized in the first-stage booster of an electricity-auxiliary turbine; and a storage battery is charged by power generation to fully utilize waste gas energy and effectively utilize fuel energy. Thus, the electricity-auxiliary two-stage supercharging system has an important energy-saving meaning.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

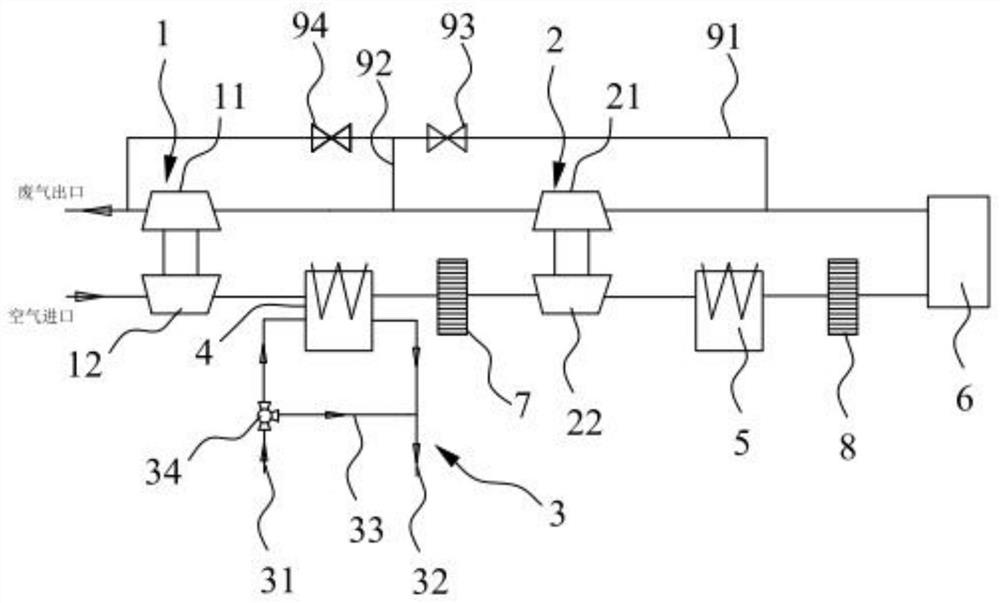

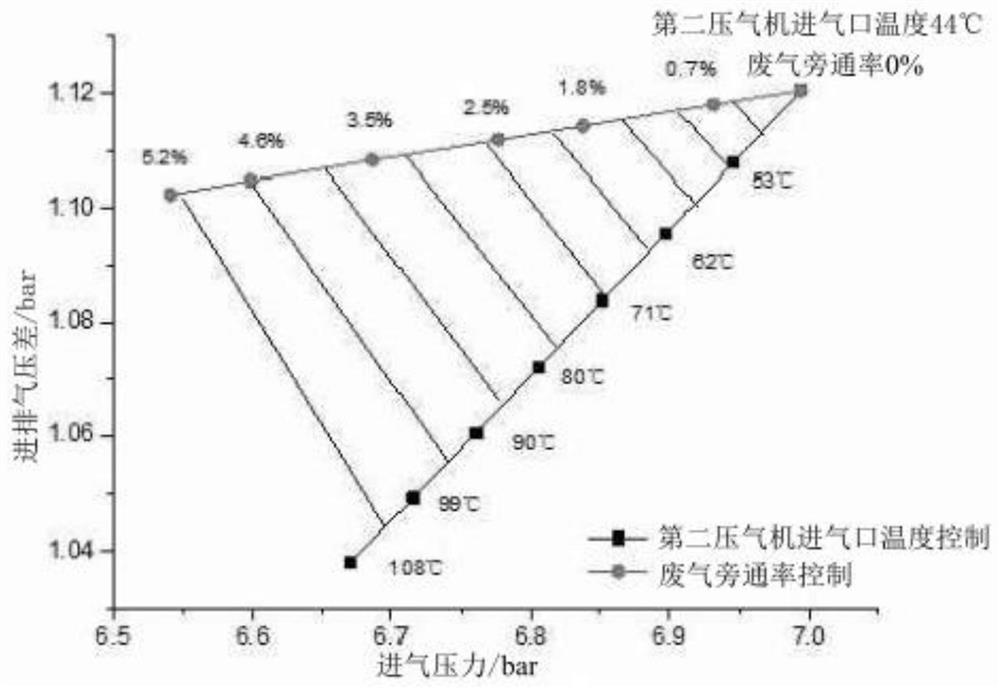

Two-stage supercharging system, engine and engine intake and exhaust pressure difference control method

PendingCN112832901AStay flammableReduce bypass openingInternal combustion piston enginesEngine componentsTurbochargerAir compressor

The invention relates to the technical field of engines, and particularly discloses a two-stage supercharging system, an engine and an engine intake and exhaust pressure difference control method. The two-stage supercharging system comprises a first turbocharger, a second turbocharger and an exhaust bypass device, wherein the first turbocharger comprises a first air compressor; the second turbocharger comprises a second air compressor; the first air compressor and the second air compressor are sequentially arranged between an air inlet and the engine at intervals; a first air cooler is arranged between the first air compressor and the second air compressor and provided with a temperature adjusting assembly; the exhaust bypass device is used for adjusting the amount of waste gas passing through the first turbocharger and / or the second turbocharger; a first pressure sensor and a second pressure sensor are used for detecting the intake pressure and the exhaust pressure of the engine correspondingly; and a controller controls the temperature adjusting assembly through data of the first pressure sensor and the second pressure sensor. By means of the arrangement, the intake pressure and the intake and exhaust pressure difference of the engine can be effectively, independently and accurately adjusted.

Owner:CSSC POWER INST CO LTD

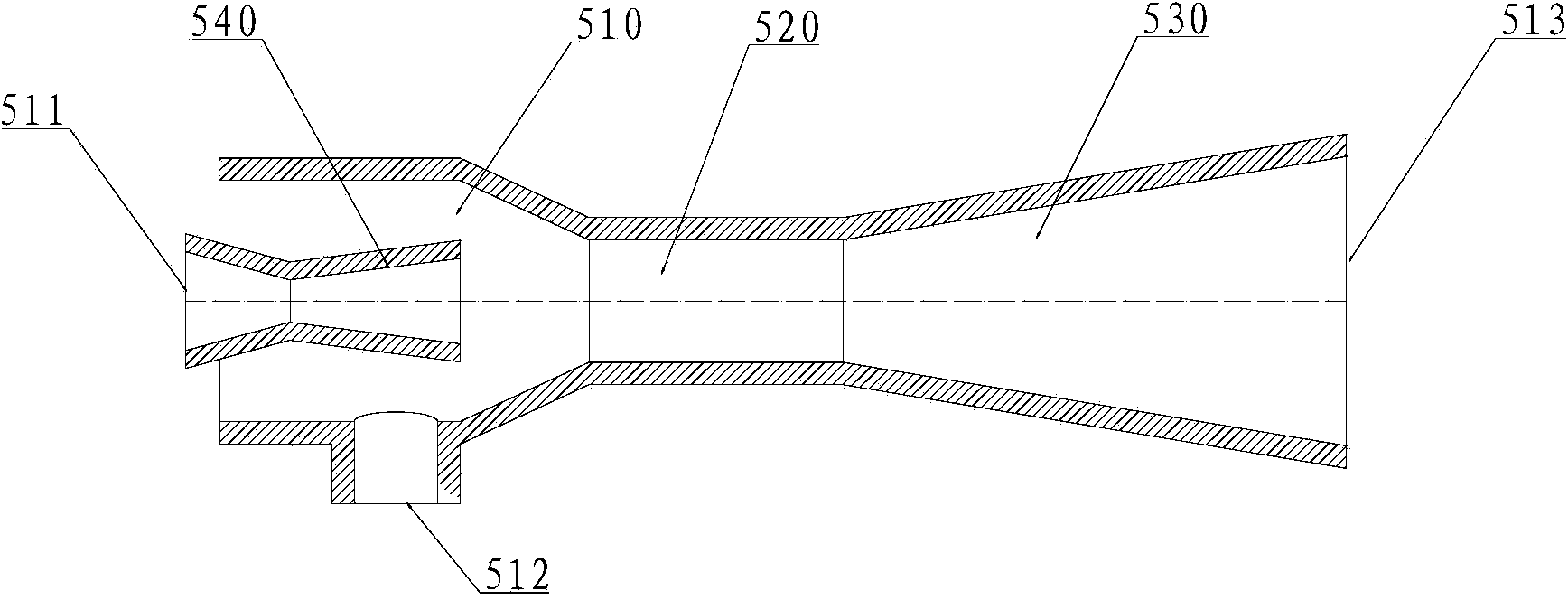

Rotating electrode preparing micro spherical metal powder and method of rotating electrode

The invention discloses a rotating electrode preparing micro spherical metal powder and a method of the rotating electrode. A plasma gun is composed of a Laval spraying pipe and a plasma gun head capable of conducting axial feeding, and a plasma gun inner gas way is formed between the plasma gun head and the Laval spraying pipe. The plasma gun head is connected with a gun head push rod, and a rotating electrode bar is connected with an electrode bar push rod. The axial relative position of the rotating electrode bar and the axial relative position of the plasma gun head are controlled and adjusted through the electrode bar push rod and the gun head push rod. A cylinder electrode bar is used as the raw material, and a plasma rotation electrode process is used for conducting the first time of atomization; supersonic speed high-temperature inert gas exerted to an electrode bar melting pool and injected by the adjustable plasma gun head is used for conducting the second time of atomization; centrifugal force of a centrifugal atomization mechanism overcomes tension on the surface of alloy liquid to serve as the upper limit of the atomization collected powder granularity; the efficiency of converting atomization energy into atomization drop surface energy is greatly improved; and the yield of micro powder smaller than 50 microns is greatly increased compared with traditional centrifugal atomization.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

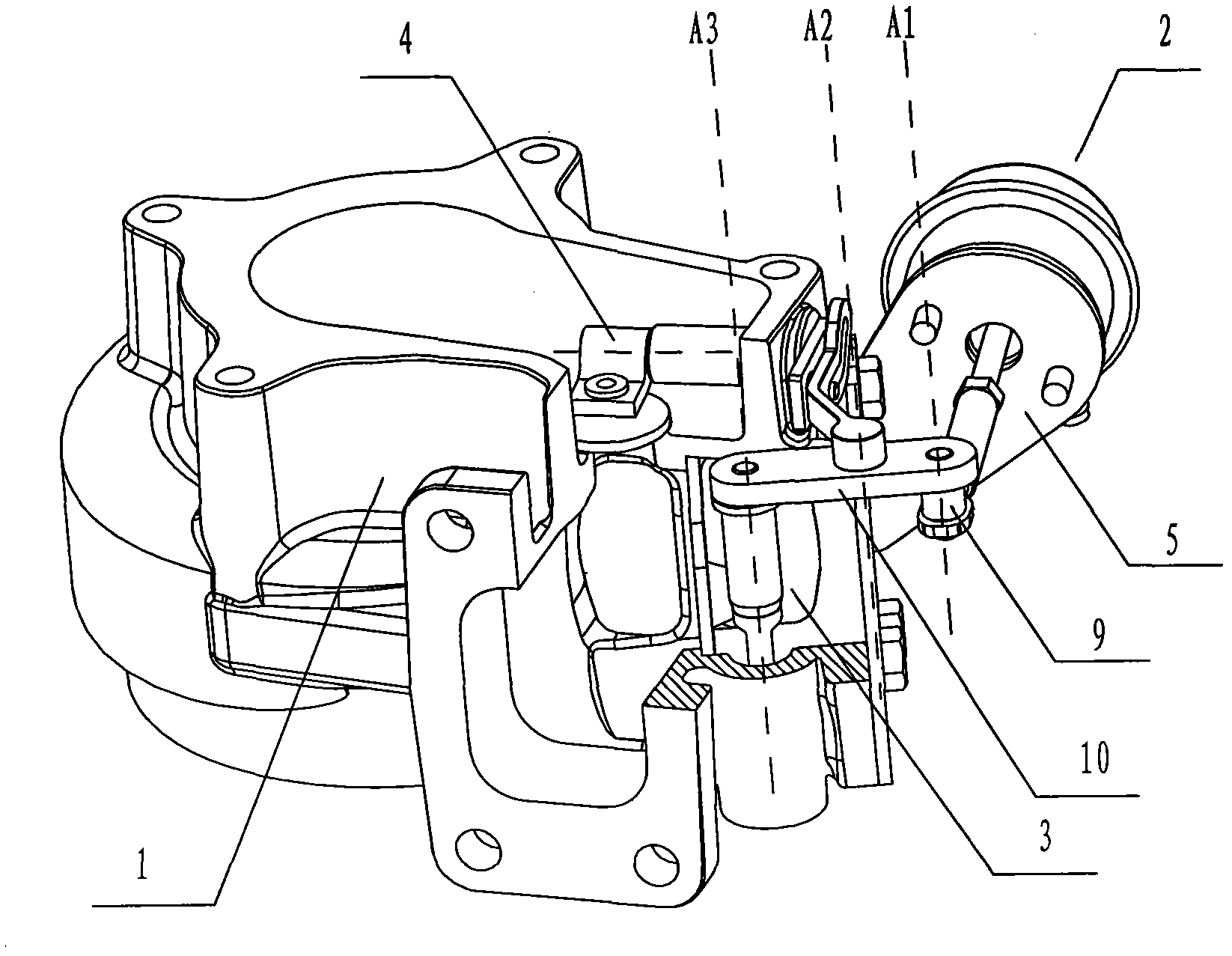

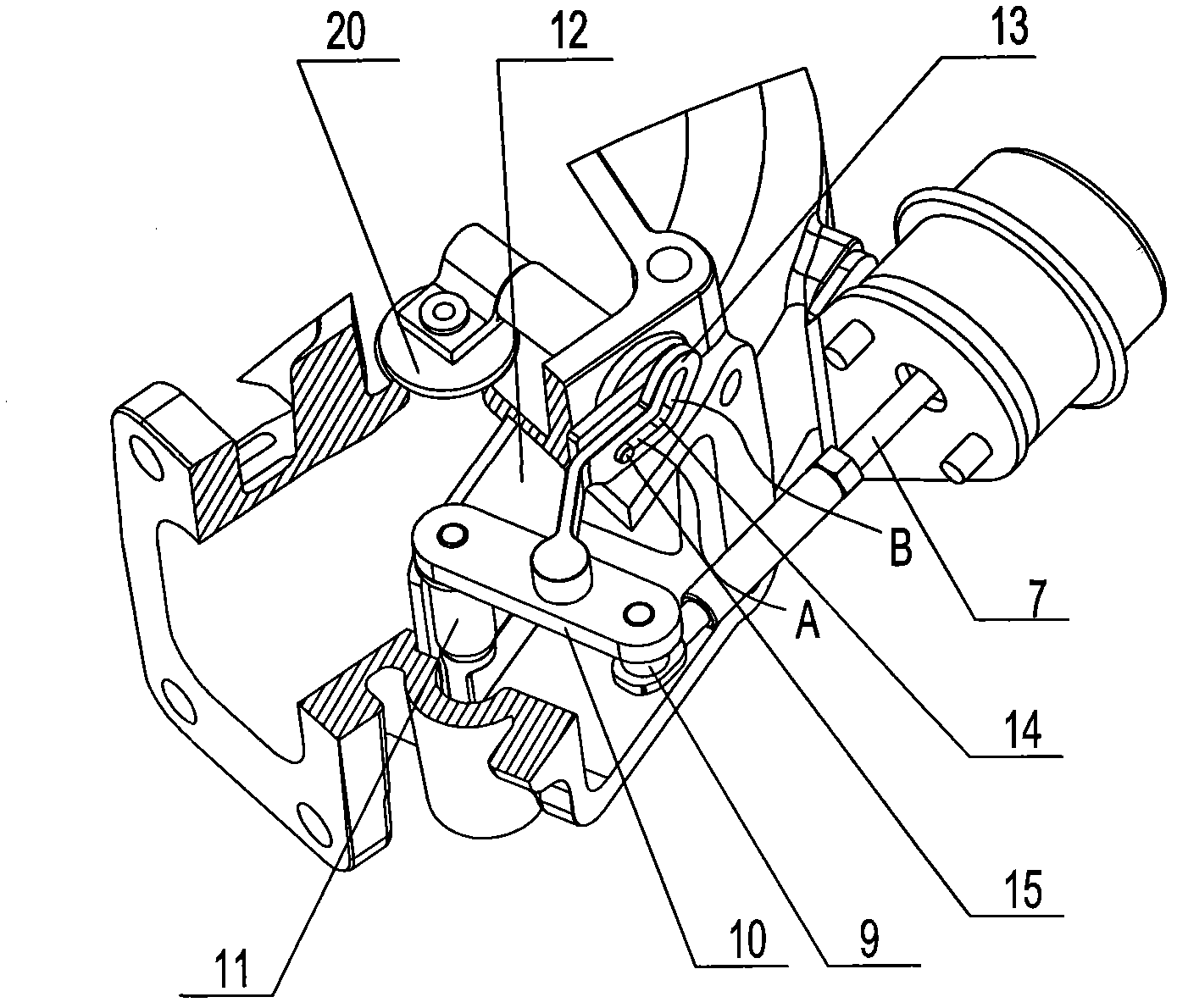

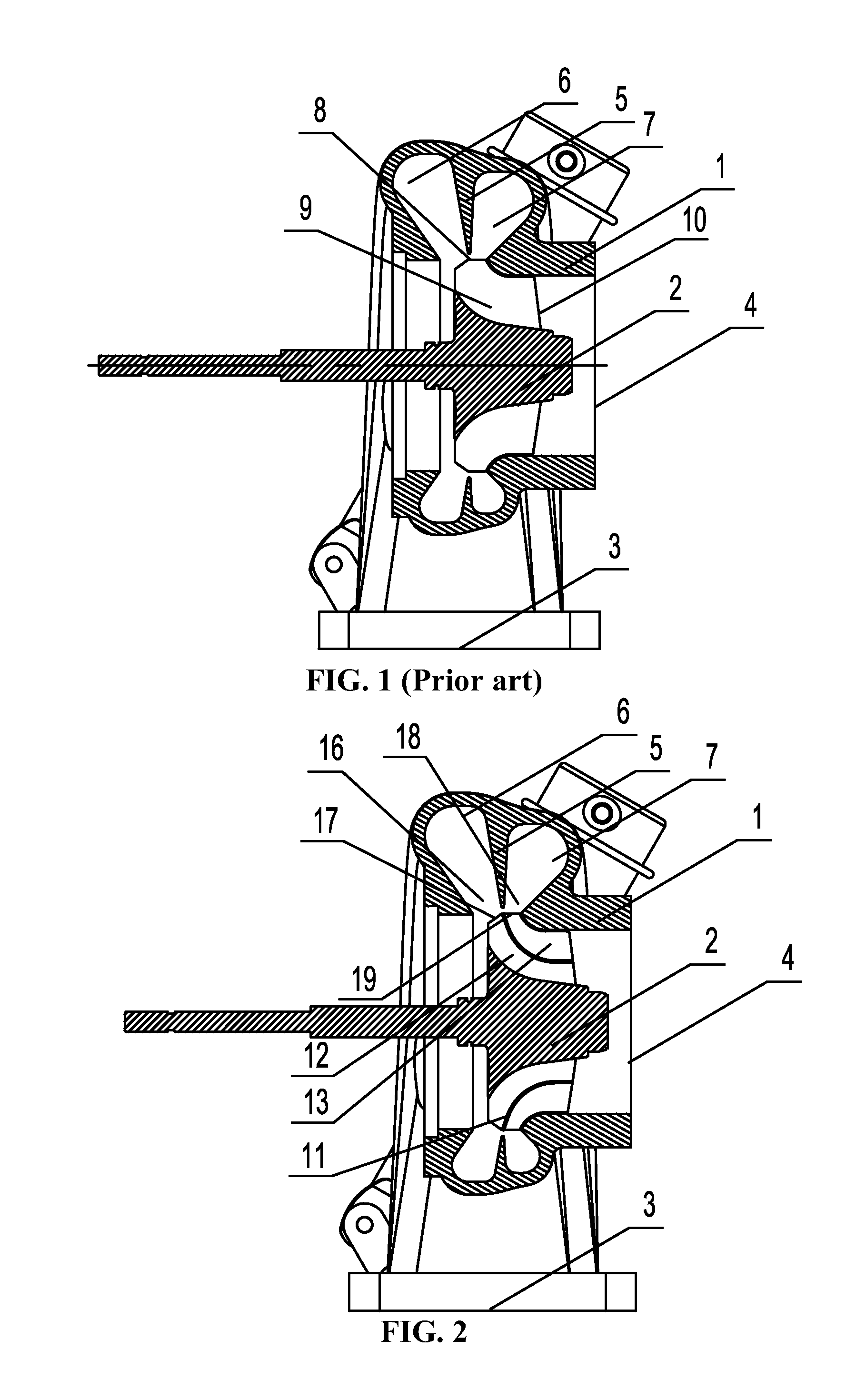

Air inlet regulating device of flow-passage-changeable turbine

ActiveCN102182544ARealize intake and exhaust pressure requirementsGuaranteed to workInternal combustion piston enginesTurbineInlet flow

The invention discloses an air inlet regulating device of a flow-passage-changeable turbine. The air inlet regulating device comprises a turbine shell, an executing device and an air inlet flow regulating device, wherein the executing device is in transmission connection with the air inlet flow regulating device; an exhaust gas bypass device is arranged on the turbine shell; and the executing device is in transmission connection with the exhaust gas bypass device. The executing device can control the air inlet flow regulating device and the exhaust gas bypass device at the same time, so as to select the air inlet flow passage of the flow-passage-changeable turbine and control the air inlet flow and the exhaust gas bypass flow; and on the premise of ensuring the high-efficiency work of the turbine, the section-changeable function of a supercharger is realized, and the requirement for the whole-working-condition pressurization of an engine can be met.

Owner:康跃科技(山东)有限公司

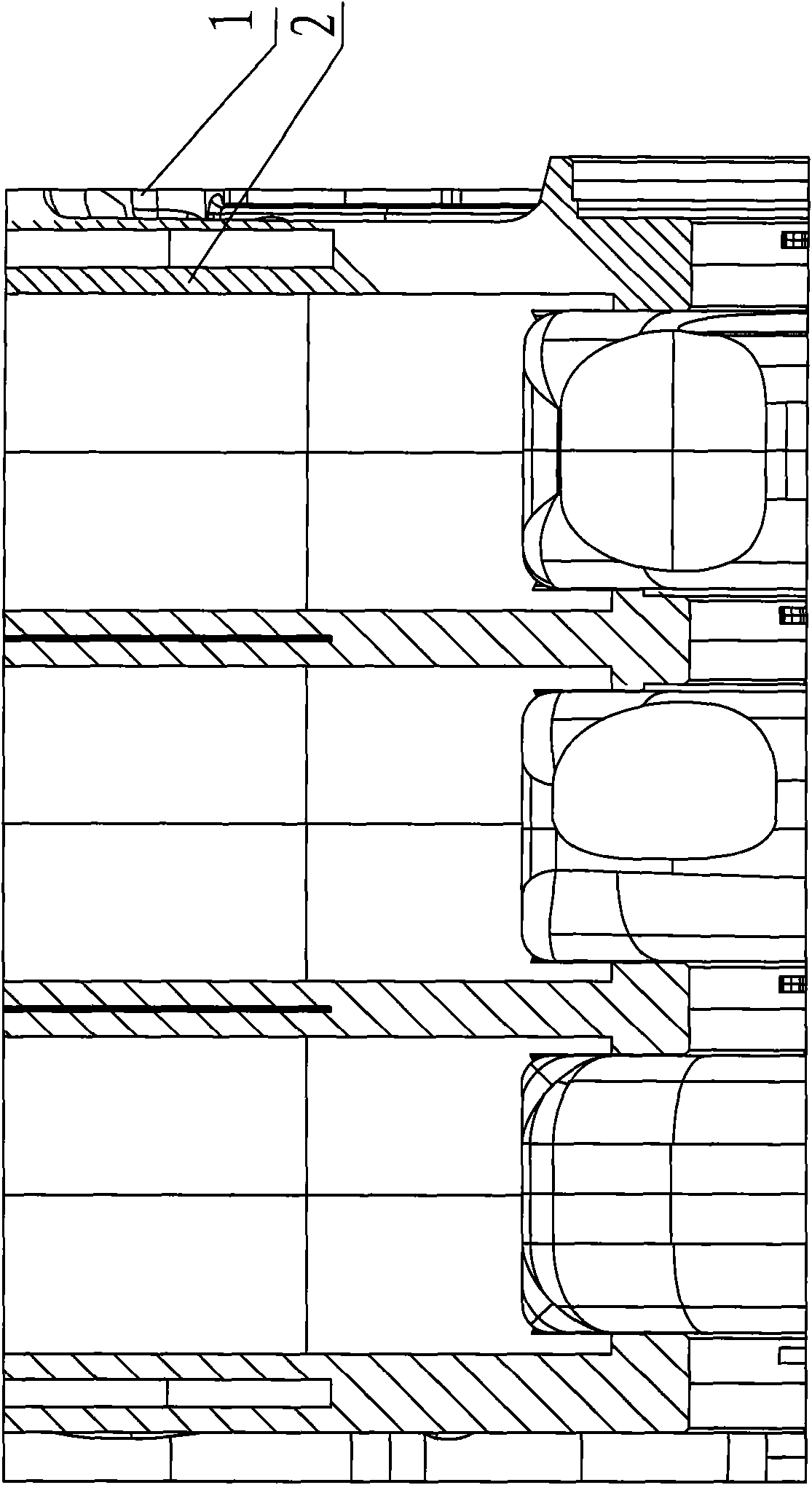

Petrol engine with turbo charging

InactiveCN101608572AIncrease intake pressureIncrease output powerValve arrangementsInternal combustion piston enginesExhaust valveCombustion chamber

The invention relates to a petrol engine with turbo charging, which comprises a cylinder body, a cylinder sleeve, an intake valve, a spark plug hole, an exhaust valve, a combustion chamber, a crankshaft, a connecting rod, a piston, an intake manifold, an exhaust manifold and a turbo charging device. The petrol engine also comprises a twin cam shaft valve timing adjusting structure arranged above a cylinder head; the twin cam shaft valve timing adjusting structure ensures that an admission cam shaft and an exhaust cam shaft is in transmission connection with the crankshaft through a timing chain; and the twin cam shaft valve timing adjusting structure is used for continuously and changeably adjusting the opening times of the intake valve and the exhaust valve of the combustion chamber, therefore, the fuel utilization and the rotation speed and the output power of the engine can be improved. The turbo charging device can increase the intake pressure of the engine, and quicken the combustion of the fuel of the engine, so as to enable the combustion to be more sufficient, therefore, the output power of the engine is improved, and the exhaust emissions are reduced. A three-way catalysis device is arranged on the exhaust manifold, therefore, the harmful gas emissions can be reduced.

Owner:苏州益方动力机械有限公司

Energy-saving supercharging device of automobile air compressor

InactiveCN101890927AReduce heat loadImprove air intake efficiencyPump controlElectric/fluid circuitAir filterTurbocharger

The invention discloses an energy-saving supercharging device of an automobile air compressor. The device comprises an air filter, a turbine supercharger, an air compressor and an air storage tank, wherein the air compressor is communicated with an air inlet cavity of an engine through an air inlet and communicated with the air storage tank through an exhaust port; the air inlet of the air compressor is provided with an energy-saving reversing valve which is connected with the air filter and the turbine supercharger respectively; and an unloading valve with a pressure feedback signal is arranged between the exhaust port of the air compressor and the air storage tank. Under the action of the energy-saving reversing valve, when the air compressor is no-load, the air enters the air compressor through a natural air inlet pipeline so that the air exhausted to the atmosphere does not consume the supercharged gas of the engine and the heat load of the air compressor is reduced; and when in full-load work, the compressed air from a braking pressure control air port pushes a power piston to move rightwards, then the natural air inlet is closed, a supercharged air inlet is connected, and the air compressor takes air from the turbine supercharger so as to improve the air inlet efficiency of the air compressor.

Owner:QINGDAO ZHIYUAN AUTO PARTS

Multi-nozzle type variable flow rate supercharging device

InactiveCN102094704AMeet low speed performanceIncrease intake pressureCombustion enginesStatorsEngineeringControl mode

The invention discloses a multi-nozzle type variable flow rate supercharging device which comprises a volute casing, wherein the volute casing is internally provided with an air inlet and a volute air inlet passageway which is communicated with the air inlet, and the volute air inlet passageway is internally provided at least one intermediate baffle plate. The multi-nozzle type variable flow rate supercharging device provided by the invention has a simple air inlet regulating and controlling mechanism, the control mode is easy to realize, the reliability is high, and the problems of the existing vane type variable turbocharger in the aspects of reliability and efficiency and too low efficiency of a tongue shape baffle plate variable cross section charger are solved effectively.

Owner:KANGYUE TECH

Air conditioning system

InactiveCN104110910ALow flow resistanceIncrease intake pressureMechanical apparatusFluid circulation arrangementVapor–liquid separatorEngineering

The invention discloses an air conditioning system. The air conditioning system comprises a compressor, a first four-way reversing valve, an outdoor unit, a second four-way reversing valve, an ejector, a gas-liquid separator, a throttling valve and an indoor unit. The four pipe openings of the first four-way reversing valve are sequentially connected with one end of the outdoor unit, the exhaust port of the compressor, one end of the indoor unit and the ejection flow inlet of the ejector. The four pipe openings of the second four-way reversing valve are sequentially connected with the other end of the indoor unit, the outlet of the throttling valve, the other end of the outdoor unit and the work flow inlet of the ejector. The inlet of the gas-liquid separator is connected with the outlet of the ejector, the first outlet of the gas-liquid separator is connected with the air suction port of the compressor, and the second outlet of the gas-liquid separator is connected with the inlet of the throttling valve. Under a heating or refrigerating mode, refrigerating fluid can flow through the ejector, and therefore the COP value of the system is increased. The air conditioning system is good in heat exchange performance and easy to operate and realize, the error-tolerant rate of the system is increased, and the cost of the system is lowered.

Owner:GREE ELECTRIC APPLIANCES INC

Low-pressure exhaust gas recirculation (EGR) system of vehicle engine

InactiveCN106837613AIncrease intake speedReduced responsivenessExhaust gas recirculationMachines/enginesExhaust fumesAutomotive engineering

The invention provides a low-pressure exhaust gas recirculation (EGR) system of a vehicle engine and relates to an EGR system. The low-pressure EGR system of the vehicle engine passes through the engine, wherein a gas inlet and a gas outlet are formed in the engine, and the system comprises a gas inlet pipeline, a gas outlet pipeline, an EGR pipeline and an electronic supercharger. The gas inlet pipeline is arranged in front of the gas inlet and used for gas inflowing of the engine. The gas outlet pipeline is arranged behind the gas outlet and used for exhaust gas discharging of the engine. The EGR pipeline is connected between the gas inlet pipeline and the gas outlet pipeline. The electronic supercharger is arranged on one side of the gas inlet pipeline through a pipeline. According to the low-pressure EGR system of the vehicle engine, the electronic supercharger is additionally arranged on a gas inlet system, and response characteristics of the engine are improved under the working conditions such as cold starting, rapid accelerating, a low rotating speed and a low load accordingly. After the electronic supercharger is applied to the engine, natural aspirated working conditions, such as cold starting, the low rotating speed and the low load, of the engine are made up, the gas inlet speed of the engine is increased, and the response speed is reduced.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

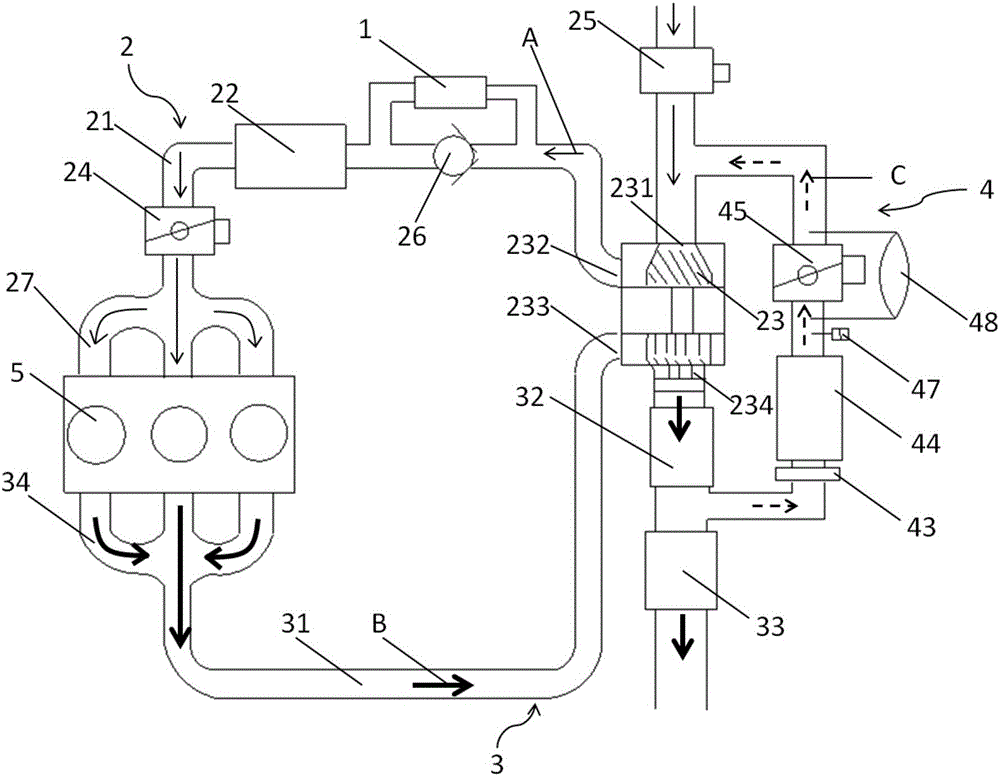

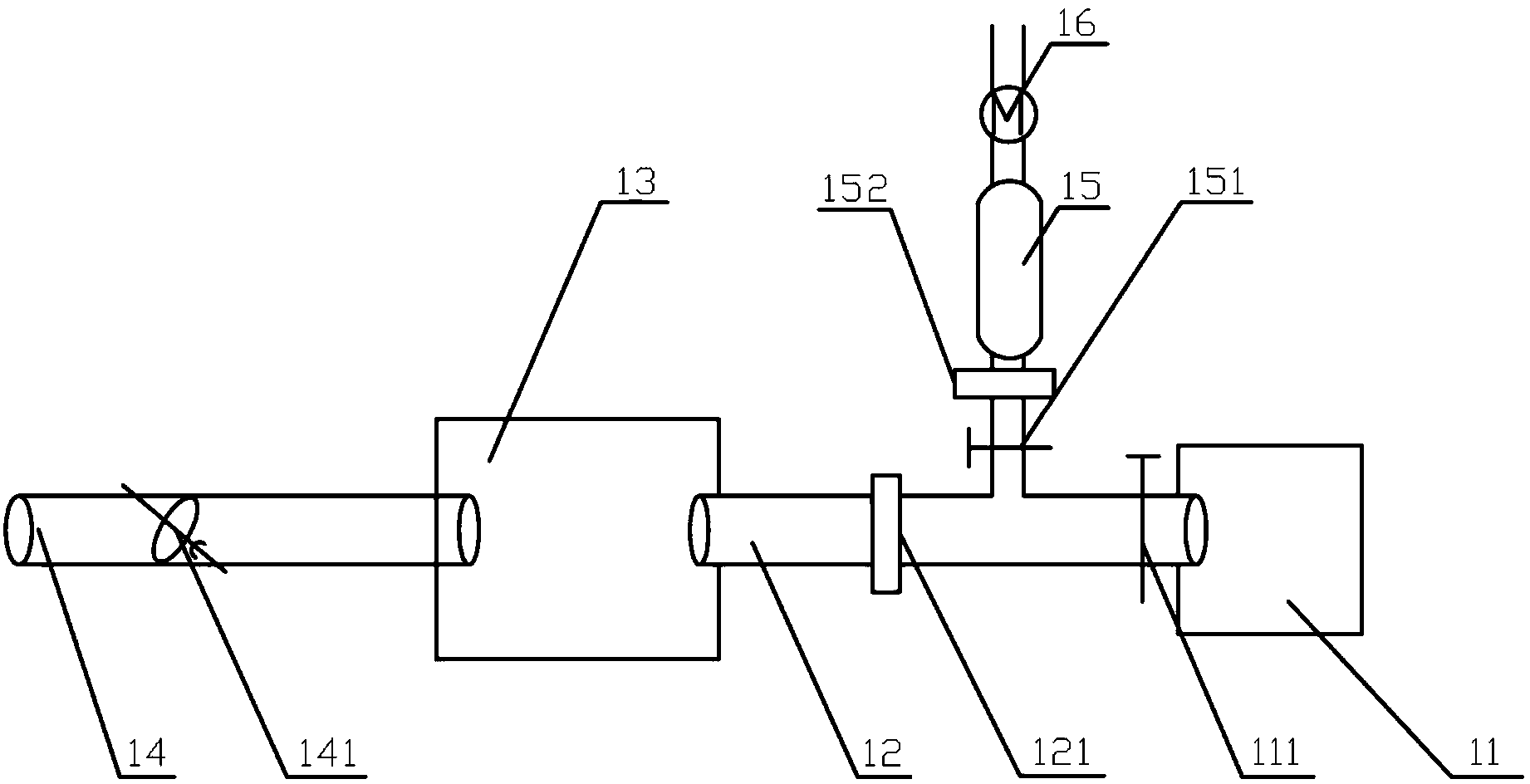

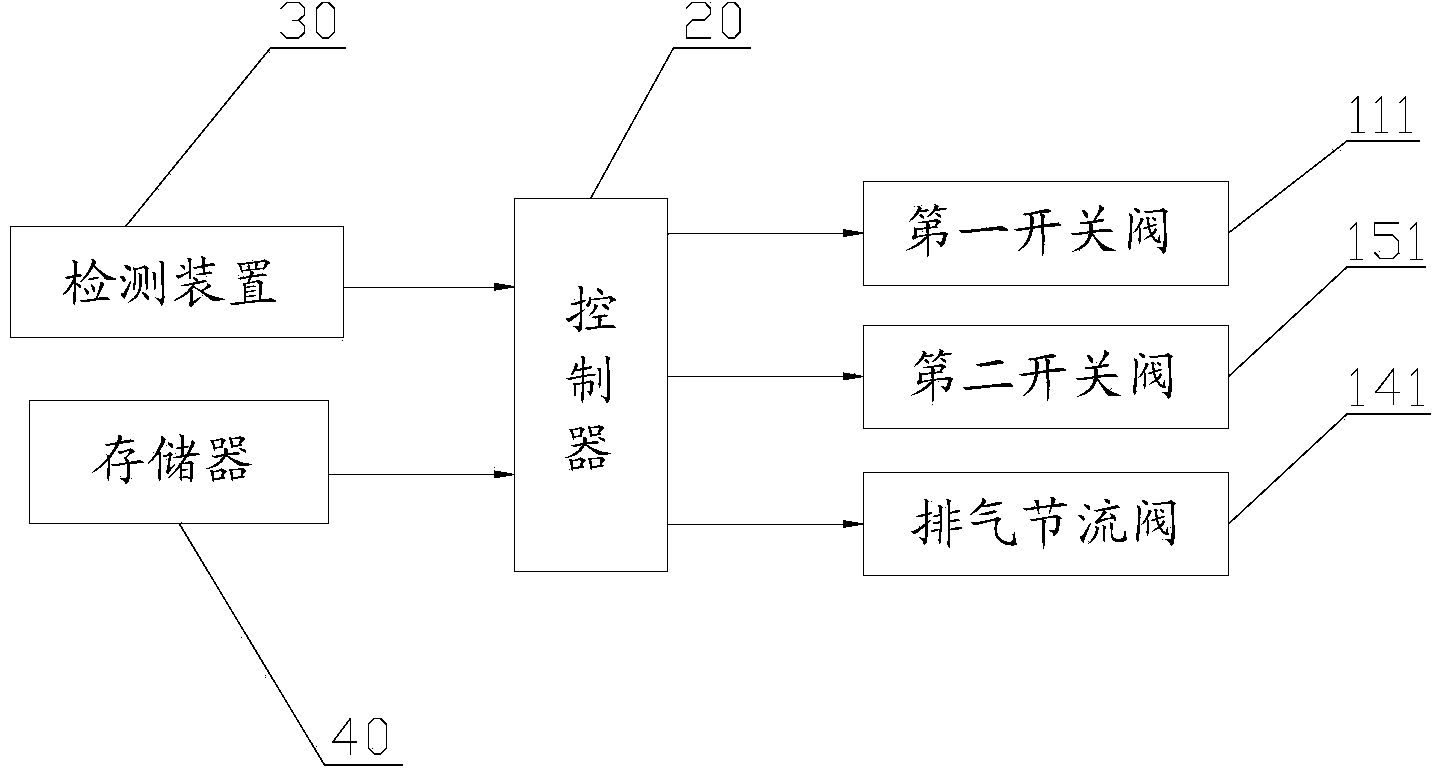

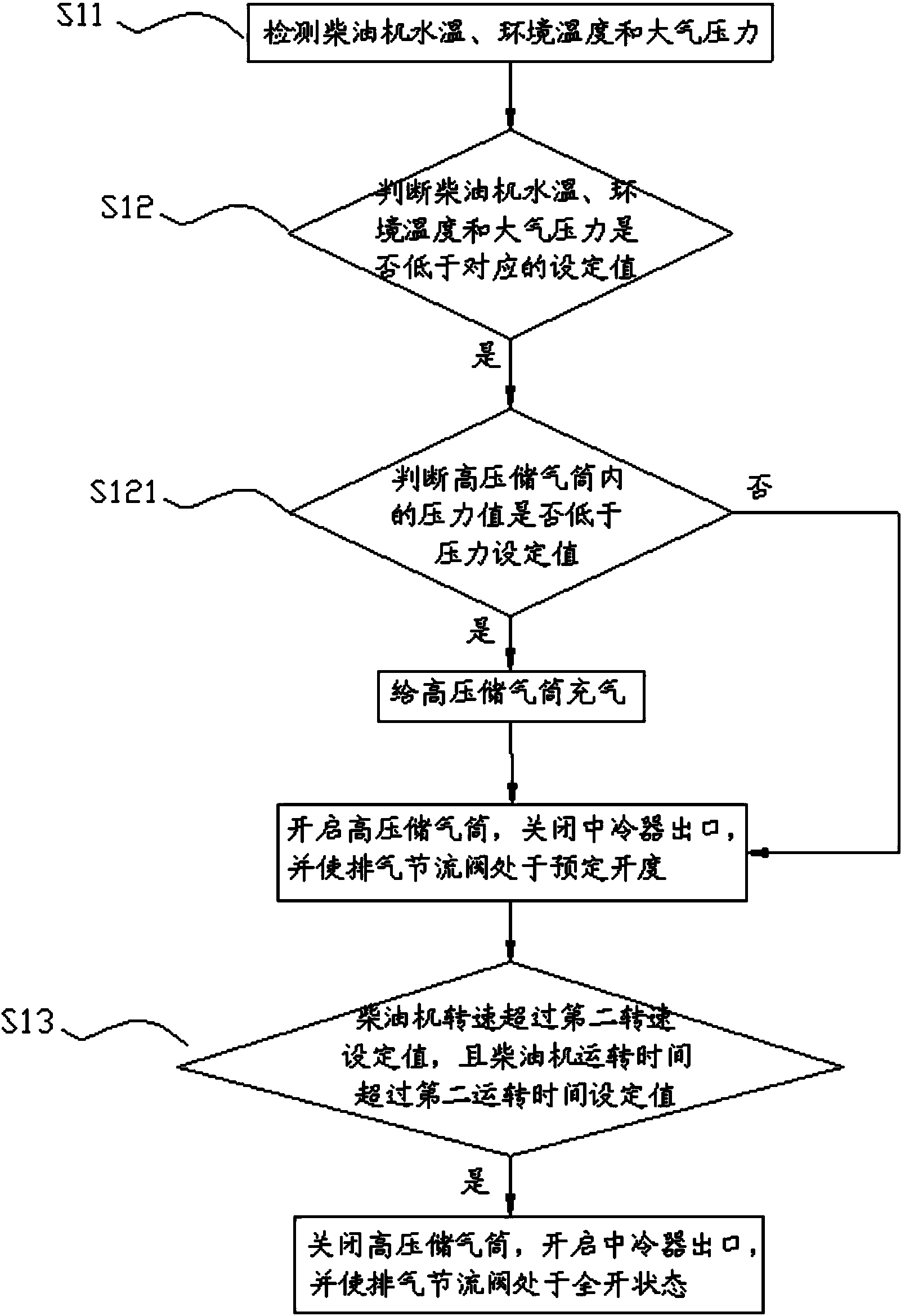

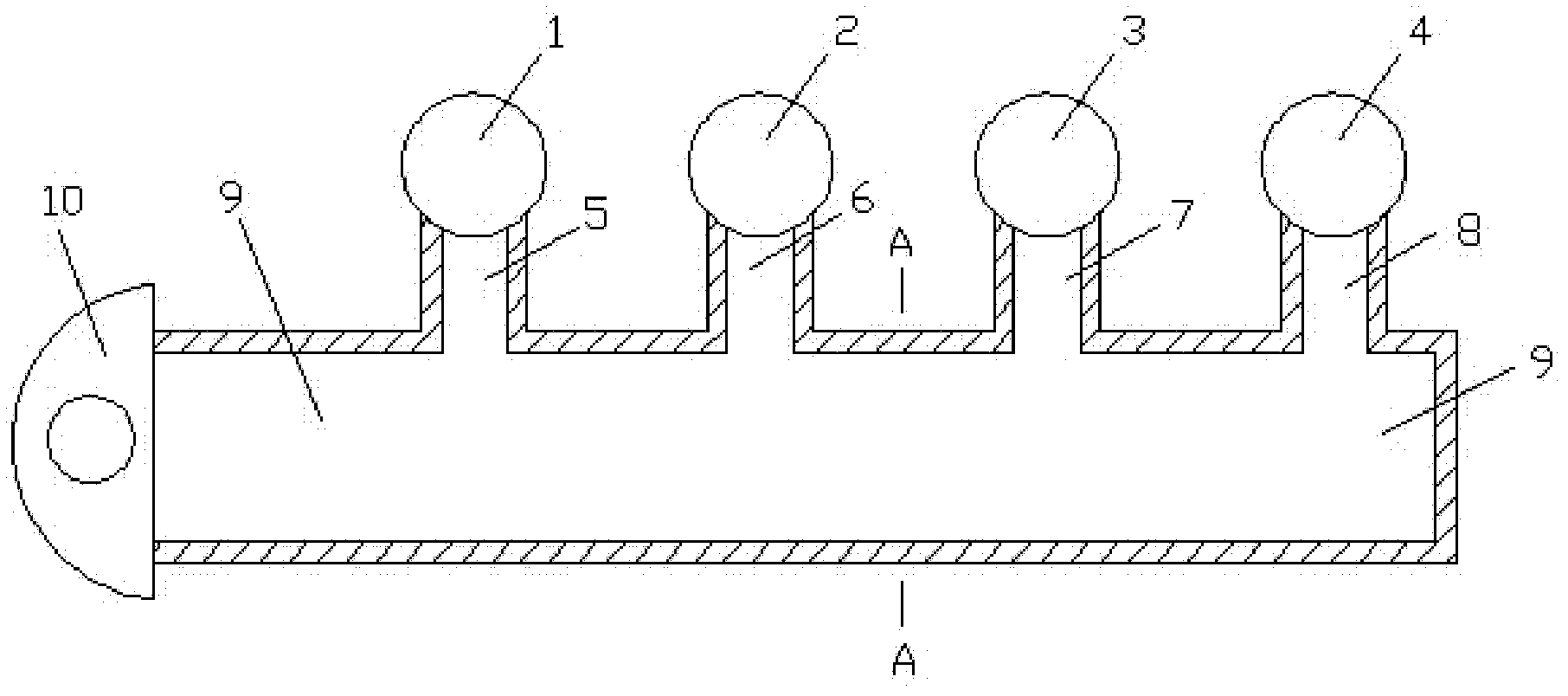

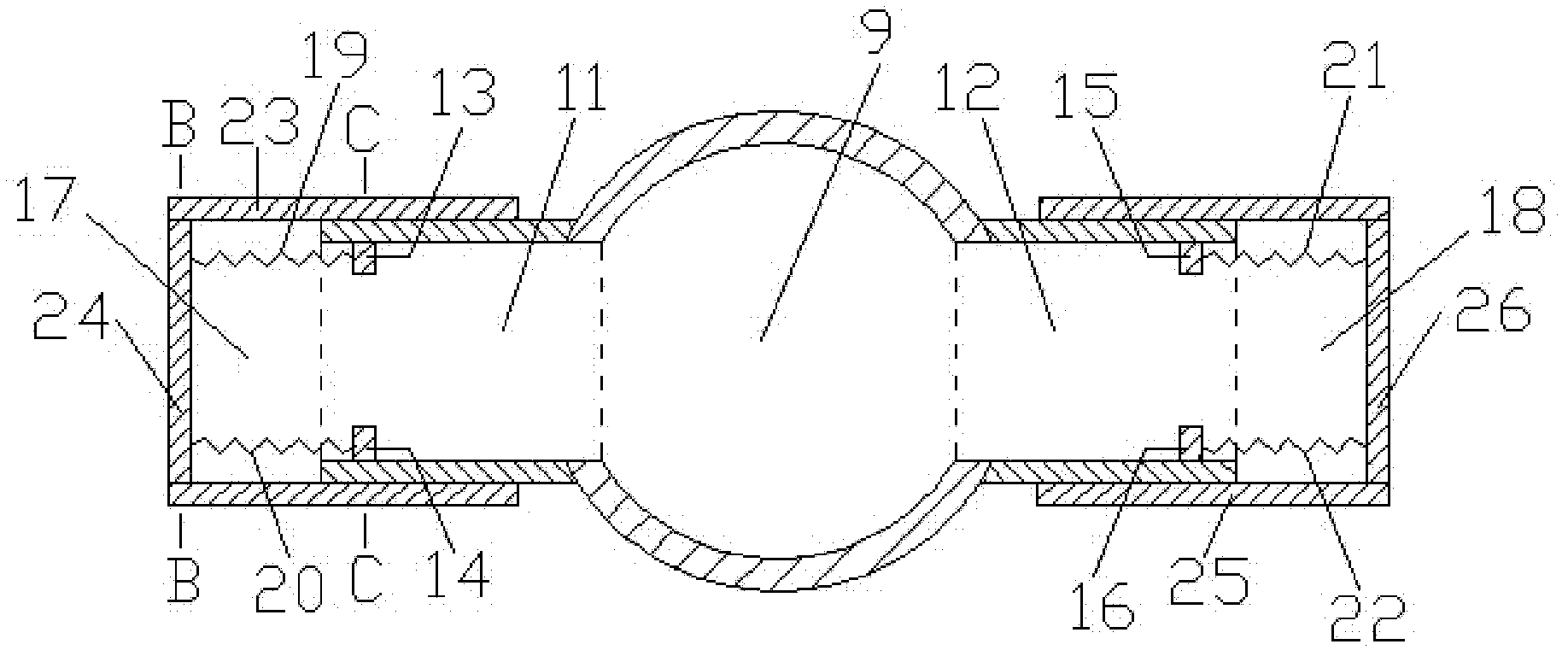

Diesel engine cold start control system and method

ActiveCN103758673AIncrease air intakeImprove cold start success rateElectric motor startersMachines/enginesControl systemAtmospheric air

The invention discloses a diesel engine cold start control system and method. The system comprises a high-pressure gas holder, a detector, a storage device, and a controller; the high-pressure gas holder connected with an intake pip is capable of filling the intake pipe with gas; the detector is used for detecting diesel engine water temperature, ambient temperature and atmospheric pressure; the storage device is used for pre-storing a diesel engine water temperature set value, an ambient temperature set value and an atmospheric pressure set value. The controller is used for receiving a cold start signal; when judging the measured diesel engine water temperature, ambient temperature and atmospheric pressure are lower than the corresponding set values; the controller outputs a signal of opening the high-pressure gas holder, a signal of closing an outlet of an intercooler and a signal of opening an exhaust throttle valve under a preset opening; when judging cold start is finished, the controller outputs a signal of closing the high-pressure gas holder, a signal of opening the outlet of the intercooler and a signal of fully opening of the exhaust throttle valve. When the diesel engine is cold-started in a cold plateau area, the high-pressure gas holder is used to supply gas; intake for cold start of the diesel engine is increased, so that the rate of successfully cold-starting the diesel engine in the cold plateau area is increased.

Owner:WEICHAI POWER CO LTD

Turbocharging system with continuously adjustable volume of exhaust pipe

InactiveCN102383916AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesCombustionLow speed

The invention discloses a turbocharging system with continuously adjustable volume of an exhaust pipe, belonging to the technical field of internal combustion engines. The turbocharging system comprises a cylinder, the exhaust pipe, a turbine, a volume cavity, a sleeve body, a baffle and an elastic part, wherein an opened end of the volume cavity is connected with the side wall surface of the exhaust pipe, and the other opened end of the volume cavity extends into an opened end of the sleeve body; the baffle is arranged in the volume cavity; the elastic part is arranged between the baffle andthe rear wall of the sleeve body; when an engine is in a low-speed working condition, the rear wall of the sleeve body moves towards the direction close to the baffle, the volume of the exhaust pipe is relatively smaller, the pulse energy can be fully utilized, the gas inlet pressure of the engine is higher and the overall performance of the engine is better; and when the engine is in a high-speed working condition, the rear wall of the sleeve body moves towards the direction far away from the baffle, the volume of the exhaust pipe is relatively larger, the pump gas loss is less, and the overall performance of the engine is better. The turbocharging system is reasonable in design and simple in structure, and one of the turbocharging system provided by the turbine is applicable to the turbine inlet.

Owner:CHUZHOU DASHI AUTO PARTS

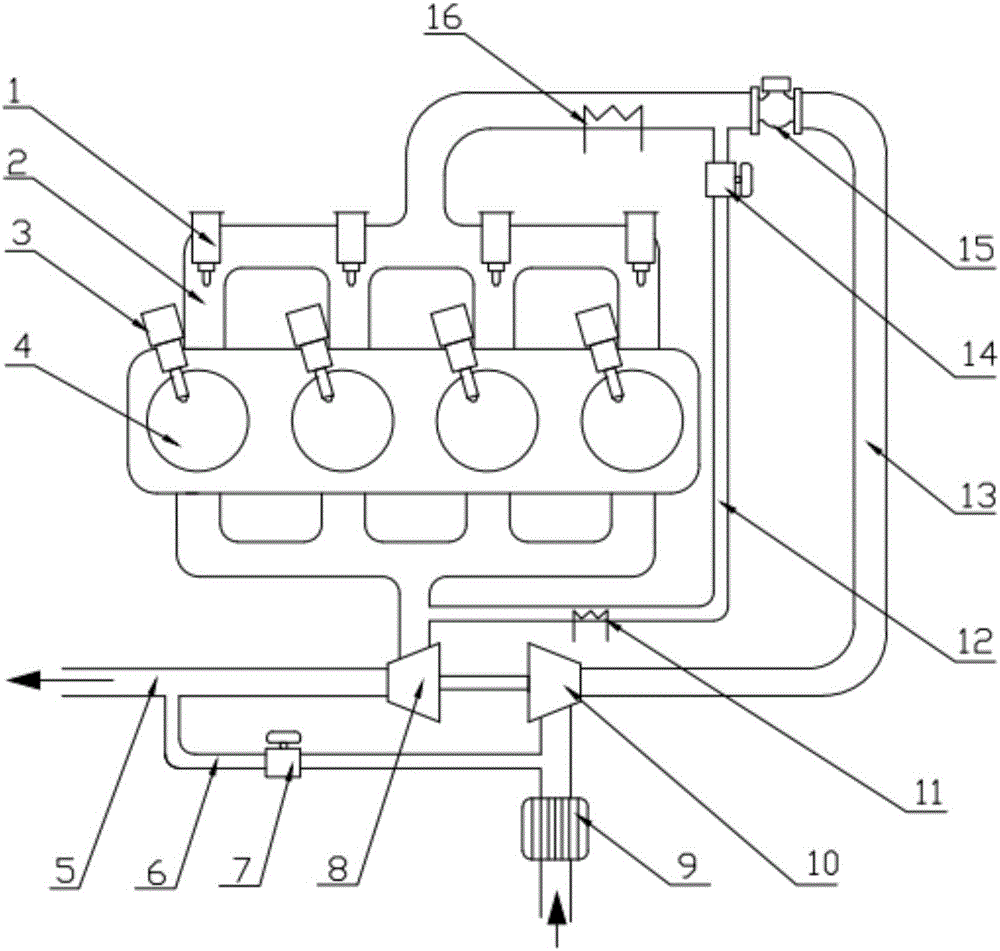

Method for flexibly controlling engine combustion mode

ActiveCN106762294AImprove consumption rateEnsure normal dischargeFuel injection apparatusMachines/enginesCombustionLow load

The invention discloses a method for flexibly controlling an engine combustion mode. Engine speed signals and throttle position signals are read by an electronic control unit to judge the engine operation load according to the read signals; if under the low load condition, an diesel injector is controlled for early injection to form PCCI combustion mode in a cylinder; if under the moderate load condition, the diesel injector is controlled for injection in advance twice, and high-pressure EGR is performed to form HP-EHPCC combustion mode; if under the medium-to-high load condition, the diesel injector is controlled for injection in advance twice, and low-pressure EGR is performed to form LP-EHPCC combustion mode; if under the high load condition, the diesel injector is controlled for delayed injection once, and the low-pressure EGR is performed to form LP-LHPCC combustion mode. High-efficiency clean combustion within a wide load range is implemented through combination of different combustion modes under different working conditions.

Owner:TIANJIN UNIV

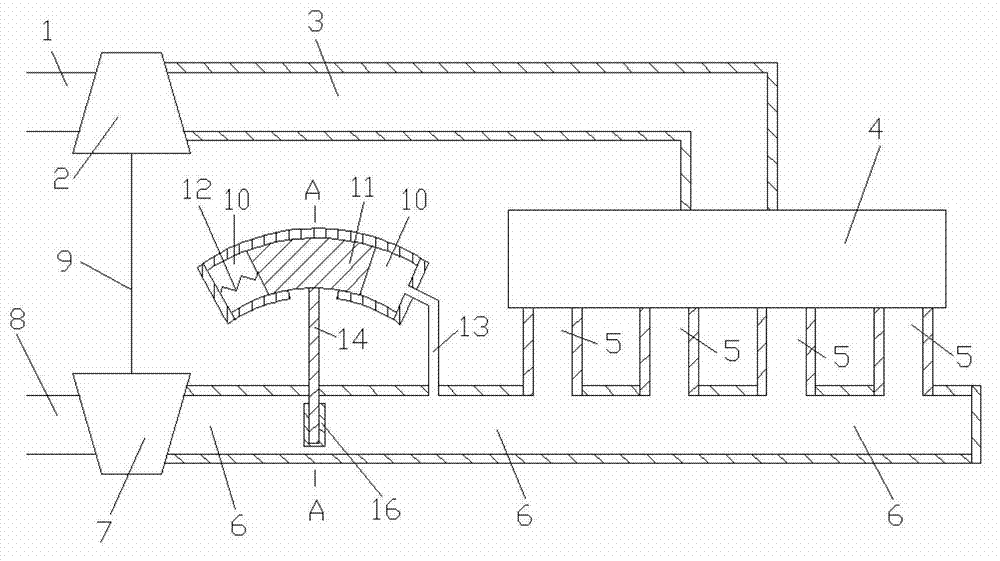

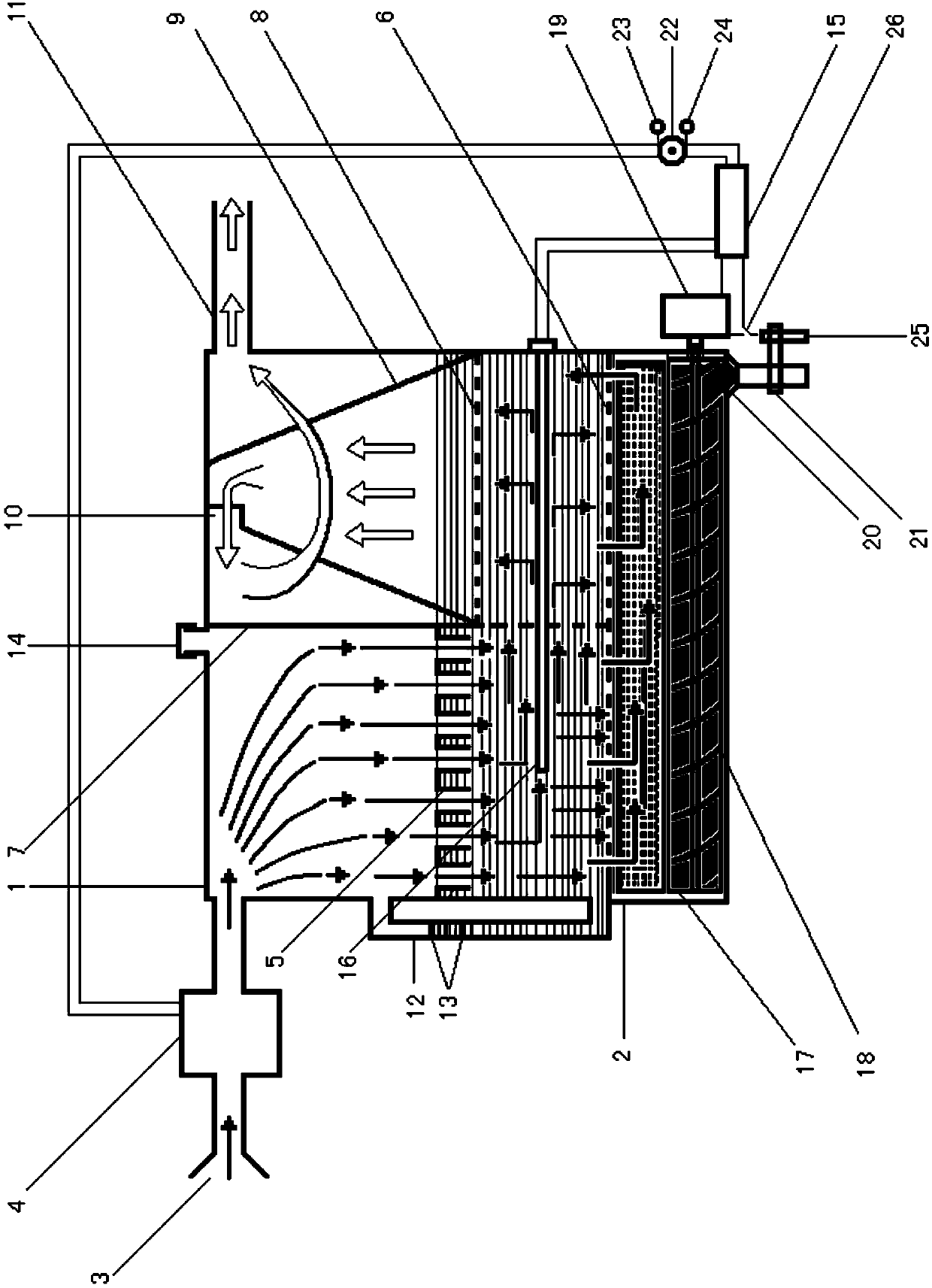

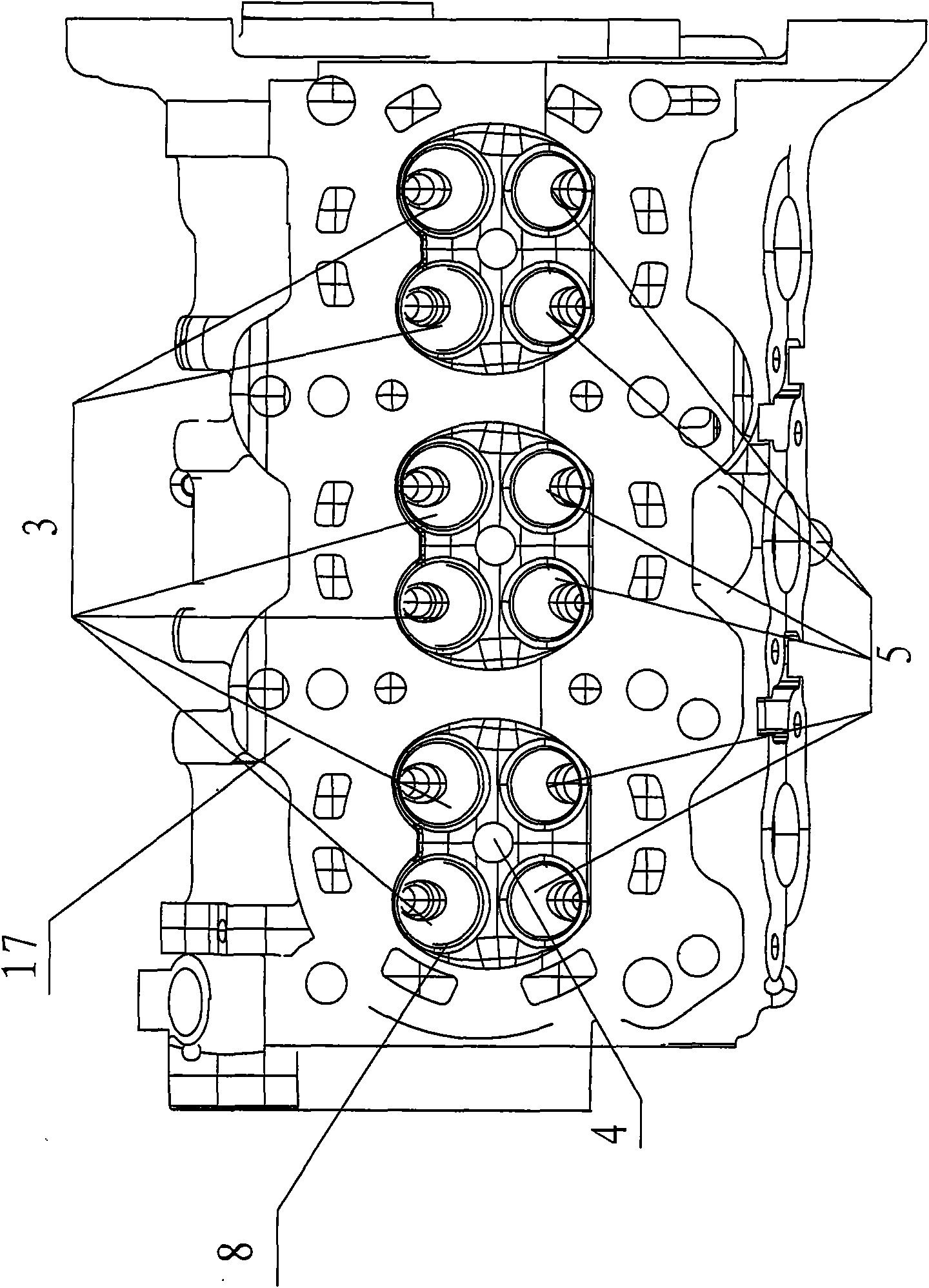

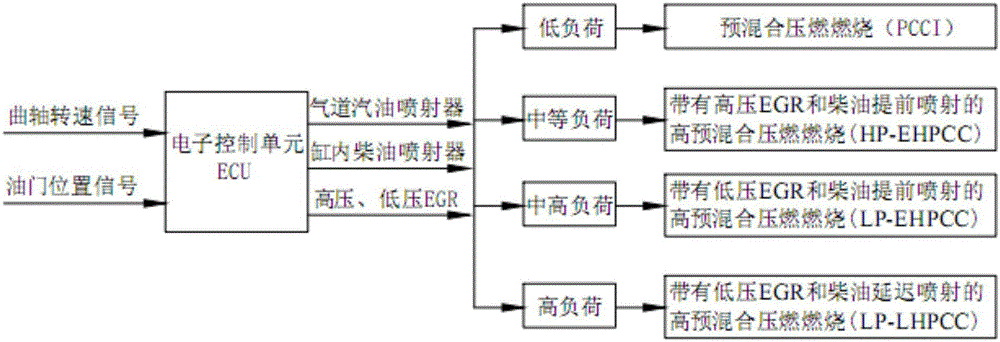

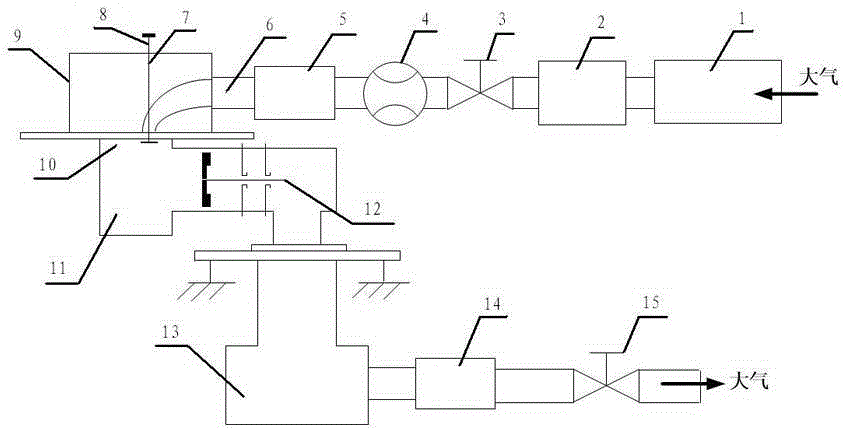

High-pressure tumble air intake testing device for engine

InactiveCN105372073AIncrease intake pressureEffective testInternal-combustion engine testingGasolineInlet pressure

The invention relates to a high-pressure tumble air intake testing device for an engine. The high-pressure tumble air intake testing device comprises an air compressor 1, a first pressure stabilizing box 2, an inlet pressure regulating valve 3, a flowmeter 4, a second pressure stabilizing box 5, an air duct pressure sensor 6, a lift sensor 7, an air valve lift adjusting mechanism 8, a to-be-measured cylinder cover 9, an in-cylinder pressure sensor 10, a simulation cylinder 11, a blade anemometer 12, a third pressure stabilizing box 13, a fourth pressure stabilizing box 14 and an outlet pressure regulating valve 15, and the high-pressure tumble air intake testing device for the engine can be used for performing testing research on change rules and influence factors of tumble and flow capacity of a gasoline engine air intake duct under high air intake pressure. The invention further relates to a high-pressure tumble air intake testing method for the engine.

Owner:ZHONGBEI UNIV

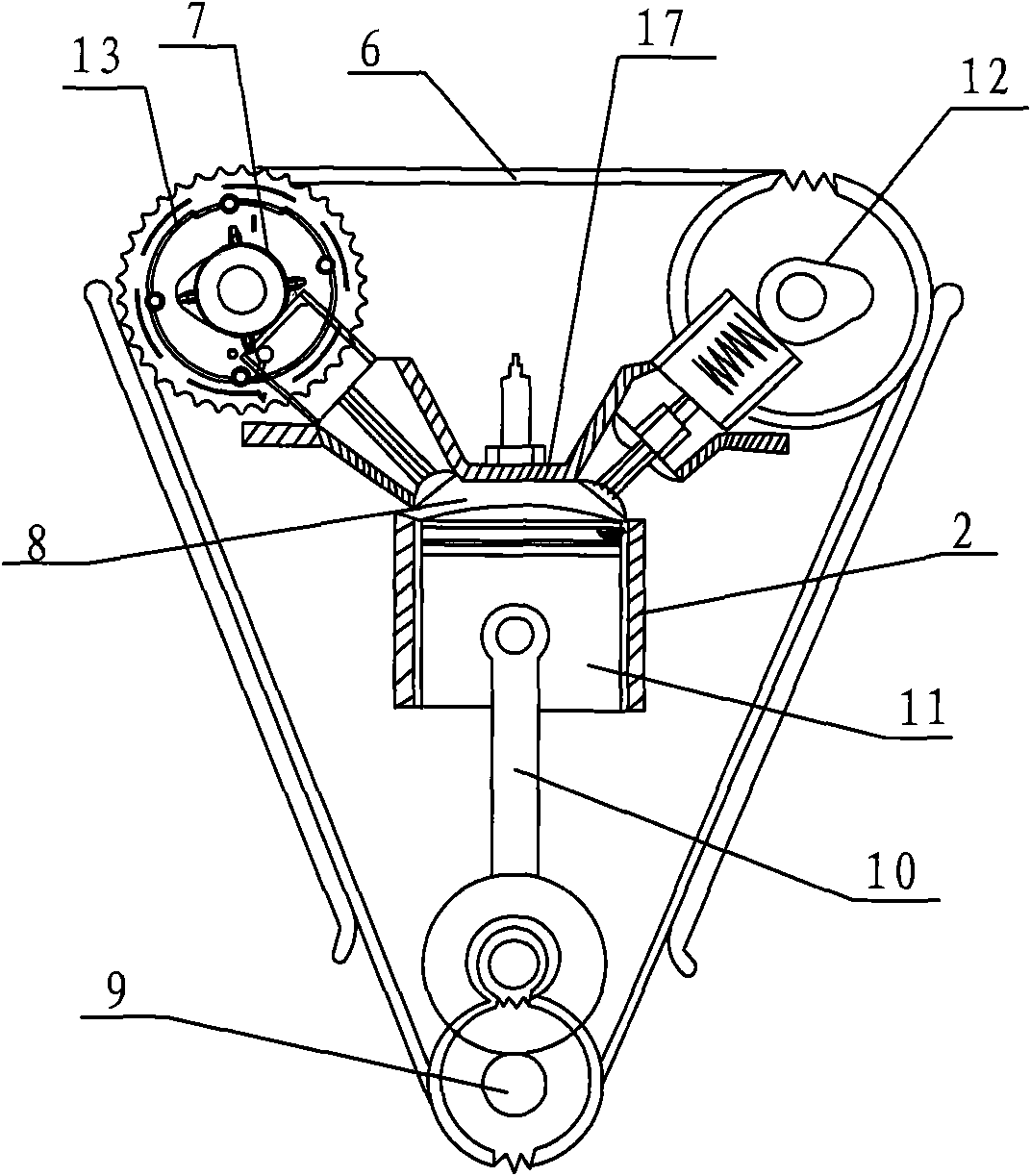

Turbocharging system with two rotating plates in front of turbine inlet

InactiveCN102562271AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesElastic componentLow speed

A turbocharging system with two rotating plates in front of a turbine inlet belongs to the technical field of internal combustion engines and comprises a cylinder, an exhaust tube, a connecting tube, a turbine, a capacity cavity, the rotating plates, a rotating shaft and an elastic component. An opening end of the capacity cavity is connected with the upper wall surface of the connecting tube, the rotating shaft is mounted between a front wall surface and a rear wall surface of the connecting tube, both the first rotating plate and the second rotating plate are integrally fixedly connected with the rotating shaft, and the second rotating plate is connected with the lower wall surface of the connecting tube via the elastic component. When an engine is in a high-speed working condition, both the two rotating plates rotate clockwise, the area of a throat of the connecting tube is large, so that pumping loss is low, and performances of the total engine are excellent; and when the engine is in a low-speed working condition, both the two rotating plates rotate anticlockwise, the area of the throat of the connecting tube is small, available energy in front of the turbine is sufficient, air inlet pressure of the engine is high, and the performances of the integral engine are excellent. The turbocharging system is reasonable in design and simple in structure. The invention is applicable to a turbocharging system with a side-mounted turbine at a turbine inlet.

Owner:SHANGHAI JIAO TONG UNIV

Ultralow-concentration gas machine combustion system and control method thereof

PendingCN111237092AIncrease intake pressureImprove inflation efficiencyElectrical controlInternal combustion piston enginesCombustion systemCommon rail

The invention provides an ultralow-concentration gas machine combustion system and a control method thereof. The ultralow-concentration gas machine combustion system comprises an air exhaust turbocharging device, an ultralow-concentration gas pressurizing inlet device, a diesel common-rail micro-jet ignition device, a diesel injector cooling circulation device, an EMS control unit and a pluralityof cylinders, wherein the air exhaust turbocharging device can improve the air inlet pressure and efficiency, the ultralow-concentration gas pressurizing inlet device can improve the gas inlet densityto meet the requirements of different loads for a high-pressure gas flow rate, and the diesel injector cooling circulation device decreases the combustion temperature of an injector under a high loadand greatly lowers the probability that the ejector burns down or gets stuck. Under the combined action of all the devices, normal ignition and normal combustion based on the ultralow-concentration gas machine combustion system are realized, and normal starting and operating of a gas machine are ensured.

Owner:中科环能(天津)动力科技有限公司

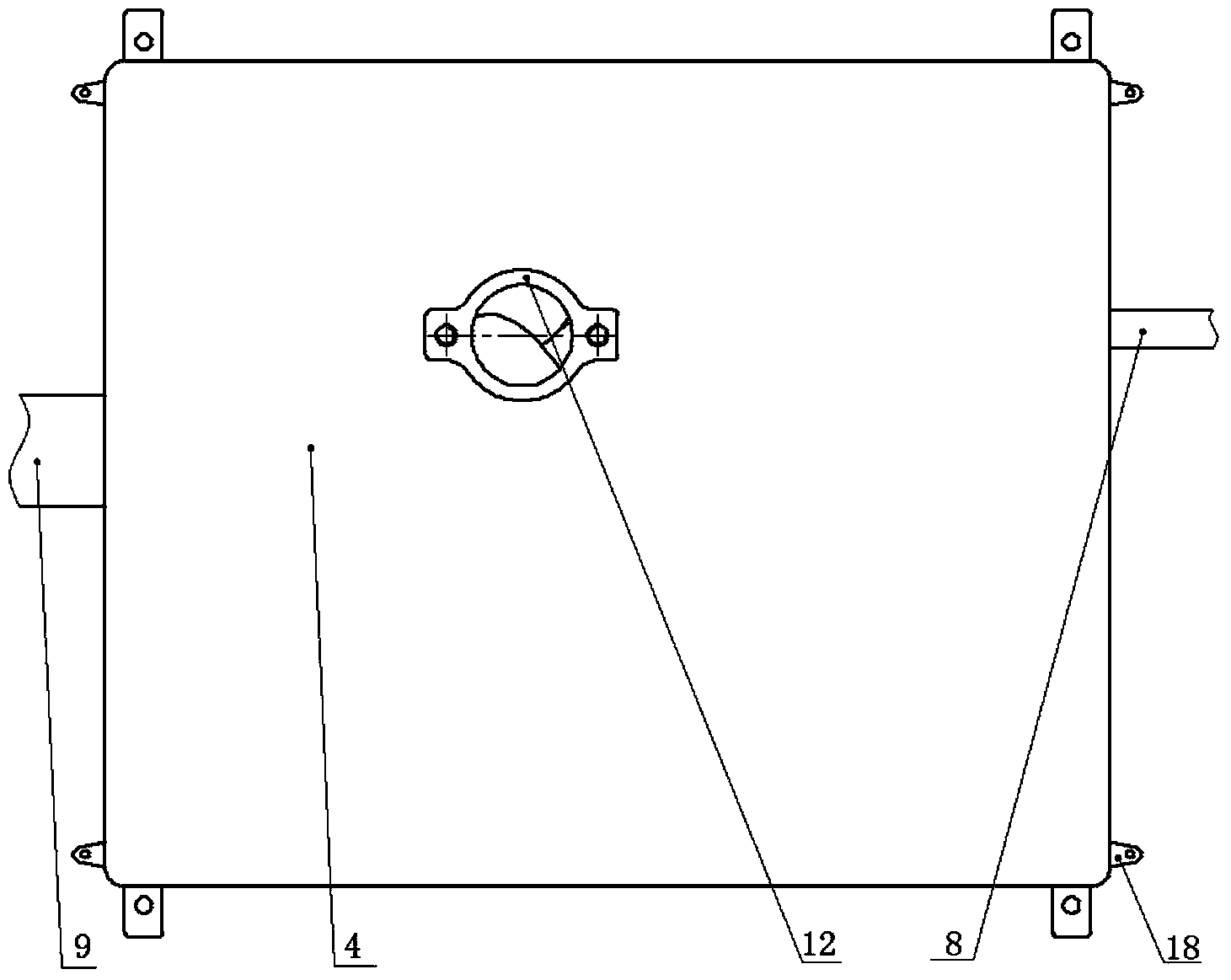

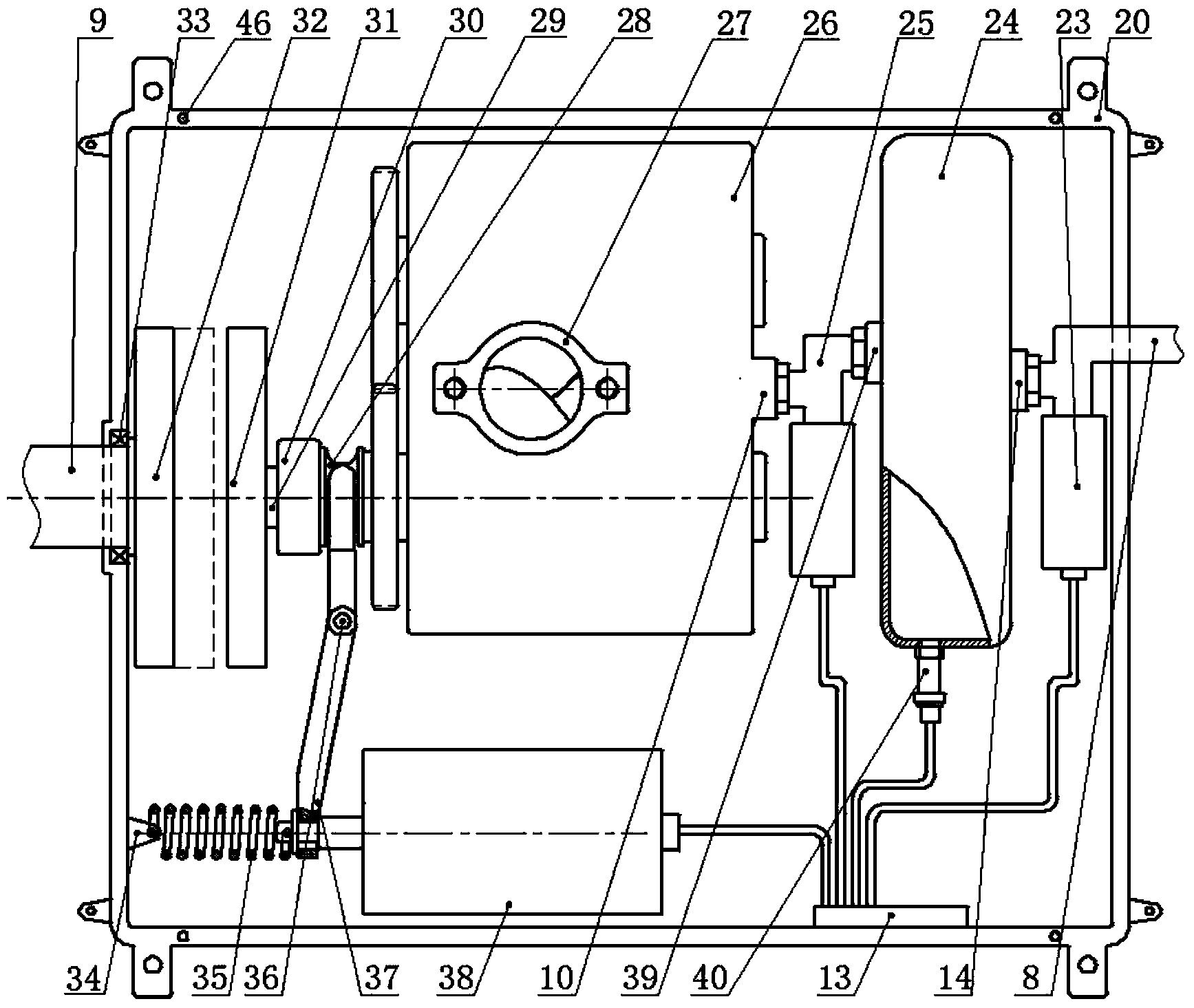

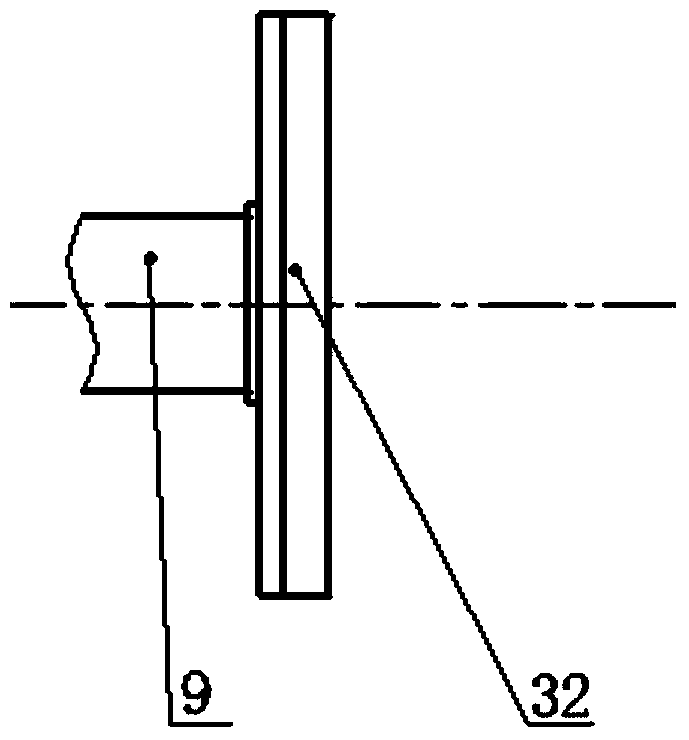

Air intake supercharging mechanism capable of recovering brake energy

ActiveCN104005836AEasy to implementSimple installationCombustion enginesEngine componentsClutchElectricity

The invention discloses an air intake supercharging mechanism capable of recovering brake energy. The air intake supercharging mechanism capable of recovering the brake energy aims at solving the problem that the brake energy recovering systems of oil-electricity hybrid power vehicles as well as air hybrid power vehicles are large in quantity and size of additional devices, high in cost and complex in techniques. The air intake supercharging mechanism capable of recovering the brake energy comprises a clutch unit, a shifting fork unit, an air compressor, an air tank and control valve unit, an air intake supercharging mechanism housing and an air intake supercharging control unit. The clutch unit is mounted on the left of the inside of the air intake supercharging mechanism housing; the air compressor is mounted inside the air intake supercharging mechanism housing on the right of the air compressor; the air tank and control valve unit is mounted inside the air intake supercharging mechanism housing on the right of the air compressor; the shifting fork unit is mounted inside the air intake supercharging mechanism housing under the clutch unit; the air intake supercharging control unit is fixed onto the inner side of the lower wall of the air intake supercharging mechanism housing and sequentially connected with the control signal wires of an air tank air intake control valve, an air tank air exhaust control valve, an air tank air pressure sensor and a lifting fork electromagnetic valve.

Owner:辽源市万通汽车部件有限公司

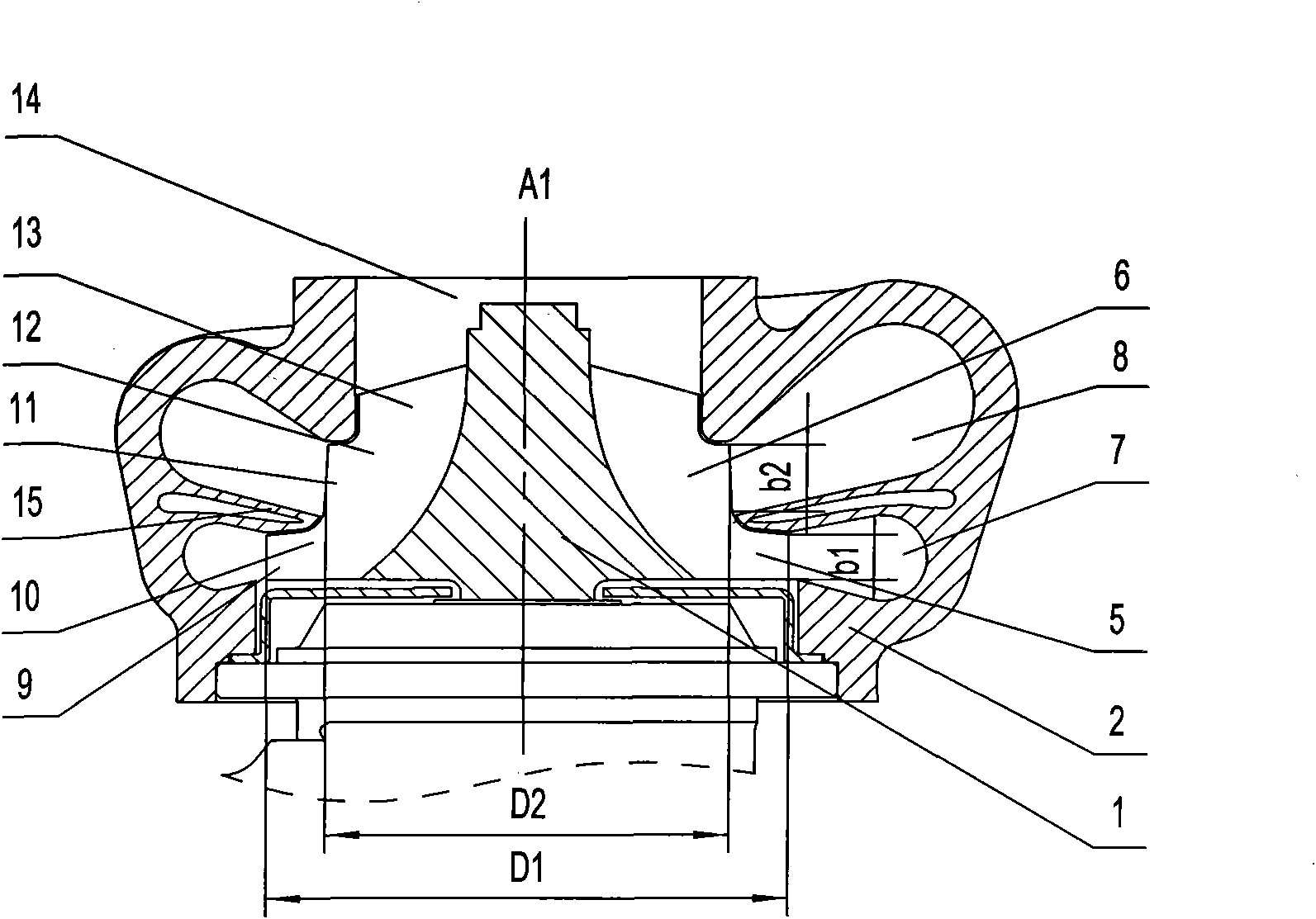

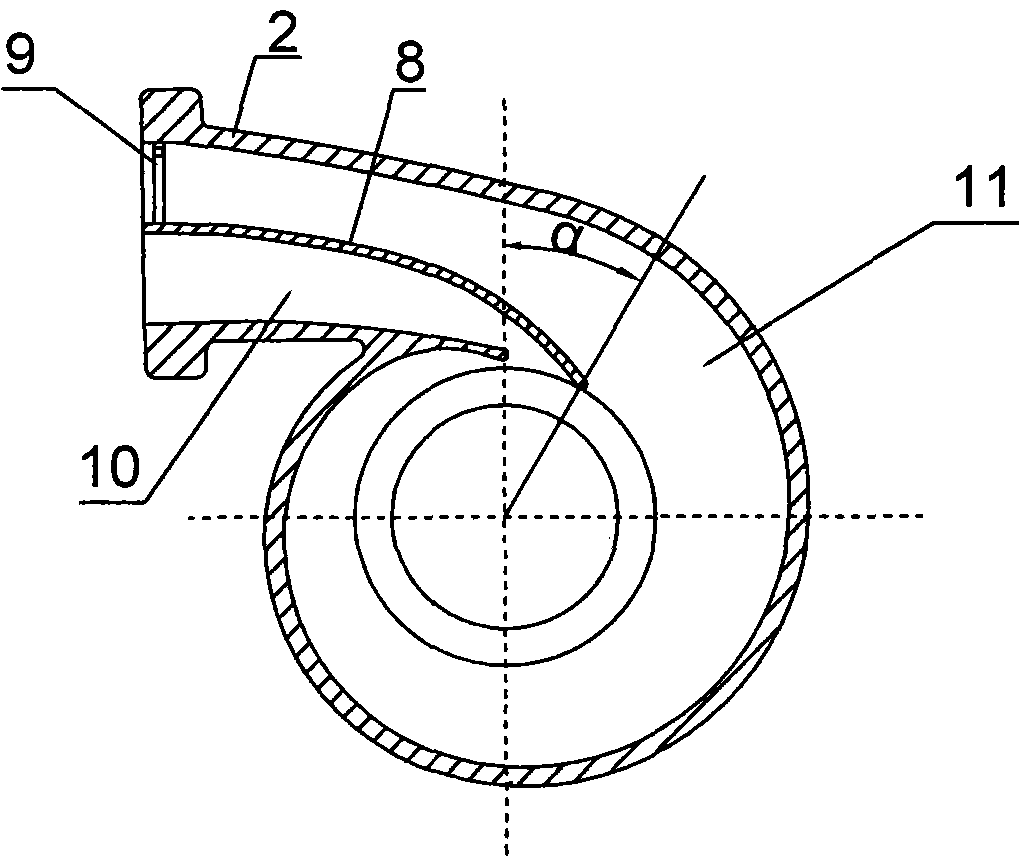

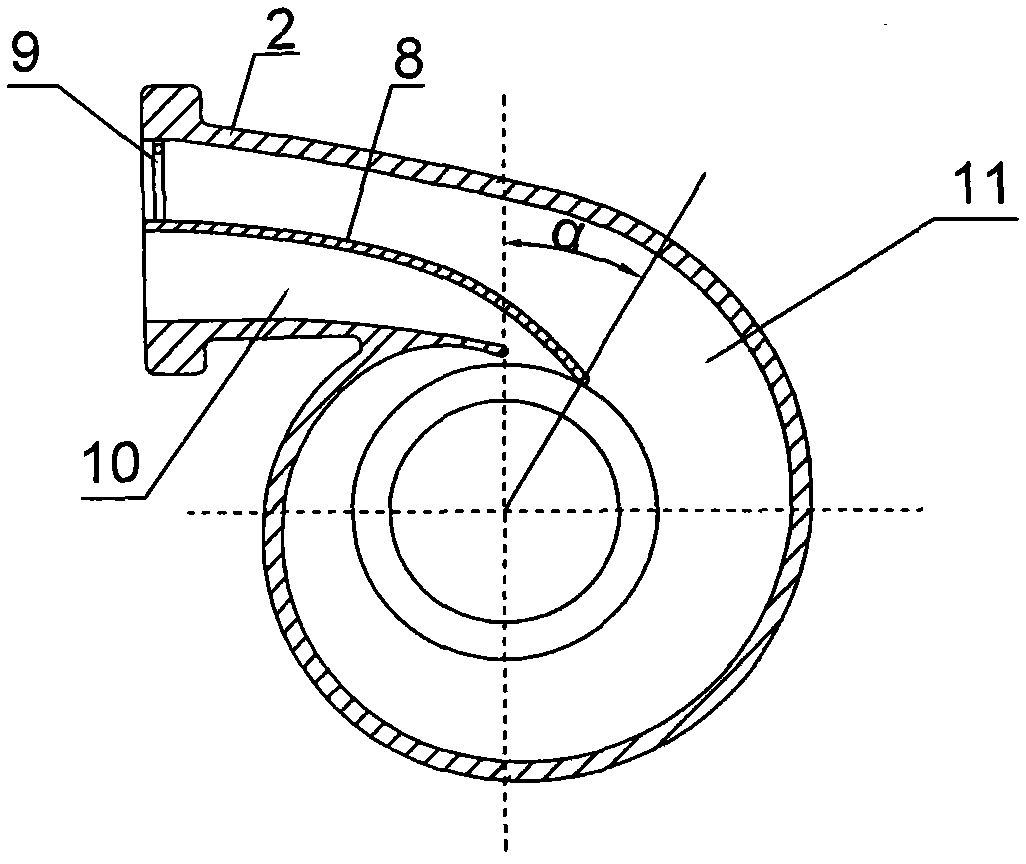

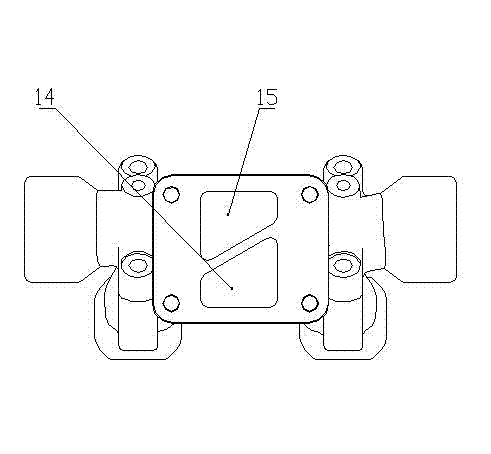

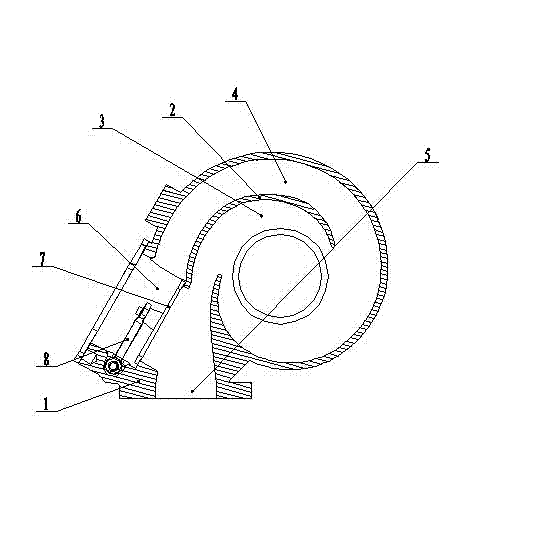

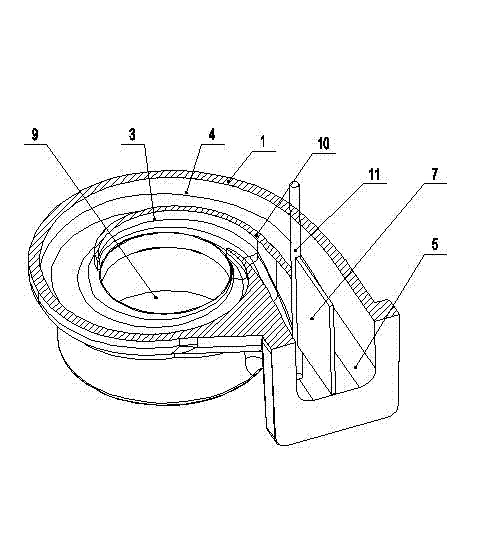

Volute device of variable geometry pulse gas inlet turbine

InactiveCN102383877AMeet low speed performanceIncrease intake pressureInternal combustion piston enginesStatorsControl mannerEngineering

The invention discloses a volute device of a variable geometry pulse gas inlet turbine, which comprises a volute. The volute is provided with a gas inlet flow passage. One end of the gas inlet flow passage is provided with a gas inlet, and the other end of the gas inlet flow passage is provided with a volute gas outlet. The gas inlet flow passage comprises two sets of working flow passages, i.e. an inner flow passage and an outer flow passage, wherein the inner flow passage comprises a first inner flow passage and a second inner flow passage; and the outer flow passage comprises a first outer flow passage and a second outer flow passage. The gas inlet comprises a first volute inlet and a second volute inlet. The first inner flow passage and the first outer flow passage are communicated with the first volute inlet and are used for realizing half-cycle gas intake in the range of 0 to 180 degrees in the circumference direction. The second inner flow passage and the second outer flow passage are communicated with the second volute inlet and are used for realizing half-cycle gas intake in the range of 180 to 360 degrees in the circumference direction. The volute device has a simple structure, good inheritance and low cost, and engineering is easily and rapidly realized. A gas inlet regulating device in the volute device has a simple structure. A control mode of the gas inlet regulating device is easy to realize. The gas inlet regulating device has high reliability.

Owner:KANGYUE TECH

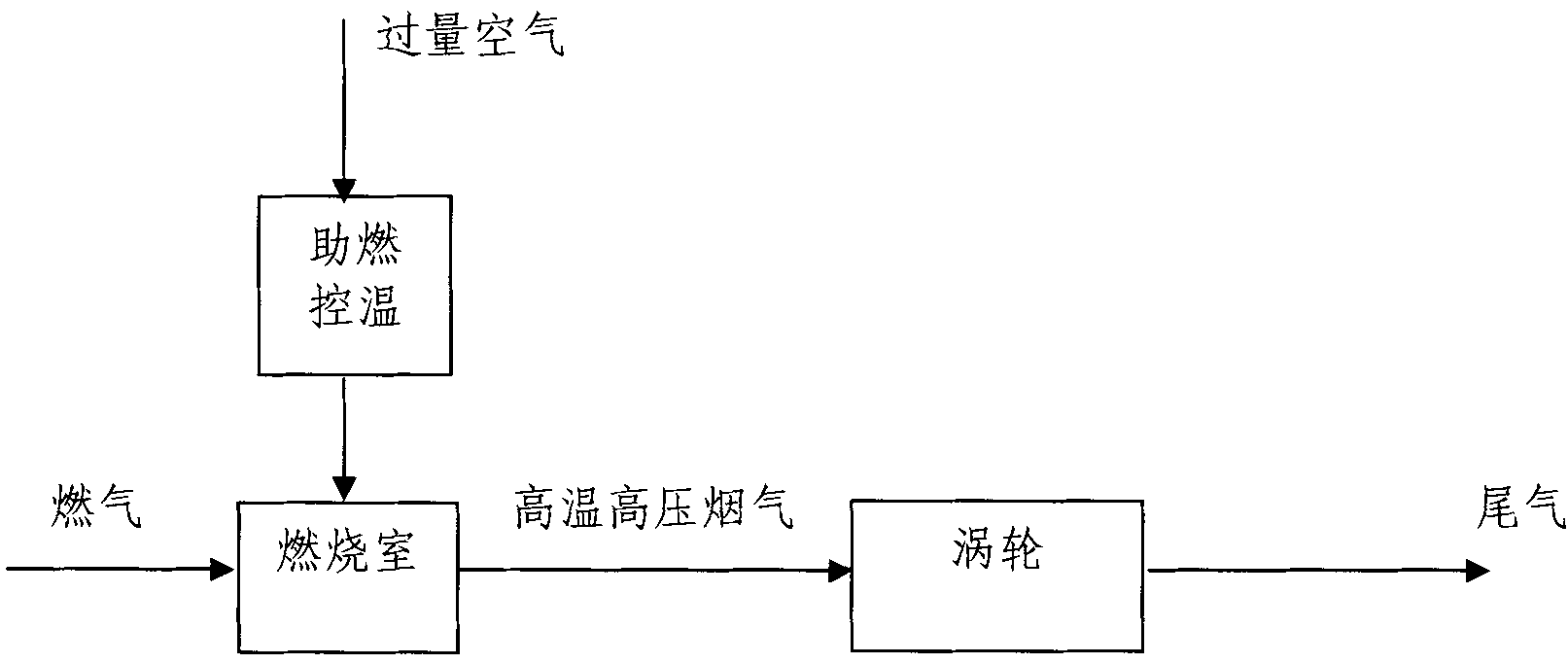

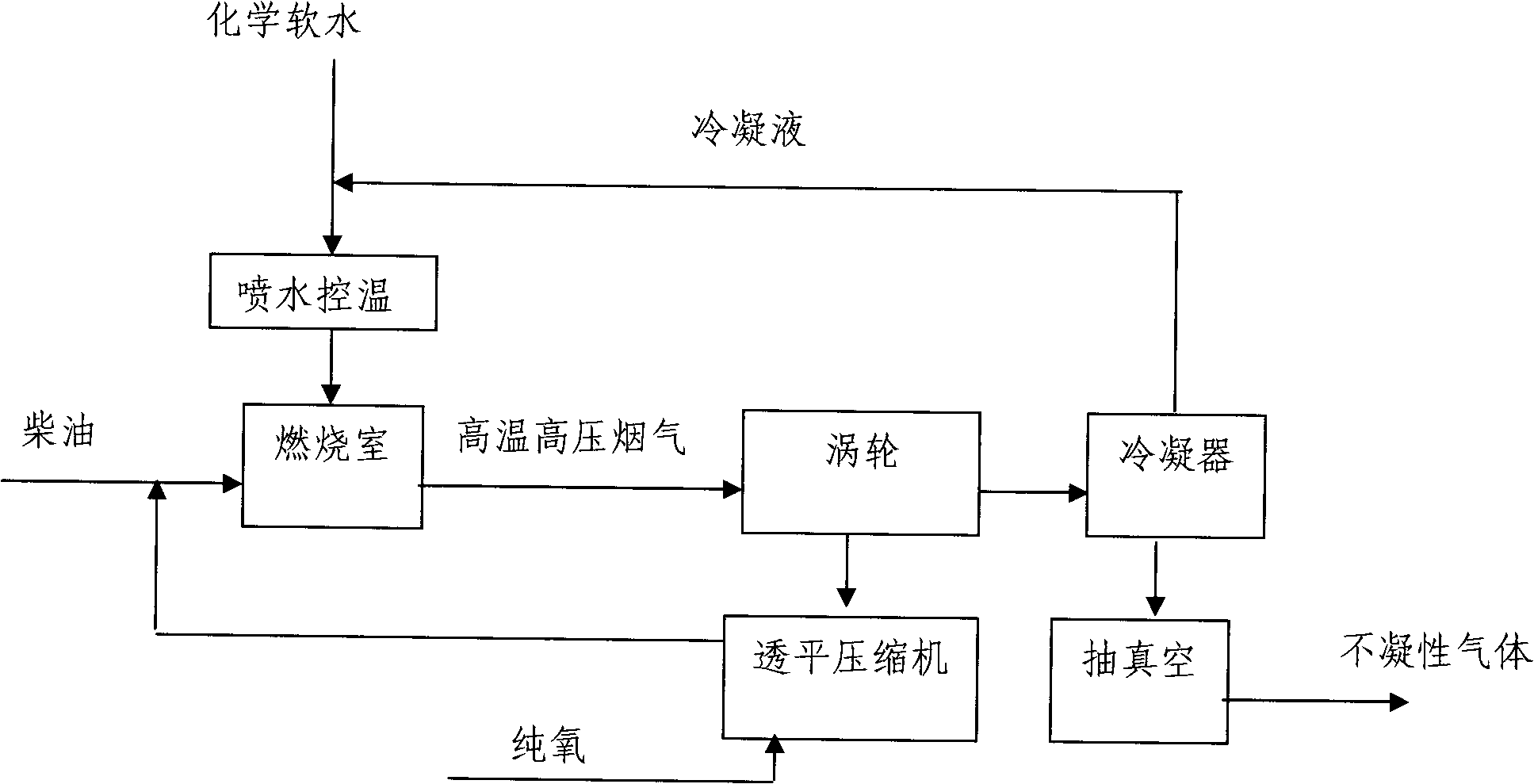

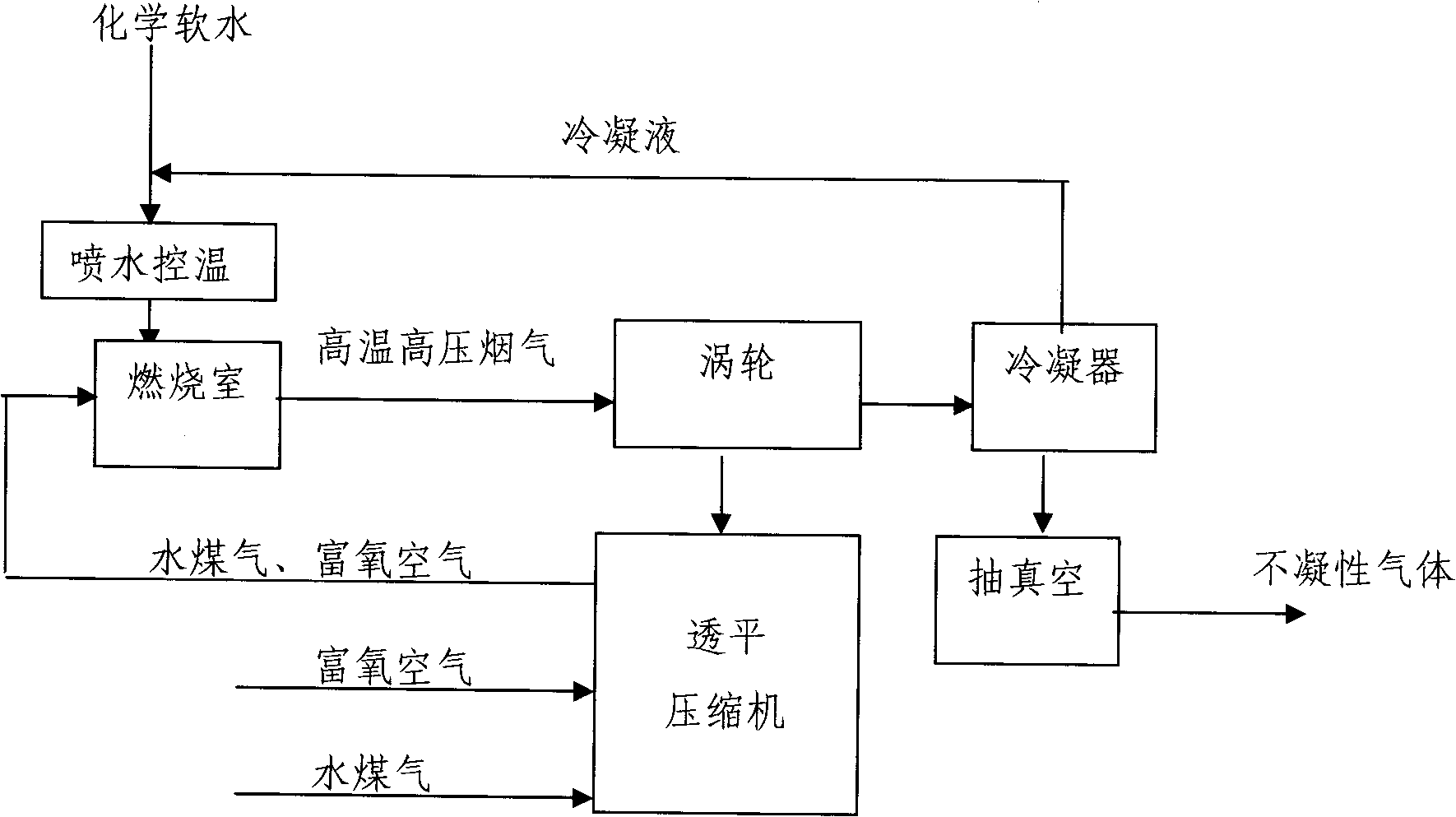

Thermal circulation process of gas turbine based on pure oxygen or oxygen-enriched combustion

InactiveCN101787930AIncrease temperatureIncrease intake pressureTurbine/propulsion engine coolingGas turbine plantsCombustion chamberWater vapor

The invention discloses a thermal circulation process of a gas turbine based on pure oxygen or oxygen-enriched combustion, which comprises the following steps: compressing liquid fuel or gas; compressing oxygen gas or oxygen-enriched air; carrying out mixed combustion of the liquid fuel or the gas and the oxygen gas or the oxygen-enriched air; spraying water for controlling temperature; expanding high temperature and high pressure flue gas after combustion in the gas turbine for applying work; cooling most of water vapor in tail gas with circulating water in a condenser, wherein the condensed water circulates to a combustion chamber to be used for spraying water for controlling temperature, and the non-condensable gas is extracted by a vacuum pump; or exhausting gas under normal pressure without the use of the vacuum pump. By adopting direct combustion of the pure oxygen or the oxygen-enriched air and adopting the water spraying mode to replace excess air for controlling temperature, the air inflow is small, the amount of compression of a compressor is small, the restriction of the optimal pressure gas ratio is eliminated, the circulating intake pressure is improved, the non-condensable gas in the tail gas is little, and the exhaust pressure can be reduced through vacuum condensation. Because the process has high circulating intake pressure and low exhaust pressure, the expansion ratio of the gas turbine is improved, thereby improving the generating efficiency.

Owner:北京名都厚德科技有限公司

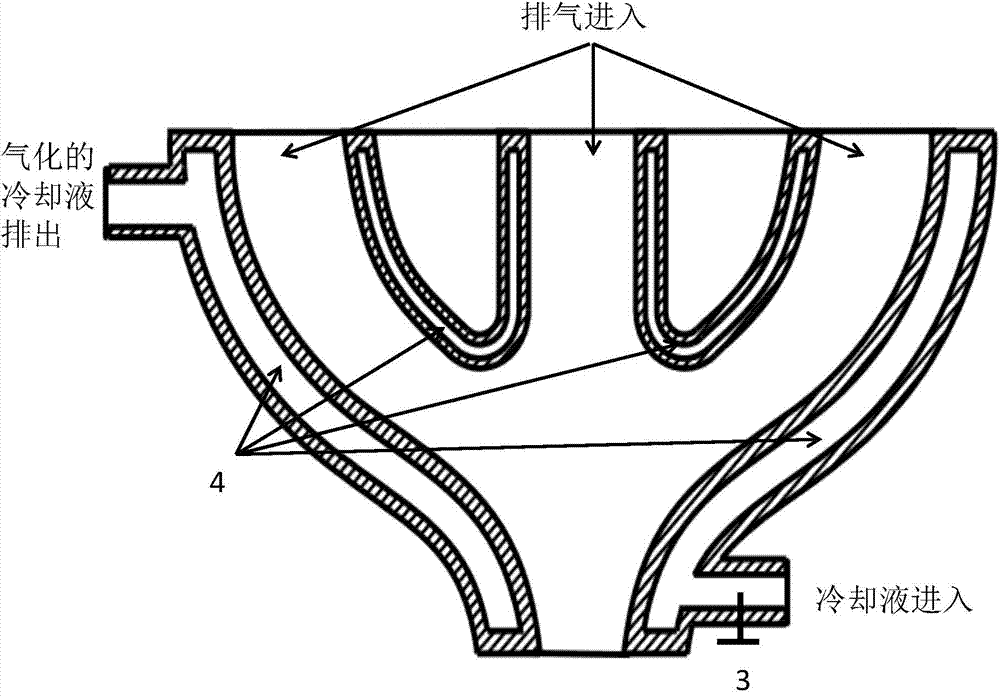

System for recycling exhaust manifold heat to realize engine boosting

ActiveCN104763510AReduce the temperatureIncrease intake pressureInternal combustion piston enginesExhaust apparatusImpellerGas compressor

The invention relates to a system for recycling exhaust manifold heat to realize engine boosting. The system comprises an exhaust manifold and a booster pushed by high-temperature steam, wherein the booster comprises a turbine and a gas compressor; a turbine blade in the turbine is in transmission connection with a gas compression blade in the gas compressor; an exhaust manifold water sleeve coats the exhaust manifold; the exhaust manifold water sleeve is an internal through cavity body; one end of the exhaust manifold is accessed into a cooling liquid from a radiator or an engine water outlet through an inlet; the cooling liquid is heated to a high-temperature gas state in the exhaust manifold water sleeve; the gasified high-temperature gas is output to a gas inlet of the turbine through an outlet; the turbine is provided with a gas inlet cavity and a turbine cavity which are separated, a spray nozzle is arranged between the two cavities, the inlet of the spray nozzle is connected into the gas inlet cavity, the spray nozzle is formed in the turbine cavity; the gas inlet cavity is used for flowing the inlet gas to a plurality of spray nozzles; high-speed gas sprayed by the spray nozzles promotes the turbine blade to rotate, and drives the gas compression impeller in the gas compressor to rotate; the gas compressor is accessed into the atmosphere or output to the engine directly or after being boosted by the gas compression impeller.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS

Turbojet engine

InactiveCN103967649AIncrease intake pressureIncrease thrust-to-weight ratioJet propulsion plantsAxial compressorExhaust valve

A turbojet engine comprises all structures of a turbojet engine such as an axial-flow air compressor, an evaporative combustion chamber, a turbine and a tail jet pipe. The turbojet engine is characterized in that a bypass pipe and an inner exhaust valve are further included, an outer exhaust valve is arranged or not arranged in a pipe outside the engine between an air inlet and an air outlet of the bypass pipe, after the engine is started and operates, the inner exhaust valve is opened, by opening and closing of the bypass pipe, the inner exhaust valve and the existing or nonexistent outer exhaust valve, the supercharge ratio of the axial-flow air compressor is increased and kept unchanged, the increased supercharge ratio is not higher than the limitation borne by the axial-flow air compressor and a turbine according to the mechanical strength, turbine inlet temperature is kept unchanged, namely the supercharge ratio and thrust-weight ratio are increased, oil consumption rate is lowered, the levels of the axial-flow air compressor and the turbine are not increased, and the turbine inlet temperature is not raised.

Owner:李吉光

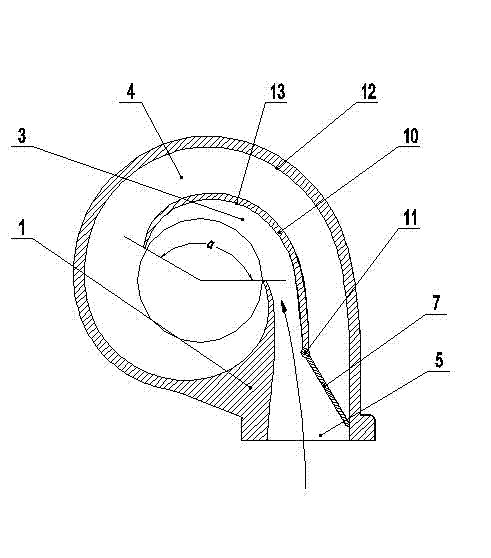

Variable passage volute device

InactiveCN102536354AIncrease available energyIncrease intake pressureInternal combustion piston enginesEngine componentsLow speedControl manner

The invention discloses a variable passage volute device, which comprises a volute. An intake passage is reserved in the volute, a volute air inlet and a volute air outlet which are respectively communicated with the intake passage are arranged on the volute, an arc pneumatic partition is arranged in the volute intake passage, the volute intake passage is divided into an inner volute intake passage and an outer volute intake passage by the pneumatic partition, and an adjustable valve device is arranged at one end, close to the volute air inlet, of the pneumatic partition. The variable passage volute device is simple in structure, easy in control means implementation and high in reliability, the supercharging requirement of an engine in low speed, medium speed and high speed can be met effectively by using the variable passage volute device, the whole structure of a supercharger is changed slightly, and the supercharger is low in cost, easy in implementation, has high marketing value and can achieve a great application effect.

Owner:KANGYUE TECH

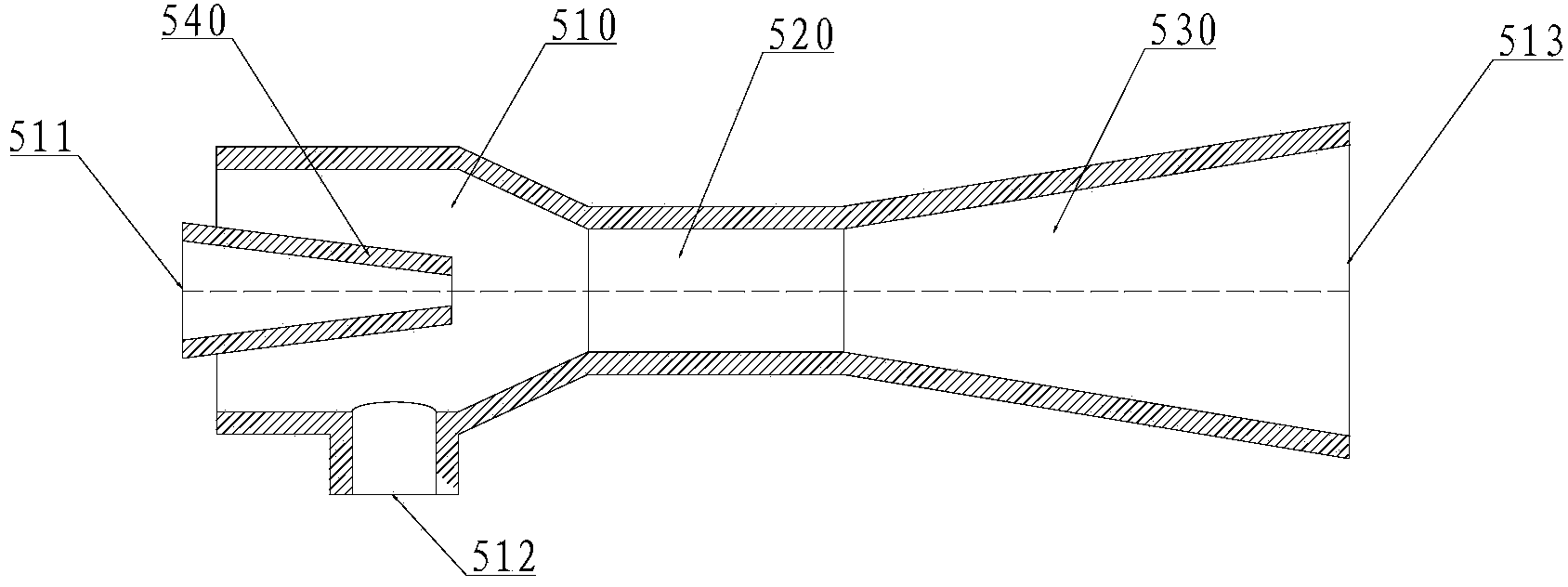

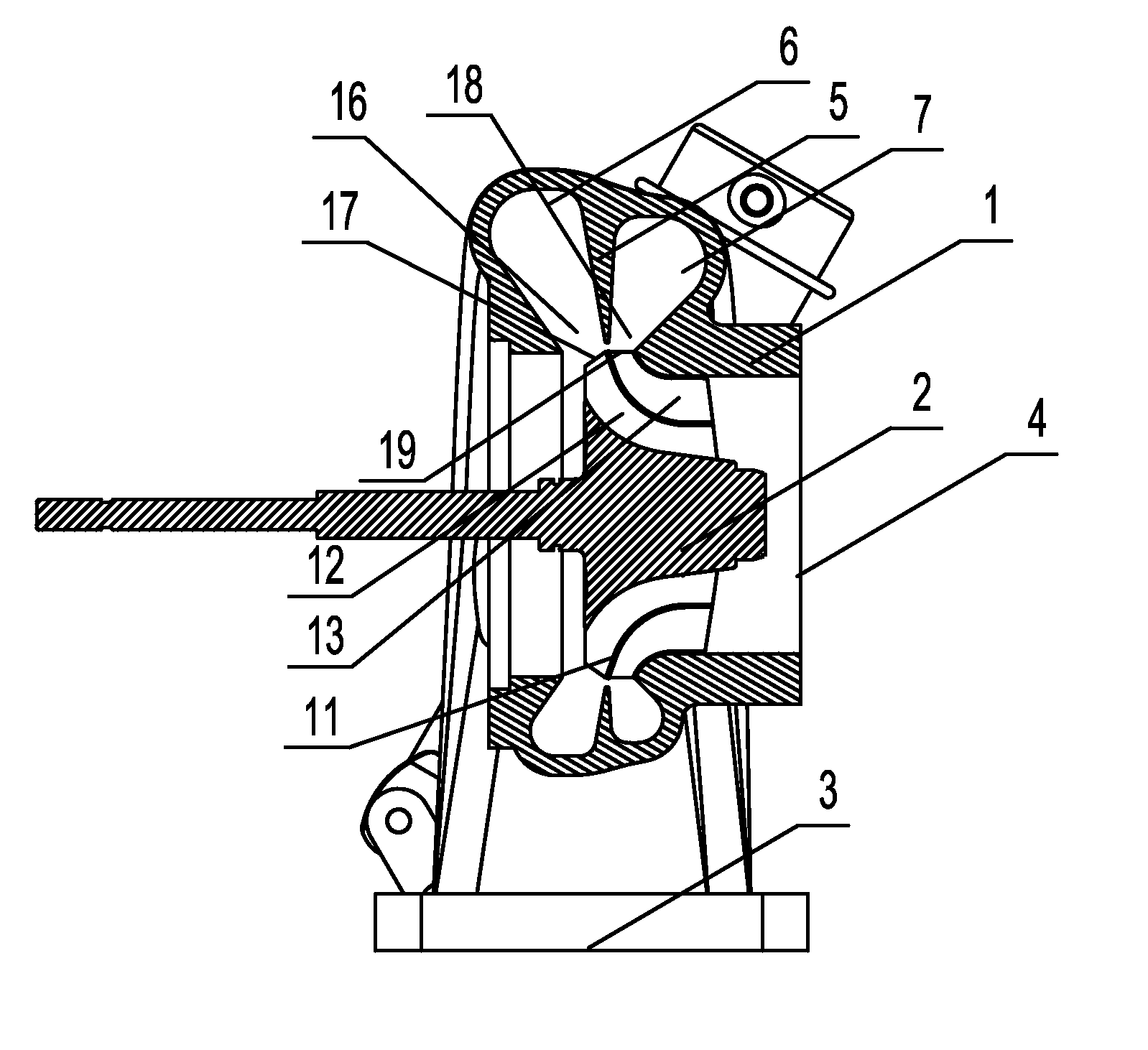

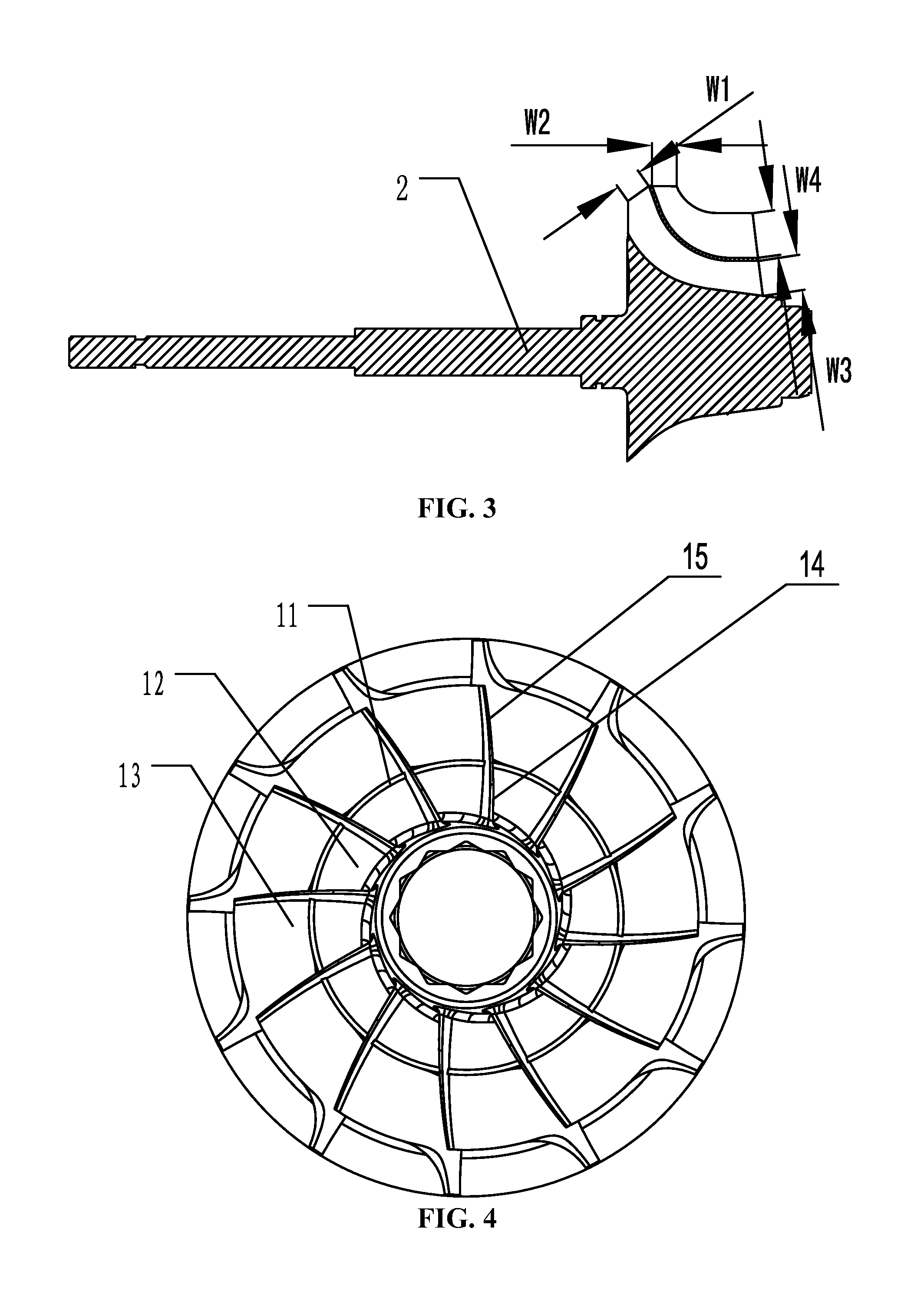

Turbine

InactiveUS20150063991A1Simple structureGood successInternal combustion piston enginesPump componentsImpellerEngineering

A turbine, including: a volute and an impeller. The volute includes: a volute gas inlet, a volute gas feeding flow passage, and a volute gas outlet. The impeller includes: blades, an impeller gas feeding flow passage, an impeller gas inlet, an impeller gas outlet, and a partition plate. The impeller gas feeding flow passage includes: an inner flow passage and an outer flow passage. The impeller is disposed inside the volute. The blades are disposed on an outer part of the impeller. The partition plate is circumferentially disposed between the impeller gas inlet and the impeller gas outlet. The partition plate divides the impeller gas feeding flow passage into the inner flow passage and the outer flow passage.

Owner:WANG HANG +6

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com