Rotating electrode preparing micro spherical metal powder and method of rotating electrode

A technology of rotating electrodes and metal powder, which is applied in the field of powder metallurgy industry, can solve the problems of low yield of fine spherical metal powder, and achieve the effects of improving maintenance characteristics, reducing average particle size, and improving atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

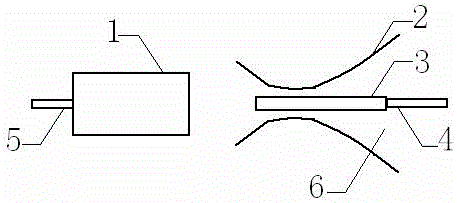

Image

Examples

Embodiment 1

[0027] A rotating electrode rod with a diameter of 70mm and a length of 600mm was prepared from a nickel-based superalloy as a raw material. The Ar:He=1:4 mixed gas was used as the protective atmosphere and gas in the atomization chamber, and the gas circulation was added. The current of the plasma gun was 1000A. After the arc, the rotating electrode rod is driven to rotate at a speed of 15000rpm. The Laval nozzle of the plasma gun is 40mm away from the end face of the rotating electrode rod. The air inlet pressure at the front of the atomization chamber is 0.15MPa, and the yield of powder <75μm in the collected finished powder is 18wt.%. According to step 2, increase the power of the plasma gun to 1.4 times by increasing the current, increase the air pressure in front of the spray chamber to 0.3MPa, and at the same time control the gun head push rod to adjust the position of the plasma gun head in the Laval nozzle to high temperature and high pressure The air flow is stable an...

Embodiment 2

[0029] Using TC4 as raw material to prepare electrode rods with a diameter of 75mm and a length of 500mm, use Ar:He=1:4 mixed gas as the protective atmosphere to fill the atomization chamber, and add gas circuit circulation. The rotating electrode is rotated to make powder, the Laval nozzle of the plasma gun is 30mm away from the end face of the bar, the air inlet pressure at the front of the atomization chamber is 0.18MPa, and the yield of <53μm powder in the collected finished powder is 4.5wt.%. According to step 2, by increasing The high current increases the power of the plasma gun to 1.5 times, increases the air pressure before the atomization chamber to 0.3MPa, and at the same time controls the gun head push rod to adjust the position of the plasma gun head in the Laval nozzle to stabilize the high temperature and high pressure airflow and collect the finished product The yield of <53μm powder in the powder is 9.7wt.%, which is increased by 2.16 times.

Embodiment 3

[0031] A rotating electrode rod with a diameter of 79 mm and a length of 690 mm was prepared using pure nickel as a raw material. The Ar:He=1:8 mixed gas was used as the protective atmosphere and the gas in the atomization chamber, and the gas circulation was added. The current of the plasma gun was 1050A. The rotation speed of 13000rpm drives the rotating electrode rod to rotate, the Laval nozzle of the plasma gun is 35mm away from the end face of the rotating electrode rod, the air inlet pressure at the front of the atomization chamber is 0.2MPa, and the yield of <75μm powder in the collected finished powder is 11wt.%; according to step 2 , increase the power of the plasma gun to 1.4 times by increasing the current, increase the air pressure in the atomization chamber to 0.3MPa, and control the gun head push rod to adjust the position of the plasma gun head in the Laval nozzle to a stable injection of high temperature and high pressure airflow , the yield of <75μm powder in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com