Patents

Literature

36 results about "Plasma rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

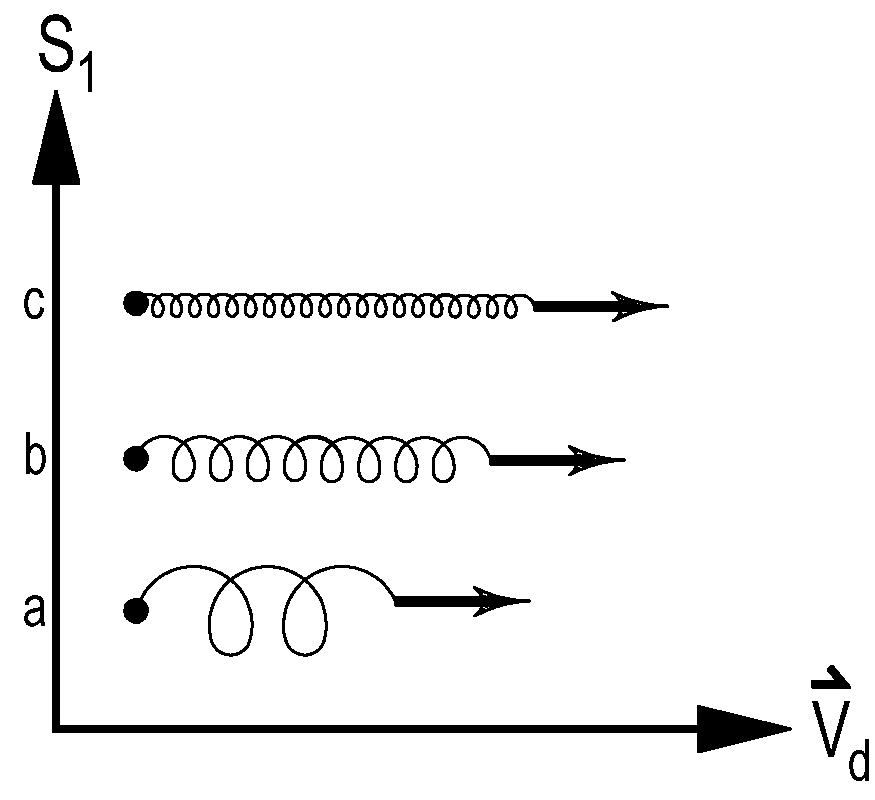

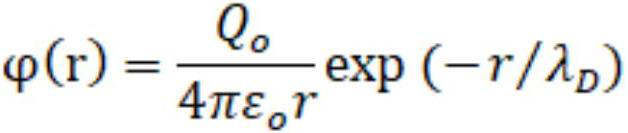

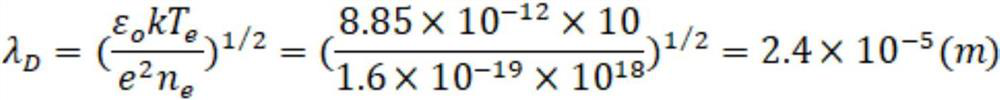

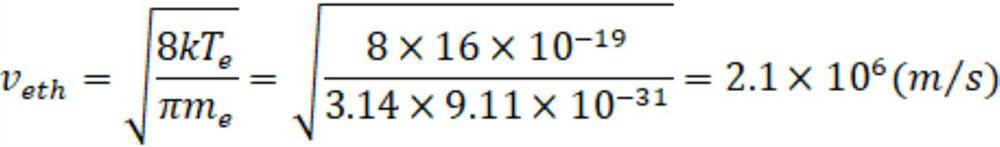

Plasma rotation can play an important role in fusion plasmas. In particular, strong shear in the rotation, or more precisely in the toroidal velocity component associated with the radial electric field, is widely believed to be an important factor for transport barriers [1, 2].

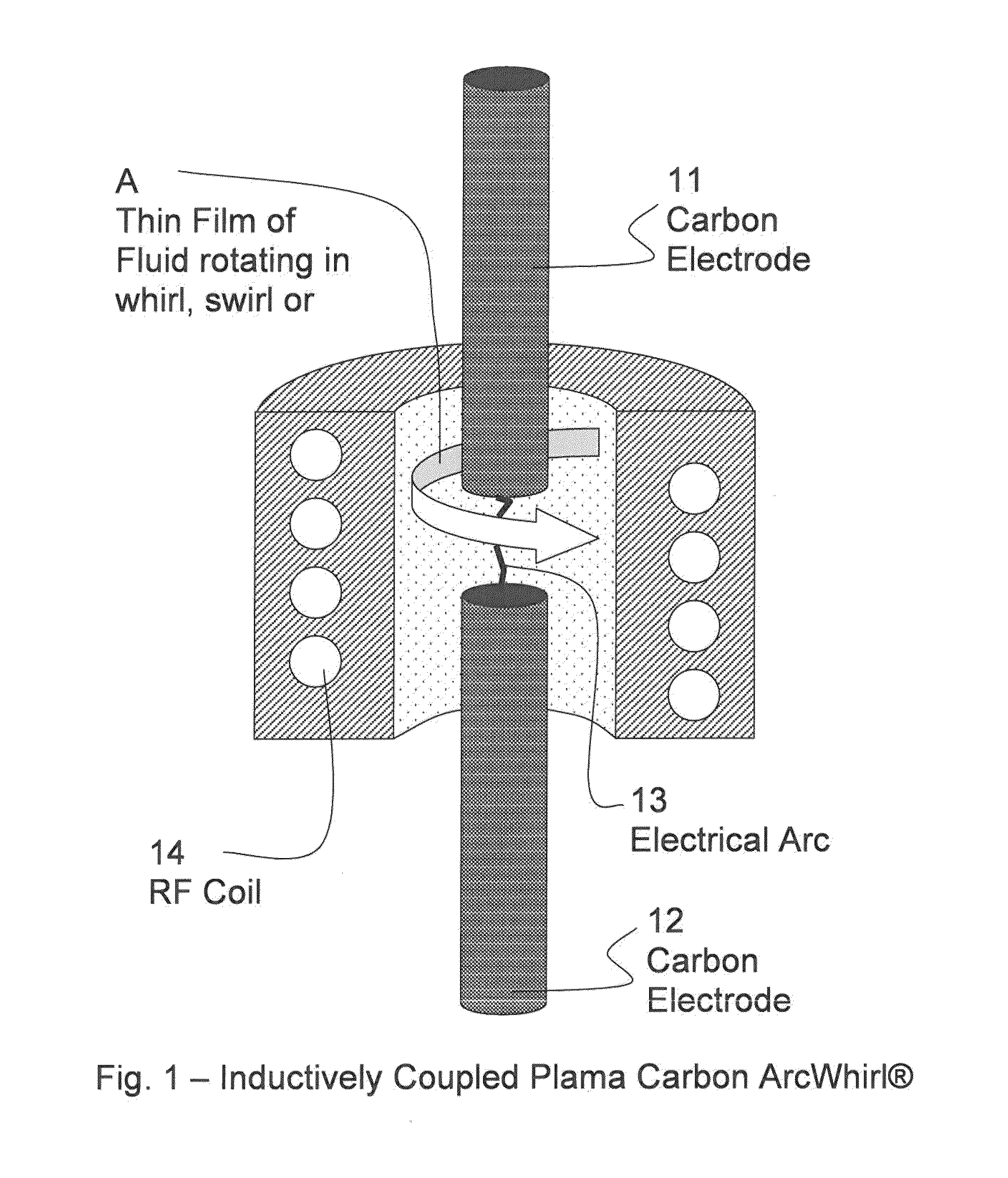

Plasma whirl reactor apparatus and methods of use

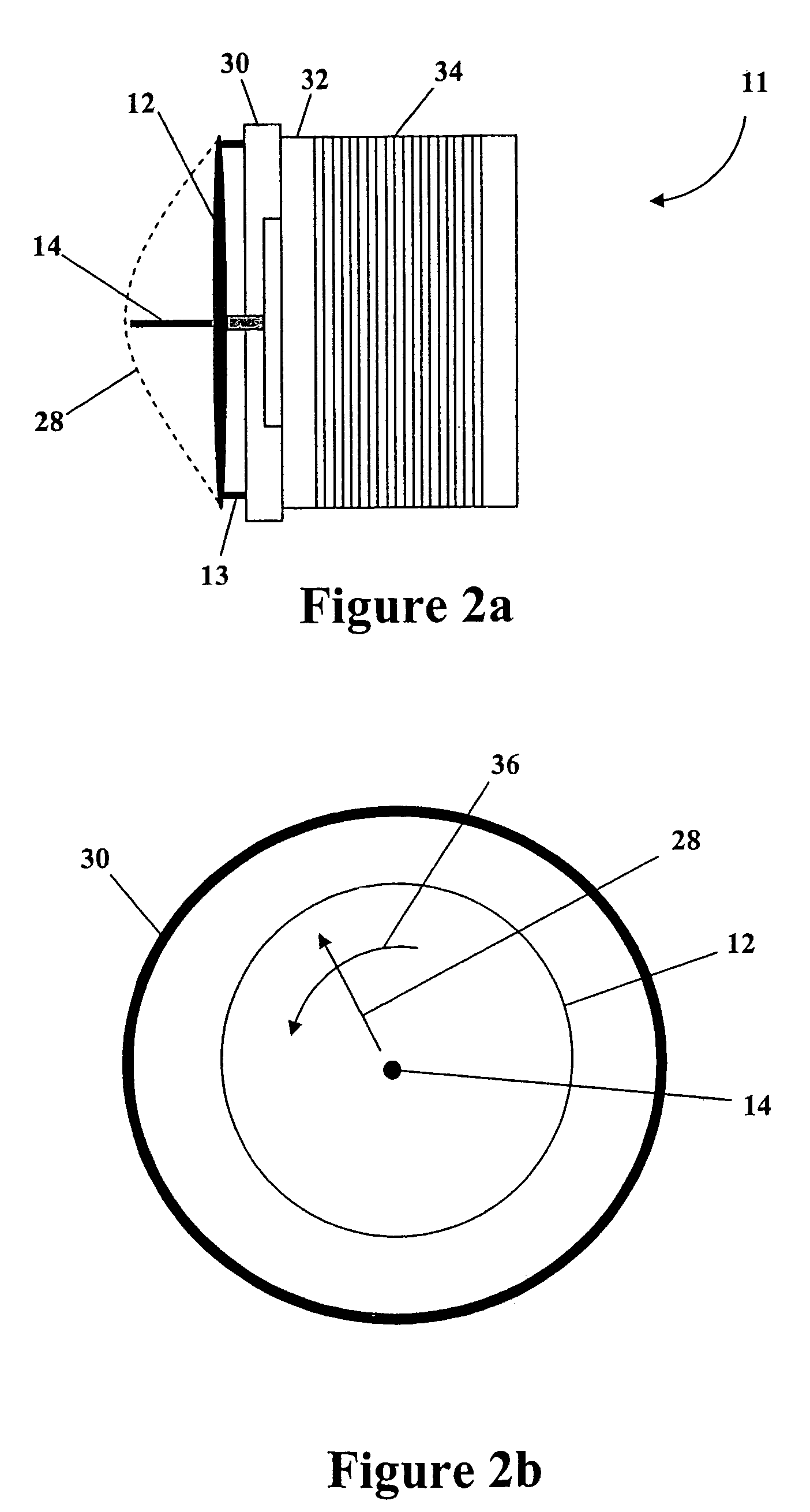

ActiveUS9445488B2Maximize anisotropyDecrease productivityGas-gas reaction as plasma stateElectron beam welding apparatusEngineeringPlasma arc welding

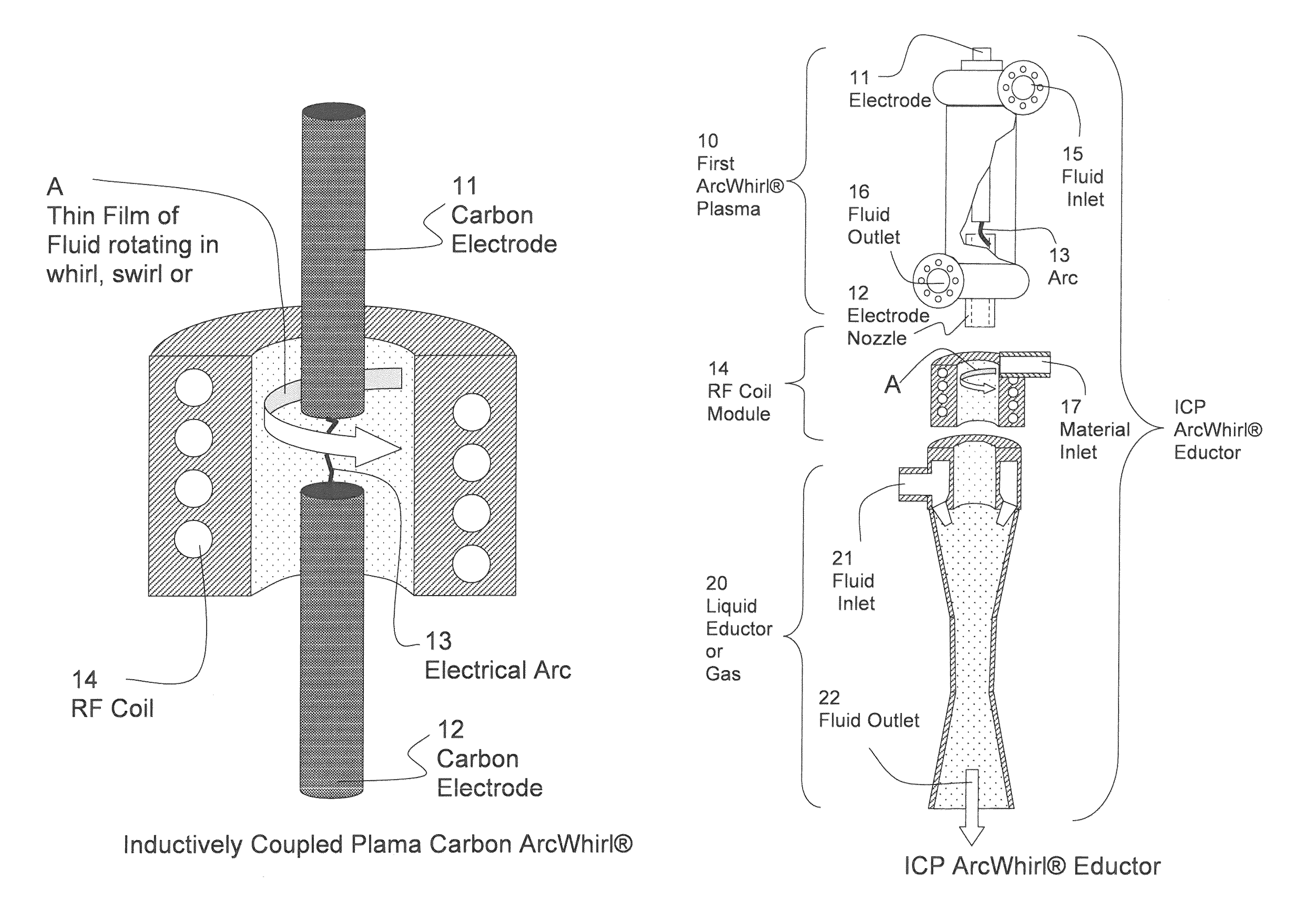

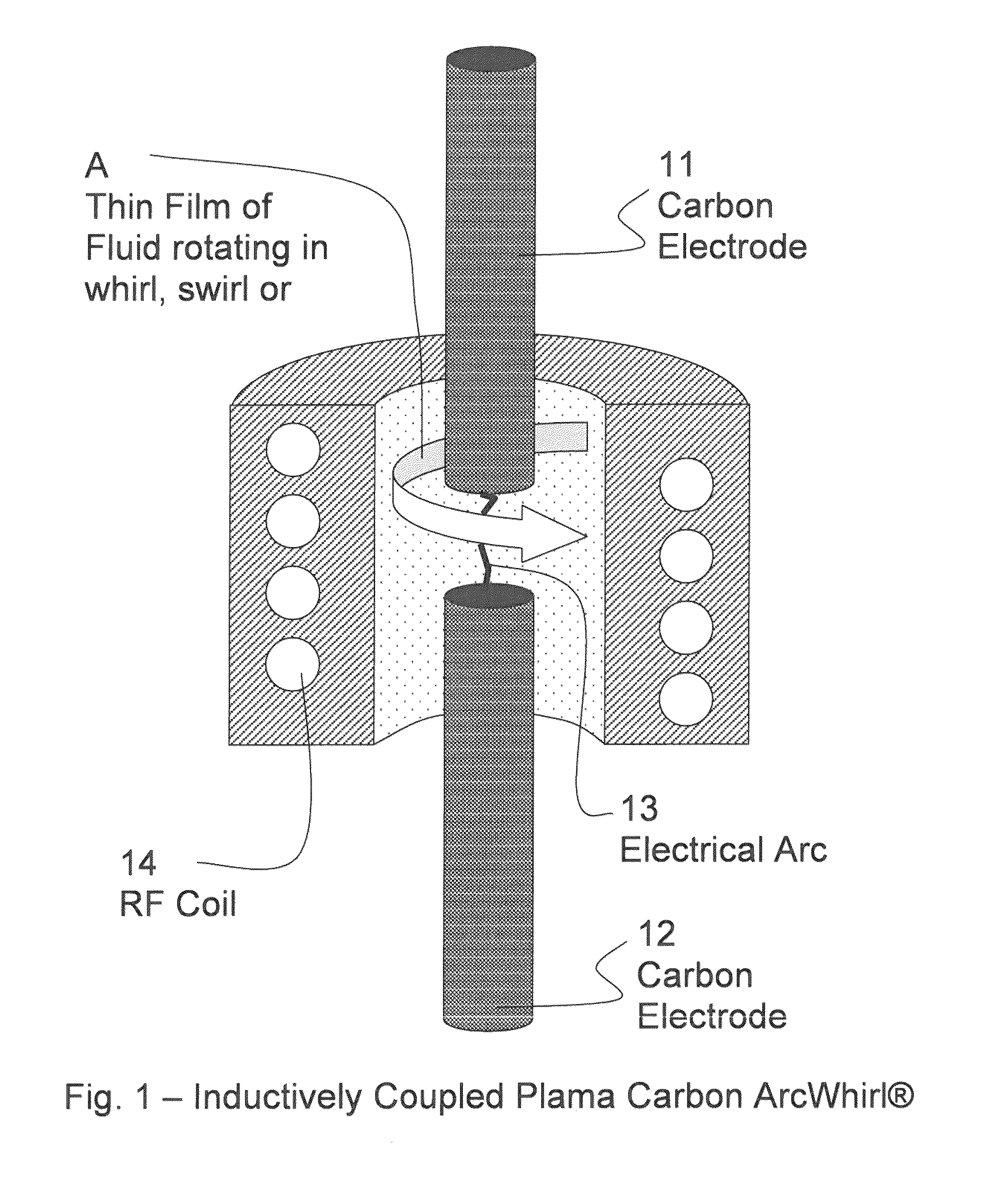

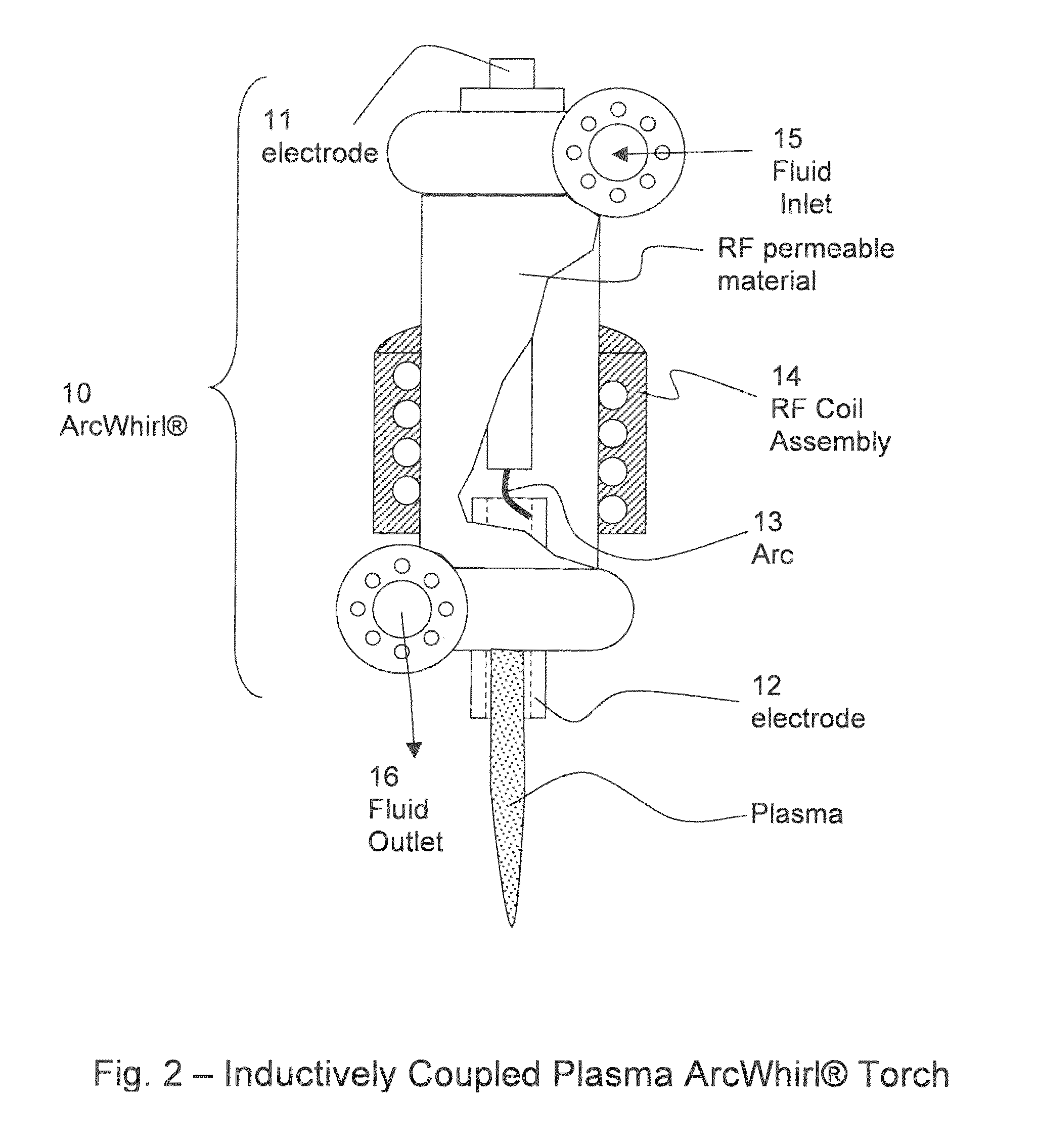

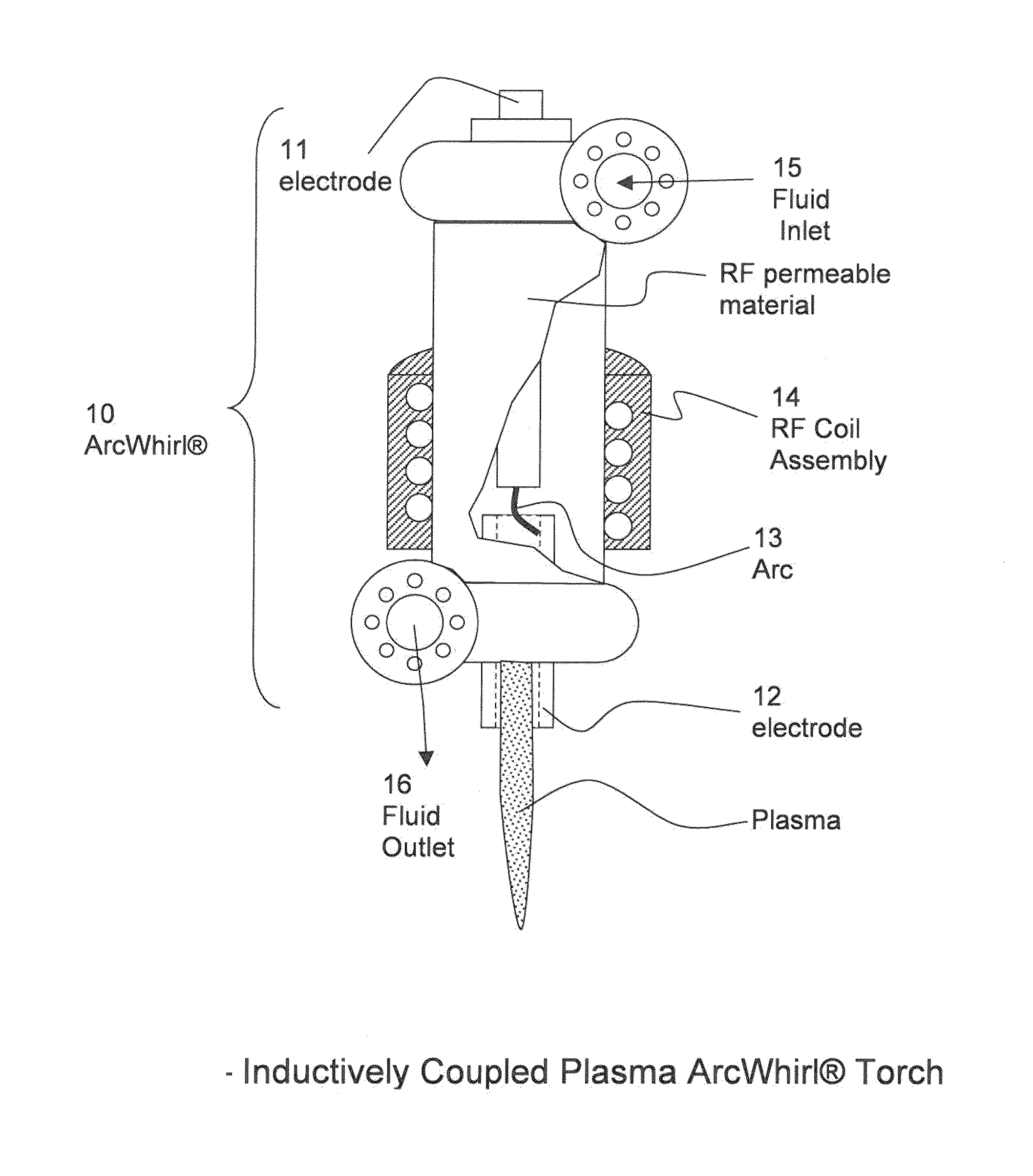

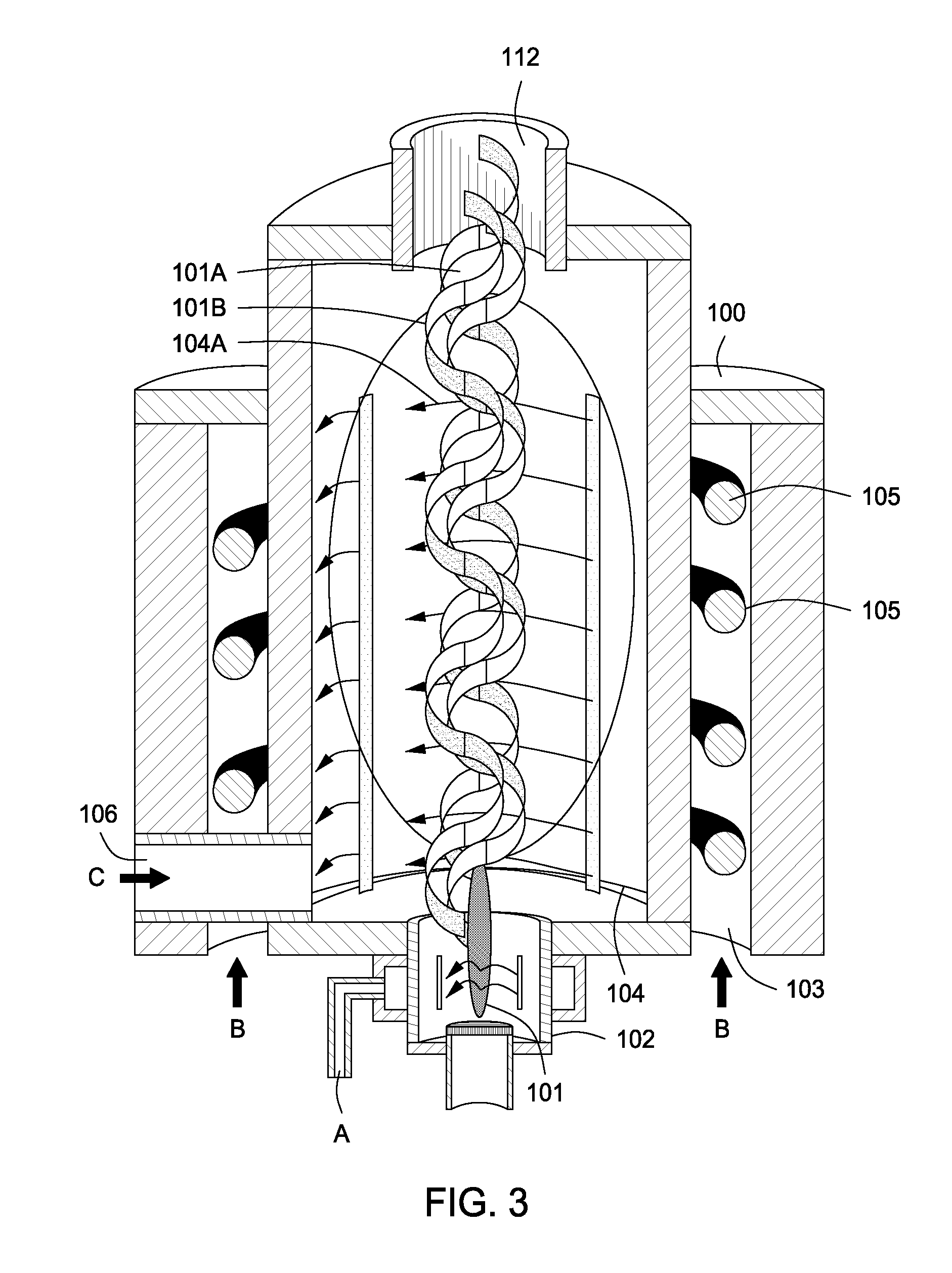

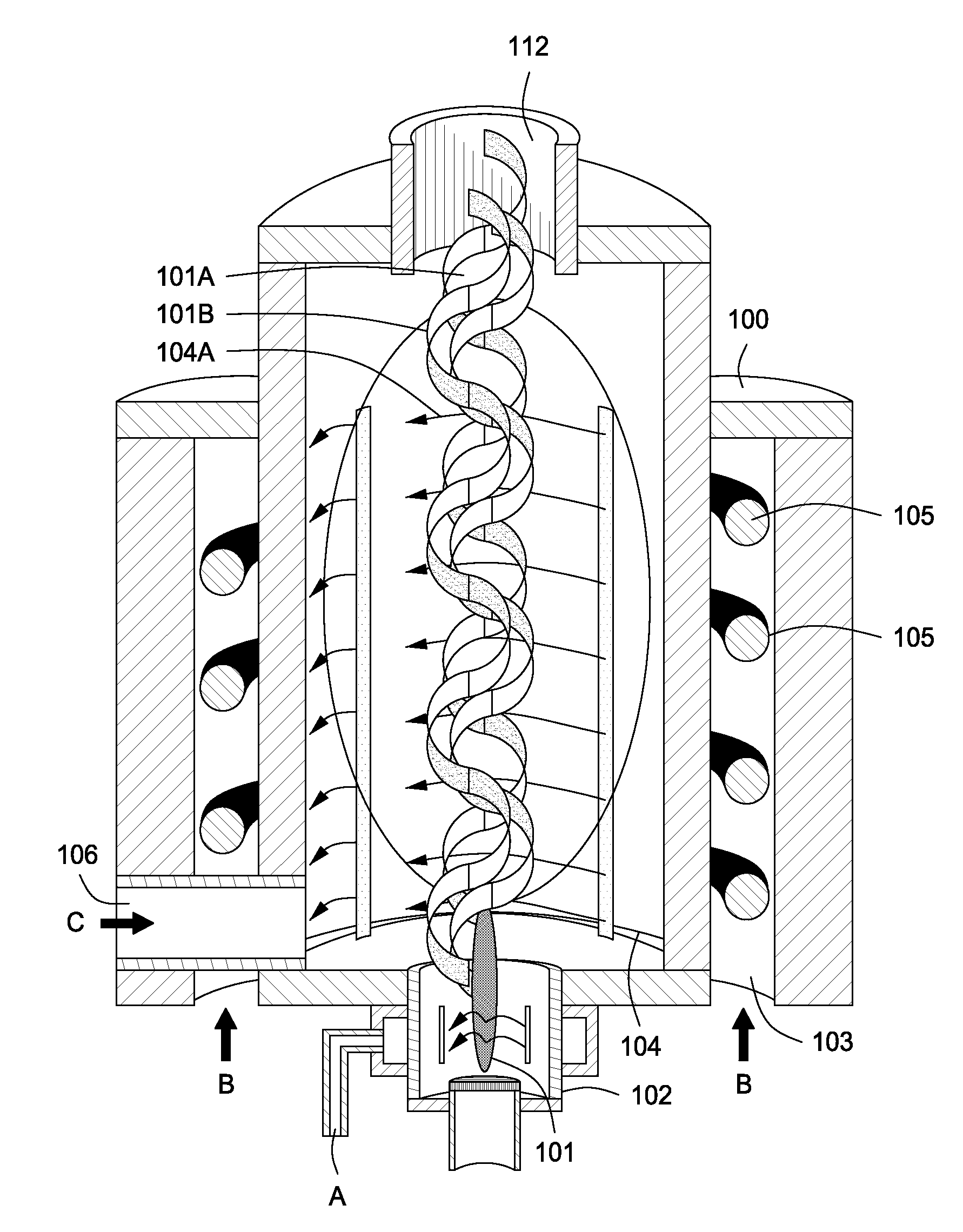

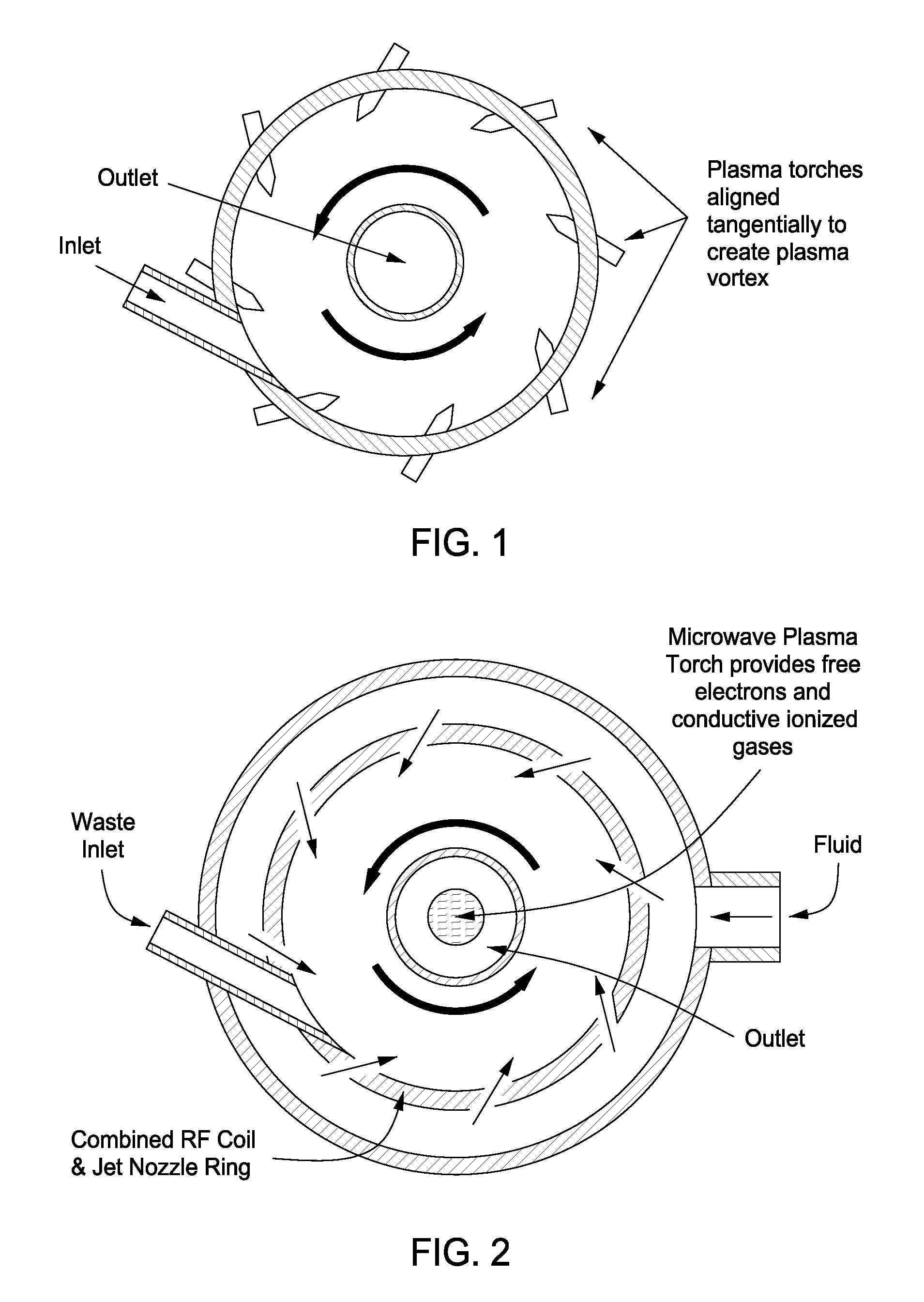

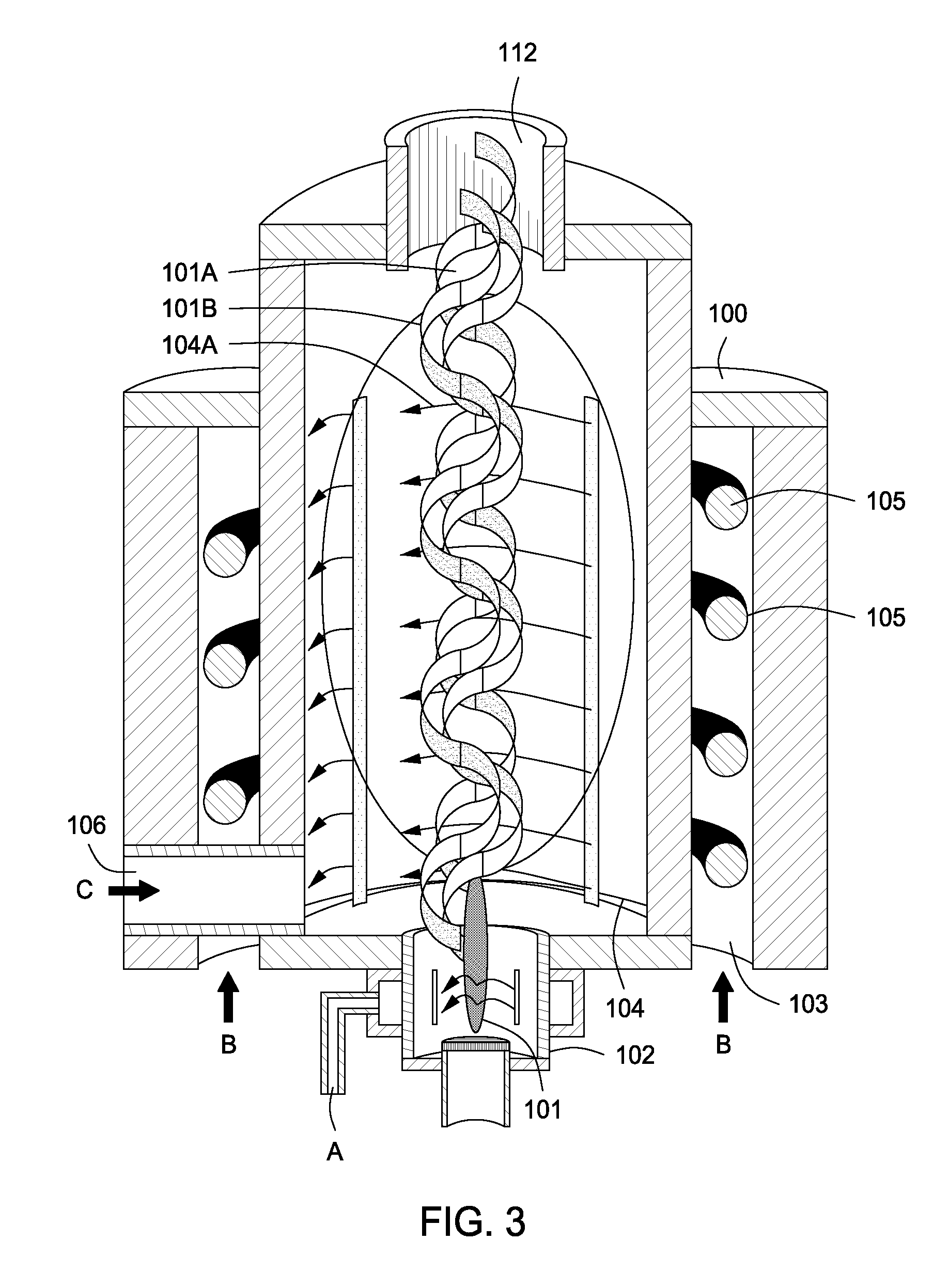

A plasma system includes a plasma arc torch, a cylindrical tube and an eductor. The plasma arc torch includes a cylindrical vessel having a first end and a second end, a first tangential inlet / outlet connected to or proximate to the first end, a second tangential inlet / outlet connected to or proximate to the second end, an electrode housing connected to the first end such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, and (b) extends into the cylindrical vessel, and a hollow electrode nozzle connected to the second end of the cylindrical vessel. The cylindrical tube is attached to the hollow electrode nozzle and aligned with the longitudinal axis, the cylindrical tube having a side inlet and a radio frequency coil disposed around or embedded within the cylindrical tube. The eductor is attached to the cylindrical tube and aligned with the longitudinal axis.

Owner:FORET PLASMA LABS

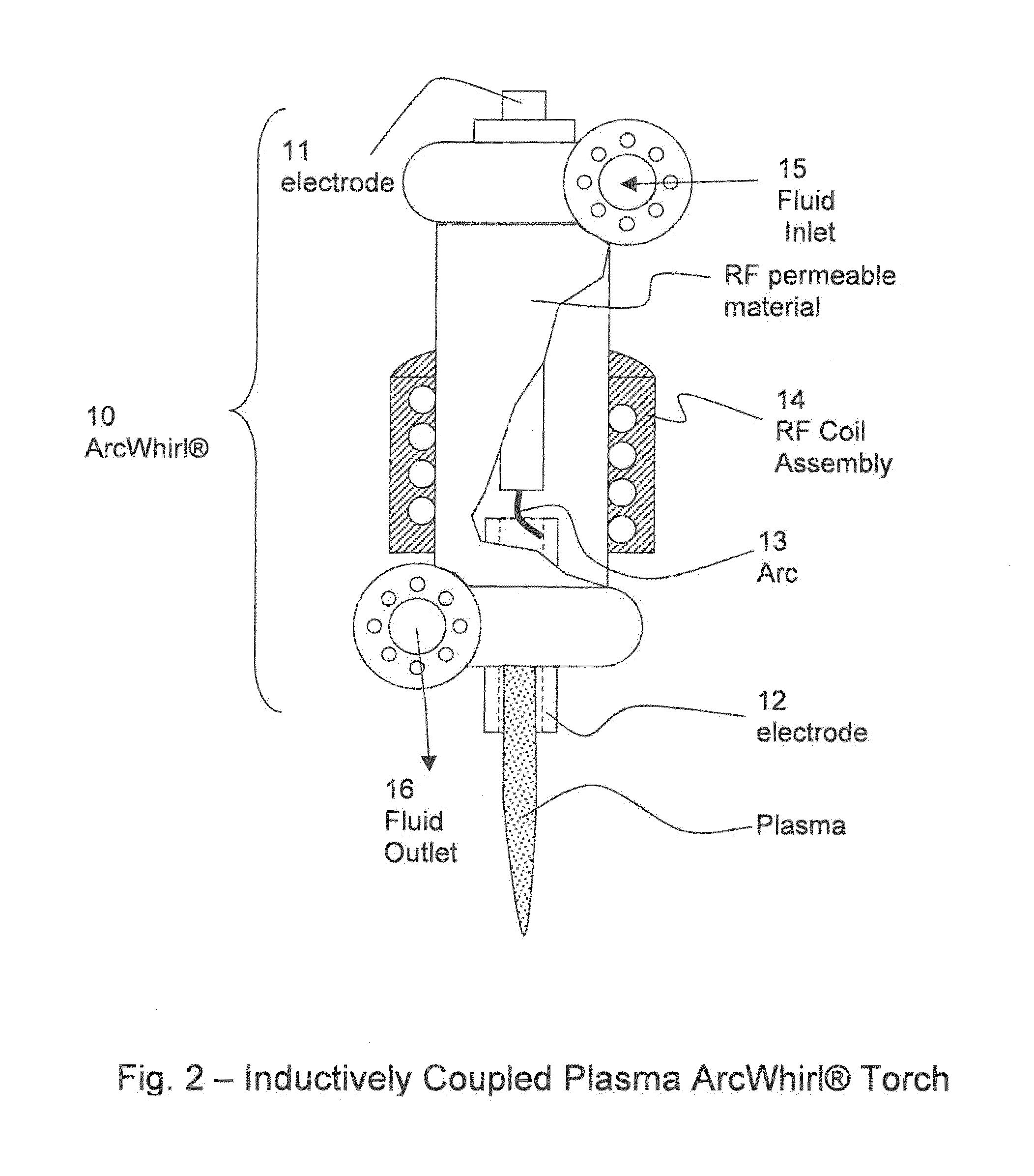

Plasma whirl reactor apparatus and methods of use

ActiveUS20150041454A1Maximize anisotropyDecrease productivityElectric discharge tubesGas-gas reaction as plasma stateEngineeringPlasma arc welding

A plasma system includes a plasma arc torch, a cylindrical tube and an eductor. The plasma arc torch includes a cylindrical vessel having a first end and a second end, a first tangential inlet / outlet connected to or proximate to the first end, a second tangential inlet / outlet connected to or proximate to the second end, an electrode housing connected to the first end such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, and (b) extends into the cylindrical vessel, and a hollow electrode nozzle connected to the second end of the cylindrical vessel. The cylindrical tube is attached to the hollow electrode nozzle and aligned with the longitudinal axis, the cylindrical tube having a side inlet and a radio frequency coil disposed around or embedded within the cylindrical tube. The eductor is attached to the cylindrical tube and aligned with the longitudinal axis.

Owner:FORET PLASMA LABS

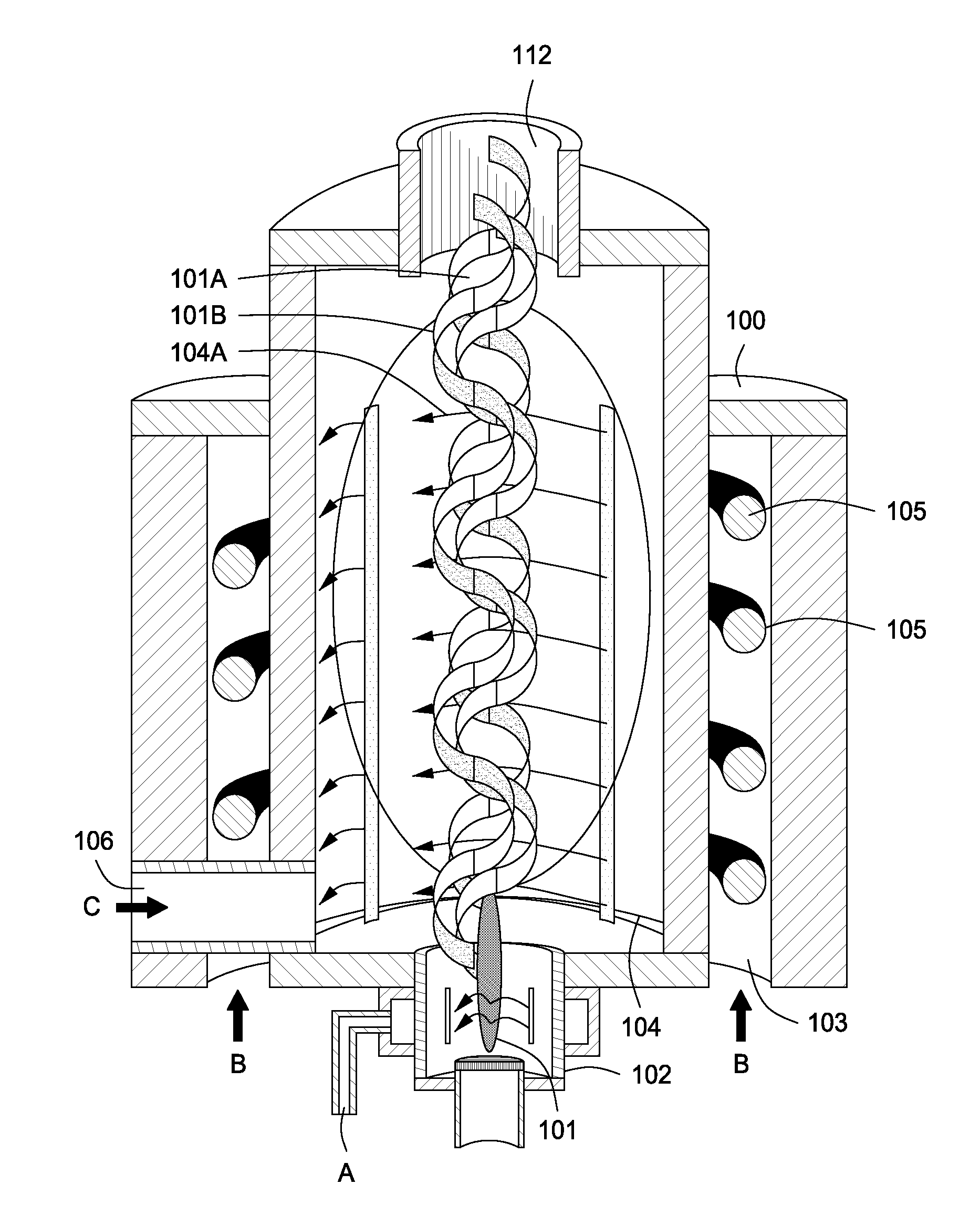

Plasma whirl reactor apparatus and methods of use

InactiveUS20100044483A1Calcium/strontium/barium carbonatesAluminium compoundsSingle processAngular momentum

An apparatus for synergistically combining a plasma with a comminution means such as a fluid kinetic energy mill (jet mill), preferably in a single reactor and / or in a single process step is provided by the present invention. Within the apparatus of the invention potential energy is converted into kinetic energy and subsequently into angular momentum by means of wave energy, for comminuting, reacting and separation of feed materials. Methods of use of the apparatus in the practice of various processes are also provided by the present invention.

Owner:FORET PLASMA LABS

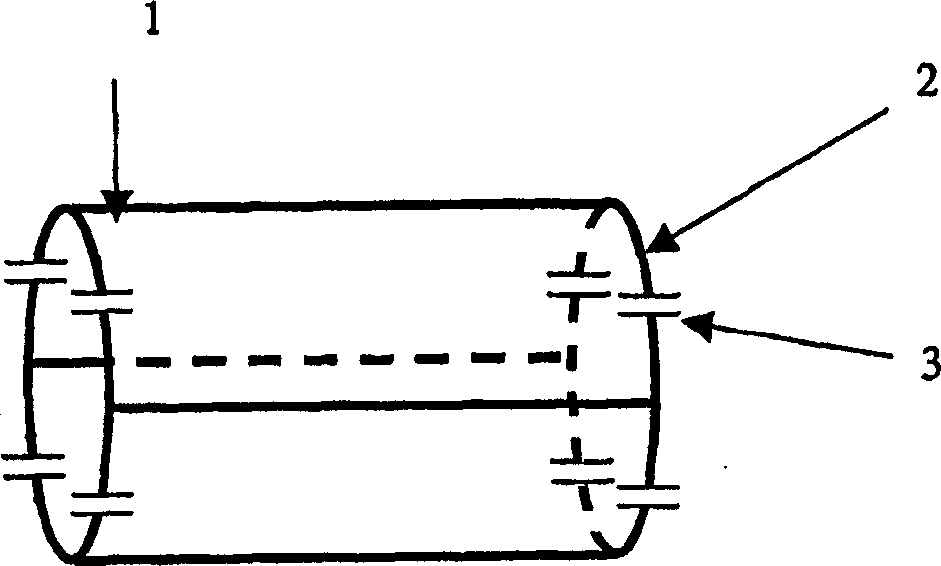

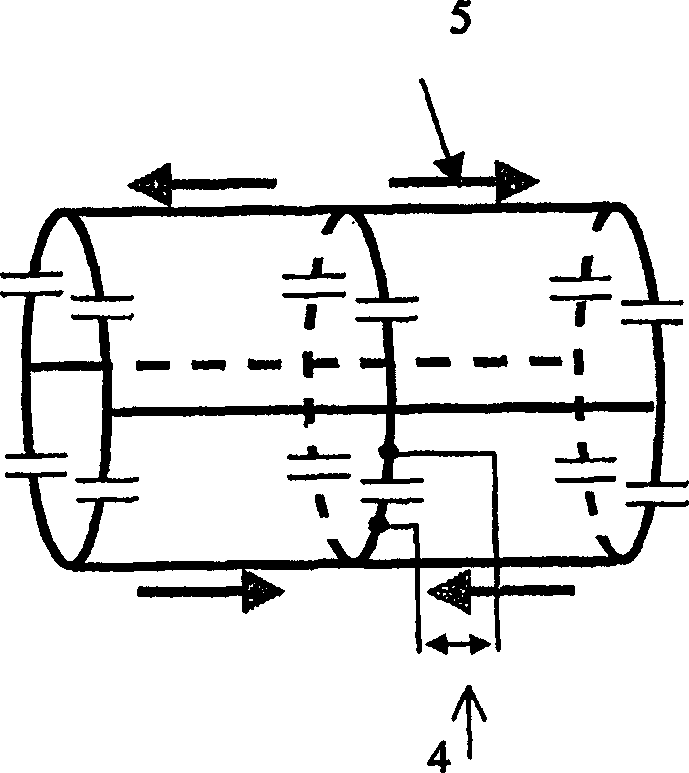

Rotating plasma current drive

InactiveUS20050249324A1Electric discharge tubesNuclear energy generationRotational axisElectrode Contact

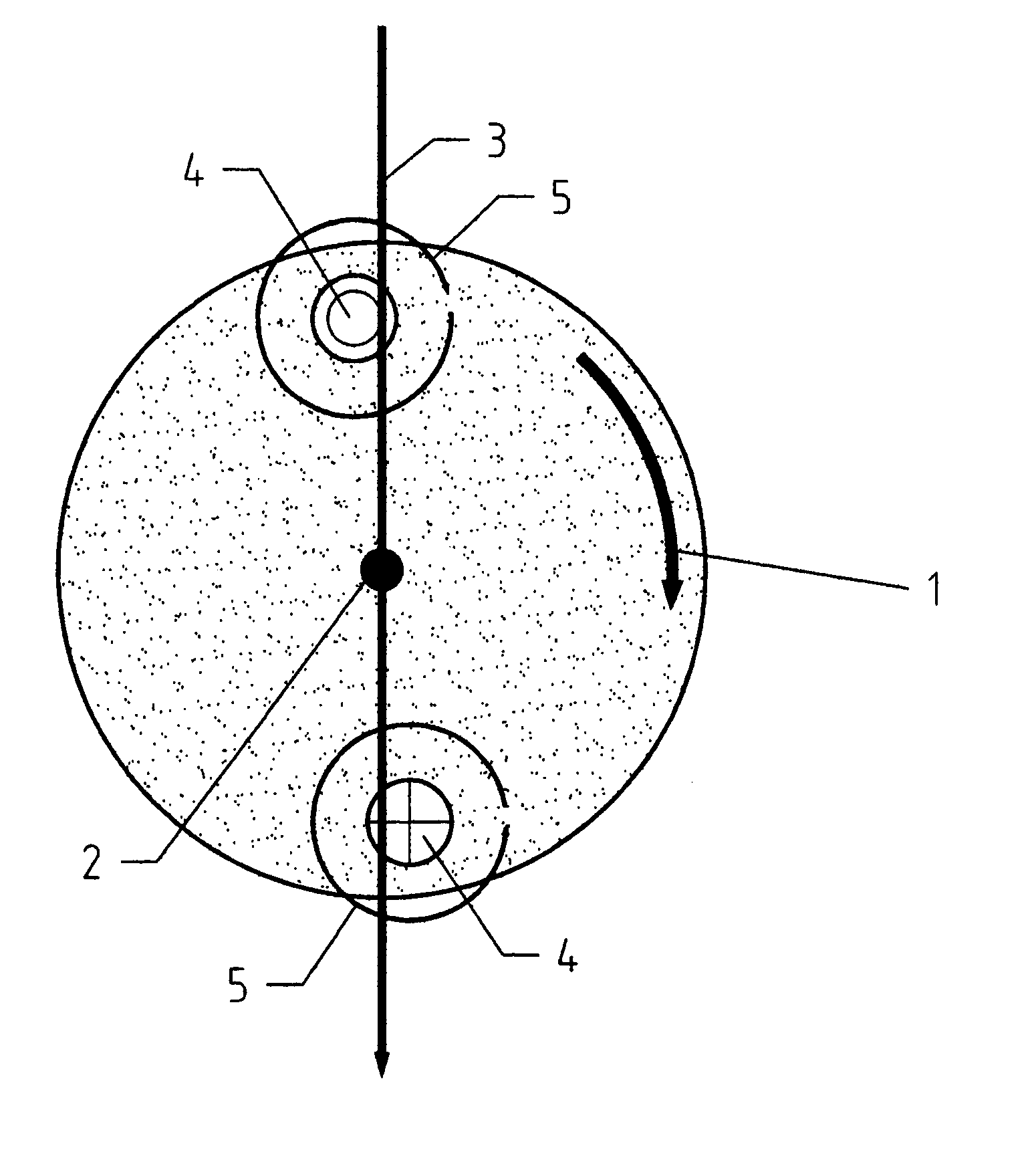

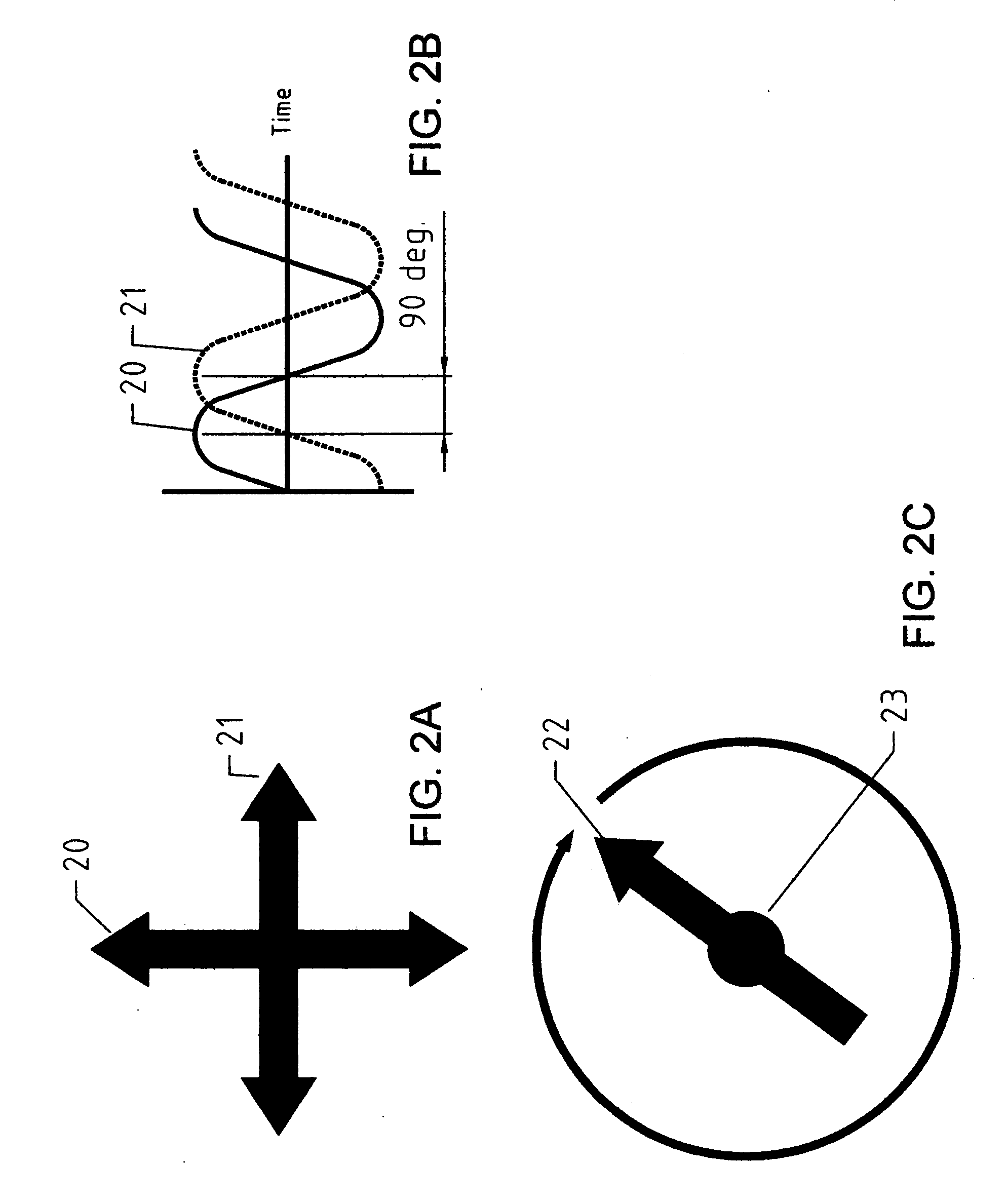

The present invention includes electromagnetic methods and apparatus to form a sustained direct current loop in a conductive fluid such as plasma for applications including gas discharge arc lamps and fusion confinement systems. The current loop is driven by rotating plasma within a stationary magnetic field perpendicular to the axis of rotation. Polyphase rotating electric or magnetic fields drive the plasma rotation, and the interaction between the rotating plasma and the stationary field forms and sustains the current loop. Plasma cooling and contamination are minimized since, unlike conventional direct current drive methods and apparatus, no electrodes contact the plasma.

Owner:MEACHAM GEORGE BEVAN KIRBY

Plasma whirl reactor apparatus and methods of use

InactiveUS20100044477A1Calcium/strontium/barium carbonatesAluminium compoundsSingle processAngular momentum

An apparatus for synergistically combining a plasma with a comminution means such as a fluid kinetic energy mill (jet mill), preferably in a single reactor and / or in a single process step is provided by the present invention. Within the apparatus of the invention potential energy is converted into kinetic energy and subsequently into angular momentum by means of wave energy, for comminuting, reacting and separation of feed materials. Methods of use of the apparatus in the practice of various processes are also provided by the present invention.

Owner:FORET PLASMA LABS

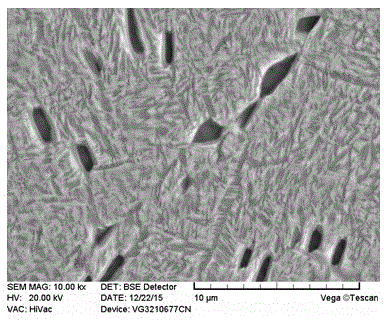

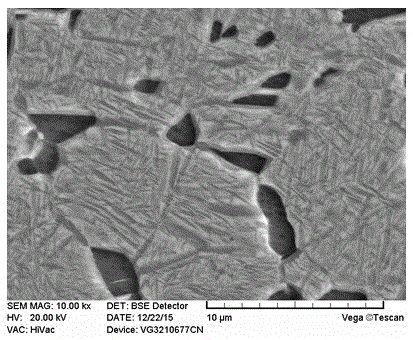

Preparation method for DD5 nickel-base high-temperature alloy powder for 3D printing

ActiveCN107326218AAvoid it happening againImprove liquidityAdditive manufacturing apparatusTransportation and packagingShielding gasHeat treated

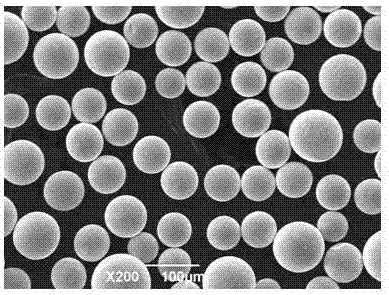

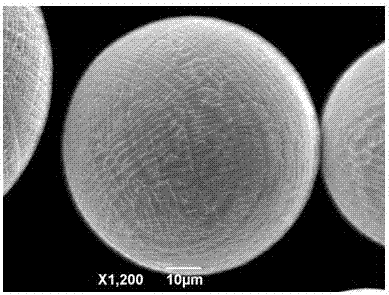

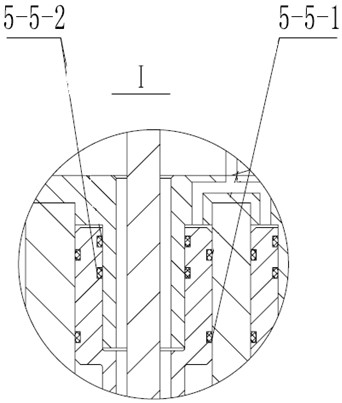

A preparation method for DD5 nickel-base high-temperature alloy powder for 3D printing includes the following steps that (1),dosing is conducted according to nominal compositions (by mass) of 7.0% of Cr, 7.5% of Co, 5.0% of W, 6.2% of Al, 6.5% of Ta, 1.5% of Mo, 3.0% of Re, 0.15% of Hf, 0.05% of C and the balance Ni, a DD5 master ingot with the diameter which is greater than 80 mm is prepared through vacuum induction melting to cut off defects of a head contraction cavity; (2) composition homogenization heat treatment is conducted on the DD5 master ingot by adopting a high vacuum heat treatment furnace, and then furnace cooling is conducted on the DD5 master ingot to the room temperature, and the vacuum degree in the heat treatment process is less than 5*10[-4] Pa; (3) the DD5 alloy ingot is fine-machined into an electrode bar; (4) DD5 alloy powder is prepared by adopting a plasma rotation electrode method, inert gas is adopted as protective gas, and the temperature of the inert gas filled into an atomizing chamber is controlled at -50-0 DEG C; and (5) under the protection of the inert gas, screening treatment is conducted on prepared spherical DD5 alloy powder by adopting a supersonic wave oscillating screen, and the spherical DD5 alloy powder is obtained, the medium powder particle size is 53-106 micron, and the fine powder particle size is 15-53 micron.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

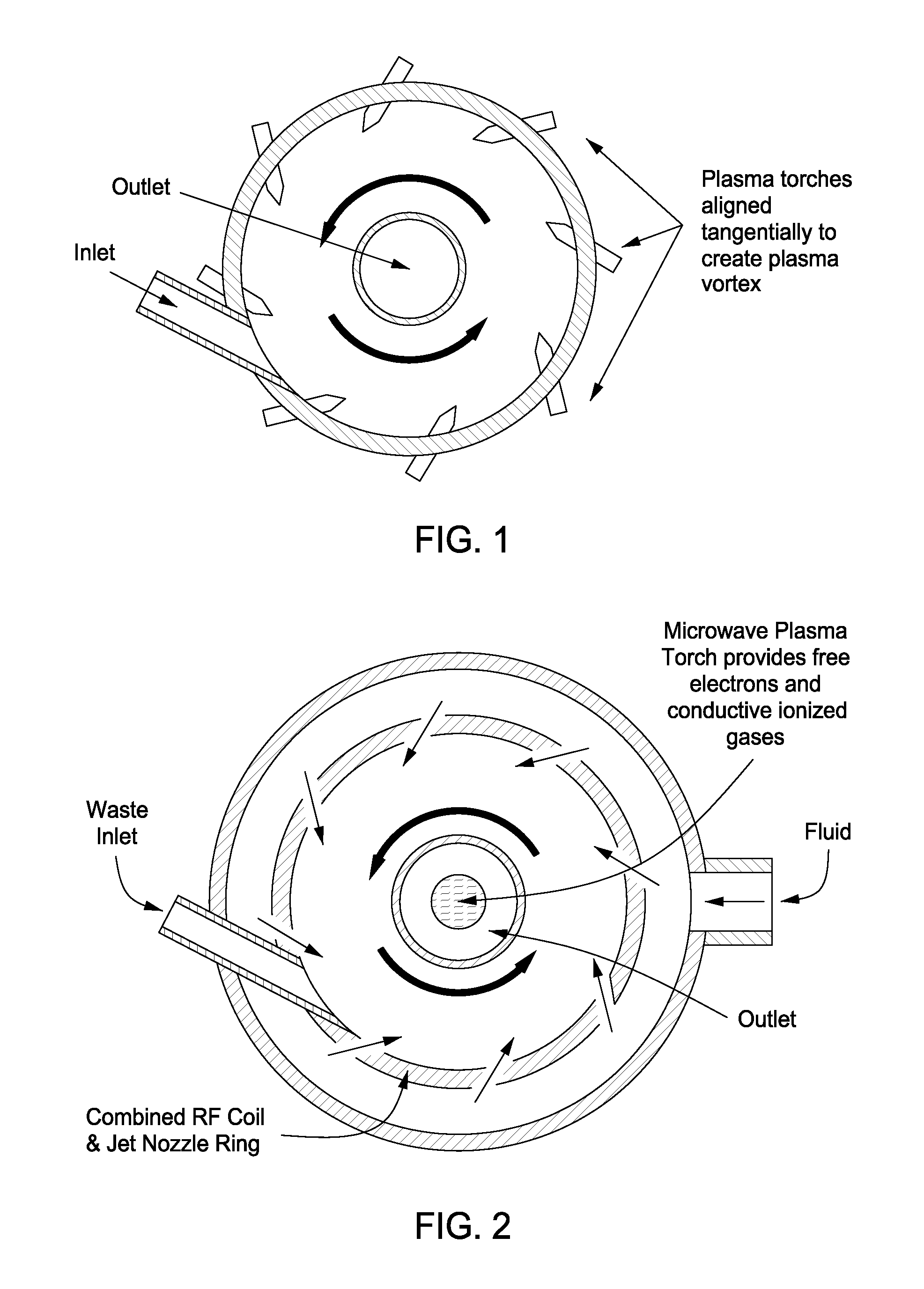

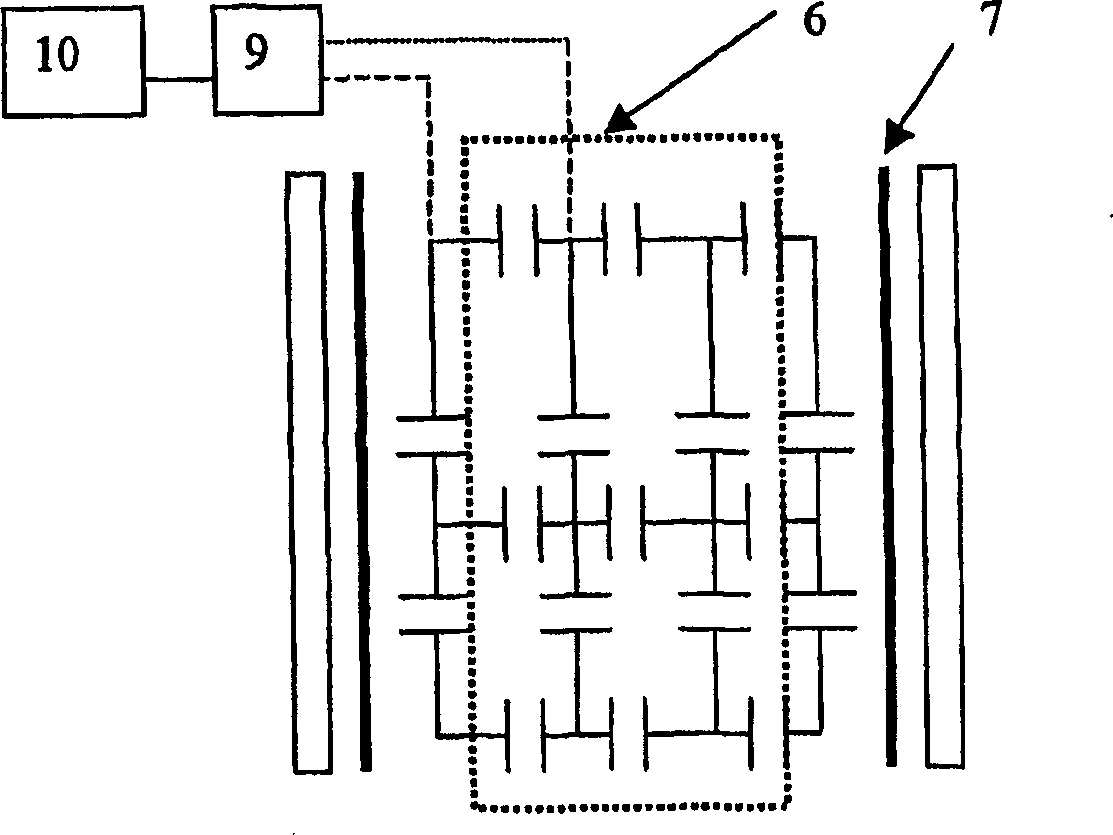

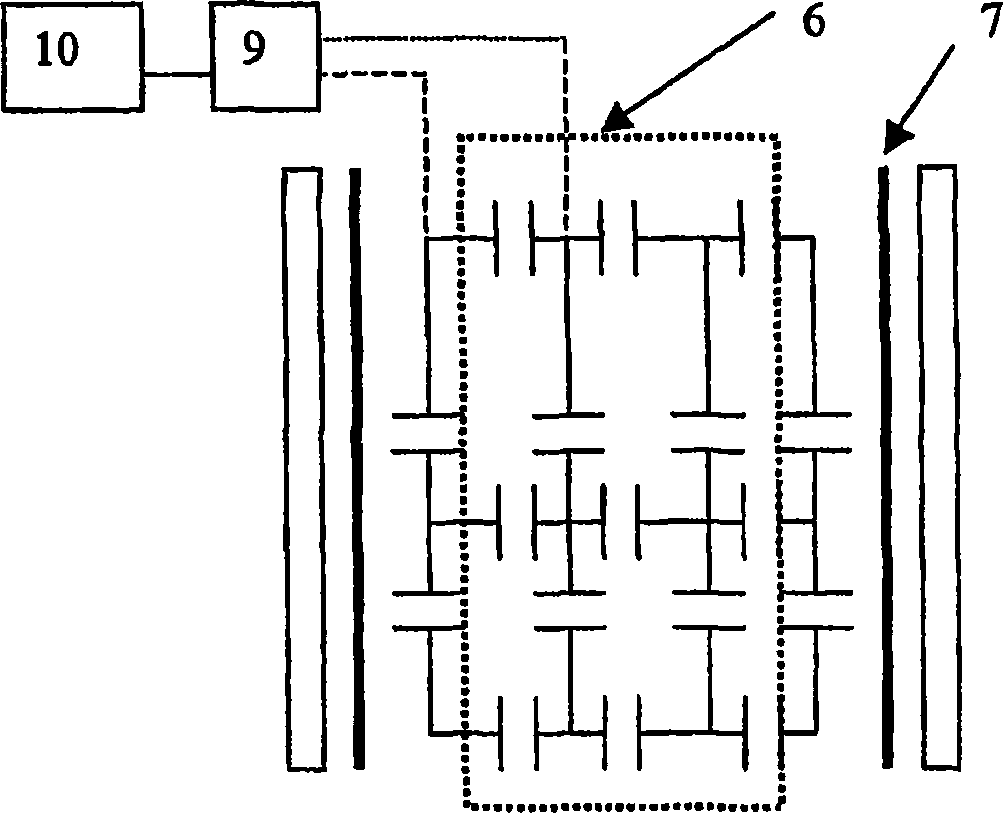

A high density plasma reactor

ActiveCN1809911AElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequency energyNuclear engineering

The high density RF plasma source of this invention uses a special antenna configuration to launch waves at frequency such as 13,56MHz. The tunability of this antenna allows to adapt actively the coupling of the RF energy into an evolutive plasma as found in plasma processings in semiconductor manufacturing. This plasma source can be used for the following applications : plasma etching, deposition, sputtering systems, space propulsion, plasma - based sterilization , plasma abatement systems. In another embodiment, the plasma source is in conjunction with one or several process chambers , which comprise an array of magnets and RF coils too . These elements can be used, on one hand, for plasma confinement or the active plasma control (Plasma rotation ) thanks to feedback control approach , and one the other hand, for in situ NMR Monitoring or analysis such as moisture monitoring inside a process chamber , before or after the plasma process, or for in situ NMR Inspection of wafers or others workpieces.

Owner:HELYSSEN

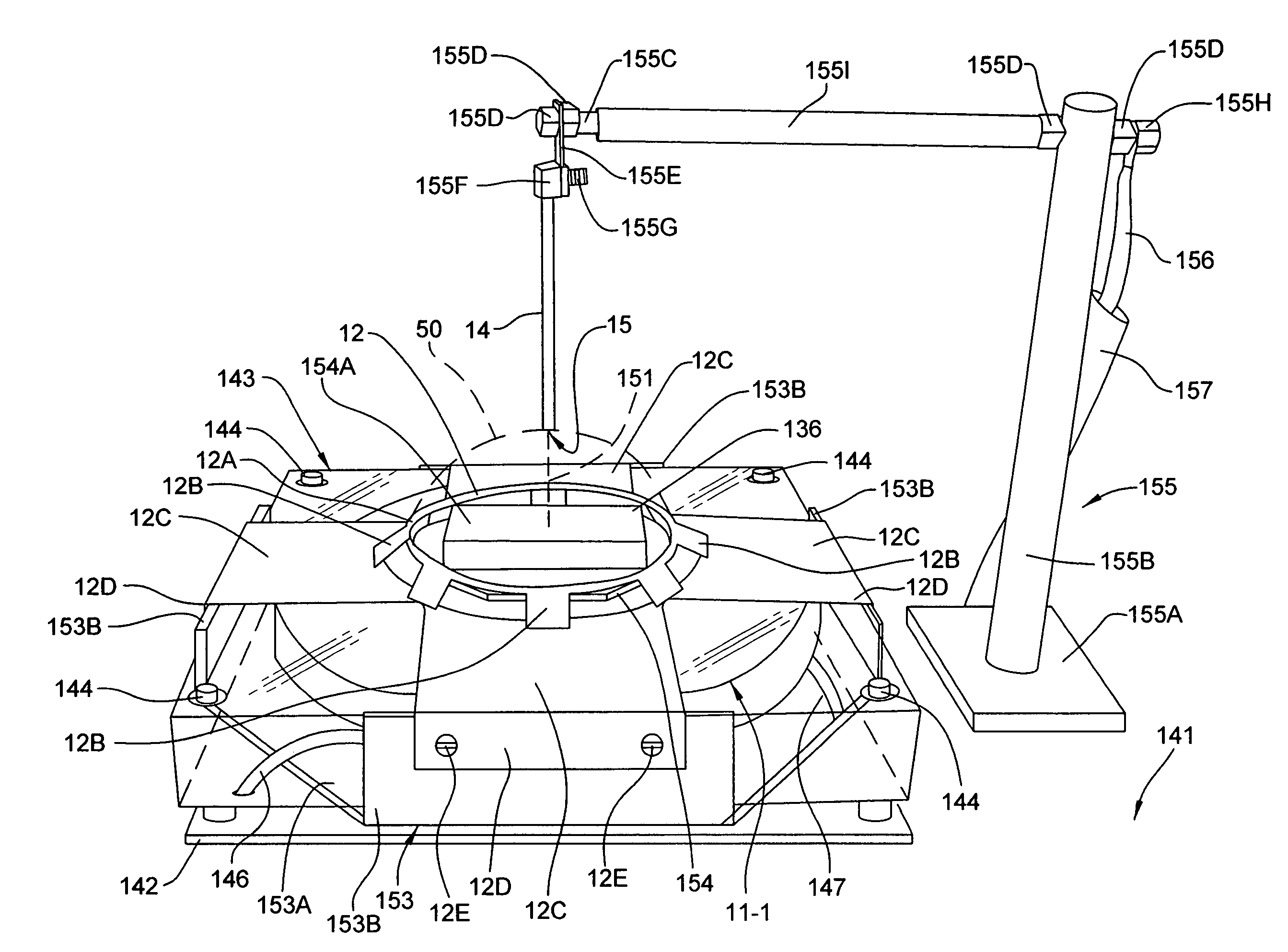

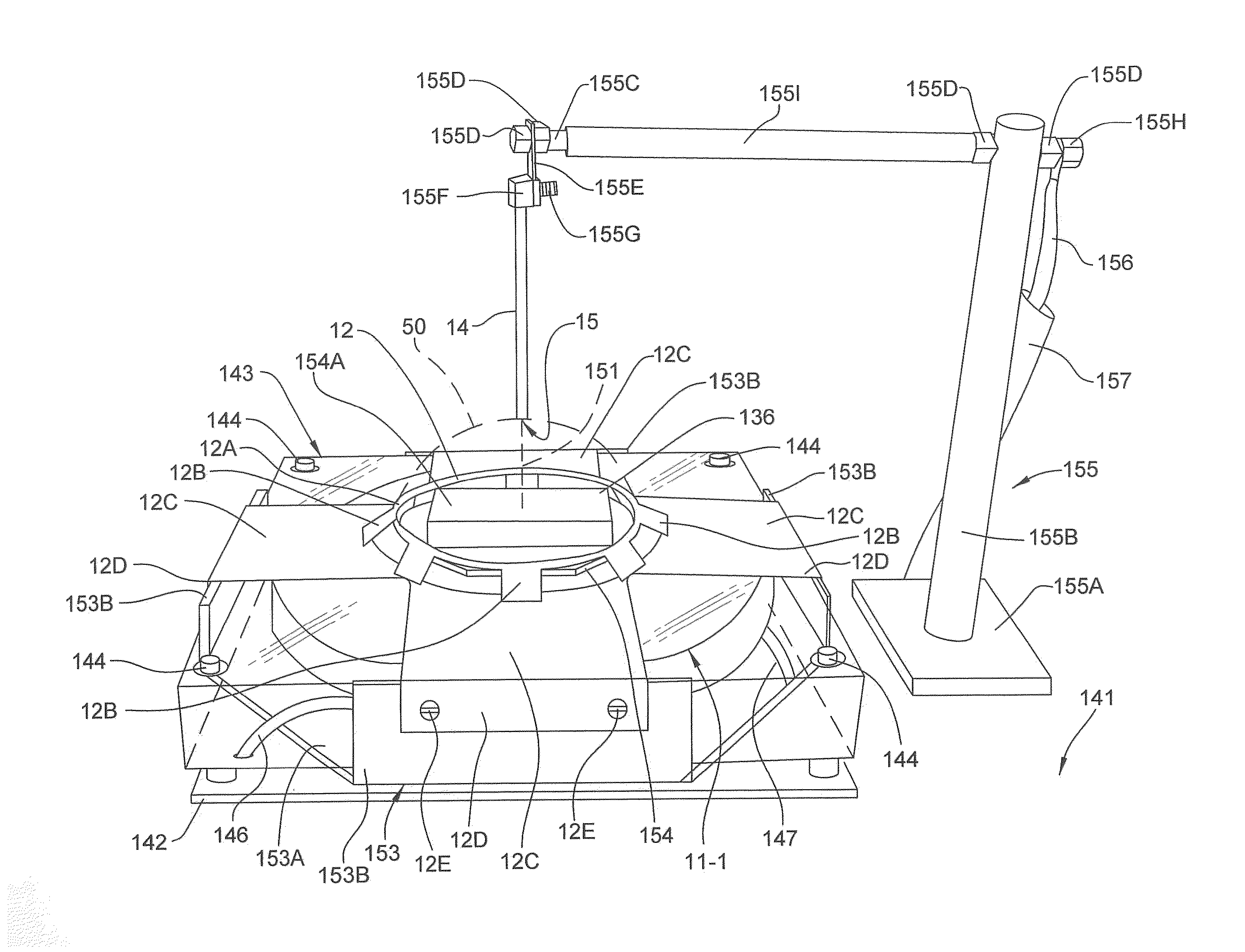

High-density Ti2AlNb powder alloy near-net forming technology

The invention provides a high-density Ti2AlNb powder alloy near-net forming technology.The technology comprises the following steps that 1, a Ti2AlNb alloy bar is smelted by taking components of Ti2AlNb-based alloy as ingredients; 2, the alloy bar processed through finish turning is put into plasma rotation electrode powder preparing equipment, and the Ti2AlNb alloy bar is prepared into Ti2AlNb spherical powder under the inert gas shielding condition; 3, the prepared Ti2AlNb spherical powder is located into a stainless steel or low-carbon steel sheath; 4, the sheath which contains the Ti2AlNb spherical powder and is compacted through vibration is degassed; 5, hot isostatic pressing forming is performed on the degassed sheath.The Ti2AlNb powder alloy prepared through the method has the isotropic character and is high in density degree, uniform in tissue and component, excellent in mechanical property and capable of achieving Ti2AlNb alloy parts with the large size and complex shapes.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

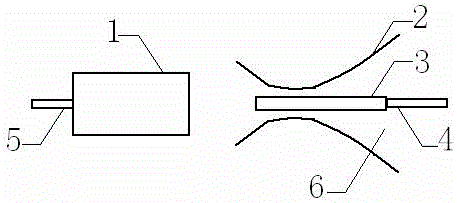

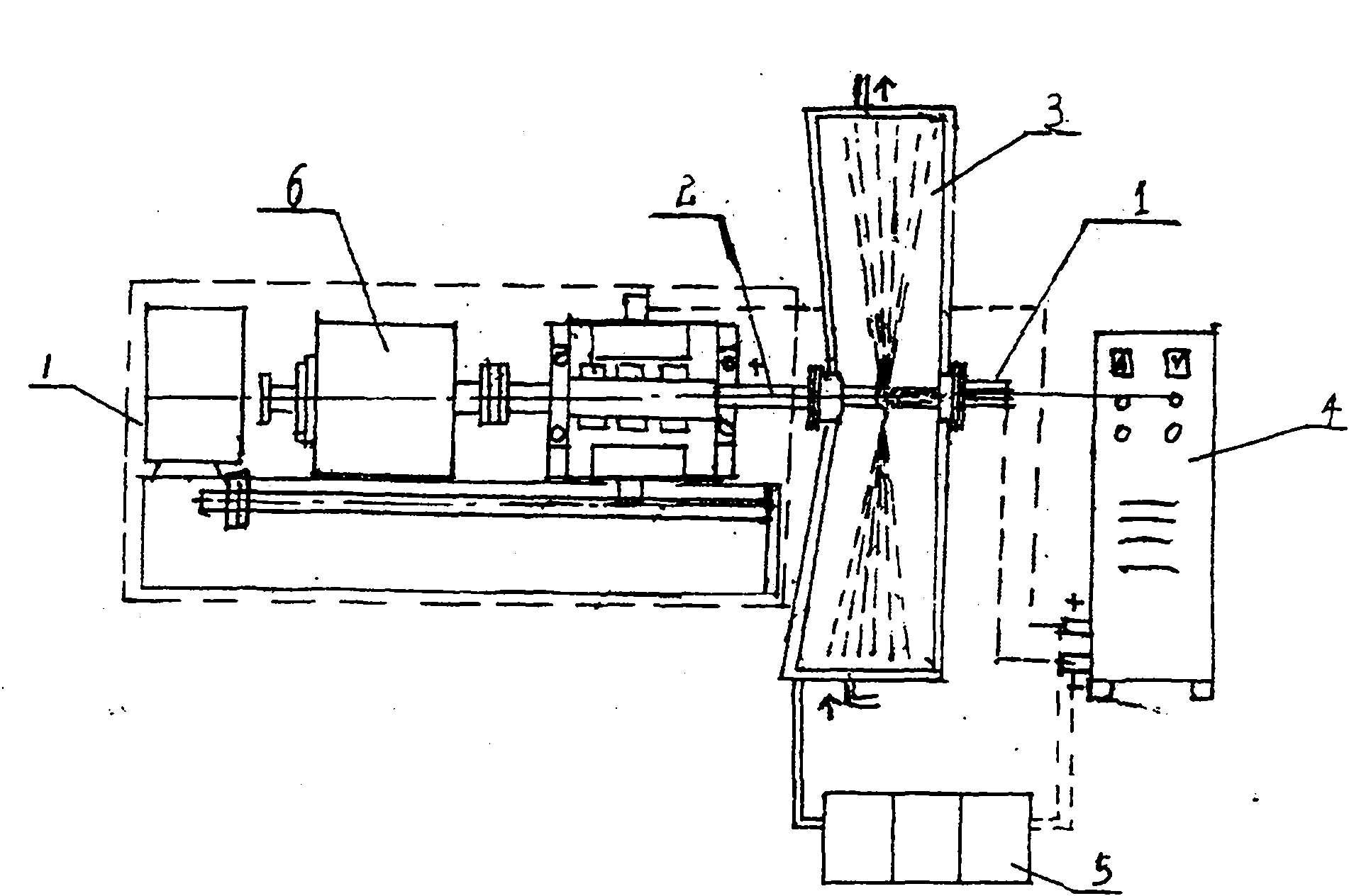

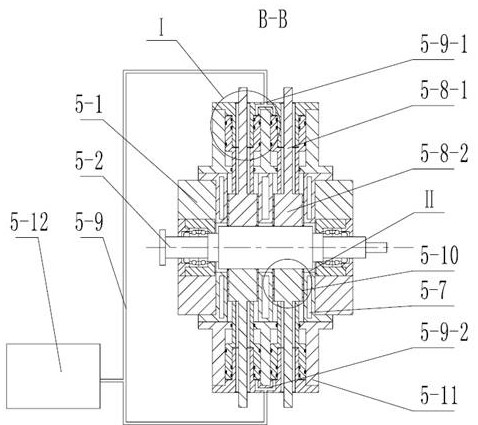

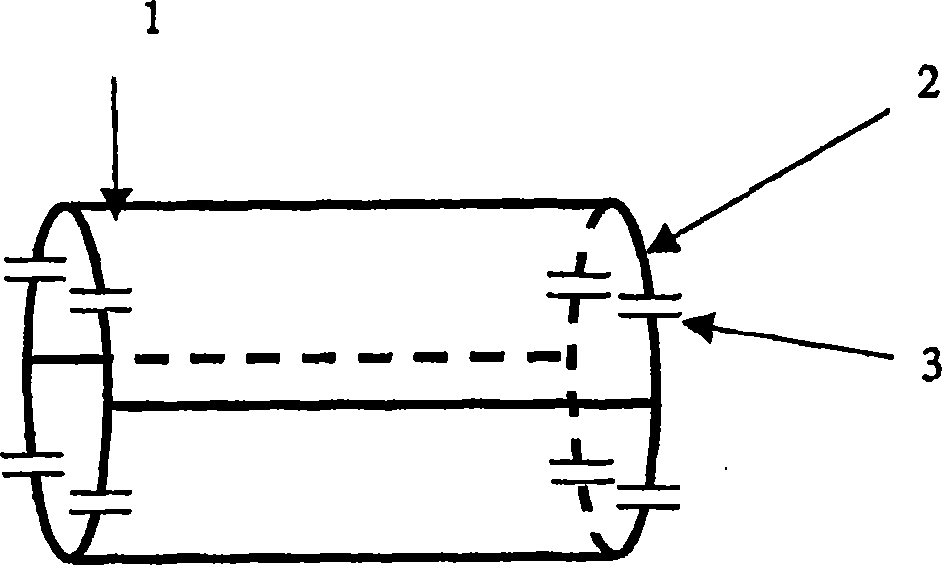

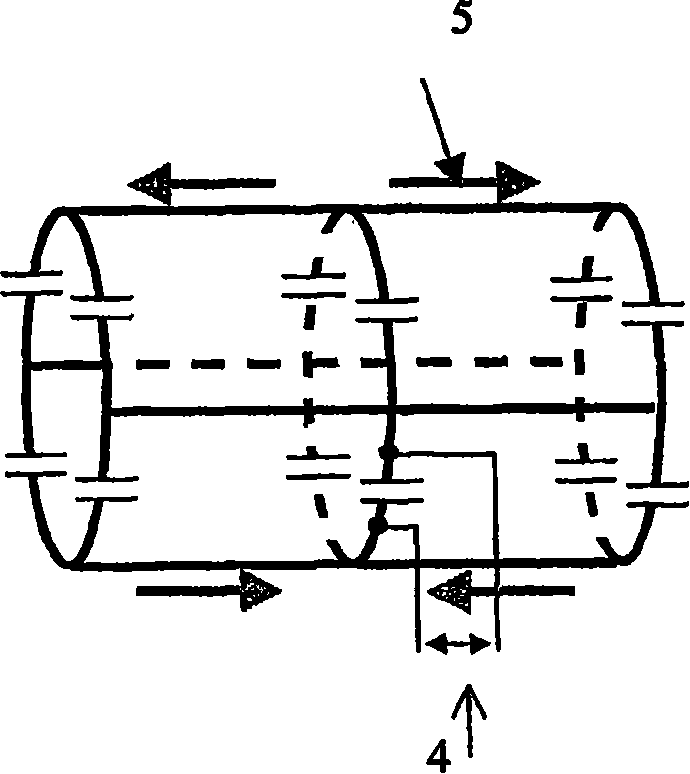

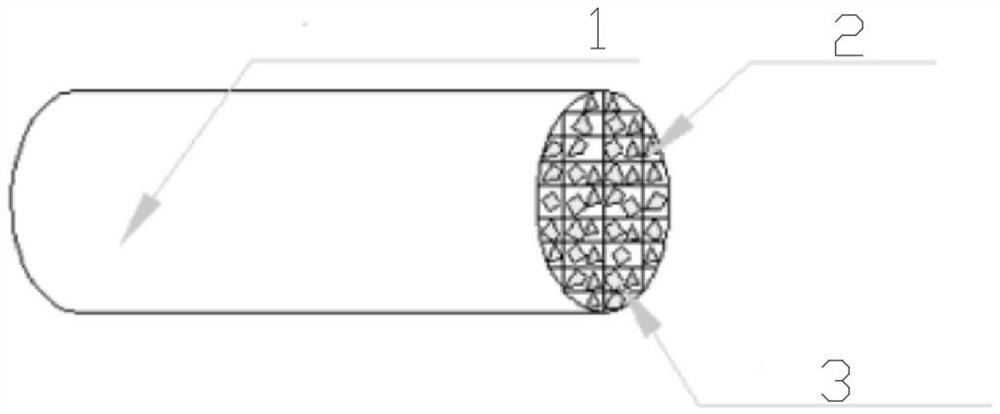

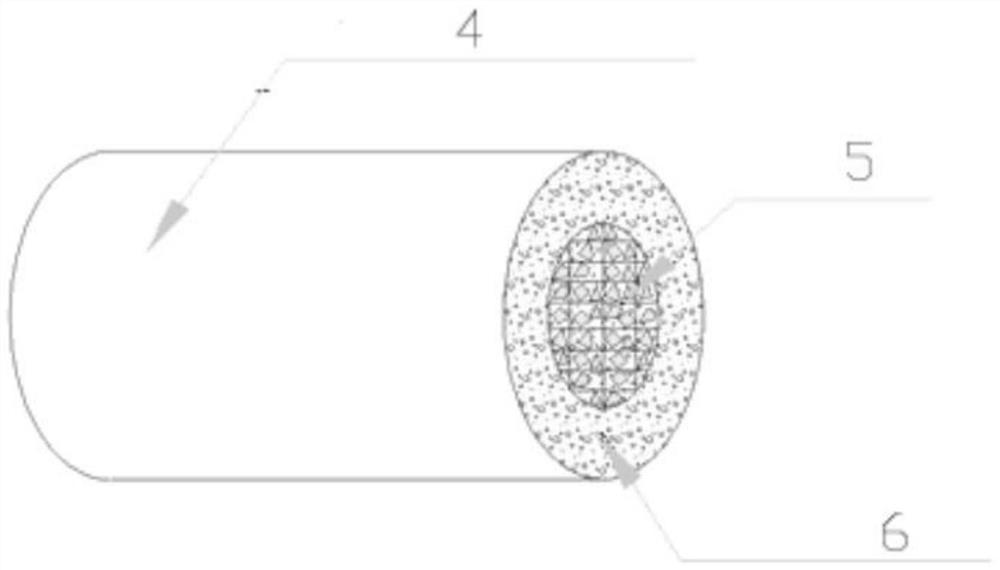

Rotating electrode preparing micro spherical metal powder and method of rotating electrode

The invention discloses a rotating electrode preparing micro spherical metal powder and a method of the rotating electrode. A plasma gun is composed of a Laval spraying pipe and a plasma gun head capable of conducting axial feeding, and a plasma gun inner gas way is formed between the plasma gun head and the Laval spraying pipe. The plasma gun head is connected with a gun head push rod, and a rotating electrode bar is connected with an electrode bar push rod. The axial relative position of the rotating electrode bar and the axial relative position of the plasma gun head are controlled and adjusted through the electrode bar push rod and the gun head push rod. A cylinder electrode bar is used as the raw material, and a plasma rotation electrode process is used for conducting the first time of atomization; supersonic speed high-temperature inert gas exerted to an electrode bar melting pool and injected by the adjustable plasma gun head is used for conducting the second time of atomization; centrifugal force of a centrifugal atomization mechanism overcomes tension on the surface of alloy liquid to serve as the upper limit of the atomization collected powder granularity; the efficiency of converting atomization energy into atomization drop surface energy is greatly improved; and the yield of micro powder smaller than 50 microns is greatly increased compared with traditional centrifugal atomization.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

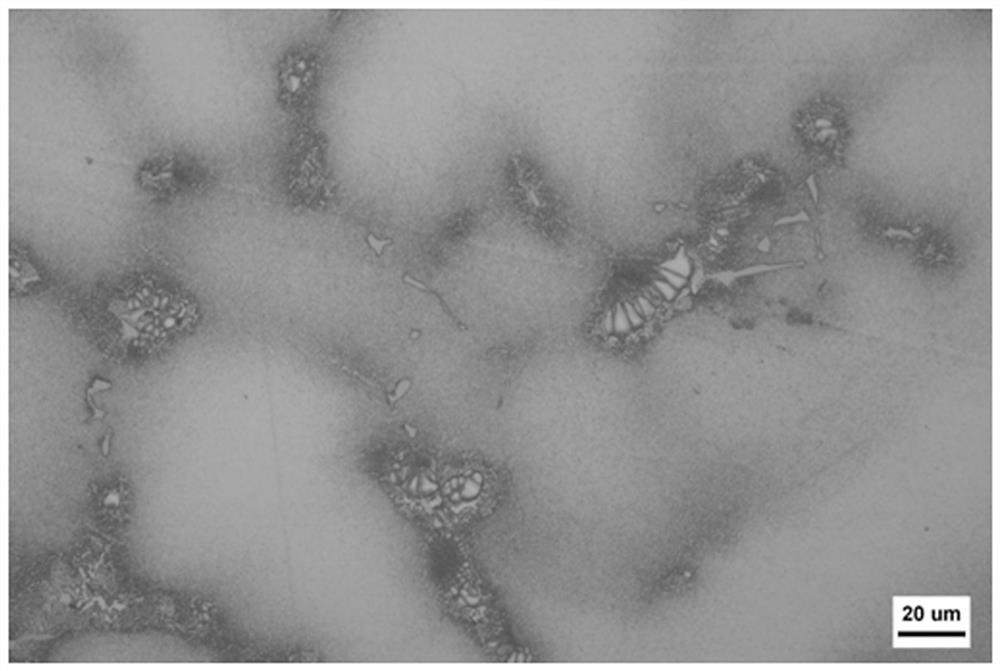

Method for preparing high temperature alloy GH 4169 metal globule by utilizing auxiliary plasma rotation electrode

The invention relates to a method for preparing high temperature alloy GH 4169 metal globule powder by utilizing a centrifugal process of an auxiliary plasma rotation electrode. Glow discharge plasma arcs are generated between the auxiliary plasma electrode and a consumption-type electrode made of cylindrical rotary high temperature alloy GH 4169 metal in a closed container under the protection of inert gases; one section of the high temperature alloy GH 4169 metal electrode near the plasma arcs is heated to form small drops of liquid via the high temperature generated by the plasma arcs; the small drops of liquid are thrown around through the centrifugal force; then the small drops of liquid of the high temperature alloy GH 4169 metal are air-cooled and solidified to form globules in the inert atmosphere of inert gases in the closed container so as to obtain high temperature alloy GH 4169 metal globules. In the method, the high temperature alloy GH 4169 metal globules with an average sphere diameter of 0.09-1.6mm and better monodispersity can be obtained. The prepared powdered metal globule has good sphericity, lower rate of abnormal particles and controllable sphere diameter. The method can be used for preparing special members of aerospace planes in the field of the laser solid shaping process.

Owner:张建利

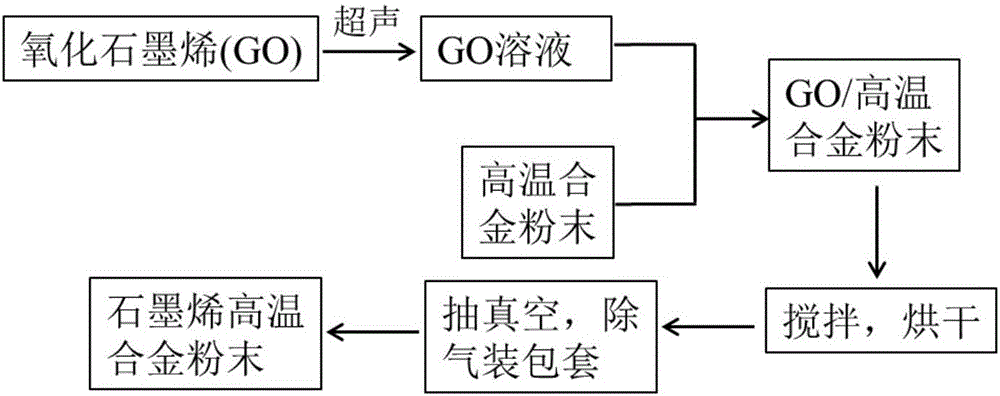

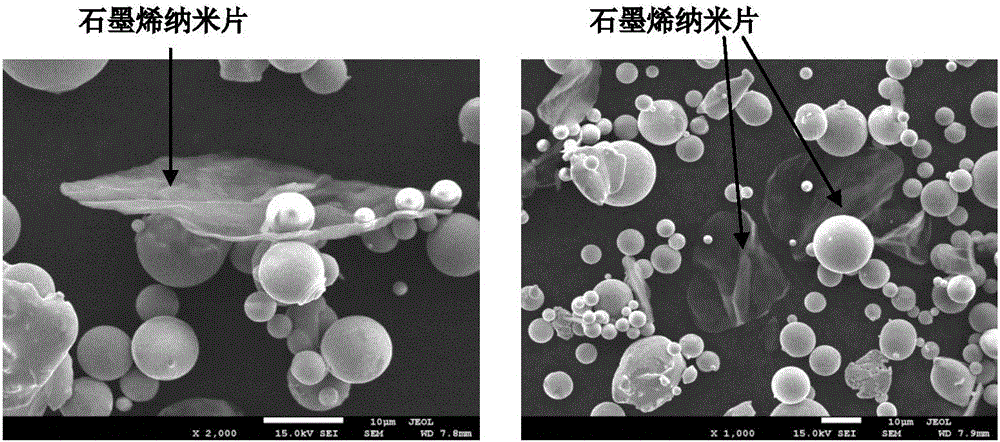

Wet mixing preparation method of nickel-based high-temperature alkene alloy powder

InactiveCN105834435AThe powder particle size is finer and more uniformProfit dispersionTransportation and packagingMetal-working apparatusAlloy compositeUltrasonic vibration

The invention proposes a preparation method of nickel-based high-temperature alkene alloy powder; and a wet mixing method is adopted to prepare the nickel-based high-temperature alkene alloy powder. Firstly, a graphene oxide slice is selected to dissolve in water to prepare a certain amount of graphene oxide solution; then, high-temperature alloy powder prepared by an argon atomizing method (AA) or a plasma rotating electrode method (PREP) is added to the graphene oxide solution, ultrasonic vibration stirring is performed to disperse the graphene oxide slice on the surfaces of high-temperature alloy powder particles; mixed graphene oxide / high-temperature alloy powder is washed, filtered and put in a drying oven for drying; and finally, the dried graphene oxide / high-temperature alloy powder is put into a stainless steel sheath, and vacuum degassing and heating are performed to prepare graphene / high-temperature alloy composite powder.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

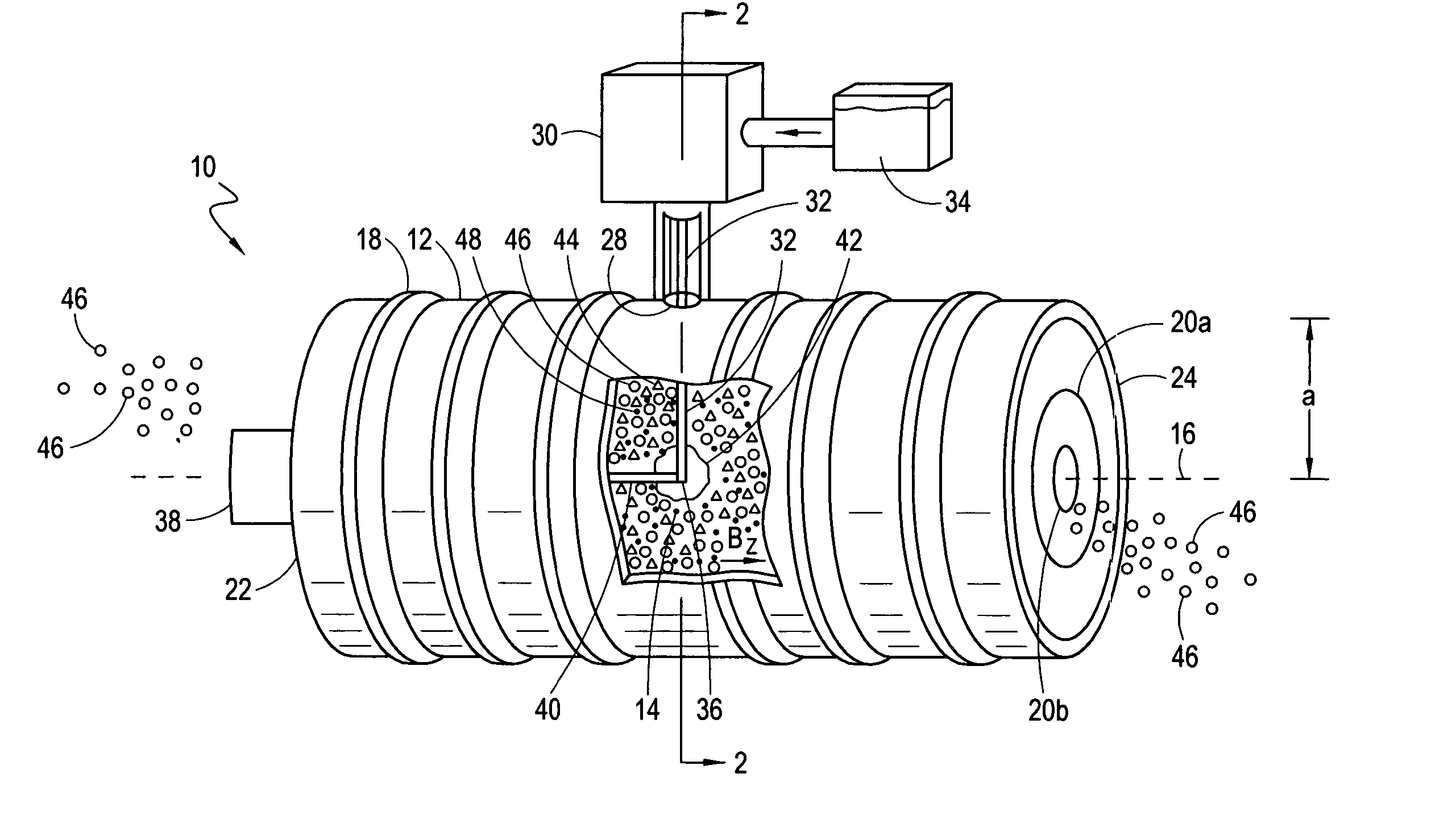

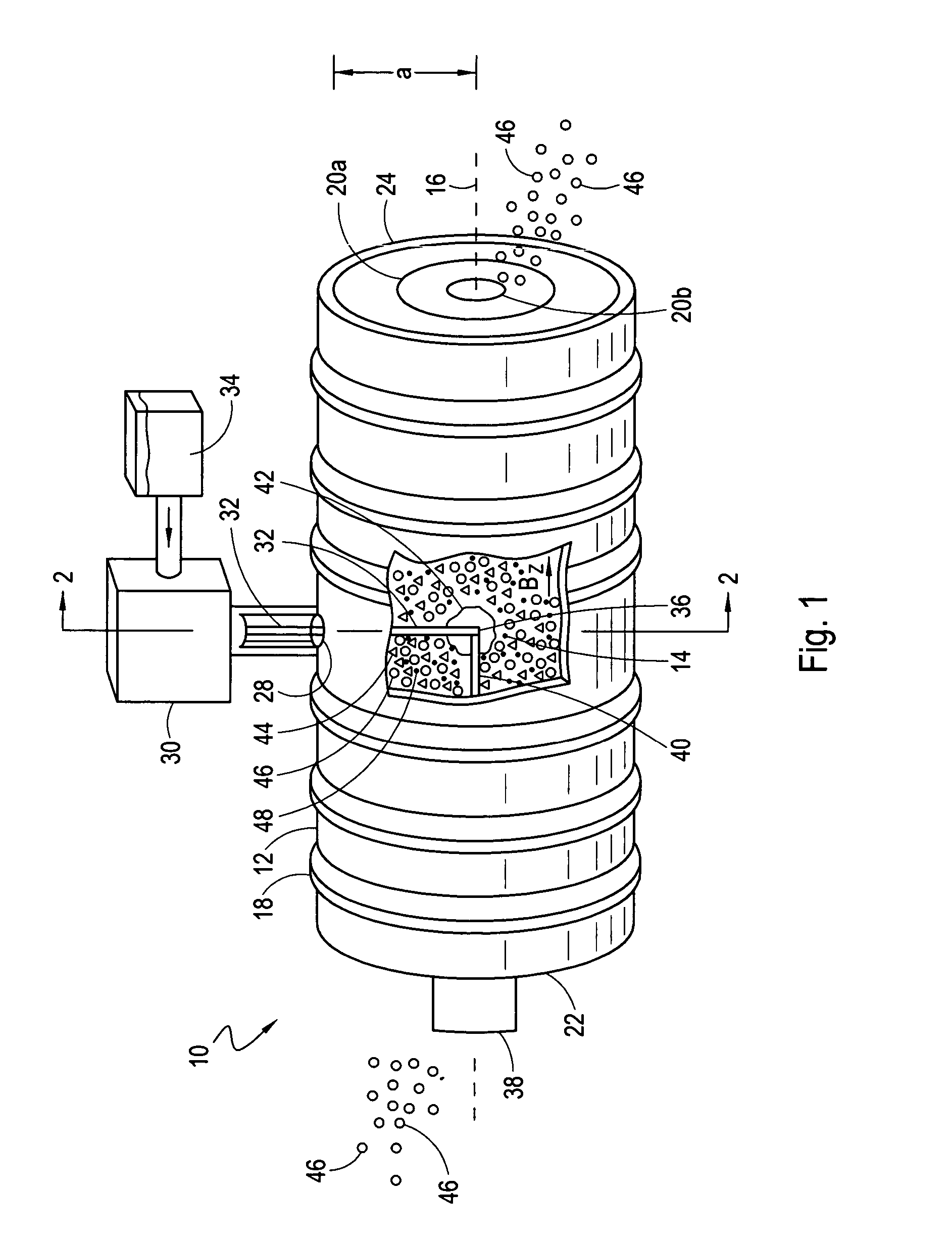

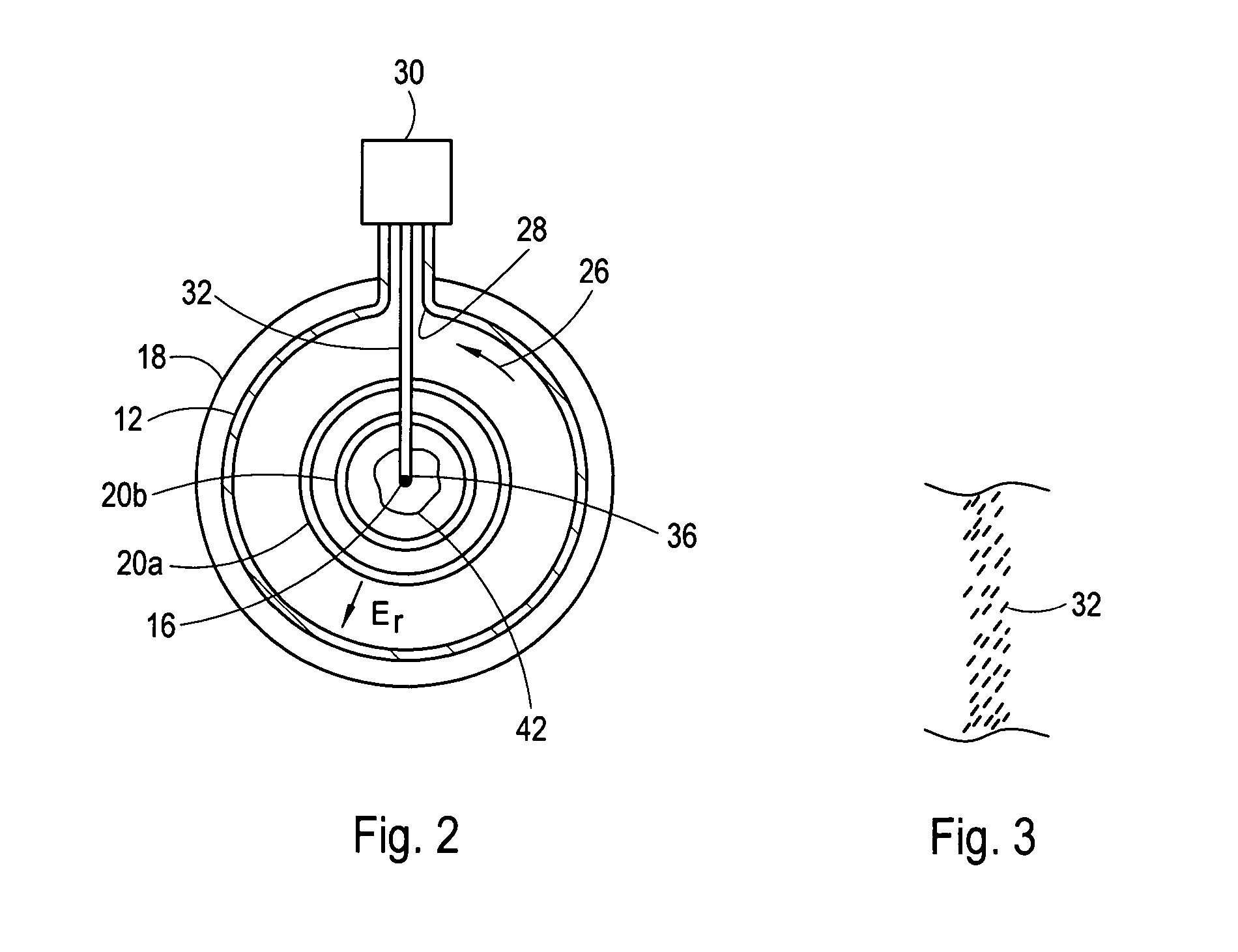

Injector for plasma mass filter

InactiveUS20050172896A1Minimize deflectionLiquid separation by electricityWater/sewage treatment by irradiationEngineeringVaporization

An injection system for introducing feed material into a plasma mass filter includes an injector for producing a jet of feed material. For a plasma mass filter having a cylindrical wall that surrounds a plasma chamber, the injector is mounted to the outside of wall and oriented to deliver a feed jet into the plasma chamber. Specifically, the injector is oriented to deliver a jet that is directed toward a target volume in the chamber that is located substantially on the longitudinal axis defined by the cylindrical wall. More specifically, the feed material is injected into the chamber to the target volume along a path that is transverse to the direction of plasma rotation in the chamber. A vaporization energy source can be included to generate and direct an energy beam toward the target volume to vaporize the jet of feed material as the jet arrives at the target volume.

Owner:ARCHIMEDES OPERATING

Process for heat treatment of high-performance Ti2AlNb powder alloy

A process for heat treatment of high-performance Ti2AlNb powder alloy comprises steps as follows: 1) spherical powder is prepared from cast Ti2AlNb alloy bars under the inert gas shielding condition by means of powder preparation equipment using a plasma rotation electrode; 2) the Ti2AlNb powder alloy is put in a capsule, and HIP (hot-isostatic-pressing) molding is performed; 3) heat treatment adopting solid solution and two-stage ageing is performed on the HIP Ti2AlNb powder alloy. The Ti2AlNb powder alloy prepared with the method has excellent room-temperature and high-temperature mechanical properties, excellent endurance life and stable performance in the high-temperature environment.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

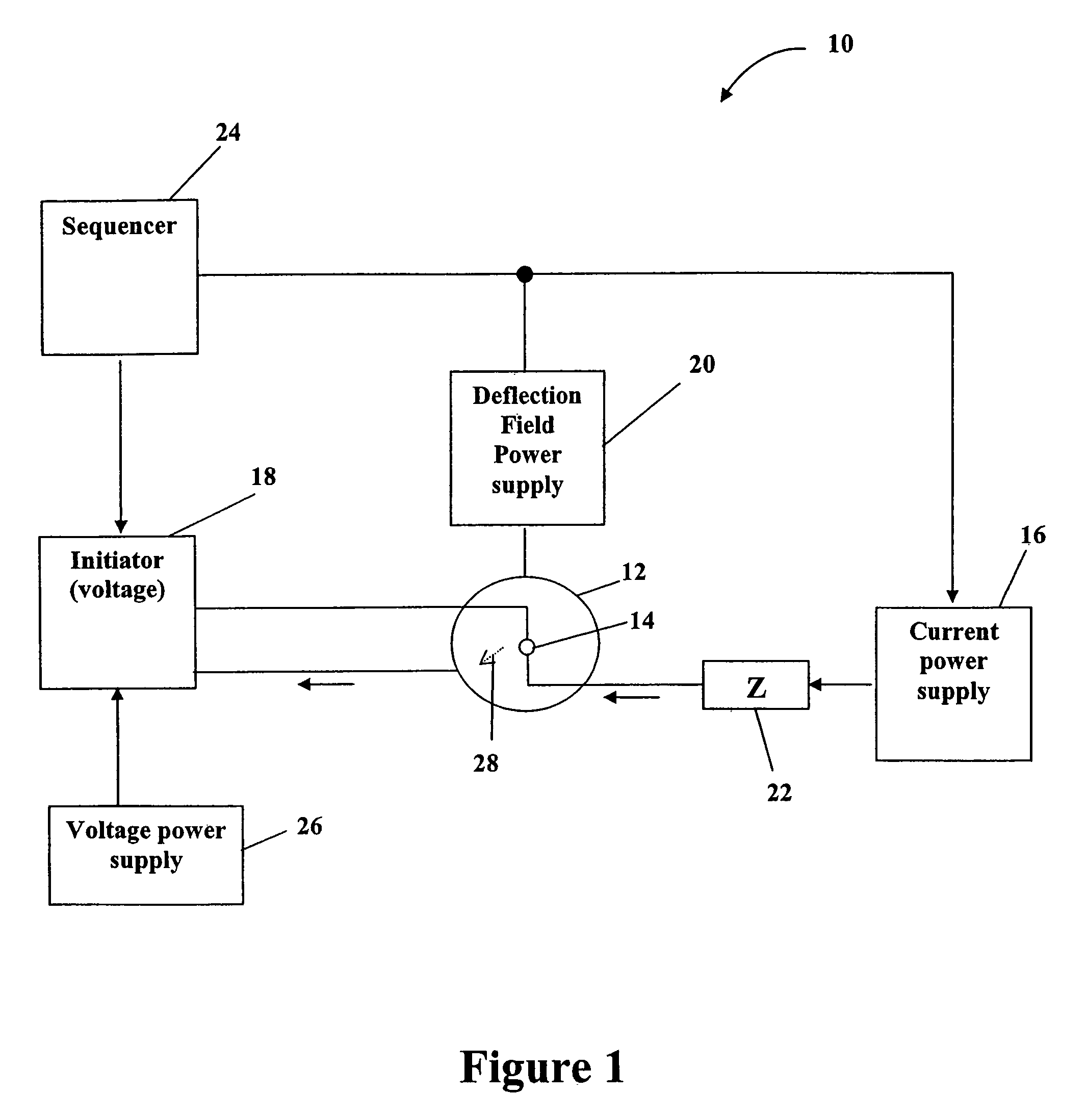

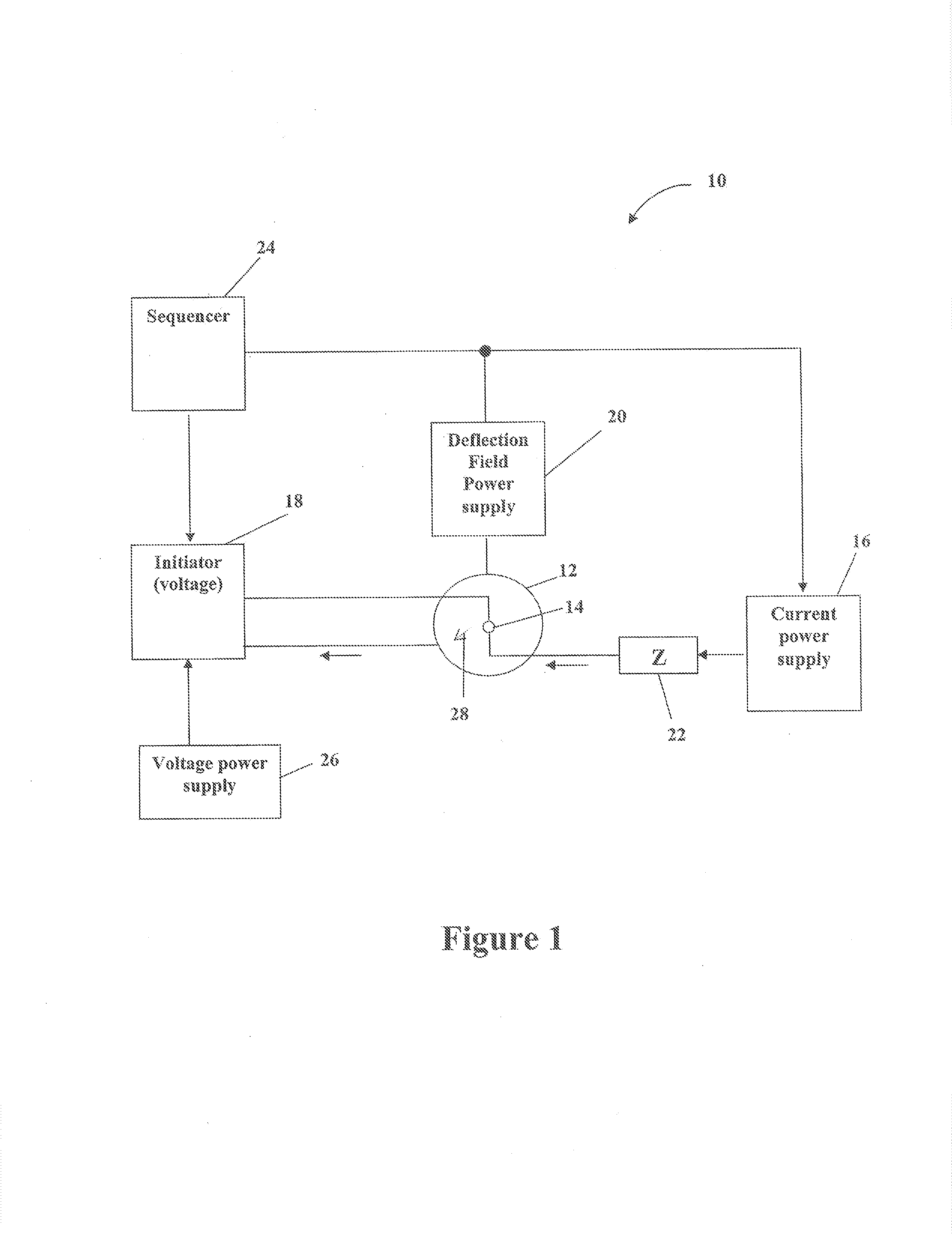

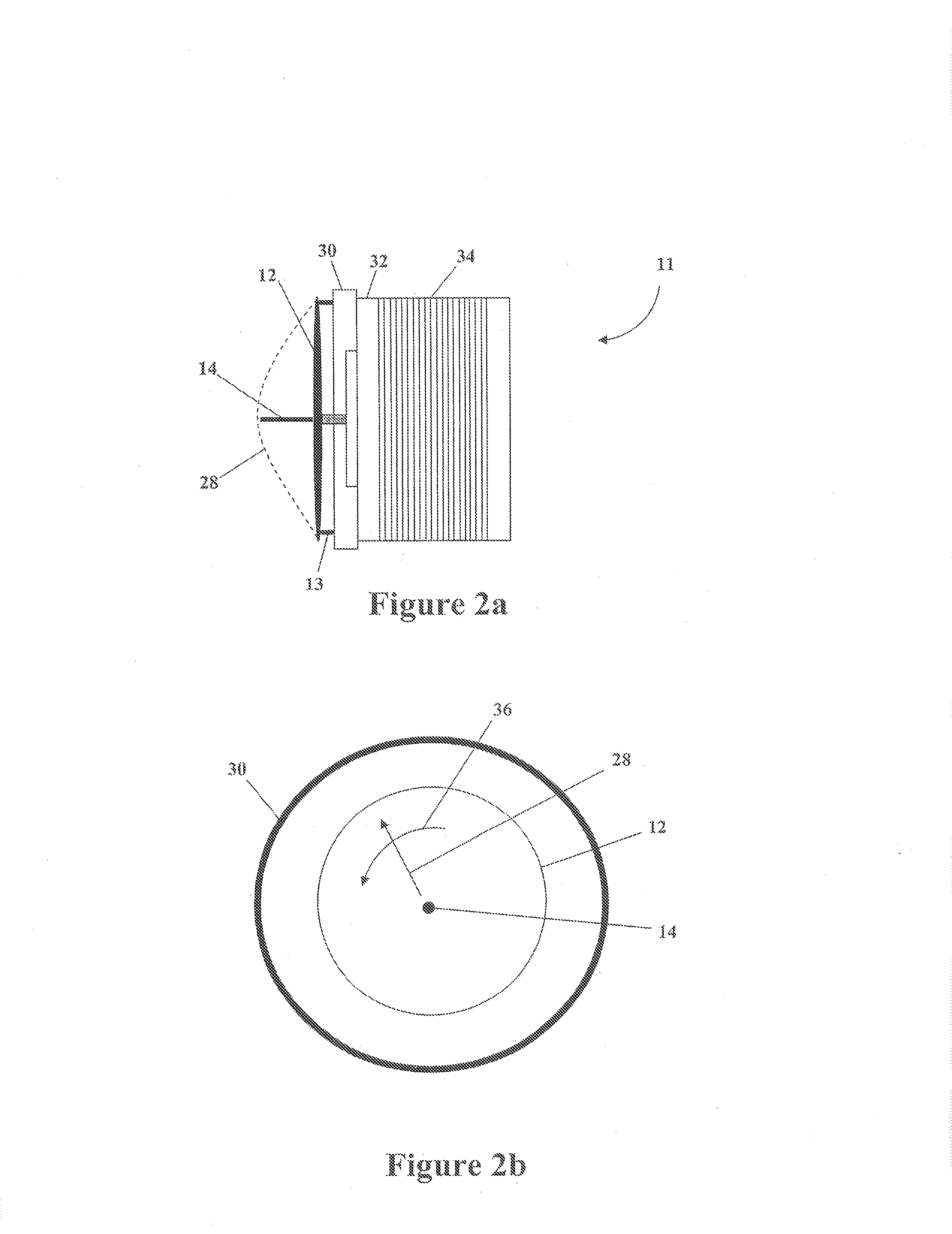

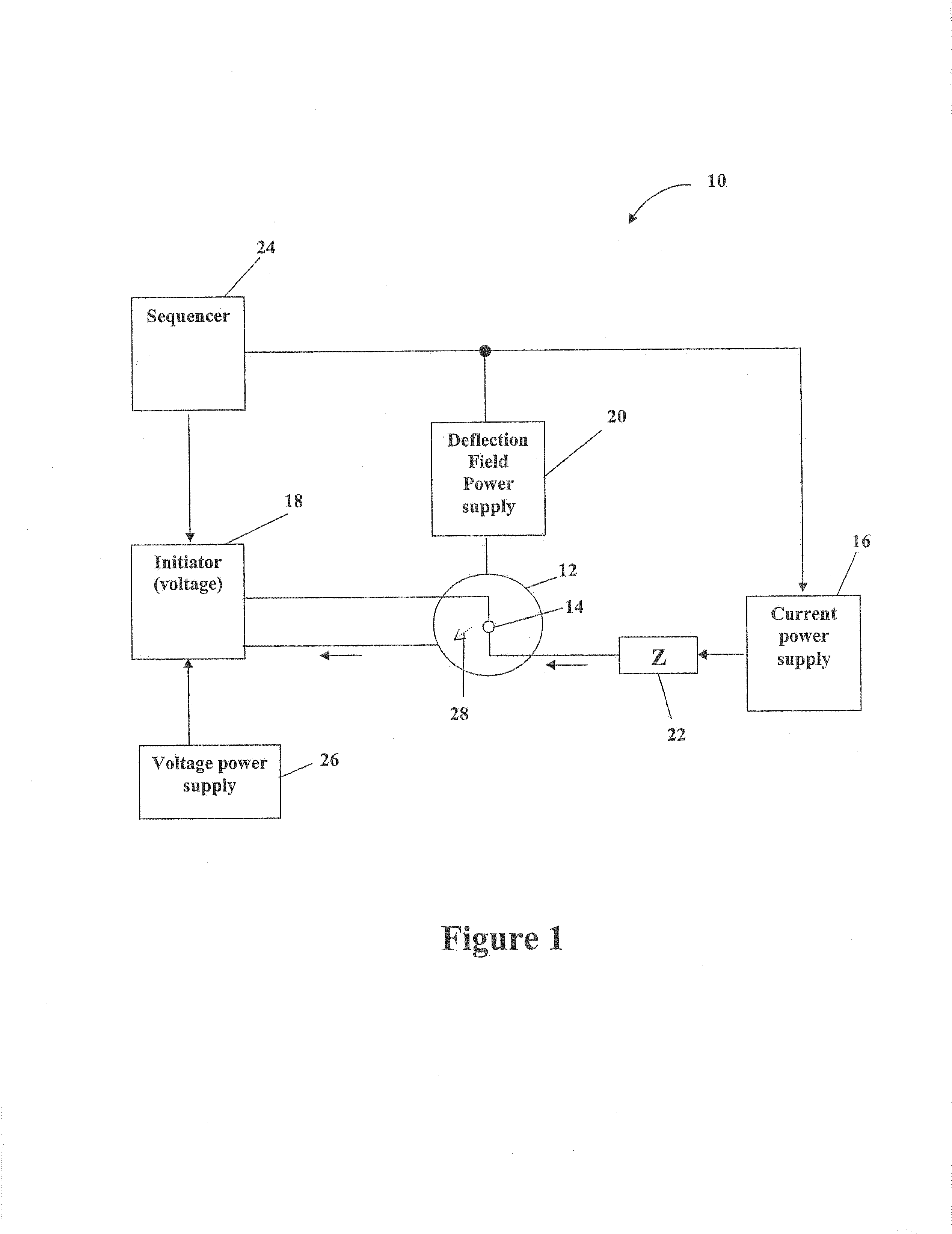

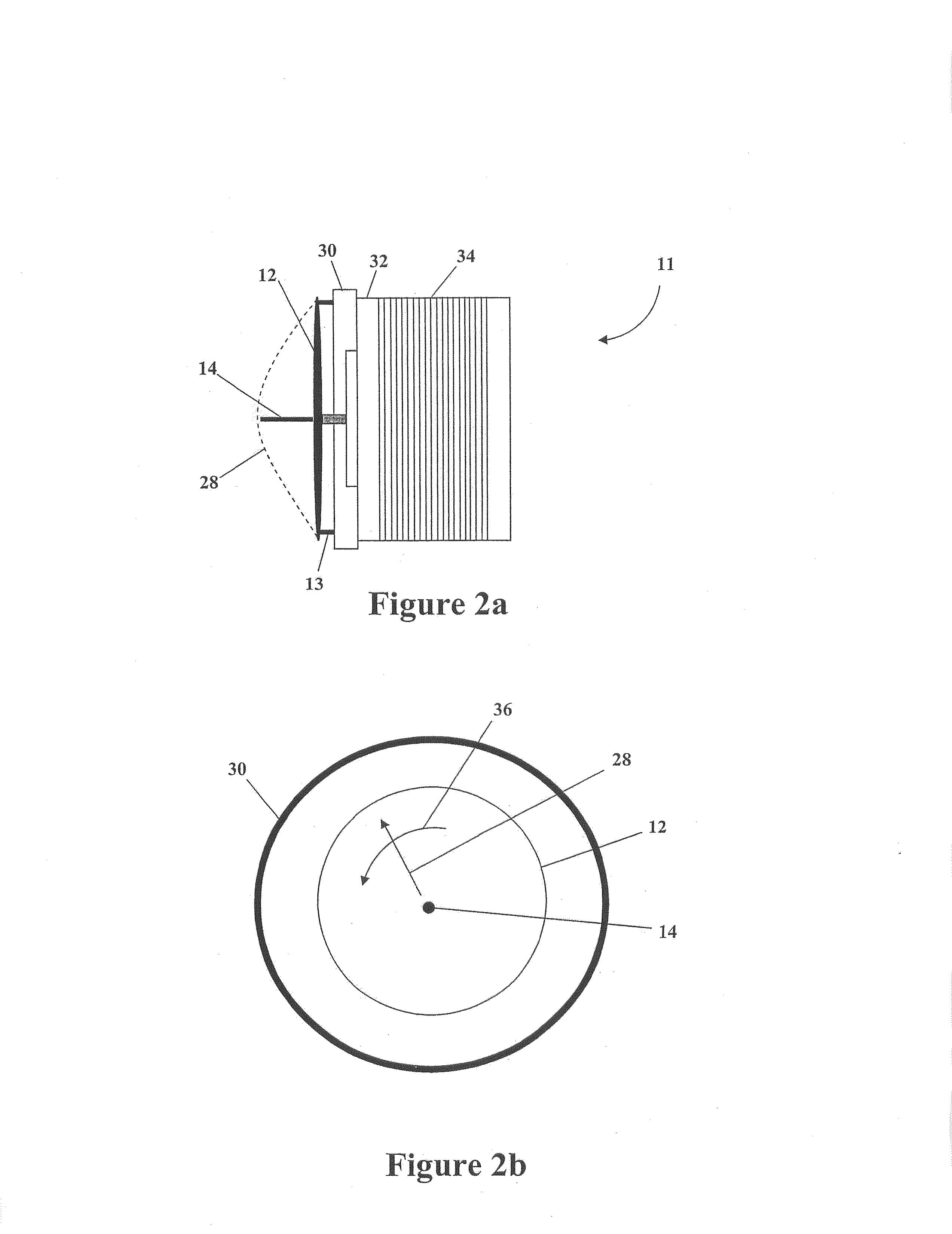

System and method for plasma generation

A system and method for generating a plasma. An embodiment of the system for generating a plasma may include a first electrode; a second electrode disposed adjacent the first electrode; a first power supply for supplying power at the second electrode; a second power supply for generating a magnetic field; and a sequencer for coordinating a discharge of power from the first power supply and a discharge of power from the second power supply. The first power supply may be configured such that the discharge of power from the first power supply generates a plasma between the first electrode and the second electrode. The second power supply may be configured such that the magnetic field generated by the discharge of power from the second power supply rotates the plasma.

Owner:PLASSEIN TECH LTD LLC +1

Manufacturing method of titanium alloy electrode bar for plasma rotation electrode

Provided is a manufacturing method of a titanium alloy electrode bar for a plasma rotation electrode. The manufacturing method includes the following steps that step1, a blank is prepared, wherein a titanium alloy ingot serves as the blank and meets the GB / T2965-2007 standard; step2, a quick forging press is used for performing blooming forging on the titanium alloy ingot, wherein blooming forging is completed through 2-4 times of heating, and a primary forged blank is obtained after air cooling; step3, hammer forging equipment is used for performing upsetting and rolling forging on the primary forged blank, and forging is performed on an intermediate forged blank obtained after water cooling through 4-6 times of heating; step4, a precision forging machine is used for performing precision forging on the intermediate forged blank obtained in the step3, and a semi-finished bar is obtained after air cooling; step5, heat treatment is performed; step6, heat straightening is performed; step7, a lathe is used for performing turning on the semi-finished bar obtained after heat straightening and air cooling so that the finished titanium alloy electrode bar for the plasma rotation electrode can be formed; step8, finishing treatment is performed; finally, appearance inspection is performed on the finished titanium alloy electrode bar for the plasma rotation electrode. The manufacturing method has the advantages that the production cycle is short, the service life is long and economic benefits are good.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Preparation method of refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure

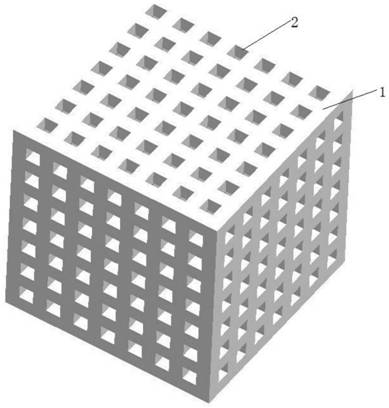

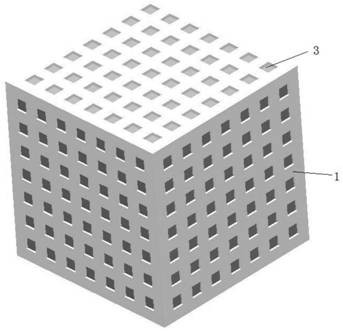

ActiveCN112024902AGood mechanical propertiesHigh strengthAdditive manufacturing apparatusSelective laser meltingHigh entropy alloys

The invention discloses a preparation method of a refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure. The method comprises the following steps of: smelting a refractory high-entropy alloy raw material to obtain an alloy ingot, and preparing refractory high-entropy alloy powder from the alloy ingot by using a plasma rotating electrode atomization method; forming the refractory high-entropy alloy powder into a preset porous skeleton structure through an electron beam or selective laser melting additive manufacturing process; and infiltrating metal copper into the porous skeleton structure by adopting an infiltration process, thereby obtaining the refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure. The structure has the characteristic of spontaneous perspiration, and is suitable for high-temperature parts such as rocket engine nozzle throat inserts, thrust chamber injector panels, missile warhead nose cones and electromagnetic gun tracks. The prepared composite structure has the advantages that the forming process is simple, the porosity can be conveniently designed and adjusted according to actual requirements, the mechanical property is good, high temperature resistance and thermal shock resistance can be achieved, and high practical value is achieved.

Owner:JIANGSU UNIV OF SCI & TECH +2

Plasma rotation electrode powder production feeding device

A plasma rotation electrode powder production feeding device comprises a material box upper cover which is connected with a material box; a feeding hole is formed in the top of the material box upper cover; the feeding hole is sealed through a feeding hole sealing device; a material cabin is distributed inside the material box; the material box is matched with a discharging sliding plate through a shifting fork at the bottom of the material box; the discharging sliding plate is connected with a plasma rotation electrode powder production device; a flange connector is connected with a vacuum and inert gas system; raw material bars are sequentially arranged inside the material cabin from the feeding hole, after the material cabin is filled up, the feeding hole sealing device is started to enable the feeding hole sealing device and the material box upper cover to be well sealed, the vacuum system is started to enable gases inside the device to be extracted from the flange connector, and then inertia protective gases are inflated inside the device; the material cabin is rotated, meanwhile a shifting fork motor is started to enable the shifting fork to rotate, then bar materials enter the shifting fork from the material cabin, the shifting fork rotates, and when the material cabin rotates to an opening below, the bar materials are sent to the plasma rotation electrode powder production device along the discharging sliding plate. The plasma rotation electrode powder production feeding device is simple in structure, convenient to operate, time-saving, labor-saving, safe and reliable.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

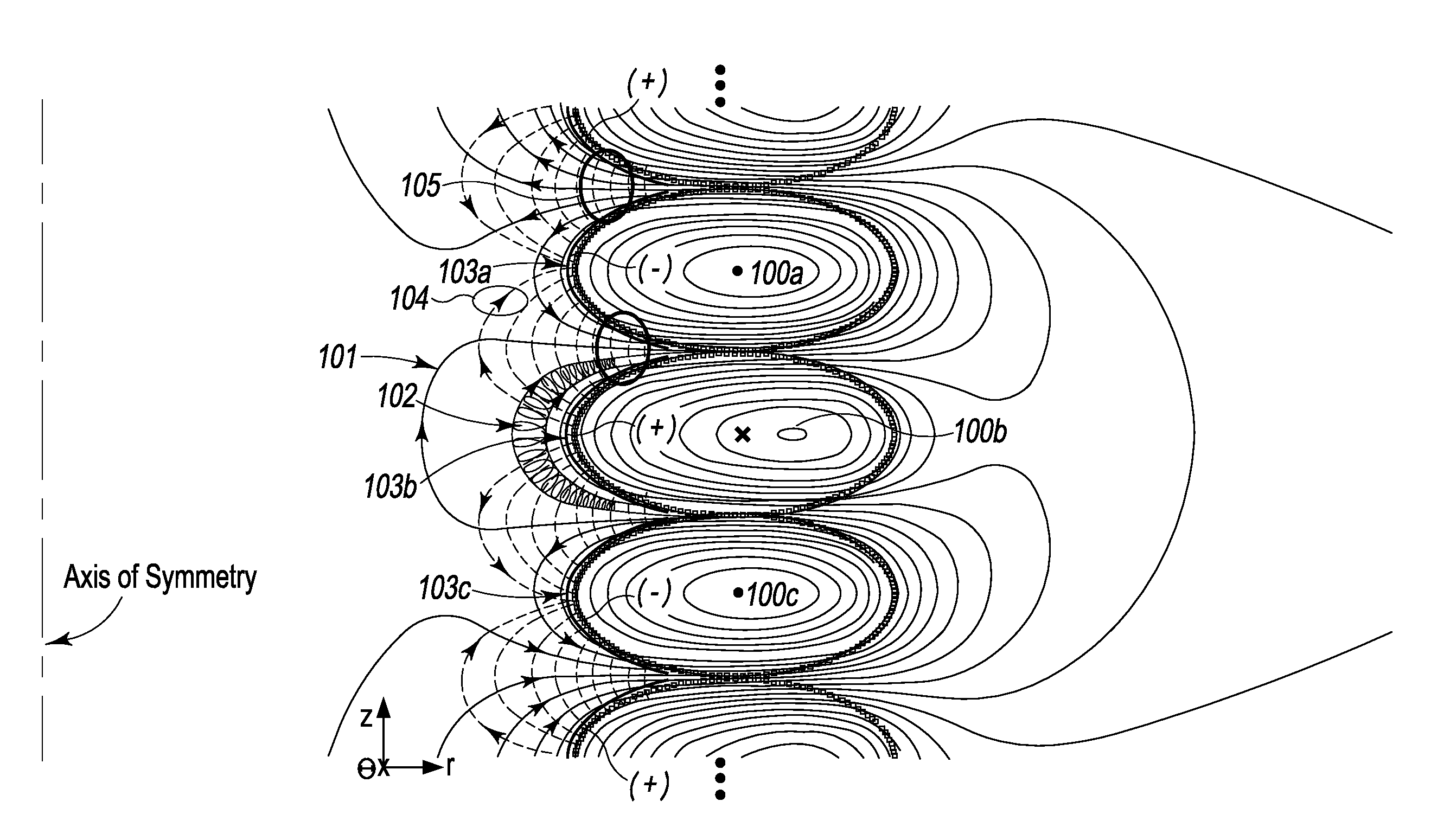

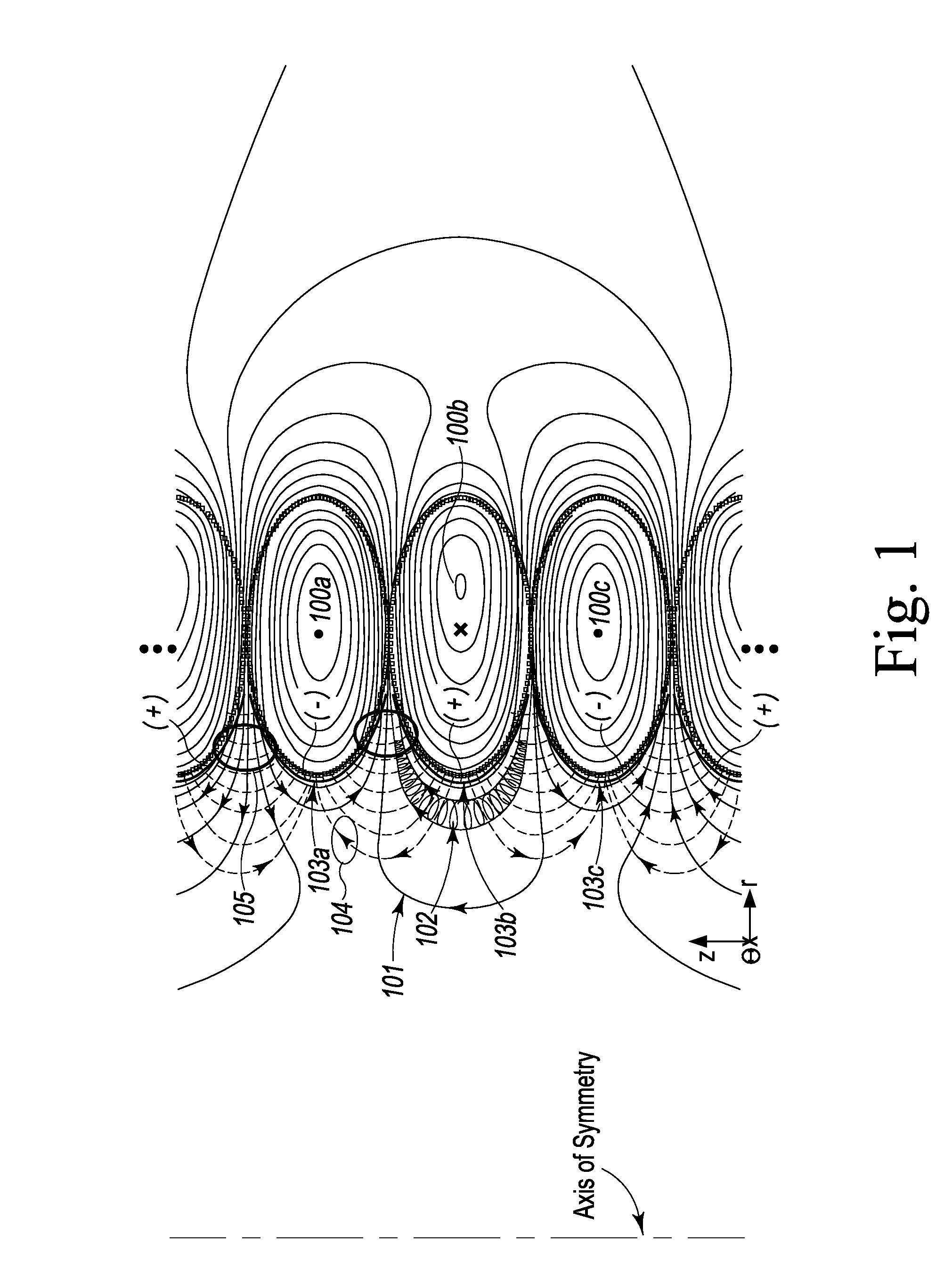

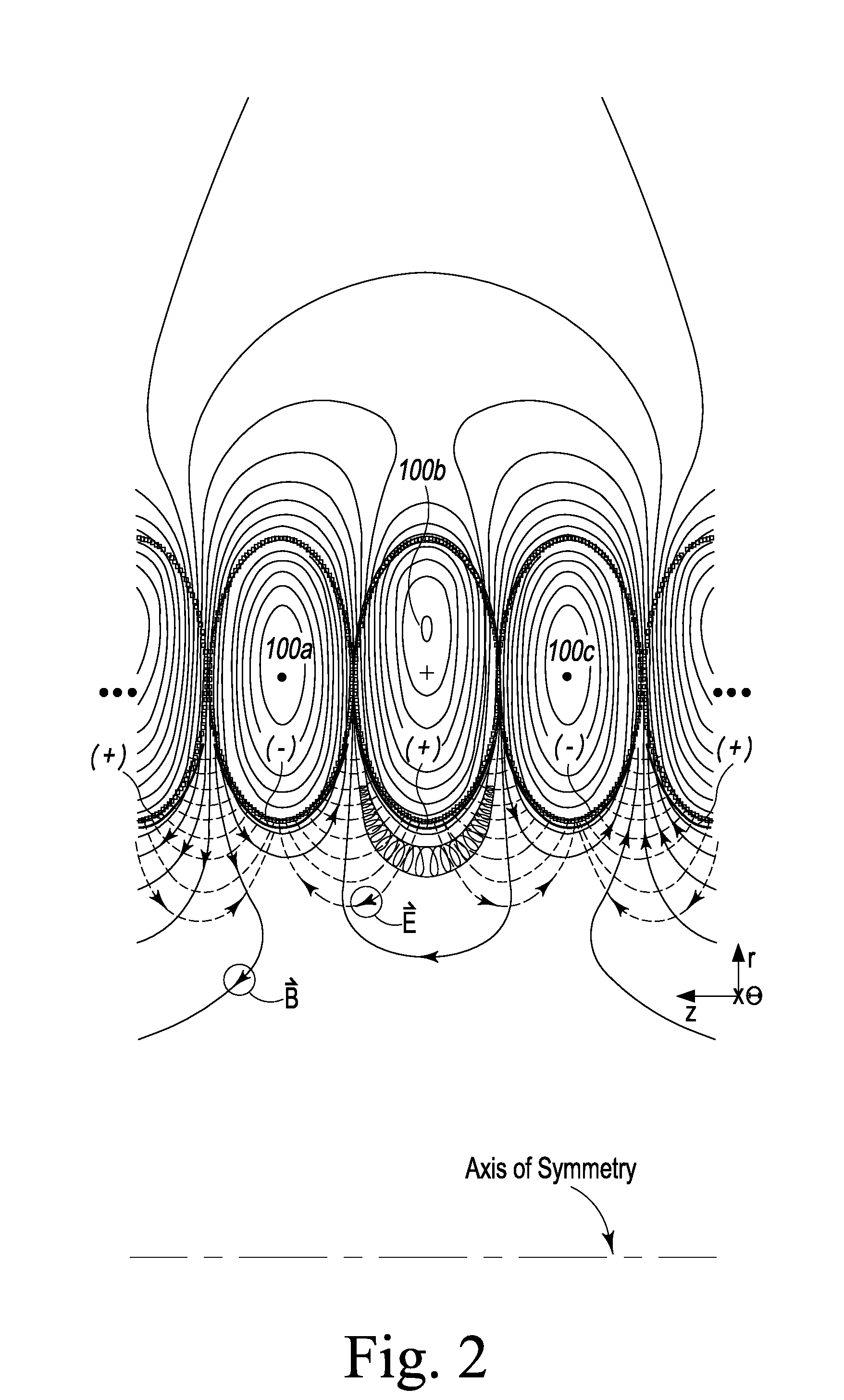

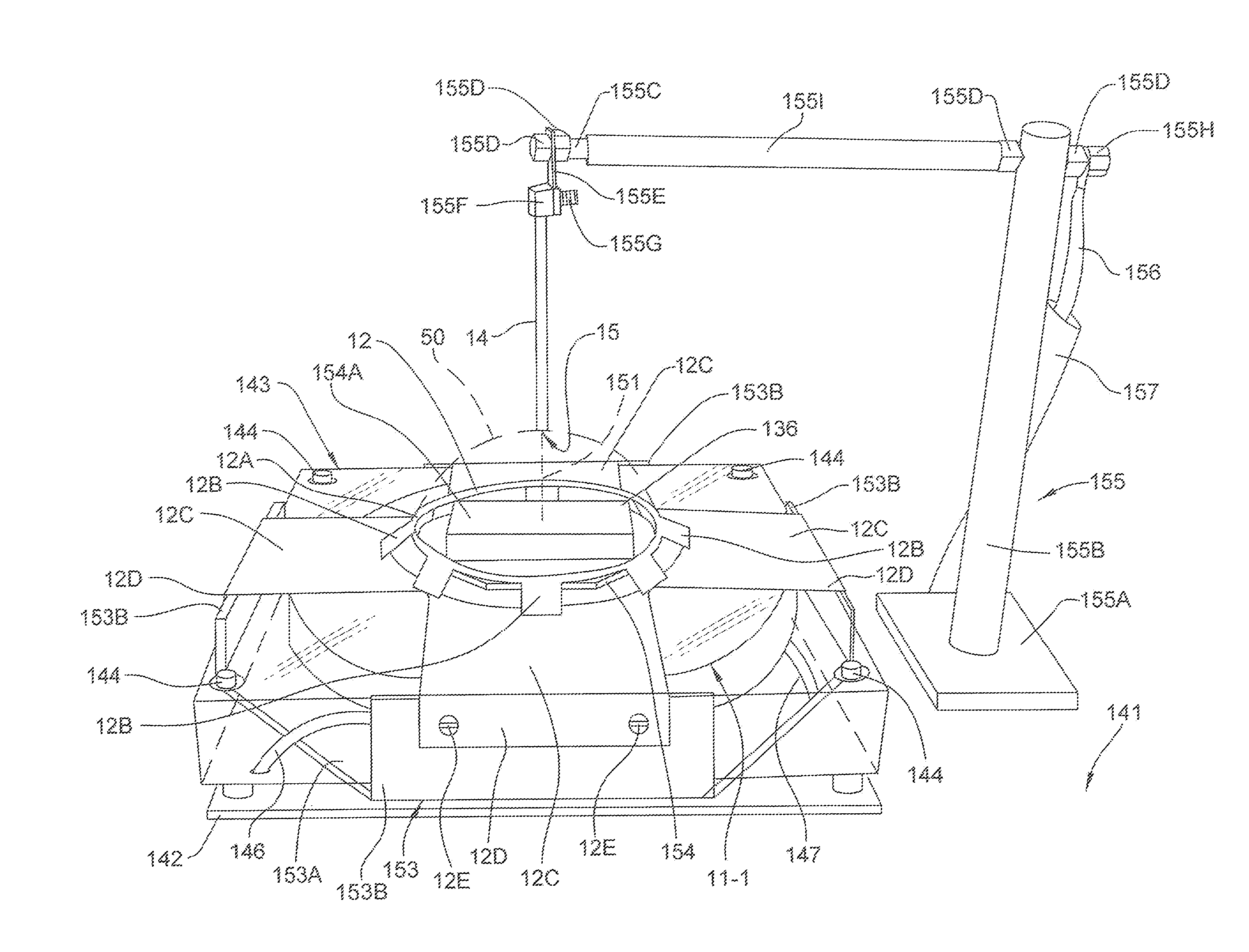

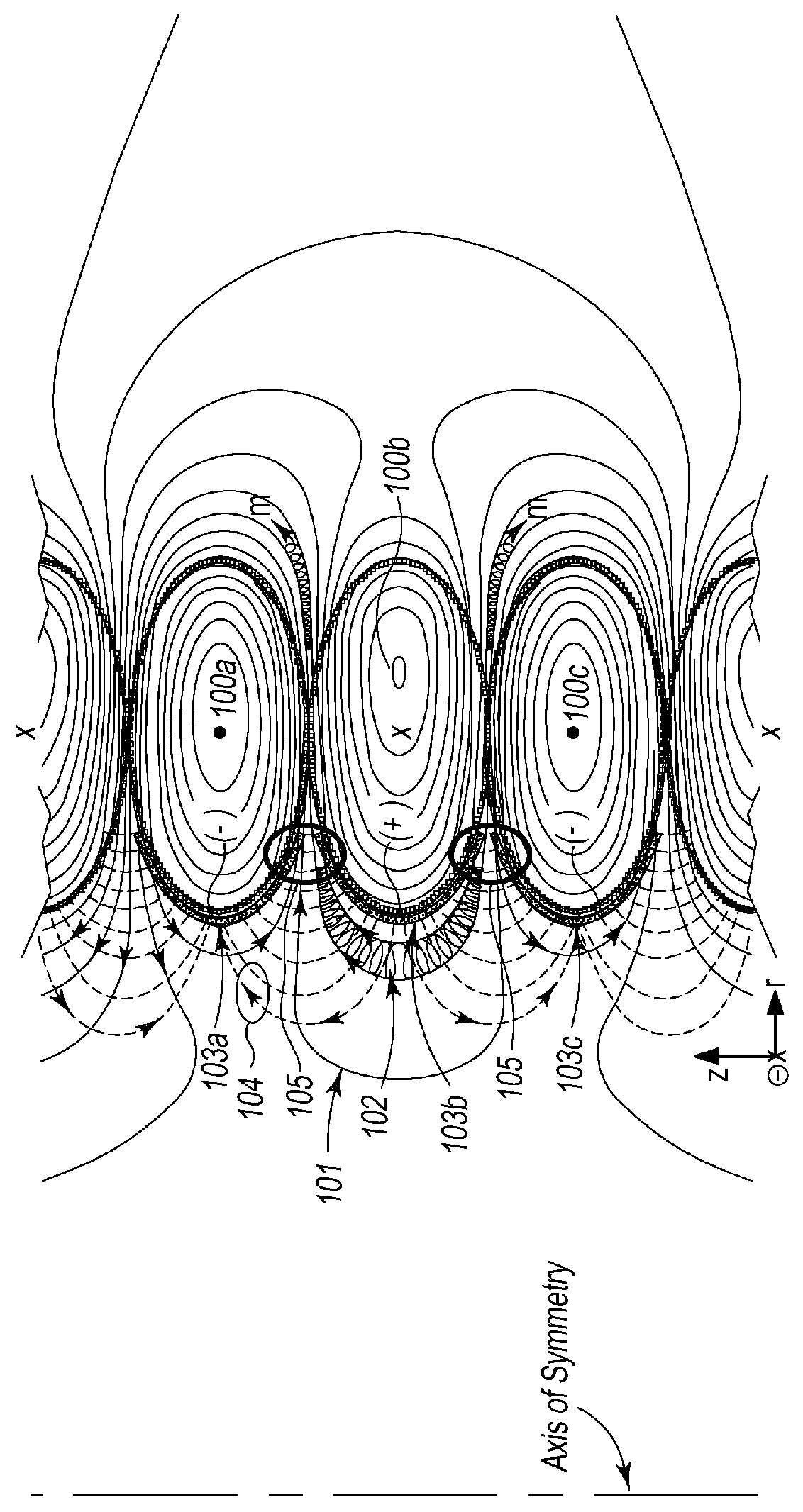

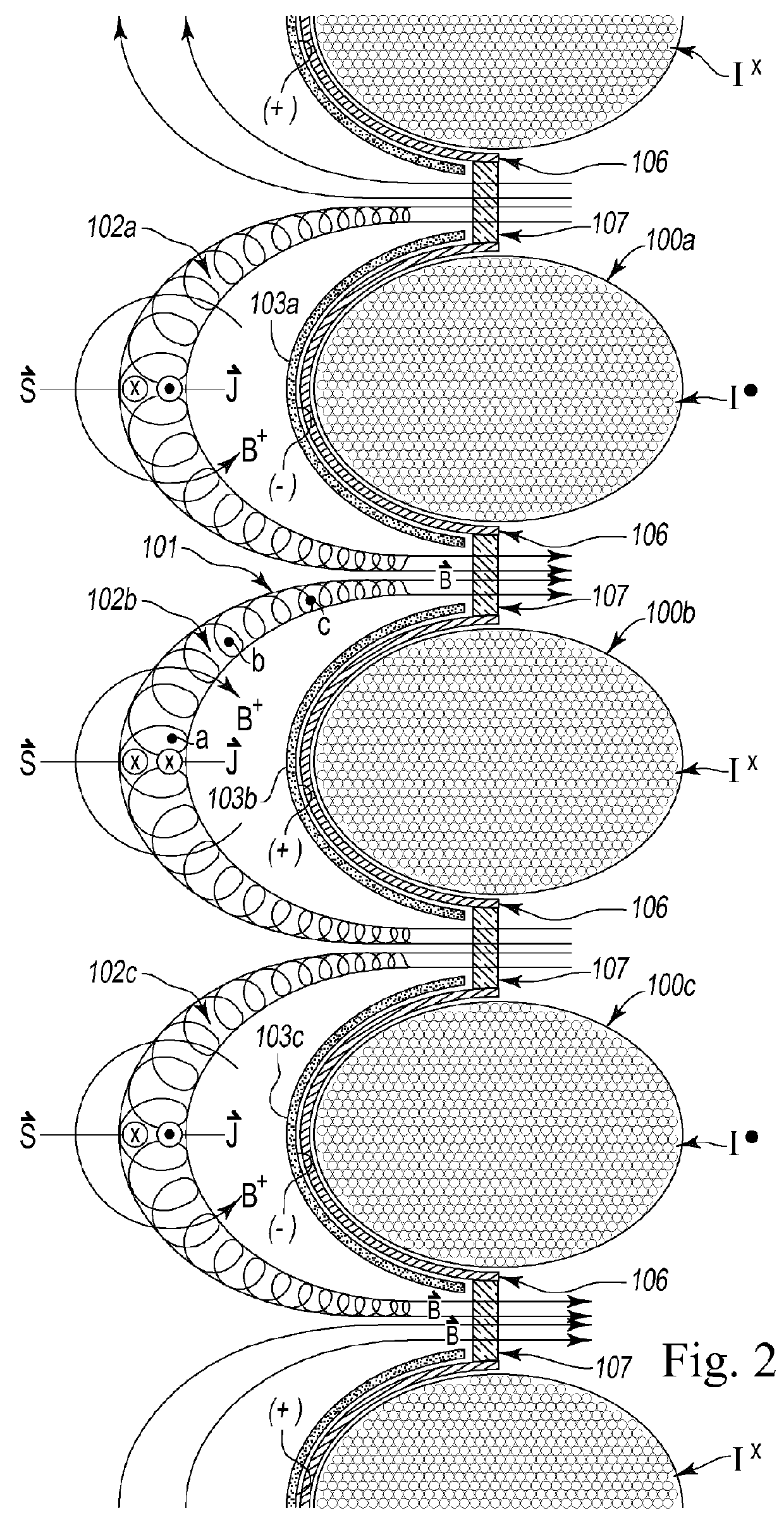

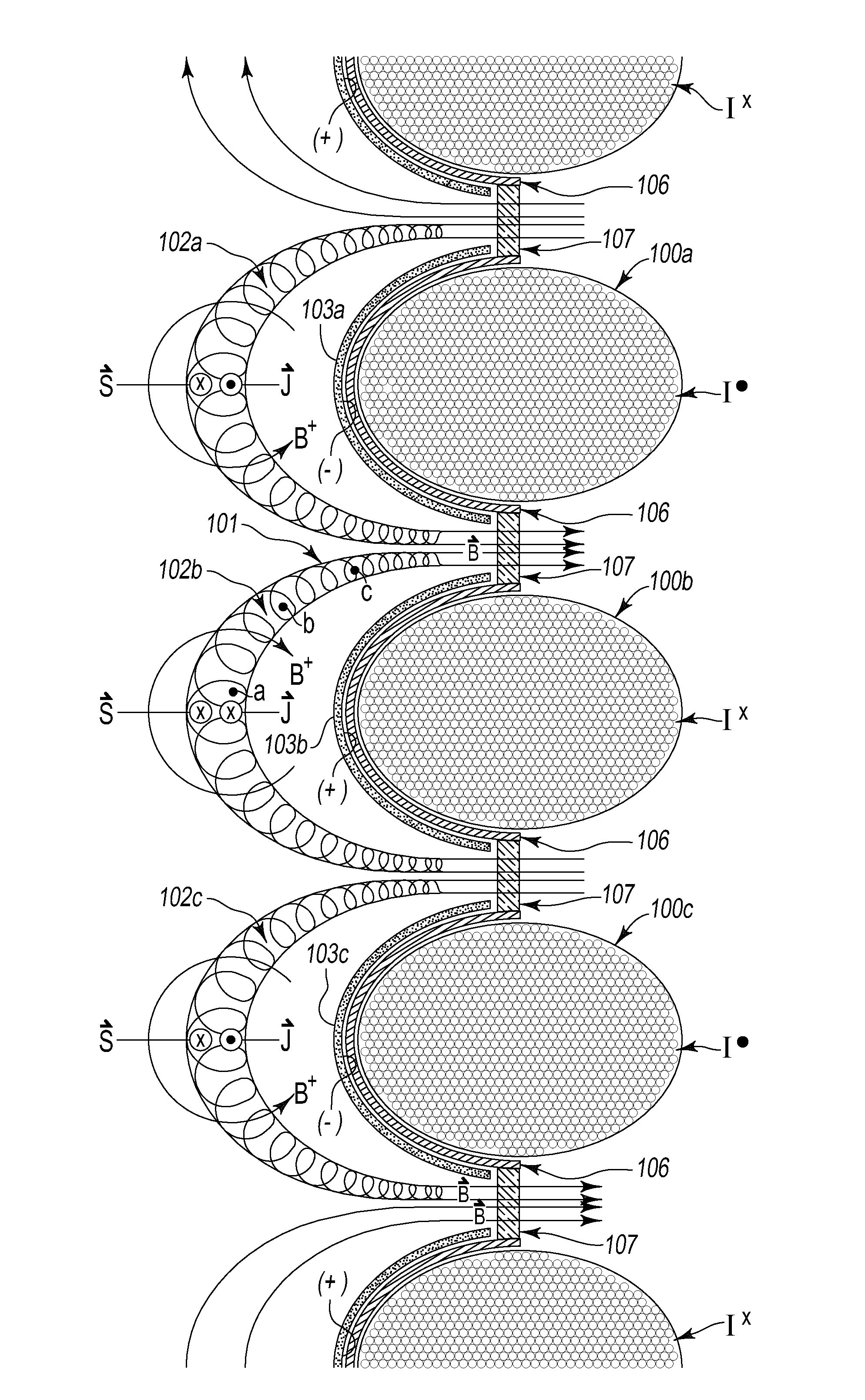

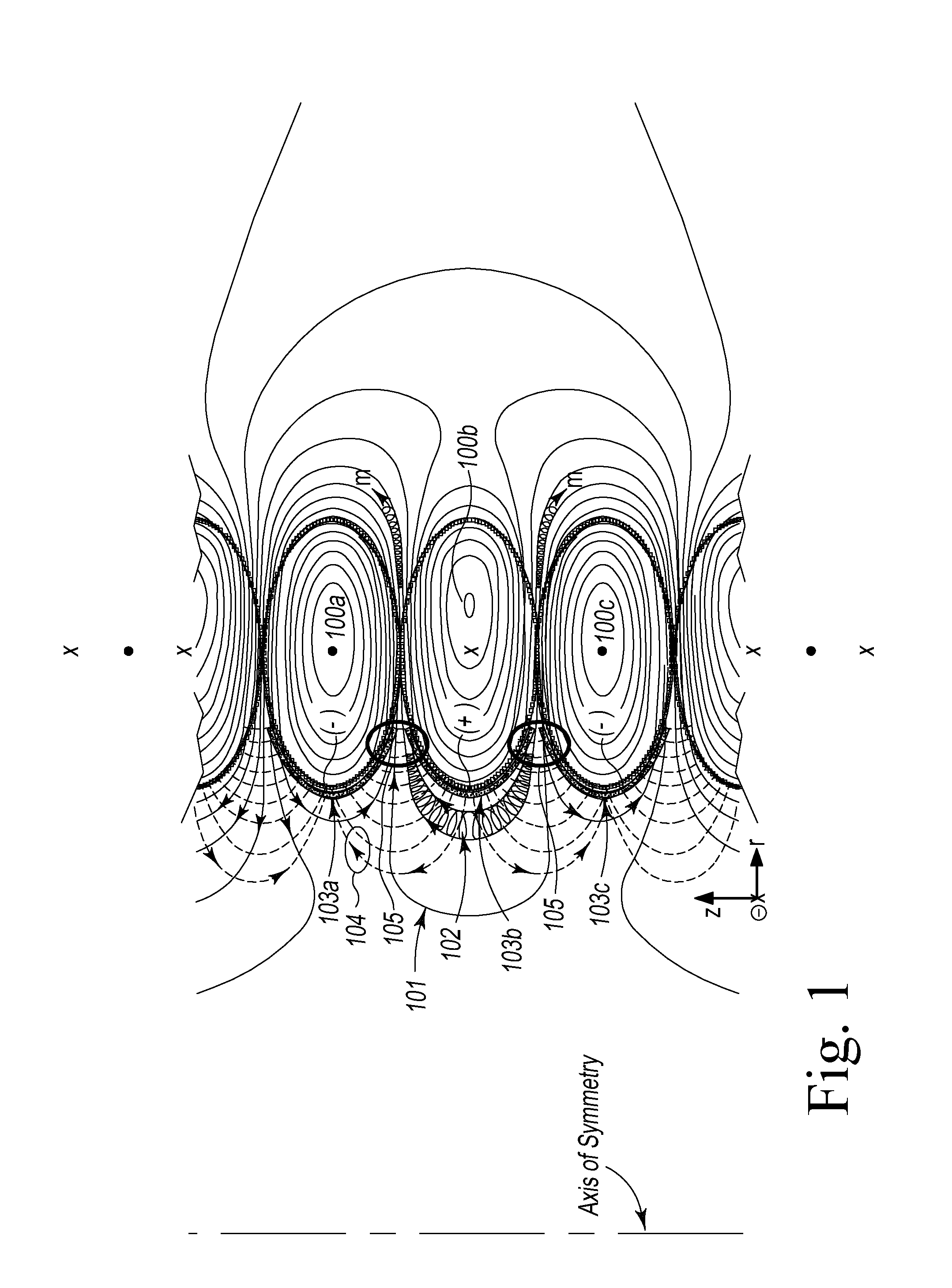

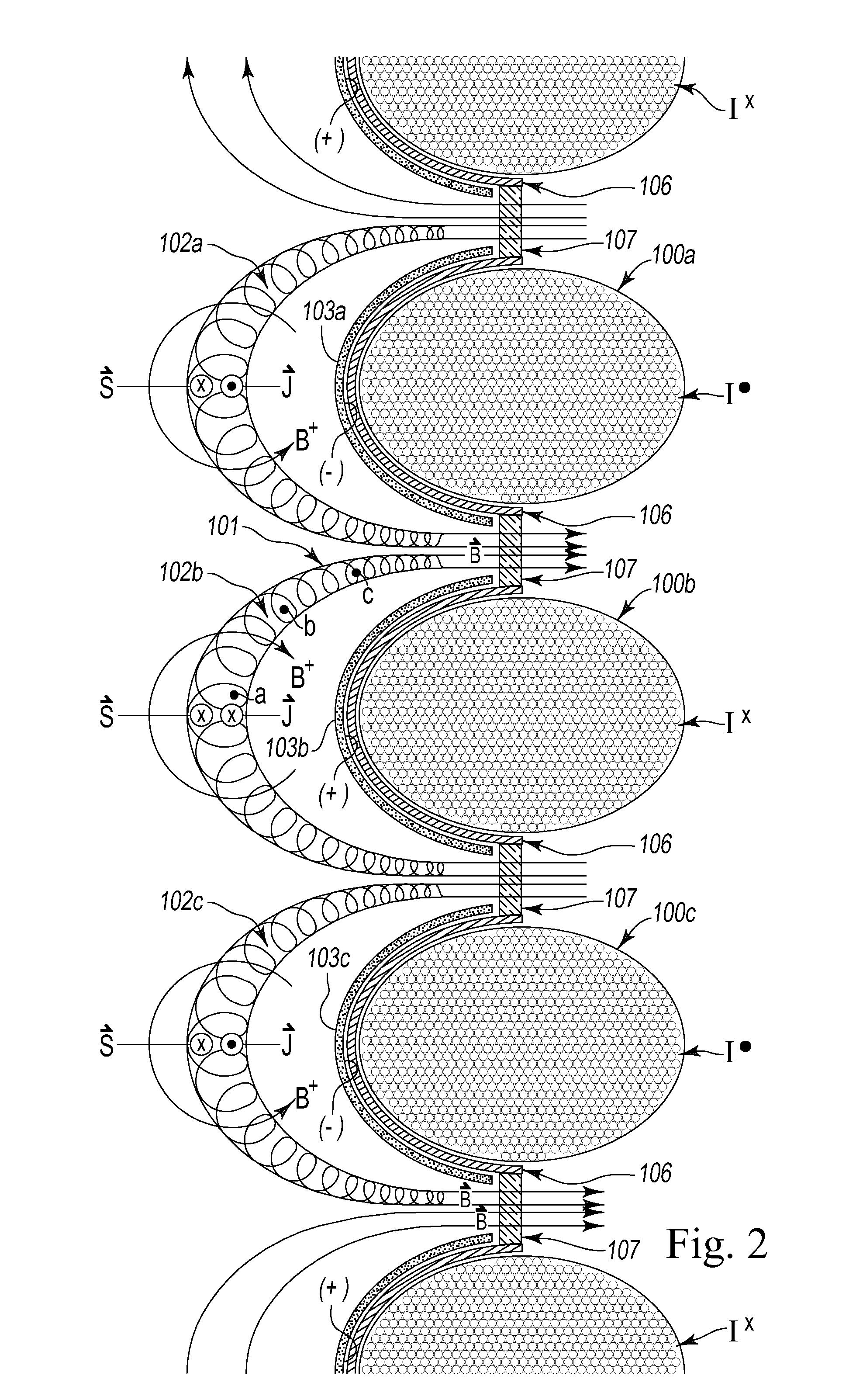

Plasma Confinement Device

A device and method for magnetic field confinement of plasma is formed by a cylindrically stacked column of direct current-carrying magnetic field coils with electrodes adjacently interior to each magnetic field coils so as to induce plasma rotation about an annular confinement region. Each field coil produces a magnetic field alternating in direction relative to adjacent coils and, so as to maintain consistent overall azimuthal direction of plasma rotation, electric field electrodes alternate accordingly in polarity along the axial length of the device. The device may be used for inducing nuclear fusion, for the ionic or isotopic separation of elements, creation of thrust by ejecting mass along the axial direction of the device, for creating a gravitational acceleration field, and for creating a state change beyond plasma.

Owner:PRATER DANIEL

System and method for plasma generation

InactiveUS20130175246A1Avoid enteringHigh energyArc welding apparatusPlasma techniqueEngineeringPlasma rotation

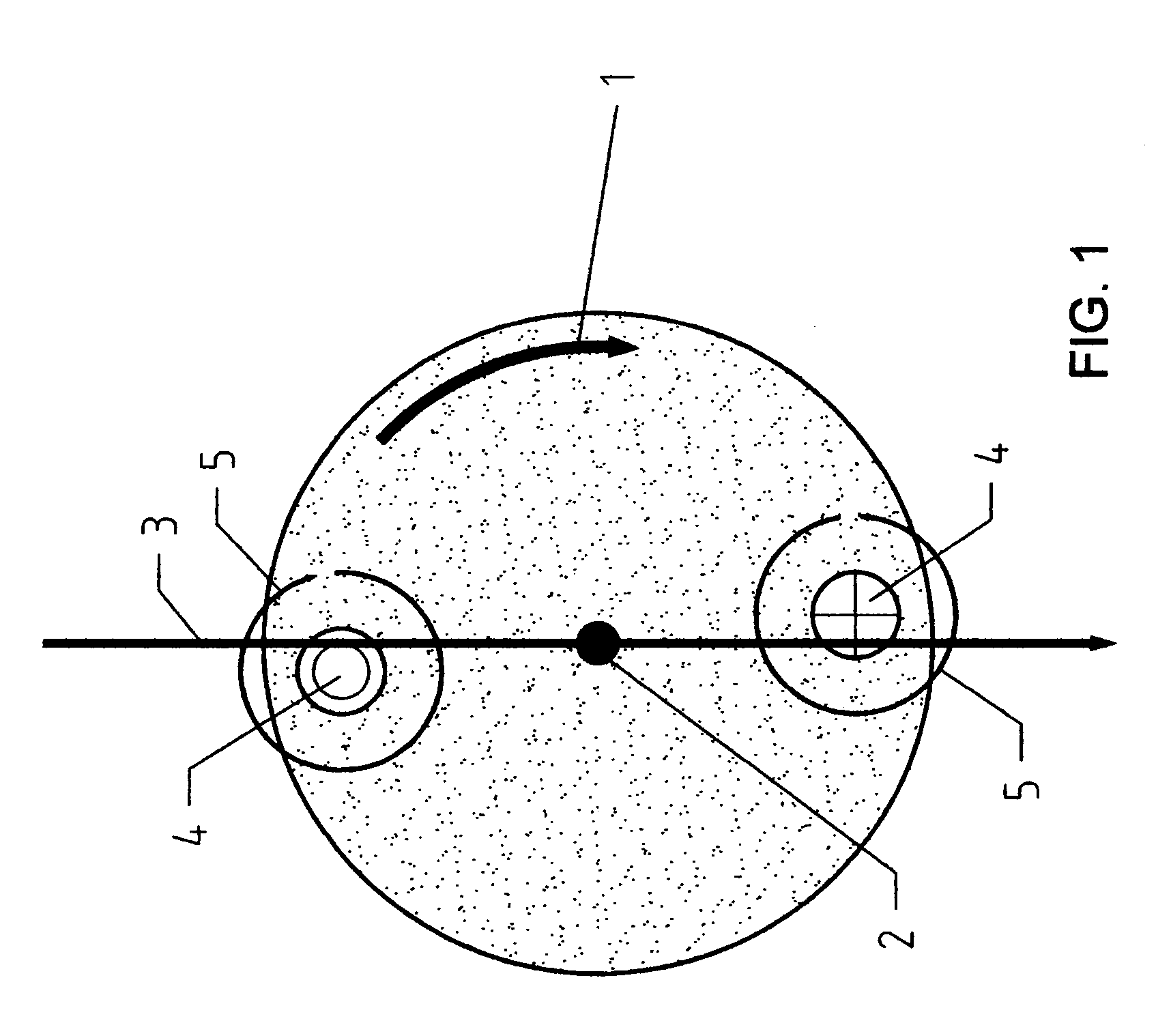

A system and method for generating a plasma. A first electrode and a second electrode are disposed adjacent to one another, not touching one another. A first power supply supplies power at the second electrode, and a second power supply generates a magnetic field. A sequencer coordinates a discharge of power from the first power supply and a discharge of power from the second power supply. The first power supply may be is configured such that the discharge of power from the first power supply generates a plasma between the first electrode and the second electrode. The second power supply is configured such that the magnetic field it generates rotates the plasma. Depending upon disclosed relative geometries of the electrodes and the magnetic field, the plasma is shaped alternatively as a disc, a dome, a sleeve, or a polygonal sheet.

Owner:PLASSEIN TECH LTD

Plasma Confinement Device

ActiveUS20160037617A1Guaranteed smooth progressElectric discharge tubesElectric arc lampsElectrical polarityAzimuth direction

A device and method for the magnetic confinement of plasma is formed by a cylindrically stacked column of current-carrying magnetic field coils with electrodes interior to each magnetic field coil so as to induce plasma fluid rotation about an annular confinement region formed of cusped-geometry magnetic fields. Electrodes are formed such that the electric fields produced are tangential to the magnetic fields, and so as to maintain consistent azimuthal direction of plasma rotation, electric field electrodes alternate accordingly in polarity along the axial length of the device.

Owner:PRATER DANIEL

Plasma confinement device

ActiveUS9462669B2Guaranteed smooth progressElectric discharge tubesPlasma techniqueElectrical polarityAzimuth direction

Owner:PRATER DANIEL

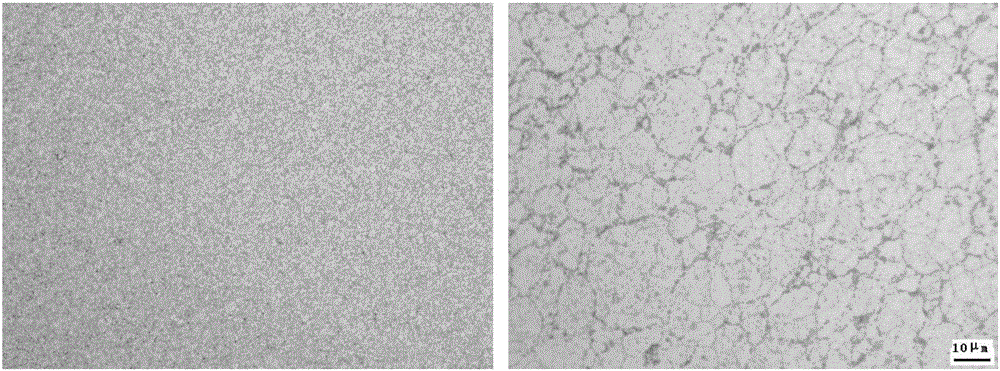

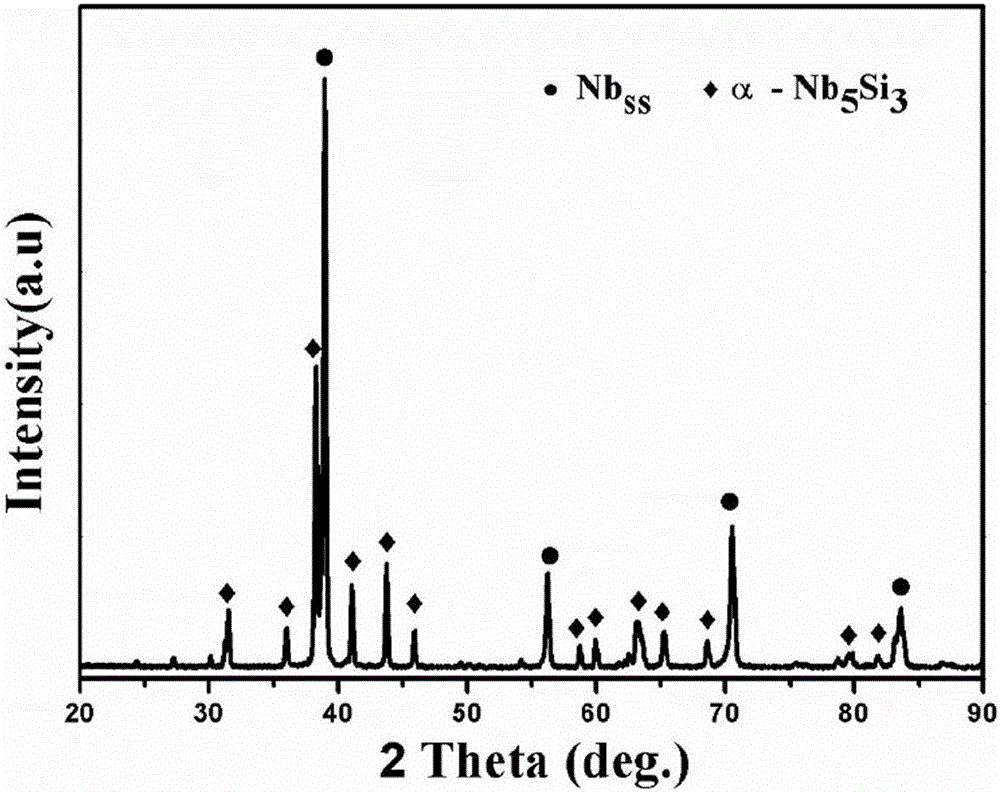

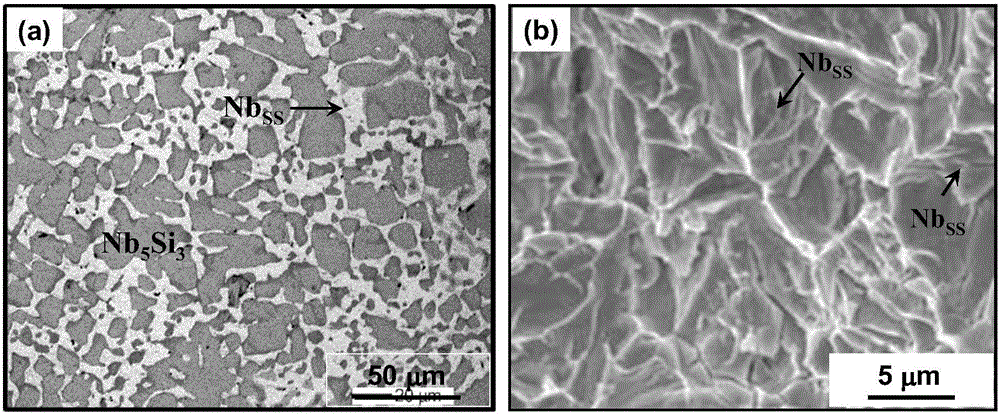

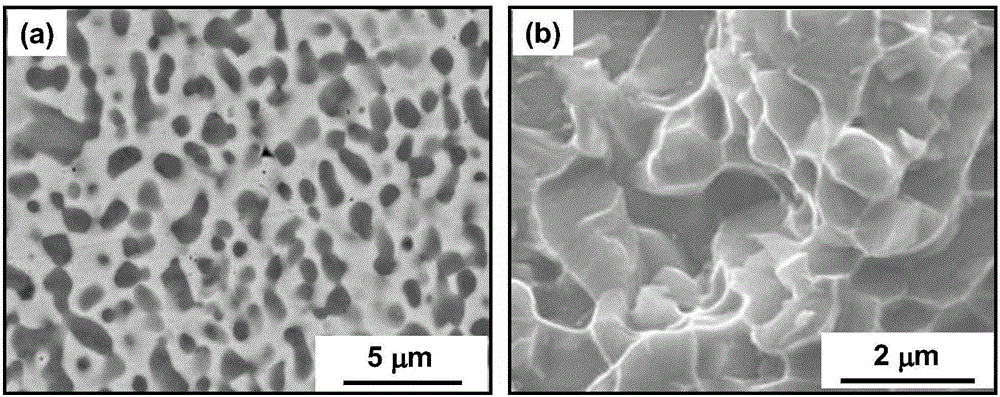

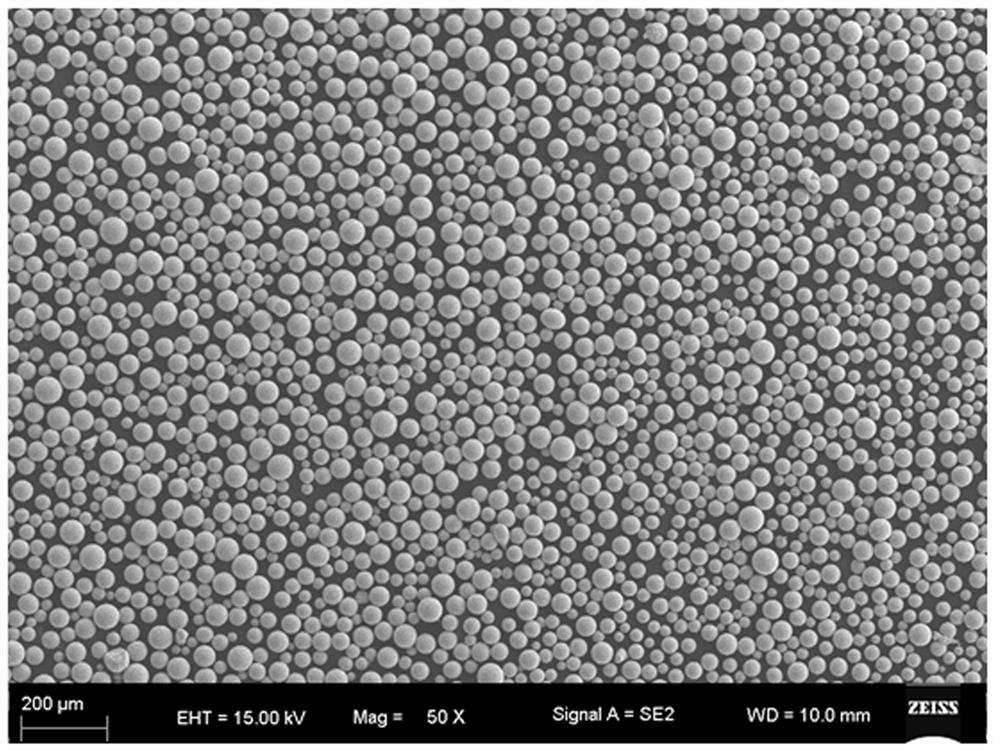

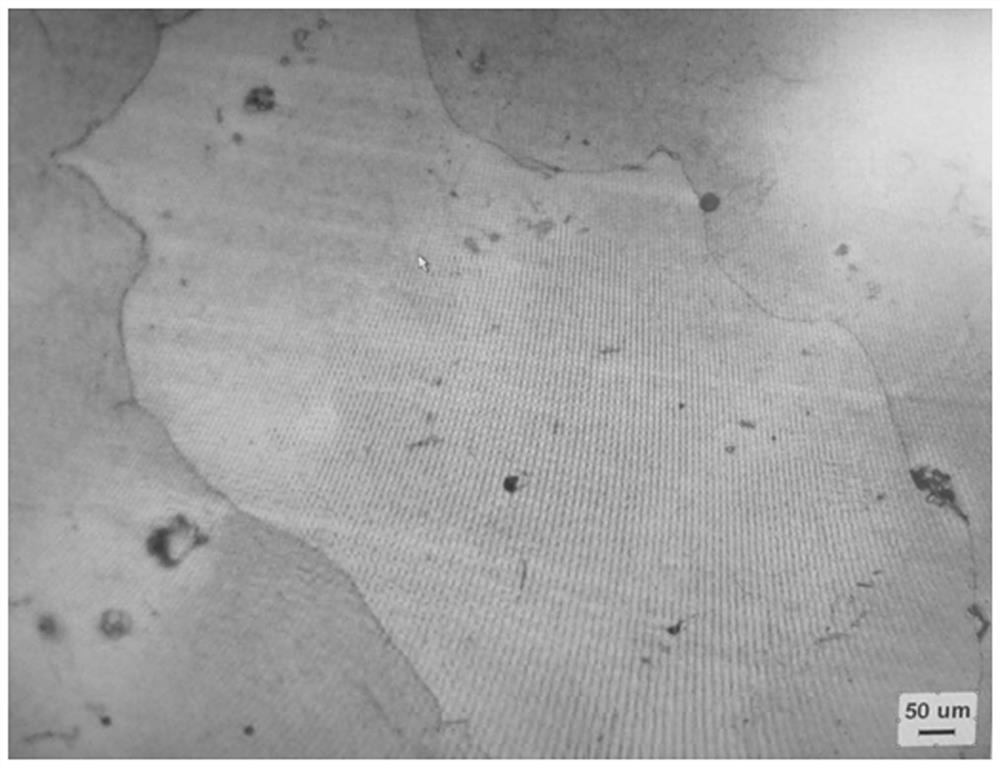

Method for improving room-temperature fracture toughness of Nb-Si-based multi-element alloy

The invention discloses a method for improving room-temperature fracture toughness of an Nb-Si-based multi-element alloy, and belongs to the field of super-high-temperature structural materials. Nb-Si-based multi-element alloy powder with a micro-submicron-grade phase dimension is prepared under a vacuum condition by applying a plasma rotation electrode atomizing method, taking a Nb-Si-based multi-element alloy rod as a rotation electrode, taking a plasma beam as a heating source and reasonably setting the rotation speed and plasma beam power parameters. By taking the powder as a raw material, an Nb-Si-based multi-element alloy ingot with a uniform and compact structure is prepared by sintering through a discharge plasma technology; and a microscopic structure is composed of a micro-submicron-grade NbSS solid solution and an Nb5Si3 strengthening phase. According to the method, a Nb-Si-based multi-element alloy structure is refined by combining a plasma rotation electrode atomizing technology with a discharge plasma sintering technology, so that the room-temperature fracture type of the NbSS solid solution phase in the Nb-Si-based multi-element alloy is converted into ductile dimple type fracture from cleavage type fracture under a conventional coagulation condition, and therefore, the room-temperature fracture toughness of the Nb-Si-based multi-element alloy is greatly improved. The preparation method for the refined Nb-Si-based multi-element alloy structure is relatively high in practicability.

Owner:BEIHANG UNIV

A kind of preparation method of graphene and titanium alloy mixed powder

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

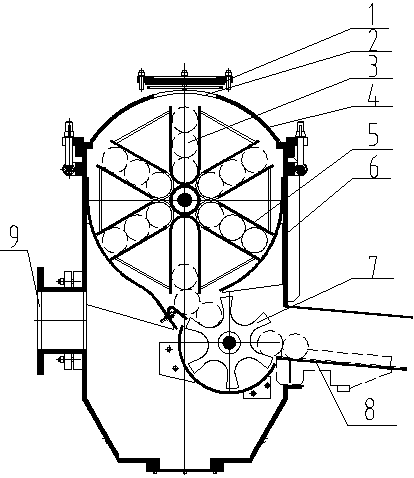

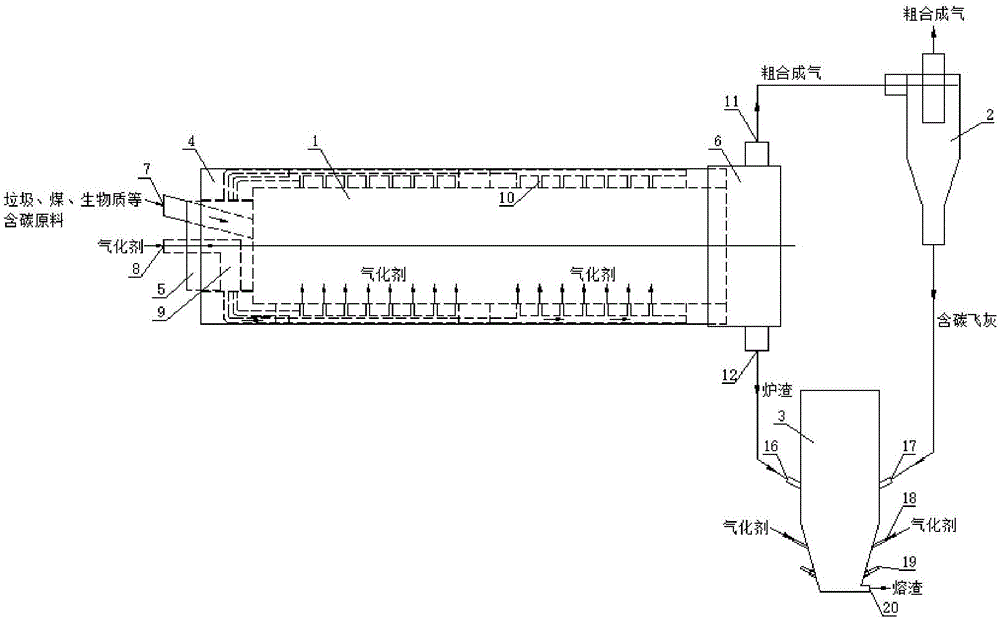

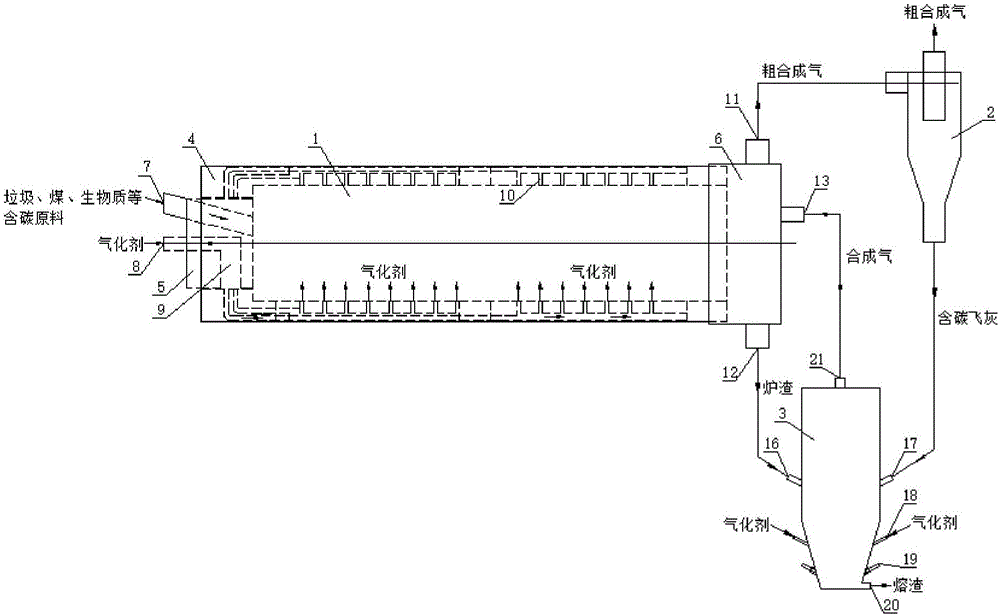

Plasma rotary kiln gasification system and pyrolysis gasification method thereof

InactiveCN106369610AFull recoveryIncrease temperatureIncinerator apparatusCombustible gas productionSyngasCombustion

The invention provides a plasma rotary kiln gasification system. The gasification system comprises a rotary kiln gasification furnace, a cyclone separator and a plasma auxiliary gasification melting furnace which communicate with one another through pipes. The plasma auxiliary gasification melting furnace is used for melting gasification of carbon-containing furnace slag discharged by the rotary kiln gasification furnace and carbon-containing flying dust gathered by the cyclone separator. The invention further provides a pyrolysis gasification method of the plasma rotary kiln gasification system. According to the plasma rotary kiln gasification system and the pyrolysis gasification method thereof, the carbon-containing flying dust and the carbon-containing furnace slag of a rotary kiln are subjected to combustion gasification through a plasma auxiliary gasification technology and melted into harmless glass bodies, and thus emission of pollutants such as dioxin is reduced; and high-temperature synthesis gas generated through carbon residue gasification is fed into the rotary kiln gasification furnace, heat is supplemented to pyrolysis and reduction of carbon-containing raw materials, high temperature which cannot be reached through traditional gasification methods is reached, and the carbon conversion rate is increased.

Owner:SUZHOU THVOW TECH LLC

System and method for plasma generation

A system and method for generating a plasma. An embodiment of the system for generating a plasma may include a first electrode; a second electrode disposed adjacent the first electrode; a first power supply for supplying power at the second electrode; a second power supply for generating a magnetic field; and a sequencer for coordinating a discharge of power from the first power supply and a discharge of power from the second power supply. The first power supply may be configured such that the discharge of power from the first power supply generates a plasma between the first electrode and the second electrode. The second power supply may be configured such that the magnetic field generated by the discharge of power from the second power supply rotates the plasma.

Owner:PLASSEIN TECH LTD LLC +1

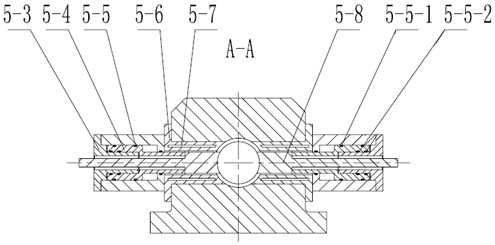

Mechanical shaft and plasma rotation electrode powdering device and method

The invention discloses a mechanical shaft and a plasma rotation electrode powdering device and method, and relates to the field of metal powder preparation. The mechanical shaft and the device and method are used for solving the problems of difficulty in online adjustment of pressing force caused by a traditional spring pressing carbon brush device, non-uniform bar melting caused by poor high-speed rotation power supply and the like. According to the mechanical shaft, one end of a carbon brush penetrates through a hollow plunger to be electrically connected with the outside, the end face of the other end makes contact with a power supply shaft, and an insulating plate is bonded to the periphery of the end; a pipeline is connected with a servo power system and is used for exerting compressed air or hydraulic oil provided by the servo power system on the hollow plunger, so that the front end of the hollow plunger tightly presses the carbon brush; and the hollow plunger is of an annularhollow structure.

Owner:西安赛隆增材技术股份有限公司

Method for reducing special-shaped powder in high-alloying nickel-based alloy powder

The invention discloses a method for reducing special-shaped powder in high-alloying nickel-based alloy powder. The method is specifically implemented according to the following steps that 1, a nickel-based high-temperature alloy bar is prepared through a vacuum horizontal continuous casting and low-temperature gradient cooling process; 2, the nickel-based high-temperature alloy bar obtained in the step 1 is subjected to first-time solution treatment; 3, the nickel-based high-temperature alloy bar obtained in the step 2 is subjected to secondary solution treatment; 4, the nickel-based high-temperature alloy bar obtained in the step 2 is prepared into nickel-based alloy powder through plasma rotation electrode manufacturing powder manufacturing equipment; and 5, the nickel-based alloy powder prepared in the step 4 is sieved and packaged under the protection of inert gas. According to the method for reducing the special-shaped powder in the high-alloying nickel-based alloy powder, and the problem that too much special-shaped powder exists in the nickel-based alloy powder is solved.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

A high density plasma reactor

ActiveCN1809911BElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyFeedback control

The high density RF plasma source of this invention uses a special antenna configuration to launch waves at frequency such as 13,56MHz. The tunability of this antenna allows to adapt actively the coupling of the RF energy into an evolutive plasma as found in plasma processings in semiconductor manufacturing. This plasma source can be used for the following applications : plasma etching, deposition, sputtering systems, space propulsion, plasma - based sterilization , plasma abatement systems. In another embodiment, the plasma source is in conjunction with one or several process chambers , which comprise an array of magnets and RF coils too . These elements can be used, on one hand, for plasma confinement or the active plasma control (Plasma rotation ) thanks to feedback control approach , and one the other hand, for in situ NMR Monitoring or analysis such as moisture monitoring inside a process chamber , before or after the plasma process, or for in situ NMR Inspection of wafers or others workpieces.

Owner:HELYSSEN

Method for preparing superfine titanium powder through magnetized plasma rotating electrode method

PendingCN114472910ASmall particle sizeGood lookingTransportation and packagingMetal-working apparatusMetallic materialsTitanium powder

The invention belongs to the technical field of metal materials, and provides a method for preparing superfine titanium powder by a magnetized plasma rotating electrode method, which comprises the step of adding a magnetic field between an electric arc and a rotating electrode in the plasma rotating electrode method. According to the method, the superfine titanium powder is prepared through electrostatic coulomb repulsive force, the technical difficulty of high-speed rotation when PREP adopts centrifugal force to separate the titanium powder is avoided, the prepared titanium powder is good in spherical morphology, the average particle size is smaller than 10 micrometers, and the application occasion with the stricter requirement for the particle size of the titanium powder can be met.

Owner:四川真火等离子研究院有限公司

Preparation process of multi-component spherical alloy powder

ActiveCN114346248AHigh sphericityHigh tap densityTransportation and packagingMetal-working apparatusRheniumNiobium

The invention discloses a preparation process of multi-component spherical alloy powder, the multi-component spherical alloy powder is prepared by adopting a plasma rotation electrode atomization (PREP) method, the multi-component alloy comprises at least one of refractory metals and compounds thereof, and the multi-component alloy specifically comprises tungsten, molybdenum, tantalum, niobium, rhenium, tungsten carbide, tantalum carbide and the like. The multi-component spherical alloy powder containing the refractory metal or the compound of the refractory metal is prepared through the PREP method, the prepared multi-component spherical alloy powder is high in sphericity degree, good in fluidity, high in tap density and low in impurity element content, the yield of hollow powder and satellite powder is small, and compared with other preparation methods, the prepared alloy powder is more excellent in performance and better in performance. The material is an ideal material for metal 3D printing; in addition, the invention also solves the problem that a round bar containing refractory metal or a compound base material thereof used in a PREP method is difficult to prepare, and provides a spatial structure netting method or an element direct mixing method or a porous skeleton method to prepare the multi-component alloy bar.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com