Plasma rotation electrode powder production feeding device

A technology of rotating electrode and feeding equipment, which is applied in the field of ion rotating electrode powder making and feeding equipment, can solve the problems of inability to continuously feed and unsafe dynamic sealing, etc., and achieve the effects of convenient operation, simple equipment structure and continuous feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

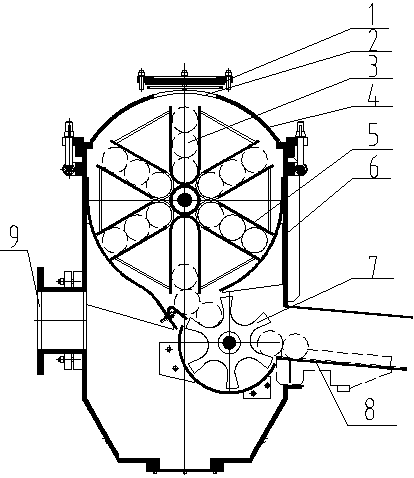

[0011] See attached figure 1 , a kind of plasma rotating electrode powder making feeding equipment, comprising a material box upper cover 4 and a feed inlet sealing device 1 connected to the feed port 2 at the top of the material box upper cover, the material box upper cover 4 is connected to the material box 6 through bolts Connection, the material box is built with a material bin 5 and a shift fork 7, the discharge slide 8 connects the material box with the plasma rotating electrode powder making equipment, and the flange interface 9 is connected with the vacuum and inert gas system to ensure that the whole equipment works under the protection of inert gas. environment to work.

[0012] When in use, open the sealing device 1 of the feeding port, and put the raw material rod 3 into the bin 5 from the feeding port 2 in turn, and after the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com