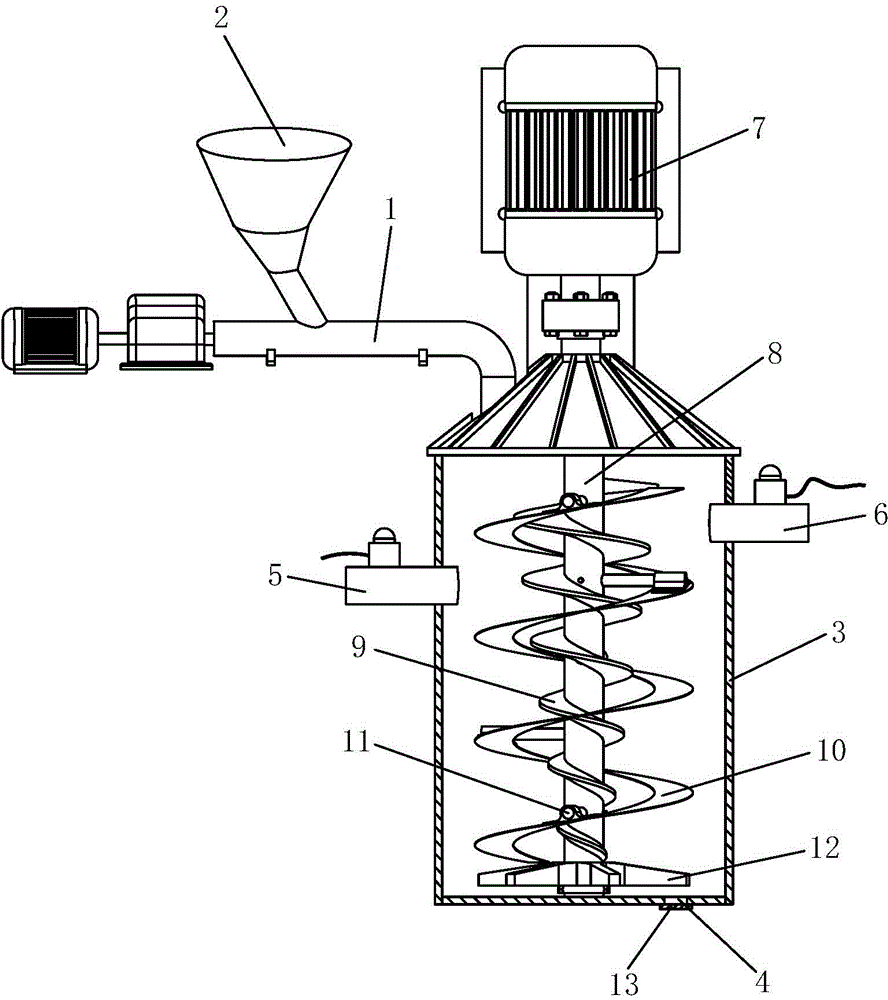

Dry and wet double-purpose stirring ball mill

A mixing ball milling, wet and dry technology, applied in grain processing and other directions, can solve the problems of affecting mixing efficiency, poor processing effect of fine-grained materials, low crushing efficiency, etc., to achieve scientific and reasonable structure design, reduce incomplete crushing, and solve the single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

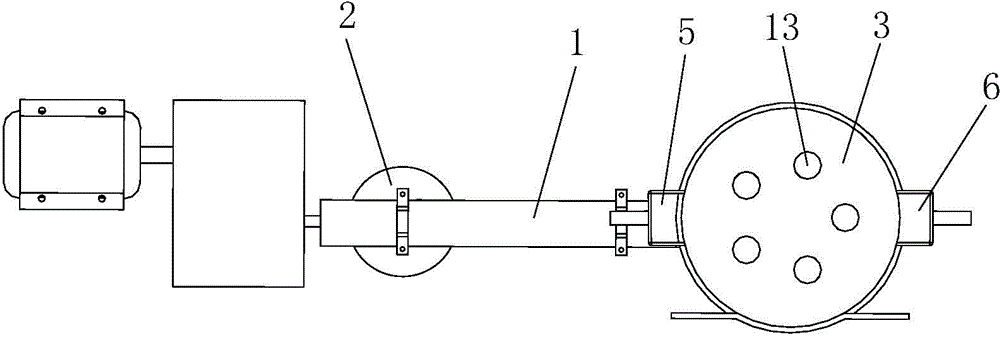

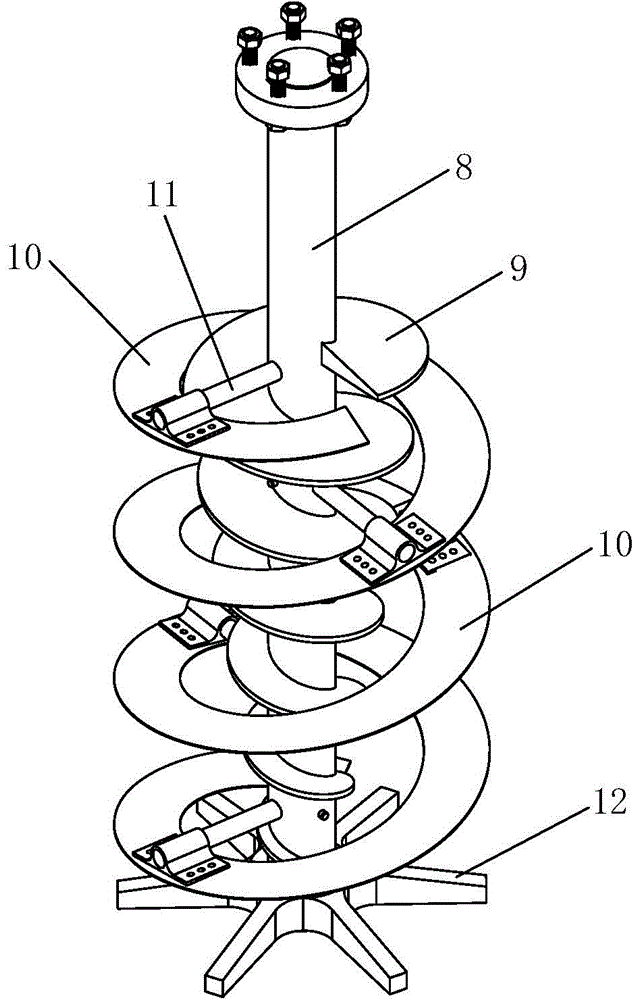

Method used

Image

Examples

Embodiment example 1

[0050] Choose the clean coal of Zhangjiamao Coal Mine in northern Shaanxi as the research object to carry out the ore grinding test, as shown in the table below, under the same sample amount (2kg) and the same feeding particle size (-0.5mm), the dry and wet two-stage grinding method of the present invention is used On the premise that the particle size of the material is effectively reduced to -37 μm by using the agitating ball mill, the grinding time of the present invention is reduced by 24% compared with ordinary grinding equipment.

[0051] Table 1 is the clean coal grinding index corresponding to the ordinary grinding equipment and the dry-wet dual-purpose agitating ball mill of the present invention

[0052]

[0053] Note: The above test data is the average value of five tests

Embodiment example 2

[0055] The middle coal of Xiqu Coal Preparation Plant was selected as the research object to carry out the ore grinding test. Under the conditions of the same sample amount (1kg), the same feed particle size (-0.5mm) and the same grinding time (10min), the ore grinding The product is subjected to laser particle size analysis to obtain a particle size distribution curve (such as Figure 4 with Figure 5 shown).

[0056] Depend on Figure 4 with Figure 5 It can be seen from the comparison that the dry-wet dual-purpose agitating ball mill of the present invention has a relatively large yield of -74 μm particle size when the grinding time is short, and has achieved a better primary grinding effect. If the present invention is enlarged, It can crush a large amount of minerals to -74μm in a short period of time, and the effect of improving the yield of -74μm particle size materials is particularly obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com