Patents

Literature

1382 results about "Slurry flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slurry Flow. Slurry transportation is required in a diverse range of sectors, from food to minerals processing; and oil sands processing to nuclear waste management. As a process it requires significant levels of energy and the abrasive nature of materials used can lead to ongoing issues of pipeline erosion.

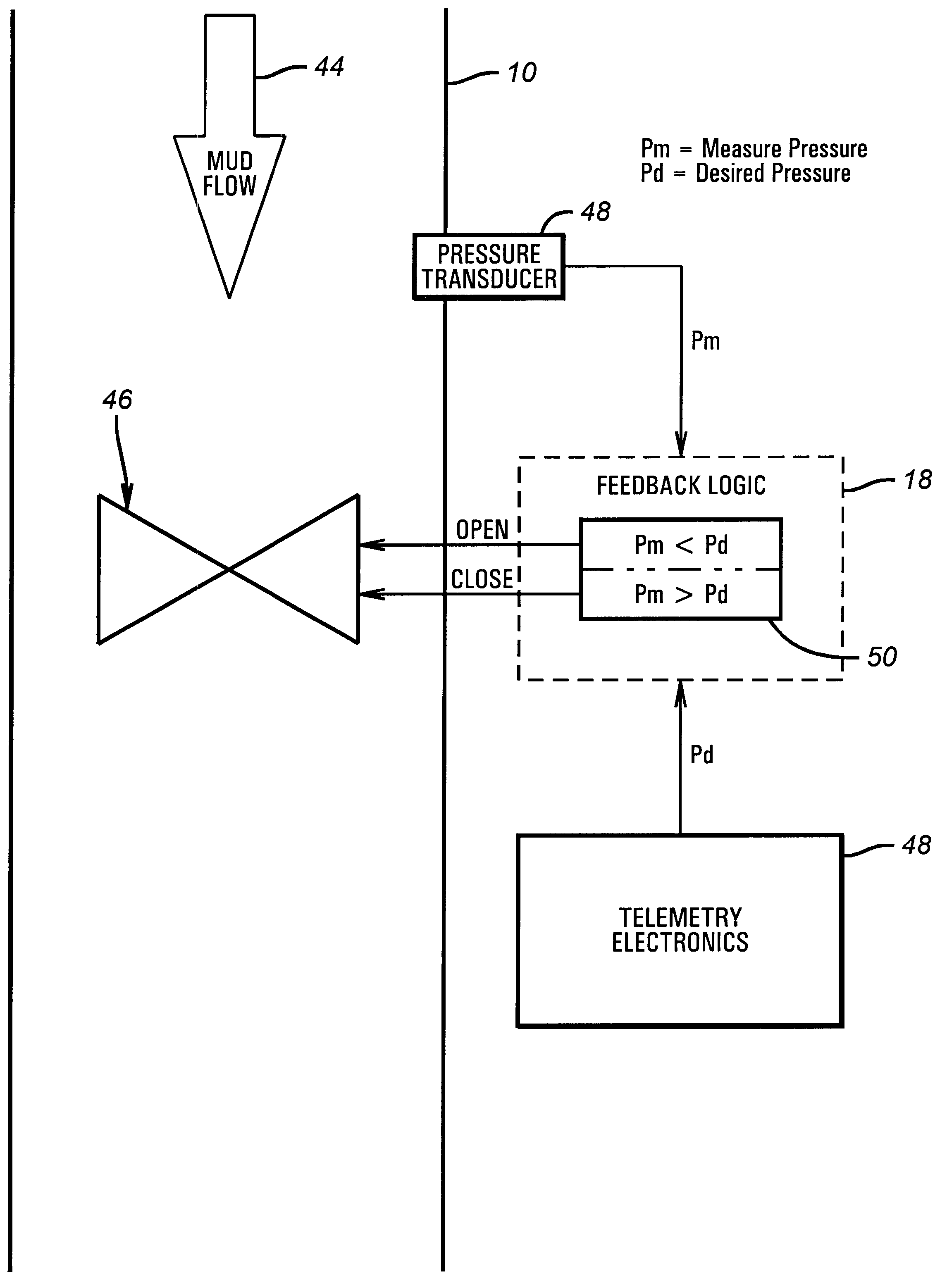

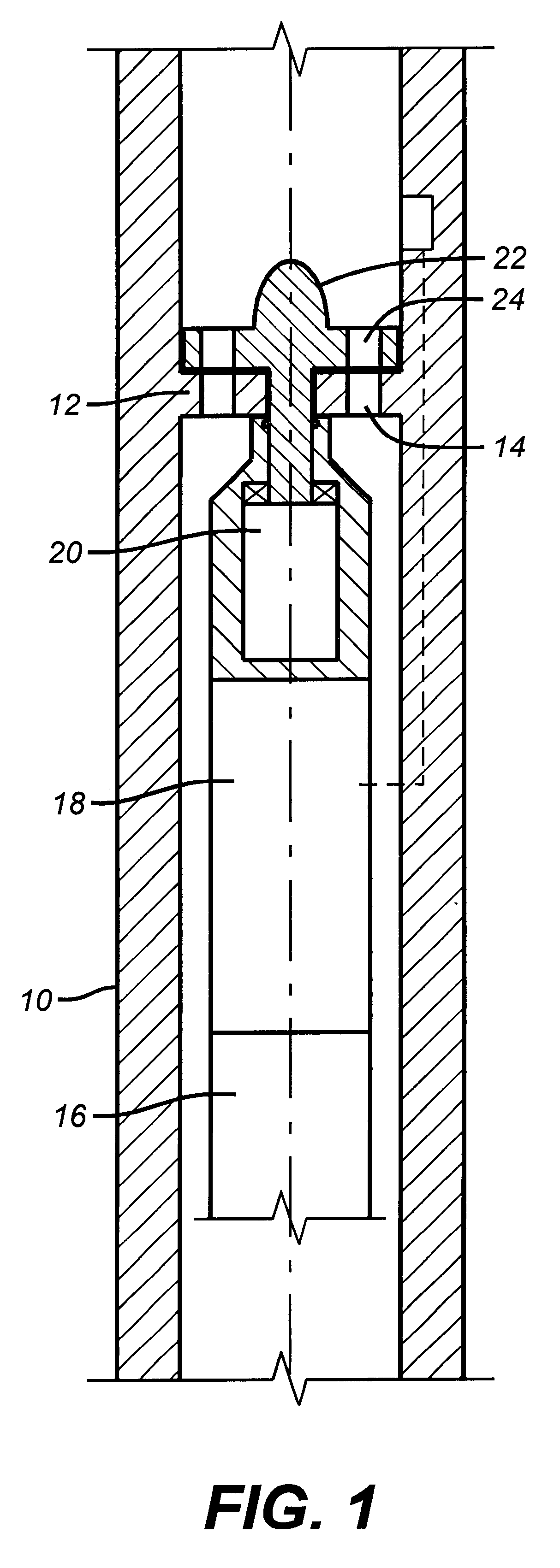

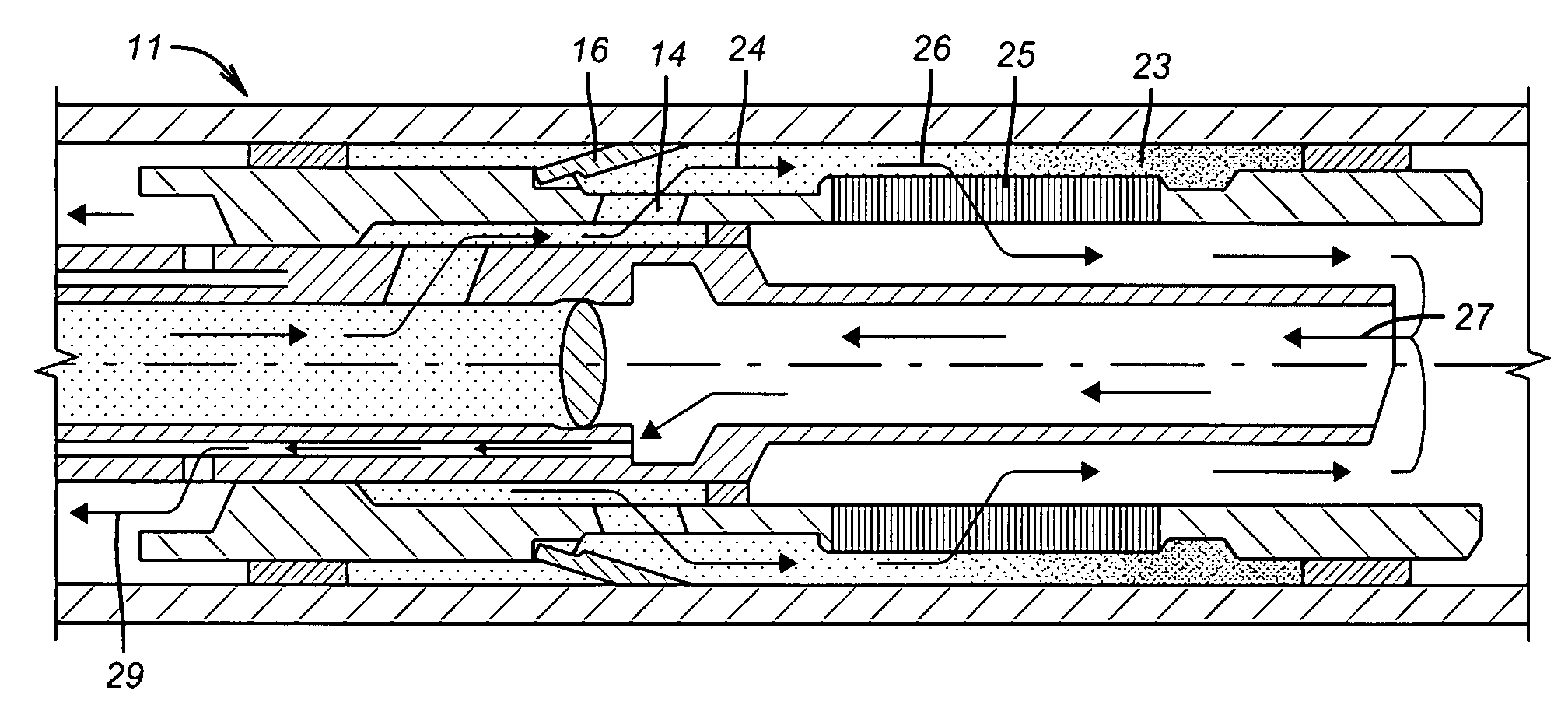

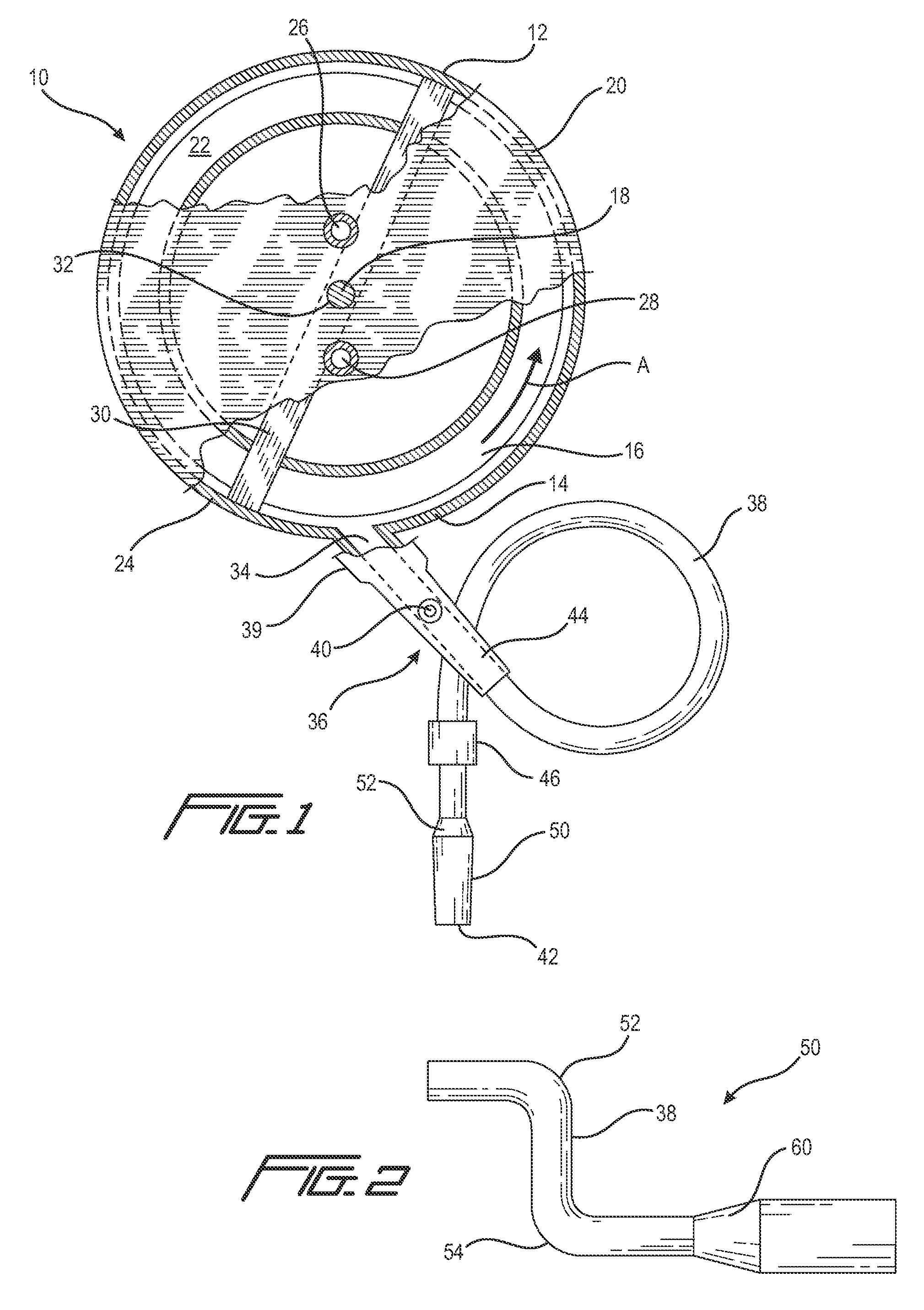

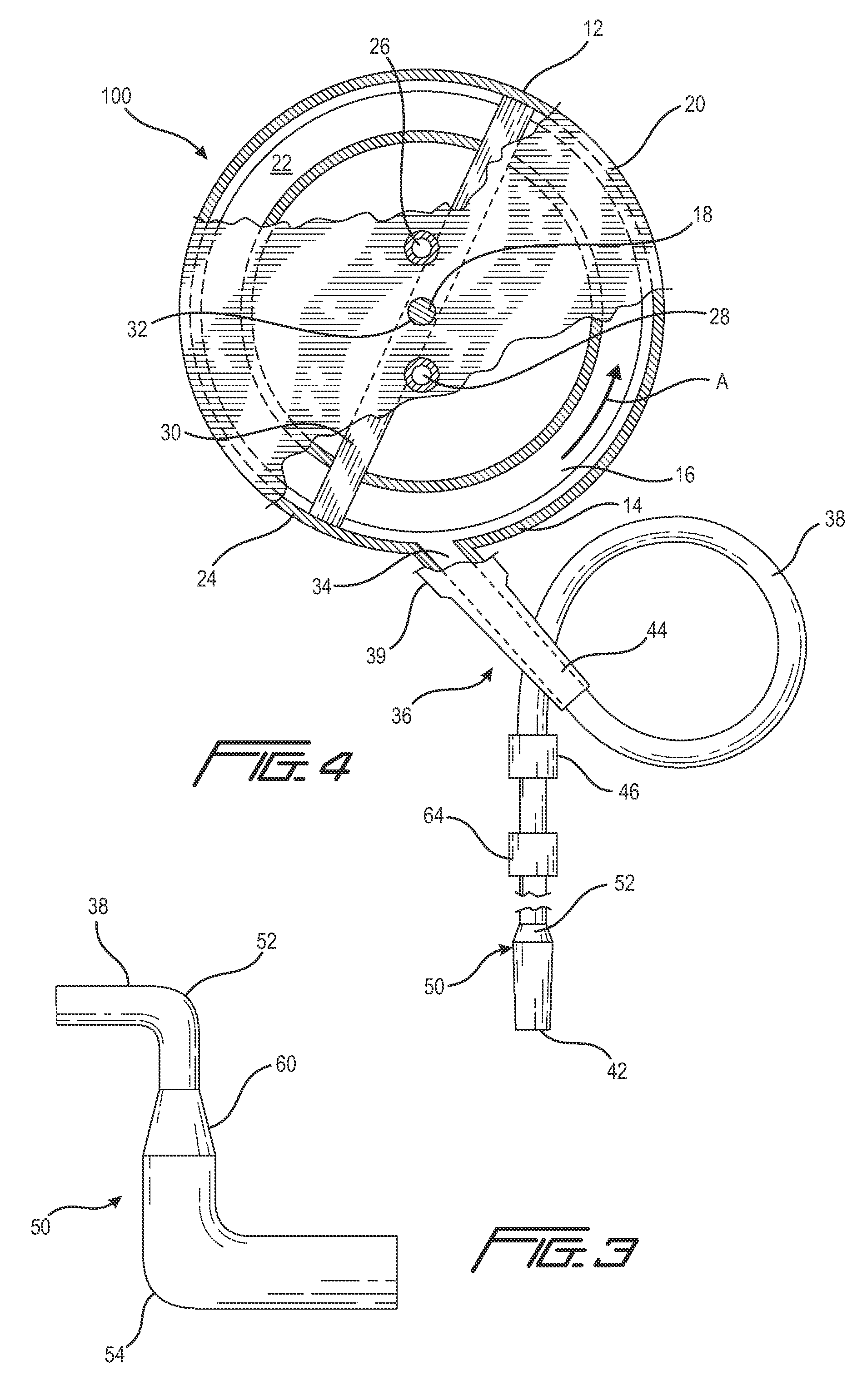

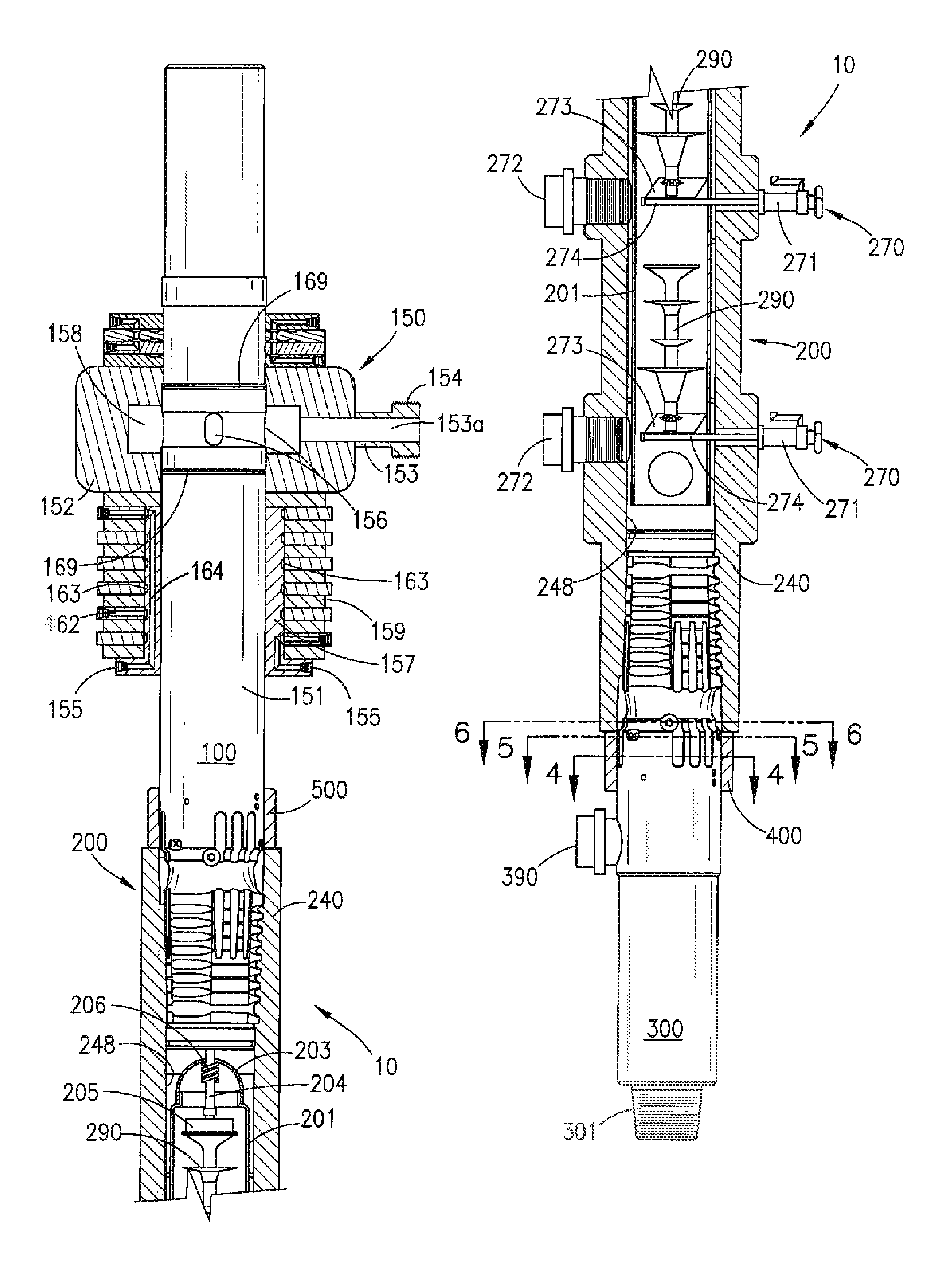

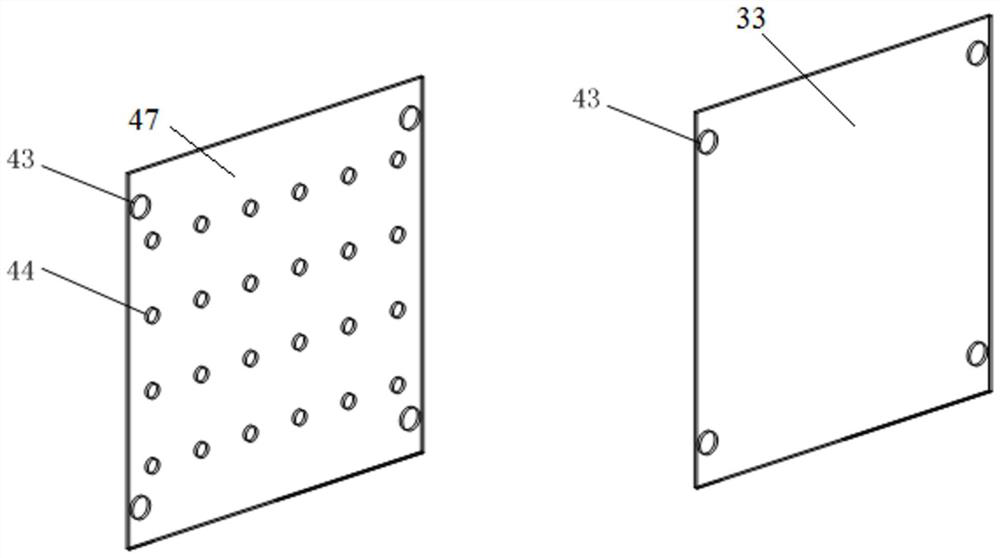

Adjustable shear valve mud pulser and controls therefor

InactiveUS6469637B1Enhanced data transmissionCompensation for wearSurveyConstructionsControl systemEngineering

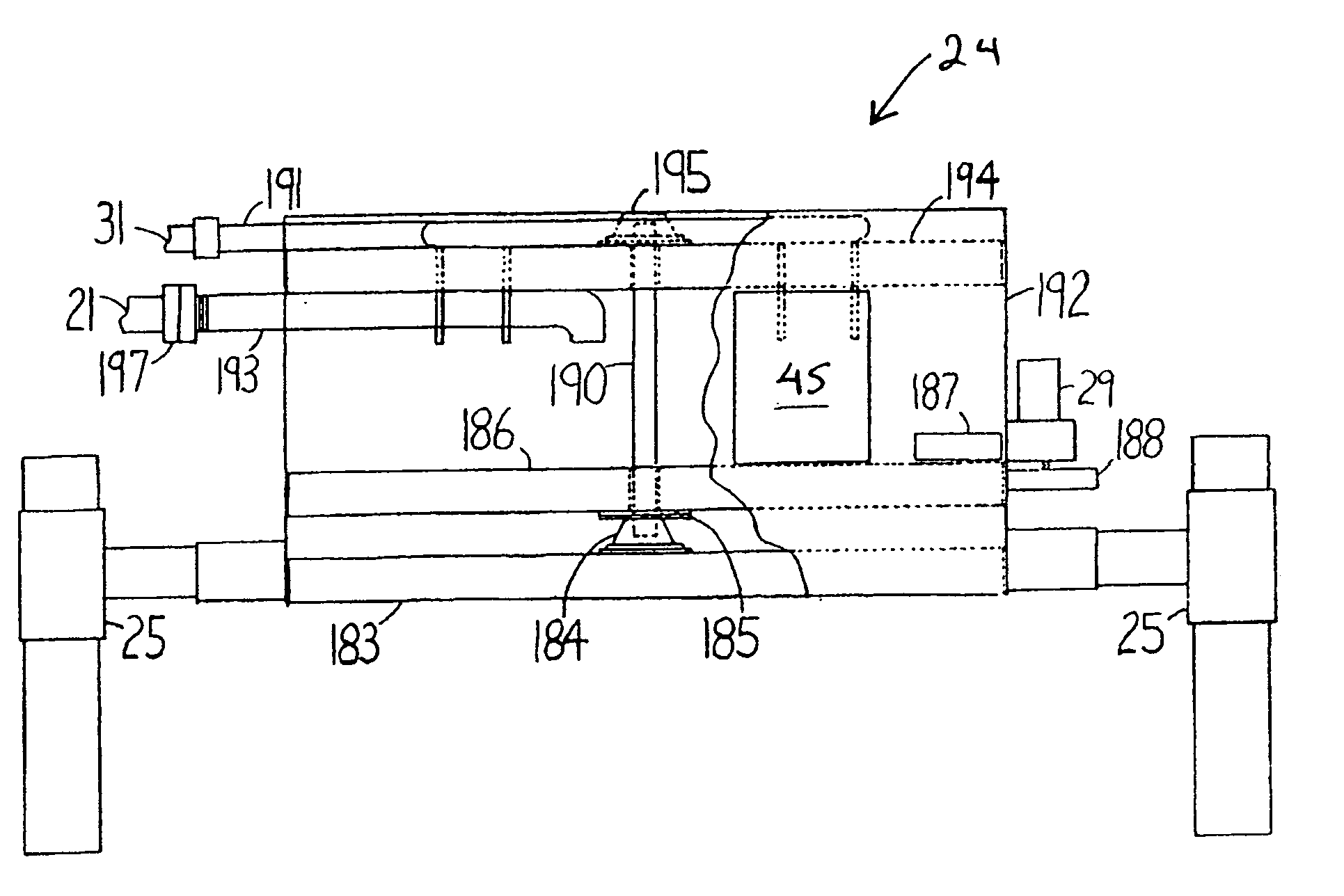

A telemetry system involving a shear-type mud pulser valve as the preferred embodiment is described. The control system includes a motor driver for the mud pulser which, in essence, moves one movable plate with respect to a stationary plate to create openings of various sizes. Pressure is sensed uphole of the pulser valve and is compared in real time to the desired pressure pulse amplitude. By allowing different relative rotational positions of the rotatable plate with respect to the stationary plate, different amplitudes can be achieved to further enhance the transmission of data to the surface. The control system compensates for wear in the mud pulser valve itself as well as drastic changes in mud flow and pressure. The configuration is simple and not prone to fouling from grit or other particles in the mud. The system is capable of creating an initial baseline array of a variety of pulse amplitudes, and thereafter providing the required relative rotation between the stationary and rotatable plates so as to be able to duplicate the baseline pulse amplitudes despite changes in the valve condition or in the flowing conditions of the mud.

Owner:BAKER HUGHES INC

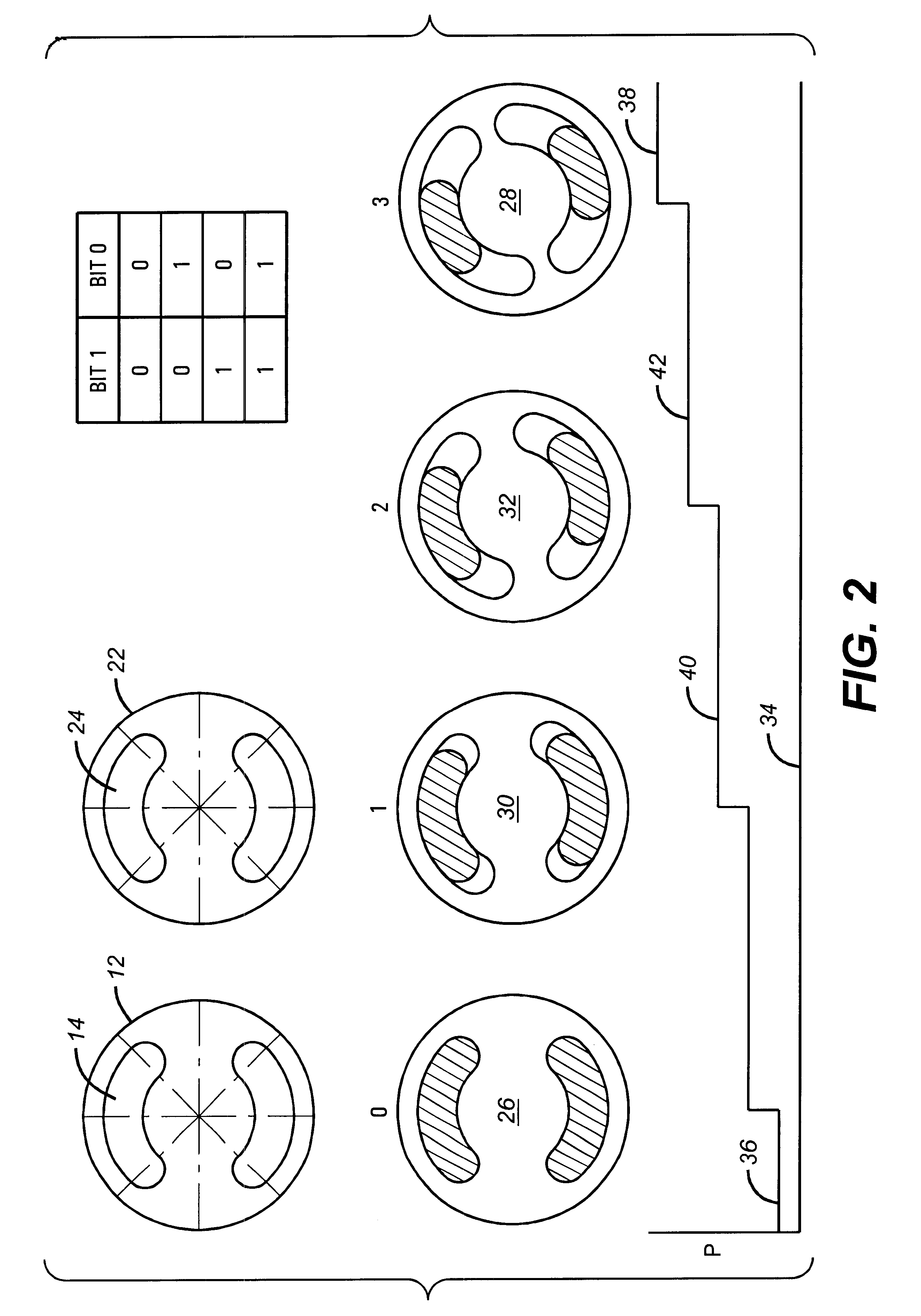

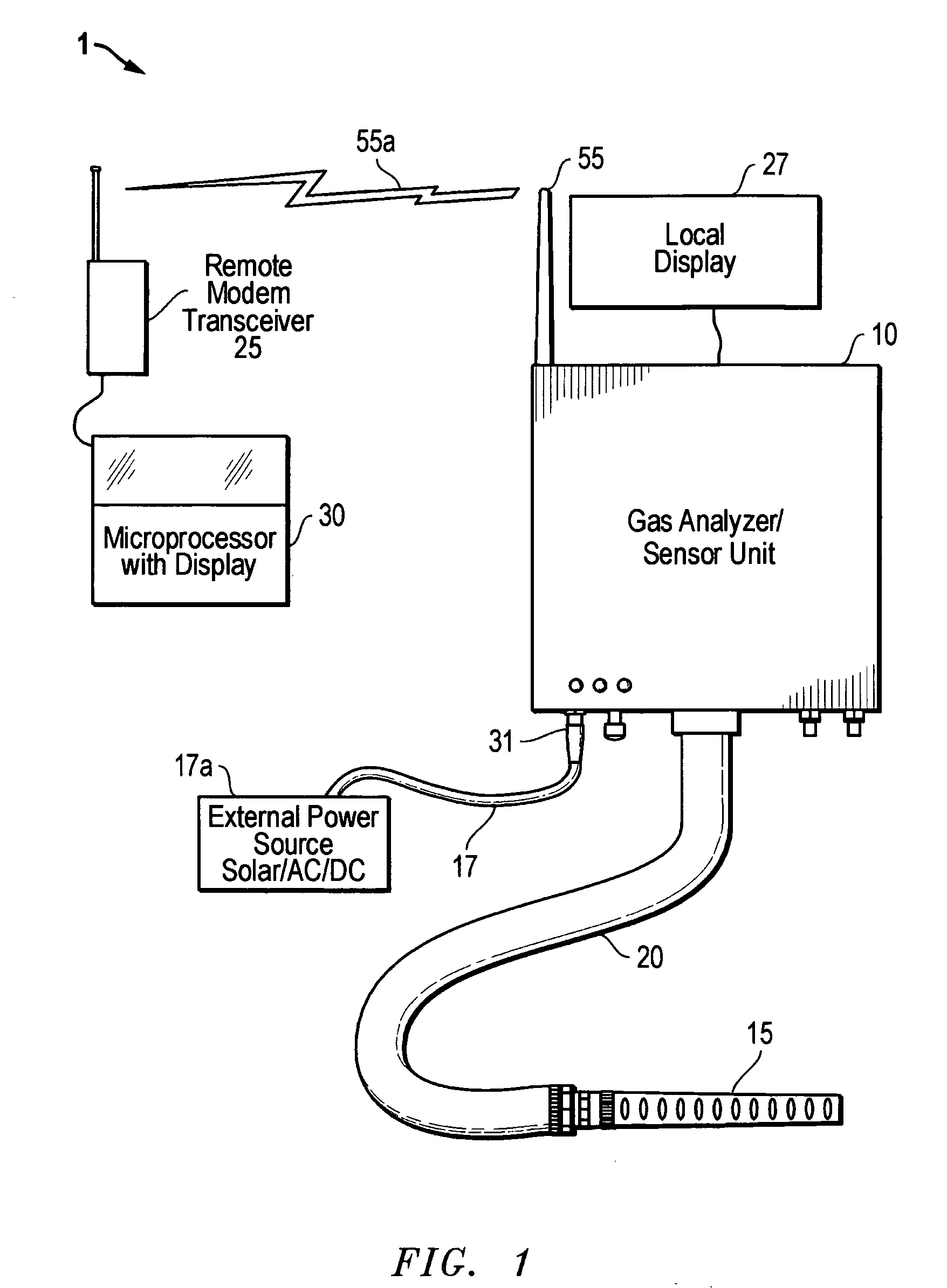

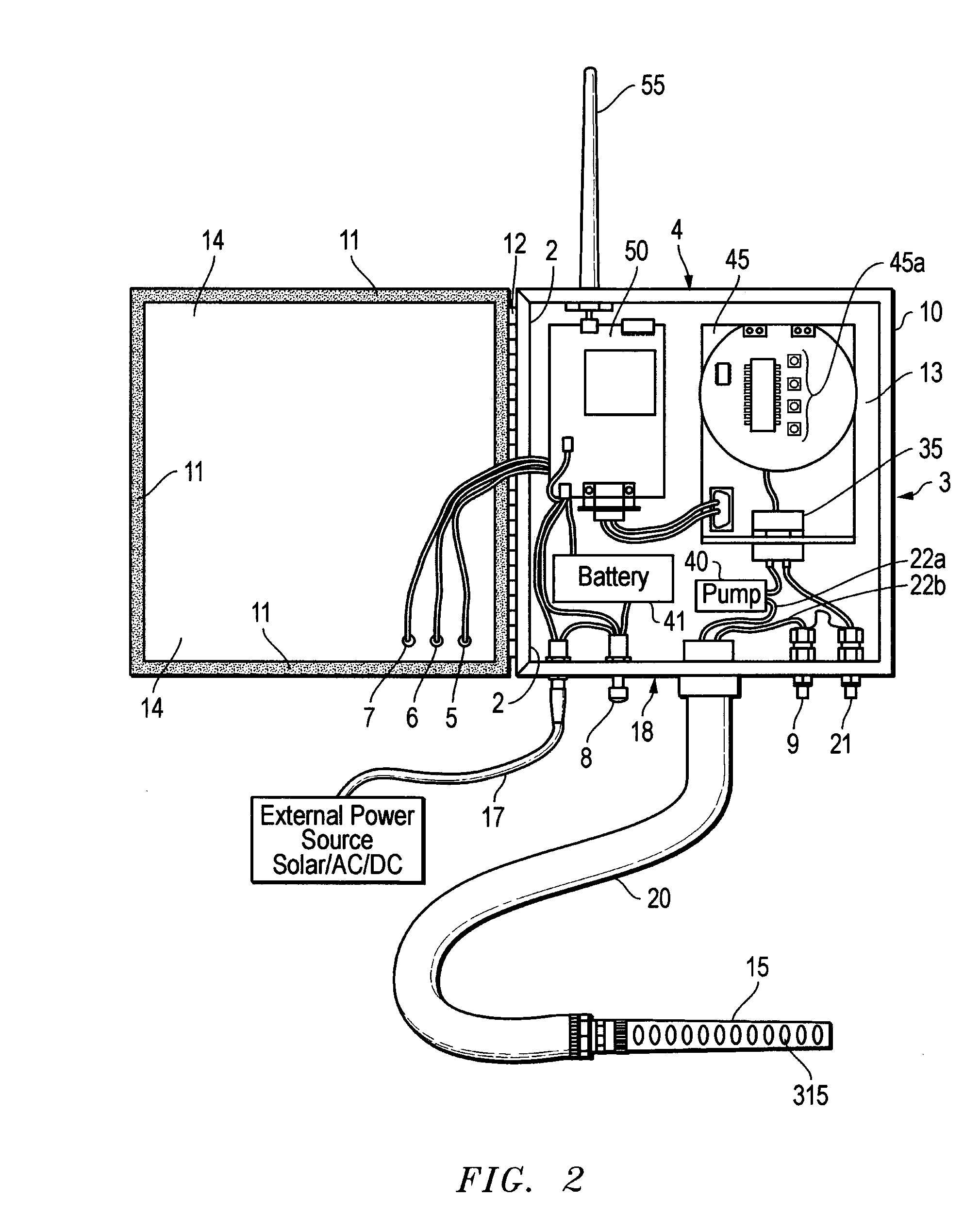

System, method and apparatus for mud-gas extraction, detection and analysis thereof

InactiveUS20060093523A1Maximum efficiencyFacilitates accurateComponent separationMaterial analysis by electric/magnetic meansWireless transceiverTransceiver

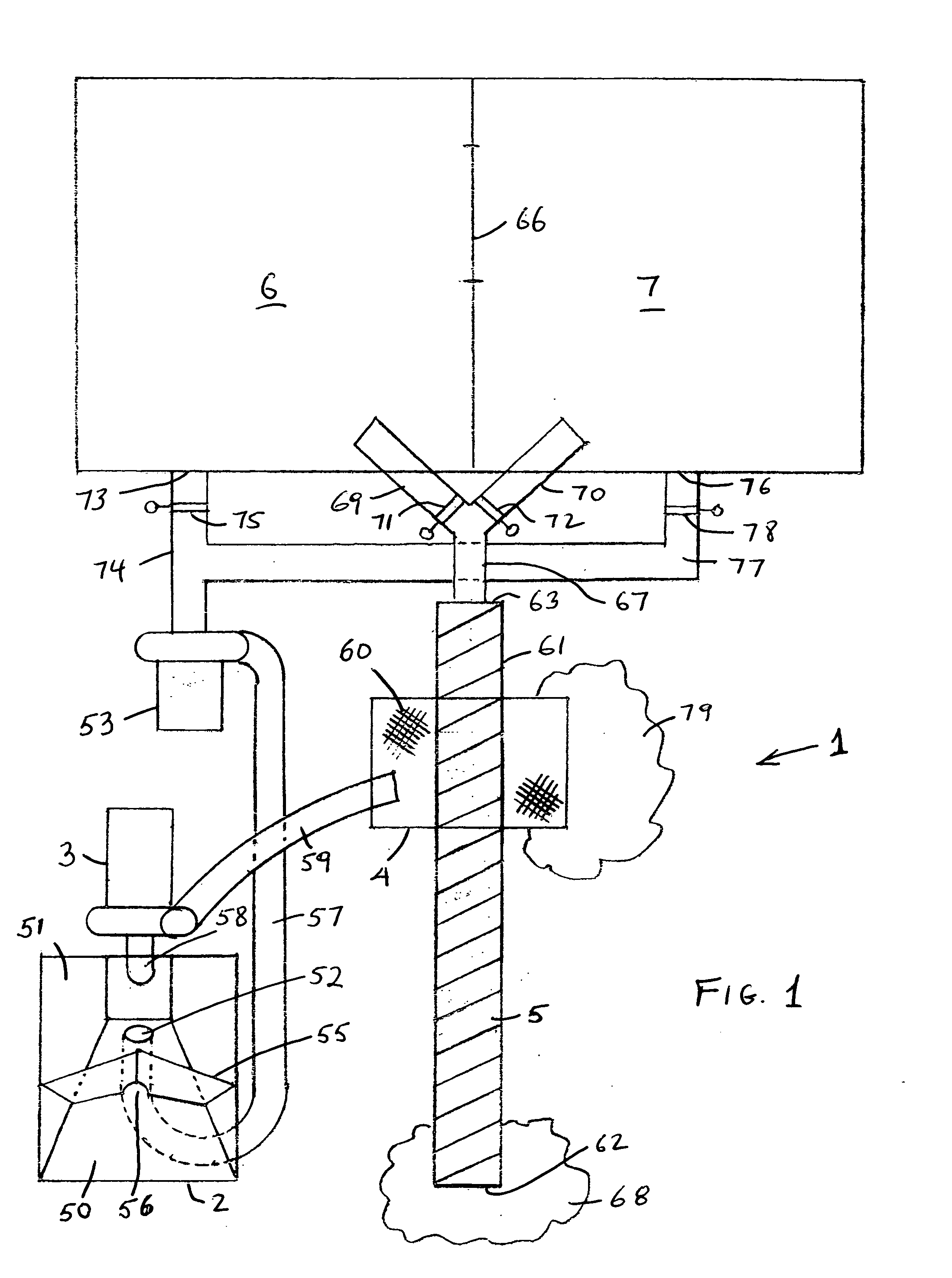

The application of a gas analyzer for gas mud logging is presented to measure gases in the return mud flow used in drilling processes. A supported membrane extraction probe from the analyzer is inserted into the mud flow. The probe extracts target gases from the mud through the membrane. Extracted gases are transported by an internal pump to an internal gas sensor unit. The infrared sensor unit is utilized to subject the gases to infrared emitted energy to excite the gasses at a molecular level for sensing and detection. The sensor then transfers sensed values electronically to a digital conditioning board. As the data is digitized in the conditioning board it is encoded with information to enable a means of correlating the derived sensor data. The data is then sent to a digital wireless transceiver for transport to a remote receiving transceiver connected to a microprocessor for data logging.

Owner:HYPERTEQ LP

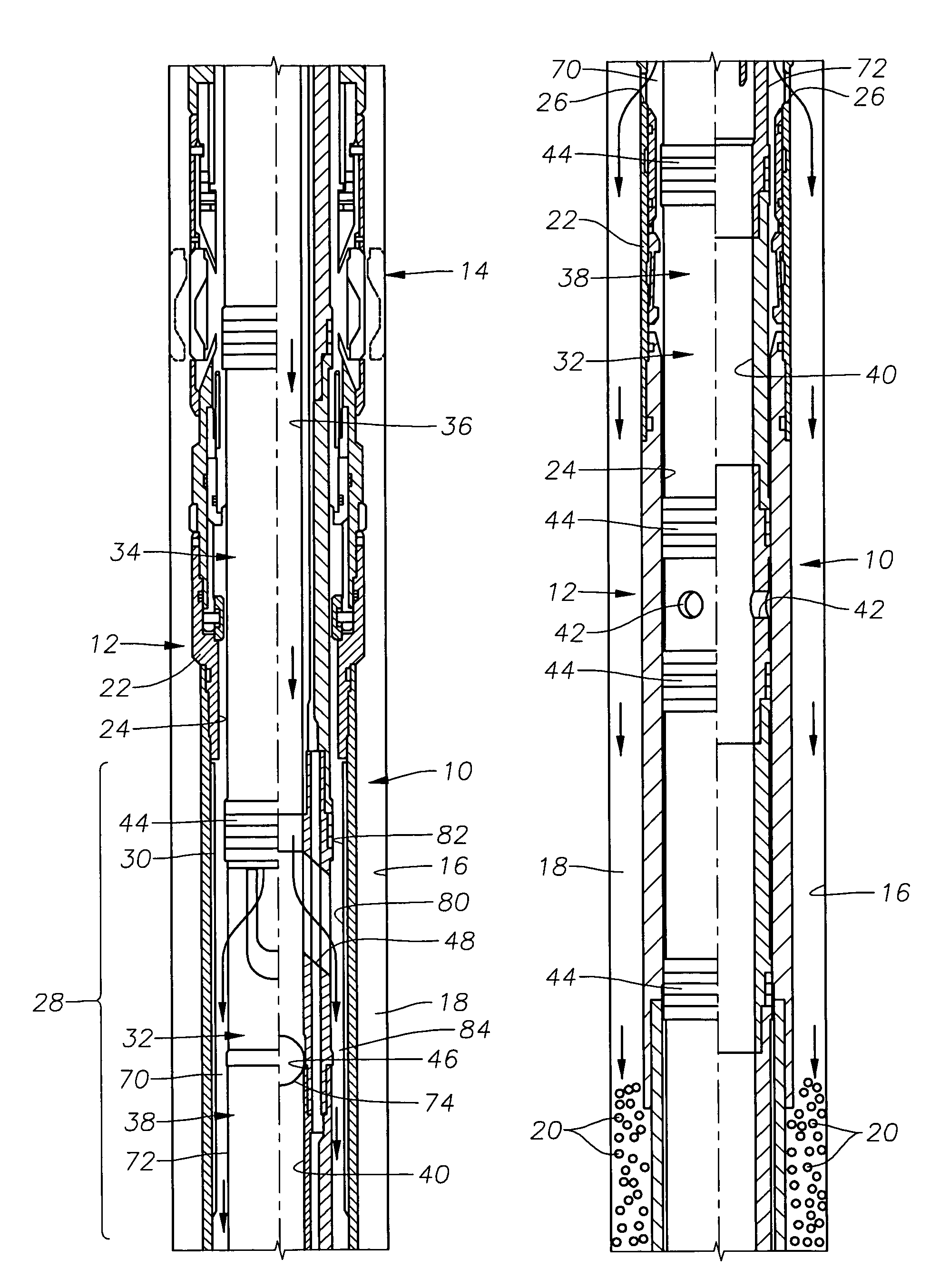

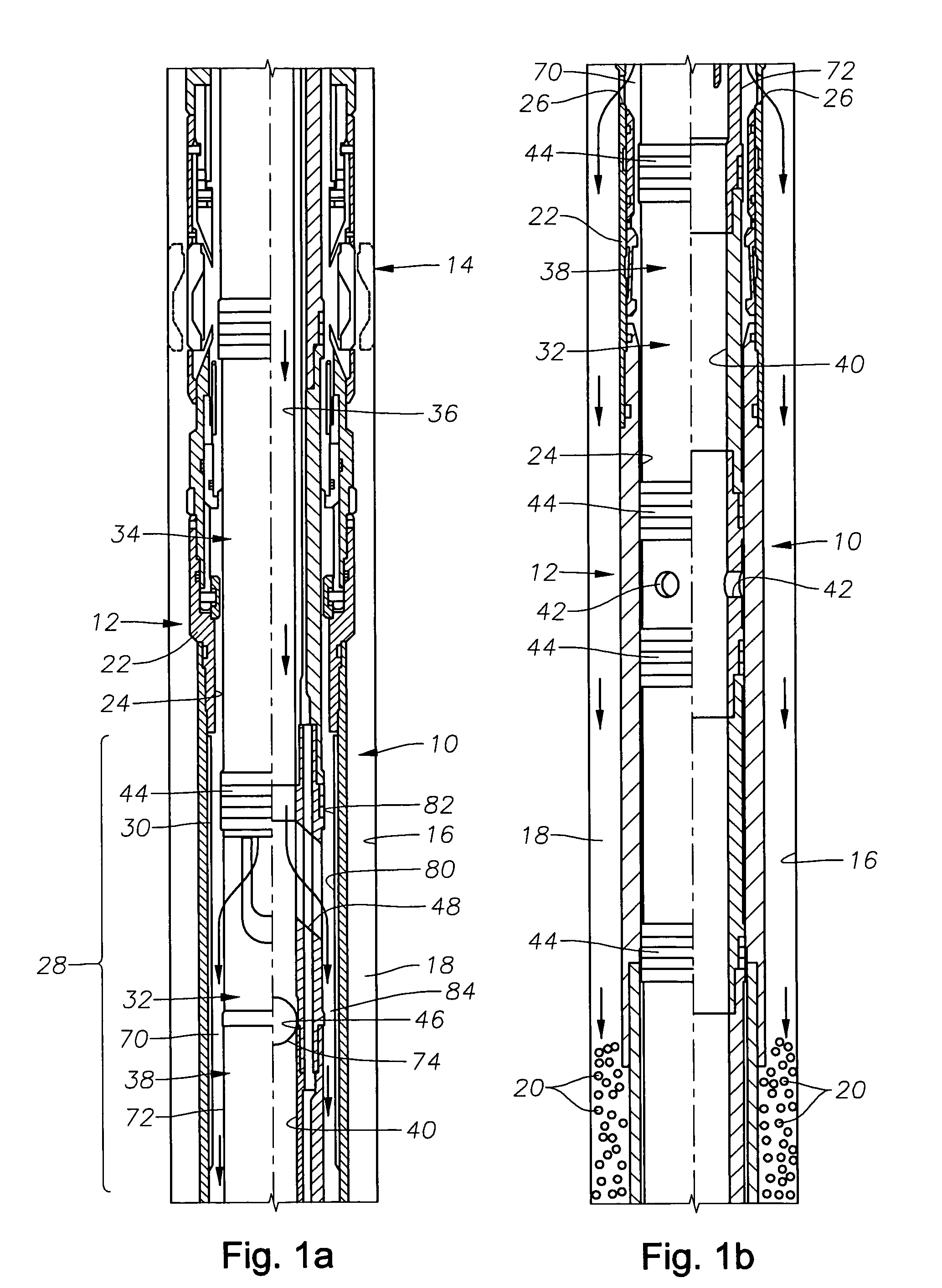

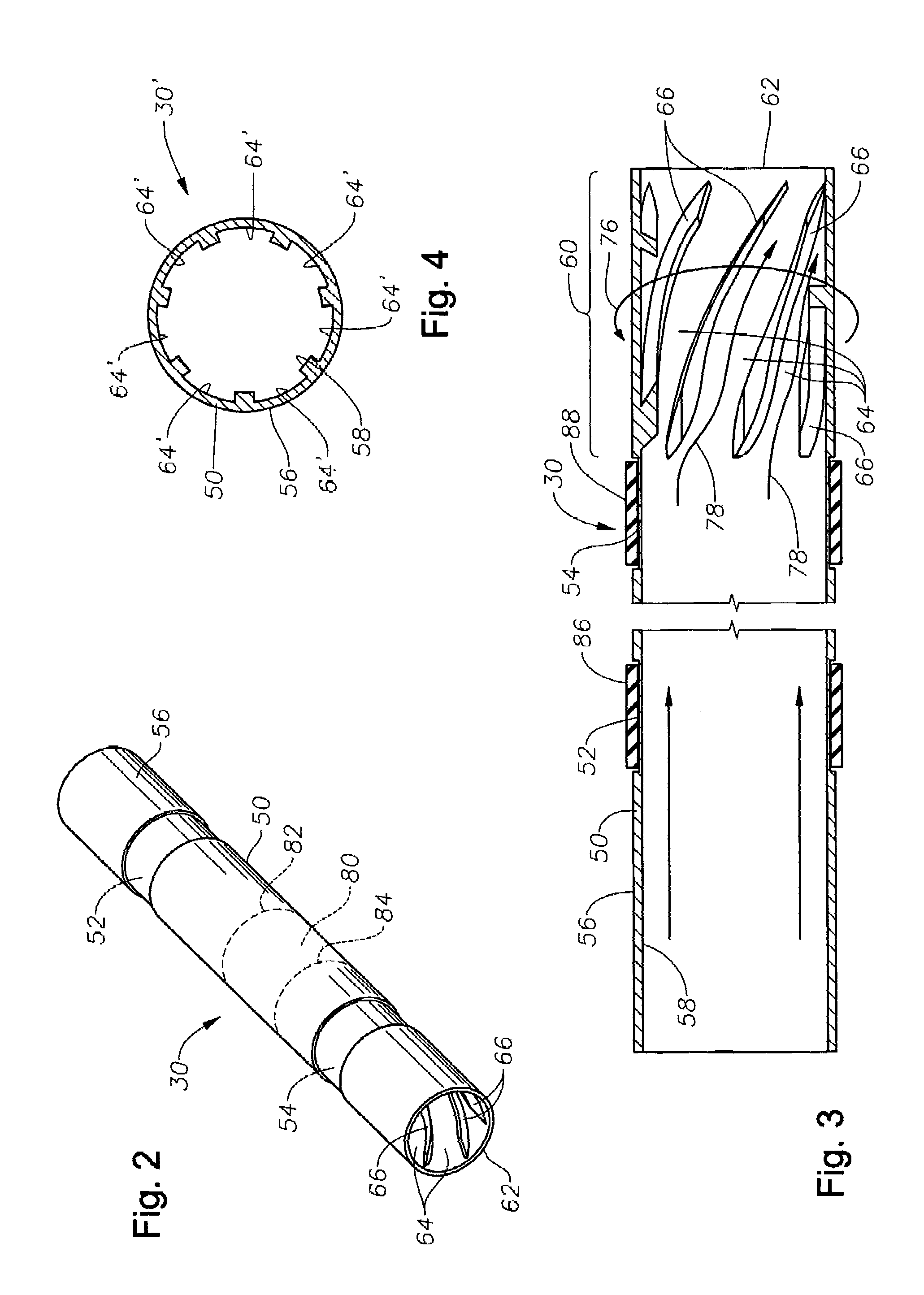

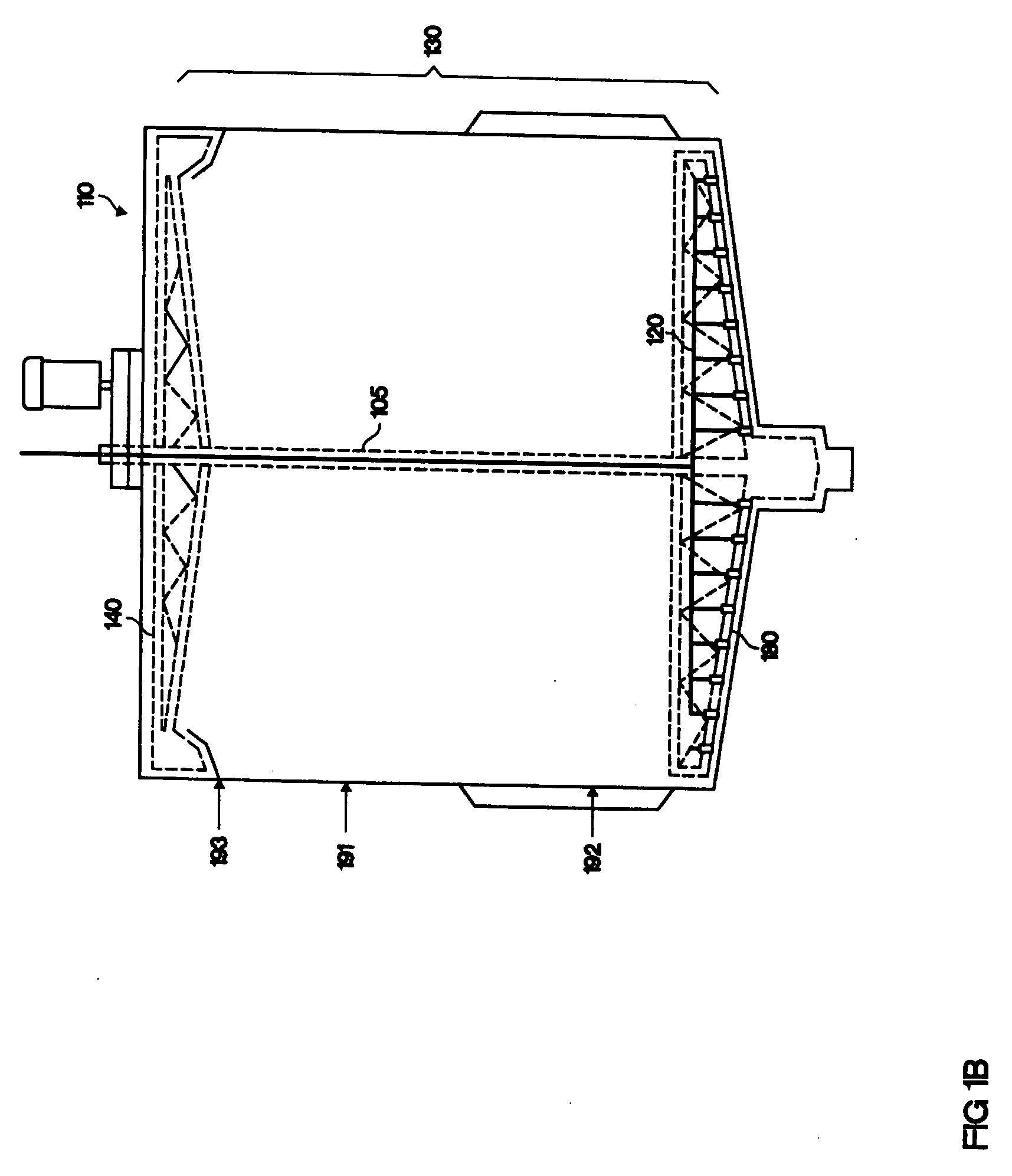

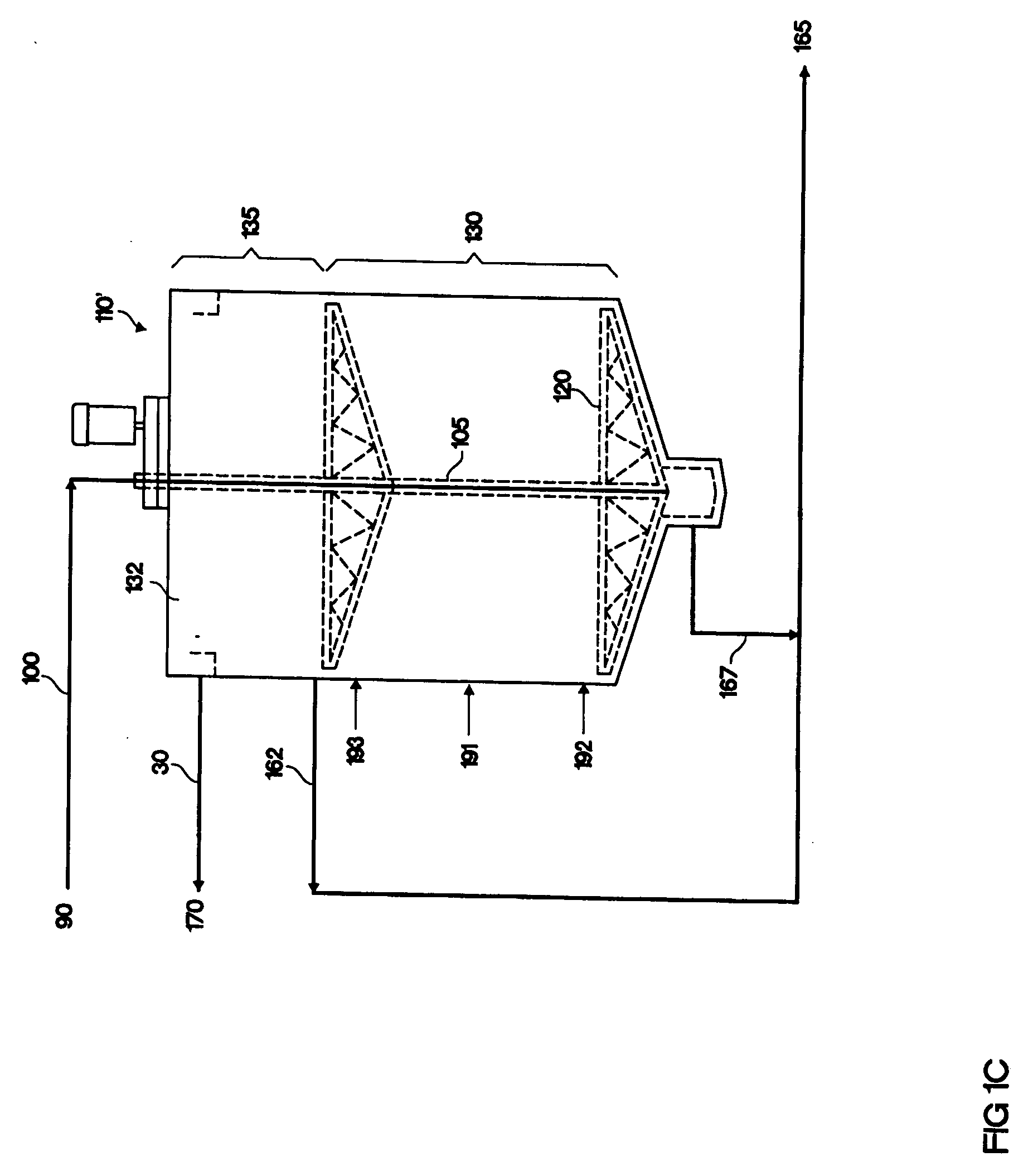

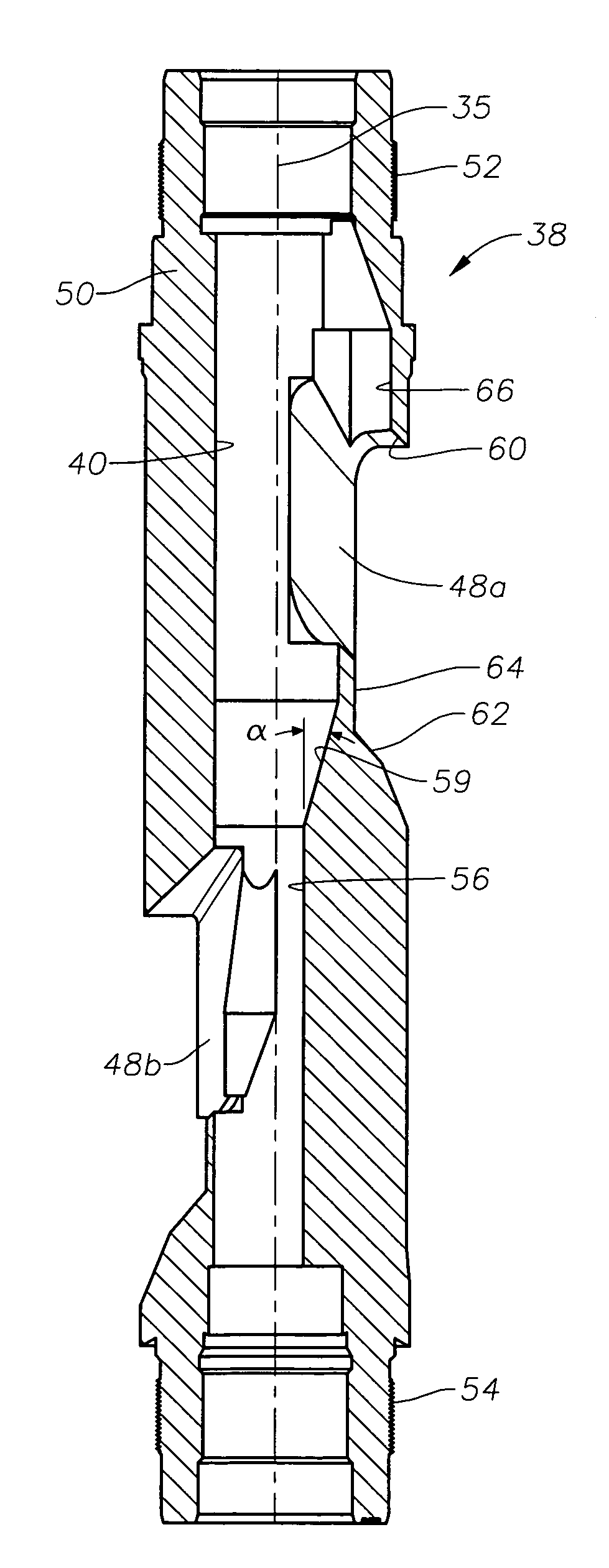

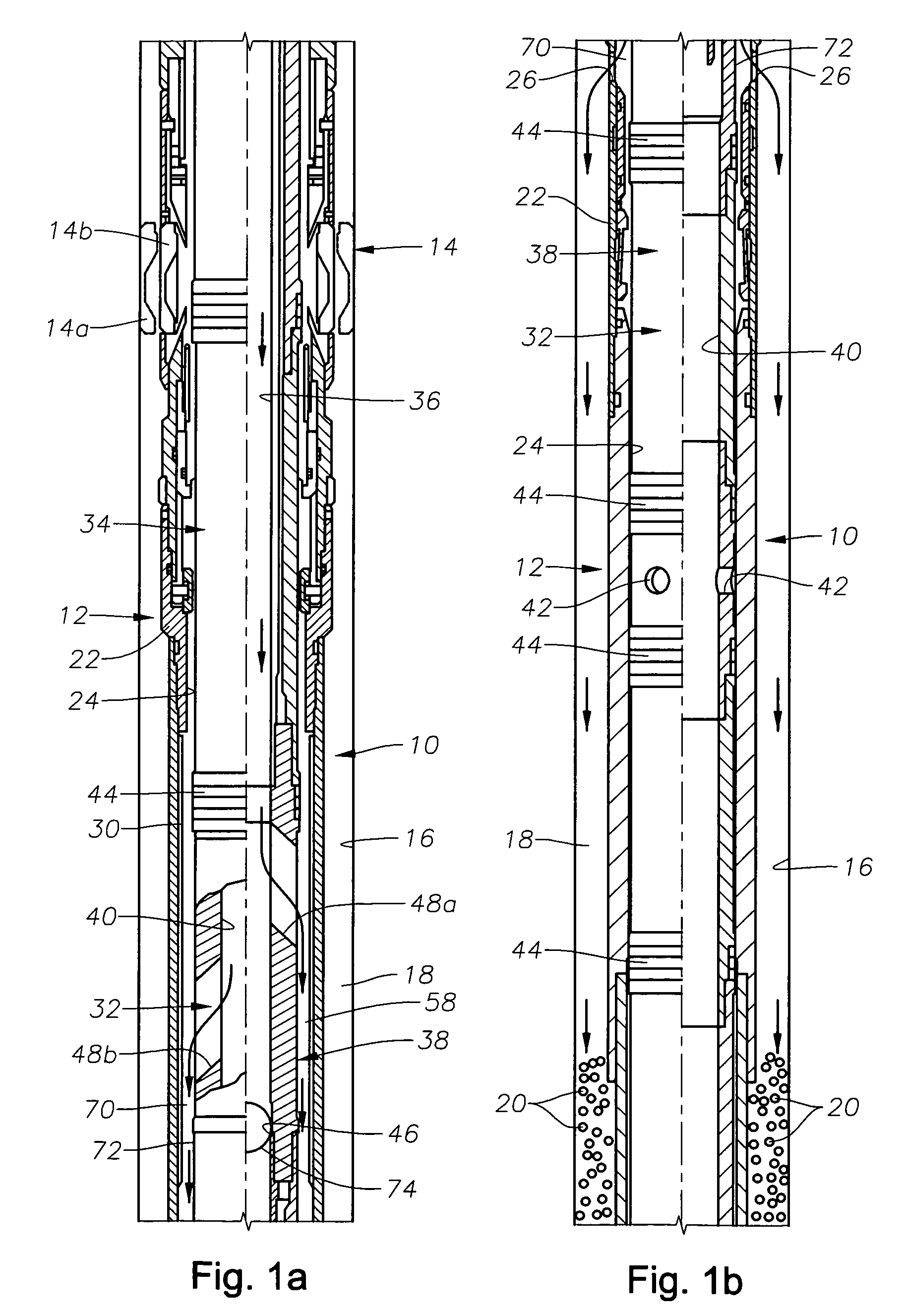

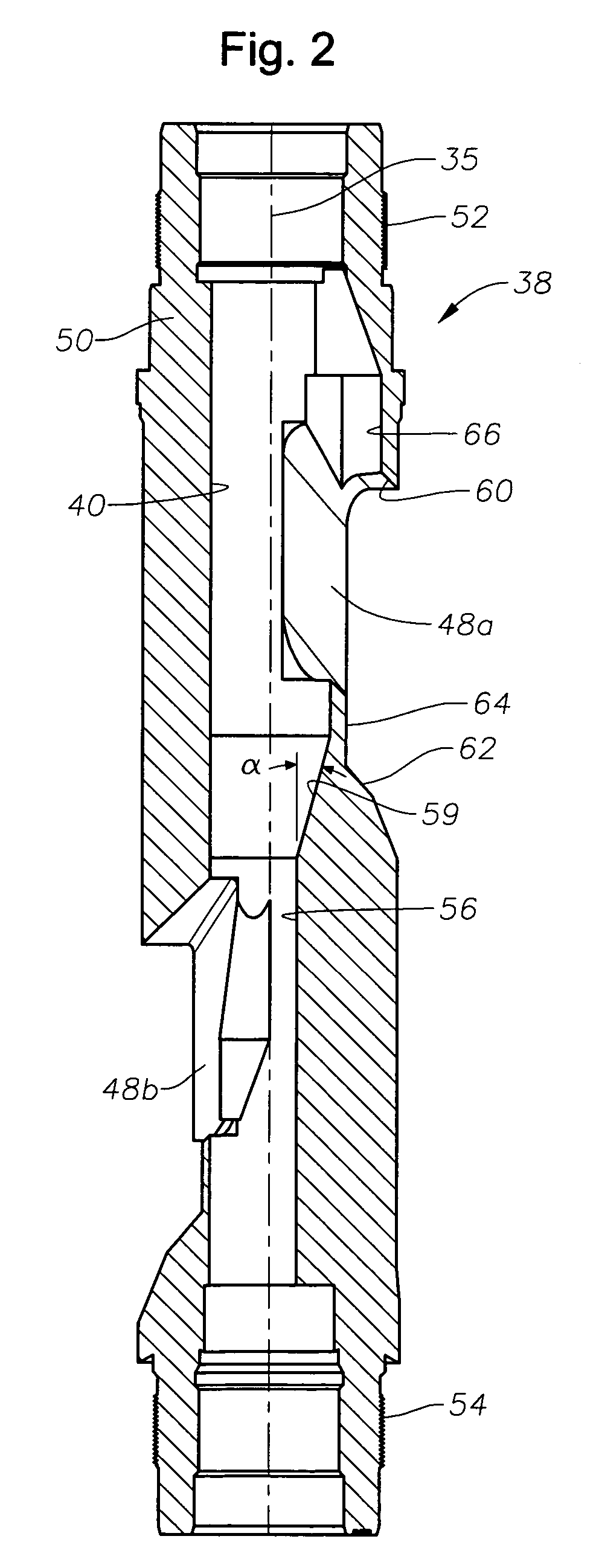

Rotating blast liner

InactiveUS7096946B2Increase the areaProlong lifeDrilling rodsFluid removalAbrasive blastingEngineering

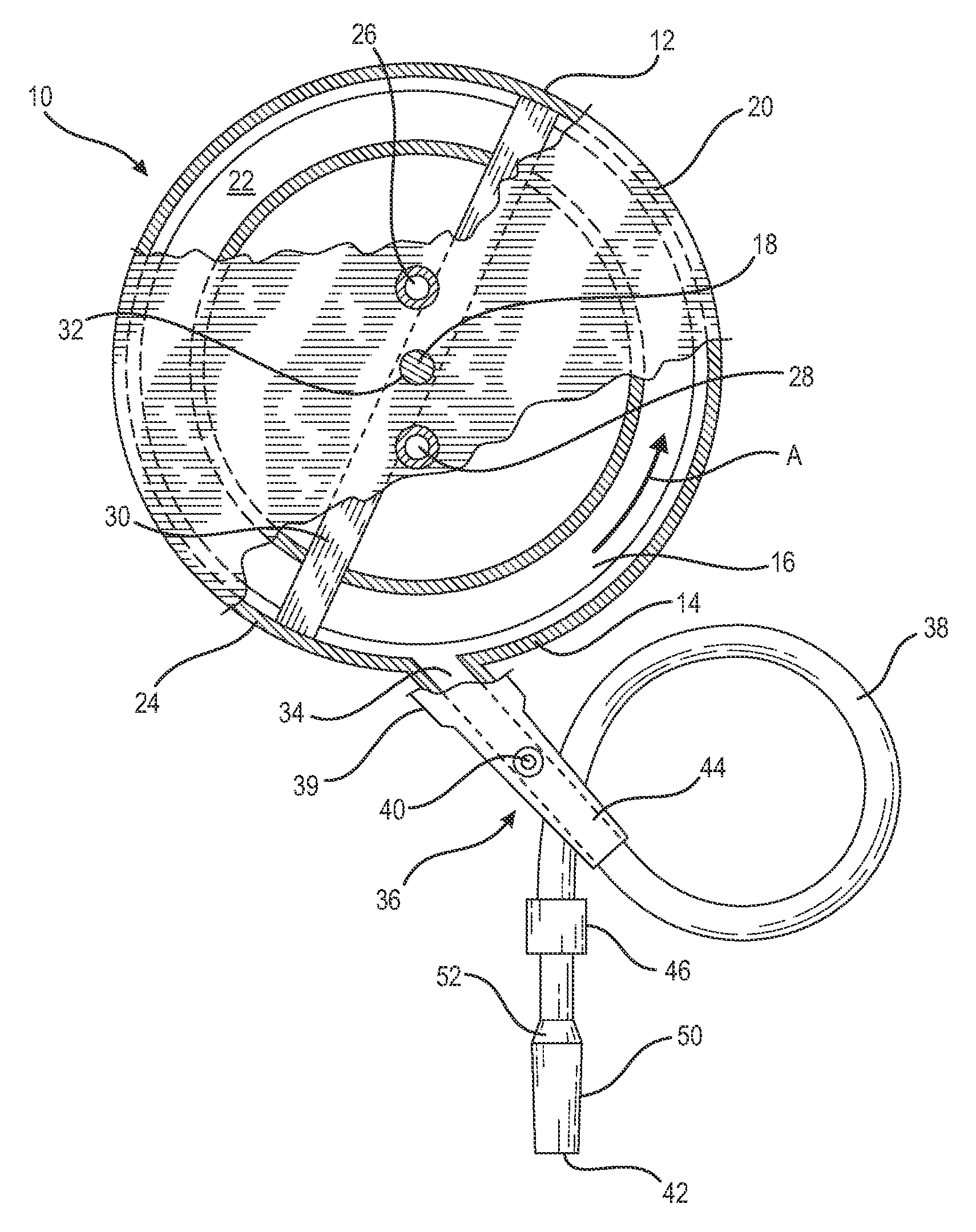

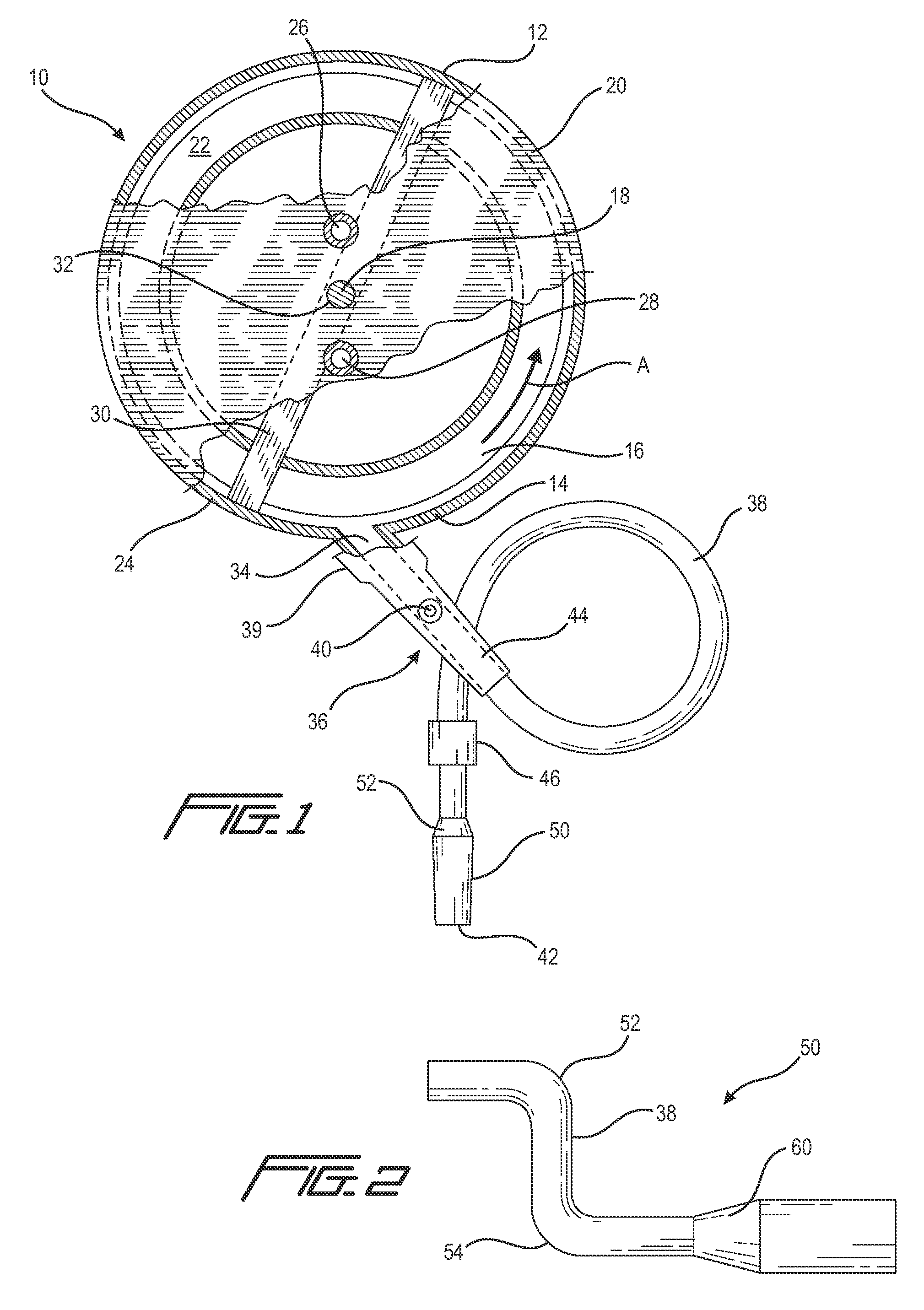

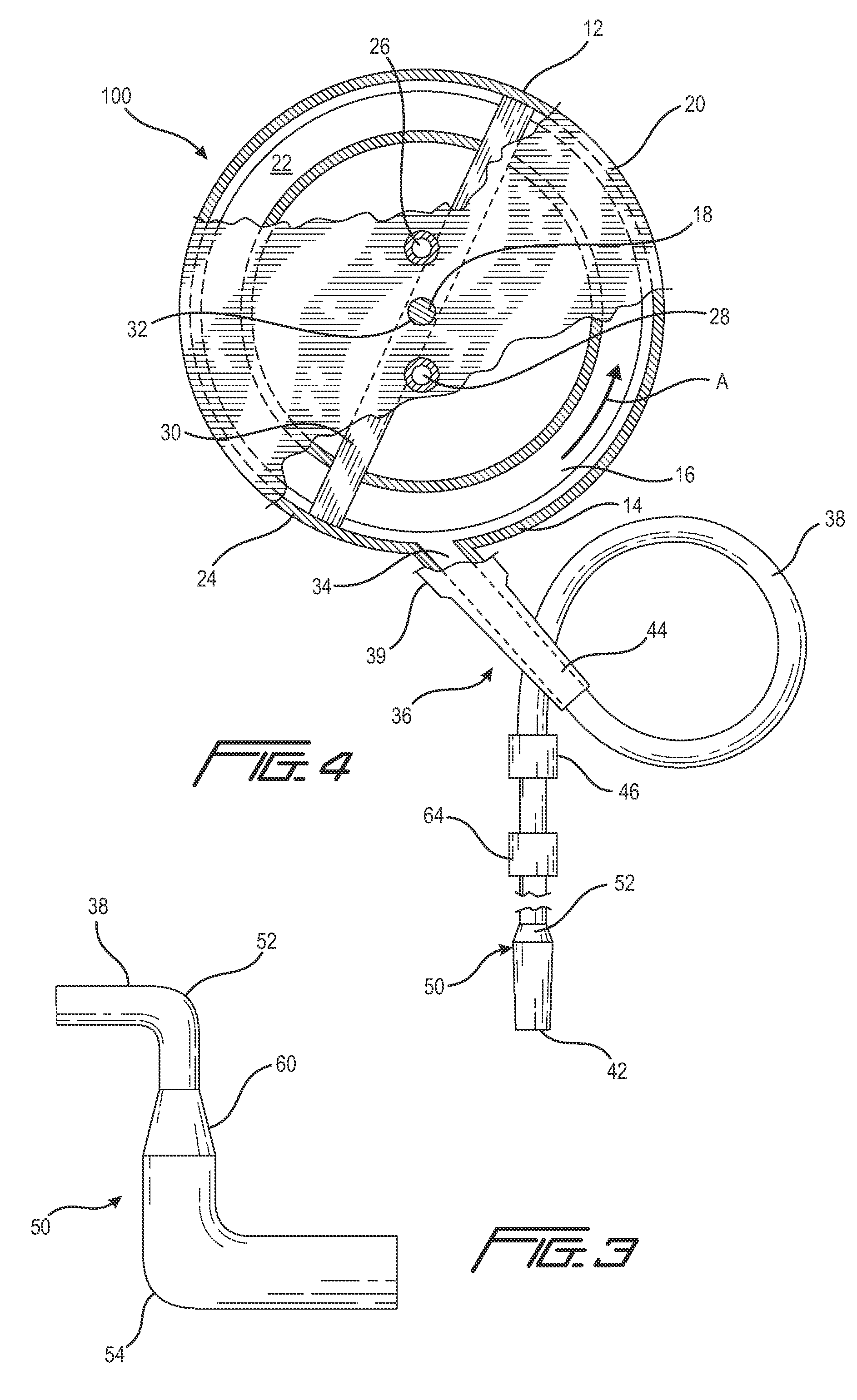

An improved blast liner assembly for use in gravel packing or fracturing operations wherein solid materials, in slurry form, are flowed out of the flowbore of a working tool and into the annulus of a wellbore. The blast liner is a cylindrical member that provides a protective shield to the interior retaining section. An angular flow diverter is provided within the blast liner and has a plurality of angled flow diversion channels formed into the inner surface of the blast liner body. Flow of slurry through the blast liner will cause the blast liner to rotate within the retaining section due to the reaction forces imparted to the blast liner from diverting the slurry flow. In this manner, the impingement area presented by the blast liner is increased, and the life of the blast liner extended. The blast liner may also be caused to move axially within the retaining section to further increase the impingement area.

Owner:BAKER HUGHES INC

Light-weight calcium silicate plate and preparation method thereof

The invention relates to a light-weight calcium silicate plate and a preparation method thereof. The light-weight calcium silicate plate comprises the following components in percentage by mass: 11-44.4% of siliceous filler, 30-40% of cement, 4.4% of calcific filler, 6-10% of fiber material, 3-5% of inorganic filler and 3-10% of reaction assistant, wherein the siliceous filler contains a light-weight siliceous material accounting for 22.2-44.4% of the total mass of the light-weight calcium silicate plate; and the sum of the mass percents of the components is 100%. According to the invention, the light-weight calcium silicate plate having low density and high strength is prepared through a slurry flow process by completely using high-activity amorphous kieselguhr instead of the traditional quartz sand as the siliceous material; and the process is simple and can be completed according to the existing technical process without changing the original calcium silicate plate production line and production conditions, and the production process does not increase the cost and can still achieve favorable effect.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

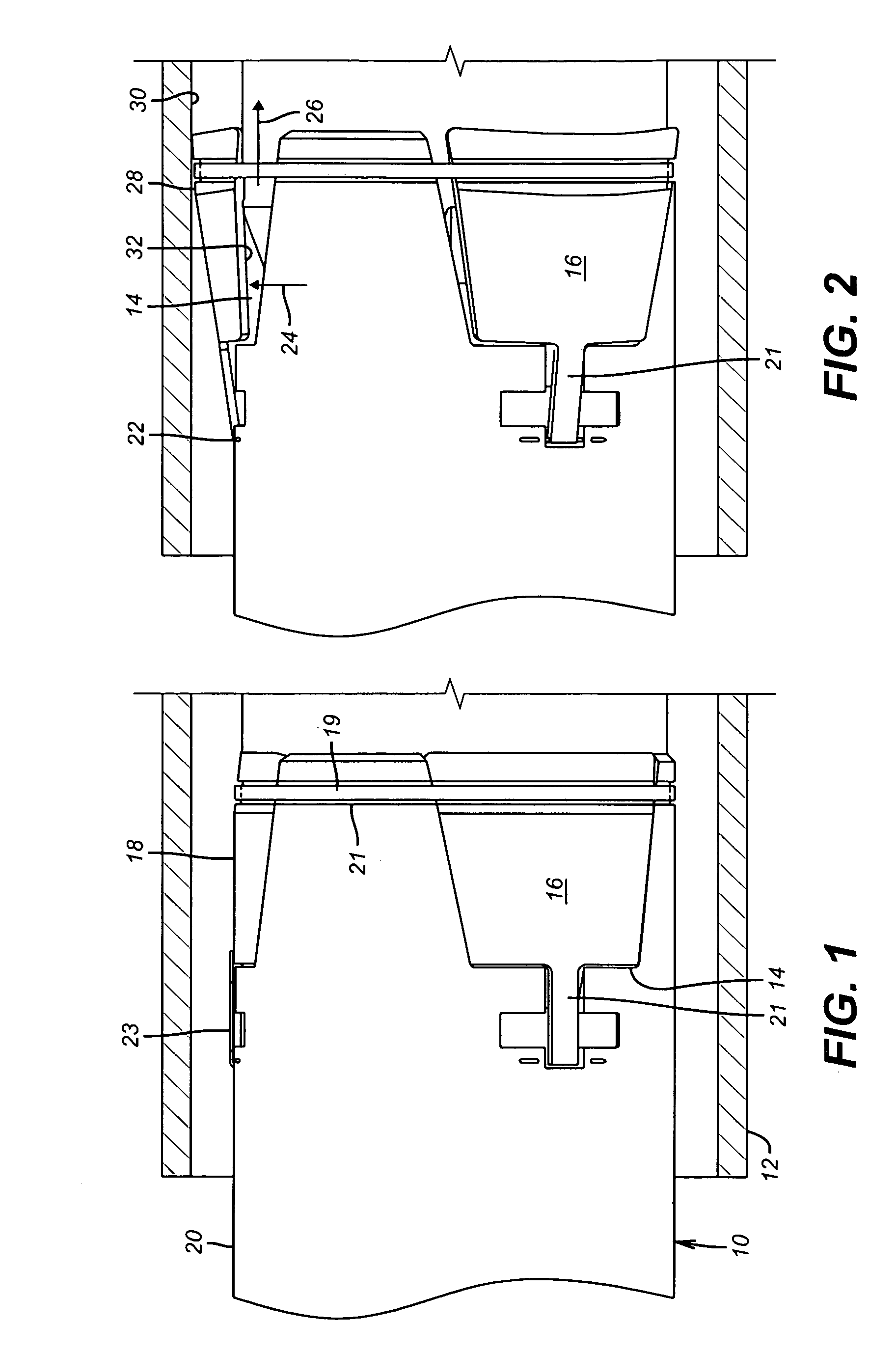

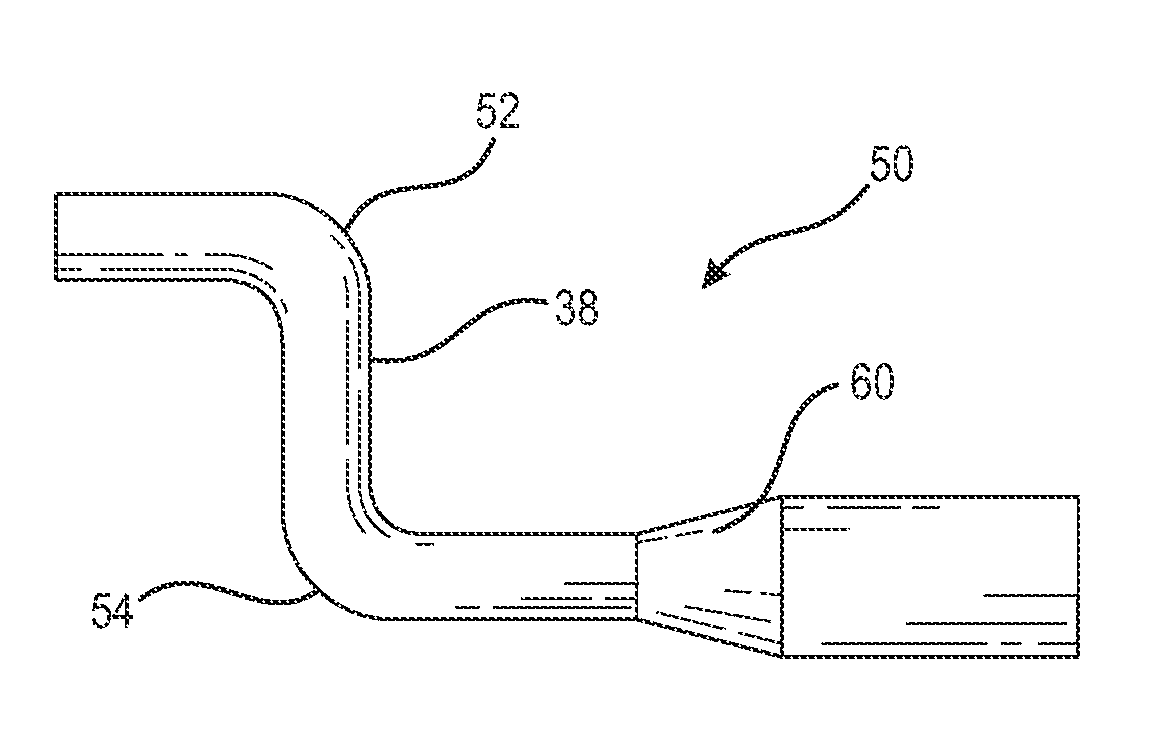

Frac-pack casing saver

InactiveUS7559357B2Prevent and minimize direct impingementSimply replacedFluid removalHigh velocityWellbore

Owner:BAKER HUGHES HLDG LLC

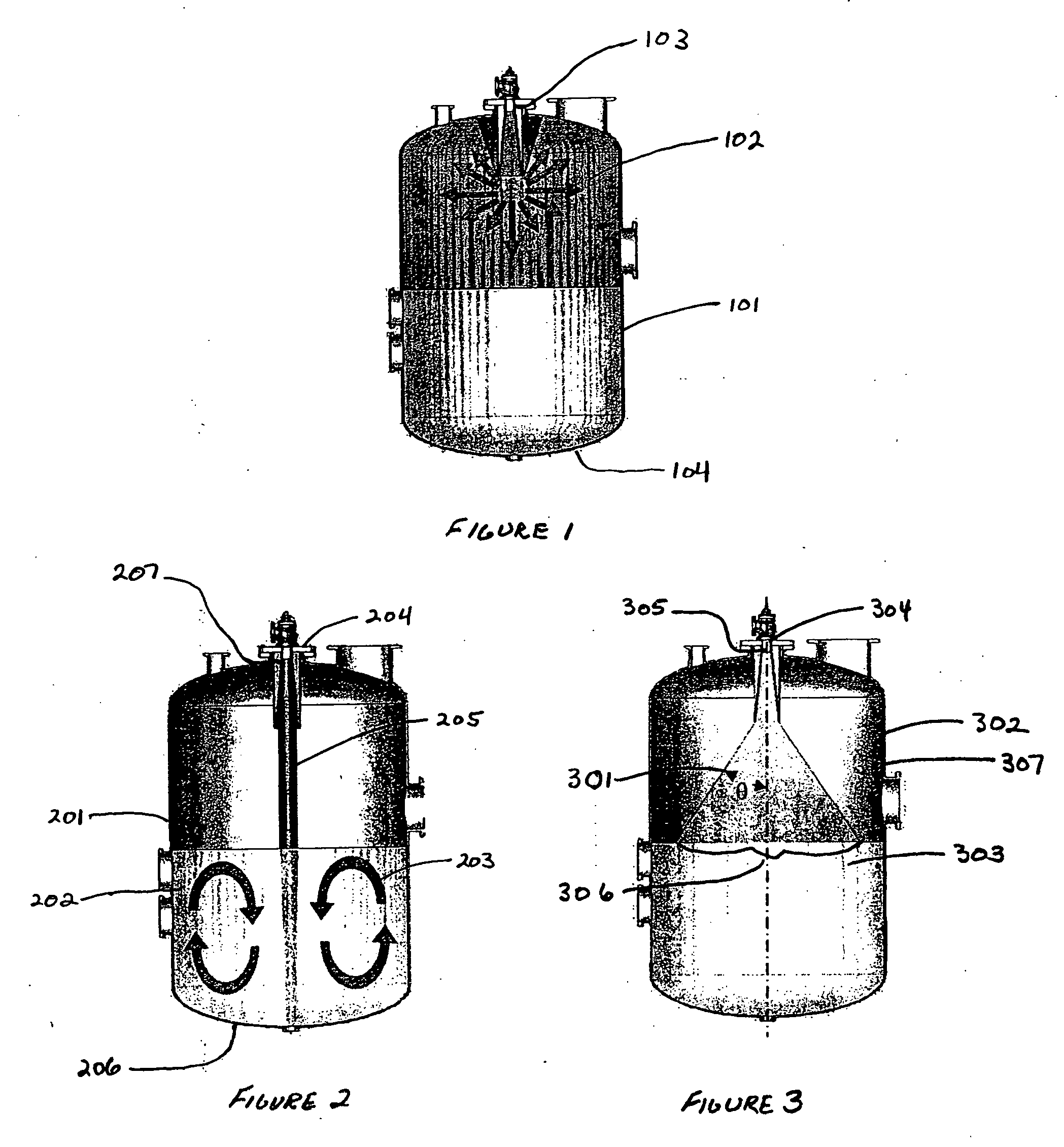

Gasifier injector

ActiveUS20060242907A1Reduce and prevent damageHigh-temperatures and abrasive matterDust removalFire preventionEngineeringHigh pressure

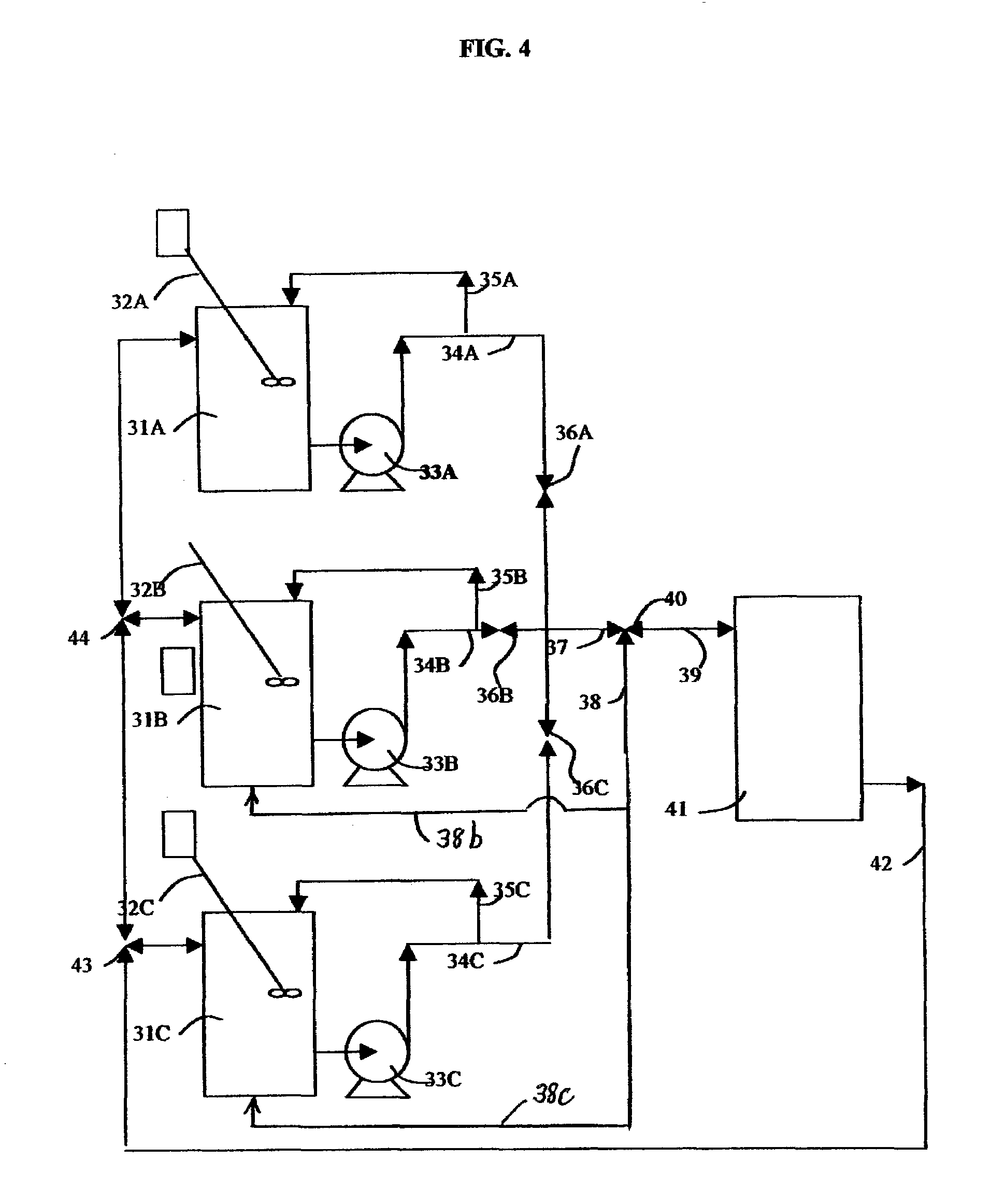

A gasifier injection module includes a two-stage slurry splitter and an injector face plate with a coolant system incorporated therein. The two-stage slurry splitter includes a main cavity into which a main slurry flow is provided. The main cavity includes a plurality of first stage flow dividers that divide the main slurry flow into a plurality of secondary slurry flows that flow into a plurality of secondary cavities that extend from the main cavity. Each secondary cavity includes a plurality of second stage flow dividers that divide each secondary slurry flow into a plurality of tertiary slurry flows that flow into a plurality of slurry injection tubes extending from the secondary cavities. The tertiary flows are injected as high pressure slurry streams into the gasification chamber via the slurry injection tubes. A reactant is impinged at high pressure, as an annular shaped spray, on each high pressure slurry stream via a plurality of annular impinging orifices incorporated into the injector face plate. The coolant system incorporated within the injector face plate maintains the injector face plate at a temperature sufficient to substantially reduce or prevent damage to the injector face plate by high temperatures and / or abrasive matter created by the resulting gasification reaction.

Owner:GAS TECH INST +1

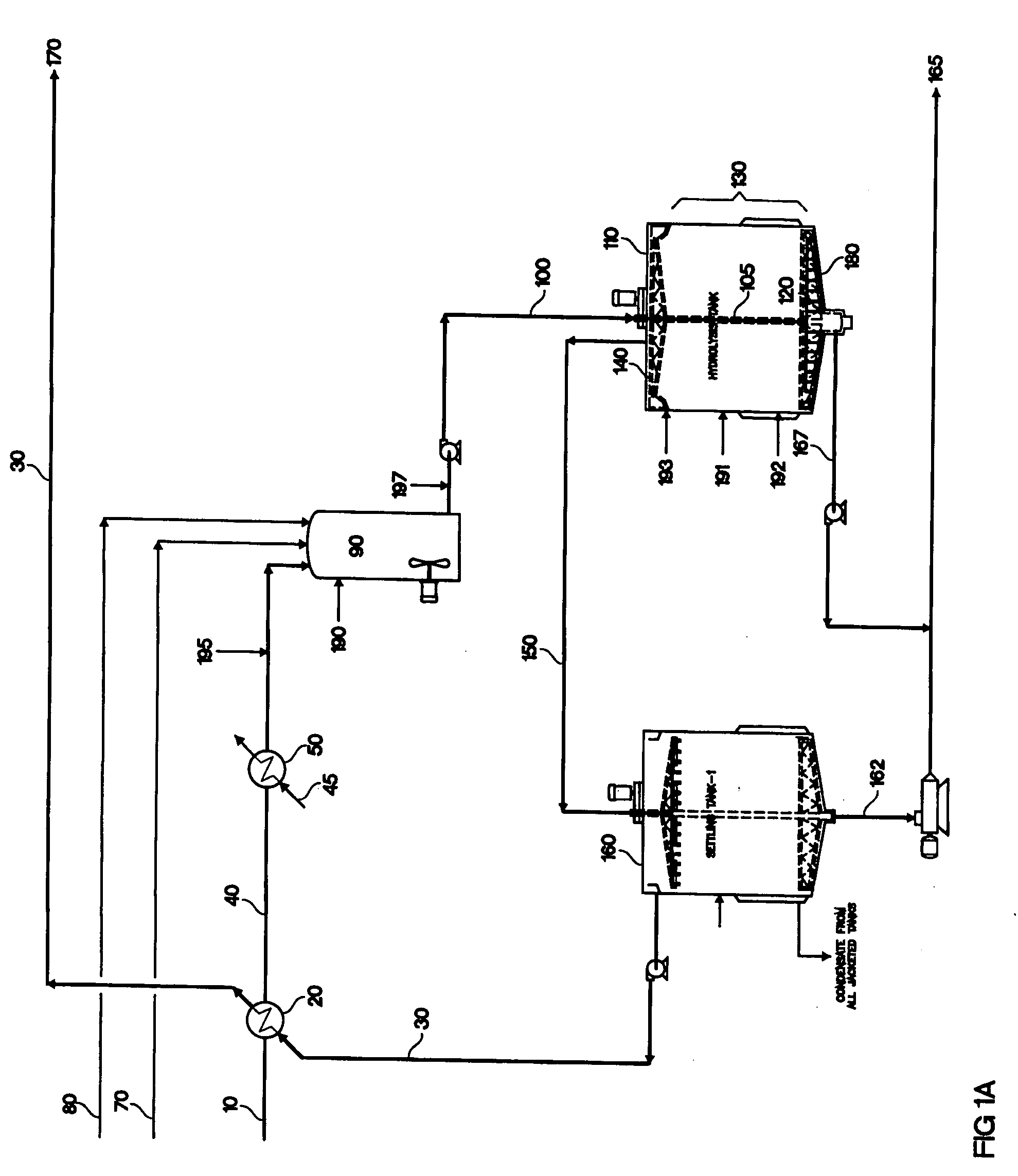

Upflow settling reactor for enzymatic hydrolysis of cellulose

InactiveUS20060154352A1Increase settlement rateEasy to operateBiological substance pretreatmentsBiofuelsEnzymatic hydrolysisHydrolysate

A process for the enzymatic hydrolysis of cellulose to produce a hydrolysis product from a pre-treated cellulosic feedstock is provided. The process comprises introducing an aqueous slurry of the pre-treated cellulosic feedstock at the bottom of a hydrolysis reactor. Axial dispersion in the reactor is limited by avoiding mixing and maintaining an average slurry flow velocity of about 0.1 to about 20 feet per hour, such that the undissolved solids flow upward at a rate slower than that of the liquid. Cellulase enzymes are added to the aqueous slurry before or during the step of introducing. An aqueous stream comprising hydrolysis product and unhydrolyzed solids is removed from the hydrolysis reactor. Also provided are enzyme compositions which comprise cellulase enzymes and flocculents for use in the process. In addition, a kit comprising cellulase enzymes and flocculent is provided.

Owner:IOGEN ENERGY CORP

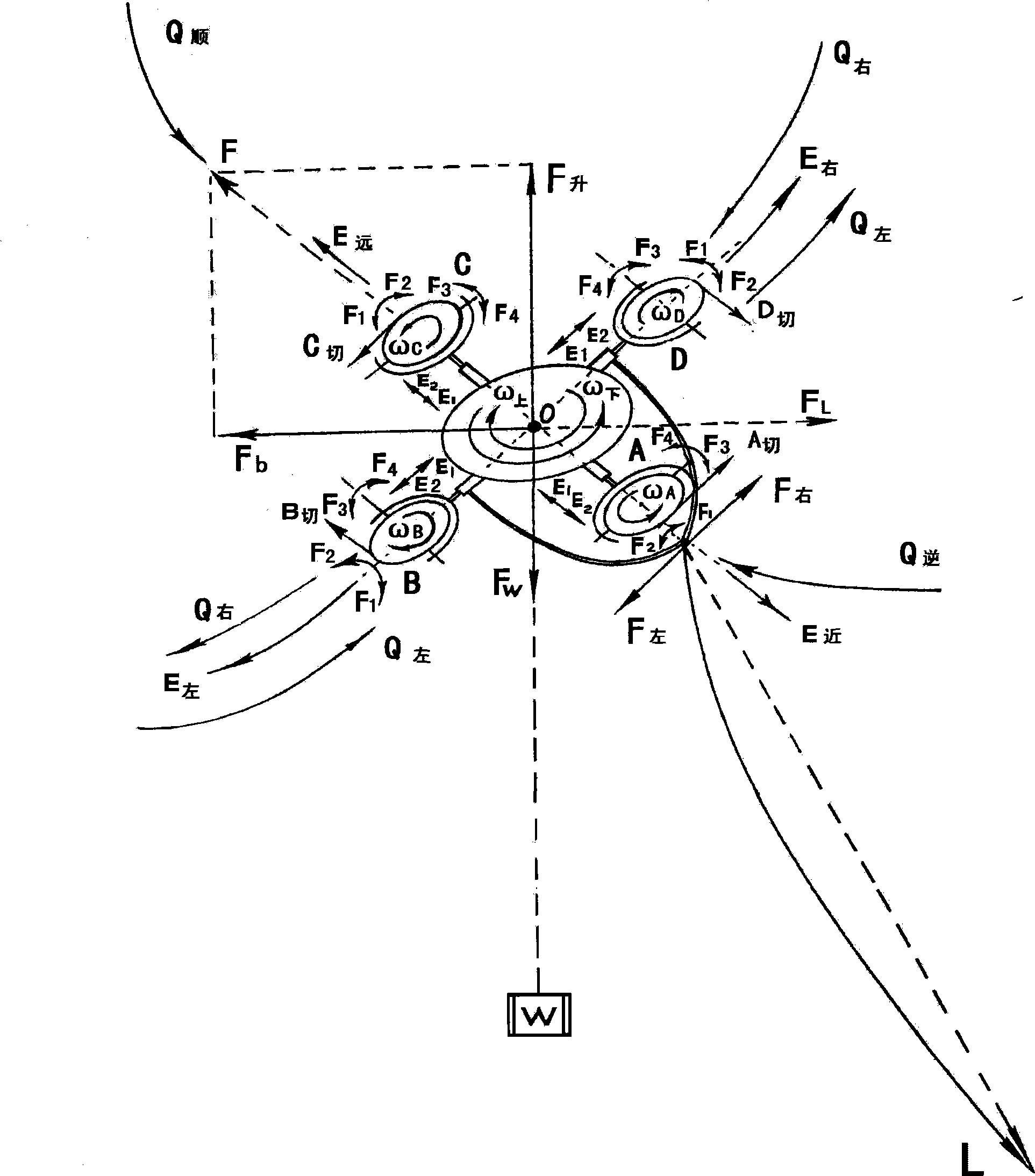

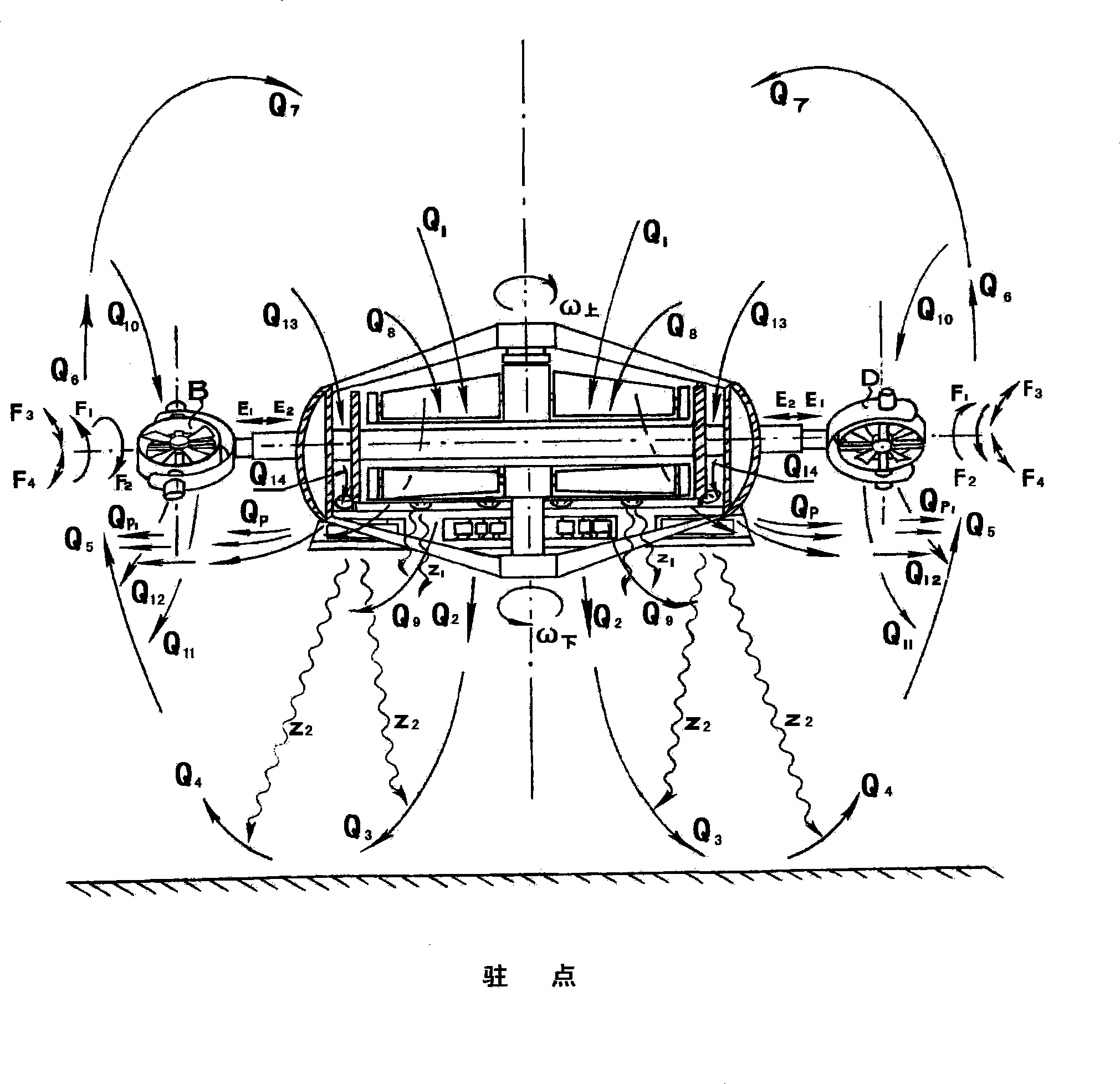

Slurry and flood current overhead-hoisting rescue method and amphibious medical ambulance

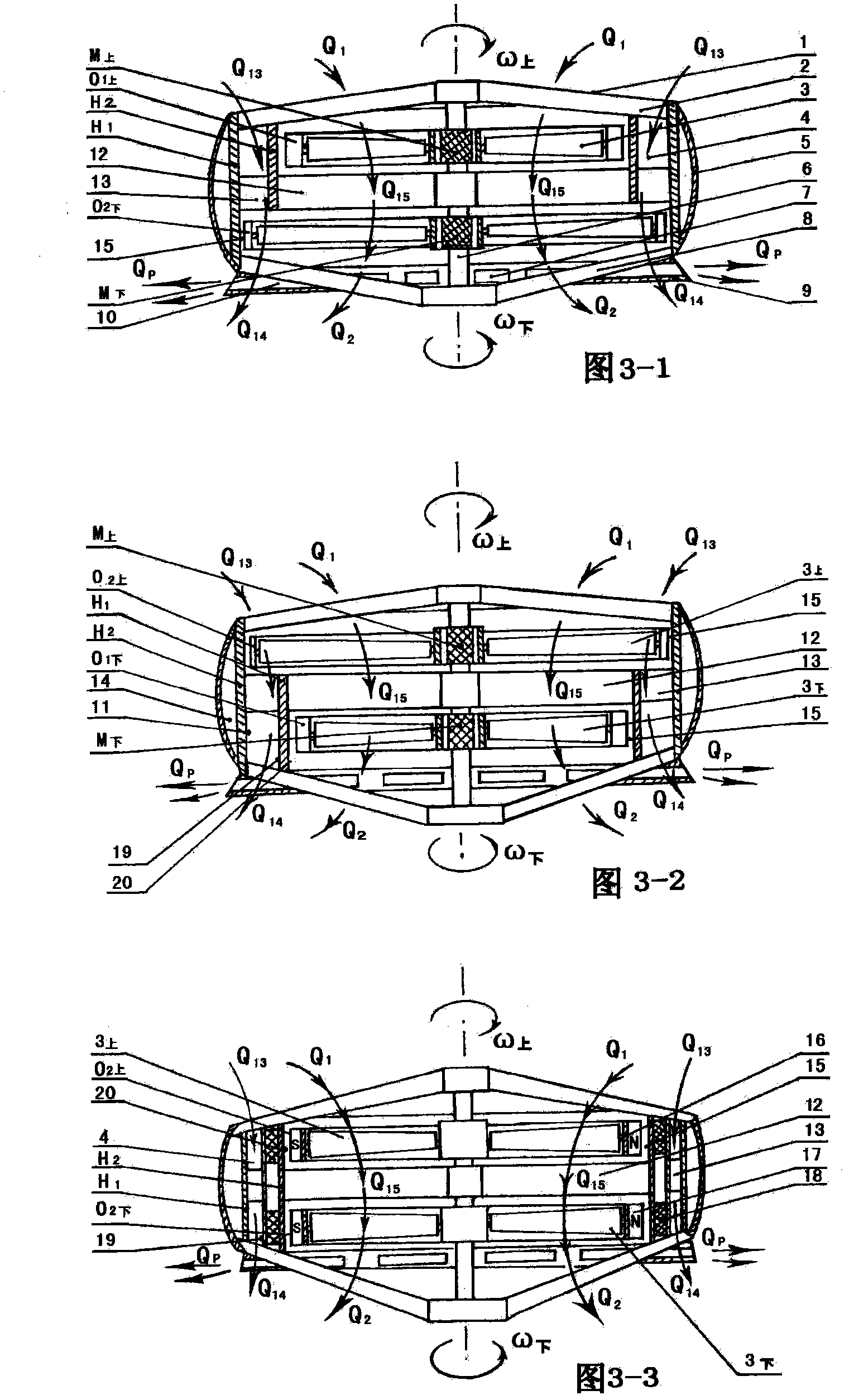

The invention adopts a large-diameter main culvert coaxial counter-rotating dual-rotor or a fan body to bear the main hoisting force, wherein multiple small-diameter auxiliary culvert rotors or fans are horizontally and symmetrically arranged at the periphery of the dual-rotor or the fan body; connecting arms of the rotors or fans can stretch and contract, twist and swing to carry out four degree-of-freedom actions, bear the auxiliary hoisting force, carry out direction control and serve as vertex prevention rings; a main side spout and a plasma energy wave generator vertex prevention ring are arranged on a main culvert; and a variable inertia system is arranged on the main rotors to realize the ability of preventing turbulent flow from changing into twisting wind. The slurry and flood current overhead-hoisting rescue method is competent for the overhead-hoisting rescue mission and can be combined with the slurry and flood current overhead-hoisting rescue amphibious medical ambulance to constitute a special overhead-hoisting rescue amphibious vehicle. Slurry current propellers such as an extension-type swing conical-head spiral front wing long roller floating type or gyro helix front wing floating head type, a crushing roller front wing floating type and a herringbone one-sided jagged-grain hub telescopic front wing crushing roller tire boosters are arranged at the four corners of a machine frame of the amphibious medical ambulance, so that the amphibious medical ambulance has the capability of floating and driving in the slurry current, and the design method of the slurry flood current special rescue method and the amphibious medical ambulance is solved.

Owner:郑鹏

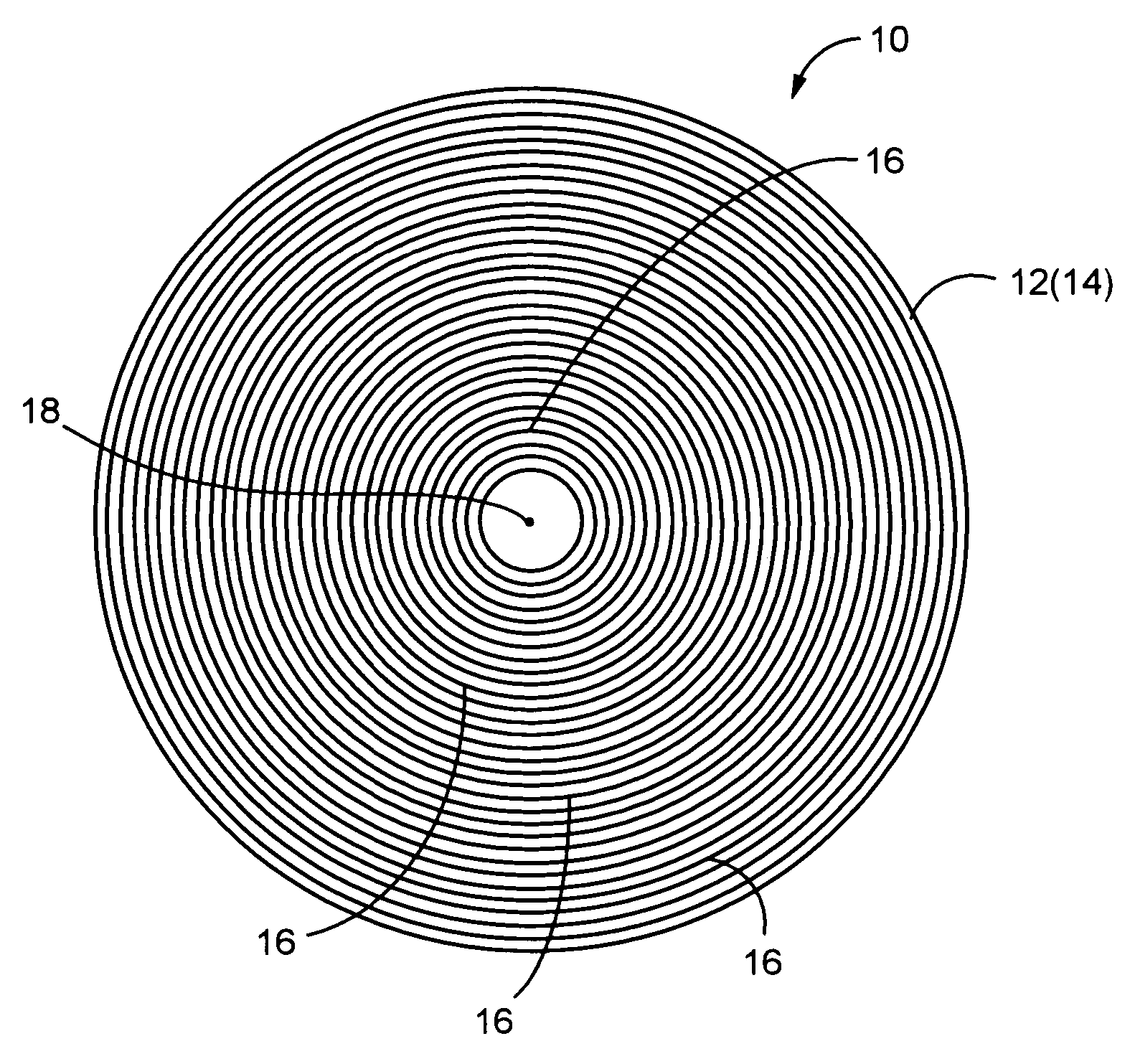

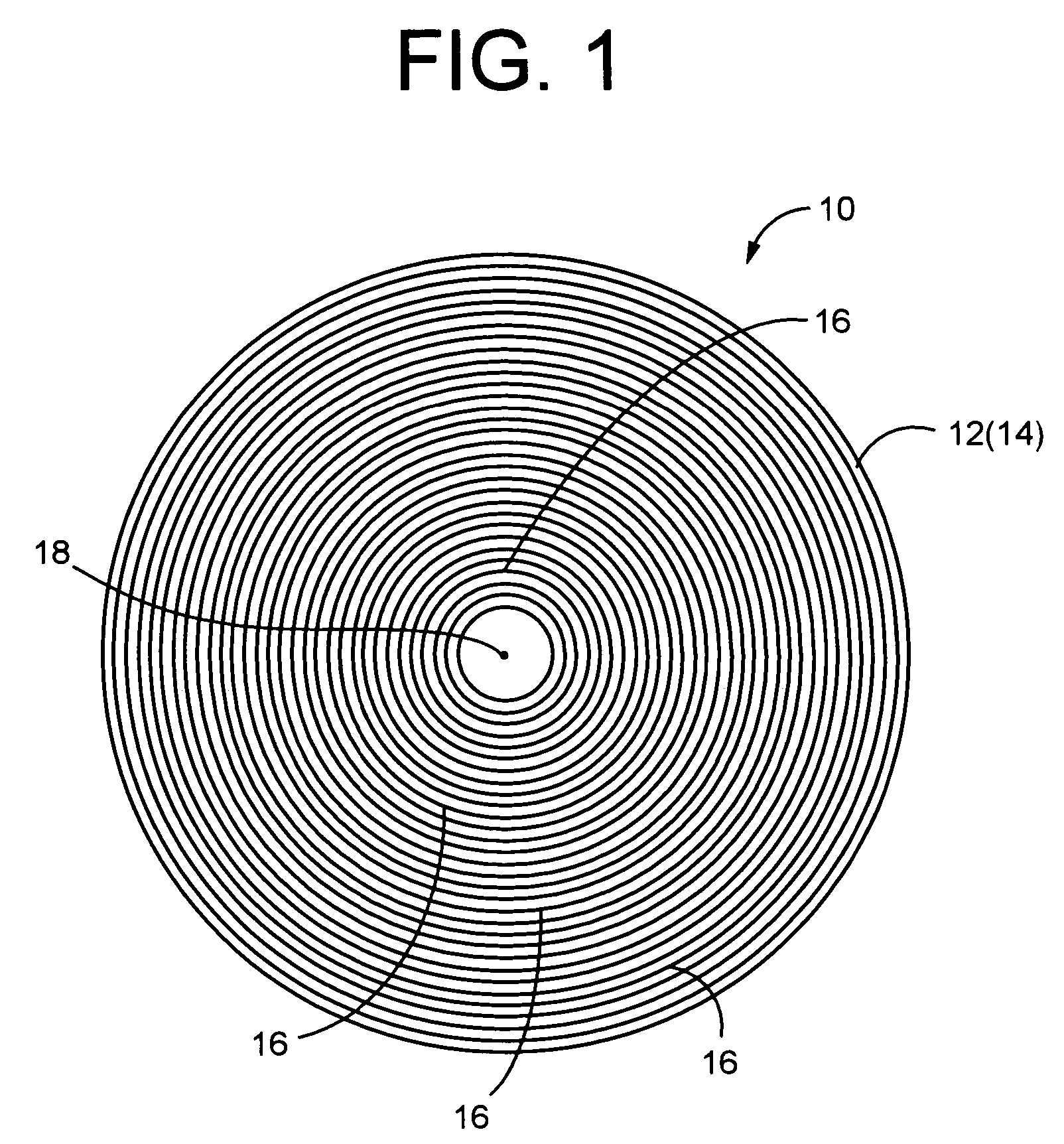

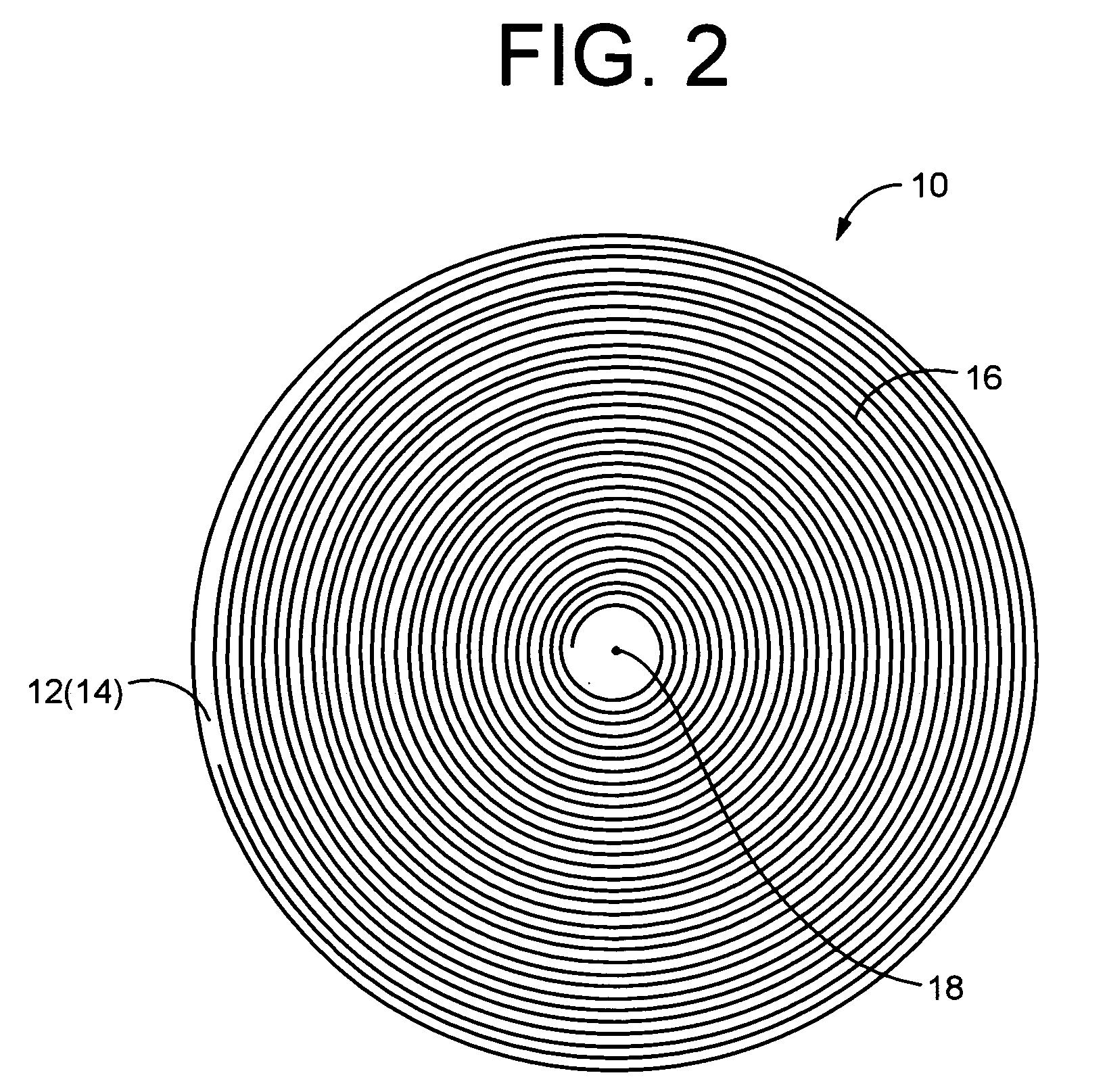

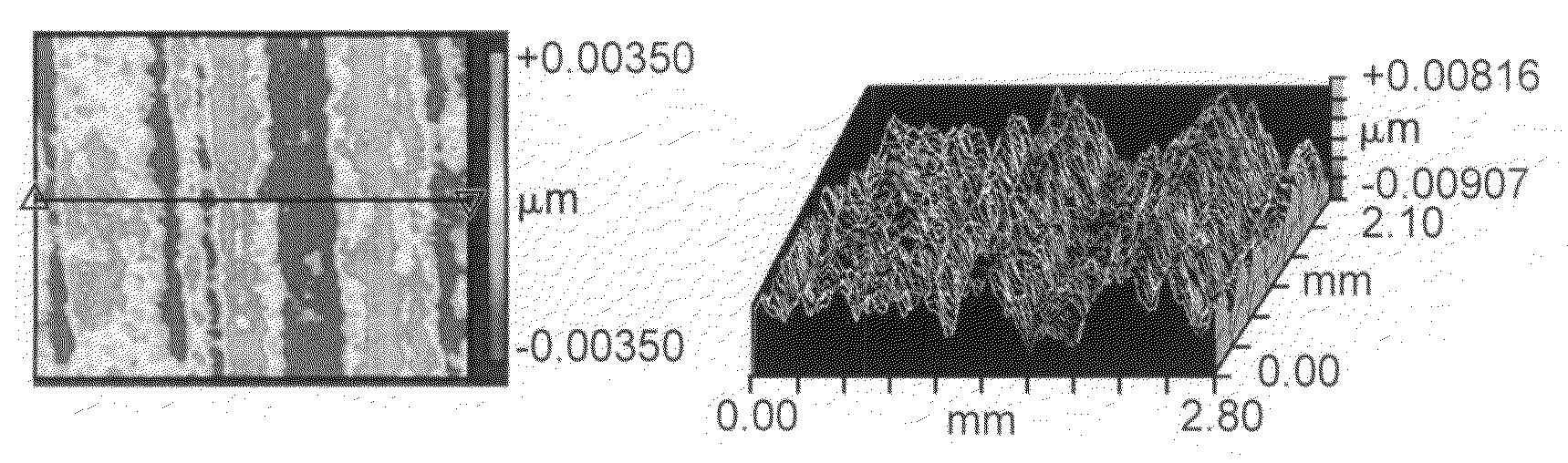

Polishing pad and method of fabricating semiconductor substrate using the pad

InactiveUS7121938B2Improve the level ofEfficient polishingPolishing machinesRevolution surface grinding machinesSynthetic resinBiomedical engineering

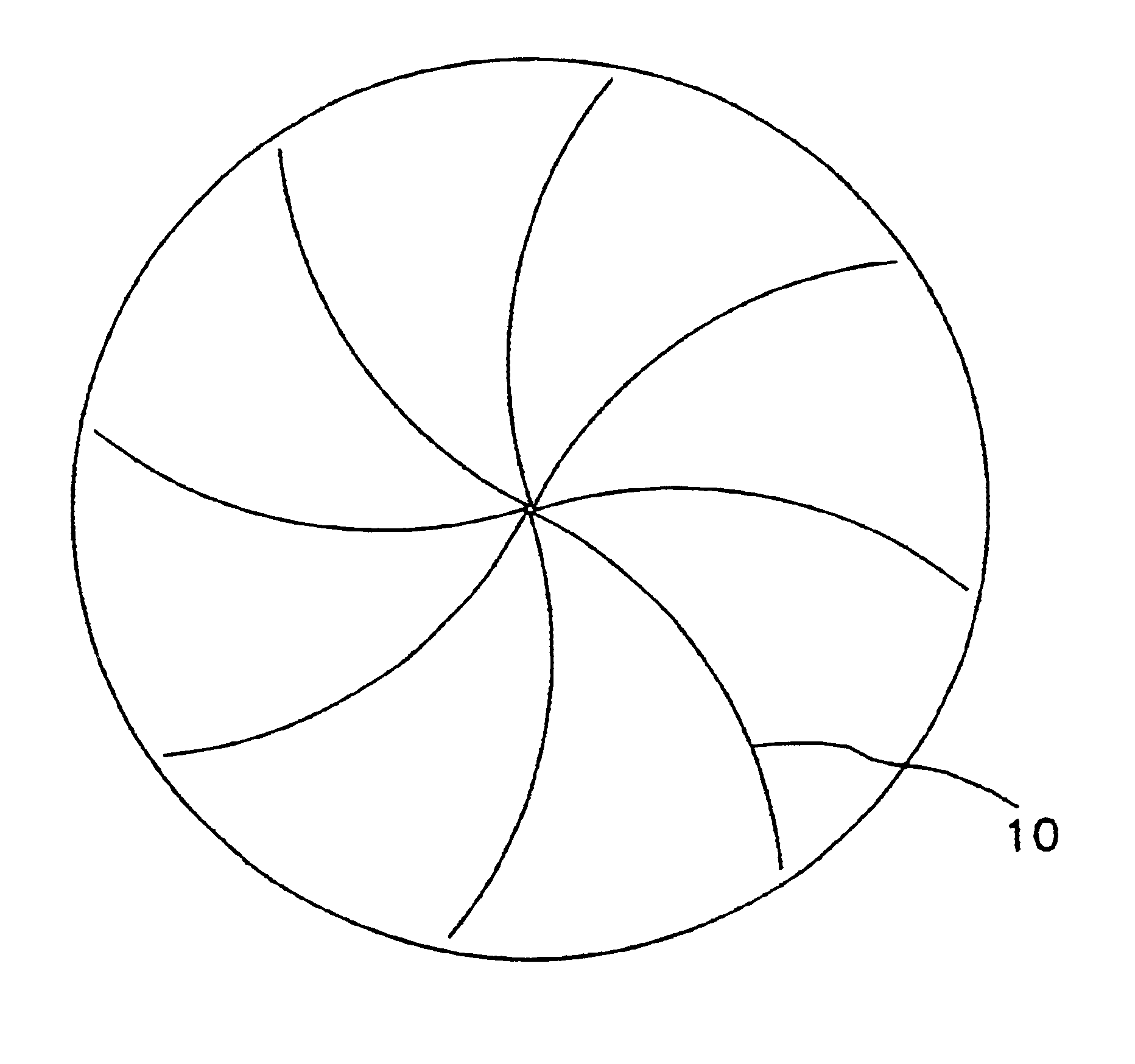

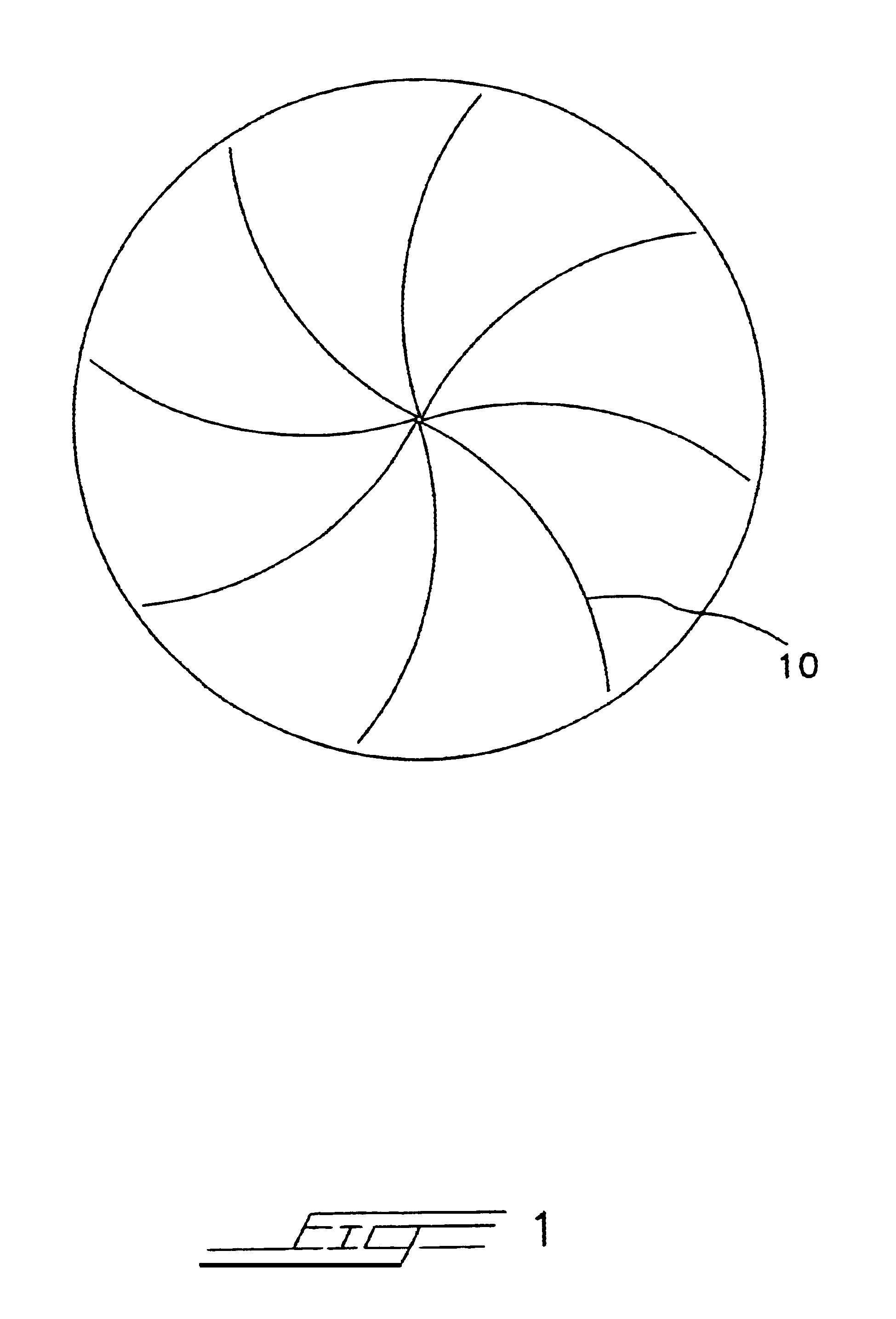

It is provided a polishing pad of novel construction capable of controlling actively and efficiently a slurry flow during polishing a surface of a semiconductor substrate, such as a wafer, thus making it possible to precisely and stably performing a desired polishing process. Onto a surface of a pad substrate 12 of synthetic resin material, formed is a groove 16 extending approximately circumferentially. An inner circumferential wall surface 20 and an outer circumferential wall surface 22 are made parallel to each other and slant with respect to a center axis 18 of the pad substrate 12.

Owner:TOHO ENG CO LTD

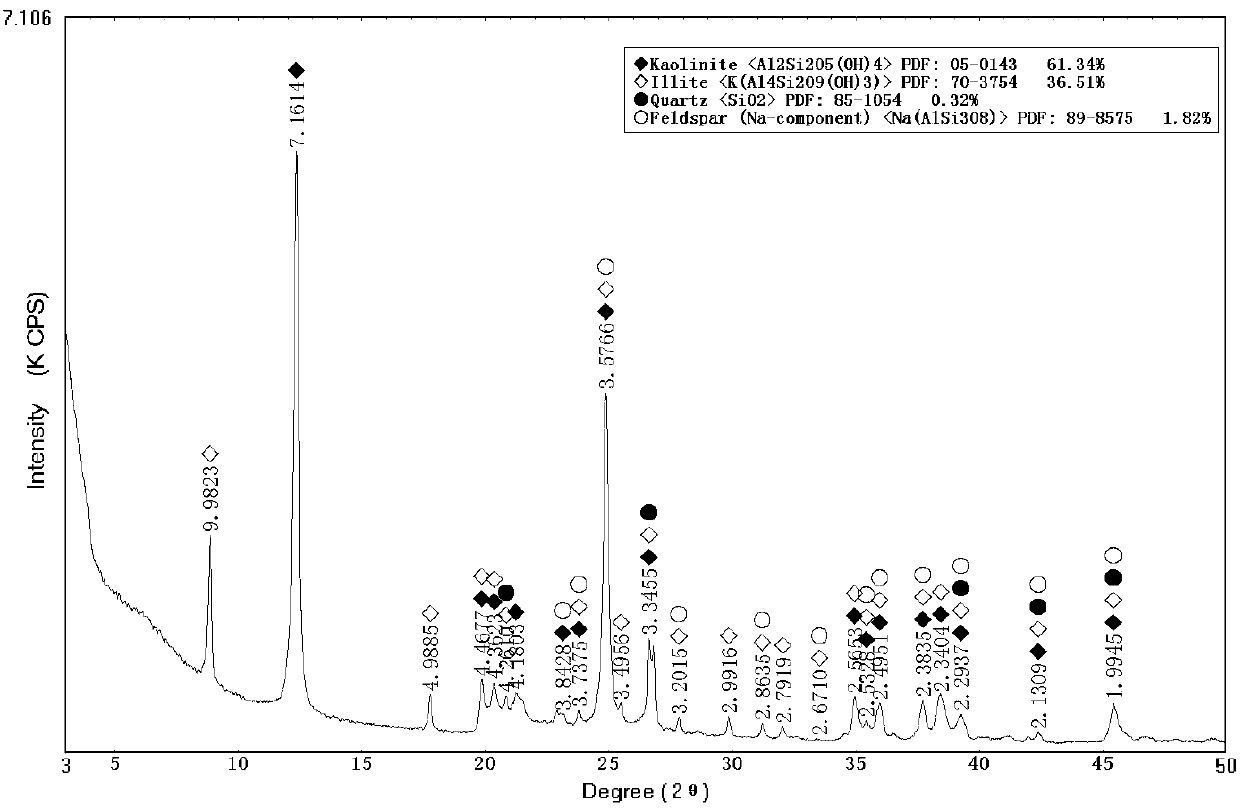

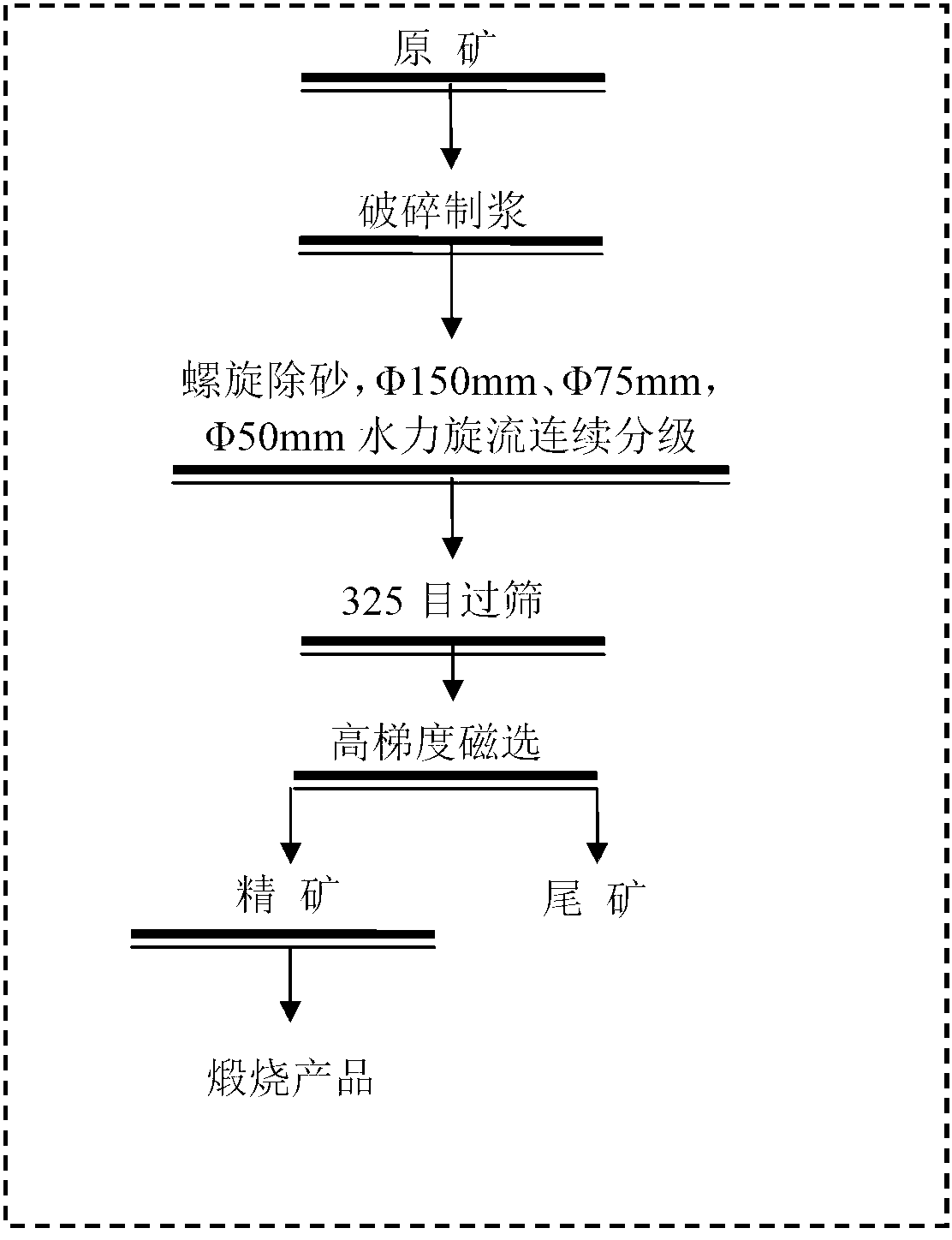

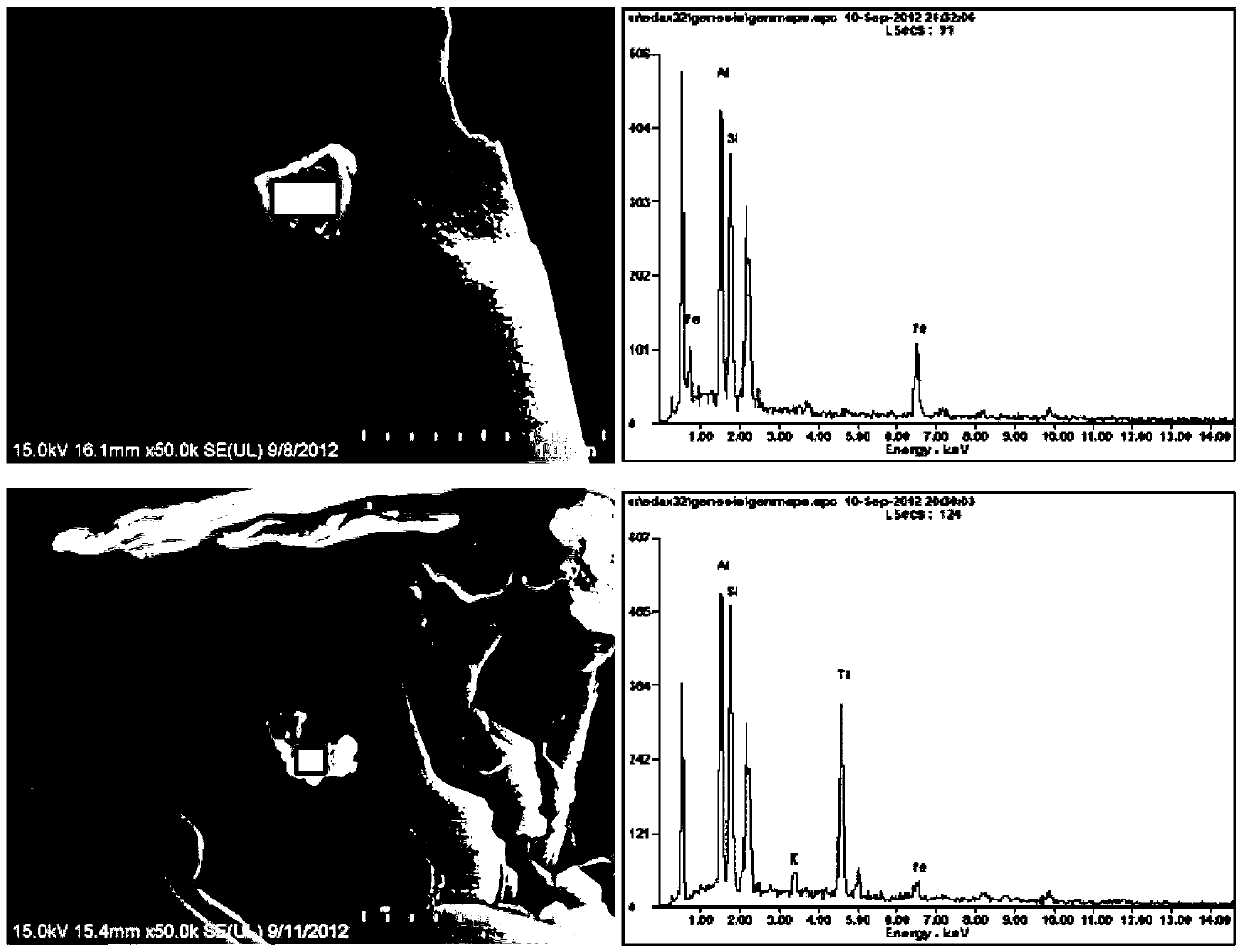

Technique for efficiently removing iron from kaolin

The invention relates to a technique for efficiently removing iron from kaolin by magnetic separation, which is characterized by comprising the following steps: (1) purifying kaolin raw ore to obtain a magnetic separation raw material; (2) adding water to the magnetic separation raw material obtained in the step (1) to prepare a mixed slurry with the solid content of 10-20 wt%, adding sodium hexametaphosphate accounting for 0.2-0.6 wt% of the magnetic separation raw material, slurrying, stirring for 20 minutes, and passing through a 325-mesh wet sieve; (3) carrying out high-gradient magnetic separation on the undersize slurry of the 325-mesh sieve in the step (2): while controlling the magnetic field intensity of the high-gradient magnetic separator at 1.0-1.8T and the slurry flow rate at 0.8-1.8cm / s, the slurry is subjected to magnetic separation by the high-gradient magnetic separator to obtain a concentrate slurry; (4) adding alum accounting for 1-6 wt% of the concentrate slurry into the concentrate slurry obtained in the step (3), flocculating, carrying out pressure filtration, drying, and packaging to obtain a magnetic concentrate; and (5) calcining the magnetic concentrate obtained in the step (4) to obtain the calcined kaolin. The technique has the advantages of high iron removal efficiency and obvious whitening effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

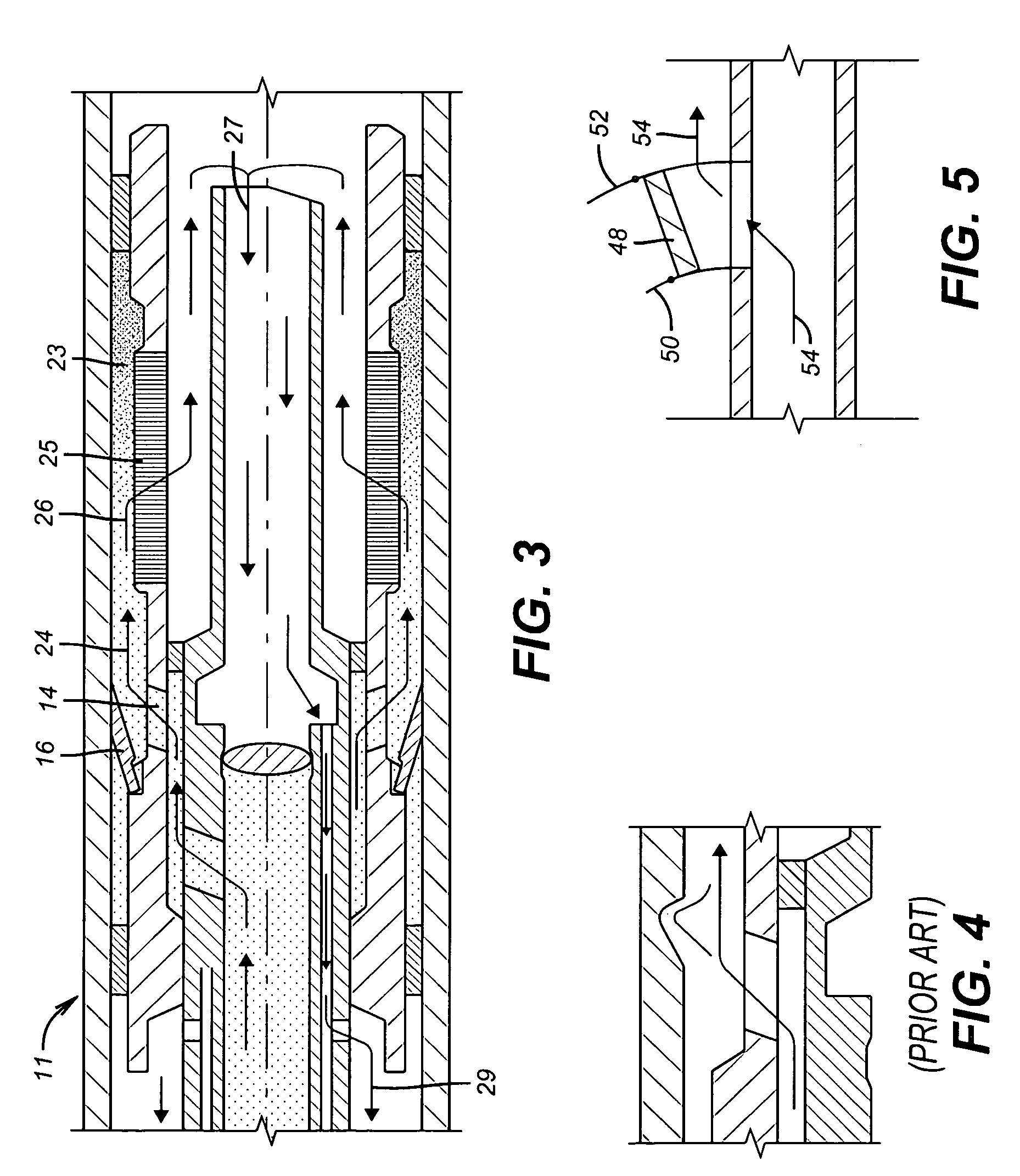

Method and apparatus to minimize air-slurry separation during gypsum slurry flow

A method and apparatus for providing an evenly mixed additive enhanced gypsum slurry to a web. Calcined gypsum and water are inserted into a mixer through at least one inlet of the mixer. The contents are agitated to form a slurry. The slurry is passed from an outlet of the mixer into a conduit. An additive is introduced into the slurry along a length of the conduit to achieve a flow stream of a slurry / additive mixture. A cross section of the flow stream is expanded in the conduit while not changing direction of the flow stream and a direction of the flow stream is changed while not expanding the cross section of the flow stream and conduit, all prior to the flow steam exiting from an outlet of the conduit.

Owner:UNITED STATES GYPSUM CO

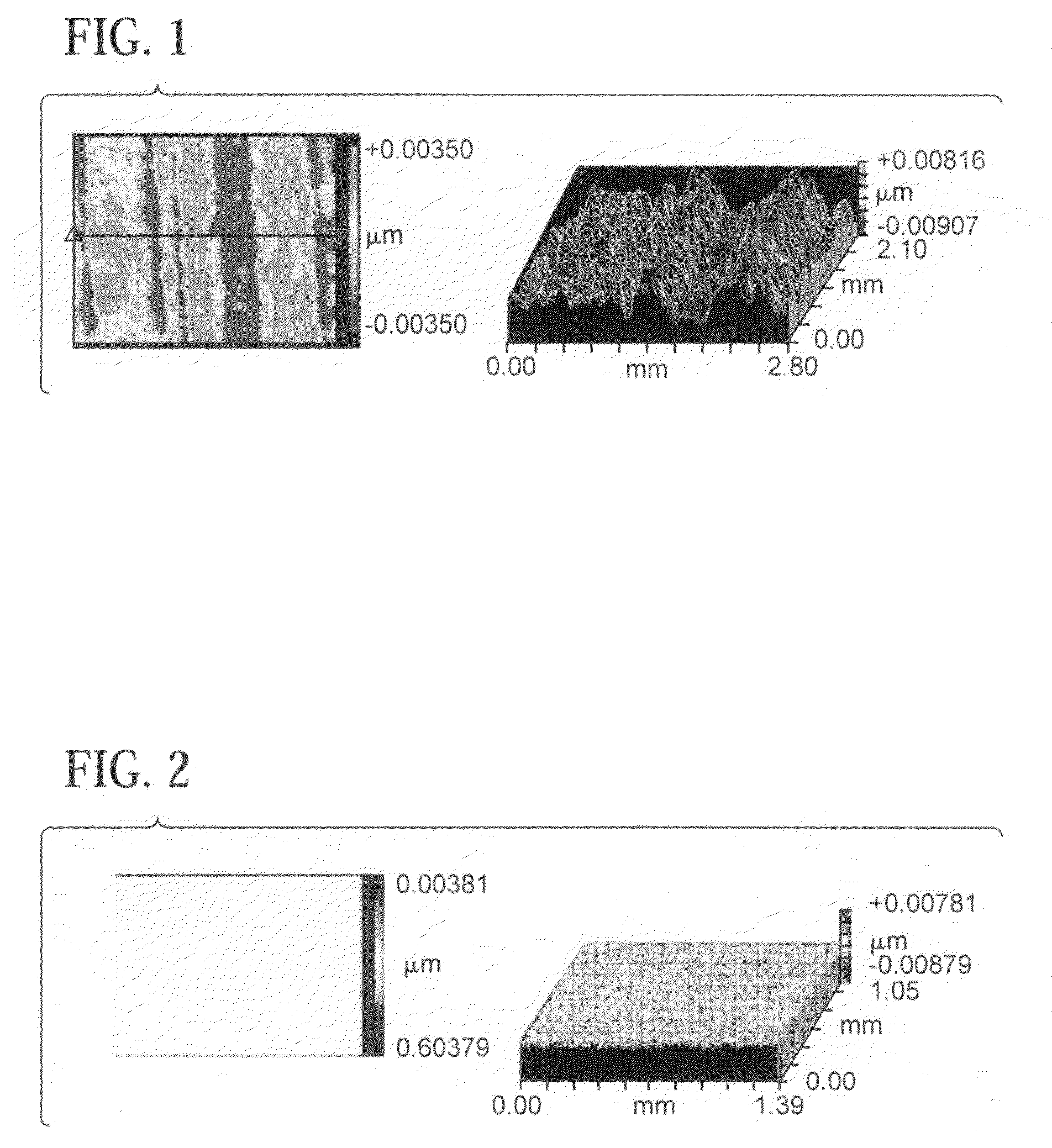

Polishing pad for use in chemical-mechanical planarization of semiconductor wafers and method of making same

InactiveUS6852020B2Prolong lifeSolution to short lifeOther chemical processesAbrasion apparatusFiberSlurry transport

A polishing pad for use in chemical mechanical polishing of substrates that being made of a porous structure comprising a matrix consisting of fibers, such as cotton linter cellulose bound with a thermoset resin, such as phenolic resin. The polishing pad surface has voids in which polishing slurry flows during chemical mechanical polishing of substrates, and in which debris formed during the chemical-mechanical polishing of substrates is temporarily stored for subsequent rinsing away. The polishing surface of the pad is ground to form asperities that aid in slurry transport and polishing, as well as opening the porous structure of the pad. The porous pad contains nanometer-sized filler-particles that reinforce the structure, imparting an increased resistance to wear as compared to prior-art pads. Also disclosed is a method of making the polishing pad.

Owner:RAYBESTOS POWERTRAIN

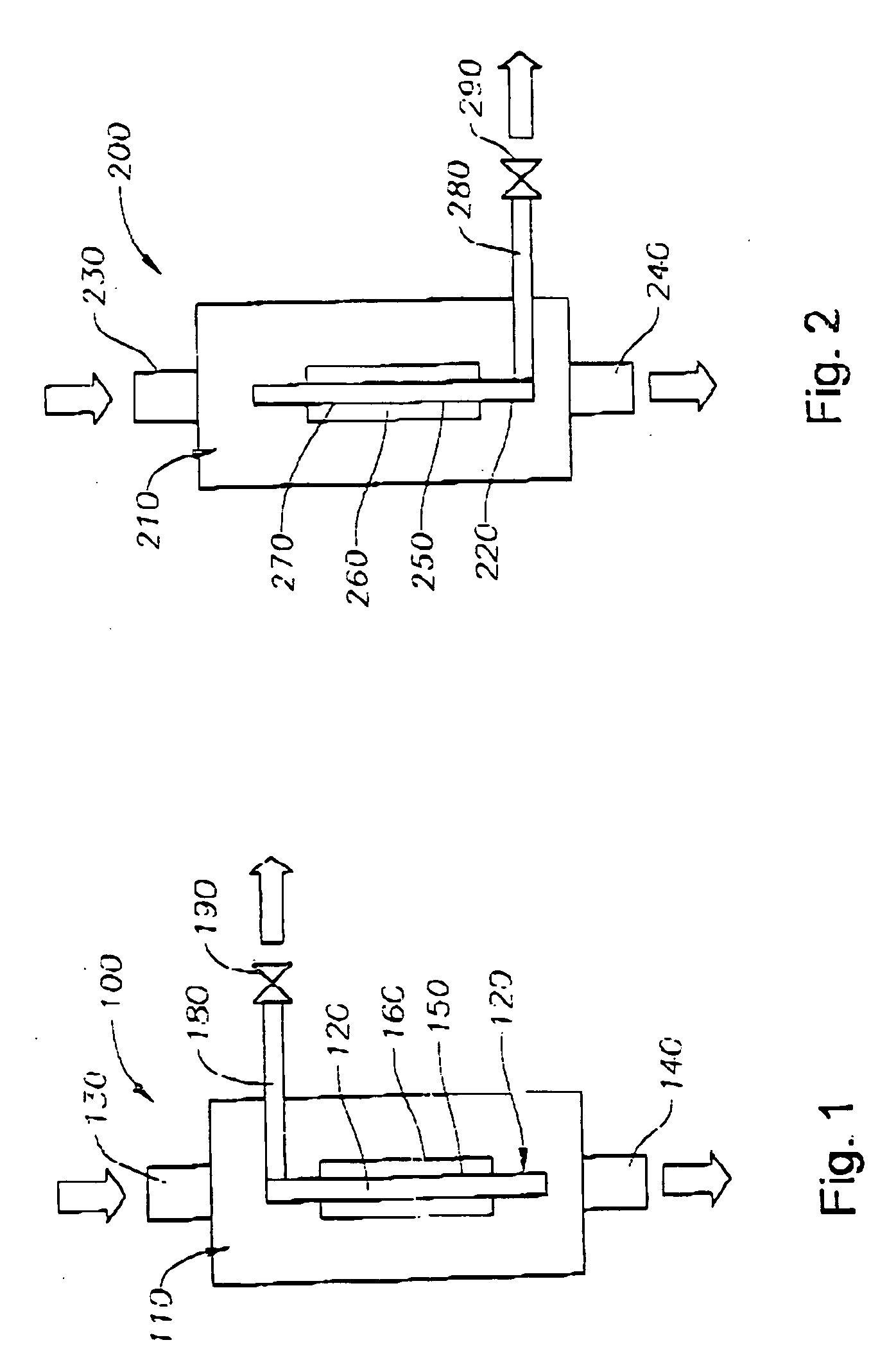

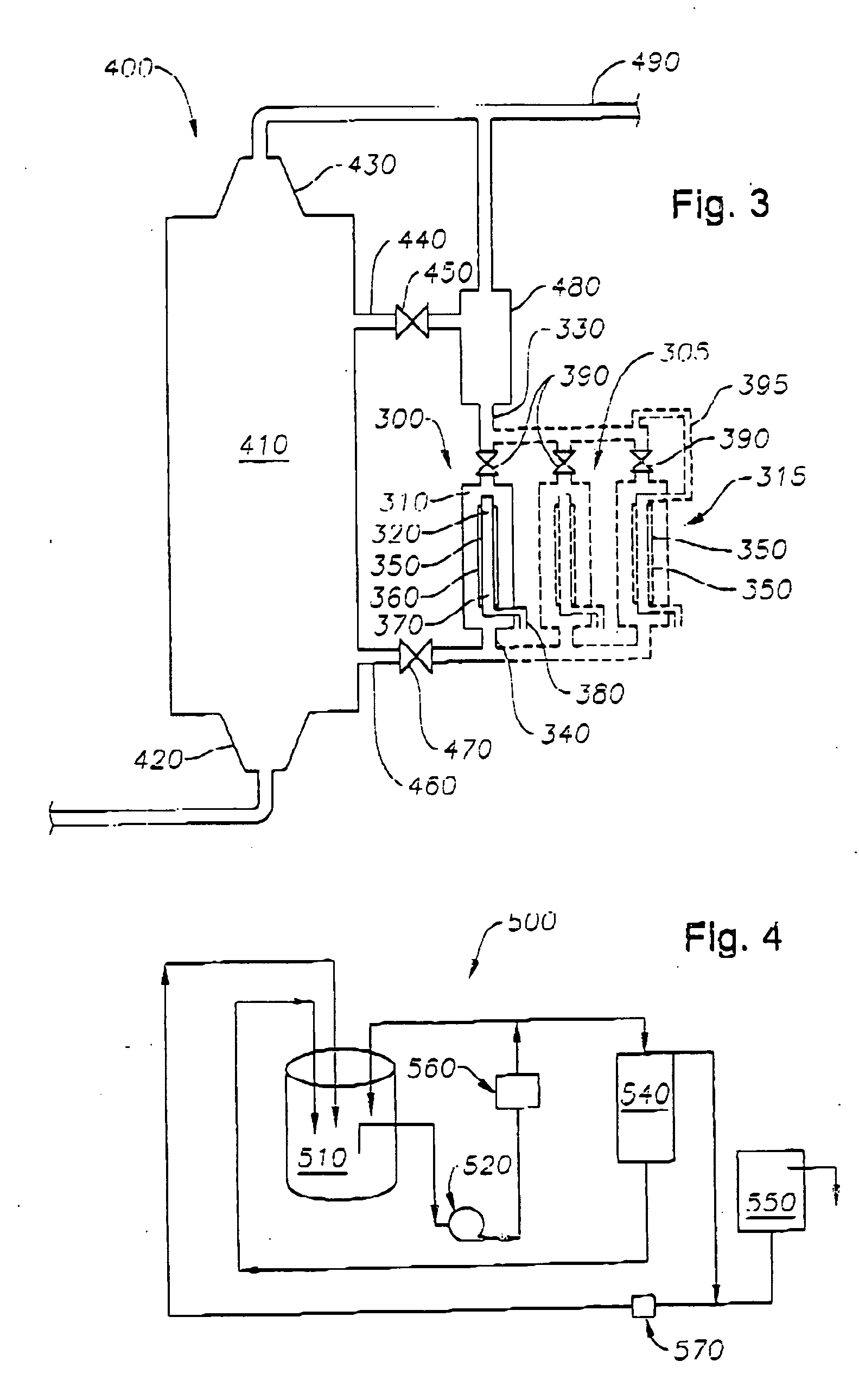

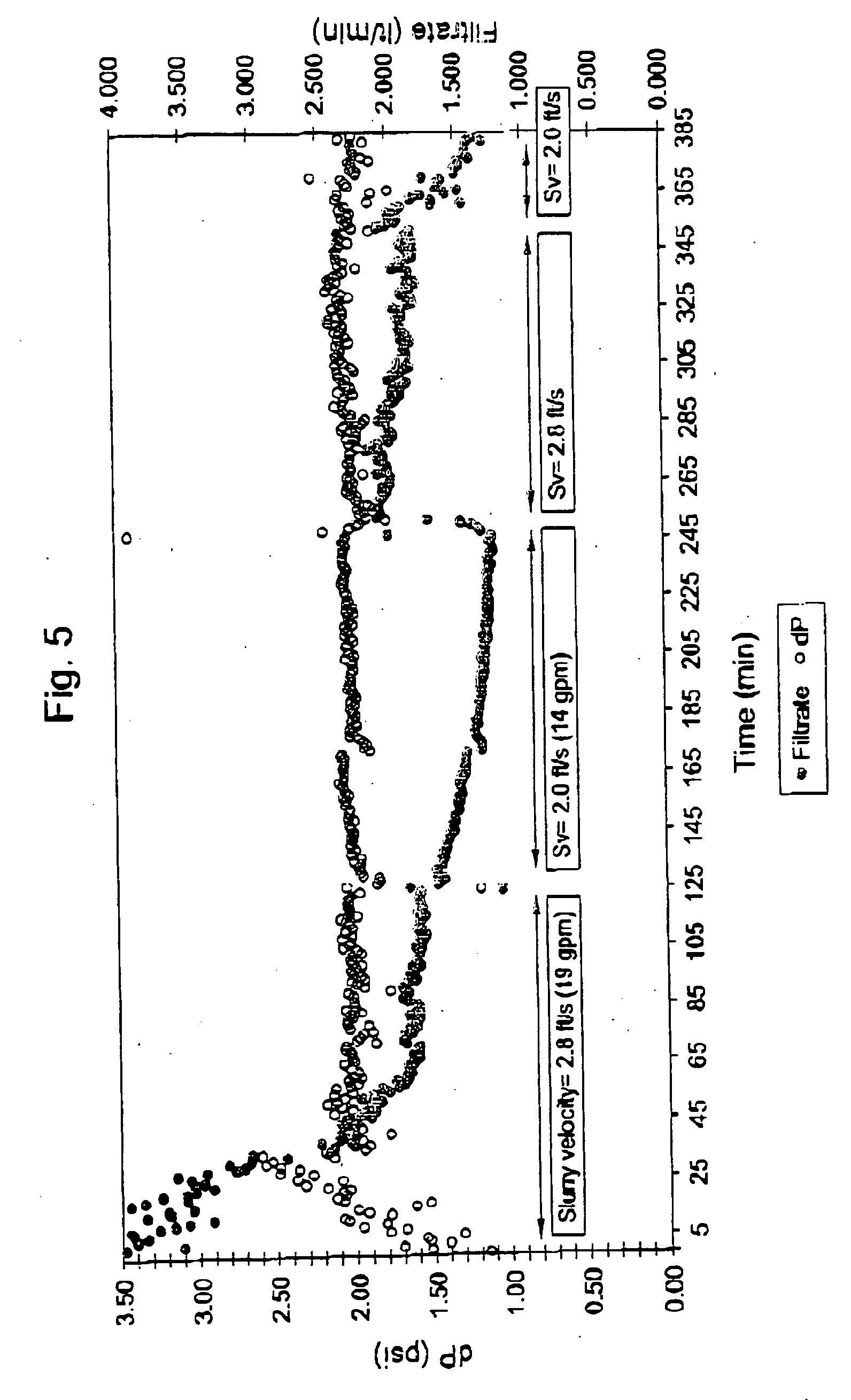

Solid/liquid separation system for multiphase converters

InactiveUS20050027021A1Barely’ toleratedEffective recoveryOrganic compounds purification/separation/stabilisationOrganic compound preparationLiquid productWax

Methods and apparatus for removing wax products from a slurry used in a Fischer-Tropsch reactor. The preferred embodiments of the present invention are characterized by a solid / liquid separation system that removes liquid products from a slurry by drawing the fluid across a filter medium composed of a filter cake disposed on a substrate. In the preferred embodiments, the filter cake is desirable and performs the majority of the filtration. In certain embodiments, the filter medium is disposed in a filter housing where slurry flows parallel to the longitudinal axis of the filter medium from and inlet to an outlet. The characteristics or properties of the cake, which will effect the performance of the solid / liquid separation system, can be controlled by regulating the velocity of the slurry flowing across the cake, where the velocity may be regulated by adjusting the slurry flow through the filter housing or may be self-regulated by changing slurry velocities influenced by the design of the filter housing.

Owner:CONOCOPHILLIPS CO

Method and apparatus for performing cementing operations on top drive rigs

ActiveUS8636067B2High tensile strengthWithout slowing down and stopping pumping operationDrilling rodsFluid removalTop driveWell drilling

Owner:FRANKS INT

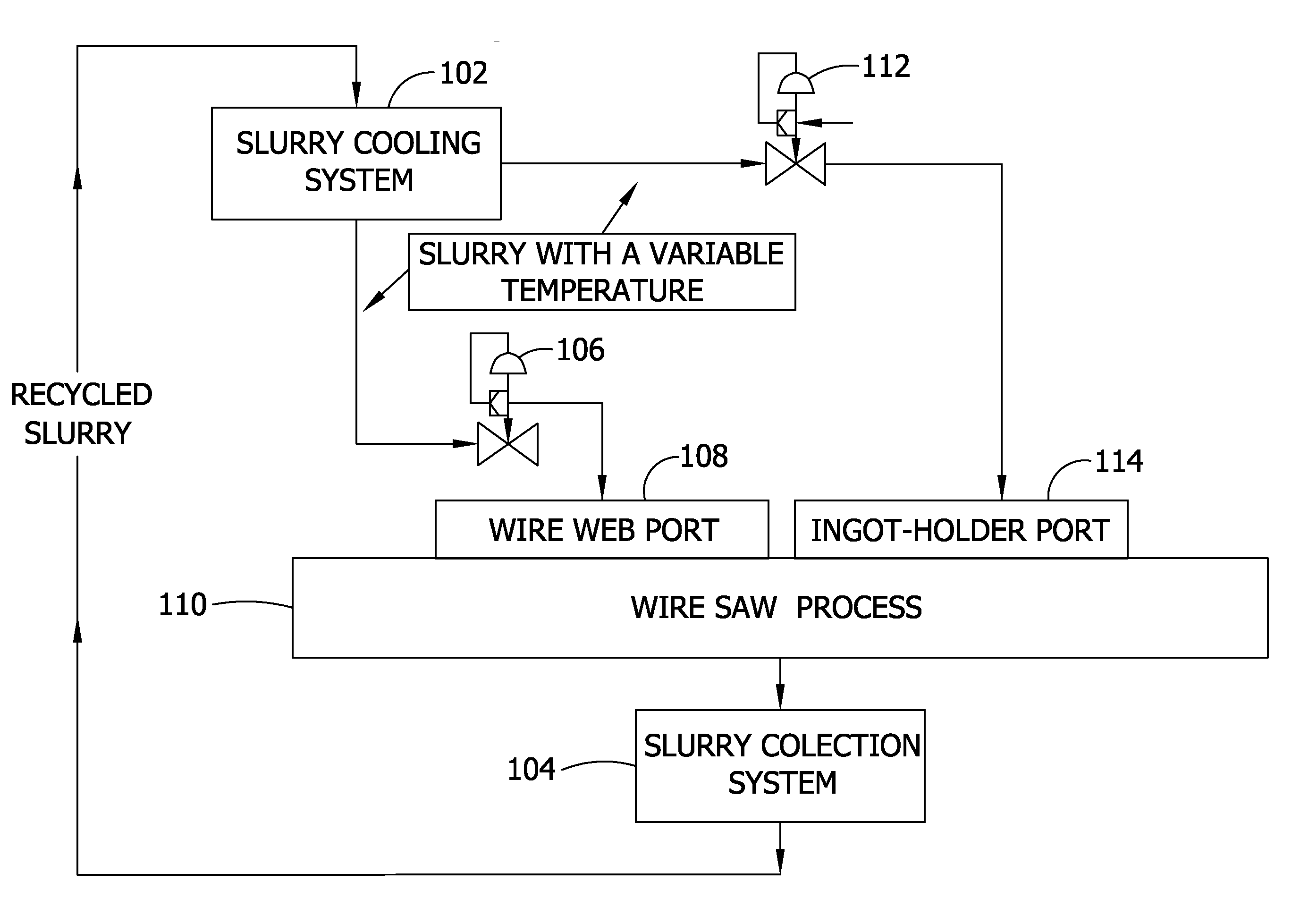

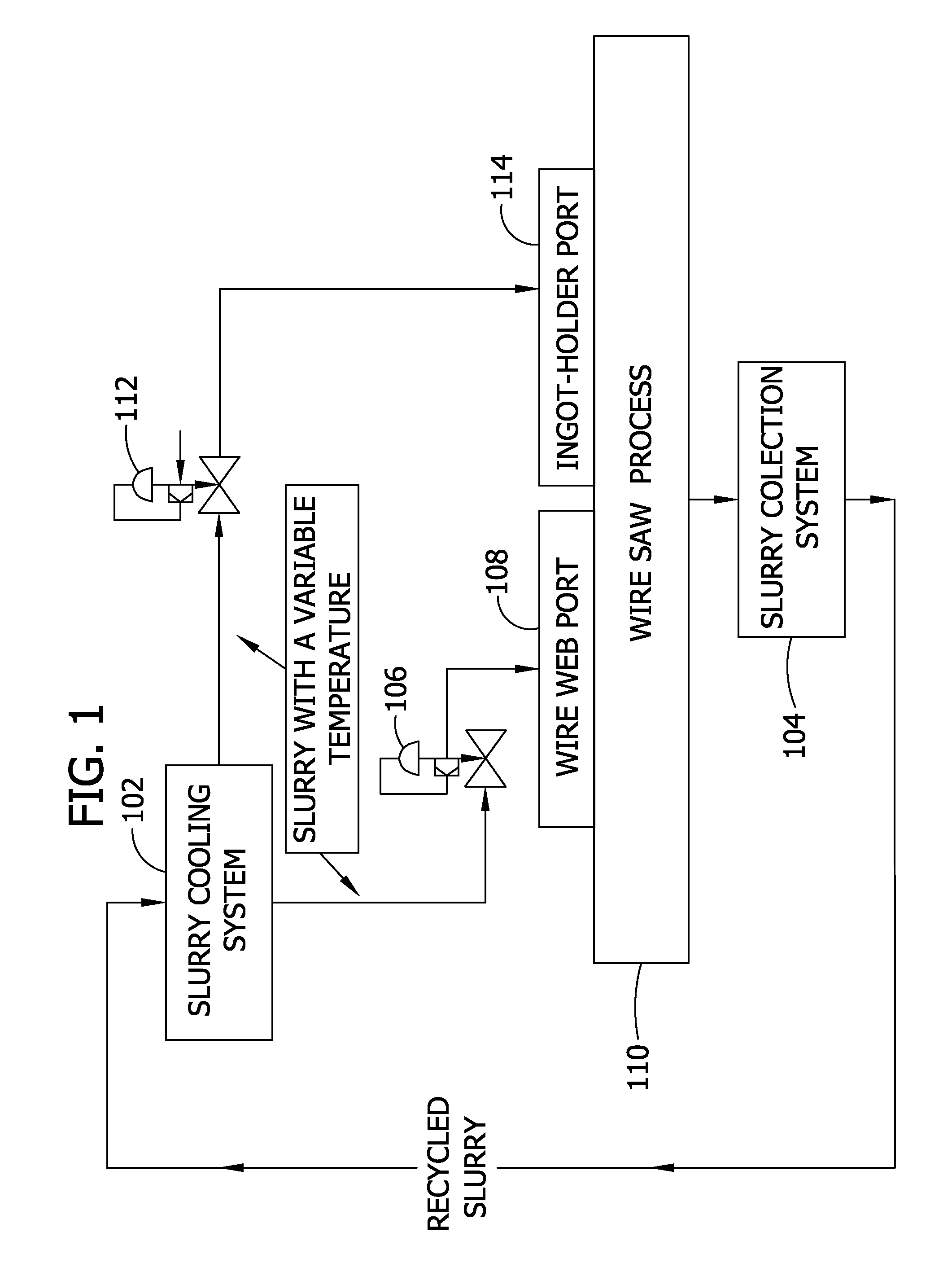

Wire saw ingot slicing system and method with ingot preheating, web preheating, slurry temperature control and/or slurry flow rate control

InactiveUS20070178807A1Reduce warpageBelt grinding machinesGrinding feed controlControl flowTemperature control

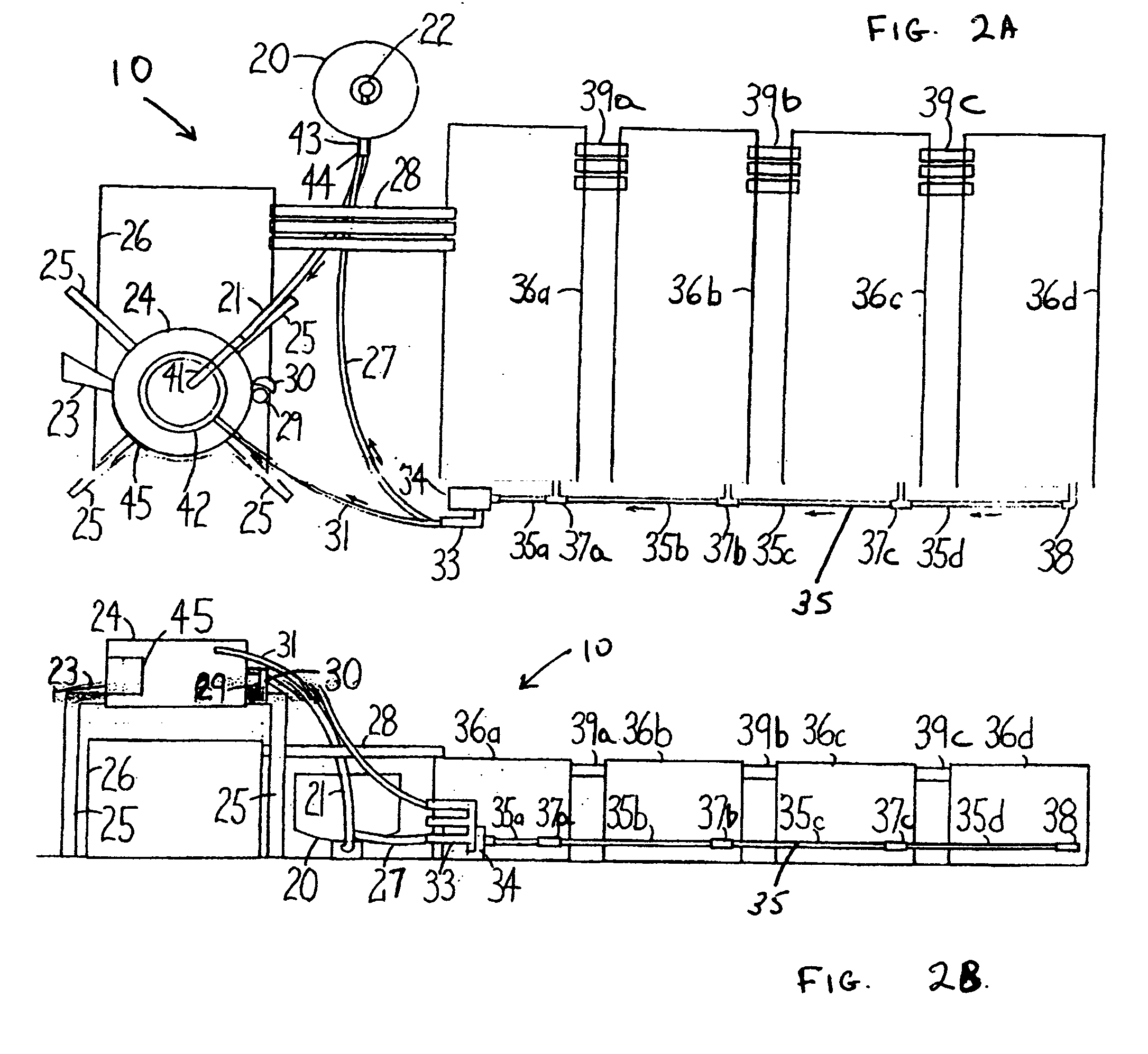

A system and method for slicing an ingot into wafers using the wire saw process. A slurry collection system collects and supplies slurry to a slurry handling system for controlling temperatures and / or flow rates of the slurry thereby providing slurry output at a controlled temperature and / or a controlled flow rate to slicing system for cutting the ingot, which may be preheated.

Owner:SUNEDISON SEMICON LIMITED UEN201334164H

Method for reclaiming concrete

A method and apparatus for reclaiming uncured concrete are disclosed. Uncured concrete containing gravel, sand and cement is mixed with water in a concrete hopper and the resultant slurry flows to a screen where the gravel is separated from the rest of the slurry material. The gravel free material flows to a separator where the sand is removed by gravity from the remaining cement water mixture. The cement water mixture flows to a tank where the cement settles out of the water by gravity. Water containing unsettled cement is recirculated to mix it with uncured concrete in the concrete hopper.

Owner:DEHART MICHAEL ROBERT +1

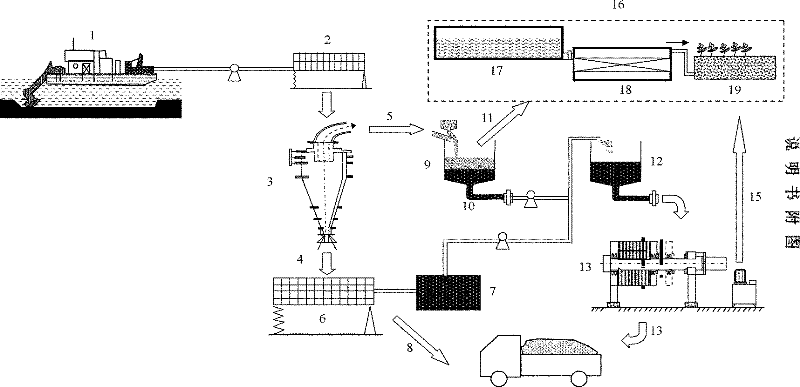

Construction method for carrying out high dehydration on dredging slurry by using swirling flow, condensation, and plate-and-frame

InactiveCN102491605AEmission safetyImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningCycloneEngineering

The invention relates to a construction method for carrying out high dehydration on a dredging slurry by using swirling flow, condensation, and plate-and-frame, comprising the following steps: conveying dredging slurry with the concentration of 15-20 % into a crude vibrating screen by a conveyer, and screening out large particles and impurities; then separating the slurry by a large-scale cyclone to obtain a downstream slurry and an upstream slurry, letting the downstream slurry pass through the fine vibrating screen to obtain sediments on the screen and a screened condensed slurry, letting the upstream slurry flow into a coagulation sedimentation basin to obtain a condensed slurry and a supernatant; precipitating the screened condensed slurry and the condensed slurry in a mud storage pond, and then hydrating with a plate-and-frame filter press to obtain a mud cake and filter-press tail water; using the sediments on the screen and the mud cake as engineering filling, and processing the supernatant of the sedimentation basin and the filter-press tail water through a tail water processing system to discharge with a standard level. According to the invention, the water content of the low-concentration dredging slurry is reduced gradedly and rapidly, thus the problems that stockyards of a lot of dredging slurry occupy land and the dredging slurry cannot be used directly are effectively solved.

Owner:HOHAI UNIV

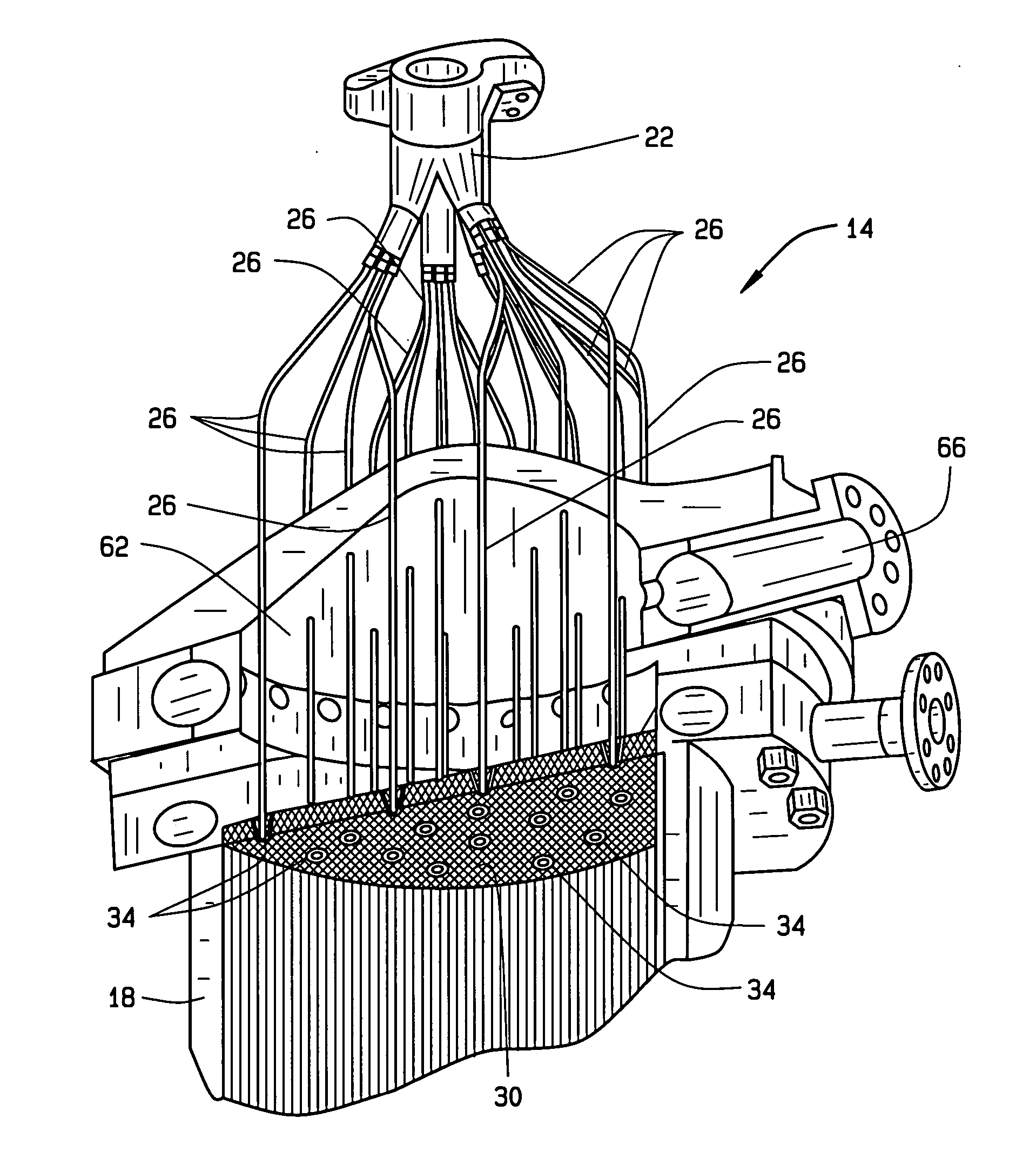

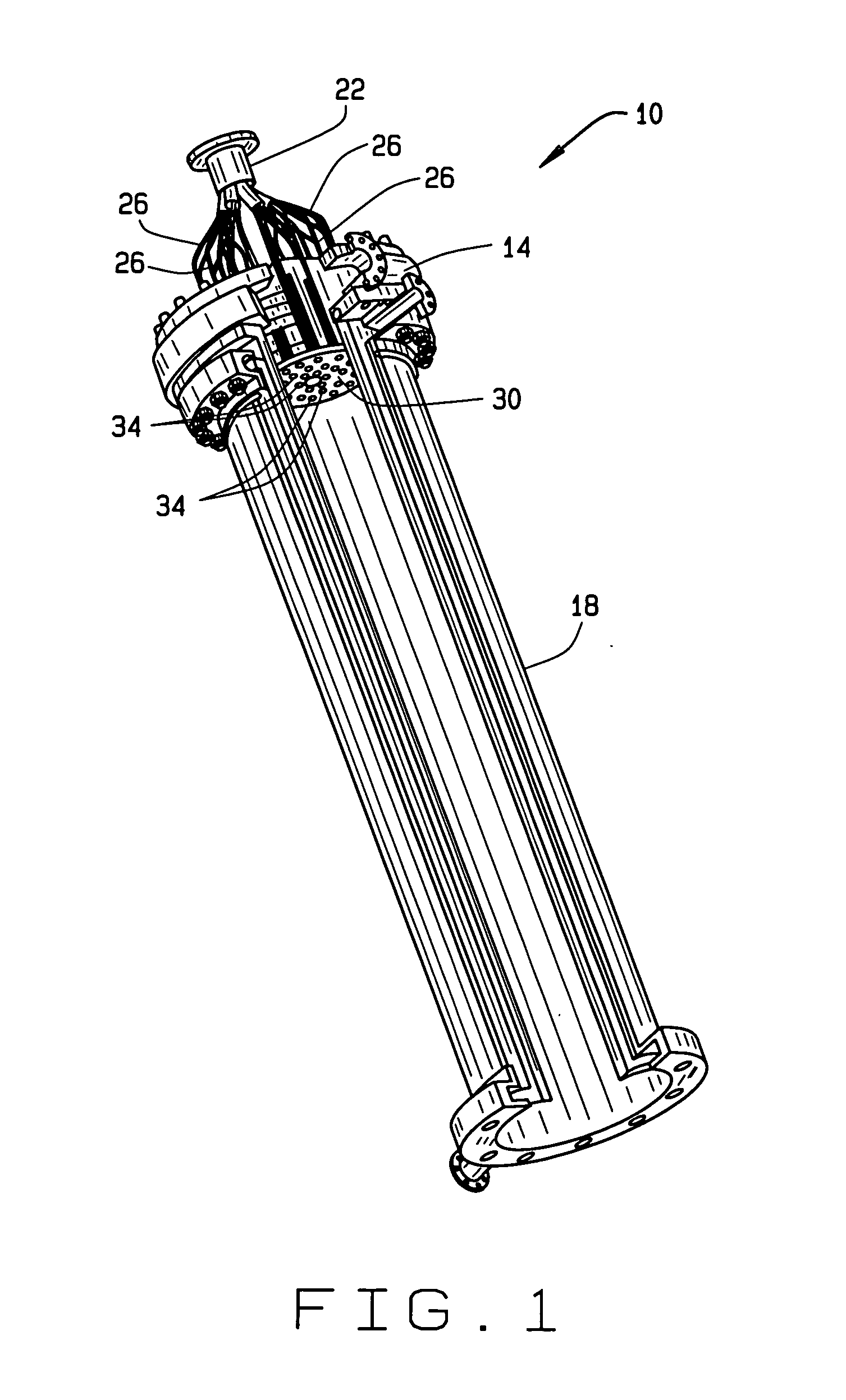

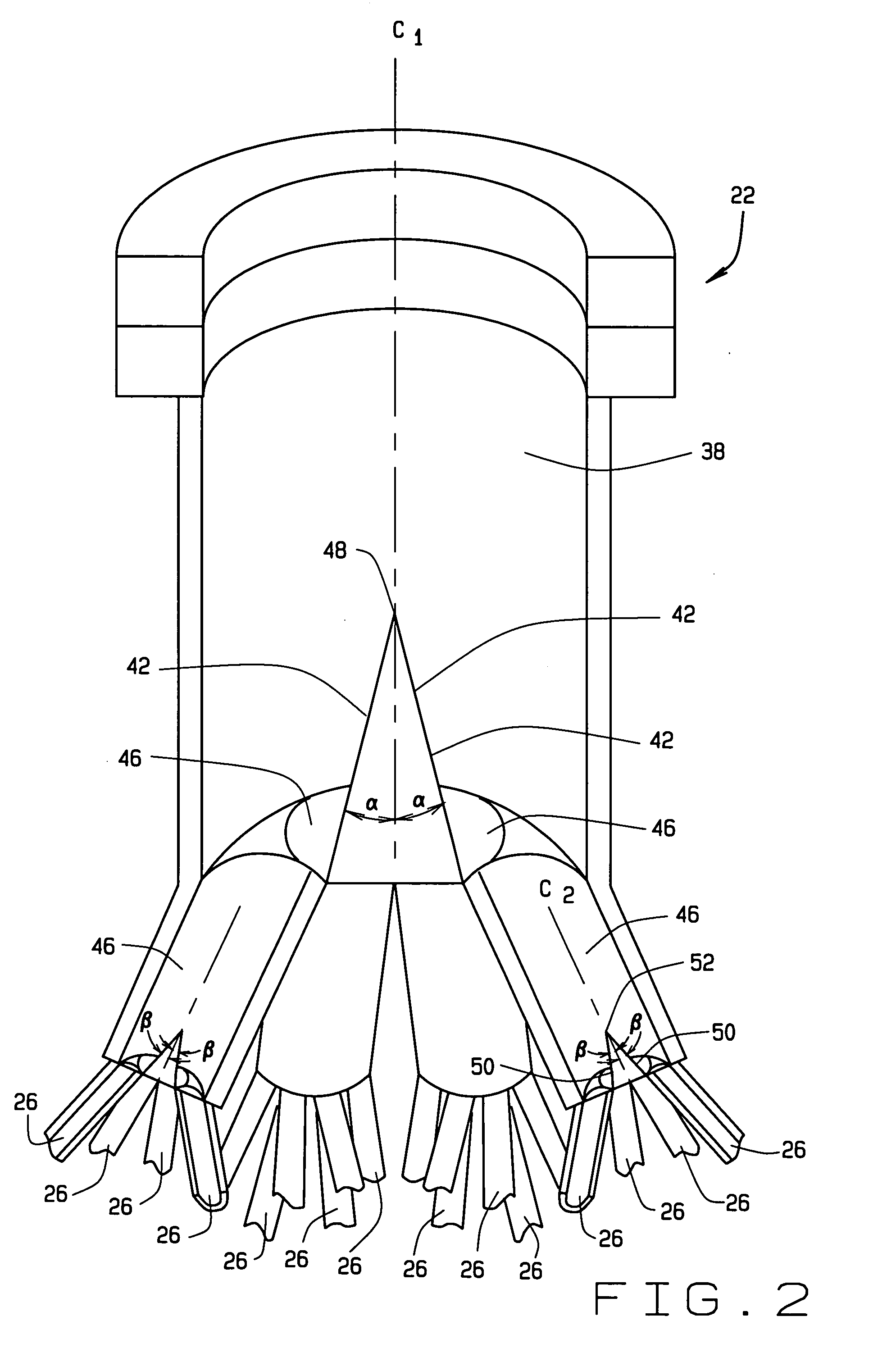

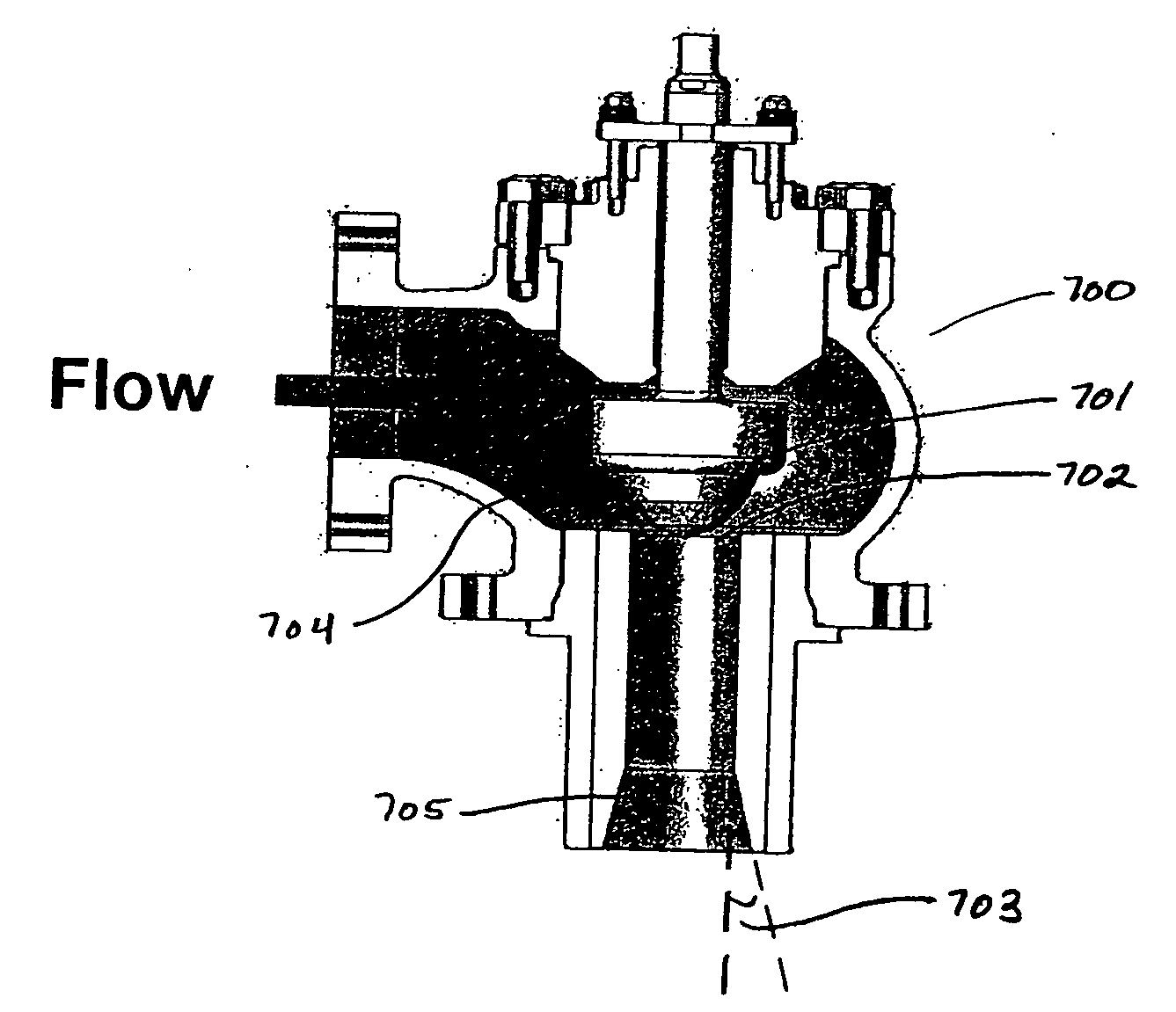

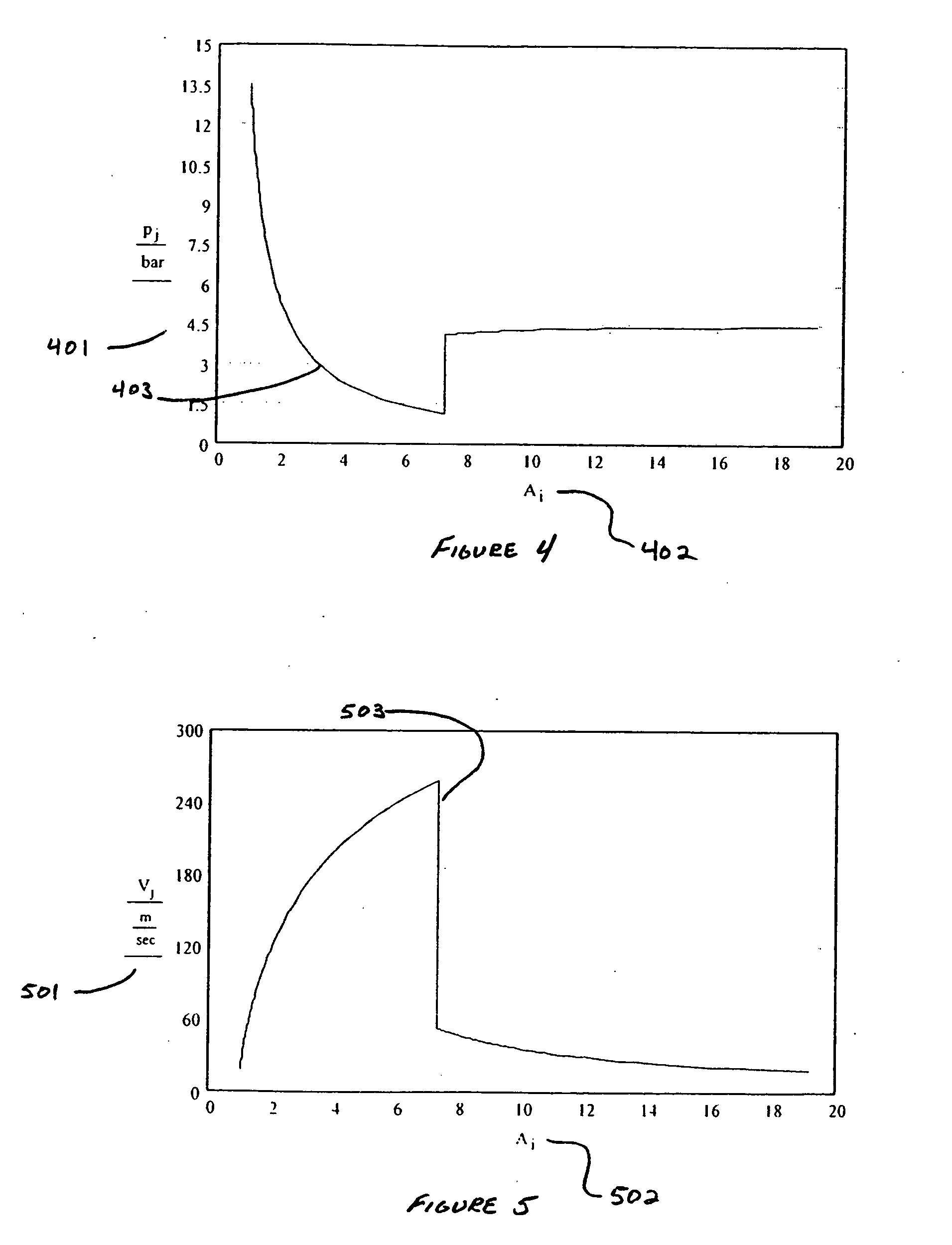

Controlled dispersion multi-phase nozzle and method of making the same

ActiveUS20060065869A1Improve flow patternDissipating letdown energyValve members for absorbing fluid energyPipe elementsSpray nozzleEngineering

A nozzle design and method for designing such a nozzle being adapted for three phase slurry flow from the choke into the flash tank during pressure let-down in autoclave mining operations that uses a selection of the expansion ratio in the choke to select a nozzle dispersion angle to select a spread of the flow over the slurry pool in the flash tank, to generally maximize the use of the pool for energy dissipation without causing undo wear and tear on the tank walls.

Owner:CALDERA ENG

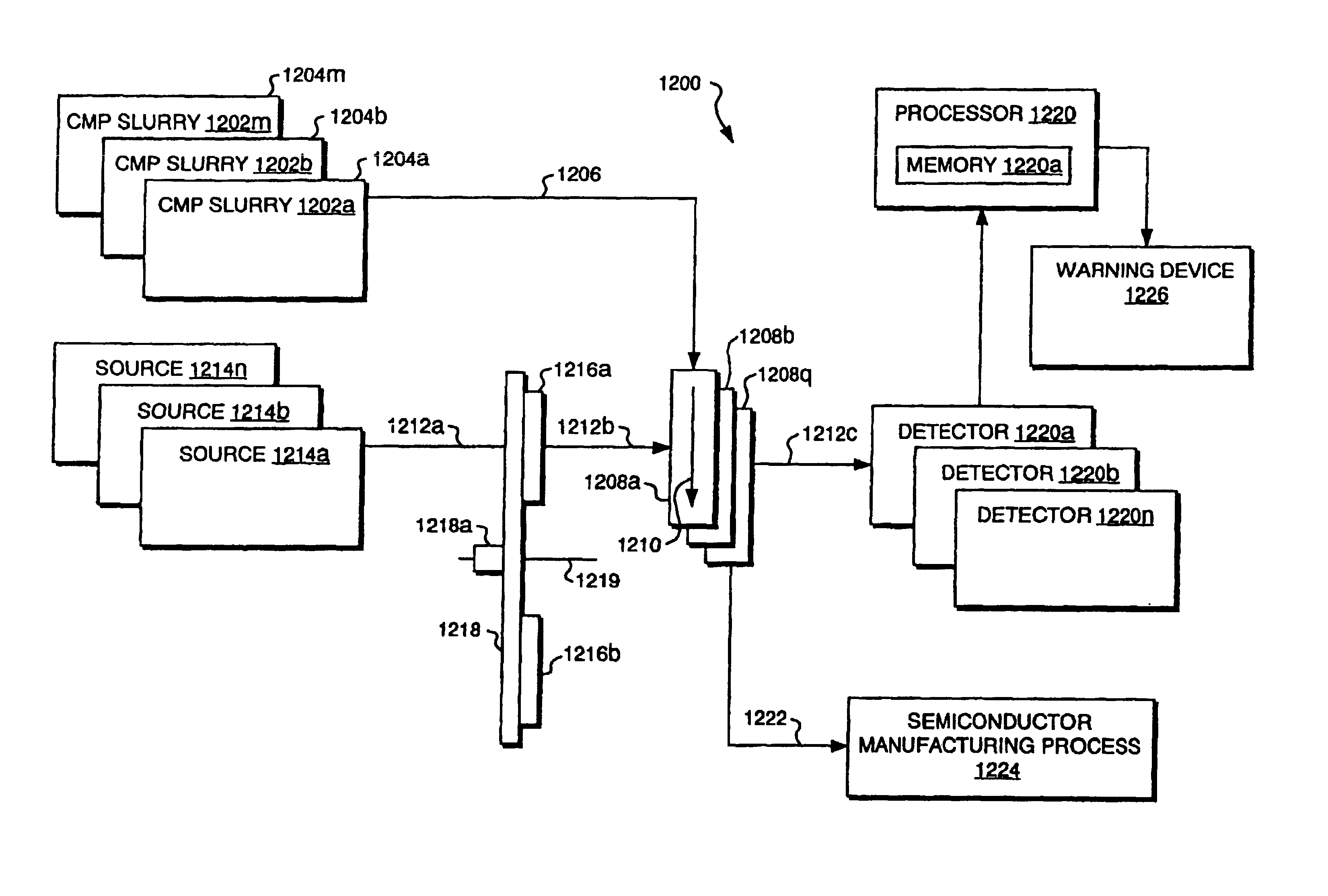

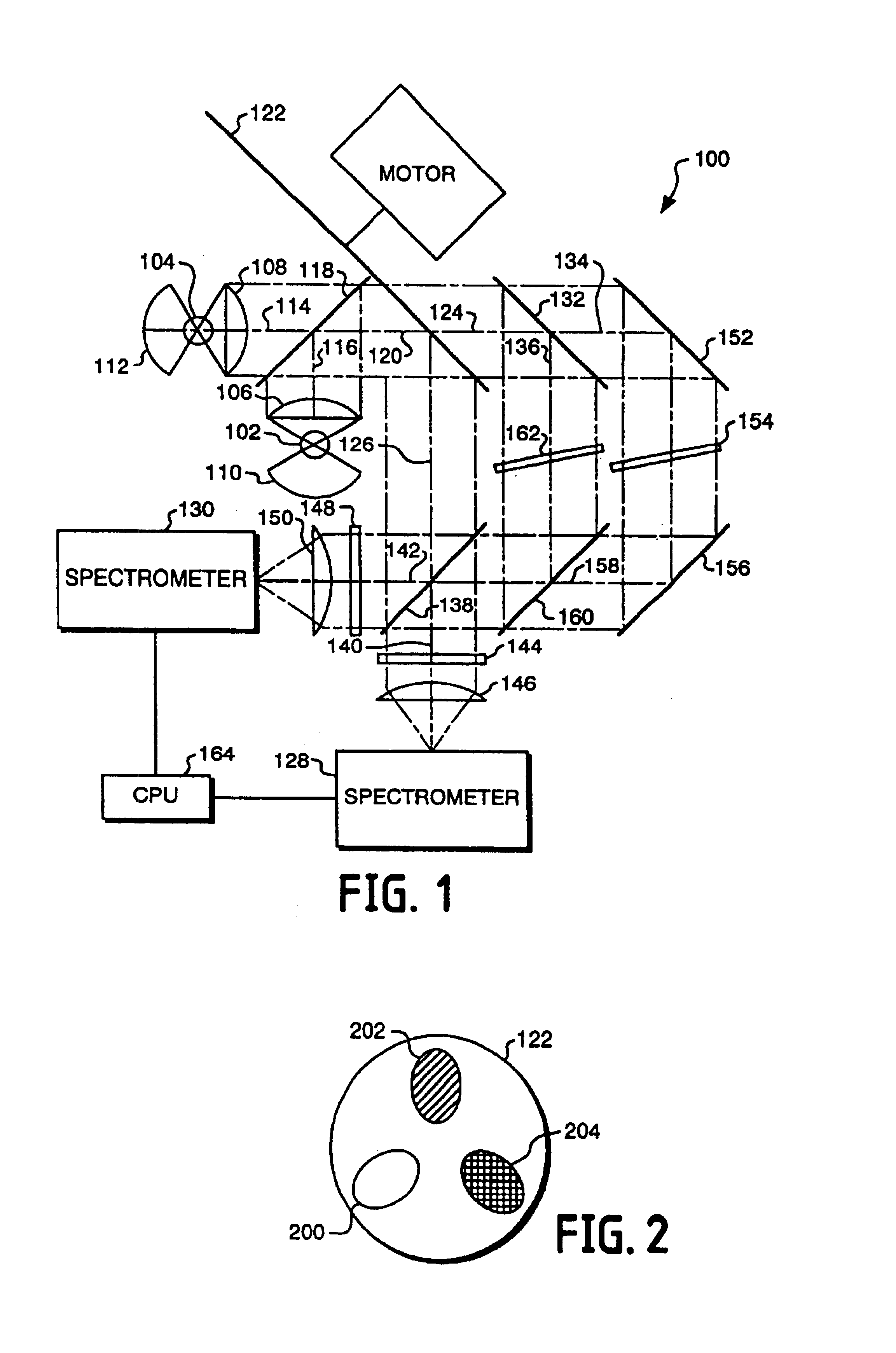

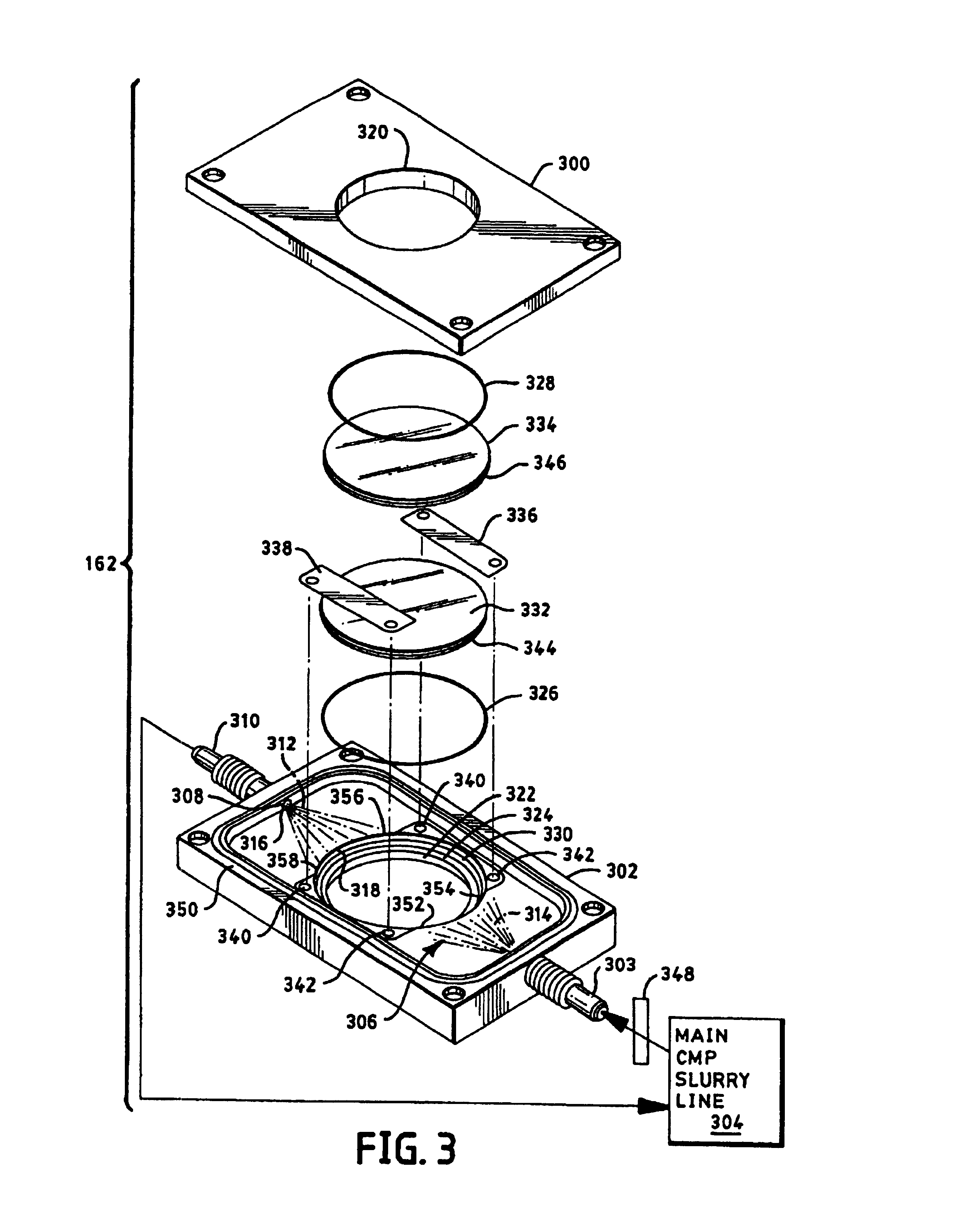

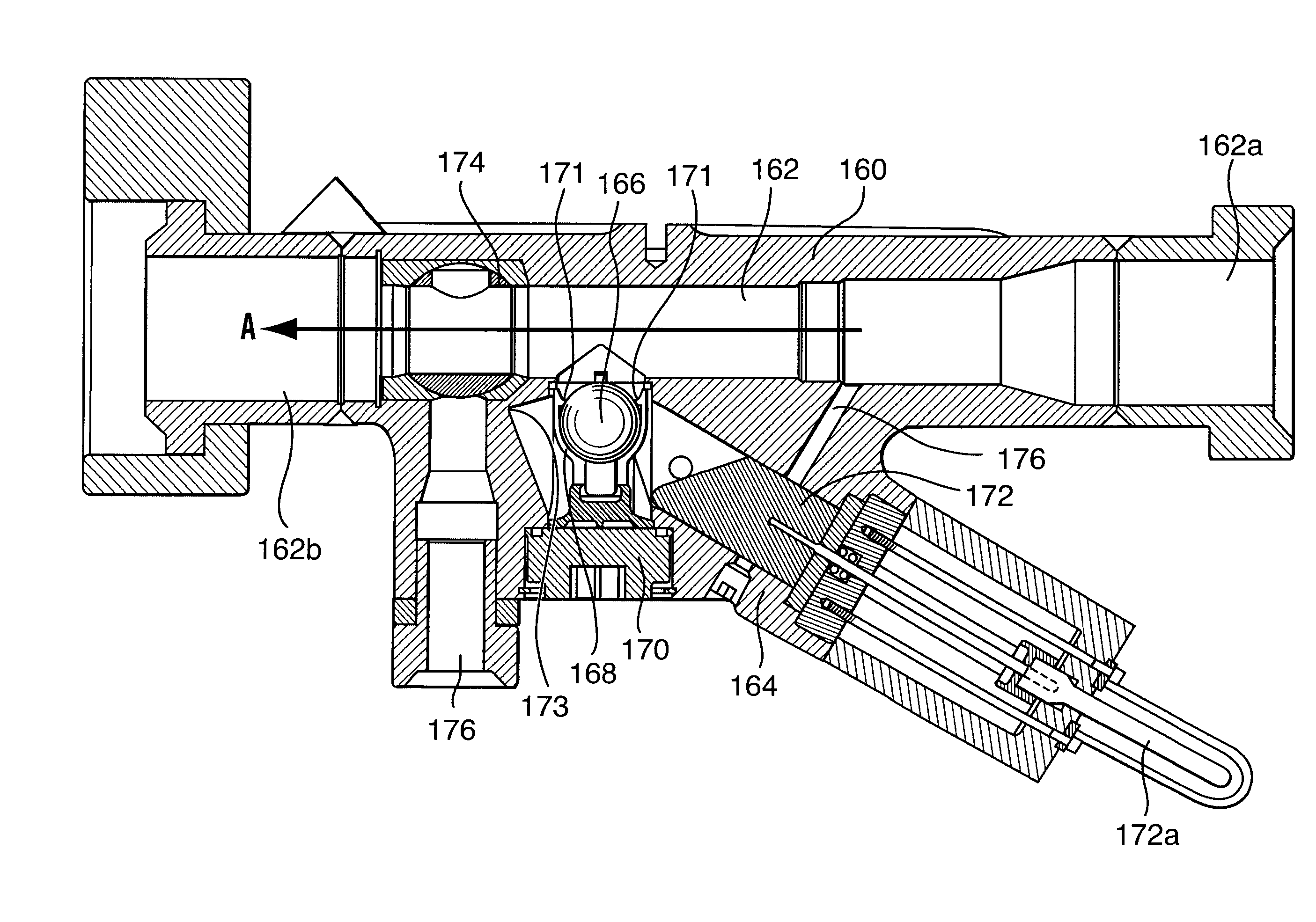

Chemical mechanical planarization (CMP) slurry quality control process and particle size distribution measuring systems

InactiveUSRE39783E1Improve accuracyEasy to measureDiagnosticsSemiconductor/solid-state device manufacturingSpectral transmissionGrating

A sensitive particle distribution probe uses special processing including a modified Twomey / Chahine iterative convergence technique and a specially constructed sample cell to obtain particle size distribution measurements from optically dense slurries, such as the slurries used in the semiconductor industry for chemical mechanical planarization. Spectral transmission data is taken over the spectral range of 0.20-2.5 microns, utilizing specially constructed, chemically resistant sample cells of 50-2000 microns thickness, and miniature, fixed grating, linear detector array spectrometers. At wavelengths greater than one micron, the preferred design utilizes InGaAs linear detector arrays. An ultrasonic disrupter can be employed to breakup harmless soft agglomerates. In addition to direct particle size distribution measurement, the invention described here could be used to detect other fundamental causes of slurry degradation, such as foaming and jelling. The probe accomplishes continuous, real time sampling of undiluted slurry. A three-position chopper allows automated operation in an industrial environment without the need for frequent reference spectra, which would require taking the probe off-line. In other embodiments, the invention provides a quality control and / or particle size measuring system for CMP slurries using transmission data through an as-used CMP slurry flow. The process of the invention detects transmission through the flow, at select wavelengths, and determines changes in the logarithmic slope of transmission versus wavelength to detect acceptable or unacceptable CMP slurries. The process can further determine CMP slurry particle size through empirical extinction data stored in memory.

Owner:PARTICLE MEASURING SYST

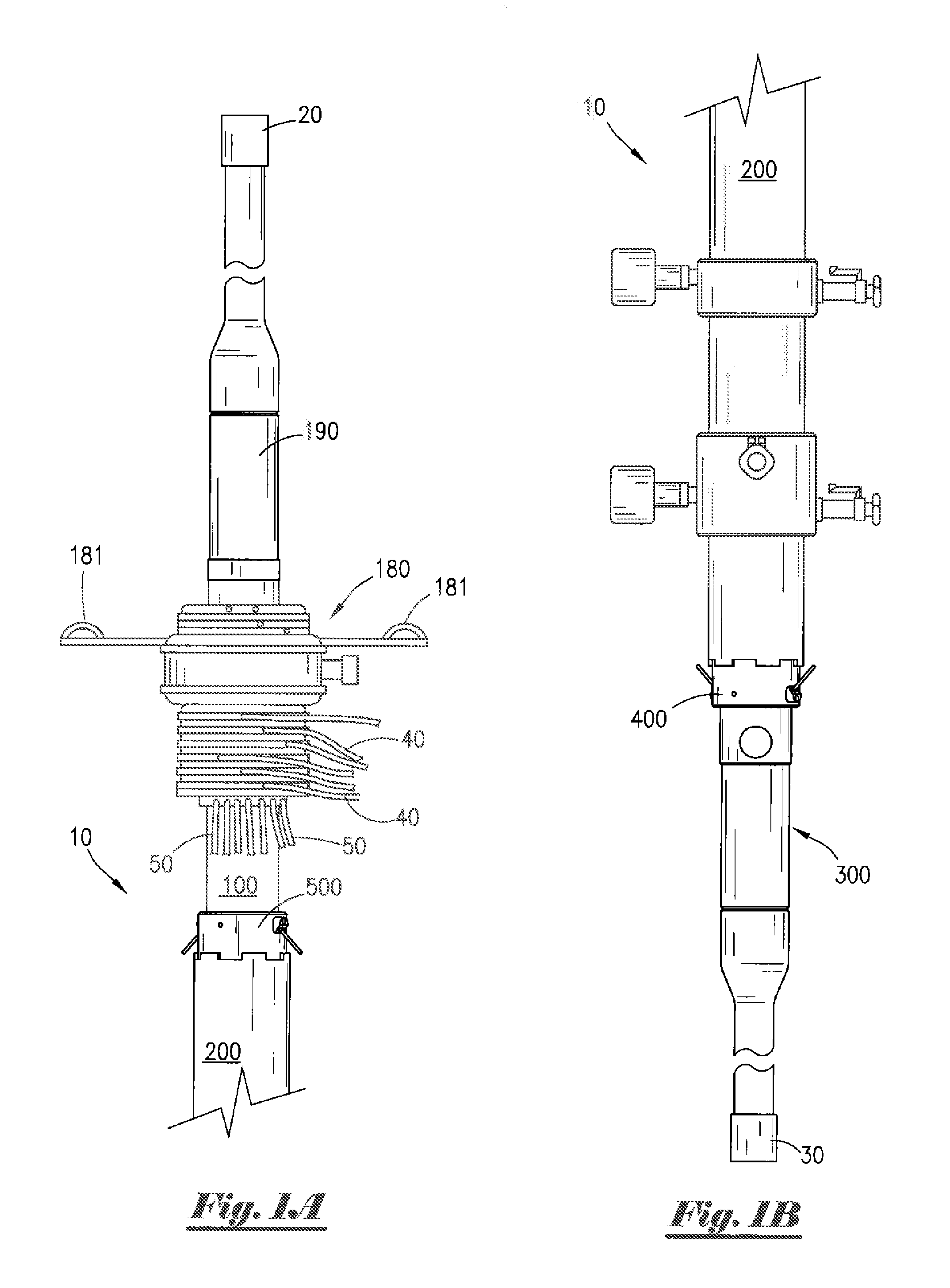

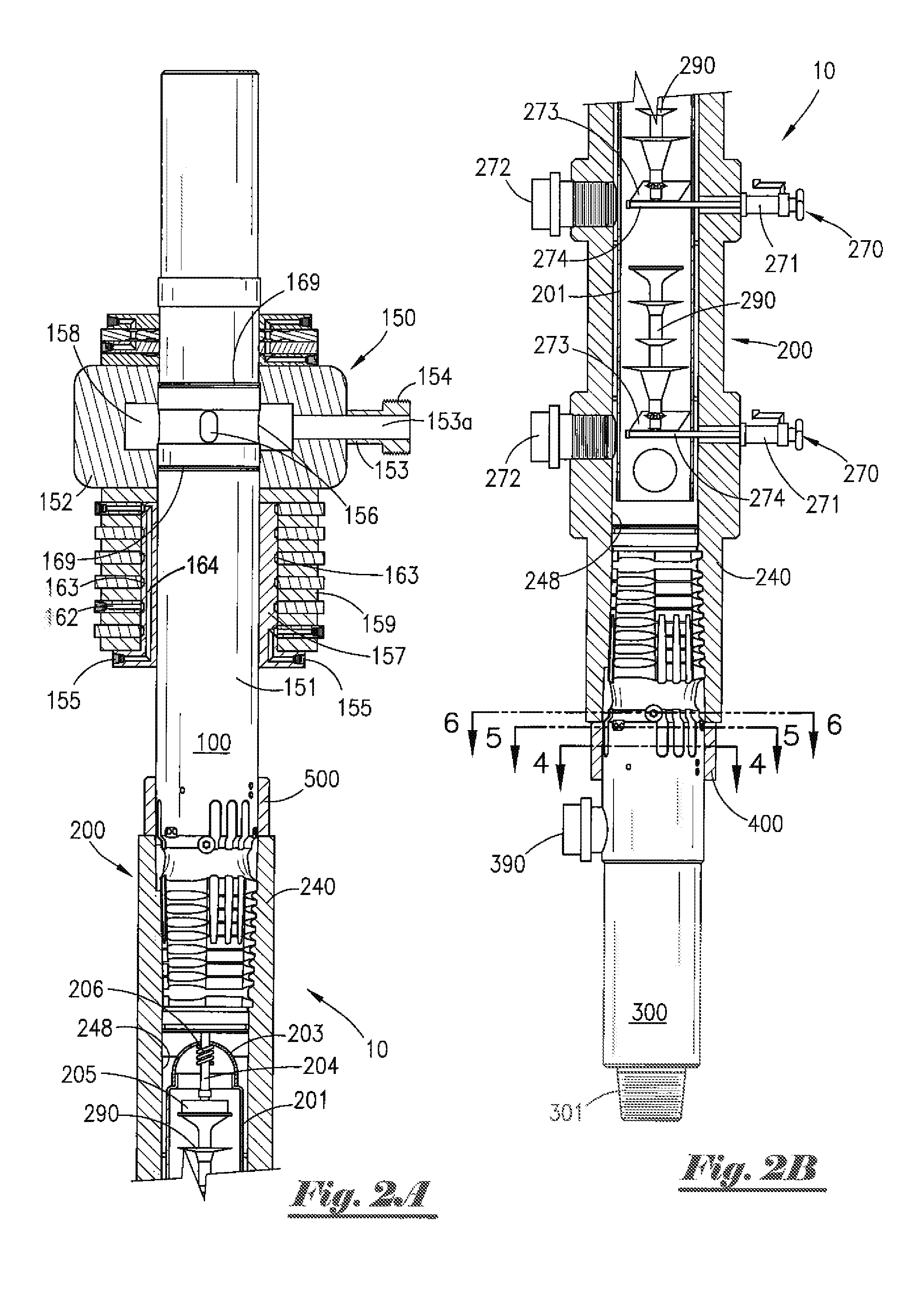

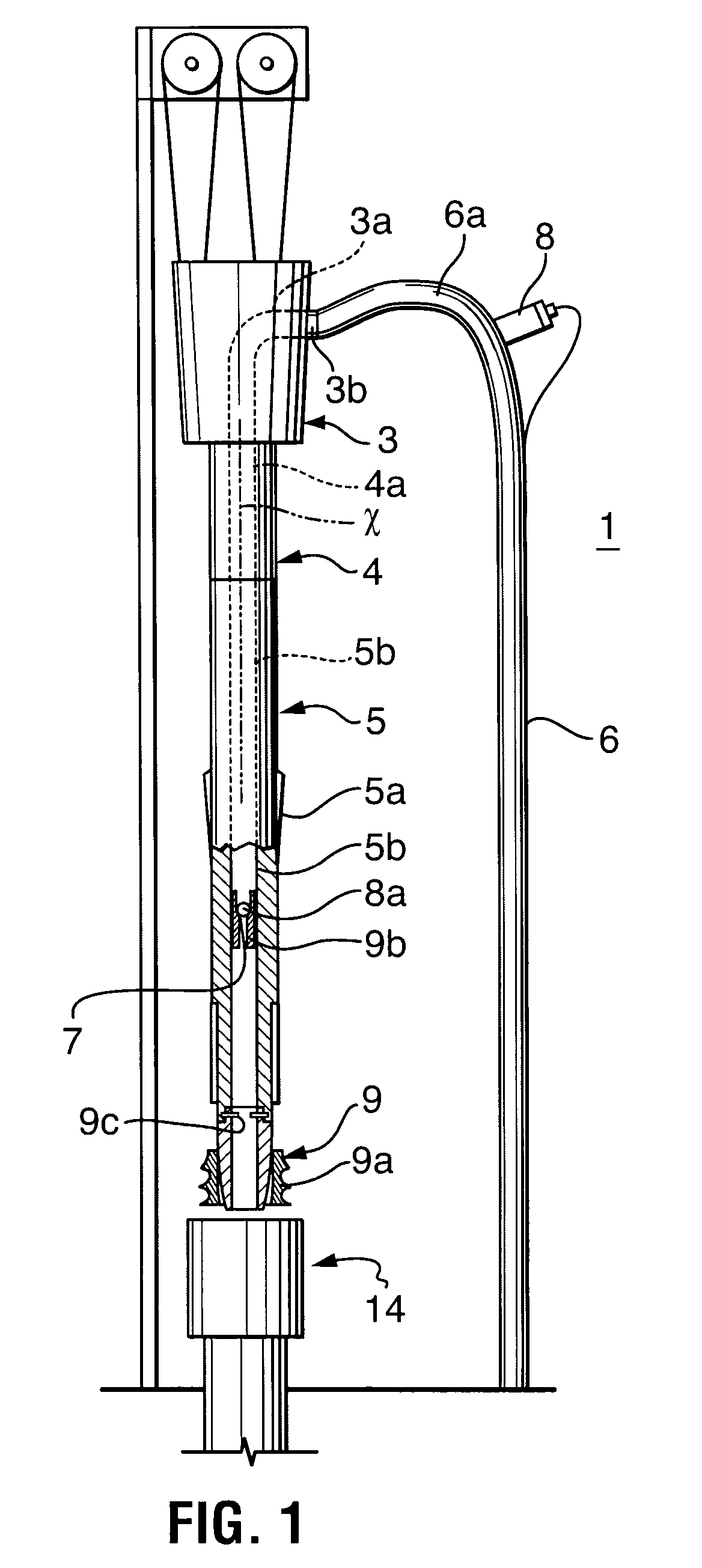

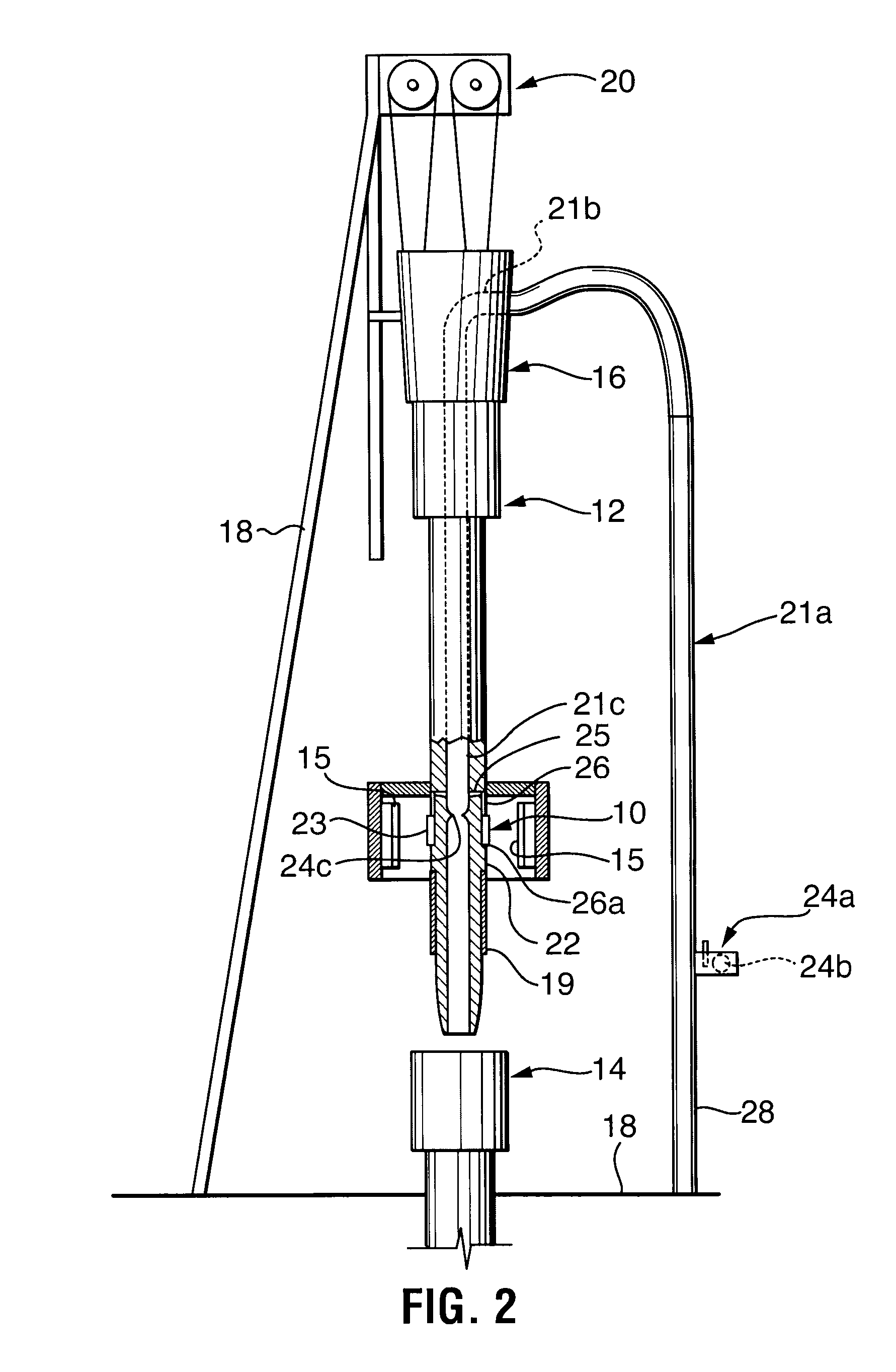

Actuation system for an oilfield tubular handling system

An actuation system for a tubular handling mechanism of a tubular handling assembly, the actuation system comprising: a mud flow path passing through rotating parts and non-rotating parts of the tubular handling assembly; a valve assembly including a valve seat in the mud flow path and a ball, the valve seat positioned to be in hydraulic driving communication with the tubular handling mechanism; and a ball drop assembly including an opening to the mud flow path through which the ball is released and wherein the ball drop assembly opening is positioned in a non-rotating part.

Owner:NABORS DRILLING TECH USA INC

EDI and related stacks and method and apparatus for preparing such

InactiveUS7094325B2Easy to controlEasy constructionSludge treatmentIon-exchanger regenerationParticulatesElectricity

Apparatus and method are disclosed for introducing ion exchange or other particulates into compartments of an already-assembled electrodeionization or comparable stack by modulating a flow of slurry into the compartments with slugs of gas such as air. The air propels liquid through the cells, scavenging ponded liquid so that the particulates (which are retained, e.g., by a strainer or obstruction, in compartment of the apparatus) are deposited as well-packed beds to fill the compartments. Pressurized air filling protocols may deliver discrete slugs of slurry between bursts of air, and the direction of filling may be periodically reversed to diminish particle bed non-homogeneities or settling gradients that arise during transport. The slugs of air may be applied in the direction of slurry flow, in the reverse direction, or both. Different slurries may be transported in a sequence to form layered and packed beds of enhanced utility. An apparatus of the invention has filled compartments of enhanced packing, and is ported or has its passages arranged so that ion exchange material may be filled, or may be replenished by a fluidized flow according to a method of this invention.

Owner:UBS AG STAMFORD BRANCH AS COLLATERAL AGENT

Method and apparatus to minimize air-slurry separation during gypsum slurry flow

A method and apparatus for providing an evenly mixed additive enhanced gypsum slurry to a web. Calcined gypsum and water are inserted into a mixer through at least one inlet of the mixer. The contents are agitated to form a slurry. The slurry is passed from an outlet of the mixer into a conduit. An additive is introduced into the slurry along a length of the conduit to achieve a flow stream of a slurry / additive mixture. A cross section of the flow stream is expanded in the conduit while not changing direction of the flow stream and a direction of the flow stream is changed while not expanding the cross section of the flow stream and conduit, all prior to the flow steam exiting from an outlet of the conduit.

Owner:UNITED STATES GYPSUM CO

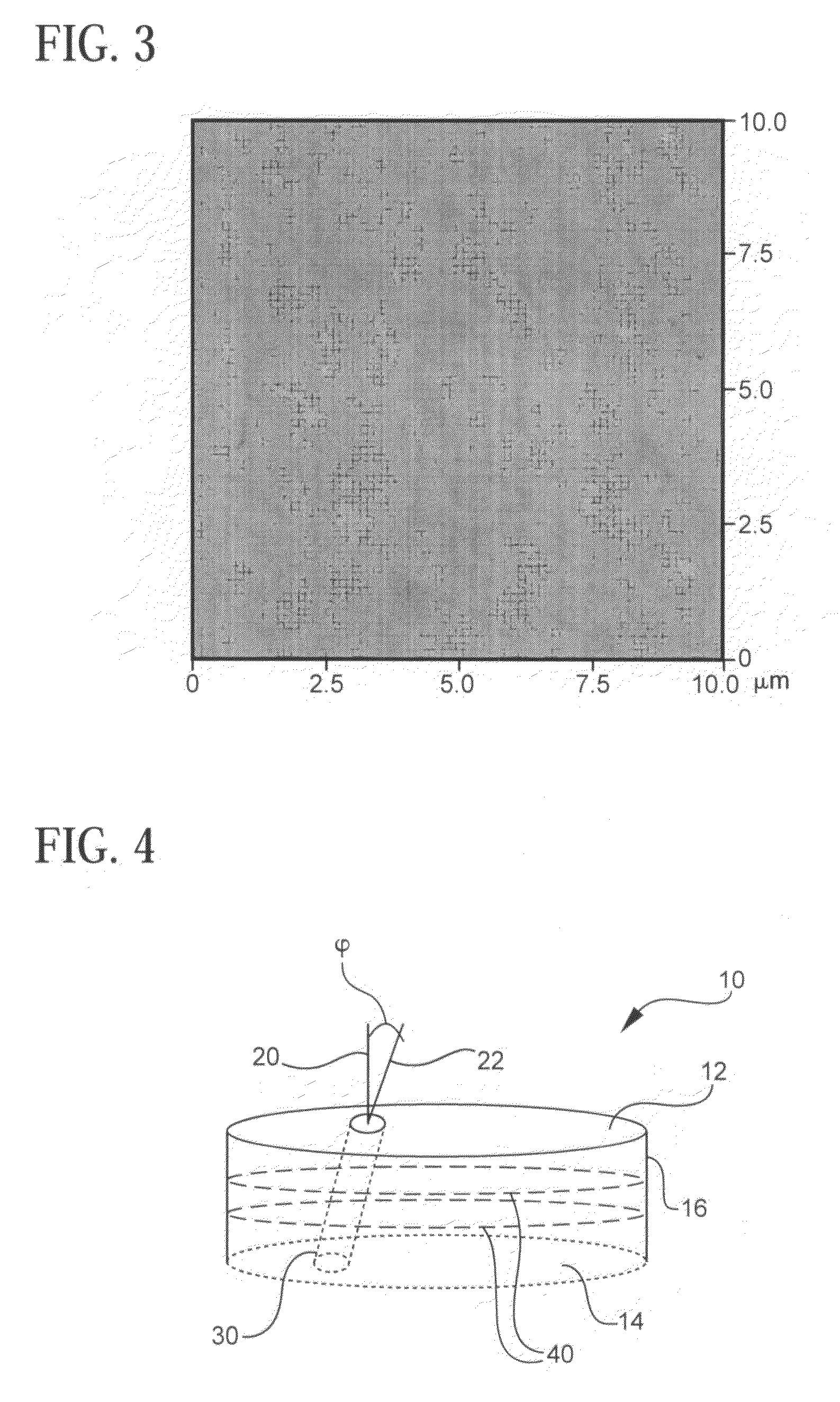

Polishing method for extreme ultraviolet optical elements and elements produced using the method

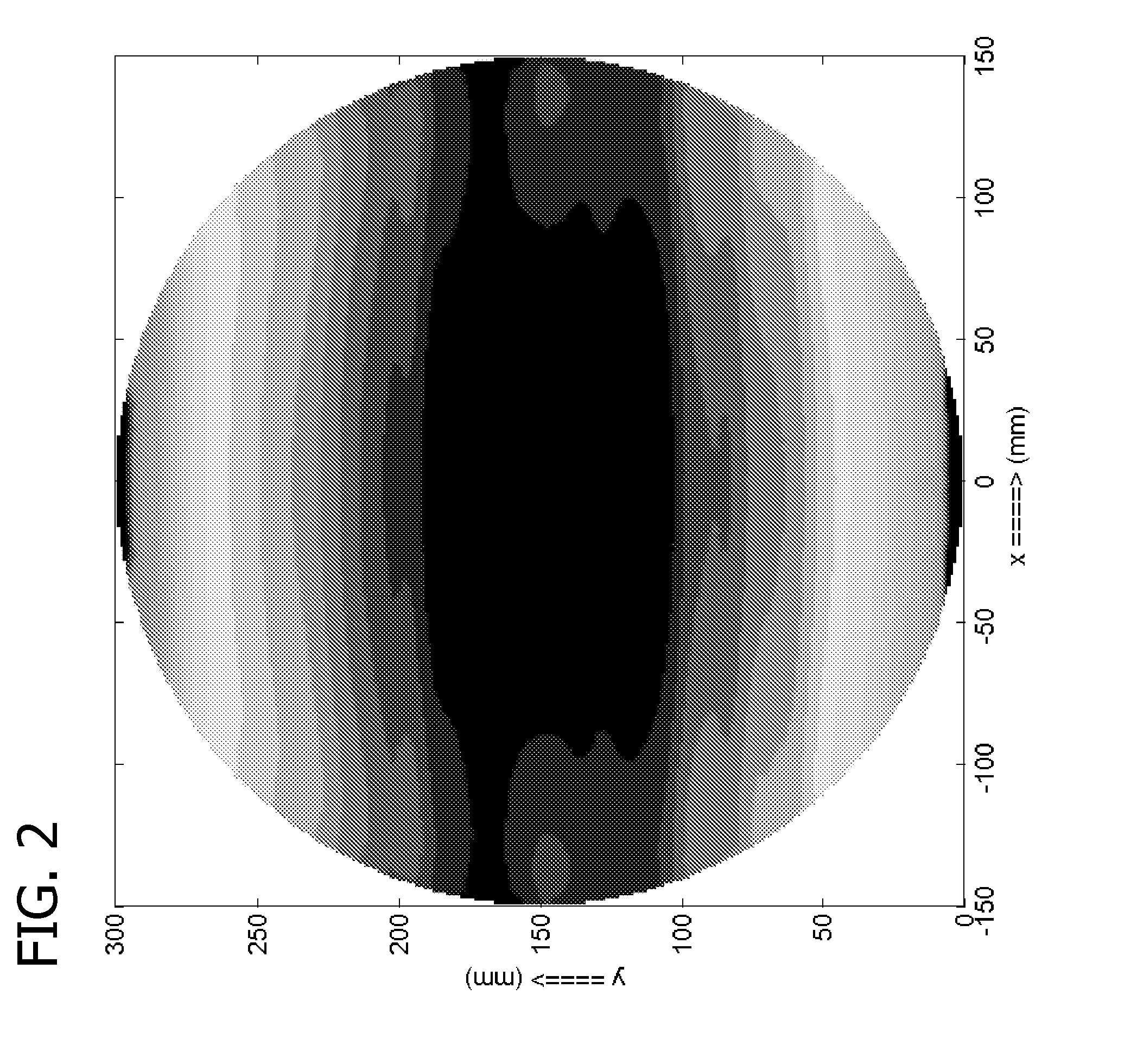

InactiveUS20080132150A1Optical surface grinding machinesRadiation/particle handlingThermal expansionExtreme ultraviolet

The invention is directed to polished glass substrates suitable for extreme ultraviolet lithography. The elements are silica-titania glass elements having a coefficient of thermal expansion of 0±30×10−9 / ° C. or less, and containing 5-10 wt. % titania. The polished elements have a mid-spatial frequency peak-to-valley roughness of <10 nm and a high-spatial frequency roughness of <0.20 nm average roughness. The invention is further directed to a method of for producing optical elements suitable for extreme ultraviolet lithography (“EUVL”), the method having at least the steps of providing a glass substrate in the shape of the desired optical element and polishing the shaped substrate using a high abrasive slurry flow rate of >2.0 ml / cm2 / min. Generally the flow rates are in the range of 2.0-10 ml / cm2 / min. Glass substrates suitable for extreme ultraviolet lithography element have a coefficient of thermal expansion of 0±30×10−9 / ° C. or less. A particular glass suitable for EUVL use is silica-titania glass containing 5-10 wt. % titania.

Owner:CORNING INC

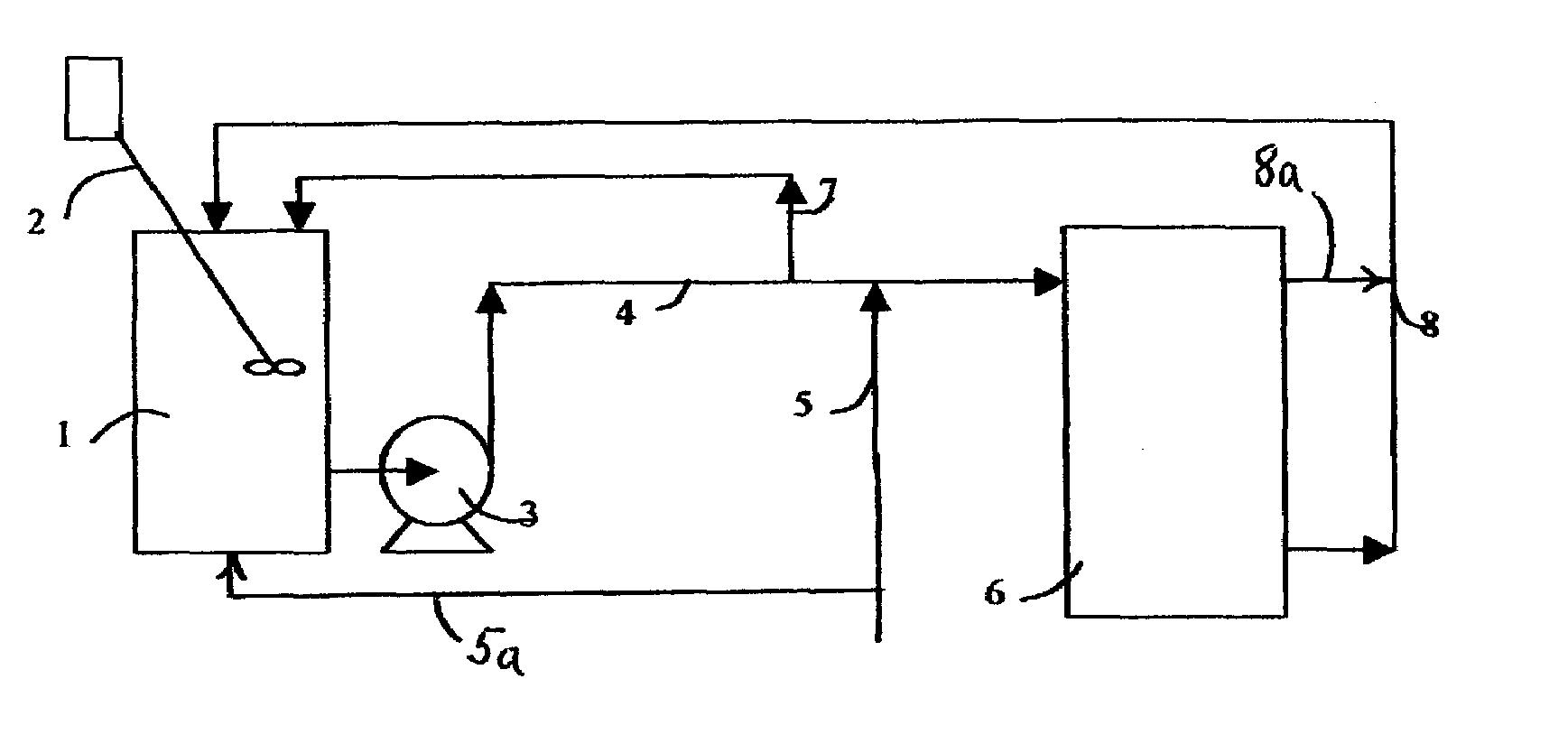

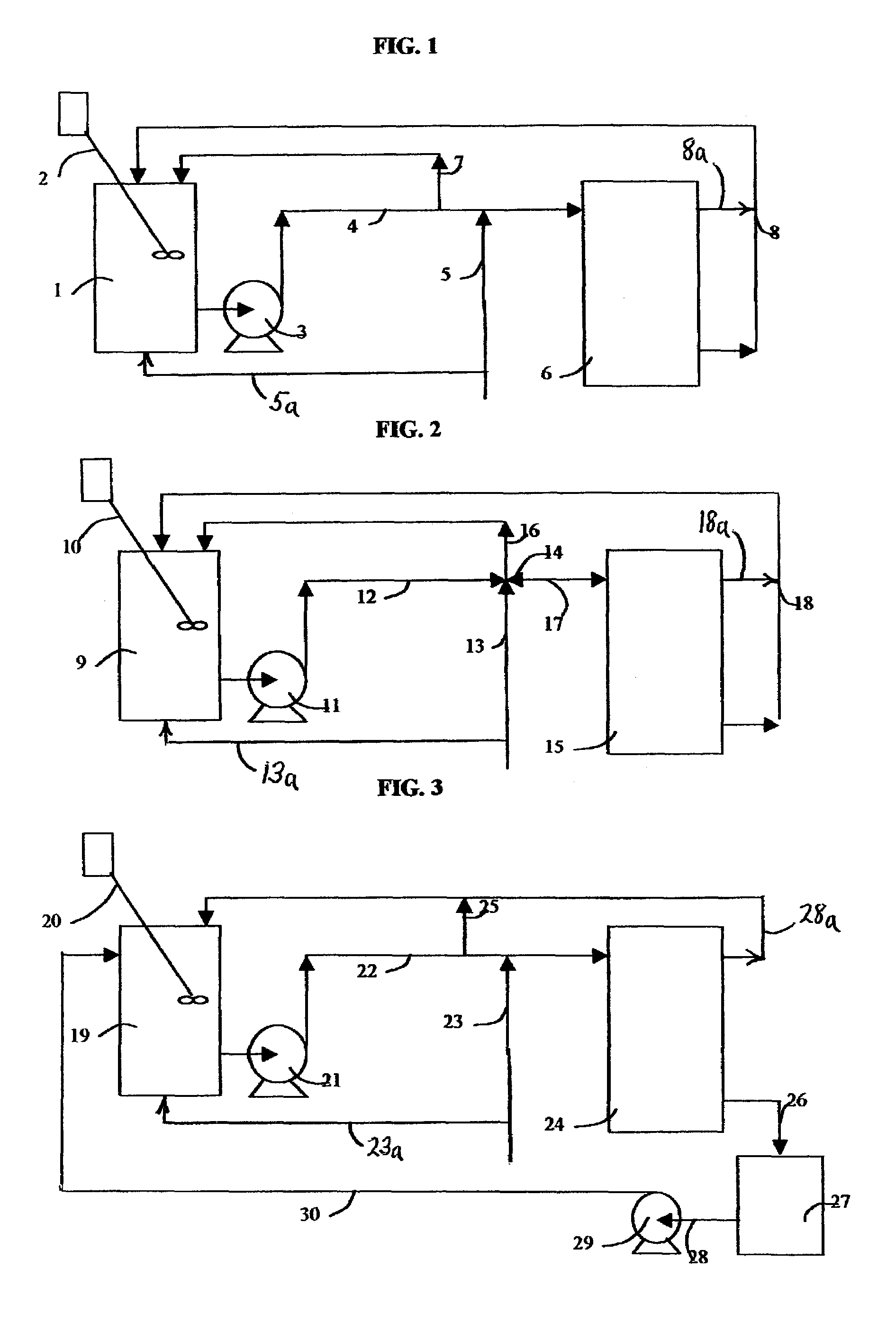

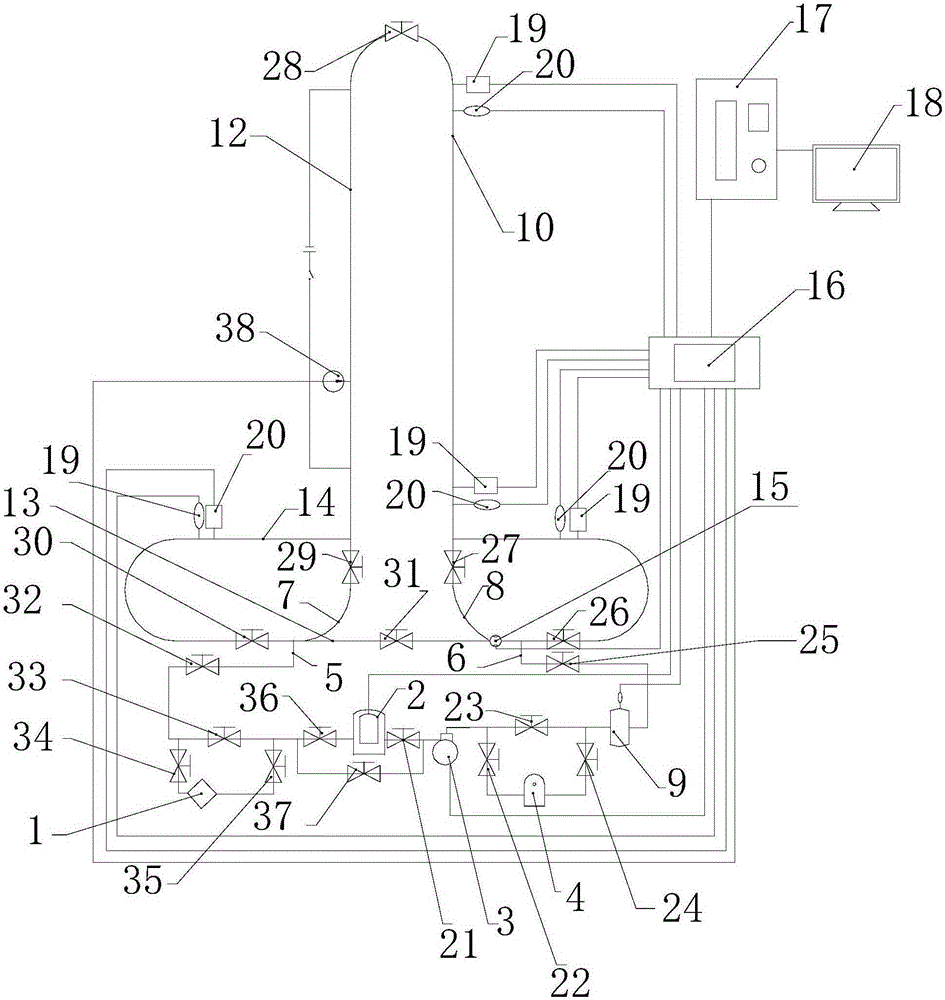

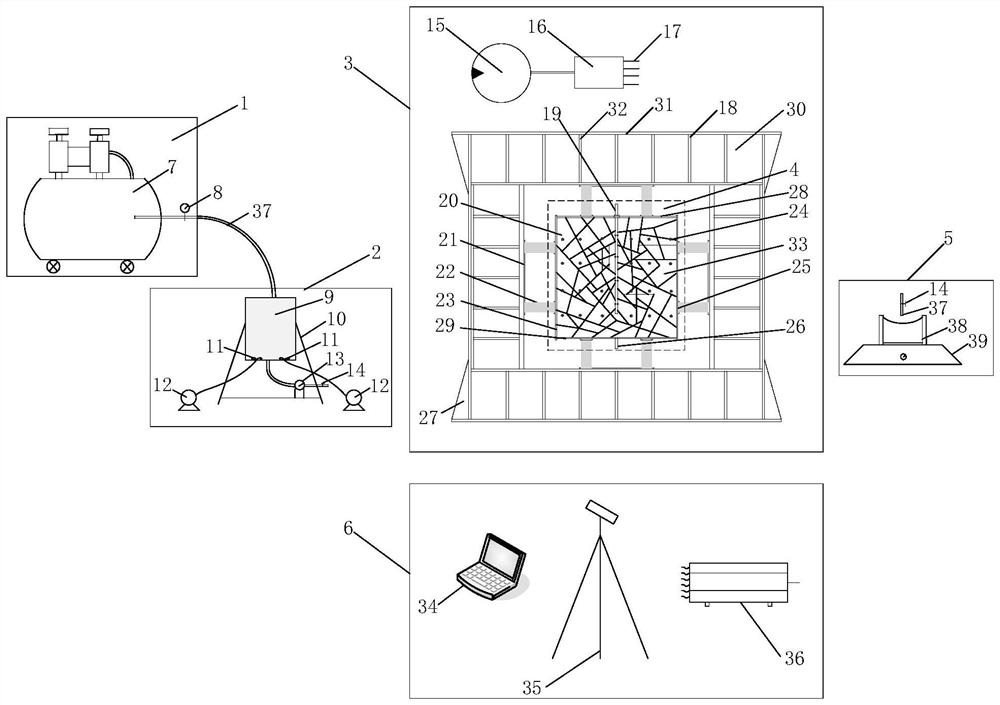

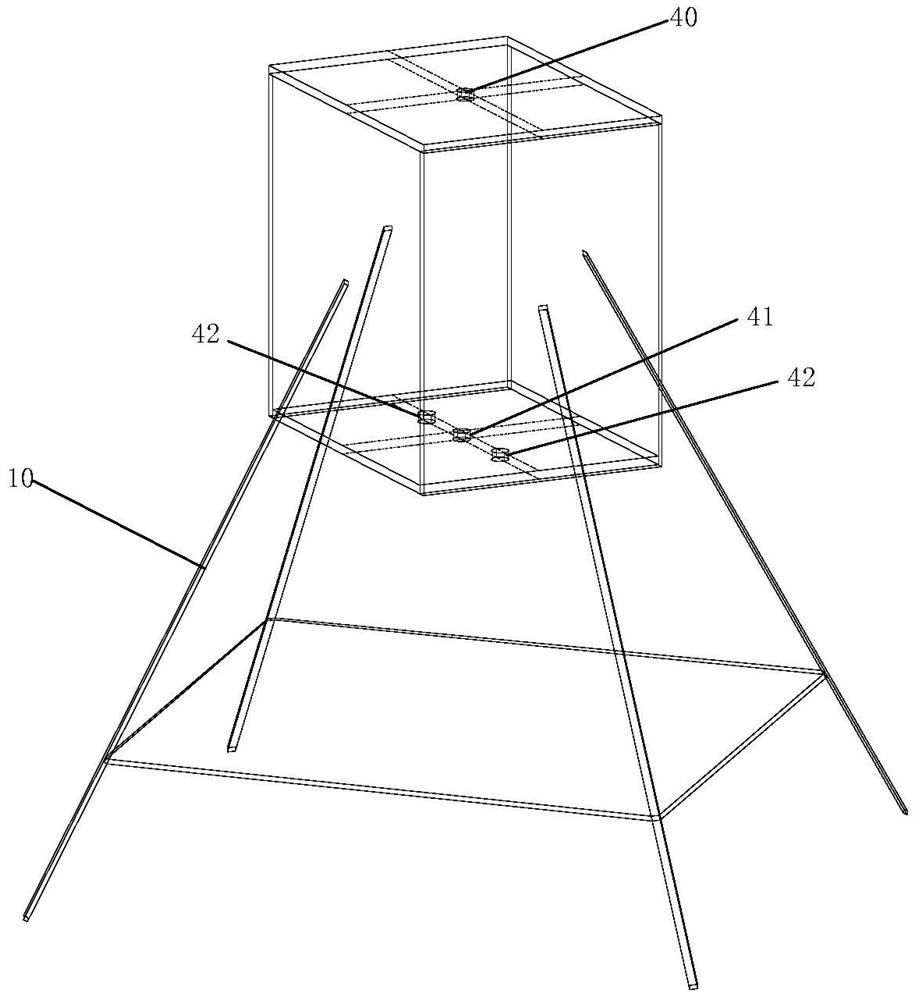

Experimental simulation device for solid-state fluidized exploiting of ocean natural gas hydrate

The invention discloses an experimental simulation device for solid-state fluidized exploiting of ocean natural gas hydrate and particularly provides the experimental simulation device for the solid-state fluidized exploiting of the ocean natural gas hydrate, which is applied to the field of ocean natural gas hydrate experiments. The experimental simulation device for the solid-state fluidized exploiting of the ocean natural gas hydrate, provided by the invention, can be used for simulating relations among a flowing pattern, a phase change, a decomposition speed and the like when hydrate slurry flows through conveying pipelines in a solid-state fluidized exploiting process, and a flowing speed, a temperature and pressure; and the experimental simulation device comprises a horizontal circulating reaction experiment pipeline, a vertical circulating reaction experiment pipeline and a hydrate preparation and treatment system. The pressure is adjusted for a plurality of times and voltage is adjusted for a plurality of times, and different seawater depths and seawater temperature conditions are simulated; and the relations among the flowing pattern, the phase change, the decomposition speed and the like when the hydrate slurry moves and flows in a vertical pipeline and a horizontal pipeline in the solid-state fluidized exploiting process, and the flowing speed, the temperature, the pressure and a crushing grain diameter of the hydrate are simulated.

Owner:SOUTHWEST PETROLEUM UNIV +2

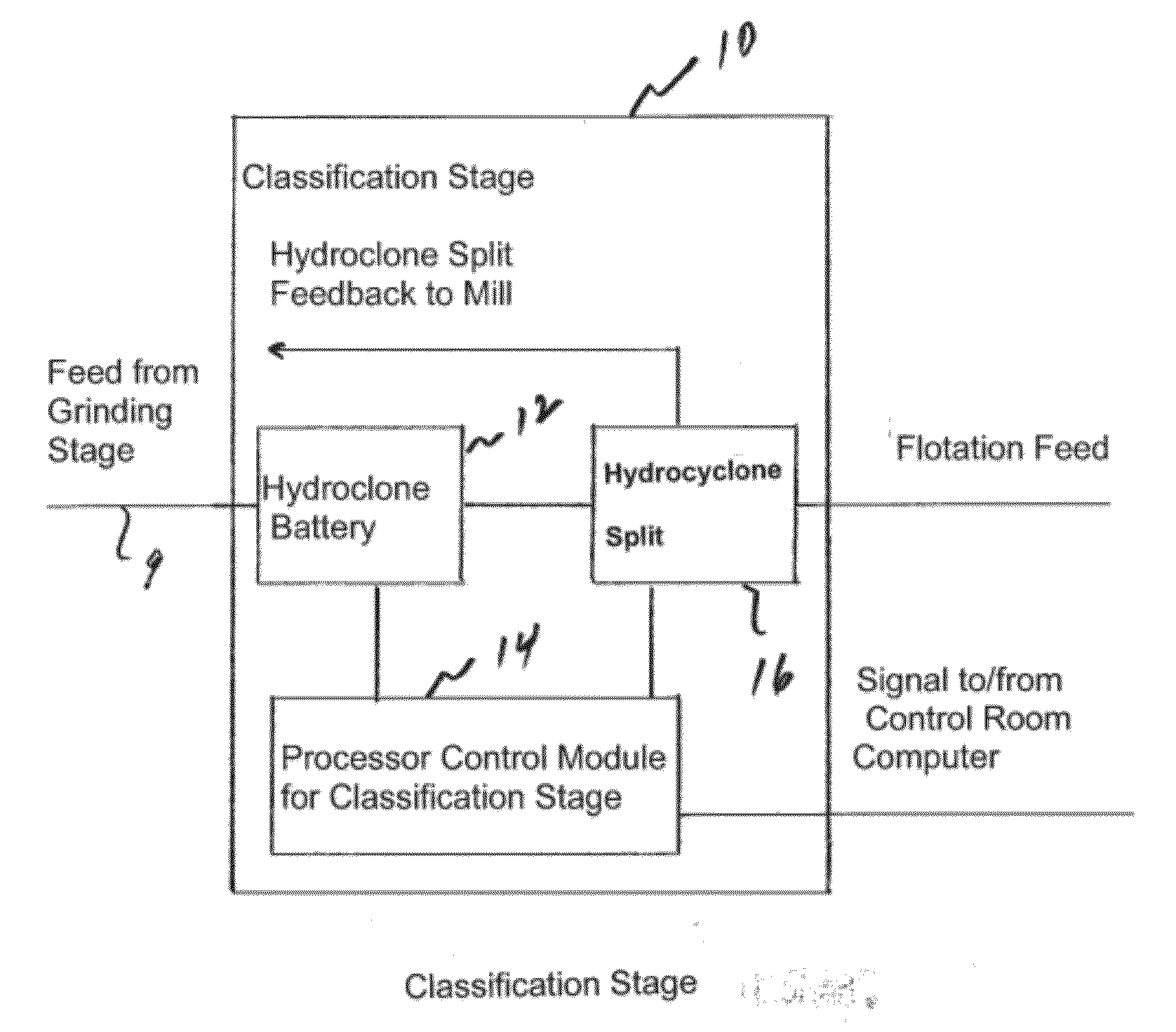

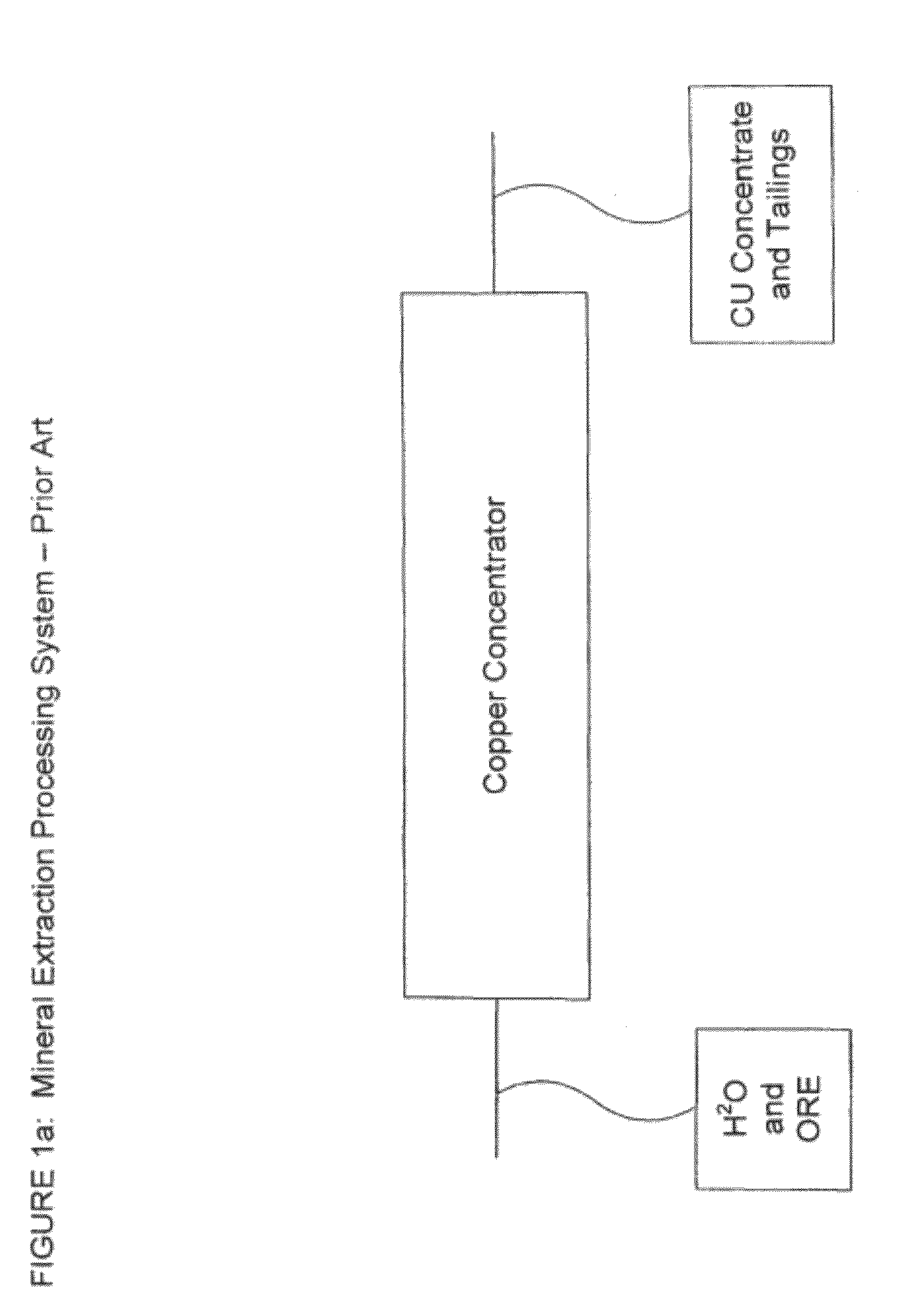

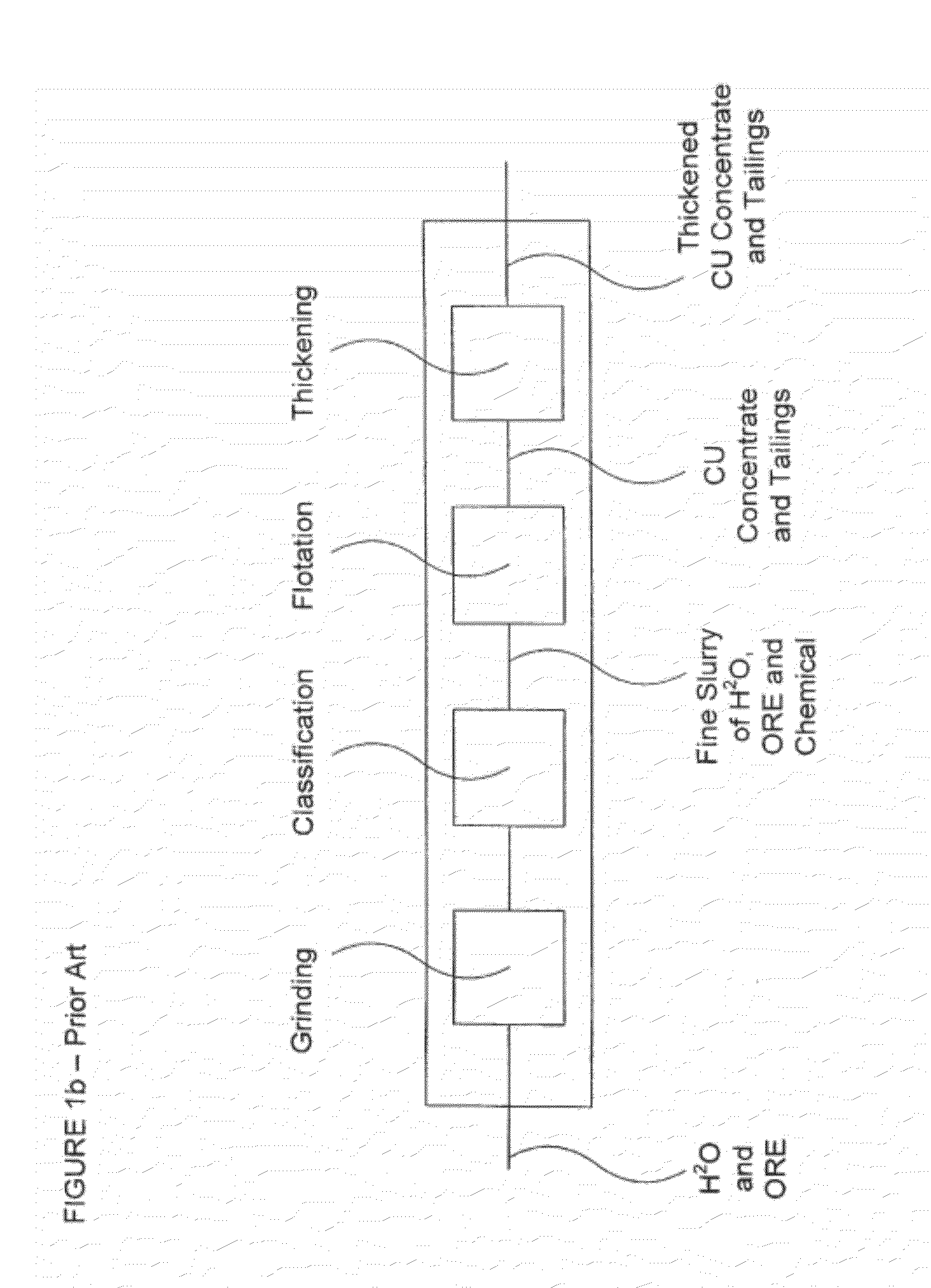

Performance monitoring of individual hydrocyclones using sonar- based slurry flow measurement

ActiveUS20120209550A1High mineral recovery rateReduce energy consumptionMachine part testingReversed direction vortexCycloneEngineering

Apparatus, including a signal processor, featuring at least one module configured to respond to signals containing information about sound propagating through a slurry flowing in part, including overflow pipes, of cyclones operating in parallel on a cyclone battery, and determine the performance of individual cyclones based at least partly on the information contained in the signals. The signal process may form part of a non-invasive acoustic-based passive monitoring system, comprising: cyclones and sensors; where the cyclones are configured in parallel to form a cyclone battery in order to process a slurry, each cyclone having an overflow pipe for providing some portion of the slurry flowing in the cyclone battery, where each sensor is configured to mount on a respective overflow pipe of a respective cyclone, to respond to sound propagating through the slurry flowing in the respective overflow pipe of the respective cyclone, and to provide a respective signal containing information about the sound propagating through the slurry flowing in the respective overflow pipe of the respective cyclone; and where the signal processor is configured to respond to respective signals from the sensors and determine the performance of individual cyclones based at least partly on the information contained in the respective signals.

Owner:CIDRA CORP SERVICES

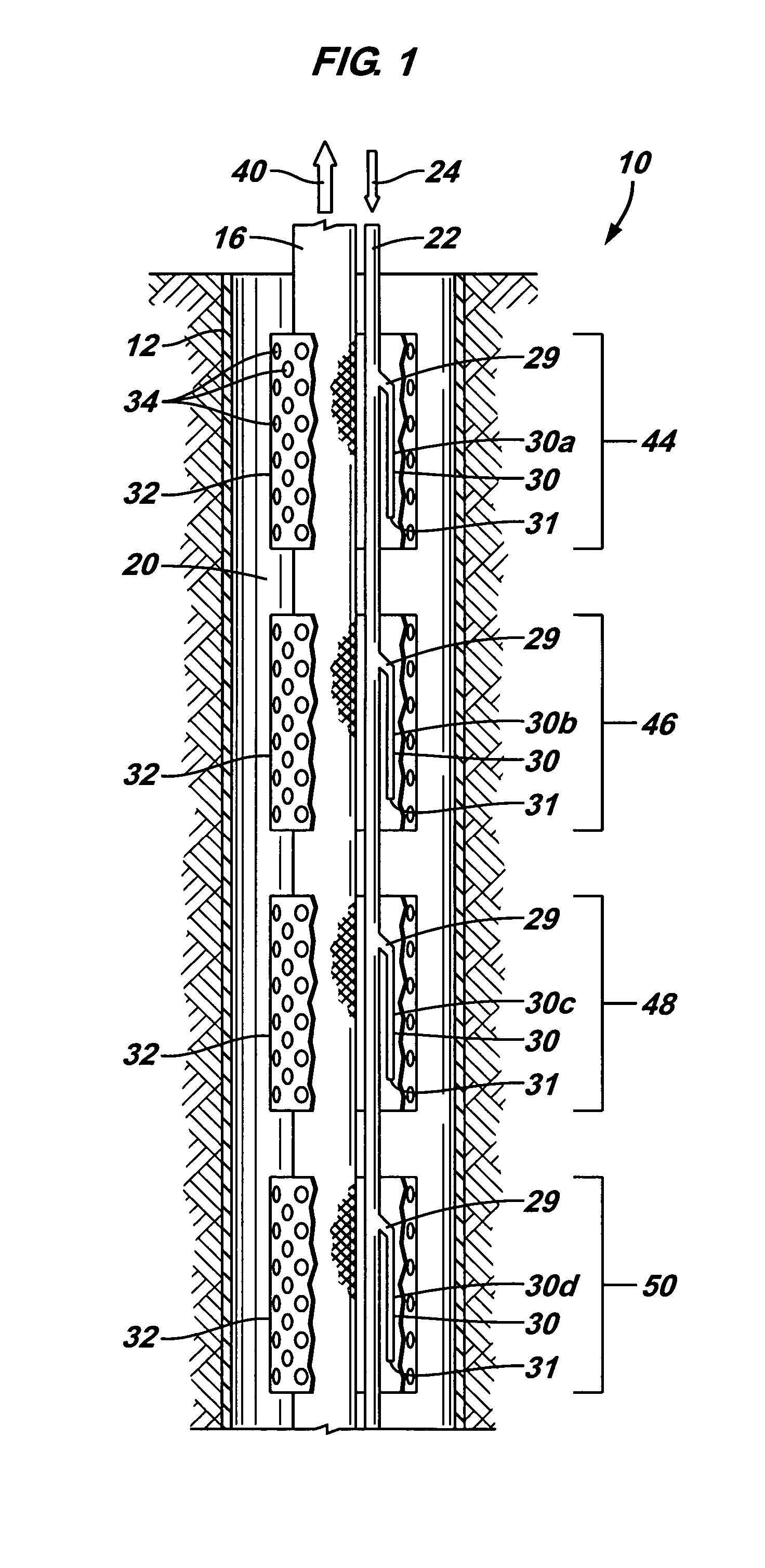

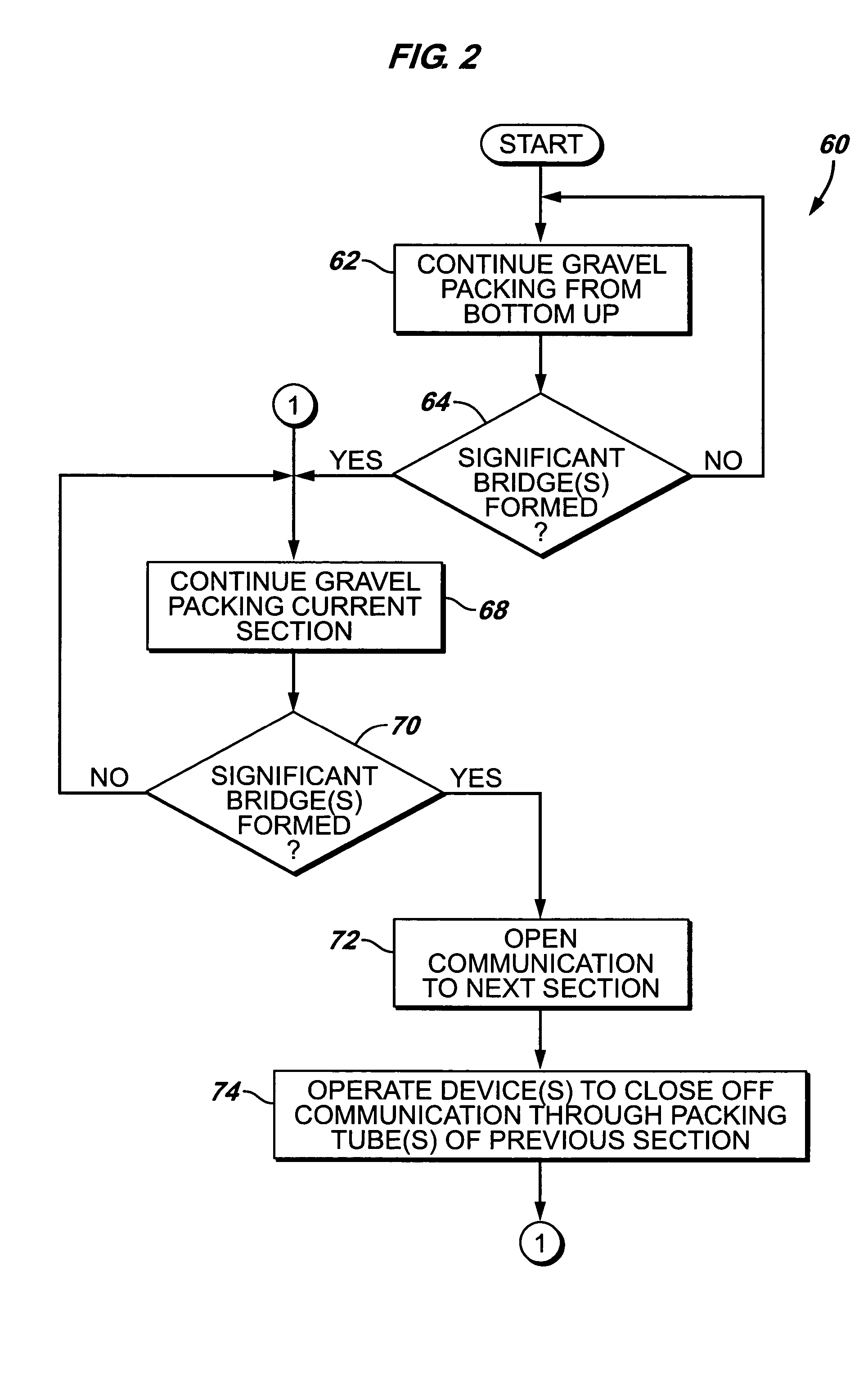

Gravel packing a well

A technique that is usable with a subterranean well includes communicating a slurry through a shunt flow path and operating a control device to isolate slurry from being communicated to an ancillary flow path. The system may include a shunt tube and a diverter. The shunt tube is adapted to communicate a slurry flow within the well to form a gravel pack. The diverter is located in a passageway of the shunt tube to divert at least part of the flow. A slurry may be communicated through the shunt flow path, and a control device may be operated to isolate the slurry from being communicated to the ancillary flow path.

Owner:SCHLUMBERGER TECH CORP

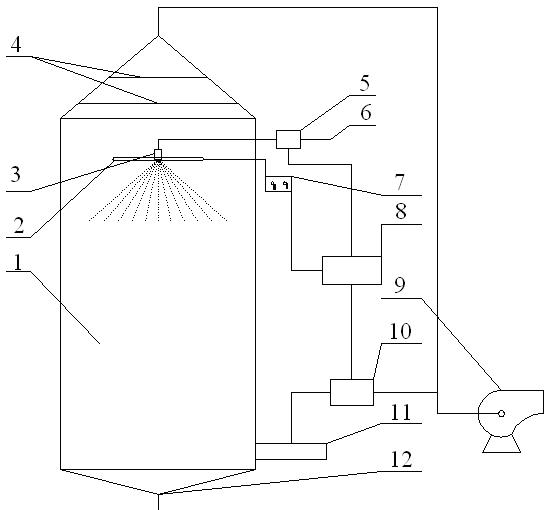

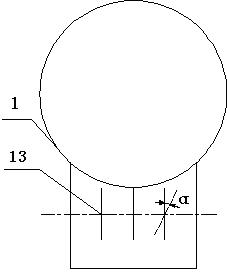

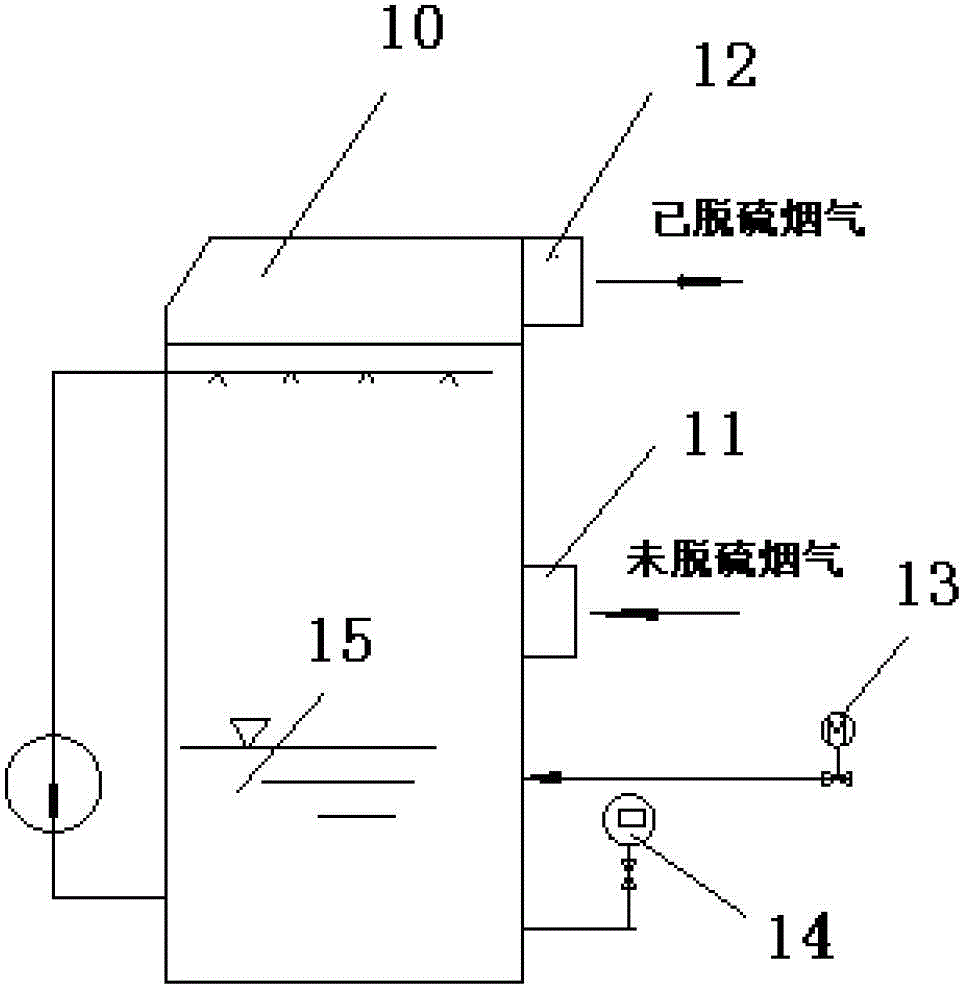

Swirling inlet type electrostatic spraying wet flue gas desulphurization dedusting apparatus

InactiveCN102198369ASmall particle sizeImprove desulfurization and dust removal effectElectrostatic separationDispersed particle separationControl signalEngineering

The invention relates to a swirling inlet type electrostatic spraying wet flue gas desulphurization dedusting apparatus for the purpose of purifying exhaust gas, comprising a spray reaction tower, an electrostatic spraying device, a demister, a flow controller, a control signal sensor, an induced draught fan, an exhaust gas inlet and a waste material inlet. In the invention, the method of electrostatic spraying, in which annular electrodes and acicular electrodes are combined to carry out induction charging and corona charging, further refines droplets of a slurry and enables high pressure polarization of charged and non-charged droplets, thereby generating an additional driving force of mass transfer; air enters through swirling inlets, thereby increasing the contact time between flue gas and droplets; a concentration on-line monitoring device is employed to automatically adjust static voltage and slurry flow and to guarantee that desulphurization efficiency is maintained in a certain scope, thereby meeting discharge standard as well as enhancing economic benefits. The flue gas desulphurization dedusting apparatus provided in the invention has high efficiency, a reduced liquid-gas ratio, low operation cost and a moderate price, and is ideal environmental protection equipment.

Owner:JIANGSU UNIV

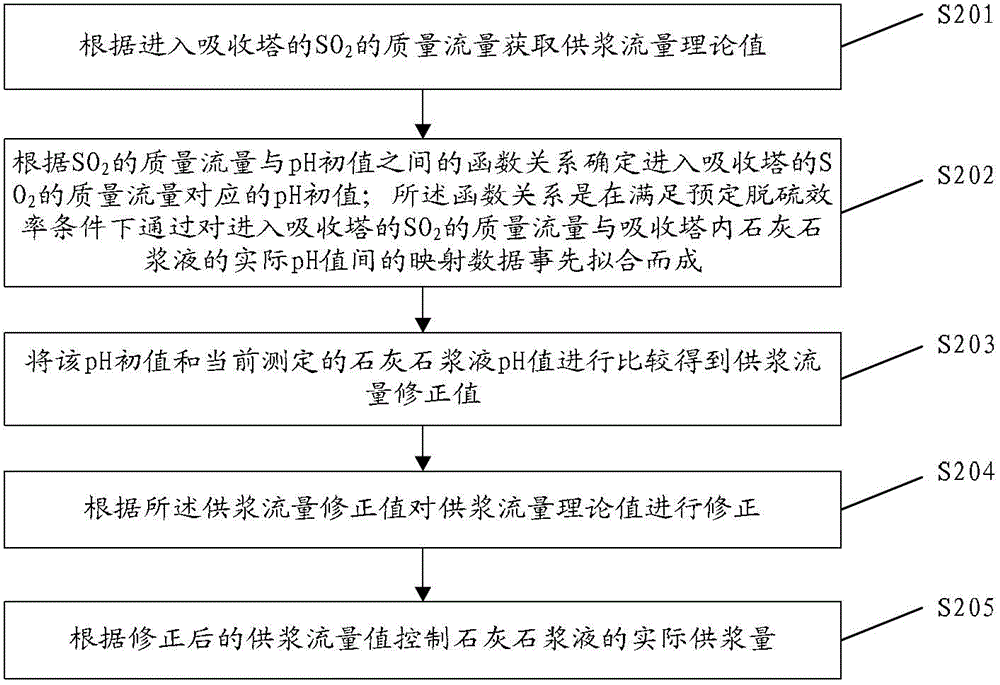

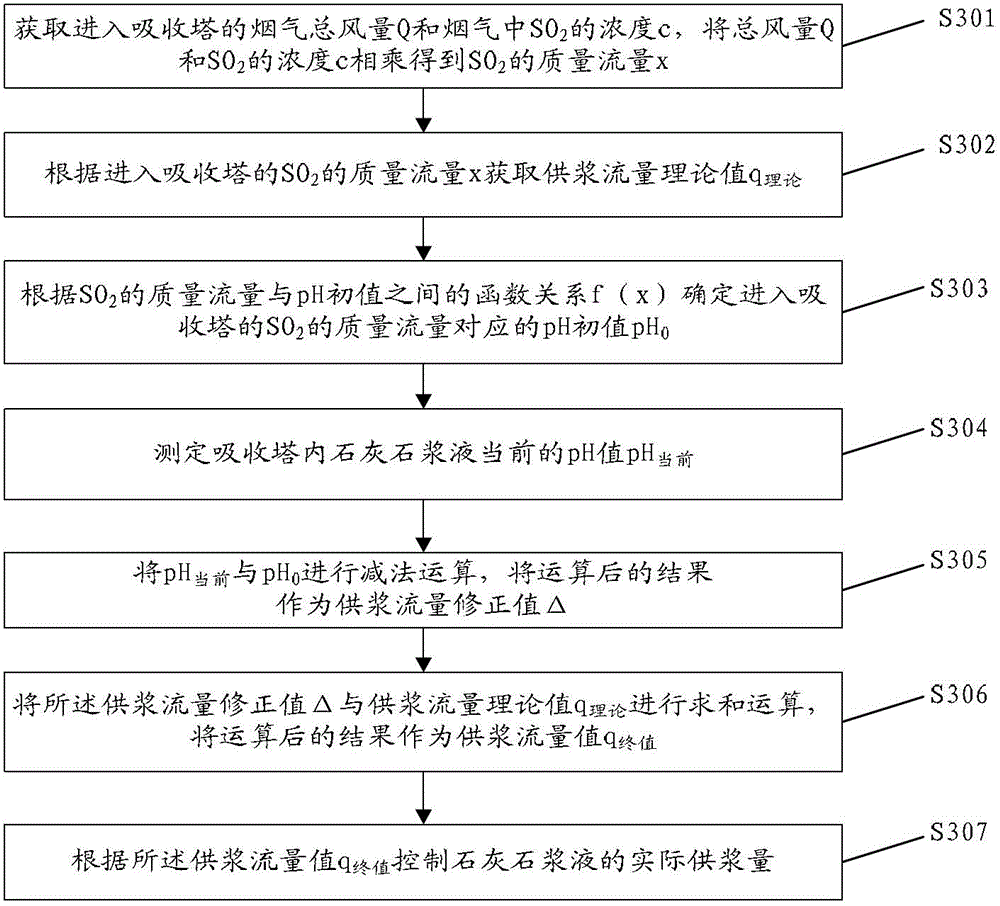

Ph value control method limestone slurry in desulfurization system

InactiveCN102743971AFully automatedImprove accuracyDispersed particle separationProcess engineeringTower

An embodiment of the invention discloses a pH value control method of limestone slurry in a desulfurization system. The method includes acquiring supply slurry flow theory value according to mass flow of SO2 entering an absorption tower, determining pH primary value that the mass flow of the SO2 entering the absorption tower corresponds to according to function relation between the mass flow of the SO2 and the pH primary value, comparing the pH primary value and measured current pH value of limestone slurry to obtain supply slurry flow modification value, modifying the supply slurry flow theory value according to the supply slurry flow medication value and controlling actual supply slurry flow of limestone slurry according to modified supply slurry flow value. The function relation is formed by matching mapping data between the mass flow of the SO2 entering the absorption tower and the actual pH value of the limestone slurry in the absorption tower in advance under the condition that the preset desulfurization efficiency requirements are met. The pH value control method achieves complete automation of pH value control.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Fractured rock mass grouting simulation visual test system and test method considering stress effect

Owner:INST OF DEFENSE ENG ACADEMY OF MILITARY SCI PLA CHINA +1

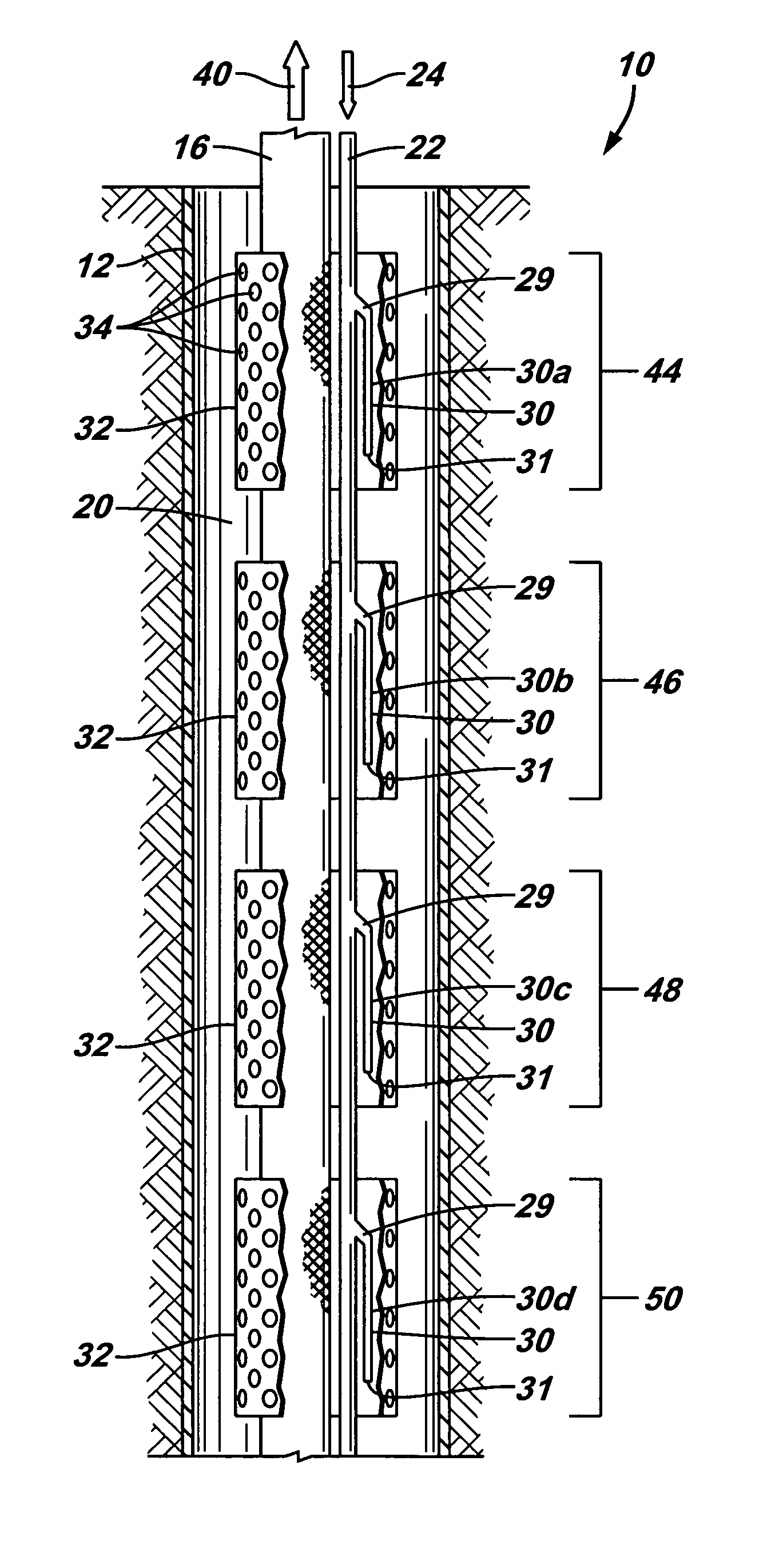

Multiple port cross-over design for frac-pack erosion mitigation

ActiveUS20060191685A1Improved Radial DistributionReduce erosionFluid removalFlushingAxial displacementEngineering

A system for use in gravel packing operations wherein a gravel placement mandrel defines an axial flowbore and two or more lateral slurry flow ports for communication of slurry from the flowbore to the interior of the wear sleeve / blast liner. The slurry flow ports are oriented so as to distribute the slurry in different outwardly radial directions. The slurry flow ports are also axially displaced from one another along the gravel placement mandrel body. Relatively equivalent flow rates or flow amounts are provided through each of the slurry flow ports. Improvements are also provided in the geometry of the slurry flow ports to enhance the flow of slurry through them.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com