Patents

Literature

223results about How to "Emission safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

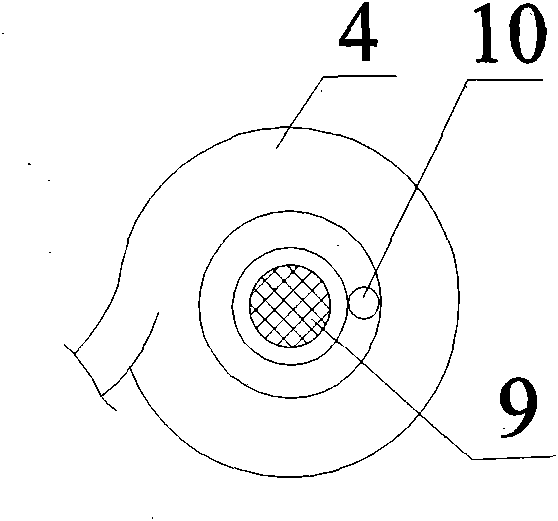

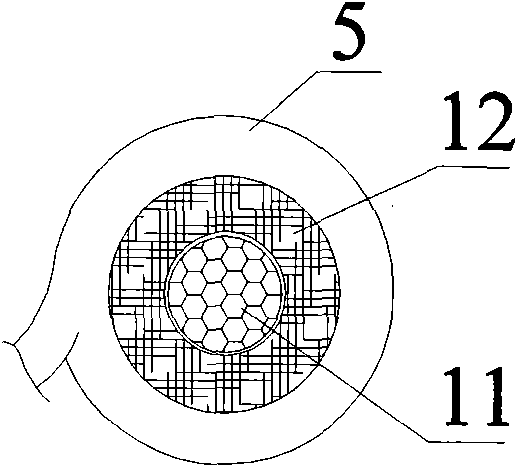

Same floor draining joint for building

InactiveCN102839724AIncrease drainage flowTo achieve the separation effectDomestic plumbingToiletCivil engineering

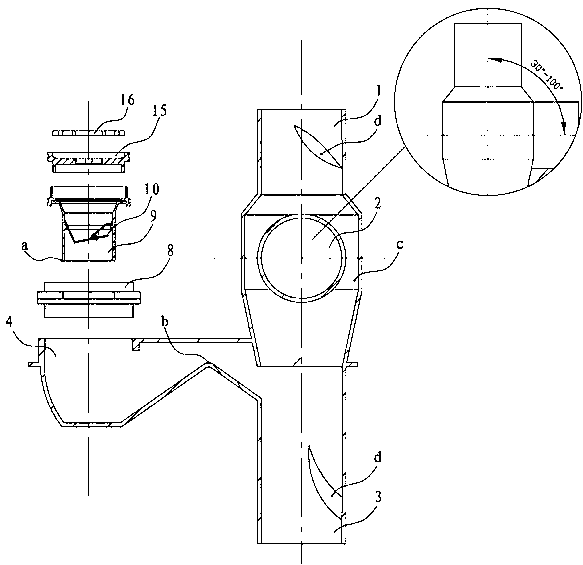

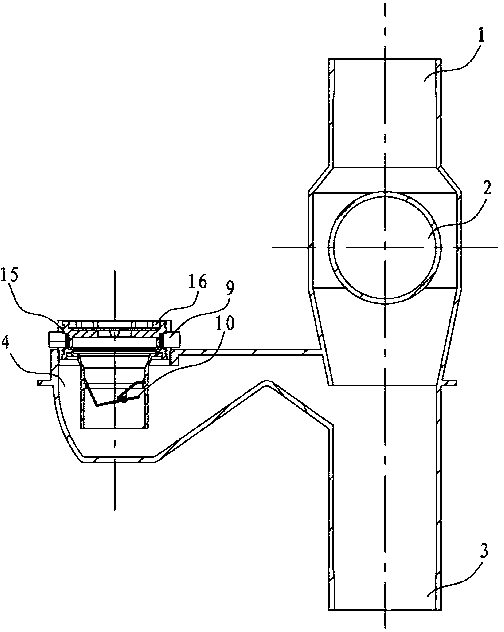

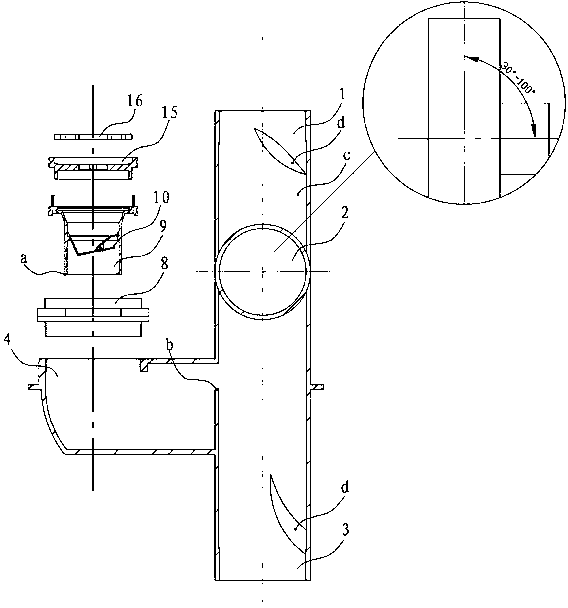

The invention relates to a same floor draining joint for a building, in particular to a same floor draining joint for a toilet, which consists of an upper vertical pipe draining port, a lower vertical pipe draining port and at least two transverse pipe draining ports; the upper vertical pipe draining port is communicated with the upper end and the lower end of the lower vertical pipe draining port; the at least two transverse pipe draining ports are staggered in position and are arranged between the upper vertical pipe draining port and the lower vertical pipe draining port; the orientation of the inlet of at least one of the transverse pipe draining ports is equal to or nearly equal to the orientation of the upper vertical pipe draining port, and the orientation of the inlet of at least one of the transverse pipe draining ports forms an included angle of 30-100 degrees with the orientation of the upper vertical pipe draining port. The same floor draining joint is rational and scientific in structure, and is capable of realizing the same floor draining and the same floor maintenance when the draining joint is adopted in the same floor draining of the non-falling plate or falling plate; the draining is more safe; the water is not easy to accumulate in the falling plate layer even the way of the falling plate is adopted, and the accumulated water is safely and completely discharged, so as to avoid the foreign smell in the room.

Owner:KUNMING QUNZHIYING TECH

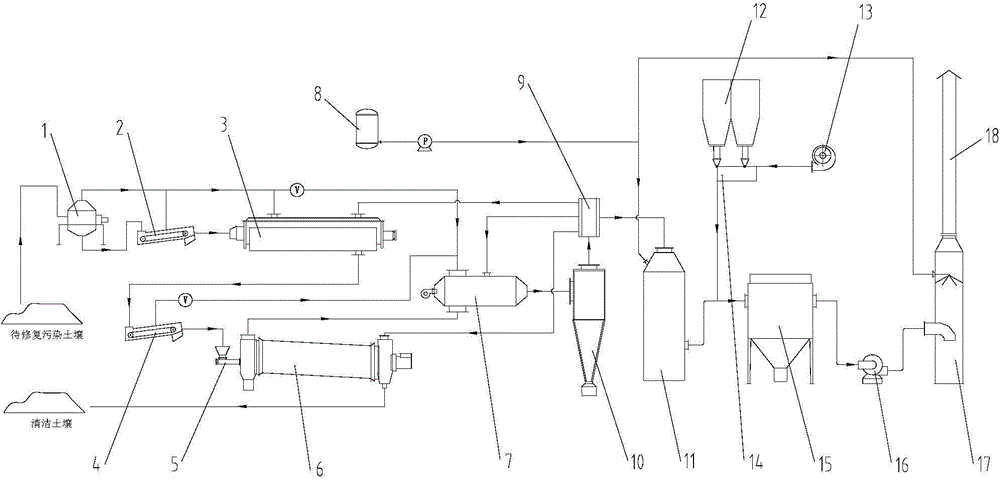

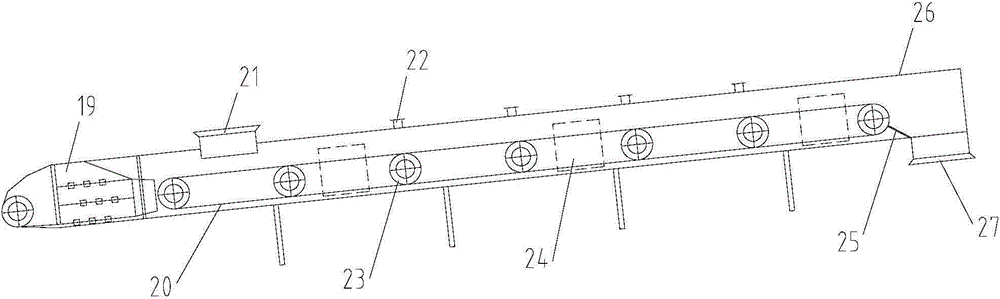

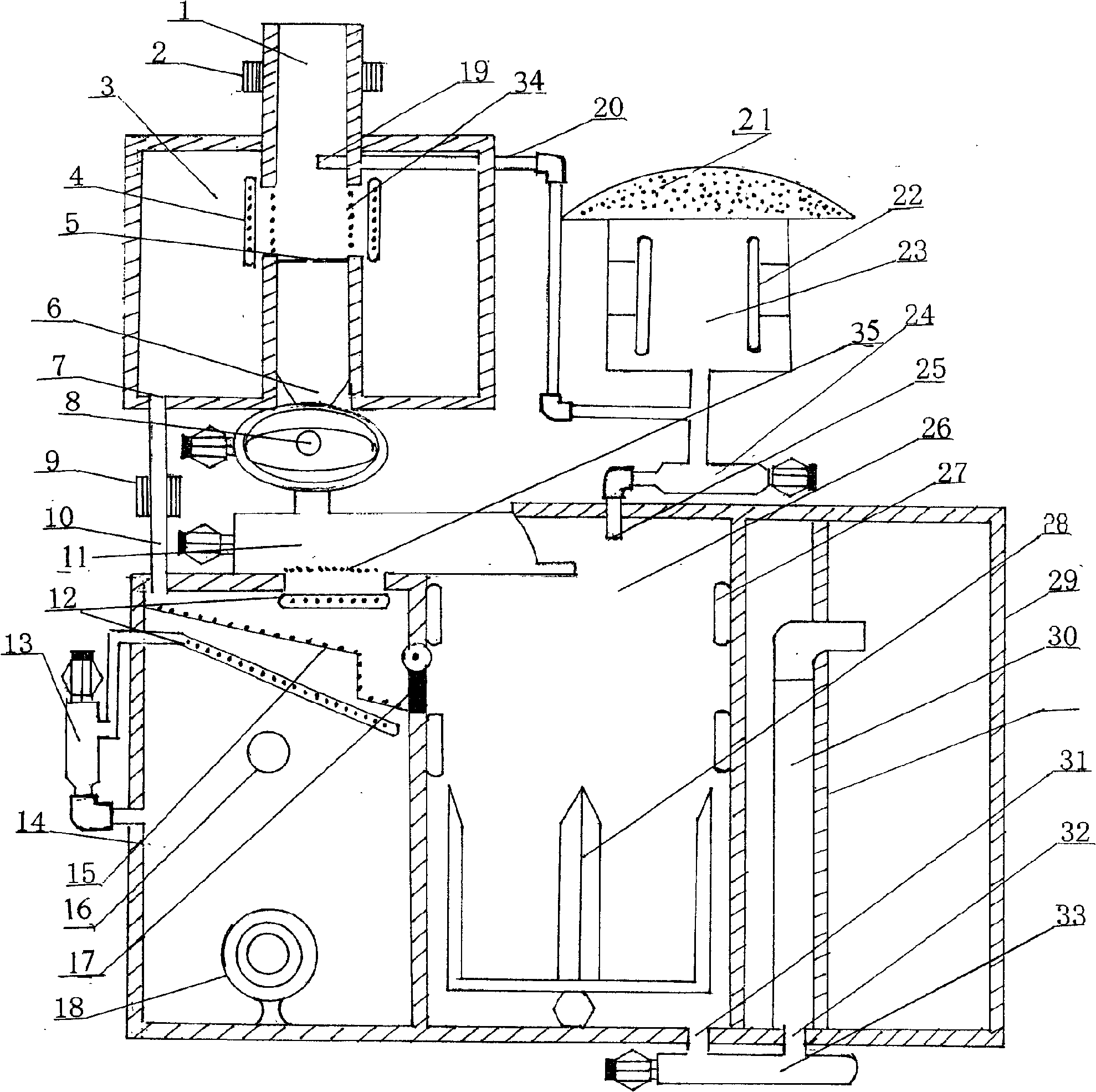

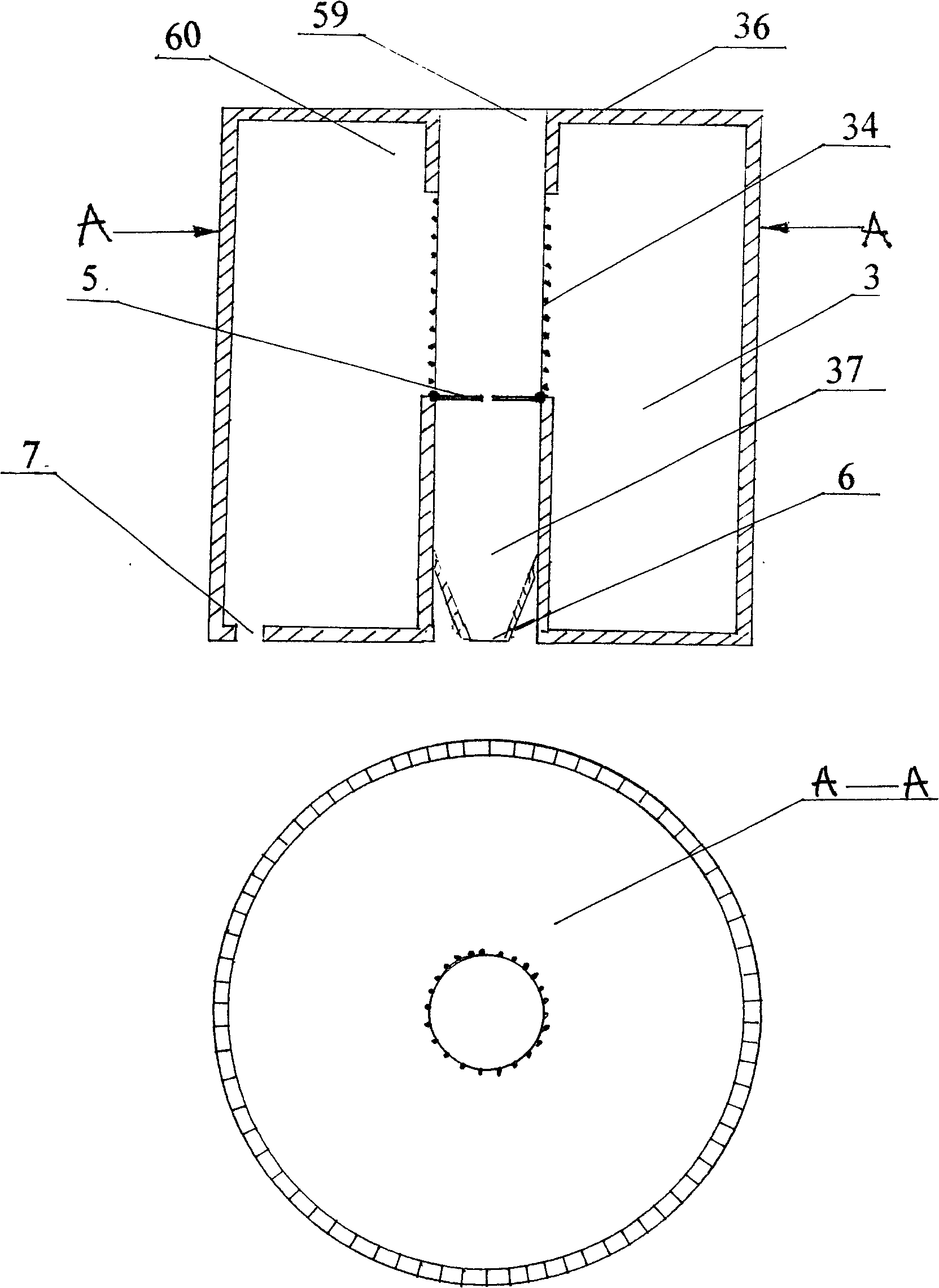

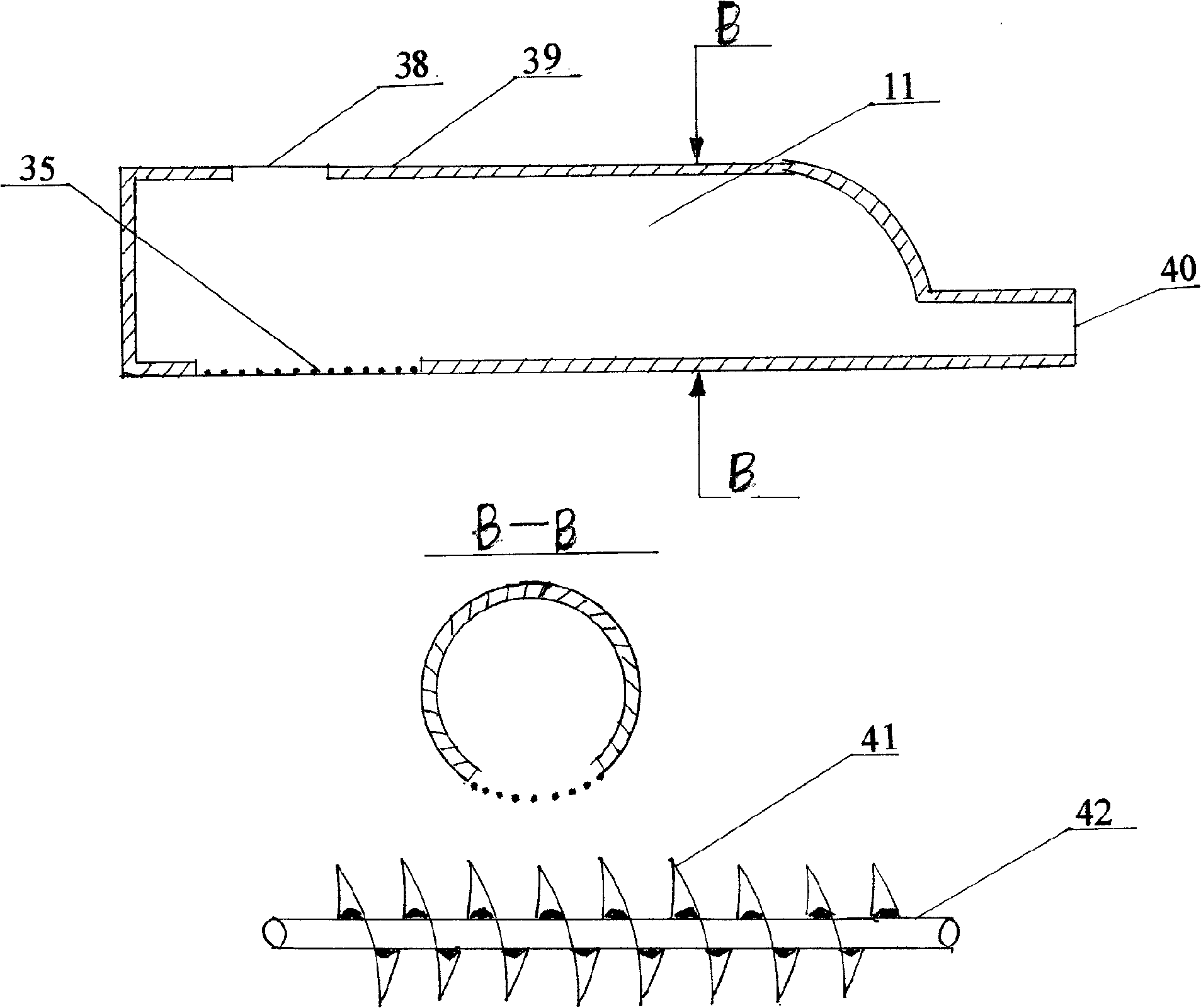

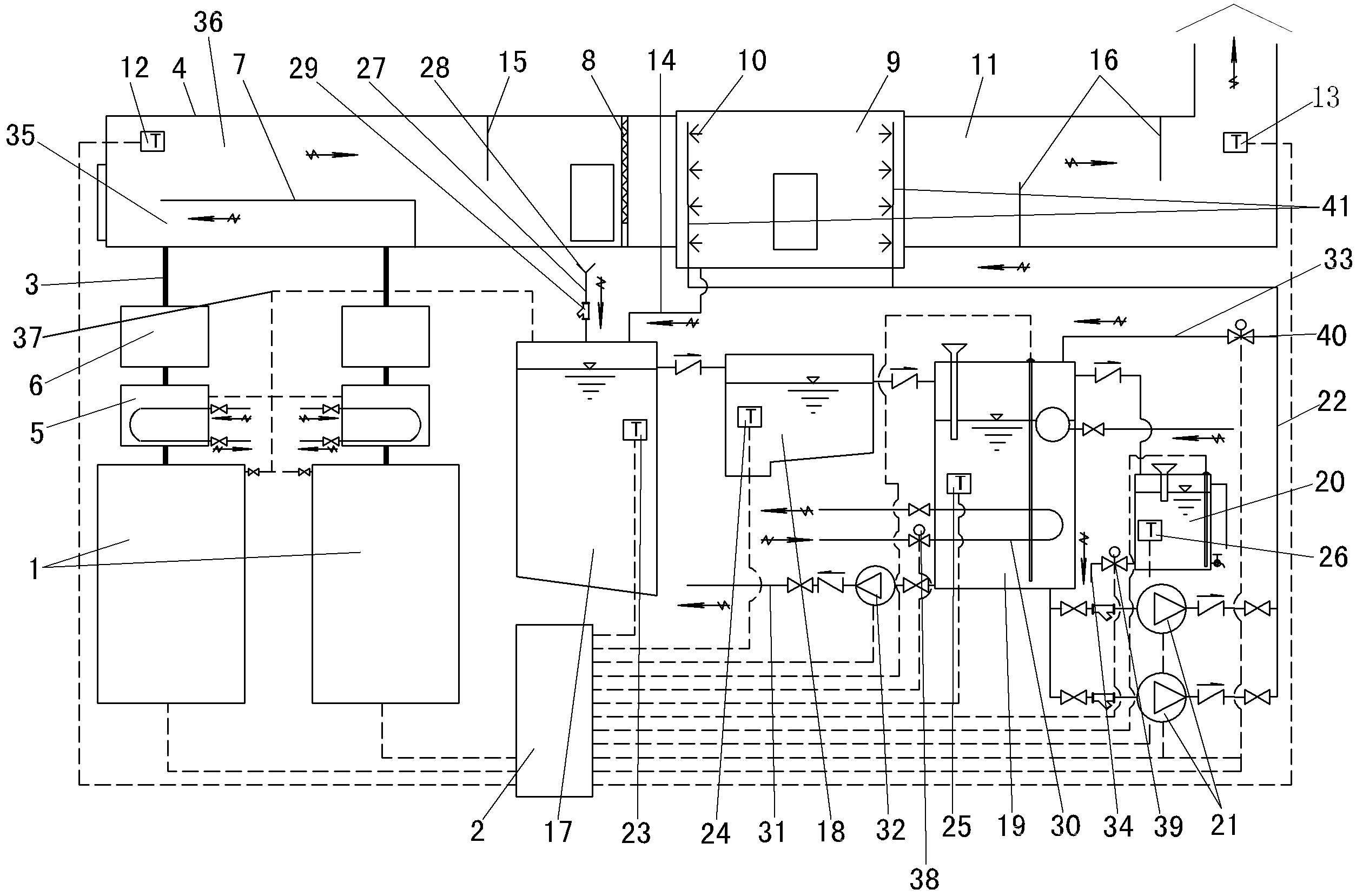

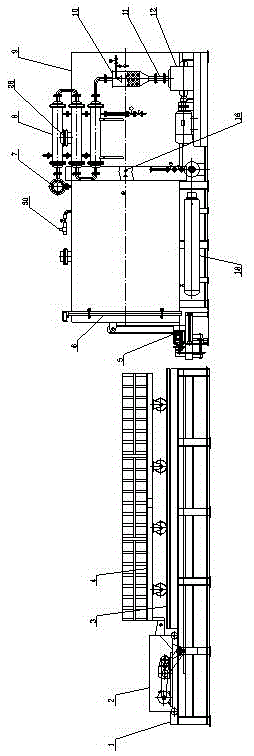

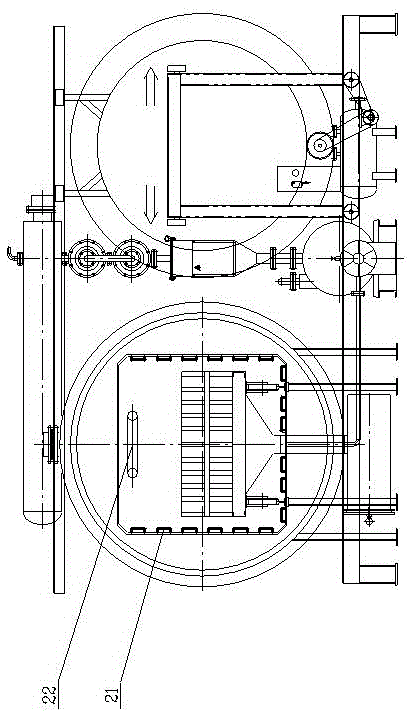

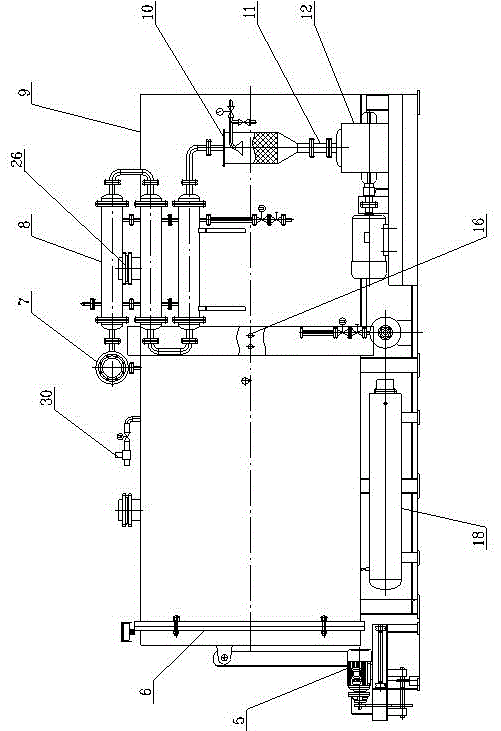

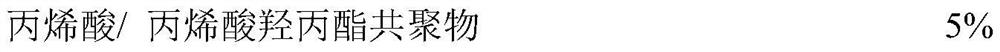

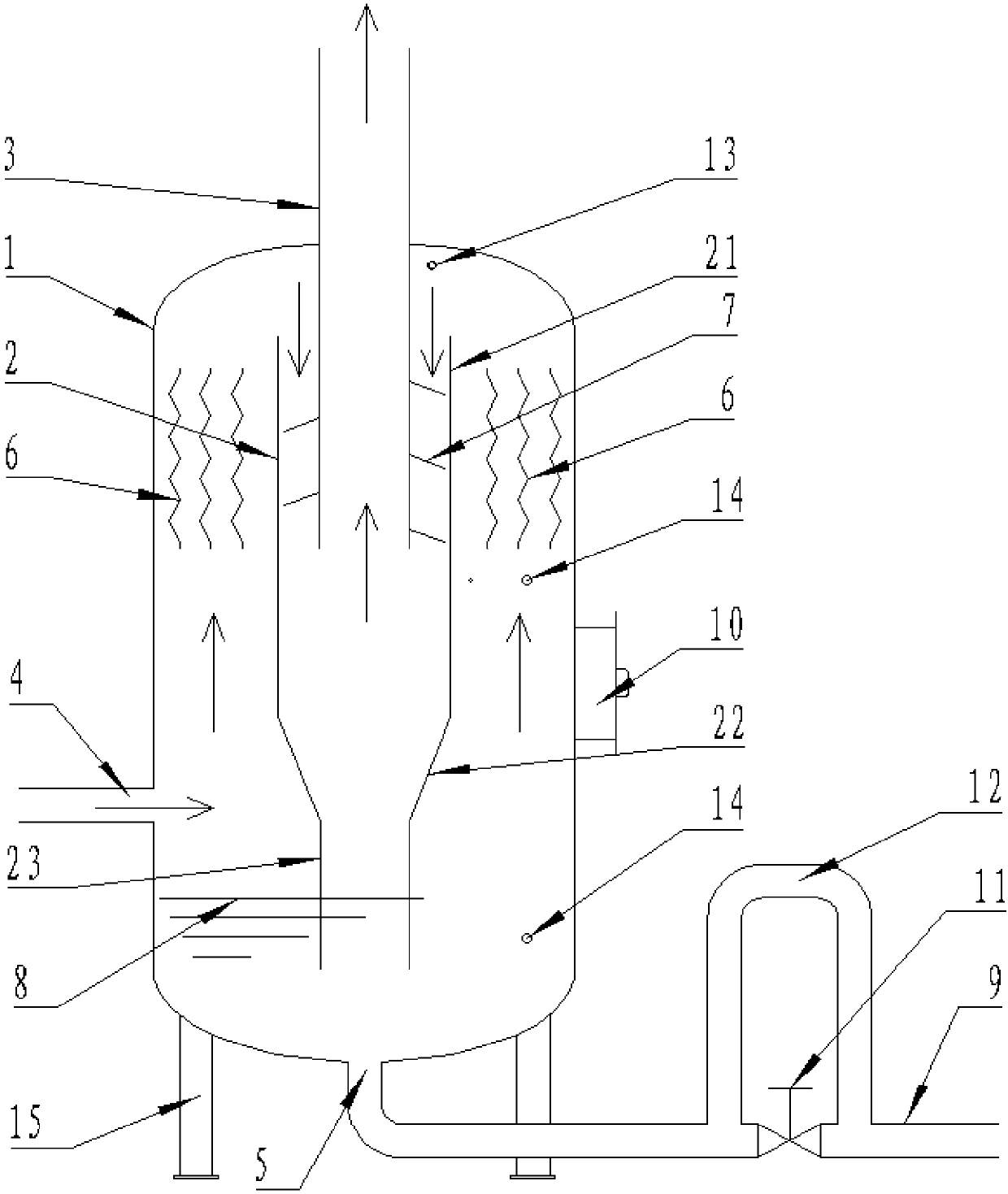

Thermal treatment restoration method and system for contaminated soil

ActiveCN104607454AReduced Diffusion EntryEmission safetyContaminated soil reclamationIncinerator apparatusCombustion chamberRestoration method

The invention discloses a thermal treatment restoration method and system for contaminated soil. The thermal treatment restoration method for the contaminated soil comprises the following steps: crushing, conveying, burning, thermally desorbing, recovering heat energy, neutralizing with acidic materials, and dedusting. The system for executing the method comprises a soil crusher, a first carrier roller belt conveyor with a sealed cabin, a paddle dryer, a second carrier roller belt conveyor with the sealed cabin, and a rotary kiln thermal desorption unit, wherein pipes are arranged at all of the soil crusher, the first carrier roller belt conveyor, the paddle dryer, the second carrier roller belt conveyor and the rotary kiln thermal desorption unit and communicated with a secondary combustor. According to the thermal treatment restoration method and the thermal treatment restoration system disclosed by the invention, the organic matters, diffusing into the atmosphere, in the soil can be reduced; the organic matters can be completely transformed into water, carbon dioxide and other non-toxic innocuous substances, and then safely discharged through exhaust gas treatment; the heat energy in the system can be reutilized, so that the system energy consumption can be further reduced, and the economic efficiency is good; the treated soil can be recycled.

Owner:苏州同和环保工程有限公司

Environmental sanitation treating apparatus for fast decomposing, sterilizing and drying solid-liquid feculence dejection

InactiveCN101265004AKill eggs quicklyImprove sterilizationMaintainance for emmission reductionSludge treatmentHuman bodyDecomposition

The invention relates to a device for rapid decomposition, sterilization, drying and sanitary treatment of solid / liquid feces, aiming to solve the problems of human feces including environmental pollution, disease transmission and body health damage. The device comprises a solid-liquid separator, a semi-solid finishing machine, a secondary solid-liquid separation spiral pump, a urine treatment tank, a microwave sterilization drying chamber, a dry matter storage tank, and a deodorizing aeration tower. The feces can be rapidly sterilized, deodorized and dried after leaving human body, so as to become sterile and odorless dried particles in a short time, which can be used as fertilizer. The inventive device prevents transmission of pathogenic bacteria from source and solves fecal pollution problem. The inventive device has the advantages of low volume, light weight, and low energy consumption; and can be used in any places. Except fixed places, the device is more suitable for being installed and used in personal vehicles such as passenger train, passenger long-distance bus and passenger ship.

Owner:齐梓凡

Neutral calcium sulfate scale cleaning agent

InactiveCN101955863AEmission safetyNo hydrogen embrittlementScale removal and water softeningOrganic non-surface-active detergent compositionsCleansing AgentsFatty alcohol

The invention relates to a chemical cleaning agent, in particular to a special chemical cleaning agent for cleaning calcium sulfate (CaSO4) scale. The invention provides a novel cleaning agent and a scheme for cleaning the calcium sulfate scale, in the actual application, the novel cleaning agent can effectively clean the calcium sulfate scale in both working and stopping sates of boilers or industrial circulated cooling water system. The novel cleaning agent is prepared from the following raw material reagents in parts by weight: 10% of HEDP (Hydroxyl Ethidene Diphosphoric Acid), 0.05% of JFC (fatty alcohol-polyoxyethylene ether), 5% of cosolvents and 0.06% of nonionic PAM (polyacrylamide), and the pH value is regulated to 7 by using caustic soda. The reagent is a special cleaning agent for the calcium sulfate scale, mainly comprising a high-polymer organic polymer containing multi-functional groups, such as carboxyl, hydroxyl, amide and the like, and is specially used for cleaning indissolvable calcium sulfate scale, and the pH value of the reagent is 7. The cleaning agent is a neutral solution and has the advantages of thoroughly scale cleanness, no corrosion on metal, enamel and glass, no toxicity to human bodies, safe emission of waste liquid, high efficiency and safety without generating the phenomenon of hydrogen brittleness.

Owner:金保全

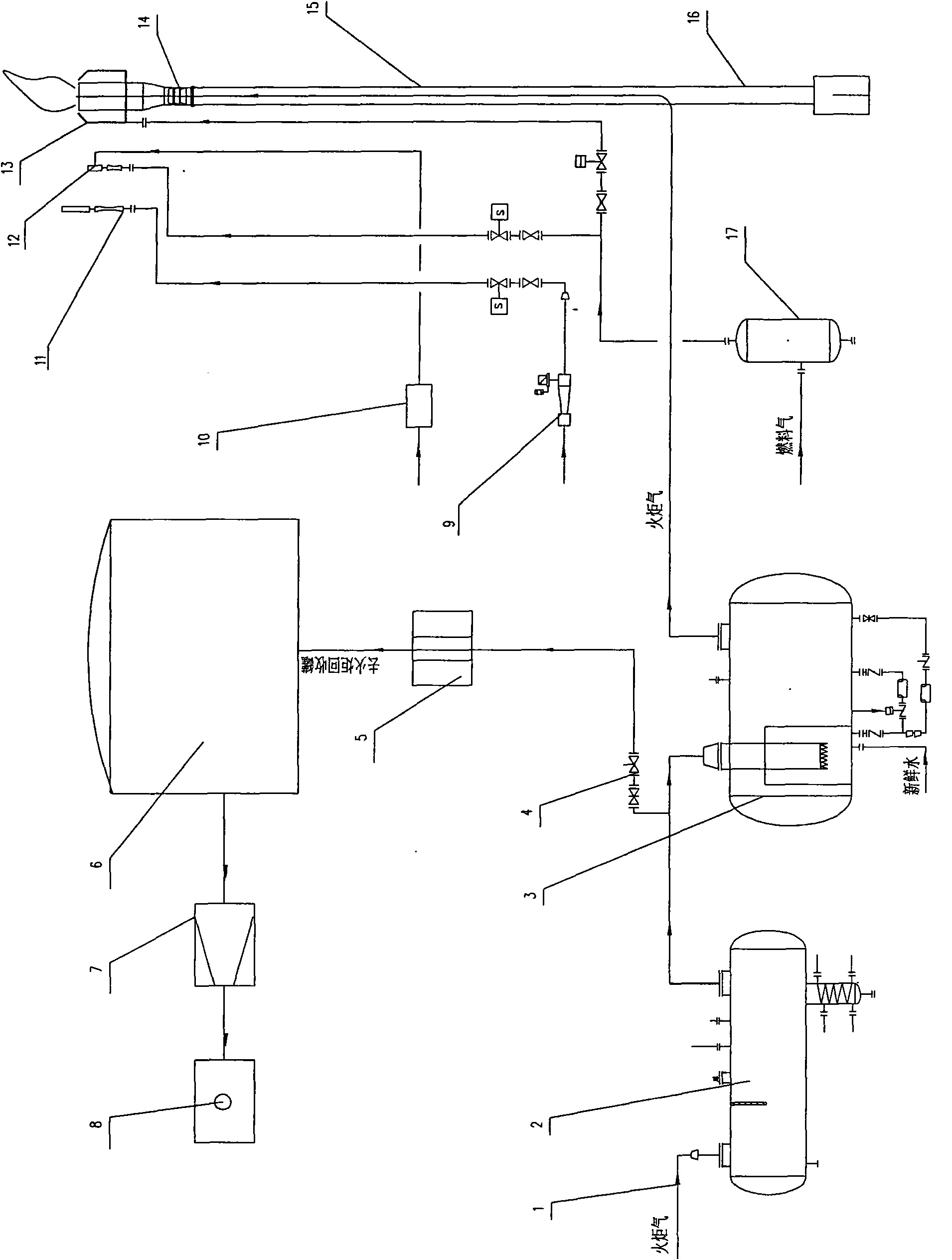

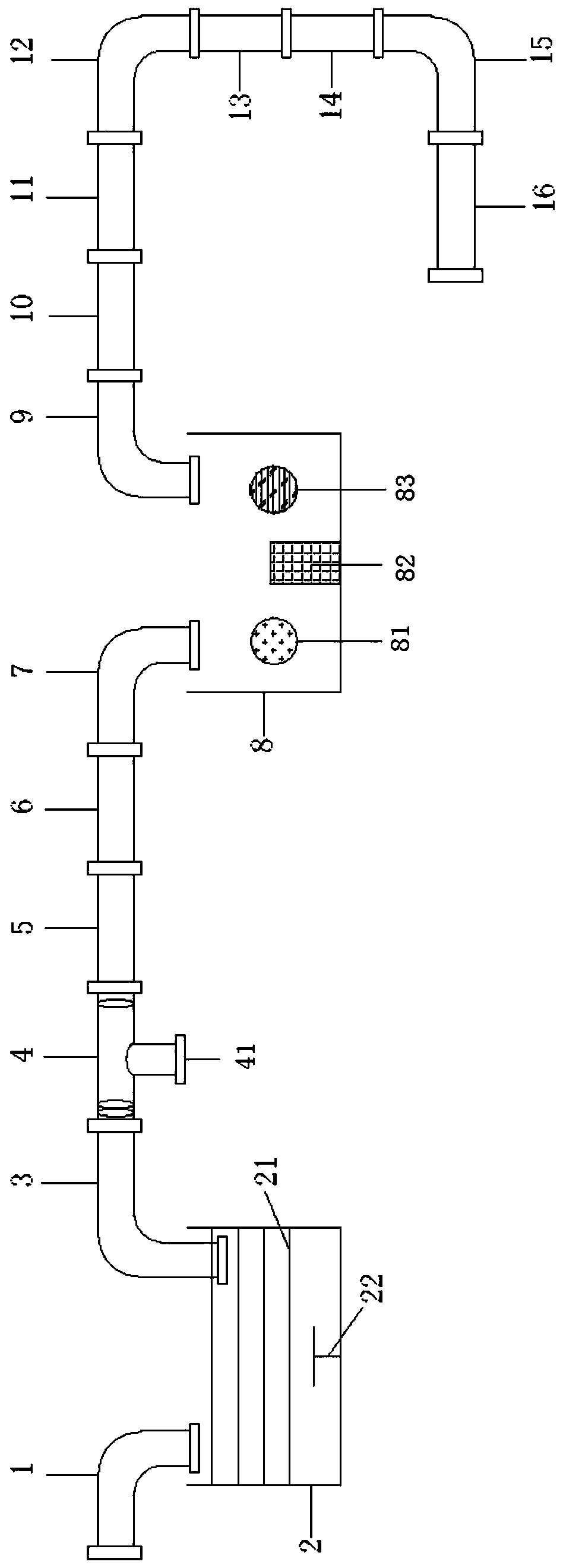

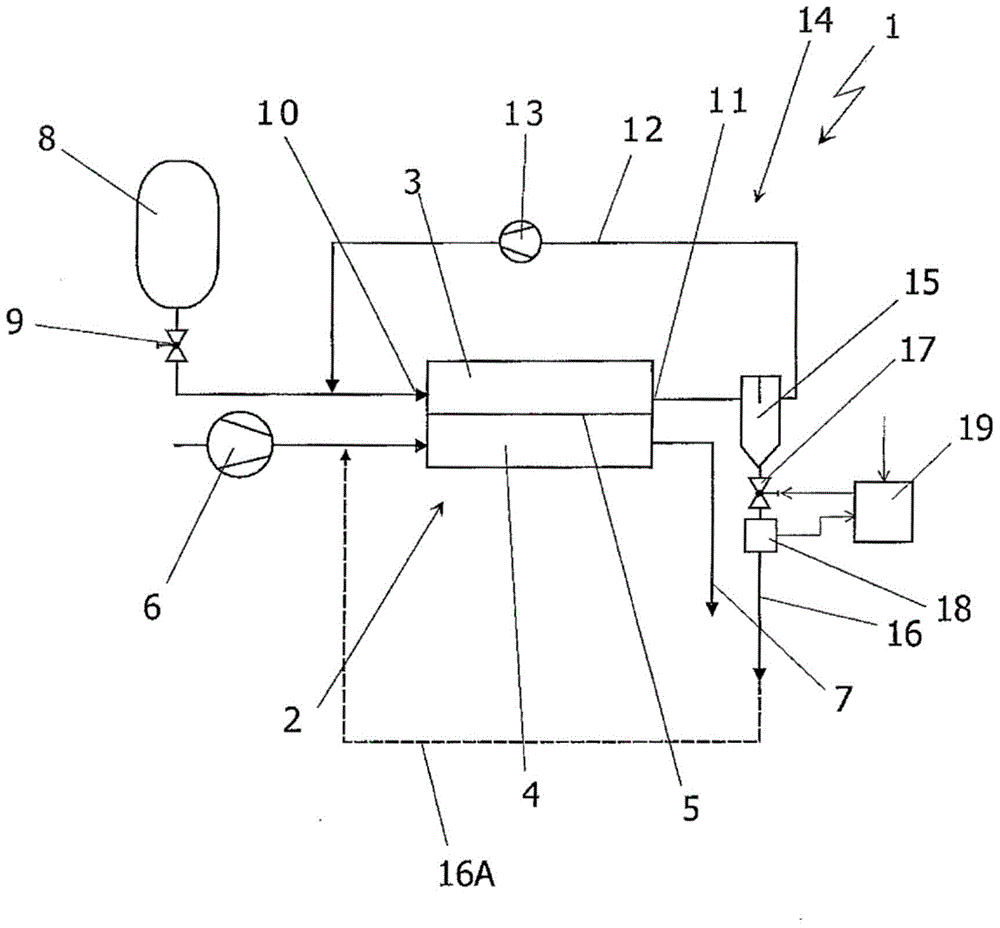

Flare gas safe recovery and discharge system

ActiveCN101672478ARealize automatic controlSafe recyclingIncinerator apparatusAutomatic controlProcess engineering

The invention provides a flare gas safe recovery and discharge system, which comprises a flare gas delivery flask (2), an automatic control water-sealed valve (3), a gas holder (6) and a flare tip (13) and is characterized in that the gas inlet end of the flare gas delivery flask (2) is connected with a flare gas source by a flare gas main pipe (1); one path of the output end of the flare gas delivery flask (2) is connected with a gas torch (6), and the other path thereof is connected with the flare tip (13) via the automatic control water-sealed valve (3); an automatic control valve (4) and aflare gas filtering tank (5) are mounted on the pipeline connecting the flare gas delivery flask (2) with the gas torch (6); the output end of the gas torch (6) is connected with a compressor (7); and the output end of the compressor (7) is connected with a gas appliance (8). The invention has the advantages of simple system structure, convenient manufacturing and installation and safe usage; andthe invention also has the characteristics of being favor of preventing environment, saving energy and the like.

Owner:JIANGSU SUNPOWER TECH

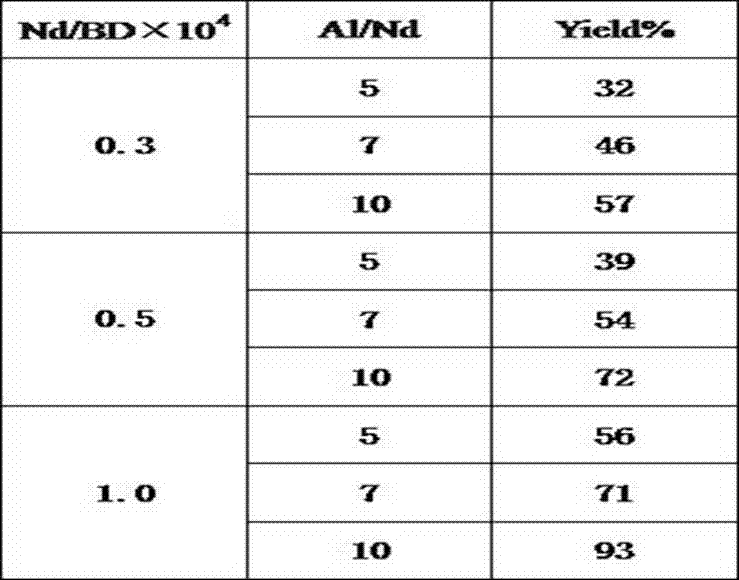

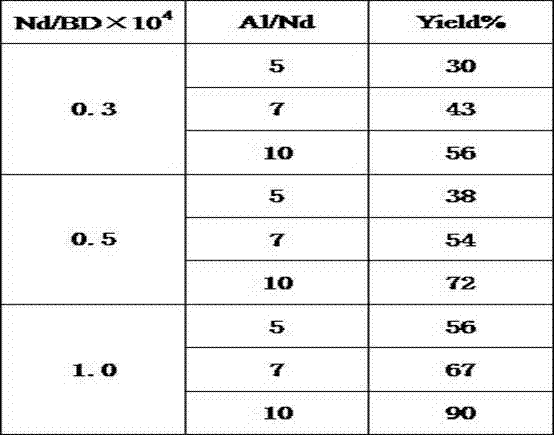

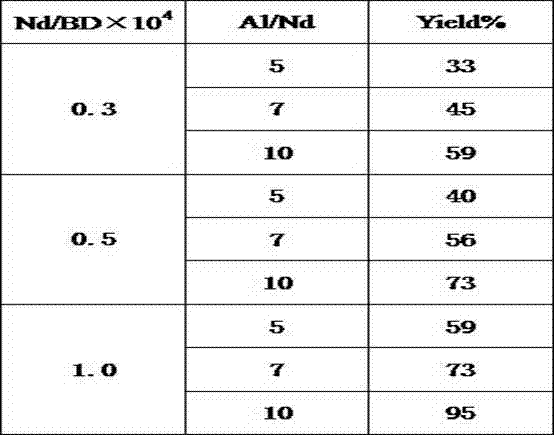

Method for synthesizing solution-type rare-earth rubber catalyst

The invention relates to a method for synthesizing a solution-type rare-earth rubber catalyst. The method comprises the following steps: preparing a neodymium trichloride water solution by using neodymium oxide and hydrochloric acid; mixing an organic phosphoric acid with an organic solvent to obtain an organic phosphoric acid solution; adding an alkaline solution to obtain saponification liquid; adjusting the viscosity of the solution by using a viscosity adjuster after completely dissolving; respectively carrying out binary ageing and ternary ageing, so as to obtain a rare-earth catalytic system which is directly applied to rubber production. The technology for preparing the rare-earth rubber catalyst provided by the invention is simple in process and low in cost, and the viscosity of organic phosphate neodymium can be freely adjusted according to the requirements. In addition, saturated alkane hexane is adopted in the preparation process, so that an organic solvent of polluting the environment is avoided; the waste water generated in the washing process comprises a main ingredient of sodium chloride, and can be safely discharged after being processed; a step of rectification dehydration is introduced to the technology, so that the moisture content in the catalyst can be strictly controlled.

Owner:华宇橡胶有限责任公司

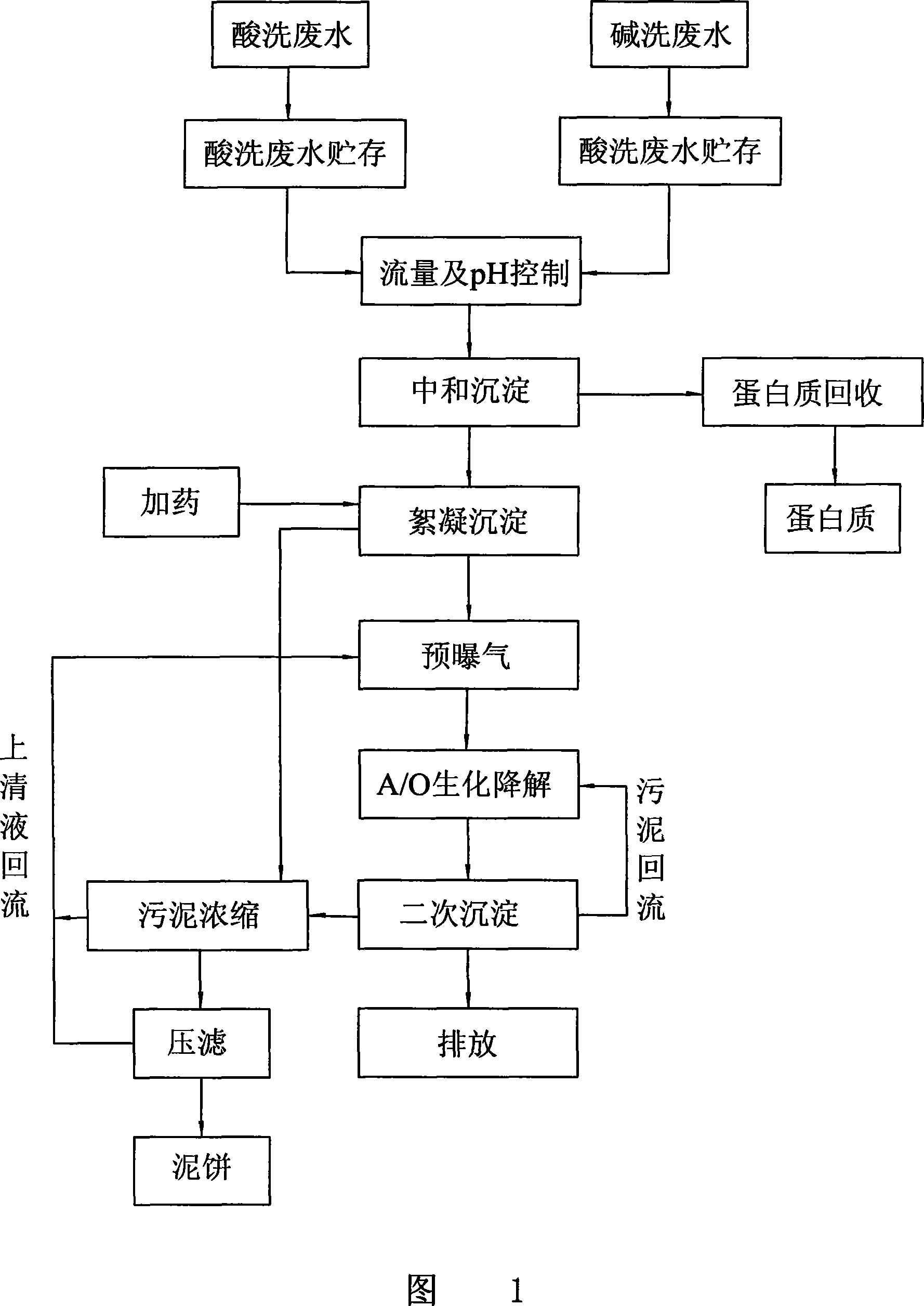

Technique for treating chitin waste water

InactiveCN101215066AIncreased processing loadCompletely degradedMultistage water/sewage treatmentWater/sewage treatment by neutralisationFlocculationChitin formation

The invention discloses a chitin wastewater treating technique. Firstly parting of acid and alkaline cleaning wastewater is stored, integrated wastewater pH is adjusted via flow-control, then neutralization settlement, flocculation settlement, pre-aeration adjustment, A / O biochemical degradation and secondary precipitation for proteins are finished sequentially, and finally the wastewater reaches the standard and is discharged. The invention precipitates proteins in the wastewater in the maximal degree before biochemical treatment of the integrated wastewater by using the electric point precipitation character of proteins and the like, thereby avoiding to increasing of waste water disposal load caused by proteolysis, lowering difficulty of the waste water disposal, ensuring feasibility of biochemical system, simultaneously recycling reasonably proteins, resolving prominent problems of chitin wastewater pollution with the characters of superacid alkali and high salt and high protein, achieving highly effective and safe treatment of the wastewater and effective reclamation and utilization of the proteins, and ensuring sectional sustainable development.

Owner:ZHEJIANG UNIV

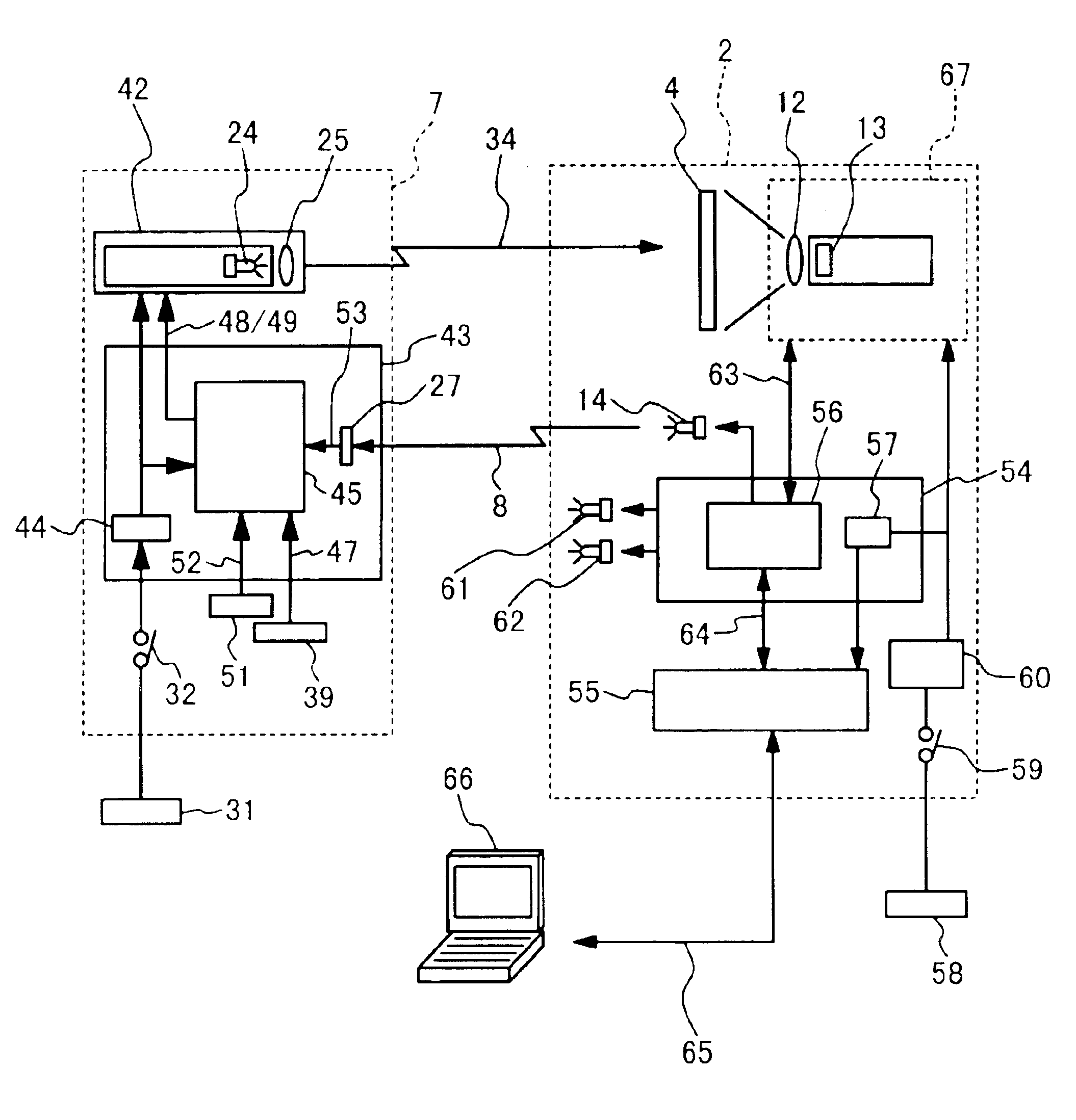

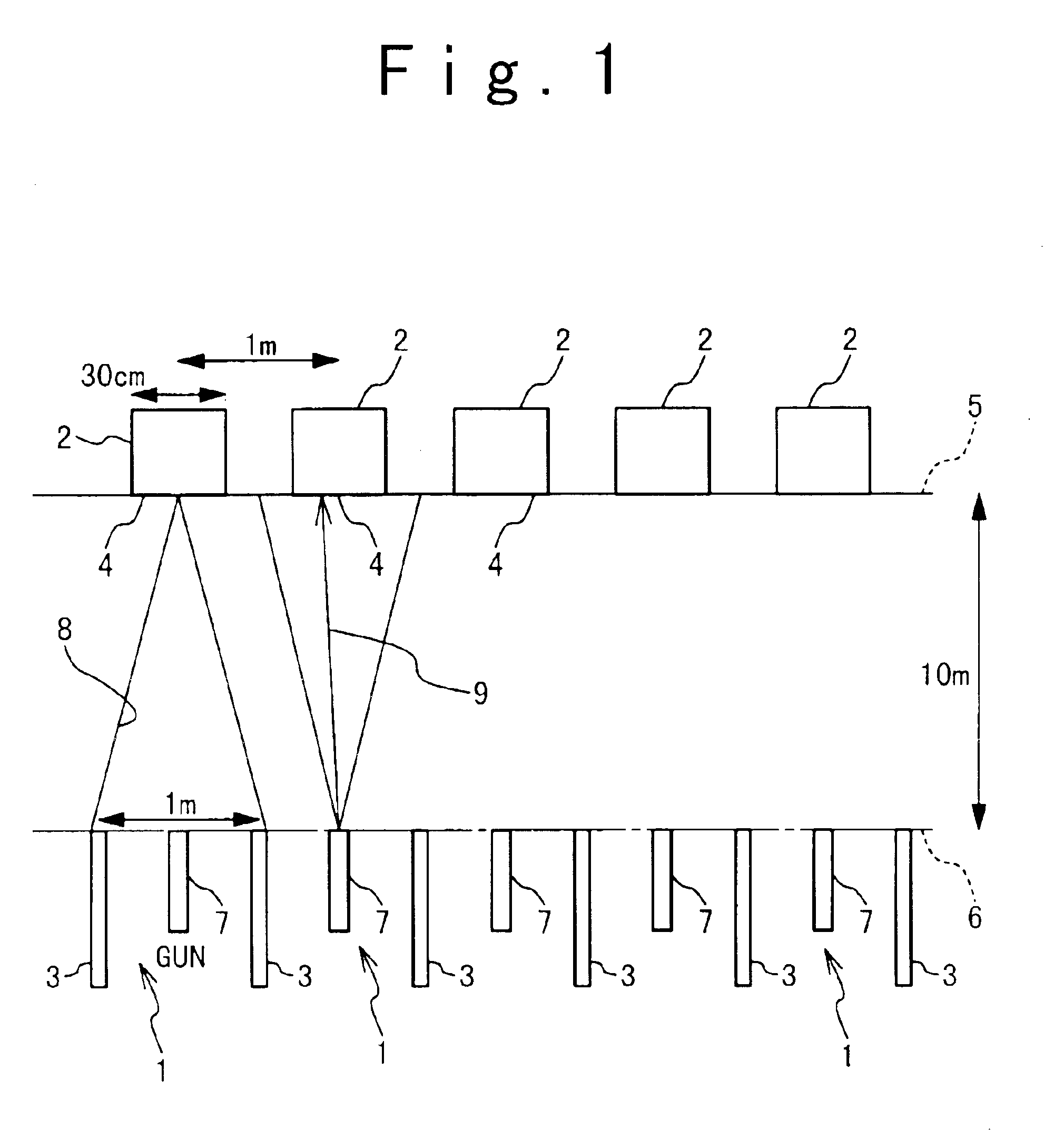

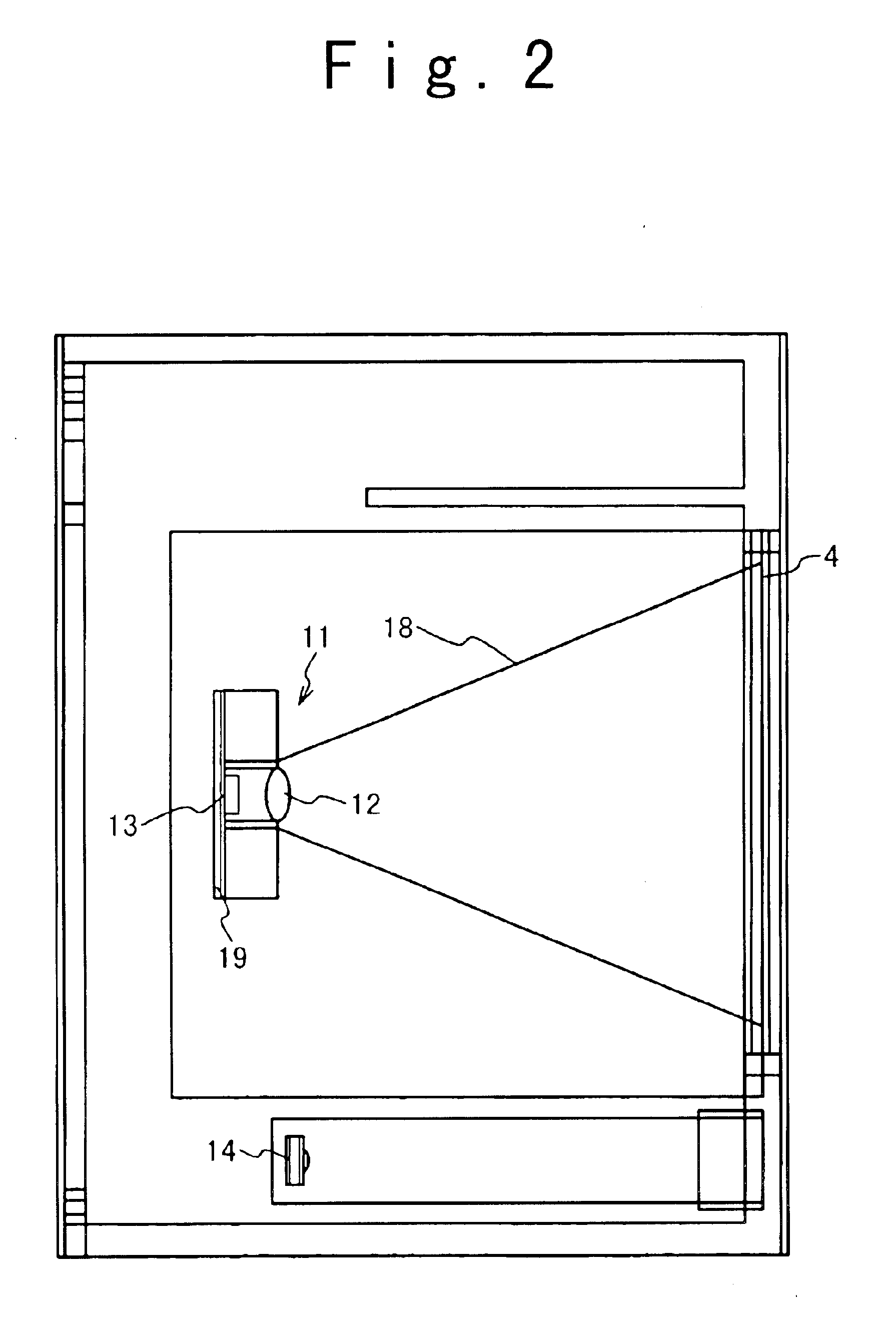

Laser gun and shooting system for the same

InactiveUS6962532B2Emission safetyCalculated quickly and accuratelyToysAiming meansOptoelectronicsGenerating unit

In a laser gun, a signal generating unit generates an emission permission signal in response to a shooting permission signal. A laser beam bullet emitting unit emits a laser beam bullet based on the emission permission signal generated by the signal generating unit in response to an operation of the trigger.

Owner:NEC CORP

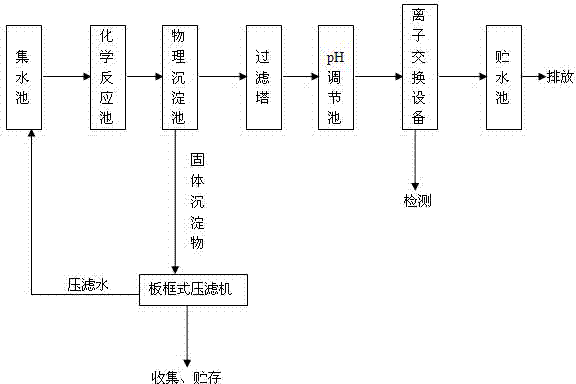

Comprehensive treatment process and device for electroplating wastewater containing heavy metal ions, Cr6+, Cu2+ and Ni2+

ActiveCN102786171AReduce the amount of solutionNo wasteWater contaminantsWaste water treatment from metallurgical processChemical reactionIon exchange

The invention discloses a comprehensive treatment process and a device for electroplating wastewater containing heavy metal ions, Cr6+, Cu2+ and Ni2+. The process includes the steps of completely converting the Cr6+, Cu2+ and Ni2+ ions into hydroxide precipitate, solid-liquid separation by sedimentation, liquid treatment, solid treatment and the like. The device comprises a water collection tank, a chemical reaction tank, a physical sedimentation tank, a filter column, a pH regulating tank, an ion exchanger and a reservoir, which are connected in sequence. The comprehensive treatment process and the device have the advantages that the process guarantees treated wastewater containing the heavy metal ions to meet national standard at lowest consumption of resources, Cr6+ is not larger than 0.2mg / L, Cu2+ is not larger than 0.5mg / L, Ni2+ is not larger than 0.5mg / L, emission is safe, the treatment process is simple, device requirements are low, production cost is saved effectively, daily effectively treating capacity for wastewater is enhanced, requirements of enterprises are met, and environment is protected.

Owner:山东同大镍网有限公司

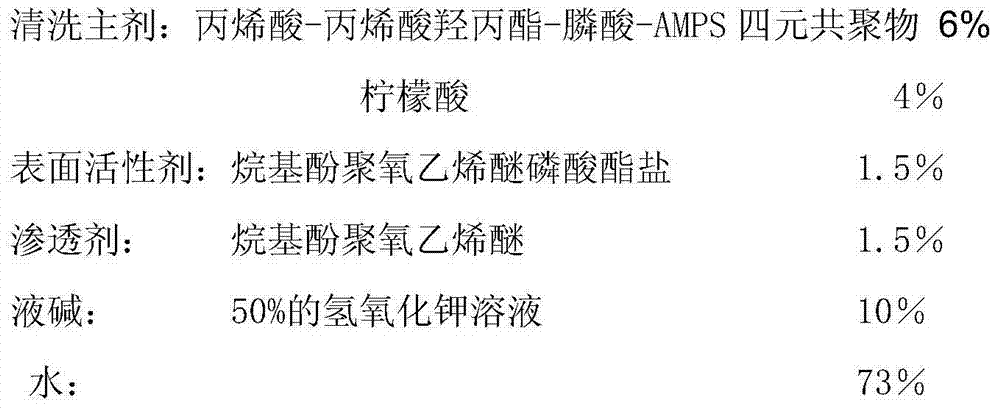

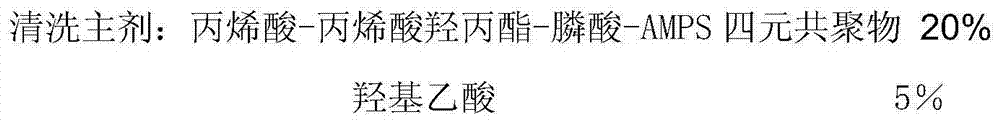

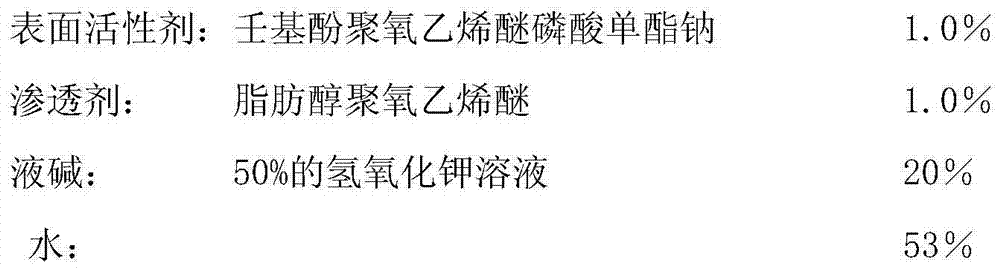

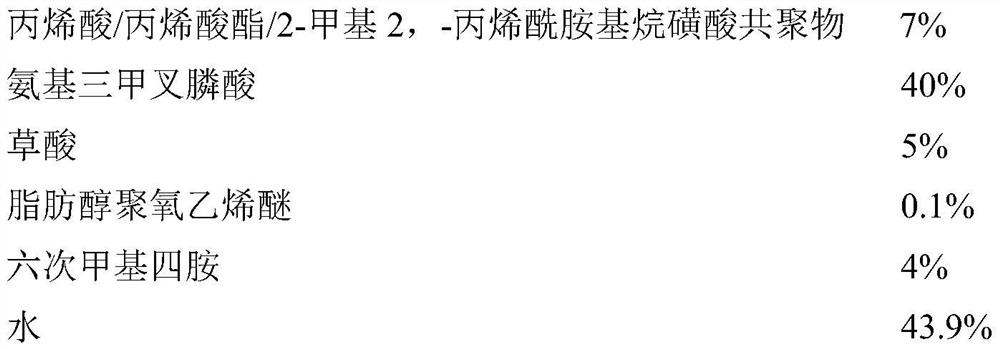

Neutral chemical cleaning agent for eliminating hard scales of air pre-heater of desulfurization system and preparation method of neutral chemical cleaning agent

InactiveCN104745337ANo adverse reactionAvoid foulingSurface-active non-soap compounds and soap mixture detergentsMetasilicateTransmittance

The invention discloses a neutral chemical cleaning agent for eliminating hard scales of an air pre-heater of a desulfurization system and a preparation method of the neutral chemical cleaning agent. The neutral chemical cleaning agent is compounded of a main cleaning agent, a surfactant, a penetrant, caustic soda liquid and water. The cleaning agent has complexing action with aluminum metasilicate and silicate scales on the surface (in contact with the cleaning agent) of the air pre-heater to achieve the purpose of dissolving dirt; by virtue of permeation and swelling, cracks and gaps are generated in an inner structure of a scale layer. The cleaning agent adopts a safe and environmental-friendly neutral scheme and is free of toxicity. The main compound, namely the main cleaning agent, is easily biodegraded so that the environmental problems are avoided; the cleaning agent has the characteristics of quickly removing scales and not corrode a steel frame, not damaging an enameled heat exchange component, not damaging the flak anticorrosive material and the like. When used for cleaning the air pre-heater, the neutral chemical cleaning agent has the beneficial effects that the removal rate of hard scales is 98% or above, and the light transmittance of the air pre-heater reaches 95% or above, and moreover, the heat exchange efficiency of the heat exchange equipment is improved, a vent channel is dredged, and safe and economical operation of the unit is guaranteed.

Owner:SHANGHAI WEILAI ENTERPRISE

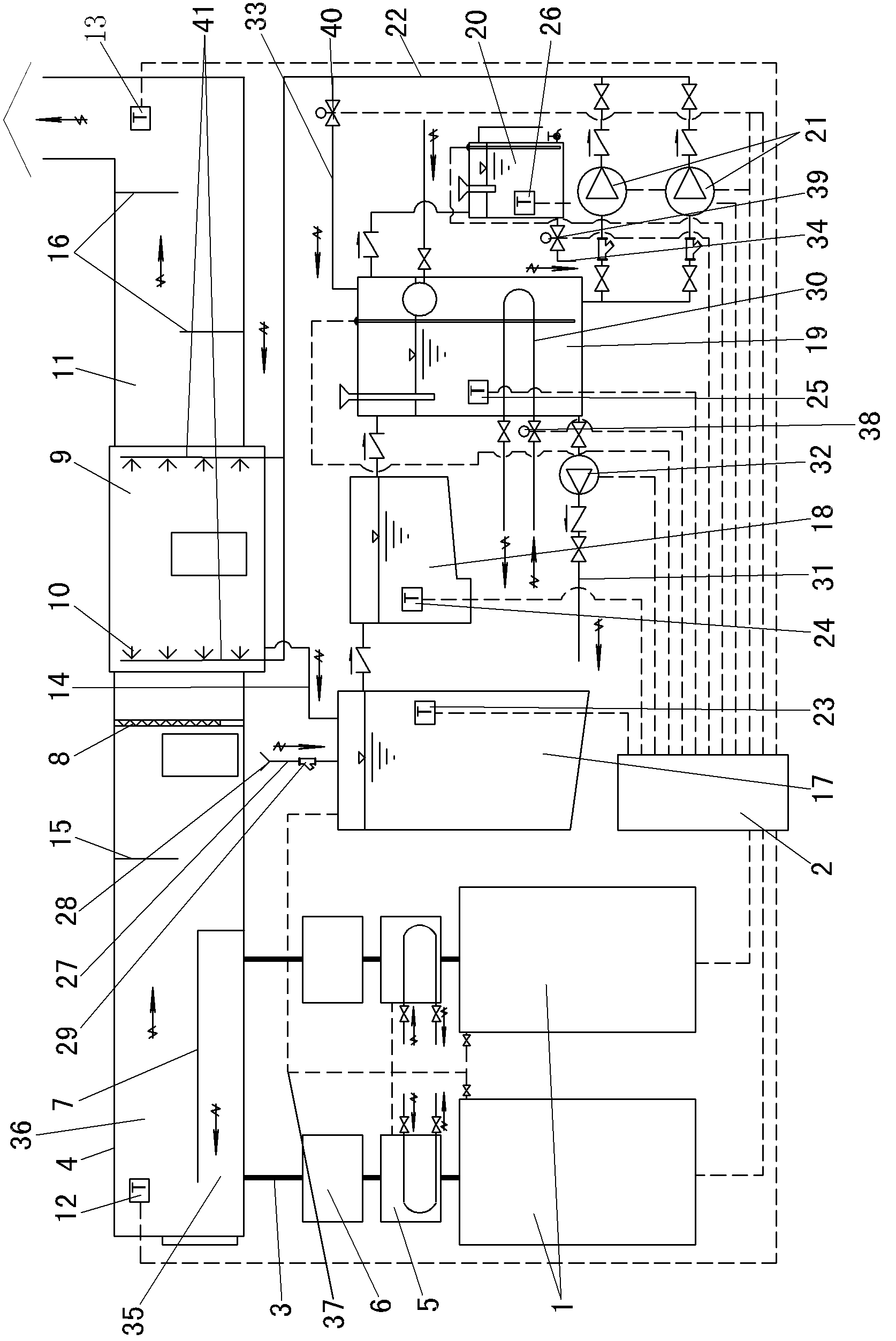

Flue gas spraying, purifying and heat recovering system for coal burning boiler

The invention discloses a flue gas spraying, purifying and heat recovering system for a coal burning boiler and belongs to the field of flue gas treatment or waste gas device configuration. The flue gas spraying, purifying and heat recovering system comprises a control system and the like; a separation board by which an inner cavity of a soot settling chamber is divided into two return flues is arranged in the inner cavity of the soot settling chamber; a smoke exhaust channel is communicated with the return flues; a waste heat receiving device and a dust remover are connected onto the smoke exhaust channel; a soot filter screen is arranged at the right part of a right cavity of a labyrinth type soot settling chamber; the right end of the soot settling chamber is communicated with a spraying chamber; the right end of the spraying chamber is communicated with a labyrinth type extended cooling channel; the labyrinth type extended cooling channel is communicated with a chimney; temperature controllers connected with the control system are respectively arranged in the soot settling chamber and an inner cavity of the labyrinth type extended cooling channel; the spraying chamber is connected with a water treatment system through a plurality of recovering water pipes; a plurality of water inlet pipes extend into the inner cavity of the spraying chamber; and spraying nozzles are arranged on the water inlet pipes. The flue gas spraying, purifying and heat recovering system disclosed by the invention is simple and convenient to manage; and according to the flue gas spraying, purifying and heat recovering system, emission heat of the coal burning boiler can be safely and reliably absorbed; thermal pollution, pollution from dust in the soot, pollution from sulfide, nitride and the like are reduced and flue gas is enabled to achieve non-hazardous emission.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT

Chemical for cleaning boiler

InactiveCN102418103ALow cleaning temperatureShorten the timeCetyldimethylbenzylammonium chlorideAcid washing

The invention relates to a chemical for cleaning a boiler, and belongs to the technical field of the chemical cleaning of equipment. The chemical comprises a corrosion-inhibiting acid-washing agent, a bleaching agent and a passivant, wherein the corrosion-inhibiting acid-washing agent consists of 1,3,5,7-tetraaza-adamantane, ethylenediamine tetracetic acid, hydrochloric acid, phosphoric acid, silicon fluoride, hydrazine hydrate, sodium silicate, cetyl dimethyl benzyl ammonium chloride, ammonium thiocyanate, sodium dodecyl benzene sulfonate and the balance of water; the bleaching agent is citric acid solution; and a passivant consists of ethidene diamine, formaldehyde, diammonium phosphate, hydrogen peroxide, sodium nitrite and the water. The chemical has stable chemical properties, low toxicity, a good sustained-release effect and high scale dissolving capacity, and does not have the damage of sour corrosion to the boiler.

Owner:CHANGSHA BLUECLEAN TECH

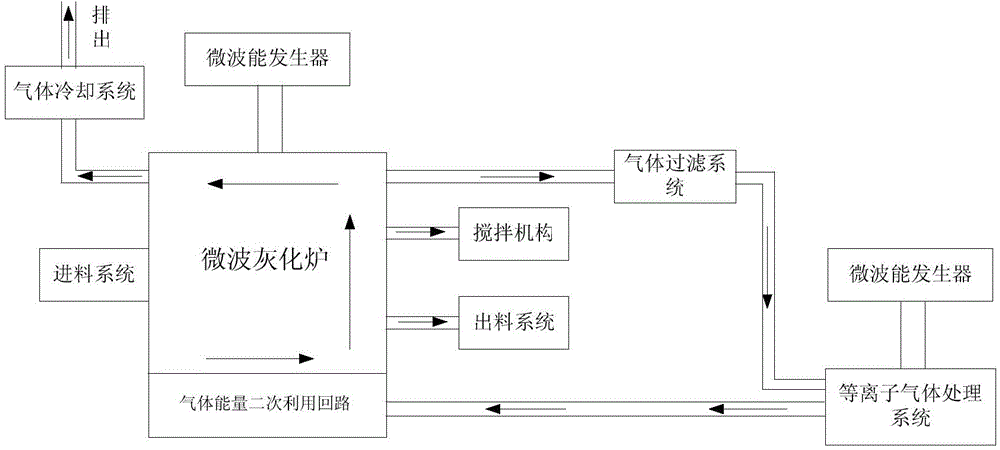

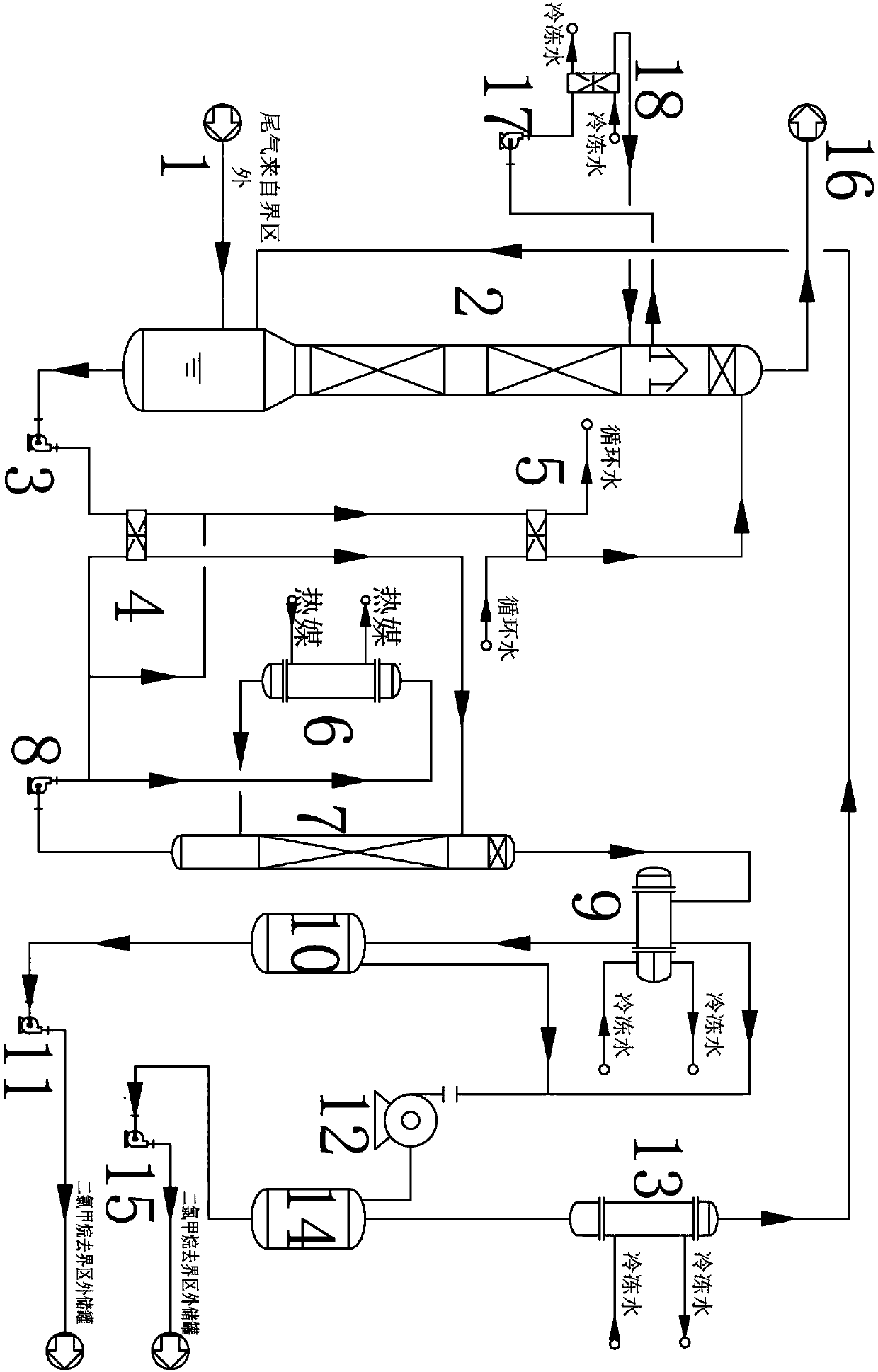

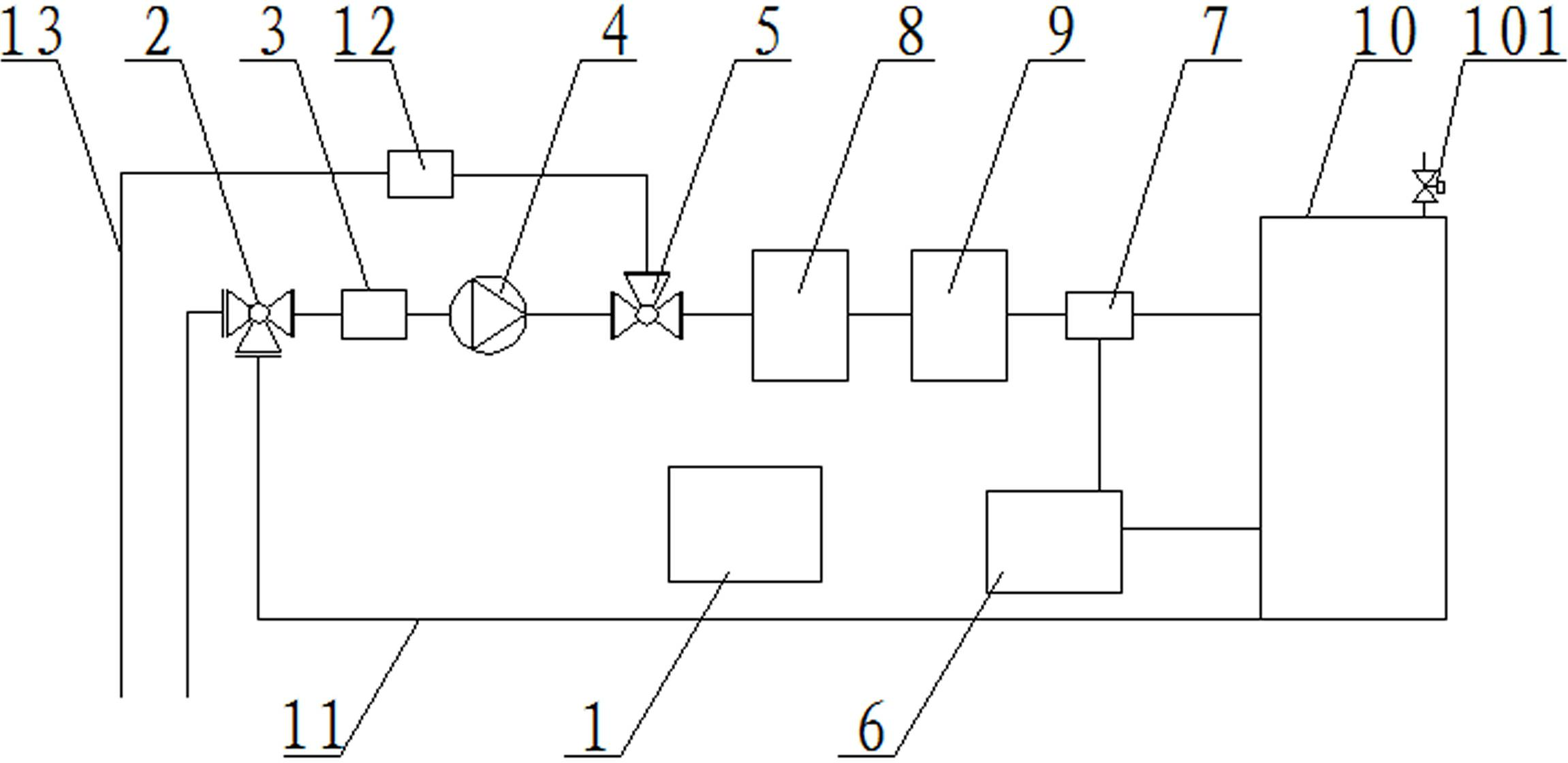

Medical waste microwave treatment method and treatment equipment

ActiveCN105444188AReduce outputEmission safetyIncinerator apparatusCombined combustion mitigationHazardous substanceDecomposition

The invention provides a medical waste microwave treatment method and treatment equipment. The medical waste microwave treatment method comprises the steps that the temperature of medical waste is increased by means of microwaves till the medical waste is incinerated; and then ionizing decomposition is conducted on gas generated in the incineration process of the medical waste in a high-voltage electric field, so that harmful substances left in the gas are removed. The equipment is composed of a medical waste feeding system, a microwave incineration furnace, a gas filtering system, a plasma gas processing system, a gas energy reutilization loop and a gas cooling system, wherein the microwave incineration furnace, the gas filtering system, the plasma gas processing system, the gas energy reutilization loop and the gas cooling system are connected with one another in sequence through gas delivery pipelines. The medical waste microwave treatment method and the treatment equipment have the advantage that minimizing, harmless, efficient, energy-saving and environment-friendly treatment of the medical waste can be achieved.

Owner:NANJING SANLE MICROWAVE TECH DEV

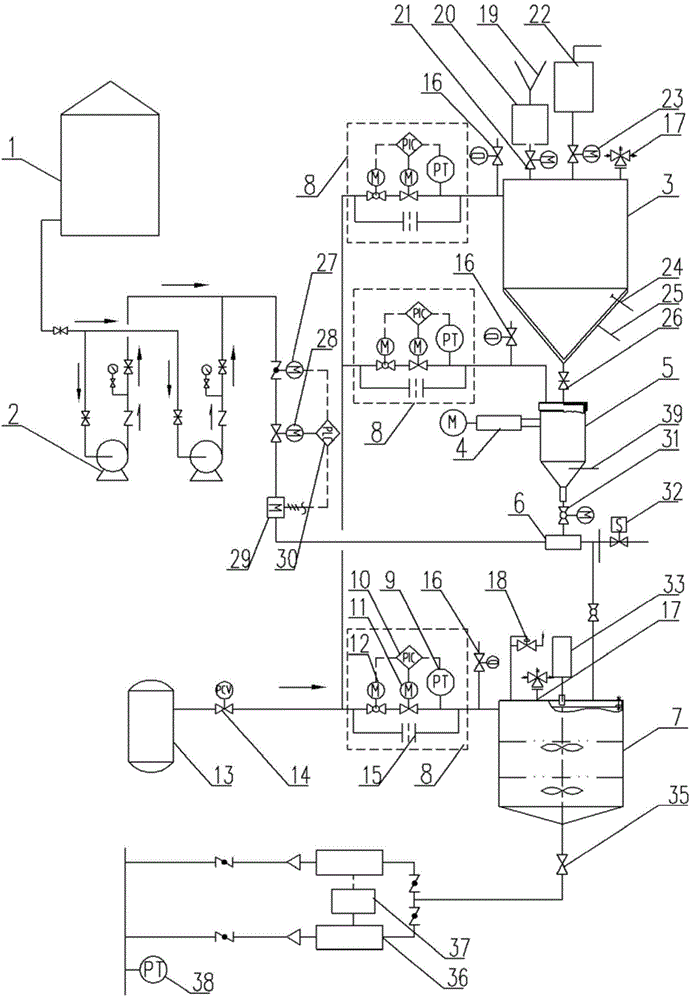

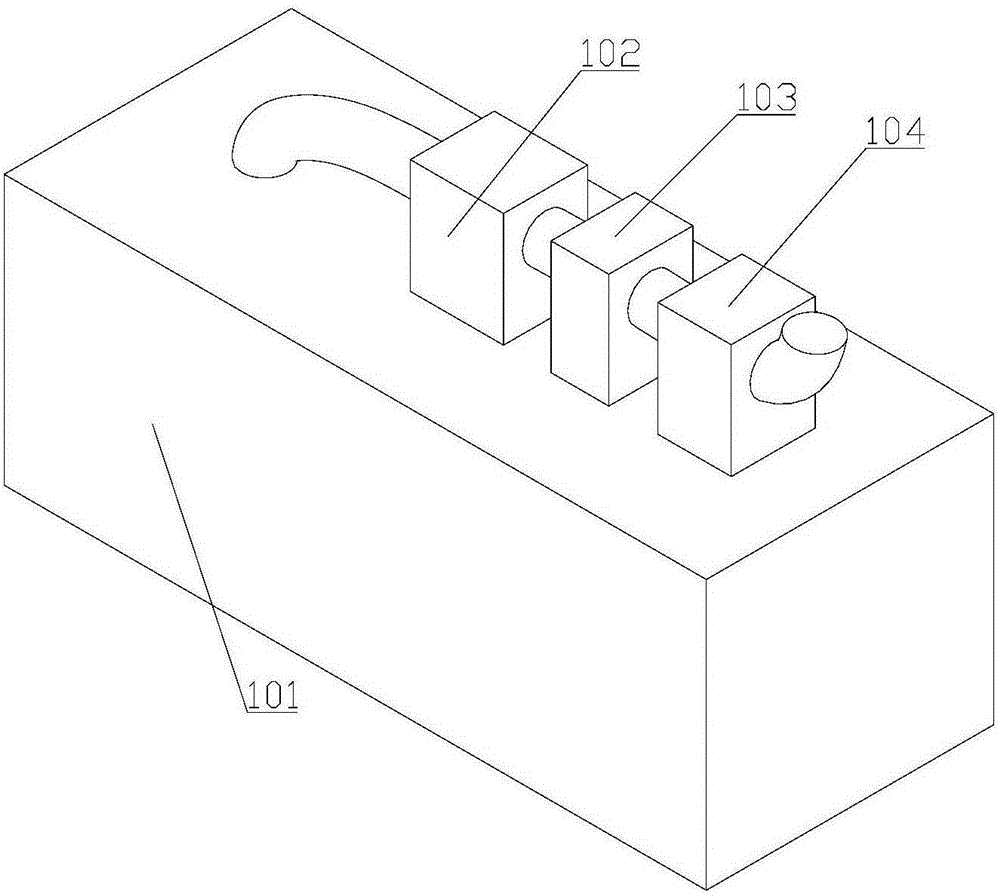

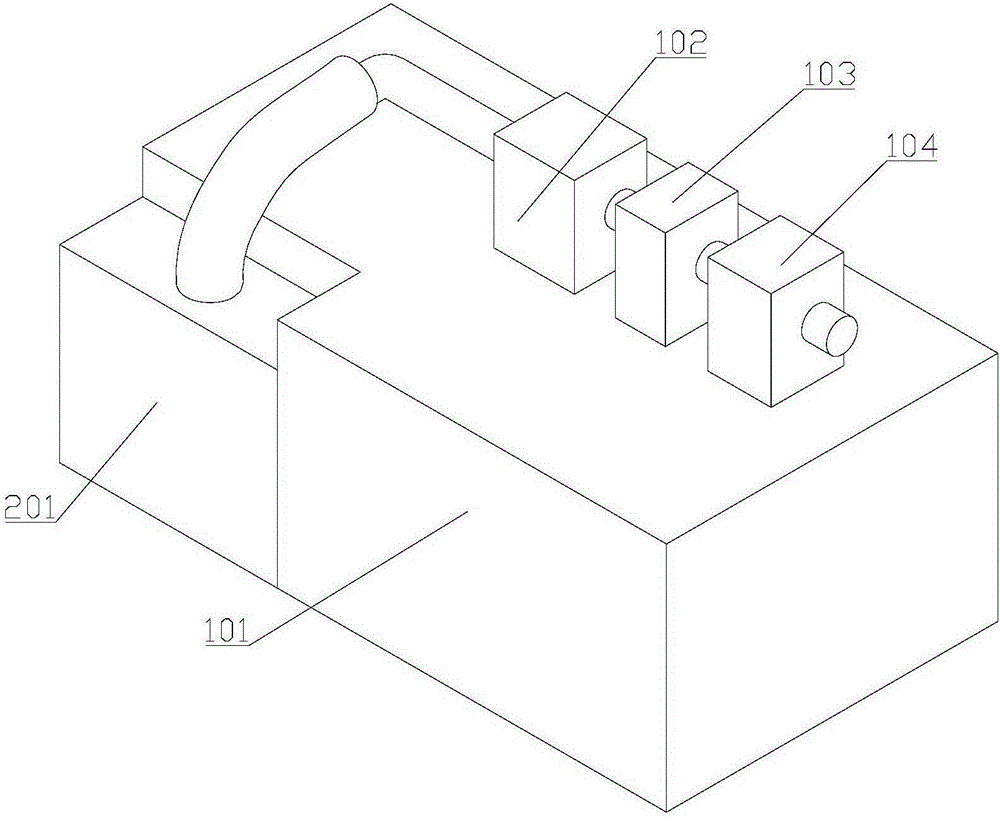

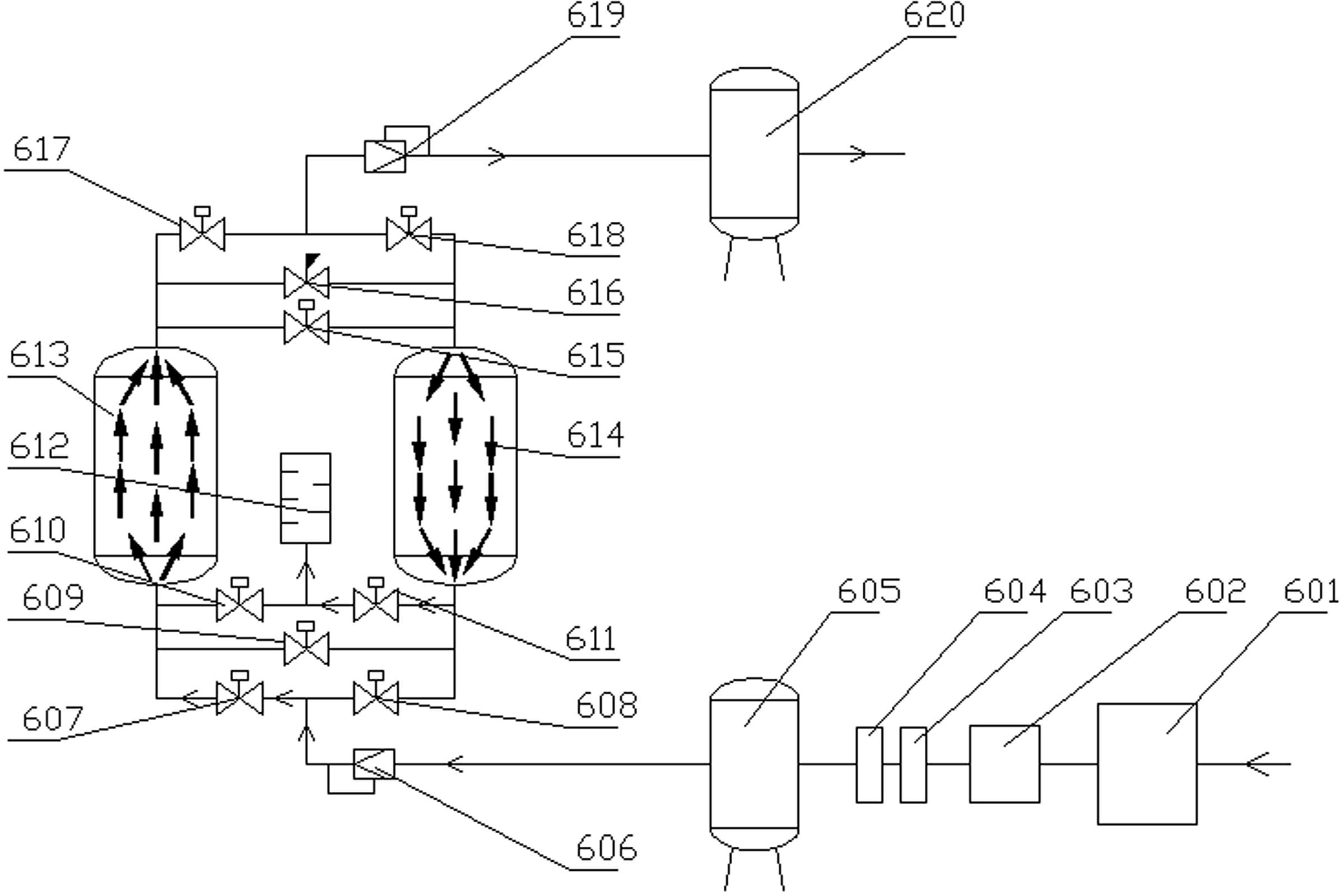

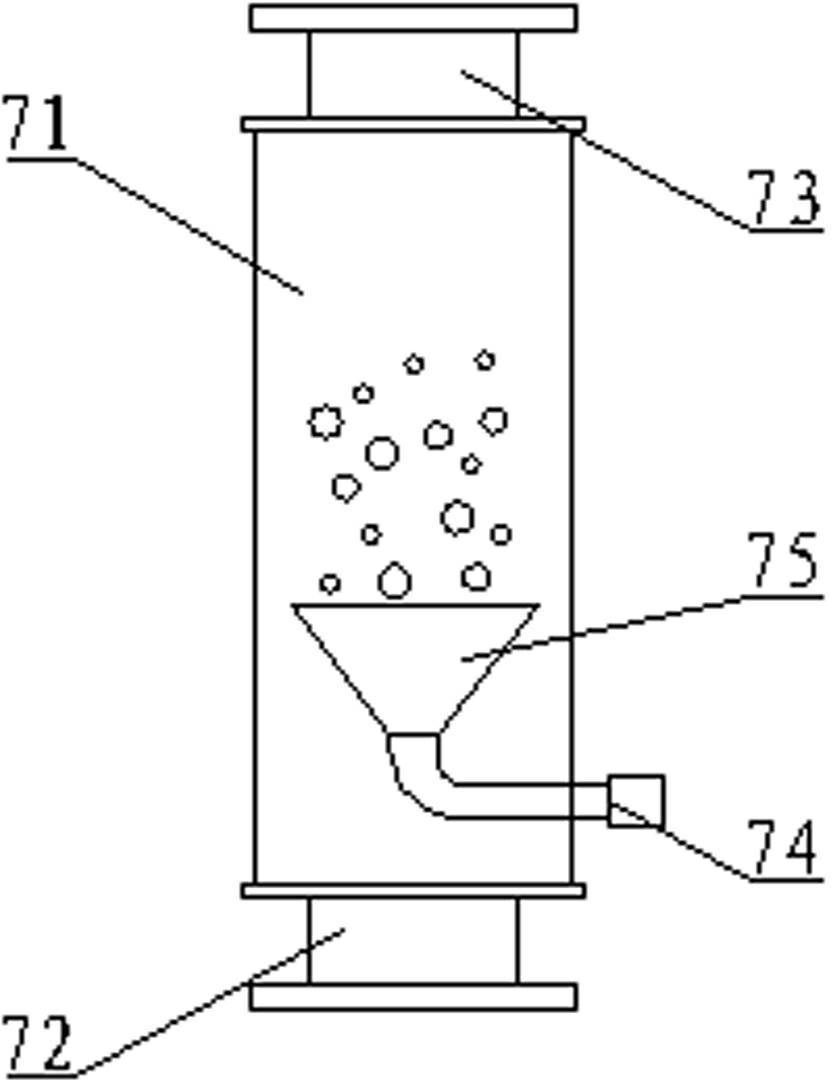

High-temperature reservoir chemical flooding airtight polymer preparation device

The invention discloses a high-temperature reservoir chemical flooding airtight polymer preparation device. The high-temperature reservoir chemical flooding airtight polymer preparation device comprises a dry powder storage tank, a screw feeder, a receiving hopper, a jet device, a curing tank and a water supply system; the water supply system is communicated with the water inlet of the jet device; the dry powder storage tank, the screw feeder, the receiving hopper, the jet device and the curing tank are orderly communicated with each other to form an airtight polymer preparation system; the high-temperature reservoir chemical flooding airtight polymer preparation device further comprises a nitrogen supply system which is communicated with the dry powder storage tank, the receiving hopper and the curing tank by use of a nitrogen supply pipeline, respectively; a nitrogen sealing pressure control system is arranged on the nitrogen supply pipeline. The high-temperature reservoir chemical flooding airtight polymer preparation device is capable of preparing polymers under the working condition of nitrogen isolated from oxygen, and therefore, the nitrogen airtight preparation of a polymer solution is realized, the content of dissolved oxygen in the polymer solution is greatly reduced, the problem of relatively high oxygen concentration in the polymer solution obtained by use of an open hydraulic jet flow polymer preparation device is solved and the requirement indexes of high-temperature reservoir chemical flooding on the oxygen content of the polymer solution are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

Resource recycling device and process of dichloromethane tail gas

PendingCN107803100ATake advantage ofReduce dosageGas treatmentDispersed particle separationCirculating pumpVacuum pump

The invention discloses a resource recycling device and process of dichloromethane tail gas. According to the device, the bottom of an absorption tower is connected with an absorbent heat exchanger through an absorption tower kettle extraction pump; the absorbent heat exchanger is connected to the upper part of an desorption tower; the absorbent heat exchanger is connected with an absorbent primary cooler; the bottom of a falling film evaporator is connected with the lower part of the desorption tower; the bottom of the desorption tower is connected with the top of the falling film evaporatorthrough a falling film circulating pump; a desorption tower top condenser is connected with the top of the desorption tower; the desorption tower top condenser is connected with the top of a desorption tower top receiving tank; the top of the desorption tower top receiving tank is connected with an after-pumping receiving tank through a vacuum pump; the vacuum pump is connected with the desorptiontower top condenser; the top of the after-pumping receiving tank is connected with an after-pumping condenser; and the top of the after-pumping condenser is connected to the lower part of the absorption tower. The device provided by the invention is simple in structure, convenient in operation, and high in solvent recovery rate; dangerous waste is not generated; the environment-friendly requirement can be met; the emission is safe; and resource recycling is realized.

Owner:烟台国邦化工机械科技有限公司

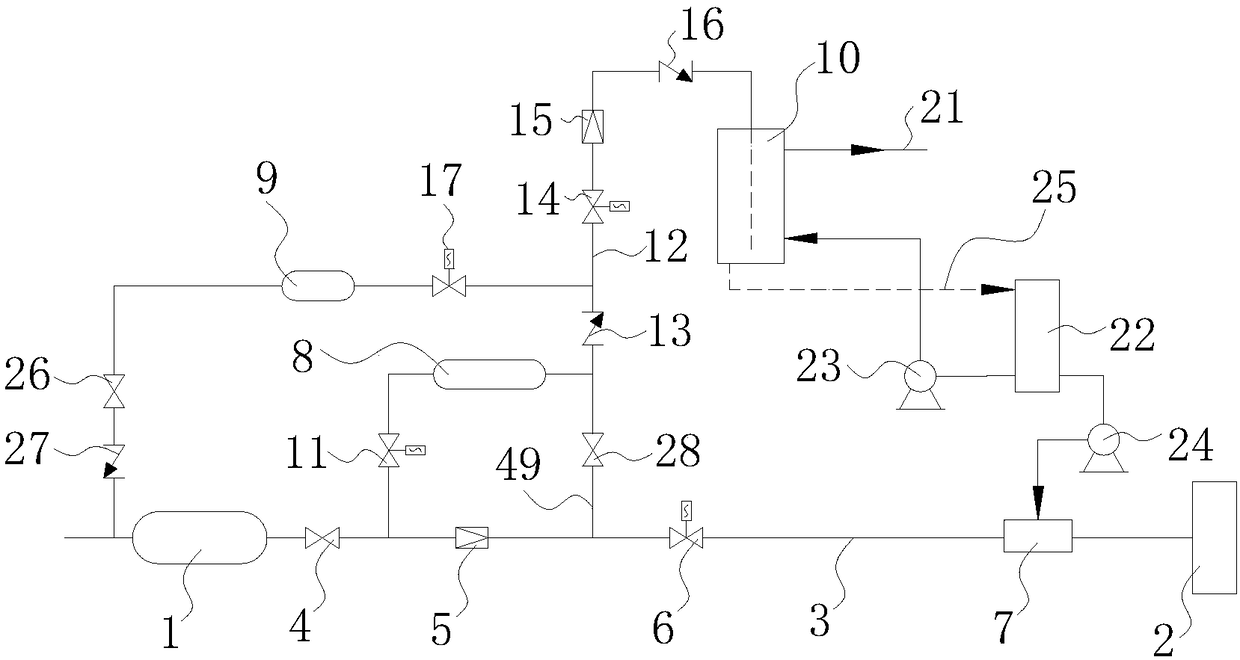

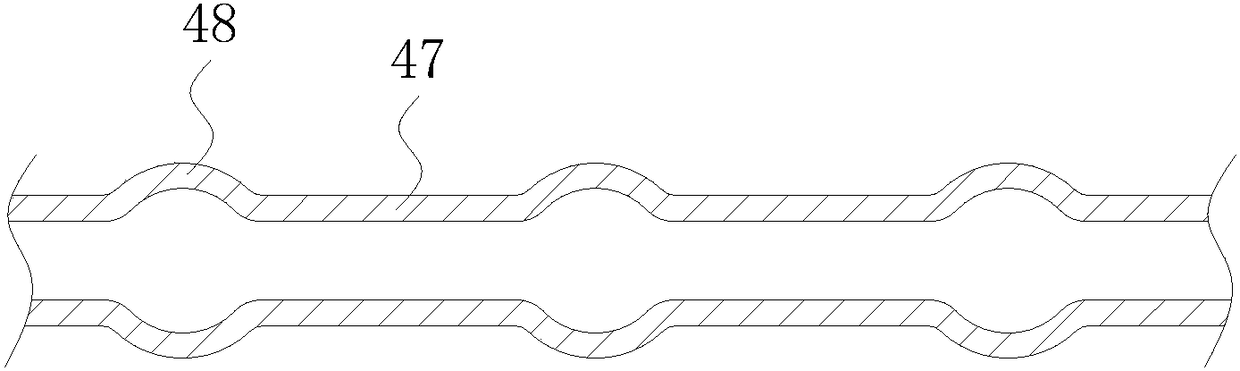

FCEV (Fuel Cell Electric Vehicle) hydrogen fuel installation unit electric-control initiative hydrogen discharging system

PendingCN108365240AReduce the risk of explosionElectronic control active avoidance of explosion riskMotive system fuel cellsRefluxWhole body

The invention relates to the technical field of fuel cell cars, and aims at providing a safe and explosion-proof hydrogen fuel installation unit electric-control initiative hydrogen discharging system. According to a technical scheme, the FCEV (Fuel Cell Electric Vehicle) hydrogen fuel installation unit electric-control initiative hydrogen discharging system comprises an electric control unit ECU,an explosion-proof hydrogen storage apparatus, a fuel cell and a hydrogen discharging apparatus, the hydrogen discharging apparatus comprises a buffer tank, a nitrogen tank, a water trough and an exhausting pipe, a branch pipe which is arranged on a hydrogen supply pipeline between the explosion-proof hydrogen storage apparatus and the fuel cell is connected with one end of the buffer tank, the branch pipe is provided with a second electromagnetic valve, and the other end of the buffer tank is separately connected with the water trough and the hydrogen supply pipeline by virtue of the hydrogen discharging pipeline and a reflux pipeline. One end of the nitrogen tank is connected to the hydrogen discharging pipeline by virtue of a pipeline, a pipeline adopted by the hydrogen supply pipelineand the hydrogen discharging pipeline is a pipeline with an expansion structure and comprises a straight pipe section and an expansion section formed by expanding the pipeline, and the expansion section and the straight pipe section are interconnected to form a whole body. The safe and explosion-proof hydrogen fuel installation unit electric-control initiative hydrogen discharging system is convenient in operation, safe and explosion-proof.

Owner:XIHUA UNIV

Neutral cleaning agent for mixed water scale and production method thereof

InactiveCN101955862ANot brokenEmission safetyOrganic non-surface-active detergent compositionsTreatment using complexing/solubilising chemicalsHydrogen fluorideCleansing Agents

The invention relates to a chemical cleaning agent, in particular to a neutral cleaning agent special for cleaning the mixed water scale and a production method thereof. The invention provides a novel cleaning agent for treating the mixed water scale and a method thereof. In the actual application, the neutral cleaning agent can be used for effectively cleaning the mixed water scale on a boiler or an industrial cooling circular water system thoroughly during parking or not parking and cannot corrode metal. The neutral cleaning agent comprises the following raw materials in percentage by weight: 5-10 percent of 1-hydoxy ethyidene-1,1-diphosphonic acid, 3-8 percent of citric acid, 0.3-1 percent of nonionic polyacrylamide, 1-2 percent of hydrogen fluoride, 0.5-1 percent of NaOH, 0.05 percent of 6501 degreasing agent and the balance of water. The agent is the cleaning agent special for the mixed water scale, is special for clearing the indissolvable scale in the mixed water scale, has the pH value of the medicament of 7, is a neutral solution, can thoroughly clean the scale without corroding metal, enamel and glass and is nontoxic to human body; and waste liquid can be safely discharged, is high-efficient and safe and avoids the phenomenon of hydrogen embrittlement.

Owner:金宏

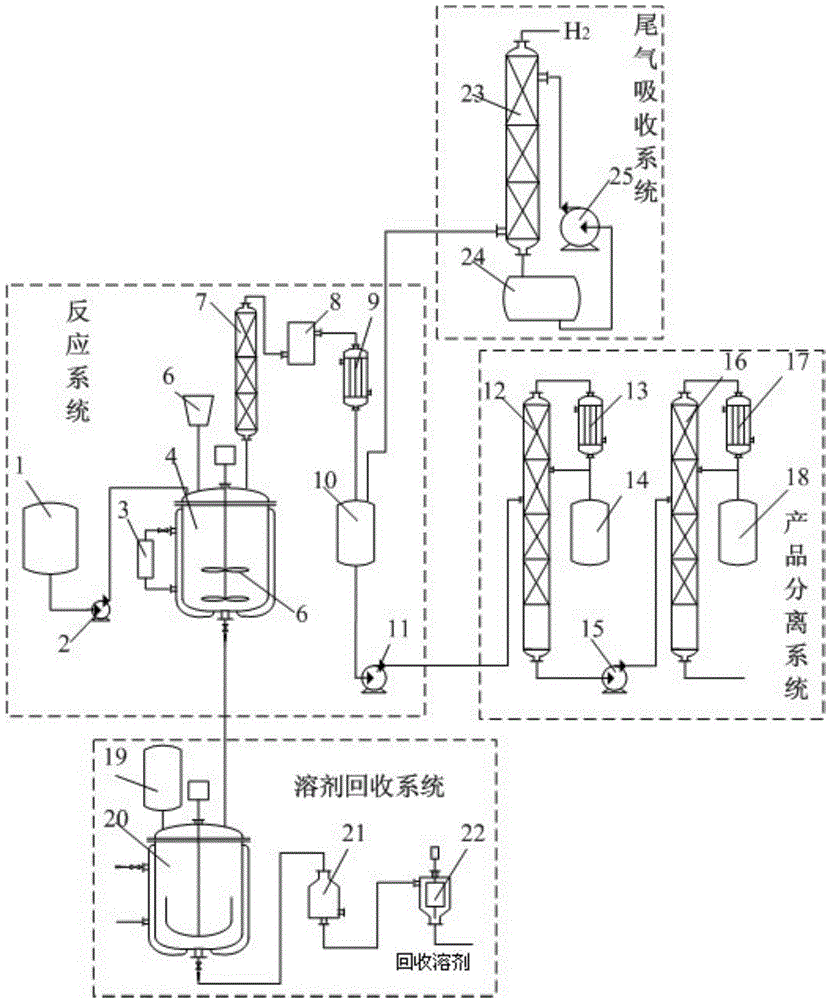

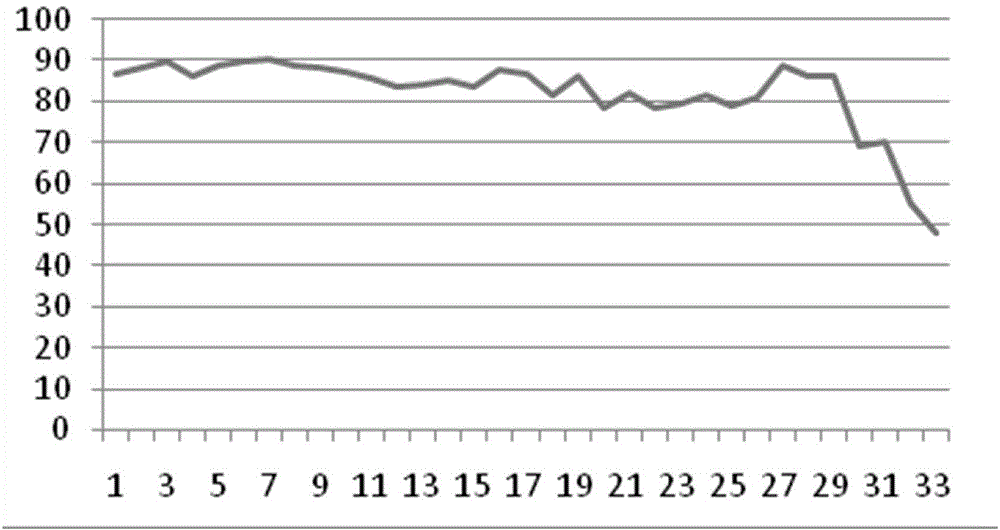

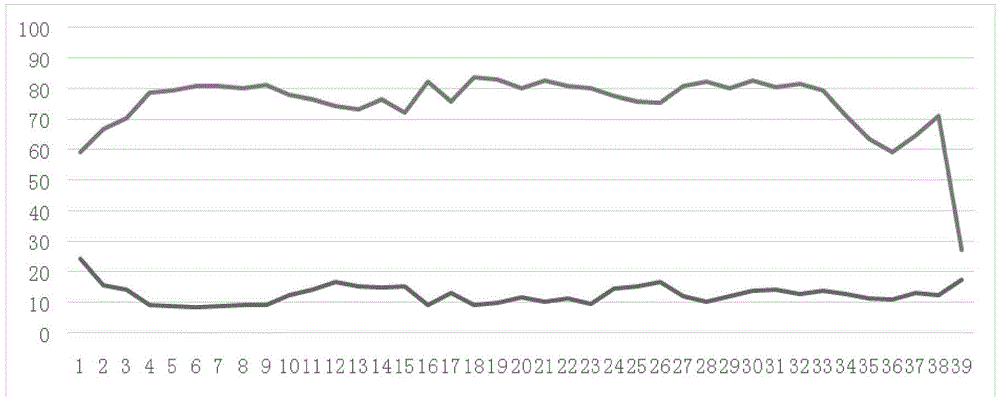

Production method for preparing trialkoxysilane by adopting direct method

ActiveCN104387413AIndustrial production process improvementSimple production processSilicon organic compoundsAlcoholSilanes

The invention provides a production method for preparing trialkoxysilane by adopting a direct method. According to the production method, firstly a copper compound is used as a precursor for preparing a catalyst intermediate body, the catalyst intermediate body is activated to form a silicon-copper intermetallic compound catalyst with catalytic activity, and the silicon-copper intermetallic compound catalyst is applied to industrial production in which the direct reaction of silicon and alcohol is catalyzed by the silicon-copper intermetallic compound catalyst in order to prepare the trialkoxysilane. An intermittent-continuous operation method is adopted to replace intermittent operation process for production, liquid alcohol is added continuously and silicon powder is replenished in batches during production, and synthesis condition is regulated duly so as to adapt to a stable production process. Besides, technological processes such as product separation, purification, suspending agent recycling and tail gas recycling are improved as well. In crude products generated in the overall reaction process, the content of trimethoxy silane is about 80%; the utilization rate of silicon powder in production adopting an intermittent process is as high as 83%; if an improved intermittent-continuous production process is adopted, the utilization rate of the silicon powder can be increased by more than 10%.

Owner:湖北武大有机硅新材料股份有限公司 +1

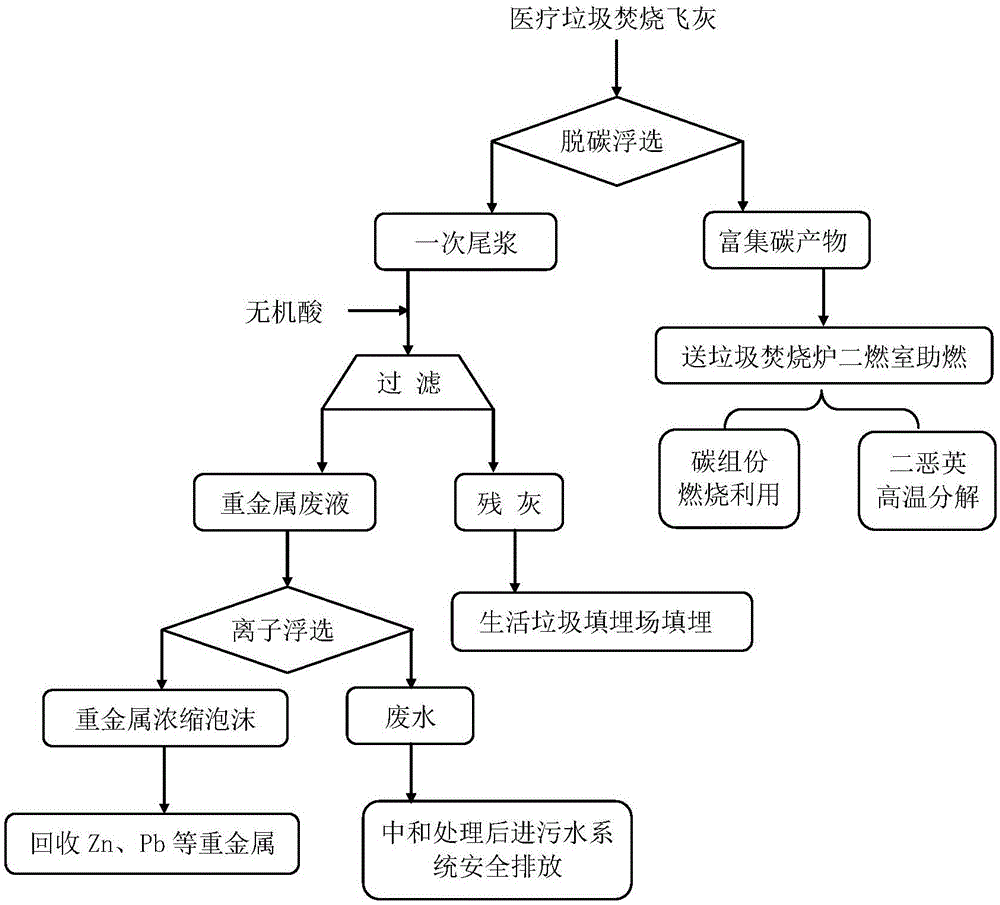

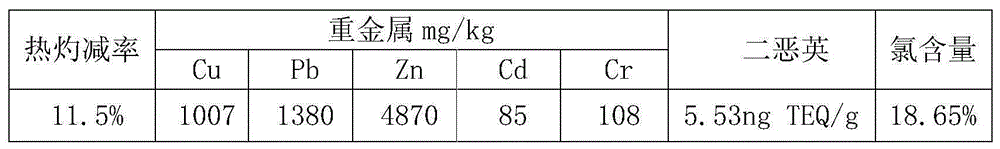

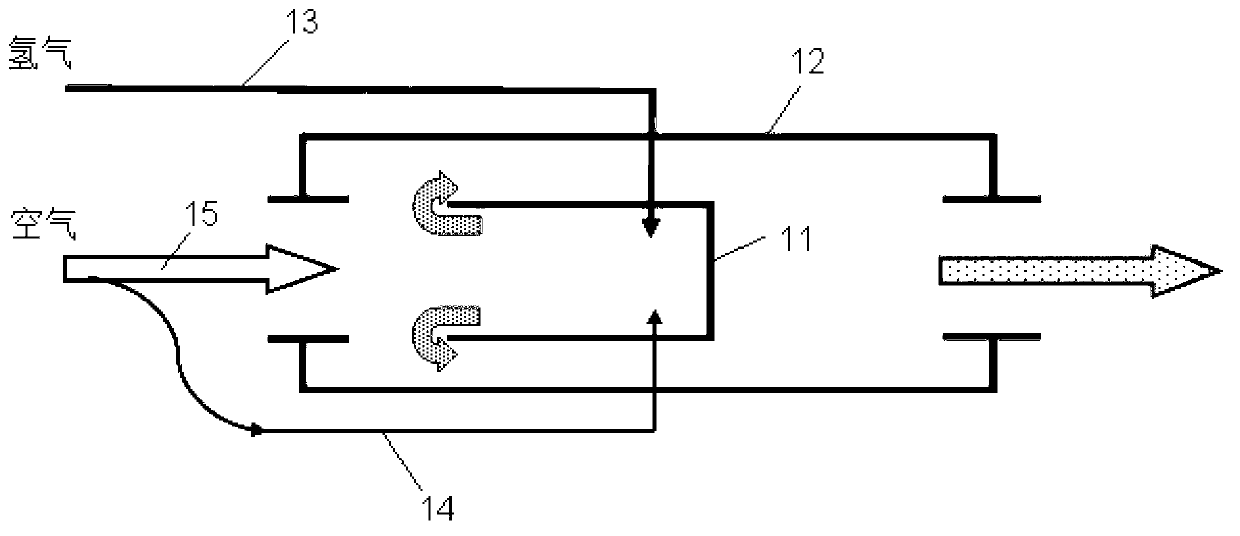

Treatment method for two-step flotation of medical waste incineration fly ash

ActiveCN105149101AReduce secondary synthesisRealize the utilization of fuelFlotationCombustion chamberMunicipal solid waste landfill

The invention discloses a treatment method for two-step flotation of medical waste incineration fly ash. The method includes the following steps that (1) decarbonization flotation is conducted, the two products of enriched carbon and primary tail pulp are obtained, and the enriched carbon product is fed into a secondary combustion chamber of a waste incinerator for helping to combust; (2) acid leaching and filtering are carried out, inorganic acid is added into the primary tail pulp which is obtained in the first step to be filtered after acid leaching is completed, and the two products of residual ash and heavy metal waste liquor are obtained; the residual ash is directly conveyed to a municipal solid waste landfill to be subjected to secure landfill disposal or reuse; (3) ion flotation is performed, flotation reagents are added into the heavy metal waste liquor which is obtained in the second step for ion flotation, and the two products of heavy metal concentration foam and waste water are obtained; the heavy metal concentration foam is fed into a smelting plant to recycle heavy metal Pb and Zn, and after reaching the standard through neutralizing treatment, the waste water is discharged into a sewage system. The treatment method has the advantages of being easy to operate, low in cost, good in treatment effect, free of secondary pollution and the like.

Owner:TIANJIN CHENGJIAN UNIV

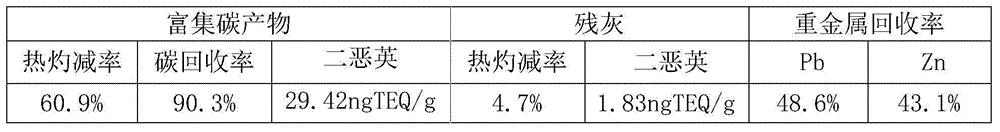

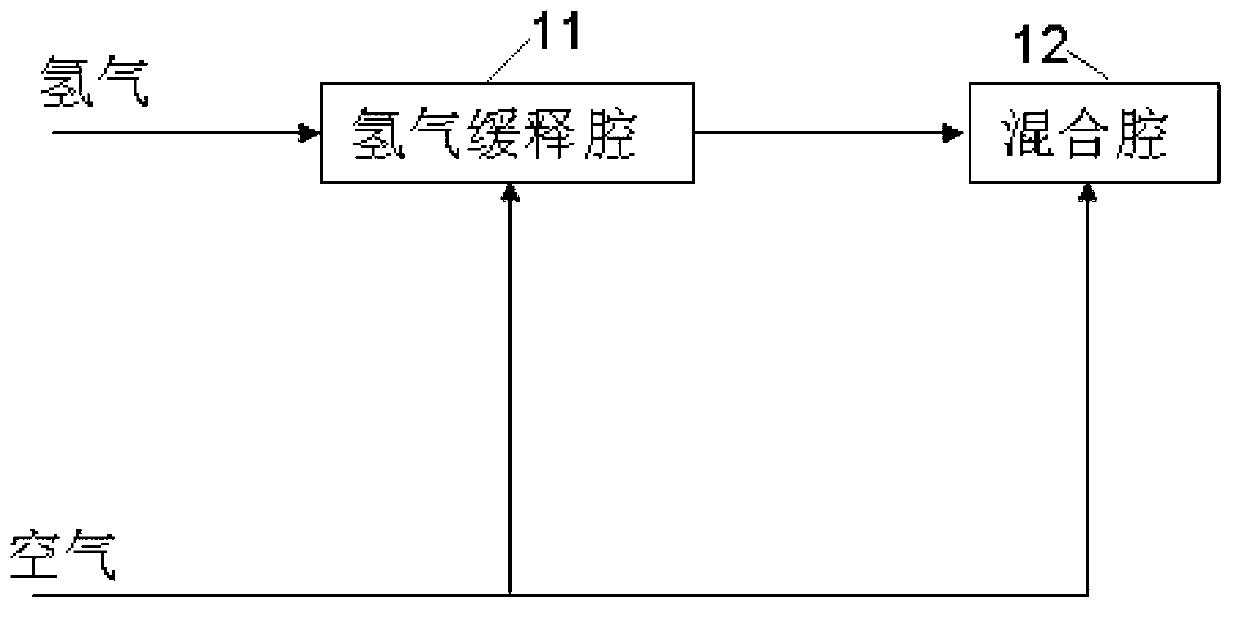

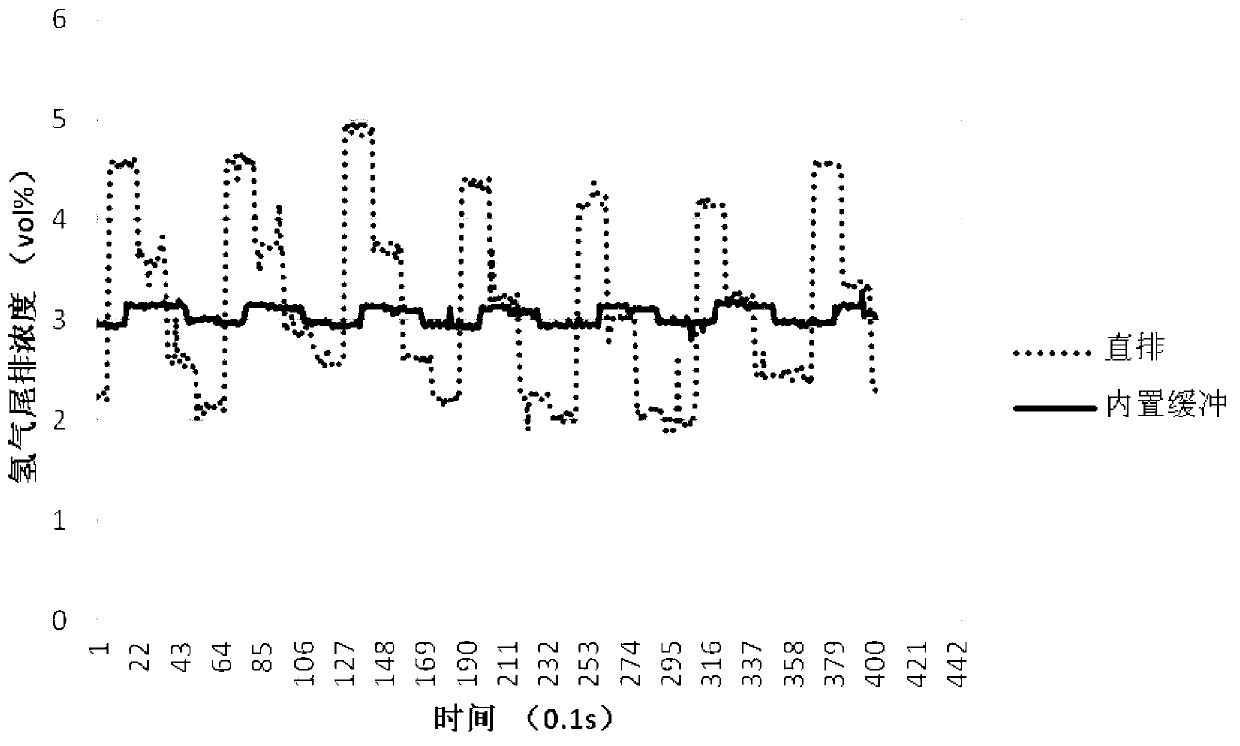

Method for lowering peak concentration of exhaust hydrogen of fuel battery system

The invention discloses a method for lowering peak concentration of exhaust hydrogen of a fuel battery system, which comprises steps as follows: air of the fuel battery system is continuously and stably discharged into a hydrogen slow release cavity through a cathode exhaust outlet by an air guide tube; hydrogen of the fuel battery system is discharged into a hydrogen slow release cavity through an anode exhaust outlet by a hydrogen guide tube, and is subjected to slow release by the air in the hydrogen slow release cavity; and after the hydrogen is discharged into a mixing cavity from the hydrogen slow release cavity by the slow release gas subjected to slow release, purging air from another way led out by the cathode exhaust outlet of the fuel battery system performs continuous and stable purging on the slow release gas to further lower the concentration of the hydrogen in the slow release gas, and the hydrogen is discharged from a discharge port of the mixing cavity. On the premise of not changing the fuel battery system, the anode exhaust hydrogen, which is discharged by pulses or discharged by combination of continuous discharge and pulse discharge, is buffered, diluted and subjected to purging mixing with cathode gas, thereby lowering the hydrogen to explosion limit below.

Owner:上海新源动力有限公司

Large-volume vacuum cracking furnace

InactiveCN105617943ASmall temperature fluctuationsEnsure normal dischargeHeat treatmentsPressurized chemical processFiberRecuperator

The invention relates to a large-volume vacuum cracking furnace and belongs to the field of chemical fiber product processing equipment. The large-volume vacuum cracking furnace is characterized in that a track is arranged on a trolley support of the large-volume vacuum cracking furnace; a trolley moves in the extension direction of the track; a trolley driver drives the trolley to move into a furnace shell; a cavity is formed in the furnace shell; an electric heating tube is arranged in the cavity; the furnace shell is connected with a waste gas heater; the waste gas heater is connected with a heat exchanger. The large-volume vacuum cracking furnace provided by the invention has the benefits that gas is supplemented after heating, so that the temperature in the furnace is small in fluctuation, and the cleaning effect is ensured; the gas is exhausted through a vacuum pump after being cooled by two sections of shell and tube type heat exchangers connected in series, so that the use safety of the vacuum pump and the safety of gas exhaust are ensured; as a nitrogen pipeline is arranged in the furnace, when the temperature in the furnace exceeds the standard, a system automatically opens a nitrogen valve and conveys a certain quantity of nitrogen into the furnace, so that a polymer on a cleaning part in the furnace does not burn, that is, the equipment safety is ensured.

Owner:JIANGSU XINLONG CHEM FIBER MACHINERY

Landfill leachate graphene integrated purification system and process

InactiveCN110526521AImprove adsorption capacityImprove featuresWater/sewage treatment by irradiationTreatment involving filtrationPhoto catalyticEnvironmental engineering

The invention provides a landfill leachate graphene integrated purification system. The system comprises a landfill leachate collection and transportation apparatus, and further comprises an anaerobictank, a multi-stage filtering apparatus, a multi-stage graphene water purification apparatus, a graphene photo-catalytic degradation apparatus, a multiple purification tank, a multi-stage graphene sterilization apparatus, and a graphene ceramic water purification apparatus. The invention also provides a purification process using the purification system. The system is used to purify landfill leachate, and can achieve effects such as thorough purification, high efficiency, and low cost.

Owner:东莞市粤绿环保有限公司

Cleaning agent for removing rust scale in plate heat exchanger and preparation method of cleaning agent

The invention relates to a cleaning agent for removing rust scale in a plate heat exchanger and a preparation method of the cleaning agent. The cleaning agent is prepared by compounding the followingcomponents of, in percentage by weight, 30%-45% of chelating agent, 4%-10% of high-efficiency dispersing agent, 0.03%-0.1% of penetrating agent, 1%-5% of corrosion inhibitor and the balance water. According to the cleaning agent for removing the rust scale in the plate heat exchanger, the cleaning agent can infiltrate, react, chelate and disperse the rust scale in the plate heat exchanger of a central heating system within 2-4 hours at normal temperature, so that a scale layer is enabled to be soft, chelated and dissolved, the scale (rust) removal rate is high, the cleaning agent is mainly composed of organic high-molecular polymers of polyfunctional groups containing carboxyl, hydroxyl and the like, rust removal is thorough, metal, enamel and glass are not corroded, the cleaning agent isnon-toxic to human bodies, waste liquid can be safely discharged, and the pollution problem is avoided.

Owner:天津全诚桓金环保科技有限公司

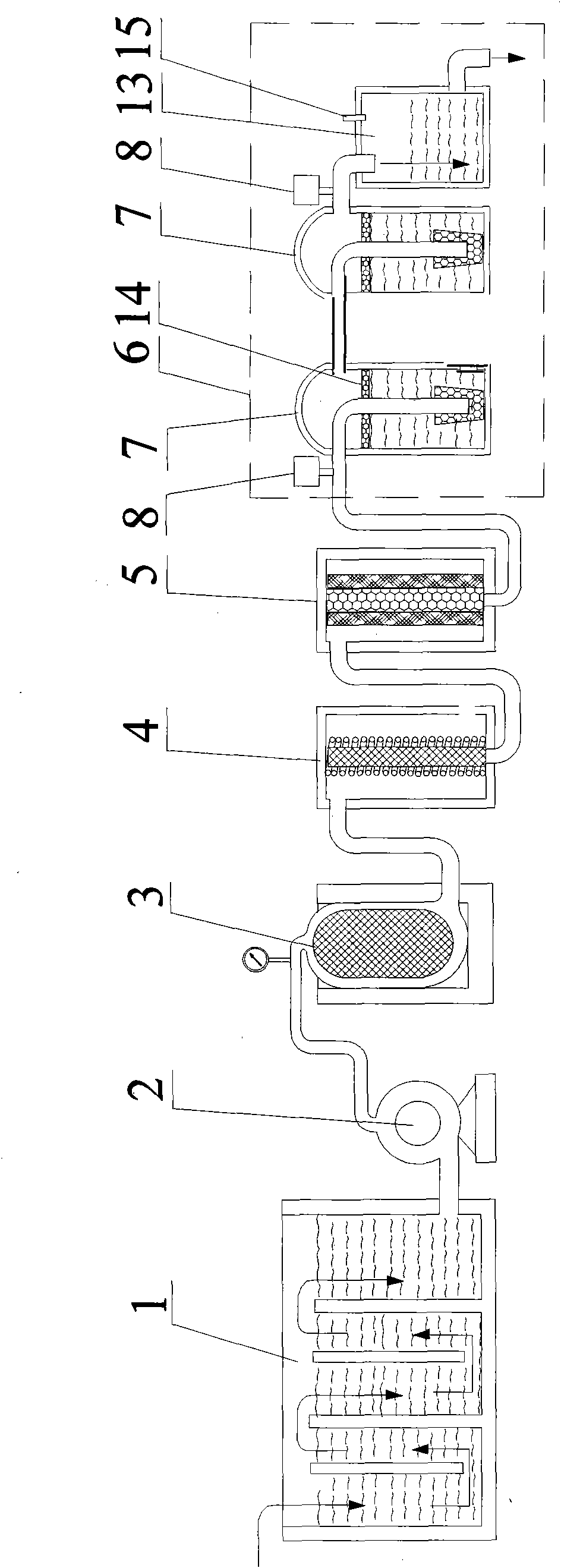

Precious metal contained waste liquid recovery processing unit

InactiveCN102021344AIncrease the adsorption capacityCompact structureWater contaminantsWaste water treatment from metallurgical processIonPrecious metal

The invention provides a precious metal contained waste liquid recovery processing unit, comprising a multi-level deposit chamber and a connecting pipeline, wherein a water pump is connected at the water outlet at the lower part of a recovery deposit chamber; the water pump is successively connected with a bag type filter with a pressure gauge, a carbon fiber disc filter and a carbon fiber felt filter through the pipeline; a group of resin adsorption devices are arranged on the pipeline at the outlet of the carbon fiber felt filter; the adsorption device comprises two resin adsorption tubes; and conductivity analyzers with alarming function are respectively arranged on the water inlet pipeline of the adsorption device and the water outlet pipeline. In the invention, for different preciousmetal ions, the carbon fiber adsorption capacity is improved by different processing modes such as activated preparation, superficial treatment, and specific organic matter adsorption; the precious metal in the waste liquid can be recovered effectively, and leaky precious metal can be adsorbed again by special resin of the adsorption device; cyanide, organic matters and other precious metal ions in the liquid can be removed; and then acid-base treatment is carried out to realize safety emission or recycling.

Owner:游京初

Painting room for treating VOCs waste gas

InactiveCN105194987AEmission safetyDispersed particle filtrationUsing liquid separation agentLacquerProduct gas

The invention provides a painting room for treating VOCs waste gas, and belongs to the technical field of waste gas treatment. The painting room comprises a painting room main body, a waste gas treating assembly and an air inducing assembly, wherein the waste gas treating assembly comprises an ultraviolet treating box and a plasma treating box which are mutually connected. When painting operation is conducted in the painting room, VOCs gas can be quickly exhausted and treated, and the environment in the painting room can be purified, so as to facilitate painting of workpieces.

Owner:成都鑫威隆机电设备有限公司

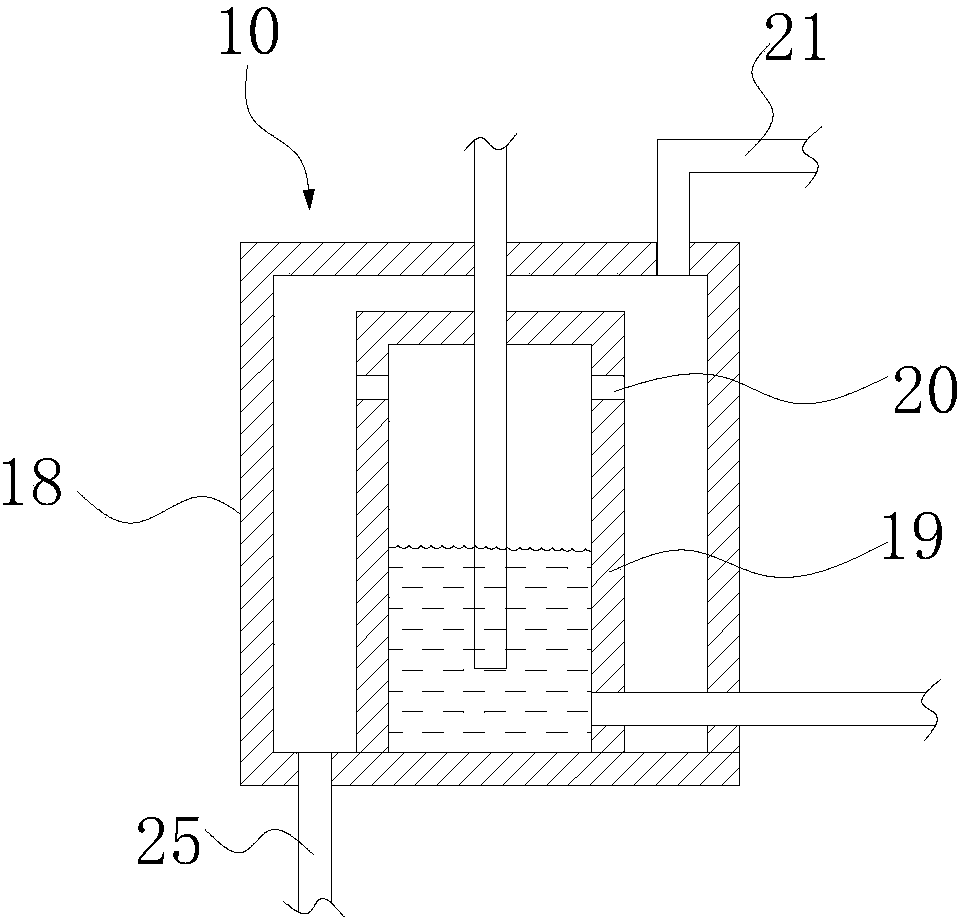

Recirculation unit for a fuel cell system

InactiveCN103563147AImprove reliabilityHigh resolutionFuel cell auxillariesVapor condensationFuel cellsEngineering

The invention relates to a recirculation unit (14) for a fuel cell system (I) comprising at least one fuel cell (2) which has an anode region (3) and a cathode region (4), comprising a recirculation line (12) which connects the outlet (11) of the anode region (3) to the inlet (10) thereof, comprising a liquid separator (15), which is arranged in the area of the recirculation line (12), and which comprises a discharge line (16) having a discharge valve (17) for liquid and / or gases. The invention is characterized in that a bubble sensor (18) for controlling the discharge valve (17) is arranged in the area of the discharge line (16). A method for discharging liquid and / or gases from such a recirculation unit (14) provides for the discharge valve (17) to be opened and then closed as a function of an event detected by the bubble sensor (18).

Owner:DAIMLER AG

Marine ballast water treatment system

ActiveCN102491569AImprove filtering effectWith self-cleaning filter functionNitrogen purification/separationMultistage water/sewage treatmentWater treatment systemBallast water treatment

The invention relates to a marine ballast water treatment system which comprises a kingston valve, a seawater coarse filter, a ballast water pump, a seawater fine filter and a ballast tank, wherein the kingston valve is communicated with the ballast tank by sequentially passing the seawater coarse filter, the ballast water pump, a mechanical filter, a microfiltration membrane filter and the seawater fine filter, a nitrogen producing device is used for supplying nitrogen to seawater via a nitrogen and water mixer, and microbes comprising sediment and organic matters in ballast water can be separated and treated so as to inhibit the growth of the residual microbes and bacteria and meet a strict discharge standard; and furthermore, the system has an automatic cleaning function, is convenientto use, maintenance-free and long in service life, and can be used for saving the use cost.

Owner:JIANGSU NANJI MACHINERY

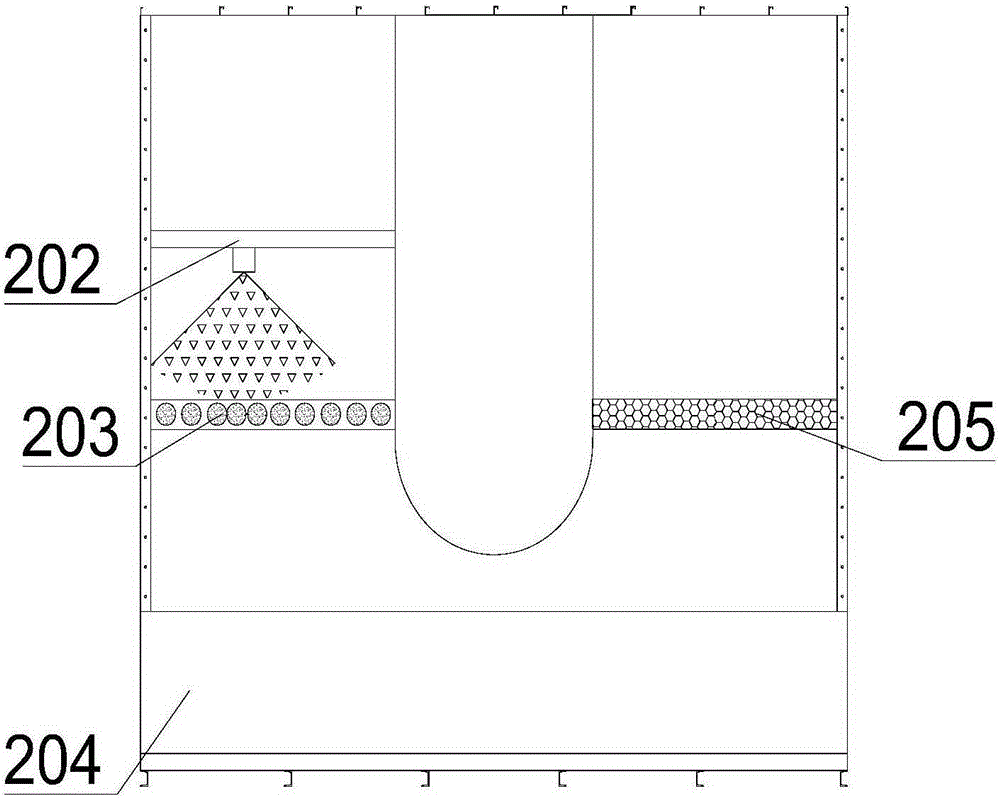

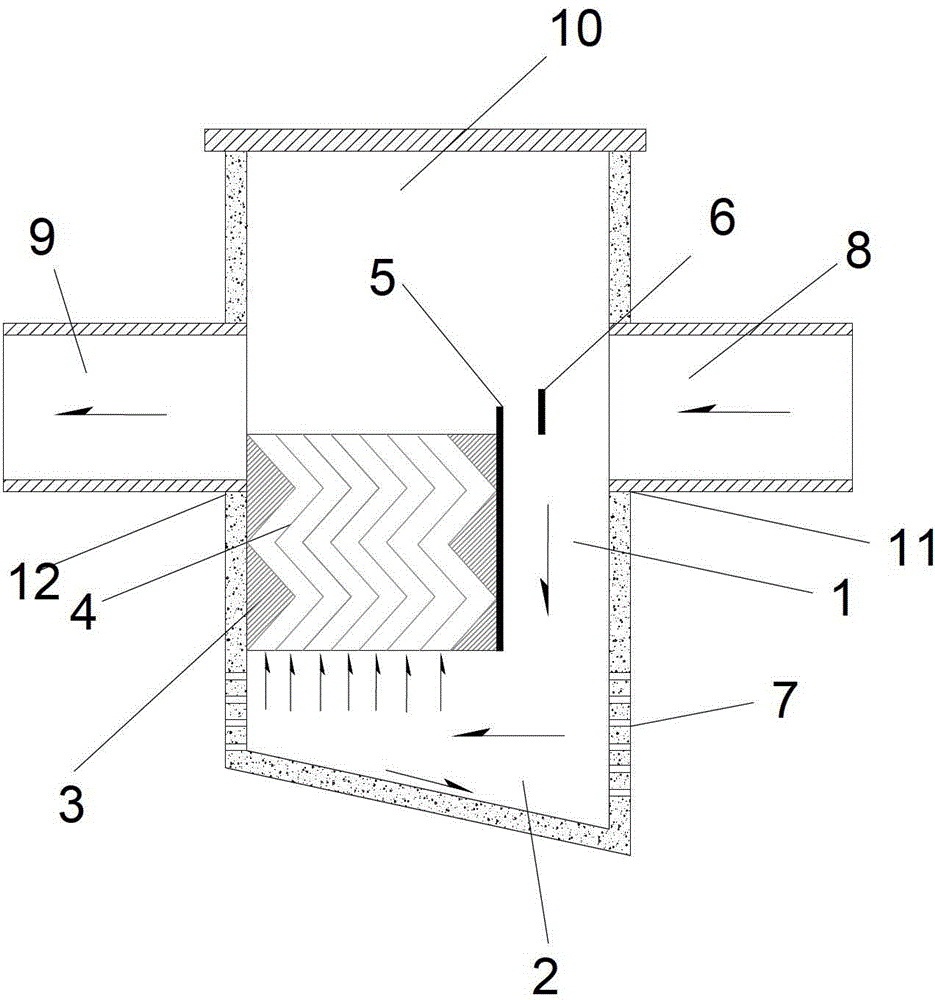

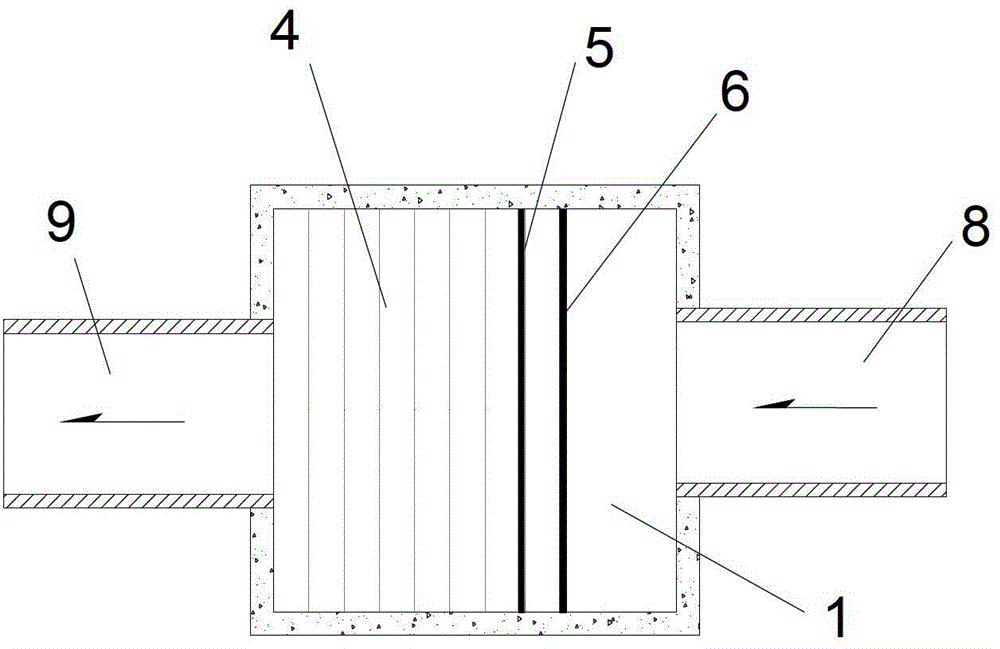

Tail end rainwater purifying well for separate system rainwater drainage system

ActiveCN103334484ASimple structureLow costFatty/oily/floating substances removal devicesEngineeringSuspended matter

The invention discloses a tail end rainwater purifying well for a separate system rainwater drainage system. The tail end rainwater purifying well comprises a water inlet and a water outlet, wherein the water inlet and the water outlet are arranged oppositely in the horizontal direction. A connection line between the water inlet and the water outlet is a reference path. A cleaning and digging area, a mud depositing area and a suspended matter separating area are sequentially communicated from the water inlet to the water outlet and arranged inside the tail end rainwater purifying well. The suspended matter separating area is divided into a plurality of channels through a folded plate assembly, wherein the channels are perpendicular to the reference path. The bottoms of the channels are entrances connected with the mud depositing area. The tops of the channels are exits communicated with the water outlet. The folded plate assembly comprises at least two folded plates which are arranged in a mutually parallel mode and are vertically arranged inside the suspended matter separating area. The tail end rainwater purifying well solves the problem that initial rainwater runoff in a rainwater system pollutes receiving water, and promotes suspended matter in rainwater to be deposited and separated in the tail end rainwater purifying well effectively on the basis of an original rainwater well and by utilizing a shallow pool principle and arranging the folded plate assembly.

Owner:ZHEJIANG UNIV

Environment-friendly intermittent blowdown flash tank

PendingCN107726291ARealize expansion flashExhaust steam contains less waterBoiler cleaning apparatusWater vaporLiquid water

The invention discloses an environment-friendly intermittent blowdown flash tank. The environment-friendly intermittent blowdown flash tank comprises an outer shell (1), a guiding cylinder (2) and anemptying cylinder (3) which sequentially sleeve from outside to inside, wherein the upper end of the emptying cylinder (3) is located outside the outer shell (1), the lower end of the emptying cylinder (3) is located in the upper end of the guiding cylinder (2), the guiding cylinder (2) is located in the outer shell (1), a discharged sewage inlet (4) is formed in the side wall of the outer shell (1), a discharged sewage outlet (5) is formed in the lower portion of the outer shell (1), and a baffle plate (6) is arranged between the outer shell (1) and the guiding cylinder (2) and is located above the discharged sewage inlet (4). The environment-friendly intermittent blowdown flash tank is provided with the baffle plate, utilizes the baffle plate to increase the contact area with water steam, makes liquid drops attached to the surface of the baffle plate to form large liquid drops, utilizes surface tension of water and the gravity action of the large liquid drops to overcome the drag force of discharged steam and decreases emptied liquid water.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

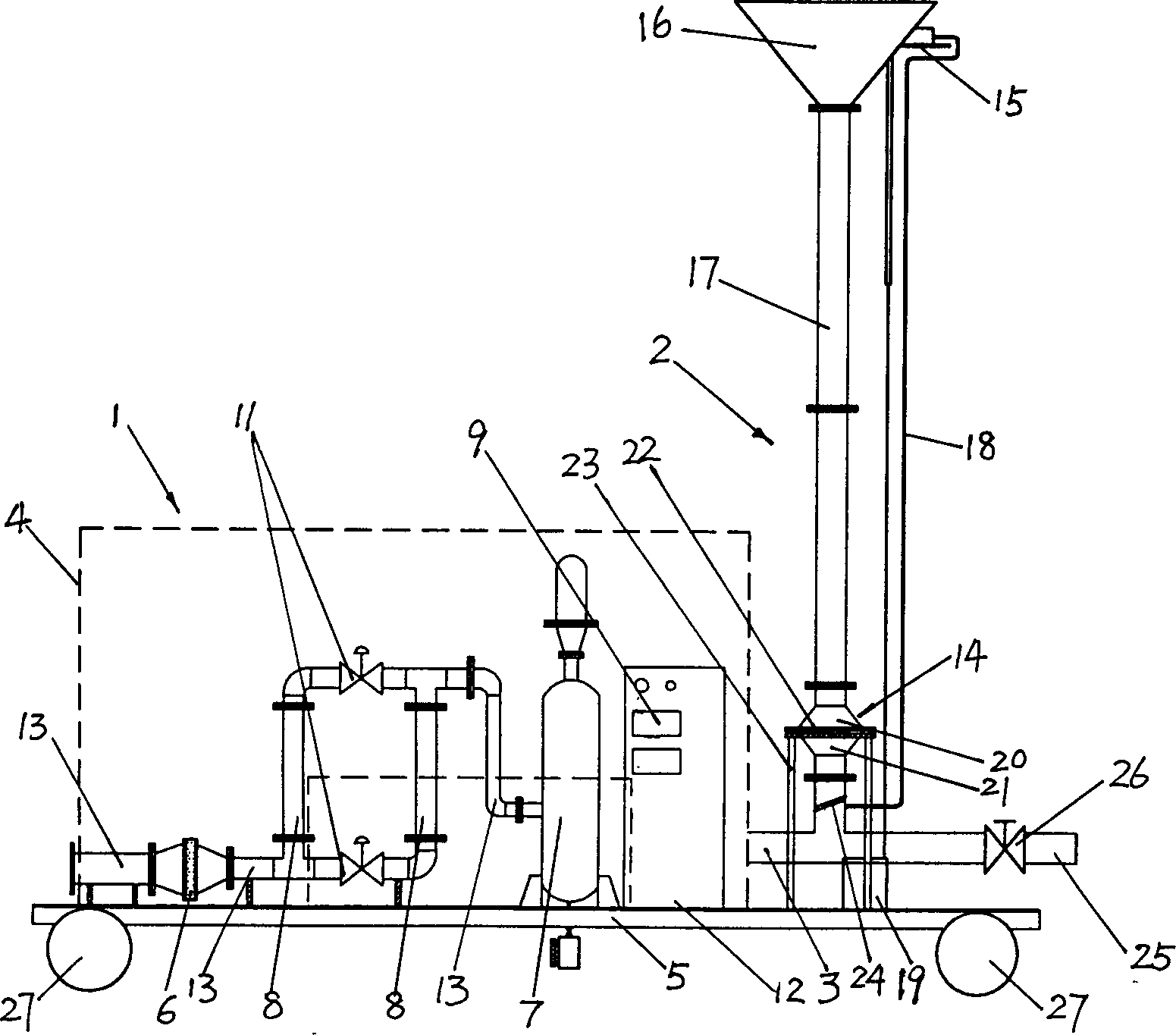

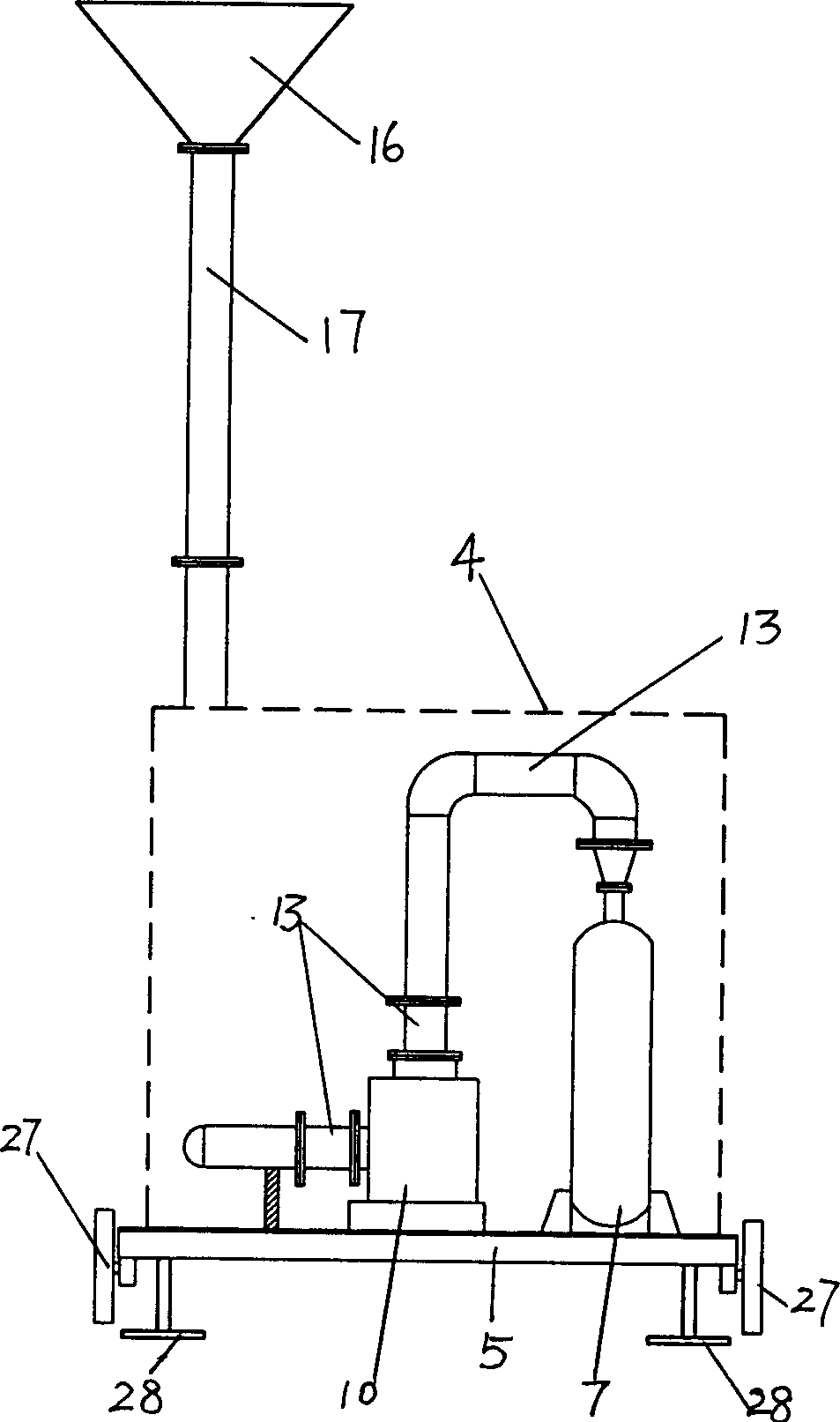

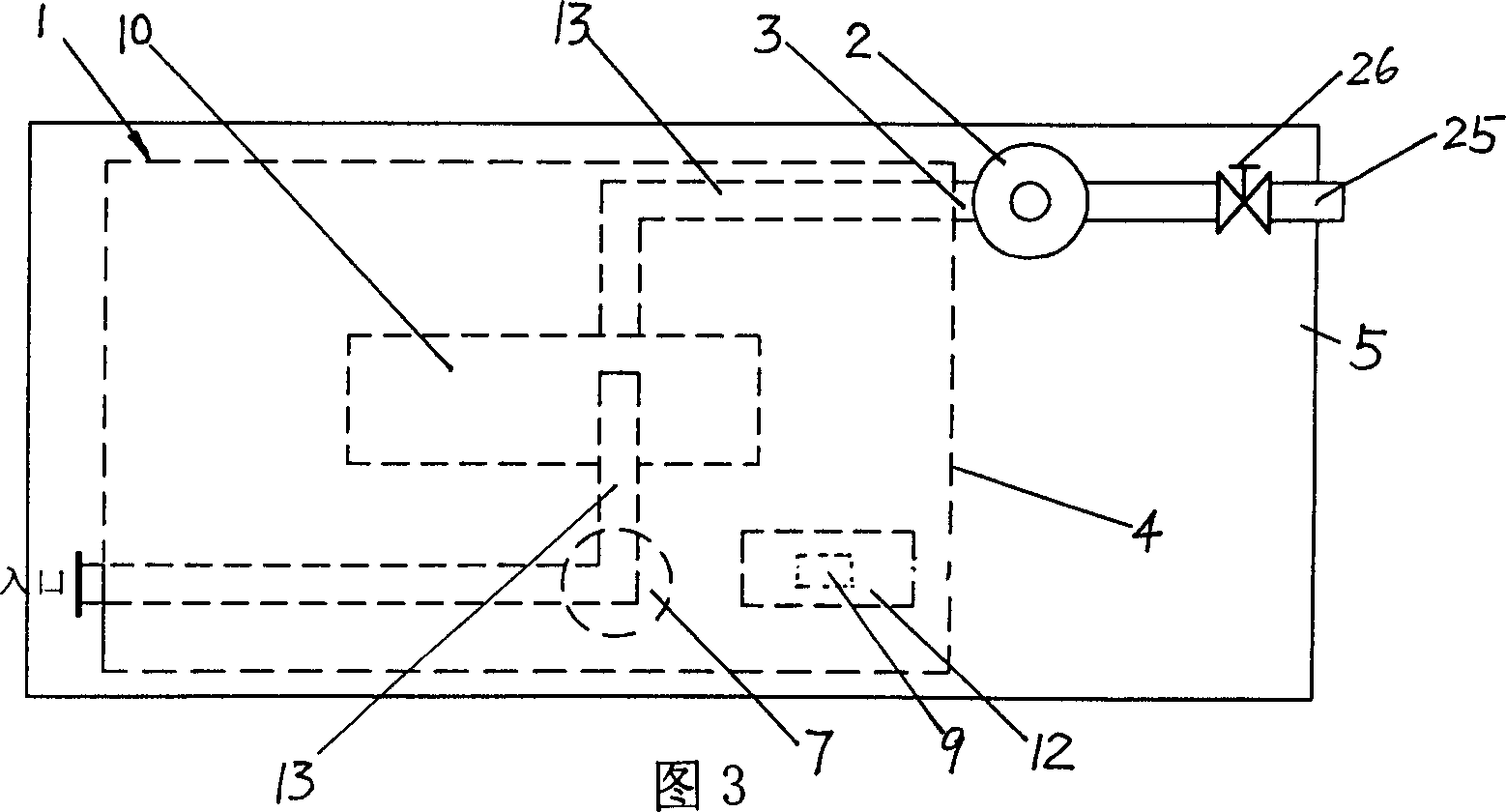

Garbage filling and burying gas test and torch device

InactiveCN1554950AImplement extractionRealize monitoringIncinerator apparatusMaterial analysisFlame arresterVapor–liquid separator

The present invention discloses landfill gas test and torch apparatus, and the apparatus is connected to the gas collecting well to extract, measure, burn and exhaust landfill gas and consists of landfill gas test unit and pollution-less burning and exhausting unit. The present invention features that the landfill gas test unit includes screen type gas filter, gas separator, flow meter, gas analyzer and blower connected together; and that the outlet of the blower is connected with flame arrester in the pollution-less burning and exhausting unit or other subsequent post-treating and utilizing unit, with the flame arrester being connected with evacuating pipe, torch burner and igniter successively.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com