Patents

Literature

75results about How to "Increased processing load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data packet processing method and device

ActiveCN104811382AIncreased processing loadReduce processing efficiencyHybrid transportNetworks interconnectionData centerVirtual switch

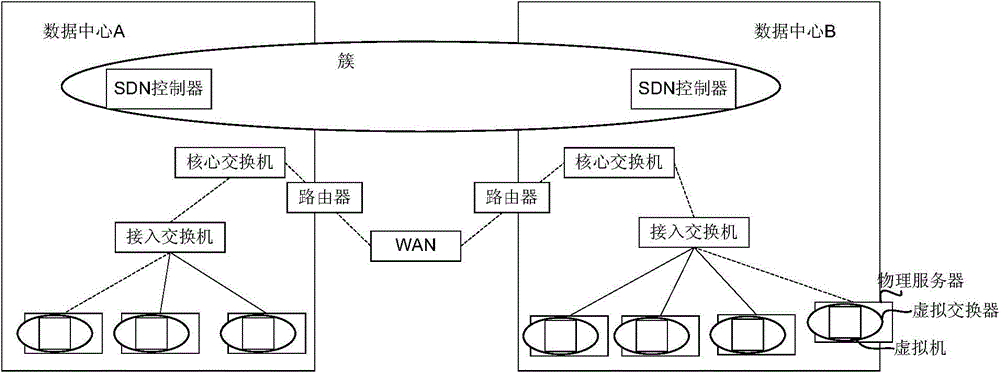

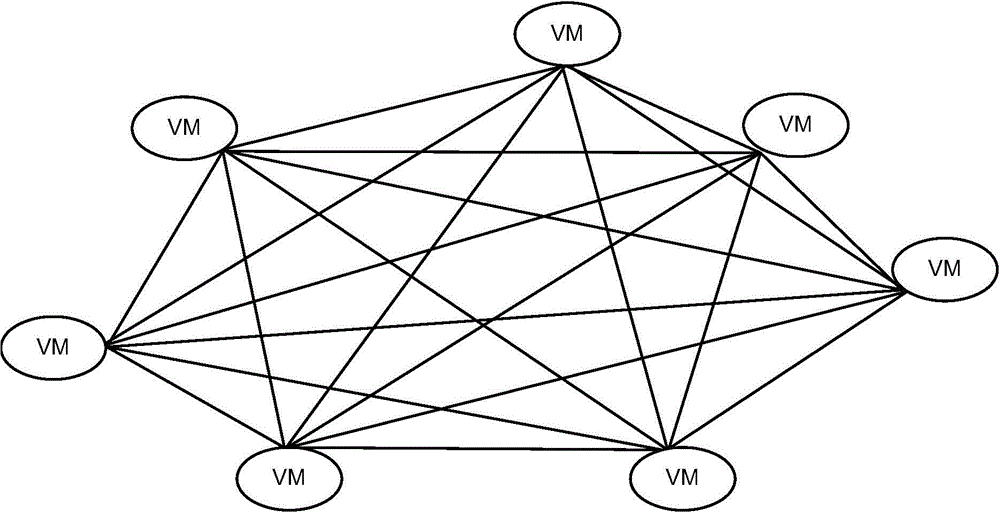

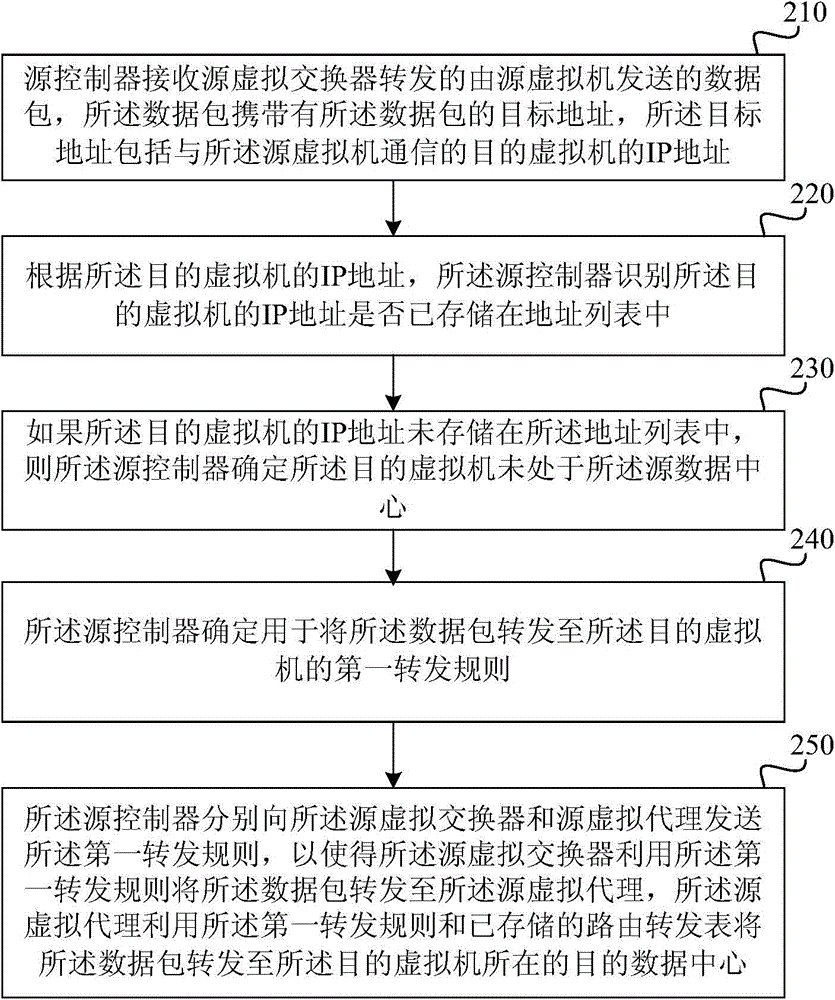

An embodiment of the invention relates to a data packet processing method and device. The method includes the steps: receiving a data packet forwarded by a source virtual switch and transmitted by a source virtual machine by a source controller; recognizing whether a TP (teleprocessing) address is stored in an address list or not by the source controller; determining that an objective virtual machine is not positioned in a source data center by the source controller if the TP address is not stored in the address list; determining first forwarding rules for forwarding the data packet to the objective virtual machine by the source controller; respectively transmitting the first forwarding rules to the source virtual switch and a source virtual proxy by the source controller, accordingly, forwarding the data packet to the source virtual proxy according to the first forwarding rules by the source virtual switch, and forwarding the data packet to an objective data center of the objective virtual machine according to the e first forwarding rules and a stored route forwarding table by the source virtual proxy. The source controller, the source virtual switch, the source virtual machine and the source virtual proxy are positioned at the source data center.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

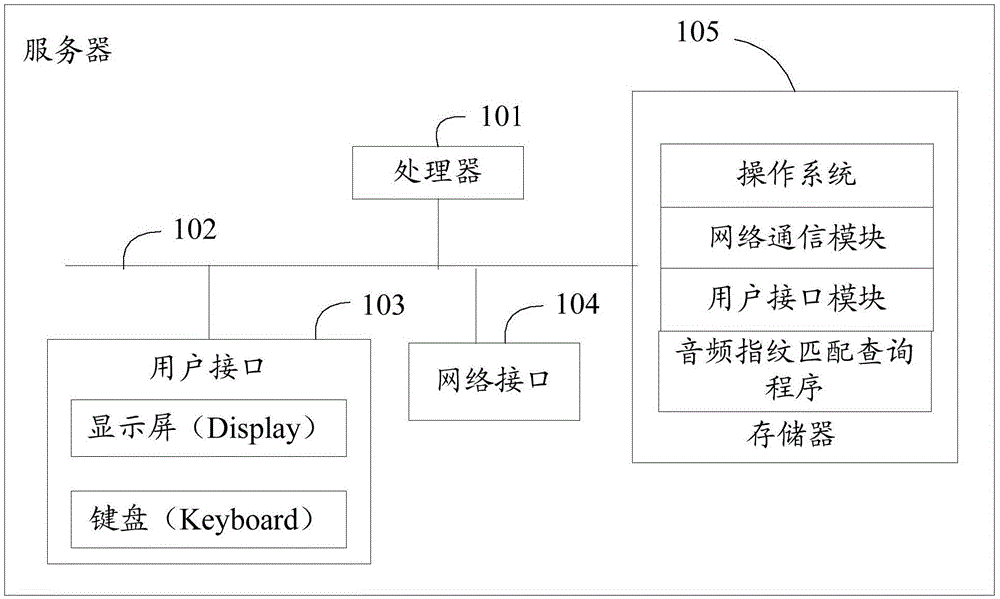

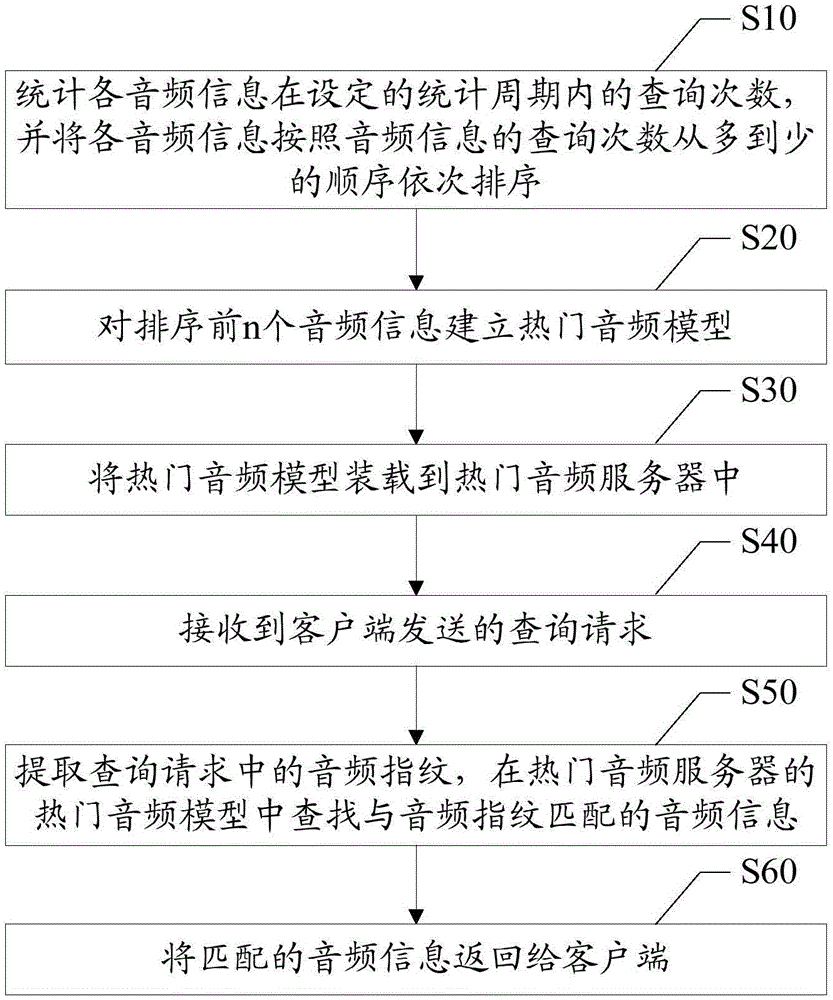

Audio fingerprint matching query method and device

ActiveCN105138541AFast query processingIncreased processing loadSpecial data processing applicationsAudio data indexingClient-sideFingerprint

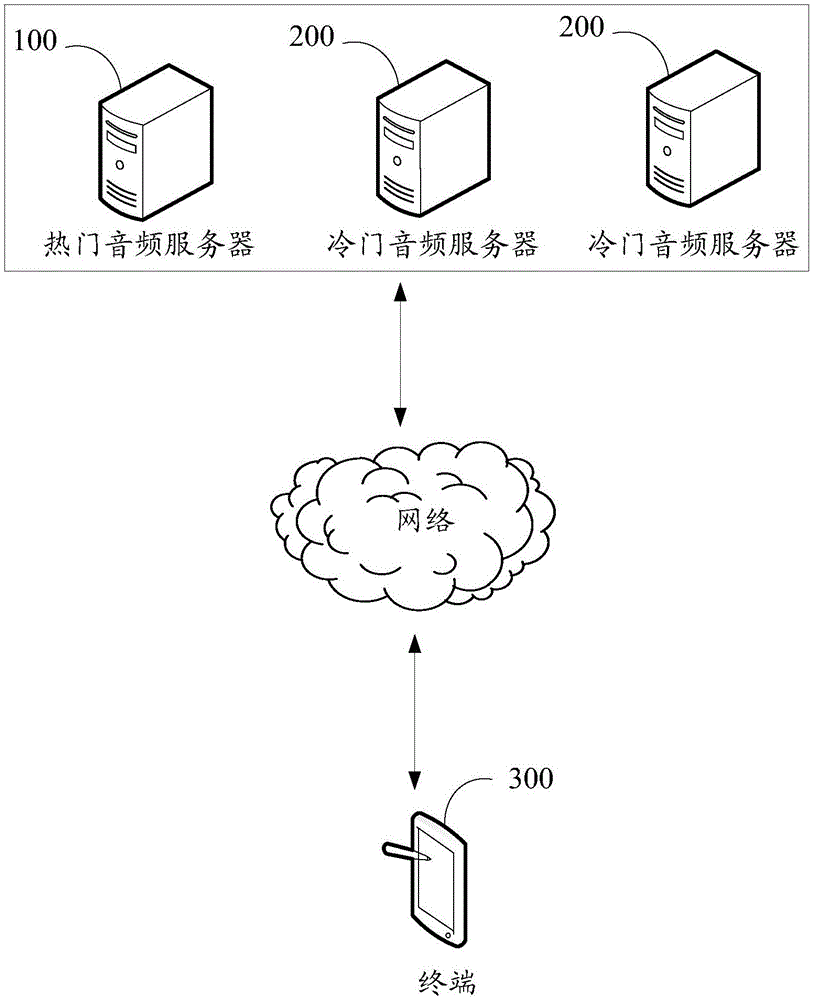

The invention discloses an audio fingerprint matching query method. The audio fingerprint matching query method comprises the following steps: counting query times of each kind of audio information within a set counting period, and sequentially ranking the audio information from high to low according to the query times; building a hot audio model for top n audio information, wherein n is a positive integer; loading the hot audio model into a hot audio server; when receiving a query request transmitted by a client, extracting an audio fingerprint in the query request, and searching the audio information matched with the audio fingerprint from the hot audio model in the hot audio server; and returning the matched audio information to the client. The invention further discloses an audio fingerprint matching query device. The hot audio model is built in the system, so that reduction of the modeling pressure of the system is facilitated. The audio information is searched by the hot audio server from the hot audio model, so that improvement of the throughput of the system is facilitated; and the audio matching query efficiency and success rate are improved.

Owner:GUANGZHOU KUGOU COMP TECH CO LTD

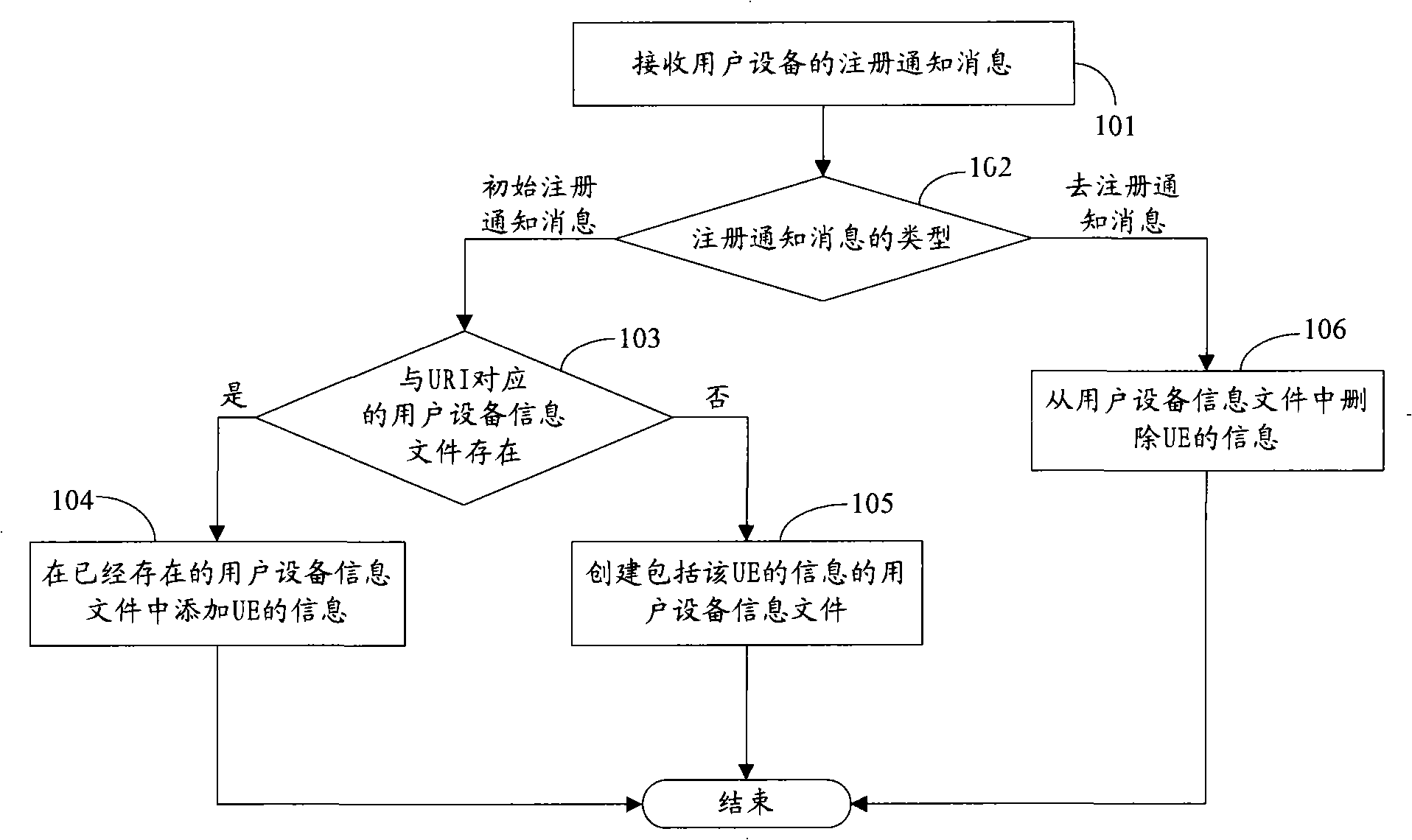

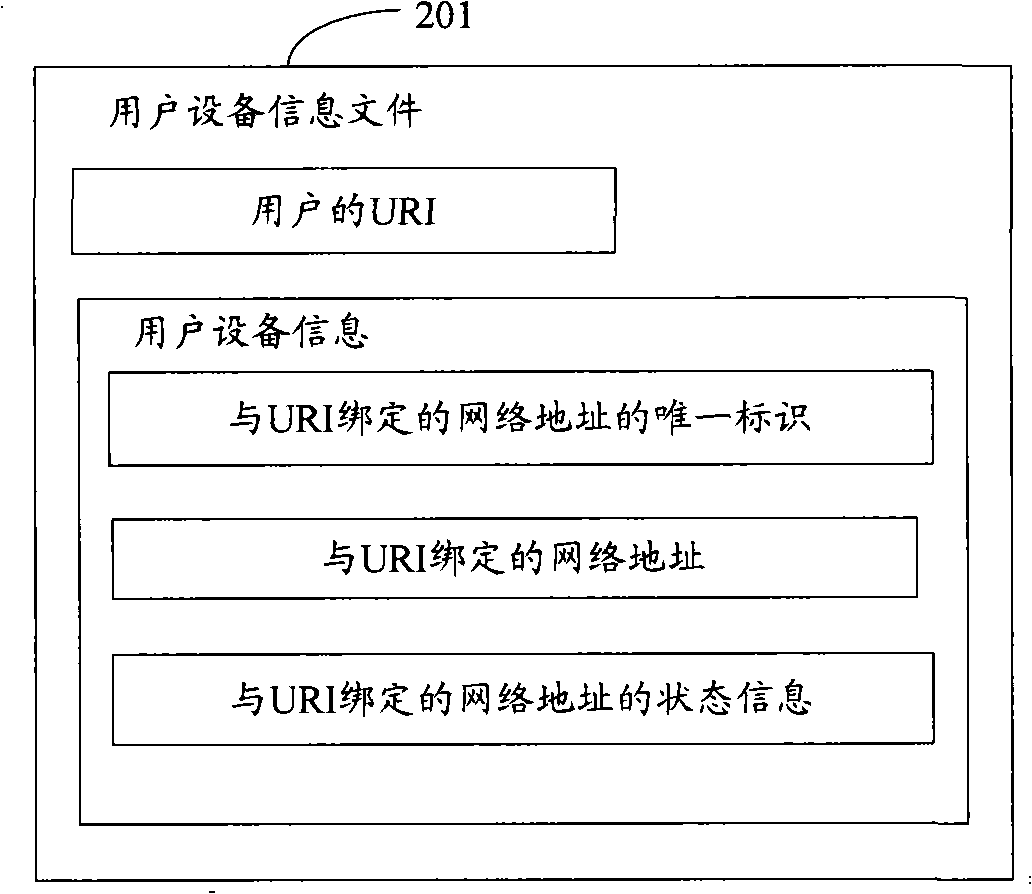

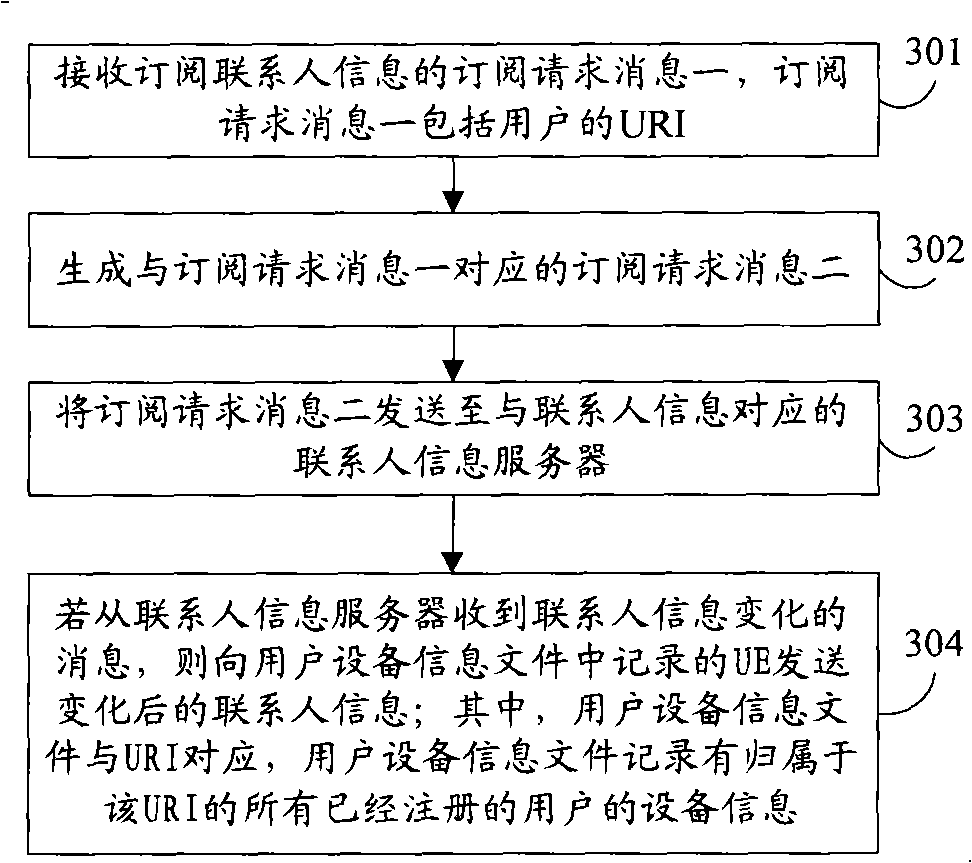

Method, system and network appliance providing contact information

ActiveCN101335634AIncreased processing loadWill not occupySpecial service provision for substationRegistered userWorld Wide Web

The invention relates to the field of communication technology, and discloses a method for providing the information of contact persons, a system and network equipment thereof, wherein, the method comprises the steps that a subscription request message one for subscribing the information of the contact persons is received, and the subscription request message one contains a user URI; a subscription request message two corresponding to the subscription request message one is generated and sent to an contact person information server corresponding to the information of the contact person; if the message of the change of the information of the contact person coming from the contact person information server is received, the changed information of the contact person is sent to UE recorded in a user equipment information file that is corresponding to a public user ID and records all registered user equipment information which belongs to the user; the invention also provides a corresponding system, that is network equipment. The use of the invention can cause a user to receive a notification message from a plurality of UE only by sending a subscribing request in one user equipment.

Owner:HUAWEI TECH CO LTD

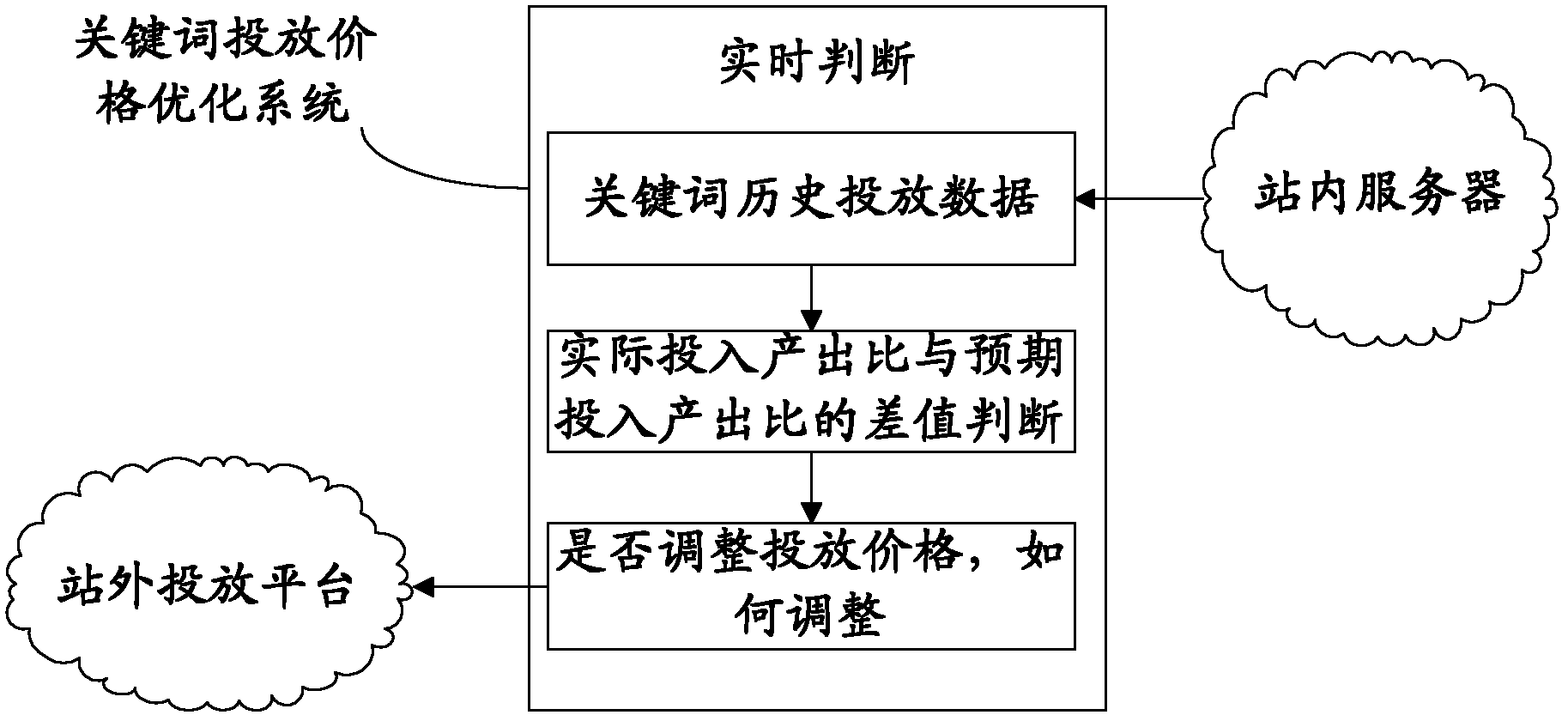

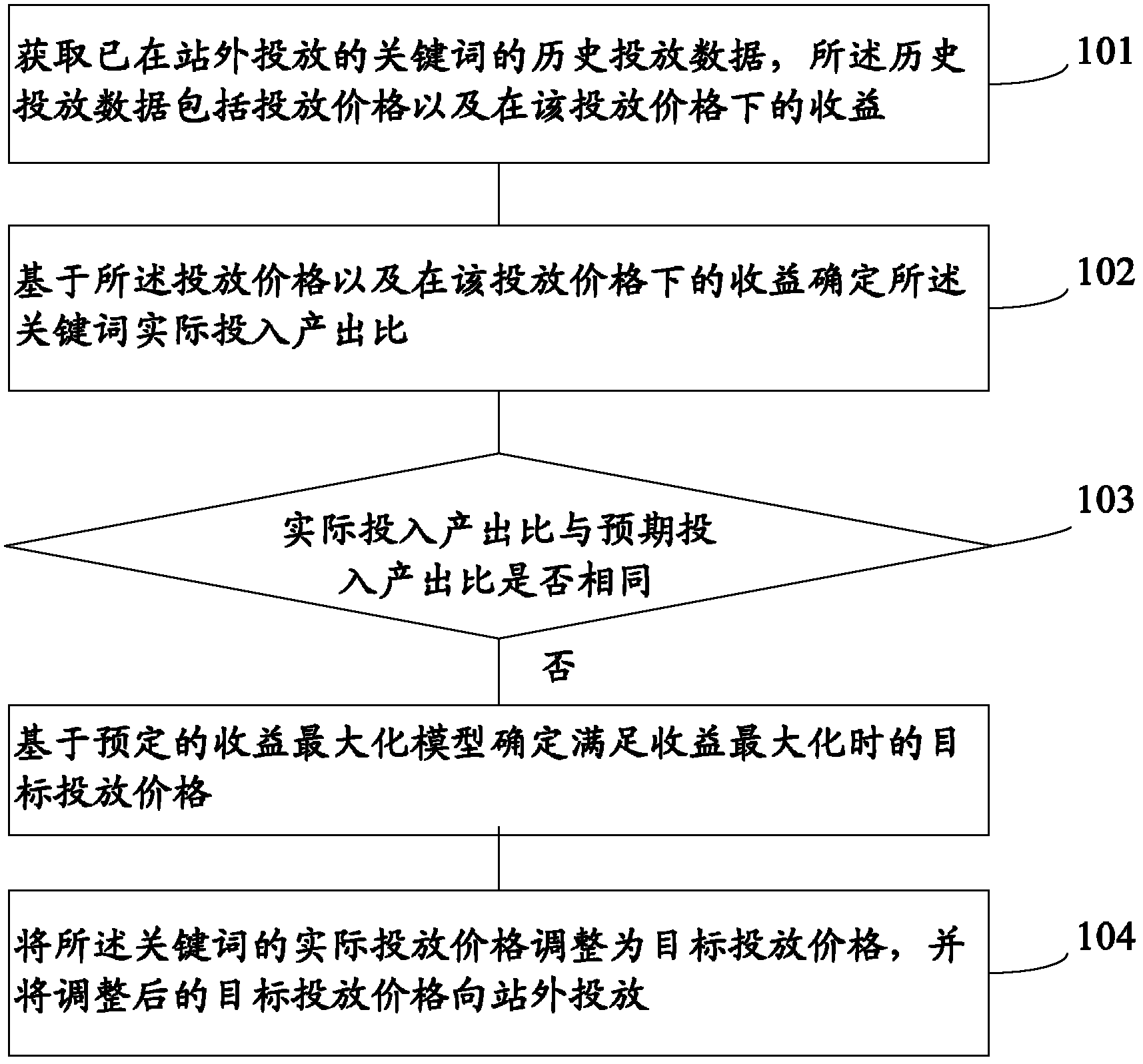

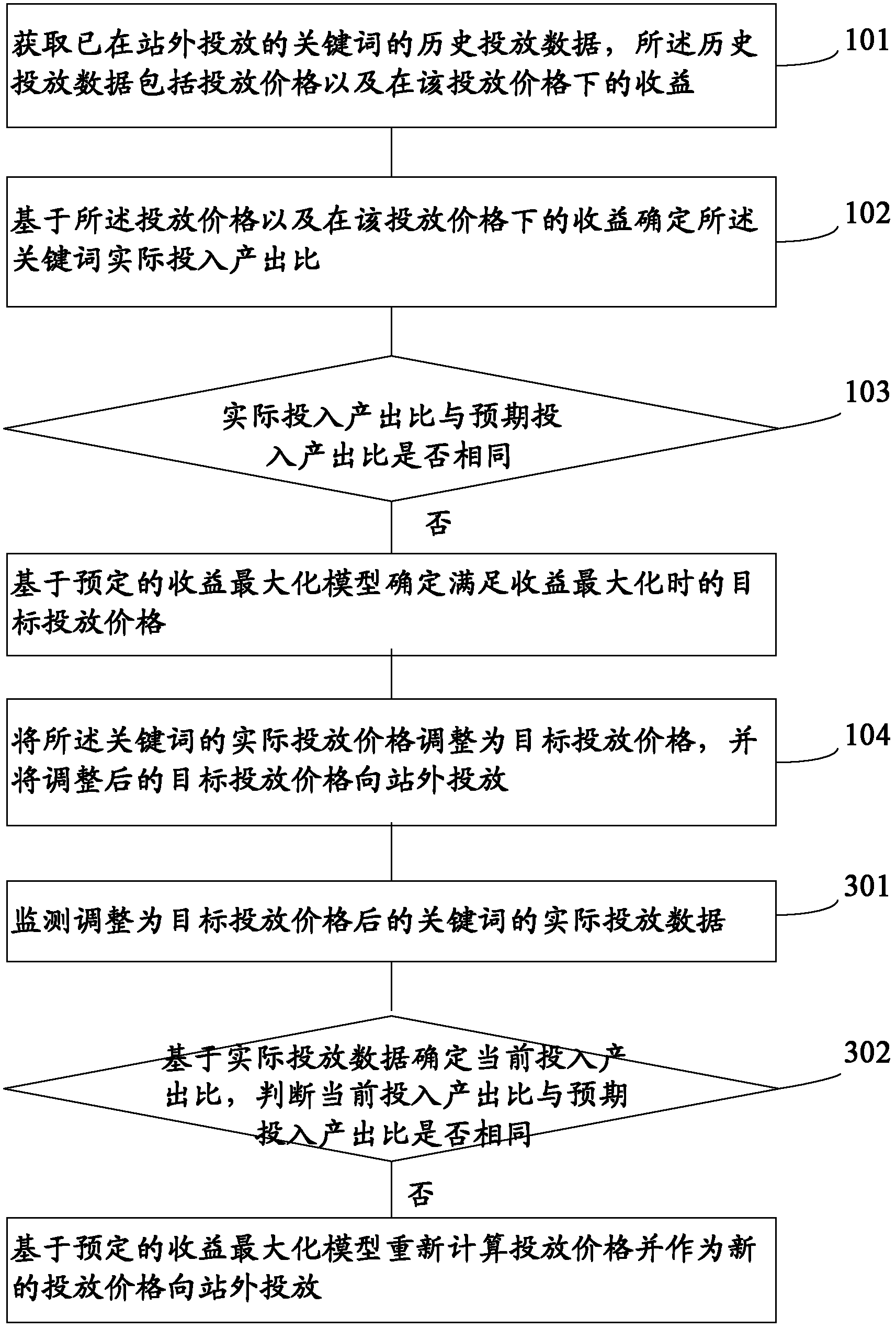

Keyword putting price optimizing process method and system

InactiveCN103164805AShorten adjustment timeIncreased processing loadMarketingSpecial data processing applicationsProcess systemsComputer science

The invention provides a keyword putting price optimizing process method. The method comprises: obtaining historical putting data of a keyword which is already put outside of a station, wherein the historical putting data comprises a putting price and income under the putting price; confirming an actual input-output ratio of the keyword based on the putting price and the income under the putting price; judging if the actual input-output ratio is the same as an expected input-output ratio, if not, confirming an object putting price which meets income maximization based on a predetermined income maximization model; adjusting the actual putting price of the keyword to the object putting price, and putting the adjusted object putting price outside the station. The invention further provides a keyword putting price optimizing process system for achieving the method. The keyword putting price optimizing process method and the system can enable the putting price, to be put outside the station, of the keyword to be accurate, and the processing of price adjustment is simple.

Owner:ALIBABA GRP HLDG LTD

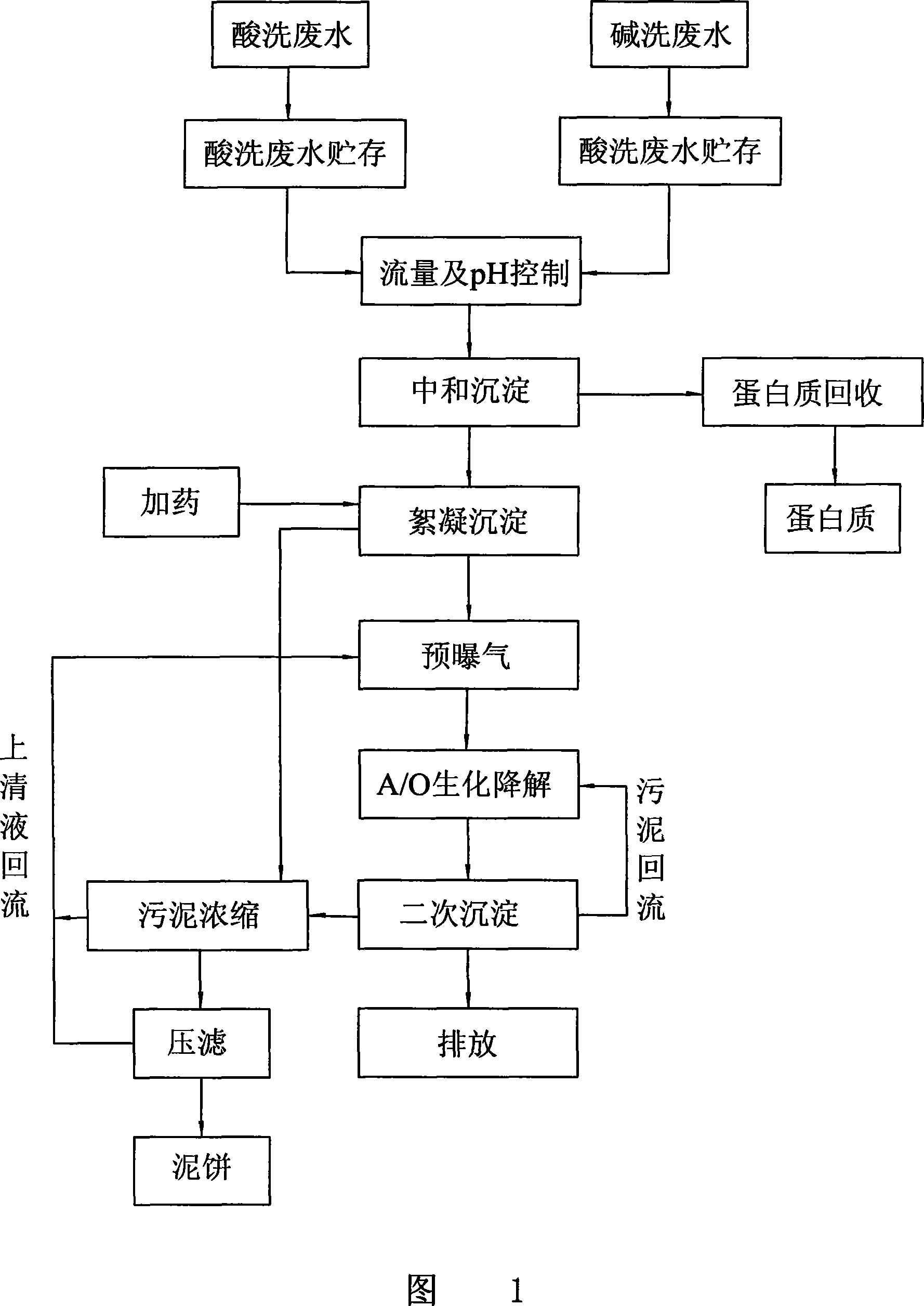

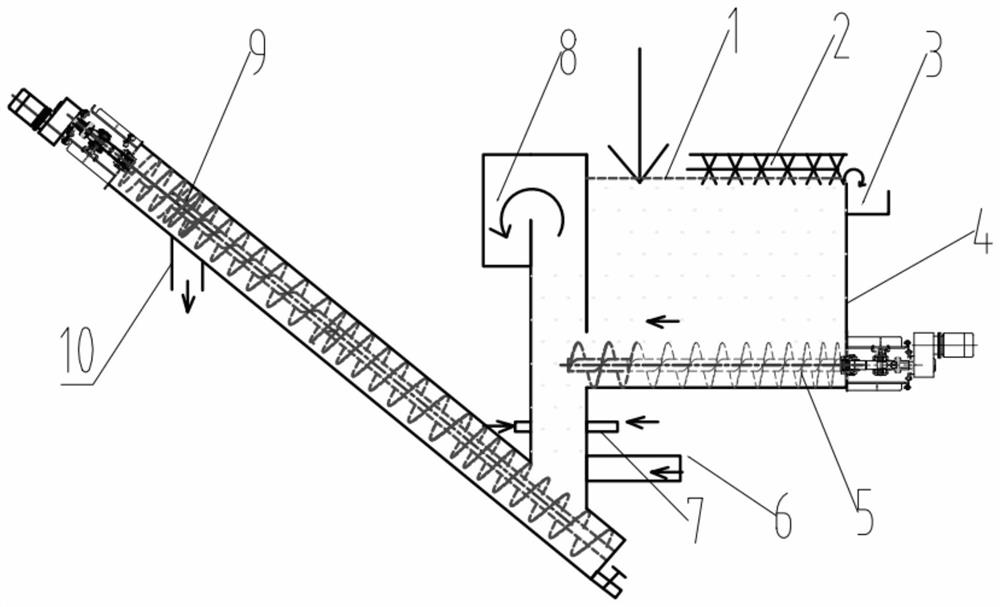

Technique for treating chitin waste water

InactiveCN101215066AIncreased processing loadCompletely degradedMultistage water/sewage treatmentWater/sewage treatment by neutralisationFlocculationChitin formation

The invention discloses a chitin wastewater treating technique. Firstly parting of acid and alkaline cleaning wastewater is stored, integrated wastewater pH is adjusted via flow-control, then neutralization settlement, flocculation settlement, pre-aeration adjustment, A / O biochemical degradation and secondary precipitation for proteins are finished sequentially, and finally the wastewater reaches the standard and is discharged. The invention precipitates proteins in the wastewater in the maximal degree before biochemical treatment of the integrated wastewater by using the electric point precipitation character of proteins and the like, thereby avoiding to increasing of waste water disposal load caused by proteolysis, lowering difficulty of the waste water disposal, ensuring feasibility of biochemical system, simultaneously recycling reasonably proteins, resolving prominent problems of chitin wastewater pollution with the characters of superacid alkali and high salt and high protein, achieving highly effective and safe treatment of the wastewater and effective reclamation and utilization of the proteins, and ensuring sectional sustainable development.

Owner:ZHEJIANG UNIV

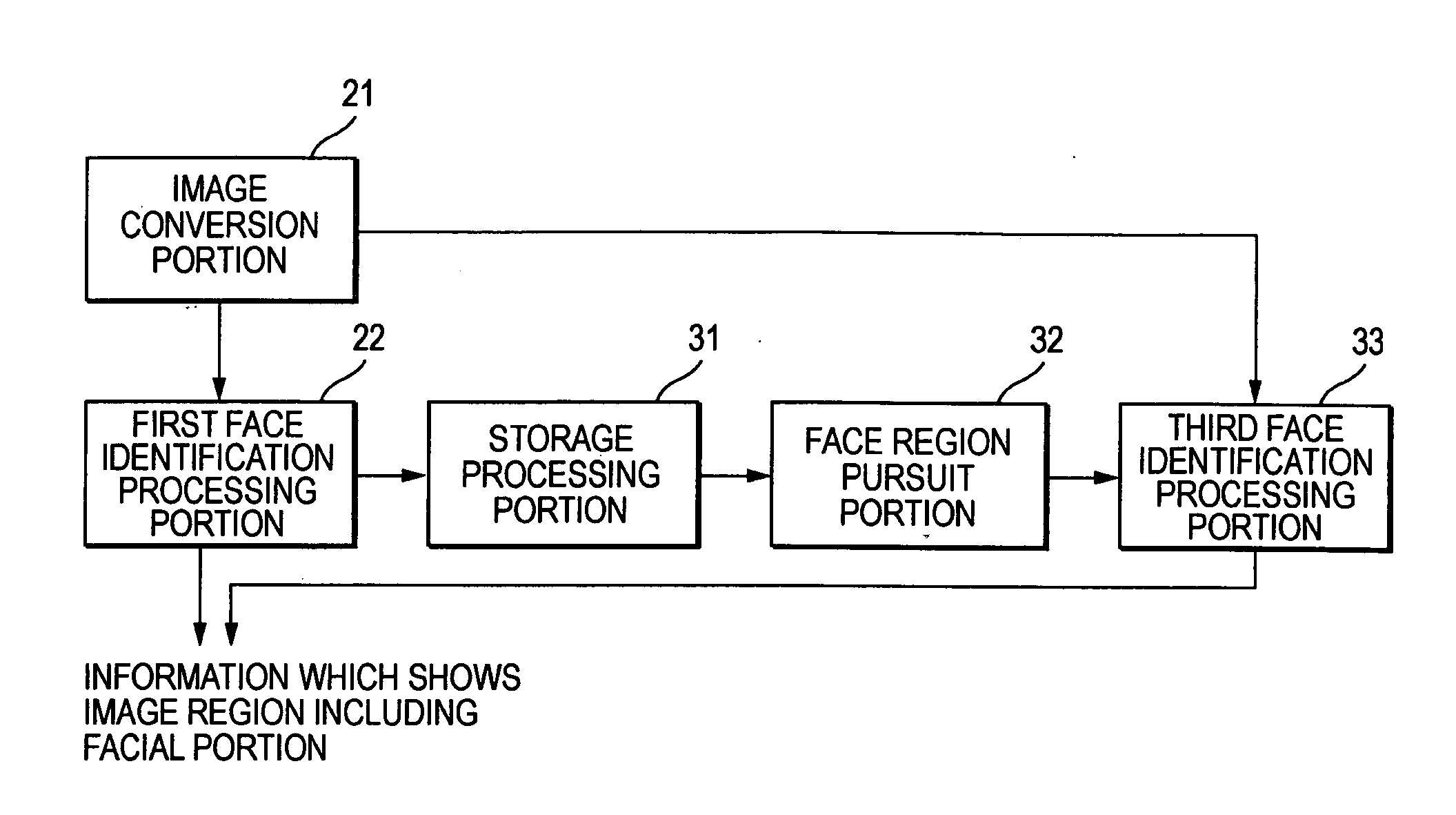

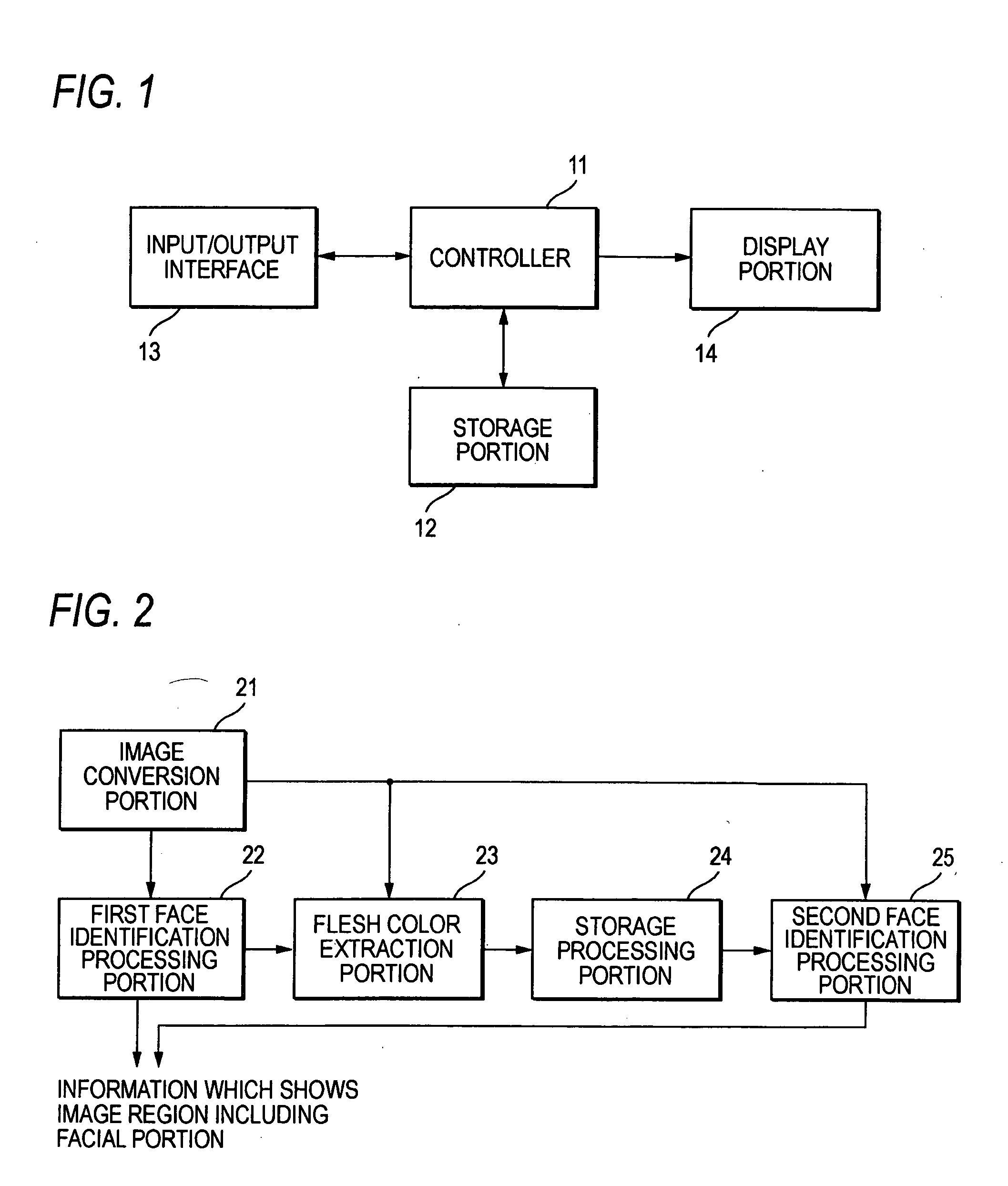

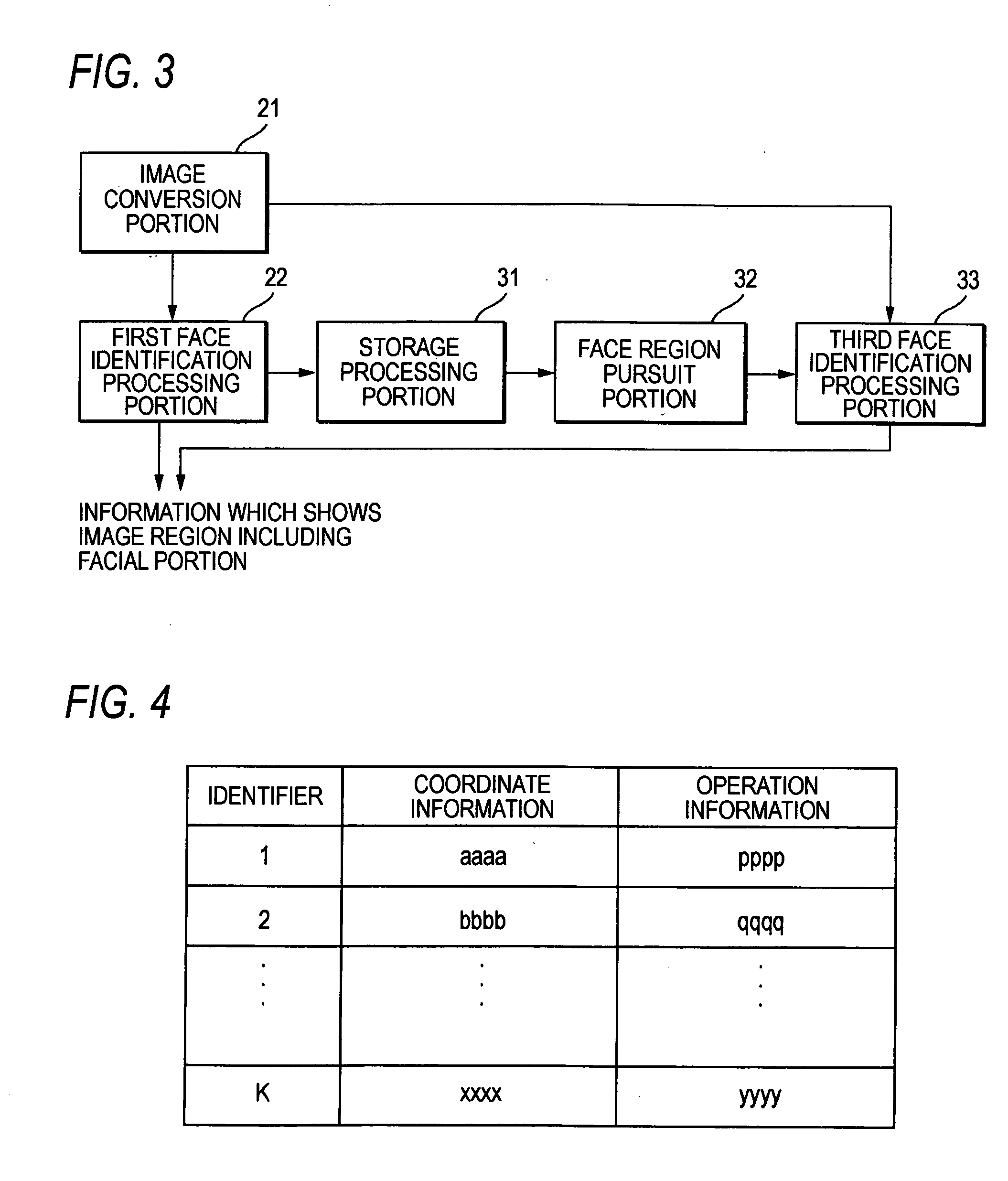

Operation-discerning apparatus and apparatus for discerning posture of subject

InactiveUS20050074167A1Improve recognition accuracyIncreased processing loadImage analysisCharacter and pattern recognitionIdentification deviceComputer science

The recognition apparatus shoots pictures at least a portion of a subject including a human face and obtains a sequence of image data. The facial portion is recognized from the image data. Each image data in the sequence of image data is processed successively. From the image data, an image region including the facial portion is identified. Either a color of the subject within a region defined based on the identified image region or the result of detection of moving regions is used for processing for identifying the image region including the facial portion.

Owner:FUJIFILM BUSINESS INNOVATION CORP

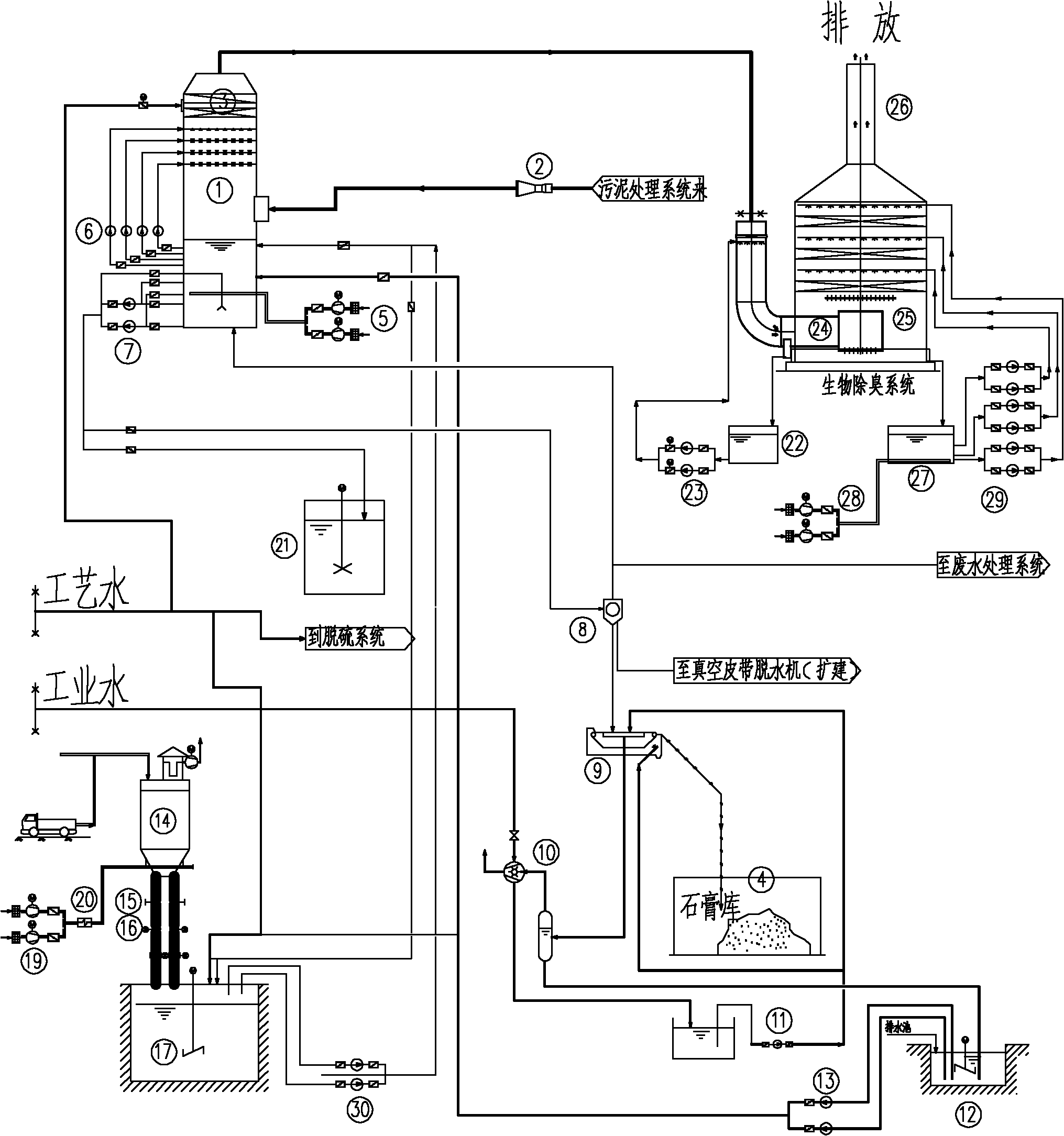

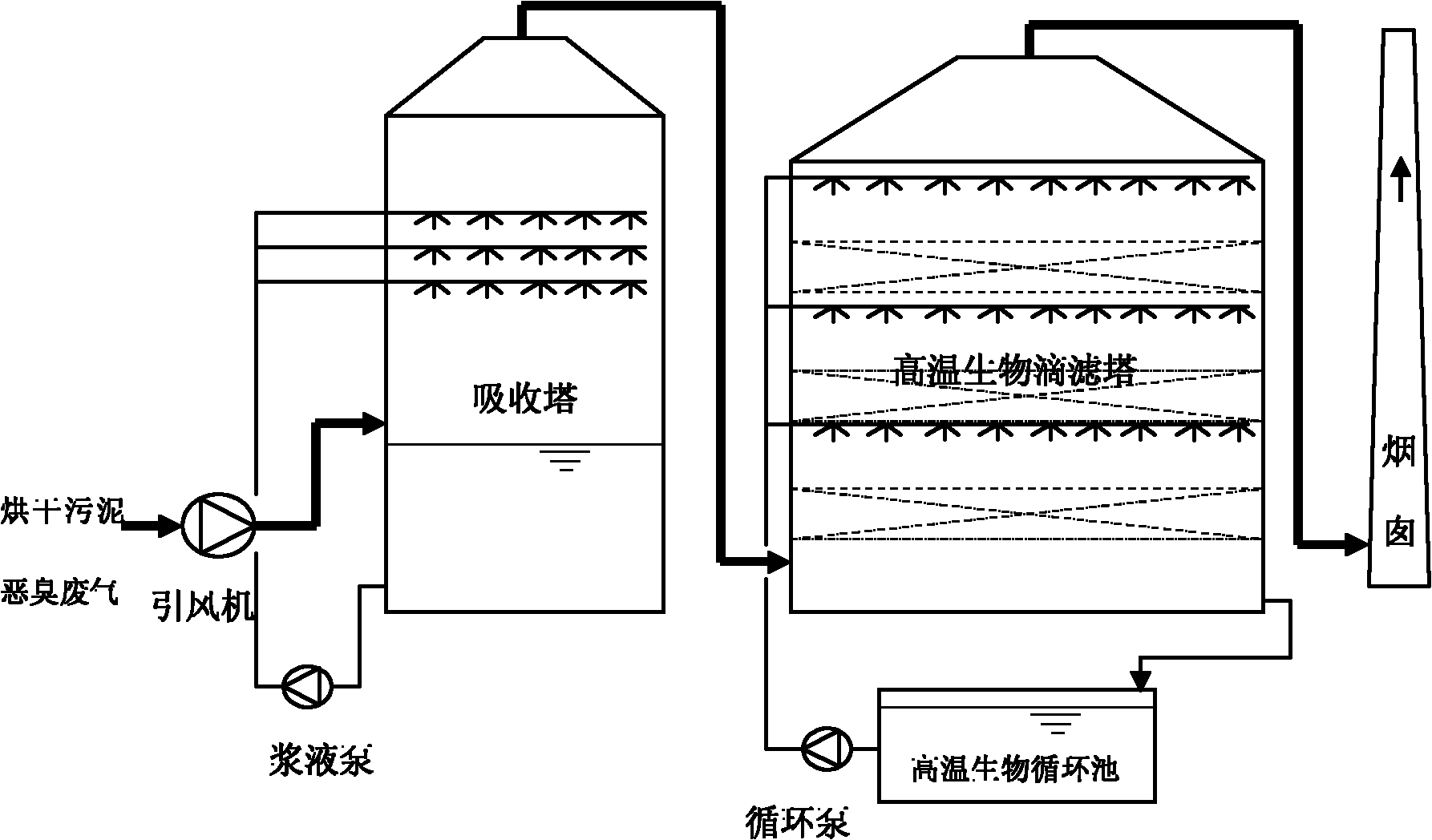

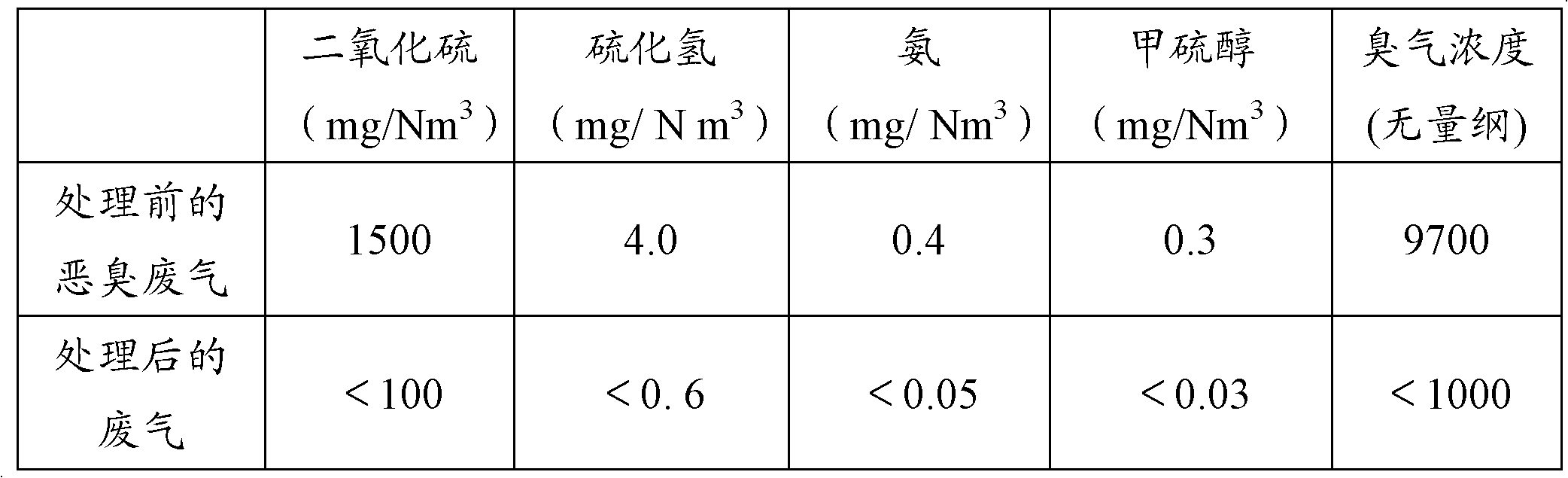

Purification method of odor waste gas produced by high-temperature dewatering of sludge

ActiveCN102179160AActiveGood low temperature survival performanceDispersed particle separationAir quality improvementPurification methodsSludge

The invention discloses a purification method of odor waste gas produced by high-temperature dewatering of sludge. In the process method, two parts, namely a limestone-gypsum desulfurization system and a high-temperature biological drop-filtering tower deodorizing system, are included, wherein SO2 in the odor waste gas is removed by a desulfurizing tower, and then high-temperature deodorizing thermophilic bacterium groups in biological fillers are used to degrade odor and organic components in the odor waste gas by the biological drop-filtering tower. The innovative combined process has the advantages that the deodorization effect is obvious, and a matched cooling system is not needed, so that a large amount of condensate water is prevented from being dissolved out, the investment is saved, the operating cost is low and no secondary pollution is caused.

Owner:广州市越堡水泥有限公司

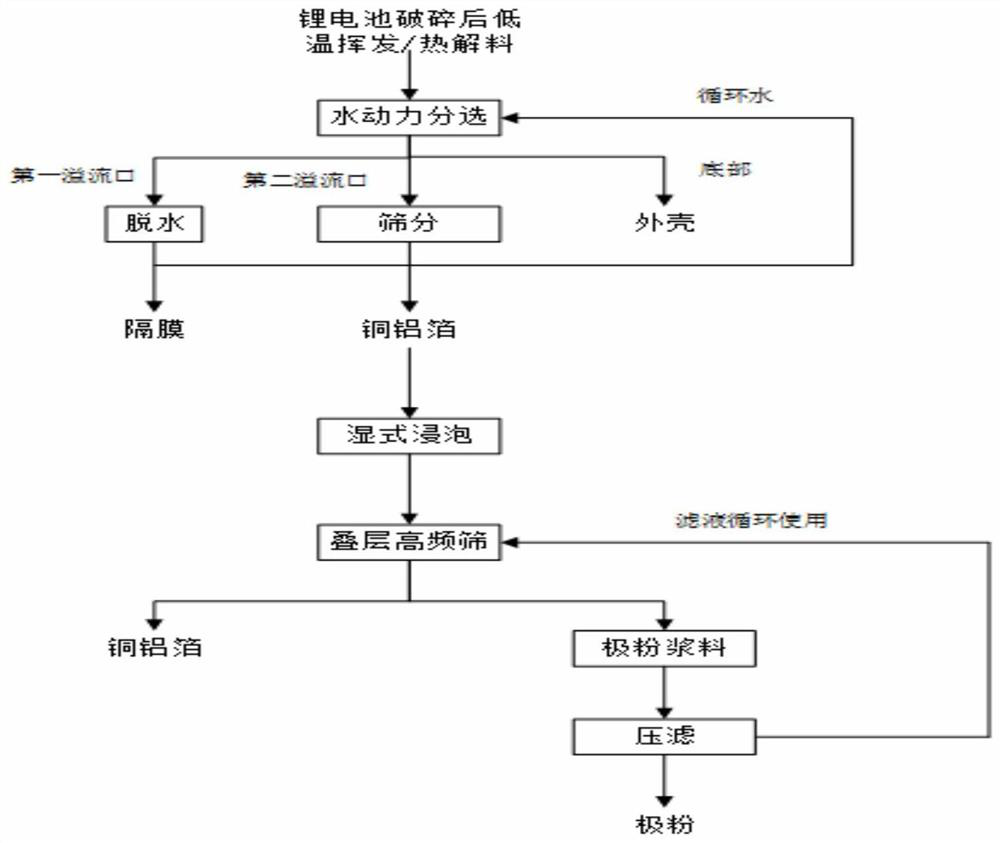

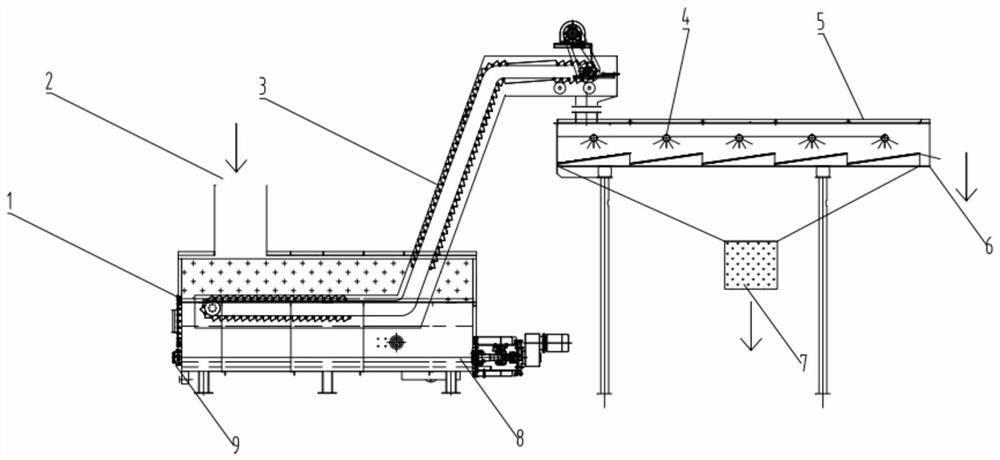

Hydrodynamic separation and wet stripping process for waste lithium ion battery broken materials

PendingCN113499853AAvoid Entrainment LossHigh recovery rateWaste processingSolid separationElectrolytic agentPhysical chemistry

The invention discloses a hydrodynamic separation and wet stripping process for waste lithium ion battery broken materials. The process comprises the following steps of firstly, carrying out crushing and electrolyte low-temperature volatilization or organic matter pyrolysis pretreatment on a waste battery, carrying out hydrodynamic separating on the treated crushed materials to separate out shells, then carrying out one-stage or multi-stage soaking on a sample by using a nucleophilic reagent, due to the fact that the nucleophilic reagent can chemically react with PVDF or aluminum and copper, some reagents can dissolve the PVDF or the aluminum and the copper, therefore, completely stripping and separating leached pole powder from the copper, the aluminum and the like, and improving the recovery rate and grade of the pole powder. According to the process, hydrodynamic force is adopted for efficient and clean pre-sorting of substances such as diaphragms, pole pieces and the shells, the separation effect is greatly improved compared with the prior art, and meanwhile the risks of dust raising, powder explosion and aluminum explosion of traditional wind power winnowing are avoided. The pole powder of the waste lithium ion battery is stripped by adopting a nucleophilic reagent leaching method, the pole powder falling effect is obvious, and the pole powder recovery rate and grade are high.

Owner:湖南江冶新能源科技股份有限公司

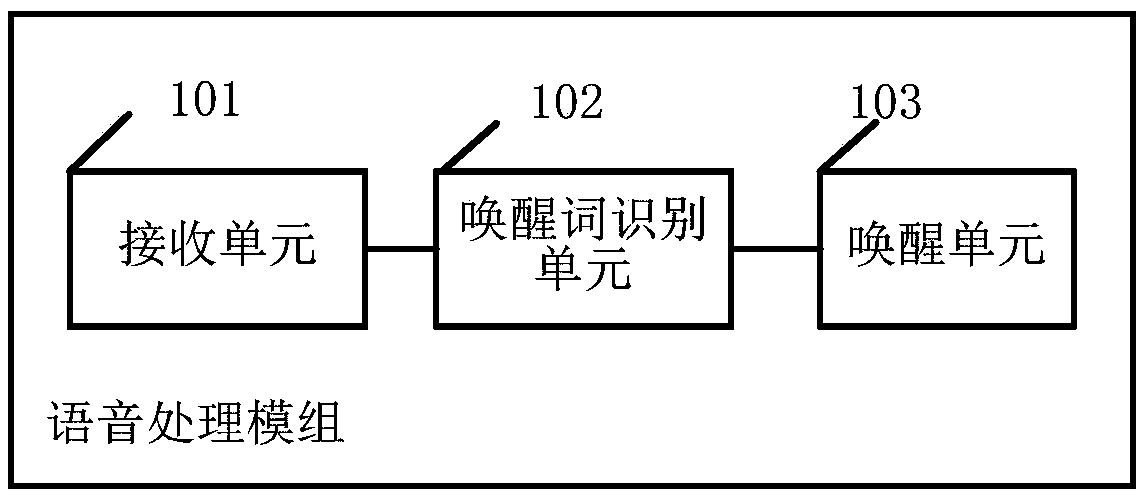

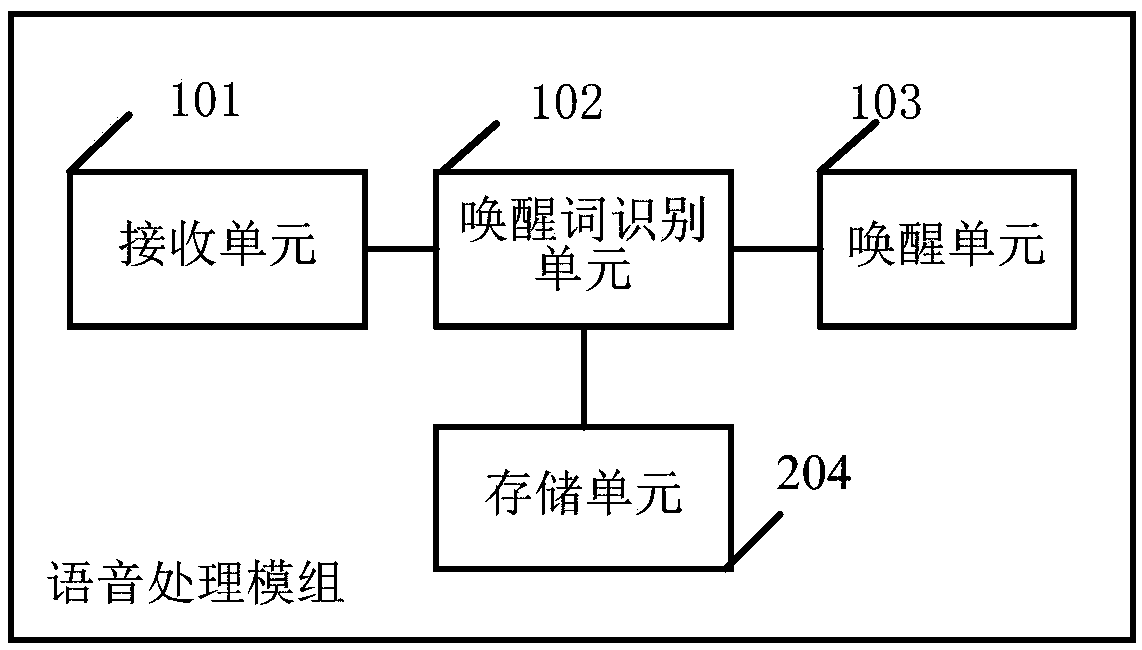

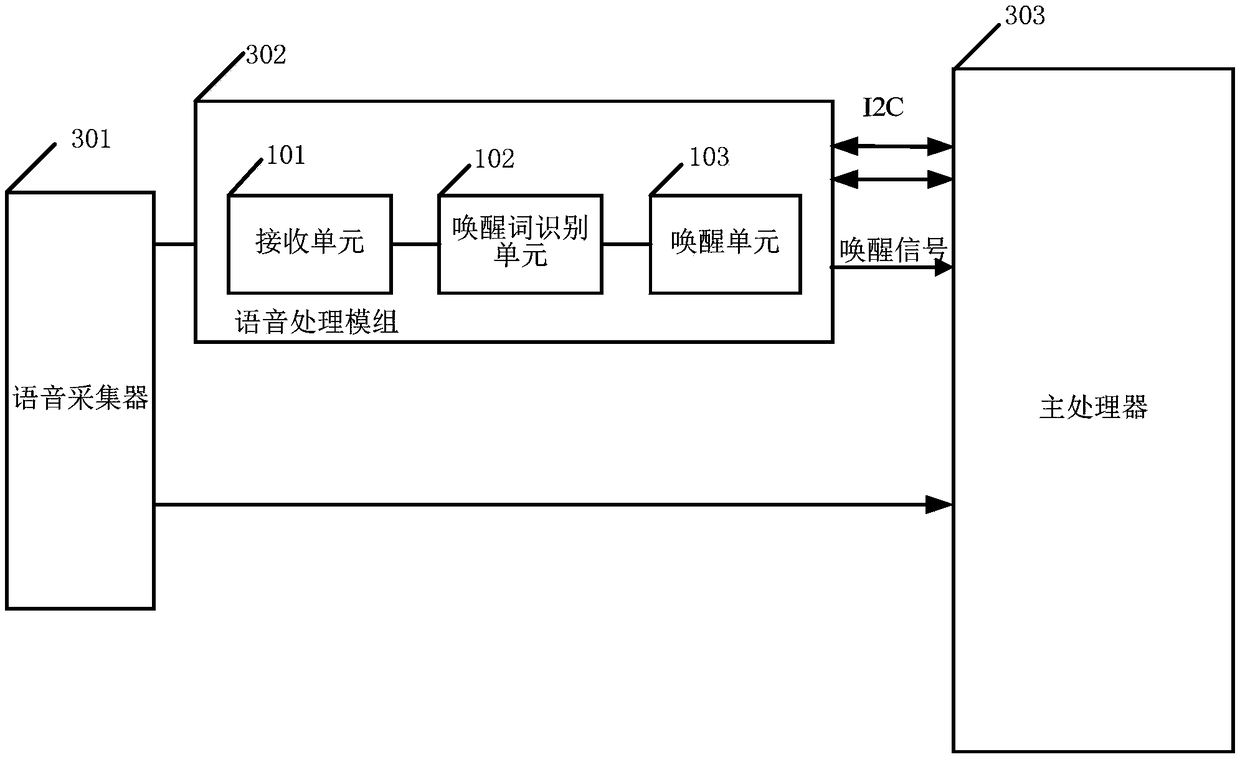

Voice processing module and terminal with voice function

PendingCN108877805AIncreased processing loadReduce processing burdenPower supply for data processingSpeech recognitionEngineeringMaster processor

The embodiment of the invention relates to the field of terminals and discloses a voice processing module and a terminal with a voice function. In the present invention, the voice processing module includes a receiving unit, a wakeup word recognition unit, and a wakeup unit. The receiving unit is configured to receive a voice signal. The wakeup word recognition unit is configured to recognize whether the received voice signal includes a predetermined wakeup word. The wakeup unit is configured to send a wakeup signal to a main processor independent of the voice processing module when the wakeupword recognition unit recognizes the predetermined wakeup word from the voice signal. Thus, when the terminal uses a voice service, the main processor with high power consumption is in an idle state,thereby reducing the overall power consumption of the terminal.

Owner:SHANGHAI YUDE COMM TECH

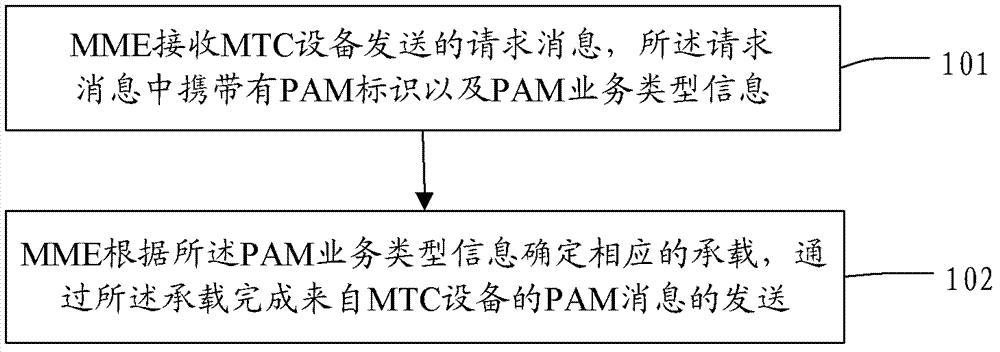

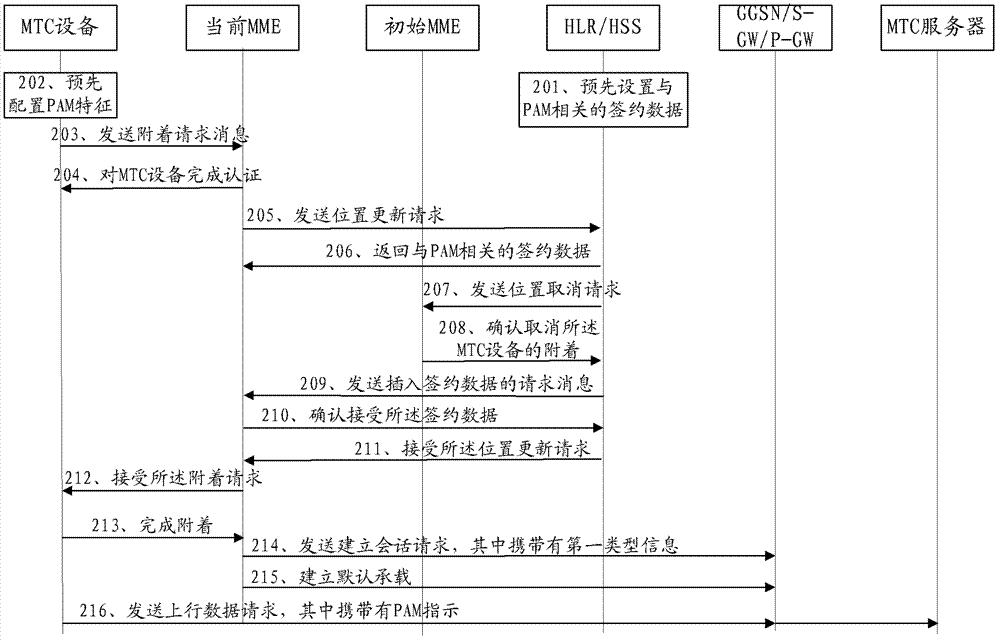

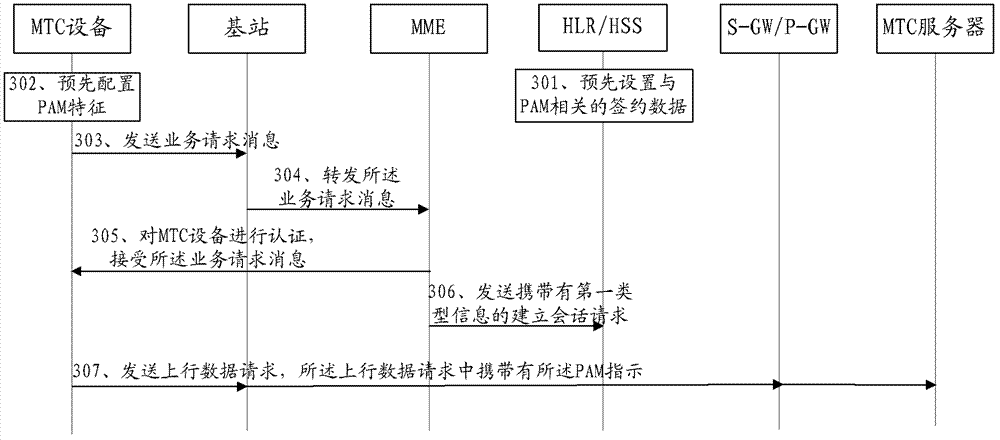

Method and device for realizing priority alarm (PAM) in communication between machines

InactiveCN102790979AAvoid congestionAvoid lostConnection managementMobility managementCommunications server

The inventive embodiment provides a method and device for realizing priority alarm (PAM) in communication between machines, which relates to the technical field of communication, and is used for solving the problems that abnormal conditions can not be transmitted to a machine type communication (MTC) server in time in a case that MTC equipment is abnormal in the prior art. The method includes receiving a request message from MTC equipment by a mobility management entity (MME), wherein the request message is carried with a PAM marker and PAM service type information, the PAM marker is used for informing the MME that the MTC equipment will transmit a PAM message, and the PAM service type information is used for showing the type of the PAM message from the MTC equipment, and includes a first type of information and / or a second type of information; and determining corresponding load by the MME according to the PAM service type information, and completing transmission of the PAM message from the MTC equipment through the load. The inventive method and device are suitable for transmitting a PAM message to a MTC server in communication between machines.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

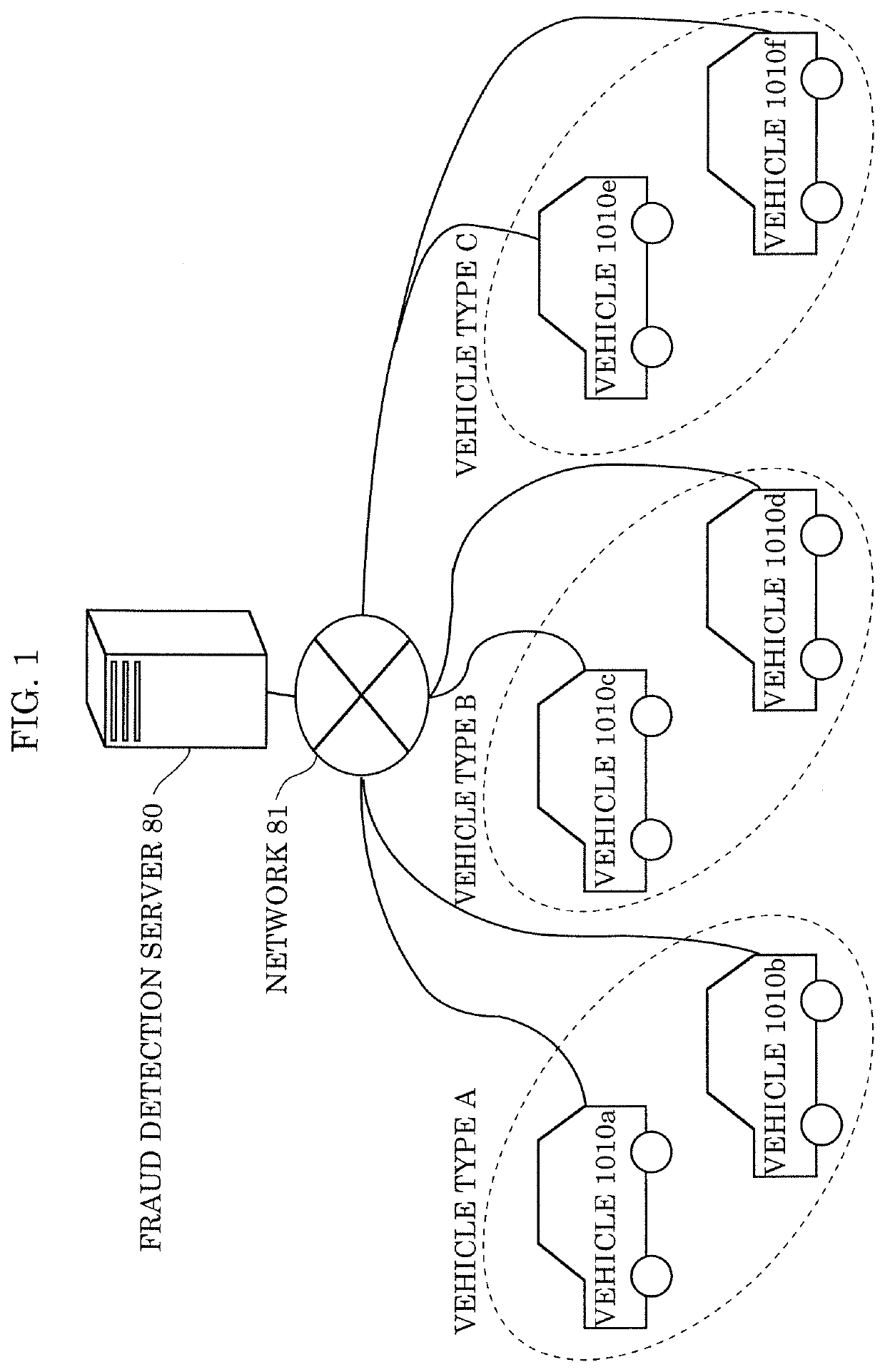

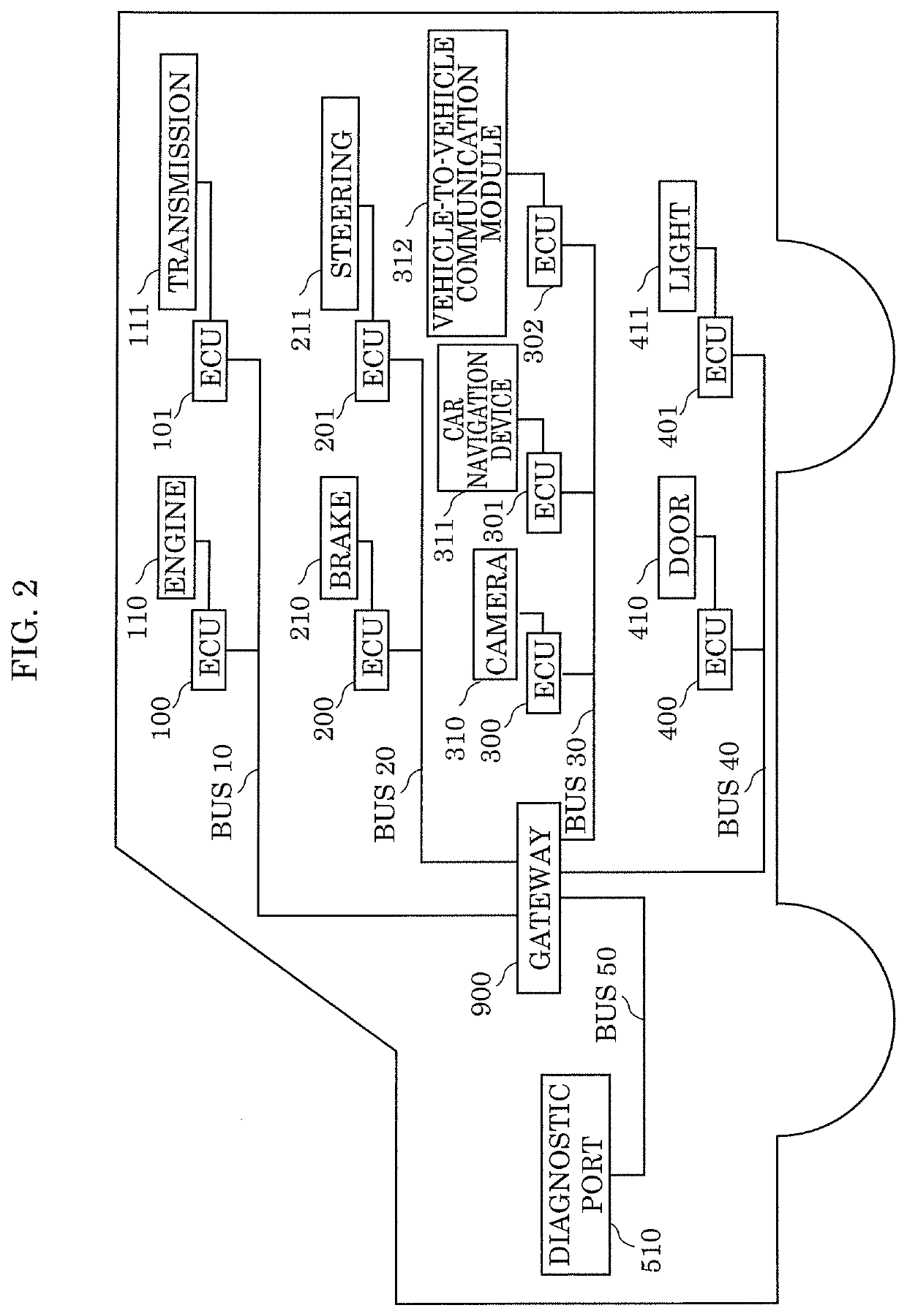

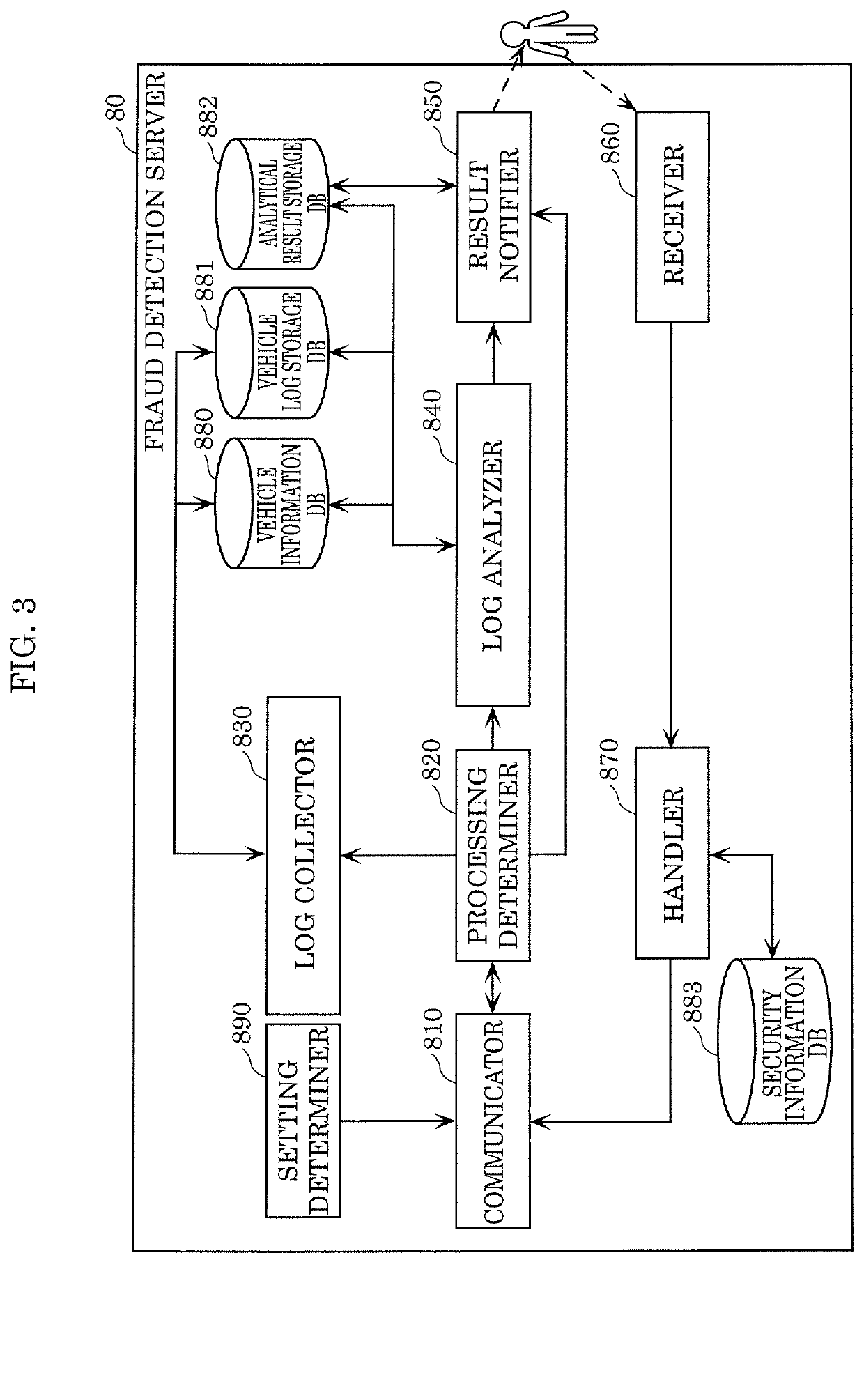

Electronic control device, fraud detection server, in-vehicle network system, in-vehicle network monitoring system, and in-vehicle network monitoring method

ActiveUS20190349394A1Increased processing loadReduce processing loadRegistering/indicating working of vehiclesParticular environment based servicesIn vehicleMonitoring system

A gateway that notifies a fraud detection server located outside a vehicle of information about an in-vehicle network system including an in-vehicle network includes: a priority determiner that determines a priority using at least one of: a state of the vehicle including the in-vehicle network system; an identifier of a message communicated on the in-vehicle network; and a result of fraud detection performed on the message; a frame transmitter-receiver that transmits and receives the message communicated on the in-vehicle network; a frame interpreter that extracts information about the in-vehicle network based on the message received by the frame transmitter-receiver; and a frame uploader that notifies the fraud detection server of notification information including the priority and the information about the in-vehicle network.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

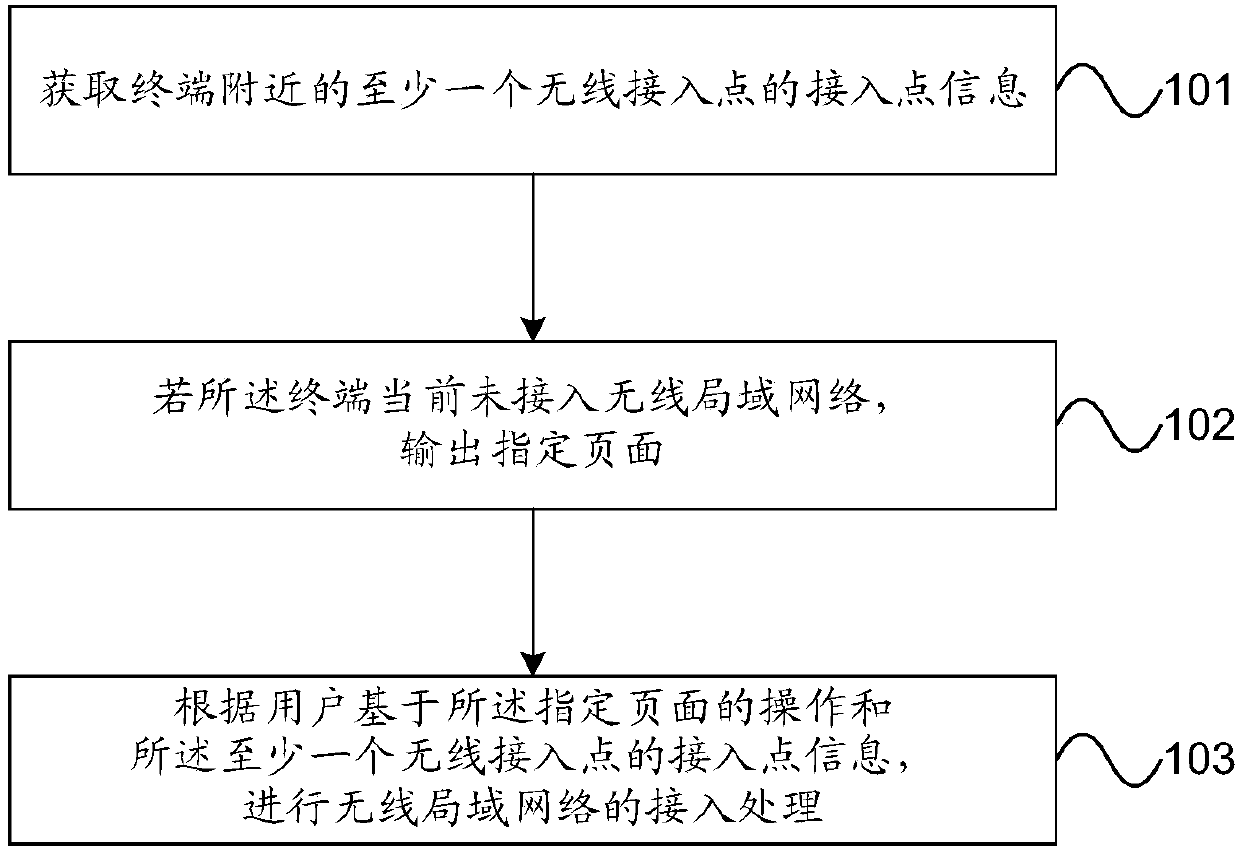

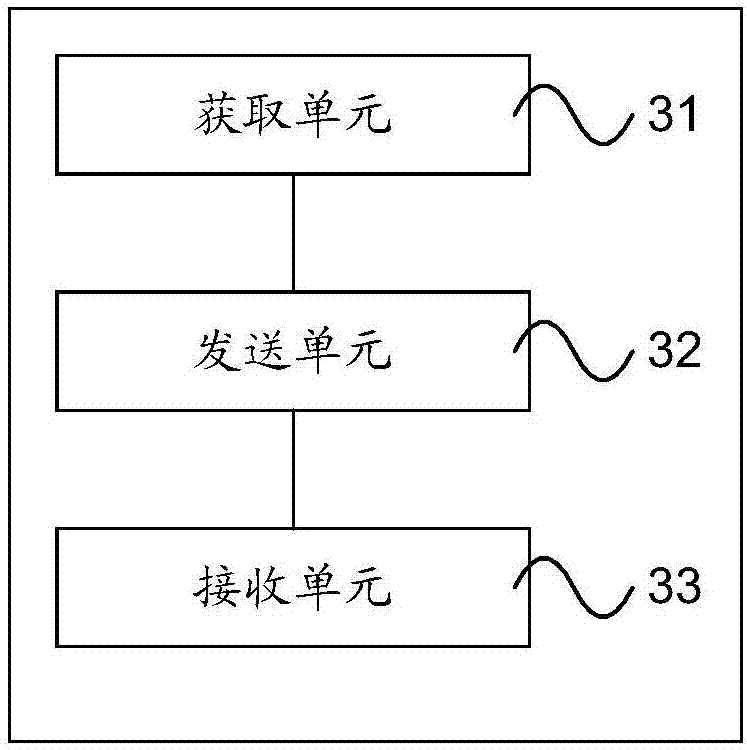

Wireless local area network connection method, equipment and computer readable storage medium

InactiveCN107864503AReduce battery consumptionIncreased processing loadAssess restrictionElectricityLocal area network

The invention provides a wireless local area network connection method, equipment and a computer readable storage medium. The method provided by the embodiment of the invention comprises the steps ofacquiring access point information of at least one wireless access point close to a terminal, if the terminal does not access a wireless local area network currently, outputting a specified page, andthus being capable of accessing the wireless local area network according to user operation based on the specified page and the access point information of the at least one wireless access point. Thetreatment that the terminal accesses the wireless local area network does not need to be performed by a terminal operating system of the terminal according to the user operation based on a system pagewhere a native wireless access point list of the system is located; the increase of processing load of the terminal operating system in the prior art caused by the fact that the terminal operating system performs the treatment that the terminal accesses the wireless local area network according to the user operation based on the system page where the native wireless access point list of the system is located can be avoided, and thus the electricity consumption of the terminal is reduced.

Owner:上海尚往网络科技有限公司

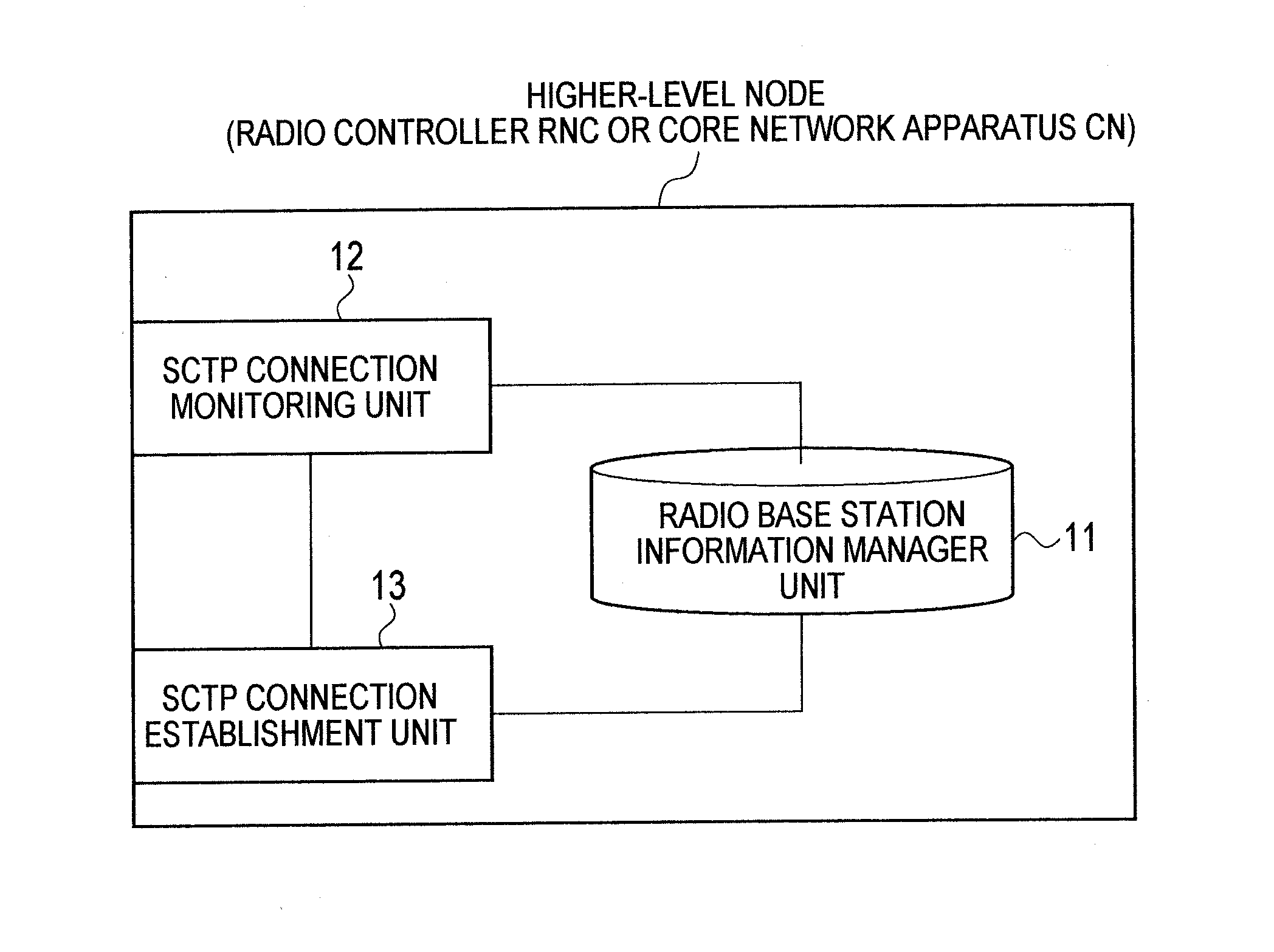

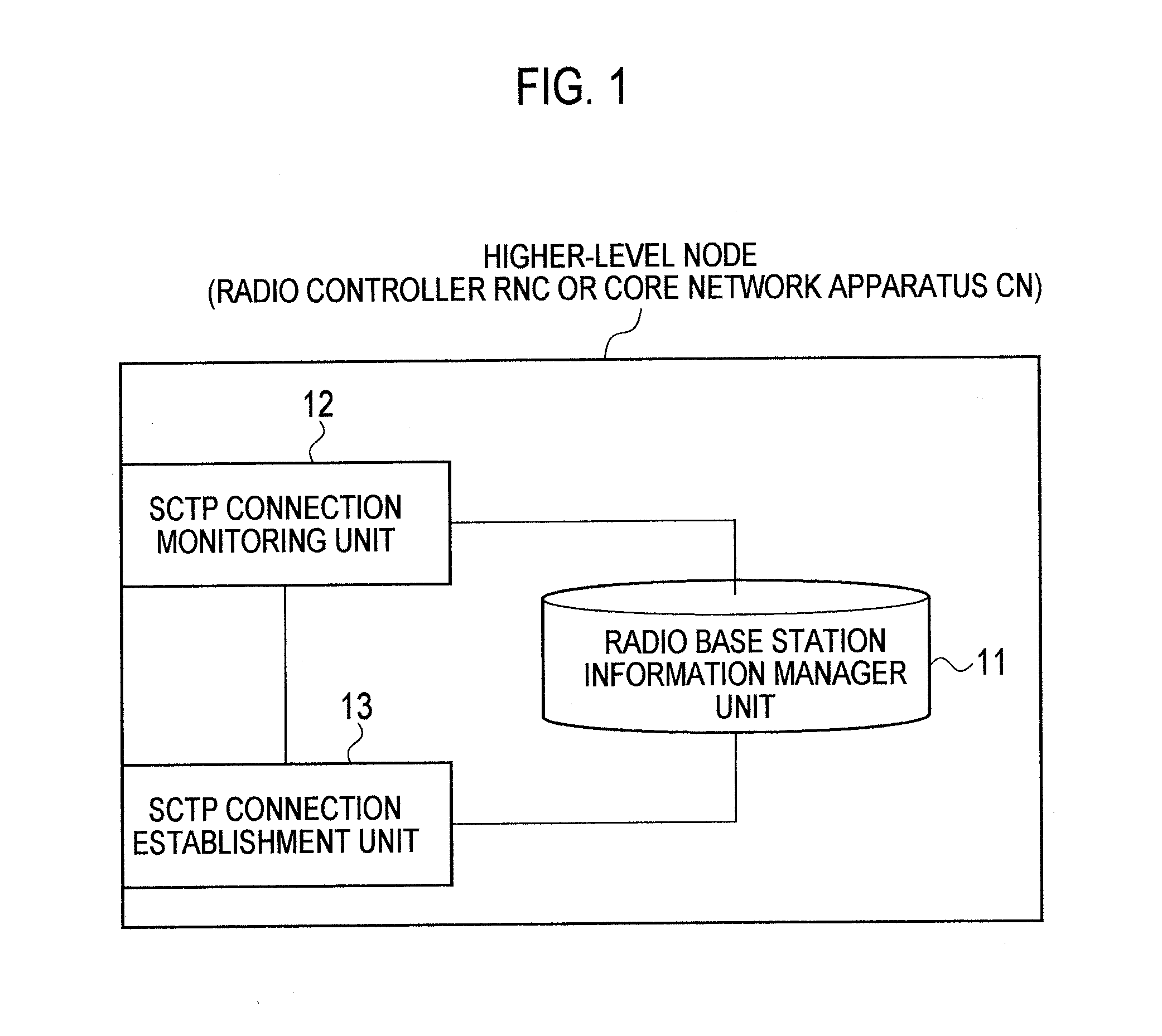

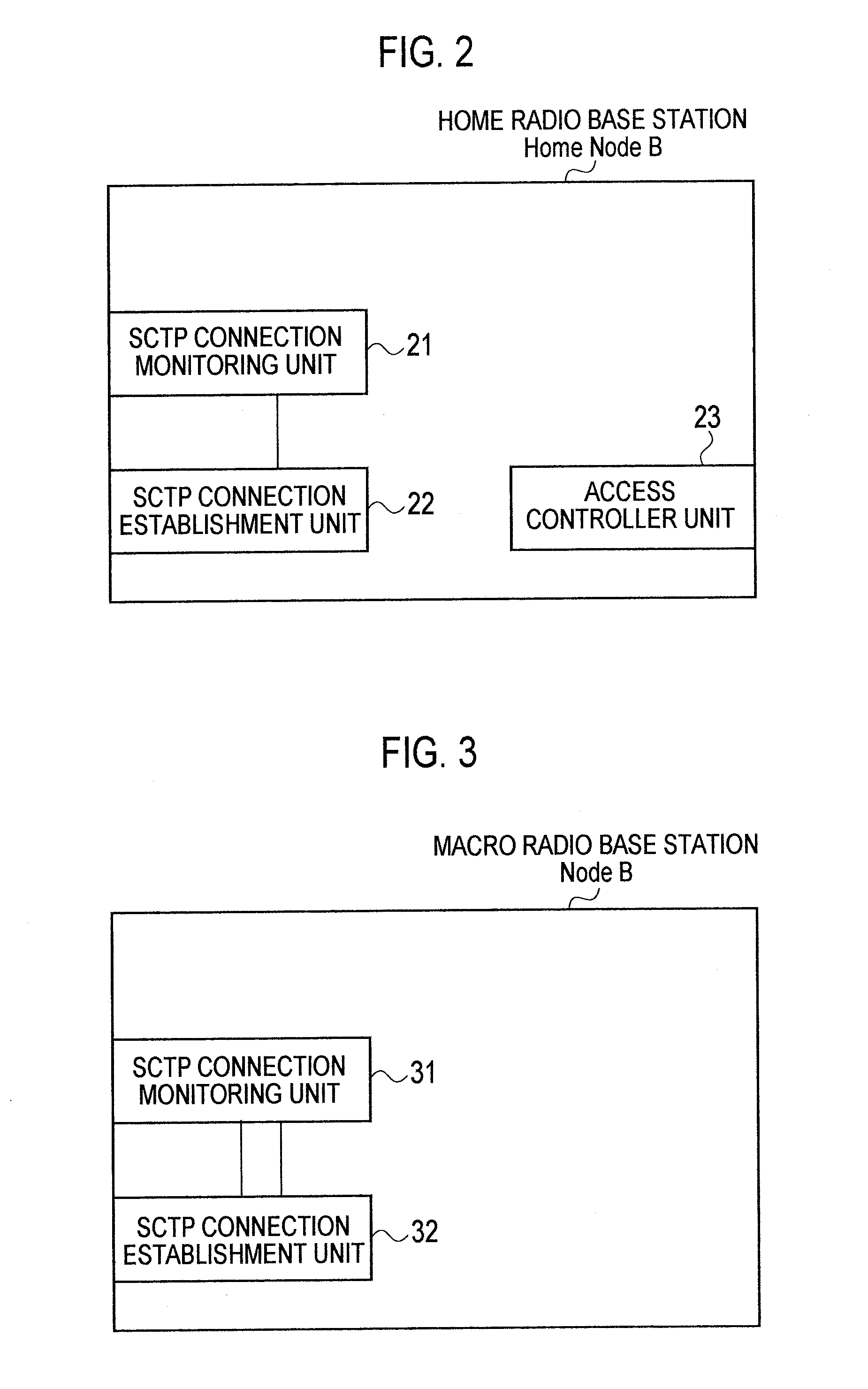

Mobile communication method and mobile communication system

InactiveUS20110021185A1Efficiently establishedIncreased processing loadNetwork topologiesWireless commuication servicesInitMobile communication systems

A mobile communication method according to the present invention includes the steps of: transmitting, from a higher-level node to a macro radio base station, an “INIT(SCTP)”, when the higher-level node detects that no SCTP connection is established with the macro radio base station; and transmitting, from a home radio base station to a higher-level node, an “INIT(SCTP)”, when the home radio base station detects that no SCTP connection is established with the higher-level node. The higher-level node does not transmit “INIT(SCTP)” to the home radio base station, even when detecting that no SCTP connection is established with the home radio base station.

Owner:NTT DOCOMO INC

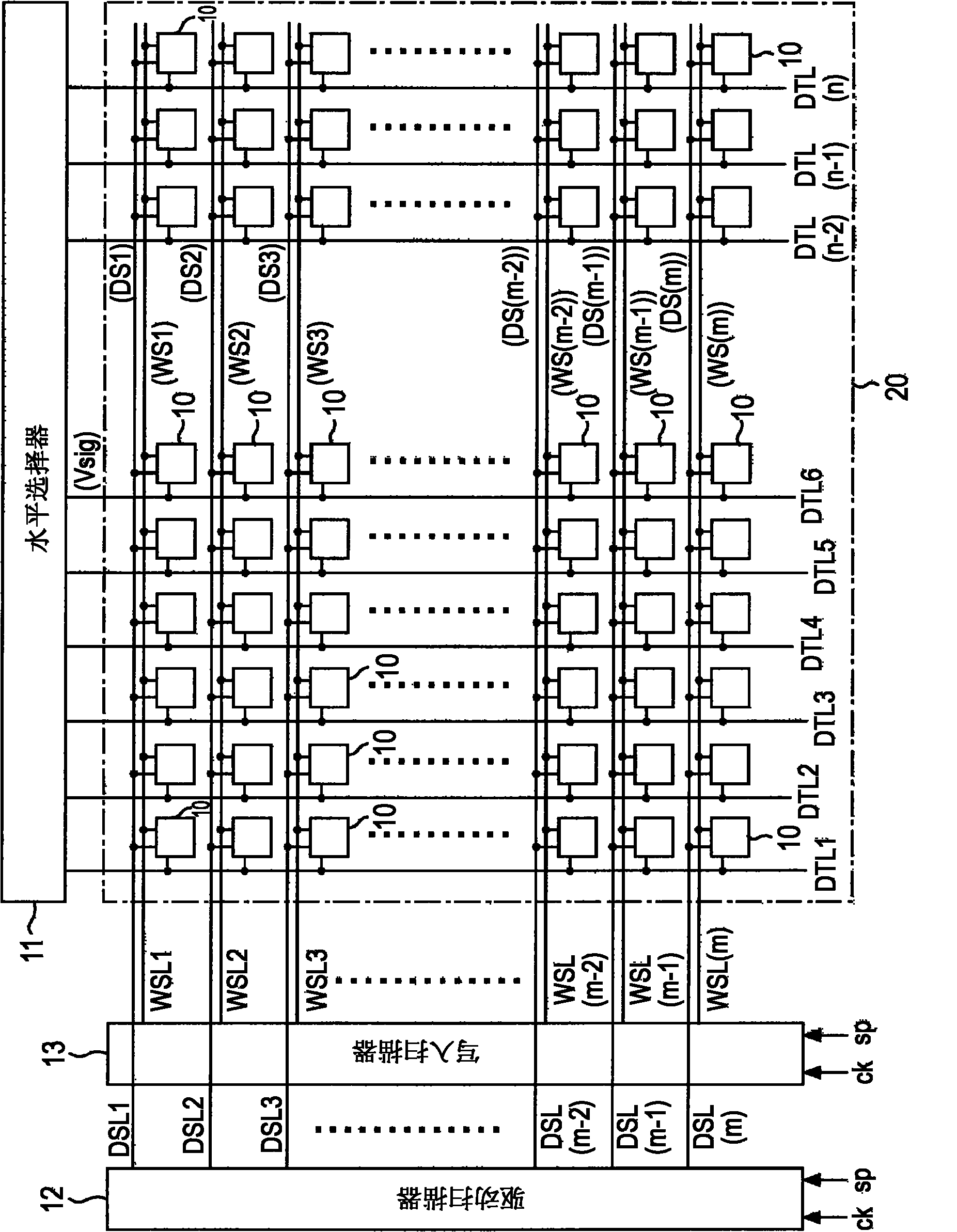

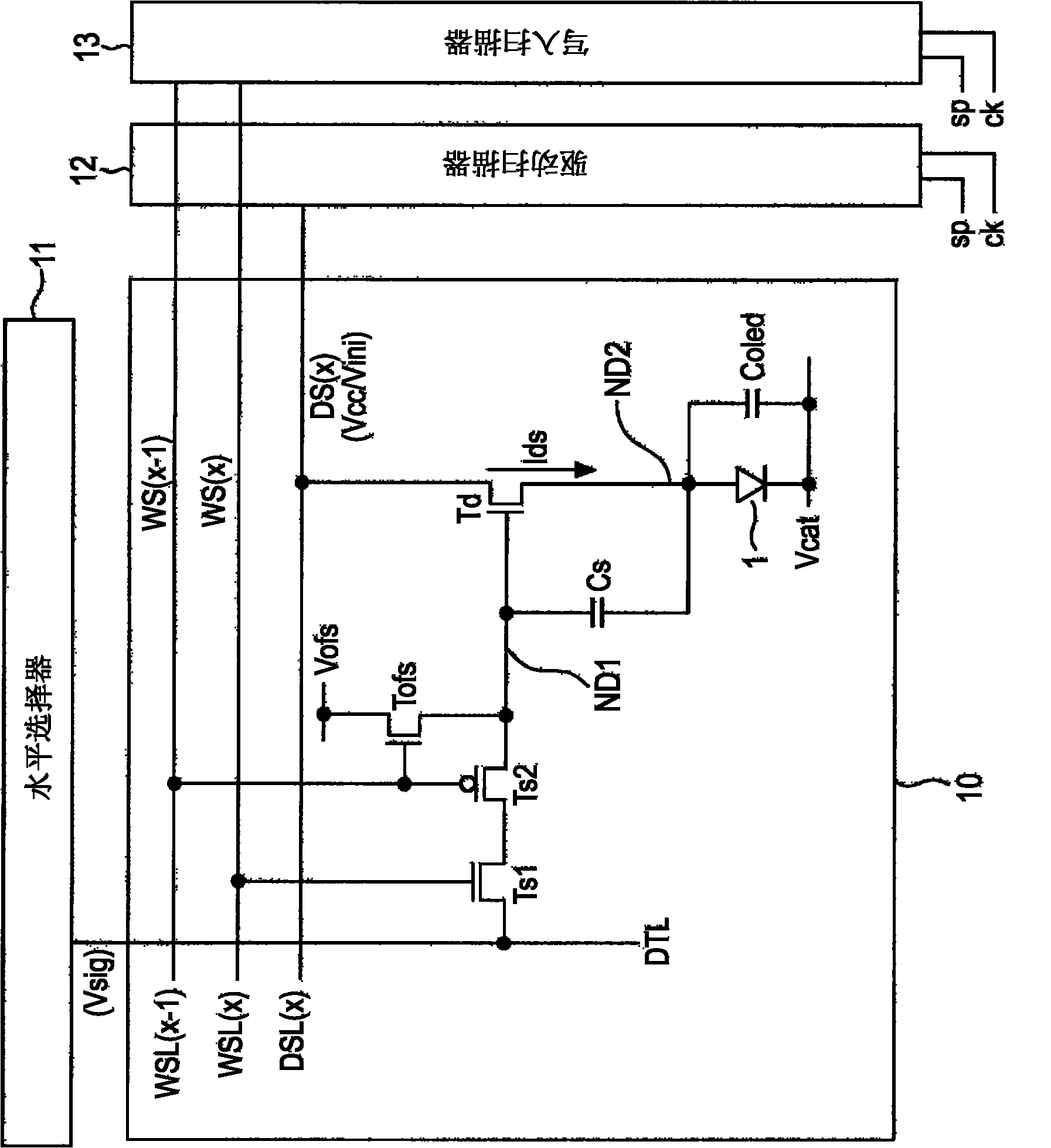

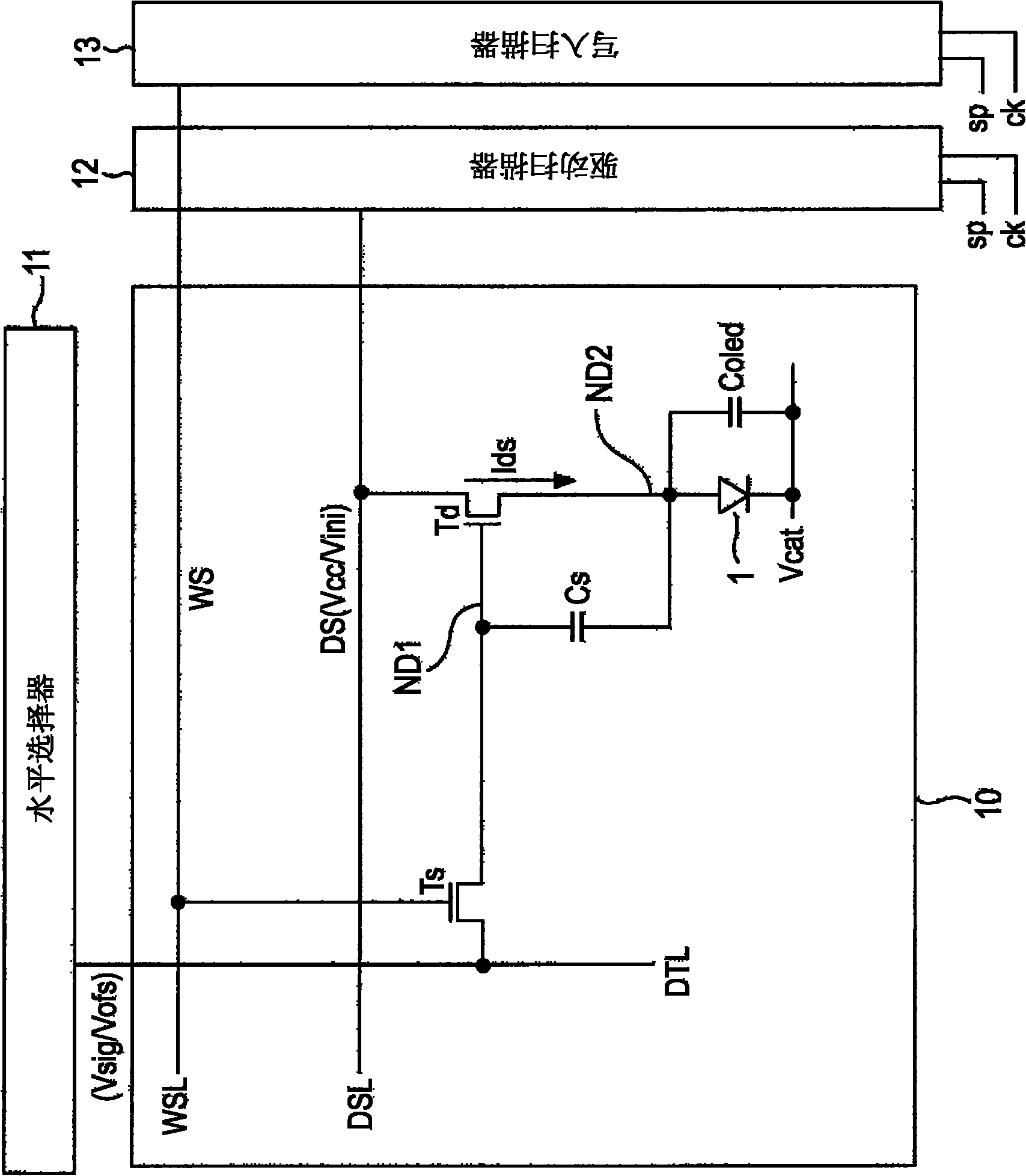

Display apparatus and display driving method

InactiveCN102129836AImprove image qualityIncreased processing loadStatic indicating devicesControl lineLight emitting device

The invention relates to a display apparatus and a display driving method. The display apparatus includes: a pixel array in which pixel circuits each having a light emitting device, a drive transistor, and a retention capacity are arranged in a matrix; a signal selector supplying a video signal voltages to signal lines arranged in columns on the pixel array; a drive control scanner providing power supply pulses to power supply control lines arranged in rows on the pixel array and applying drive voltages to the transistors; and a write scanner providing scan pulses to writing control lines arranged in rows on the pixel array and executing input of the video signal voltages to the pixel circuits. A threshold correction of setting a gate-source voltage of the transistor to a threshold voltage of the transistor and an input of the video signal voltage from the signal line to between the gate and the source of the transistor are controlled by the scan pulse of the row of the pixel circuit and the scan pulse of the previous row of the pixel circuit.

Owner:SONY CORP

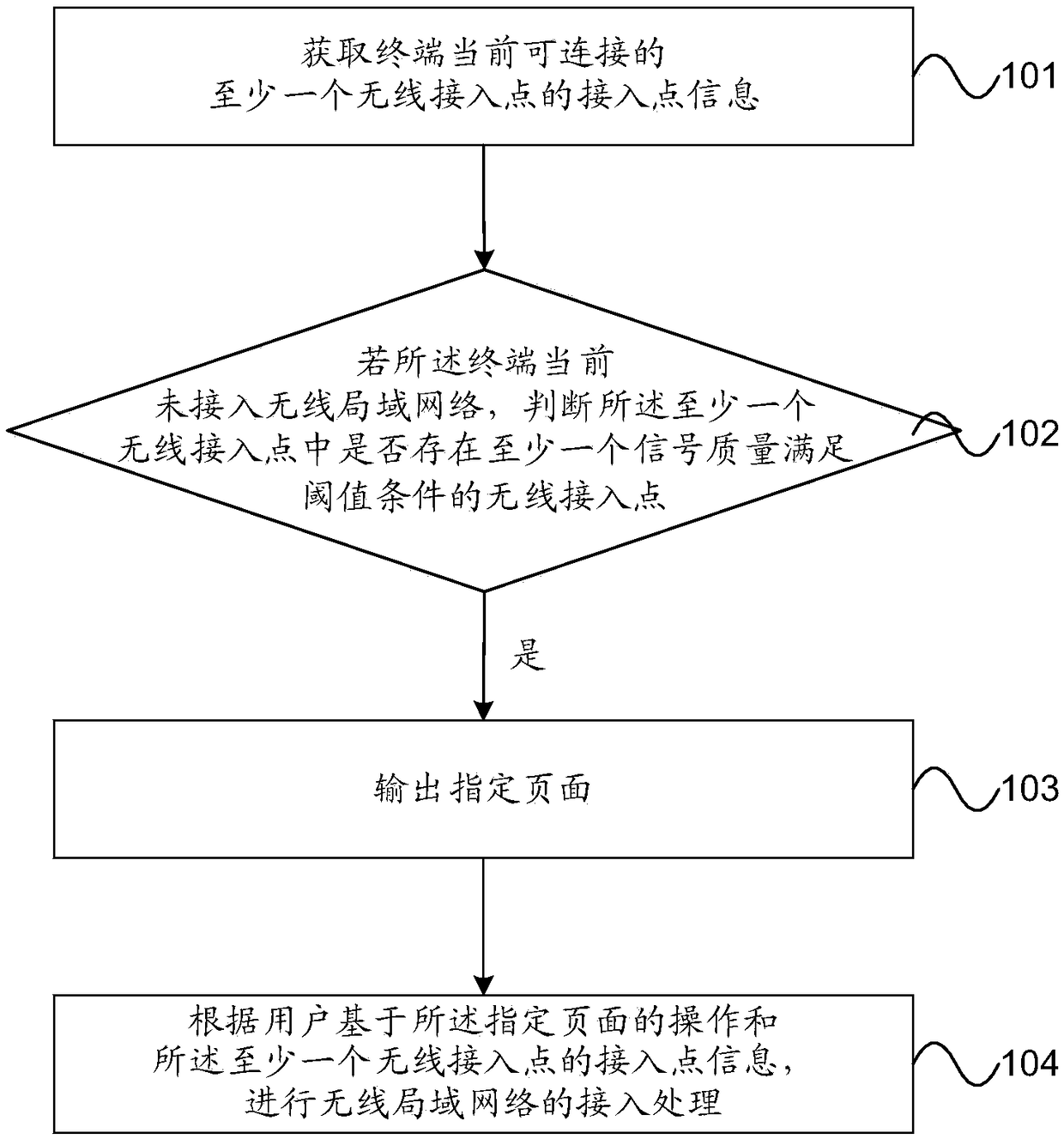

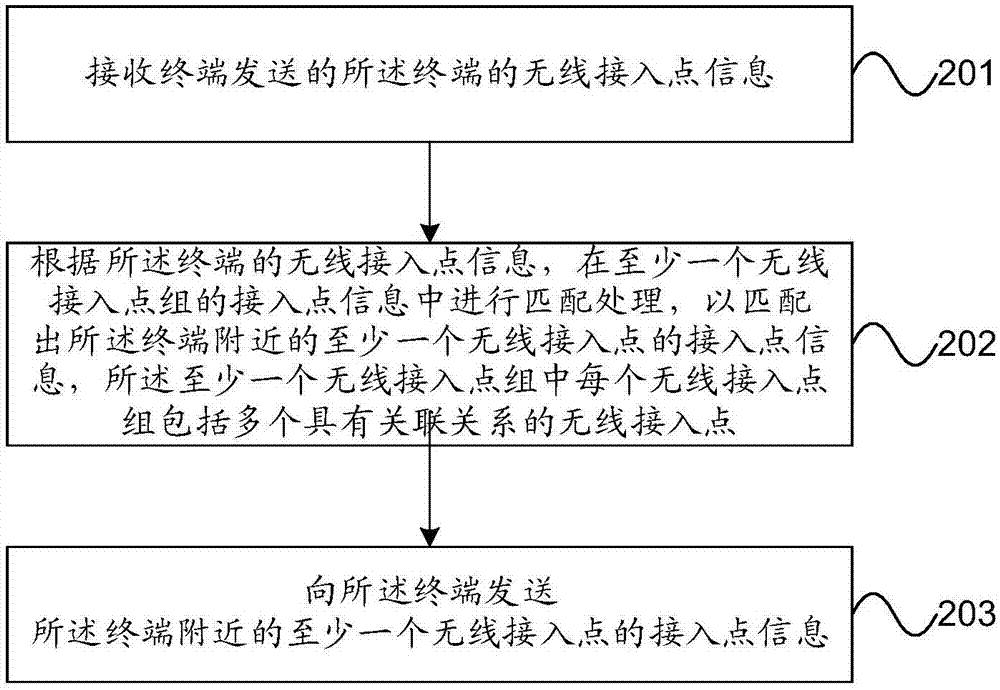

Connection method of wireless local area network, device and computer readable storage medium

InactiveCN108135023AReduce battery consumptionIncreased processing loadPower managementAssess restrictionSignal qualityOperational system

The invention provides a connection method of a wireless local area network, a device and a computer readable storage medium. In the embodiment of the invention, access point information of at least one wireless access point currently connectable of a terminal is acquired, if the terminal currently does not access to the wireless local area network, then, whether at least one wireless access pointof which signal quality satisfies a threshold value condition exists in the at least one wireless access point is judged, if so, a specified page can be output, thus, access processing of the wireless local area network can be executed according to user operations based on the specified page and the access point information of the at least one wireless access point; a terminal operating system ofthe terminal is free from performing access processing of the wireless local area network of the terminal according to the user operations based on a system page where a system native wireless accesspoint list is, increase of processing load on the terminal operating system caused by that the terminal operation system performs access processing of the wireless local area network of the terminalaccording to the user operations based on the system page where the system native wireless access point list is in the existing technology can be avoided, and power consumption of the terminal is reduced.

Owner:上海尚往网络科技有限公司

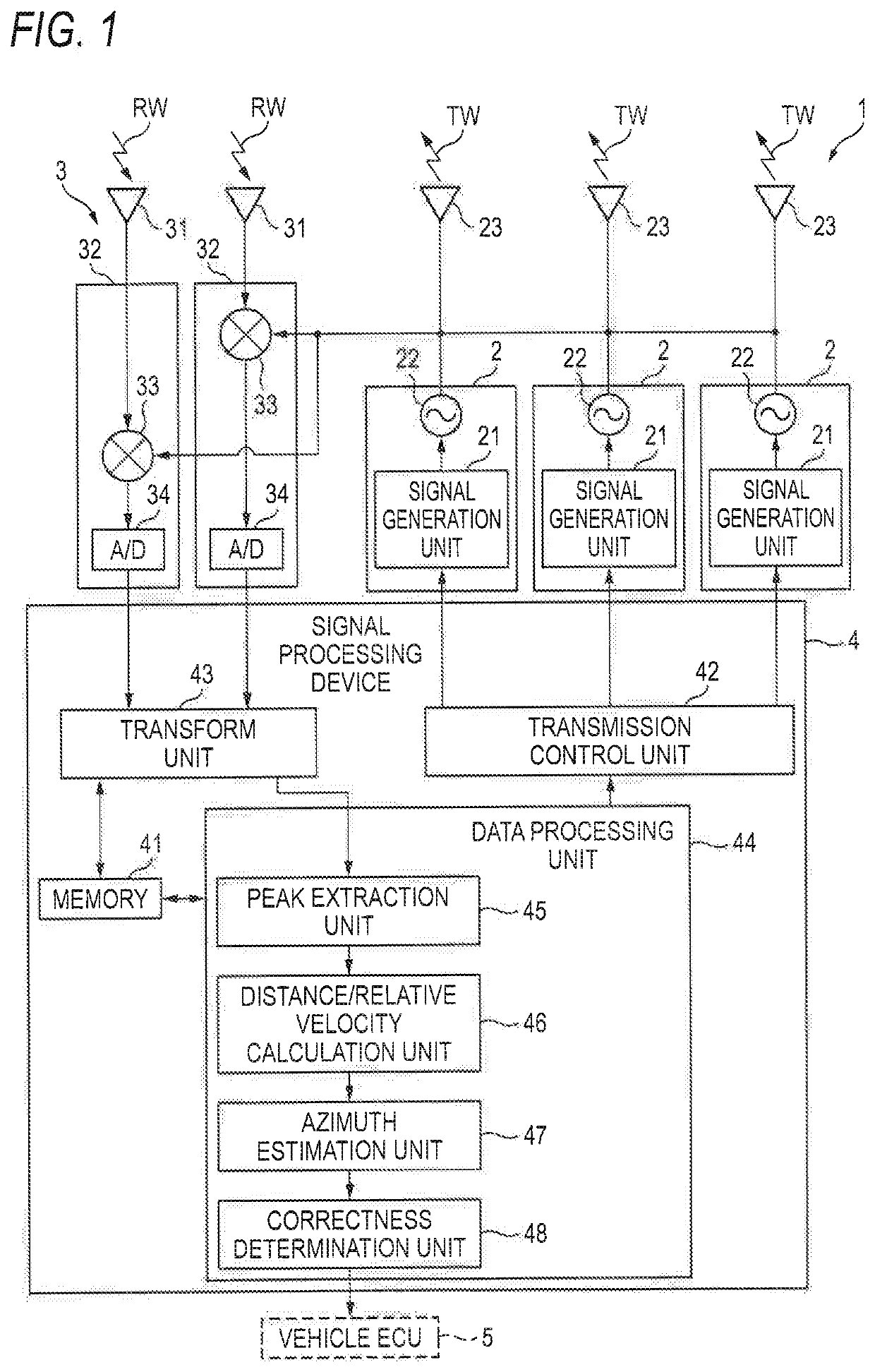

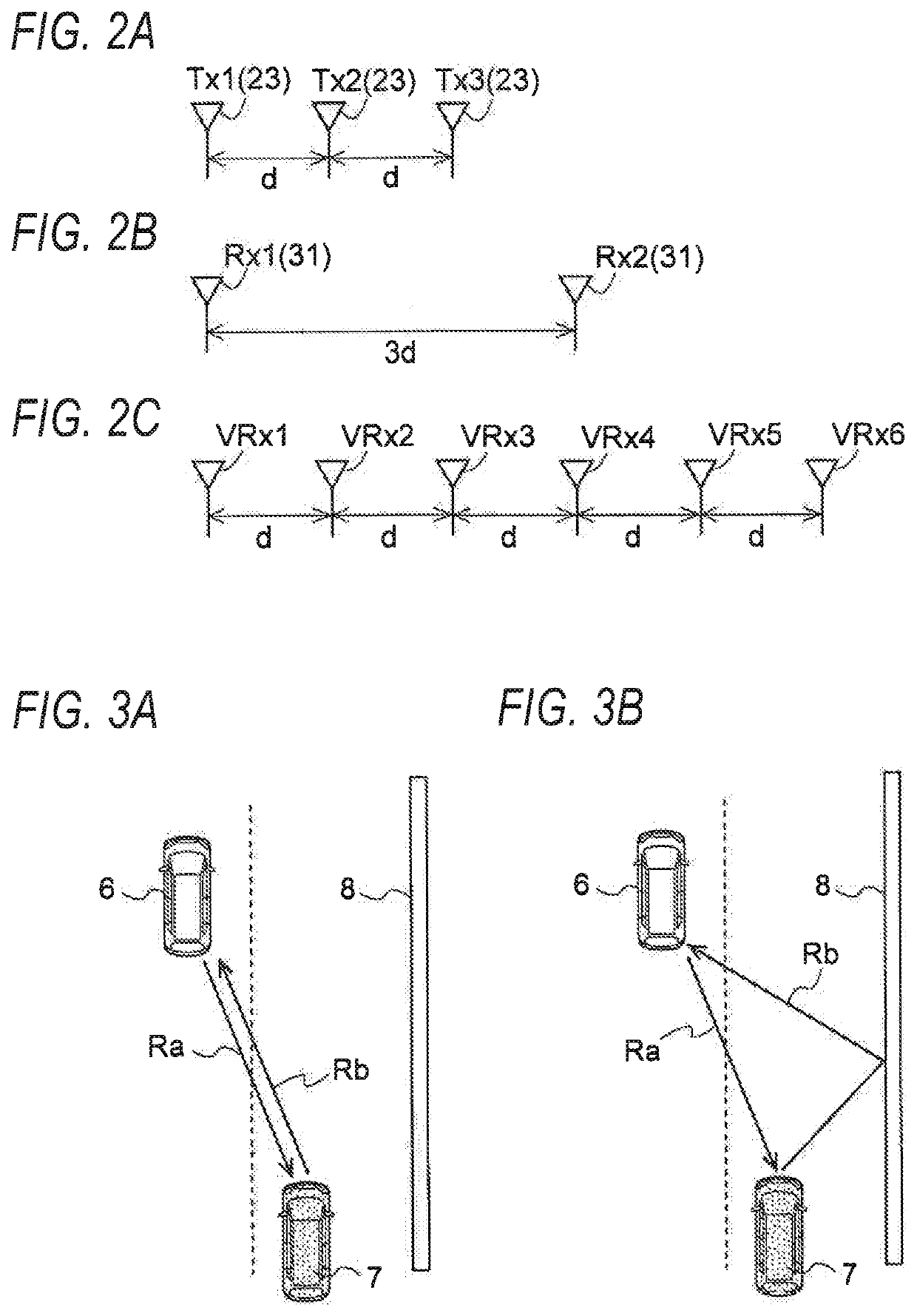

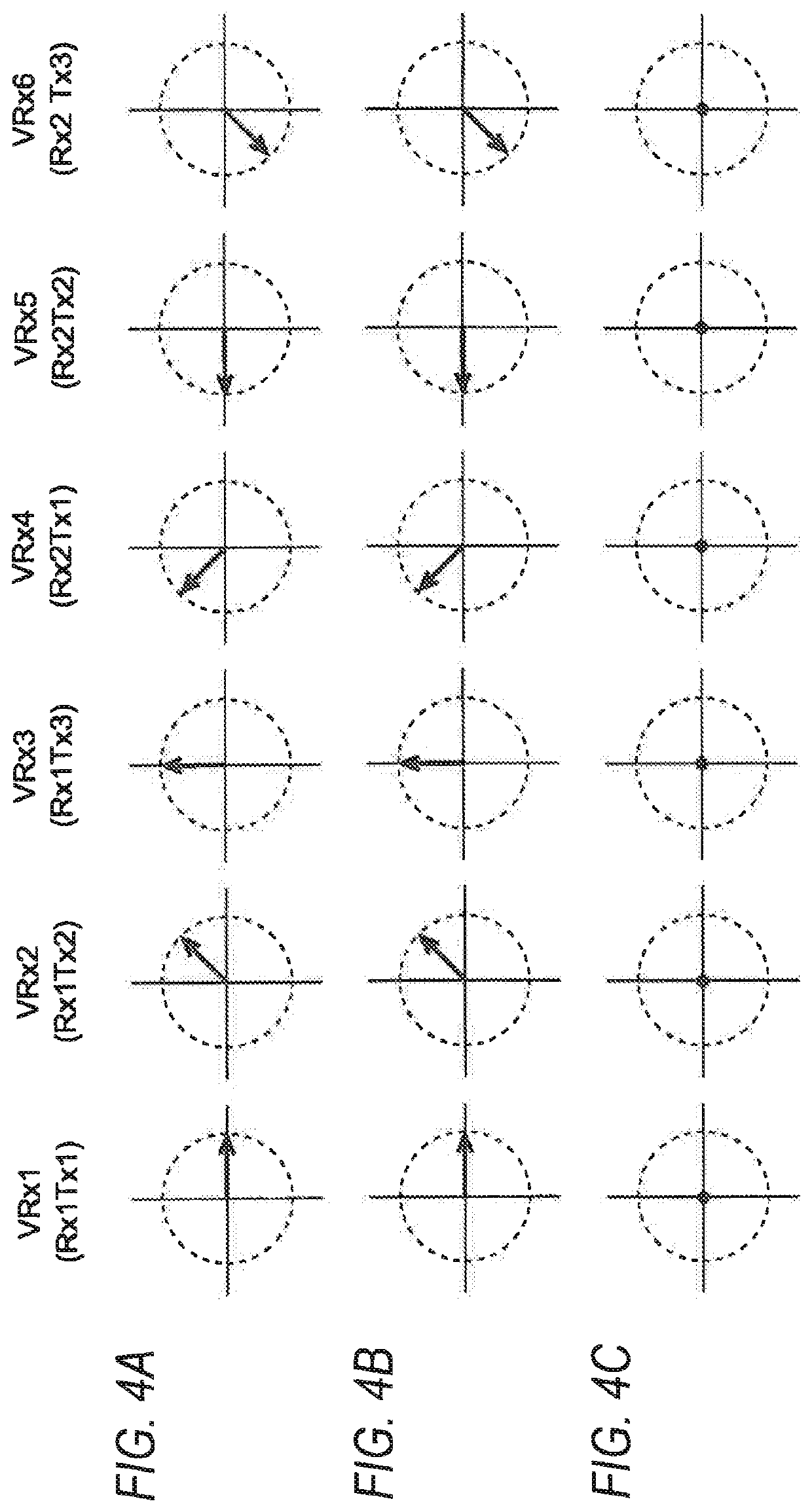

Signal processing device, radar device and signal processing method

ActiveUS20200363522A1Increased processing loadErroneous detection of targetRadio transmissionRadio wave reradiation/reflectionRadio waveAzimuth

A signal processing device, includes: an azimuth estimation unit configured to estimate an arrival azimuth of a radio wave based on a reception signal of plural antennas; an estimated reception signal calculation unit configured to calculate an estimated reception signal based on an estimation result of the arrival azimuth, for comparison with the reception signal; a residual signal calculation unit configured to calculate a residual signal which is a difference between the reception signal and the estimated reception signal; and a determination unit configured to determine whether the estimation result of the arrival azimuth is correct based on the residual signal.

Owner:DENSO TEN LTD

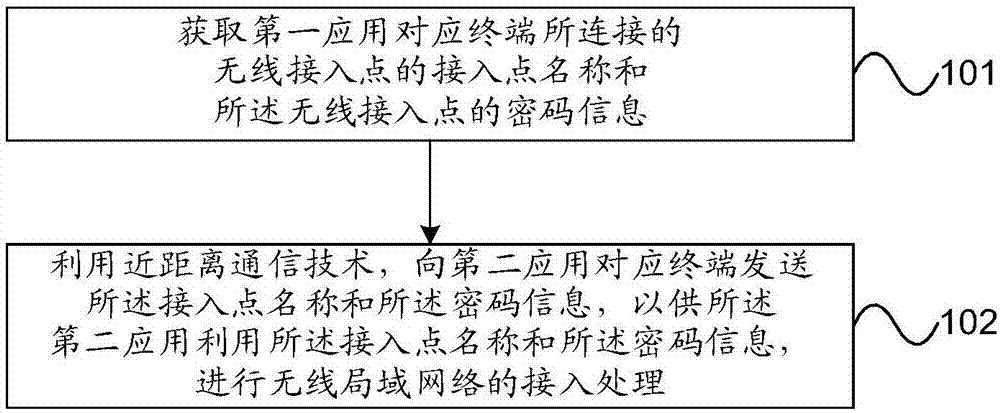

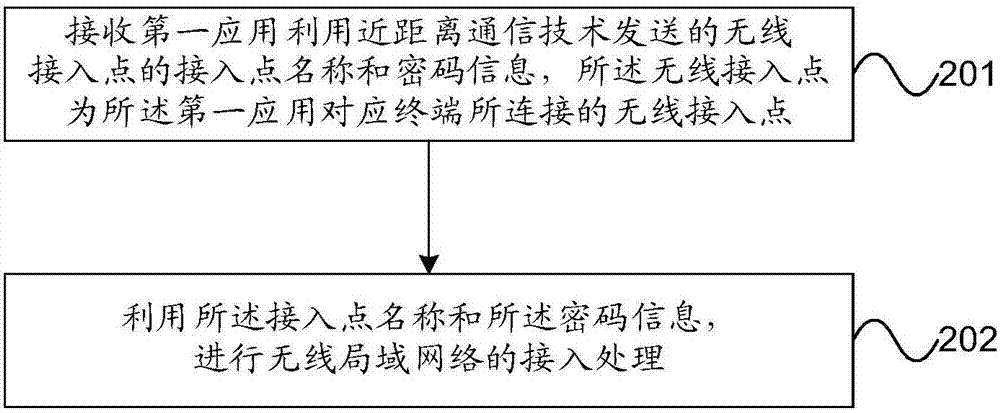

Method and device for processing information of wireless access point, and computer readable storage medium

ActiveCN107959932AAvoid Increased Processing BurdenReduce battery consumptionAssess restrictionSecurity arrangementAccess Point NameLocal area network

The invention provides a method and device for processing information of a wireless access point, and a computer readable storage medium. On one hand, in the method and device provided by the embodiment of the invention, an access point name and password information of a wireless access point are shared with applications on other terminals by using the near field communication technology, so thatthe applications on the other terminals can directly use the access point name and the password information to perform access processing of a wireless local area network, terminal operating systems ofthe other terminals do not need to perform the access processing of the wireless local area network of the terminals according to the operation of a user based on a system page where an original wireless access point list of the system is located, therefore avoiding increasing the processing burden of the terminal operating systems because the terminal operating systems perform the access processing of the wireless local area network of the terminals according to the operation of the user based on the system page where the original wireless access point list of the system is located in the prior art, and thus the power consumption of the terminals is reduced.

Owner:上海尚往网络科技有限公司

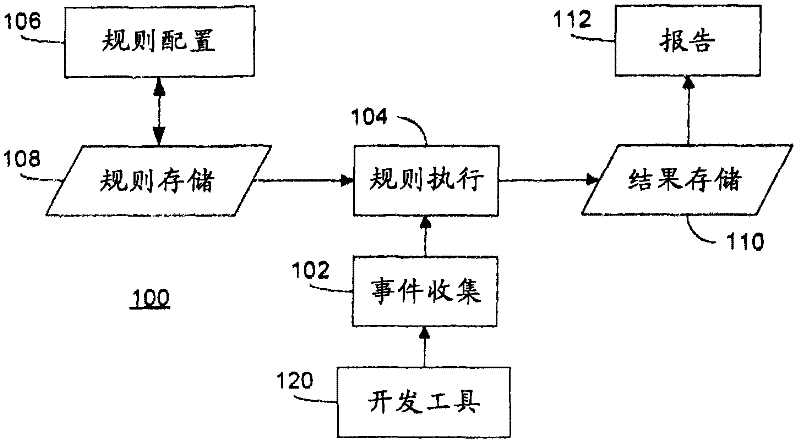

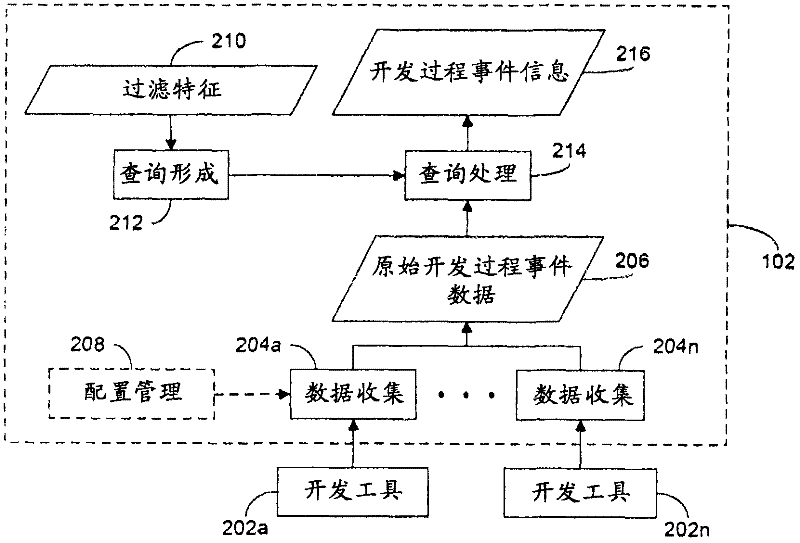

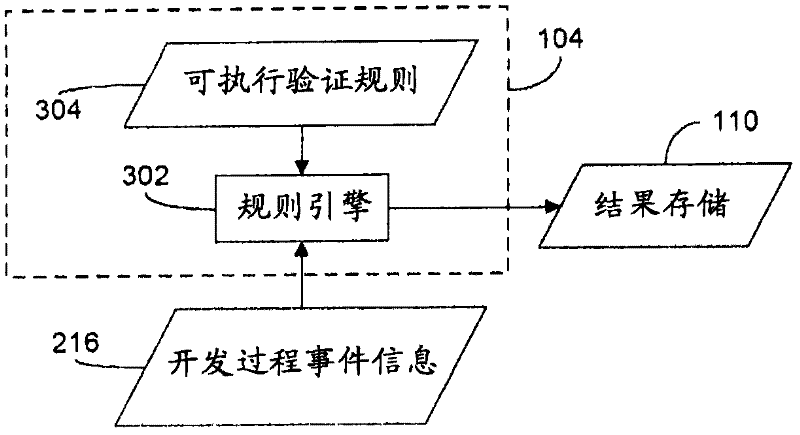

Rule merging in system for monitoring adherence by developers to a software code development process

ActiveCN102253829AQuality improvementImprove satisfactionError detection/correctionSpecific program execution arrangementsSoftware development processSubject-matter expert

The invention relates to the rule merging in system for monitoring adherence by developers to a software code development process. In a rule-based system for monitoring process adherence, first and second processing patterns are received and merged to provide a merged processing pattern. Each processing pattern, which may be expressed in a state graph representation, embodies at least a portion of a desired software code development process. Optionally, the merged processing pattern may be presented to a subject-matter expert to obtain feedback thereon. The merged processing pattern may then be converted into an executable process verification rule for use in monitoring process adherence. In an embodiment, development process event data is compared to the executable process verification rules. Violations of the rules result in the generation of failure indications that may be stored and subsequently reported as needed. In this manner, efficiency of automated process adherence monitoring systems may be improved when determining the level of compliance by developers with one or more software code development processes.

Owner:ACCENTURE GLOBAL SERVICES LTD

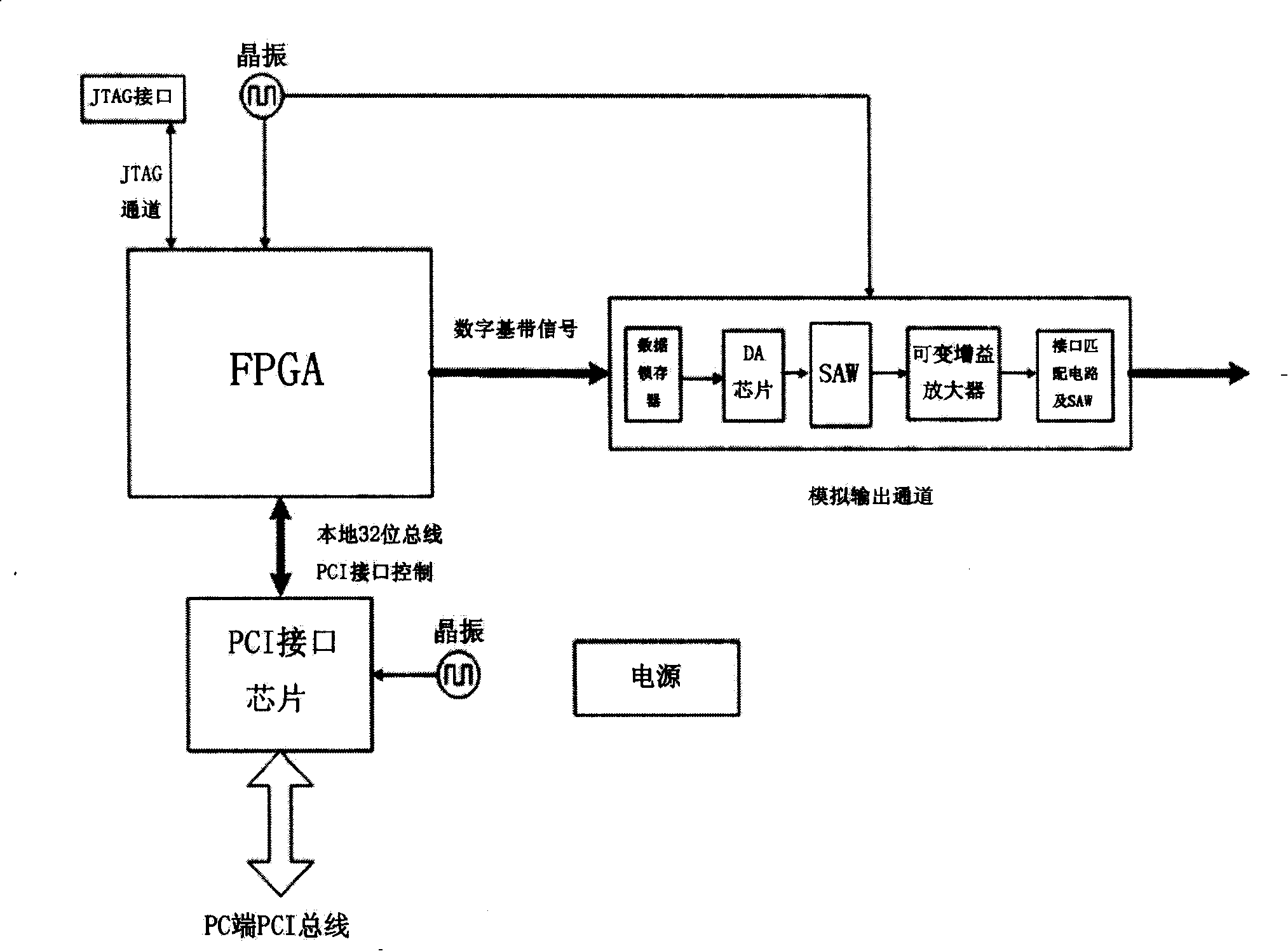

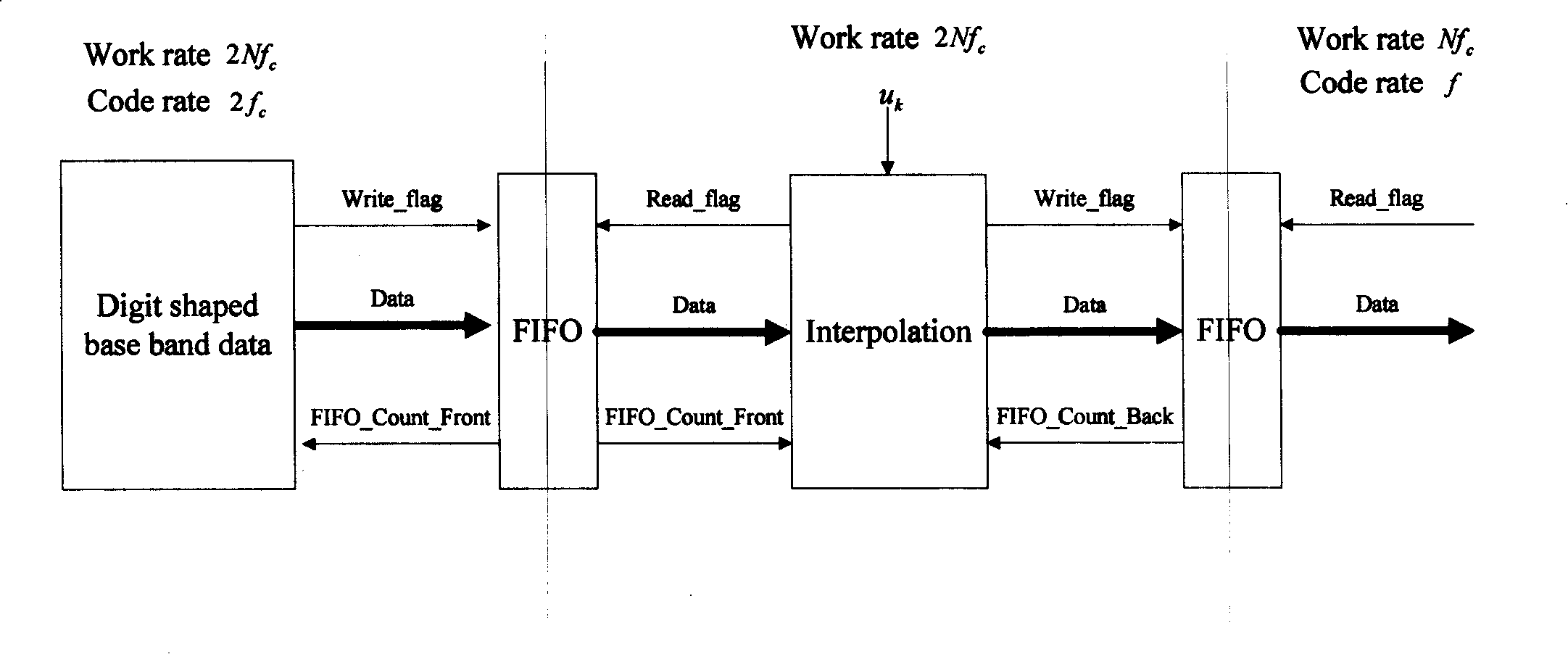

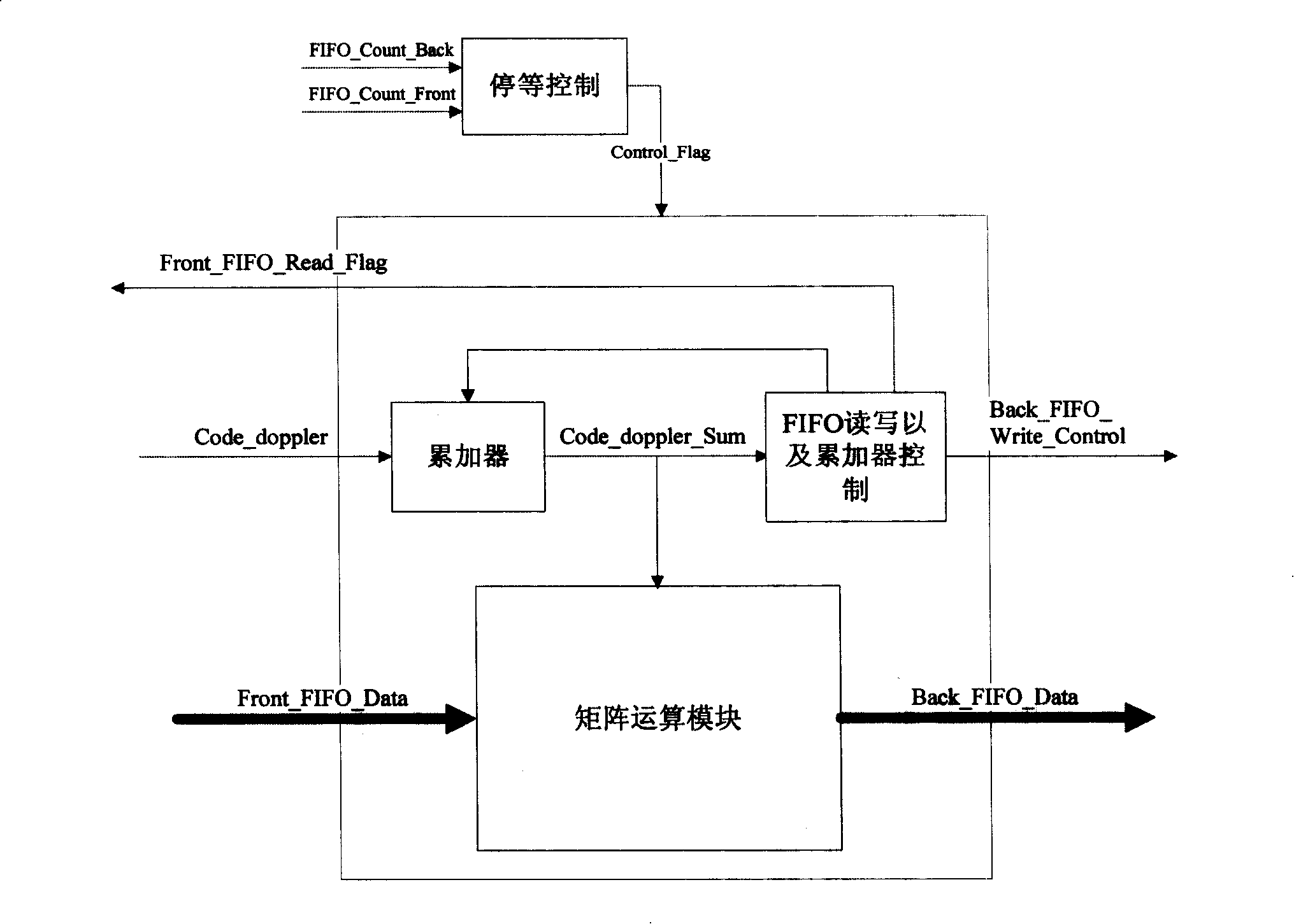

A Doppler simulation realization method based on digital interposition value

InactiveCN101242197AIncrease sampling rateHigh resolutionReceivers monitoringRadio transmissionParallel computingSignal source

The invention discloses a technical method for accomplishing Doppler offset stacking analog of digital signal source. The method simulates influence of the Doppler offset stacking to digital signal in reality via processing digital interpolation process for sampling point after high power code speed digit is formed. A secondary interpolation method is adopted to calculate value on interpolation point. Speed of the digital symbol after interpolation alters according to simulating code offset. Constant processing speed is implemented ordinarily by FPGA so as to correspond to altering characteristic of the code stream. Processing speed is improved and FIFO cache is configured, implementing alternation of code speed by waiting method. In order to improve shortcoming that the interpolation has large matrix operation, implementing interpolation operation by way of Farrow filter. The structure is simpler and operation is smaller.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

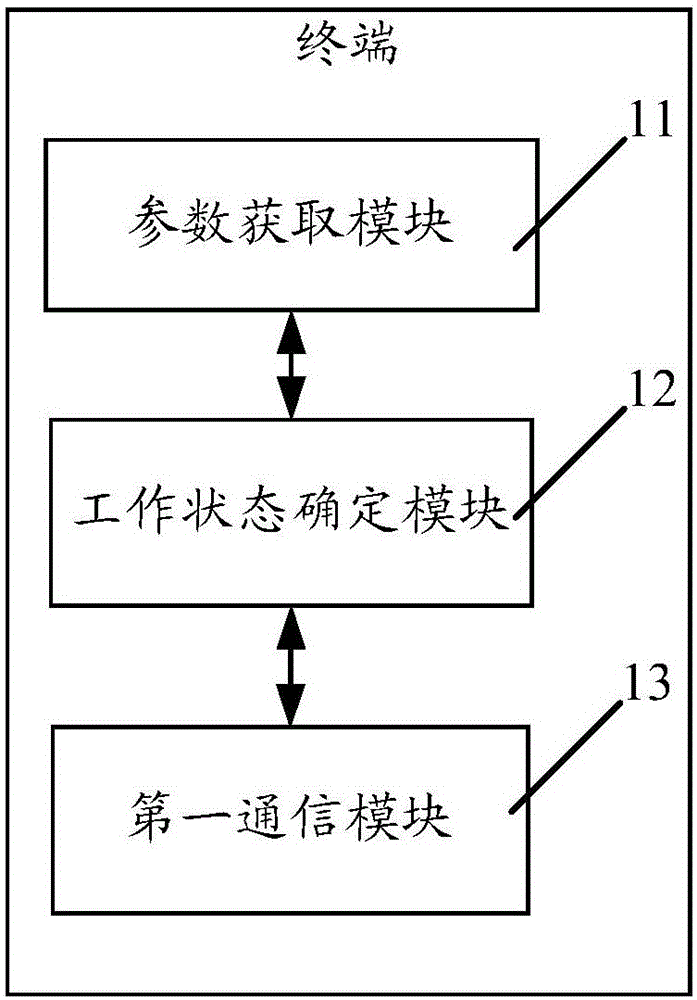

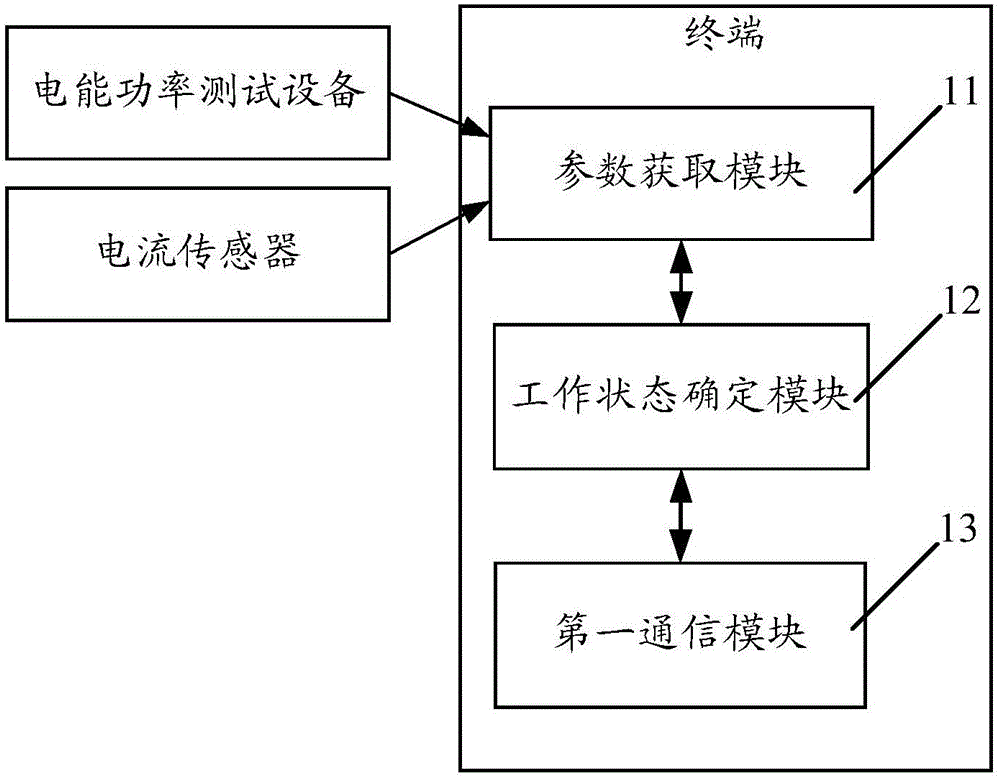

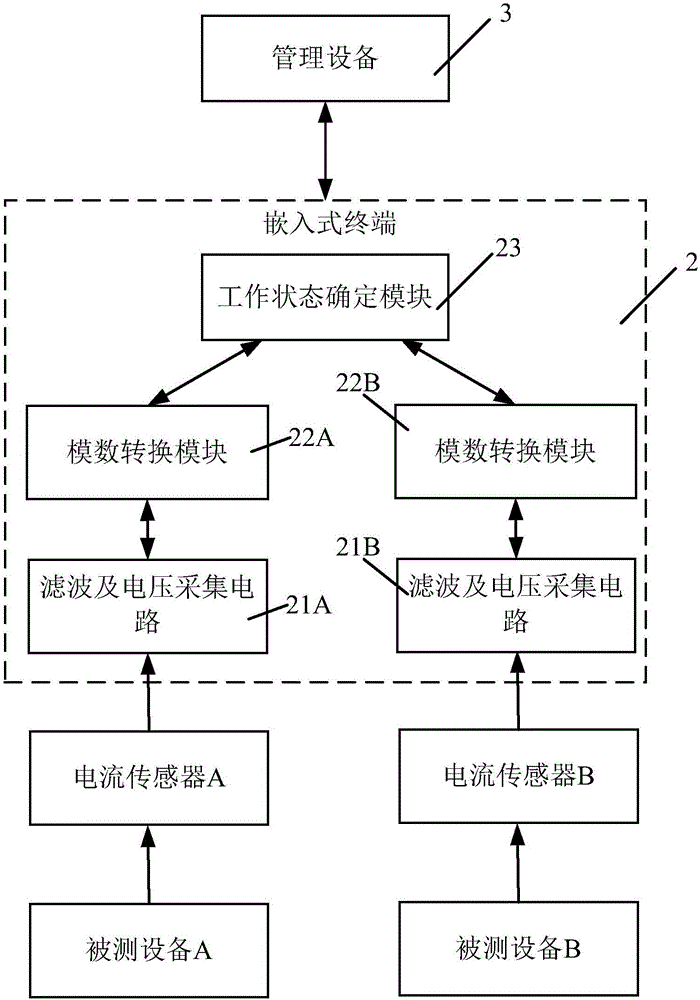

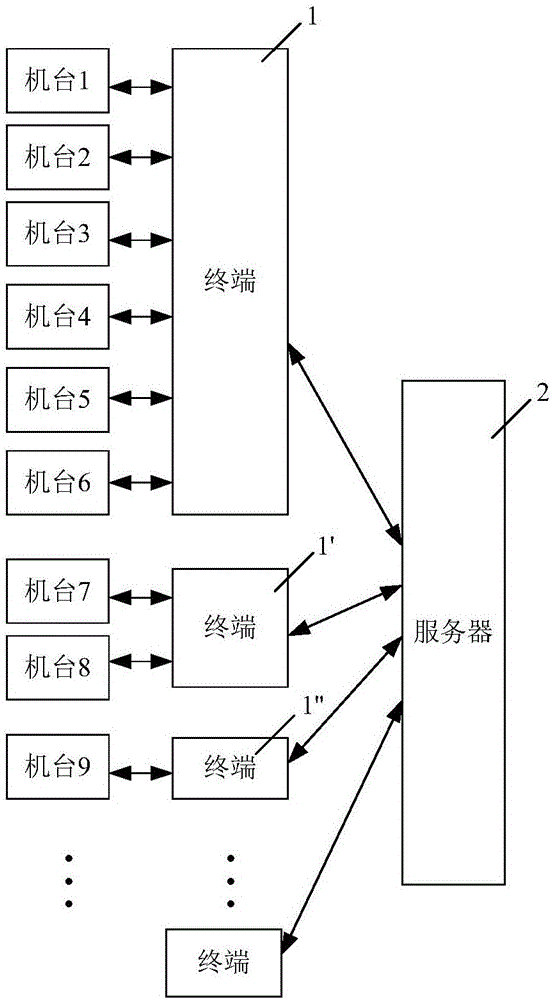

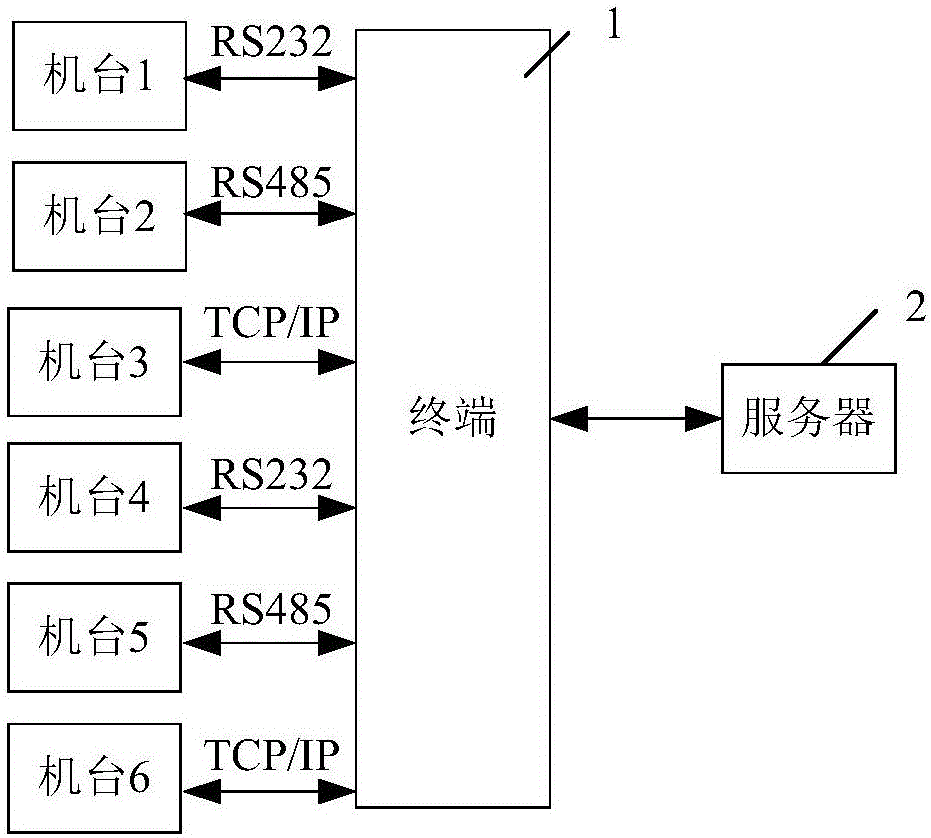

A utilization rate determination system and method and a terminal

InactiveCN106094771AReduce the burden onIncreased processing loadTotal factory controlProgramme total factory controlEngineeringSoftware requirements

The invention discloses a utilization rate determination system and method and a terminal. The terminal comprises a parameter obtaining module used for obtaining operation parameters of detected equipment; a working state determination module used for determining the working state of the detected equipment according to the obtained operation parameters and a working state determination rule, wherein the working state determination rule includes a corresponding relation between a plurality of working states and a range of parameter values of the operating parameters; and a first communication module used for sending the determined working state to a utilization rate determination device, wherein the working state is regarded as a parameter for the utilization rate determination device to determine a utilization rate. The utilization rate determination system and method and the terminal of the invention can reduce the load of the utilization rate determination device, guarantee the real-time performance of utilization rate counting, reduce the hardware and software requirements of the utilization rate determination device and save the cost.

Owner:NINGBO SUNNY INTELLIGENT TECH CO LTD

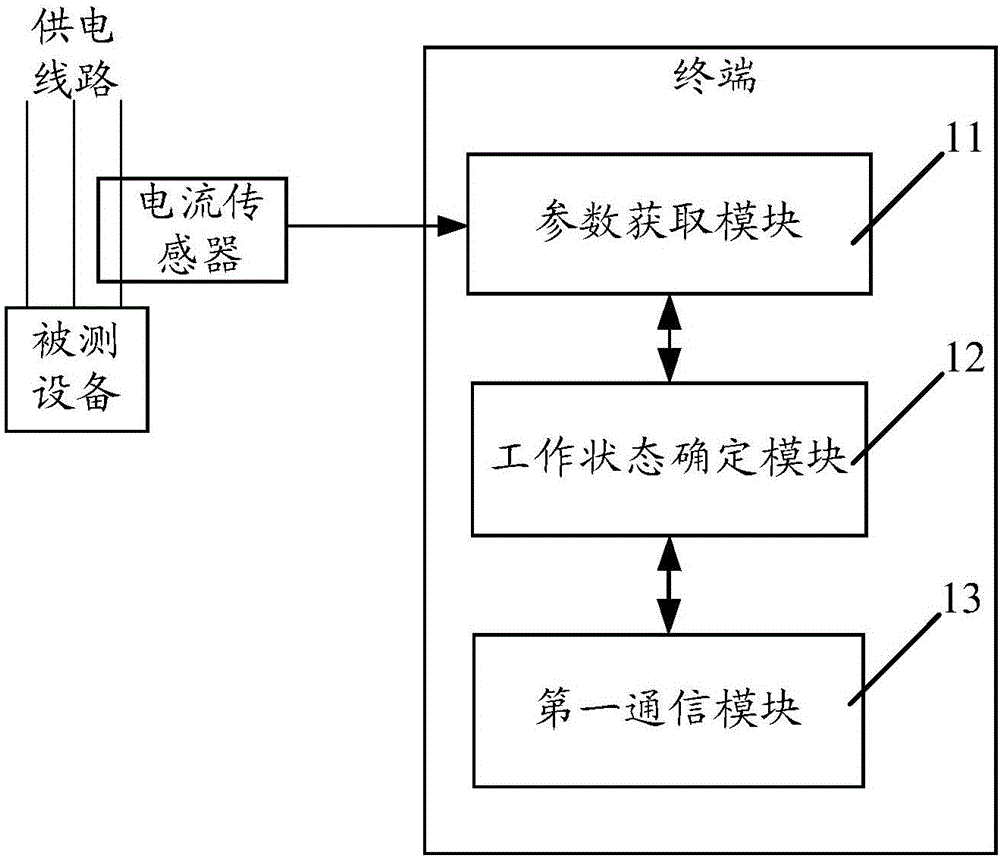

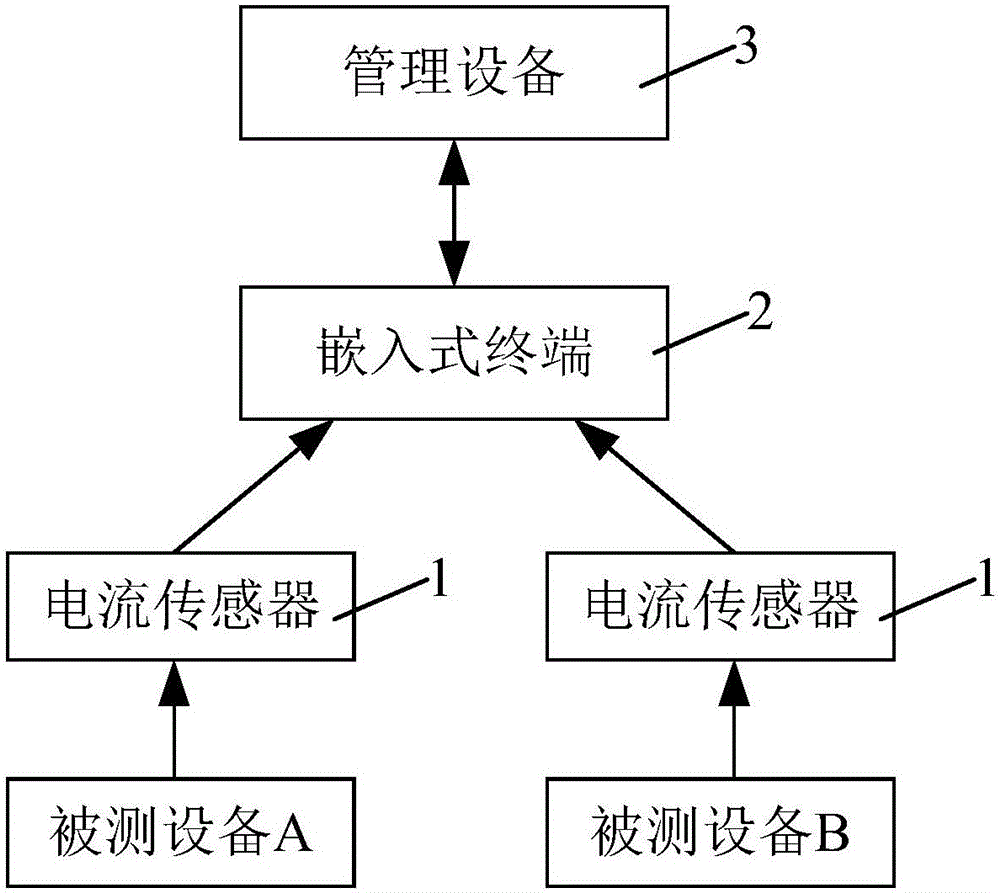

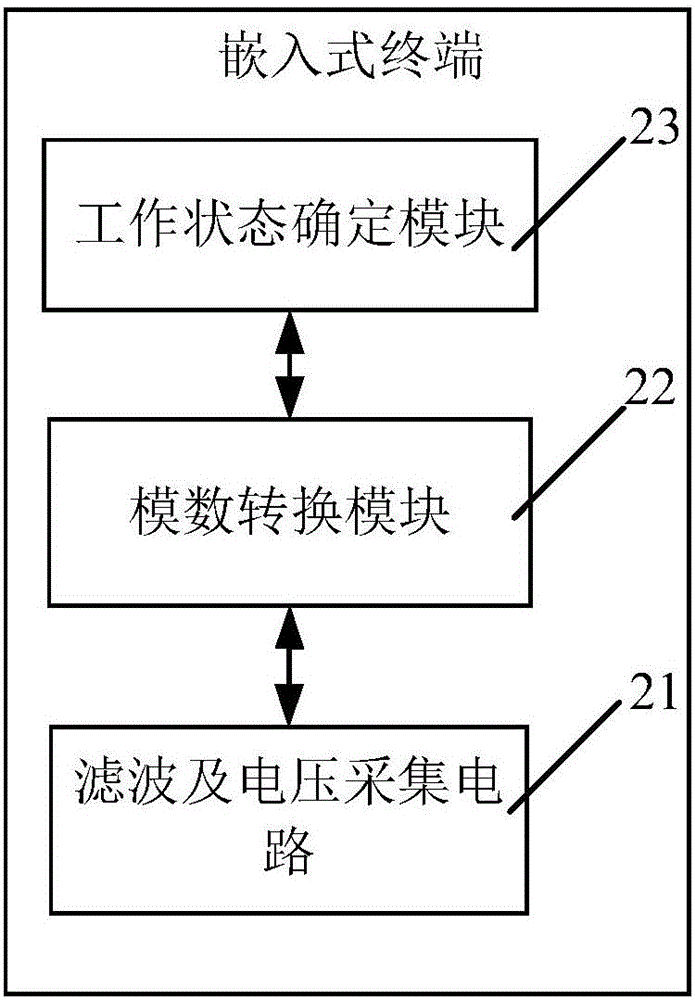

Utilization rate determination system and method

ActiveCN106353576AReduce the burden onIncreased processing loadElectrical testingMeasurement using digital techniquesPower flowCurrent sensor

The invention discloses an utilization rate determination system and method. The system comprises a current sensor for generating an induced current signal according to the current of the power supply line of the device under test, an embedded terminal which is used for processing the induced current signal from the current sensor into a digital level signal, determining the actual current value of the power supply line of the device under test according to the digital level signal, determining the working state of the device according to the determined actual current value and the working state determination rule and reporting the determined working state, wherein the working state determination rule includes a correspondence relationship between a plurality of working states and a current value range, as well as a management device for receiving the working state reported by the embedded terminal and determining the utilization rate of the device under test according to the reported working state. The invention can reduce the burden of management equipment, decrease hardware and software requirements, and save costs.

Owner:NINGBO SUNNY INTELLIGENT TECH CO LTD

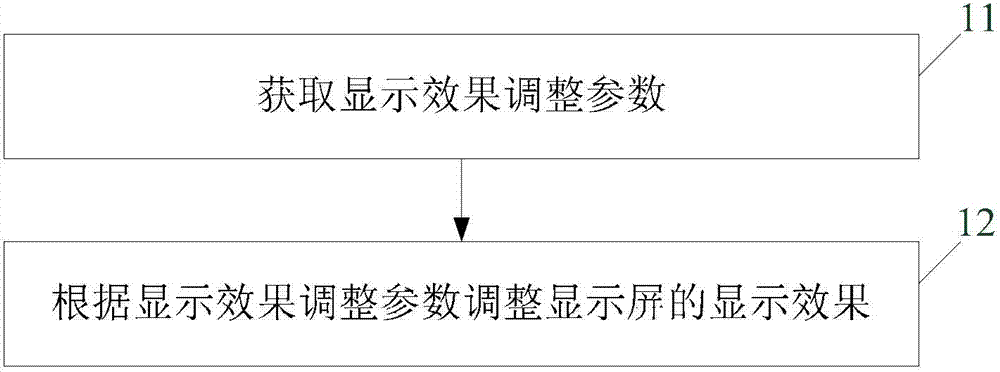

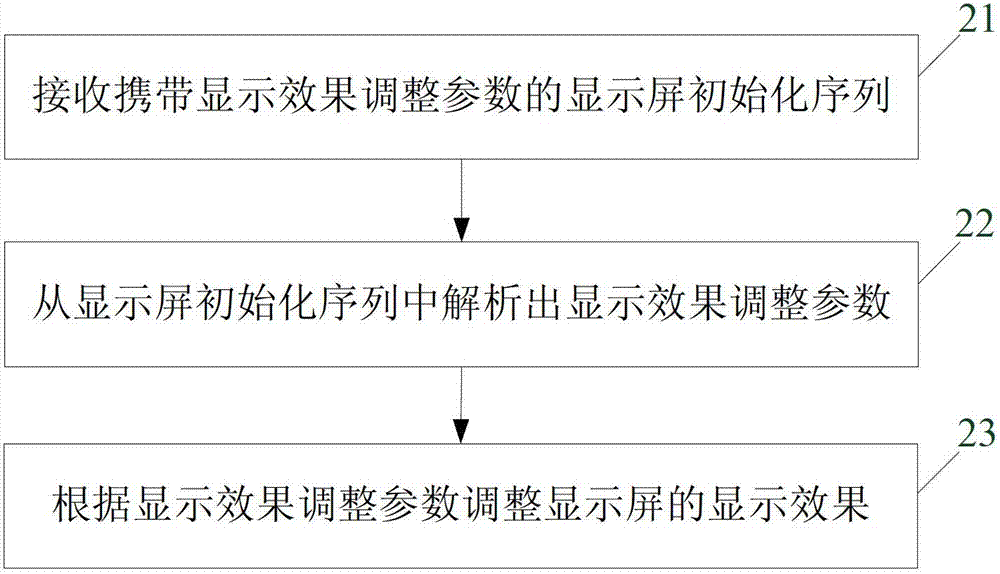

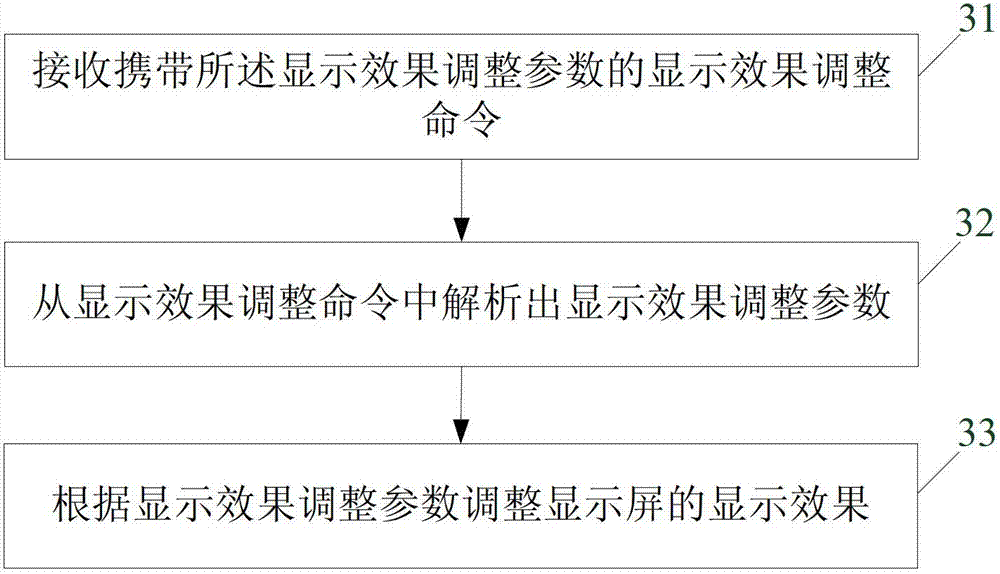

Method and device for adjusting display effect

The invention discloses a method and a device for adjusting a display effect. The display effect of a screen is adjusted by a display driving chip integrated in the display screen according to a display effect adjusting parameter, so that not only is the inner processing burden of a terminal not increased, but also the diversified display demands are satisfied.

Owner:XIAOMI INC

Updating method for address information and cache device

InactiveCN106790494AIncreased processing loadReduce consumptionTransmissionTraffic volumeTraffic capacity

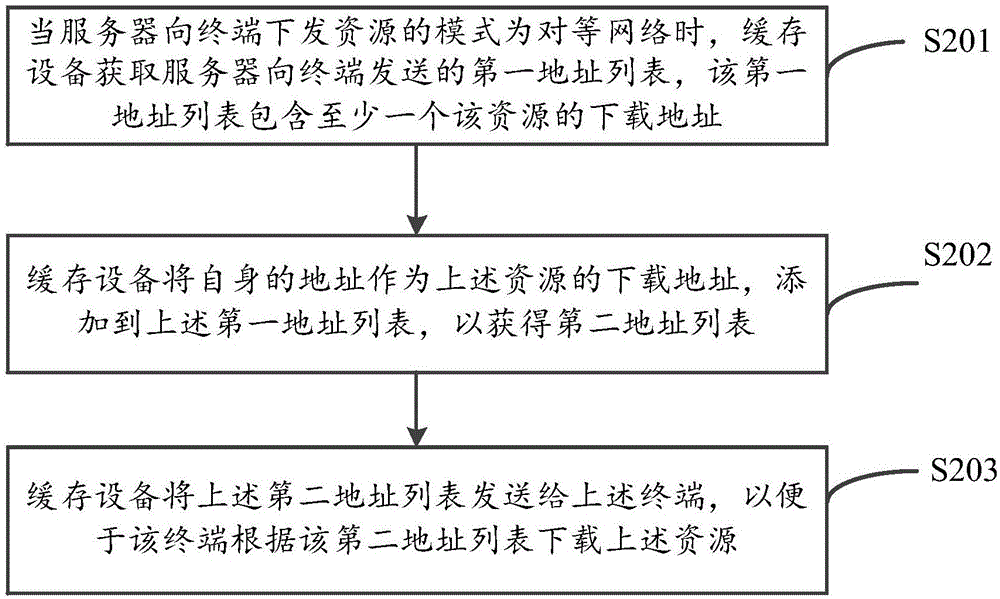

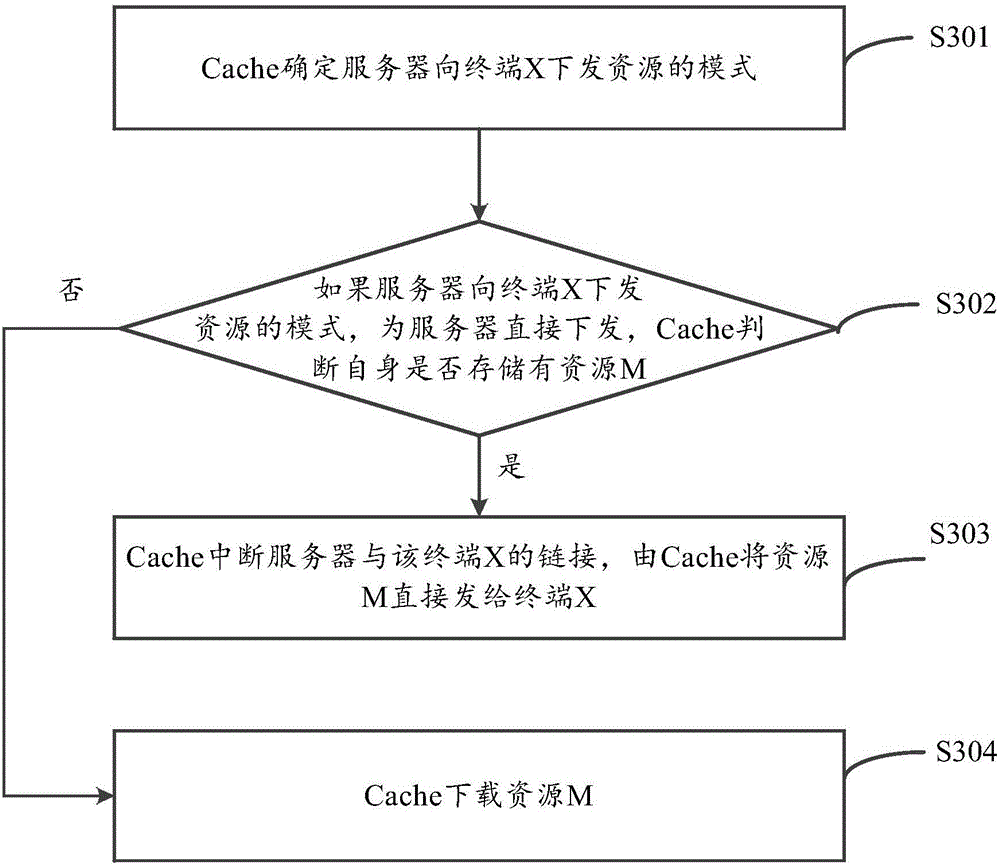

The embodiment of the invention provides an updating method for address information and a cache device. The method comprises the steps that when a mode of issuing a resource to a terminal by a server is a peer to peer network, the cache device obtains a first address list sent to the terminal by the server, wherein the first address list comprises at least one download address of the resource; the cache device takes own address as the download address of the resource and adds the download address to the first address list, thereby obtaining a second address list; and the cache device sends the second address list to the terminal, so the terminal can download the resource according to the second address list. According to the embodiment of the invention, the utilization frequency of the cache device is increased, the traffic consumption of the terminal for providing the resource is reduced, the processing load of the terminal for providing the resource is reduced, and the efficiency of obtaining the resource by the terminal is improved.

Owner:BAICELLS TECH CO LTD

Wireless local area network connection method and device, equipment and computer readable storage medium

ActiveCN107889191AReduce battery consumptionIncreased processing loadAssess restrictionNetwork topologiesThird partyOperational system

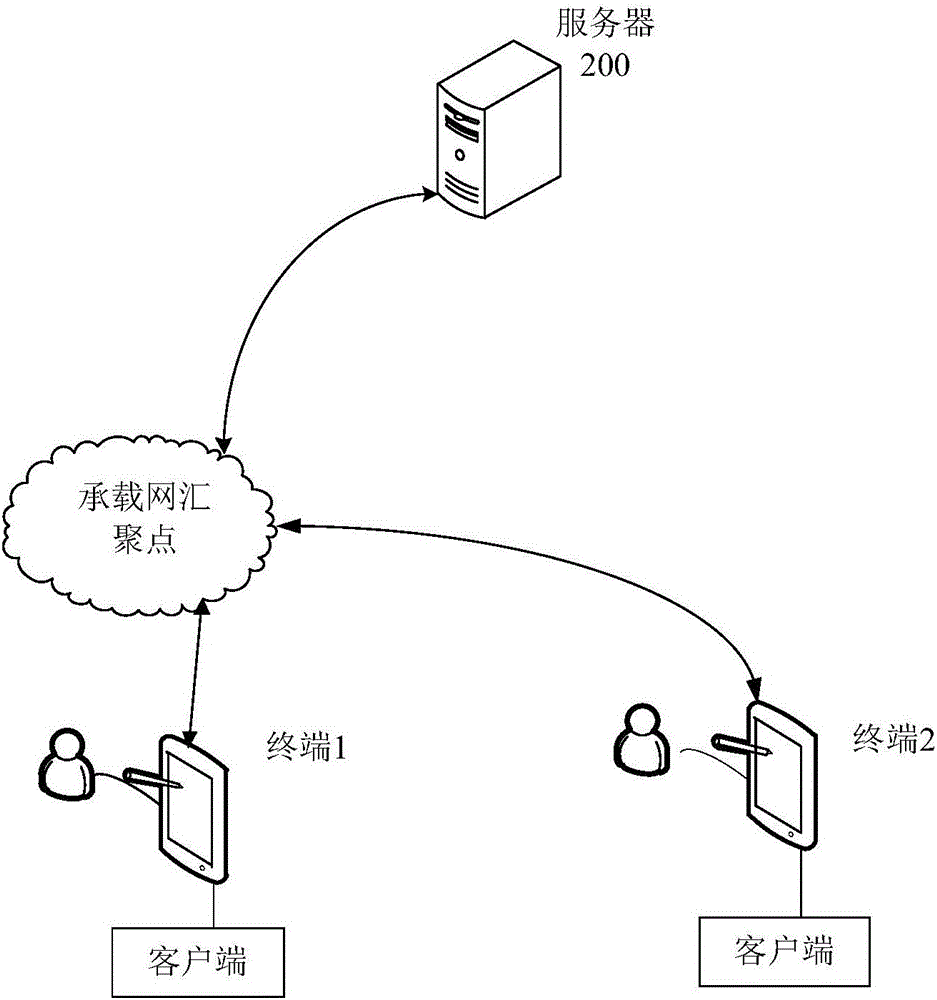

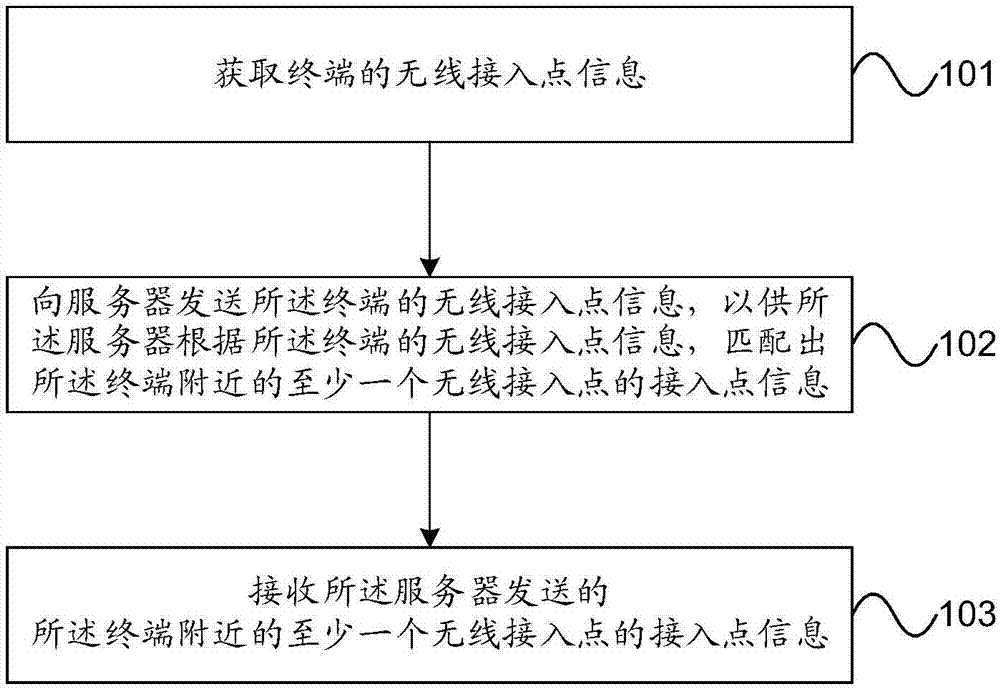

The invention provides a wireless local area network connection method and device, equipment and a computer readable storage medium. On one hand, according to the embodiments of the invention, wireless access point information of a terminal is obtained, and then the wireless access point information of the terminal is sent to a server, so that the server can match access point information of at least one wireless access point near the terminal according to the wireless access point information of the terminal, and the access point information, which is sent by the server, of at least one wireless access point near the terminal can be received. In this way, specific applications running on the terminal, such as a third-party networking application, can carry out access processing of the wireless local area network of the terminal based on the access point information of at least one wireless access point near the terminal, so that increase of the processing burden of a terminal operating system, which is caused by access processing of the wireless local area network of the terminal through the terminal operating system, in the prior art can be avoided, and thus the electric quantityconsumption of the terminal is reduced.

Owner:上海尚往网络科技有限公司

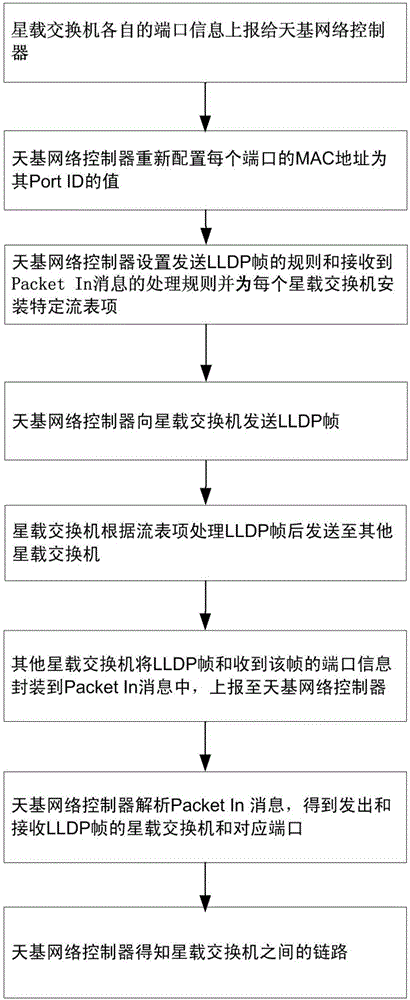

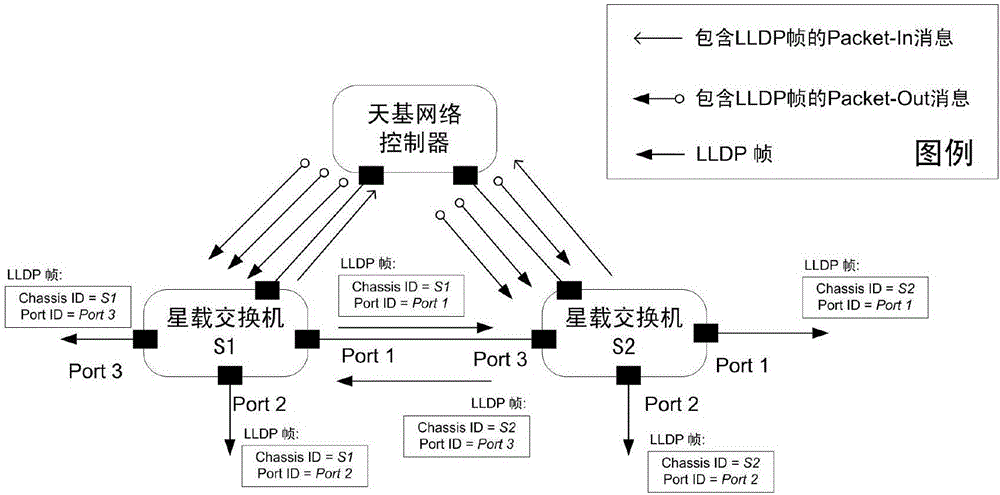

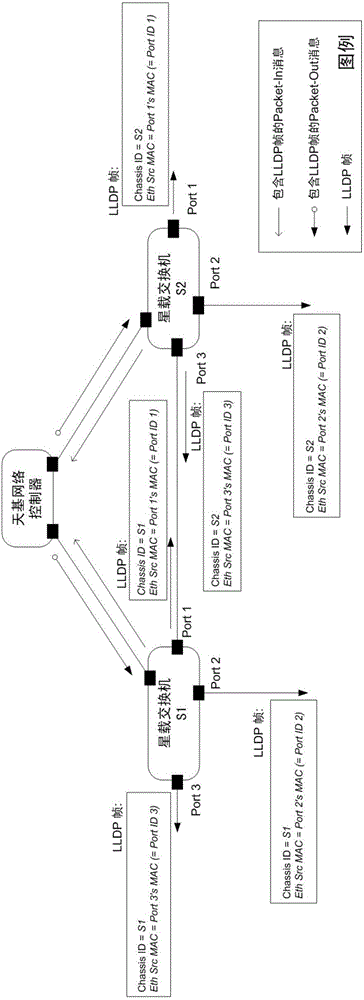

Software define link topology discovery method in space-based backbone network

InactiveCN106533948AIncreased processing loadImprove compatibilityData switching networksHigh level techniquesNetwork controlMAC address

The invention discloses a software define link topology discovery method in a space-based backbone network. The detection overhead of a space-based network controller which uses an OpenFlow protocol to realize the topology discovery of a space-based backbone network onboard borne switch. The method comprises the steps that a specific flow entry is set for the onboard switch to realize port-by-port LLDP frame copy on LLDP frames from the controller; the source MAC address is rewritten into the MAC address of the port (the Port ID value); and the number of the LLDP frames sent by the controller is reduced from being proportional to the total number of the ports of whole network onboard switches to being proportional to the total number of whole network onboard switches, so as to reduce the topology discovery detection overhead.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

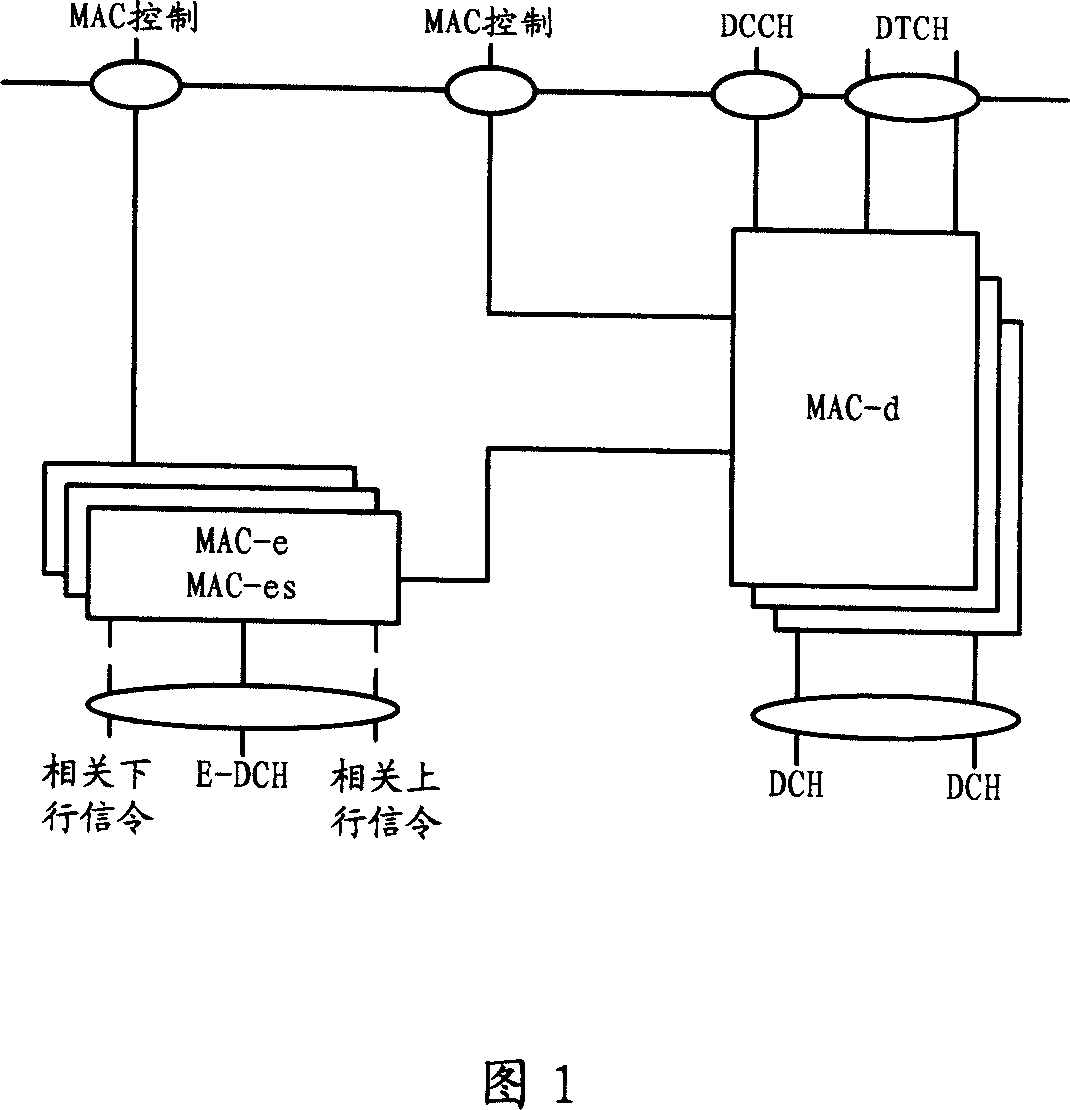

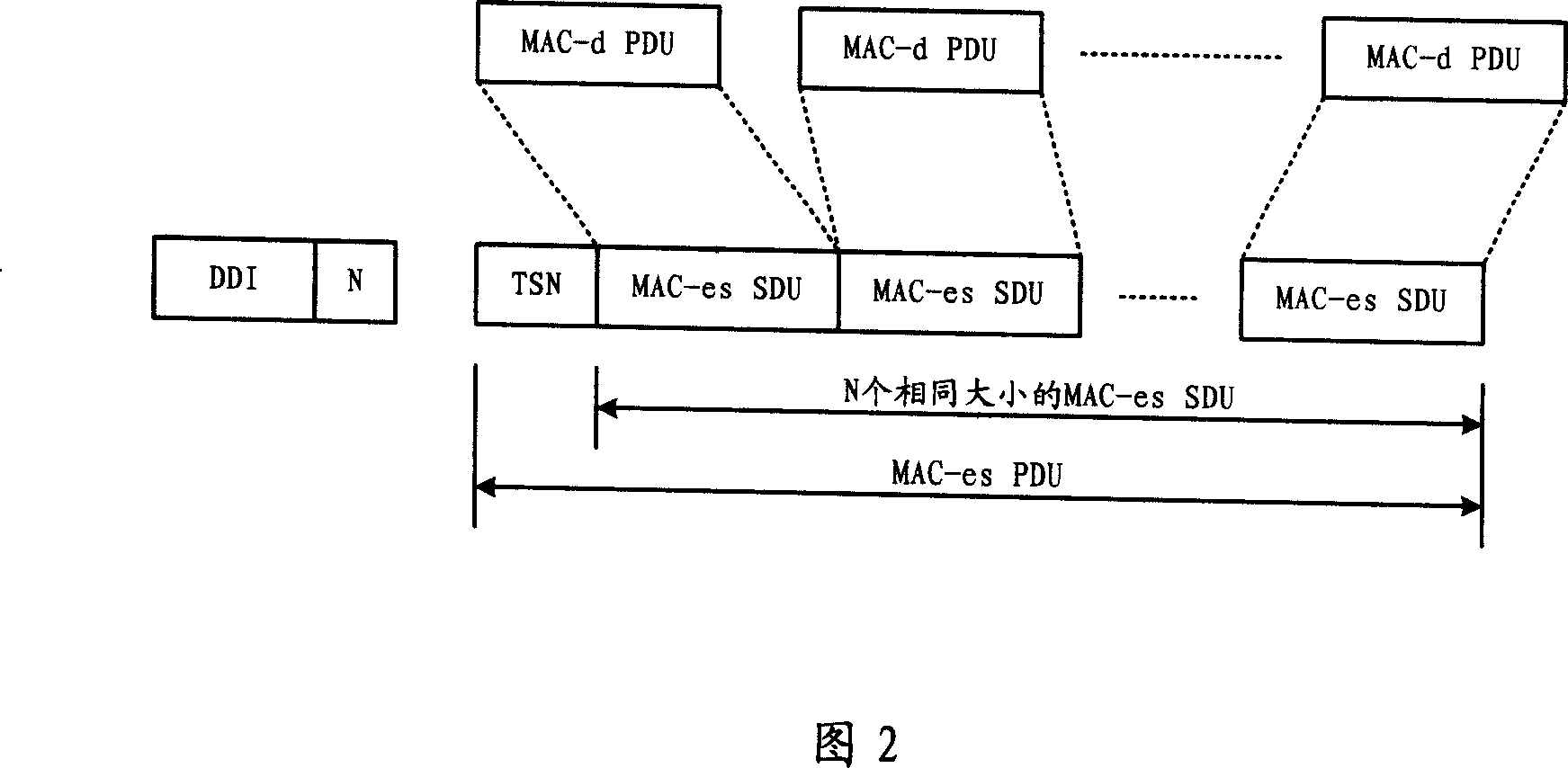

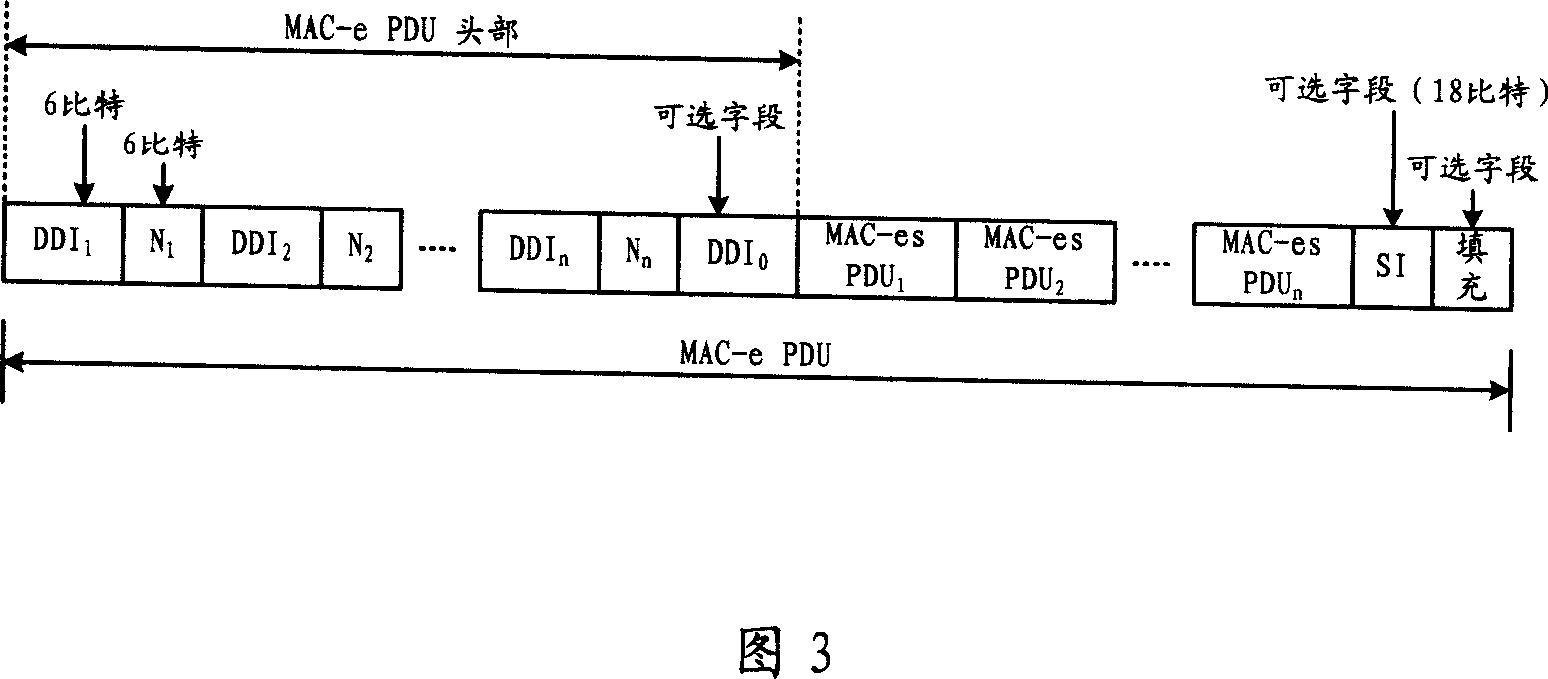

Method and system for transmitting optional field in data packet

ActiveCN101030920AAddresses an issue where redundant SI reports had to be sentIncreased processing loadData switching networksNetwork packetComputer science

The method can correctly indicate whether or not the optional fields exist in the data packet in case of not adding the extra field. In the invention, the different filling modes are used to indicate whether or not the optional fields exist; the typical filling mode is all bits are 0 or 1.

Owner:XFUSION DIGITAL TECH CO LTD

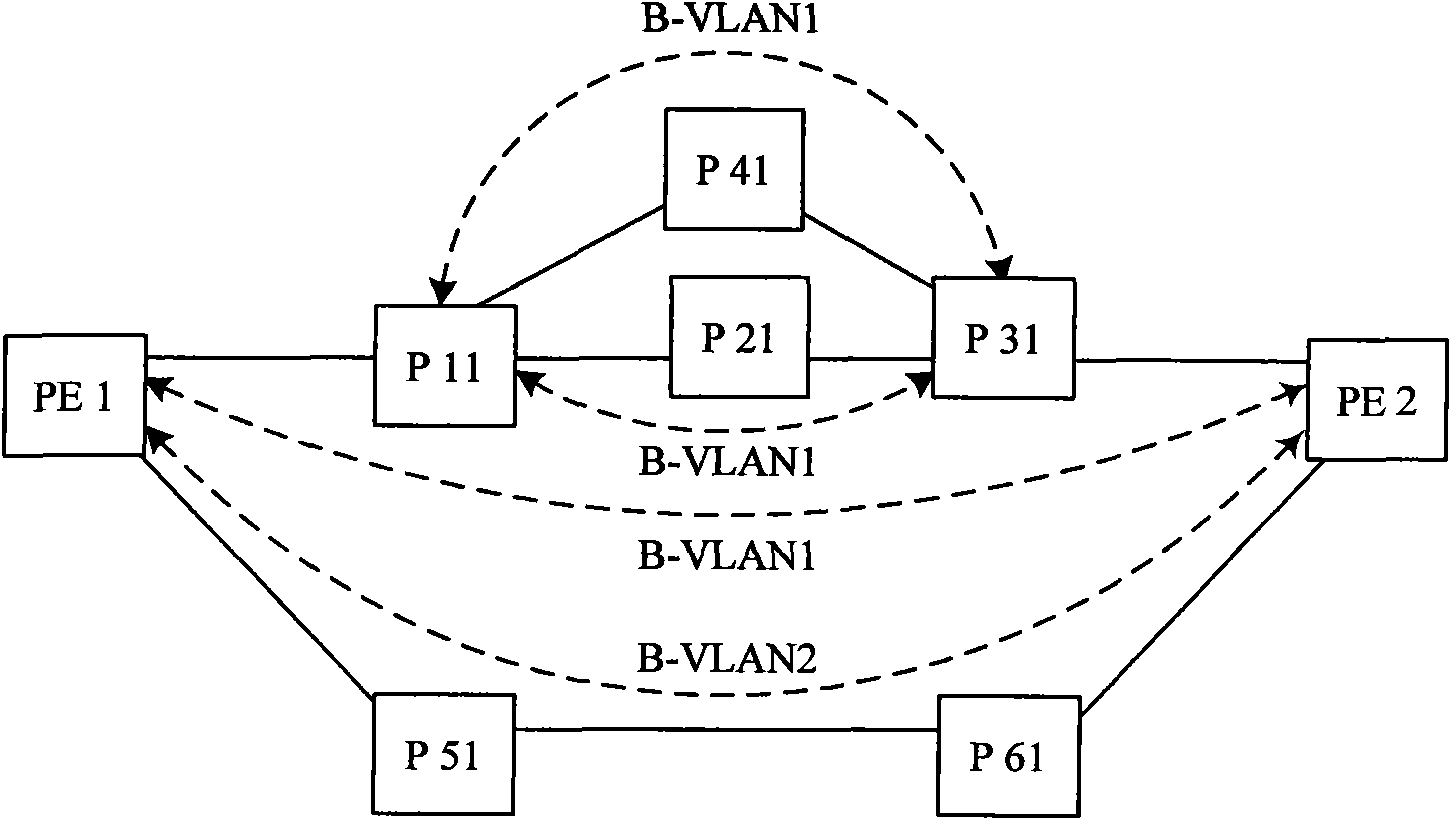

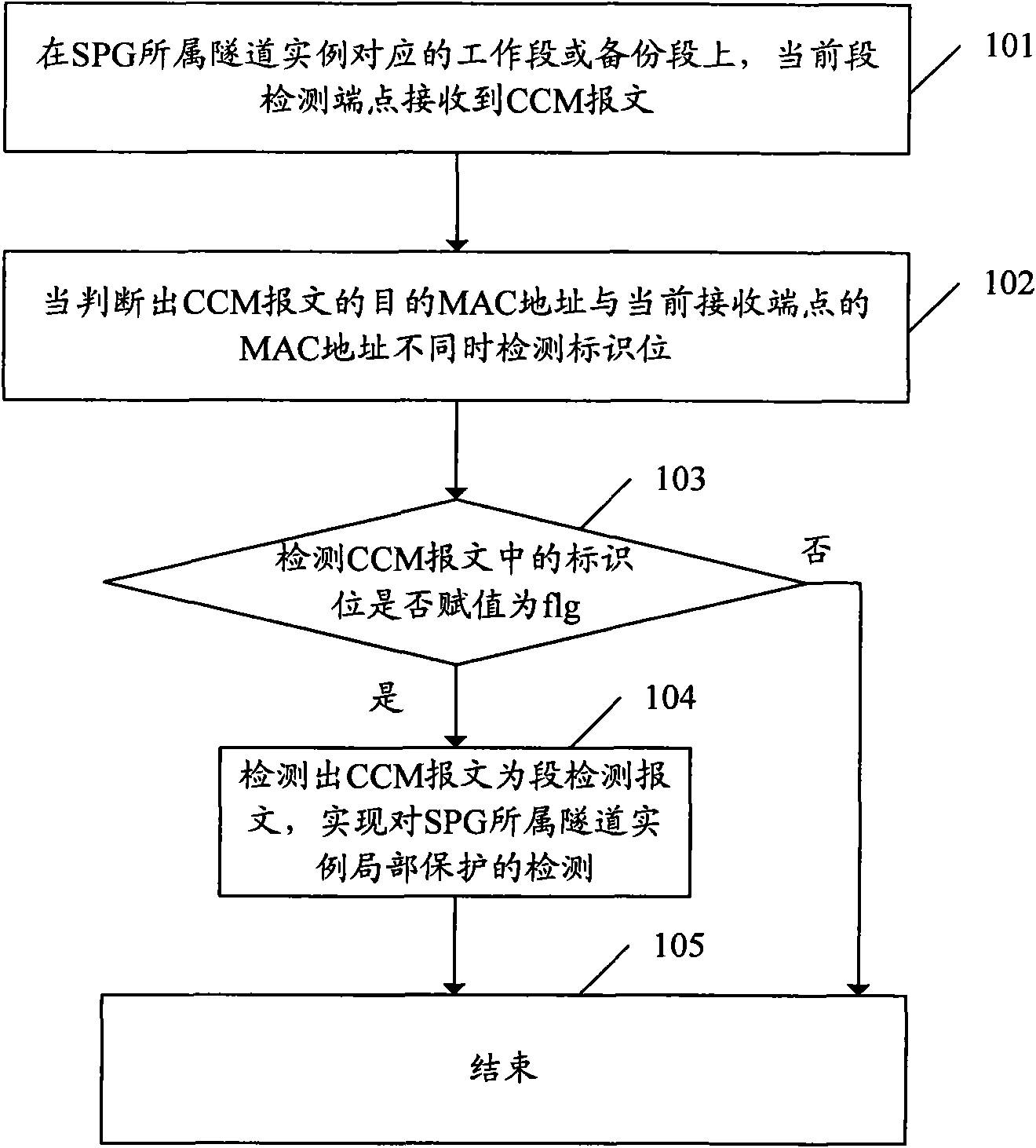

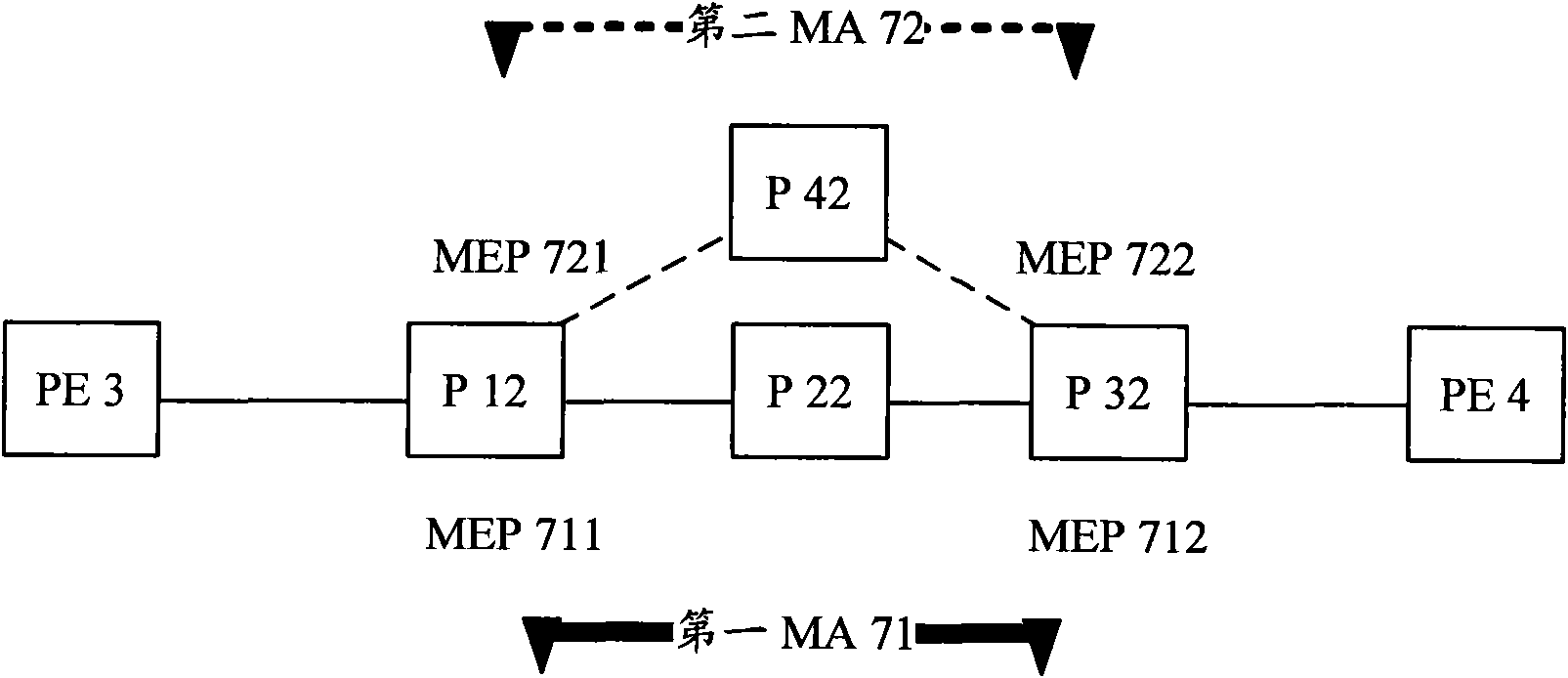

Method and system for detecting local protection of Ethernet tunnel

InactiveCN101854265AAchieve protectionImprove reliabilityNetworks interconnectionMedia access controlComputer science

The invention discloses a method for detecting local protection of an Ethernet tunnel. The method comprises a step of detecting the connectivity of a section corresponding to a tunnel example according to a media access control address at an end point of the tunnel example. The invention also discloses a system for detecting the local protection of the Ethernet tunnel. The system comprises a detection unit used for detecting the connectivity of the section corresponding to the tunnel example according to the media access control address at the end point of the tunnel example. The method and the system of the invention realize connectivity detection of the section corresponding to the tunnel example, and improve the reliability, precision and efficiency of the detection.

Owner:ZTE CORP

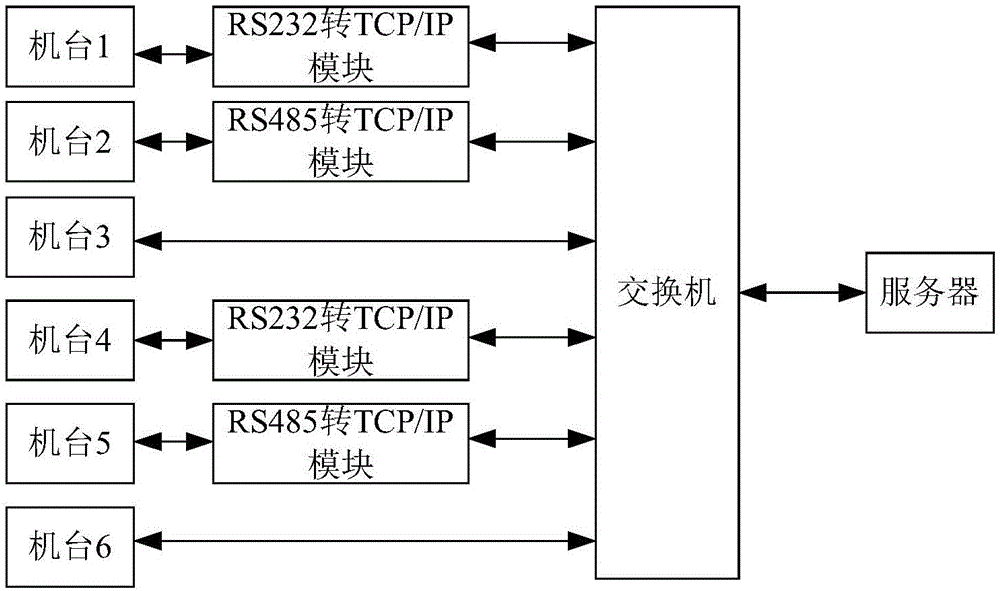

Device management system and method

The invention discloses a device management system and method. The system comprises terminals and a server; the terminals are used for acquiring the operation data of devices, decoding the acquired operation data to obtain information expressed by the operation data, extracting information specified by information extraction instructions from the information according to preset information extraction instructions, converting the extracted information into information of preset formats and sending the information of the preset formats; and the server is used for receiving the converted information sent by the terminal. With the device management system and method of the invention adopted, work such as the sorting of data content and format conversion on data can be distributed to each terminal, so that the server does not need to process a large amount of useless information, and the transmission of the useless information can be reduced, and network overhead can be reduced; and the processing burden of the server is not increased significantly with the increase of the scale of production, and therefore, the requirements of the server for hardware and software can be lowered, system complexity can be also decreased, stability can be improved, and costs can be saved.

Owner:NINGBO SUNNY INTELLIGENT TECH CO LTD +1

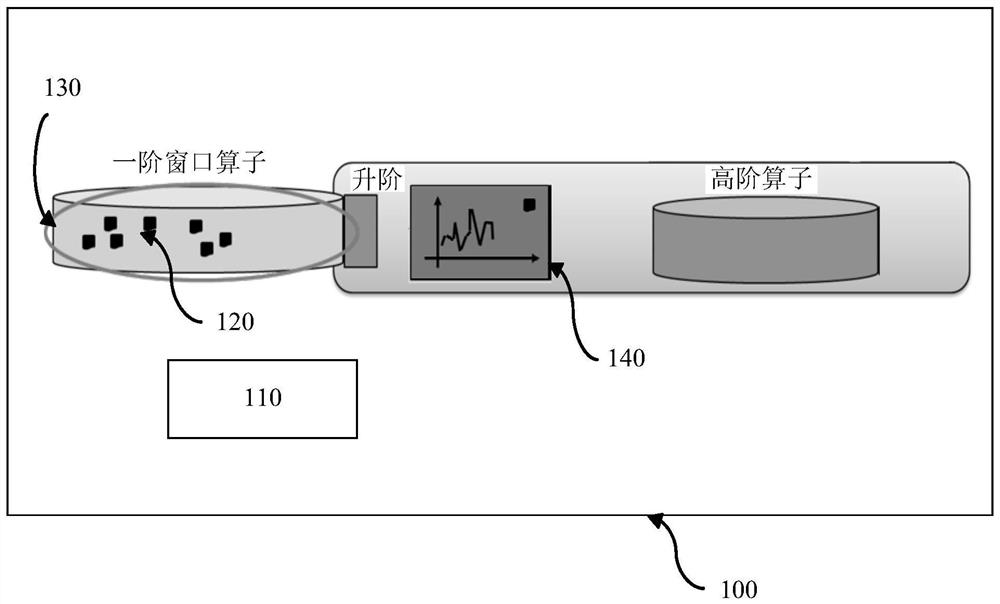

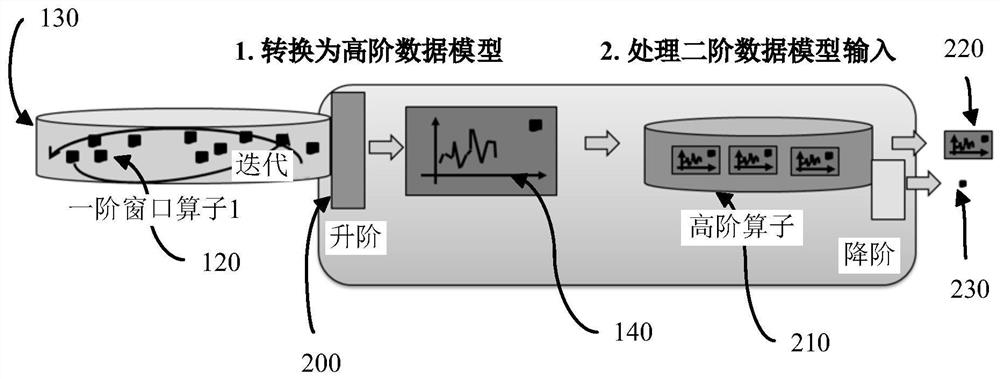

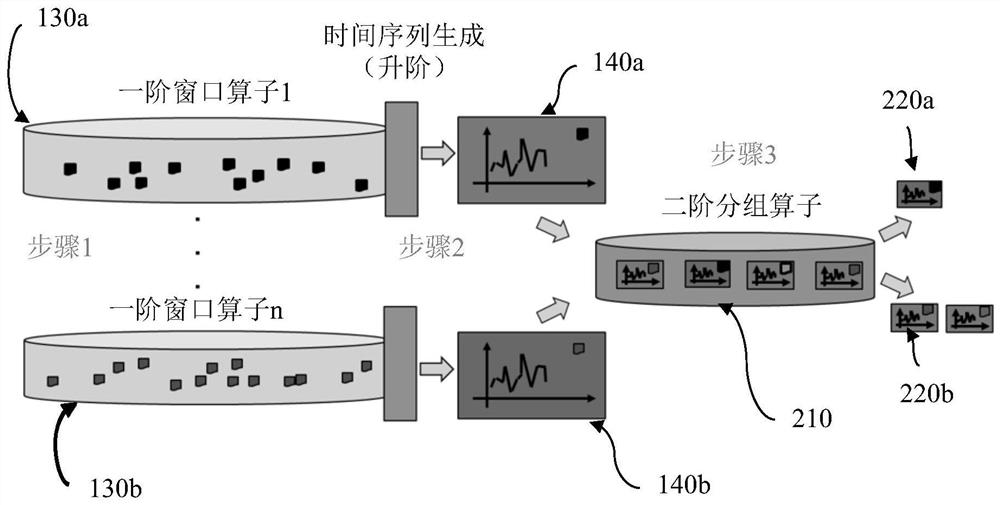

Stream processing device and method of processing a stream of data

PendingCN111771195AEfficient and effective pattern matchingResponse to a wide rangeDigital data information retrievalComplex mathematical operationsComputational scienceData stream processing

The present invention provides a stream processing device (100) with a processor (110) for processing a stream of data (120) inside a streaming window (130). The processor (110) is configured to generate a higher order representation (140) from the content of the streaming window (130), and the processor (110) is configured to process the higher order representation (140).

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

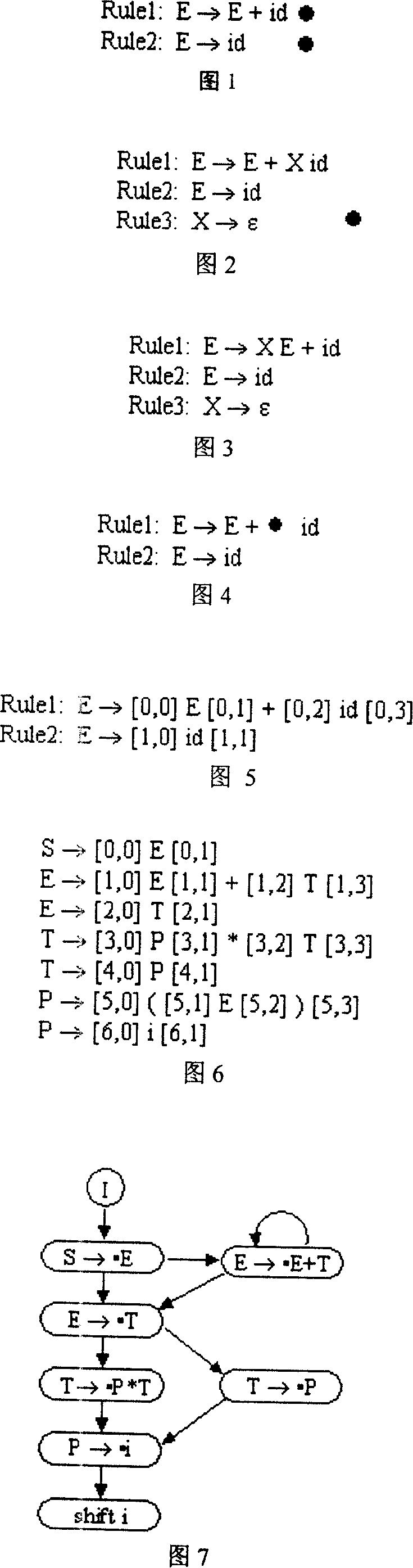

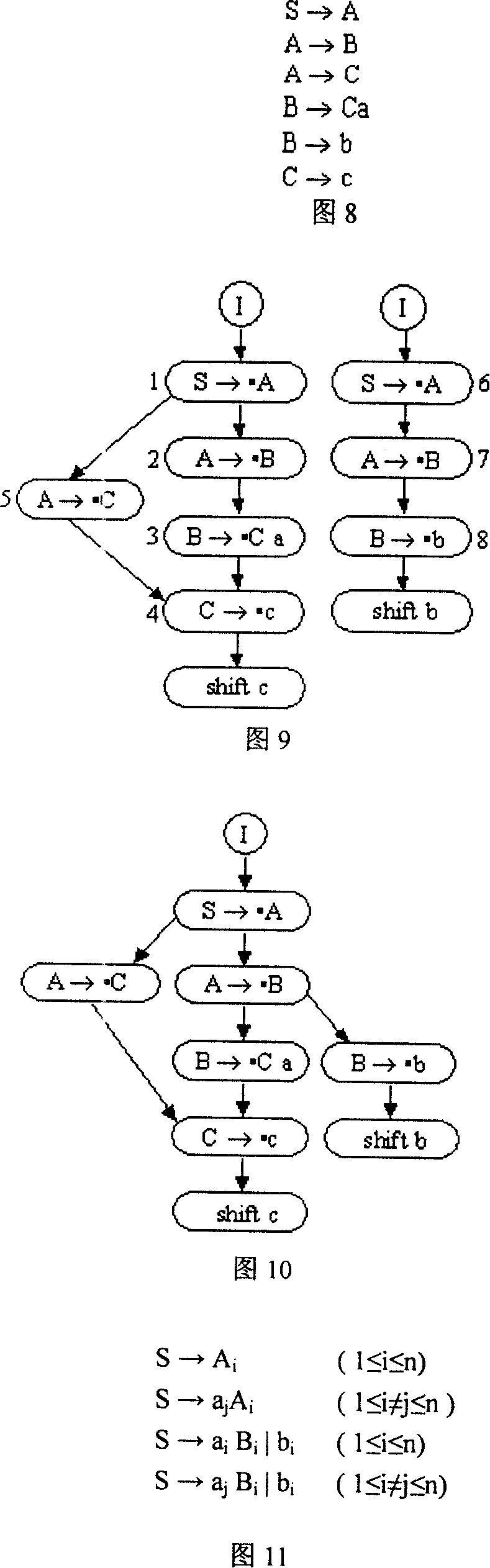

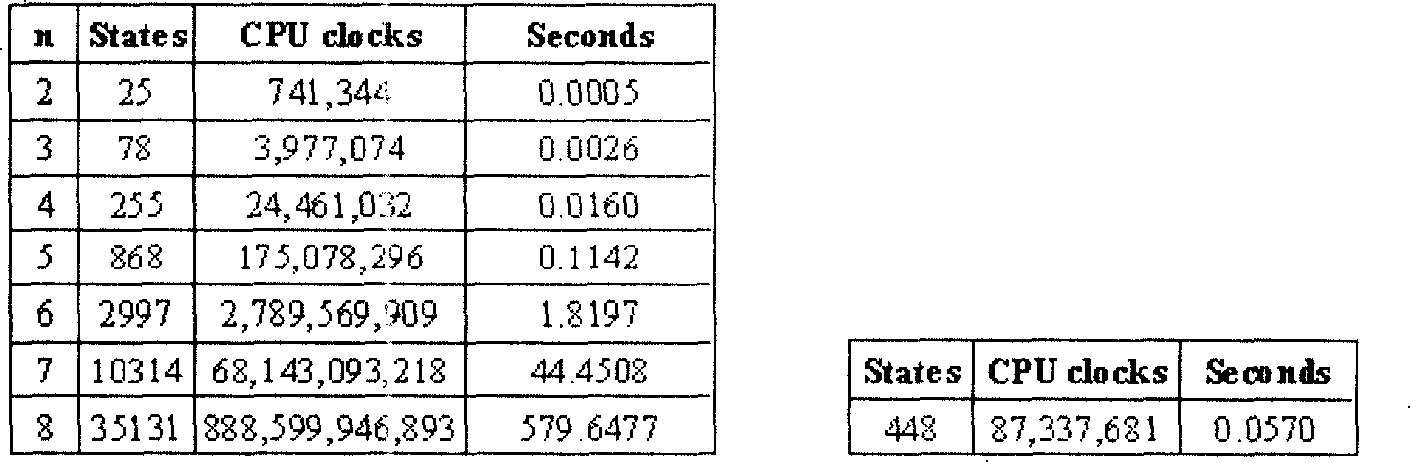

Breakpoint debugging method for LR(k) grammar random grammar position

InactiveCN101149687AIncreased processing loadSimple and intuitive to useProgram controlMemory systemsCurrent analysisParsing

This invention relates to the break point debug method in the LR(k) random grammar position, its steps is: Defines language LR(k) grammar or LR(k) grammar subclass grammar G; Inserts the break point in the corresponding grammar position; Inspects each break point, if this break point establishes in some grammar position right middle of the production pattern, then adds the useless non-end mark, thus obtains new grammar G'; to generate the grammar G' analytical statement; to calculate the type of each break point; to analysis the input string, until meets a reduction operation, inspects this position whether corresponds a break point, if it is, then adopts the following: To the effective break point, suspends the parsing process, demonstrates the current analysis status messages; To the invalid break point, neglects this break point, continues the parsing process; To indefinite break point, then neglects or joints with current input string and the position the break point established, further judges this position whether effective or not, if this position of the current input string is effective, presses effective break point position processing, if this position is invalid, then neglects this position, continues the parsing process. This invention obviously increases the break point number which may track and debug, may track the fine grain grammar ingredient, helps the user to carry on the grammar debugging well, and reduces the development difficulty of analyzer.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com