Technique for treating chitin waste water

A wastewater treatment and chitin technology, which is applied in biological water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

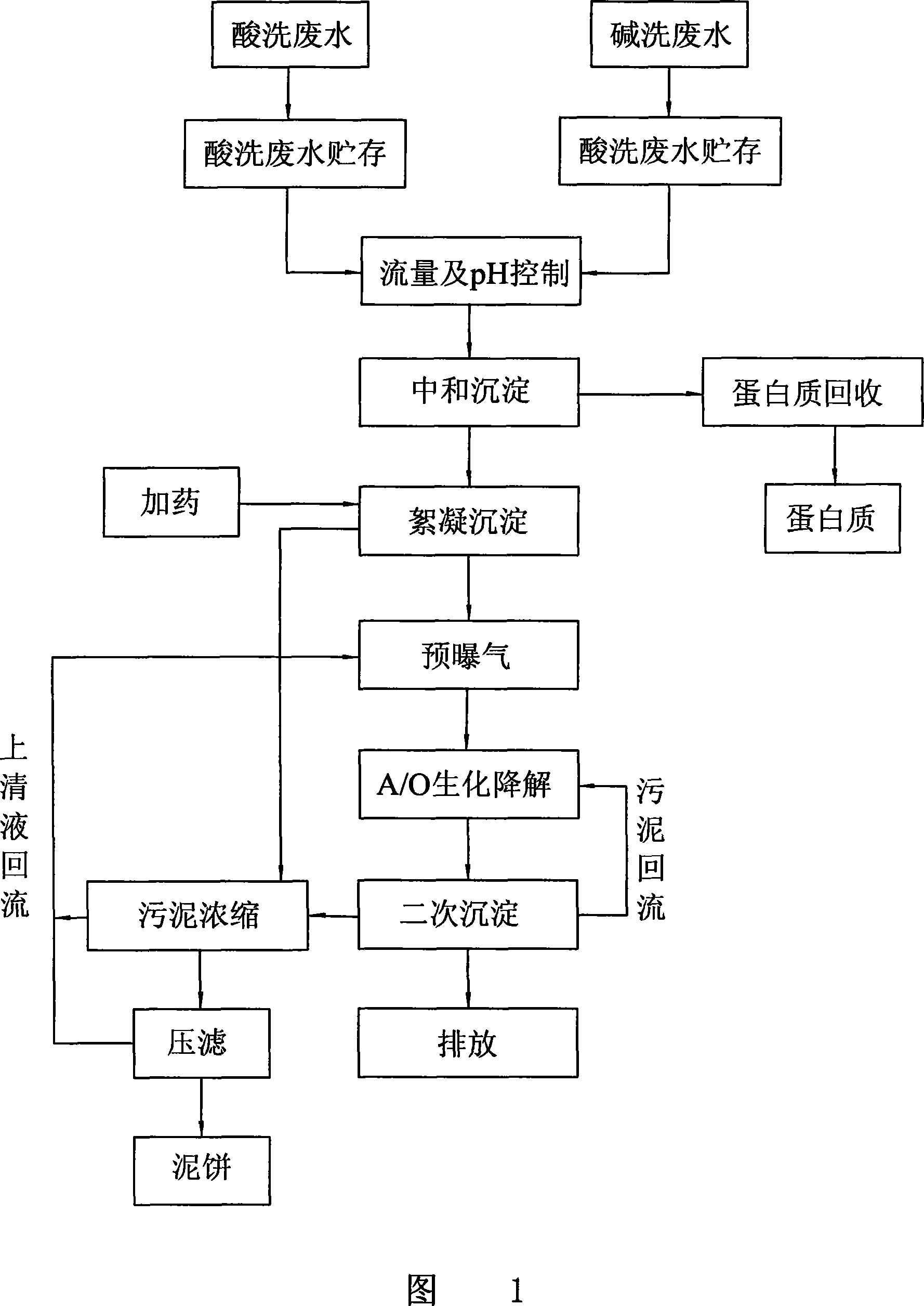

[0015] As shown in Figure 1, the pickling wastewater and alkali washing wastewater generated in the production of chitin are stored separately. During treatment, the two wastewaters are firstly mixed for neutralization and precipitation. The pH is more accurately controlled at 6.0-6.5. At this time, the comprehensive wastewater COD Cr About 28000-40000mg / L, NH 4 + -N about 350-700mg / L. After fully neutralizing the precipitated wastewater, the protein is immediately precipitated, and the protein precipitate is immediately pumped out through the sludge pump. The fresh protein has a density of about 0.94g / ml and a moisture content of about 95-97%. After dehydration and drying, the protein is recovered for use as For feed, etc., the equivalent dry protein recovery is 7.0-7.8g / L comprehensive wastewater. The supernatant after neutralization and precipitation enters the flocculation sedimentation tank through the outlet weir and enters the flocculation sedimentation tank for floc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com