Patents

Literature

191 results about "Animal fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Animal fibers are natural fibers that consist largely of particular proteins. Instances are silk, hair/fur (including wool) and feathers. The animal fibers used most commonly both in the manufacturing world as well as by the hand spinners are wool from domestic sheep and silk. Also very popular are alpaca fiber and mohair from Angora goats. Unusual fibers such as Angora wool from rabbits and Chiengora from dogs also exist, but are rarely used for mass production.

High-count single-warp single-abb worsted plus single thread and processing method thereof

The invention discloses a high denier single spinning single yarn and the processing method. The yarn general branch is 35-60S / 1. The material is pure wool or the mixing yarn by wool and terylene, mucilage glue, nylon, the cashmere and floret. It selects the proper material and the using mass in process; also in strip dye and combing process, the animal fiber such as wool, cashmere and floret is dying in low temperature, but for terylene, it uses the dye water in 130deg.C to add the assistant agent in dye or back treat process. In spinning process, it uses the compact spinning or multi spinning to protect the wool fiber and improve the dye quality. So the single yarn has little feather and big strength, good elasticity and good abrasion resistance.

Owner:JIANGSU DANMAO TEXTILE

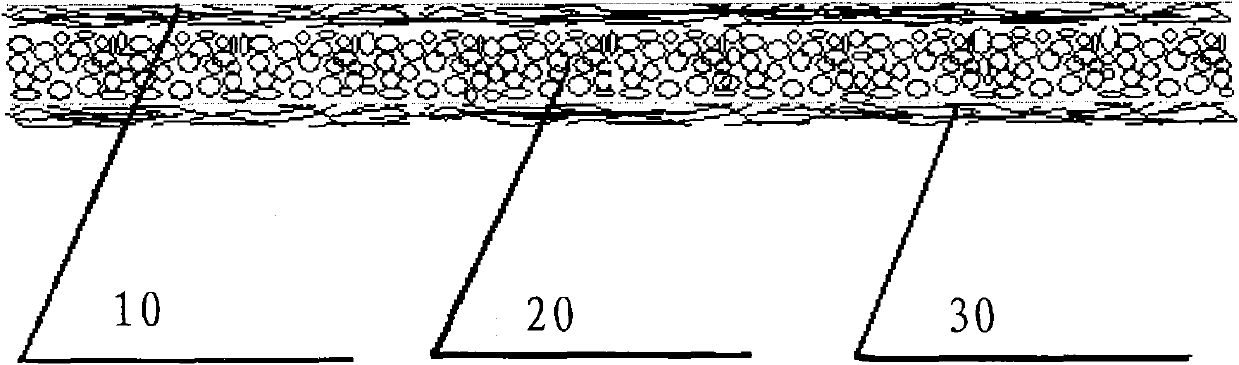

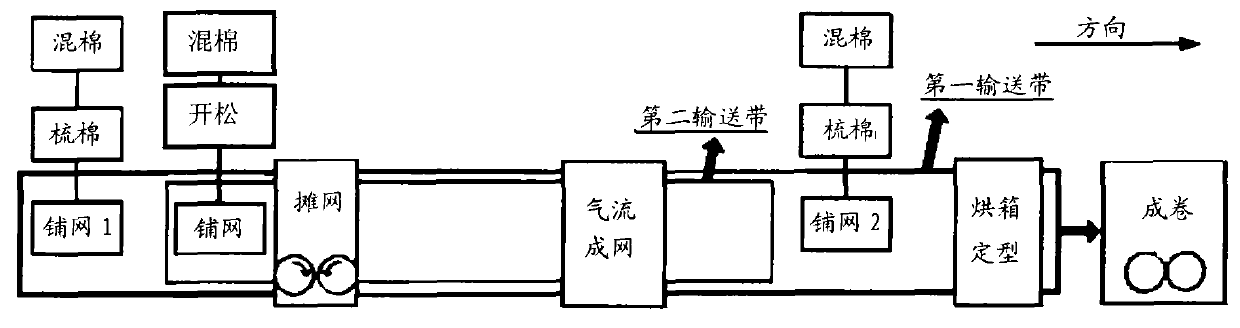

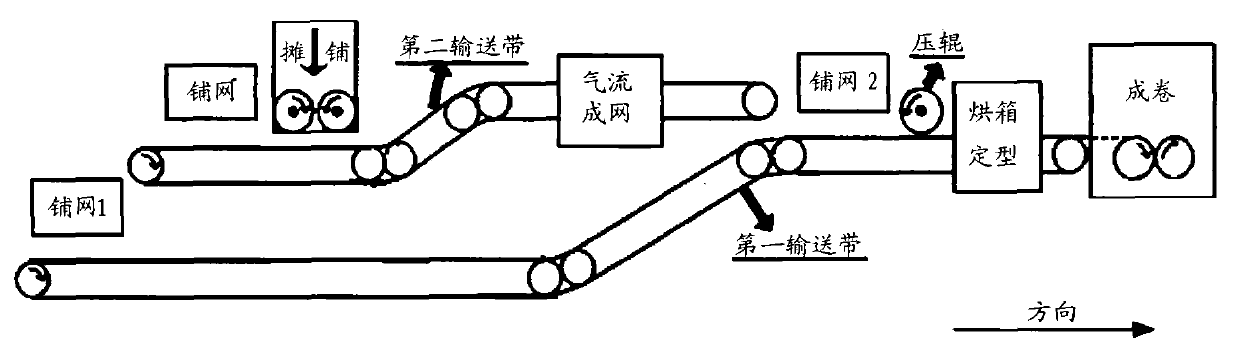

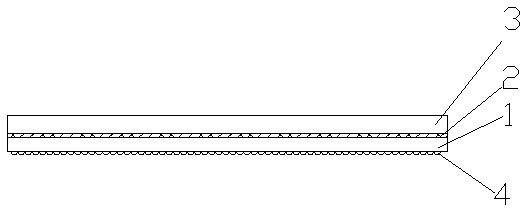

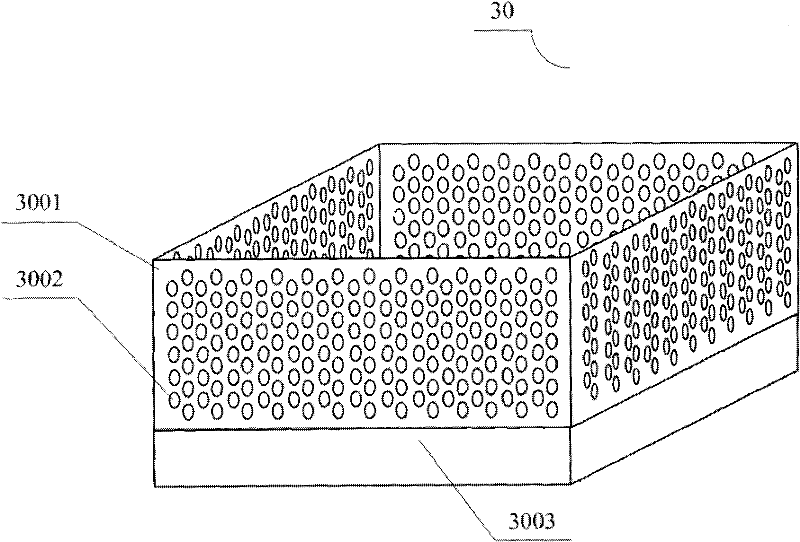

Three-layer sandwiched composite eiderdown flake and manufacturing method thereof

InactiveCN101787619AKeep the advantagesSolve the shortageNon-woven fabricsAdhesivesCardingPlant fibre

The invention relates to a three-layer sandwiched composite eiderdown flake and a manufacturing method thereof. The three-layer sandwiched composite eiderdown flake comprises a lower flake, a middle flake and an upper flake; the upper flake comprises animal and plant fibers and low-melting fibers; the middle flake comprises eiderdown fibers, animal and plant fibers and low-melting fibers; the lower flake comprises animal and plant fibers and low-melting fibers; and the upper flake, the middle flake and the lower flake are thermally fused together. The manufacturing method comprises the following steps: manufacturing the lower flake by using the animal and plant fibers and the low-melting fibers by cotton blending, cotton carding and lapping; manufacturing the middle flake by cotton blending, opening and lapping of the animal and plant fibers and the low-melting fibers, paving of the eiderdown fibers and air laying, and paving the middle flake above the lower flake; manufacturing the upper flake by using the animal and plant fibers and the low-melting fibers by cotton blending, cotton carding and lapping, and paving the lower flake above the middle flake; and thermally fusing the lower flake, the middle flake and the upper flake together.

Owner:杭州飞利弘羽绒寝具有限公司

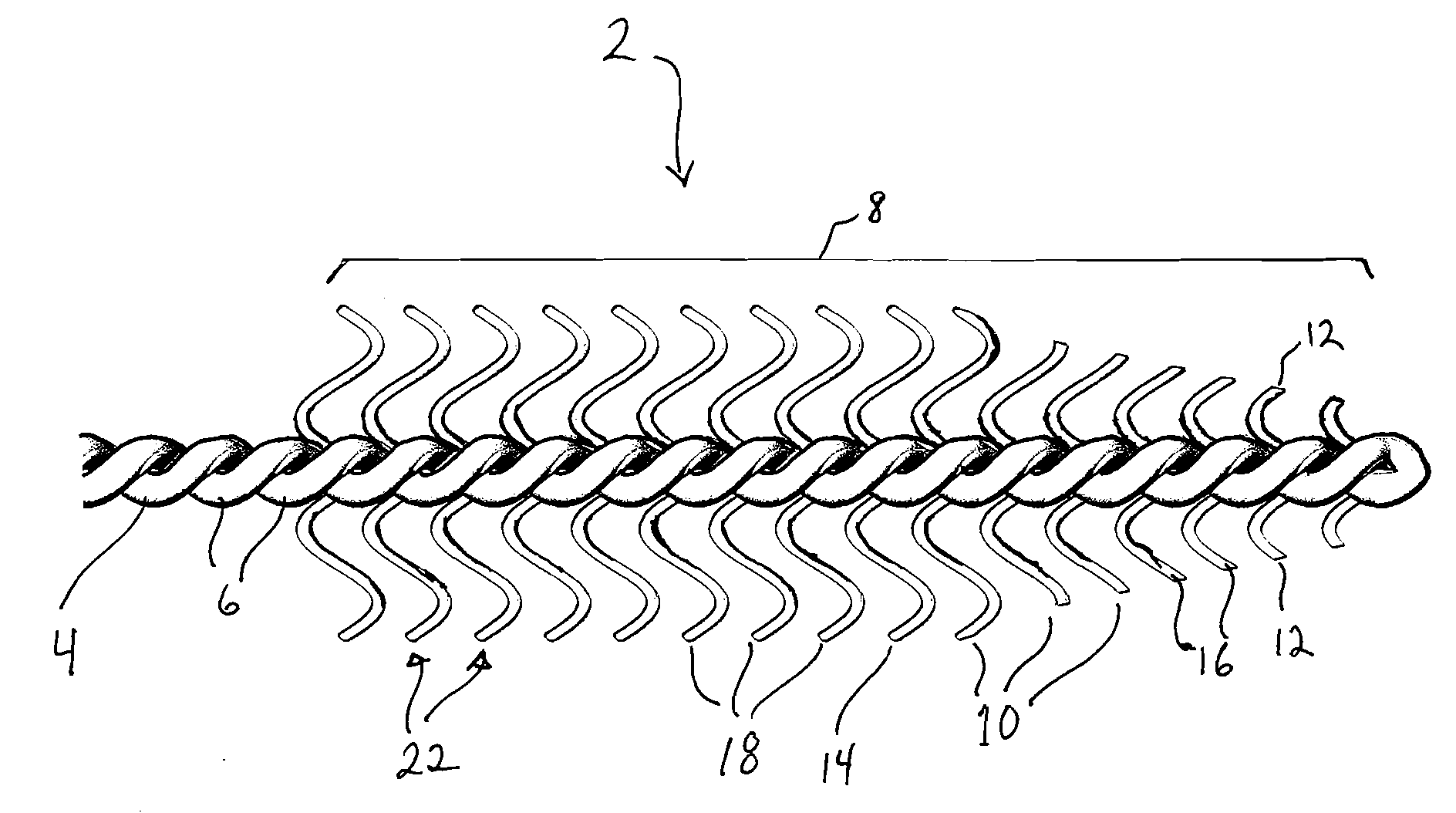

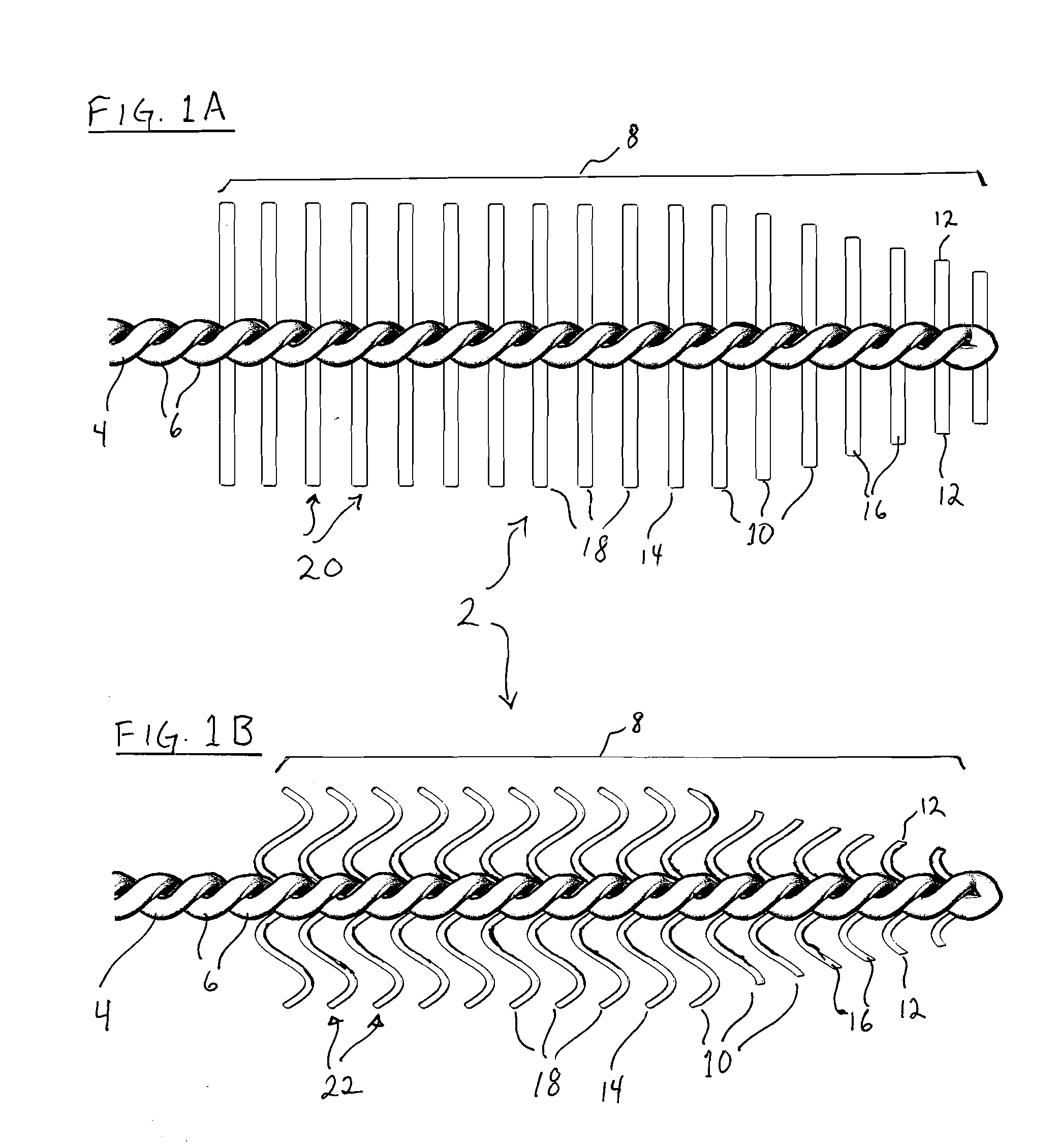

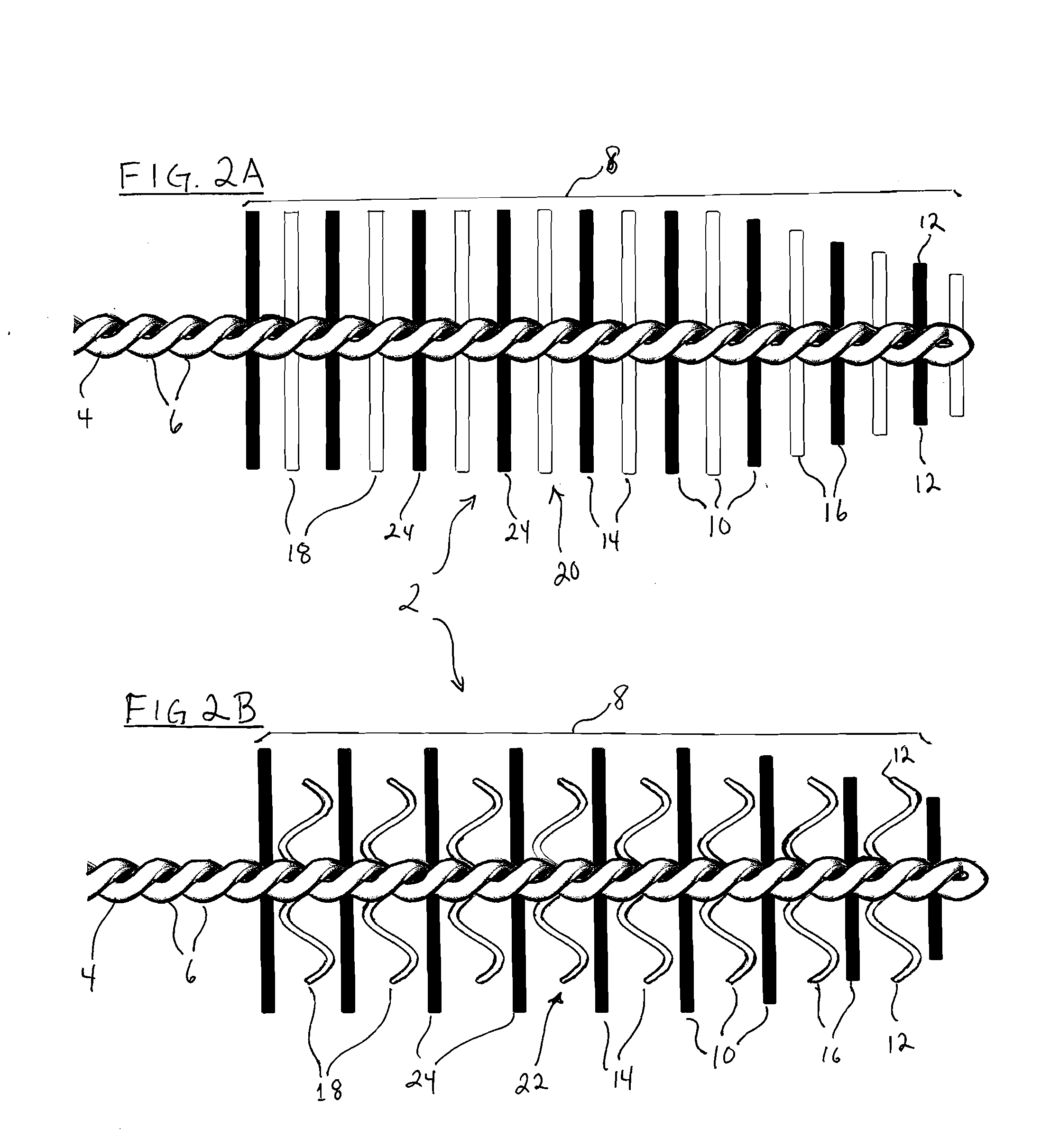

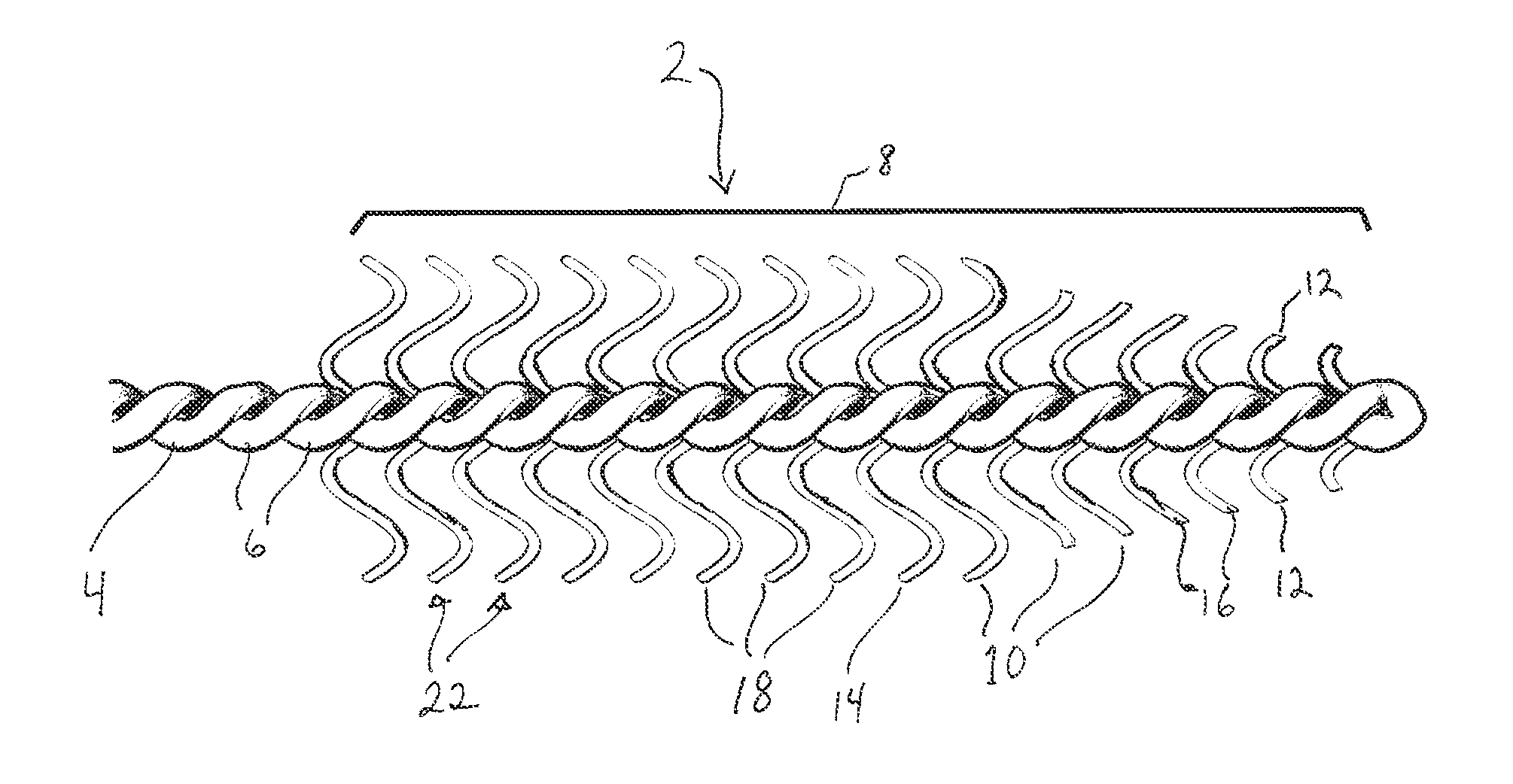

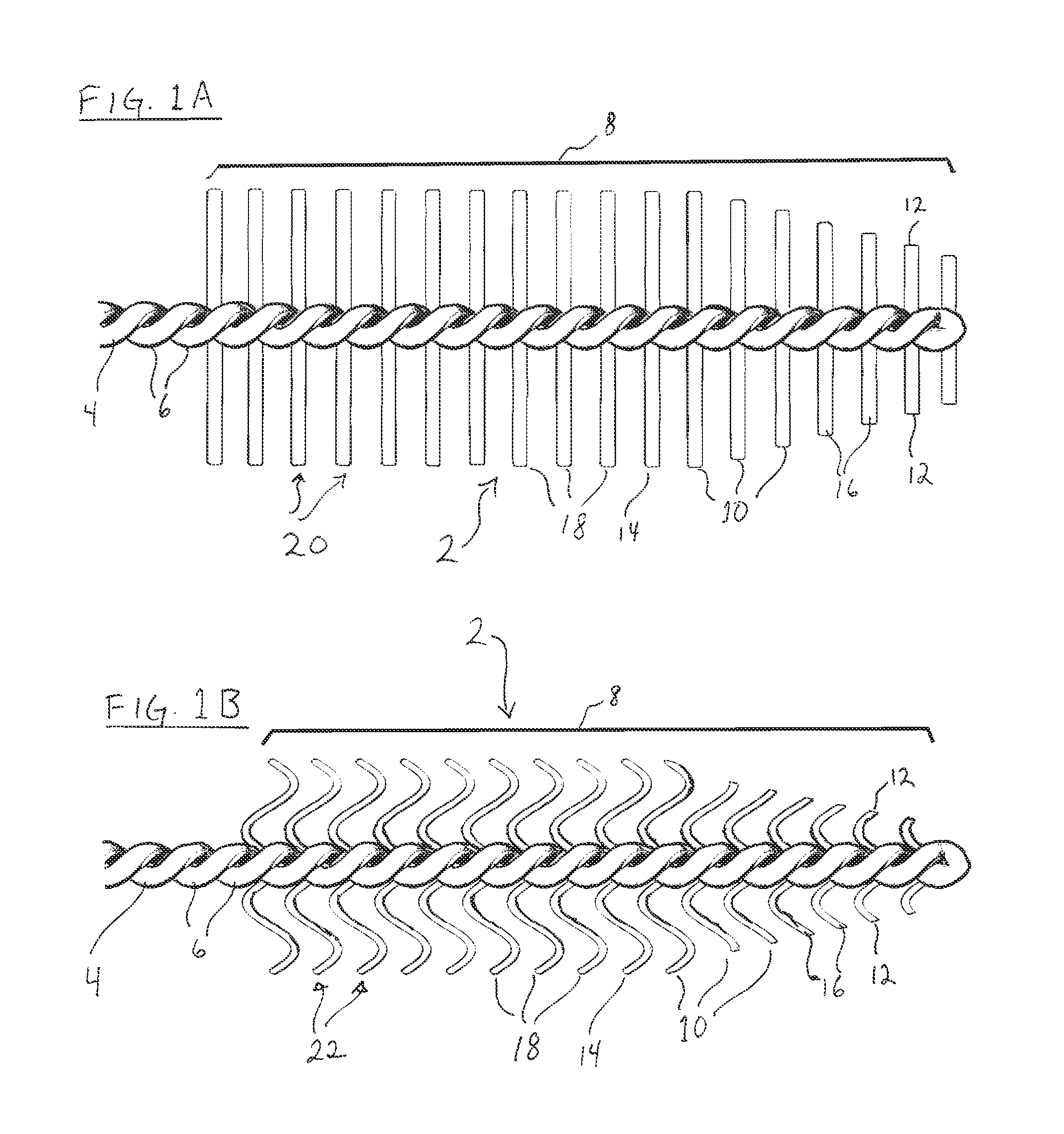

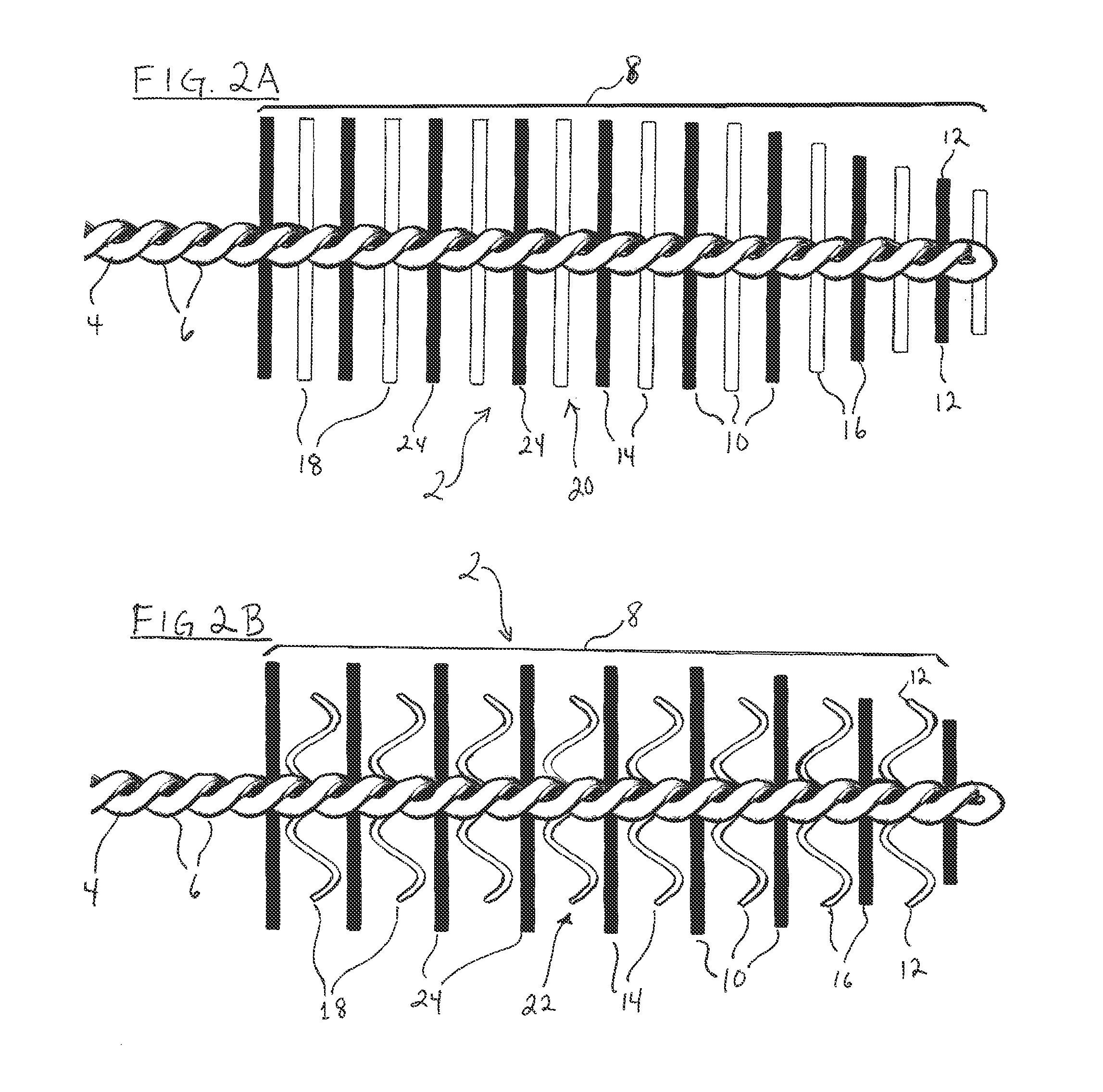

Shape Memory Polymer Mascara Brush

ActiveUS20100071715A1Uniform bristle quantityUniform orientationBristlePackaging toiletriesFiberBristle

A mascara brush head includes bristles made from shape memory polymer (SMP) filaments or fibers. The shape memory polymer filaments are selected to exhibit a first shape during assembly of the brush, and a second shape after exposure to an external stimulus in the form of heat or other energy. The brush head is initially assembled, i.e., lengths of SMP filaments are placed between wire segments and the wire segments are then twisted about each other to form a twisted wire core. The core grips the filament lengths medially of their outer ends, usually substantially at their midpoints, so as to clamp them. The first shape can be straight to facilitate assembly of the fibers in the wire core. The second shape, after assembly in the core and after being subjected to the external stimulus, can be any bristle shape suitable for enhancing the function of the brush, e.g., kinked, wavy or coiled. The brush head may be comprised solely of SMP filaments, or may be a blend of SMP filaments and any other suitable filament (e.g., nylon, natural plant or animal fibers, etc.).

Owner:ELC MANAGEMENT LLC

Blended centrifuging glass cotton fiber felt and its making method

InactiveCN1619038ALess investment in equipmentIncrease production capacityNon-woven fabricsWoolPlant fibre

The present invention relates to a mixed centrifugal glass wool fibre felt. It is formed from mixture of centrifugal glass wool and inorganic fibre or organic fibre, in which the mass ratio of centrifugal glass wool and inorganic fibre or organic fibre is 2:8-6:4. The described organic fibre can be plant fibre or animal fibre, and the described inorganic fibre can be mineral wool, rock wool or glass fibre. Said invention also provides its production method.

Owner:严煜

Shape memory polymer mascara brush

A mascara brush includes bristles made from shape memory polymer (SMP) filaments. The SMP filaments are selected to exhibit a first shape during assembly of the brush, and a second shape after exposure to an external stimulus in the form of heat or other energy. During assembly, the SMP filaments are clamped between wire segments twisted to form a core. The first shape can be straight to facilitate assembly of the fibers in the wire core. The second shape, after assembly in the core and after being subjected to the external stimulus, can be any bristle shape suitable for enhancing the function of the brush, e.g., kinked, wavy or coiled. The brush head may be made solely of SMP filaments, or may be a blend of SMP filaments and any other suitable filament (e.g., nylon, natural plant or animal fibers, etc.).

Owner:ELC MANAGEMENT LLC

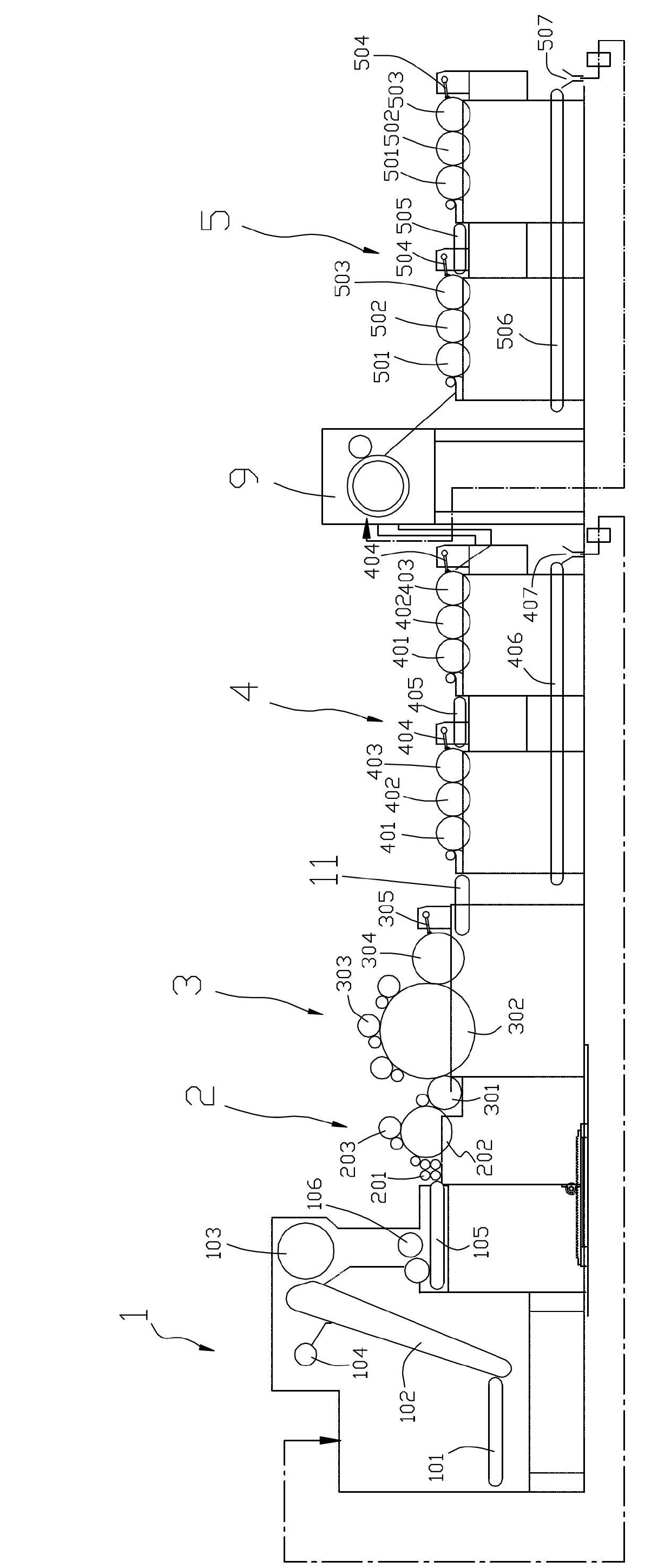

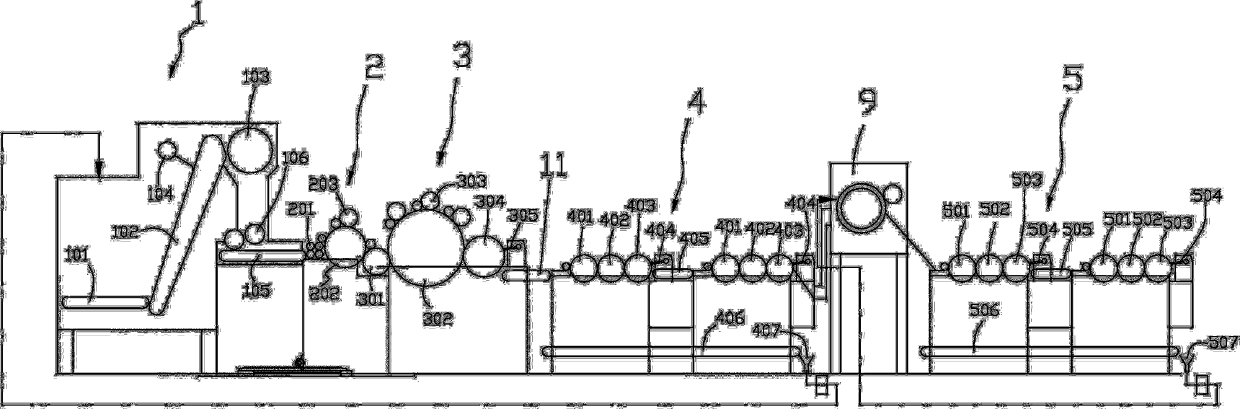

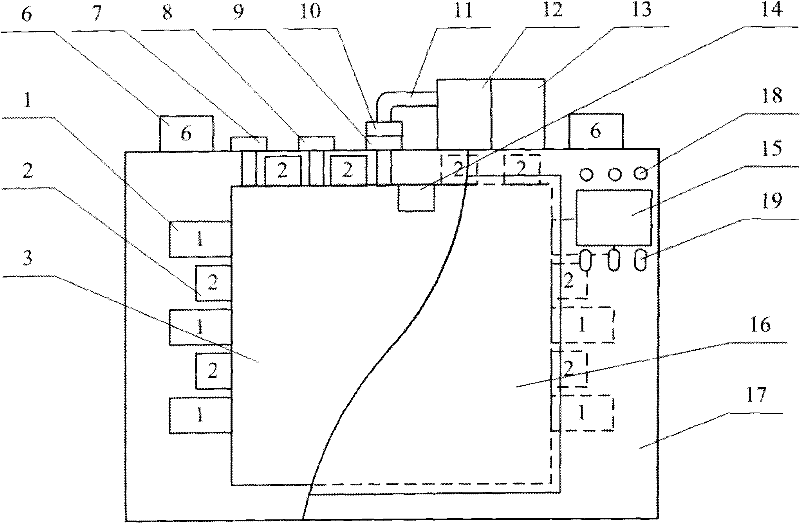

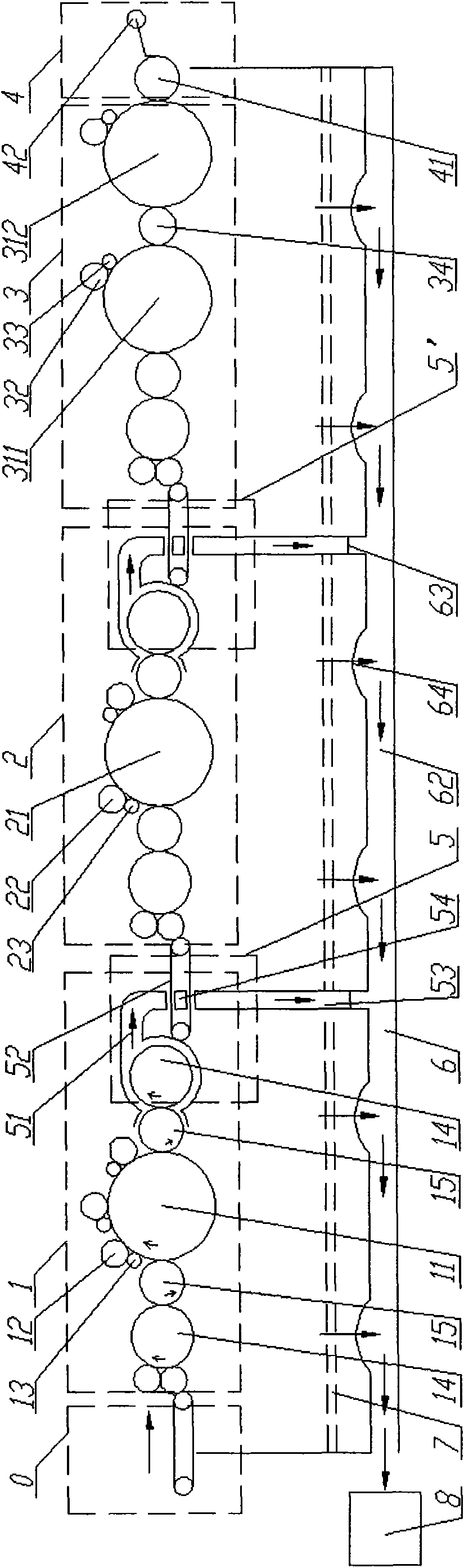

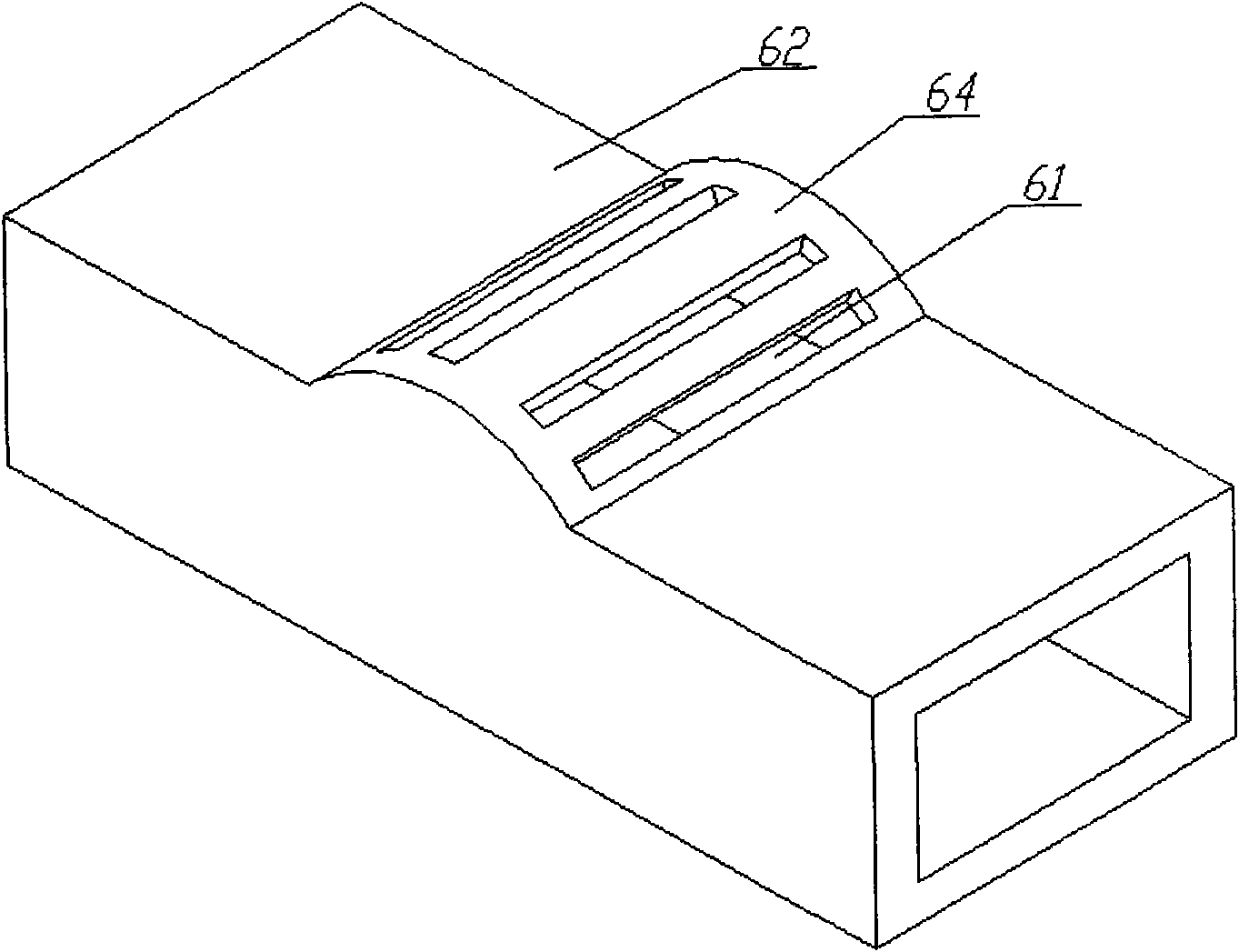

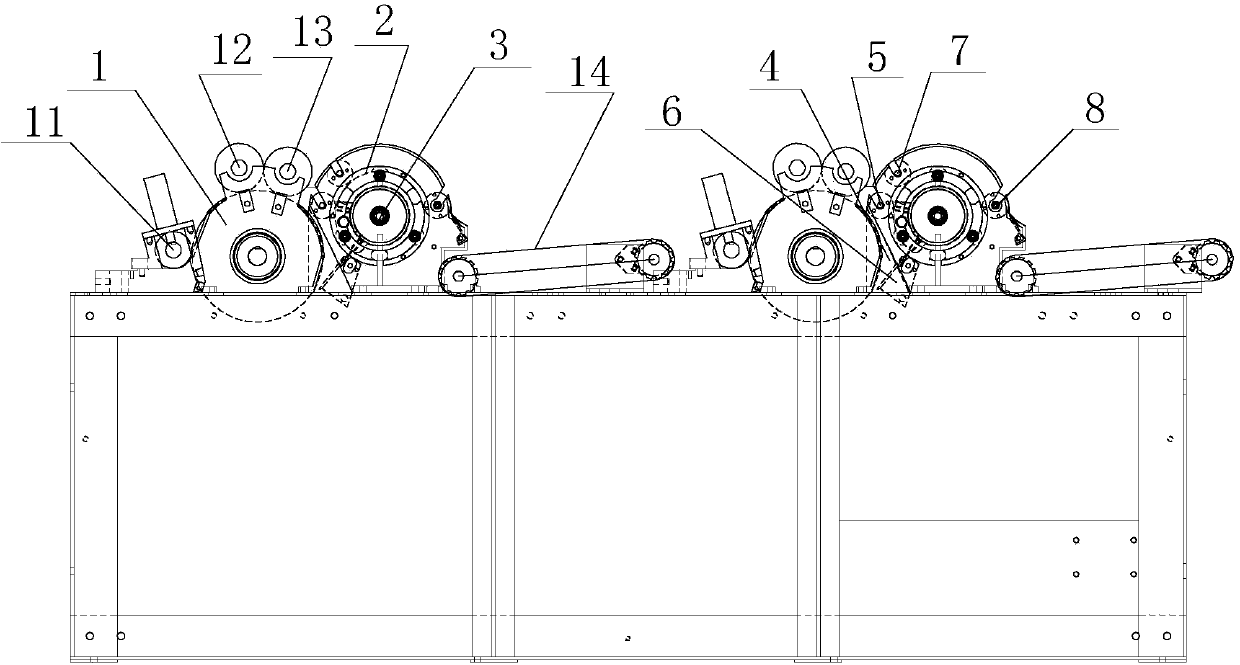

Cashmere carding machine

The invention discloses a cashmere carding machine, which comprises a feeding mechanism, an opening mechanism, a coarse wool and impurity removing mechanism and a carding mechanism, wherein the coarse wool and impurity removing mechanism comprises a plurality of coarse wool and impurity removing units, and each coarse wool and impurity removing unit comprises two coarse wool and impurity removing subunits, each coarse wool and impurity removing subunit comprises a licker-in, a cylinder and a doffer, the licker-in, the cylinder and the doffer are arranged in a straight line, the coarse wool and impurity removing unit also comprises a bottom delivery flat curtain used for collecting dropped material, the front side of the bottom delivery flat curtain is provided with a material collecting groove, a condenser is arranged between two adjacent coarse wool and impurity removing units, and the material collecting grooves in the coarse wool and impurity removing units are connected with the feeding mechanism or the condensers through a conveying fan and a feedback pipeline. By the cashmere carding machine, the removing effect of impurities in raw material fiber can be further improved, and machine is conductive to improving the quality of a finished animal fiber product and at the same time helps to improve the extraction ratio of dehaired wool.

Owner:青岛东佳纺机(集团)有限公司

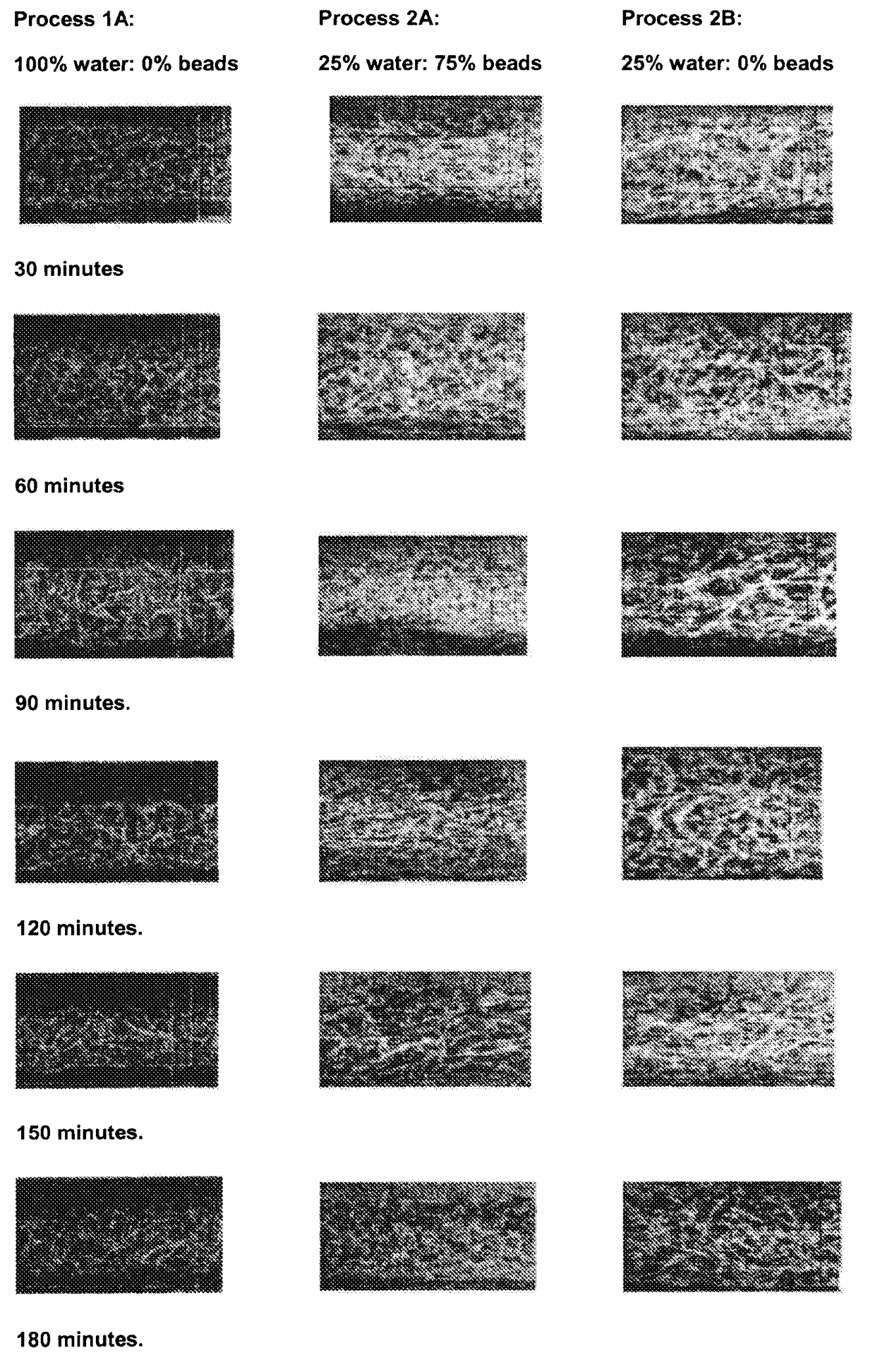

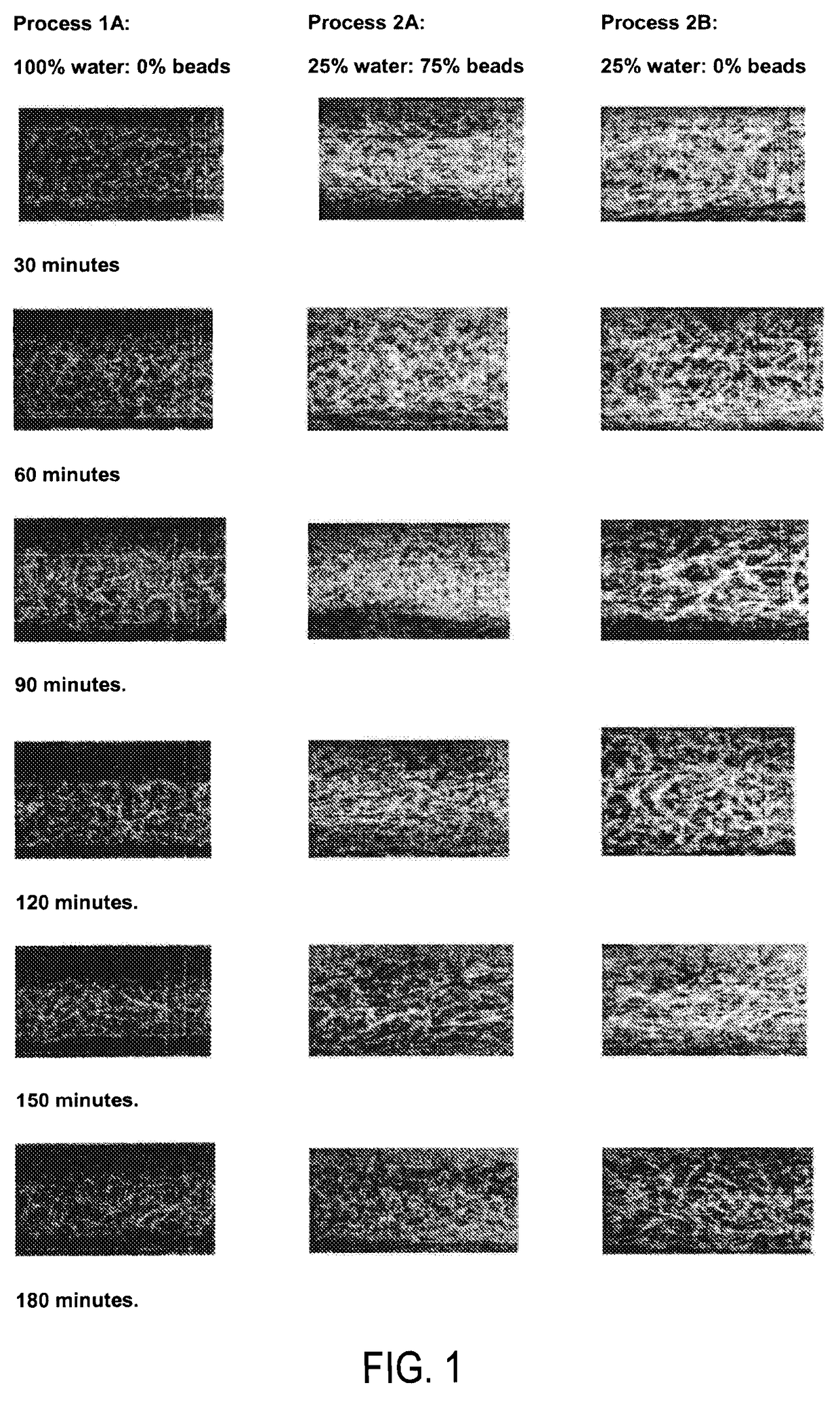

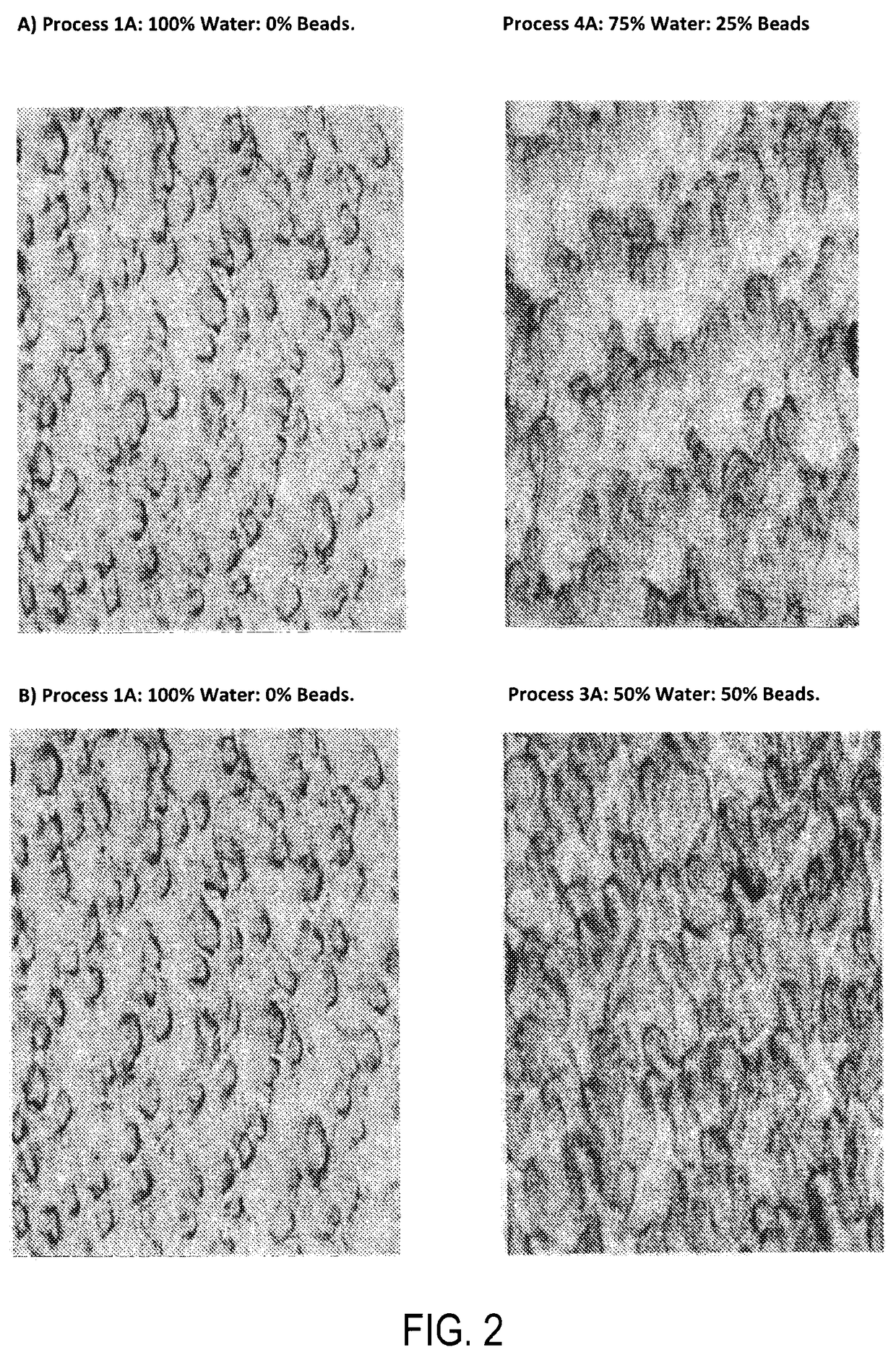

Method for treating a substrate made of animal fibers with solid particles and a chemical formulation

ActiveUS20160040260A1Easy to useShorten the construction periodTanning treatmentPre-tanning chemical treatmentFiberProcedure Agents

The invention discloses a method for treating an animal substrate comprising: agitating the moistened animal substrate with a treatment formulation and a solid particulate material in a sealed apparatus wherein the treatment formulation comprises a tanning agent or a tannery process agent. The method can comprise applying the tanning agent or tannery process agent to the animal substrate wherein at least some of the agent so applied originates from the treatment formulation. There is also disclosed an animal substrate obtained by the method. The treatment formulation can be aqueous.

Owner:XEROS LTD

High-elasticity warm healthy knitted fabric

InactiveCN102517769AIncrease elasticityGood moisture conductivityWeft knittingWarp knittingSurface layerAnimal fiber

Owner:SUZHOU CHUANGYU WEAVING

Method for dyeing of loose fibre with natural dye

ActiveCN101270550AReduce pollutant contentAntibacterial health careFibre treatmentDyeing processPlant fibreAnimal fiber

The invention provides a method for dyeing a loose fiber by a natural dye, which comprises the steps of carrying out boiling, mordant dyeing, dyeing and fixation on the loose fiber. The method selects the natural dyes with corresponding variety and amount according to the dyeing color and the depth of the dyeing to dissolve in water according to a bath ratio of 1 to 20; putting the fiber through mordant dyeing into a cylinder; raising the temperature from 30 to 100 DEG C with a speed of 2 DEG C per minutes, preserving the temperature for 30 minutes and then carrying out dyeing. The method uses the natural materials during the manufacture technique of dyeing; the content of the contaminations in the waste water generated during the manufacture process is very low, thus having the advantage on sewage treatment and according with the national environment protection policy compared with the traditional technique. The invention can be applied to various loose fiber dyeing like animal fibers, plant fibers and chemical fibers, has a broad application range and the fiber dyed by using the natural dye, has excellent color brilliance and color fastness.

Owner:东阳市神农纺织品有限公司

Method for treating a substrate made of animal fibers with solid particles and a chemical formulation comprising a colourant

ActiveUS20160032522A1Significant environmental benefitsReduce in quantityTanning treatmentPre-tanning chemical treatmentFiberMedicine

The invention discloses a method for treating an animal substrate comprising: agitating the moistened animal substrate with an aqueous treatment formulation and a solid particulate material in a sealed apparatus, wherein the aqueous treatment formulation comprises at least one colourant. There is also disclosed an animal substrate obtained by the method and finished leather goods obtained by the method.

Owner:XEROS LTD

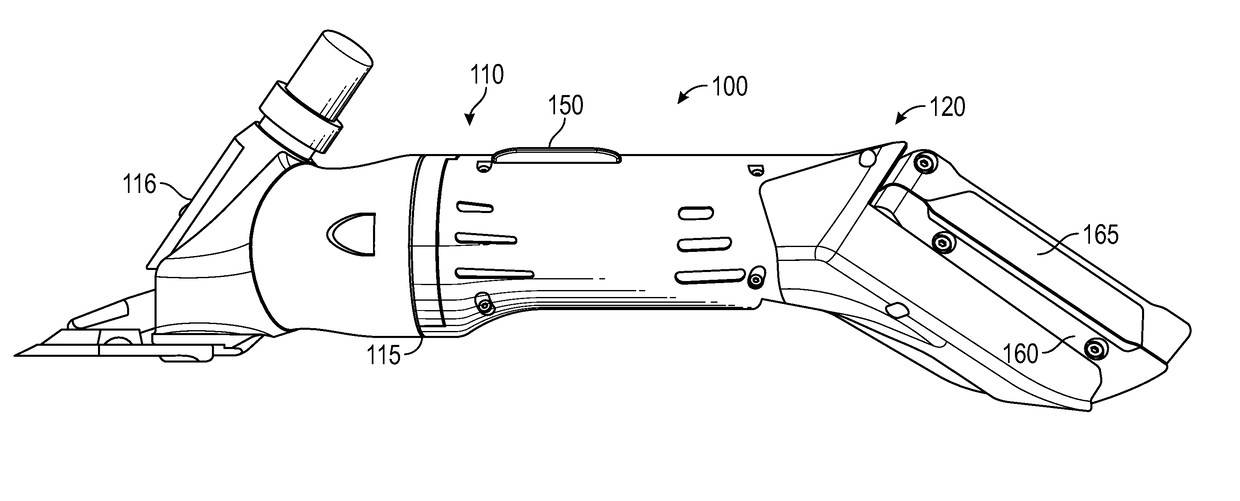

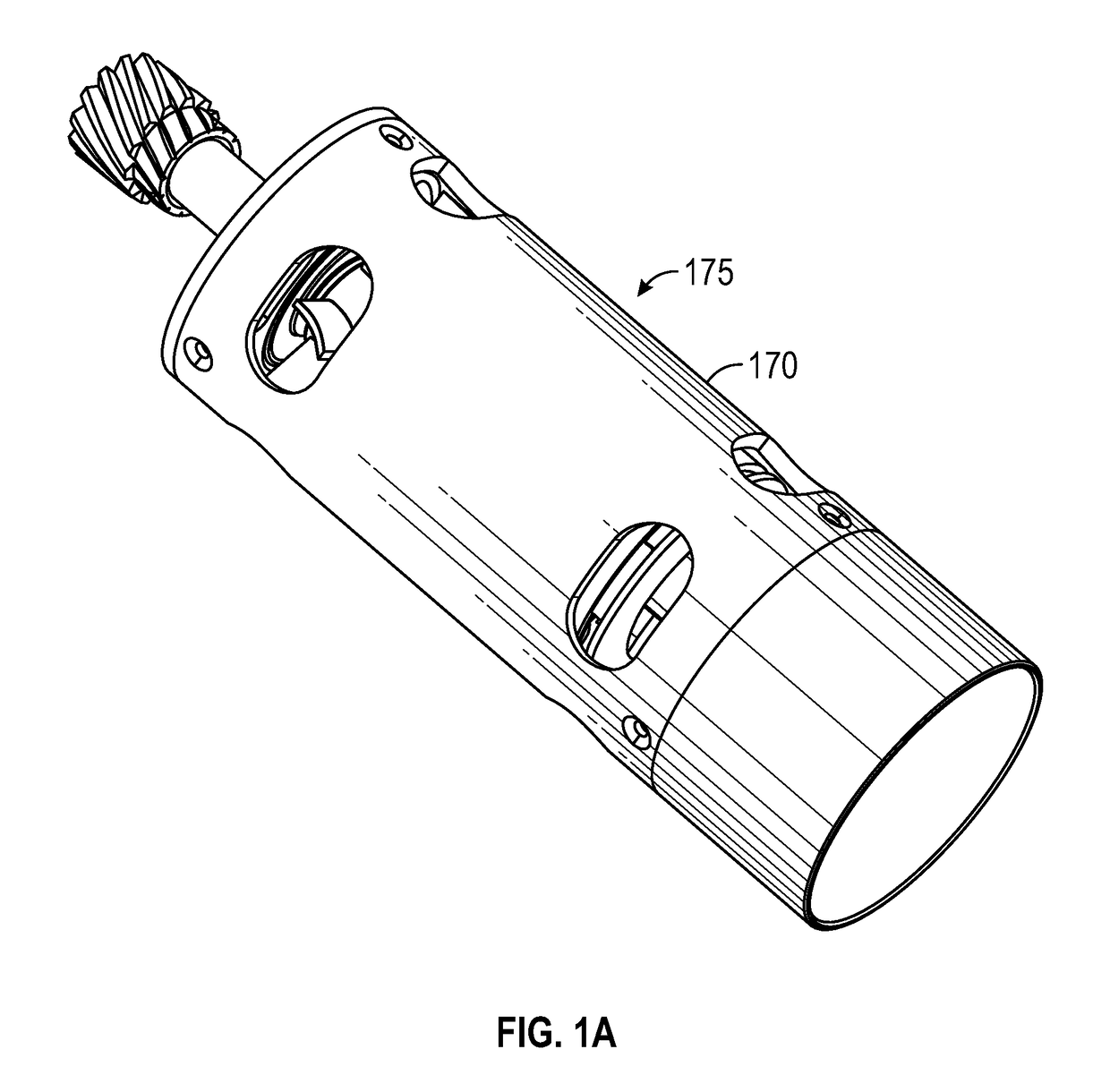

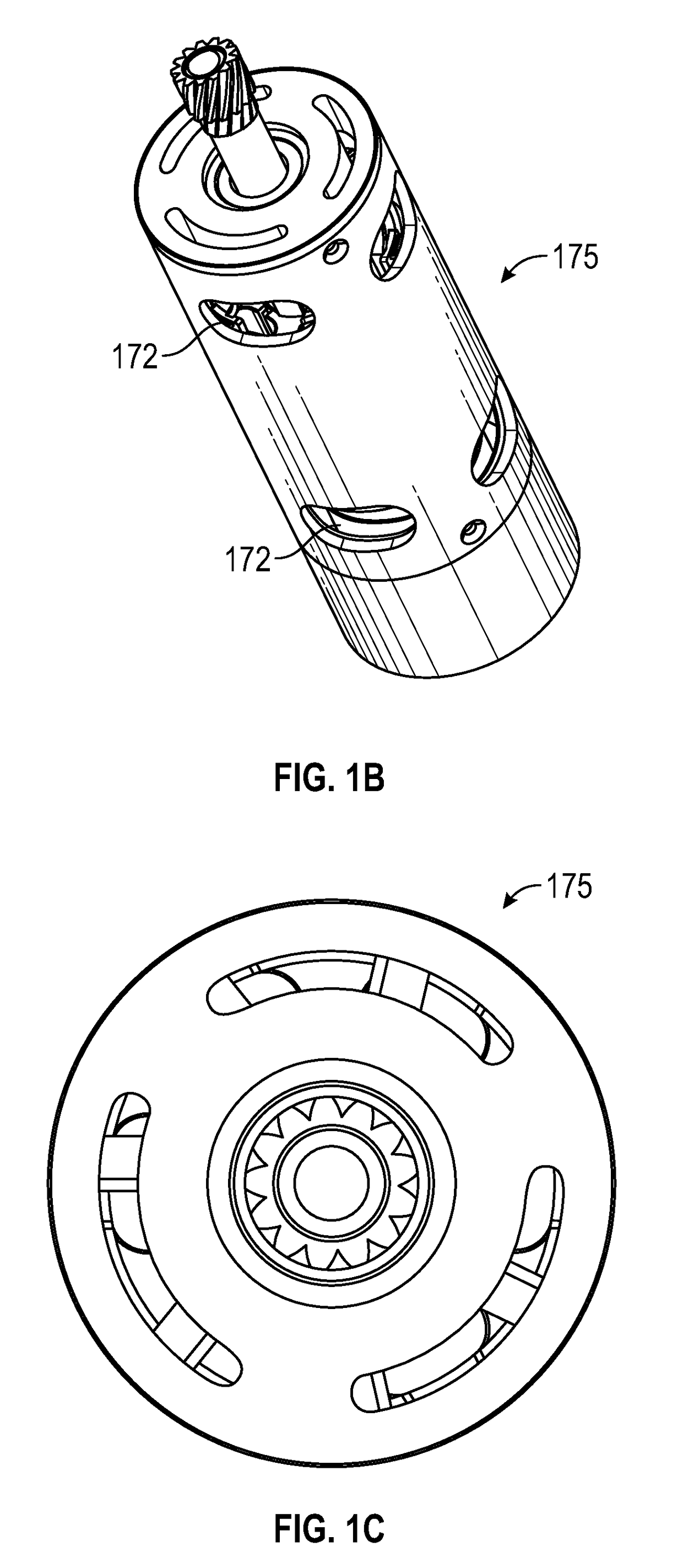

Animal Shears/Clippers

ActiveUS20170203450A1Safe and effectiveOperational securityMetal working apparatusAnimal fiberEngineering

A cordless animal shearing / clipping device is disclosed. The cordless shear / clipper includes a shear portion and a handle portion. The shear portion includes a shear or clipping head interface that allows for an interchangeable shear / clipper head to be coupled to the shear head interface. The handle portion includes a motor casing, a switch, and a battery slide. This design allows for easy, safe, and efficient shearing of animal fibers in any location.

Owner:HITSON NATHAN

Underclothes, underdrawers, bra and swimsuit made by ceiba fiber

An underwear, a drawer, a bra and a bathing suit are prepared by the kapok fiber, wherein the constituent and the mass percent content of the fiber material is that 5-100% of fiber is the kapok fiber and 0-95% of fiber is the other fiber, and the other fiber can be the natural fiber and the chemical fiber, in particular to one of or a plurality of or total of the plant fiber, the animal fiber, the mineral fiber, the artifical fiber, the synthetic fiber and the inorganic fiber, which is one of or a plurality of or total of the chemical fiber, the synthetic fiber, the fiber of the cotton, the fur, the silk, the hemp, the soybean, the milk, the jade and so on more particularly. A gasket made of the kapok fiber is arranged at the position of the drawer positioned on the pudendum. The kapok fiber or the other fiber is made into the face fabric by carding, drawing and spinning after being mixed and loosed. The face fabric is made into the underwear, the drawer, the bra and the bathing suit by cutting and sewing. The invention has the advantages of electrostatic resistance, balling resistance, bacterium resistance, softness, moisture absorption, moisture conductivity, green, thermal retention and teredo protection.

Owner:晏国新 +1

Method for treating a substrate made of animal fibers with solid particles and a chemical formulation comprising a colourant

ActiveUS9845516B2Maximize capacityPrevent buildupTanning treatmentPre-tanning chemical treatmentFiberMedicine

The invention discloses a method for treating an animal substrate comprising: agitating the moistened animal substrate with an aqueous treatment formulation and a solid particulate material in a sealed apparatus, wherein the aqueous treatment formulation comprises at least one colorant. There is also disclosed an animal substrate obtained by the method and finished leather goods obtained by the method.

Owner:XEROS LTD

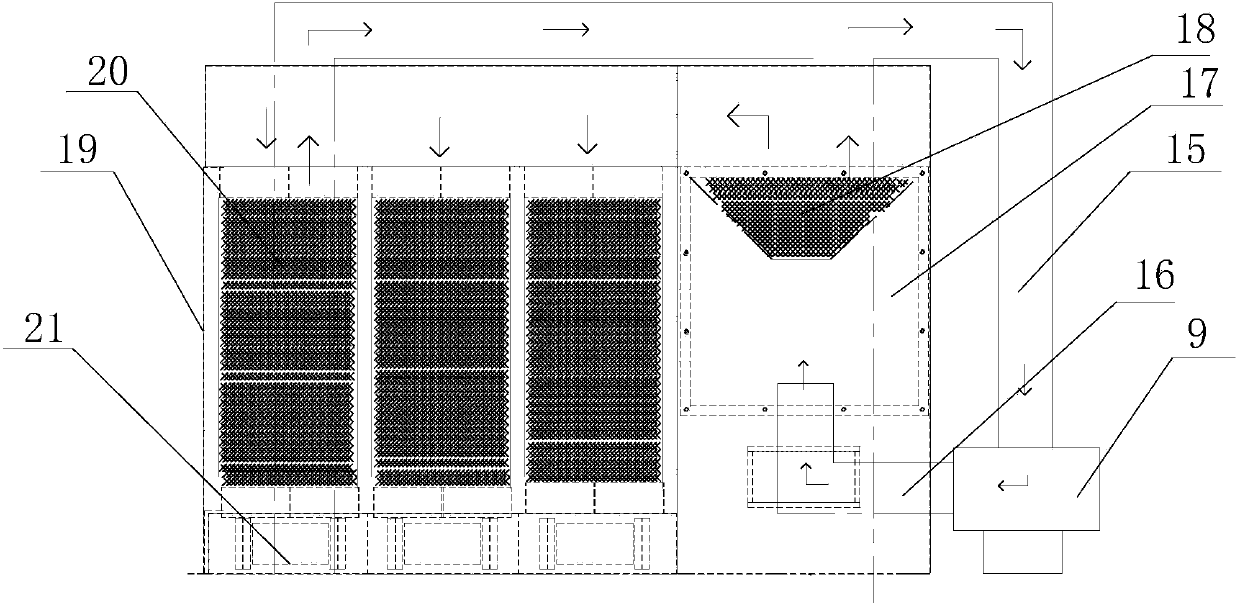

Low-temperature negative pressure drying method and device for textile materials and textiles

InactiveCN102175071AOvercoming the bottleneck of the relatively long isokinetic drying phaseFast drying processDrying using combination processesDrying machines with local agitationResonant cavityMicrowave

The invention discloses a low-temperature negative pressure drying method and a low-temperature negative pressure drying device for textile materials and textiles. The device comprises a microwave source, a temperature sensor, a resonant cavity, an air-cooled or water-cooled device, a vacuum sensor, an air release valve, a humidity sensor, an air extraction valve, an air extraction pipeline, a vacuum pump, a vacuum pump motor, a stirrer, a panel, a controller, a shielding sealing door, a shell, an indicating lamp, a switch, a scattered article drying box and a cheese drying bracket; and the scattered textile materials or textiles are put into the scattered article drying box, or cheeses are stacked on the cheese drying bracket and then put into the resonant cavity, and the dried articles are heated and dried under the low-temperature negative pressure working condition. Relatively long bottleneck at the uniform velocity drying stage when single microwave is used for drying can be effectively overcome, over drying is avoided, and the whole drying process is quick and energy-saving; and the method and the device can particularly meet the drying requirements of special animal fibers, artificial fibers, synthetic fibers and like and the products thereof with special temperature requirements.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

Textile fabric with antisepsis and anti-inflammation functions

InactiveCN105350298AHas antibacterial and anti-inflammatory functionsWith moisture absorption and breathable functionLiquid/gas/vapor removalVegetal fibresTextile technologyTextile fiber

A textile fabric with antisepsis and anti-inflammation functions relates to the technical field of textiles and is produced by the following processes: cleaning wormwood with purified water, placing the cleaned wormwood in distilled water, and heating to be boiled, wherein the mass ratio of wormwood to distilled water is 1: (100-200) (a heating device is equipped with a backflow device, so that steam generated by heating can flow back into the heating device); after heating for 30-60 min, cooling and filtering; removing slag and taking the liquid to obtain a scouring liquid; placing textile fibers, such as cotton fibers, ramie fibers, animal fibers, silk fibers and the like into the scouring liquid to be soaked for 7-14 days at the room temperature, wherein the mass ratio of the textile fibers to the scouring liquid is 1: 1,000; fishing out the soaked textile fibers, naturally airing at the room temperature, and then placing the aired textile fibers into a drying oven to be dried; weaving the dried textile fibers by the textile technology to form the fabric. Besides the functions of moisture absorption and air permeability, the textile fabric also has the antisepsis and anti-inflammation functions, and the prepared fabric is more preferred.

Owner:HENAN XINYE TEXTILE

Ecological algae flocculating material

InactiveCN101234809AFast and efficient flocculation removalTotal Phosphorus and Nitrogen ReductionWater/sewage treatment by flocculation/precipitationAquatic animalFresh water organism

The invention relates to an algae setting material, which comprises 5 to 70 percent of natural fiber material and 30 to 95 percent of natural high polymer material, wherein, the natural fiber material is selected from plant fiber and / or animal fiber, and the natural high polymer material is selected from crab derivatives and / or shrimp derivatives and plant viscous juice with a proportion no less than 5 percent. The algae setting material is the natural substance without any harm to human bodies, livestock, environment as well as aquatic animals and plants, and has coagulation, adsorption, tangling and enmeshing function for the algae. When the use amount of the algae material is 0.1 to 10mg / L, the removal efficiency of the algae is over 95 percent. The obtained algae setting body of the flocculation has strong holding power, good performance of floating and drainability, little algae mug and convenient post-process, so the invention is applicable to urgent treatment of burst red tide in ease water and water bloom in fresh water.

Owner:合肥市东方美捷分子材料技术有限公司

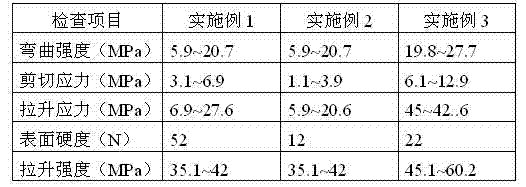

Method for producing paperboards and paper tubes

InactiveCN102248562AImprove adhesionHigh compressive and flexural strengthWood compressionGrain treatmentsFiberAnimal fiber

The invention relates to a method for producing paperboards and paper tubes, comprising the following steps of: (1) carrying out steam blasting and fluid energy milling on plant waste materials to obtain a raw material A; (2) carrying out the steam blasting on waste and old textiles and animal fibers to obtain a raw material B; (3) preparing a sodium silicate solution with the mass concentration of 12-15% to obtain a raw material C; (4) uniformly mixing the raw material A with the mass percent of 84-86%, the raw material B with the mass percent of 6-9%, the raw material C with the mass percent of 6-8% and thermosetting resin with the mass percent of 0-4%, putting the mixture into a paper pressing machine to prepare the paperboards and the paper tubes; and (5) carrying out air drying and curing on the obtained paperboards and paper tubes or curing by adopting a drying machine or a blast blower. The invention has the advantages that: process is simple, raw materials are available; manpower and energy are saved, production efficiency is improved, production cost is reduced; and the obtained paperboards and the paper tubes have good and stable quality, thus the method is applicable topopularization and application and is environment-friendly for papermaking.

Owner:强光初

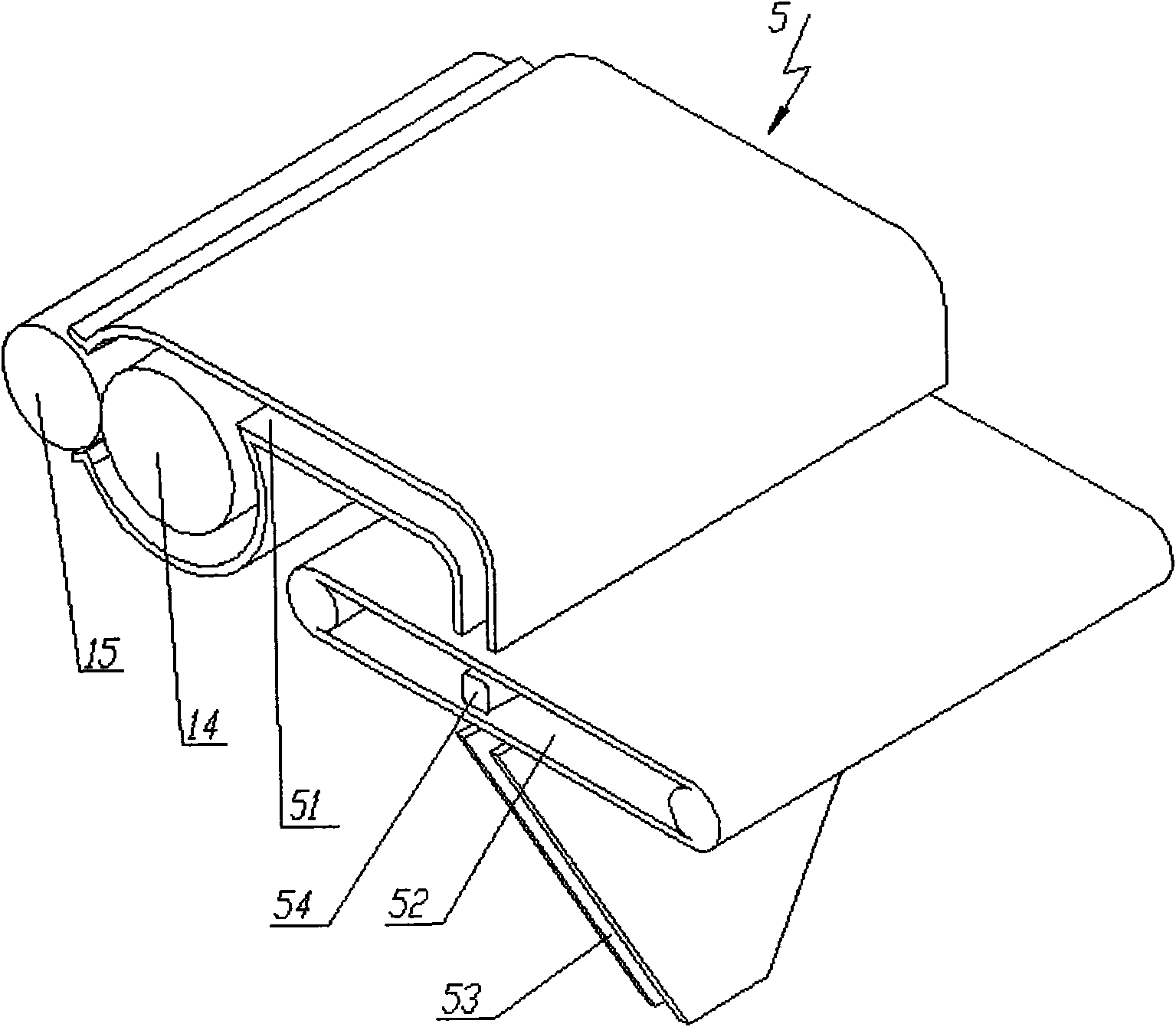

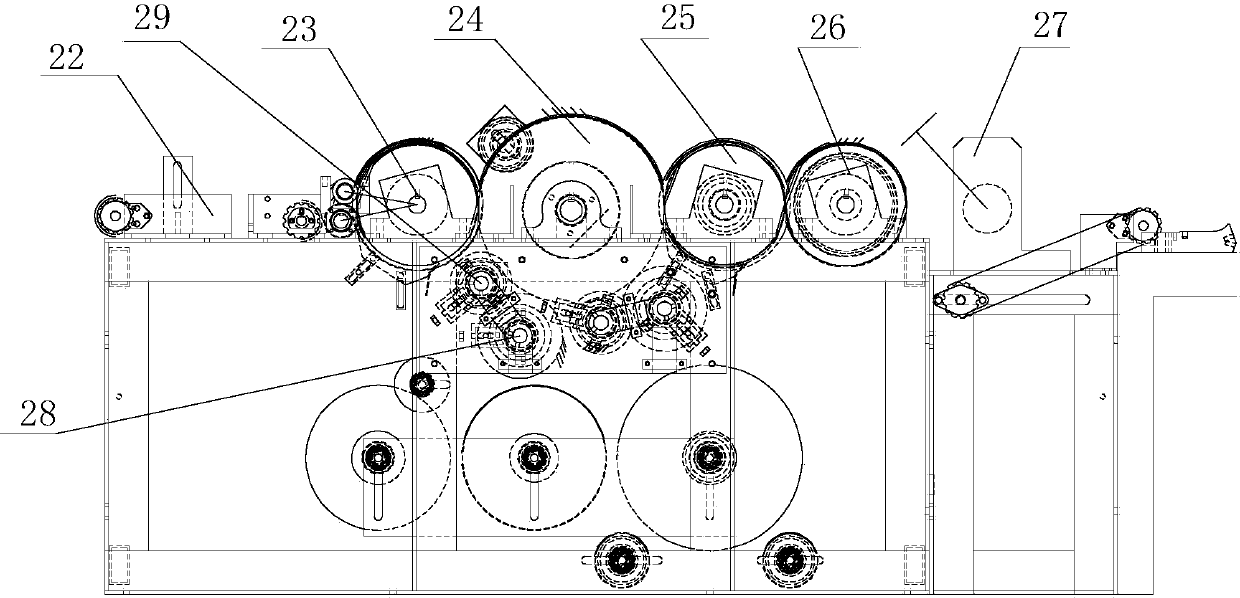

Heterogeneous animal fiber carding machine

InactiveCN101608353AProtection lengthProtected growthCarding machinesAnimal fiberMechanical engineering

The invention discloses a heterogeneous animal fiber carding machine which sequentially comprises an automatic feeder, 2-6 sections of carding machines and an output mechanism. The heterogeneous animal fiber carding machine is characterized in that an air draft net curtain device is arranged between every two adjacent sections of carding machines; the air draft net curtain device comprises a reticular transport curtain which is horizontally installed, a special-shaped air draft cover, an air draft pipe, an air draft pipeline and a negative pressure source; wherein the air draft pipeline comprises a main air channel which is evenly provided with air suction holes and connected with the negative pressure source, and a branch air channel; a main cylinder of the carding machines is provided with 1-4 pairs of working rolls and wiper rolls, and the number of the working rolls and the wiper rolls is reduce progressively from the feeding direction of the carding machine to the output direction; screens are arranged under all the sections of carding machines; the air suction holes are positioned under the screens, and the number of the air suction holes is not less than the that of the sections of the carding machines.

Owner:吴孔希

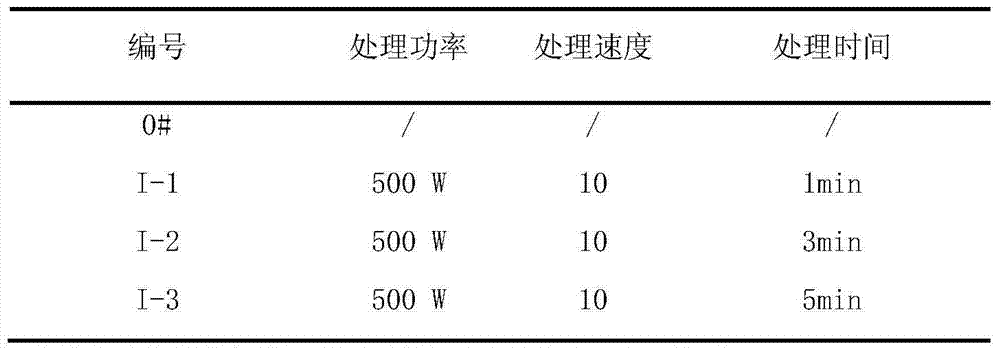

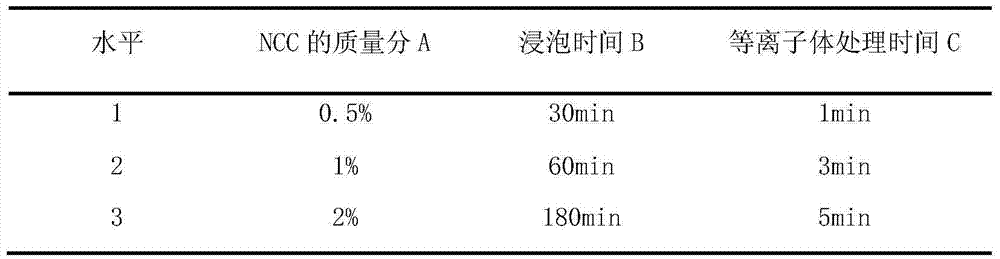

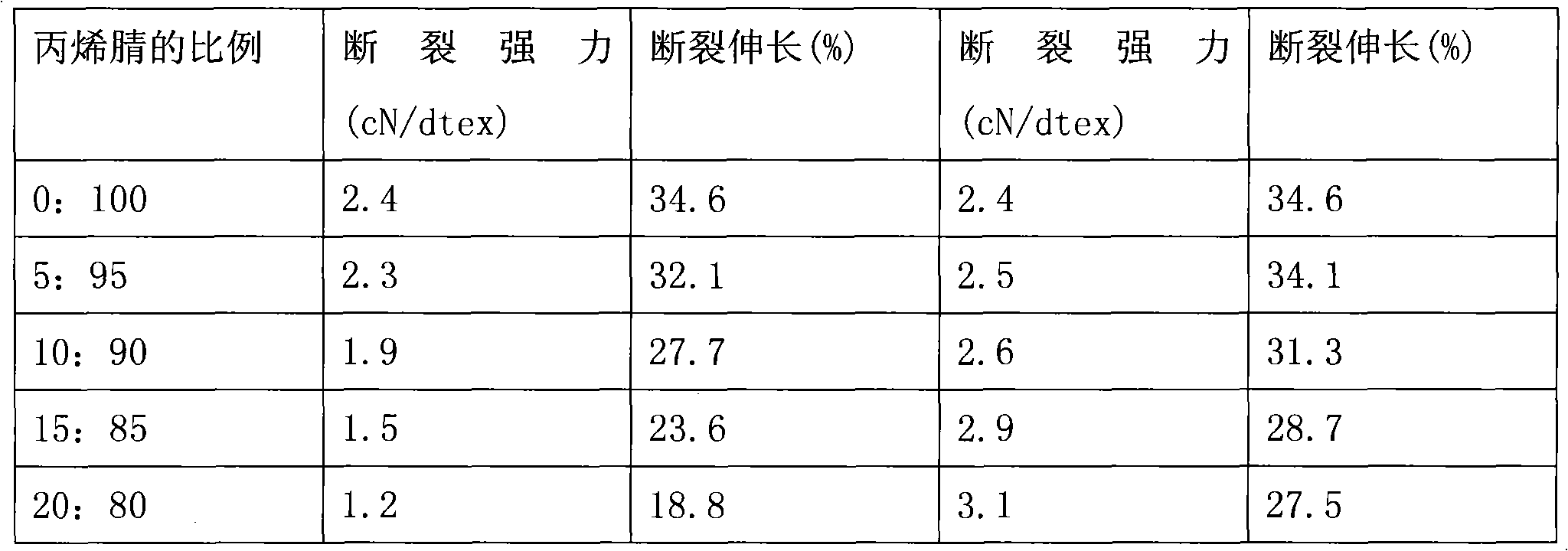

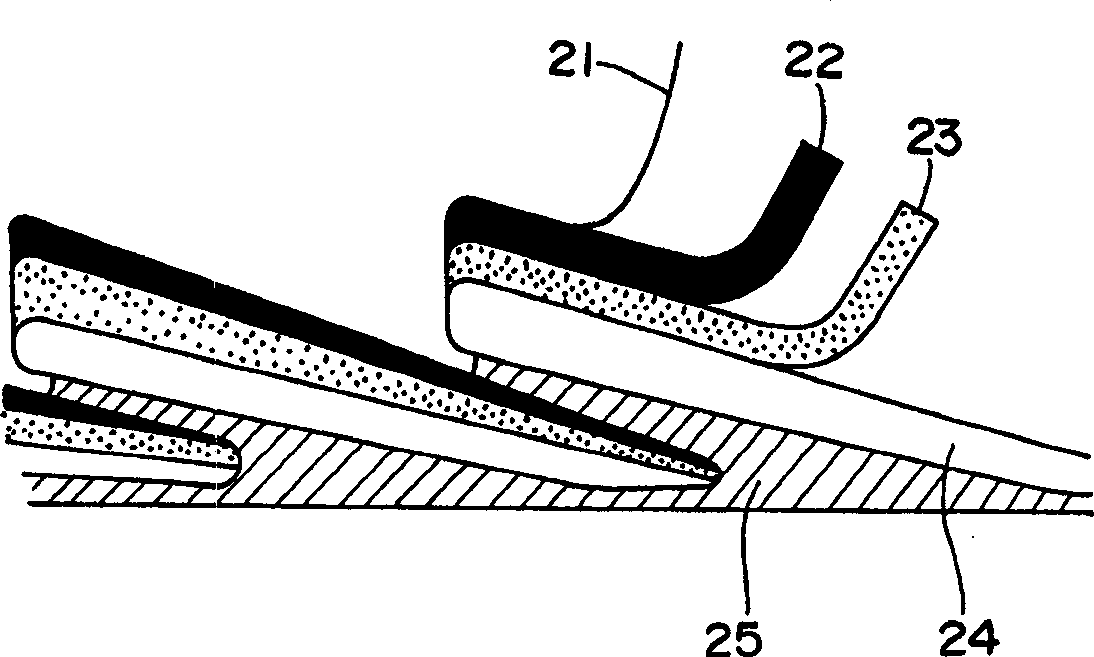

Method for improving felting resistance and pilling resistance of animal fibers or fabric thereof

The invention discloses a method for improving felting resistance and pilling resistance of animal fibers or a fabric thereof. The method specifically comprises the following steps: performing plasma treatment on the animal fibers or the fabric thereof; and further treating the animal fibers or the fabric thereof by using cellulose. The method adopts the combination of normal pressure air plasma treatment and nano cellulose finishing to regulate and control the surface friction mechanical properties of the animal fibers such as wool, cashmere, rabbit hairs and other animal fibers with scale layers covering the surfaces, thereby improving the felting resistance and the pilling resistance of the animal fibers, and improving the hand feeling comfort of the products of the animal fibers.

Owner:JIAXING UNIV

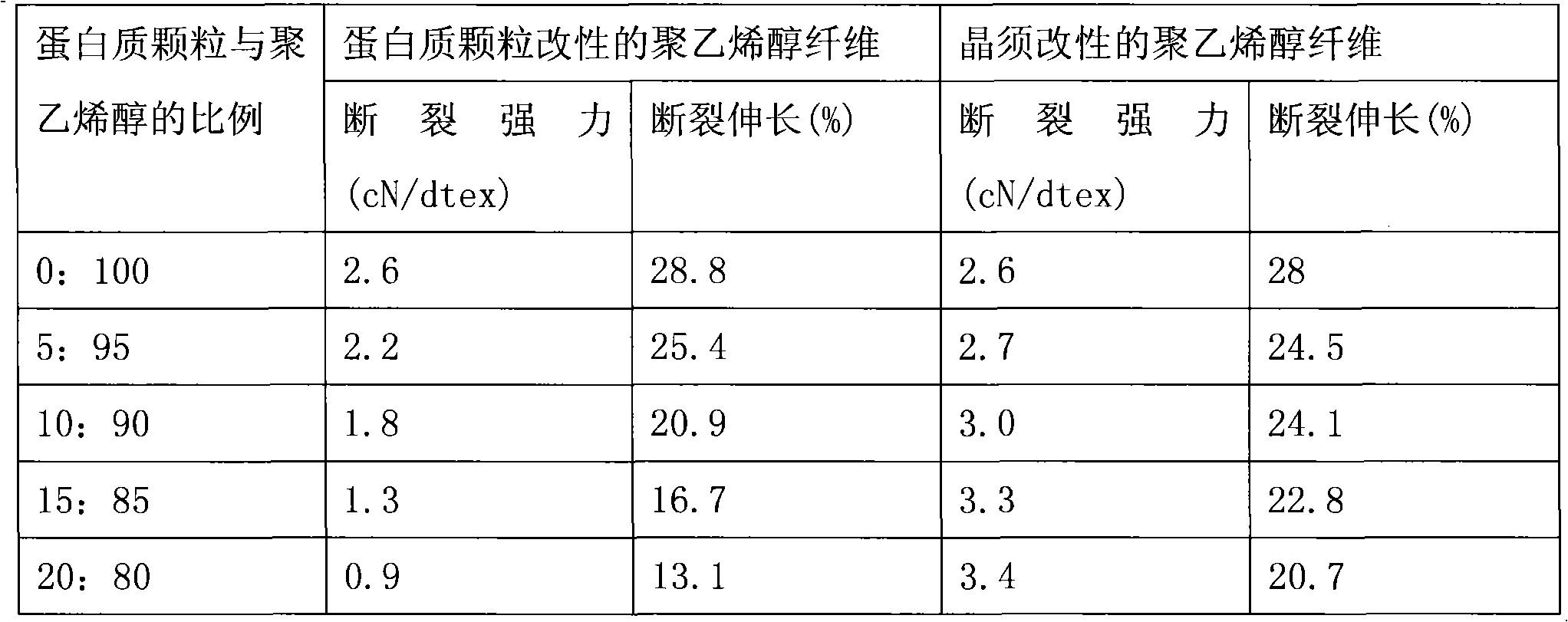

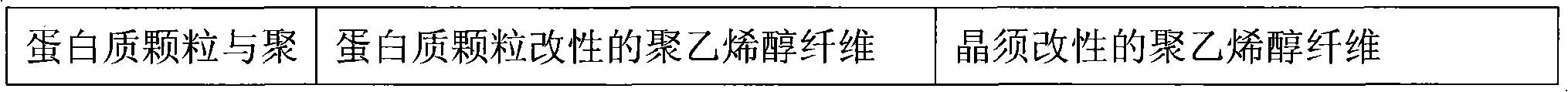

Keratin crystal whisker enhanced homogeneous composite fiber and preparation method thereof

InactiveCN101575749AOvercome the technical bottleneck that the molecular weight is small and cannot be directly spun into fibersOvercome the technical bottleneck that cannot be directly spun into fibersMonocomponent protein artificial filamentWet spinning methodsFiberRegenerating fibers

The invention provides a keratin crystal whisker enhanced homogeneous composite fiber and a preparation method thereof. The keratin crystal whisker enhanced homogeneous composite fiber consists of keratin matrixes and keratin crystal whiskers dispersed in the keratin matrixes, wherein the weight ratio of the keratin crystal whiskers to the keratin matrixes is 10-30:70-90; and the keratin crystal whiskers are distributed in the composite fiber along the axial direction of the fiber. The keratin crystal whisker enhanced homogeneous composite fiber and the preparation method can achieve homogenization spinning processing of keratin regenerated fibers. The keratin crystal whiskers can be prepared from waste wools or other animal fiber materials without spinning values, the raw materials have wide sources, the cost is low and the processing technique is simple.

Owner:DONGHUA UNIV

Production method of animal-imitative glistening cashmere fabric

The invention relates to a production method of an animal-imitative glistening cashmere fabric, and the method comprises dyeing, an afterfinish procedure, ironing, and decating; a sueding gigging procedure and a reeling procedure are added between the afterfinish procedure and the ironing procedure, wherein the sueding gigging procedure relates to gigging in water after sueding; a hair side of a woolen cloth blank is combed into a mode that the hair is in a hair-growing direction on a gigging machine, and uneven hair is cut to become even; the reeling procedure relates to the addition of 3%-5% of a potassium sulfate additive which reels around itself with a constant speed at 65 DEG C with a water content of 100% for 2 hours to perform a chemical reaction, and then is washed off. The beneficial effects of the invention are that: the production method for improving cashmere fabric glistening solves a current deficiency through changing traditional process and procedures, wherein the deficiency is that the original luster of animal fibers is destroyed.

Owner:HANGZHOU SMART CASHMERE PROD CO LTD

Base fabric material for embroidery and embroidery thread

The invention relates to a base fabric material for embroidery and an embroidery thread. The base fabric material is characterized by comprising following paper base fabrics: writing paper, copying paper, decorating paper, newspaper, coated paper, offset paper, halftone paper, plate paper, cellophane, one-side / two-side transparent glazed paper, synthetic fabric paper, cast coated paper, coating paper, cartridge paper, wallpaper, brown paper, parchment, foaming paper, packaging paper, honeycomb paper, waterproof paper, fireproof paper and mothproofing paper; and following paperboard base fabrics: a case board, a straw board, a white board, a binding paperboard, compound multi-layer paper and a corrugated board. The embroidery thread comprises a plant fibre thread, an animal fiber thread, a chemical fiber thread, a metal fiber thread and a mixed fiber thread. An embroidery product manufactured by the base fabric material and the embroidery thread can be used for decorating and finishing walls, table-boards, ground and furniture, can be used permanently or temporally, has waterproof, mothproof and fireproof performances, is durable, is long in service life, and has good environmental performance.

Owner:单虹岩

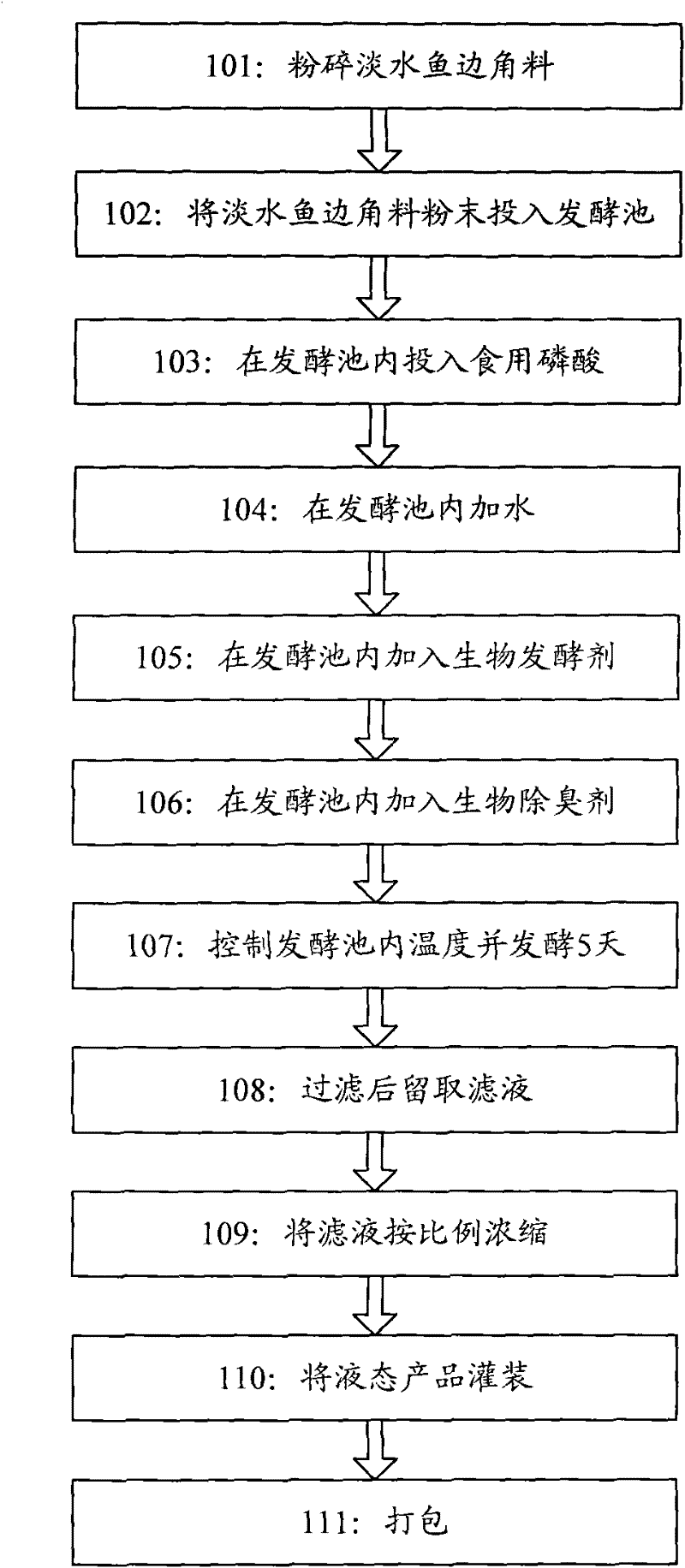

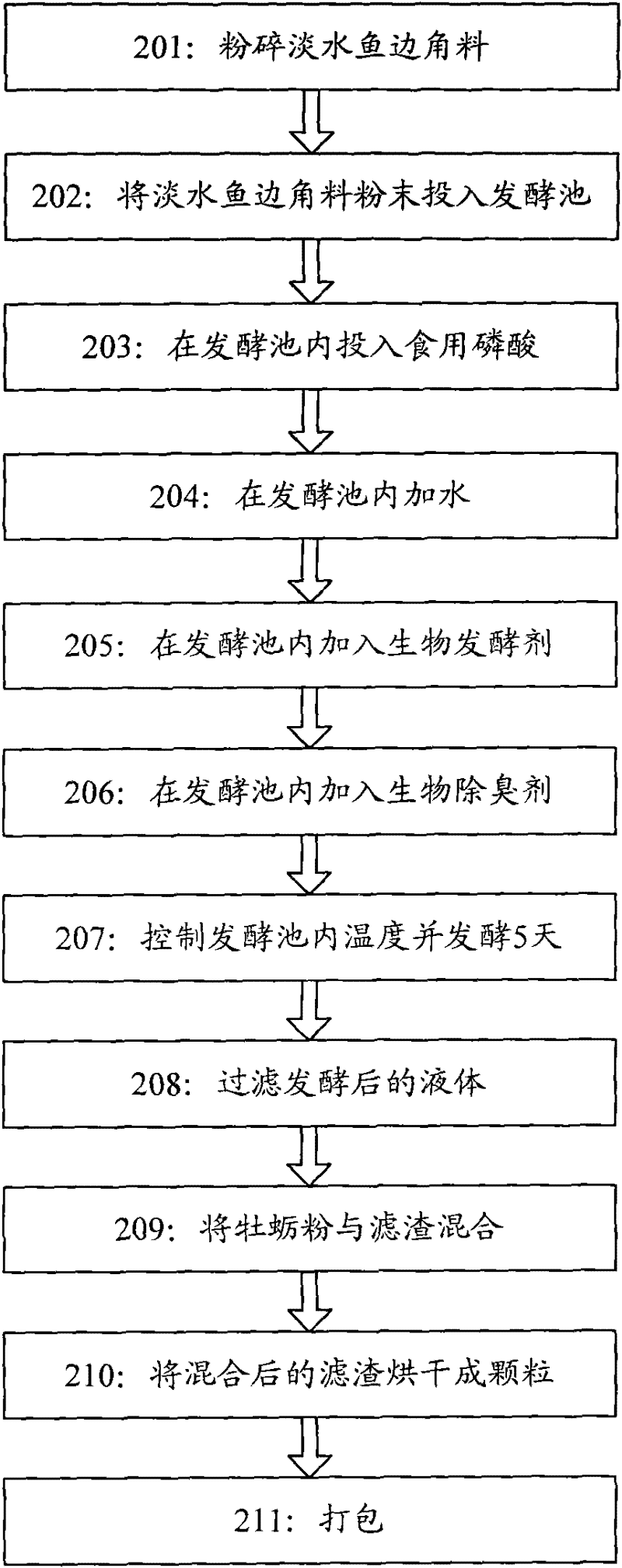

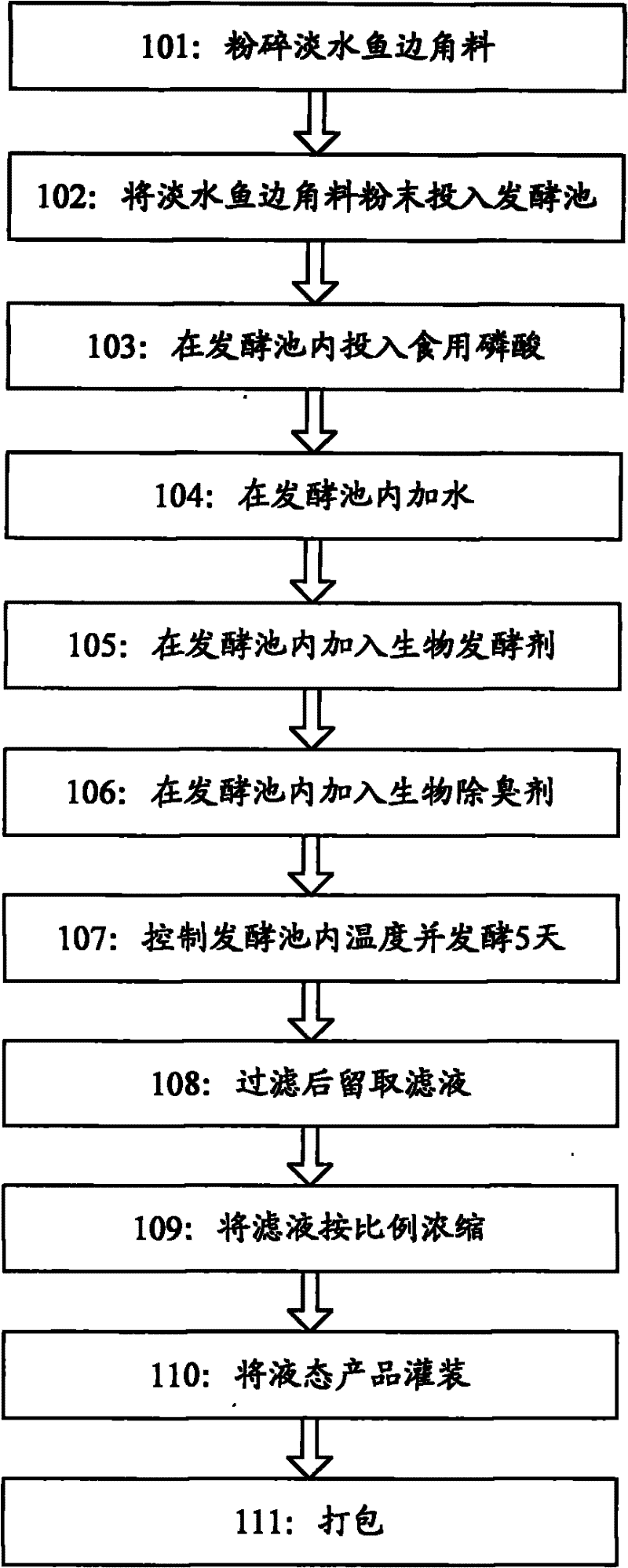

Process for preparing biological organic fertilizer from fish

InactiveCN102219563AImprove nutrient activityImprove fertilityAnimal corpse fertilisersClimate change adaptationAdditive ingredientDecomposition

The invention relates to a process for preparing biological organic fertilizer from fish. The process comprises the following steps of: crushing leftover materials of freshwater fish into powder; throwing the powder into a fermenting tank; throwing edible phosphoric acid into the fermenting tank; adding water into the fermenting tank; adding biological leaven into the fermenting tank; fermenting for 5 days by controlling the temperature of the fermenting tank to be between 16 and 35 DEG C; and filtering the liquid after fermentation. In the process, the powder of the leftover materials of the freshwater fish and the main ingredient leaven bacteria in the biological leaven are subjected to aerobic fermentation to decompose animal protein and animal fiber of the leftover materials of the freshwater fish; and nitrogen-fixing bacteria, phosphorus-dissolving bacteria, silicate bacteria, lactic acid bacteria and the like which are easily absorbed by plants are generated after decomposition, so the activity of soil nutrient, soil fertility and quality of agricultural products can be improved.

Owner:武汉市绿丹茂科技股份有限公司

Complex fiber modified by keratin whiskers and preparation method thereof

InactiveCN101525781APlay a reinforcing roleMeet the needs of production and processingWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention provides complex fiber modified by keratin whiskers and a preparation method thereof. The complex fiber modified by keratin whiskers consists of a high molecular material and the keratin whiskers extracted from natural keratin fiber and distributed in the high molecular material, wherein, weight ratio of the keratin whiskers to the high molecular material is 5-20:80-95, and the keratin whiskers are oriented along an axial direction of the fiber in the complex fiber. The complex fiber has mechanical properties meeting production and processing needs, and obviously improved hygroscopicity, dyeability, ultraviolet resistance and static resistance properties. Protein whiskers can be prepared from waste wool or other animal fiber materials without spinning value, and has wide sources of raw materials, low cot and simple processing. The production of whiskers modified complex fiber by wet spinning or dry spinning has the same processing course as the traditional process, is easy to be industrialized and has significant economic benefit.

Owner:DONGHUA UNIV

Production of pulp and materials utilizing pulp from fibrous proteins

A pulp material that comprises a fibrous protein fiber is suitable for incorporation into paper or paper composites. The fibrous protein of the fibrous protein fiber is typically a keratin, fibrin, collagen, or elastin. Preferably, the fibrous protein is a collagen, such as a β-keratin. The β-keratin can be obtained from avian feathers, such as chicken feathers. The pulp material can further comprise at least one additive such as mordants. dyes. binders. foaming agents. hardeners. chemical sizing agents, fillers. wetting agents. plant fibers, or animal fibers. The pulp material can be treated with a crosslinking agent or an oxidizing agent. Other aspects of the invention include a biodegradable polymer comprising the pulp material and a filter comprising the pulp material. Still another aspect of the invention is a composite material comprising: (1) the pulp material; and (2) a fiber selected from the group consisting of an animal fiber and a plant fiber. Still another aspect of the invention is a multilayer material comprising: (1) a first layer that is the pulp material; and (2) a second layer including a material selected from the group consisting of paper and a biopolymer.

Owner:LICATA CARLO

Bamboo fiber short fiber roved woolen fabric

The bamboo fiber-short fiber roved woolen fabric is blended or interwoven with bamboo fiber, short fiber and animal fiber, including wool, cashmere, rabbit hair and rabbit fluff. The fabric has hygroscopicity similar to that of bamboo fiber, as well as elasticity, softness and warming performance like animal fiber, and is pendent, elegant, bright, full and smooth.

Owner:浙江神州毛纺织有限公司

Composite fibrofelt of centrifugal glass wool and fabrication method

A compound centrifugal glass cotton fiber felt is compounded by a layer of glass cotton and a layer of organic or inorganic fibers, their mass percentage is; centrifugal glass cotton 20-60%, organic or inorganic fibers 80-40%. The organic can be fibers of plants or animals such as flax, palm or wools, inorganic fibers can be ore cotton, rock cotton or glass fibers. This invention discloses its production method.

Owner:严煜

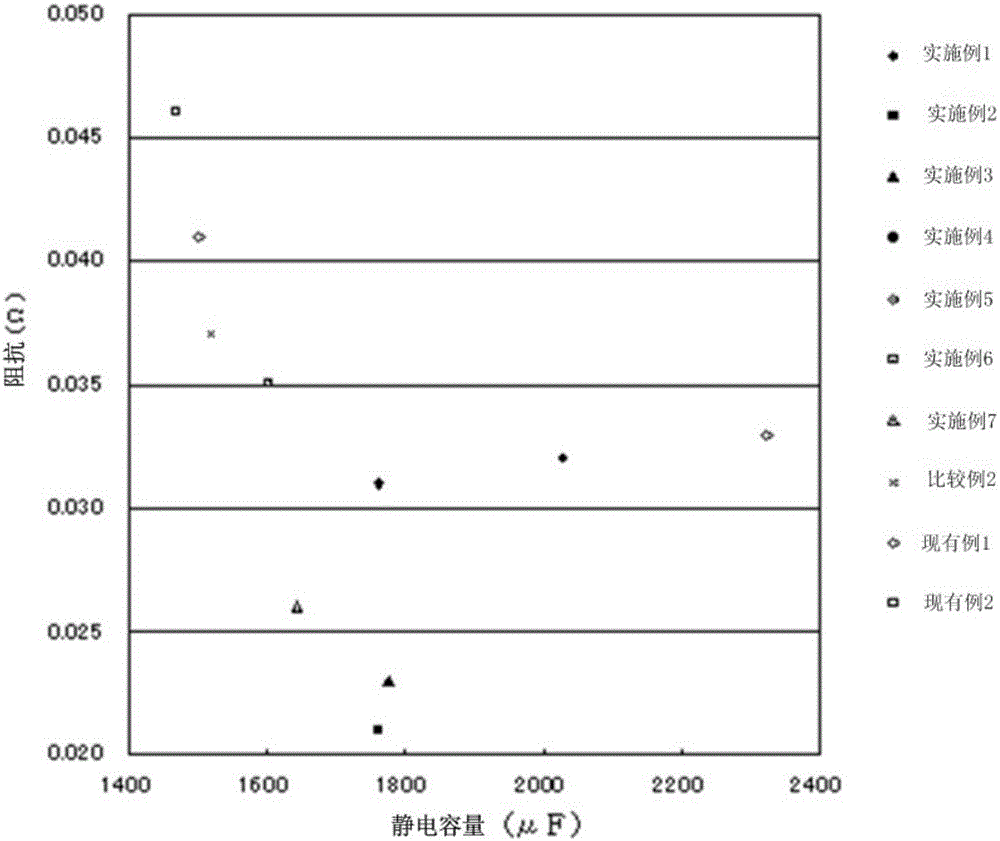

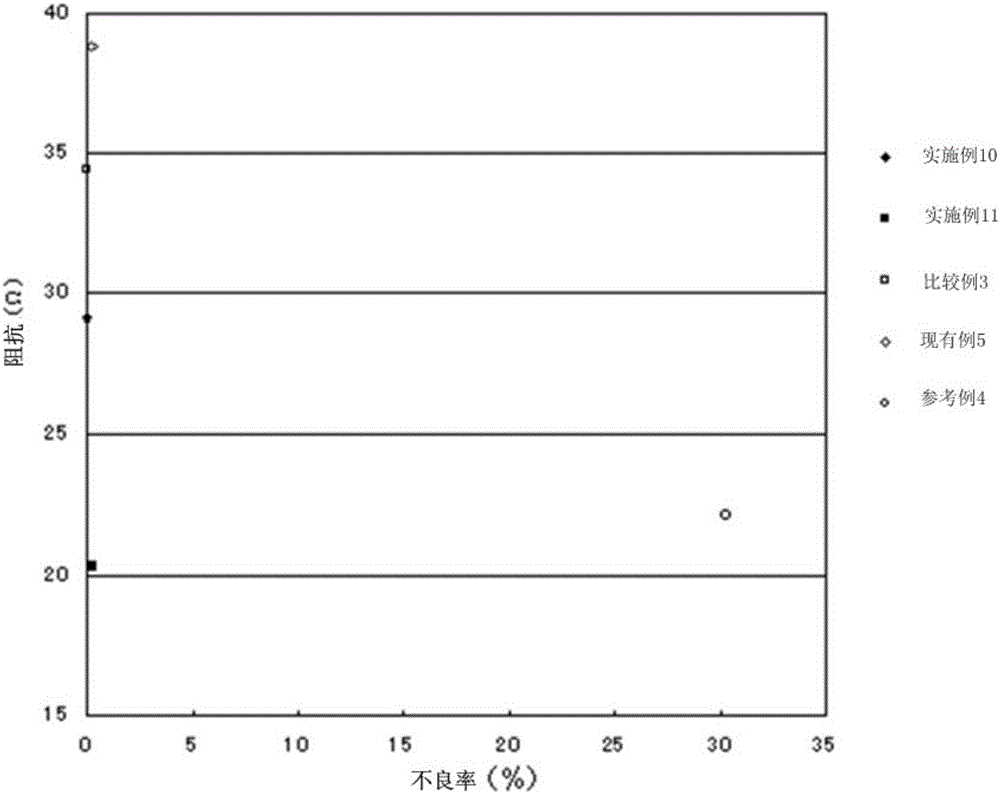

Capacitor separator and capacitor

InactiveCN105917429AGood strength propertiesImprove short circuit resistanceHybrid capacitor separatorsElectrolytic capacitorsCapacitanceAnimal fiber

A capacitor separator having excellent impedance characteristics and short-circuiting resistance, and allowing the capacitor to be reduced in size and / or increased in capacitance; and a capacitor in which the separator is used are provided. The separator for the capacitor includes a porous film made of cellulose dissolved and regenerated without forming a cellulose derivative (A) and a fibrous component (B), for example, the fibrous component (B) can be one or more kinds of fibers selected from a plant-based pulp, regenerated cellulose fiber, cellulose fiber, animal fiber, inorganic fiber, and synthetic fiber that are available as paper raw material. The regenerated cellulose (A) can be obtained by forming in a film form a cellulose solution made by dissolving cellulose in an amine oxide solvent, immersing the resulting cellulose solution in water or a poor solvent of the amine oxide solvent so as to coagulate and regenerate the cellulose, washing the regenerated cellulose with water to remove the amine oxide solvent, and drying the resulting cellulose, and therefore the porous film is a porous film the chlorine content of which is 2 ppm or below, the sulfate content of which is 10 ppm or below, the thickness of which is 3-70 mum, the density of which is 0.1 g / cm<3> or above, and the average pore diameter of which is 5 mum or below. The capacitor is characterized by adopting the separator.

Owner:NIPPON KODOSHI

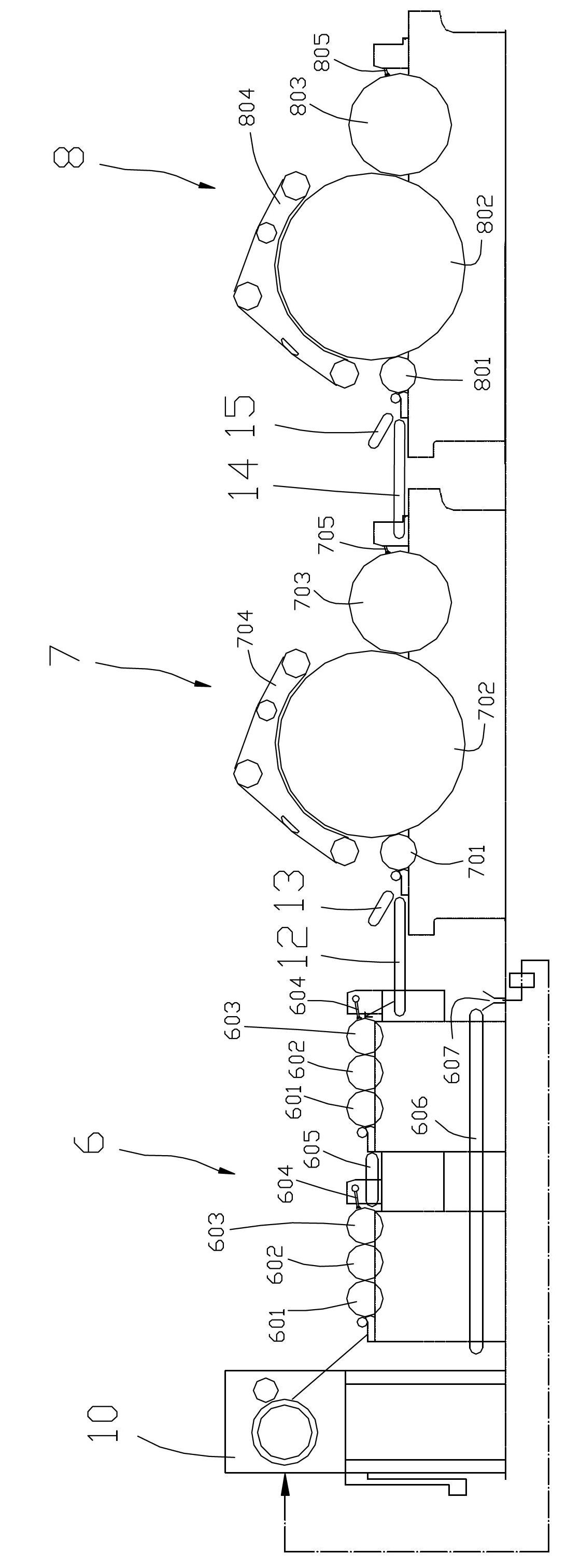

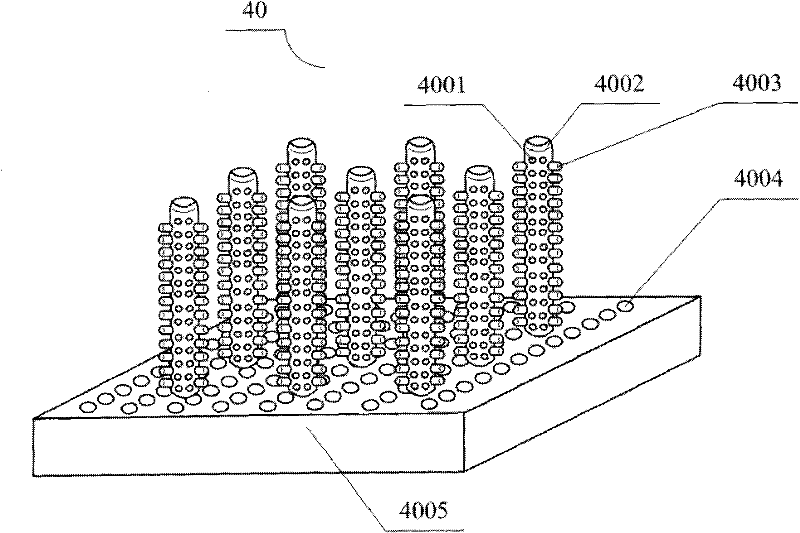

Heterogeneous animal fiber carding device and equipment thereof

The invention discloses a heterogeneous animal fiber carding device and equipment thereof. The device comprises a rotary carding roller, wherein a rotary dust cage is arranged on one side of the carding roller, a plurality of air holes are uniformly formed in a cylinder body of the dust cage, an air absorbing cylinder in a still position is arranged in the dust cage, the air absorbing cylinder is provided with an air absorbing passage towards the carding roller, a negative pressure zone is formed between the dust cage and the carding roller by the air absorbing passage, fibers in the carding roller can be continuously absorbed to the rotary dust cage by generated absorbing airflow when passing through the negative pressure zone, and the equipment comprises the carding device for the heterogeneous animal fibers. According to the invention, the way of clothes carding in the prior art is replaced by the way of airflow carding, the length and the surface of villi are effectively protected, and the damage to the villi in the carding process is reduced. By the initial verification, the extraction ratio of the villi is improved about 6%, the fallen crude villi does not need repeated recovering treatment.

Owner:青岛合力纺织机械厂

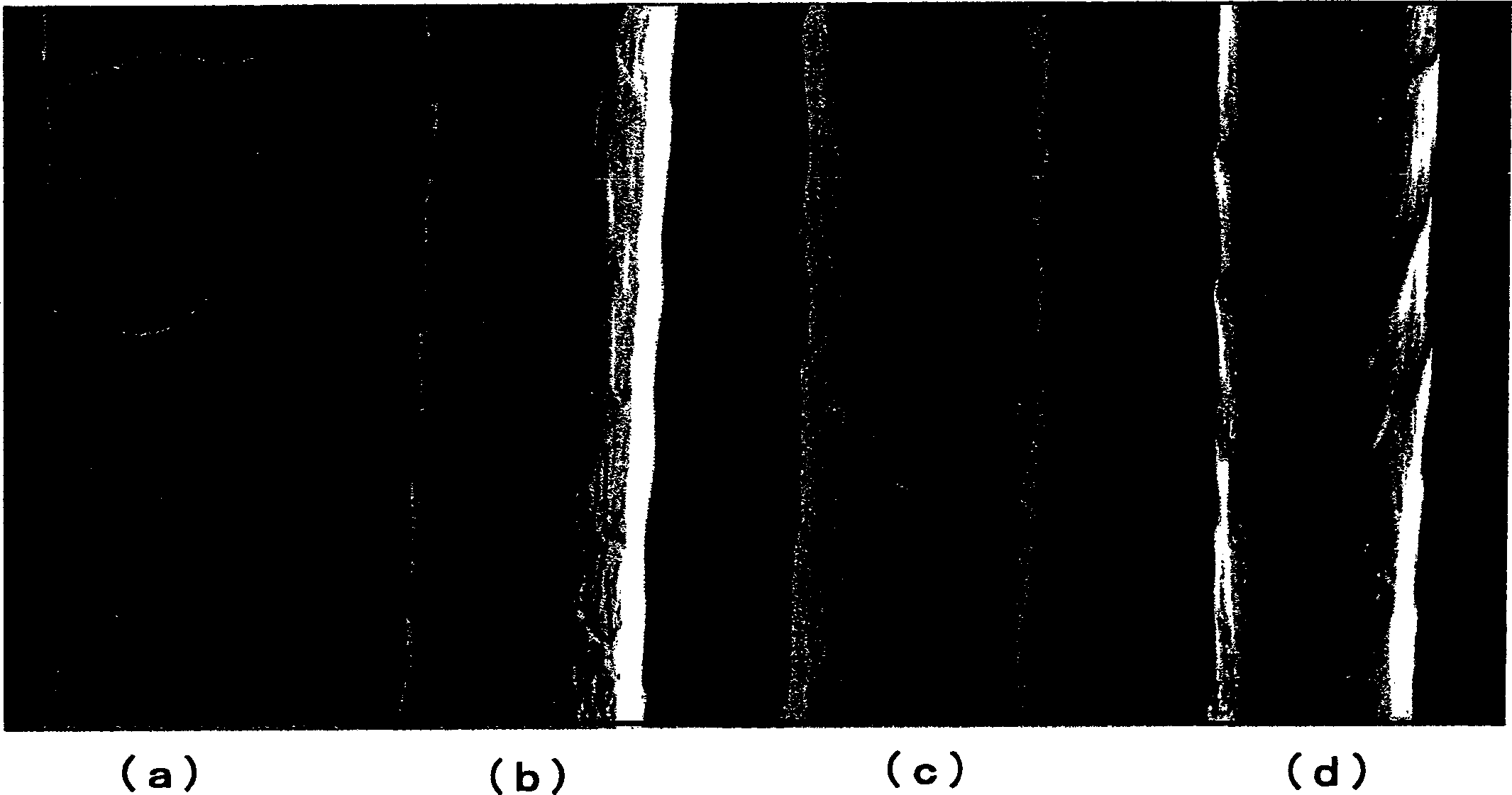

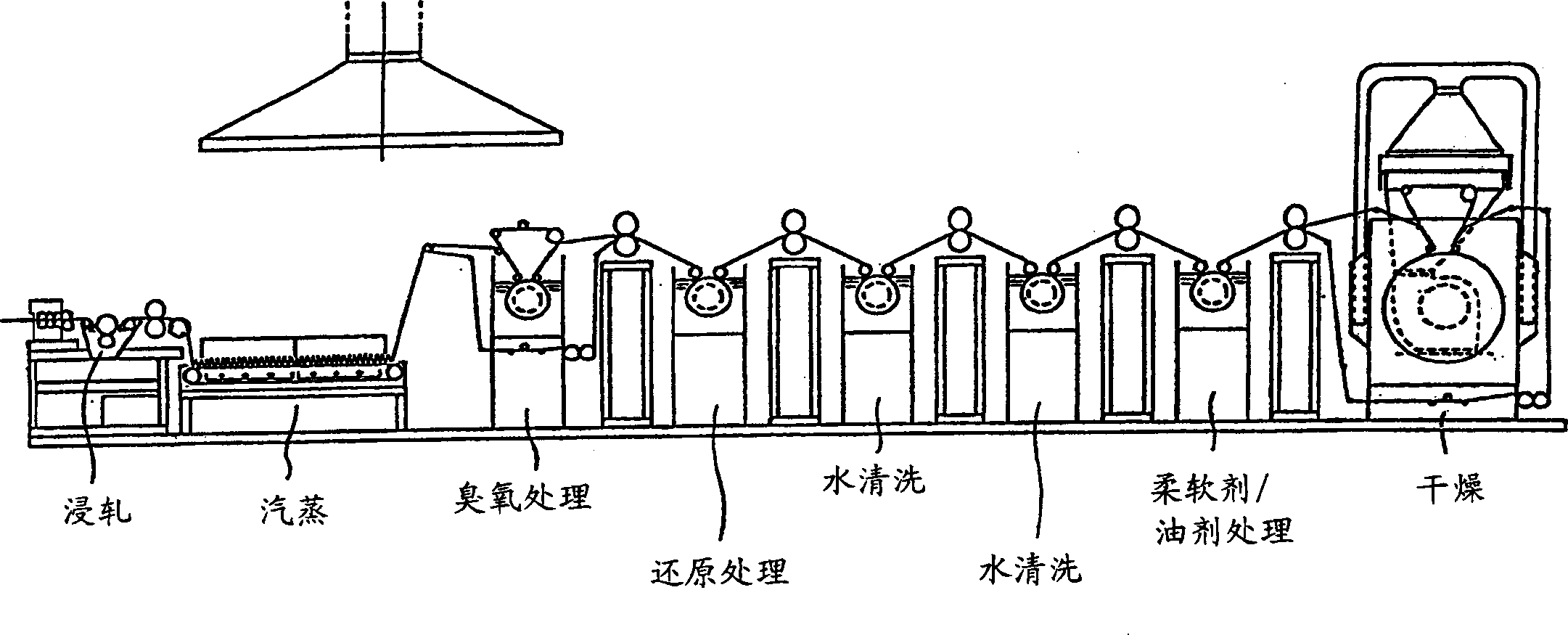

Excellent shrink resistance animal fibre and method for preparing same

The present invention provides an animal fibers having improved shrink proofing and pilling resistance properties and method for preparation thereof. An animal fiber having excellent shrink proofing and pilling resistance and retaining its original water repellency is also provided. A method of treating animal fiber in which a surface layer part of animal fiber is primary-oxidized in advance with an oxidizer, and aqueous treatment liquid containing ozone in the form of ultrafine bubbles of 5 mu or less is allowed to collide against the fiber by blowing the liquid on the fiber in the aqueous treatment solution, and then, the fiber is treated with a reducing agent. Particularly, the above-mentioned method for treating animal fiber in which ultrafine bubbles of ozone are formed by using a line mixer. The method in which an apparatus which collects the ultrafine ozone bubbles in aqueous treatment liquid on the fiber is used so that the bubbles are not scattered out of a treatment reaction bowl.

Owner:KURASHIKI BOSEKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com