Excellent shrink resistance animal fibre and method for preparing same

An animal fiber, an excellent technology, applied in the field of animal fiber and its preparation, can solve the problems of not being able to obtain sufficient shrinkage, ozone bubbles, fiber aggregates, and large bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

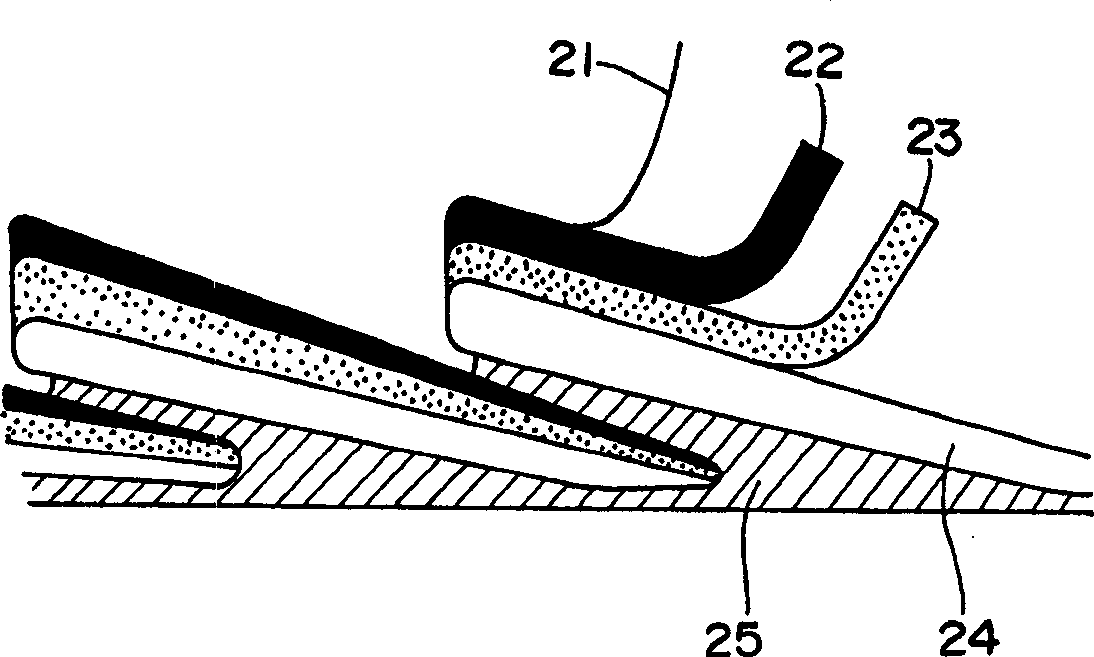

[0081] The method for the production of animal fibers according to the invention is characterized by a two-stage oxidation comprising a first step, primary oxidation of the animal fibers and a second step, subjecting the primary oxidized animal fibers to a higher order oxidation, and further comprising the subsequent step of subjecting the higher order oxidation to Reduction of cysteine bond cleavage.

[0082] Next, the method in the present invention will be described in more detail.

[0083] In the method of the present invention, the first step is a pretreatment step of oxidizing the cysteine bond with ozone, at this stage, the cysteine bond in the fibrous epidermis utilizes an oxidizing agent that can oxidize the animal fiber-S-S-bond Primary oxidation, to an essentially single-oxidation state.

[0084] As the preferred oxidizing agent used in the primary oxidation, persulfuric acid, peracetic acid, performic acid, various peroxyacids and neutral or acidic salts of ...

Embodiment 1

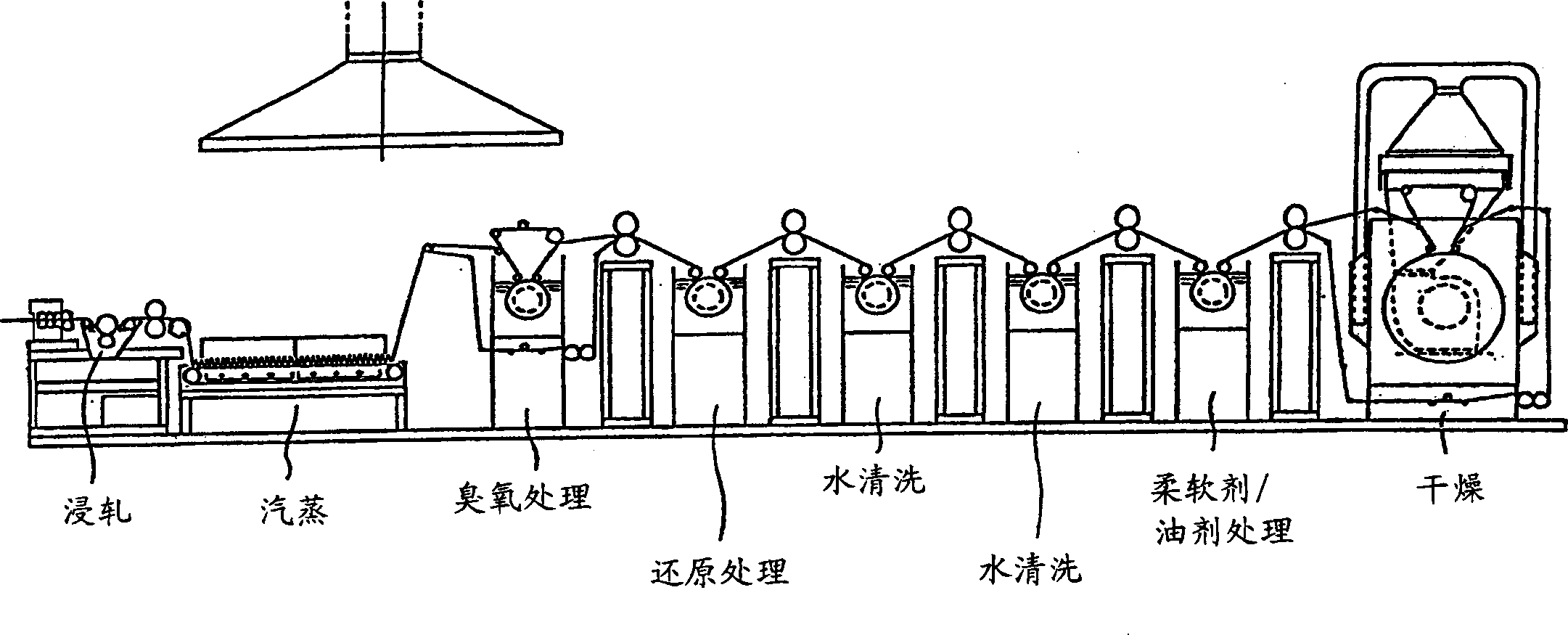

[0136] Wool tops according to image 3 The depicted flow diagrams are continuously processed. The moving speed of the top through the process, that is, the speed of the padding treatment mandrel, the ozone treatment tank, the reduction treatment tank, the water washing treatment tank and the drying process, was 2 m / min.

[0137] [Padding process]

[0138] 9 tops (25 g / m) made of 20.7 μm Australian Merino wool were transferred to a rotary needle bar, which wool tops were then “fiber-carded” into ribbons by drafting 1.66 times. The strip-shaped tops were padded in an aqueous solution having the following composition and squeezed dry by a liquid manger.

[0139] Composition of padding aqueous solution

[0140] Potassium hydrogen persulfate KHSO 5 : Concentration is 40g / L

[0141] ("Oxone", manufactured by DuPont)

[0142] Wetting agent "Alcopol 650" concentration is 2g / L

[0143] (manufactured by Ciba-Geigy Specialty Chemicals)

[0144] processing conditions

[0145] Con...

Embodiment 2

[0201] A top of 20.7μ Australian Merino wool was processed according to the method of Example 1. But the difference is that the top feeding speed is 0.55m / min, and the contact time between the treatment liquid and the wool in the ozone treatment tank and other treatment tanks is 2 minutes. The apparent feed rate of ozone to wool was 5.37% owf.

[0202] 25g / mX9X1 / 1.66=135.5g / m wool

[0203] 135.5g / mX0.55m / minXcontact time 2min=149.05g wool

[0204] 4g / min(O 3 )X2min=8g(O 3 )

[0205] 8g / 149.05gX100 = 5.37% owf O 3

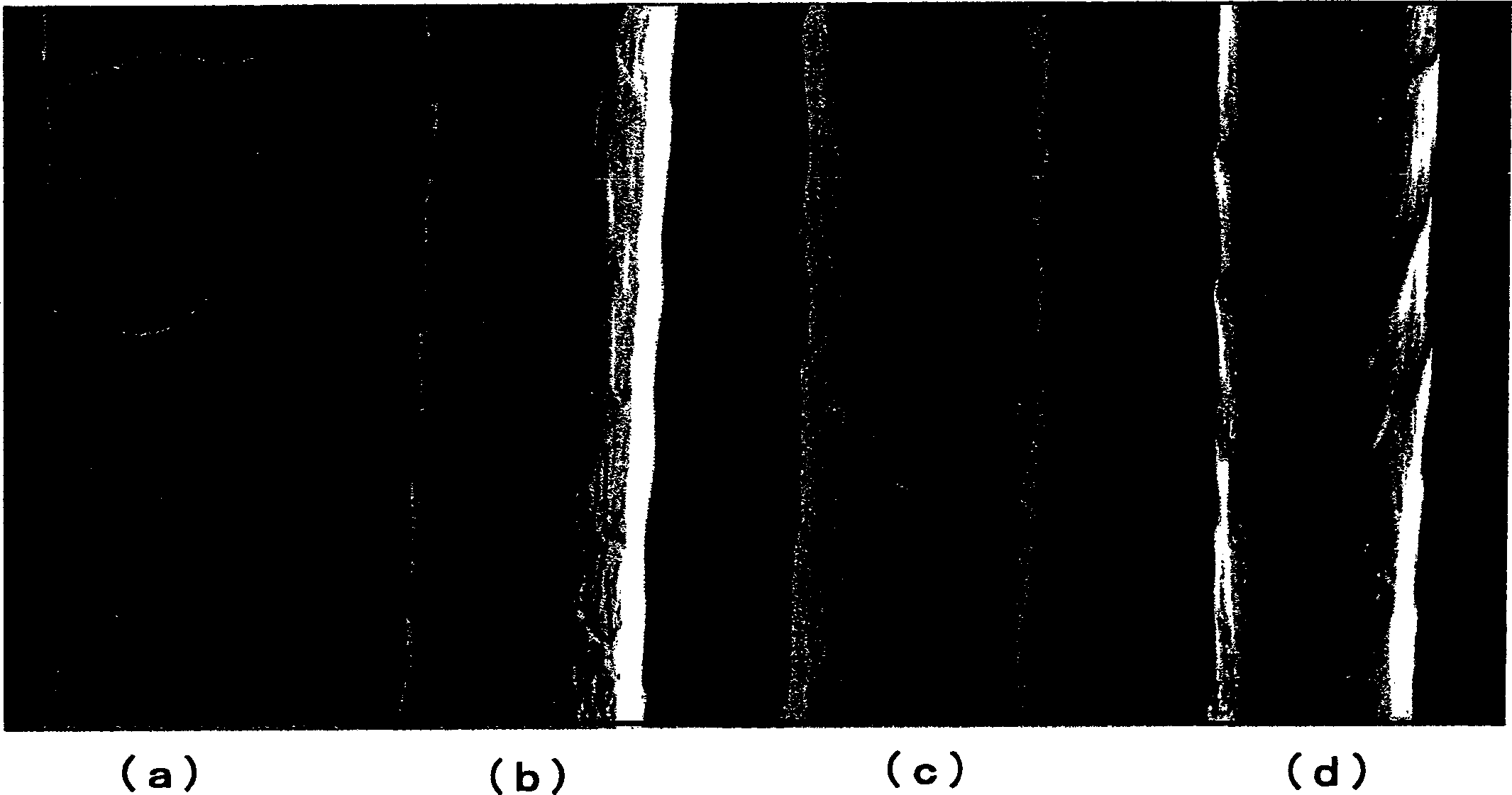

[0206] The treated wool tops were needled and spun into hosiery yarns of 2 / 48Nm x twist Z500XS300, then knitted into a density with a cover factor C.F. equal to 0.41, and washed continuously for 1 hour and 3 hours on the Cubex shrinkage test equipment, and then , was subjected to a 5-hour pilling test on an ICI pilling tester, and the strength and elongation of the knitted yarn were also measured. In order to observe the modification state of the wool surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com