Three-layer sandwiched composite eiderdown flake and manufacturing method thereof

A manufacturing method and sandwich technology, applied in non-woven fabrics, textiles and papermaking, adhesives, etc., to achieve the effects of reducing labor costs, reducing losses, and reducing labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-21

[0055] As described in Table 1, the raw materials and raw material weight ratios of Examples 1-21 were selected.

[0056] Table 1, the raw material of embodiment 1-21 and raw material weight ratio

[0057]

[0058] Make the three-layer sandwich type composite down wadding sheet of embodiment 1-21 according to the following steps:

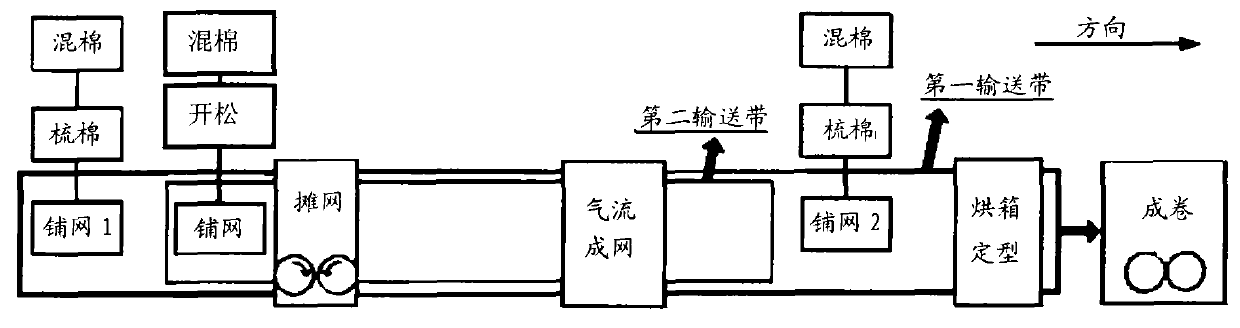

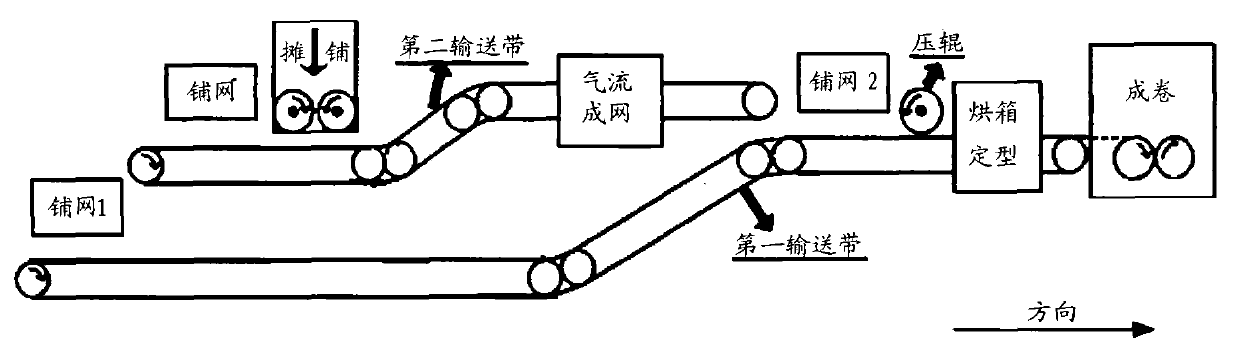

[0059] see figure 1 and figure 2 As shown, step (1): the animal and plant fibers and low-melting point fibers are mixed, carded, and laid at the laying point 1 to make continuous lower layer flakes, which are sent to the Laying 2 places; After mixing, opening and spreading the animal and plant fibers and low-melting point fibers, the down fibers are spread, and the middle layer flakes are made by air-laid netting, which is also transported by the second conveyor belt. Sent to Laying 2; Animal and plant fibers and low melting point fibers are blended, carded, and made into continuous upper flakes at Laying 2. Step (2): The stacked lower layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com