Cashmere carding machine

A carding machine and cashmere technology, which is applied in the field of cashmere carding machines, to achieve the effect of increasing extraction rate, improving removal effect and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

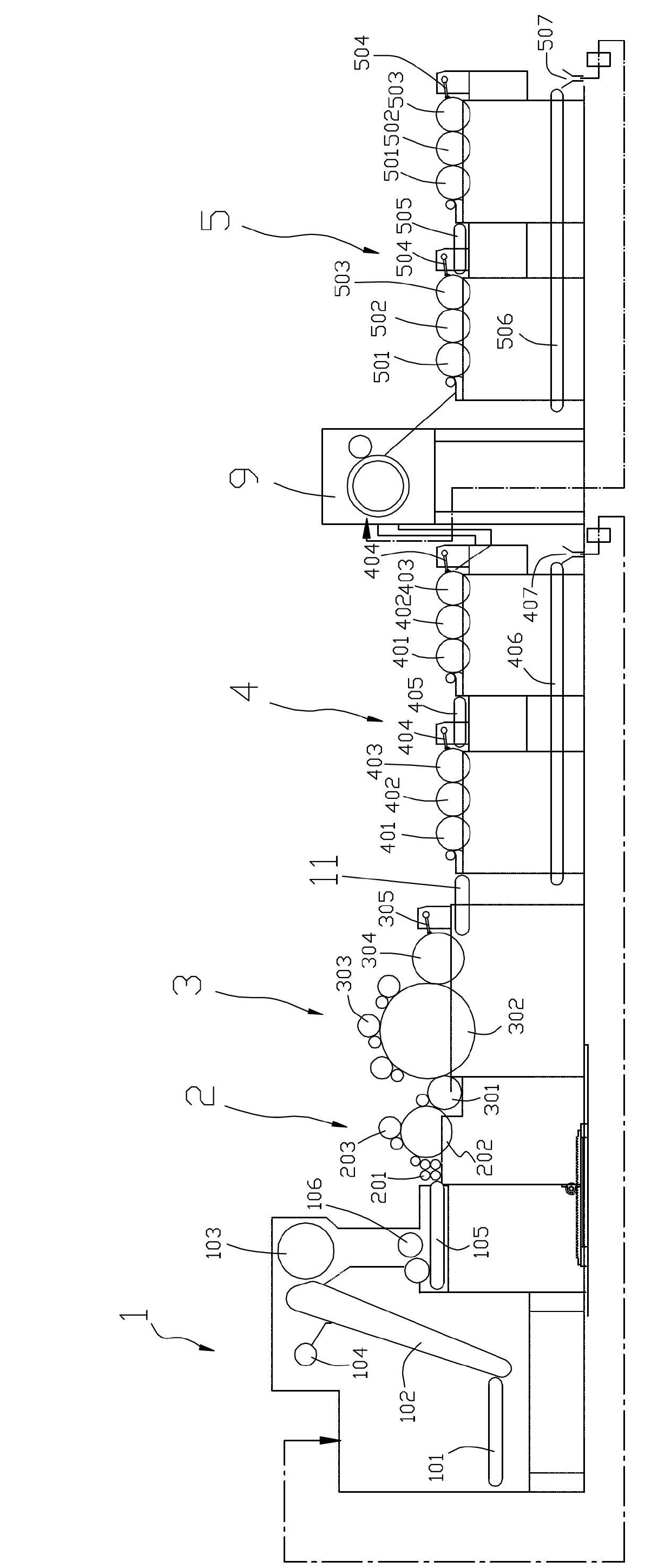

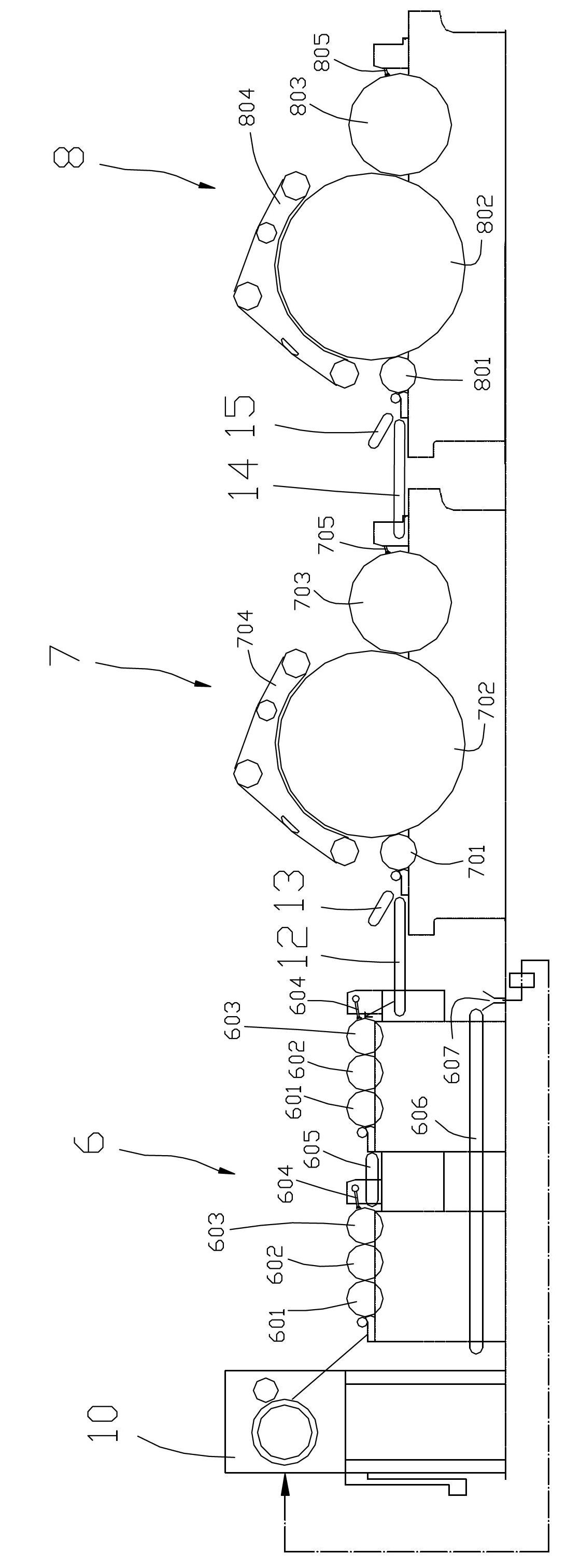

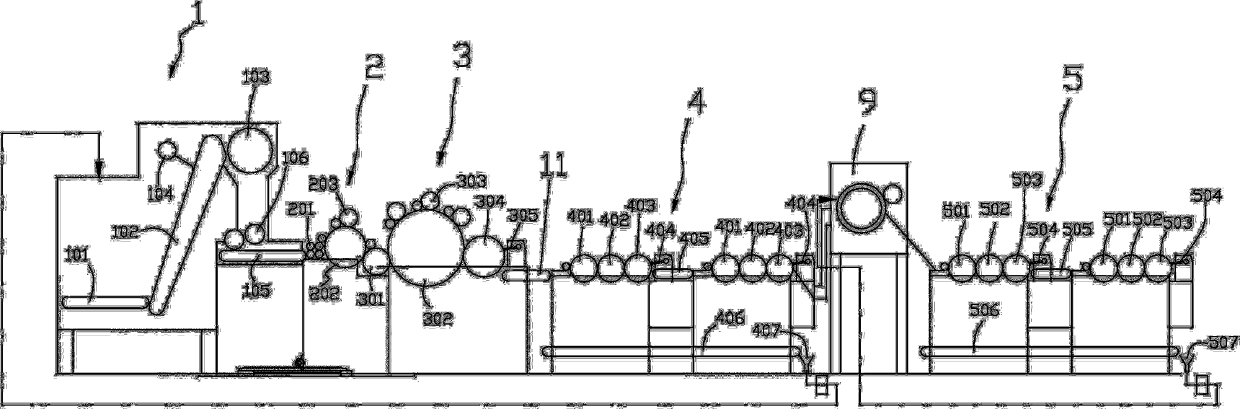

[0015] combine figure 1 and figure 2 , a cashmere carding machine, including a feeding mechanism, an opening mechanism, a roughing and impurity removing mechanism and a carding mechanism, and each mechanism is arranged in the above order.

[0016] The above-mentioned coarse and impurity removal mechanism includes several coarse and impurity removal units, three in this example, namely the coarse and impurity removal unit 4 , the coarse and impurity removal unit 5 and the coarse and impurity removal unit 6 . The above-mentioned coarse and impurity removal unit 4, as the coarse and impurity removal unit located at the rearmost position, includes two coarse and impurity removal subunits, each of which includes a first licker-in roller 401 and a first cylinder 402. Arranged in line with the first doffer 403, the first licker-in roller, the first cylinder and the first doffer, the stripping knife 404 is arranged on the front side of the first doffer, and a The first conveying fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com