Patents

Literature

106 results about "Camel hair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Camel hair specifically refers to the fur from the body of a camel, but more generally refers to the fibre (and cloth) that may be made from either pure camel hair or a blend of camel hair and another fibre.

Keratin solution and solid preparing process

InactiveCN1435432AInnovative method of extracting keratinAnimals/human peptidesInorganic saltsCamel hair

Owner:INNER MONGOLIA ERDUOSI CASHMERE PRODS

Method for preparing solution of keratin

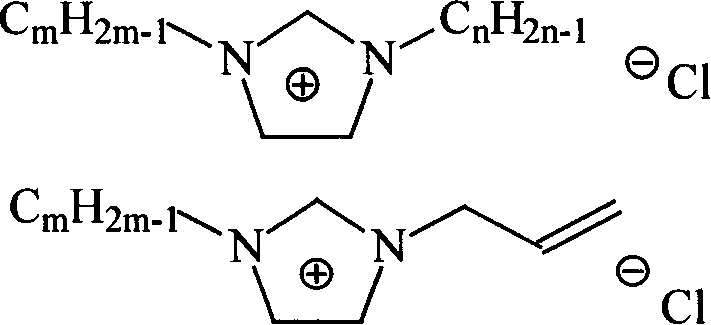

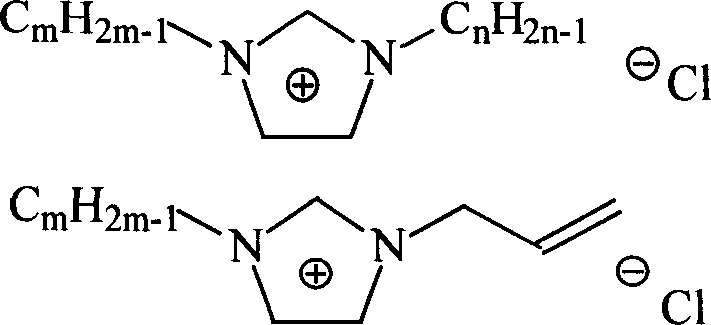

A process for preparing ceratin solution includes such steps as washing wool of sheep and goat, camel hair, yak hair, pig hair, etc in water, immersing in alcohol or acetone for removing fat, adding it to chlorinated imidazole salt series ionized liquid, heating to 100-150 deg.C and stirring for 2-10 hrs.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method and dry-wet spinning method of regenerated protein chitosan blended solution

InactiveCN103114351AIncrease elongationIncrease elasticityArtificial filament washing/dryingConjugated cellulose/protein artificial filamentsTextile fiberProtein solution

The invention relates to a preparation method and a dry-wet spinning method of a regenerated protein chitosan blended solution. The preparation method comprises the steps of: carrying out ultrafine grinding on raw materials of leftovers of reeling silks and leftovers of animal coarse hairs such as goat hairs, pig hairs, camel hairs and wools, dissolving the crushed raw materials in an ionic liquid to obtain a regenerated protein solution with high molecular weight, and blending the regenerated protein solution with a chitosan liquid to obtain a spinning solution. The spinning solution is molded by using a dry-wet spinning technology, the structure uniformity and the orientation degree of fibers are enhanced through solidification and drafting, and the elongation and the elasticity of the fibers are improved through oxidation crosslinking. The regenerated protein chitosan blended fiber has high protein content, and has functions of bacteria resistance, moisture prevention and promotion of blood coagulation and wound healing; and all compositions in the fiber are in biomass states, have good biodegradability and biocompatibility and can be applied to textile fibers and biomedical materials.

Owner:河南鼎大生物科技有限公司

Method for preparation and wet spinning of regenerative keratin and silk-fibroin blended solution

InactiveCN103102694AGood orientationHigh crystallinityConjugated cellulose/protein artificial filamentsWet spinning methodsCamel hairPolymer science

The invention relates to a fibrosis technology for a regenerative keratin and silk-fibroin blended solution of animal hairs, and in particular relates to a method for preparation and wet spinning of the regenerative keratin and silk-fibroin blended solution. The method is characterized by comprising the following steps of: blending a regenerative keratin solution and a regenerative silk-fibroin solution, which use an ionic liquid as a solvent, by using waste mulberry silks, animal hairs and wools as raw materials to obtain a spinning solution, wherein the animal hairs include pig hairs, sheep wools, rabbit hairs, camel hairs, yak hairs and the like, and the wools do not have spinning and weaving utility values; molding by adopting wet spinning; improving the degree of orientation of fibers through multi-stage drawing; improving the crystallinity of the fibers through heat treatment and ethanol treatment; and improving the elasticity and tensibility of the fibers through oxidation crosslinking. The regenerative keratin and silk-fibroin fibers prepared by the method are protein fibers in an absolute sense, do not need to be blended and molded with synthetic polymer, and have excellent characteristics of natural cashmere fibers and silk fibers.

Owner:河南鼎大生物科技有限公司

Weft knitting cashmere double-faced pile fabric and production method thereof

The invention discloses a weft knitting cashmere double-faced pile fabric and a production method of the weft knitting cashmere double-faced pile fabric. The weft knitting cashmere double-faced pile fabric is formed by alternately knitting cashmere wool type yarns and synthetic fiber high-elasticity or low-elasticity yarns into weft knitting double-faced base cloth through double-faced napping, wherein cashmere napping is conducted on the front face, and synthetic fiber napping is conducted on the bottom face. The production method includes the steps that a double-faced weft knitting fabric is woven on a circular weaving machine through the cashmere wool type yarns and the synthetic fiber high-elasticity or low-elasticity yarns, and double-faced napping is conducted through a napping machine, wherein an upper work drum and a lower work drum of the circular weaving machine adopt different knitting needles, different needle pitches, and different stroke widths and angles of an upper casting-in track and a lower casting-in track respectively, and upper card clothing and lower card clothing of the napping machine adopt napping steel needles of different types and different angles. The weft knitting cashmere double-faced pile fabric is firm in texture, the two faces of the fabric are cashmere double-faced pile fabric cloth with different textures, and therefore the noble style of cashmere is not lost, cost is greatly lowered, and the weft knitting cashmere double-faced pile fabric is suitable for all animal type plush yarns, such as cashmere yarns, mink cashmere yarns, rabbit wool yarns, camel hair yarns. The novel, cheap and fine cashmere double-faced pile fabric is provided for double-faced pile dress goods.

Owner:YUCHENG XIANGYUN WOOLEN CO LTD

Composite accompanying environment-friendly imitation goose down thermal material and method for producing same

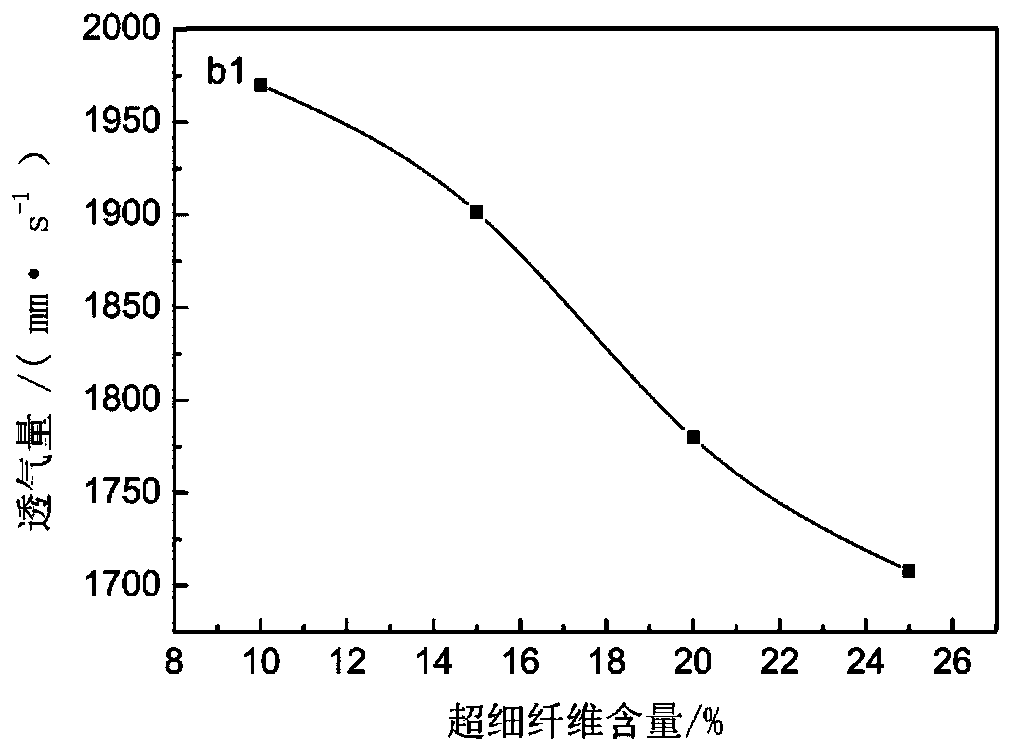

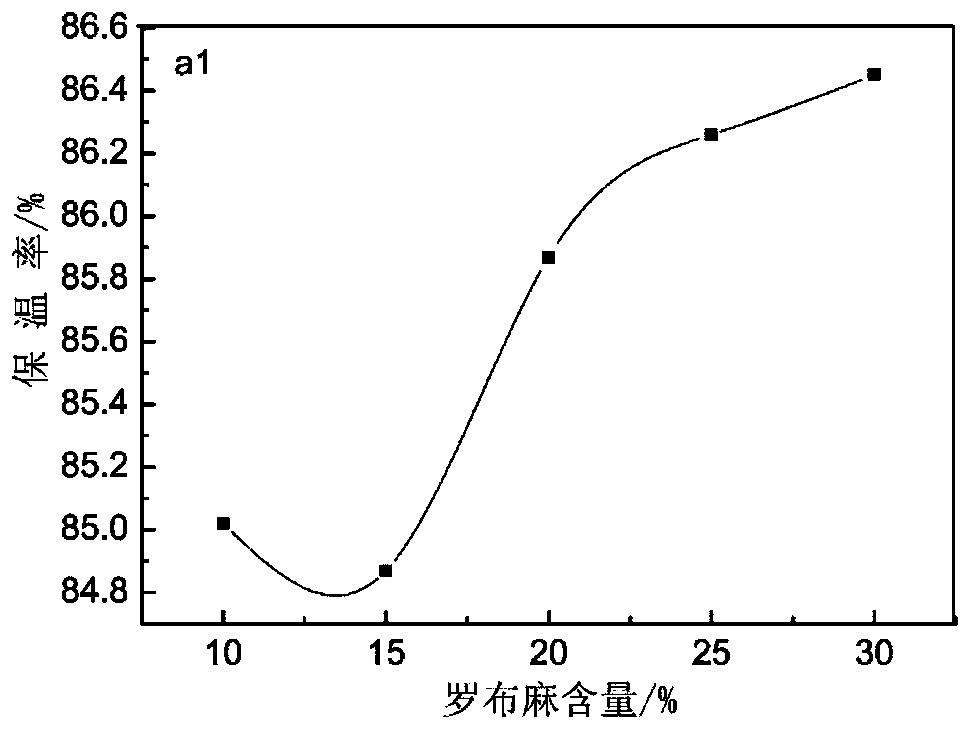

ActiveCN105780297ANot easy to drill downHas a warming effectMelt spinning methodsNon-woven fabricsCamel hairMelt blowing

The invention discloses a composite accompanying environment-friendly imitation goose down thermal material and a method for producing the same.The composite accompanying environment-friendly imitation goose down thermal material is prepared from PLA (polylactic acid) melt-blown superfine short fibers and a type or a plurality of types of cashmere, camel hair, alpaca wool and rabbit hair fibers.The surface density of the composite accompanying environment-friendly imitation goose down thermal material is 50-300 g / m<2>, the thickness of the composite accompanying environment-friendly imitation goose down thermal material is 3-30 mm, a CLO value of the composite accompanying environment-friendly imitation goose down thermal material is 0.8-3, the warmth retention rate of the composite accompanying environment-friendly imitation goose down thermal material is 50-85%, and a thermal resistance value R of the composite accompanying environment-friendly imitation goose down thermal material is 0.5-3.The composite accompanying environment-friendly imitation goose down thermal material and the method have the advantages that shortcomings of bulkiness, easiness in deformation due to water washing, down piercing and the like of the traditional down feather can be effectively overcome; existing melt-blowing equipment is modified, so that the light, thin, environment-friendly and efficient imitation goose down thermal material can be developed and is wide in service range, and development of the thermal material industry can be effectively promoted.

Owner:吉祥三宝高科纺织有限公司

Moisture-absorbing air-permeable silk composite fiber and preparation method thereof

InactiveCN104213248AAntibacterialWith deodorizing adsorptionConjugated cellulose/protein artificial filamentsArtifical filament manufacturePyrophosphatePolyphenol

Disclosed moisture-absorbing air-permeable silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-19 parts of silk, 13-15 parts of camel hair, 7-9 parts of coral fleece, 10-12 parts of ramie fiber, 8-11 parts of PTT short fiber, 5-7 parts of soybean fiber, 2.3-4.7 parts of milk protein fiber, 0.4-0.8 parts of tea polyphenol, 1.2-3.2 parts of plastic starch, 0.3-0.6 parts of sodium pyrophosphate, 1.2-2.4 parts of cocounut oil essence, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 1-2 parts of frankincense, 0.5-0.9 parts of sediment of human urine, 0.6-0.8 part of flos lonicerae, 2-4 parts of an auxiliary agent, and proper amount of water. By adding ramie fiber, the silk composite fiber has functions of resisting bacteria, inhibiting bacteria, eliminating and adsorbing odor, absorbing moisture and breathing, and the like, and by adding tea polyphenol, the improved silk composite fiber also has effects of resisting radiation, being smooth and light, keeping warm and resisting static electricity.

Owner:TONGCHENG SHUANGLONG SILK

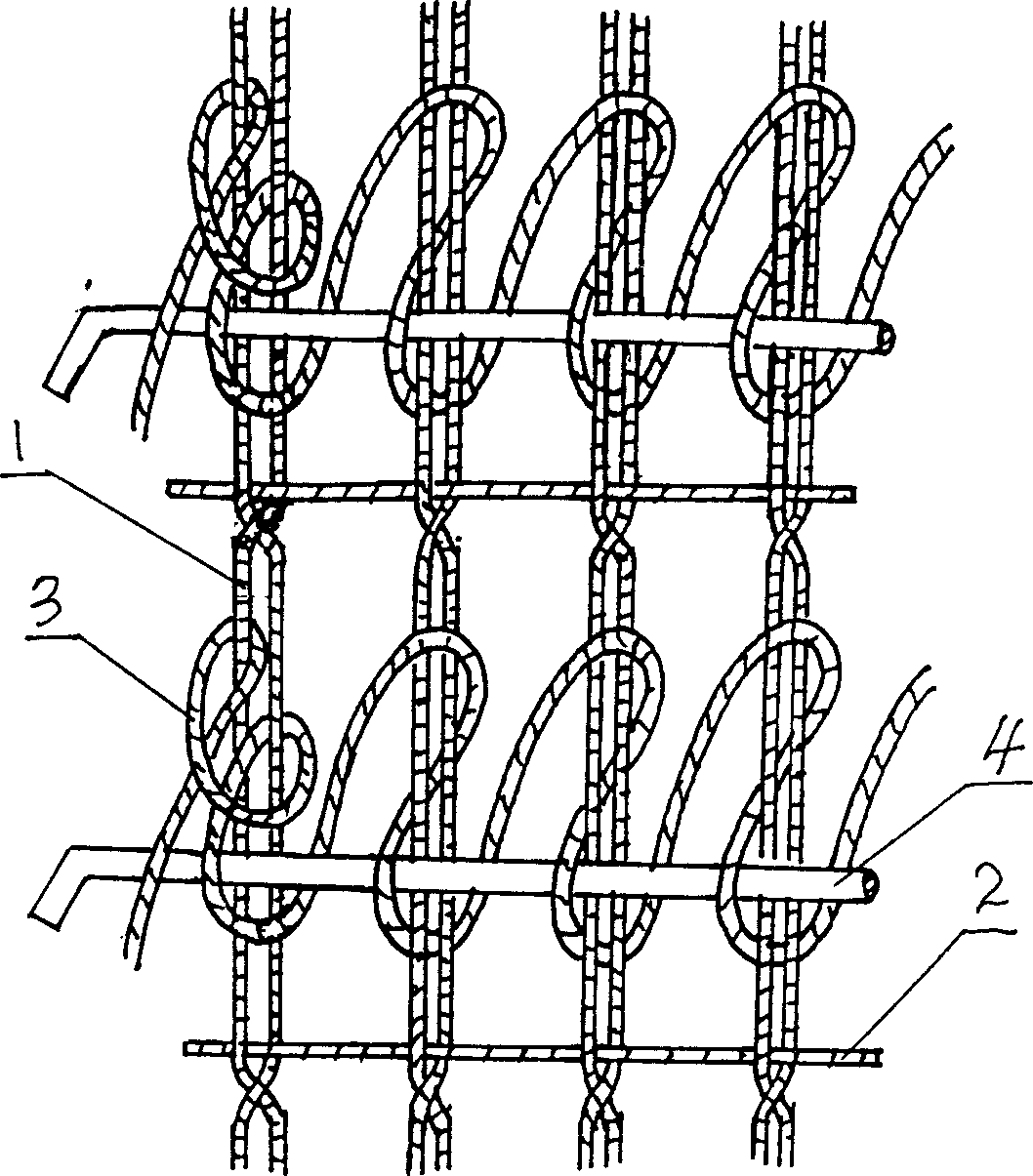

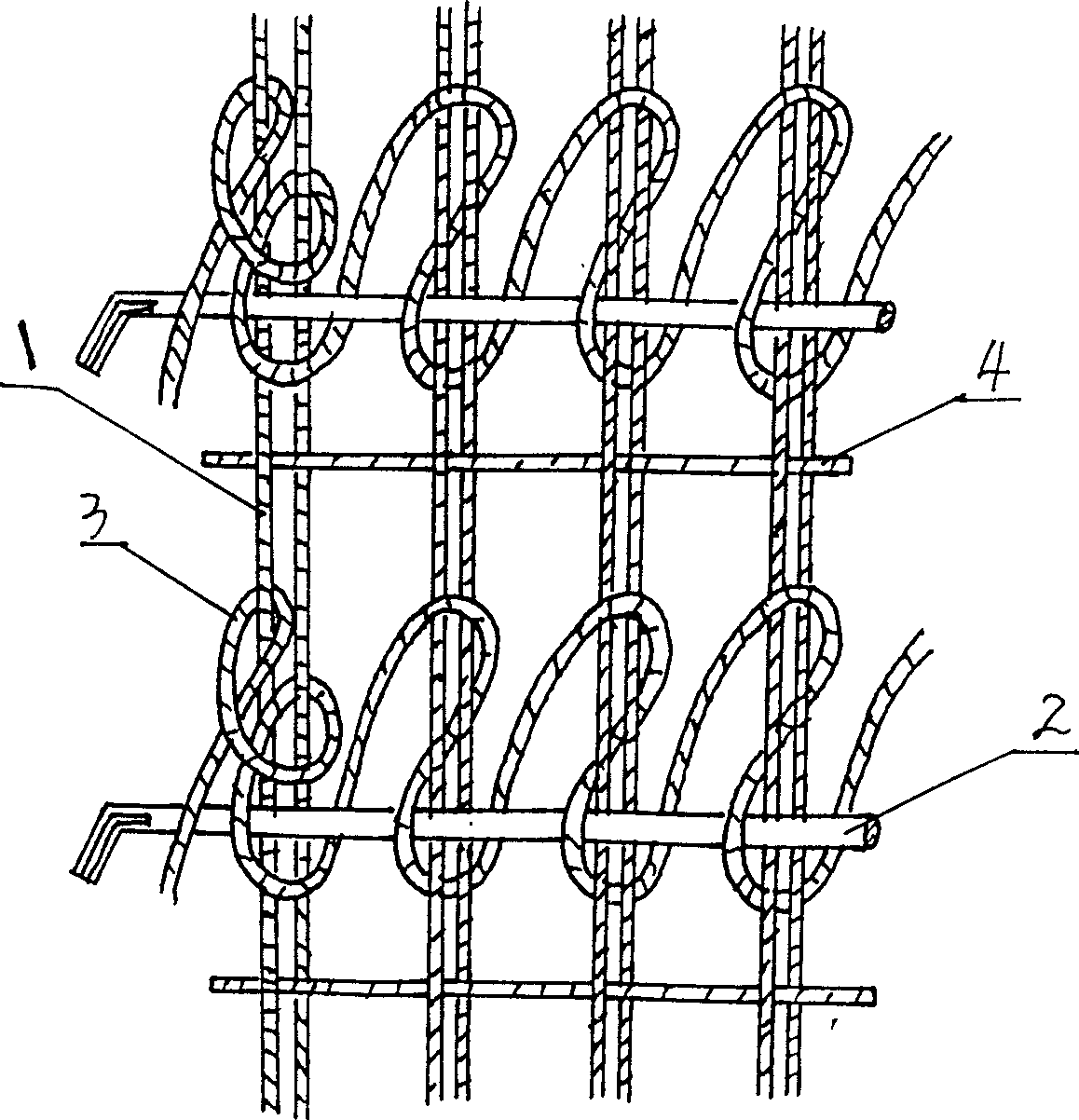

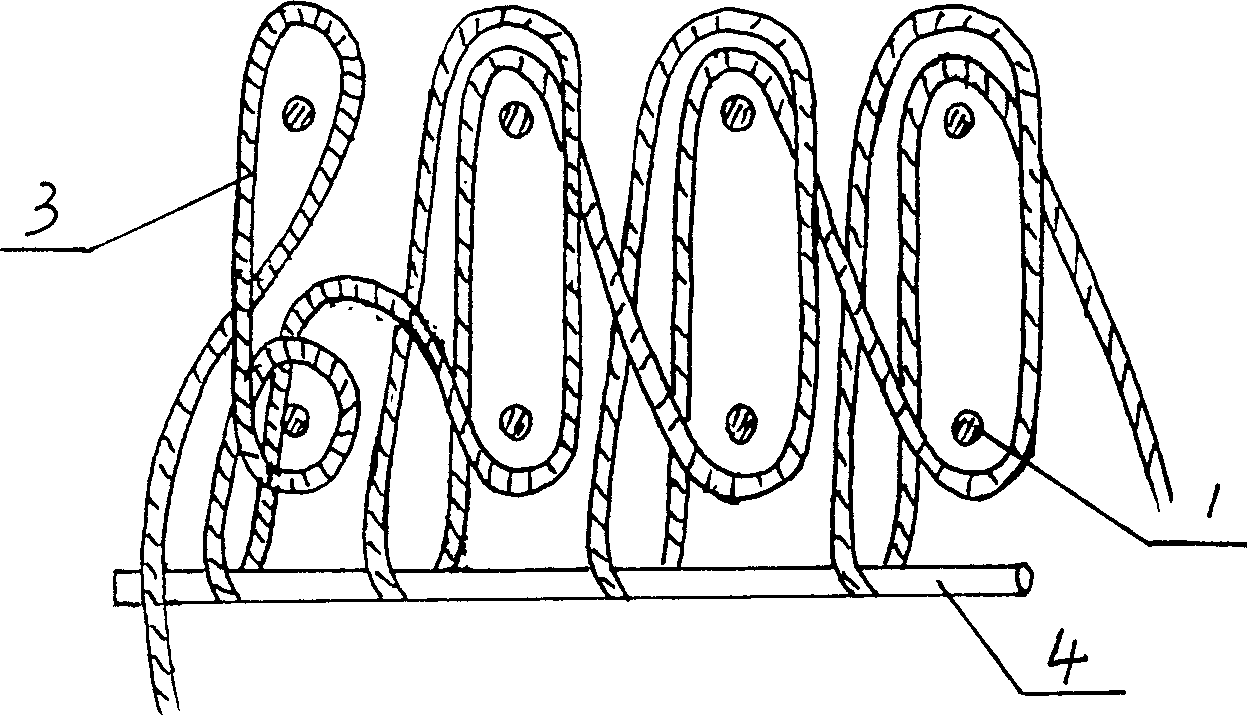

Down textile carpet and its weaving and knot tying method

A braided carpet is composed of warps, wefts and hair yarns chosen from cashmere yarn, ox hair yarn, and camel hair. When it is braiding, the "fixed knot" and "braiding knot" are used. For the braiding knot, the hair yarn by-passes the two warps to form a U-shaped ring and then be pulled out forward through the gap between said two warps and annothe two warps to sleeve on a braiding rod, forming a complete braiding knot. Its advantages are good handle, natural lustre and not dropping hair.

Owner:青海藏羊地毯(集团)有限公司

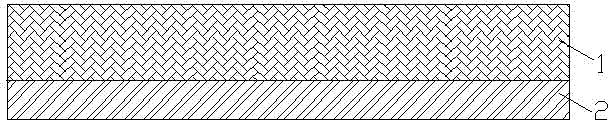

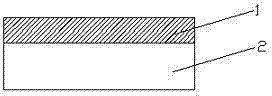

Soft and abrasion-resistant denim fabric

InactiveCN102963047AImprove wear resistanceGood warmth retentionLayered productsSoft layerCamel hair

The invention discloses a soft abrasion-resistant denim fabric which comprises a surface abrasion-resistant layer and an inner elastic soft layer, wherein the abrasion-resistant layer is woven of warp yarns and weft yarns; the warp yarns are blended and woven of khaki fibers and sateen fibers, and the weft yarns are blended and woven of mohair fibers and camel hair fibers; and the elastic soft layer is blended and woven of imported long lint fibers and acrylic fibers. The abrasion-resistant layer is made from soft and thick fabrics with good abrasion resistance, such as the khaki fiber, the sateen fibers, the mohair fibers and the camel hair fibers, so the abrasion-resistant layer is soft in handfeeling and abrasion-resistant and has no rough feeling; and the inner layer is blended and woven of the imported long lint fibers and the acrylic fibers, so the inner layer is soft, elastic and comfortable and in well fit with a body and has a very good warm-keeping effect.

Owner:常熟市东鑫经纬编织造有限公司

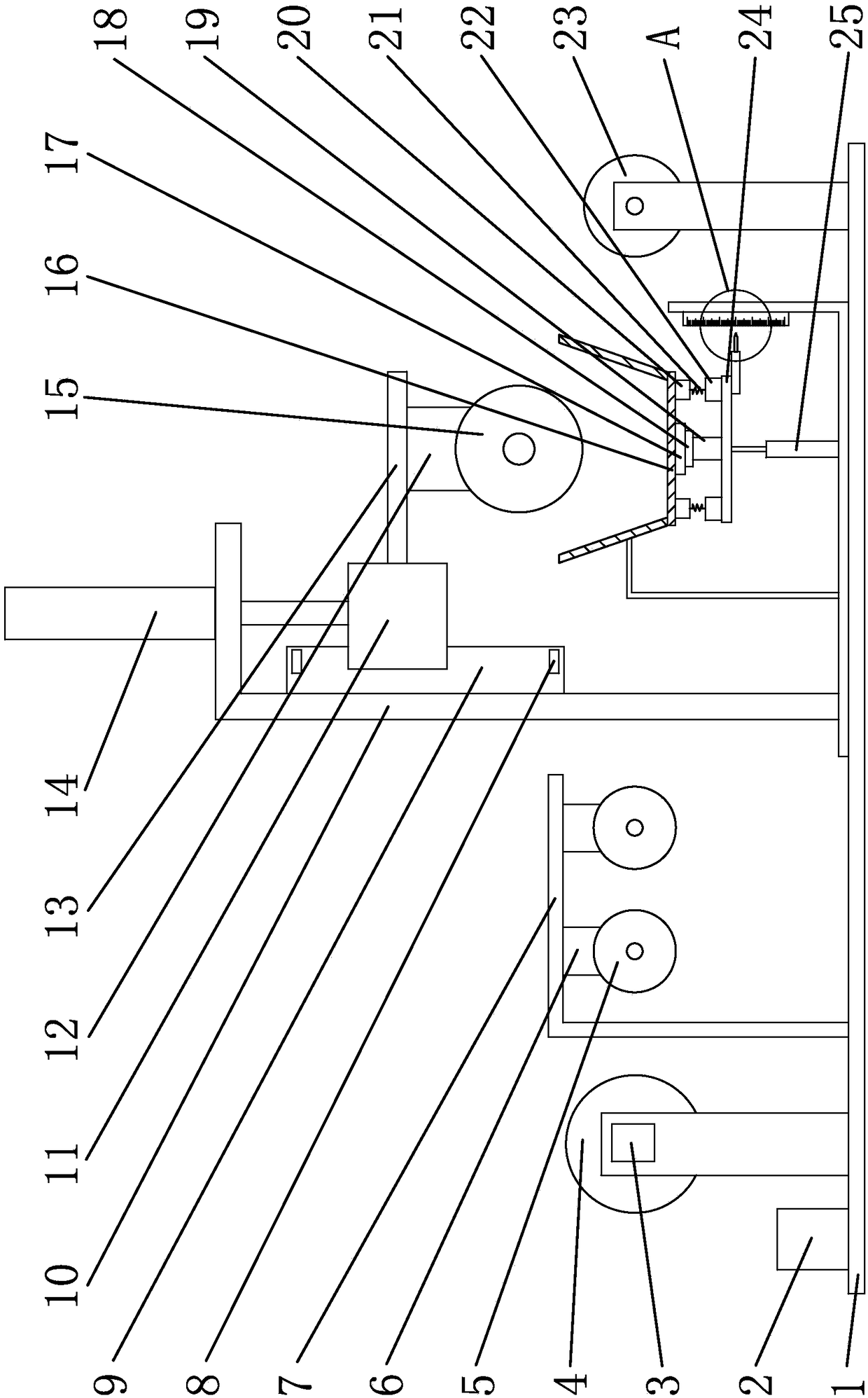

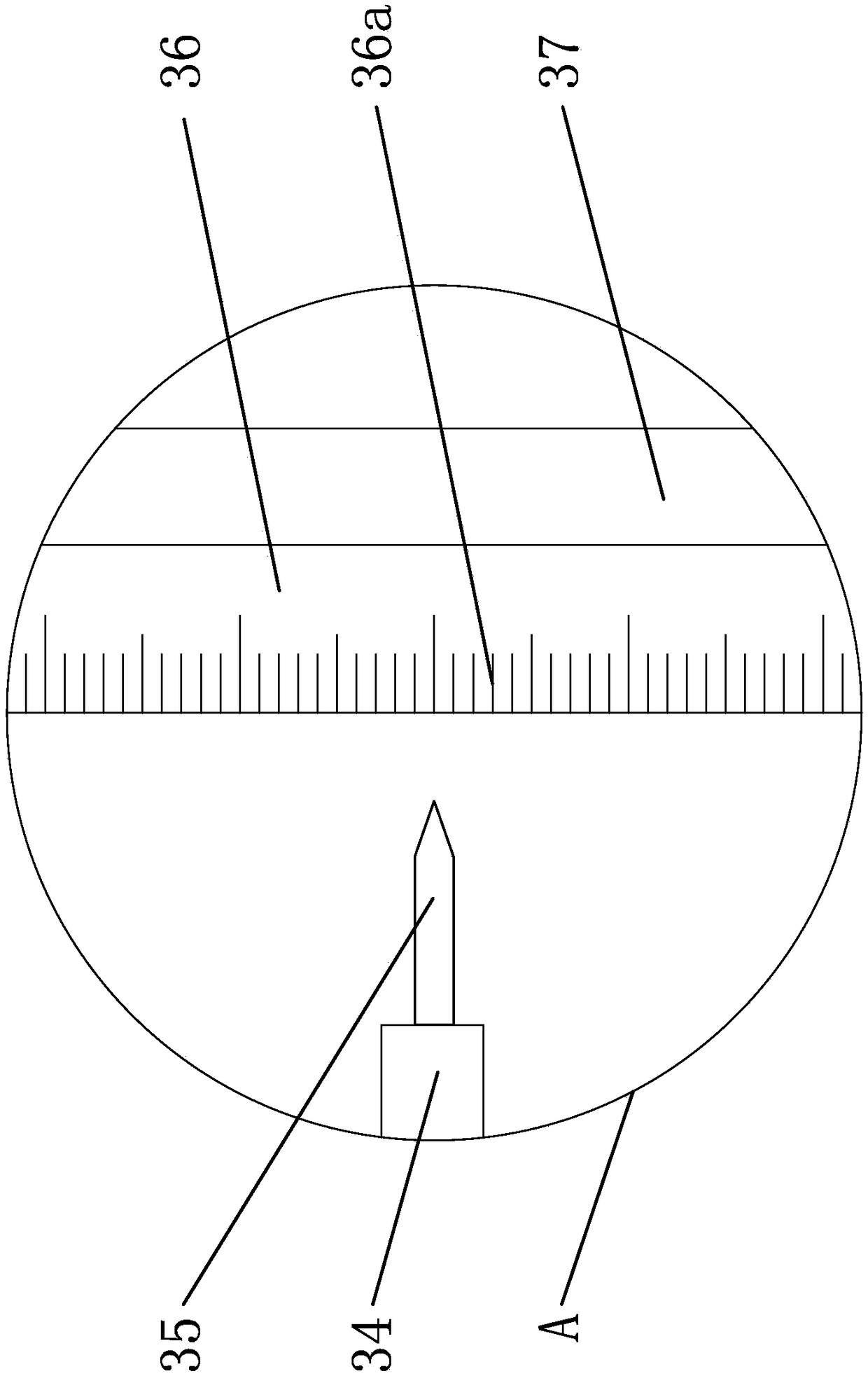

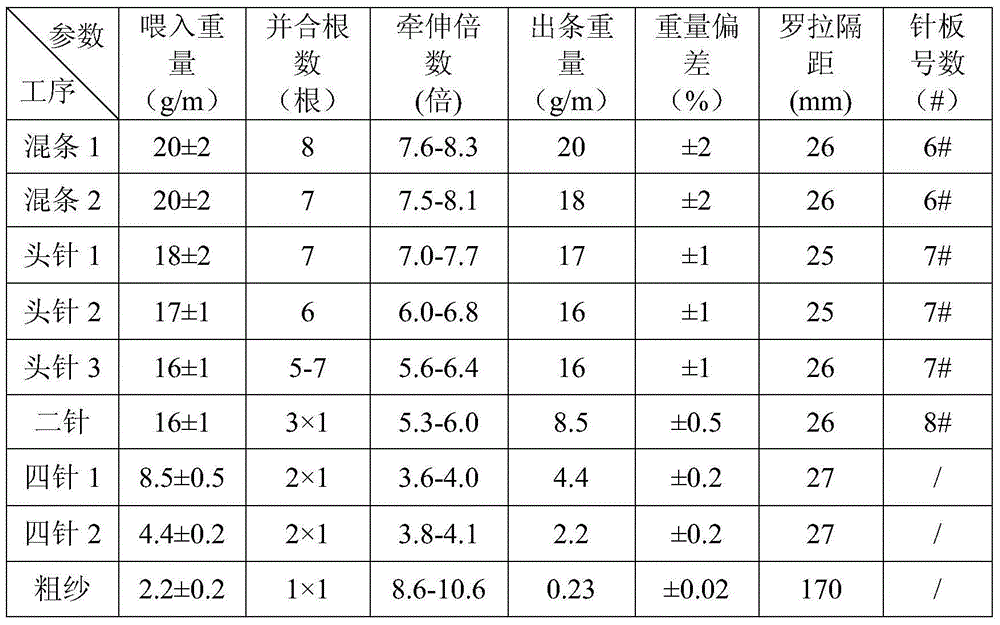

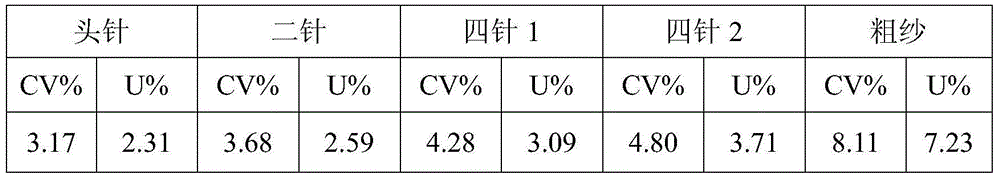

Process for spinning super-high count yarns/camel hair combed yarns

The invention discloses a process for spinning super-high count yarns / camel hair combed yarns. The process comprises the following specific steps: carding, combing, performing primary sliver mixing, performing double combing, performing secondary sliver mixing, roving and spinning. According to the mode, due to the process for spinning super-high count yarns / camel hair combed yarns of more than 200Nm, disclosed by the invention, the yarns are low in hairiness and even in running thread, the prepared yarns are high in tensile properties, and the wear resistance, running threads, gloss, card neps and the like meet the usage requirements of high-grade thin and light camel hair combing woven fabrics.

Owner:张家港中孚达绒业科技有限公司

Manufacturing process of multifunctional composite fabric

ActiveCN108466471AAchieve preparationFast productionLaminationLamination apparatusPolyesterCamel hair

The invention provides a manufacturing process of a multifunctional composite fabric. The technical problems that an existing multifunctional composite fabric has no corresponding manufacturing process, slow manufacture speed and the like are solved. The manufacturing process comprises the following steps of a, manufacture of a surface layer: blending, by weight, polyester fiber 35-45%, activatedcarbon fiber 24-32%, camel hair fiber 10-20% and alginate fiber 6-12% to weave a first fabric; applying protective liquid to both surfaces of the first fabric by using a surface treatment device to obtain the coated first fabric, namely, the surface layer; b, manufacture of a lining layer: blending, by weight, cotton fiber 25%-35%, hemp fiber 15-20%, mulberry silk fiber 25-35% and alginate fiber 15-20% to weave a second fabric as the lining layer; c, bonding: bonding the surface layer and the lining layer by using a laminating machine to prepare the multifunctional composite fabric. The manufacturing process has the advantage of fast production speed.

Owner:SHANGHAI JIABO CLOTHING SCI & TECH

High-count combed camel hair woven yarn

The invention relates to high-count combed camel hair woven yarn. The high-count combed camel hair woven yarn is formed by blending 50% of camel hair fiber and 50% of water-soluble vinylon fiber, wherein the metric count of actually-spun yarn is 100 Nm / 2, the metric count of vinylon-dissolved yarn is 200 Nm / 2, the single yarn twist coefficient is 105, and the doubled yarn twist coefficient is 87. A manufacturing method of the yarn includes the steps that oiling and life preserving are conducted on camel hair fiber and pile, combed camel hair strips are formed through the carding procedure, the gilling procedure, the combing procedure and the gilling procedure, the camel hair strips are mixed, oiling and life preserving are conducted on the mixed strips, and drawing silver suitable for spinning production is manufactured after the strips and 50% of vinylon strips are mixed, combined and combed; the camel hair and vinylon fiber blended yarn is manufactured through the other seven procedures of pre-spinning, the spun yarn procedure, the spooling procedure, the doubling procedure, the two-for-one twisting procedure, a product is formed by the yarn through beaming and weaving, and the high-count combed camel hair woven yarn is obtained after water-soluble vinylon fiber is dissolved and removed in the normal washing and contracting process. The input-output ratio of the produced vinylon-treated high-count camel hair blended woven yarn is higher than that of normal pure camel hair yarn, and fabric is lighter and thinner.

Owner:宁夏嘉源绒业集团有限公司

Fox pile knitted underwear

The present invention belongs to the field of textile technology, and is especially knitted fox fleece underwear. The knitted fox fleece underwear contains fox fleece in 1-100 wt%, preferably in 40-75 wt%, as well as polyurethane fiber, Jinlun, soybean protein fiber, Tencel, modal fiber or viscose fiber, shinkproof mercerized wool and / or long staple cotton. The knitted fox fleece underwear has the advantages of underwear of cashmere, underwear of rabbit fleece and underwear of camel hair, and is superior to the later mentioned underwears. In addition, the fox fleece is the side product of fox fur processing, so that the present invention is the technology of reusing the resource.

Owner:济南元首针织股份有限公司

Low-temperature plasma pre-treatment process

InactiveCN104674577AGood hair effectGood moisture absorptionSucessive textile treatmentsDyeing processCamel hairPolymer science

The invention relates to a low-temperature plasma pre-treatment process which is characterized by comprising the following steps: sorting wool; washing wool; drying; carrying out low-temperature plasma treatment; sizing and the like. The invention is the low-temperature plasma pre-treatment process which is clean and uniform to treat and has water-saving and energy-saving effects, and the surface hydrophilic performance of spinnable blanket wool (yak hair, wool, camel hair and the like) is effectively improved, so that the dyeing property of the wool is improved, and the dyeing, coating and bonding performances are improved.

Owner:青海大自然地毯纱有限公司

Preparation method and dry-wet spinning method of regenerated protein chitosan blended solution

InactiveCN103114351BIncrease elasticityImprove uniformityArtificial filament washing/dryingConjugated cellulose/protein artificial filamentsTextile fiberProtein solution

The invention relates to a preparation method and a dry-wet spinning method of a regenerated protein chitosan blended solution. The preparation method comprises the steps of: carrying out ultrafine grinding on raw materials of leftovers of reeling silks and leftovers of animal coarse hairs such as goat hairs, pig hairs, camel hairs and wools, dissolving the crushed raw materials in an ionic liquid to obtain a regenerated protein solution with high molecular weight, and blending the regenerated protein solution with a chitosan liquid to obtain a spinning solution. The spinning solution is molded by using a dry-wet spinning technology, the structure uniformity and the orientation degree of fibers are enhanced through solidification and drafting, and the elongation and the elasticity of the fibers are improved through oxidation crosslinking. The regenerated protein chitosan blended fiber has high protein content, and has functions of bacteria resistance, moisture prevention and promotion of blood coagulation and wound healing; and all compositions in the fiber are in biomass states, have good biodegradability and biocompatibility and can be applied to textile fibers and biomedical materials.

Owner:河南鼎大生物科技有限公司

Method for producing dyeing-free camel hair and yak wool blended fabric

The invention discloses a production method for mixed fabric of dyed-free lambsdown and yakwool, and aims to provide a production method for mixed fabric of lambsdown and yakwool, which needs no color stripping and dyeing and does not decolor. The production method comprises the following steps: using the lambsdown and the yakwool with natural colors to produce yarns, using the yarns to weave grey cloth with different component proportions and / or different colors, and treating the grey cloth through the prior post treatment to produce the mixed fabric of the lambsdown and the yakwool. The production method makes full use of the natural colors of the lambsdown and the yakwool to mix colors and spin the mixed fabric of the lambsdown and the yakwool, the mixed fabric does not decolor without stripping treatment and chemical dyeing, has natural color, does not produce pollutant during production, does not cause damage to the lambsdown and the yakwool materials, has low production cost, is a pure natural environment-friendly fabric, has greatly promoted grade, and has more competitiveness and economic benefit compared with common fabrics.

Owner:浙江神州毛纺织有限公司

Wool fabric

InactiveCN102943394AIncrease elasticityStrong warmth retentionTextiles and paperCamel hairWear resistant

The invention discloses a wool fabric which comprises the following raw materials in parts by weight: 40-50 parts of wool fiber, 18-22 parts of camel hair fiber, 8-10 parts of silk fiber, 6-8 parts of soybean protein fiber and 10-14 parts of lycra fiber. The wool fabric is good in elasticity, crease resistant, durable, wear resistant, excellent in heat retention property, comfortable and attractive.

Owner:HAIAN COUNTY HENGYUAN SILK FACBRICS CO LTD

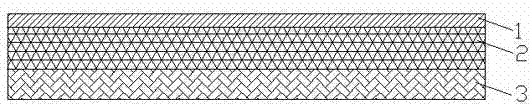

Windproof insulating fabric

The invention discloses a windproof insulating fabric which comprises a heat-absorbing insulating layer on the surface layer and a windproof fabric layer on the inner layer, wherein the heat-absorbing insulating layer is formed by blending heat-absorbing glass fiber and camel hair fiber; the windproof fabric layer is formed by weaving warps and woofs mutually; the warps are formed by blending acrylic fiber and chinlon fiber; and the woofs are formed by blending khaki fiber and lint fiber. As the surface layer is formed by blending heat-absorbing glass fiber and camel hair fiber, heat is absorbed, and the fabric with the heat-absorbing insulating layer not only can absorb heat and be insulating, but also is wear-resistant and warm; as the inner layer is formed by blending wear-resistant, comfortable, windproof and warm fabric fiber, the fabric has a close-fitting fabric layer which not only is windproof, but also is warm and comfortable when worn by a user; and the insulating layer on the outer layer transmits heat to the inner layer, so that the user wearing the windproof heat-insulating fabric can feel warm.

Owner:WUJIANG DONGXU TEXTILE CLOTH FIRM

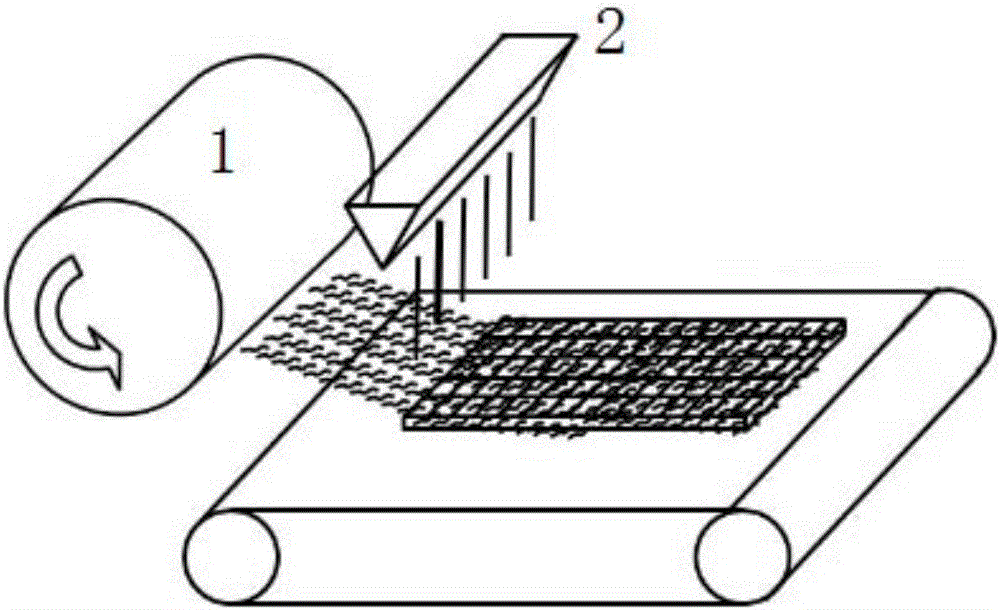

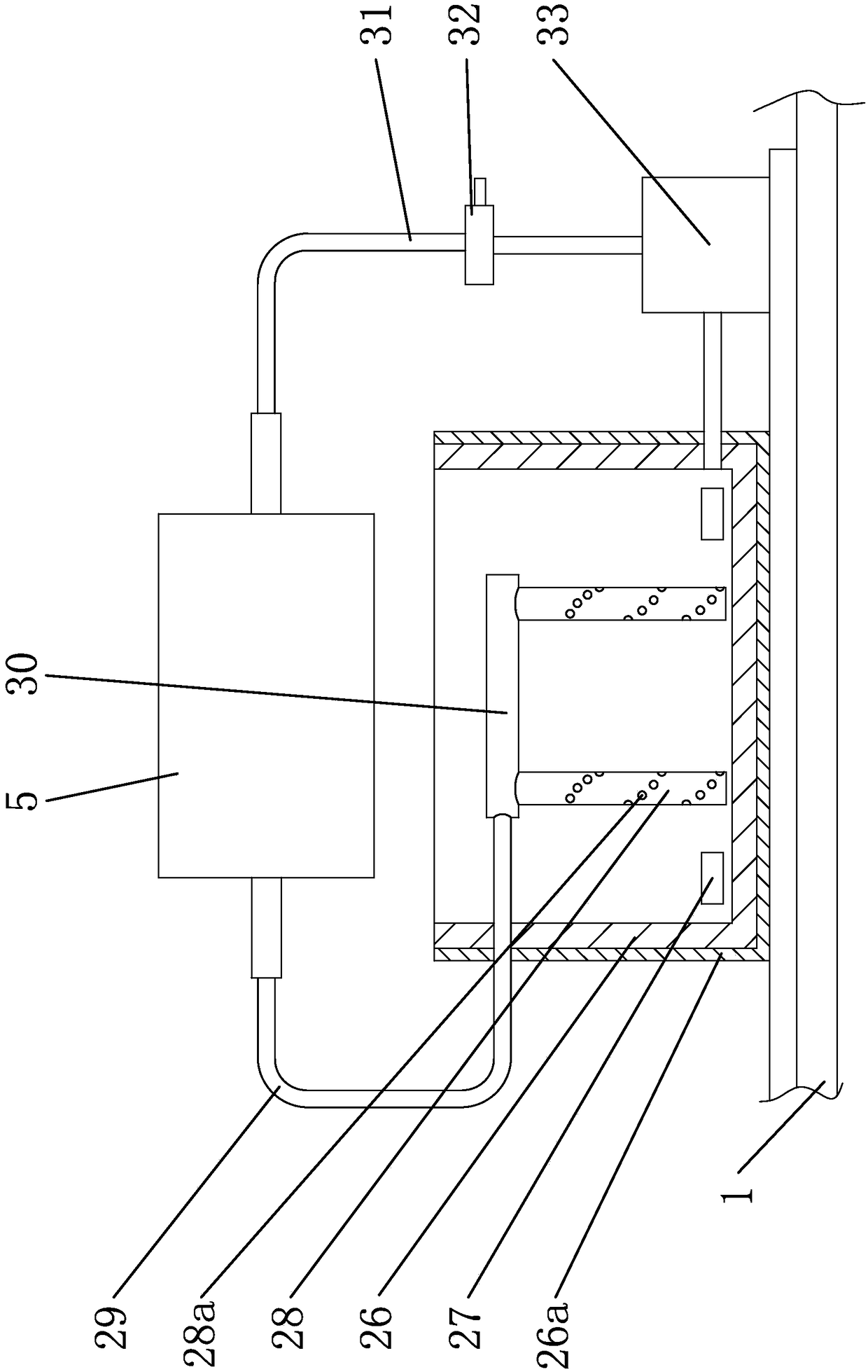

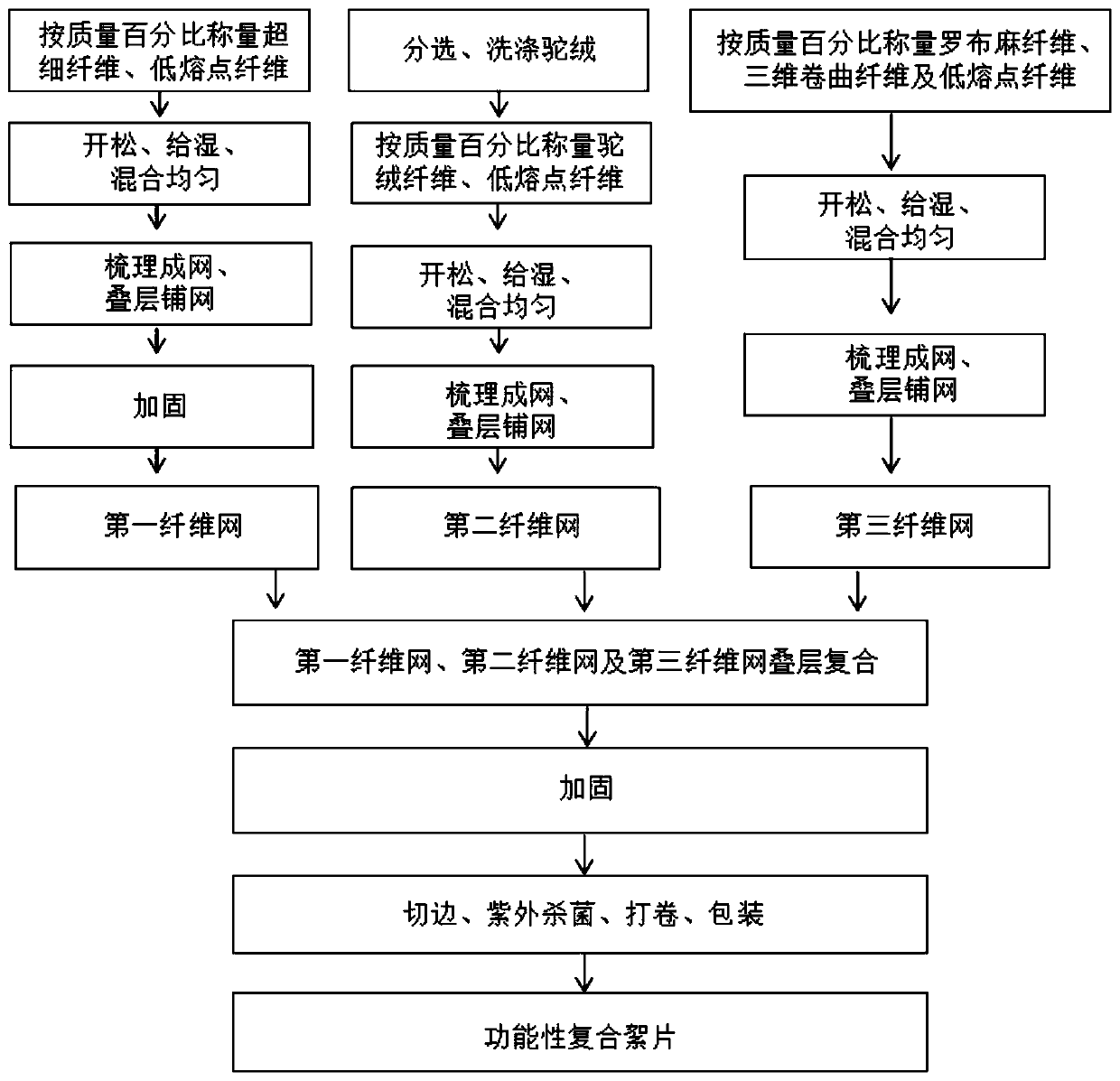

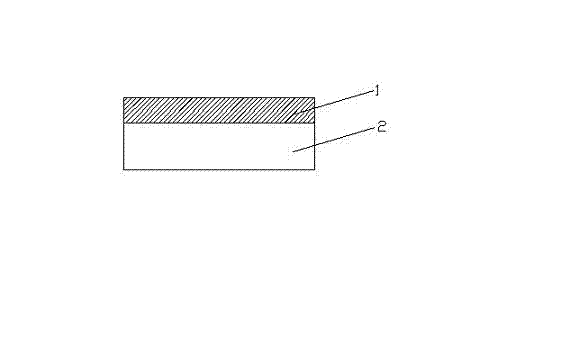

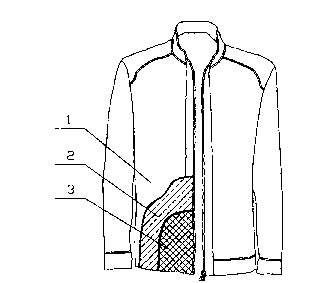

Preparation method of windproof warm camel hair composite flake

ActiveCN110241512AHigh densityStrong wind resistanceNon-woven fabricsAdhesivesCamel hairOptoelectronics

The invention relates to a windproof warm camel hair composite flake and a preparation method thereof. The preparation method comprises the following steps that firstly, a fiber raw material of a first fiber net is carded into a net, laid flat, stacked and reinforced to prepare the first fiber net, then fiber raw materials of a second fiber net and third fiber net are carded into nets, laid flat and stacked to prepare the second fiber net and the third fiber net respectively, the first fiber net, the second fiber net and the third fiber net are laid flat, stacked and reinforced in sequence, the reinforced flake is subjected to side cutting, ultraviolet sterilization, rolling and packaging to prepare the windproof warm camel hair composite flake, and the finally prepared windproof warm camel hair composite flake has a composite layer structure, and comprises the first fiber net, the second fiber net and the third fiber net which are adjacent to one another and connected through low melting point fiber bonding in sequence. The windproof warm camel hair composite flake and the preparation method thereof have the advantages that by adopting a composite fiber, and designing the fiber nets in layers, the windproofness and warmth retention of the camel hair flake are improved, and the flake is endowed with an anti-static function and other health care functions.

Owner:XINJIANG HABAHE YAJU BEDDING & GARMENTS

Production process for vicugna double-faced woolen fleece

The invention discloses a production process for vicugna double-faced woolen fleece. The production process for the vicugna double-faced woolen fleece comprises the following process steps: preparingthe following raw materials of the vicugna double-faced woolen fleece in percentages by weight: 50% of camel hair cloth fibers, 25% of Australian wool top fibers with the quality number being 66S and25% of Australian wool top fibers with the quality number being 70S; preparing dyed or non-dyed camel hair cloth fibers into coarse yarns with the metric count being 14 / 1 by willey, carding, mule spinning and an automatic spooling process; preparing the dyed or non-dyed Australian wool top fibers with the quality number being 66S and the dyed or non-dyed Australian wool top fibers with the qualitynumber being 70S into coarse yarns with the metric count being 14 / 1 by willey, carding, mule spinning and an automatic spooling process; carrying out warping on the obtained yarns; weaving the spun yarns on a rapier loom by a single-warp and single-weft mode; and successively carrying out hemming, fulling, scouring of wool fabric, dewatering, drying, decatizing, fuzzing, burring, drying, scaldingscissoring and decatizing processes on the woven cloth to obtain the finished product. The double-faced woolen fleece feels soft, and is high in heat-insulation property.

Owner:江阴市长泾花园毛纺织有限公司

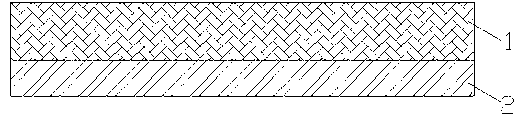

Cold-proof and health care fabric

The invention discloses cold-proof and health care fabric, which comprises a surface layer and an inner layer. The surface layer is covered on the outer surface of the inner layer, the surface layer is formed by blending polyester and polyamide, the inner layer is made of camel hair fibers, and the polyester is made of polyester fibers. The polyamide is made of polyamide fibers, and the camel hair fibers are of porous hollow bamboo joint structures. The cold-proof and health care fabric can have cold-proof and heath care functions when being worn so as to be particularly suitable for use of old people and children and in gloomy, cold and wet areas.

Owner:CHANGSHU FUJIALI WEAVING

Soft leather fabric

InactiveCN102963051ASoftSoft and comfortable to wearSynthetic resin layered productsCamel hairSoft layer

The invention discloses a soft leather fabric which comprises a superficial soft layer, a leather layer and close-fitting layer, wherein the leather layer is located below the soft layer; the close-fitting layer is located below the leather layer; the soft layer is a thin-film layer which is formed by polyimide fibers; the leather layer is made of fish leather; the close-fitting layer is an elastic layer which is formed by mutually knitting warps and wefts; the warps are formed by blending and knitting tribute silk fibers and mohair fibers; and the wefts are formed by blending and knitting cashmere fibers and camel hair cloth fibers. The superficial soft layer is the thin-film layer which is formed by knitting the polyimide fibers, so that the mechanical property is good, abrasion is difficulty to occur and soft hand feel is provided; the leather layer is formed by the fish leather, so that the material is soft and the hand feel is good; the close-fitting layer is formed by blending and knitting elastic and soft fabrics, so that the prepared fabric is soft and comfortable to wear; and at the same time, according to the elastic fabric, the clothing is close-filling, warm and non-breathable.

Owner:CHANGSHU FUYI PRINTING & DYEING

Wind-resistant comfortable denim fabric

The invention discloses a wind-resistant comfortable denim fabric. The wind-resistant comfortable denim fabric comprises a denim wind-resistant layer and a comfortable layer, wherein the denim wind-resistant layer is positioned on a surface layer; the comfortable layer is positioned on an inner layer; the denim wind-resistant layer is formed by weaving warp threads and weft threads; the warp threads are formed by weaving nylon fibers and viscose fibers in a blending way; the weft threads are formed by weaving polyester ramie blend fibers; and the comfortable layer is formed by weaving orlon fibers and camel hair fibers in a blending way. The denim fabric disclosed by the invention is abrasion-resistant and wind-resistant when worn by being weaved in a blending way by adopting abrasion-resistant fabrics and wind-resistant fabrics, thereby preventing a human body from being blown by cold wind and keeping the human body warm; and the denim fabric disclosed by the invention is comfortable and close-fitting to wear as the inner layer is formed by weaving soft and elastic fabrics.

Owner:苏州金尚豪纺织有限公司

Warm-keeping camel hair fur clothing

The invention discloses warm-keeping camel hair fur clothing which comprises a leather shell fabric layer and a lining layer. A camel hair warm-keeping layer is arranged between the leather shell fabric layer and the lining layer, the leather shell fabric layer is first-layer full-grain face leather, the lining layer is made of silk acupuncture cotton, the thickness of the camel hair warm-keeping layer is 5-15cm, and the mass per unit is 120-360g / m2. Through the mentioned mode, the warm-keeping camel hair fur clothing is soft and fine, camel hair warm keeping can reach a five-grade cold-proof standard, the silk layer can be attached to the skin better, and unprecedented advanced matching is achieved.

Owner:扬州茱萸珠宝实业有限公司

Heat-insulation heat-retention fabric

The invention discloses a heat-insulation heat-retention fabric. The heat-insulation heat-retention fabric comprises a heat-insulation fabric layer and a heat-retention comfortable fabric layer, wherein the heat-insulation fabric layer is positioned on a surface layer; the heat-retention comfortable fabric layer is positioned on an inner layer; the heat-insulation fabric layer is formed from warp yarns and weft yarns; the warp yarns are formed from camel hair fibers; and the weft yarns are formed from 100% merino wool. According to the invention, the heat-insulation fabric layer which has the advantages of heat resistance and hand feeling is formed by blending glass fibers with high heat resistance and mulberry silk fibers with better heat resistance, and the inner layer is formed by adopting elastic heat-retention fabrics, so that comfortableness and heat-retention during wear can be achieved.

Owner:苏州金尚豪纺织有限公司

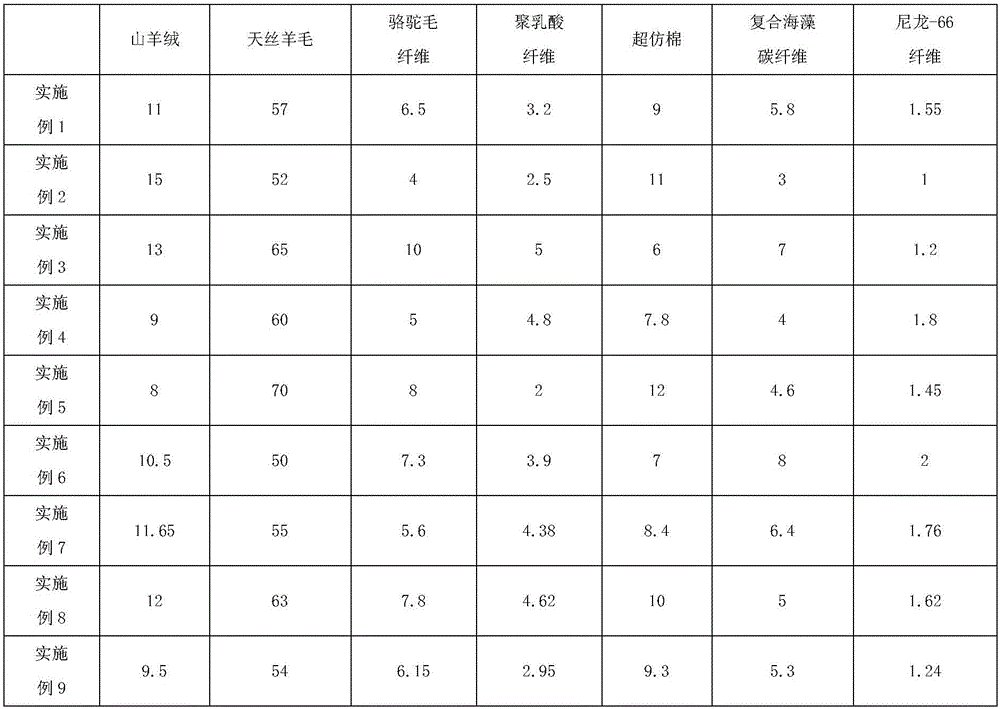

Blended woolen sweater

InactiveCN105876901AComfortable and smooth to the touchBeautiful feelYarnProtective garmentCamel hairCarbon fibers

The invention provides a blended wool sweater, which includes the following raw materials: cashmere, Tencel wool, camel hair fiber, polylactic acid fiber, super imitation cotton, composite seaweed carbon fiber and nylon-66 fiber; Blended wool sweater is made of a variety of special raw materials. The wool and fiber blended wool sweater feels comfortable and smooth, and has excellent stretch resistance; the blended wool sweater has good affinity with human skin and has a warm effect Remarkable; at the same time, the blended wool sweater is durable and wear-resistant, not only has the effects of flame retardancy, corrosion resistance and antibacterial effect, but also has the functions of moisture absorption and ventilation.

Owner:TAICANG SHARTEX SHENTAI SWEATER

Windproof and water-repellent wool fabric

InactiveCN109249655AImprove the bactericidal effectWater-repellent and breathableBiochemical fibre treatmentCellulosic plastic layered productsNano siliconMasterbatch

The invention provides a windproof and water-repellent wool fabric. The windproof and water-repellent wool fabric has good windproof and water repellent effects, and has certain sterilization function, and the warmth effect is better. The windproof and water-repellent wool fabric comprises a fabric body and a waterproof and breathable sterilizing layer adhered to one side of the fabric body, the thickness of the waterproof and breathable sterilizing layer is 10% to 15% of the thickness of the fabric body, the fabric body comprises the following raw materials in parts by mass: 40-50 parts of wool fiber, 18-22 parts of camel hair fiber, 6-8 parts of soybean protein fiber, 10-14 parts of Lycra fiber, and 6-8 parts of viscose fiber; the waterproof and breathable sterilizing layer is prepared by mixing 40% of collagen fiber, 20% of bamboo fiber, 20% of alga carbon fiber, and 20% of nano antibacterial silver ion masterbatch native fiber by weight percentage; and both side surfaces of the waterproof and breathable sterilizing layer are coated with a treatment layer formed by mixing nano silicon particles and nano titanium dioxide.

Owner:JIANGSU SUNSHINE

Washable light down feather composite fiber and preparation method thereof

InactiveCN104278355AIncrease profitLow costConjugated cellulose/protein artificial filamentsArtifical filament manufactureRhizomeMaterials science

The invention discloses a washable light down feather composite fiber. The washable light down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 12-14 parts of goose down, 15-20 parts of pig hair, 14-17 parts of camel hair, 6-8 parts of plumetis fibers, 10-12 parts of tencel fibers, 7-9 parts of cheviot fibers, 2.1-3.3 parts of sorbitol, 1.2-3.4 parts of glycerol monolaurate, 10-13 parts of grapevine, 1.2-3.1 parts of citric acid, 2-4 parts of phellodendron amurense, 1-3 parts of white atractylodes rhizome, 2-3 parts of the root bark of white mulberry, 0.3-0.5 part of magnesium chloride, 3-5 parts of oxidized castor oil, 100-120 parts of 1-butyl-3-methylimidazolium acetate, 110-130 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 1-3 parts of assistants and an appropriate amount of water. According to the washable light down feather composite fiber, the pig hairs and the camel hairs are added, and therefore, the feather utilization rate is increased and the cost is reduced; and the phellodendron amurense, the white atractylodes rhizome, the root bark of white mulberry and other Chinese herbal medicines are added, so that the washable light down feather composite fiber has the advantages of health keeping, sterilization, excellent breathability, washing durability and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Cotton fibers capable of releasing far infrared negative ions and production method of cotton fibers

InactiveCN104278357AGood antibacterial effectAntibacterial, anti-mite and flame retardantConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsNano al2o3Staphylococcus aureus

The invention discloses cotton fibers capable of releasing far infrared negative ions. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 20-23 parts of cotton fibers, 7-9 part of active carbon fibers, 6-10 parts of camel hair fiber, 10-12 parts of ramie fibers, 5-7 parts of polypropylene fibers, 3-5 parts of fructus xanthii extract, 2-4 parts of far infrared negative ion powder, 1-2 parts of nano aluminum oxide, 1-3 parts of medical stones, 2.1-3.5 parts of hot melt adhesive powder, 15-18 parts of C12 alcohol polyoxyethylene ether, 9-12 parts of citric acid, 12-15 parts of monoacetin, 2-4 parts of divaricate saposhnikovia root, 1-3 parts of isatis tinctoria, 100-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-105 parts of 1-butyl-3-methylimidazolium acetate, 4-6 parts of an addition agent and a proper amount of water. According to the cotton fibers capable of releasing the far infrared negative ions, the fructus xanthii extract is added into the raw materials by using an ultrasonic technology and has a good bacterium inhibition effect on staphylococcus aureus; and meanwhile, active ingredients including the far infrared negative ion powder, divaricate saposhnikovia root, isatis tinctoria and the like are added so that the prepared cotton fibers can release the negative ions beneficial to a human body and also have the effects of resisting bacteria, preventing mites, retarding flame and the like.

Owner:ANHUI SWAN TECH IND GRP

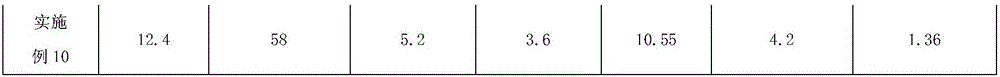

Exposure suit or downy piece of thermal underwear

A down hair sheet for the winter-proofing clothes or heat-insulating underwear is made up of cashmere, camel hair, yak hair, etc through screening down hair, opening, carding, washing, high-temp defatting and disinfecting, applying softening agent, flushing, baking, carding, lapping, covering both surfaces by air-permeable non-woven cloth, covering with cotton cloth and sewing.

Owner:杨魁武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com