Patents

Literature

577results about How to "Less hairy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

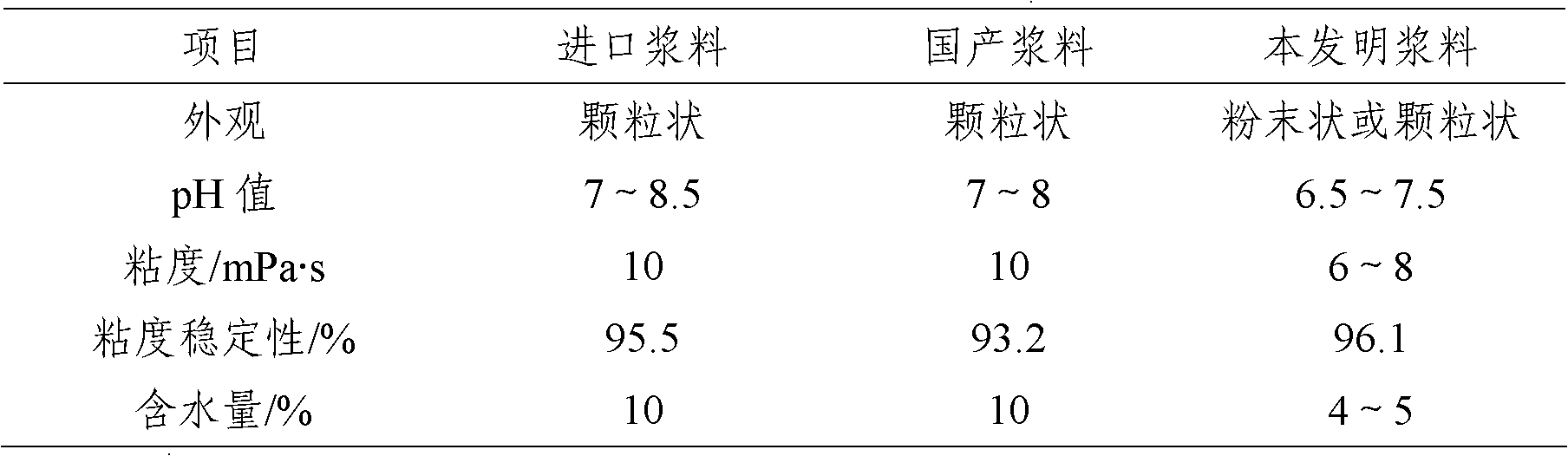

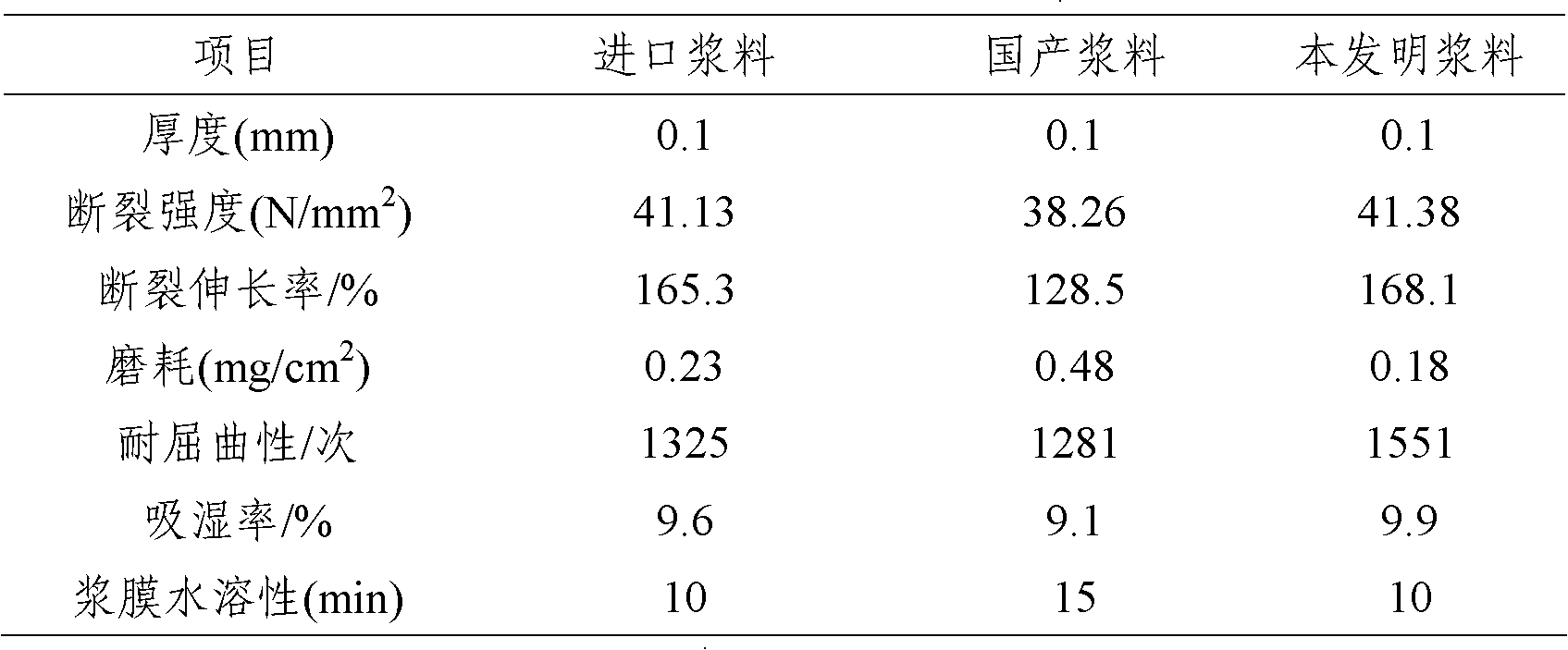

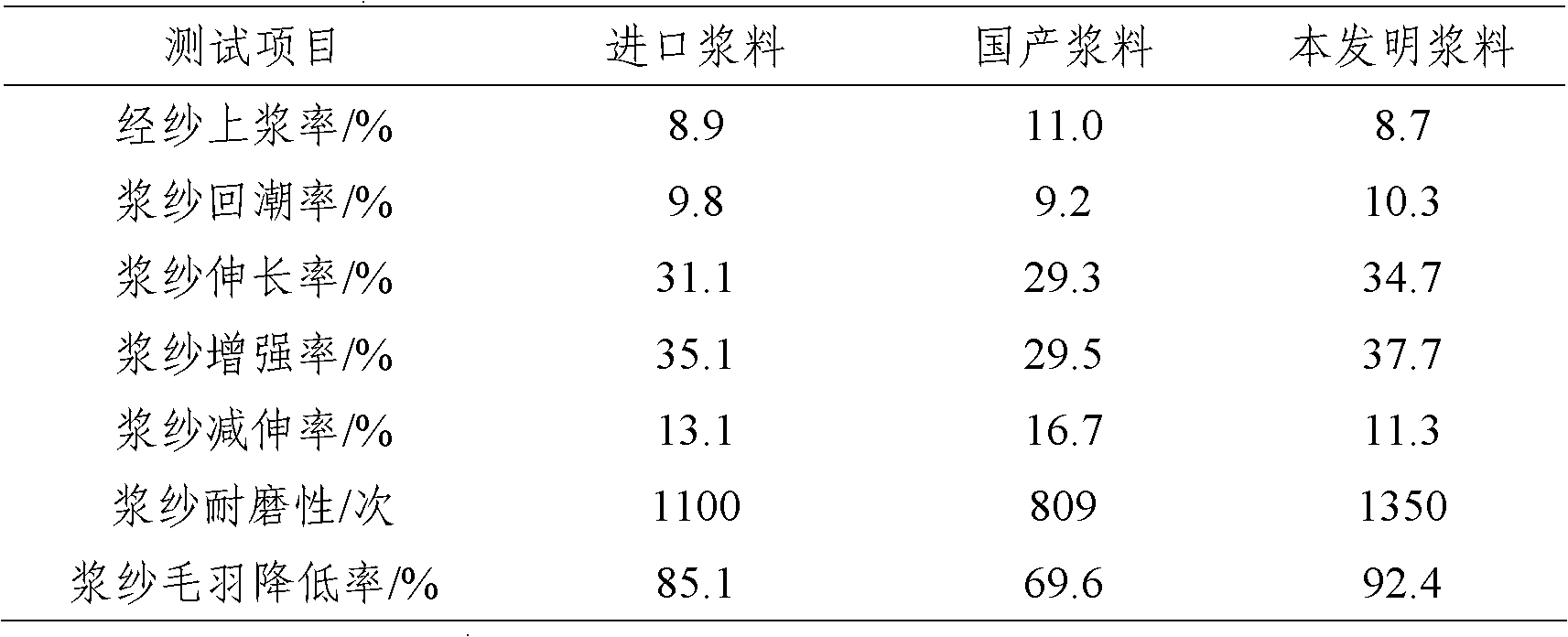

Textile size combination

The invention provides a textile size combination which is prepared by mixing solid acrylate with nano SiO2 compound modified starch in proportion, wherein the solid acrylate is prepared by the following steps: mixing acrylonitrile, methyl acrylate, butyl acrylate, methyl methacrylate, acroleic acid, methacrylic acid with acrylamide in proportion, and enabling the mixed solvent to be subject to internal polymerization under the action of compound initiator and chain transfer agent, neutralizing with sodium hydroxide and drying; and the nano SiO2 compound modified starch is prepared by the following steps: sequentially acidifying, crosslinking and oxidizing starch, introducing surface-modified nano-level SiO2 and carrying out ultrasonic dispersion. The size can obviously improve the warp sizing performance and improve the weaving efficiency, can be completely replace PVA and imported sizes in the same amount or partial amount, and is widely used for the warp sizing of purified cotton, terylens, novel fibers and mixed yarns of various counts.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

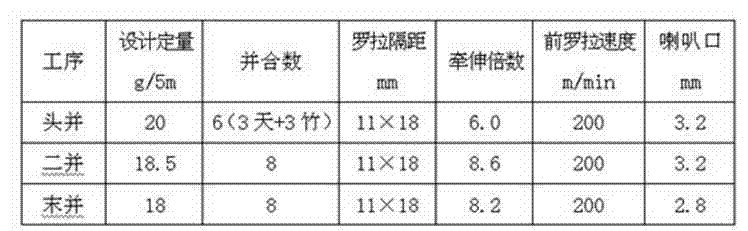

Natural bamboo fiber shirt fabric and manufacture method thereof

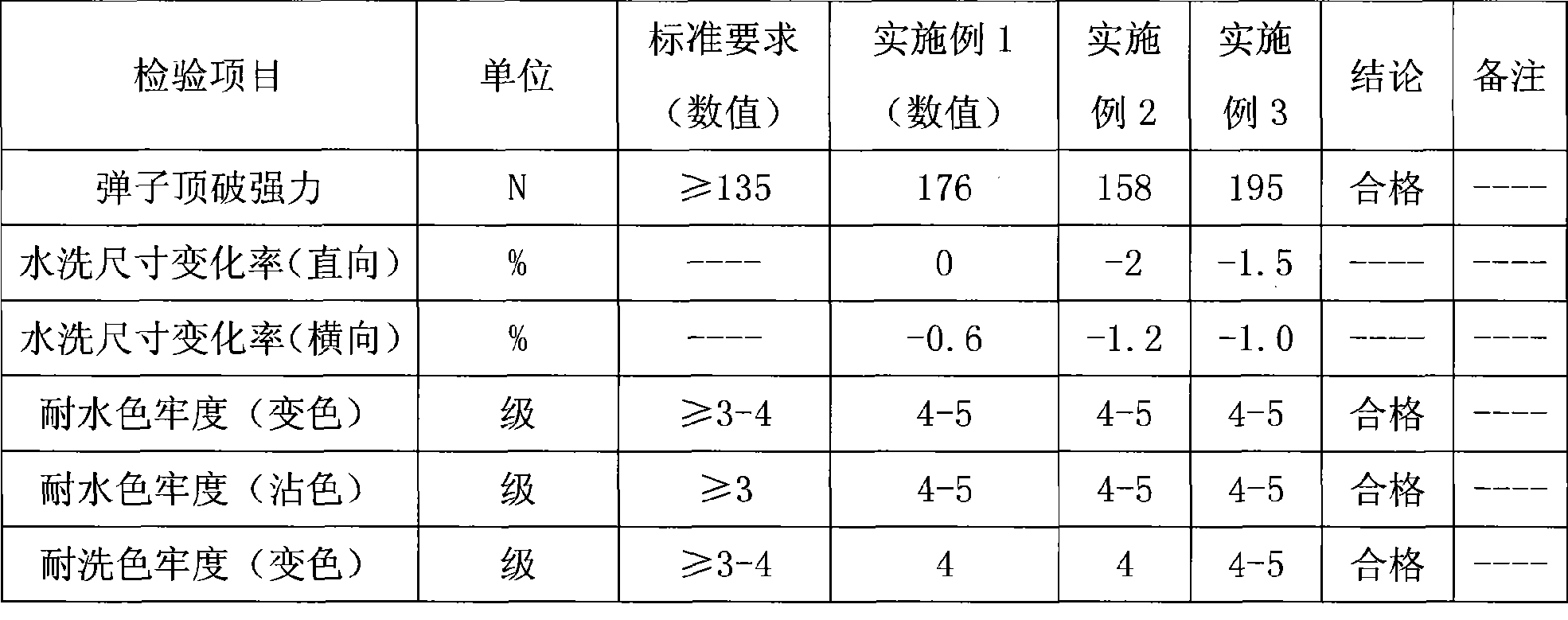

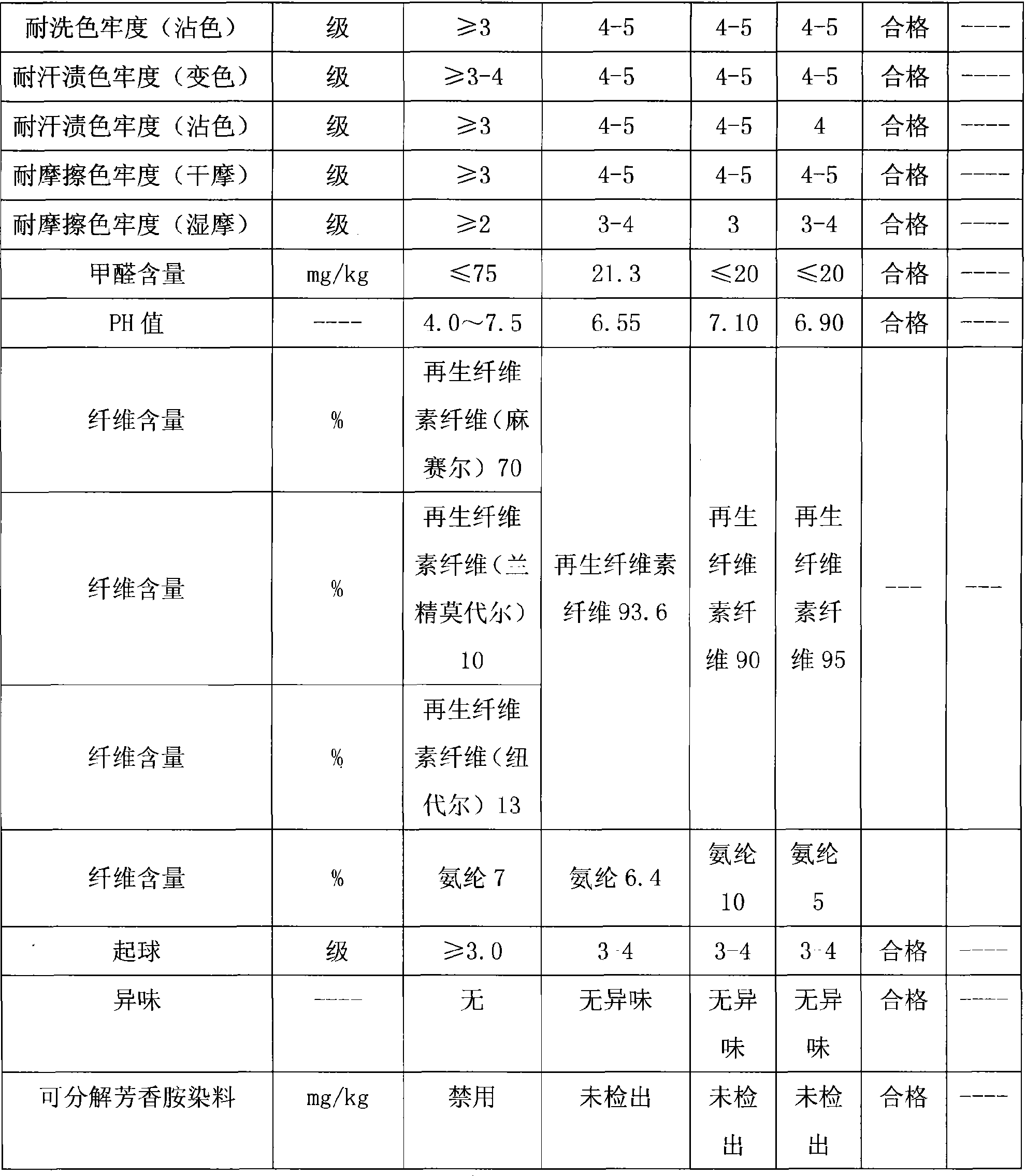

The invention provides natural bamboo fiber shirt fabric which has silky gloss, good feel and drapability, and is rich in graceful feeling, antibiosis, moisture-adsorption and ventilating. Warps and wefts of the fabric are both natural fiber / bamboo viscose blended yarns, the blending ratio of the warps and the wefts is 1:1, the warp density is 512 / 10cm, and the weft density is 338.5 / 10cm. A manufacture method of the natural bamboo fiber shirt fabric comprises the following steps: a, blending: opening picking, carding cotton, drawing out, roving and spun yarn; b, drum yarn dying: tube loosening, pretreatment, dying, dehydration and drying, wherein the pretreatment comprises bleaching and enzyme treatment; during bleaching: soda ash is 1-3g / L, hydrogen peroxide is 1-2g / L, the temperature is 95 DEG C, the time is 35-45min; and during the enzyme treatment, HontonezymePA is 1-1.5g / L, pH value is 4.5-5.5, the bath ratio is 1:15, and the time is 25-35min; and during dying, the drum yarn density is 0.33-0.35g / cm<3>, and MegafixB type reactive dying is adopted; c, weaving: winding, warp pulp connection, drawing in or warp tying and weaving; and d, after treatment: singeing, desizing, sizing and preshrinking.

Owner:JIANGSU YDTEX GRP LTD

Production method of under-twisted yarn towel

The invention discloses a towel manufacturing process, which relates to the textile field. The towel manufacturing process comprises the steps: combed long-staple cotton yarns are woven into a piece of grey cloth by a high speed weaving machine; the grey cloth is soaked into a solution of a continuous washing and bleaching range to remove the impurities and slurries in the cotton yarns; the grey cloth is deoxidized, dyed, enzyme-washed, softened, dried by vibration and sewn into towels. Through adopting the long-staple cotton, shorter fibers are eliminated through fine combing, and the long-staple cotton is spun into yarns through twisting, the fibers are parallel and smooth, the gloss is better, and the hairiness is less. Without the water soluble yarn working procedure, the product woven through soft twist yarns reaches the effect of the non-twisted yarn, the labor intensity of workers is reduced, the sewage treatment pressure is relieved, the problem of the environmental pollution is reduced, and the product service life is prolonged.

Owner:孙日贵

Thin breathable warm fabric and manufacture method thereof

InactiveCN102605523AHigh standardFullnessWeft knittingLiquid/gas/vapor treatment of propelled fabricsYarnMoisture absorption

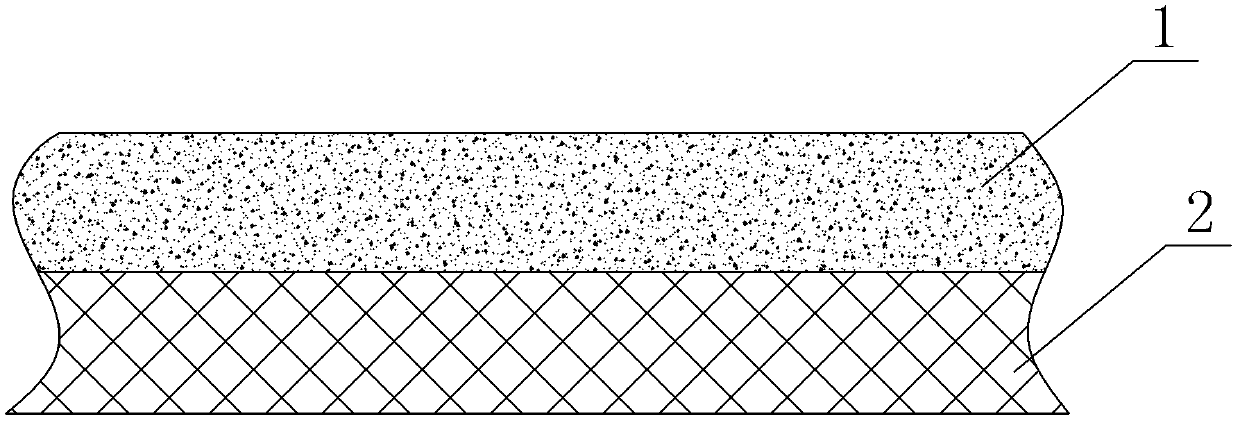

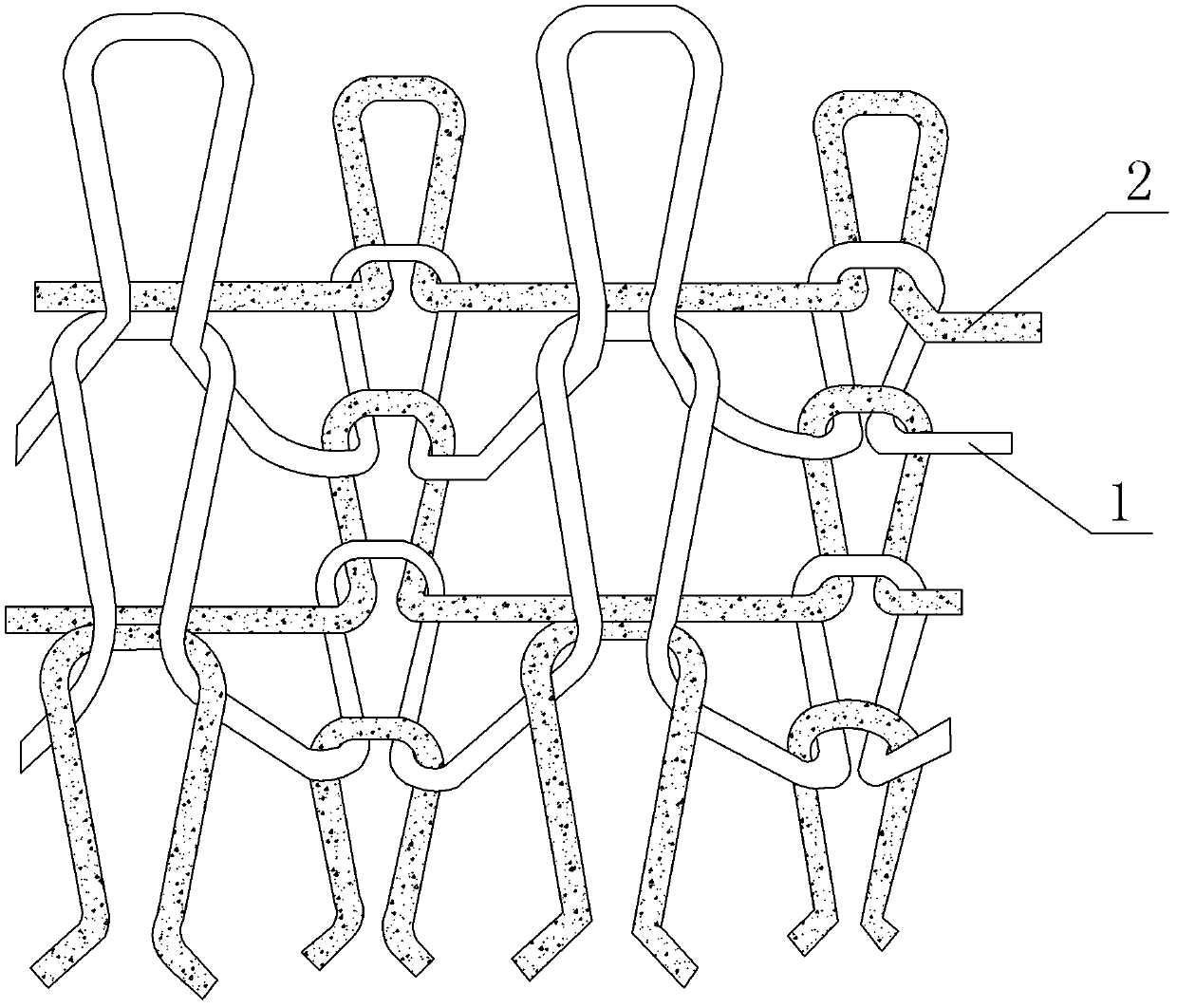

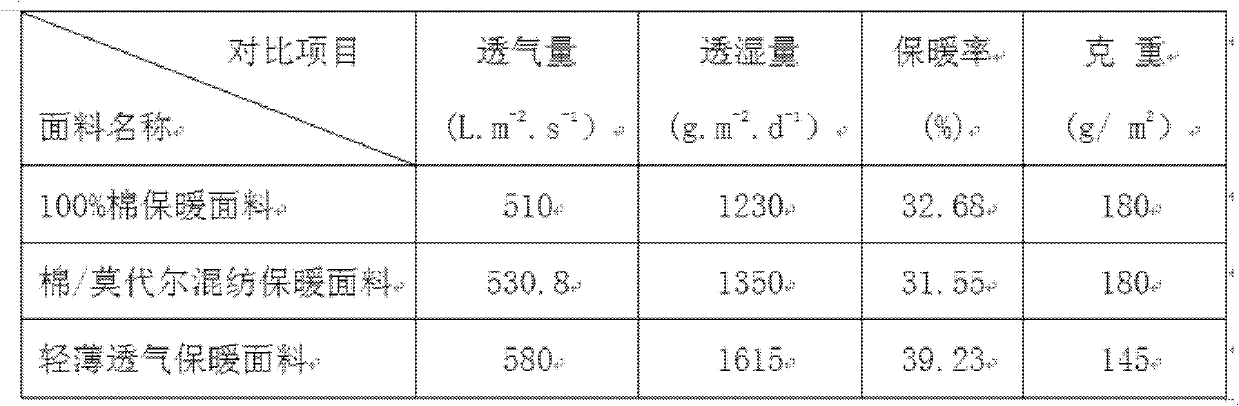

The invention relates to a thin breathable warm fabric, comprising a surface fabric and an inner layer fabric, wherein the inner layer fabric is a moisture absorption and heating layer; the surface fabric is a warm breathable and moisture-leading layer; the moisture absorption and heating layer is formed by blending 30-60% of moisture absorption and heating EKS fibers and 40-70% of ordinary acrylic fibers; the warm breathable and moisture-leading layer is formed by blending 15-40% of bulk acrylic fibers, 20-60% of superfine acrylic fibers and 0-65% of modal fibers. The invention further relates to a manufacture method of thin breathable warm fabrics, comprising the steps of preparing yarns, weaving, sanding, dyeing, finishing softly and shaping; and the thin breathable warm fabric provided by the invention has the advantages of high wearing comfort, good thin and breathable performance as well as good anti-dropping, anti-static and warmth retention performances.

Owner:SHENZHEN HUIJIE GROUP

Bamboo carbon fiber underwear fabric and manufacture method thereof

InactiveCN101532204AFully reflect the decomposition of odorFully reflect the functionWeft knittingYarnFiberTextile technology

The invention relates to a bamboo carbon fiber underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The bamboo carbon fiber underwear fabric consists of a lining layer and an external layer, and is characterized in that the lining layer consists of bamboo carbon fibers and cotton fibers according to the weight ratio of 15-30:70-85; the external layer consists of cotton fibers, Newdal fibers and polyurethane elastic fibers according to the weight ratio of 43-54:40-54:3-6. The manufacture method comprises that: the bamboo carbon fibers and the cotton fibers, the cotton fibers and the Newdal fibers are respectively spun into Sirospun blended yarns; the Sirospun blended yarns are interwoven with polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric forms a final finished product, namely the bamboo carbon fiber underwear fabric through dyeing, drying, sanding and shaping treatment. The fabric and the manufacture method have the advantages that the bamboo carbon fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, and has functions of good odor decomposition, smell elimination and the like.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

Polysulfonamide core-spun and wrapped composite yarns and conditioning friction tight composite spinning device thereof

The invention relates to polysulfonamide core-spun and wrapped composite yarns produced in the textile industry. Core-spun yarns consist of core yarn polyester yarns and externally-wrapping polysulfonamide fibers, and flame-retardant viscose filaments wrap the core-spun yarns. A conditioning friction tight composite spinning device for the composite yarns comprises a pair of dust cage friction false twisters corresponding to each spinning spindle, wherein a dust cage consists of two thin-wall sleeves and is fixed on an internal air suction pipe; the internal air suction pipe is connected with a main air suction pipe through a rubber pipe; the main air suction pipe is connected with a negative pressure fan; a conditioning groove is formed above the dust cage; a core yarn tensioner and a core yarn bobbin are arranged above a front roller and a front rubber roller; and a wrapped yarn tensioner and a wrapped yarn bobbin are arranged above a yarn guide hook. The invention has the advantages that: the polysulfonamide core-spun and wrapped composite yarns have a unique structure, a few hairs and high strength and can replace the conventional plied yarns, doubling and twisting processes are eliminated, the ration of coarse yarns can be improved by 40 percent compared with that of the conventional process, the tearing strength of the prepared fabric can be improved, and the structure of a ring spinning frame is not changed when the device is adopted.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD +1

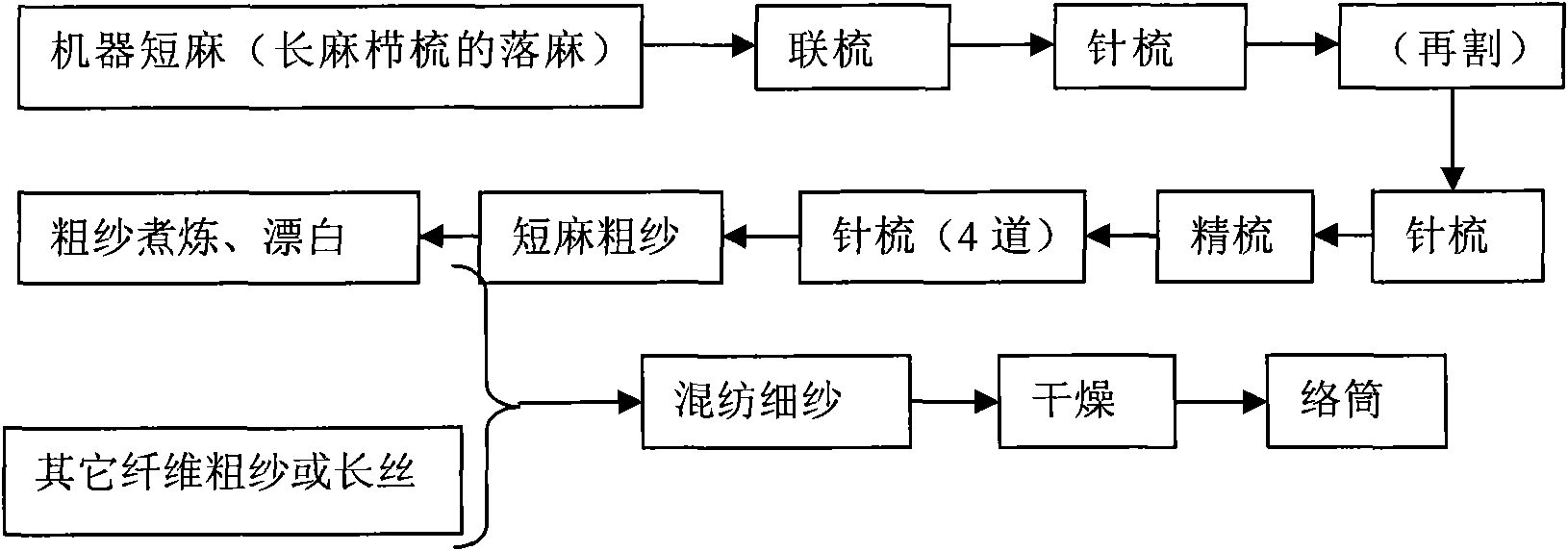

Blending method using hemp fiber as main material

InactiveCN101871147AIncrease the degree of splittingImprove impurity removalHackling machinesBleaching apparatusImpurityMaterials science

The invention relates to a blending method using a hemp fiber as a main material. The method comprises the following steps of: firstly, processing the hemp fiber into rovings; secondly, mixing the roving yarns of the hemp fiber with the rovings or filaments of other fibers in proportion to form bunch yarns; and finally, spinning the mixed bunch yarns in the second step into spun yarns. The blending method has the advantages of improving the disintegration degree of the hemp fiber and removing impurity without damaging the performance of the blended fibers, ensuring a high spinning yam count and quality of the blended yarns and greatly improving the quality of the blended yarns of the hemp fiber along with simple process.

Owner:肇融亚麻纺织有限公司

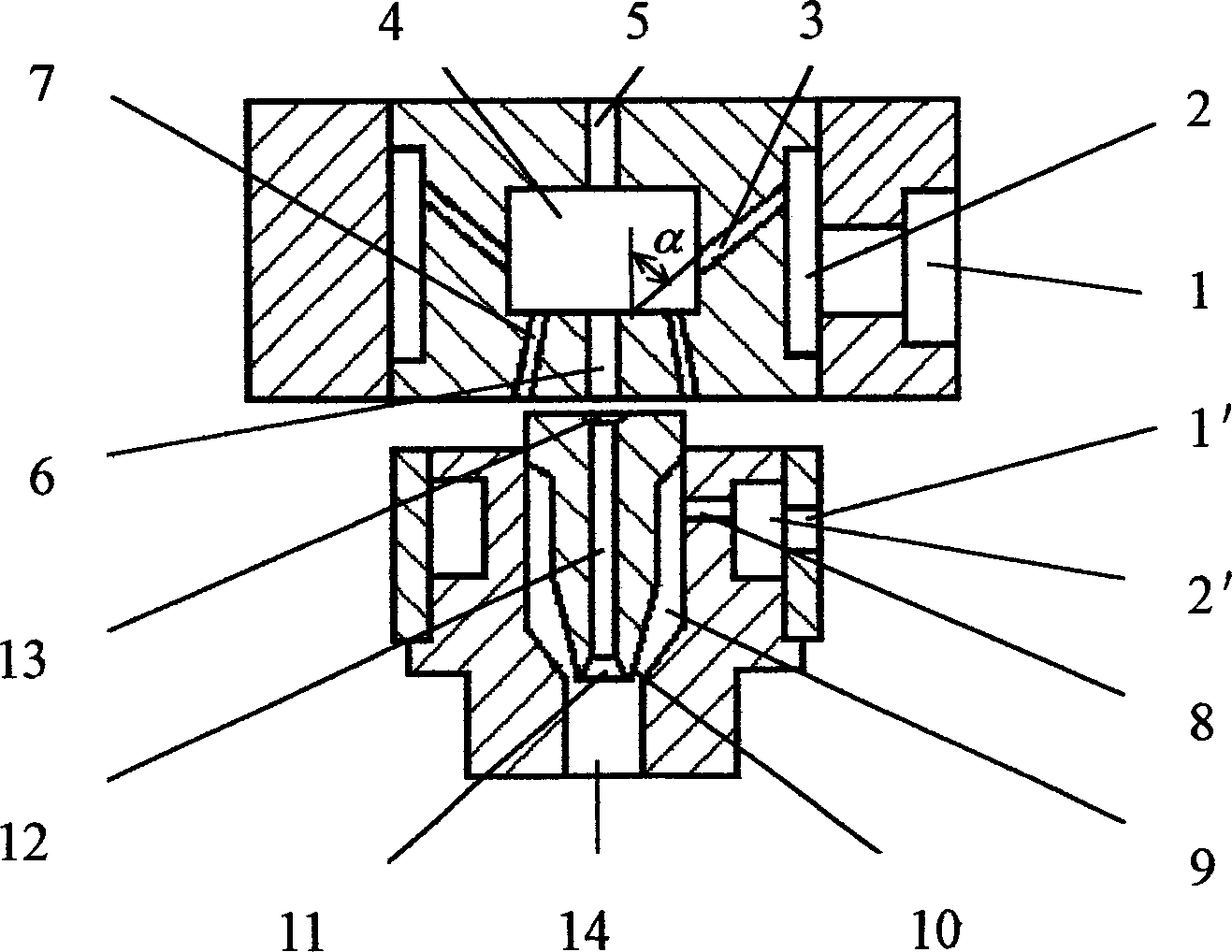

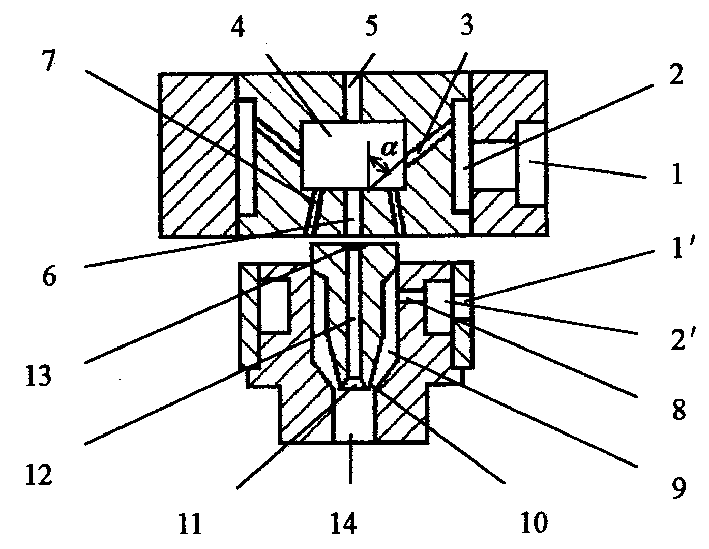

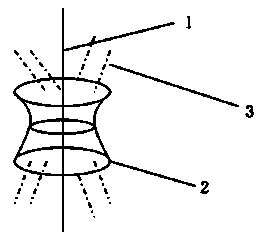

Complex twisting device for air-jet eddy-current spinning

InactiveCN1388278ANo suction phenomenonImprove production rateContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The complex twisting device for air-jet eddyc-current spining to twist fiber strand consists of the upper twisting unit and the lowr twisting unit. Positive pressure air flow is utilized to produce eddy-current field and pipe flow and the fiber is fed to the eddy-current field via the conveying pipe. Fiber strand rotates with the high-speed rotating air flow while the pipe flow protects and guides the twisted fiber strand to leave from the eddy-current field. During the process, fiber strand is twisted to produce twisted yarn in high speed. The present invention makes it possible to produce high-quality yarn at low cost and high speed.

Owner:DONGHUA UNIV

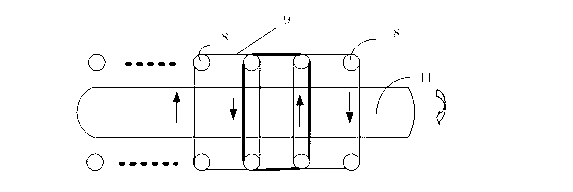

Method and device for improving fiber yarn forming performance

A method for improving the spinning performance of fibres features that the fibres are modified by a thermal shape-fixating equipment in their spinning procedure. Said thermal shape-fixating equipment is composed of internal tube and external tube. When the fibres pass through the internal tube, they are acted by high-temp steam to make their macro-molecular chains flexible and extended.

Owner:WUHAN TEXTILE UNIV

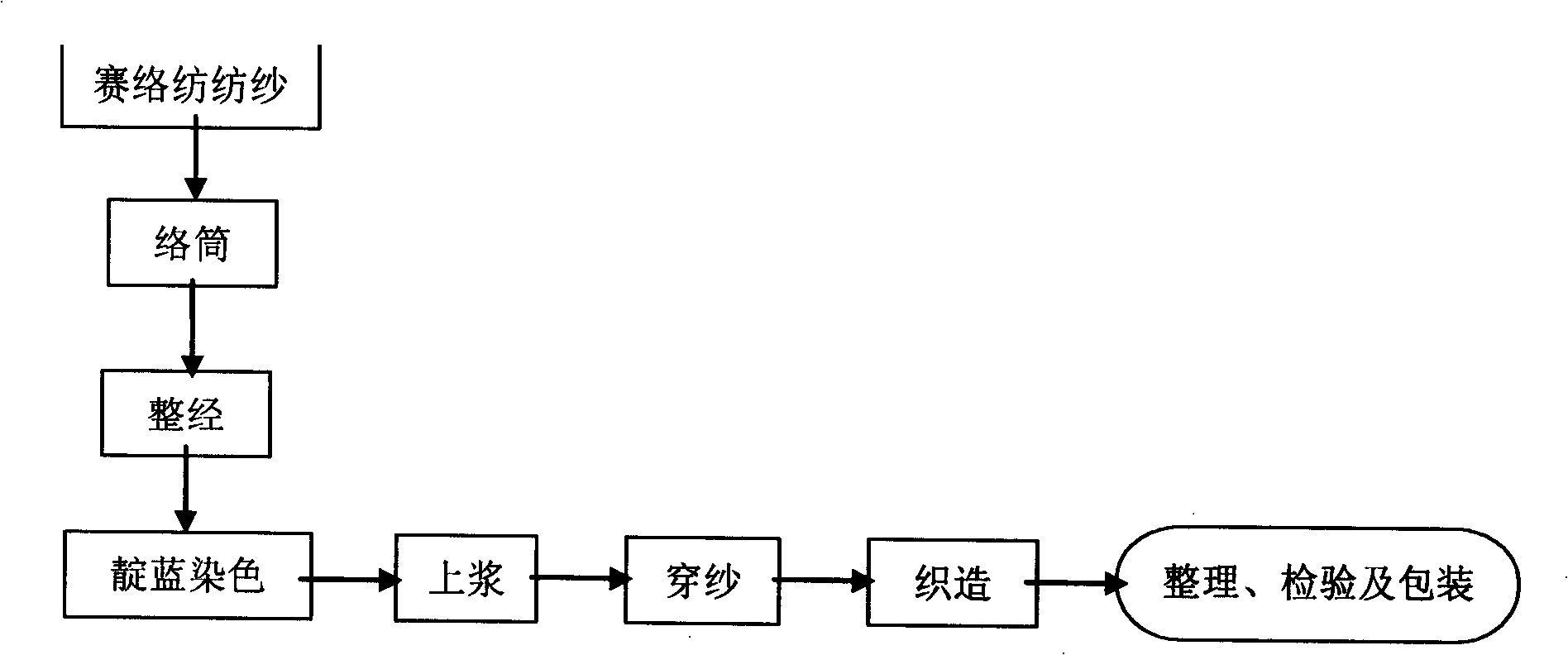

Process for manufacturing sirospun yarn jean facing material

The invention discloses a manufacture technique of a siro yarn jean fabric, in which, firstly an advanced siro yarn spinning technology is adopted to manufacture the siro yarn; the spun siro yarn is wound; then the wound siro yarn which is used as a warp is warped, dyed and starched be manufactured into a beam; then the siro yarn is used as the warp and the siro yarn, a rotor spun yarn or a ring yarn are used as an abb to be woven on a loom according to the fabric weave and the weaving technique of the jean to manufacture a grey fabric and finally the grey fabric is made into a finished product through subsequent finishing. As the siro yarn with better quality is adopted as the warp, the method has the advantages of easy yarn splitting, few broken ends, uniform colorizing, reducible sizing quality requirement as well as high heddle draft and reeding efficiency during the dyeing process, clear cut, uniform tension, few broken ends and stopping, few fly wastes in a workshop and on a machine station as well as being beneficial to the cleanness of the workshop and the maintenance of the machine station when weaving.

Owner:佛山市致兴纺织服装有限公司

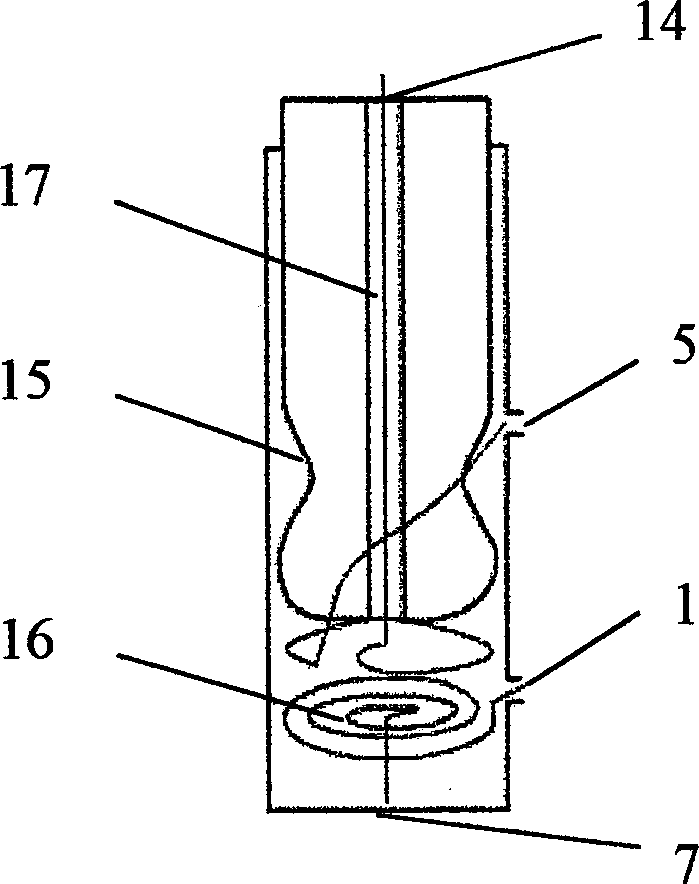

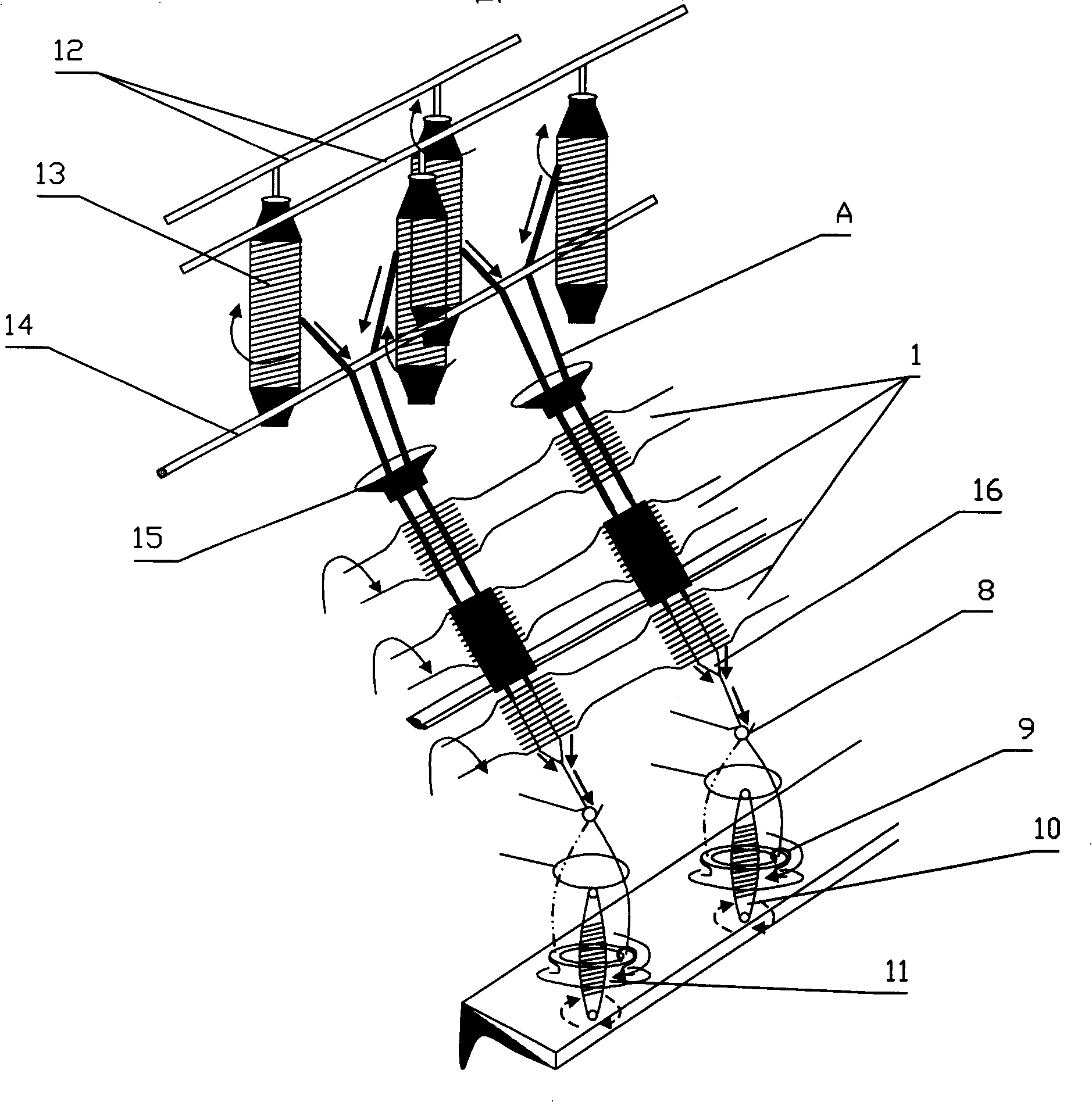

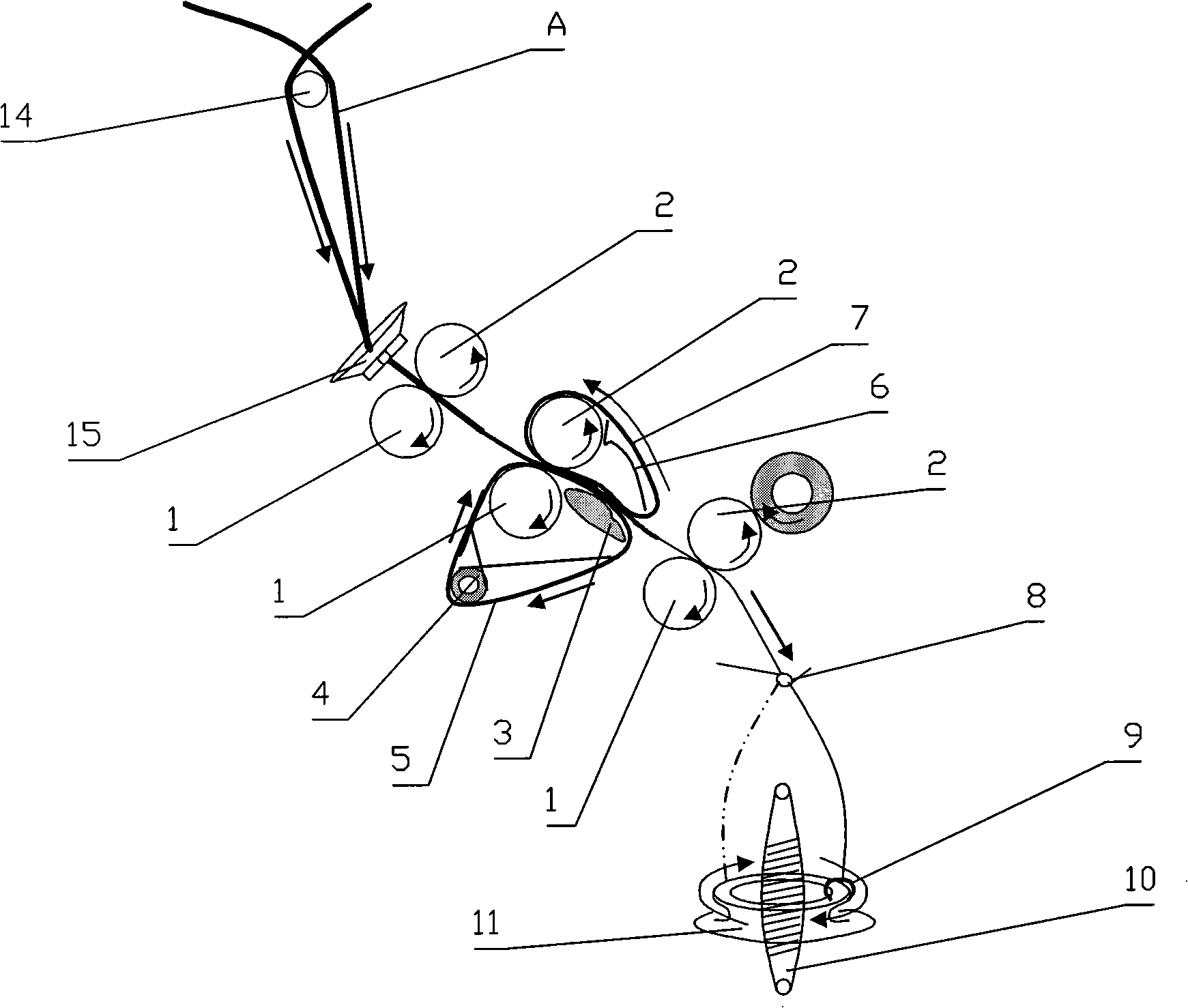

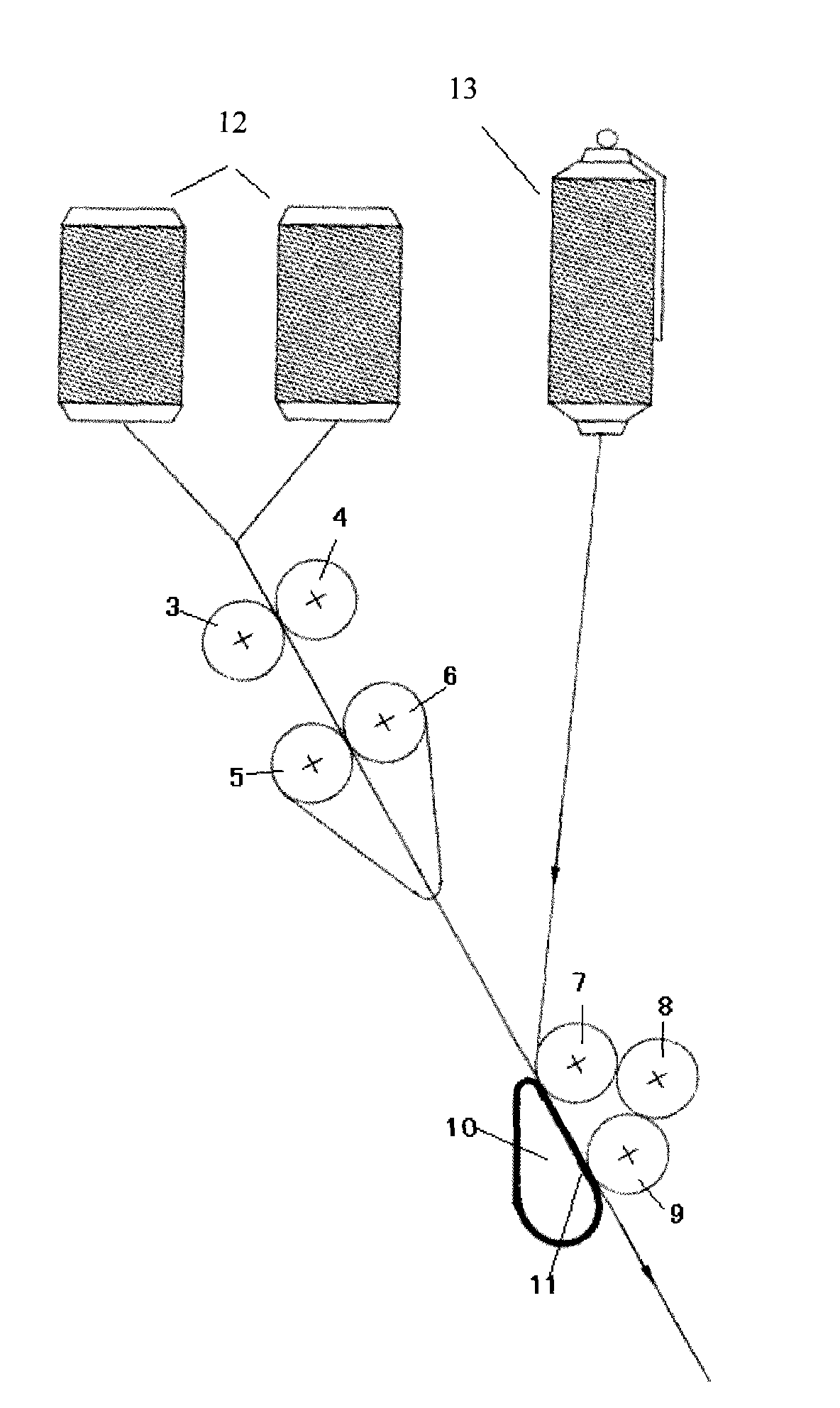

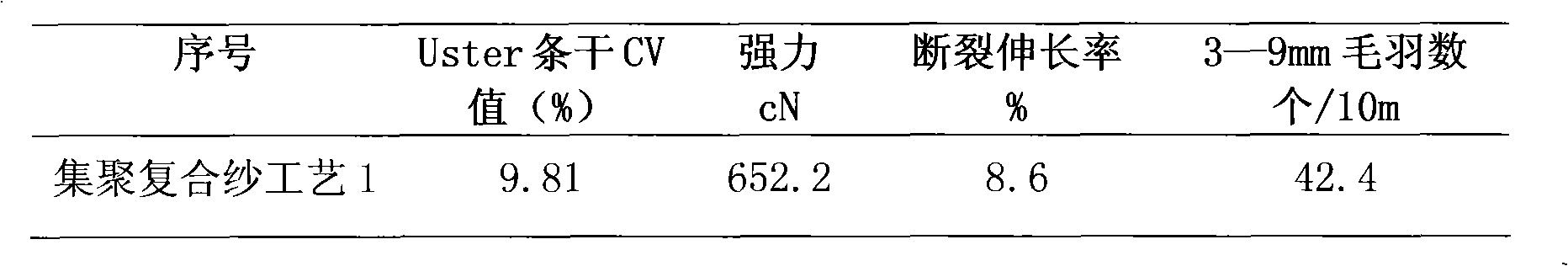

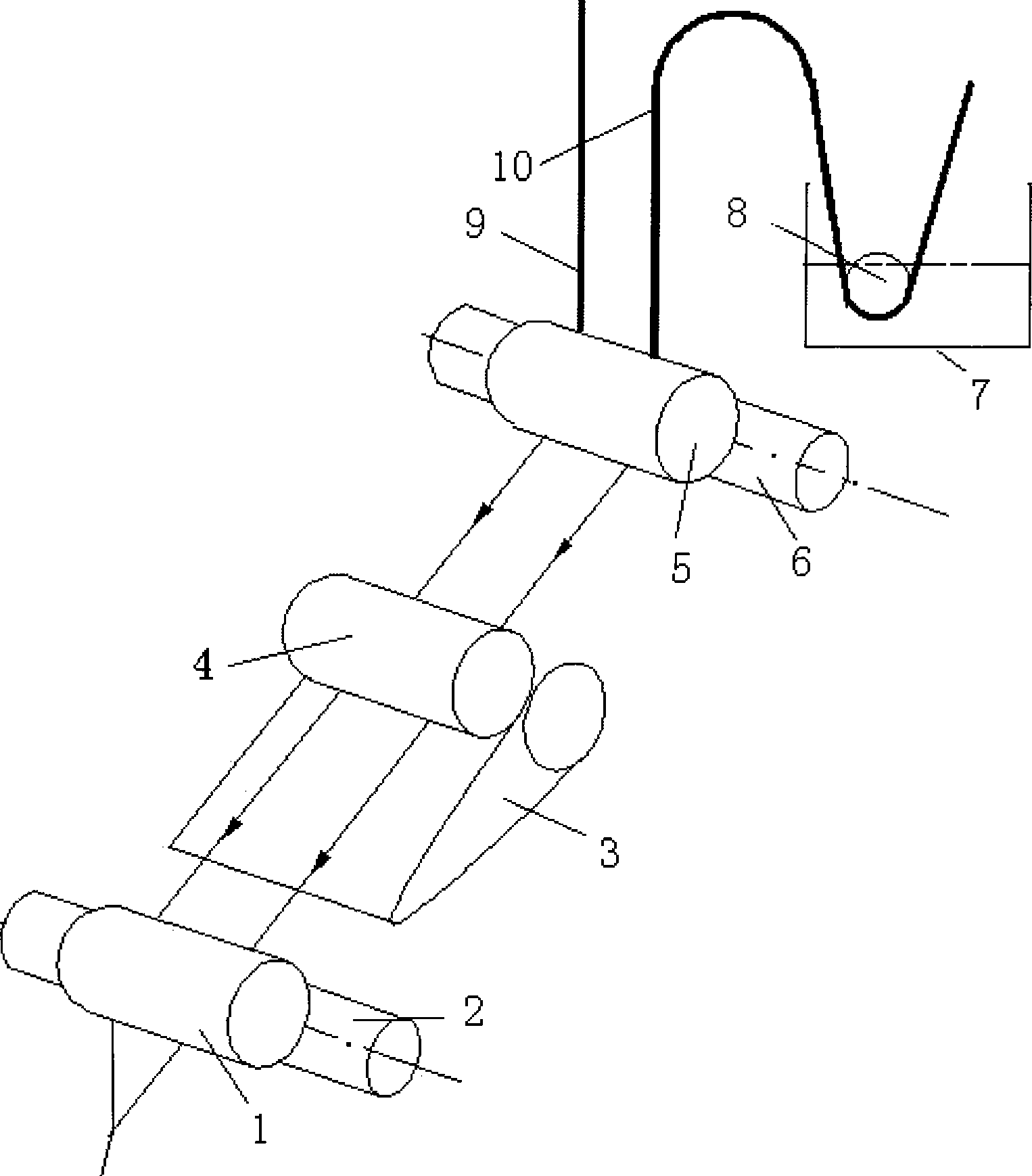

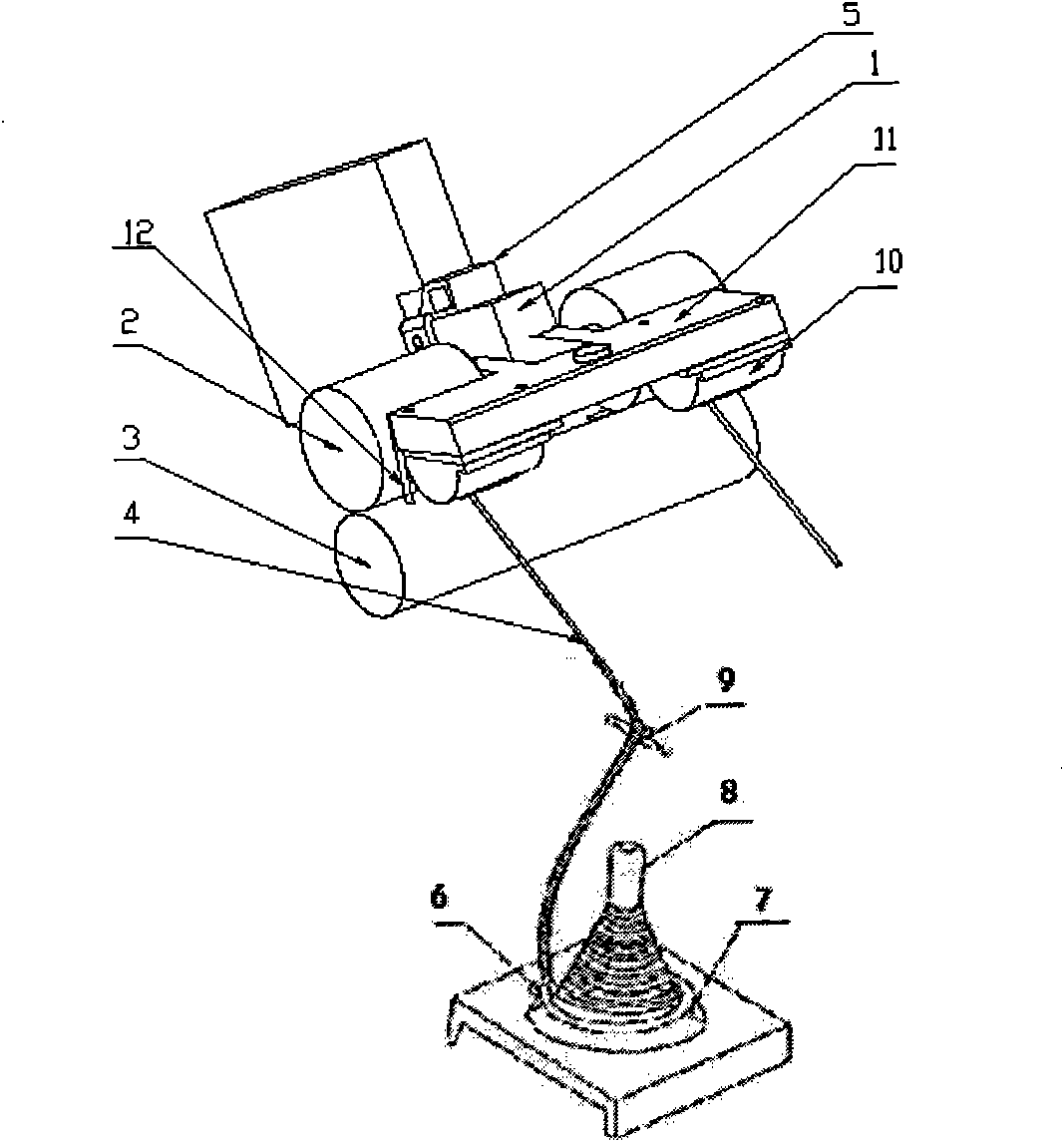

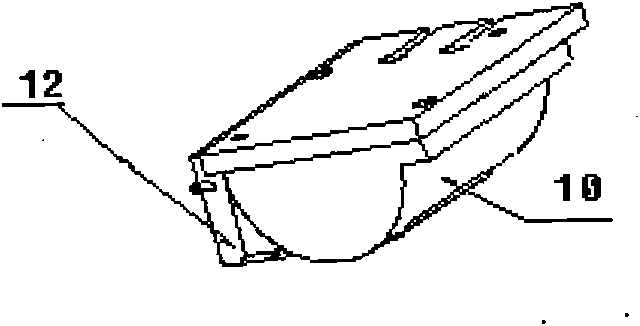

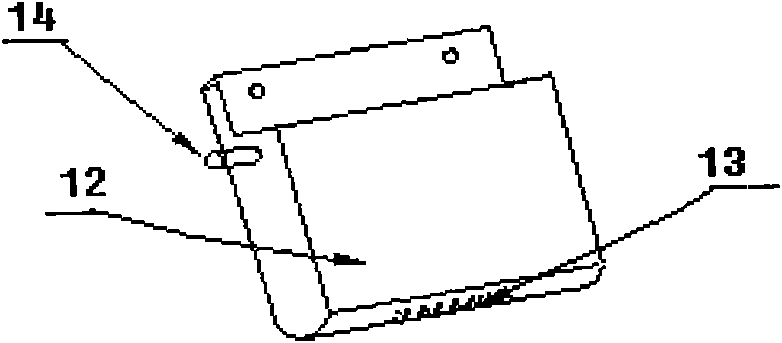

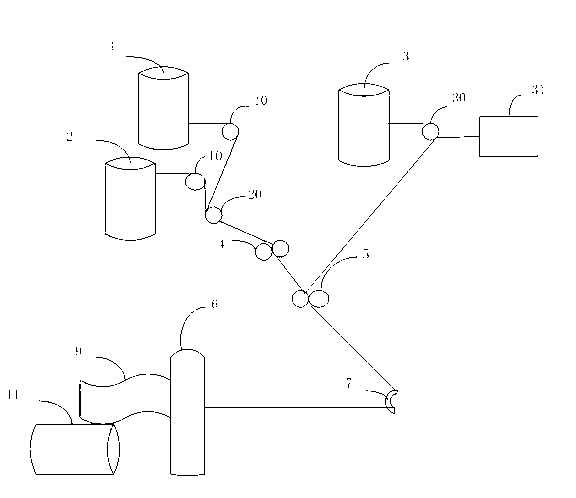

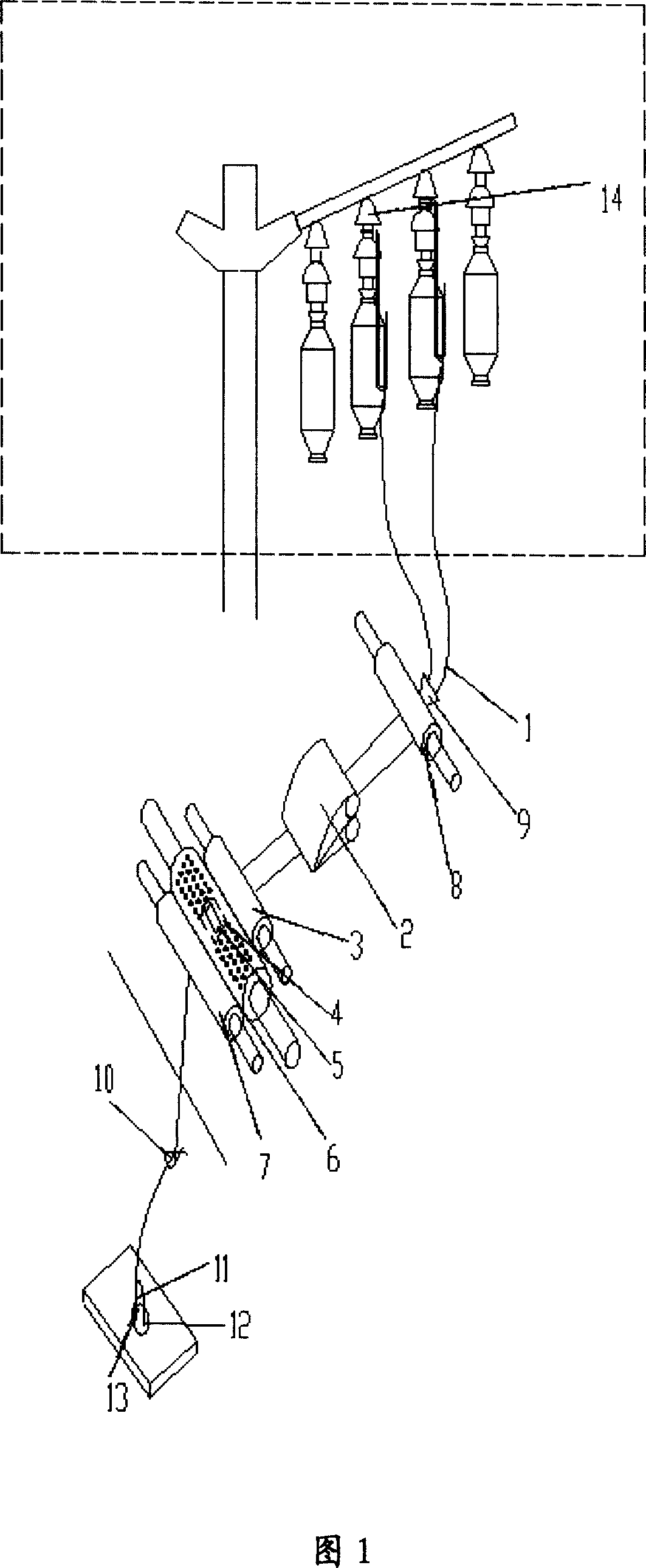

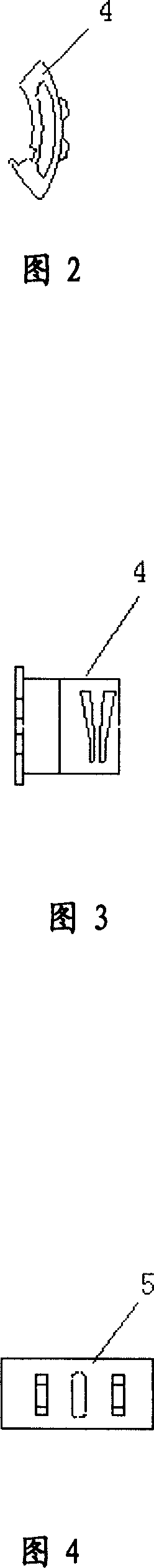

Spinning device for concentrating composite yarns

InactiveCN101665998AEasy to installLess hairyDrafting machinesContinuous wound-up machinesYarnBobbin

The invention provides a spinning device for concentrating composite yarns. The device comprises a creel, wherein yarn guiding rods are arranged in the center of hanging spindles on both sides of the creel; the left and the right side in the center of a straight rod of the creel are provided with a transverse yarn guiding flare opening making slow reciprocation respectively; the bottom end of thestraight rod of the creel is provided with a rack; both sides of the top end of the rack are provided with a drafting device respectively; the left side of the rack close to the top end is provided with a yarn guiding hook; a bobbin is arranged under the yarn guiding hook; and a wire ring is arranged under the bobbin. The spinning device is characterized in that the hanging spindles of the creel are provided with feeding devices, and the front end of the drafting device is provided with a concentrating device. The spinning device has the advantages that: the device is simple, and can be modified on a common ring spindle spinning machine; and the concentrated composite yarns spun by the spinning device has the characteristics of less hairiness, high strength and good yarn evenness, and hasthe characteristics of siro yarns and sirofil yarns.

Owner:DONGHUA UNIV

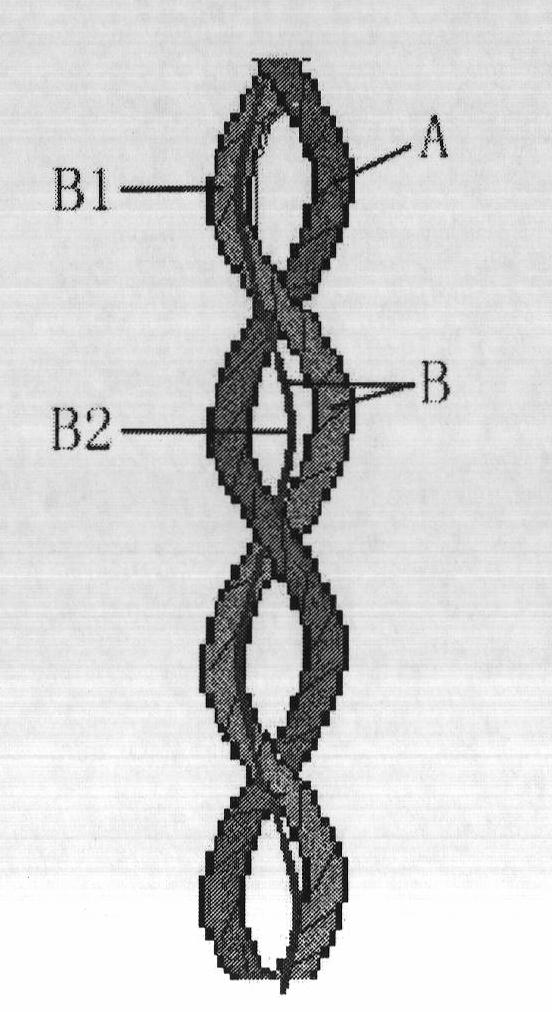

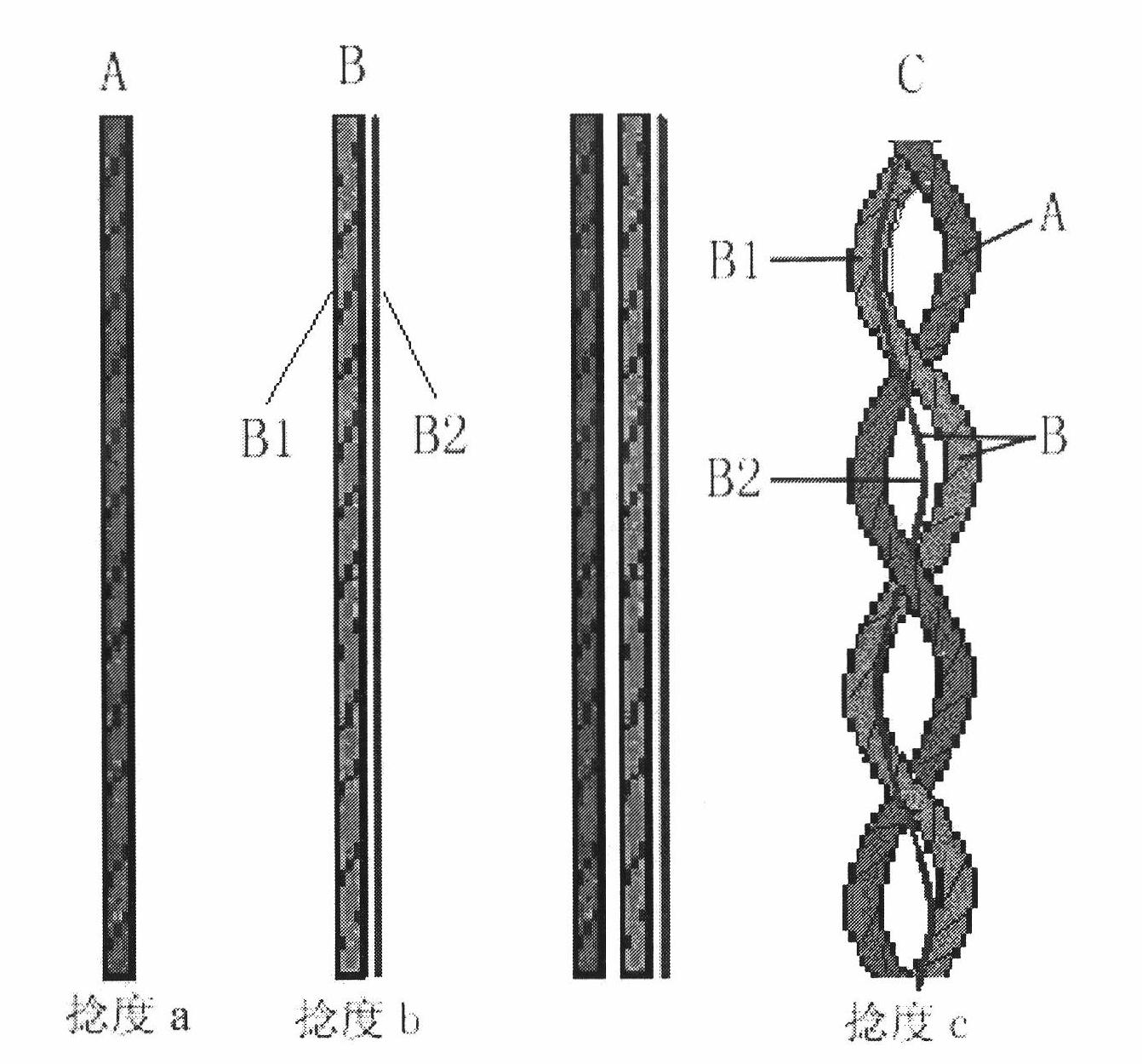

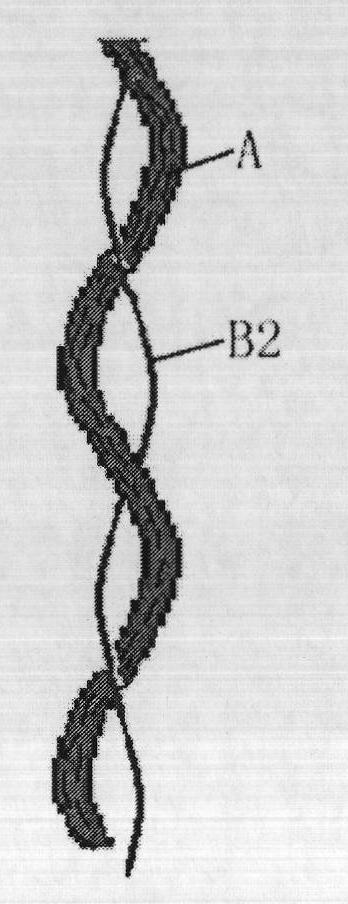

Yarn for preparing fabric with bundling structure and preparation method thereof

The invention provides a yarn for preparing a fabric with a bundling structure and a preparation method thereof. The yarn is prepared by the doubling and back twisting of a sliver A and a sliver B, wherein a first twist of the sliver A is a, the sliver B does not have a twist or has a first twist b, and a second twist of the back twisting is c. The yarn is characterized in that: the sliver B is a conjunct of water soluble vinylon and a fine denier chemical fiber long yarn. The preparation method of the yarn comprises the following steps of: applying the first twist a to the sliver A; combining the water soluble vinylon with the fine denier chemical fiber long yarn to form the sliver B, and not twisting the sliver B or applying the first twist b to the sliver B, wherein the twisting direction is the same as that of the sliver A; and doubling the sliver A and the sliver B on a doubling and twisting machine and then performing back twisting on a two-for-one twisting machine to obtain the yarn, wherein the second twist c is applied during the back twisting. When the yarn of the invention is used to prepare the fabric, the water soluble vinylon is dissolved by a vinylon dissolving process, the sliver A does not have a twist or has a low twist, and the fine denier chemical fiber long yarn is wound on the sliver A to form the bundling structure.

Owner:JIANGSU JIANLU WOOLEN +5

Coal mine protective clothing fabric and preparation method thereof

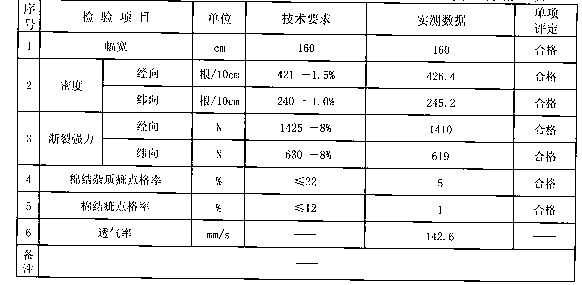

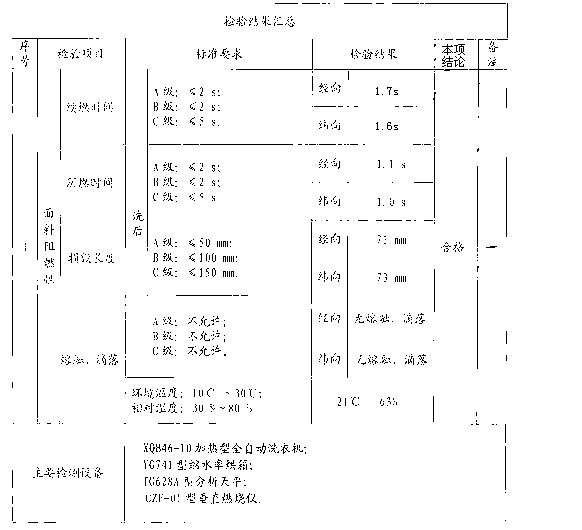

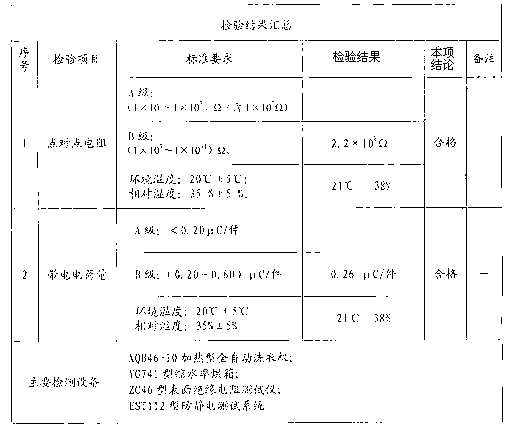

InactiveCN103061000ALess hairyGuarantee the basic protection requirementsWoven fabricsVegetal fibresEngineeringFire retardant

The invention provides a coal mine protective clothing fabric which is durable and comfortable to wear, flame-retardant, anti-static, oil-proof, waterproof, good in antifouling performance and low in price. The coal mine protective clothing fabric is prepared from warp yarns and weft yarns by embedding a PET100D conductive filament every 2cm in the warp direction, wherein each warp yarn is a vortex spinning all-cotton MVS CM18.2texX2 two-fold yarn, each weft yarn is a vortex spinning all-cotton MVS CM32.4tex single yarn, warp density is 421 pieces / 10cm, and weft density is 240 pieces / 10cm. The preparation method of the coal mine protective clothing fabric includes the steps: a, spinning; b, weaving including warping, sizing and drafting; c, printing and dyeing; and d, afterfinish including flame-retardant finish and tri-proof finish, wherein during flame-retardant finish, Pyrovatex CP new serves as fire retardant, and RUCOSTAR EEE serves as tri-proof finish agent.

Owner:JIANGSU YDTEX GRP LTD

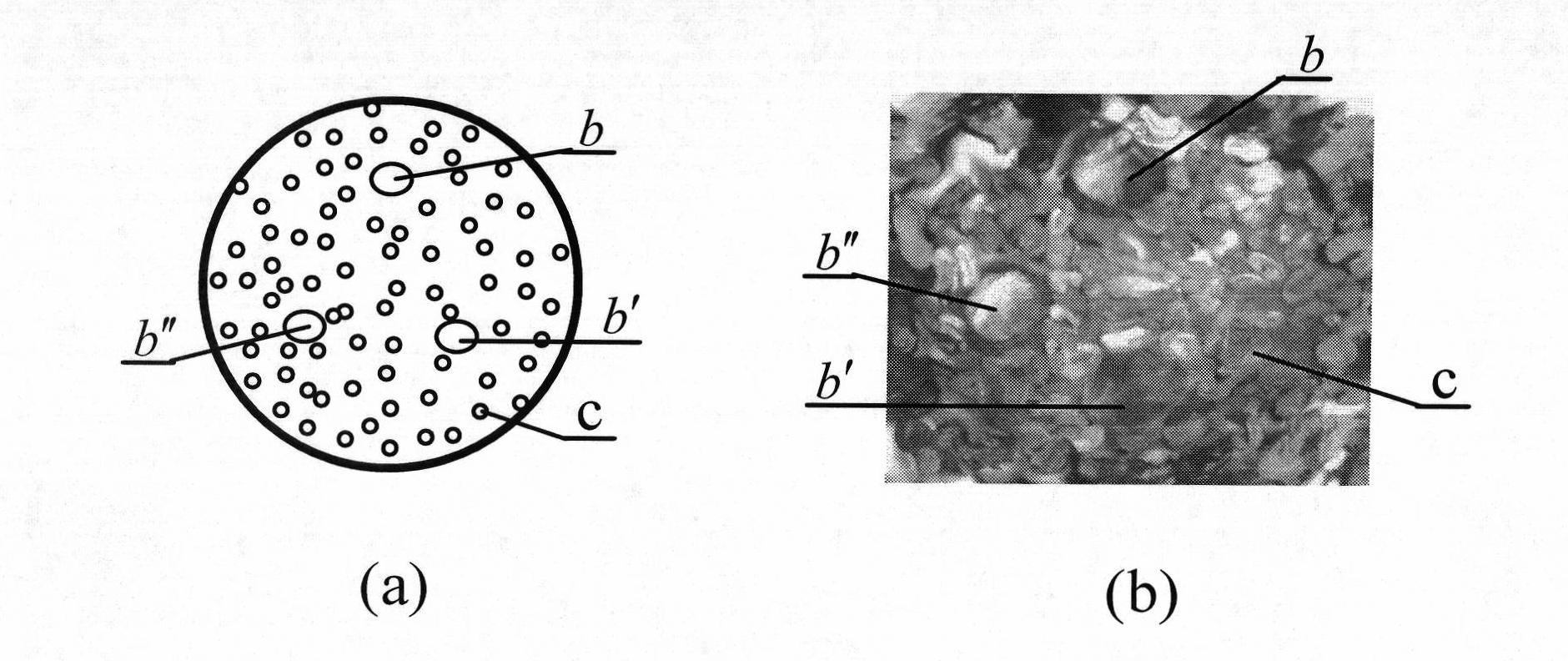

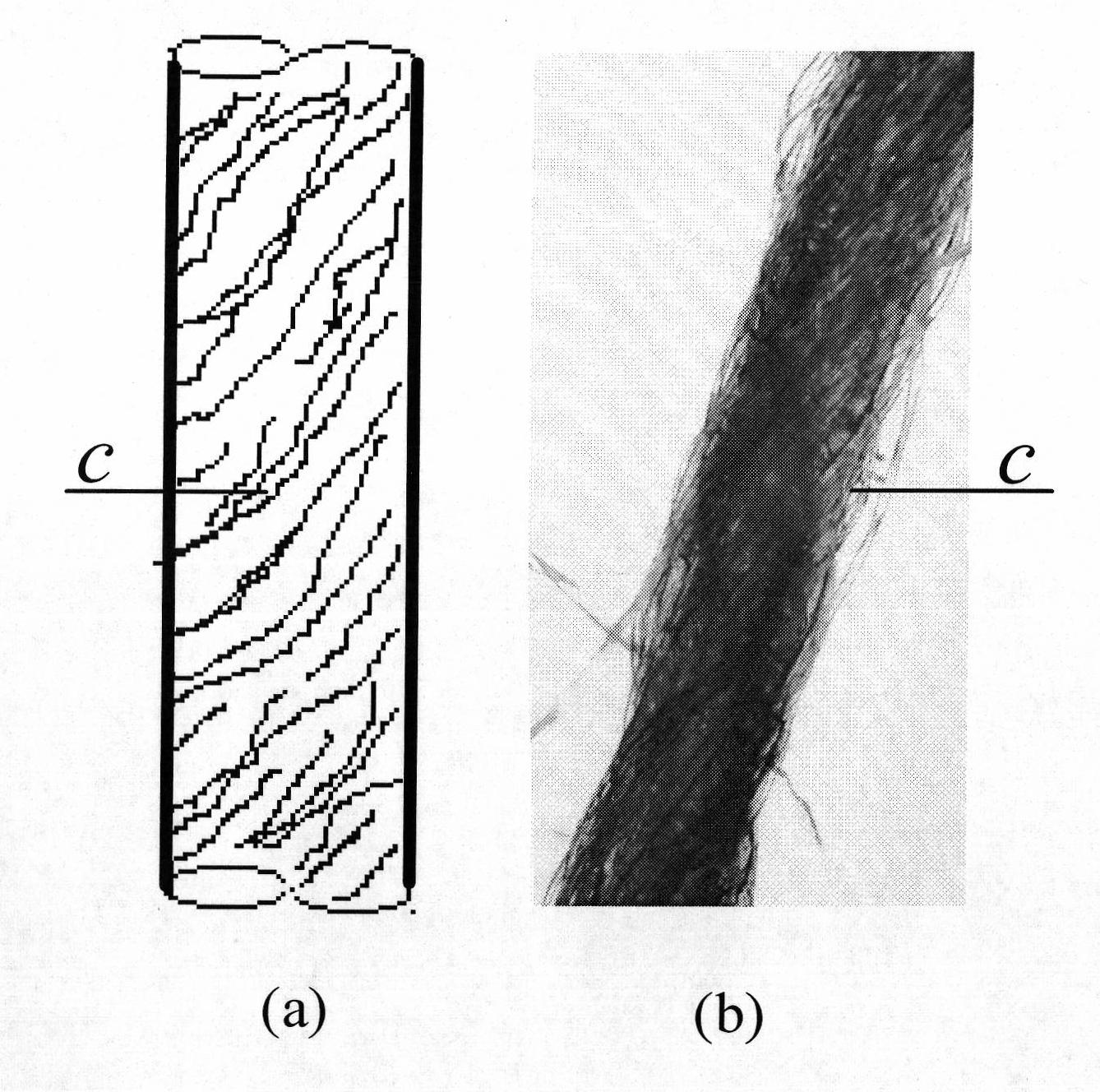

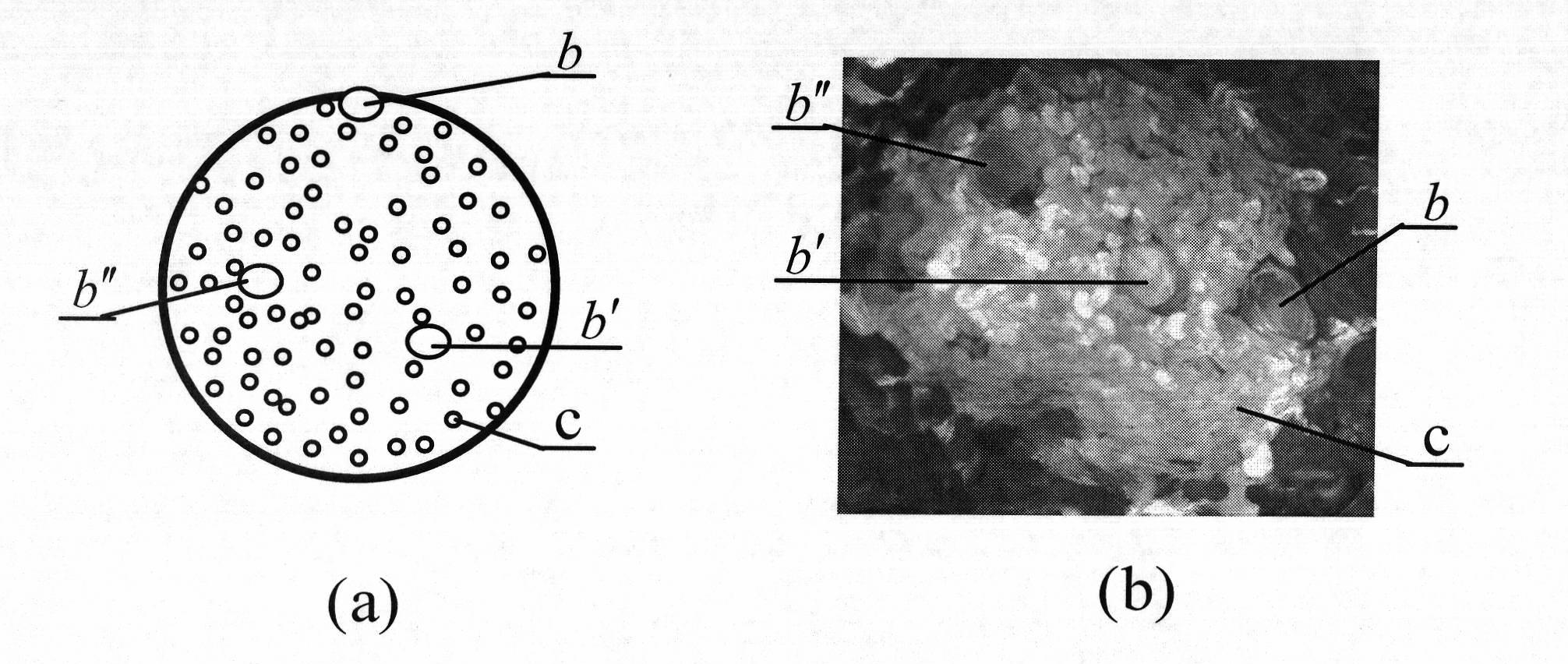

Filament short-fiber composite yarn

The invention relates to filament short-fiber composite yarn with a novel structure, which is formed by compositely twisting filament and short fiber. The yarn is characterized in that the filament in the yarn is generally three or more than three monofilaments or multifilaments which are respectively and dispersedly distributed and form organic combination with short fiber. According to the distribution position of the filament and short fiber in the cross section of the yarn, the composite yarn can be of a structure that the filament is coated by the short fiber or of a structure that the filament is distributed both inside and outside and short fiber is coated by the filament and short fiber on external faces. The filament can be silk, chemical fiber filament or metal wire, and the short fiber can be natural fiber or chemical short fiber. The invention has the advantage of increasing the strength, wear resistance, flexural rigidity and the like of the yarn. The composite structure yarn can be used for dress and clothes and special type yarns, and has the advantages of convenient and fast processing and both the properties of the filament and the short fiber.

Owner:重庆三峡技术纺织有限公司 +1

Process for knitting towel

The invention discloses a process for knitting a towel, which comprises the procedures of warping, kitting and grey cloth post-processing. The process for knitting a towel is characterized by adopting yarn made from zein fiber and cotton fiber, and after the procedures of the warping, the kitting and the grey cloth post-processing, the yarn is prepared into a finished towel product. The towel prepared by the process has little filoplume, good appearance transparence, soft texture, textural quality, good resiliency, is easy to degrade, has good stability for solvents, such as a dry cleaning agent and can resist the dirt, the sunlight and the weather. The process for knitting a towel can reduce the environmental pollution and prolong the service life of the towel. The towel with the zein fiber feels good on skin and has good permeability, smoothness, better gloss and wash-and-wear effect, thereby being a new generation green product.

Owner:SUNVIM GROUP

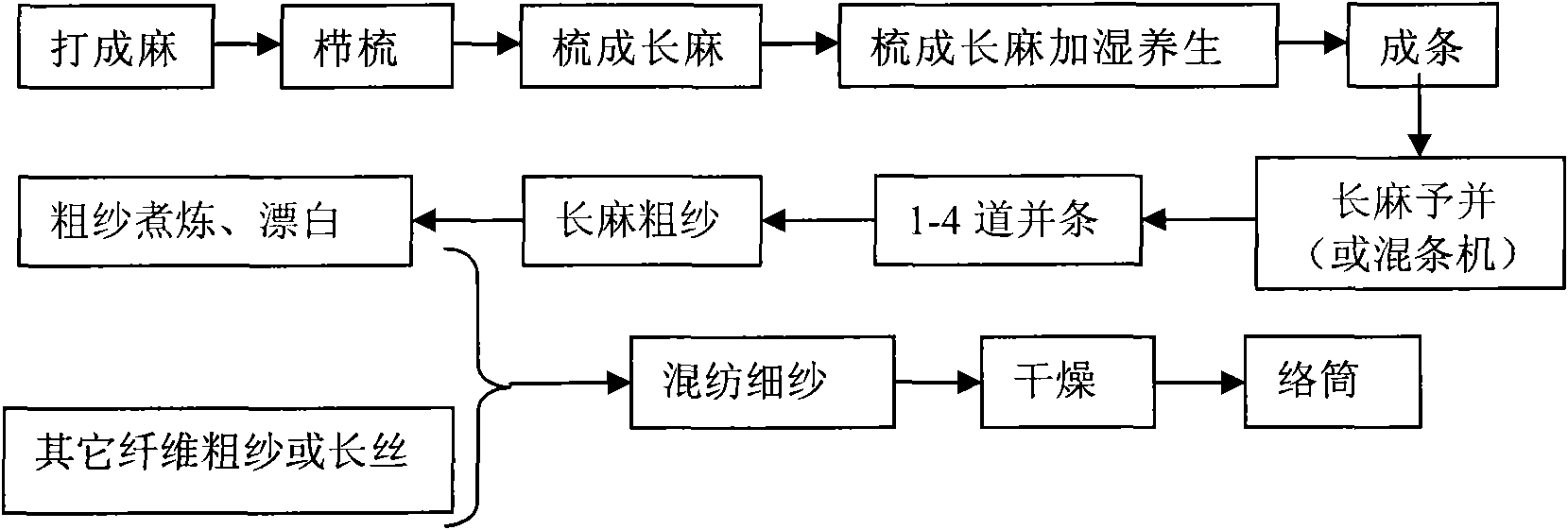

Blended spinning method of long spinning and damp spinning for bast fibers

The invention provides a method integrated with long spinning, wet spinning and blended spinning for bast fibers. The method comprises the following steps: the bast fibers are scotched into flax; the flax is humidified and soaked for a period of time; the flax is carded into long flax; and the long flax is subjected to matching, silvering, drawing, roving, scouring, bleaching, spinning, drying and winding. The method is characterized in that after the bast fibers are bleached, the obtained rove of the bast fibers and rove or filaments of other fibers are blended on a spinning machine. With the method, blended fibers are not bleached and scoured together with the bast fibers, so the defect that the performance of blended yarn is affected due to the damage of bleaching and scouring agents to the blended fibers in the prior wet spinning and blended spinning is overcome, and the obtained blended yarn has the characteristics of bright and clean yarn body, less hairness, evenness and good wear resistance. In addition, the method can fully play a role in respective advantages of the bast fibers and the blended fibers, complement respective disadvantages of the bast fibers and the blended fibers, has simple process, is favorable for improving the quality of blended yarn of the bast fibers, and realizes the high count, high grade and diversification of varieties of the bast fibers.

Owner:DONGHUA UNIV

Production method of rabbit hair, cashmere and silk three-in-one face fabric

InactiveCN101225568ASoft and smoothNatural elegant lusterHeating/cooling textile fabricsLiquid/gas/vapor removalYarnEngineering

The invention relates to a triad producing method of clothing face fabric with rabbit hair, cashmere and silk, which is characterized in that: the raw material comprises 14% of the silk, 39% of the rabbit hair, 44% of the wool and 3% of the cashmere, the clothing face fabric with rabbit hair, cashmere and silk is made by the processes of dyeing, garneting, spun yarn, warping, weaving and after-finishing. The triad producing method of clothing face fabric with rabbit hair, cashmere and silk has the advantages of gathering the elasticity and heat retention of the wool, and the excellent properties of the rabbit hair and the silk, soft and satiny hand feeling, natural and elegant luster, excellent heat retention, and suitable for the demand of higher consumption level stratum.

Owner:江阴市天鹅制呢厂有限公司

Spinning method for performing damp heat ironing treatment to fiber strands

The invention relates to a spinning method for performing damp heat ironing treatment to fiber strands, and belongs to the technical field of textile processing. A damp heat ironing treatment device is additionally installed in a twist trigonal zone in front of a front leather roller and a front roller of a ring spinning frame and used for performing damp heat ironing treatment to fibers in the fiber strands; the damp heat ironing treatment device comprises a base, a humidifying component and an ironing treatment component; the damp heat ironing treatment device can perform humidifying to the fibers in the fiber strands in the twist trigonal zone and then perform high-temperature ironing treatment, so that the rigidity of the fibers is instantaneously reduced, and the flexibility of the fibers is enhanced; and meanwhile, the movement of the fibers in the fiber strands in the twist trigonal zone is controlled. The spinning method can remarkably reduce the fibrous yarn of resultant yarn, enhance the strength of yarn formation and reduce the phenomenon of kinking due to twisting. The damp heat ironing treatment device is convenient for a knitter to operate, has little influence on the operation of the knitter, and is suitable for cotton fibers, wool fibers, fibrilia, polyester fibers, polyamide fibers and acrylic fibers.

Owner:WUHAN TEXTILE UNIV

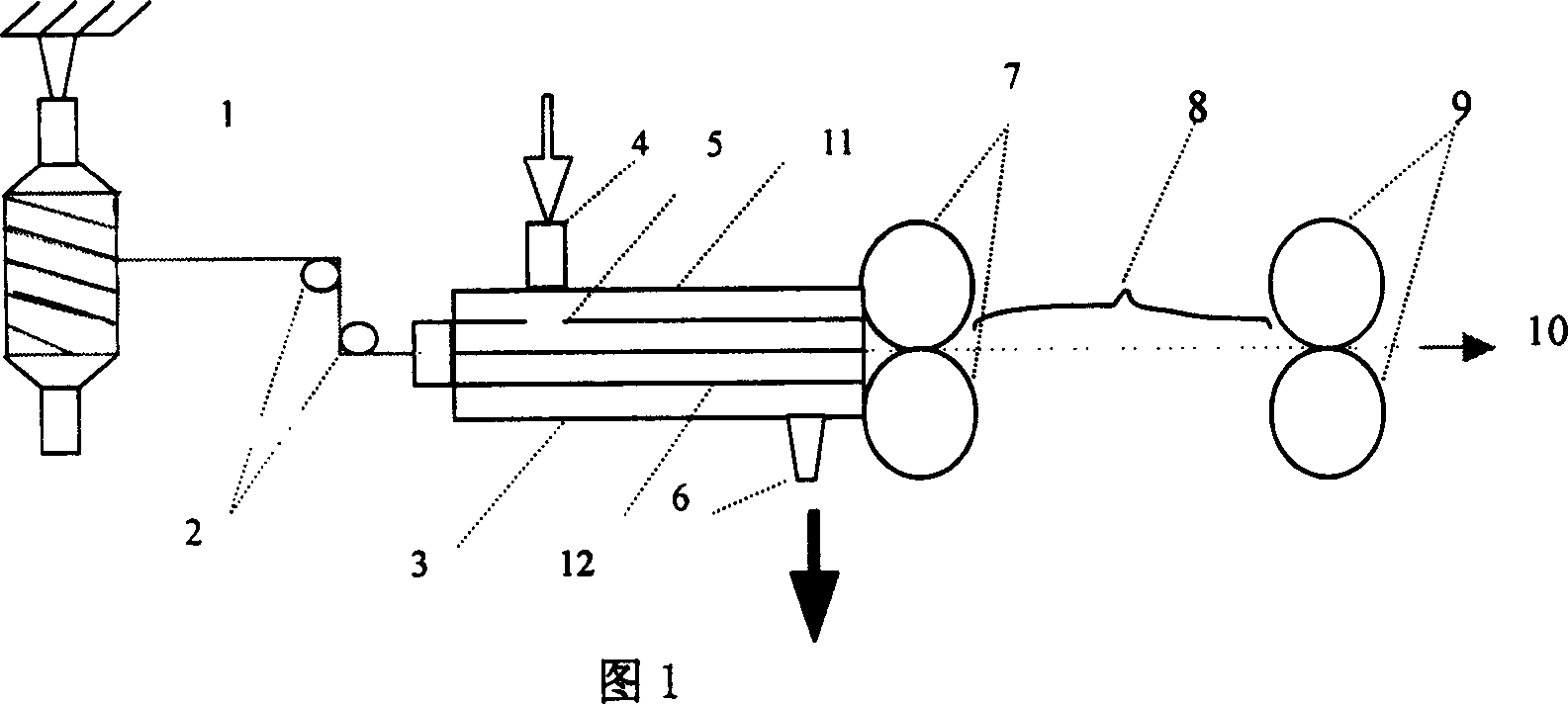

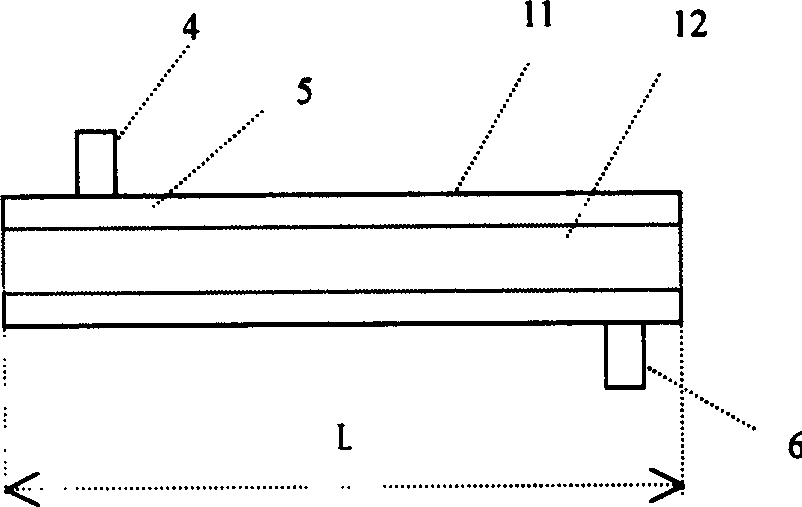

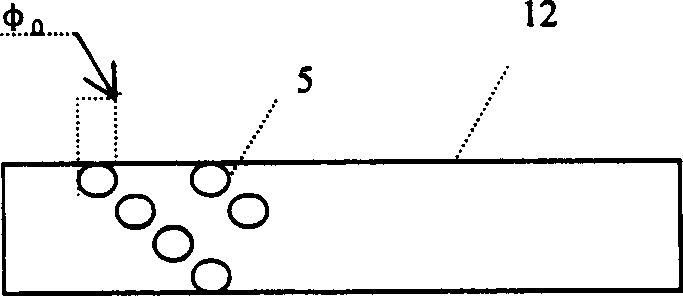

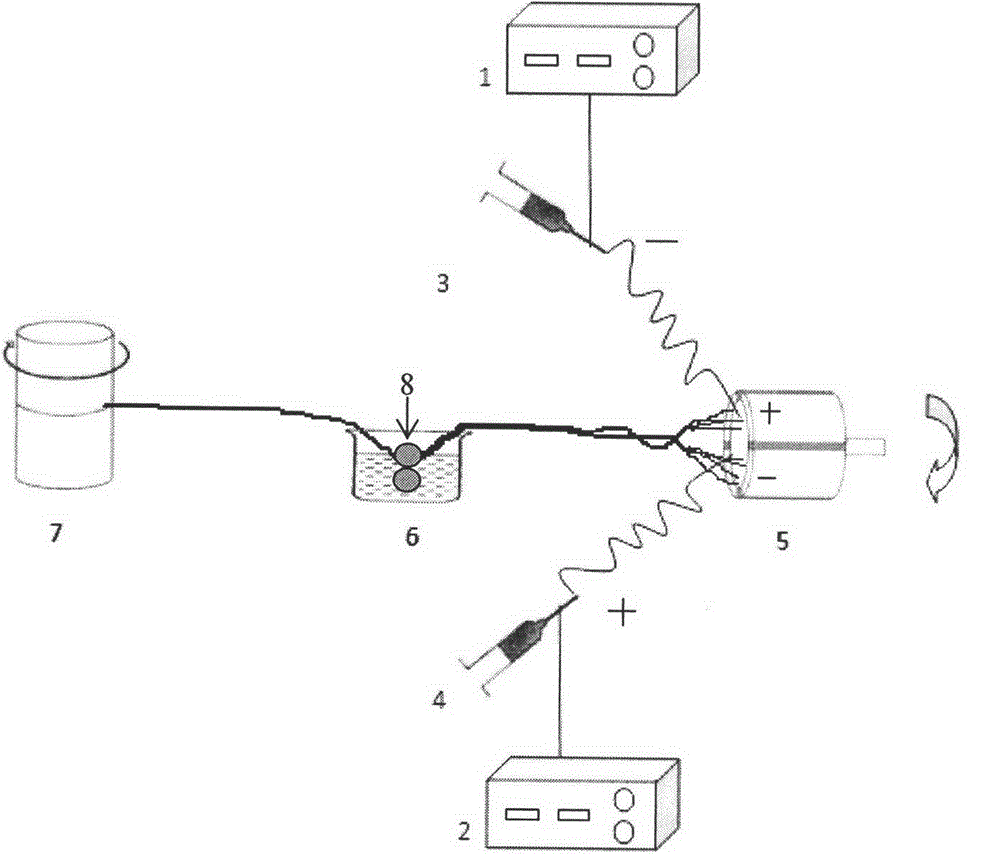

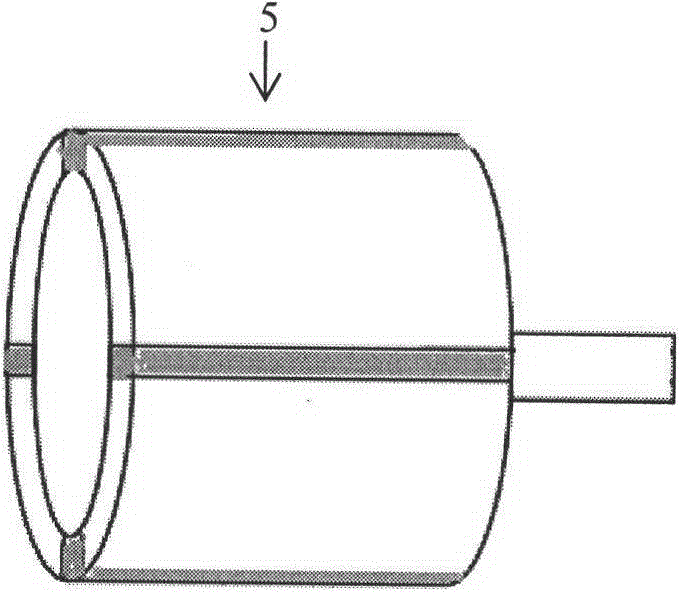

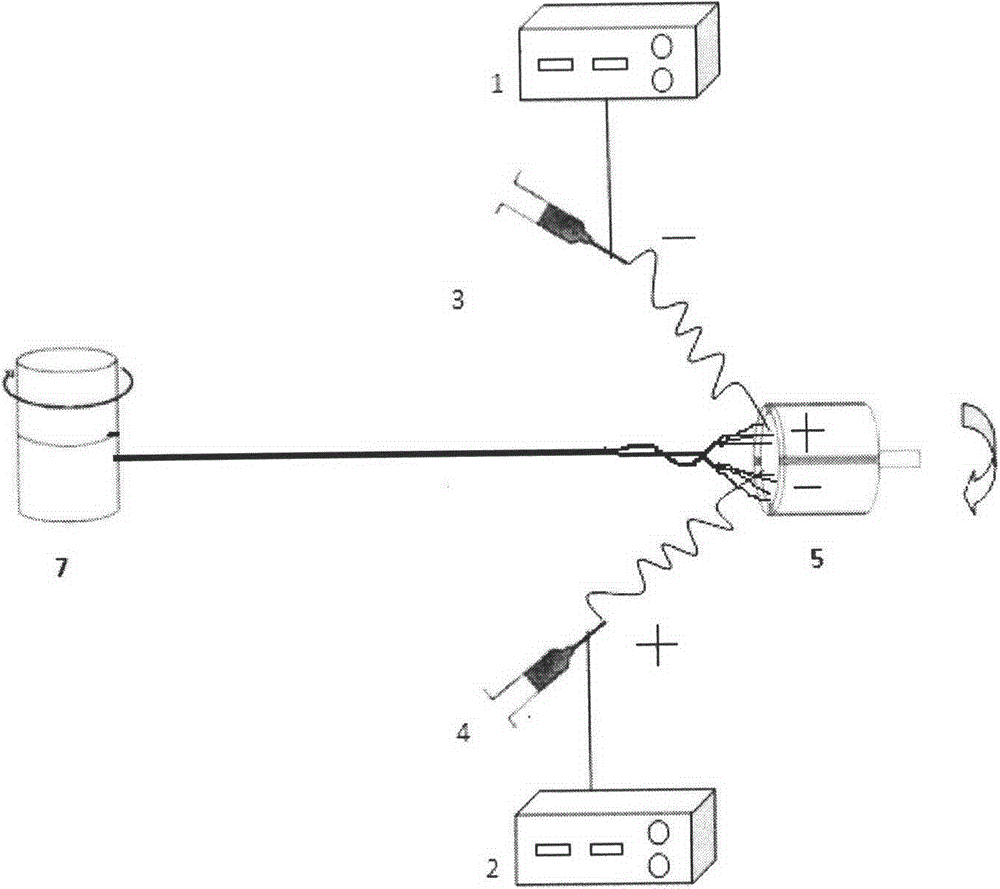

Production method and device for continuous nano-fiber yarn

ActiveCN104060355ARealize continuous preparationImprove mechanical propertiesArtificial thread manufacturing machinesFilament/thread formingYarnSpinning

The invention discloses a production method and device for a continuous nano-fiber yarn. The production method comprises the following processing steps: (1) preparing a polymer solution; (2) performing nano-jet injection and forming fibers; (3) forming the continuous nano-fiber yarn. The production device is designed according to the production method provided by the invention and mainly comprises a spinning system, a twisting system and a winding system, wherein the spinning system comprises an injection pump, an injector, a spinning nozzle and a high-voltage power supply; the twisting system comprises a controller and a turntable; the winding system comprises a solution tank, a roller and a controller. Compared with the prior art, the production method and device provided by the invention are characterized in that the continuous nano-fiber yarn is prepared by rotating and twisting two nano-fiber bundles which are formed by controlling the polarity of the turntable by an electric brush; the continuous preparation of the nano-fiber yarn is realized; the mechanical property of the yarn is increased; the twisting of the yarn is uniform; the yarn levelness is good; the hairiness is less; the application value is huge.

Owner:TIANJIN POLYTECHNIC UNIV

Warp knitted fabric containing cotton and processing method for warp knitted fabric

ActiveCN104131408AReduce uniformityHigh elongation at breakSucessive textile treatmentsFibre treatmentPolymer scienceSpinning

The invention discloses a warp knitted fabric containing cotton. The warp knitted fabric containing the cotton is formed by face filaments and middle filaments or face filaments, middle filaments and bottom filaments in a warp knitting mode, wherein the face filaments are polyester filament yarns, the middle filaments are natural fiber yarns, the bottom filaments are spandex stretch yarns, and the natural fiber yarns are processed through spinning, singeing, reeling, concentrated alkaline mercerizing, drying, wet waxing, dry waxing, rewinding and the like. The natural fiber yarns have the advantages of being high in strength, even in yarn evenness, good in wear resistance and the like, and can meet the requirement of warp knitting, and thus the natural fiber yarns can be used on a 28-stitch high stitch length warp knitting machine to serve as raw knitting materials of the warp knitted fabric containing the cotton. The natural fiber yarns contained in the warp knitted fabric containing the cotton have the skin friendly performance, and the warp knitted fabric containing the cotton is suitable for being worn by all people. The invention further discloses a processing method for the warp knitted fabric containing the cotton.

Owner:楠华技术信息(江苏)有限公司

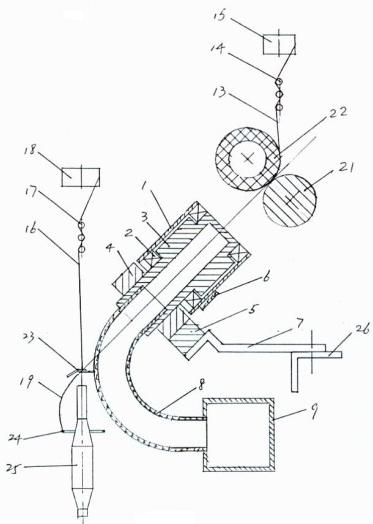

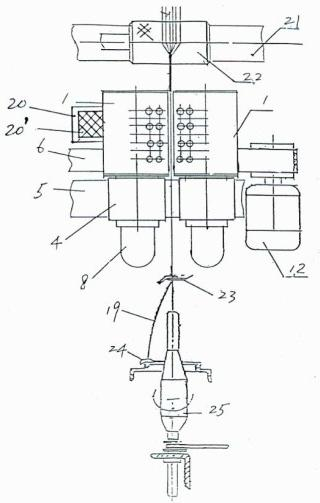

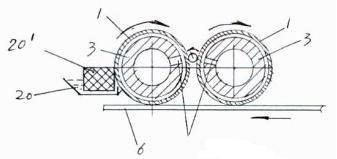

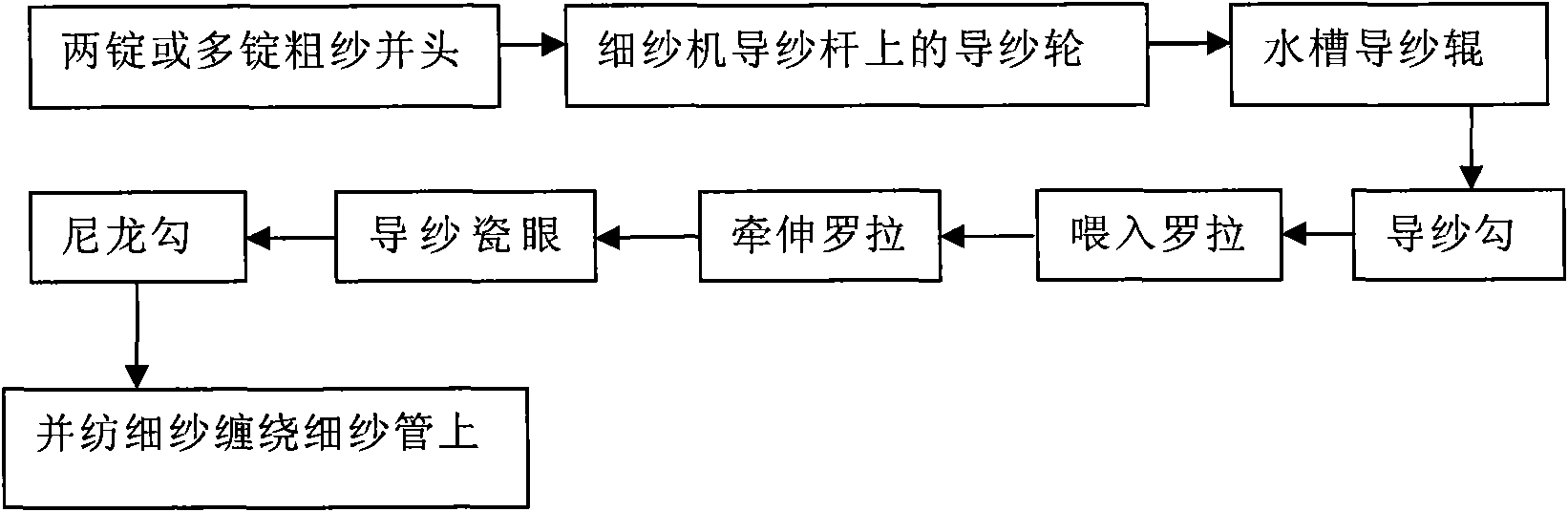

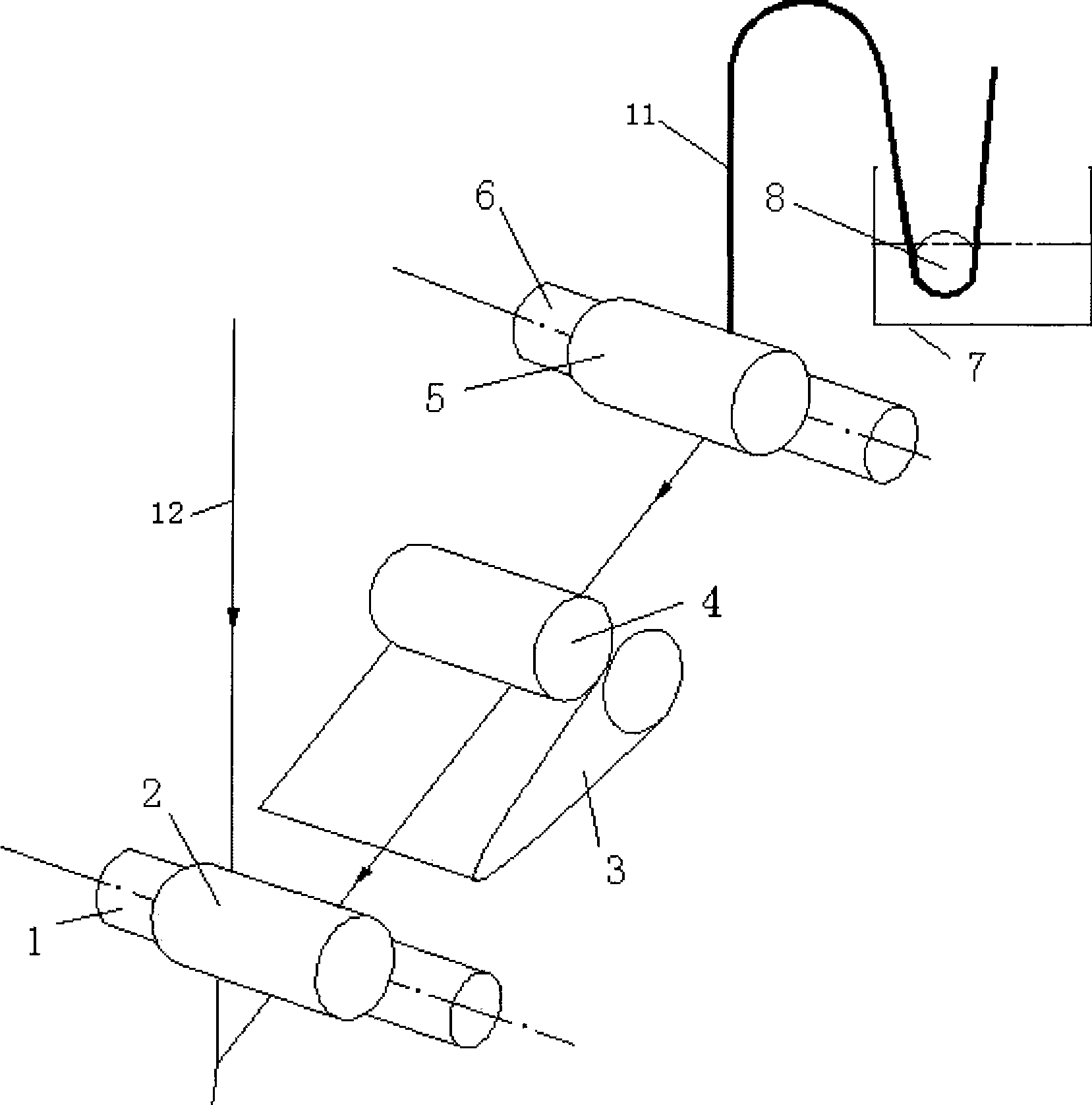

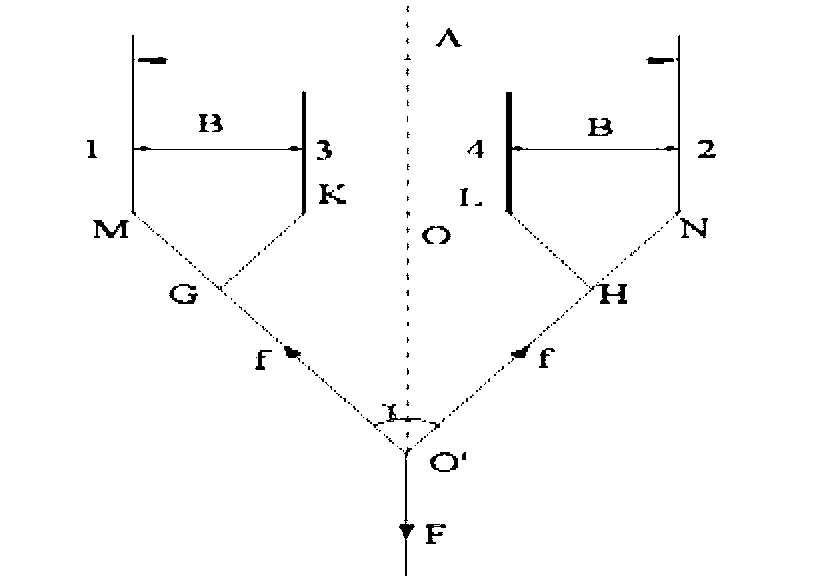

Flax wet-spun blended yarn and preparation method and spinning frame of flax wet-spun blended yarn

ActiveCN102704109AShinyColorfulBiochemical fibre treatmentDry-cleaning apparatus for textilesPolymer sciencePolymer chemistry

The invention discloses a flax wet-spun blended yarn comprising flax roves, wherein the flax roves comprise first flax roves and second flax roves, the number difference of the first flax roves and the second flax roves is not larger than 1.2, polyester filament yarns are added in the flax roves to form a flax wet-spun blended yarn main body, and the flax wet-spun blended yarn main body is in an S direction of twist. The invention also discloses a preparation method of flax wet-spun blended yarn. The invention also discloses a spinning frame for preparing the flax wet-spun blended yarn. The preparation method of the flax wet-spun blended yarn comprises the steps of: threading the polyester filaments with the first flax roves and the second flax roves to form the flax wet-spun blended yarn, wherein the flax wet-spun blended yarn is in the S direction of twist. The flax wet-spun blended yarn disclosed by the invention has the advantages of being gorgeous, glossy, stiff and smooth and durable, and needing no ironing.

Owner:JIANGSU HUAXIN LINEN TEXTILE

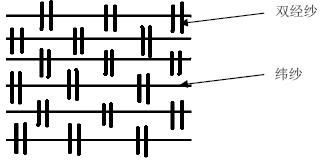

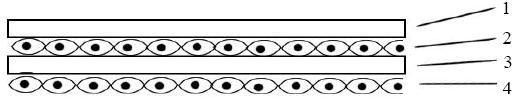

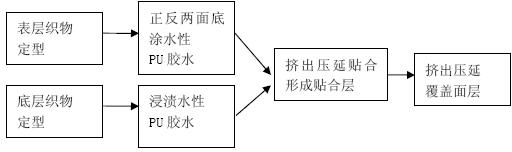

Burr-proof thermoplastic polyurethane elastic body conveying belt for food industry and manufacture method thereof

The invention relates to a burr-proof thermoplastic polyurethane elastic body conveying belt for food industry, which has the total thickness being 1.2 to 1.5mm and sequentially comprises a covering surface layer, surface layer fabrics, a pasting layer and bottom layer fabrics from top to bottom, wherein the fabrics are respectively formed by two warp yarns and one weft yarn through plain interweaving, in addition, the bottom layer fabrics are soaked with polyurethane (PU) glue water, and both the covering surface layer and the pasting layer are made of thermoplastic polyurethane (TPU). A manufacture method comprises the following steps that: the surface layer fabrics and the bottom layer fabrics are formed, so the fabric surface temperature reaches 180 to 190 DEG C, the front side and the back side of the surface layer fabrics are subject to prime coating by aqueous polyurethane glue water, and then, the surface layer fabrics are placed into a baking oven to be dried; the bottom layer fabrics are soaked into a soaking tank of the aqueous polyurethane glue water, are rolled by an anilox roller and are placed into the baking oven to be dried; the surface layer fabrics and the bottom layer fabrics are calendered and pasted; and a TPU covering surface layer is calendered on the surface of a semi-finished product. The burr-proof thermoplastic polyurethane elastic body conveying belt and the manufacture method have the advantages that periphery burrs are prevented from being mixed into food in the food conveying process, the food pollution is reduced, the burrs are reduced, the damage to two sides of the conveying belt is reduced, the post hemming tidying is not needed, and the production efficiency is improved.

Owner:SHANGHAI YONGLI BELTING +1

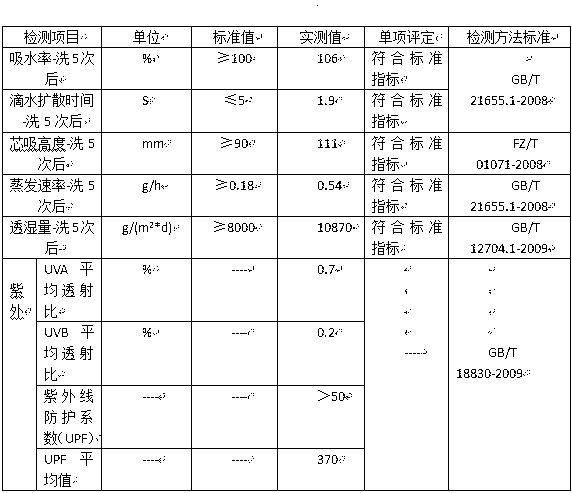

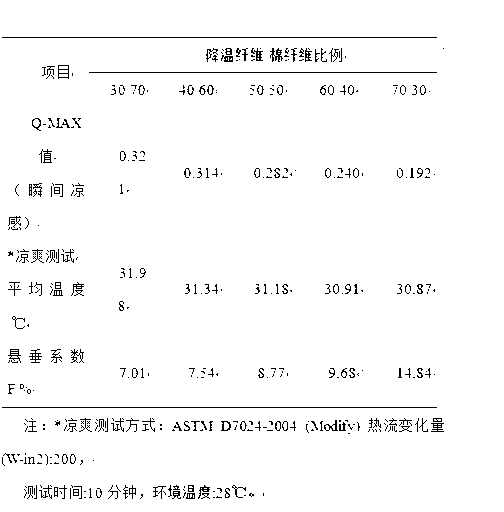

Tooling fabric with cooling function and uvio-resistant function

The invention relates to tooling fabric with a cooling function and an uvio-resistant function. A method for manufacturing the tooling fabric with the cooling function and the uvio-resistant function comprises a first step of using cooling master batch as raw materials and manufacturing the cooling master batch to slicing sheets, a second step of drying the slice sheets, a third step of carrying out spinning on the slicing sheets through a spinning box to manufacture nylon base cooling fibers, a fourth step of adopting a siro spinning technology to spin cotton fibers and the nylon base cooling fibers into blended yarn, and a fifth step of adopting technological measures of 'early opening, later weft insertion and on-machine tension slightly larger' to carry out weaving. A formula of the cooling master batch comprises PA6, bowlder powder, zirconium dioxide powder, silicon dioxide powder, stearic acid dispersants, polystyrene dispersants, low molecular wax dispersants and titanate coupling agents. The tooling fabric has functions of fast heat absorption and fast heat dissipation, and an everlasting cooling feature is guaranteed. Meanwhile, the tooling fabric further has a notable uvio-resistant feature.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

High-grade elastic moisture-absorbing quick-drying face fabric

InactiveCN1804198AImprove textureSoft touchWeft knittingBiochemical fibre treatmentYarnColour fastness

The disclosed processing method for a high-grade plastic hygroscopic quick-drying face fabric comprises: using cotton yarn as face yarn and terylene as ground yarn, joining elastic yarn for weft knitting; then, sorting by bio-enzyme and resin by turns, and treating for hygroscopic quick-drying. This product is fine and smooth for soft hand feeling, can show people elegant line and enhance stretch range by well elasticity and color fastness, and reduces its friction and stimulation to skin.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

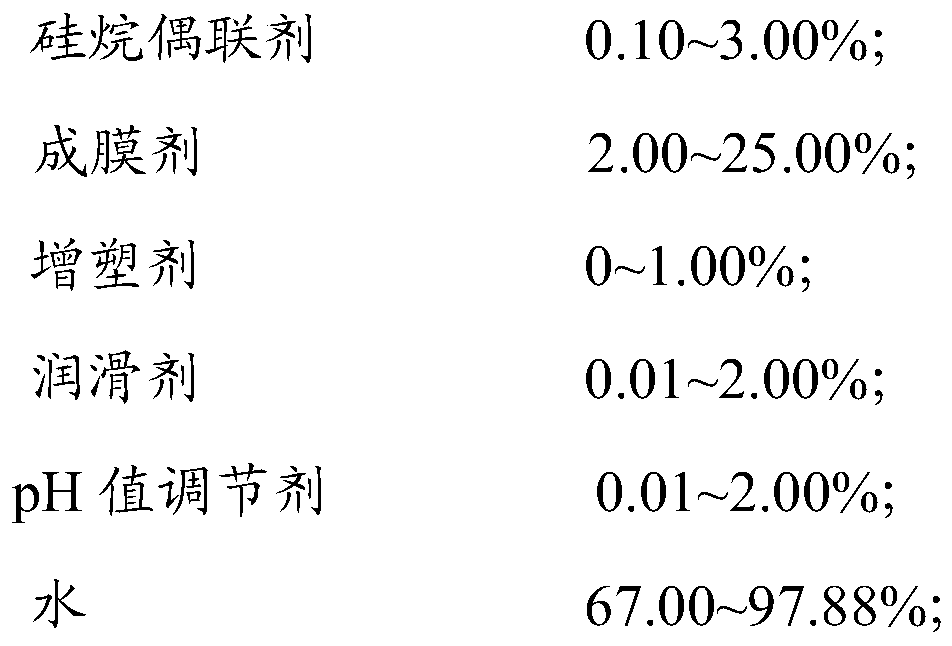

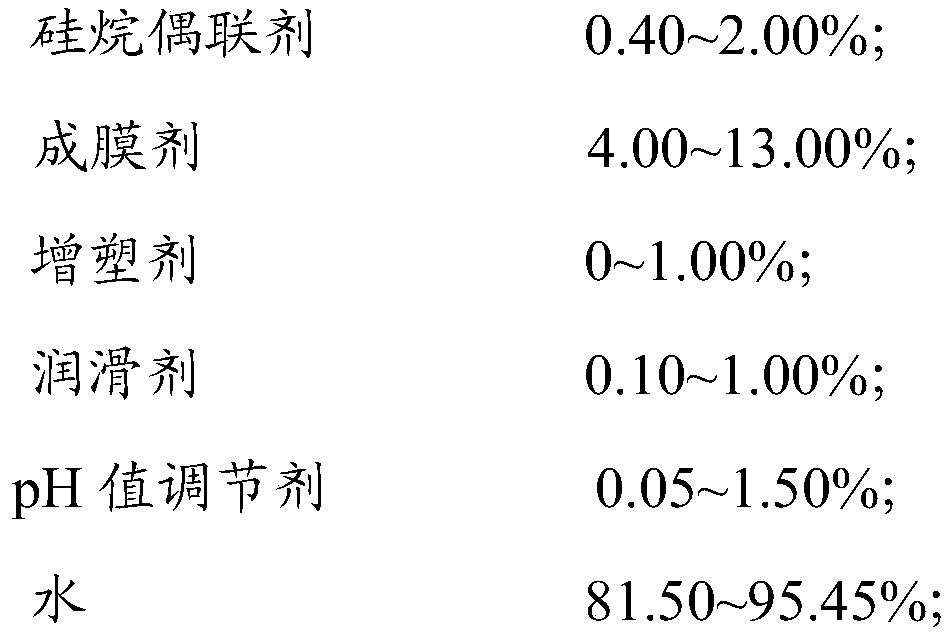

Glass fiber soakage agent and preparation method and application thereof

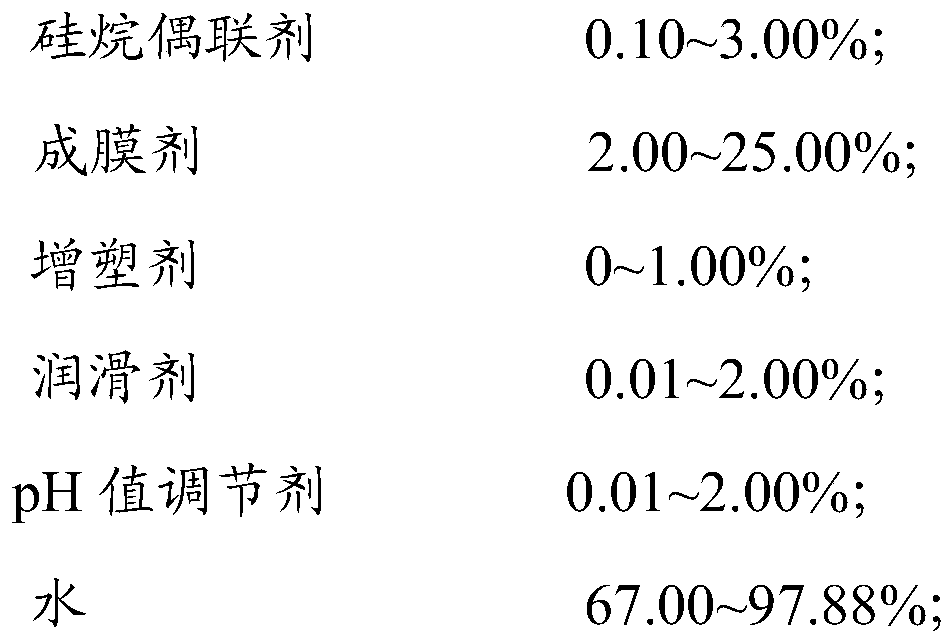

The invention provides a glass fiber soakage agent. The glass fiber soakage agent is suitable for an extrusion and injection moulding process. The glass fiber soakage agent is prepared from, by mass,0.10-3.00% of a silane coupling agent, 2.00-25.00% of a film forming agent, 0-1.00% of a plasticizer, 0.01-2.00% of a lubricating agent, 0.01-2.00% of a pH regulating agent and 67.00-97.88% of water;the film forming agent is a mixture of a first film forming agent and a second film forming agent, and the mass ratio of the first film forming agent to the second film forming agent is 10:1-1:8. Produced glass fiber twistless roving coated with the soakage agent is suitable for production of glass fiber reinforcement thermoplastic plastic.

Owner:JUSHI GRP CO

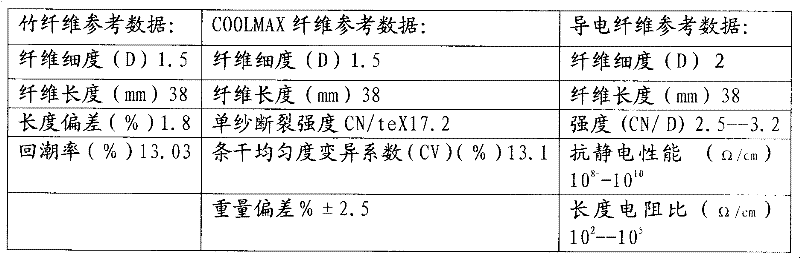

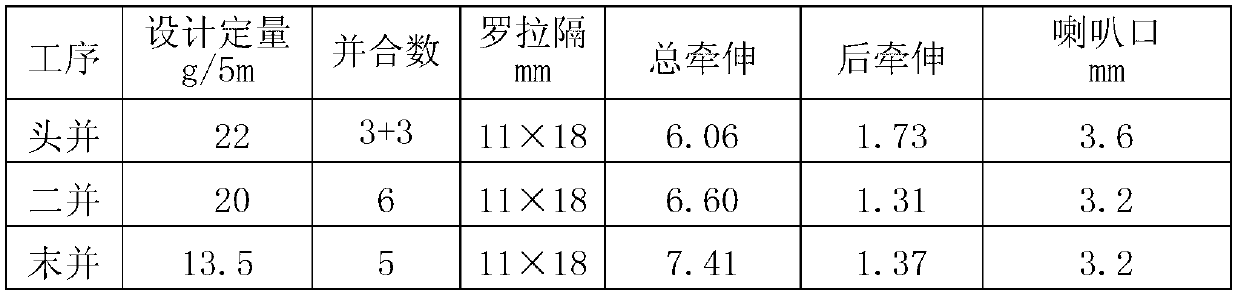

Bamboo fiber, Coolmax fiber and conductive fiber blended yarn and method for producing same

The invention discloses a bamboo fiber, Coolmax fiber and conductive fiber blended yarn and a method for producing the same. The bamboo fiber, Coolmax fiber and conductive fiber blended yarn has functions and characters of the three types of fibers, has complementary advantages, and has unique nobility by being spun by siro-spinning technology. The functional yarn can be used for knitting and tatting. A fabric made of the bamboo fiber, Coolmax fiber and conductive fiber blended yarns has the functions and characters of high strength, fine shape retention, high breathability, high moisture absorption, high sweat releasing, antibiosis, dust proofing, electrostatic resistance, ultraviolet resistance, environment-friendliness, easiness in caring, resistance to washing, stable size, softness and smoothness in touch and the like, is especially suitable for being made into knitted sports underwear, underpants, T-shirts, sportswear, shirts, hats and the like, and contributes to clothing grade increase and improvement on people's life quality, and commercial opportunities are supplied to textile enterprises. Therefore, great social benefit and economic benefit are achieved.

Owner:SHAOXING HENGMEI FANCY SILK +1

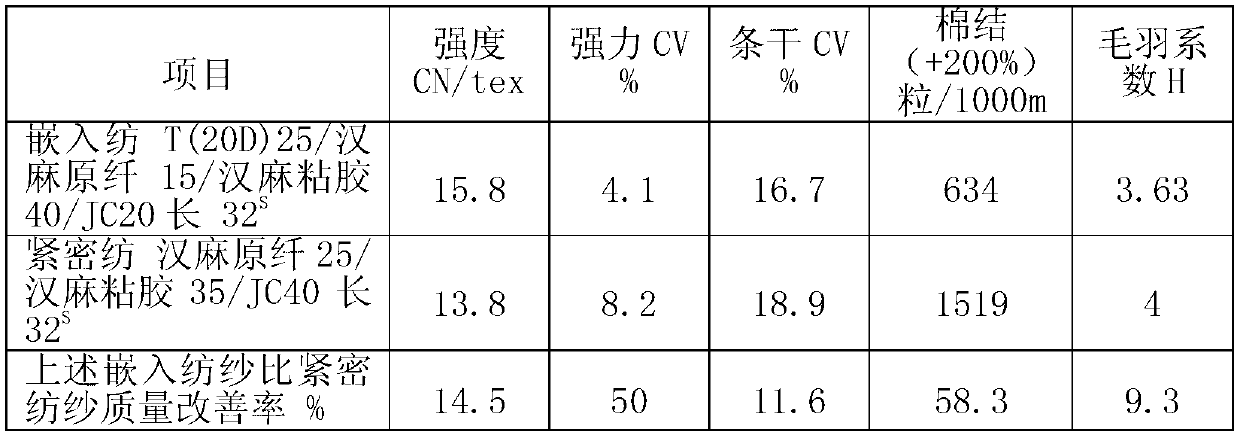

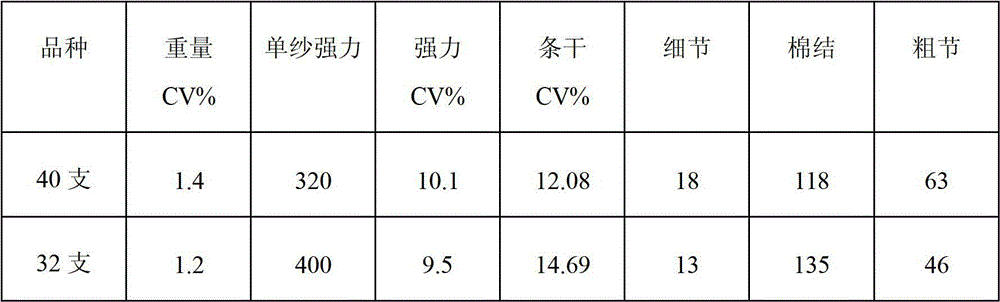

China hemp native fiber multicomponent blended yarn and preparing method thereof

The invention provides a China hemp native fiber multicomponent blended yarn. The China hemp native fiber multicomponent blended yarn is high in brute force, good in evenness, and anti-pilling, has a soft and smooth yarn body, and is obvious in characteristic and stable in quality. The China hemp native fiber multicomponent blended yarn is blended of 25% of filaments, 15% of China hemp native fibers, 40% of China hemp viscose fibers and 20% of long stapled cotton and made through embedding spinning technique. The invention further provides a preparing method of the China hemp native fiber multicomponent blended yarn. The preparing method comprises the following steps: a, maintenance pretreatment of the China hemp native fibers is conducted, and softening antistatic oiling agents are spayed on the China hemp native fibers; b, blowing and carding of the China hemp native fibers are conducted; c, the processed China hemp native fibers and the long stapled cotton are combed and blended into strips; d, the China hemp viscose fibers are processed into strips independently; and e, the blending combining strips of the China hemp native fibers and the long stapled cotton, and the China hemp viscose fibers are pre-drawn and mixed, then roving and embedding finespinning are conducted, and the filaments are combined during embedding finespinning.

Owner:江苏悦达棉纺有限公司

Tencel blended yarn and preparation method thereof by vortex spinning

ActiveCN102747477ALess hairySuitable yarn requirements for knitted garmentsContinuous wound-up machinesOpen-end spinning machinesYarnCarding

The invention discloses a tencel blended yarn. The tencel blended yarn is characterized by consisting of the following components in percentage by weight: 20-50 percent of tencel fiber and 50-80 percent of chemical fiber. The invention also discloses a preparation method for the tencel blended yarn. The preparation method comprises the steps of raw material selection, cotton winding, cotton carding, mixing and blending and vortex blending. Control parameters comprise that the spinning speed is 330-360turn / min, the total draft multiple is 238-245; the main draft multiple is 28-32, the BR start rate is 120, the temperature of a workshop is controlled to 25-28DEG C and the humidity is controlled to 60-65 percent. The tencel blended yarn disclosed by the invention has the advantages of less feather and suitability of meeting the requirement on yarns for knitted clothing. In addition, the tencel fiber is successfully spun by the vortex spinning for the first time; and rougher yarns with great yarn twist can be generally spun by traditional rotor spinning. According to the preparation method disclosed by the invention, the defects are overcome and functional fibers are spun by vortex spinning so as to improve the quality of yarns.

Owner:ZHEJIANG SHUANGDUN TEXTILE TECH CO LTD

Jutecell underwear fabric and manufacture method thereof

The invention discloses a Jutecell underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The Jutecell underwear fabric is characterized by comprising the following components based on part by weight: 50 to 70 parts of Jutecell, 10 to 20 parts of Modal, 10 to 20 parts of Newdal, and 5 to 10 parts of polyurethane elastic fibers. The manufacture method comprises the following steps that: the Jutecell, the Modal and the Newdal are spun into compact spinning blended yarns; the compact spinning blended yarns are interwoven with the polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric is subjected to preshaping, dyeing, drying and shaping treatment. The fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also sufficiently reflects itching feel, bactericidal and antifungal activity, moisture absorption and fast dryness; and Modal has soft hand feeling, bright color, the Newdal is smooth and has good drapability, and the polyurethane elastic fiber has excellent performance of stretching and extending. The fabric adopts a unique textile structure to lead the appearance of the fabric to be more unique.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

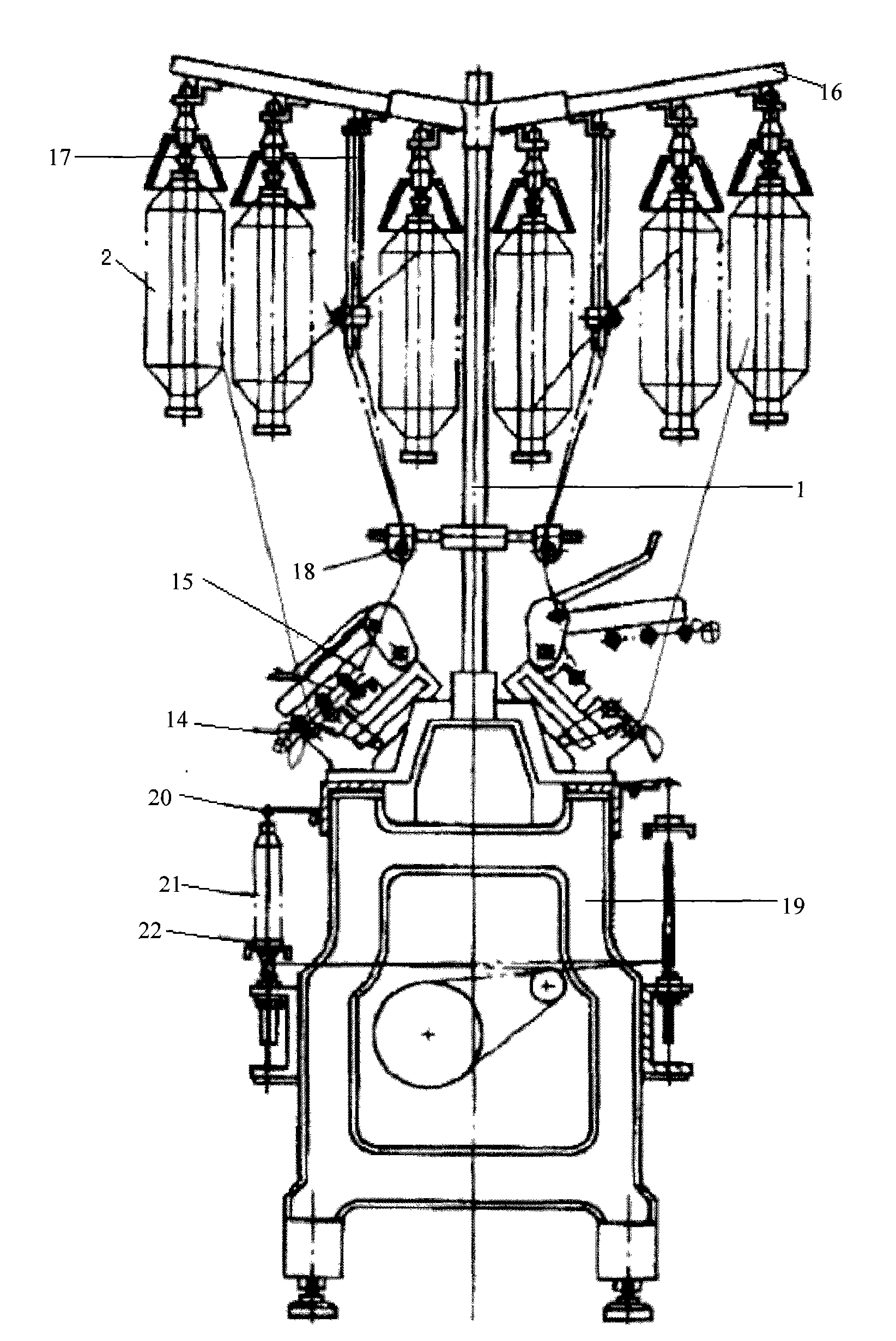

Device and method for producing compound yarn by compact siro spun

The invention relates to a device and method used compact Siro spinning to produce folded yarn. The device includes ingot crane, two parallel rove, back leather roller, traversing guide trumpet port, draft field, front leather roller, plug-in unit sucking sheet, draught-deflector presser bit, gathering roller, guide leather roller, guide wire, traveler, spindle, and ring cop. The method includes the following steps: making two roves enter the draft field through traversing guide trumpet port, lead out by gathering roller and guide leather roller; forming V shape arrange in gathering area with compact structure without spinning triangular space; twisting to roll around the ring cop. The invention has simple structure, convenient operation, can solve the problem of instable spinning performance.

Owner:SHIJIAZHUANG CHANGSHAN HENGXIN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com