Spinning method for performing damp heat ironing treatment to fiber strands

A technology of ironing and damp heat, applied in textiles and papermaking, etc., can solve the problems such as insignificant improvement of yarn hairiness, evenness and strength, little improvement in yarn evenness and strength, underutilization of denaturation, etc. , to achieve the effect of improving yarn strength, small operation influence and reducing kink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

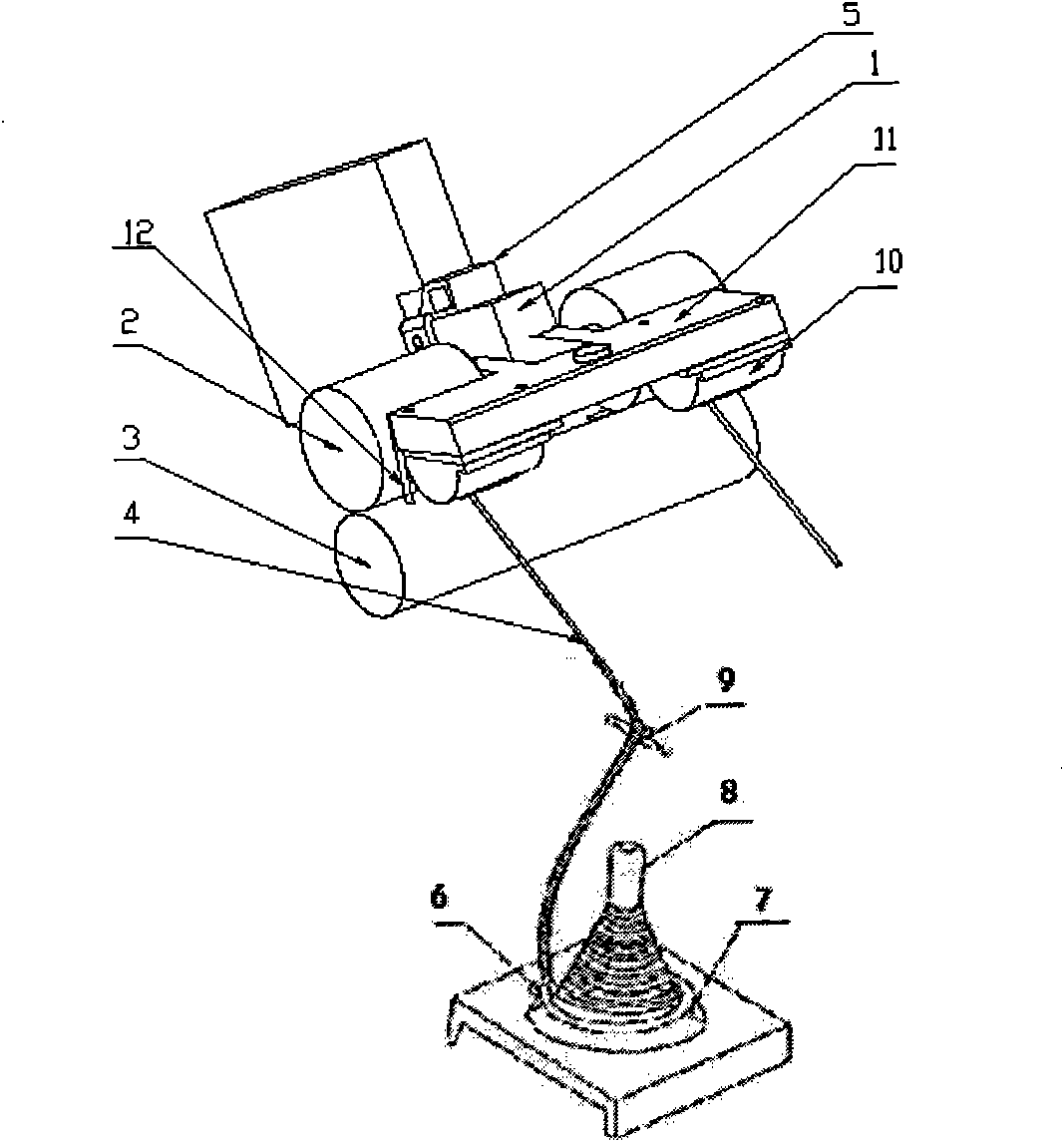

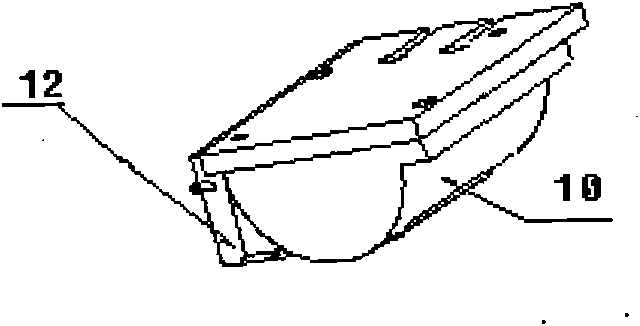

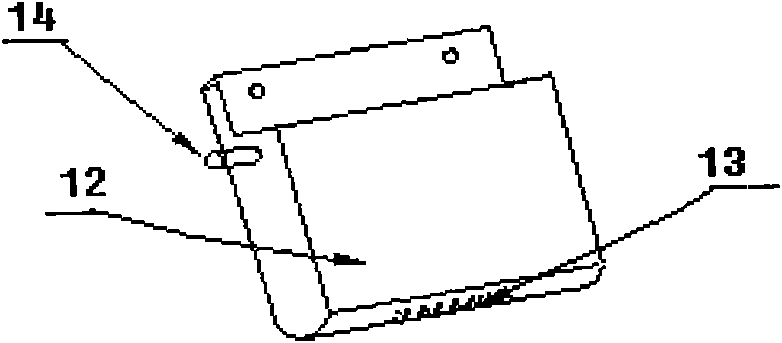

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail, see accompanying drawing.

[0018] 1 is the cradle body, 2 is the front top roller, 3 is the front roller, 4 is the beard, 5 is the limit device, 6 is the traveler, 7 is the steel ring, 8 is the spinning bobbin, 9 is the guide hook, 10 is an ironing treatment part, 11 is a base, 12 is a humidifying device, 13 is a small through hole, and 14 is a liquid inlet.

[0019] As mentioned above, in the spinning process, the physical properties of the fibers are an important internal factor affecting the hairiness of the yarn. , the fibers are easily squeezed to the outer layer of the yarn to form hairiness. Studies have shown that the stiffness of the fiber decreases with the increase of humidity and temperature. The present invention is based on the principle that the stiffness of fibers decreases under high humidity and high temperature. A damp heat ironing treatment device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com