Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

A technology of rare earth alloys and manufacturing methods, applied in the direction of metal/alloy conductors, root rods/rods/wires/strip conductors, etc., can solve the problems of unguaranteed conductor performance and restrictions on the promotion of aluminum conductors, and achieve good strength and toughness The effect of matching, reducing defect density, and increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

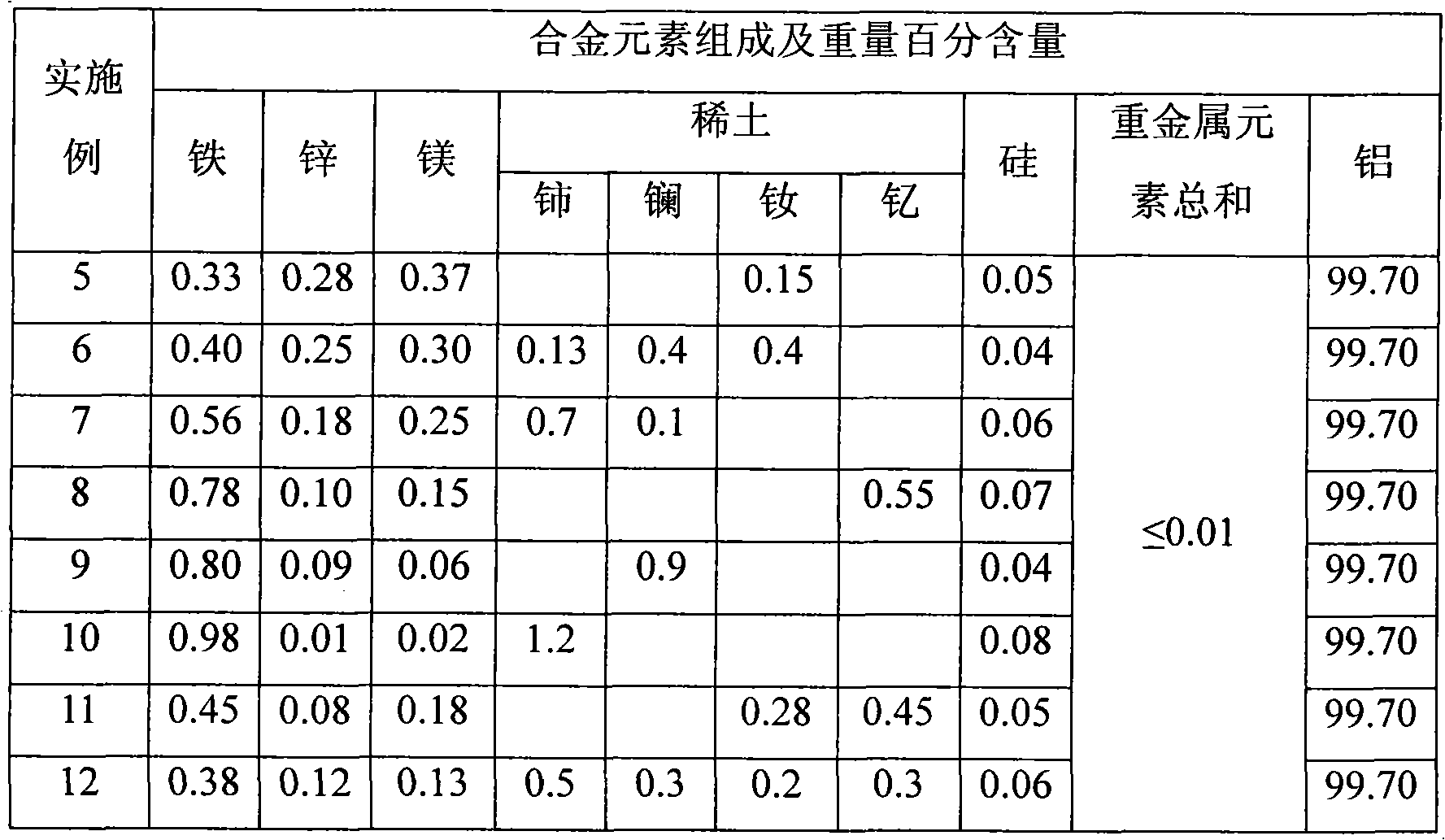

[0019] An aluminum-iron-zinc-magnesium rare-earth alloy wire, the composition and weight percentage are: 0.3-1.2% iron, for example, 0.4%, 0.5%, 0.6%, 0.7%, 0.9%, 1.1%; 0.01-0.3% % zinc, for example, can be selected as 0.05%, 0.1%, 0.2%, 0.22%; 0.01-0.4% of magnesium, for example, magnesium can be selected as 0.05%, 0.1%, 0.2%, 0.22%, 0.3%, 0.35; 0.1 -1.5% rare earth elements, rare earth elements can be selected as 0.3%, 0.5%, 0.8%, 1.2%, 1.4%, and the rest are aluminum and unavoidable impurities. The rare earth element is one or more of cerium, lanthanum, neodymium, and yttrium, and if it is a mixture, it can be in any proportion. The silicon content of the alloy is ≤0.1%, and the total weight percentage content of vanadium, titanium, chromium and manganese heavy metals is ≤0.01%.

Embodiment 2

[0021] 1. A method for manufacturing aluminum-iron-zinc-magnesium rare-earth alloy cloth wires. The ratio described in Example 1 is used, and aluminum ingots are put into a shaft furnace for melting. When the aluminum alloy liquid flows into the holding furnace, the temperature is controlled at 710-750°C.

[0022] 2. Raise the temperature of the furnace to 750-780°C, add aluminum-iron master alloy, aluminum-zinc master alloy, and aluminum-magnesium in sequence, and use electric stirring for 10 minutes to make it evenly distributed.

[0023] 3. Add the aluminum rare earth master alloy, add 2 / 3 of the aluminum rare earth master alloy in the first 10 minutes, stir for 5 minutes, then add 1 / 3 of the aluminum rare earth master alloy after 10 minutes, stir for 10 minutes, fully stir to make the alloy composition And the distribution of rare earth as even as possible, so that the effect of rare earth treatment to achieve the best.

[0024] 4. After the aluminum alloy liquid fills the...

Embodiment 3

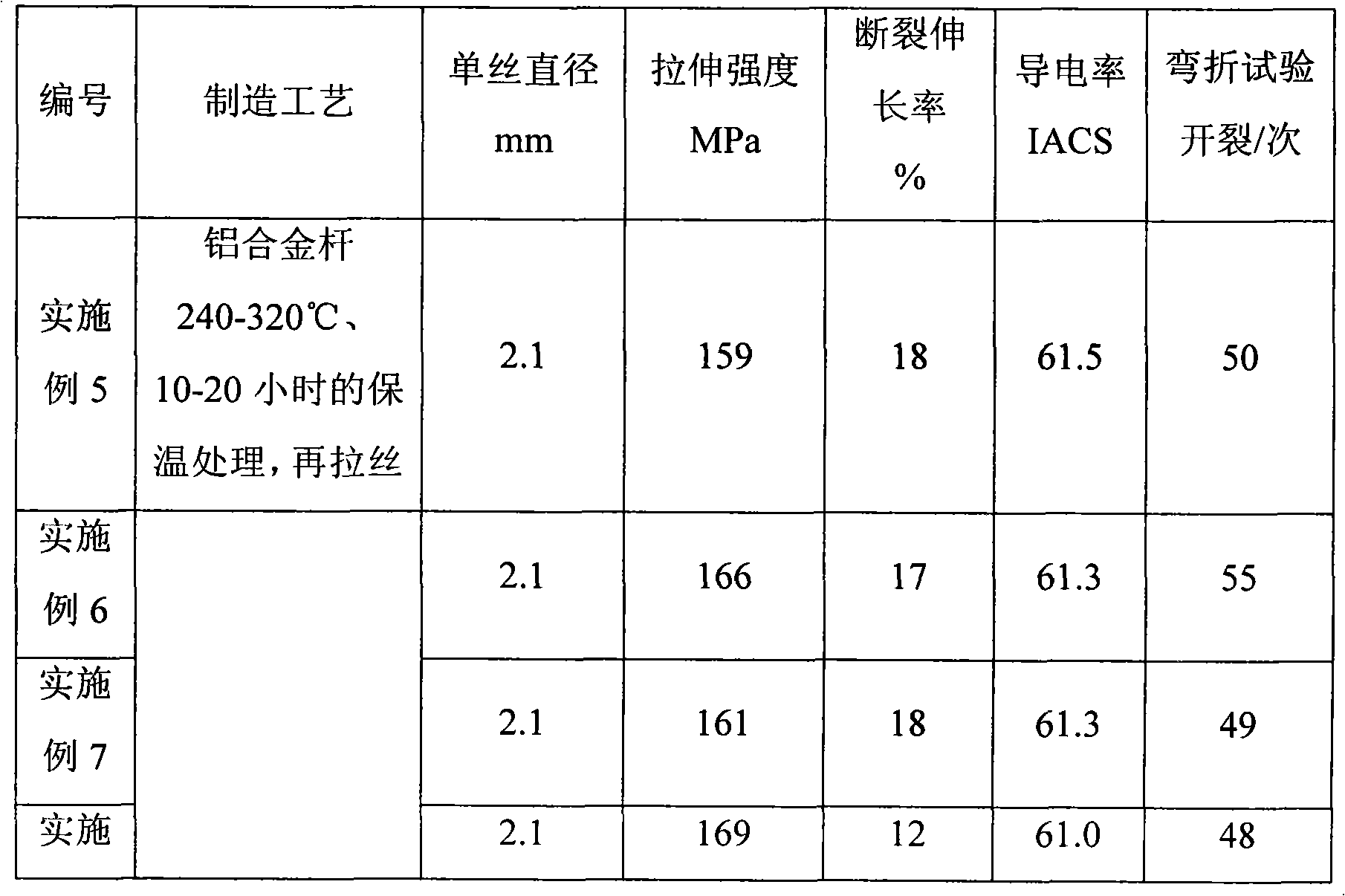

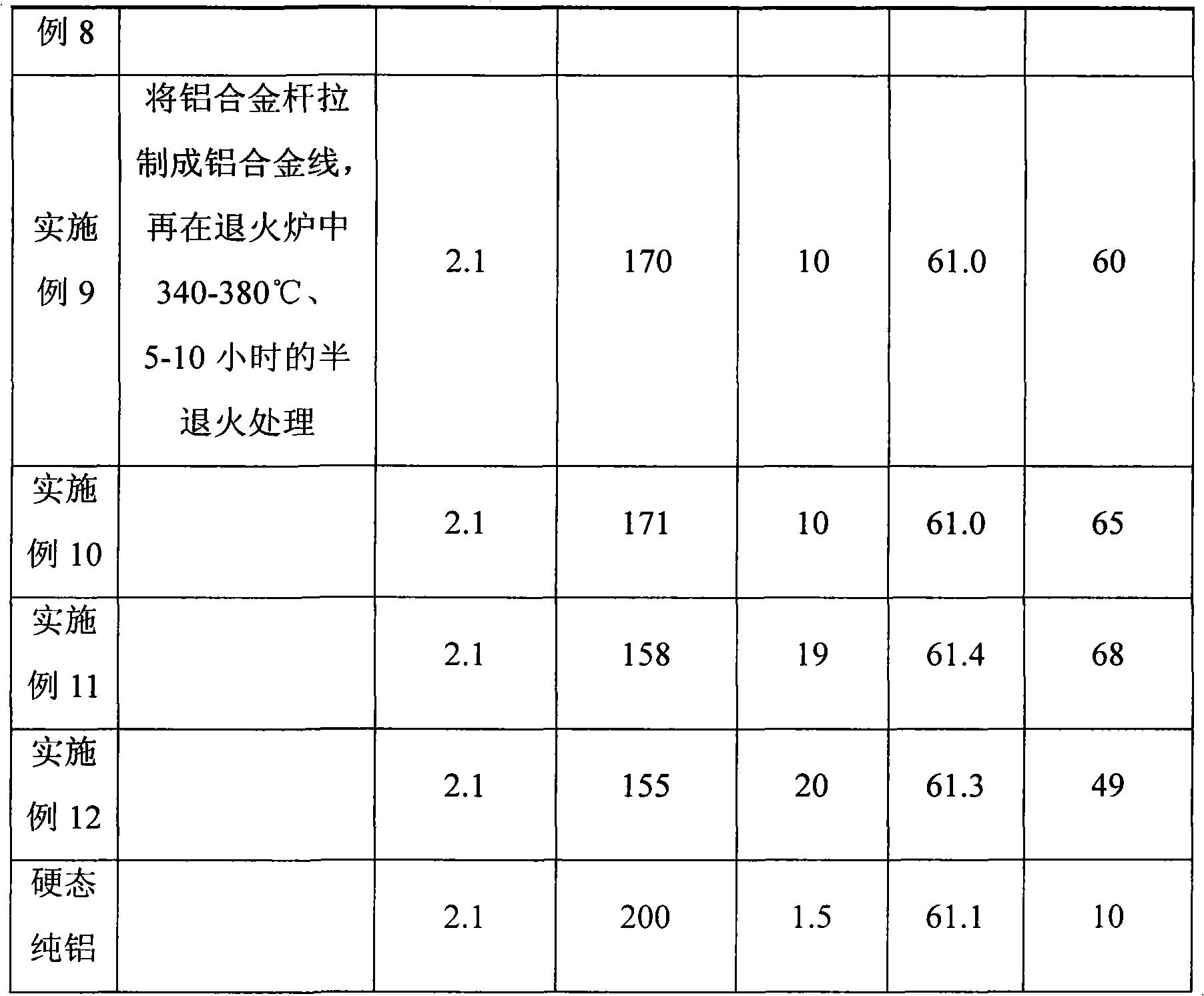

[0036]A method for manufacturing aluminum-iron-zinc-magnesium rare-earth alloy cloth wires. According to the composition ratio described in Example 1, the process method described in Example 2 is rolled into an aluminum alloy, and the aluminum alloy wire is cold-drawn from an aluminum alloy rod , and then conduct semi-annealing treatment at 340-380°C for 5-10 hours, and finally extrude the insulation. For example, the temperature can be selected as 350°C, 360°C, 365°C, and the treatment time can be selected as 6 hours, 7.5 hours, and 9 hours. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com