Patents

Literature

78results about How to "Improve yarn strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

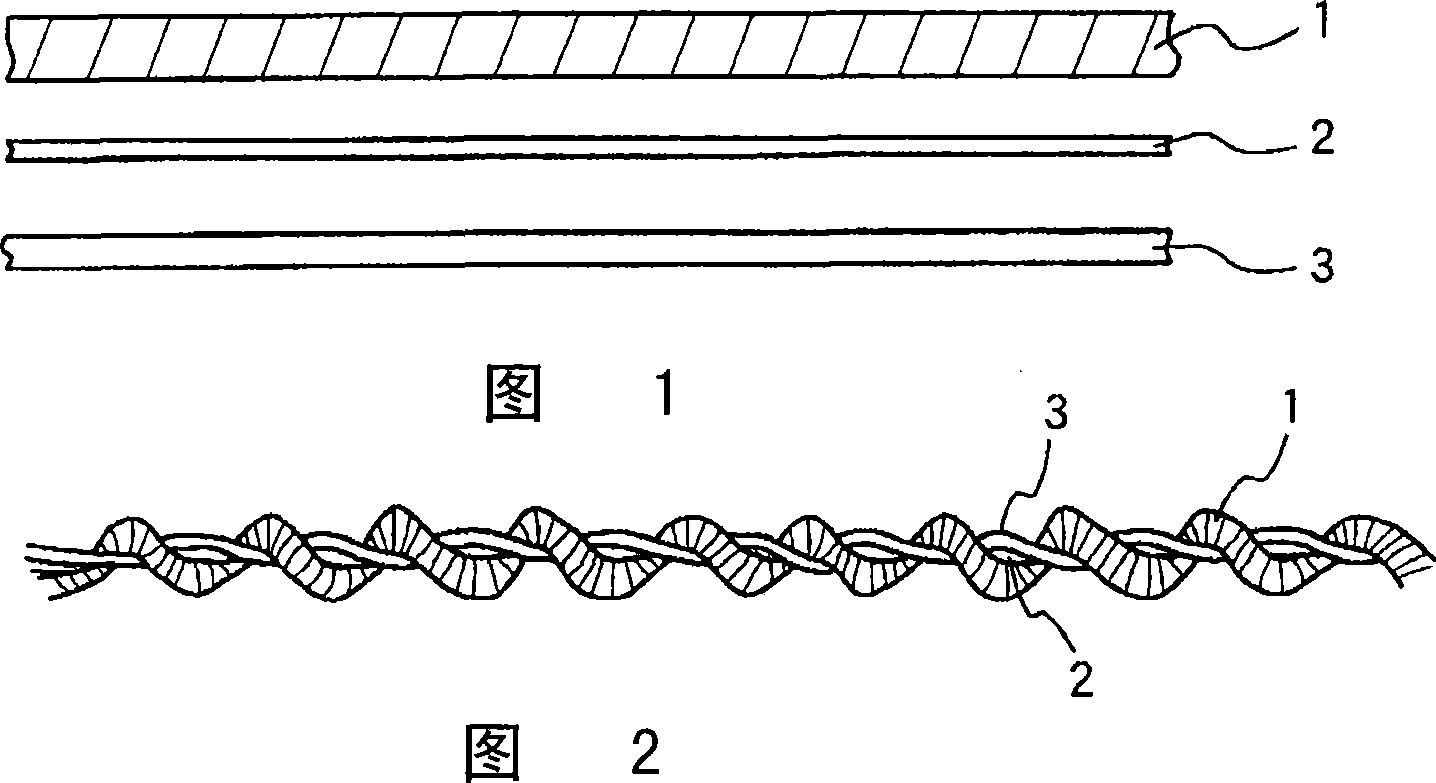

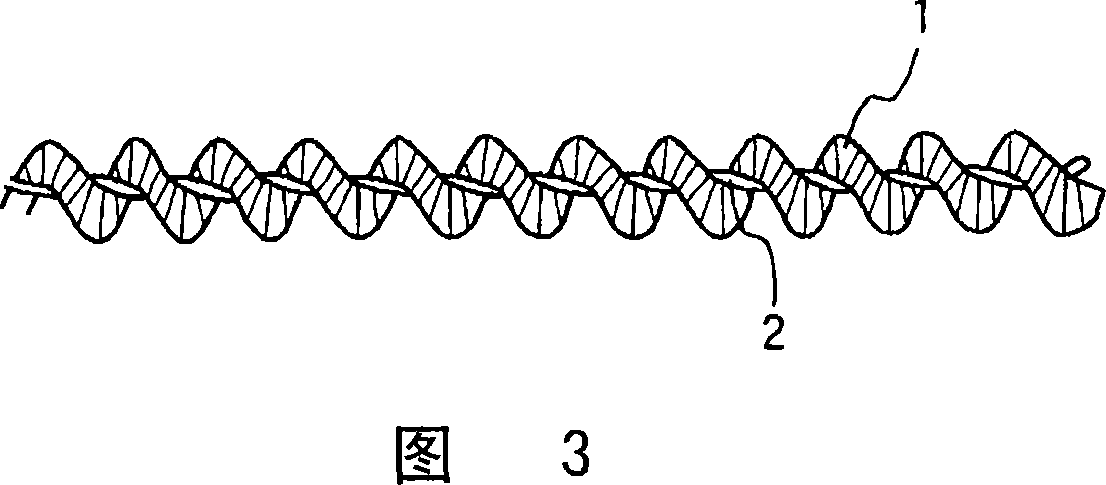

Composite twist yarn

The present invention relates to the production of woven or knitted fabrics or fabrics, which have high yarn strength, can be woven or knitted with high-speed looms or knitting machines, will not cause problems such as thread breakage, and have high stretchability sex. The present invention also prepares a composite twisted yarn, which at least twists a spun yarn and a water-soluble yarn, the twist direction of the composite twisted yarn is opposite to that of the spun yarn, and satisfies the following necessary conditions (1 ) or (2): (1) The twist number of the composite twisted yarn is 1.3-3 times that of the spun yarn, and the ratio (weight ratio) of the spun yarn to the water-soluble yarn is spun yarn / Water-soluble yarn = 20 / 80-98 / 2; (2) further twist the elastic yarn (2) stretched to 2-5 times, and the twist number of the composite twisted yarn relative to the twist number of the spun yarn is 0.3-3 times, while the ratio (weight ratio) of spun yarn (1) to the above-mentioned elastic yarn (2) is spun yarn (1) / elastic yarn (2)=50 / 50-99.9 / 0.1, spun yarn (1) and the total amount of elastic yarn (2) and the ratio (weight ratio) of water-soluble yarn (3) is: total amount of spun yarn (1) and elastic yarn (2) / water-soluble yarn (3)= 30 / 70-99 / 1.

Owner:KURARAY TRADING CO LTD +1

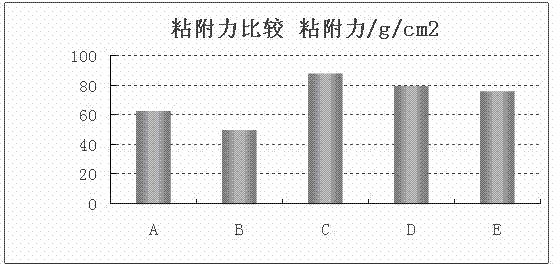

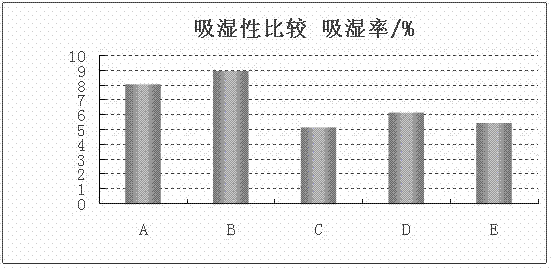

Acrylic acid textile size and preparation method thereof

ActiveCN102532399AImprove yarn strengthReduced yarn hairinessFibre treatmentAmmonium sulfateSolubility

The invention relates to an acrylic acid textile size and a preparation method thereof. Raw materials of the size include methyl acrylate (MA), butyl acrylate (BA), acrylic acid (AA), acrylamide (AM), ammonium persulfate (APS), a composite emulsifier, ammonia water and deionized water, wherein the composite emulsifier is a mixture of AEO-5 and AEO-7. The size prepared with the method has high adhesion, low hydroscopic property and high water solubility.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

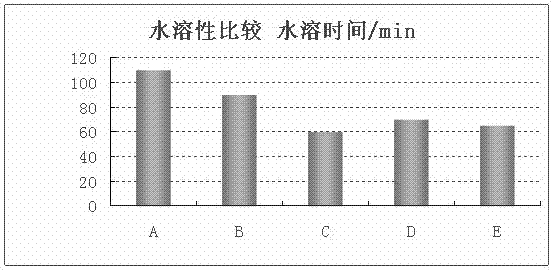

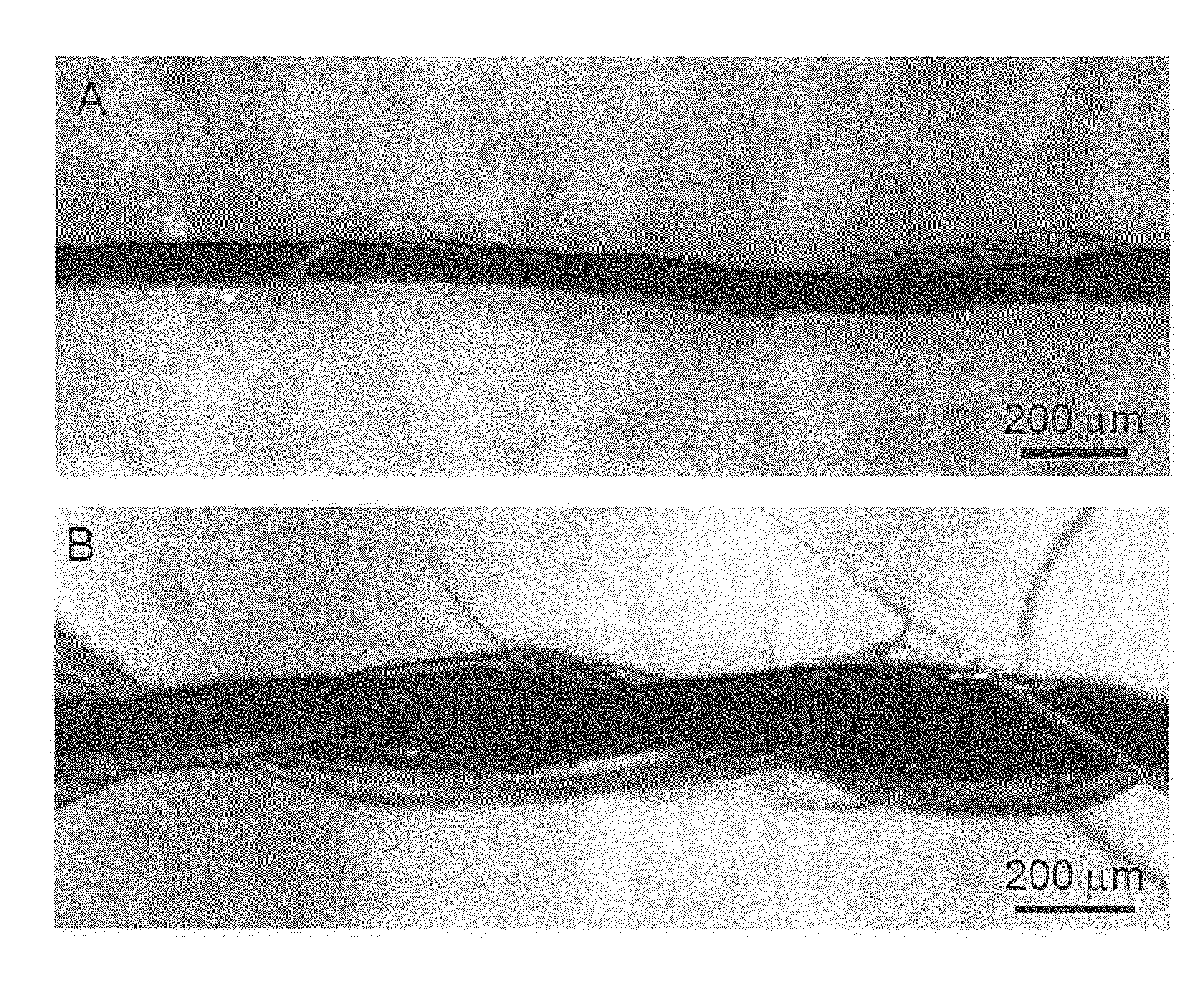

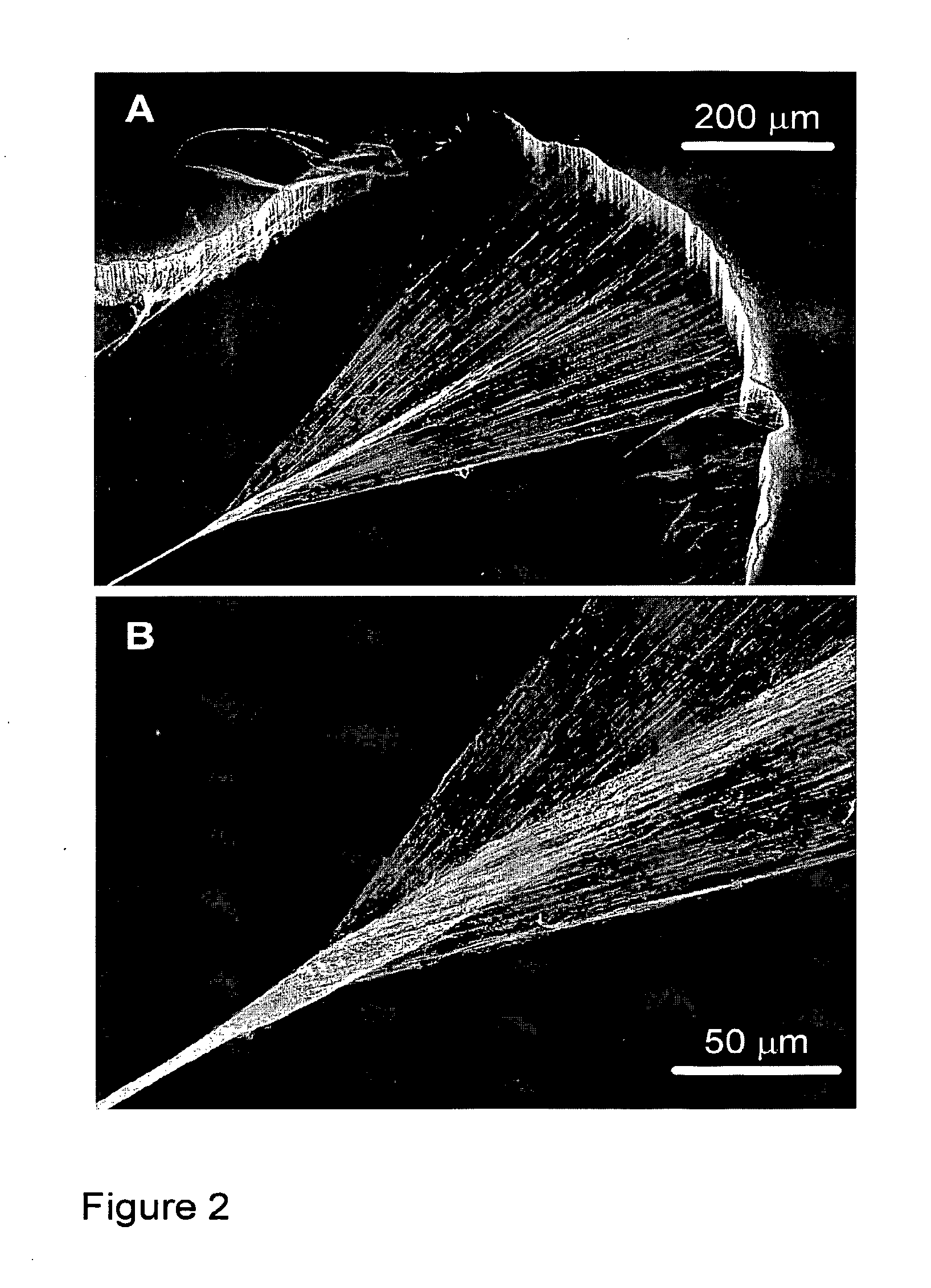

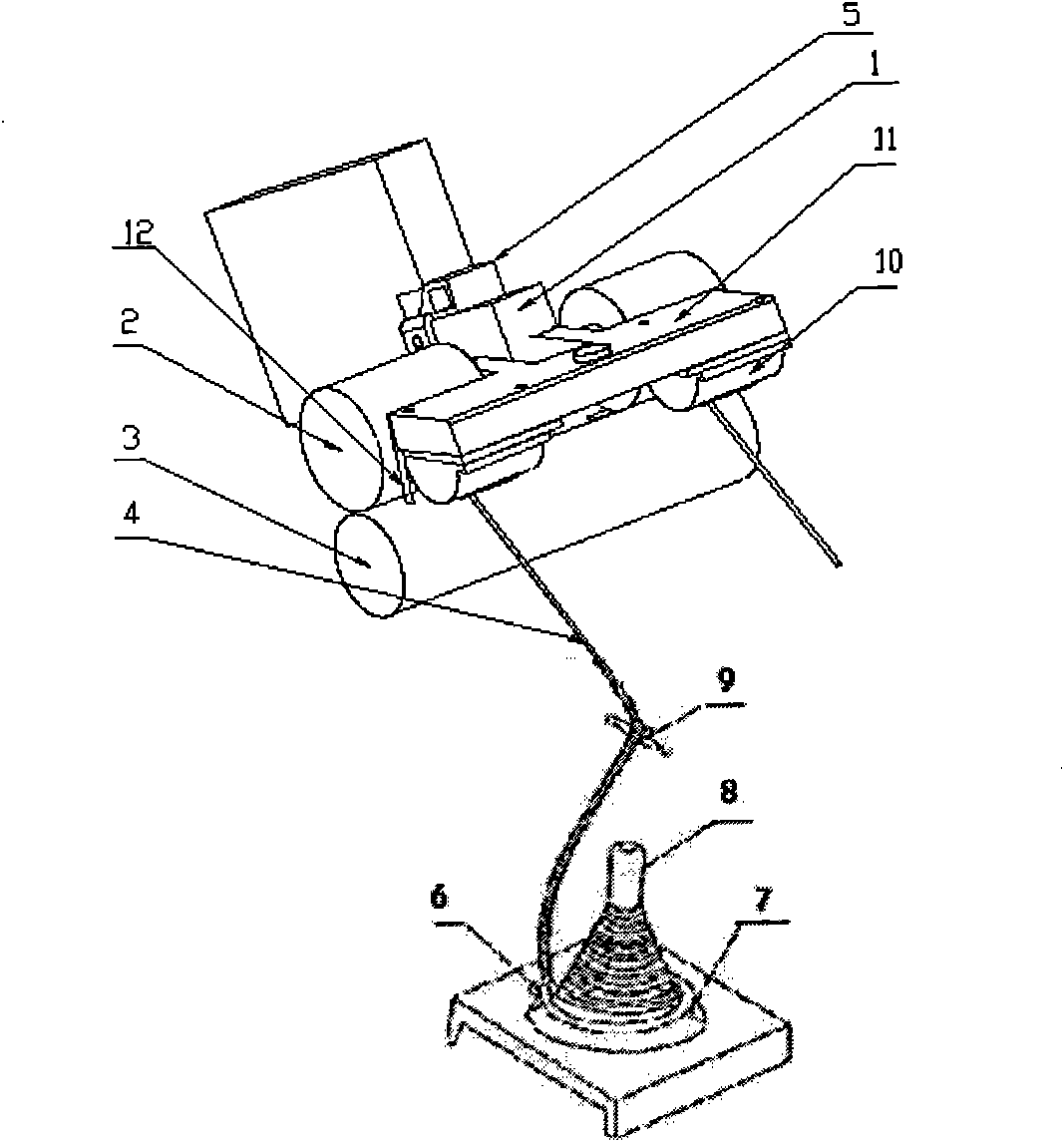

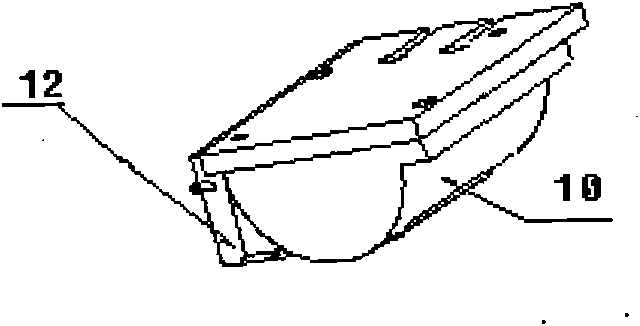

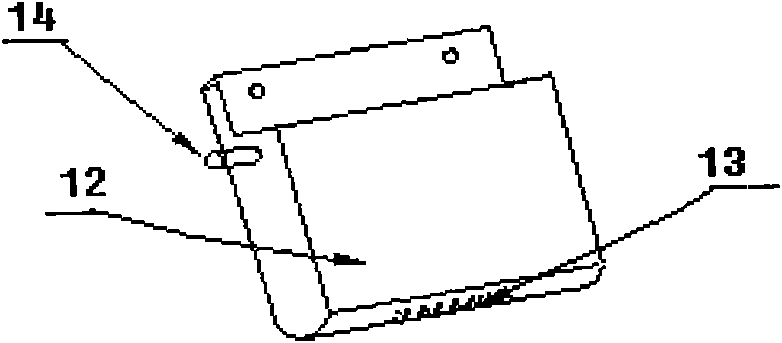

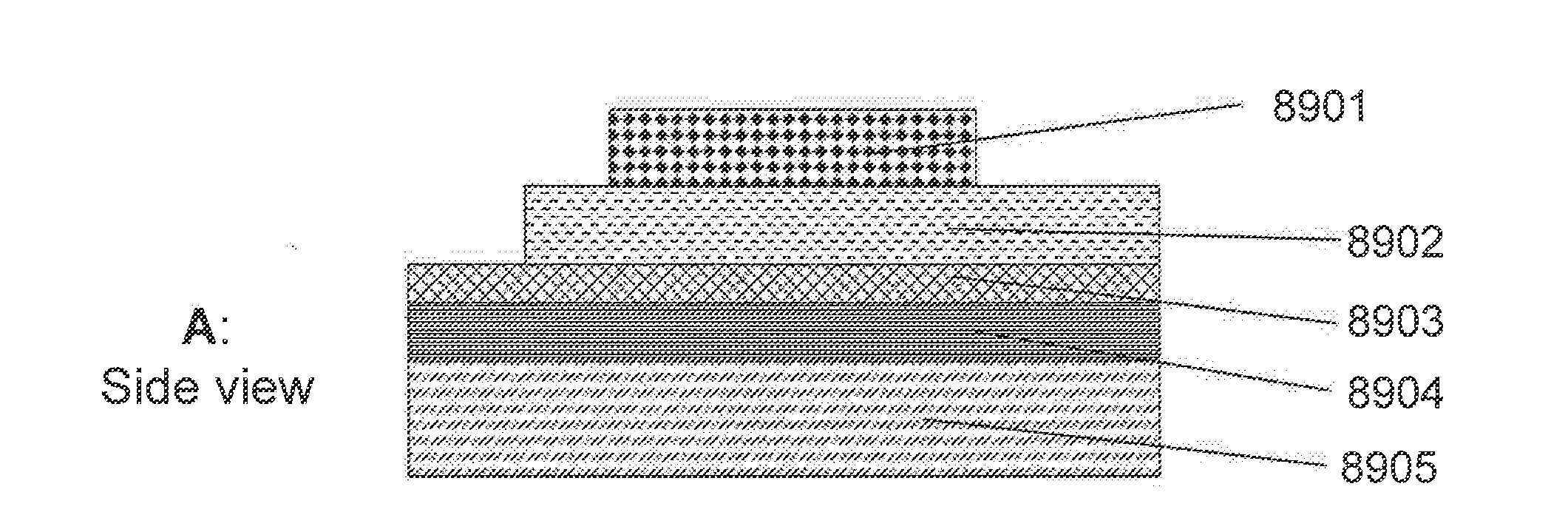

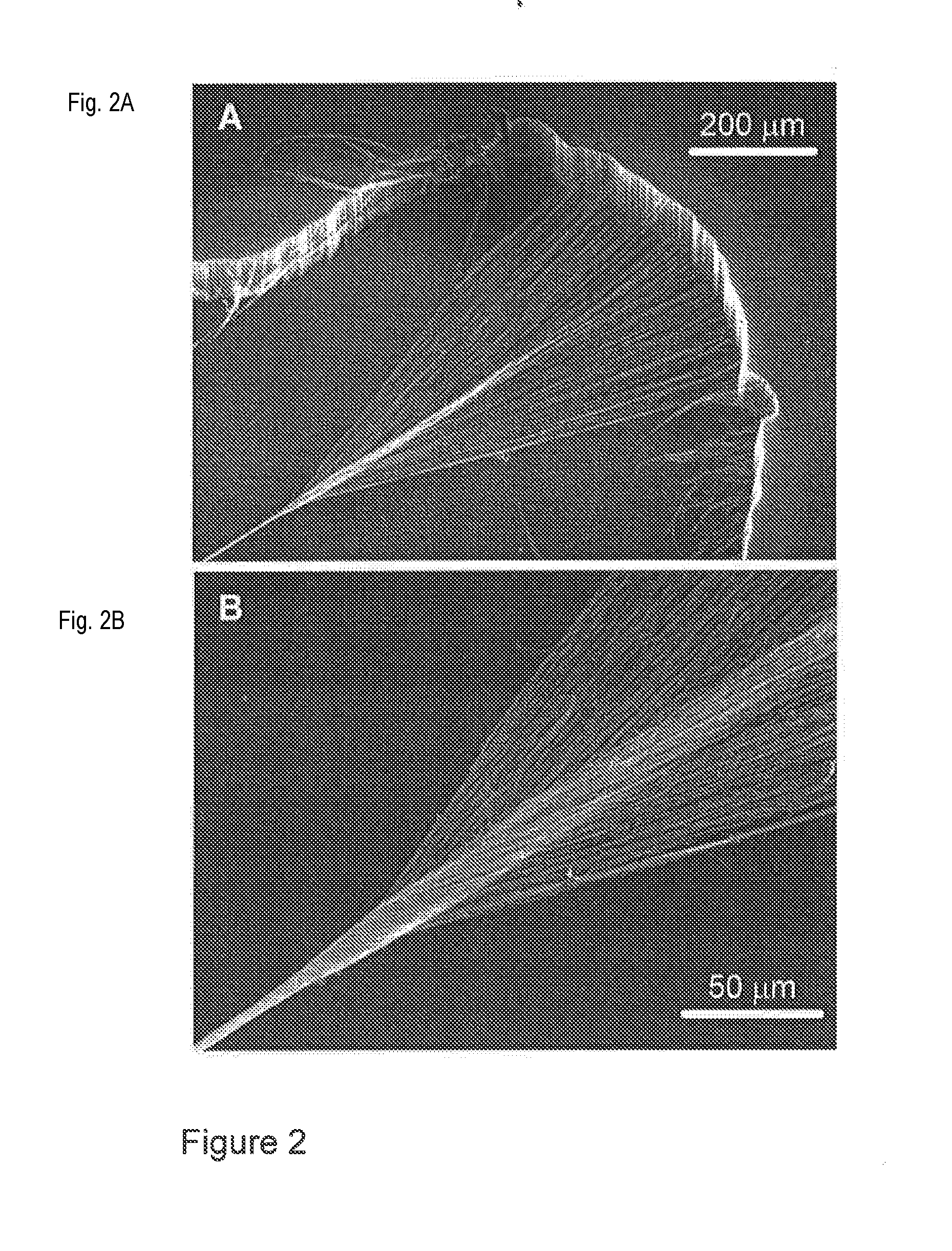

Fabrication and application of nanofiber ribbons and sheets and twisted and non-twisted nanofiber yarns

ActiveUS20150308018A1High strengthImprove yarn strengthMaterial nanotechnologyNon-insulated conductorsFiberHigh resistance

The present invention is directed to nanofiber yarns, ribbons, and sheets; to methods of making said yarns, ribbons, and sheets; and to applications of said yarns, ribbons, and sheets. In some embodiments, the nanotube yarns, ribbons, and sheets comprise carbon nanotubes. Particularly, such carbon nanotube yarns of the present invention provide unique properties and property combinations such as extreme toughness, resistance to failure at knots, high electrical and thermal conductivities, high absorption of energy that occurs reversibly, up to 13% strain-to-failure compared with the few percent strain-to-failure of other fibers with similar toughness, very high resistance to creep, retention of strength even when heated in air at 450° C. for one hour, and very high radiation and IJV resistance, even when irradiated in air. Furthermore these nanotube yarns can be spun as one micron diameter yarns and plied at will to make two-fold, four-fold, and higher fold yarns. Additional embodiments provide for the spinning of nanofiber sheets having arbitrarily large widths. In still additional embodiments, the present invention is directed to applications and devices that utilize and / or comprise the nanofiber yarns, ribbons, and sheets of the present invention.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

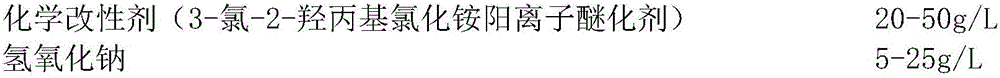

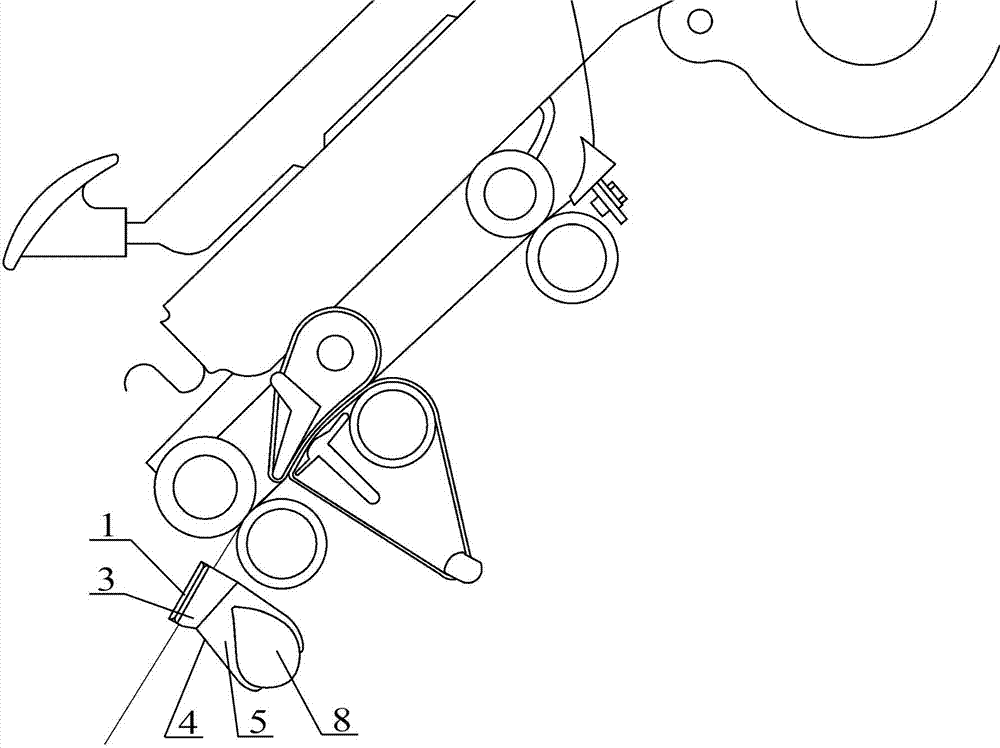

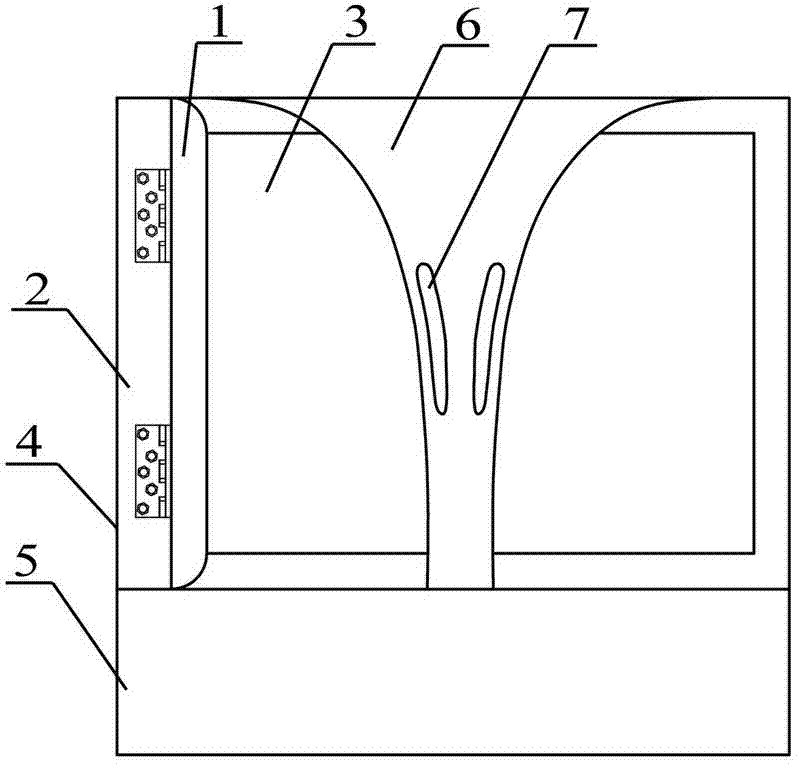

Spinning method for performing damp heat ironing treatment to fiber strands

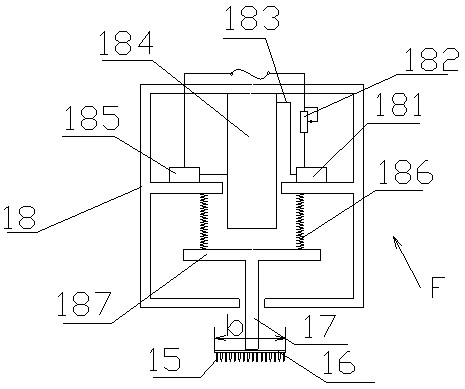

The invention relates to a spinning method for performing damp heat ironing treatment to fiber strands, and belongs to the technical field of textile processing. A damp heat ironing treatment device is additionally installed in a twist trigonal zone in front of a front leather roller and a front roller of a ring spinning frame and used for performing damp heat ironing treatment to fibers in the fiber strands; the damp heat ironing treatment device comprises a base, a humidifying component and an ironing treatment component; the damp heat ironing treatment device can perform humidifying to the fibers in the fiber strands in the twist trigonal zone and then perform high-temperature ironing treatment, so that the rigidity of the fibers is instantaneously reduced, and the flexibility of the fibers is enhanced; and meanwhile, the movement of the fibers in the fiber strands in the twist trigonal zone is controlled. The spinning method can remarkably reduce the fibrous yarn of resultant yarn, enhance the strength of yarn formation and reduce the phenomenon of kinking due to twisting. The damp heat ironing treatment device is convenient for a knitter to operate, has little influence on the operation of the knitter, and is suitable for cotton fibers, wool fibers, fibrilia, polyester fibers, polyamide fibers and acrylic fibers.

Owner:WUHAN TEXTILE UNIV

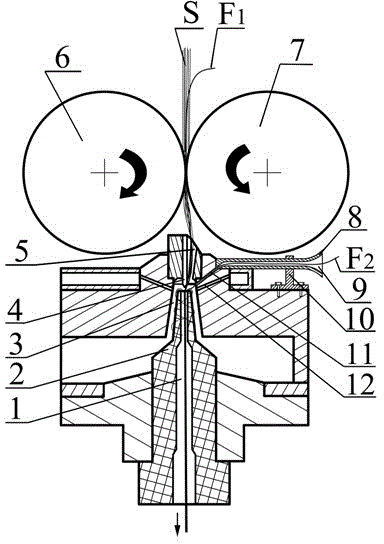

A kind of eddy current composite spinning method for producing fancy yarn

InactiveCN103215700BRealize intermittent feedingRealize feeding with periodic change in tensionContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention relates to a vortex composite spinning method for producing structured yarns, which belongs to the technical field of textile processing. According to the method, a yarn conveying channel which forms an included angle of 15-65 degrees with a guide pin is formed on each vortex spinning device outer tube of a vortex spinning machine; the yarn conveying channel is positioned on the same side as a front rubber roll; a yarn outlet of the yarn conveying channel is positioned at the fiber outlet of a fiber conveying channel and the yarn inlet of a yarn channel; the yarn inlet of the yarn conveying channel is communicated with a yarn leading channel of a yarn leading tube; and decorative yarns F2 are directly fed into the yarn inlet of the yarn channel without passing through a front jaw, and are wound on the surfaces of vortex core-spun yarns formed by F1 and short fiber rods S, so that the vortex composite structured yarns are formed. Due to the adoption of the method, short fibers produced in the conventional vortex spinning process can be prevented from being taken away by air flow, the fiber falling rate of short fibers is lowered, the yarn forming capacity during vortex composite spinning is improved greatly, end breakage of resultant yarns is eliminated, the requirements of vortex resultant yarns on a short fiber raw material are lowered, and the spinnable fiber raw material range of the vortex spinning is expanded greatly.

Owner:WUHAN TEXTILE UNIV +1

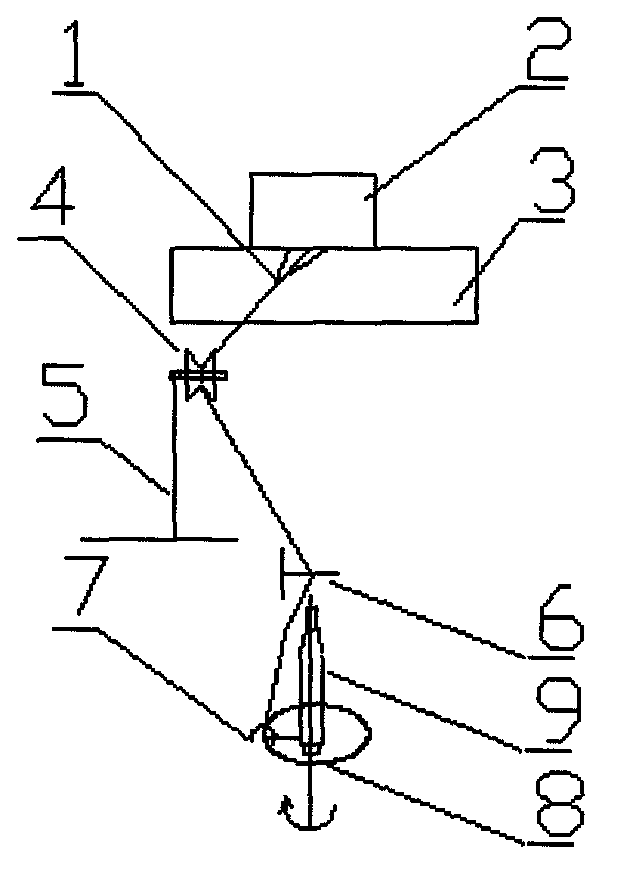

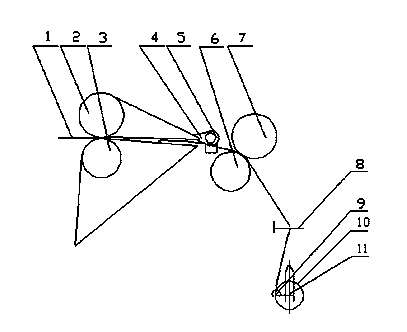

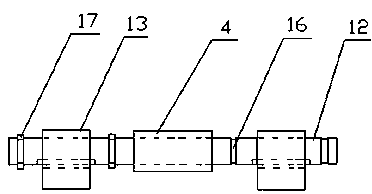

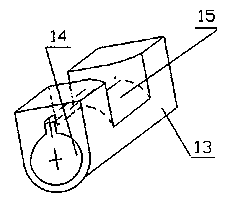

Guide wheel system positioning spinning method

The invention relates to a guide wheel system positioning spinning method and belongs to the technical field of textile processing. Guide wheels are additionally mounted on a front roll of a ring throstle and in front of a front roller. A groove of the guide wheel is V-shaped. A V-shaped bottom of the guide wheel groove is located in one side of a common tangent face of the front roll and the front roller. A shaft of the guide wheel is perpendicular to the common tangent face, yarn is output from a jaw formed by the front roll and the front roller, guided by the guide wheel, and wound on a ring bobbin through a yarn guide hook, a steel collar and a steel wire ring. A non-twist section of the yarn output from a front jaw is eliminated, and spinning efficiency is improved. Yarn texture is more compact, yarn hair is strong, and evenness of yarn is more excellent. The method is suitable for all technical ring throstle spinning systems, simple to modify and convenient to operate and use.

Owner:WUHAN TEXTILE UNIV

Fabrication and application of nanofiber ribbons and sheets and twisted and non-twisted nanofiber yarns

ActiveUS20160251778A1High strengthImprove yarn strengthMaterial nanotechnologyNon-insulated conductorsHigh resistanceFiber

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Spinning method of terylene-viscose blended yarn

The invention provides a spinning method of terylene-viscose blended yarn, which comprises the following steps: opening and cleaning cotton, combing the cotton, making ribbons, spinning coarse yarn and spinning fine yarn; while spinning the coarse yarn, feeding two pieces of coarse yarn in parallel into the same drawing mechanism of a spinning machine at 9-13 mm intervals so as to simultaneously draw the two pieces of coarse yarn in parallel. The method applies a Sirospun technology to the spinning of the terylene-viscose blended yarn. The two pieces of coarse yarn are simultaneously fed intothe spinning machine, the single yarn twist area is shorter, and the applied degree of twist is low, so that the included angle of the fiber spiral yarn and the yarn shaft in the single yarn is relatively small, and the single fiber in the single yarn can not transversely protrude out of the outer surface of the yarn due to the strong effect of the twisting force. Thus, the terylene-viscose blended yarn has the advantages of little filoplume, smooth surface, even yarn, high strength and few defects. The method enhances the quality grade of the terylene-viscose blended yarn.

Owner:JIANGYIN CITY HUAXIAO TEXTILE

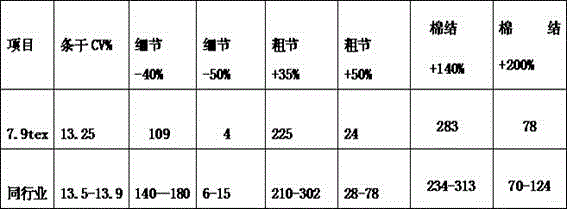

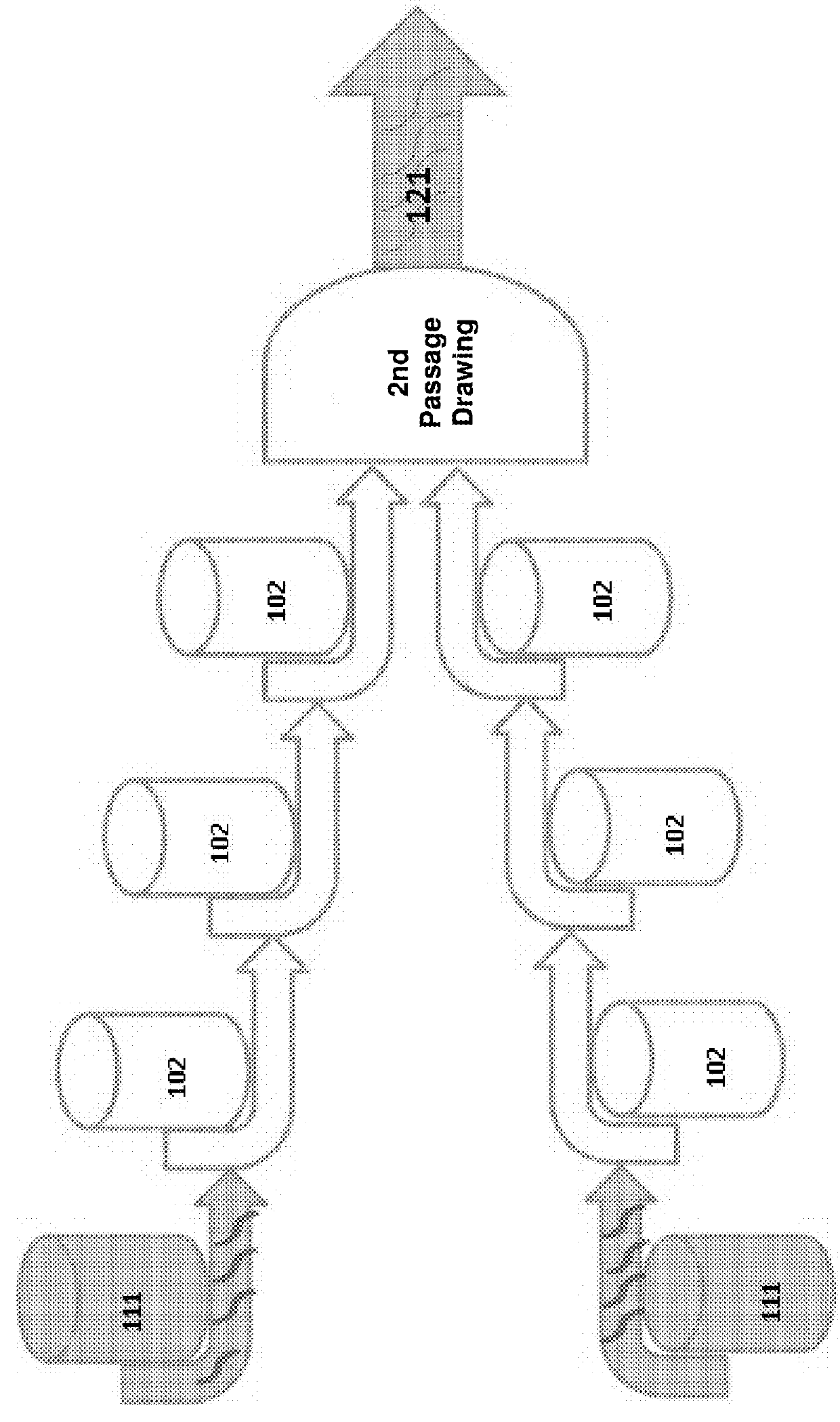

Method for producing extra high count compact spinning yarn by using superfine denier tencel fiber

The invention discloses a method for producing extra high count compact spinning yarn by using superfine denier tencel fiber. The tencel fiber is adopted, wherein the fineness of the tencel fiber is less than or equal to 1.0 dtex, and the length of the tencel fiber is 38 mm. The method includes: pretreatment of raw material, blowing, cotton carding, drawing, roving, spinning and spooling; the method is short in process, cotton carding can strictly control short fiber of cotton slivers, spinning can control stability of fiber strand on a coagulating tank through compact spinning, a part of yarn defects are cleared up during spooling, and 70-180 extra high count compact spinning yarns can be produced. The relative humidity of the production environment is 50%-60% during each process; the obtained yarns are compact in structure, are less in hairiness, are high in strength of the yarns, are few in defects, are energy-saving and environment-friendly, and can be produced into various high-grade spinning ready-made garment.

Owner:JIHUA 3542 TEXTILE CO LTD

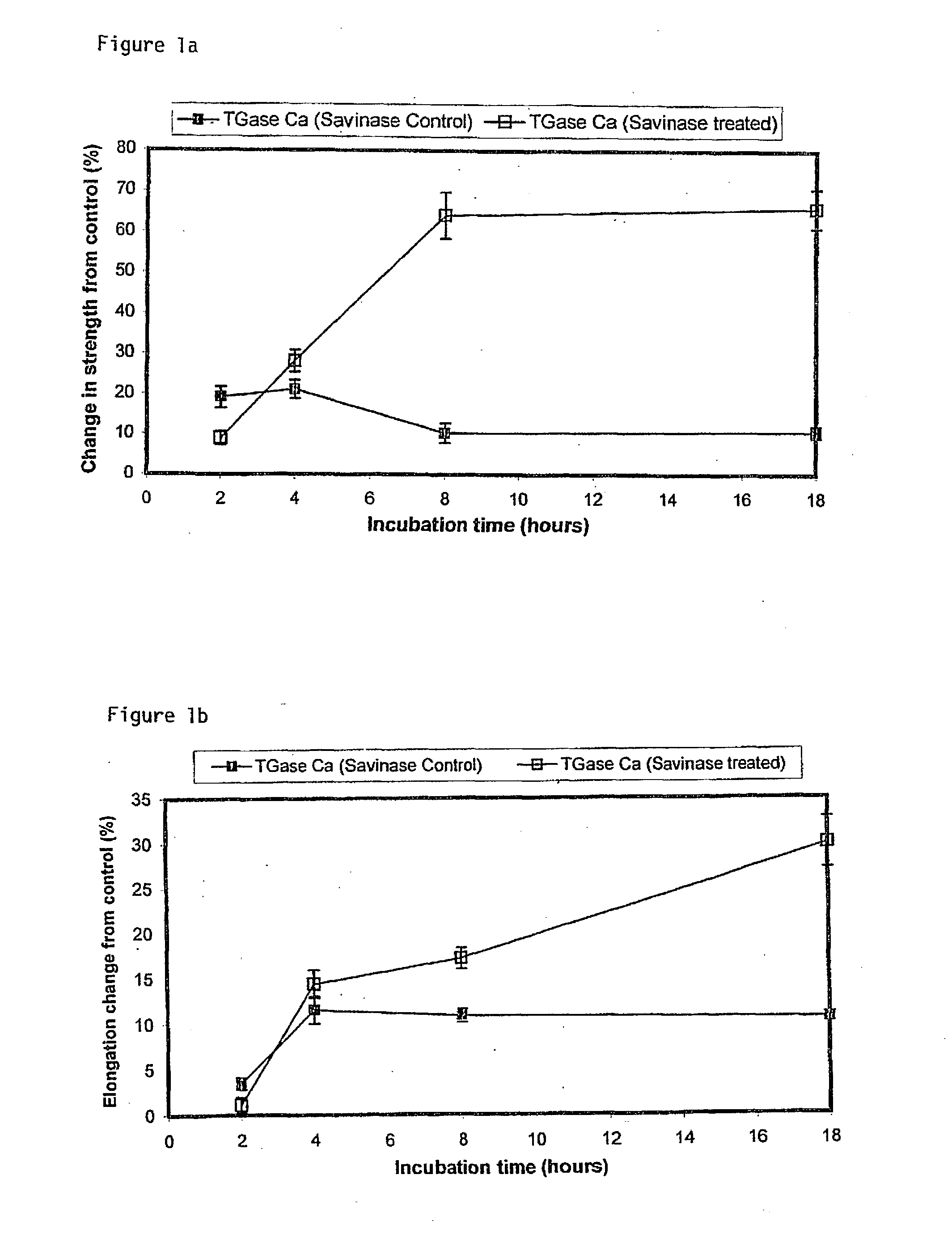

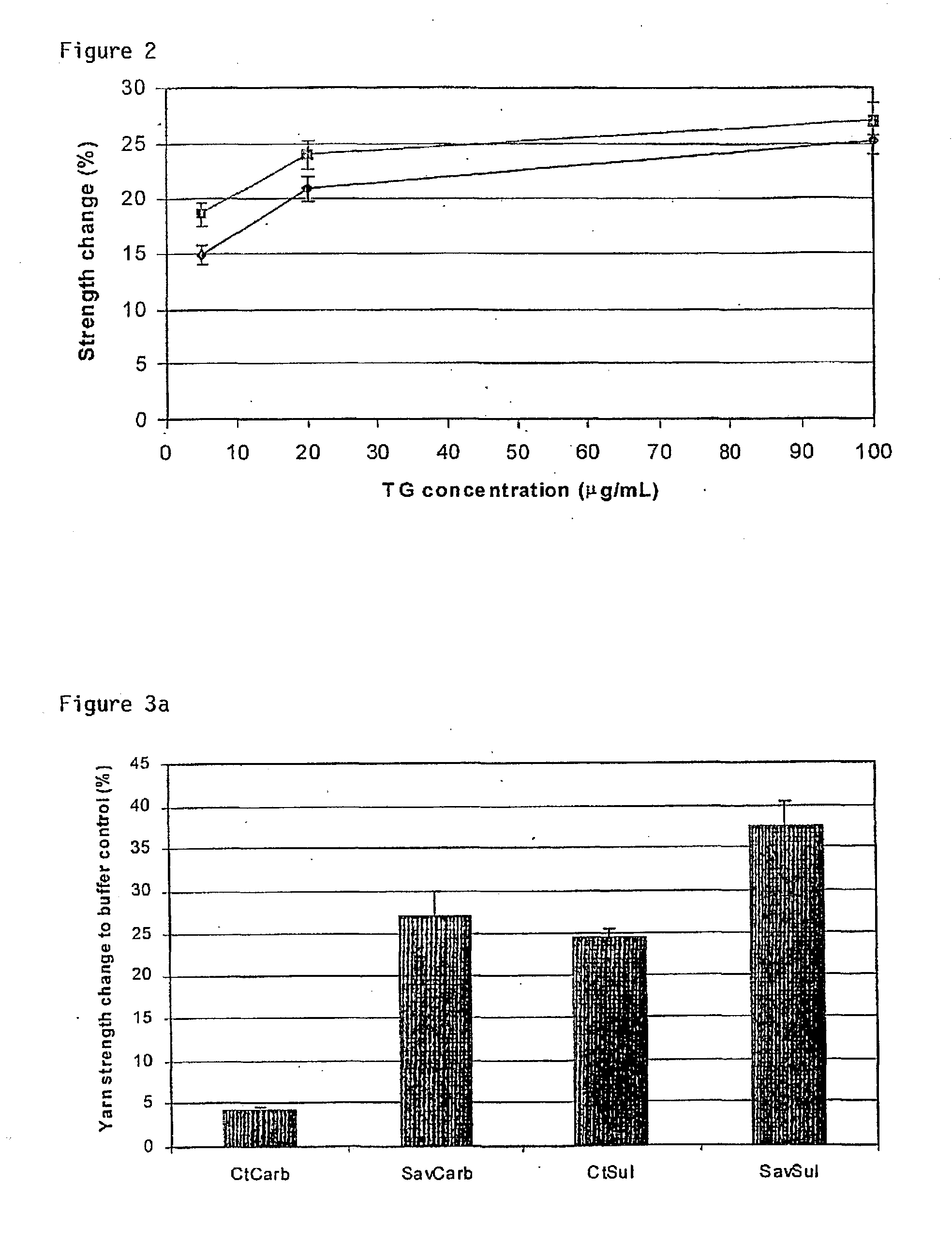

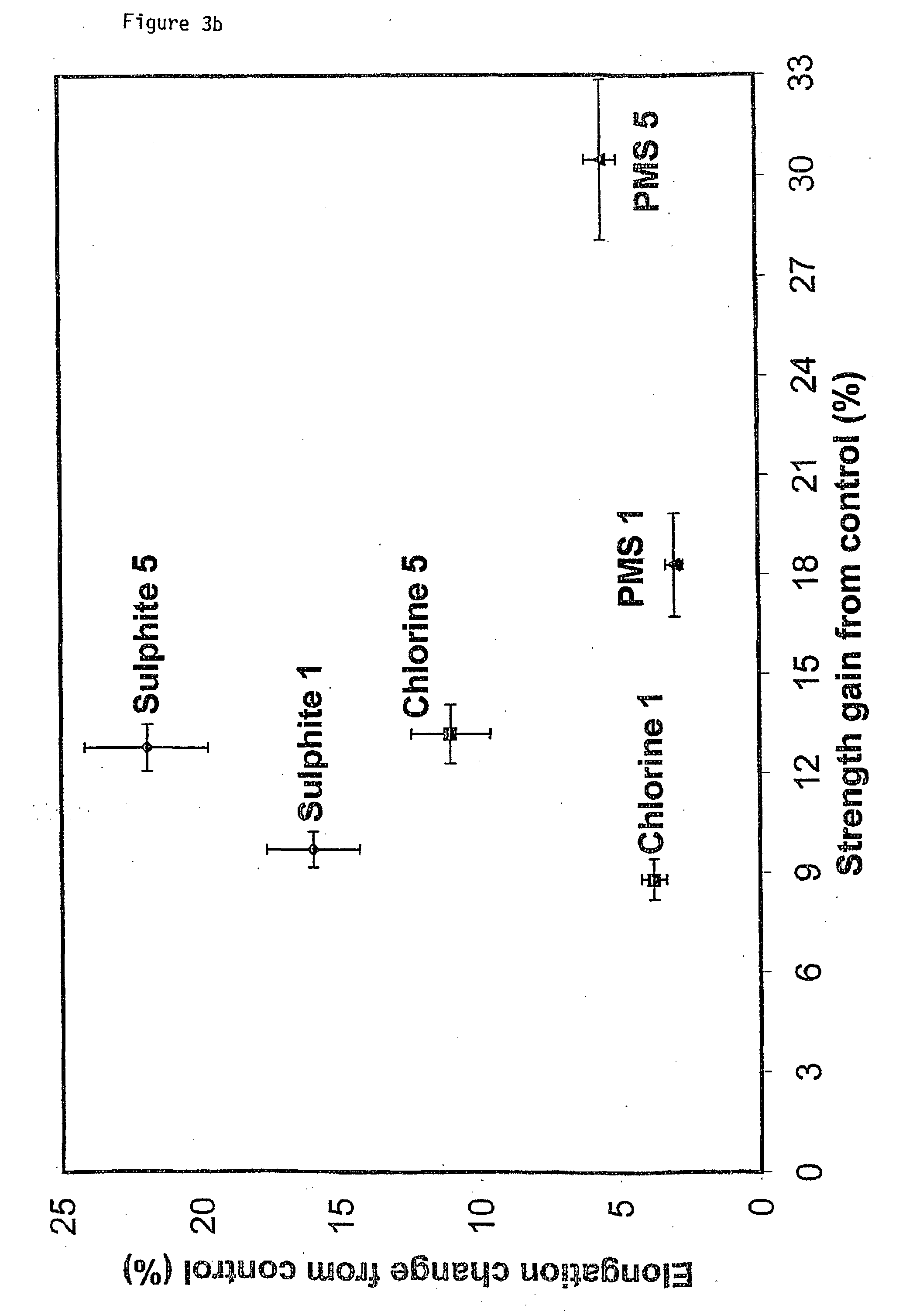

Method for enzymatic treatment of textiles such as wool

InactiveUS20030154555A1Good dimensional stabilityImprove yarn strengthPhysical treatmentWrinkle resistant fibresFiberActive agent

The application provides a method of treating fibrous textile goods comprising treating the fibrous textile goods with an enzyme. This enzyme can be used to covalently link one or more active functional compounds to the fibres and / or to trap one or more acitve functional compound within an inter-fibre matrix and / or within an intra-fibre matrix formed by the action of the enzyme. Preferably, the enzyme is a traglutaminase, especially a calcium-dependent transglutaminase. The enzyme may be used to add primary-amine containing active agents to the textile goods and also for the addition of proteins or peptides that have functional groups linked to them.

Owner:NOTTINGHAM TRENT UNIVERSITY

Special yarn for thermal underwear and producing method thereof

InactiveCN101403151AMeet the needs of cohesionImprove yarn strengthDrafting machinesCombing machinesYarnCarding

The invention discloses muslin dedicated for thermal underwear, and a manufacturing method thereof, wherein, long stapled mutton and viscose fiber are adopted as raw materials; a combing technology is adopted for the long stapled mutton to manufacture combed sliver; a carded cotton carding technology is adopted for viscose fiber to manufacture viscose fiber stripe; after drawing, roving and spun yarn are carried out to the combed sliver and the viscose fiber, high-woven yarn dedicated for the thermal underwear with the weight blend ratio of 68-72 percent of the long stapled mutton and 28-32 percent of the viscose fiber is manufactured. With the adoption of current spinning equipment, the manufacturing method can manufacture the high-woven yarn used for manufacturing high range clothing fabric or knitwear such as thermal underwear, and the like; besides, the number of fibrogen inside the cross section of the manufactured high-woven yarn can fully satisfy the need of cohesive force between fiber and fiber; the yarn strength is improved, thus being entirely capable of adapting to the requirements for manufacturing high range clothing fabric or knitwear such as thermal underwear, and the like.

Owner:丁宏利

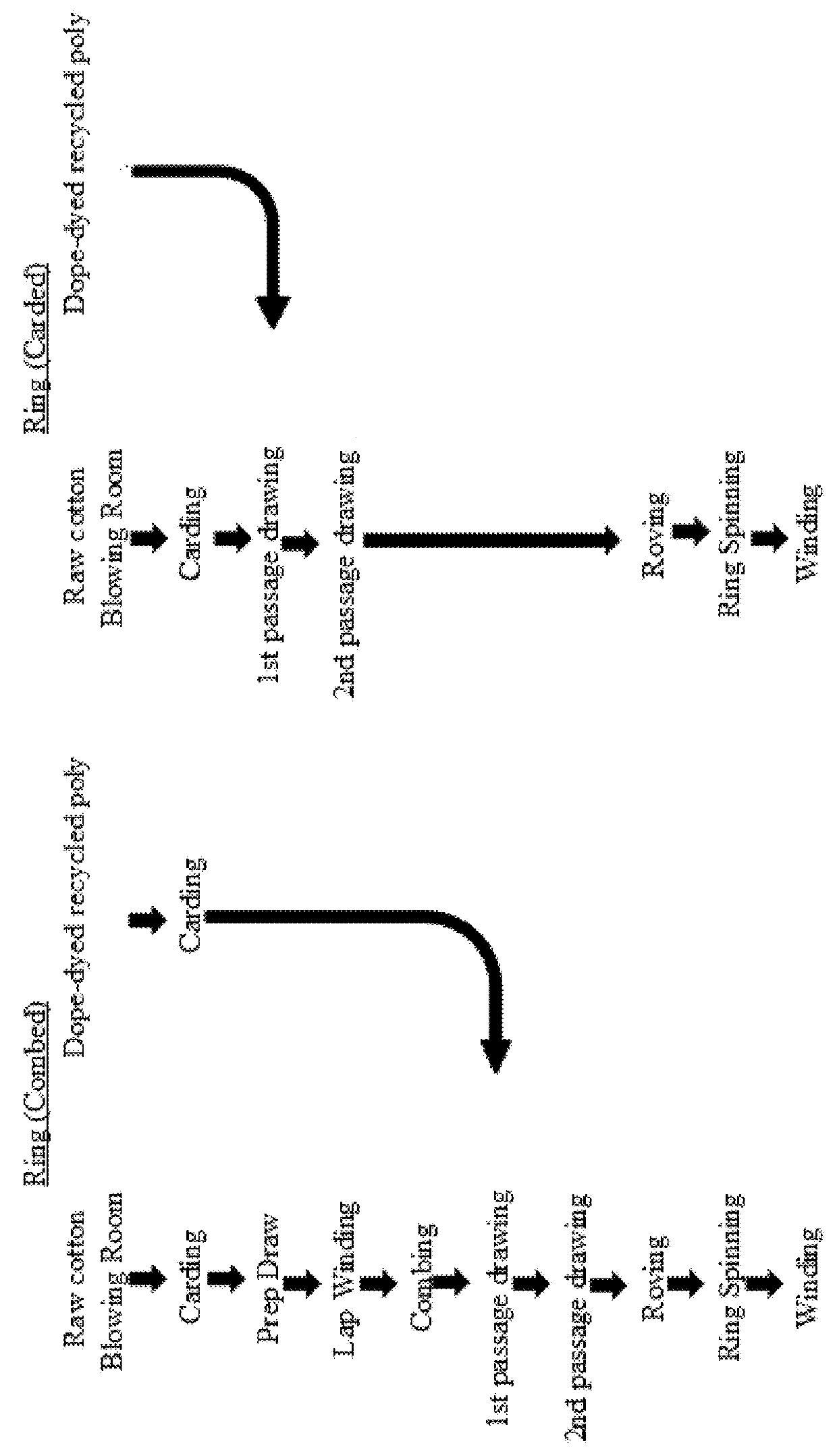

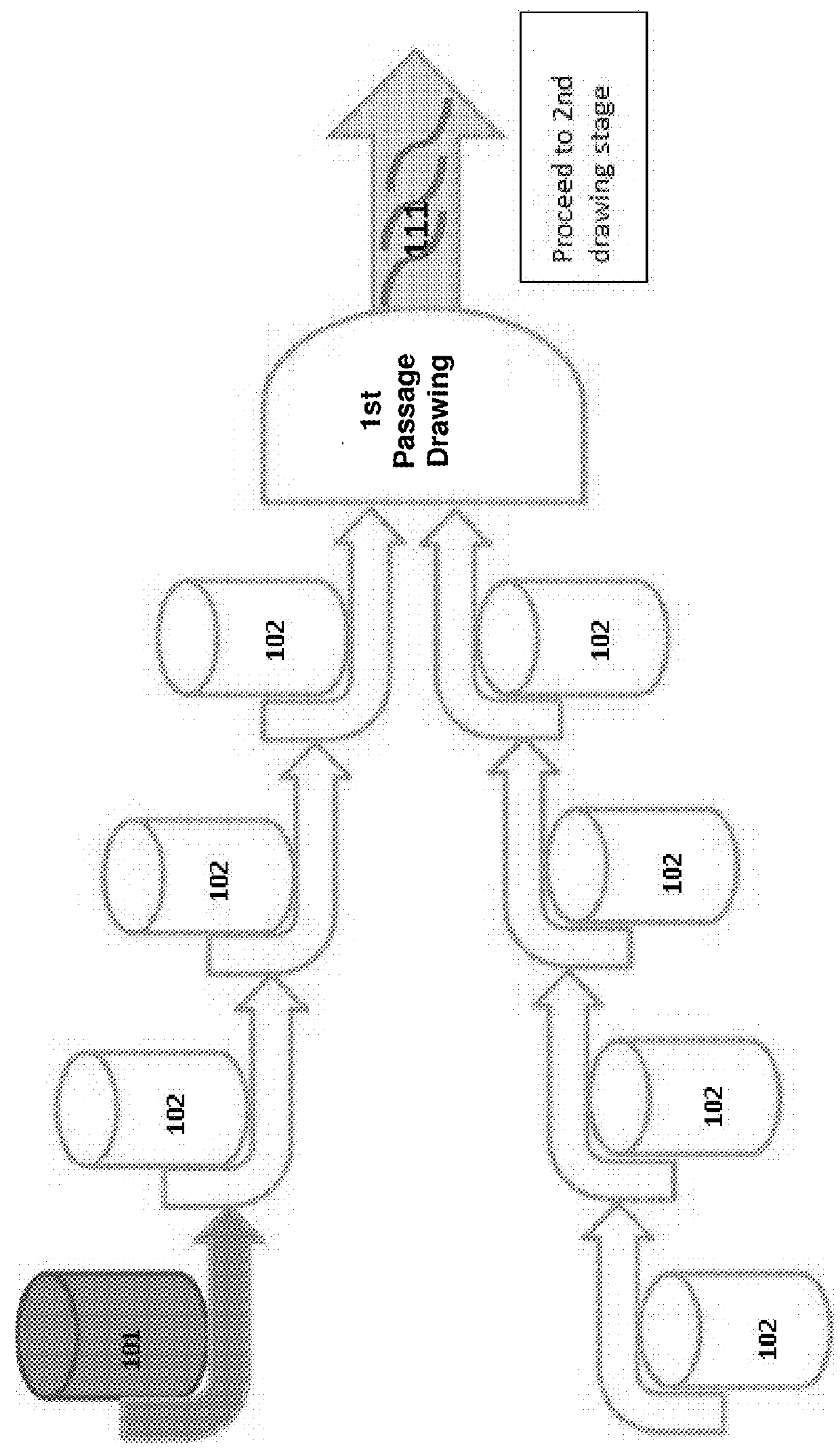

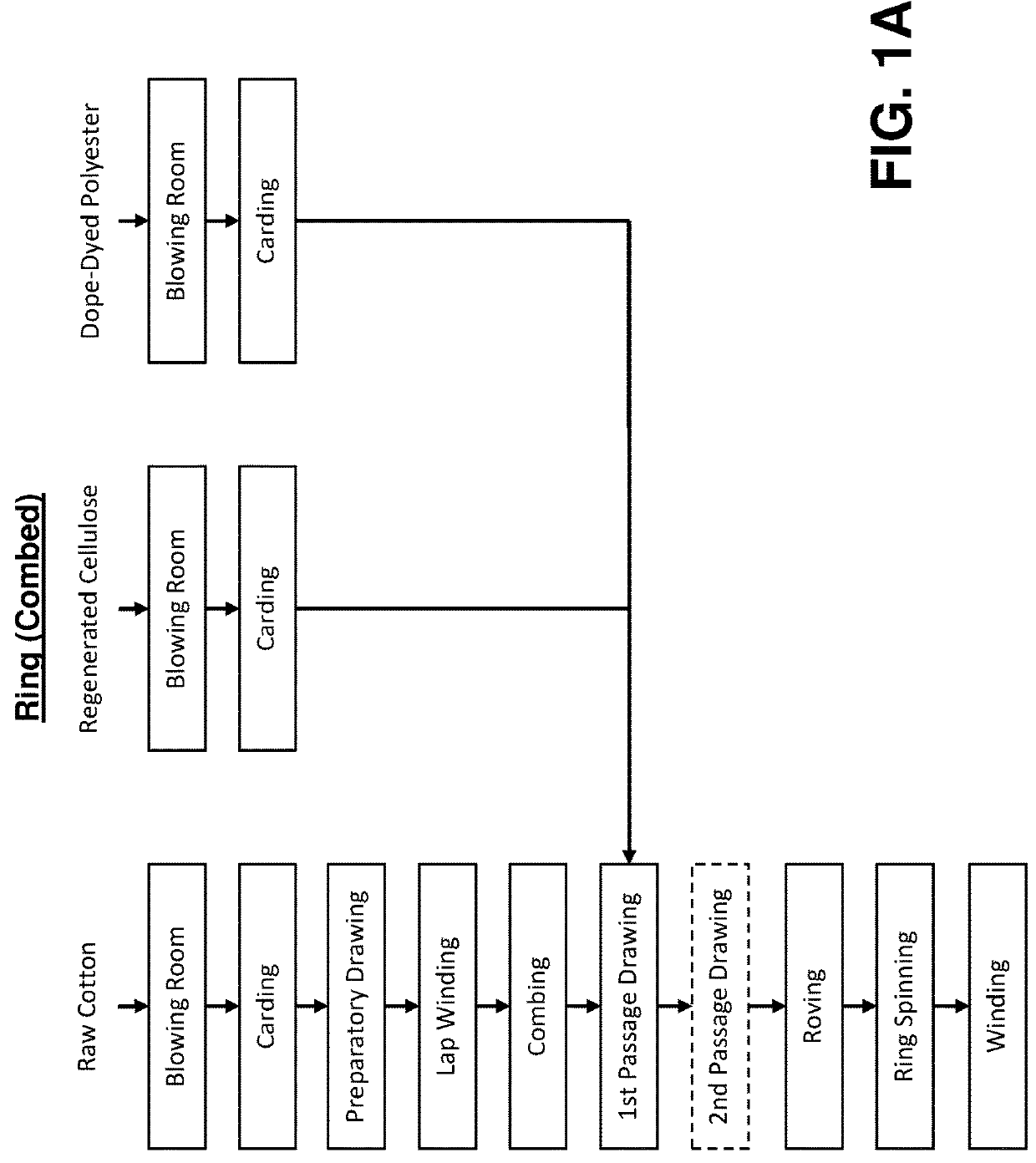

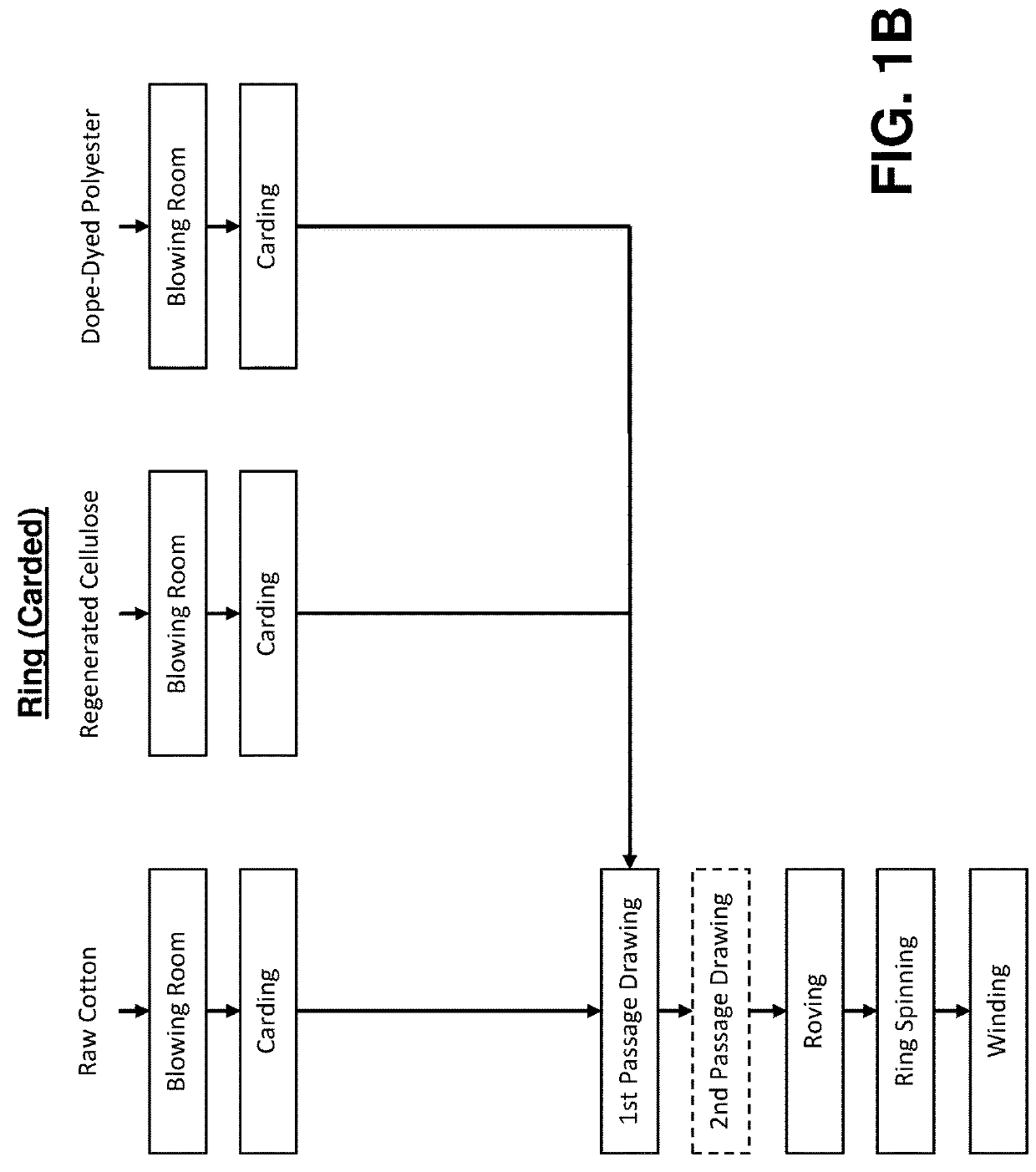

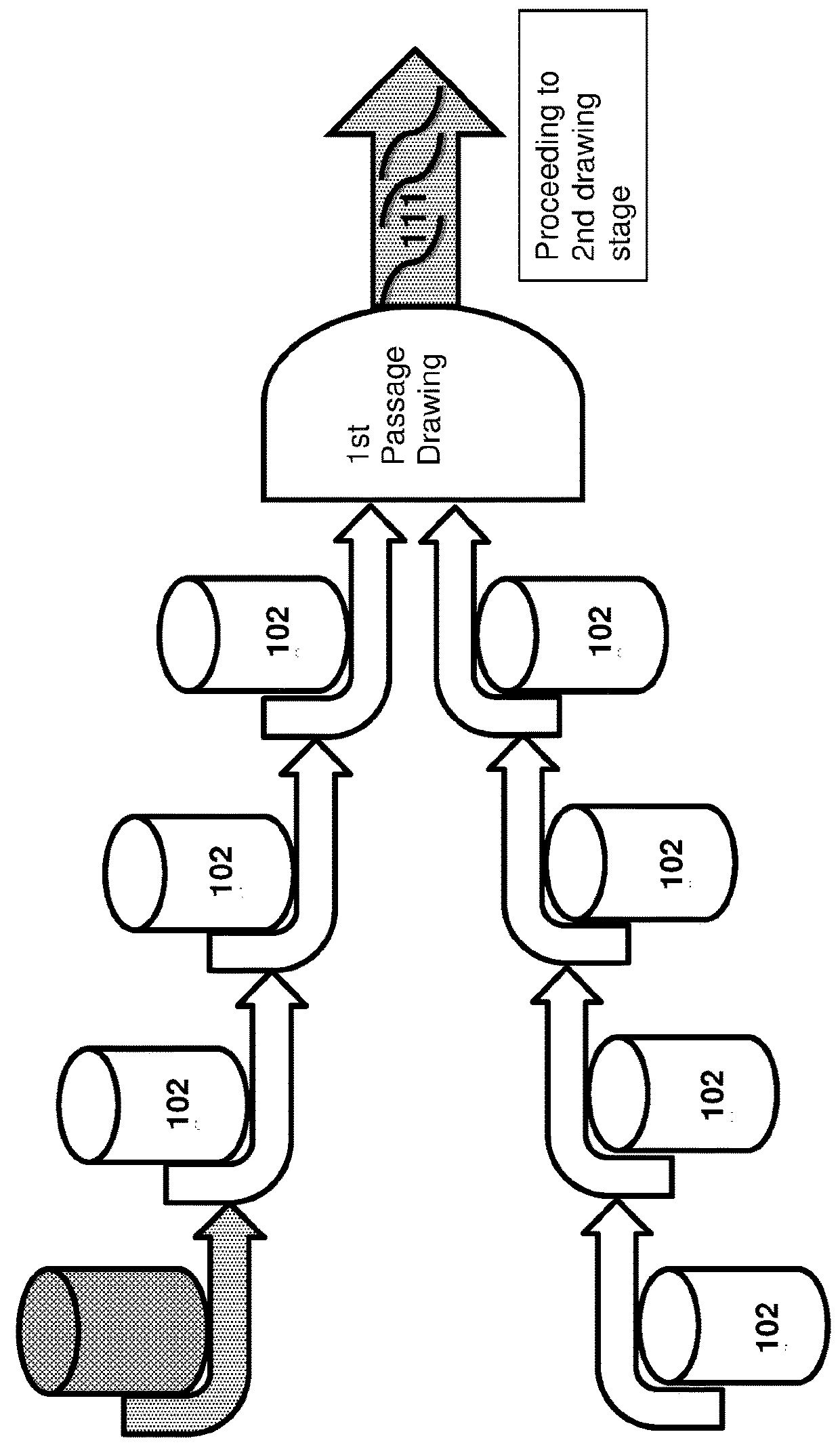

Spinning Process of Waterless Colored Heather Yarns

InactiveUS20180179672A1Quality improvementImprove yarn strengthFilament/thread formingCarding machinesYarnPolymer science

A method of forming a colored heather yarn, comprising the sequential steps: (a) processing a natural fiber; (b) producing a waterless dope-dyed man-made fiber; (c) blending the individual fibers from steps (a) and (b) to produce a blended composite of fibers; and (d) roving, spinning and winding the blended composite of fibers of step (c) into a final colored heather yarn; wherein the colored heather yarn comprises a predetermined fiber content ratio. There is also provided a colored heather yarn made according to the foregoing method.

Owner:TAYLOR HOME & FASHIONS LTD

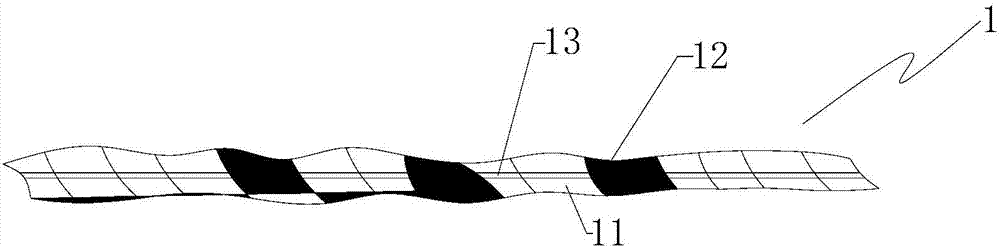

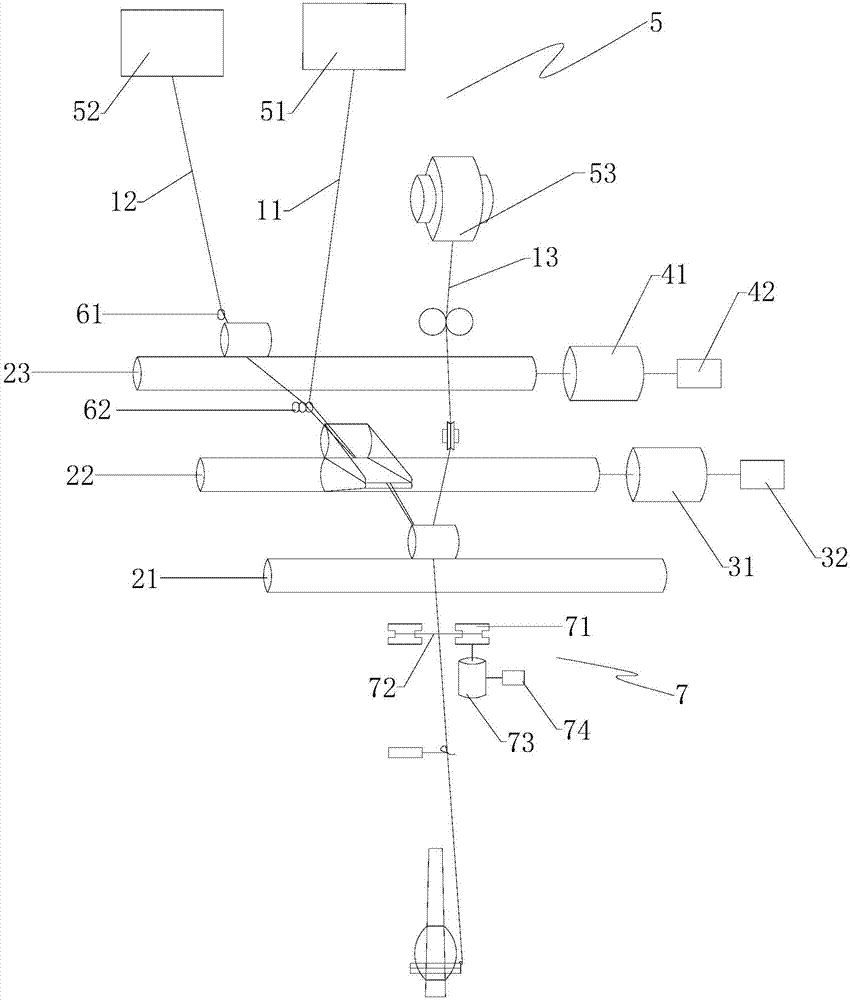

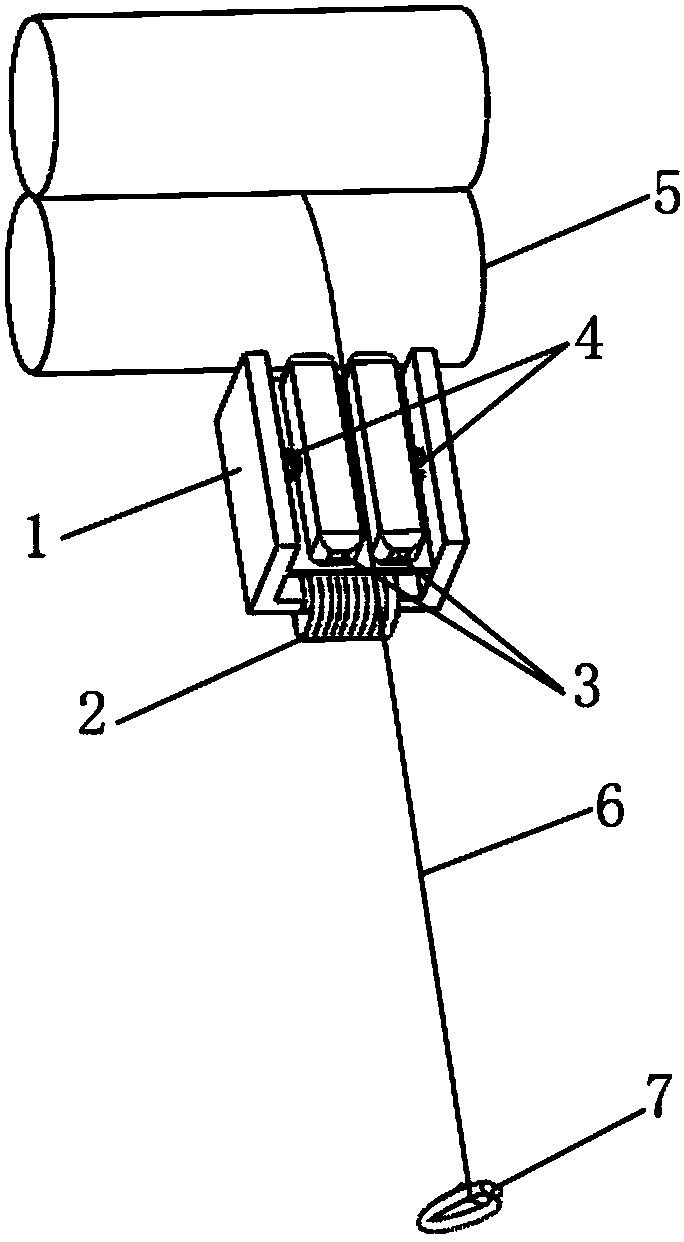

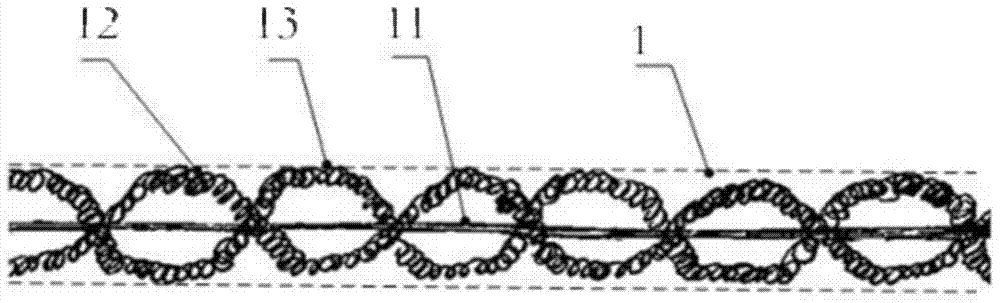

Novel colorful yarn on low-torque section, preparation method and preparation device thereof, fabric using the yarn

The invention discloses a novel colorful yarn on a low-torque section, a preparation method and a preparation device thereof, and a fabric using the yarn, wherein the colorful yarn on the low-torque section is mainly formed by mutually wrapping and twisting more than one of basic fiber fringings and colorful fibers, and its twisting coefficient is below 4.6. The novel colorful yarn on the low-torque section is characterized by low residual torque, softness, smooth and bright surface, low hairiness and high yarn-forming strength, without fiber migration; the prepared textile fabric is characterized by moisture absorption and ventilation, the fabric surface is characterized by smoothness, low hairiness, and soft and smooth hand feeling, before being dyed, the fabric has the special and irregular color change effect, after being dyed, the fabric has the more wonderful outward appearance color, enriches hierarchy and three-dimensional sense, and memorable characters; through the preparation device, yarns are produced under different operating modes, thereby supporting a distribution mode of a spinning system and being convenient to expand capacity in a cotton mill.

Owner:ZHANJIANG ZHONGZHAN TEXTILE

Production method of cotton and coconut carbon fiber blended slub yarn

Disclosed is a production method of cotton and coconut carbon fiber blended slub yarn. Quality and grade of yarn can be improved well by applying compact spinning and slub yarn technology to development of cotton and coconut carbon fiber blended yarn. The slub yarn is unique in style, the problem that common cotton and coconut carbon blended yarn is poor in evenness well can be solved, and compact spinning can reduce hairiness of reluctant yarn better and improve strength of the reluctant yarn, so that the cotton and coconut carbon fiber blended slub yarn has excellent characteristics of two kinds of fibers including cotton and coconut carbon, is high in strength, few in hairiness and has unique bamboo-joint style.

Owner:JIANGNAN UNIV

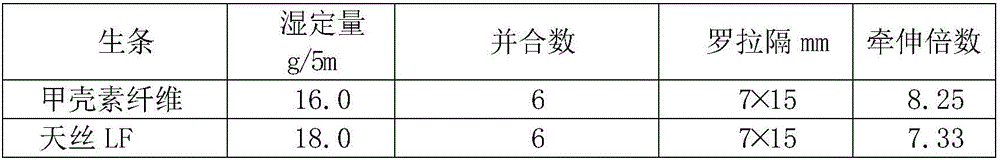

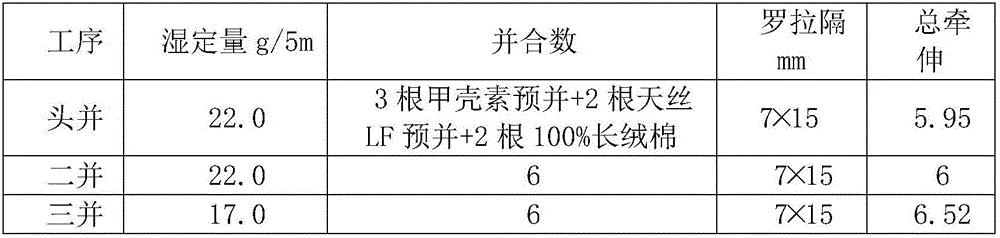

Compact spinning chitin/tencel/cotton blended knitted fabric and production method thereof

ActiveCN105887298AAvoid damageSolve the problem of network formation and strip difficultyWeft knittingDry-cleaning apparatus for textilesFiberYarn

The invention provides a compact spinning chitin / tencel / cotton blended knitted fabric. The fabric is made from 40 parts of CF compact spinning chitin, 30 parts of tencel and 30 parts of long stapled cotton, wherein 19.8tex (60<s>) compact spinning knitting yarn accounts for 95%, 20D spandex accounts for 5%, and the fabric is of a weft plain stitch weave. A production method of the fabric includes the steps of 1, spinning; 2, fabric weaving, wherein a bobbin winder and a circular knitting machine are used, and cropping spot check is carried out; 3, fabric printing and dyeing and after-finishing; 4, fabric after-finishing. The knitted garment fabric made from the three types of fiber blended yarn meets the requirements of people for the functions, comfort and environmental friendliness of fabric and has broad market prospects.

Owner:JIANGSU YDTEX GRP LTD

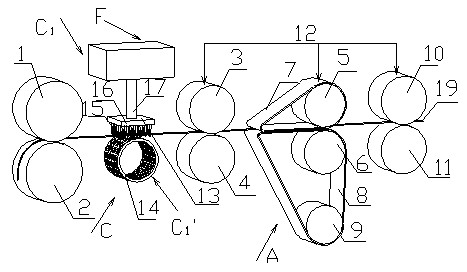

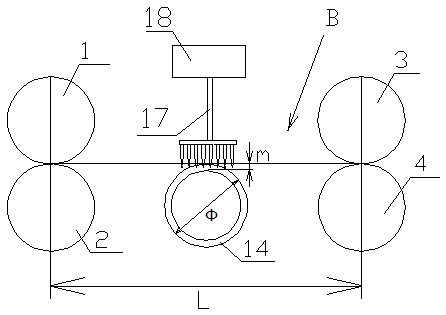

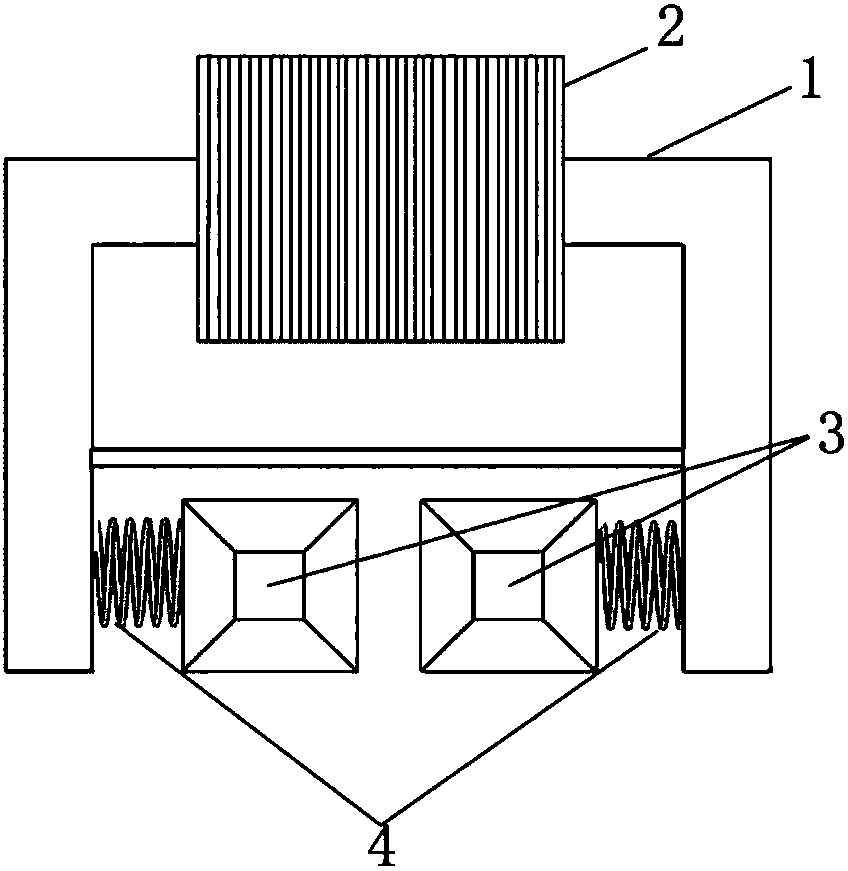

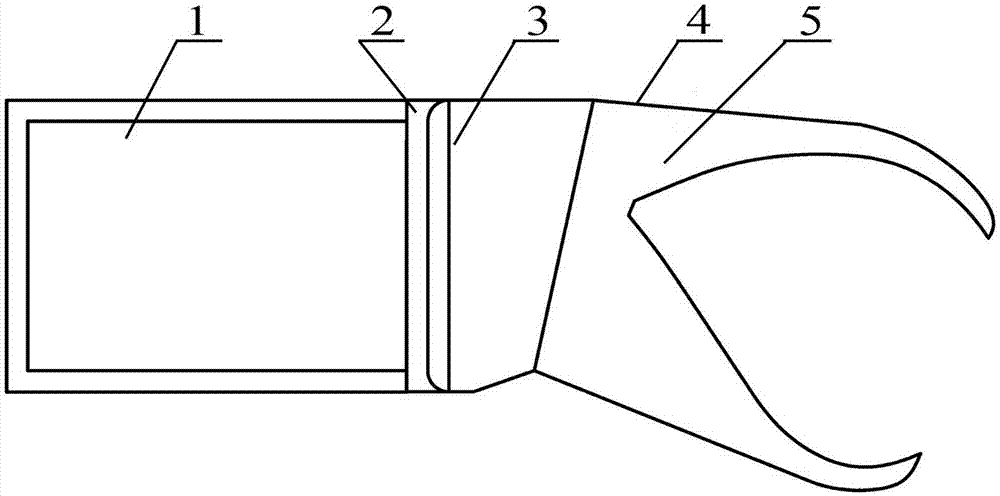

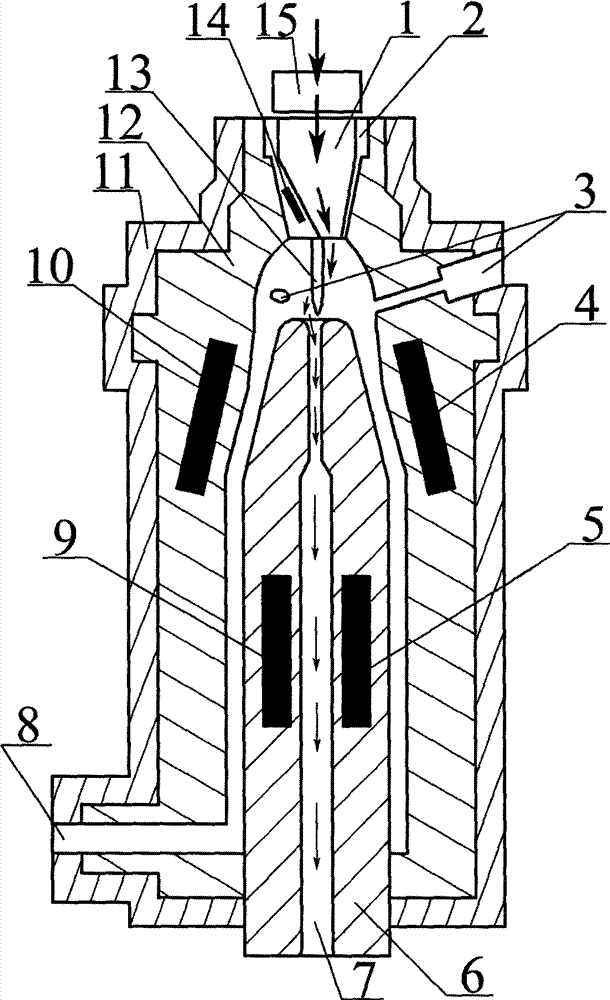

Device for improving single thread strength by high-frequency needling method

The invention relates to a device for improving the single thread strength by a high-frequency needling method, which comprises a drafting mechanism and is characterized in that the front side of the drafting mechanism is provided with a needling type fiber entangling mechanism; the needling type fiber entangling mechanism consists of an upper fiber entangling mechanism and a lower fiber entangling mechanism; the upper fiber entangling mechanism comprises a needling mechanism; the lower fiber entangling mechanism comprises a roller with a hole; the roller with the hole is arranged below the needling mechanism; and the front side of the needling type fiber entangling mechanism is provided with an advanced roller pair consisting of an advanced upper leather roller and an advanced lower roller. By the device, the yarn strength after fiber strands are twisted can be improved so that yarns have capability of bearing subsequent severe friction; meanwhile, the required twisting coefficient can also be effectively reduced and the production efficiency is effectively improved. The device for improving the single thread strength by the high-frequency needling method has the characteristics of simple structure, stability and reliability in operation, convenience for reforming on the original spinning frame, low cost and easiness in popularization.

Owner:DONGHUA UNIV +1

Process for producing novel antibacterial thermal home textile yarns

InactiveCN108193336ASkin-friendly and comfortableImprove yarn strengthCarbon fibresBiochemical fibre treatmentCardingCarbon fibers

The invention discloses a method for spinning and weaving novel antibacterial thermal home textile yarns. The novel antibacterial thermal home textile yarns comprise, by weight, 35%-65% of coffee carbon fibers, 15%-25% of modal fibers and 15%-25% of PTT (polytrimethylene terephthalate) fibers. The coffee carbon fibers, the modal fibers and the PTT fibers are blended to form the novel antibacterialthermal home textile yarns. The method for processing the novel antibacterial thermal home textile yarns includes working procedures of blowing, cotton carding, drawing, roving, spinning and the like. The method has the advantages that the method includes simple processes, and the novel antibacterial thermal home textile yarns can be automatically produced by the aid of the method on a large scale; the novel antibacterial thermal home textile yarns are skin-friendly, comfortable, antibacterial and thermal, and are high in yarn strength, low in hairiness and excellent in moisture absorption and breathability, pilling can be prevented, requirements of consumers in family, hotels and the like can be met, home textile fabrics woven by the aid of the method are fluffy and thermal, and accordingly the method has an excellent application prospect.

Owner:IANGSU COLLEGE OF ENG & TECH

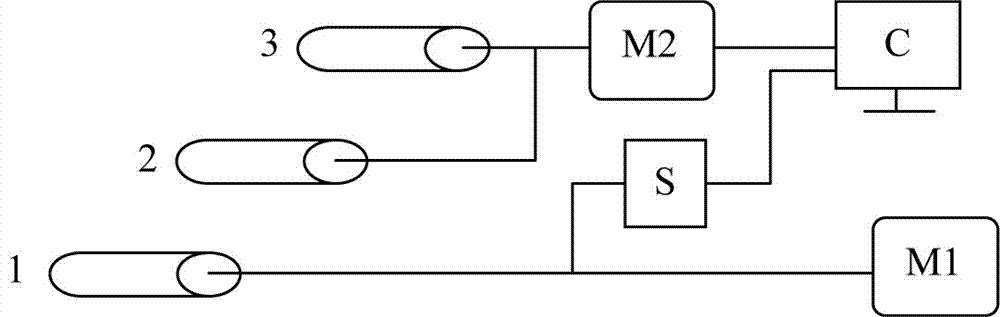

Spinning device and parallel spinning method with the same

The invention relates to a spinning device and a parallel spinning method with the same. The spinning device is characterized in that a spinning vibrator is arranged between a front roller and a guidewire and comprises at least one pair of vibratory agglomeration rollers, and the vibratory agglomeration rollers in the pair are two agglomeration rollers which are arranged on the two sides of a fiber strand and symmetrically vibrate; the symmetrical vibration direction does not include the fiber strand moving direction; the axial angle of the two rollers is 0 degree to 10 degrees; when the tworollers are static, the axis of the fiber strand and the axes of the two rollers are located in the same plane. The spinning method includes the steps that the fiber strand is agglomerated and subjected to resistant twisting through the vibratory agglomeration rollers to be prepared into yarn, and the running direction of the fiber strand is perpendicular to the vibration direction of the agglomeration rollers, wherein agglomeration means that the fiber strand is vibrated through the agglomeration rollers, and wandering fibers suffer from agglomeration acting force to be wrapped and wound in the fiber strand, resistant twisting means that the agglomeration rollers are in contact with the fiber strand to generate friction force, and the resistant twisting torque is generated in the processthat the fiber strand is twisted back and transferred upwards, and parallel spinning is achieved by lengthening a twisting trigonum. The spinning device is simple in structure and low in cost; hairiness is reduced with the spinning method.

Owner:DONGHUA UNIV

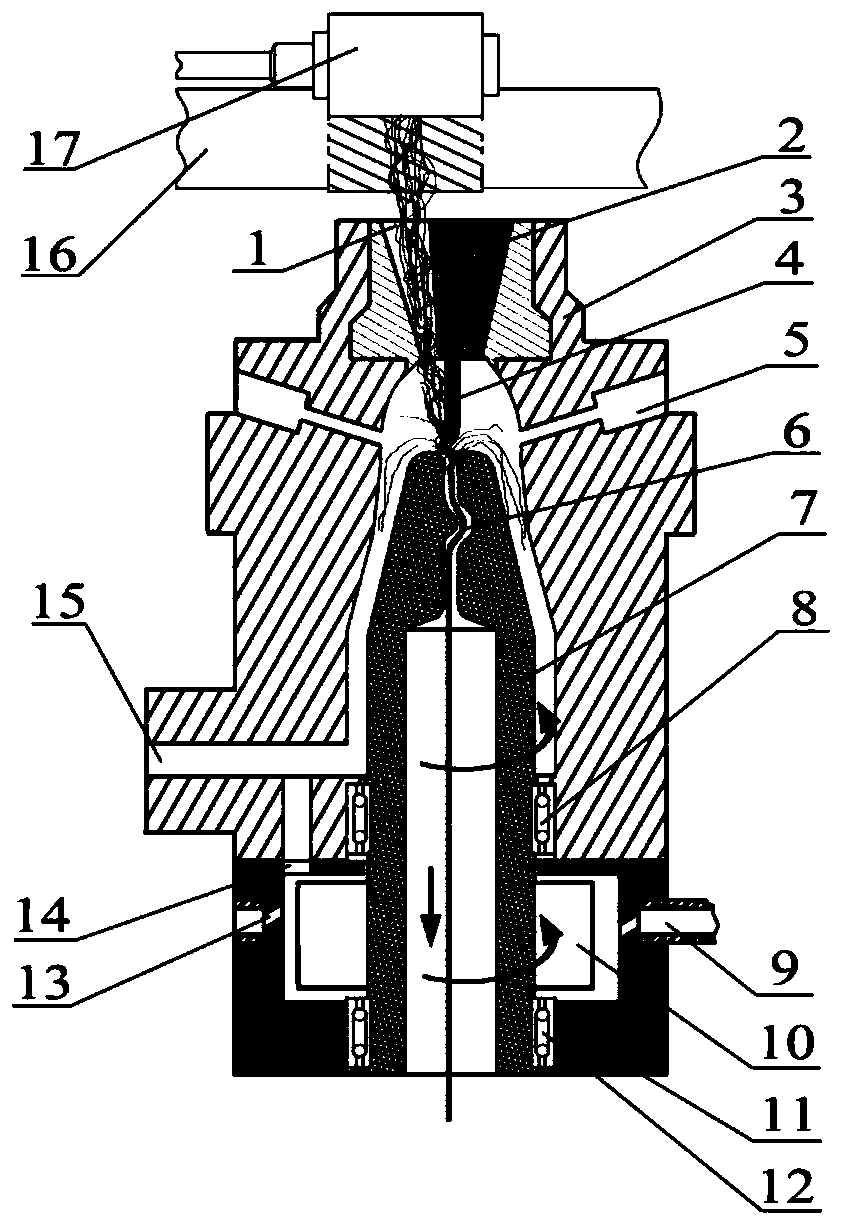

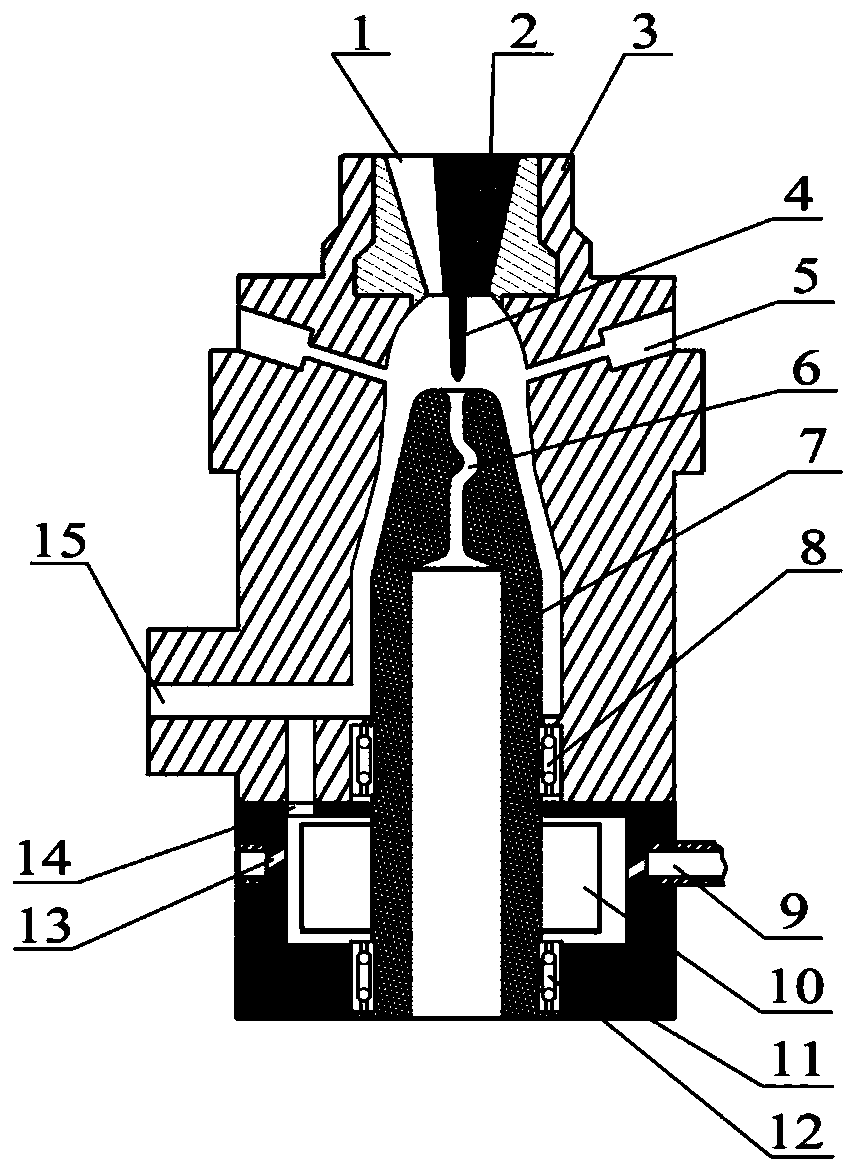

Rotary spindle vortex spinning method

ActiveCN109735971AIncrease intensityHigh fastnessContinuous wound-up machinesOpen-end spinning machinesFiberYarn

The invention relates to a rotary spindle vortex spinning method and relates to the technical field of textile processing. A static spindle in a spinning apparatus of a vortex flow spinner is changedinto a rotary spindle, the method for performing vortex wrapping to form yarns by adopting the static spindle in the traditional spinner is changed, fiber fringing main body torsion and hold type twisting and outer fiber vortex wrapping are integrated actually, and yarn forming of performing external transfer twisting and holding on internal main body fibers and performing tight wrapping on outerfibers can be realized. After the formed yarns pass through a C-shaped bend, the yarn bodies rotate along a direction opposite to a surface fiber wrapping direction, the wrapping tightness of the fibers on the surfaces of the yarns is cured, fibers inside the deformed yarns are twisted, the cohesive force and spirality of the fibers inside the yarns are enhanced, and soft and high-strength smoothyarns are finally formed. According to the spinning method disclosed by the invention, the twist yarn forming process and mechanism of the yarns are simplified, the strength, softness and smooth finish of the formed yarns are improved, and the range of vortex spinning raw materials and the limit of the spun yarn count can be extended.

Owner:WUHAN TEXTILE UNIV

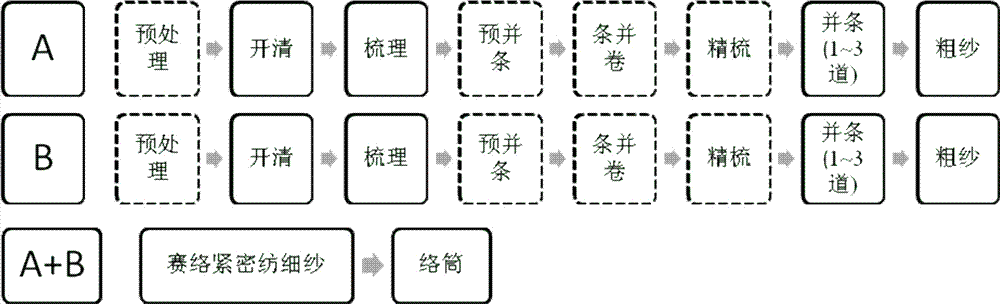

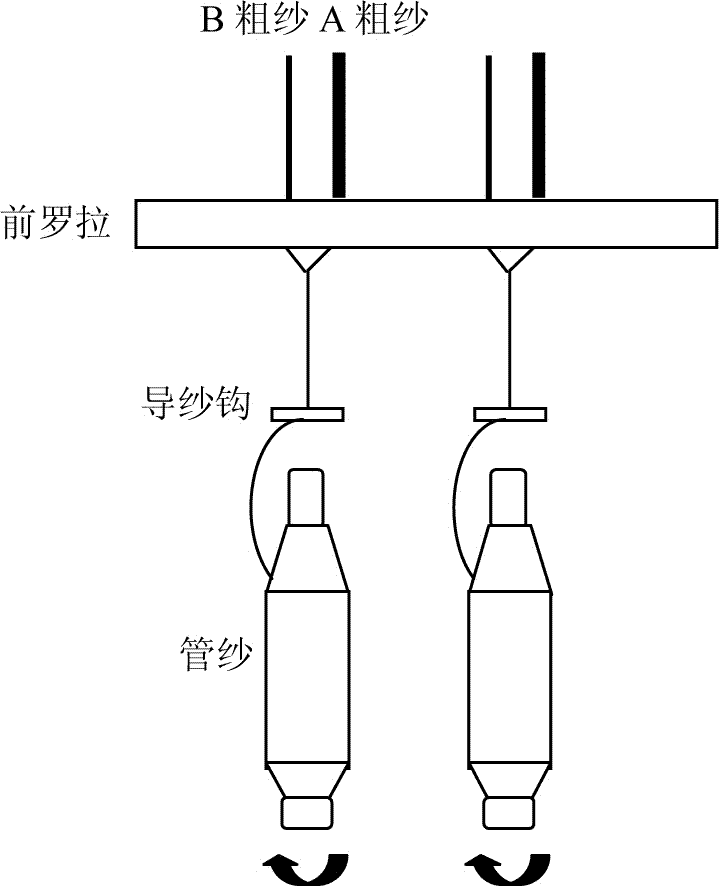

Spinning method of large-difference AB slubby yarn through siro-compact spinning

The invention provides a spinning method of large-difference AB slubby yarn through siro-compact spinning. A raw material A and a raw material B which are different in dyeing property or color are subjected to opening, carding, combing preparation, combing, drawing and roving according to processing needs respectively, and rough yarn A and rough yarn B are separately prepared. The weight ratio of the rough yarn A to the rough yarn B under the commercial moisture regain is 3 or more, then on a four-roller siro-compact spinning machine with a slubby control device, the rough yarn A and the rough yarn B are fed into a drafting zone through a double-hole horn mouth and output after drafting and compacting, the output fiber strand is twisted to form yarn in a dislocation spinning mode, and then the large-difference AB slubby yarn is produced. An antistatic agent accounting for 0.3% by dry weight of the raw material rough yarn B and water accounting for 3% by dry weight of the raw material rough yarn B are mixed to form a mixed aqueous solution, the mixed aqueous solution is uniformly sprayed on the raw material rough yarn B, and then the raw material rough yarn B is laid up for 24 hours in a sealed mode for enzymatic treatment. On the four-roller siro-compact spinning machine, transmission between a middle rear roller and a front roller is cut off, and the dislocation spinning mode is adopted in the spinning process.

Owner:山东联润新材料科技有限公司

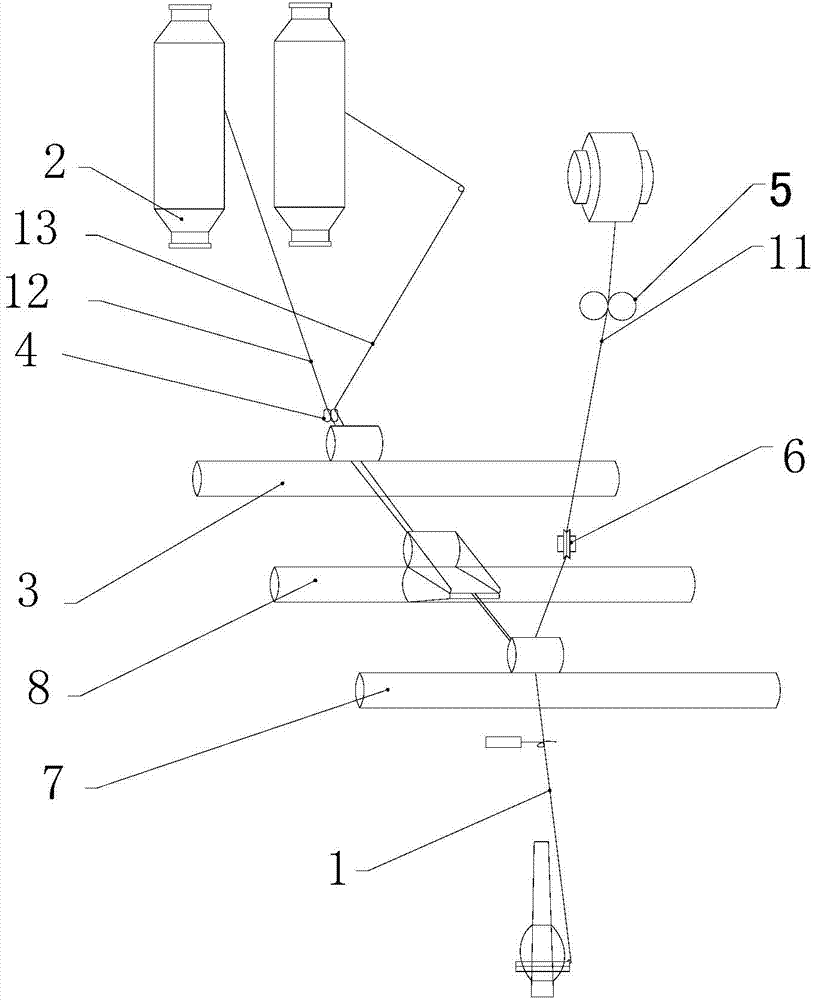

Novel composite elastomeric yarn, textile fabric, and method and device for manufacturing novel composite elastomeric yarn

The invention discloses a novel composite elastomeric yarn. The novel composite elastomeric yarn mainly comprises two groups of fiber fringings and a core filament; and the core filament is a composite elastic filament. The invention also discloses a textile fabric woven by using the composite elastomeric yarn, and a method and a device for manufacturing the novel composite elastomeric yarn. The novel composite elastomeric yarn has a smooth surface and few of hairs; fibers of the novel composite elastomeric yarn cannot drop easily; and the novel composite elastomeric yarn is high in yarn forming power and is wear-resistant. The textile fabric manufactured by using the novel composite elastomeric yarn has a smooth surface and few of hairs, is wear-resistant, is high in tension and tearing force and high in elastic recovery rate, and feels soft and smooth. The device is modified simply and conveniently, is high in applicability, easy to maintain and high in cost performance; a modified spinning frame not only can be used for spinning the novel composite elastomeric yarn, but also can be used for spinning the other traditional ring spinning yarns or the other traditional ring siro spinning yarns; flexible deployment can be carried out in production; and flexible and versatile market requirements can be feasibly met.

Owner:ZHANJIANG ZHONGZHAN TEXTILE

Spinning process of waterless colored heather yarns

InactiveUS20180179673A1Quality improvementImprove yarn strengthCarding machinesContinuous wound-up machinesYarnNatural fiber

A method of forming a colored heather yarn, comprising the sequential steps: (a) processing a natural fiber; (b) obtaining a regenerated cellulose man-made fiber; (c) producing a waterless dope-dyed man-made fiber; (d) blending the individual fibers from steps (a)-(c) to produce a blended composite of fibers; and (e) roving, spinning and winding the blended composite of fibers of step (d) into a final colored heather yarn; wherein the colored heather yarn comprises a predetermined fiber content ratio. There is also provided a colored heather yarn made according to the foregoing method.

Owner:TAYLOR HOME & FASHIONS LTD

Negative pressure guide capturing type ring spinning method

InactiveCN104746189AIncrease profitHigh energy consumptionDrafting machinesContinuous wound-up machinesYarnFiber

Owner:WUHAN TEXTILE UNIV

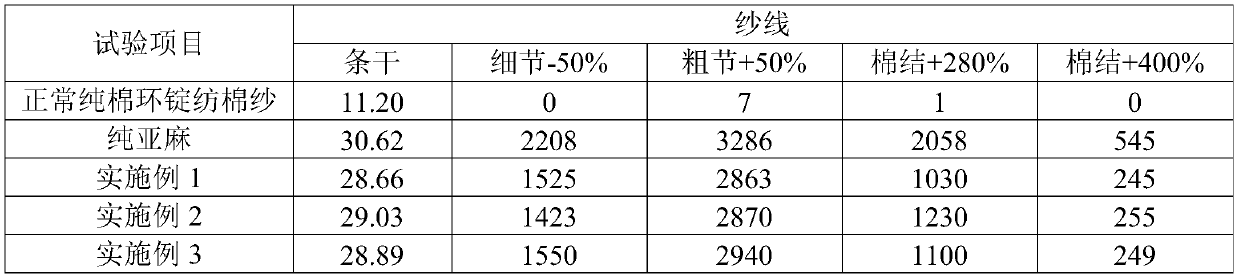

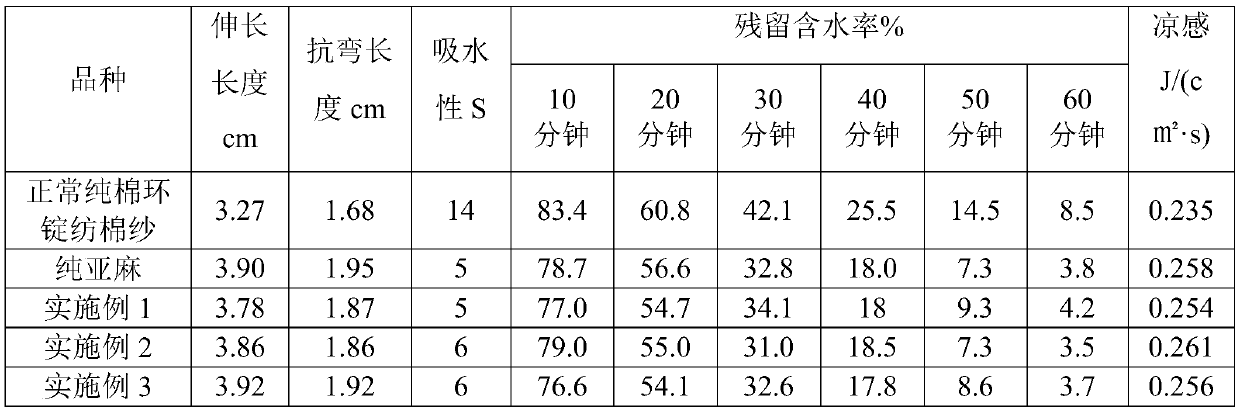

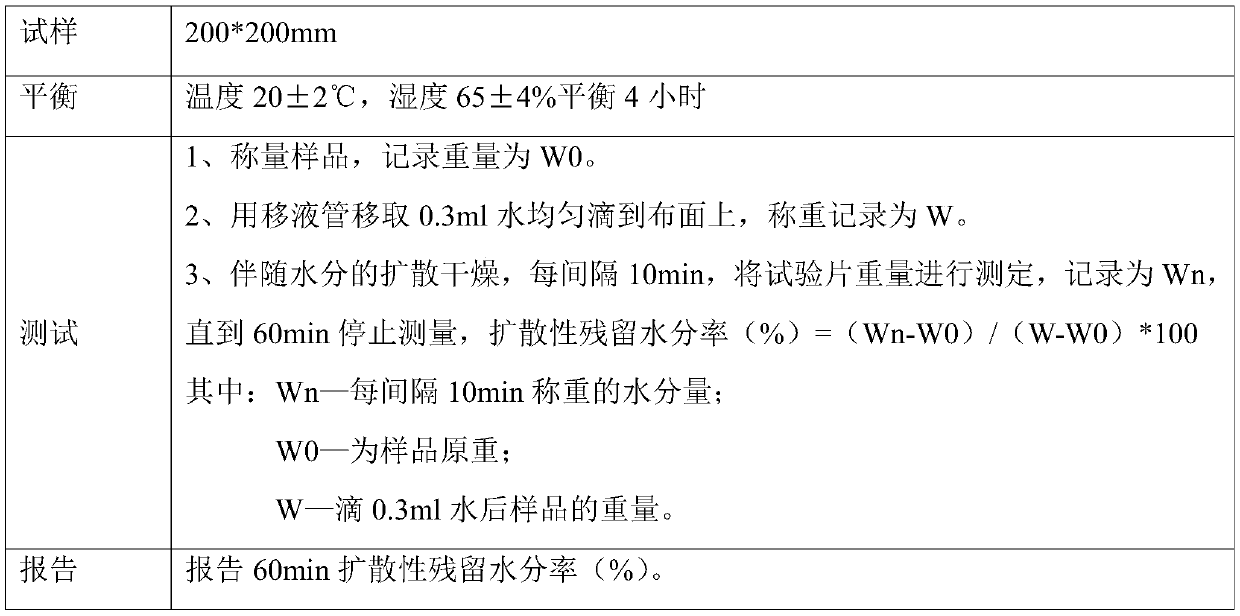

Cotton and hemp blended yarn based imitation pure hemp yarn and spinning method thereof

The invention belongs to the technical field of textiles, and particularly relates to a cotton and hemp blended yarn based imitation pure hemp yarn and a spinning method thereof. The cotton and hemp blended yarn based imitation pure hemp yarn comprises the following raw materials: 40-70% of fine staple cotton carding noil, 30-50% of fine staple cotton and 0-10% of flax loose fibers. According to the cotton and hemp blended yarn based imitation pure hemp yarn and the spinning method thereof, used spun roving contains a large amount of short fibers; in a drafting process of a spinning frame, dueto the fact that the number of floating fibers is increased, irregular and bamboo-joint-like slubs are formed on the surface of the yarn, are just like hemp joints of a hemp yarn and are similar to hemp in appearance and characteristic; and when the twist factor of a cotton yarn is increased, the cotton yarn is reduced in diameter and becomes hard, a gap between the fibers is reduced, the capillary effect is improved, and the characteristics of water absorption and quick drying can appear.

Owner:LUTAI TEXTILE

Spinning method for bundling and pressing fiber strands

The invention relates to a spinning method for bundling and pressing fiber strands, and belongs to the technical filed of textile processing. According to the invention, a bundling and pressing device is additionally arranged on a front drafting zone separation block of a ring spinning frame, so that the cross section width of fiber strands in a front drafting zone can be controlled in an on-line manner, the edge fibers of fiber strands in a twisting triangle area of spun yarns can be reduced, the diameter of the cross section of a resultant yarn is reduced, the structure of the resultant yarn is more compact; besides, the additional friction force field of the front drafting zone is vertically reinforced to control the variable motion of fibers in fiber strands of the front drafting zone. The spinning method provided by the invention can remarkably reduce the hairiness of the resultant yarn, improve the yarn evenness and strength of the resultant yarn, besides reduces the possibility of forming air bellow yarns caused by the fact that edge fibers in the twisting triangle area of spun yarns are absorbed by a yarn absorbing pipe, and facilitates improving the yield of spun yarns. The spinning method for bundling and pressing fiber strands, provided by the invention, is convenient to operate, and slightly influences the operation of tenders.

Owner:WUHAN TEXTILE UNIV

Method for improving performances of yarns formed by vortex spinning

InactiveCN102691143BImprove yarn tightnessLow modulusContinuous wound-up machinesOpen-end spinning machinesEngineeringYarn strength

The invention relates to a method for improving performances of yarns formed by vortex spinning by reducing the modulus and the rigidity of fibers on line and belongs to the field of textile processing. According to the method disclosed by the invention, a sectional softening treatment method is applied for carrying out progressive softening treatment on fibers subjected to vortex spinning on a vortex spinning machine, and thus the fiber modulus and the bending rigidity are quickly reduced on line and the performances of the resultant yarns prepared from fibers by vortex are improved. For a vortex yarn structure, the structure compactness is improved, the yarn strength is enhanced and residual torque of the yarns is small; in addition, the non-spinning fibers can be subjected to vortex spinning on the vortex spinning machine; the fibers with poorer quality for the resultant yarns formed by the vortex spinning are subjected to high-quality spinning on the vortex spinning machine; and particularly, the improvement on the spun count of the fibers on the vortex spinning machine is facilitated and the smooth production of high grade cotton yarns formed by vortex spinning is realized. The method disclosed by the invention has the advantages of short work procedure flow, strong pertinence, high efficiency, lower cost, reasonable structure, convenience in operation and easiness in large-area popularization and use.

Owner:WUHAN TEXTILE UNIV

Method for manufacturing composite yarn for flame-retardant protective clothing

The invention provides a method for manufacturing a composite yarn for flame-retardant protective clothing, and relates to the field of the textile industry. The method for manufacturing the composite yarn for the flame-retardant protective clothing comprises the steps as follows: guiding and feeding a polyphenylene sulfide (PPS) fiber filament to a front roller on a spinning frame, feeding two rough yarns independently, drafting and twisting the two rough yarns for the first time, twisting the two rough yarns with the PPS fiber filament, and obtaining the composite yarn for the flame-retardant protective clothing, wherein each rough yarn is made from one or more flame-retardant and fusion-resistant fibers. With the adoption of the composite yarn for the flame-retardant protective clothing manufactured by the method, high temperature resistance of a PPS fiber is improved, the service life of the PPS fiber is prolonged, the problem of high temperature fusion of the PPS fiber is avoided, and the application field of the PPS fiber is expanded.

Owner:JIANGSU TANGWEAR IND

Soft-smooth-warming home-textile blanket fabric and production method thereof

InactiveCN108456975AImprove wear resistanceGuaranteed normal operationSingeingDrafting machinesCardingPulp and paper industry

The invention provides a soft-smooth-warming home-textile blanket fabric and a production method thereof. The production method includes the steps that compact spinning Meiyabi is selected as a warp-yarn raw material, a bamboo fiber is selected as a weft-yarn raw material, the materials are subjected to opening picking, cotton carding, drawing, roving, yarn spinning and spooling respectively, andwarp yarn and weft yarn are obtained; the warp yarn and the weft yarn are subjected to spool bleaching and dyeing respectively, wherein the warp yarn is subjected to base yarn treating, slack spooling, bleaching and dyeing, slack drying, tight spooling and color yarn warping, and the weft yarn is subjected to base yarn treating, slack spooling, bleaching and dyeing, slack drying and tight spooling; weaving is carried out, wherein warping, slashing, drafting, weaving and finishing are carried out; after-finishing is carried out, wherein cloth-unfolding seam allowance, singeing, desizing refining, PH washing, shaping and preshrinking are carried out. The fabric prepared with the method has the good soft-smooth-warming property, light-thin property, antibacterial property, glossiness, humidity-absorbing and air-permeability property, anti-wrinkle property and drapability, and also has the certain pilling resistance.

Owner:江苏悦达棉纺有限公司

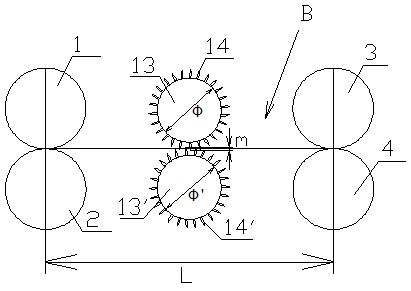

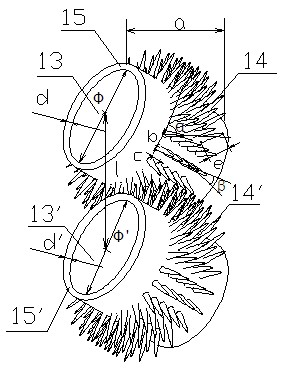

Device for improving strength of ring spinning single thread by adopting porcupine roller mode

The invention provides a device for improving the strength of a ring spinning single thread by adopting a porcupine roller mode, which comprises a drafting mechanism and is characterized in that the front side of the drafting mechanism is provided with a porcupine roller fiber winding mechanism; the porcupine roller fiber winding mechanism consists of an upper fiber winding device and a lower fiber winding device; and the front side of the porcupine roller fiber winding mechanism is provided with an advance roller pair consisting of an advance upper roller and an advance lower roller. By adopting the device, fiber strands before being twisted by a ring spinning frame can be changed into a manual winding state from a conventional manual parallel state and the friction force between fibers is strengthened, so that the strength of a yarn obtained after wrapping and twisting the fiber strands is improved and the yarn has the capability of bearing subsequent strenuous friction. Meanwhile, by adopting the device, the required twisting coefficient can also be effectively reduced and the production efficiency is effectively improved. The device has the characteristics of simple structure,stability and reliability in operation, convenience for reconstruction on the original spinning frame, low cost, and easiness in popularization.

Owner:DONGHUA UNIV +1

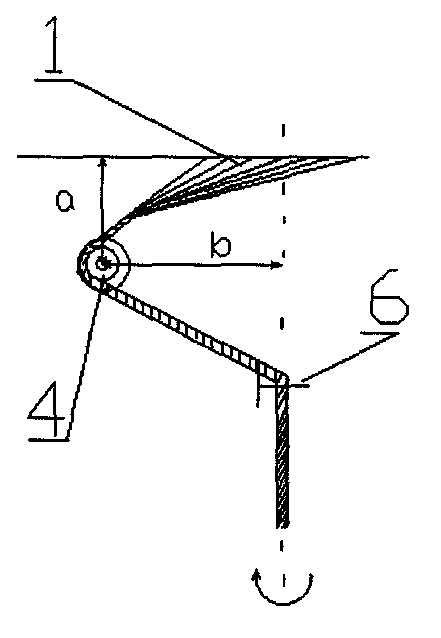

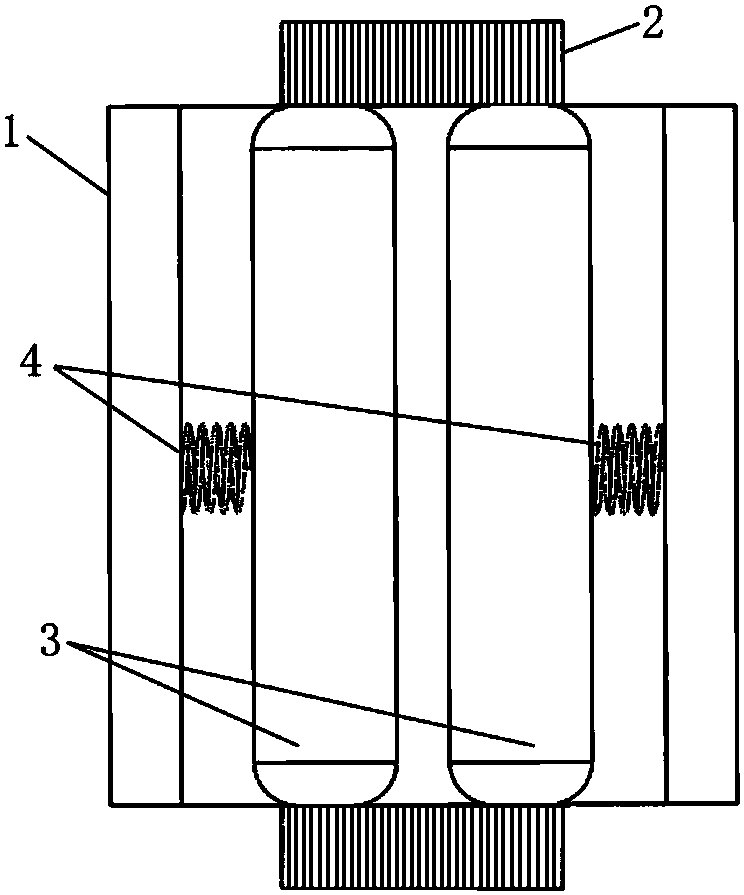

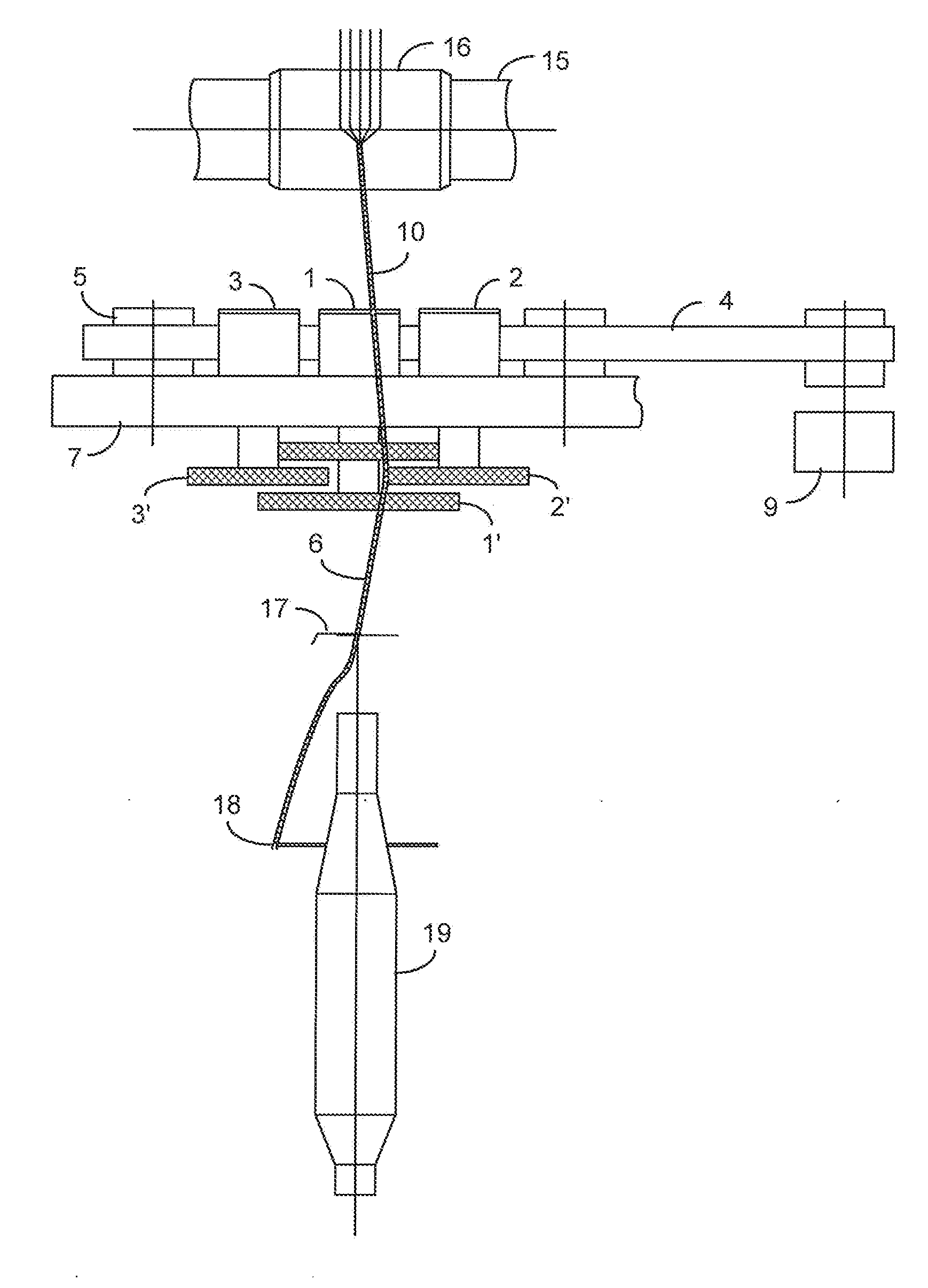

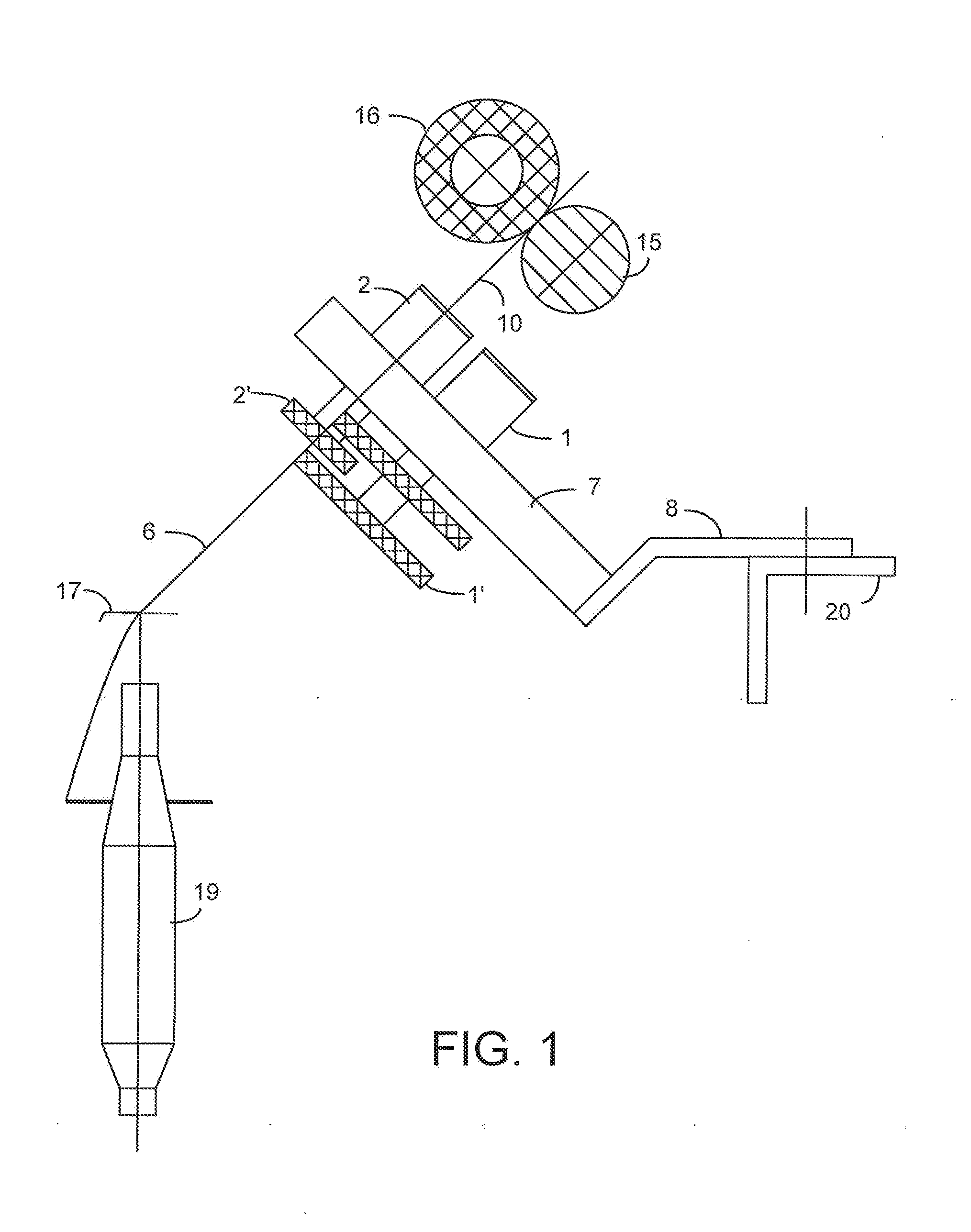

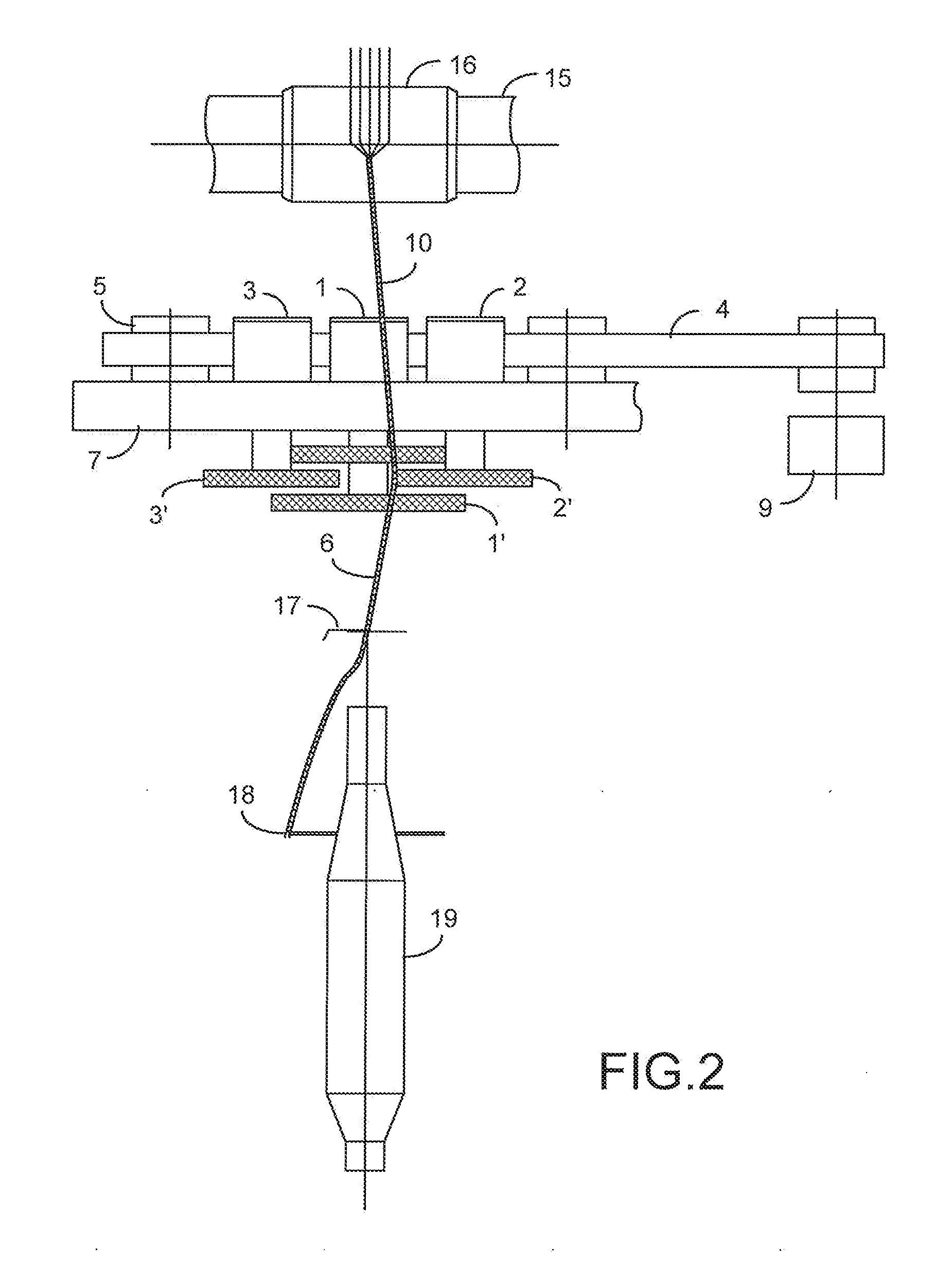

Combined frictional false twisting device for ring spinning frame

InactiveUS20150128555A1Reduce the overall heightImprove yarn strengthContinuous wound-up machinesYarnYarnEngineering

A frictional false twister is disclosed. The twister has a plurality of rotating friction plates located between the nip of the front rollers and the yarn guide. The friction plates are staggeringly arranged for rubbing a twisted yarn. The spinning direction of the twisted yarn is opposite to the rotating direction of the friction plates. Through the action of the frictional false twister, the twist of the yarn between the false twisting device to the front nip can be increased, shortening the twisting triangle height, and increasing the spinning strength. As the yarn and the outer surface of the friction plate make relative sliding and rubbing, the friction damping force correspondingly reduces the spinning tension in the twisting triangle.

Owner:INST OF WOOL & HEMP TEXTILE SCI SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com