Patents

Literature

329results about How to "Improve lightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foam of thermoplastic urethane elastomer composition and process for producing the foam

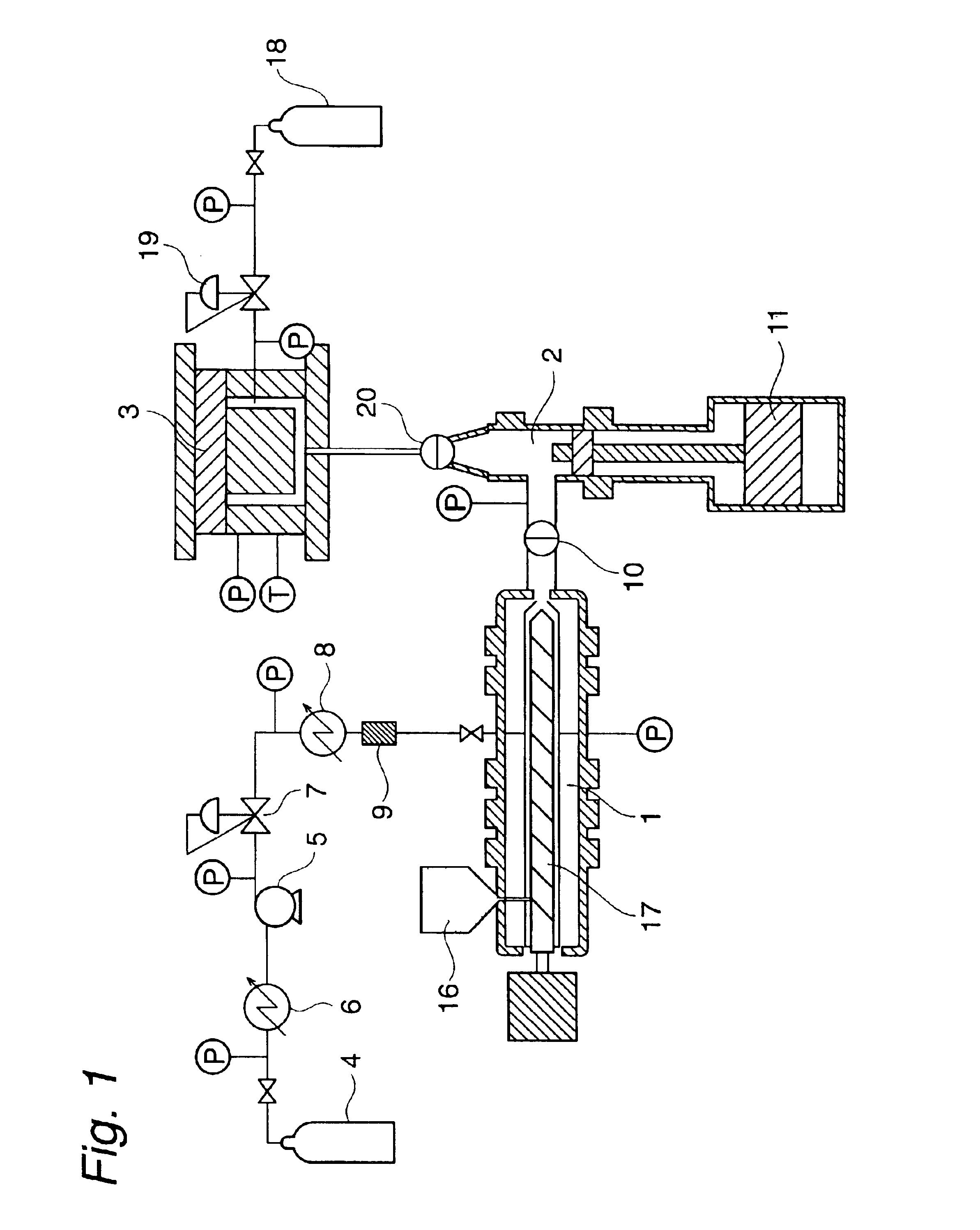

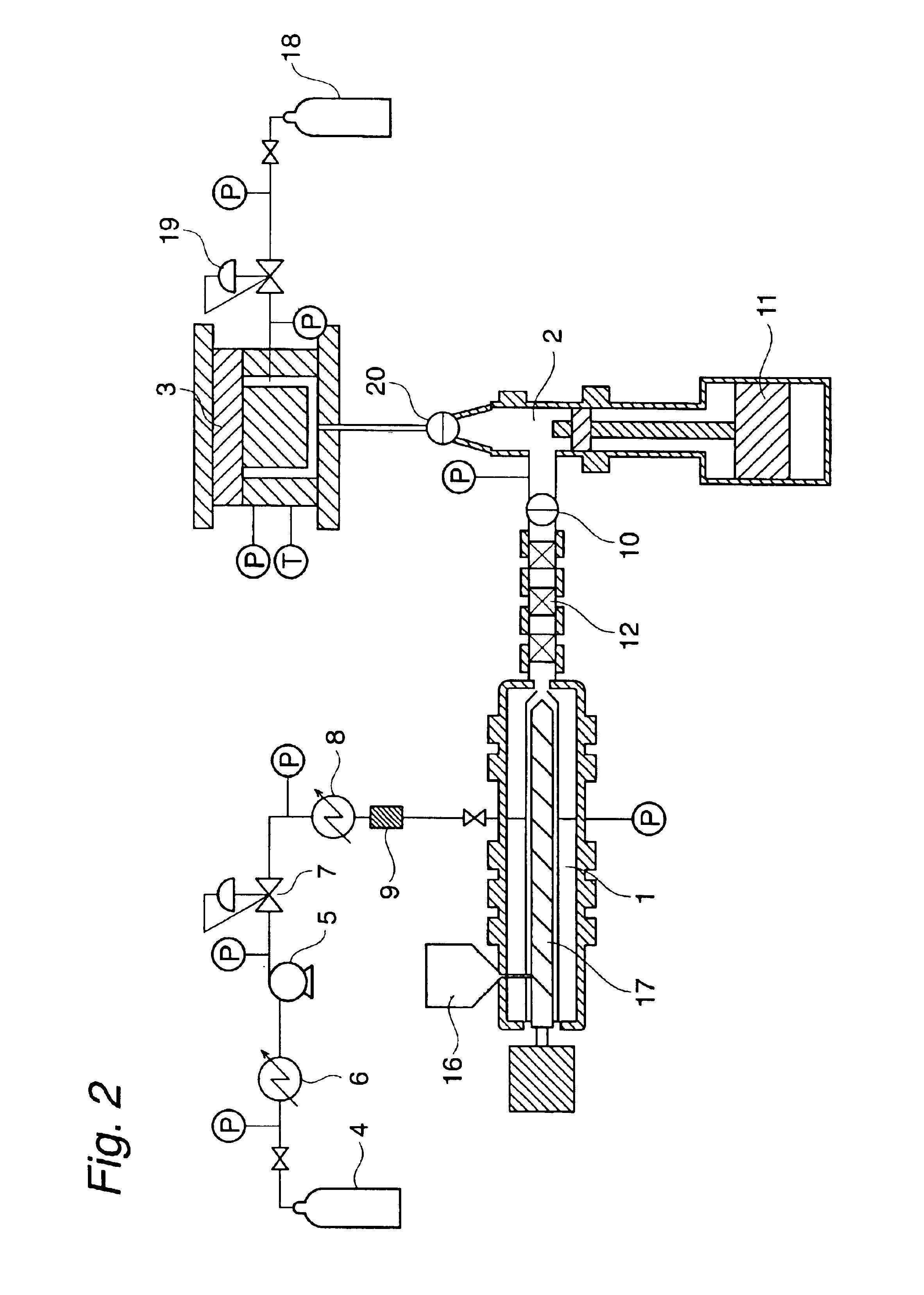

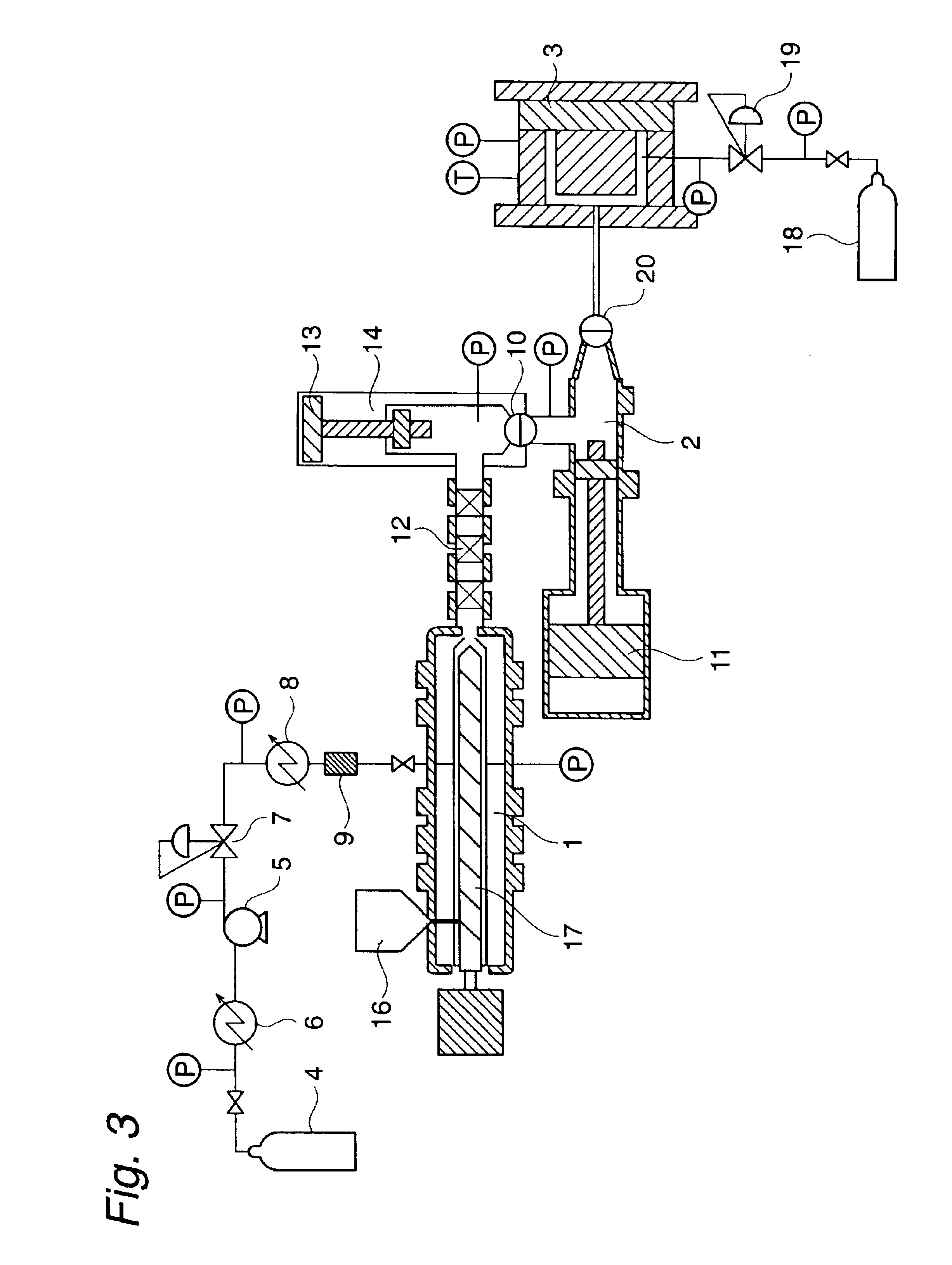

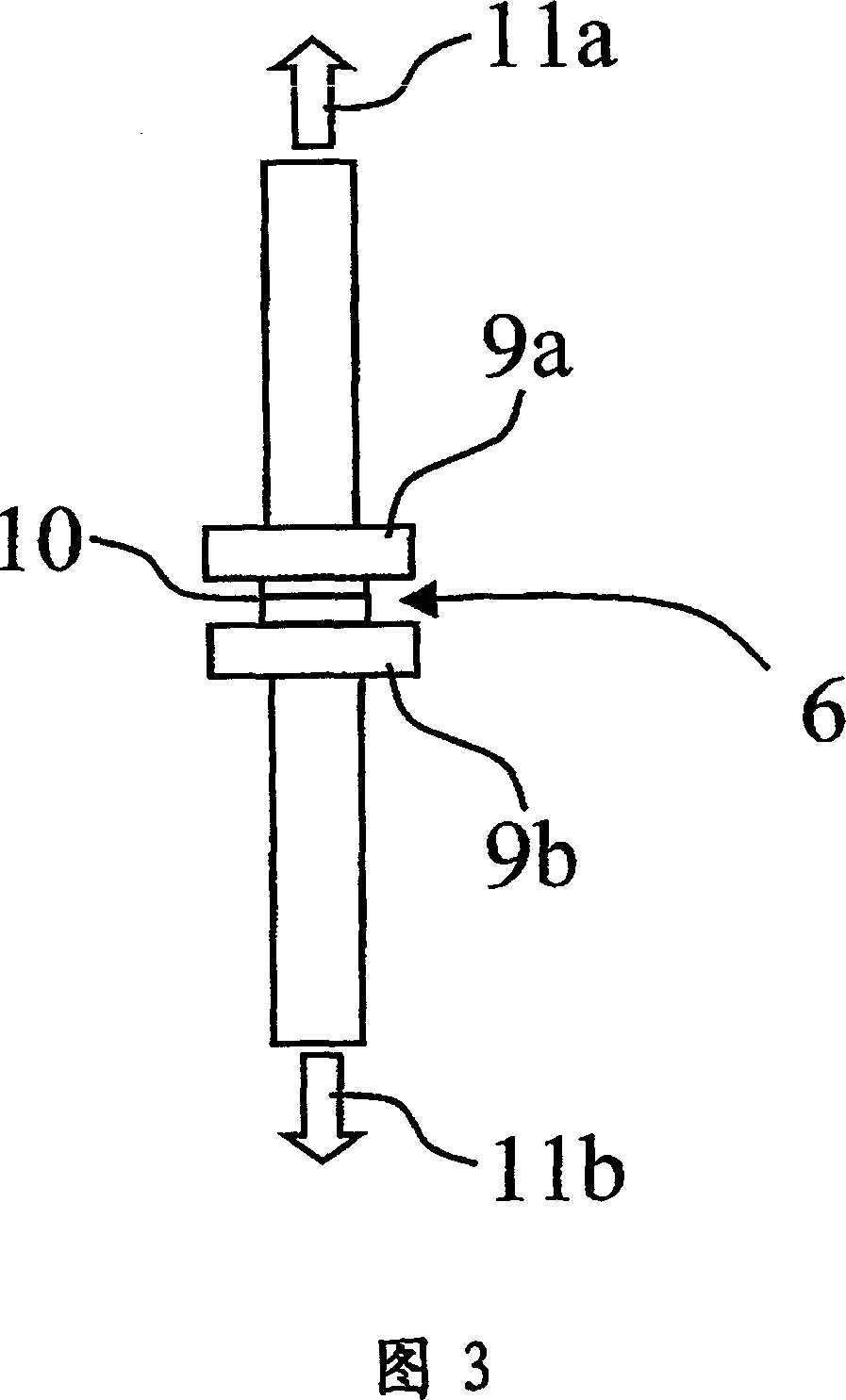

The method of the present invention for producing a urethane-based thermoplastic elastomer composition foam comprises the steps of:adding and mixing 0.1 to 30 parts by weight of carbon dioxide (B) to 100 parts by weight of a urethane-based thermoplastic elastomer composition (A) in a molten state, wherein said urethane-based thermoplastic elastomer composition (A) comprises a urethane-based thermoplastic elastomer (A-1) and other thermoplastic elastomer (A-2) in an (A-1) / (A-2) ratio of 20 / 80 to 99 / 1 by weight, to form a molten urethane-based thermoplastic elastomer composition (C) which is in a state of a mixture of the urethane-based thermoplastic elastomer composition (A) and the carbon dioxide (B) (gas dissolving step); andlowering a temperature of said molten urethane-based thermoplastic elastomer composition (C) (cooling step).The present invention can produce the urethane-based thermoplastic elastomer foam of stable quality over a range from low foamed product to highly foamed product by adding a given quantity of carbon dioxide in the molten urethane-based thermoplastic elastomer quantitatively and stably. It can also produce the foam excellent in flexibility, thermal insulation and surface appearances. It is also excellent in safety, because of use of carbon dioxide in place of the common foaming agent of fluorochlorohydrocarbon or butane, thus causing no air pollution or destruction of the ozone layer.

Owner:MITSUI CHEM INC

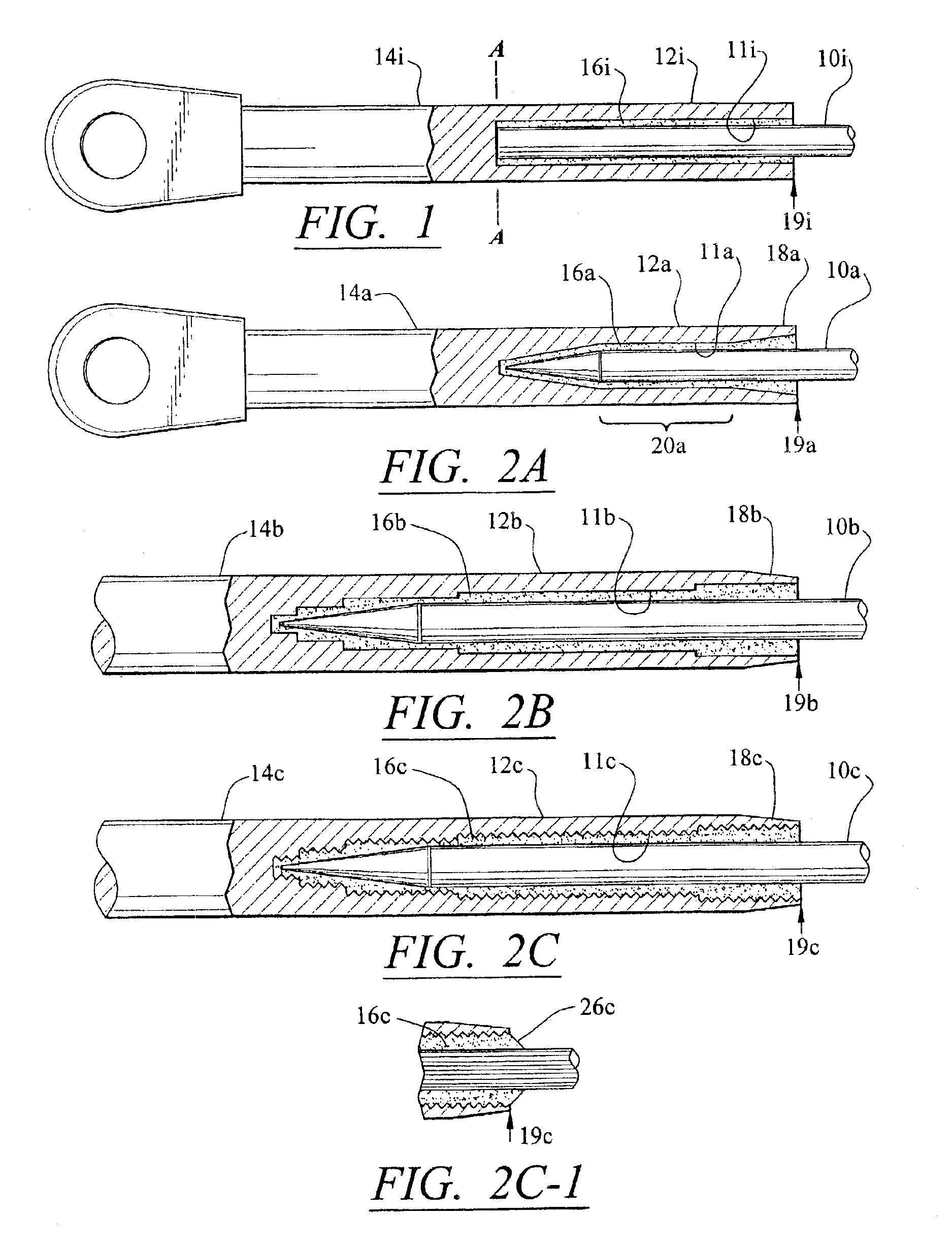

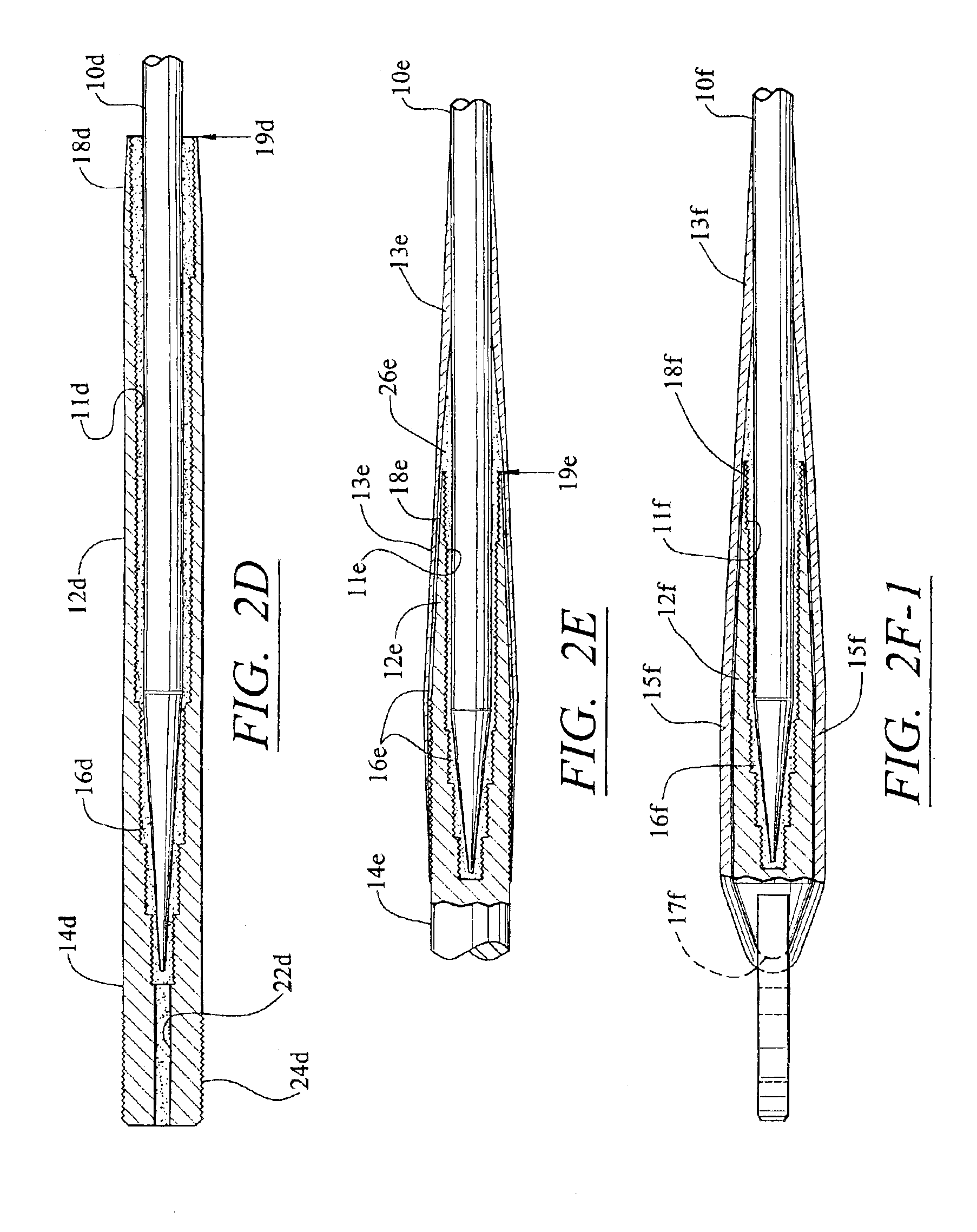

Composite tension rod terminal systems

InactiveUS6886484B2Superior combination of strengthSuperior combination of lightnessConnecting rodsRod connectionsFiberMechanical engineering

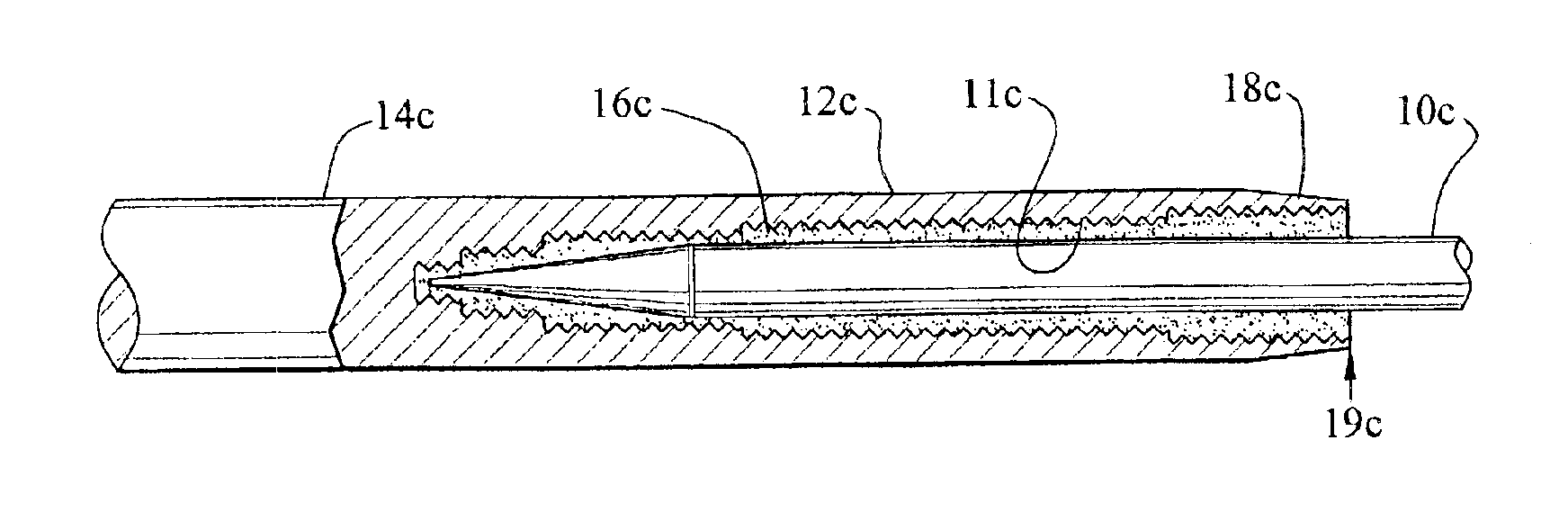

A composite tension rod is received in the sleeve portion of a shank that forms part of a terminal fitting, and is spaced from the shank sleeve and connected thereto by a potting resin. The shank sleeve wall tapers out from thin at its distal end to thick at the bury depth of the rod. The rod is tapered outwardly from a point of minimum diameter at its inner end to its full diameter a given distance from the end. The shank sleeve and rod have complementary dual tapering along said length such that as the diameter of the rod along said distance increases, the wall thickness of the shank sleeve decreases. The resin layer and the rod are secured to each other against relative longitudinal movement, as are the resin layer and the shank sleeve.In another aspect of the invention, a tension rod sleeve is fixed to the tension rod and extends over the distal end of the shank sleeve and along all or a majority of the length of the shank sleeve. The rod sleeve is tapered so that its wall thickness decreases to a minimum in the vicinity of the proximal end of the shank sleeve, or the rod sleeve, as it extends along the shank sleeve, is divided, or divides, into two halves or bands which join to form loop extending around a loop-engaging, convex, fiber-turnaround face formed on the terminal fitting. Such face extends transversely from one side to the other of the fitting.

Owner:THOMAS GEORG K

Epoxy resin composition for carbon-fiber-reinforced composite material, prepreg, integrated molding, sheet of fiber-reinforced composite material and cabinet for electrical/electronic equipment

ActiveCN1946780AIncrease flame retardancyExcellent mechanical propertiesPigmenting treatmentLayered productsCombustionHalogen

A lightweight fiber-reinforced composite material that exhibits excellent flame resistance and mechanical properties and does not emit any halogen gas at combustion; an epoxy resin composition and prepreg suitable for obtaining the above fiber-reinforced composite material; and an integrated molding suitable to electrical / electronic equipment cabinet, in which use is made of the above fiber-reinforced composite material. There is provided an epoxy resin composition for carbon-fiber-reinforced composite material, comprising: [A] epoxy resin, [B] amine curing agent, and [C] phosphorus compound, the component [C] contained in an amount, in terms of concentration of phosphorus atoms, of 0.2 to 15 wt.%.

Owner:TORAY IND INC

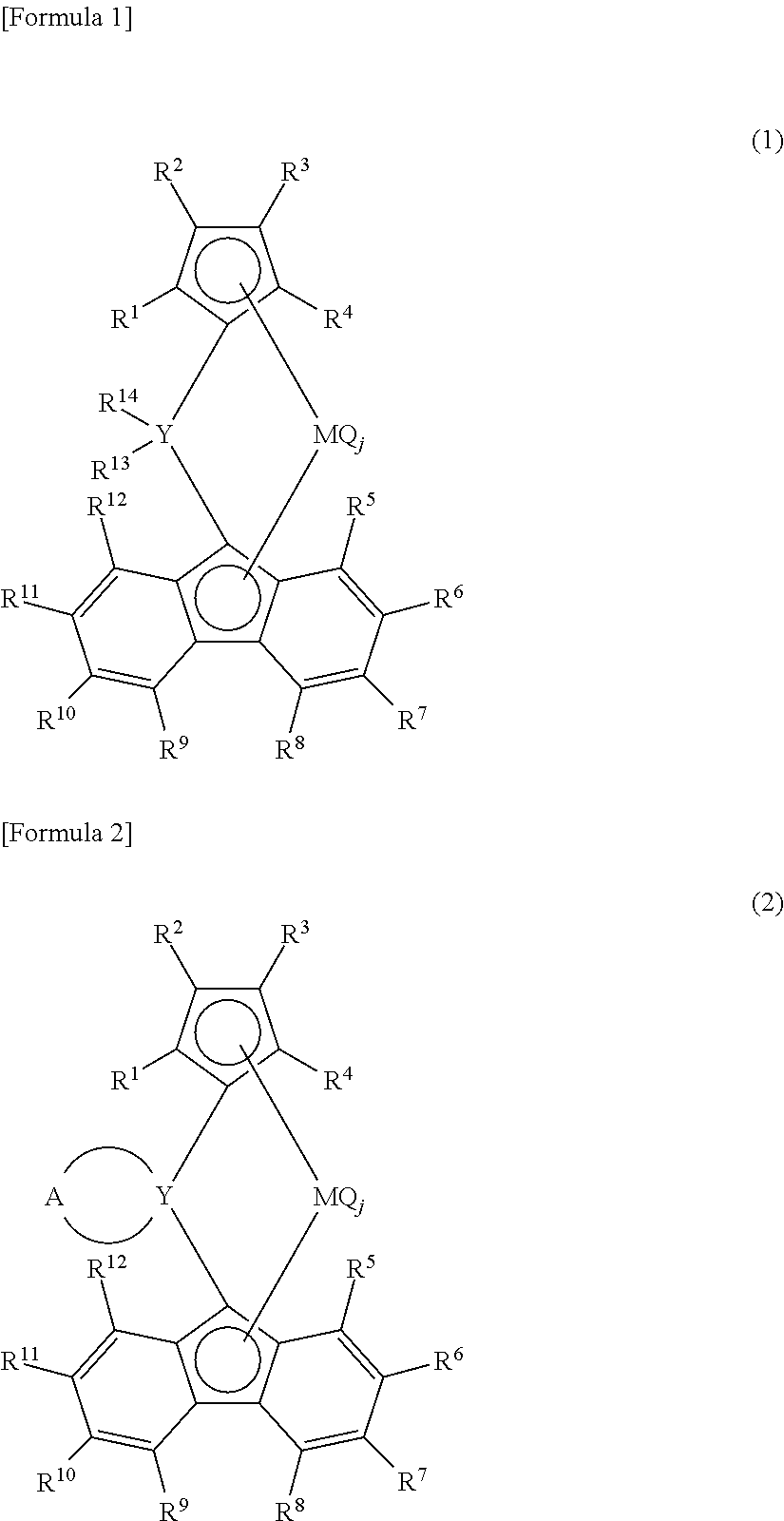

4-METHYL-1-PENTENE/a-OLEFIN COPOLYMER, COMPOSITION COMPRISING THE COPOLYMER AND 4-METHYL-1-PENTENE COPOLYMER COMPOSITION

ActiveUS20120220728A1Preferable in of flexibilityPreferable in of mechanical propertyPolymer scienceStress relaxation

The present invention provides a 4-methyl-1-pentene / α-olefin copolymer being excellent in lightness, stress absorption, stress relaxation, vibration damping properties, scratch resistance, abrasion resistance, toughness, mechanical properties and flexibility, having no stickiness during molding operation and being excellent in the balance among these properties; a composition comprising the polymer; and uses thereof. The 4-methyl-1-pentene / α-olefin copolymer (A) of the present invention satisfies specific requirements, and comprises 5 to 95 mol % of a structural unit (i) derived from 4-methyl-1-pentene, 5 to 95 mol % of a structural unit (ii) derived from at least one kind of α-olefin selected from α-olefins having 2 to 20 carbon atoms excluding 4-methyl-1-pentene and 0 to 10 mol % of a structural unit (iii) derived from a non-conjugated polyene, provided that the total of the structural units (i), (ii), and (iii) is 100 mol %.

Owner:MITSUI CHEM INC

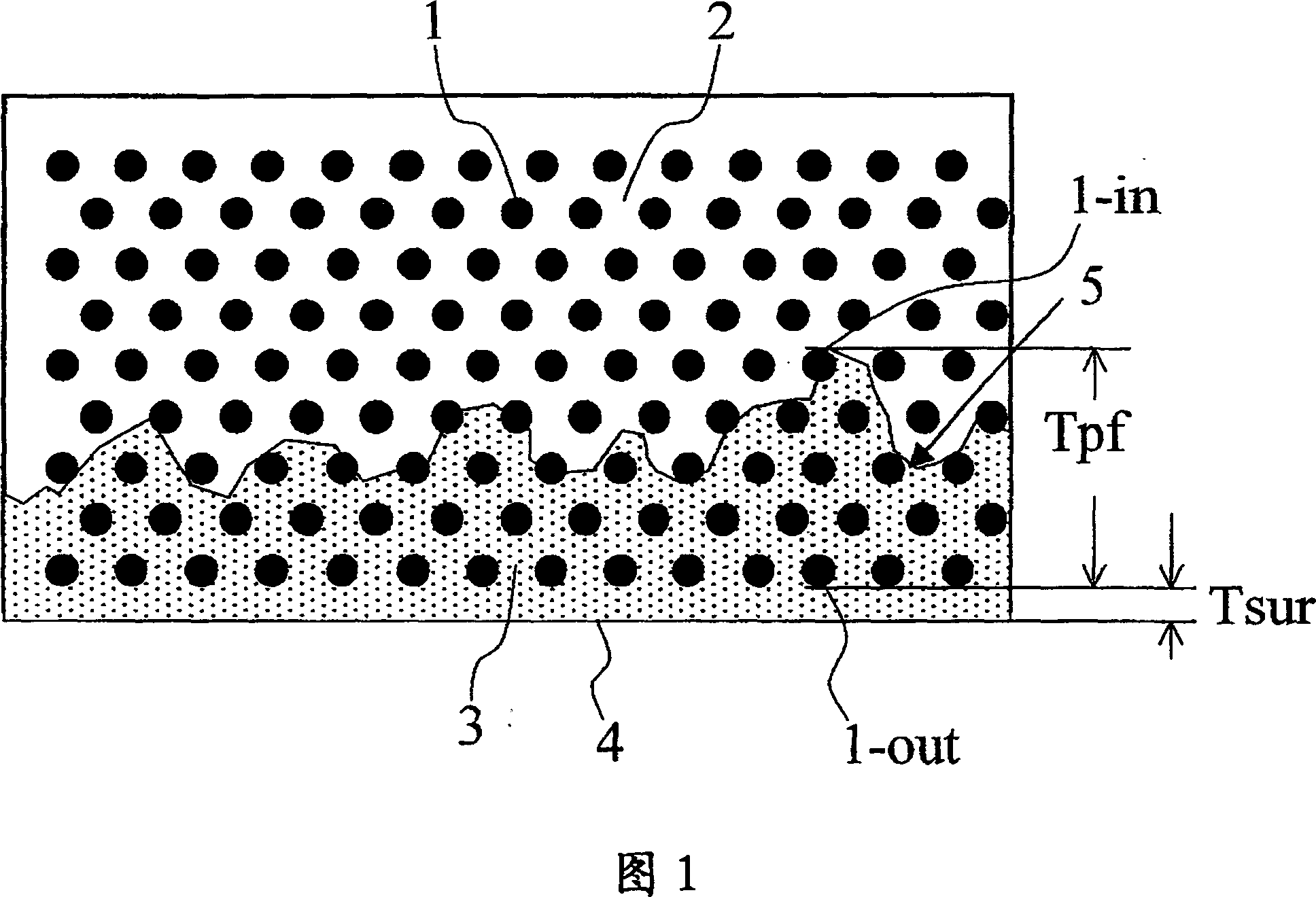

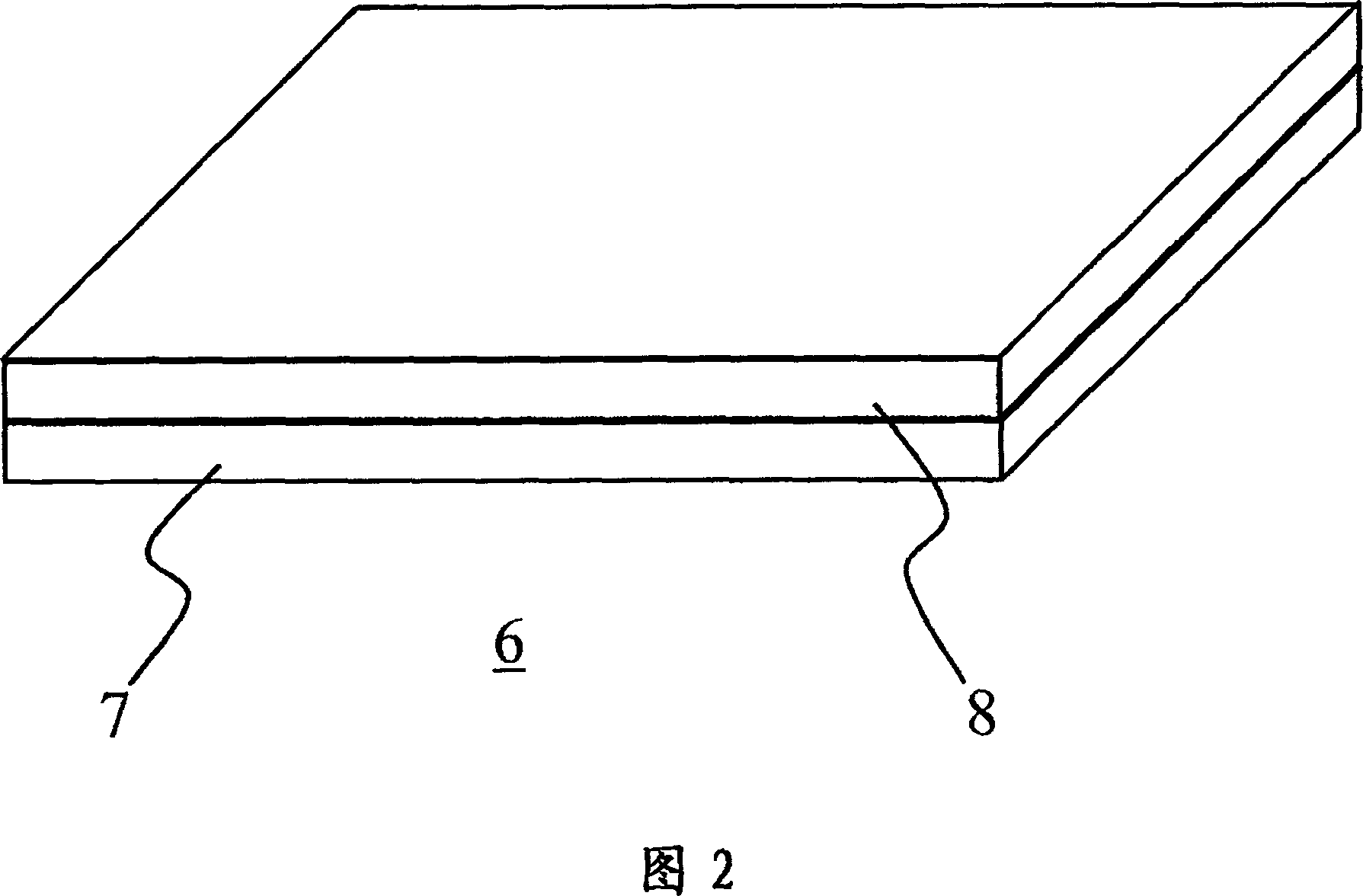

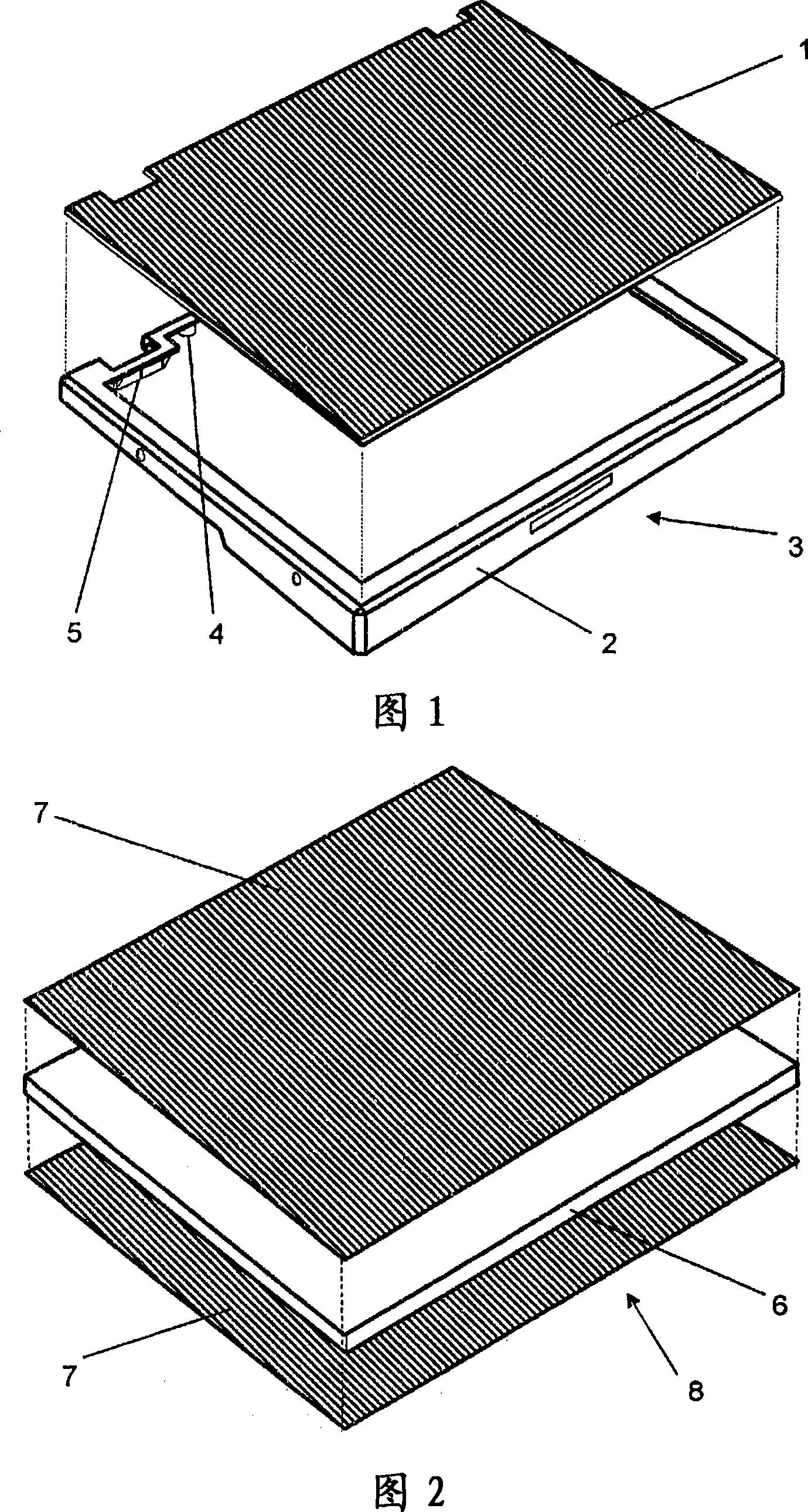

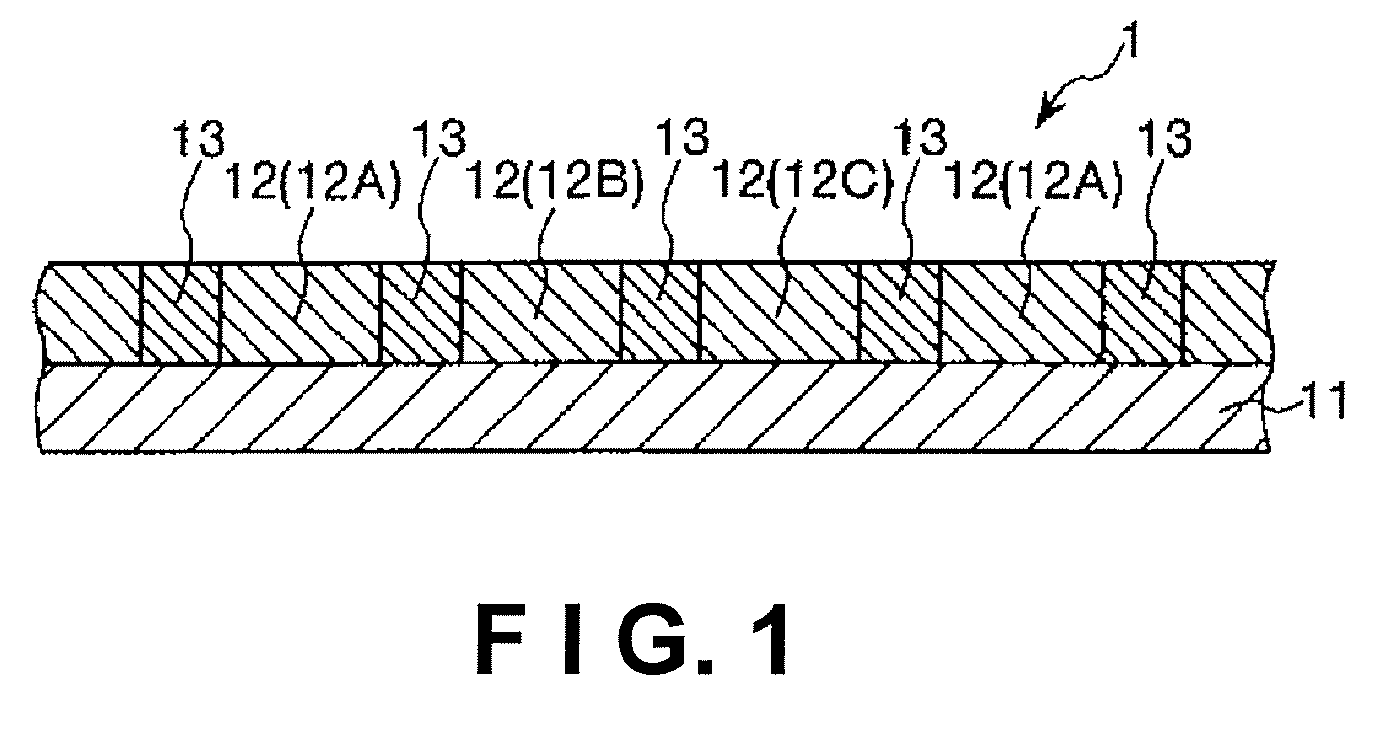

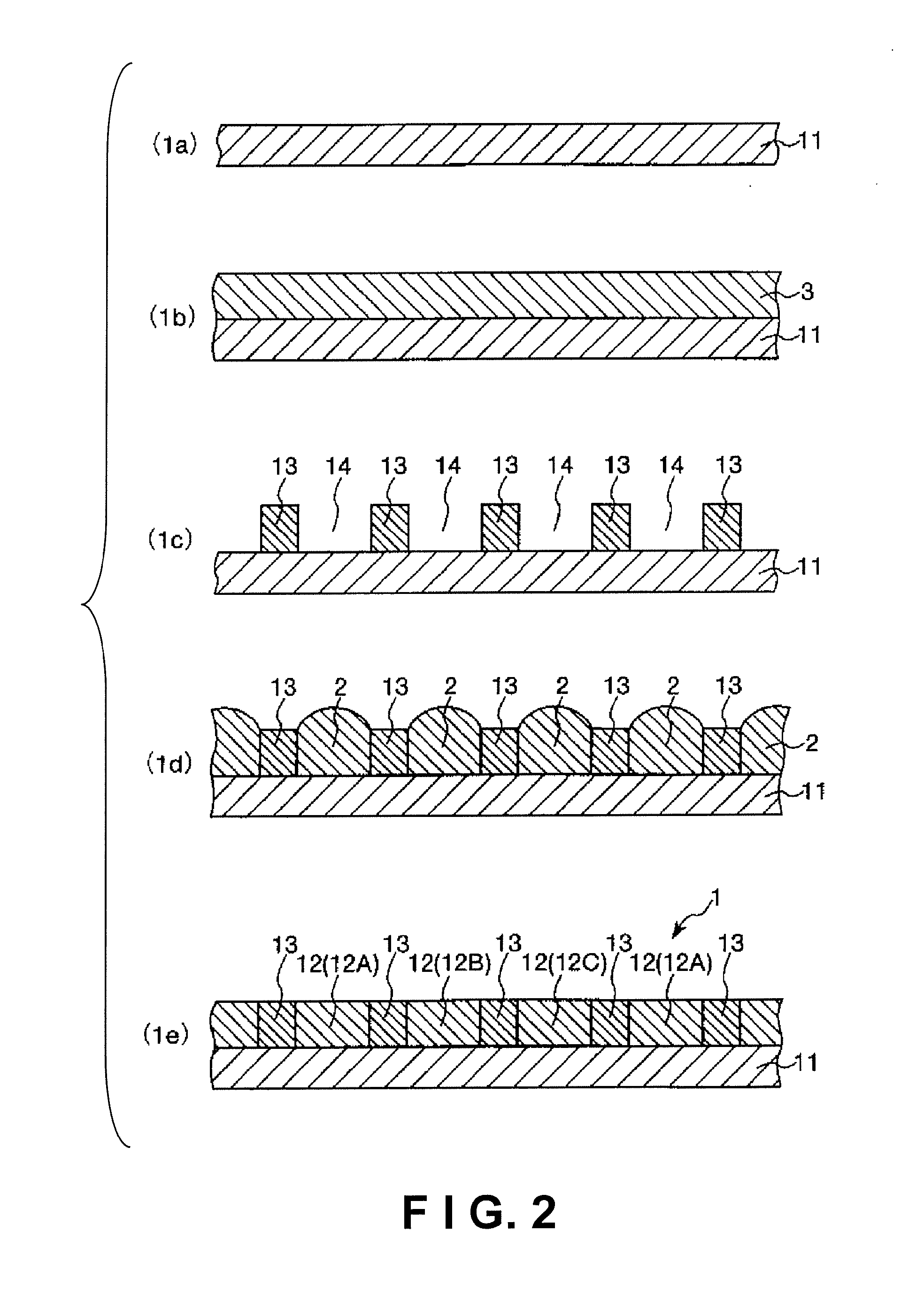

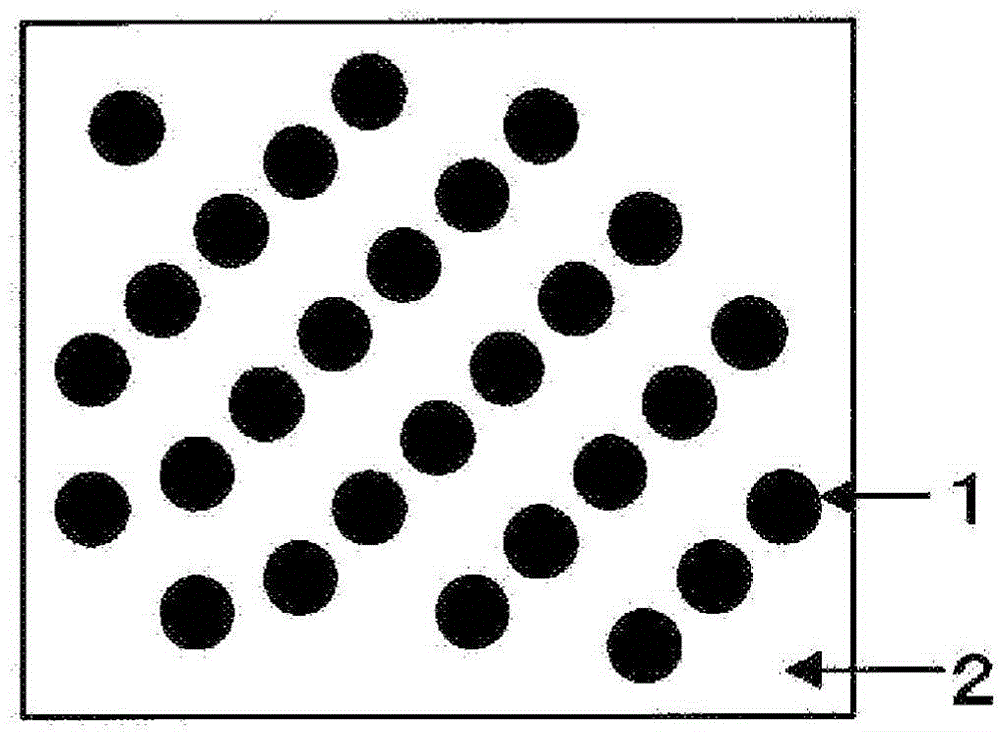

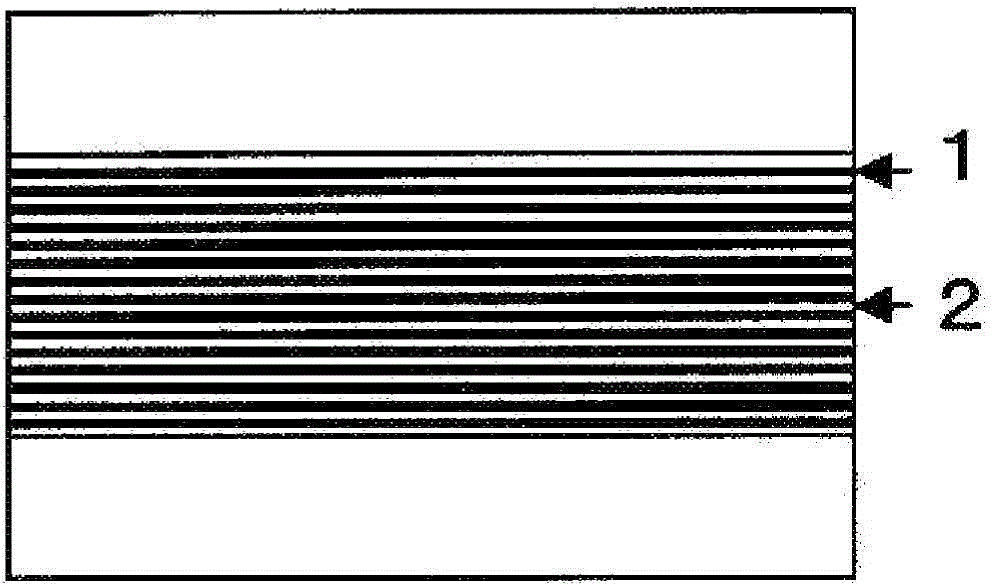

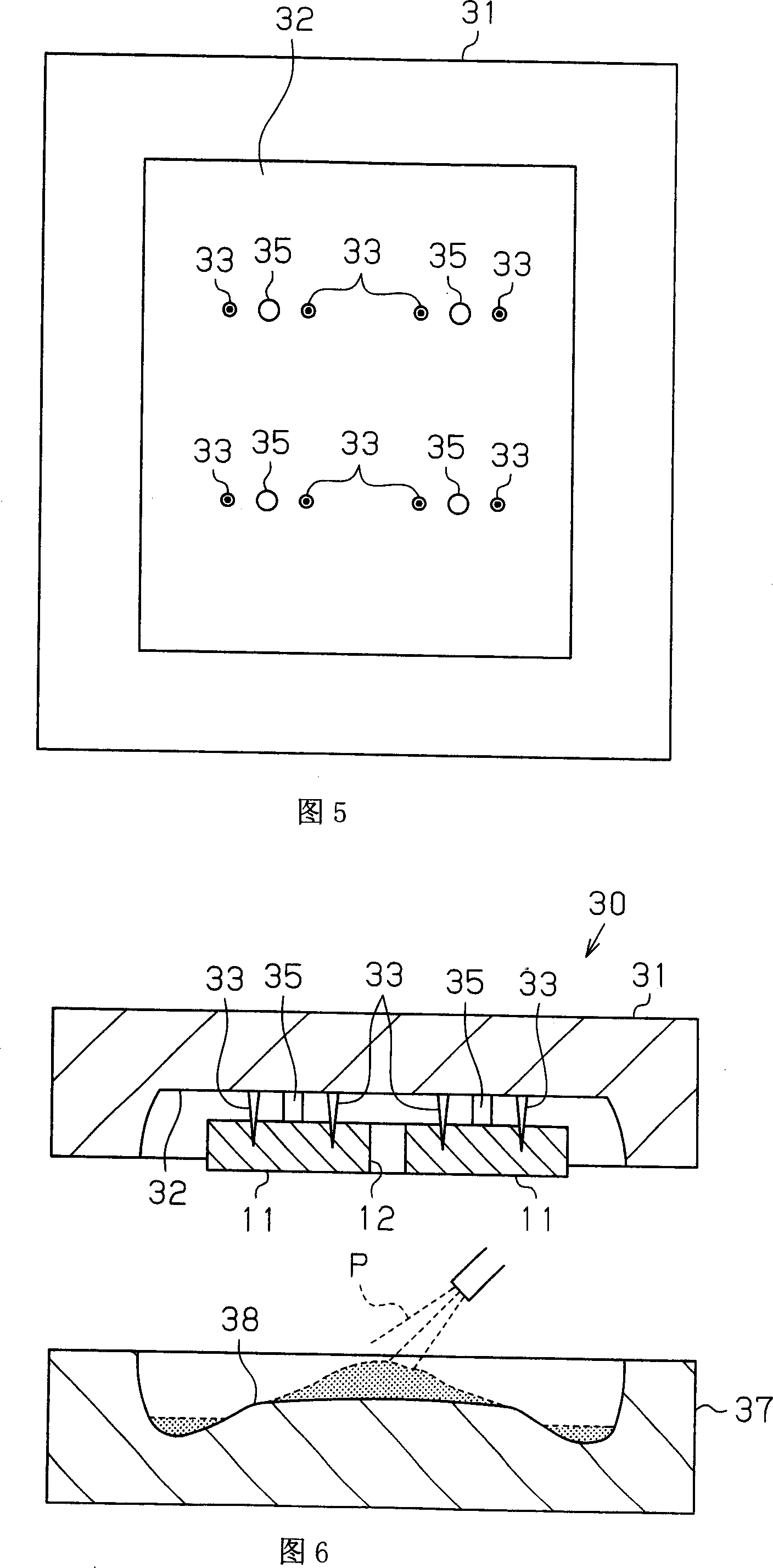

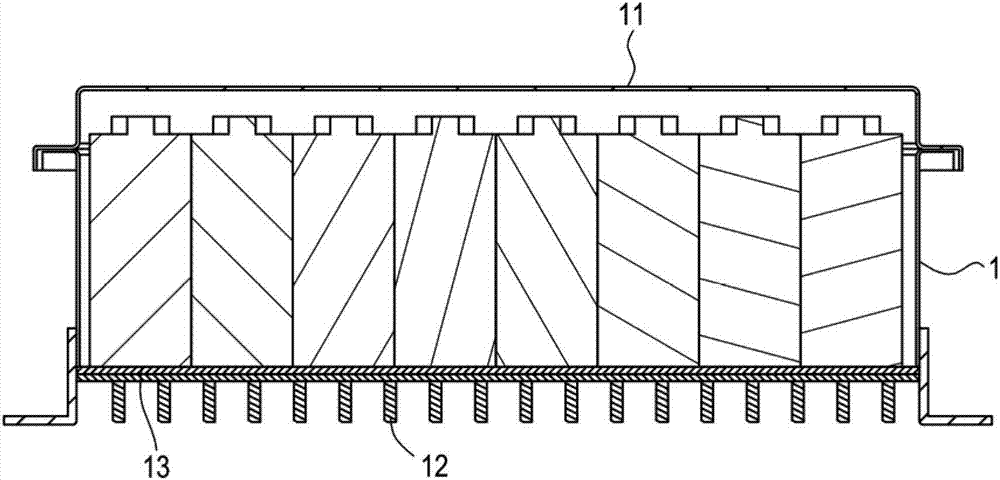

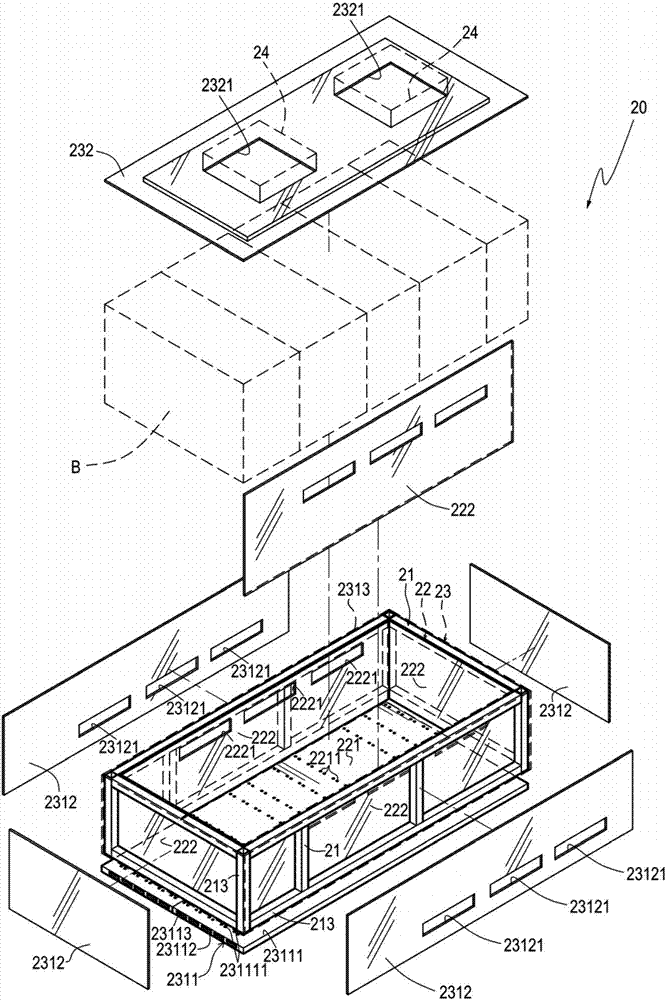

Sandwich structure and integrated formed article using the same

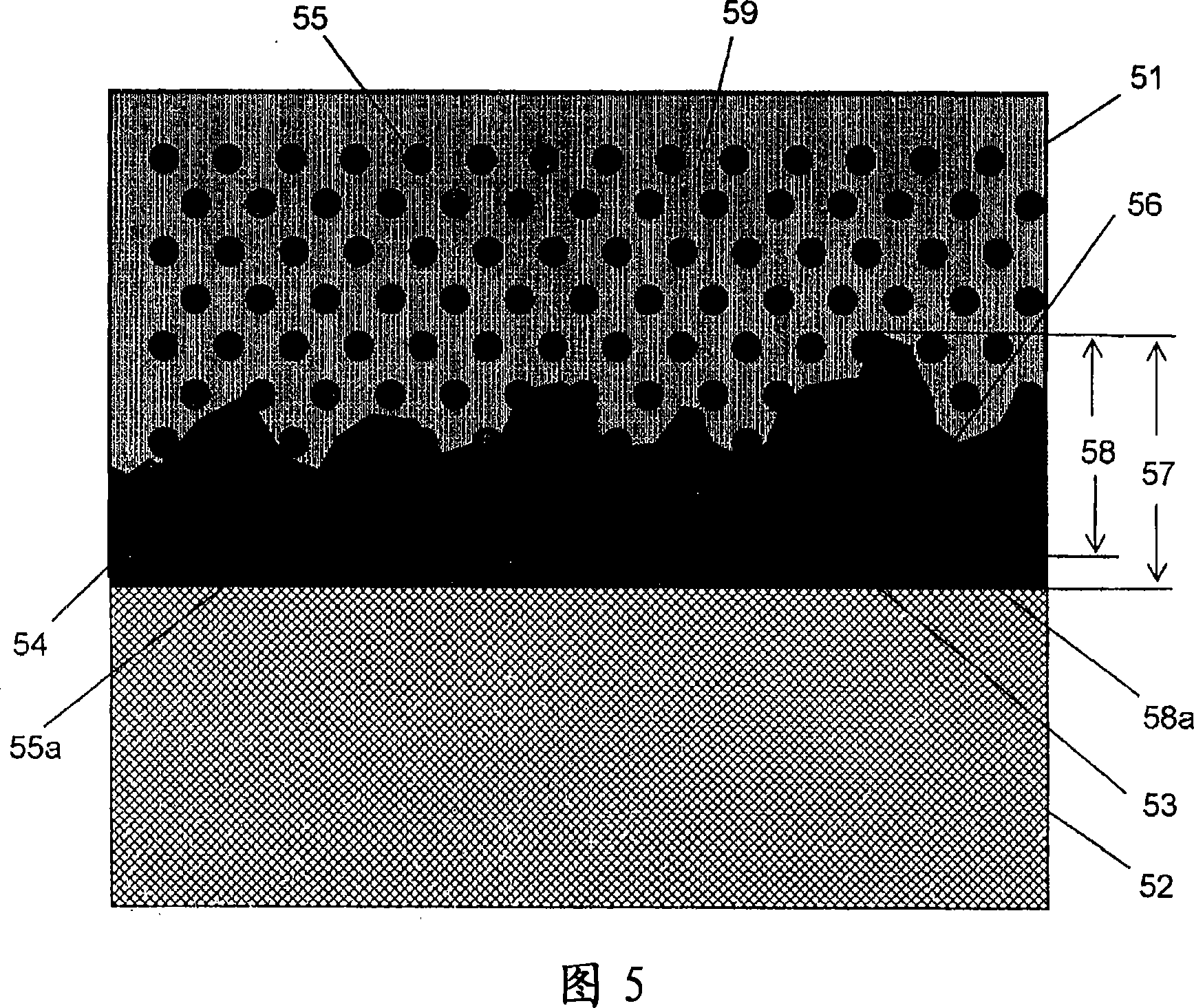

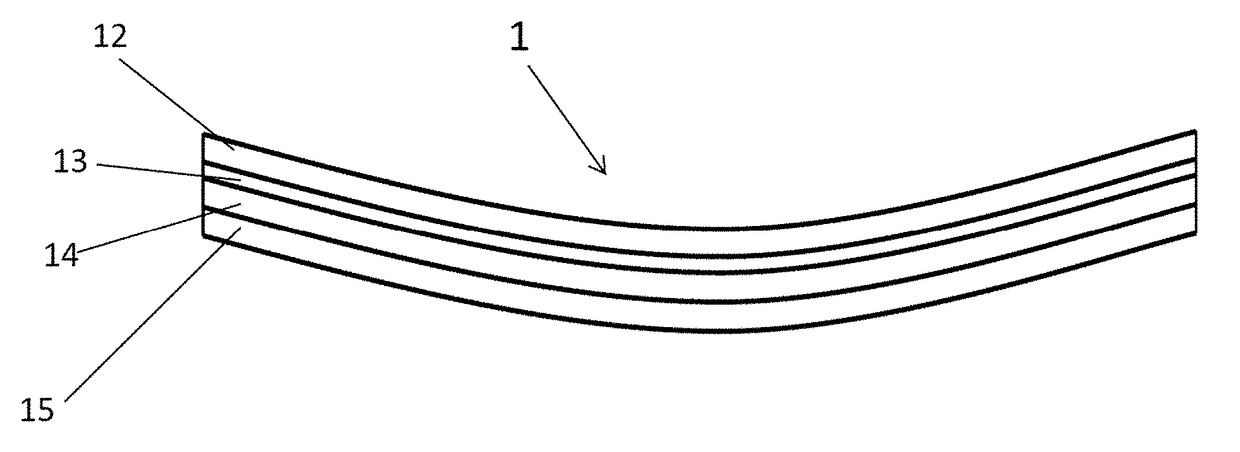

ActiveCN101010188AExcellent mechanical propertiesImprove lightnessSynthetic resin layered productsThin material handlingFiberPolymer science

A sandwich structure (III) which has a core material (I) and, arranged on the both surfaces of said core material (I), a fiber-reinforced material (II) composed of a continuous reinforcing fiber (A) and a matrix fiber (B), wherein the above core material (I) comprises a void. The void is formed by bubbles of a foamed material or, the core is composed of a discontinuous reinforcing fiber and a thermoplastic resin and the void is formed by interstices formed at crossings of filaments of said reinforcing fiber.

Owner:TORAY IND INC

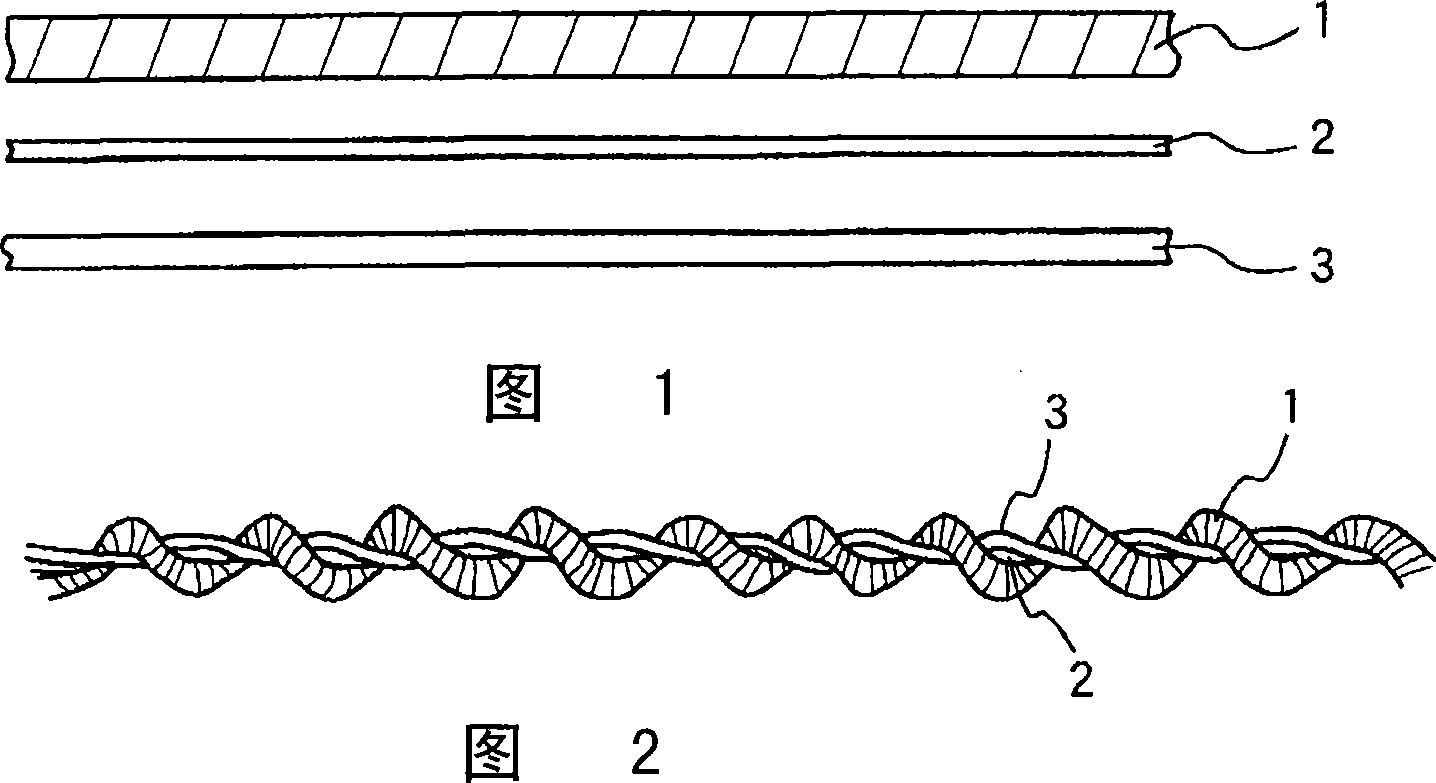

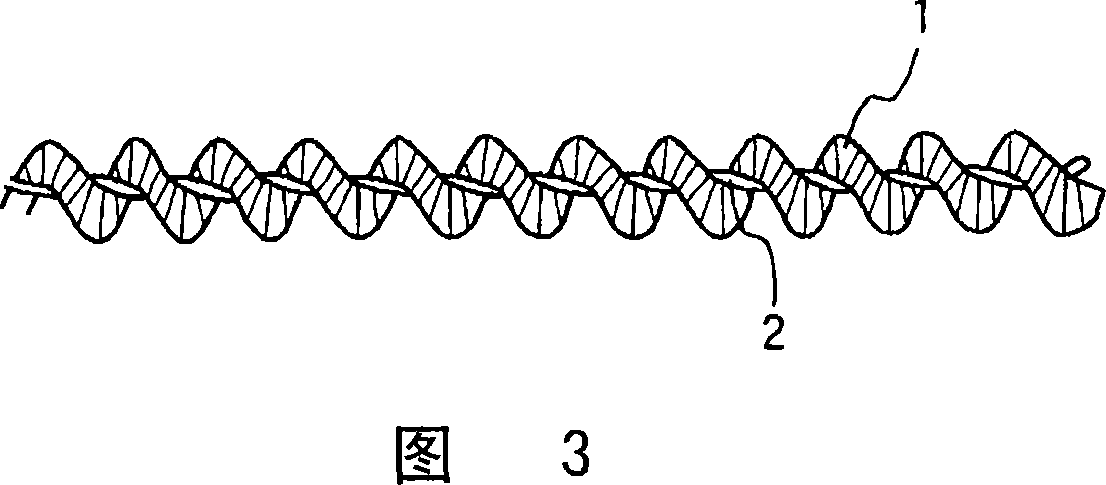

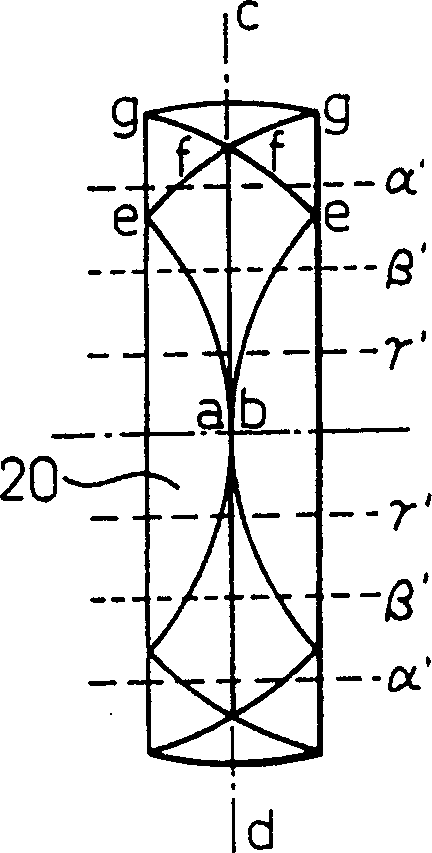

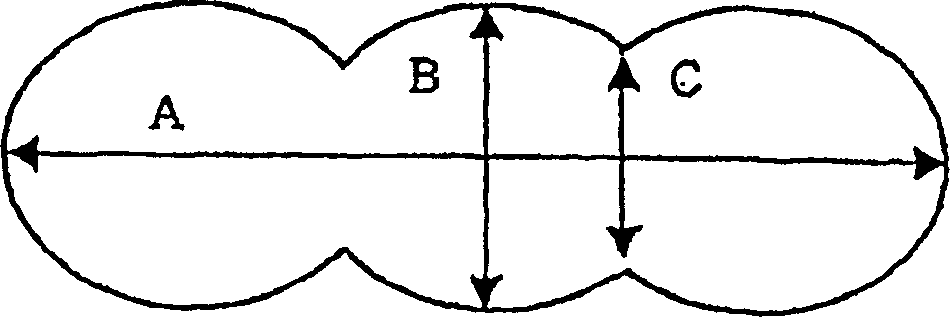

Composite twist yarn

The present invention relates to the production of woven or knitted fabrics or fabrics, which have high yarn strength, can be woven or knitted with high-speed looms or knitting machines, will not cause problems such as thread breakage, and have high stretchability sex. The present invention also prepares a composite twisted yarn, which at least twists a spun yarn and a water-soluble yarn, the twist direction of the composite twisted yarn is opposite to that of the spun yarn, and satisfies the following necessary conditions (1 ) or (2): (1) The twist number of the composite twisted yarn is 1.3-3 times that of the spun yarn, and the ratio (weight ratio) of the spun yarn to the water-soluble yarn is spun yarn / Water-soluble yarn = 20 / 80-98 / 2; (2) further twist the elastic yarn (2) stretched to 2-5 times, and the twist number of the composite twisted yarn relative to the twist number of the spun yarn is 0.3-3 times, while the ratio (weight ratio) of spun yarn (1) to the above-mentioned elastic yarn (2) is spun yarn (1) / elastic yarn (2)=50 / 50-99.9 / 0.1, spun yarn (1) and the total amount of elastic yarn (2) and the ratio (weight ratio) of water-soluble yarn (3) is: total amount of spun yarn (1) and elastic yarn (2) / water-soluble yarn (3)= 30 / 70-99 / 1.

Owner:KURARAY TRADING CO LTD +1

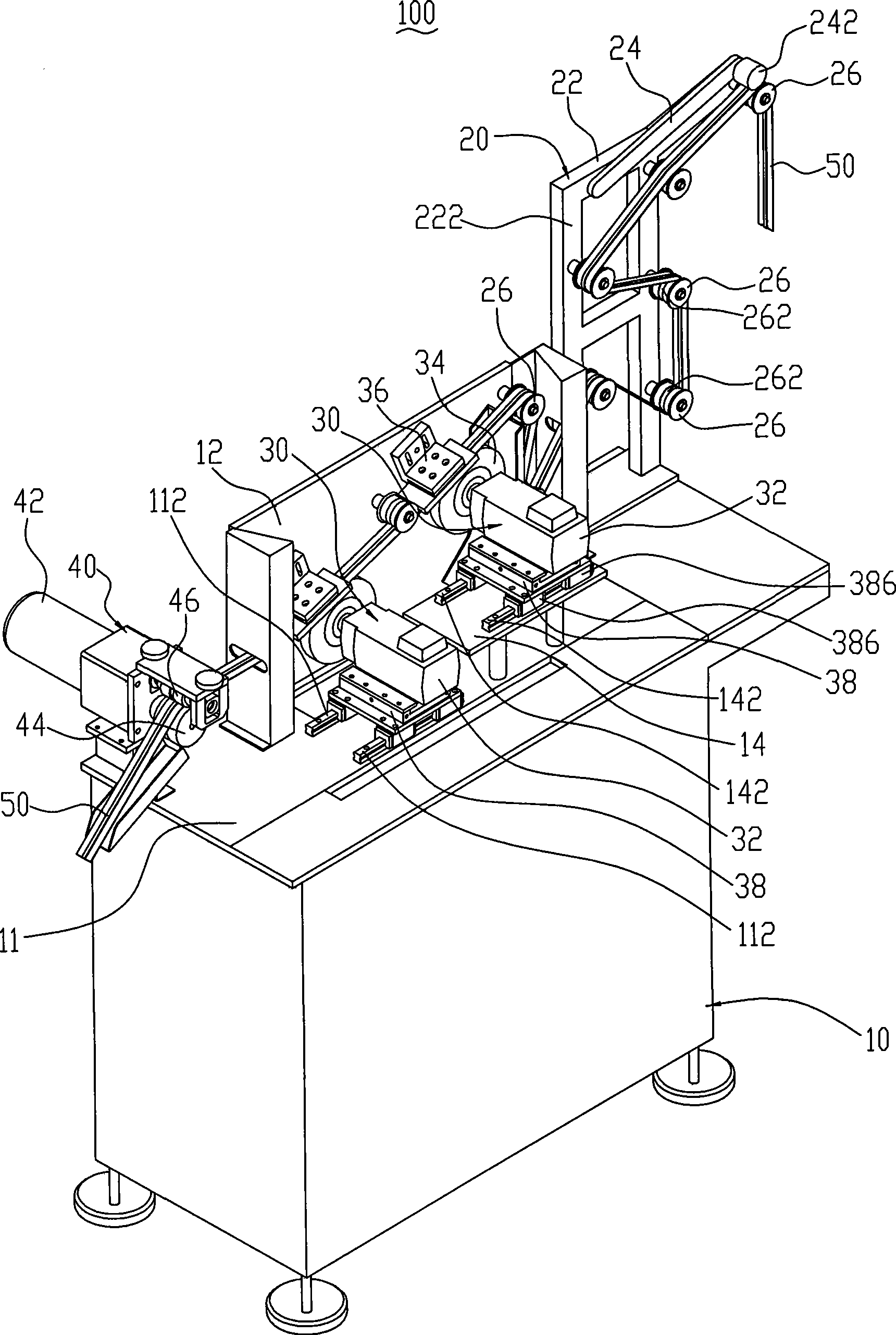

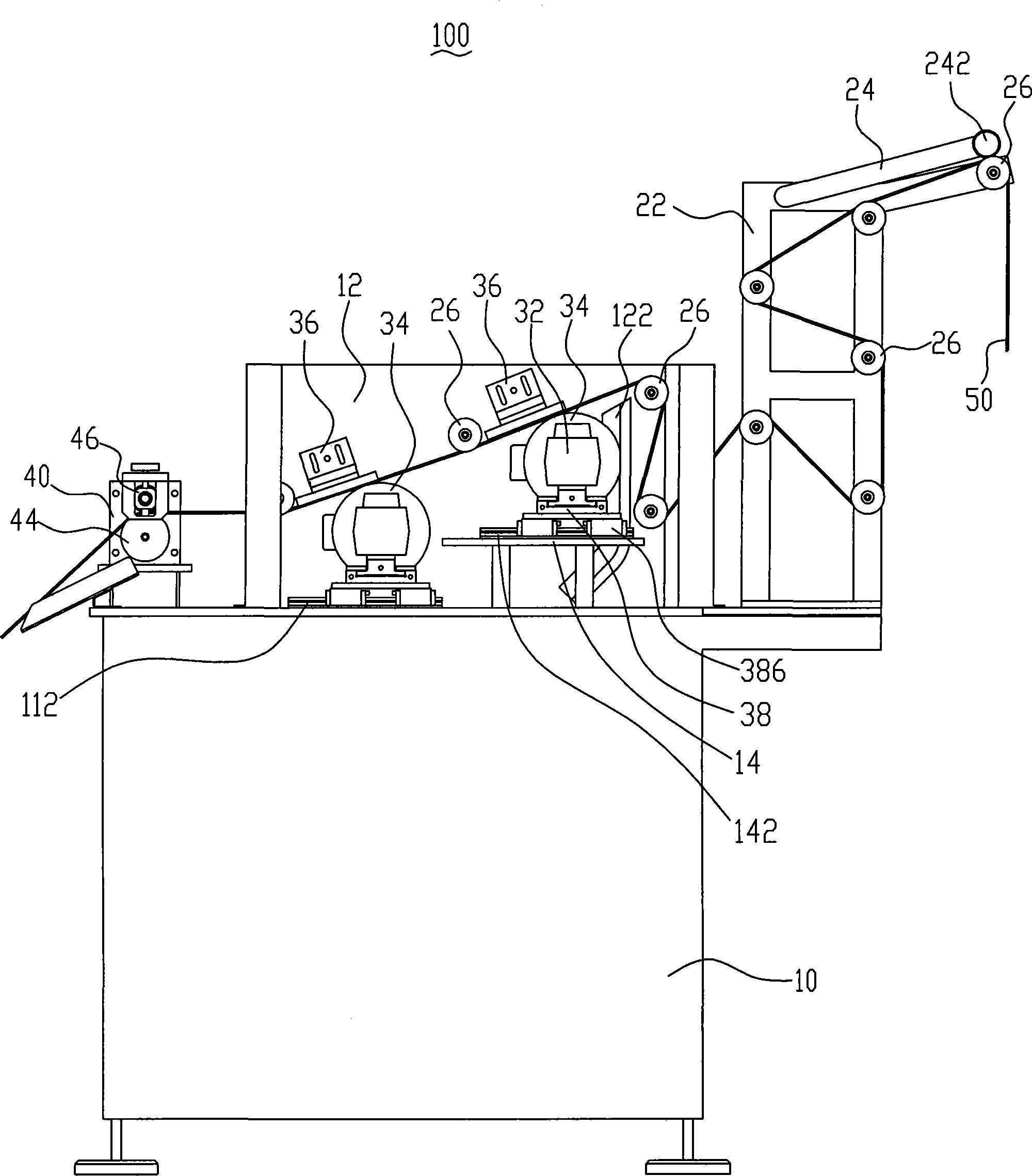

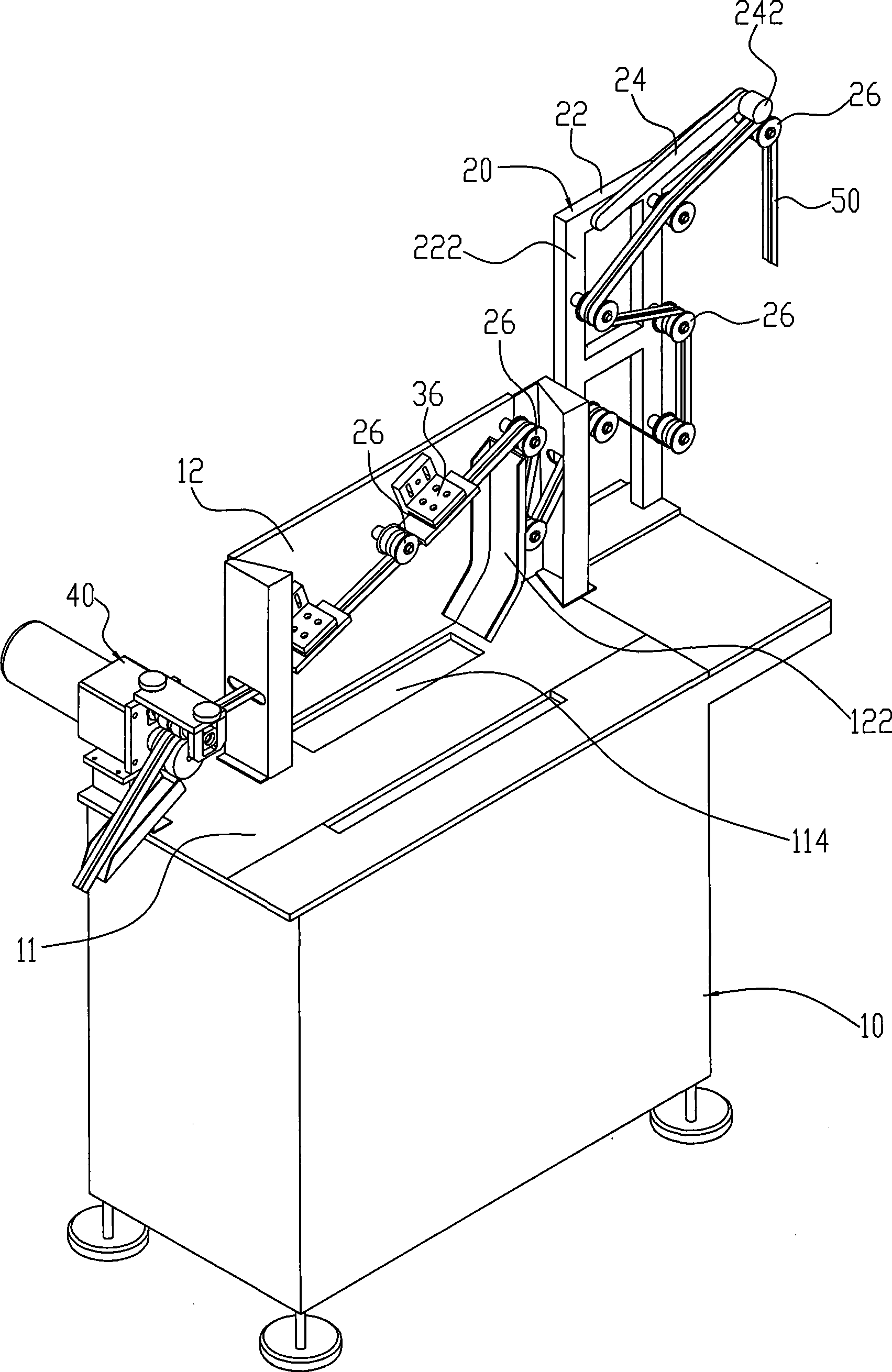

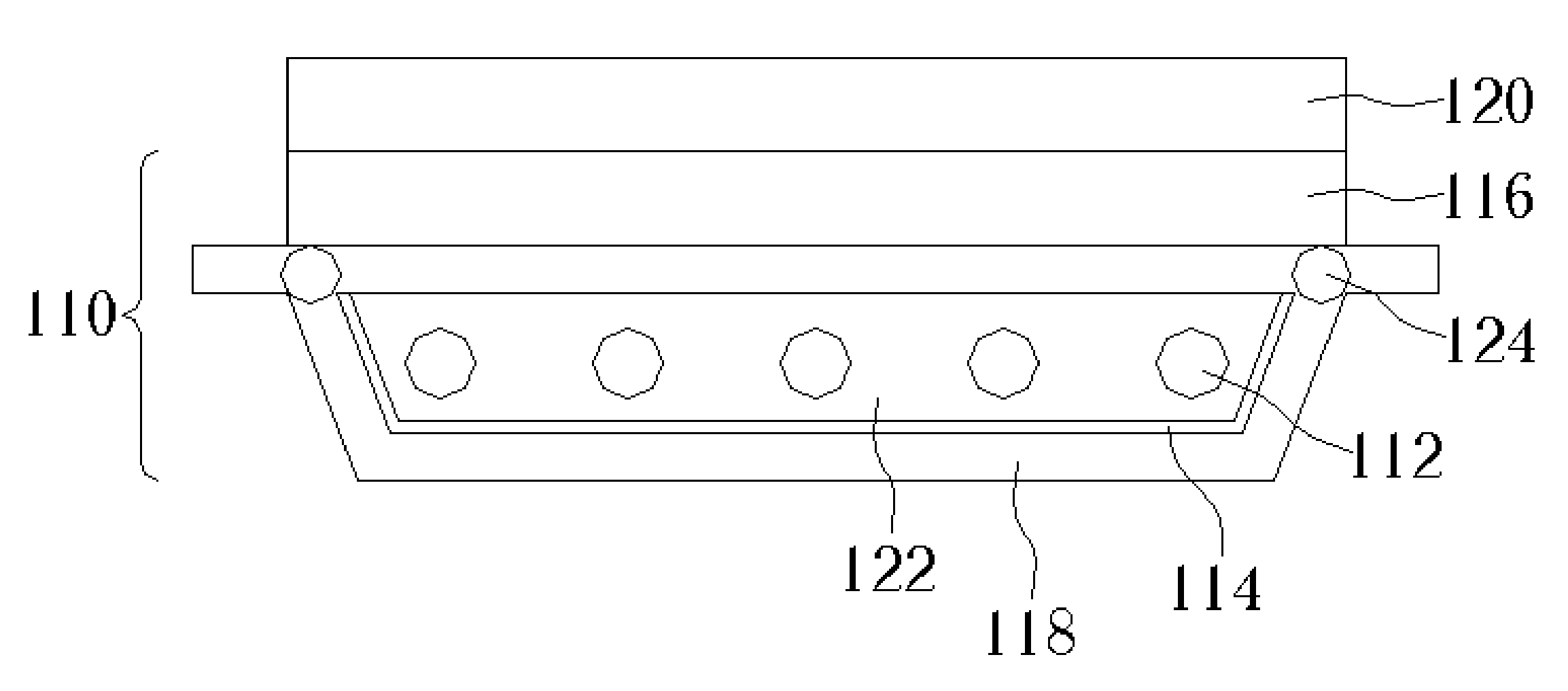

Metal slide fastener as well as surface working apparatus and surface working method thereof

InactiveCN101461589AImprove oxidation and corrosion resistanceImprove lightnessSlide fastenersGrinding machinesMotor driveEngineering

The invention relates to a metal zipper, surface processing equipment and surface processing method thereof. The metal zipper surface processing equipment is used for surface processing zipper tooth of the metal zipper belt, which comprises a machine body, a transporting mechanism and a traction mechanism. The transporting mechanism and the traction mechanism are disposed on the machine body, which are used for transporting and tracting the metal zipper belt. A milling mechanism disposed on the machine body between the transporting mechanism and the traction mechanism is further included, which comprises a motor, a milling wheel, and a clip. The clip abuts the zipper tooth of the metal zipper belt against the milling wheel. The motor drives the milling wheel to rotate for milling the zipper tooth on the metal zipper belt. The metal zipper surface processing equipment is capable of effectively controlling milling depth of the milling, eliminating deep mark on the zipper tooth surface, and making the metal zipper tooth surface smooth and bright.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

Polypropylene-based resin composition and molded article thereof

A polypropylene-based resin composition of drastically improved dimensional stability realized by incorporating a polypropylene resin of specific structure with an inorganic filler of specific particle size, carbon fibers of specific fiber diameter and length, and, as required, an ethylene- and / or styrene-based elastomer. Another polypropylene-based resin composition of well-balanced properties of rigidity, heat-resistance, impact resistance and lightness even essentially in the absence of inorganic filler, realized by compositing a propylene / ethylene block copolymer of specific structure and well-balanced mechanical properties with an ethylene- and / or styrene-based elastomer, and carbon fibers of specific structure.

Owner:JAPAN POLYPROPYLENE CORP

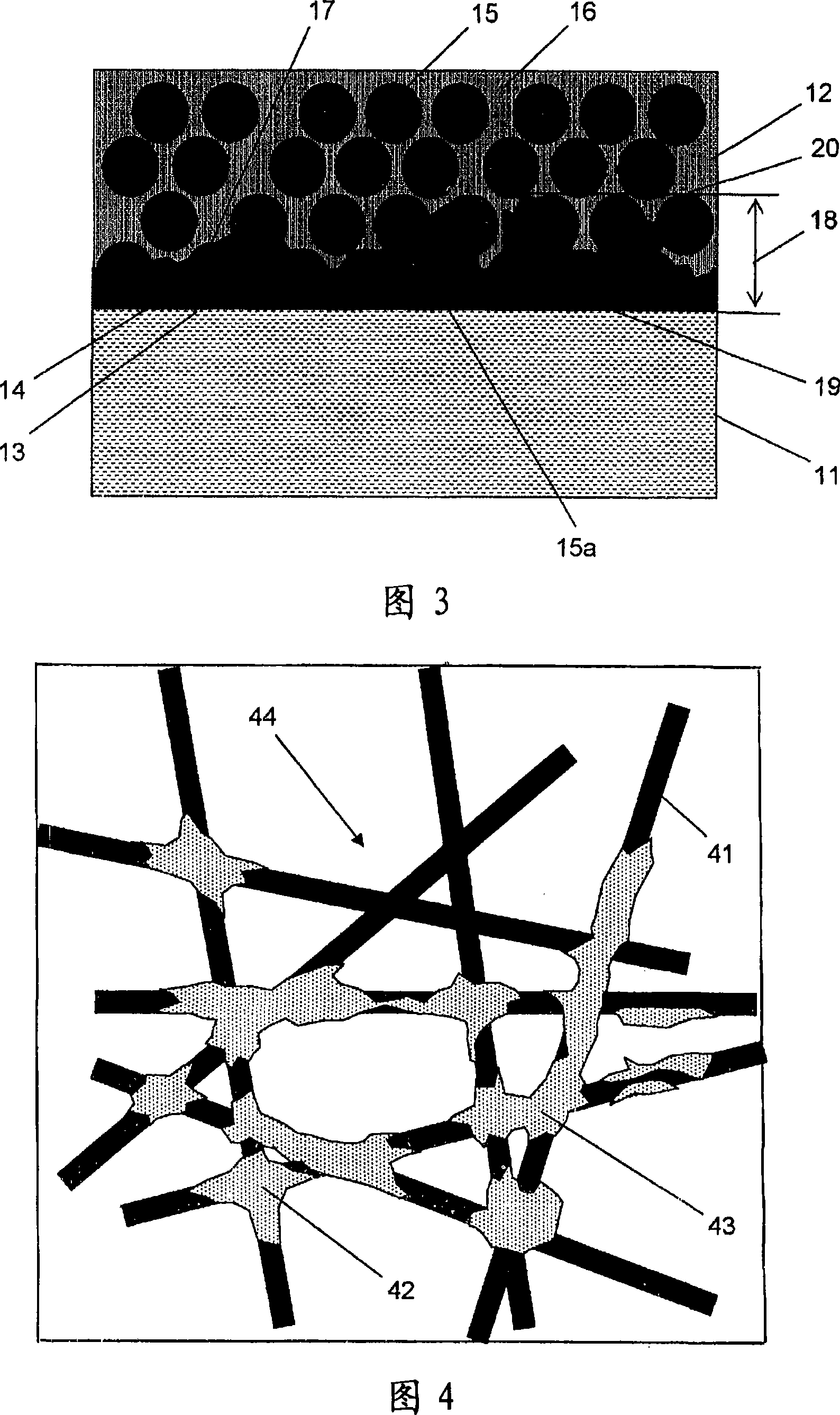

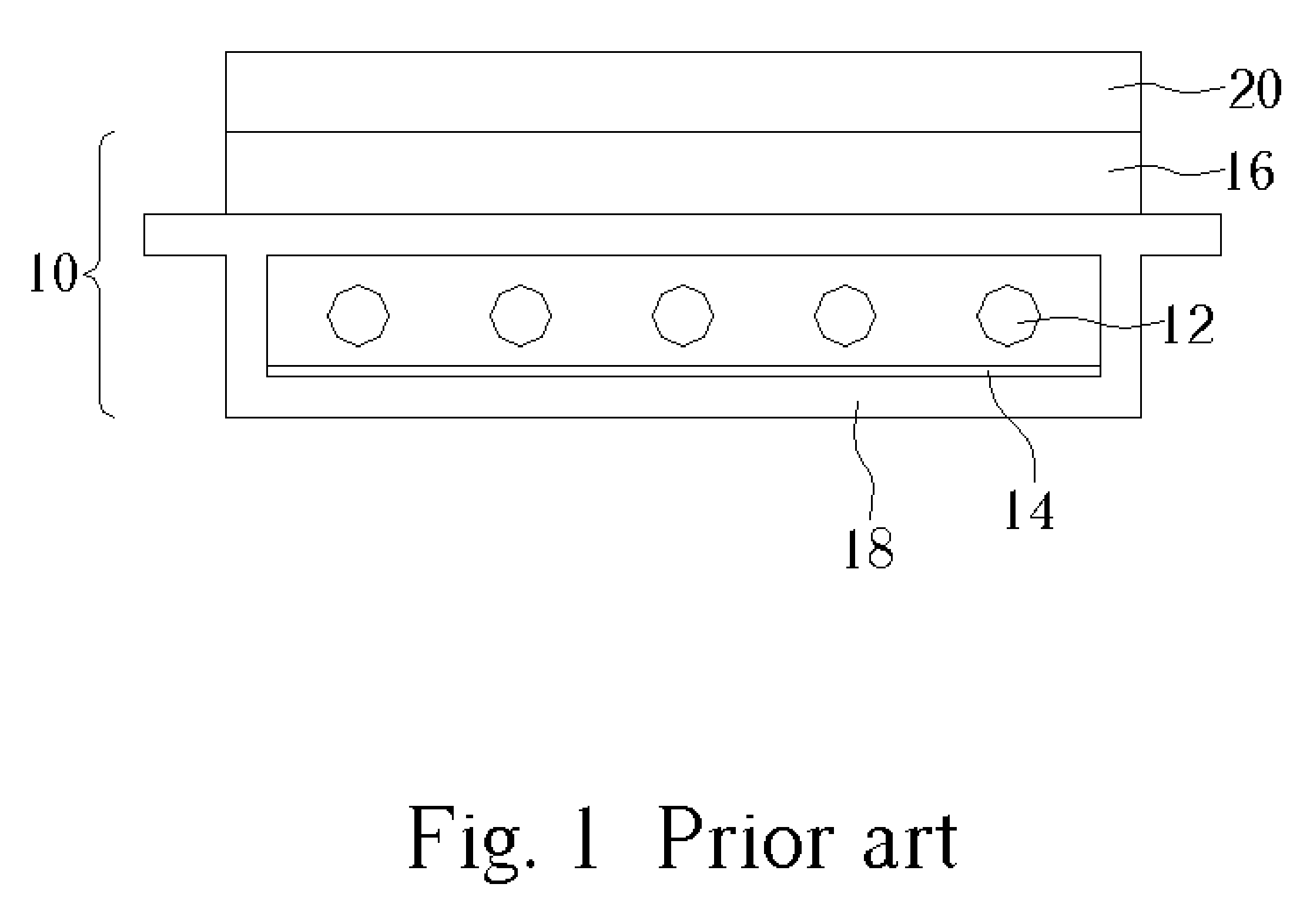

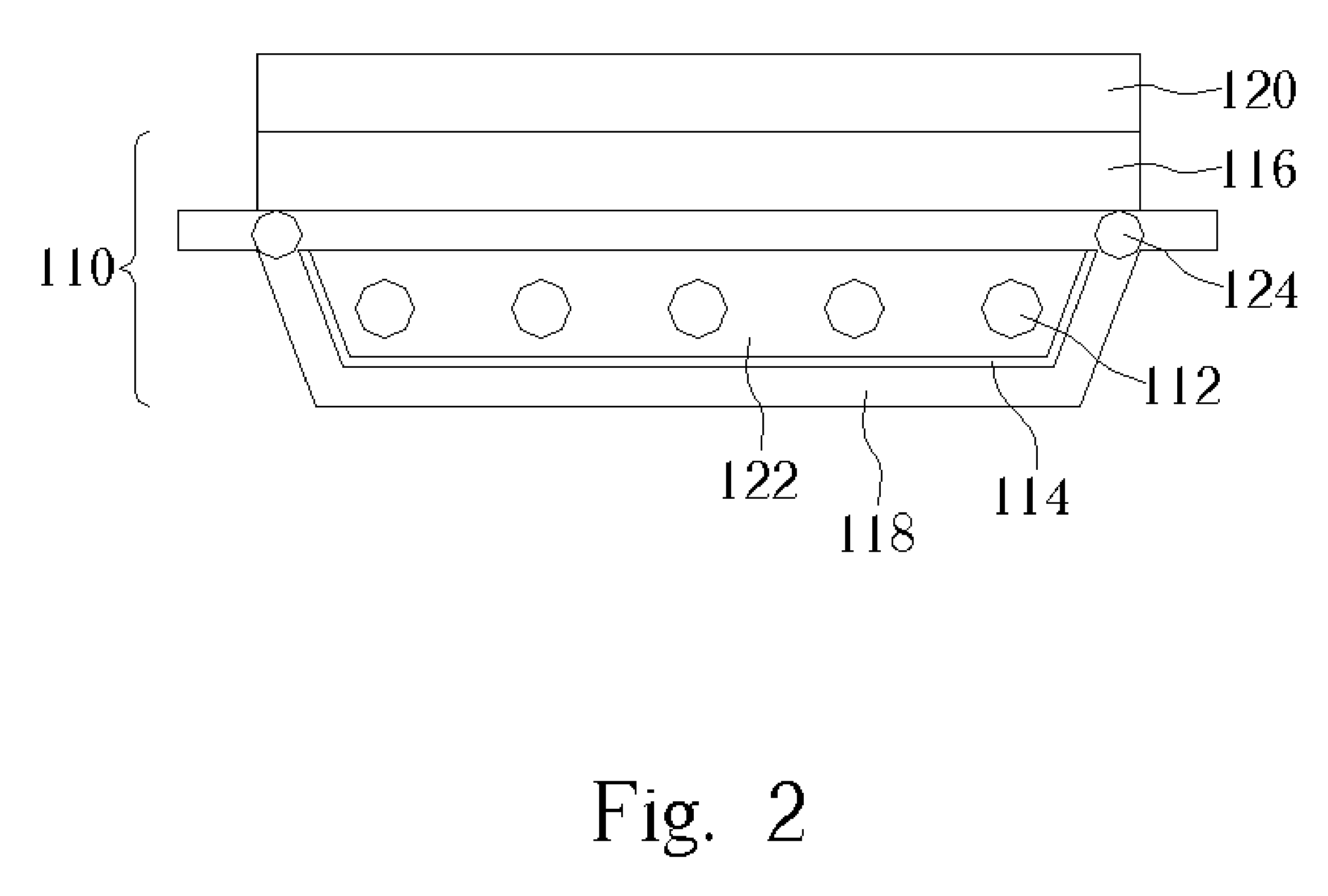

Direct back light unit with heat exchange

ActiveUS7101055B2Improve thermal conductivityAvoid heatingMeasurement apparatus componentsLighting heating/cooling arrangementsLight beamOptoelectronics

A backlight unit with high thermal dissipation. The back light unit includes a light source generator positioned in a backside of a display panel for providing light beams to the display panel, a diffuser positioned between the light source generator and the display panel for uniformly scattering light beams from the light source generator to the display panel, and a housing enclosing the light source generator and connecting to the diffuser for reflecting the light beams to the diffuser. The housing further includes a heat pipe for being a heat transfer interface between the back light unit and an external environment.

Owner:AU OPTRONICS CORP

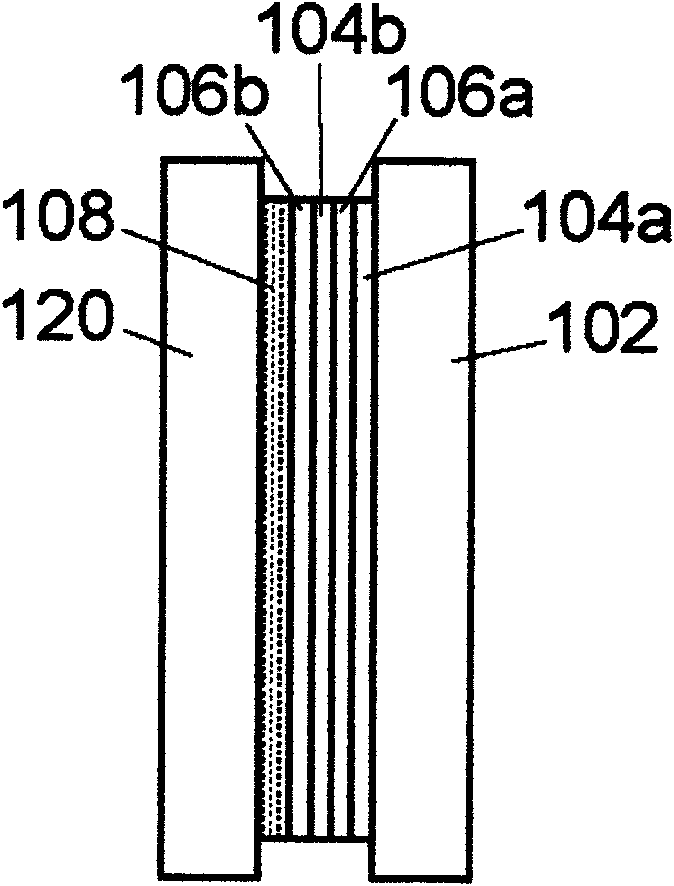

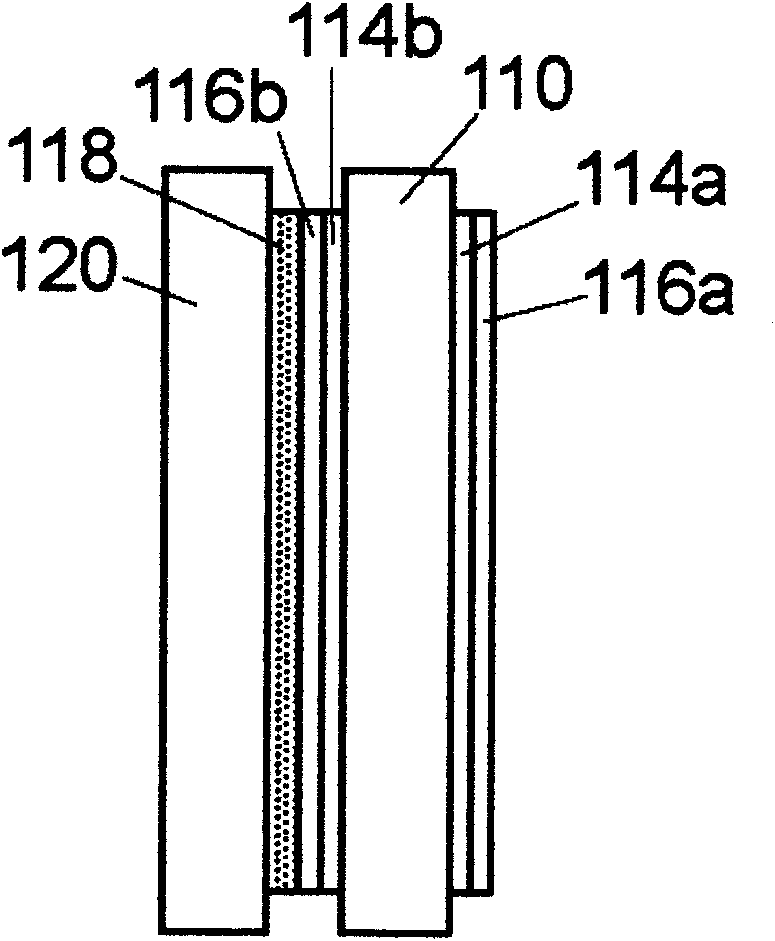

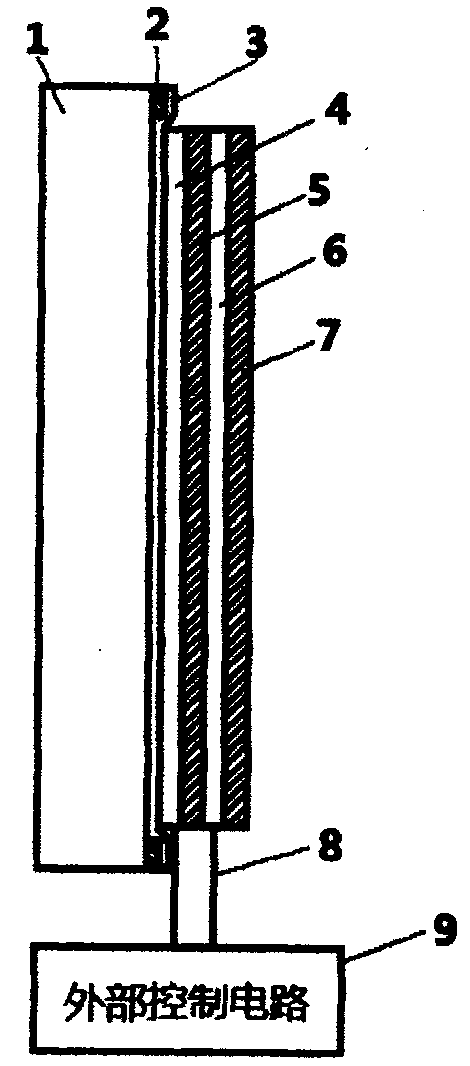

Integrated projection-type capacitive touch screen and manufacturing method thereof

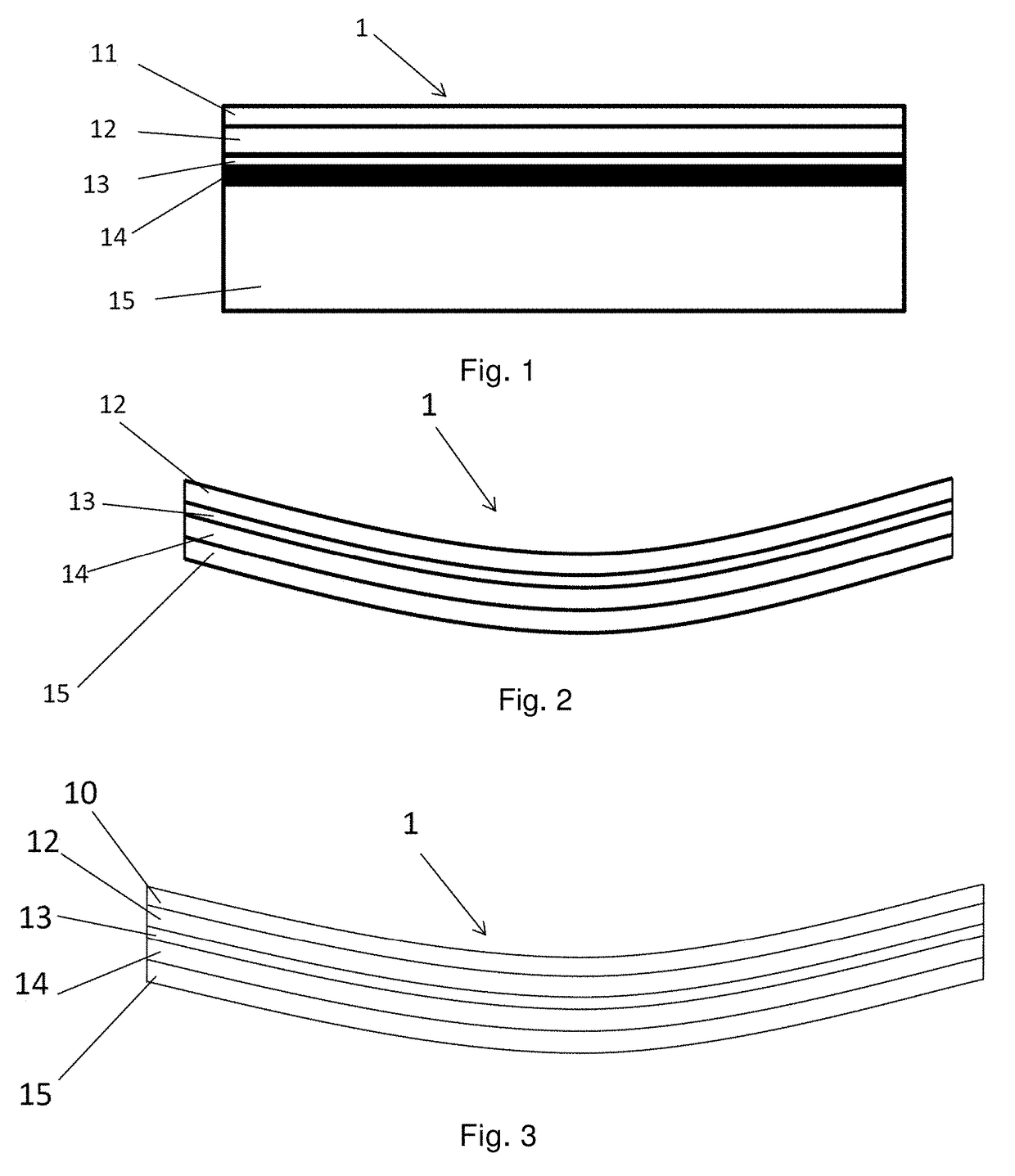

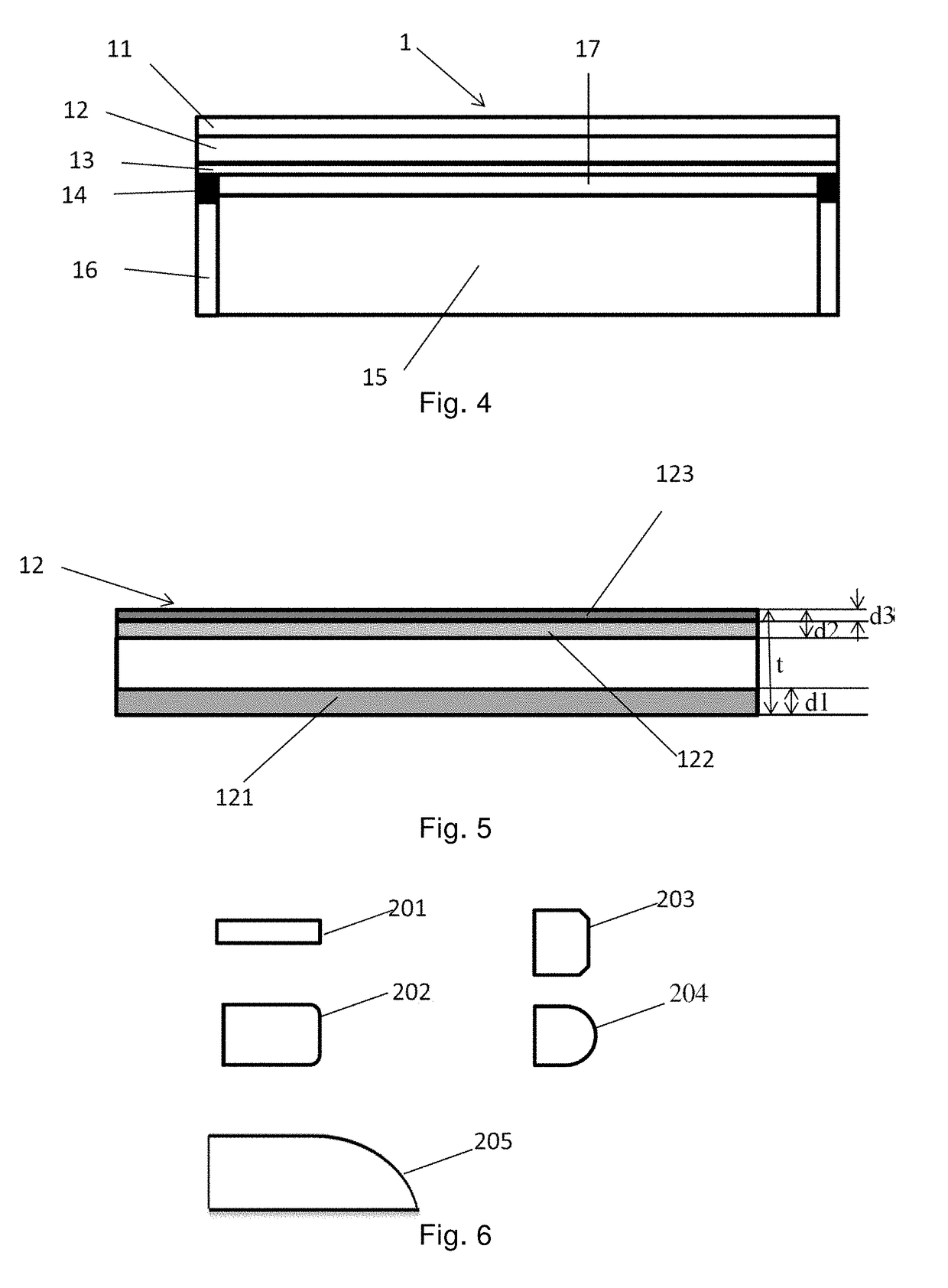

InactiveCN101853115AReduce thicknessGuaranteed transmittanceInput/output processes for data processingDielectricComposite film

The invention relates to an integrated projection-type capacitive touch screen and a manufacturing method thereof. The integrated projection-type capacitive touch screen only adopts a substrate, and a color coating is arranged in the non-visible range of the substrate; a backing insulating film is arranged on the whole surface of the substrate with the color coating, and a first electrode pattern is arranged on the backing insulating film; a dielectric insulating film is arranged on the first electrode pattern, and a second electrode pattern is arranged on electrolyte insulating film; the coverage of the electrolyte insulating film does not include joint terminals of the first electrode pattern, and a protective insulating film is arranged on the second electrode pattern; and the coverage of the protective insulating film does not include joint terminals on the edges of the first electrode pattern and the second electrode pattern, and the upper ends of the joint terminals are connected with an external control circuit through collecting lines. The single substrate with the color coating adopts a multi-layer composite film structure of the backing insulating film, an ITO film, the dielectric insulating film, the ITO film and the protective insulating film, can substantially reduce the thickness of the touch screen, and improves lightness thinness and yield.

Owner:上海优熠电子科技有限公司

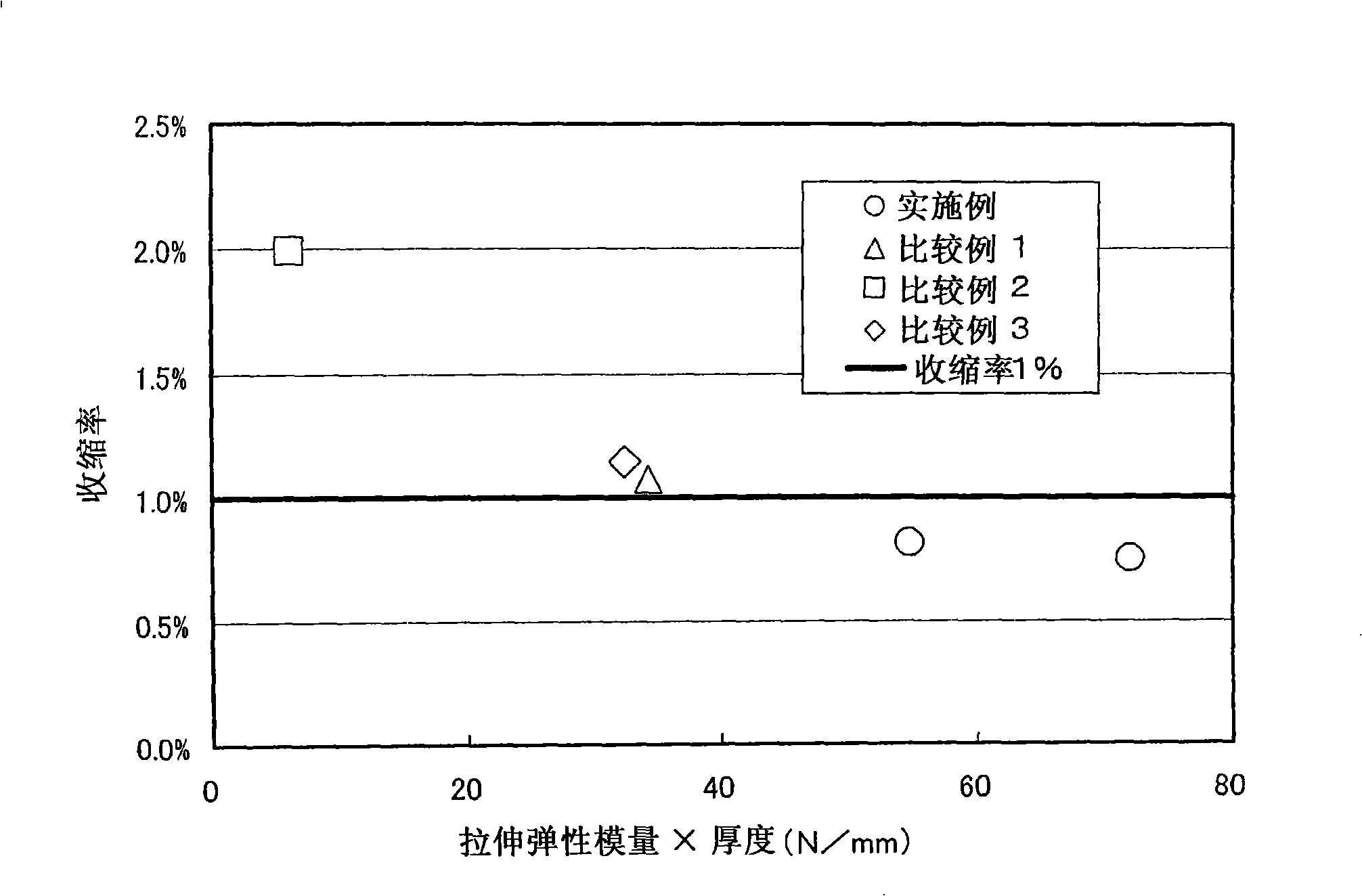

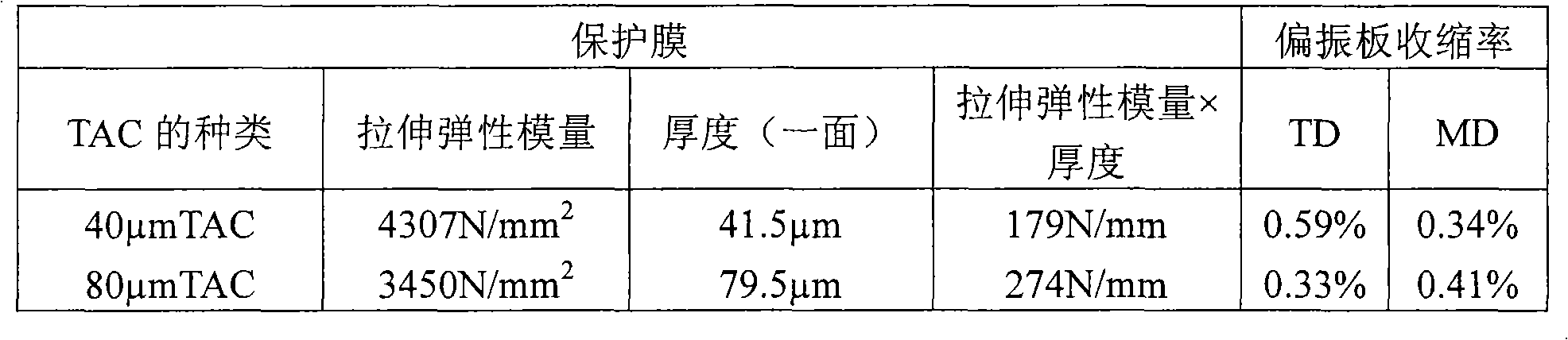

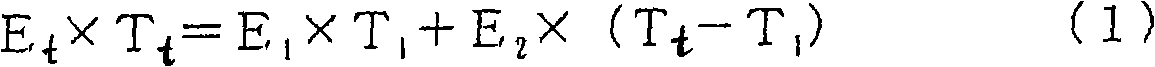

Polarization plate and optical component

InactiveCN101344608AExcellent adhesionExcellent lightnessPolarising elementsNon-linear opticsTectorial membraneUV curing

The invention provides an optical component capable of satisfying the polarizing plate having light weight thin slice and excellent durability and supplying excellent reliability and forming liquid crystal display device for mobile use or large television use and so on, A protective with thickness less than 20 microns is on at least one side of the polarizing sheet composed by polyvinyl alcohol resin; the protective film is formed that the product of the tensile modulus of elasticity (unit:N / mm2) and thickness (unit: mm) is over than 40N / mm. the protective film is able to be formed by coating the surface of the polarizing sheet; the invention has the advantages of: the coating is formed by curing the coating composition of inorganic filler cooperating in the UV curing resin. The invention further provides the optical component overlapped on the polarizing plate for displaying the optical layer having other optical functions.

Owner:SUMITOMO CHEM CO LTD

Oil extended 1,2-polybutadiene and method of manufacturing polybutadiene, and composition and formed product thereof

InactiveCN1511176AExcellent formabilityHigh mechanical strengthSynthetic resin layered productsHeelsFoaming agentWear resistance

Disclosed are oil-extended 1,2-polybutadiene containing an extender oil in a specific amount based on 1, 2-polybutadiene and a production method thereof, and a composition further containing another (co)polymer, a foaming agent, a crosslinking agent, a softening agent and other additives. The resulting oil-extended 1,2-polybutadiene and the composition thereof has excellent functions characterizing conventional 1,2-polybutadiene and is further excellent in wear resistance, fluidity (processability), coloring properties (high distinctness of images), flexibility, attachability and the like, so that they can be applied to various formed articles, shoe sole materials and laminate having high performances.

Owner:JSR CORPORATIOON

Electronic device structure with an ultra-thin glass sheet

ActiveUS20180101253A1Improve sensitivity and propertyHigh sensitivityDigital data processing detailsElectrical equipmentQuality assuranceTotal thickness

An electronic device structure and an ultra-thin glass sheet used therein. The electronic device structure includes a functional device and an ultra-thin glass above the functional device. The ultra-thin glass has a thickness of no more than 0.4 mm and also has a toughening layer, of which the thickness does not exceed 50% of the thickness of the ultra-thin glass. The ultra-thin glass has a total thickness variation of no more than 20 μm. The ultra-thin glass used in the electronic device structure according to the present invention provides quality assurance for subsequent potential processes, such as cutting, drilling, coating, screen-printing, laminating, gluing and the like, due to the toughening layer. Moreover, the ultra-thin glass improves functionality of the electronic device structure, in particular of the device, due to its small total thickness variation.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

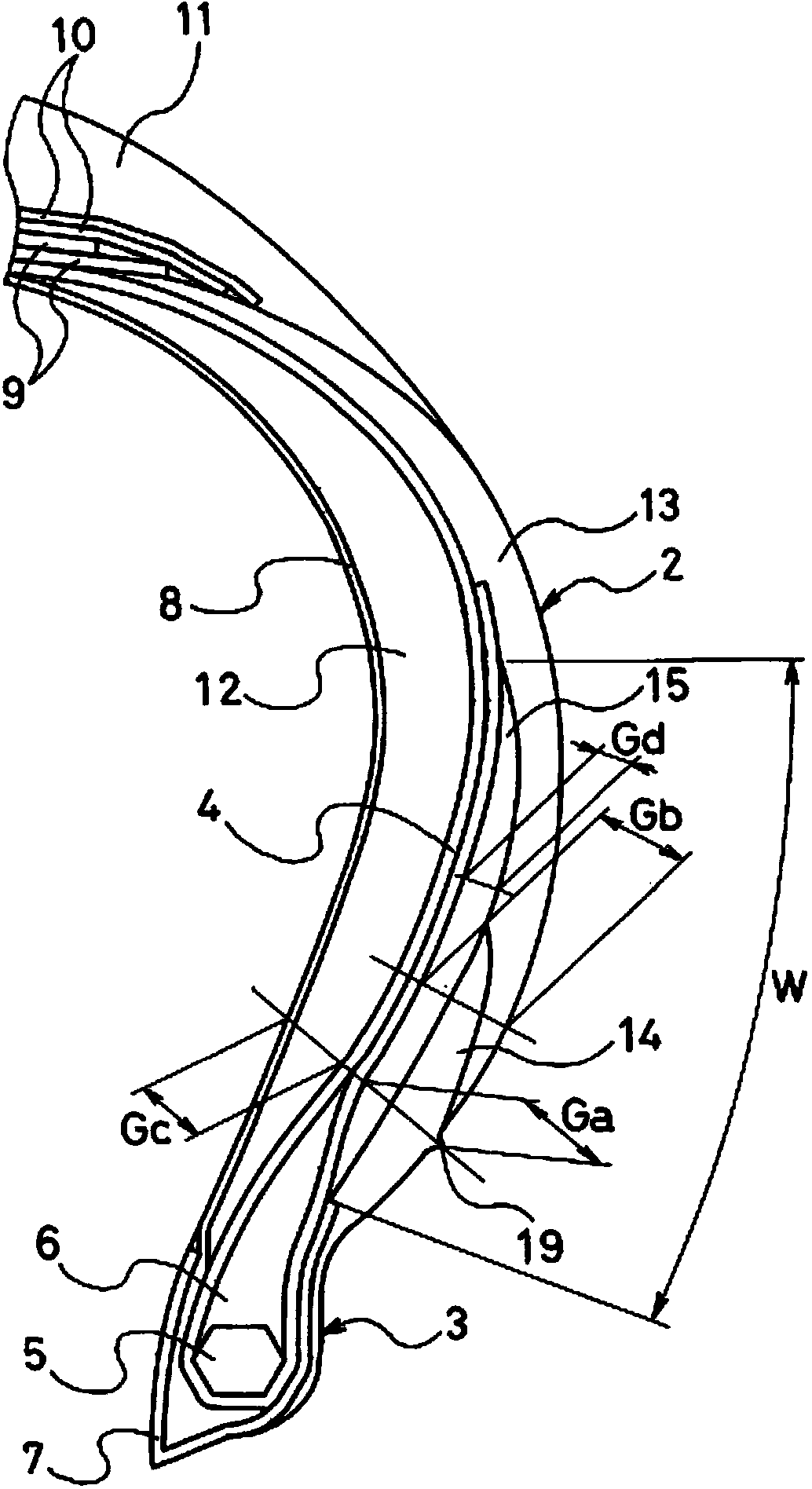

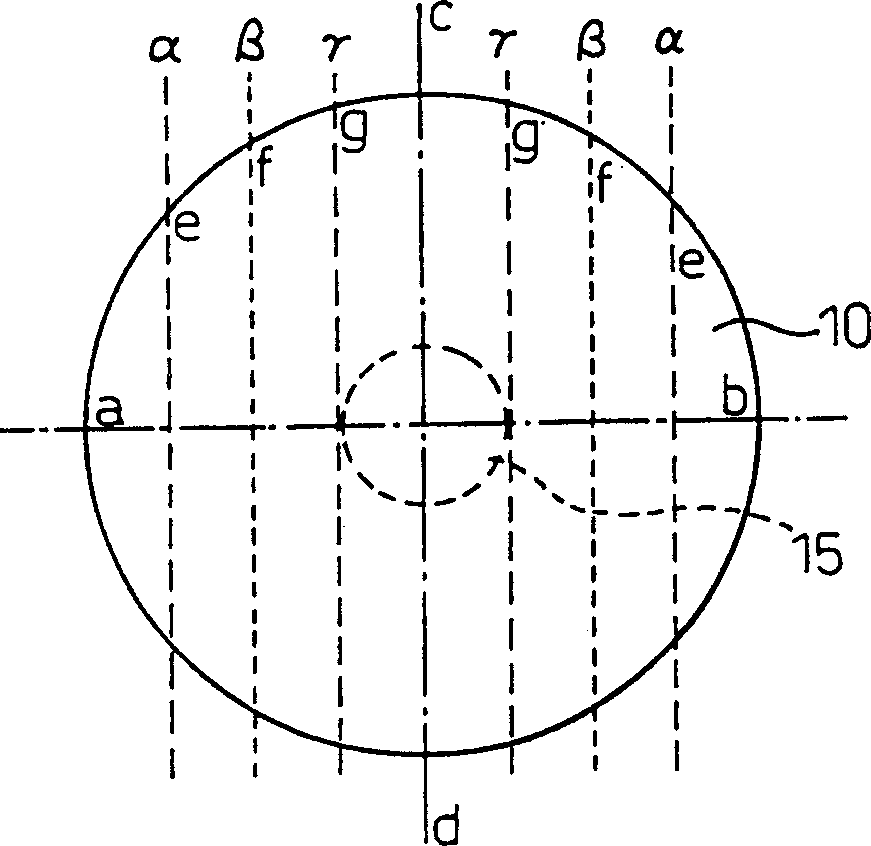

Run-flat tire

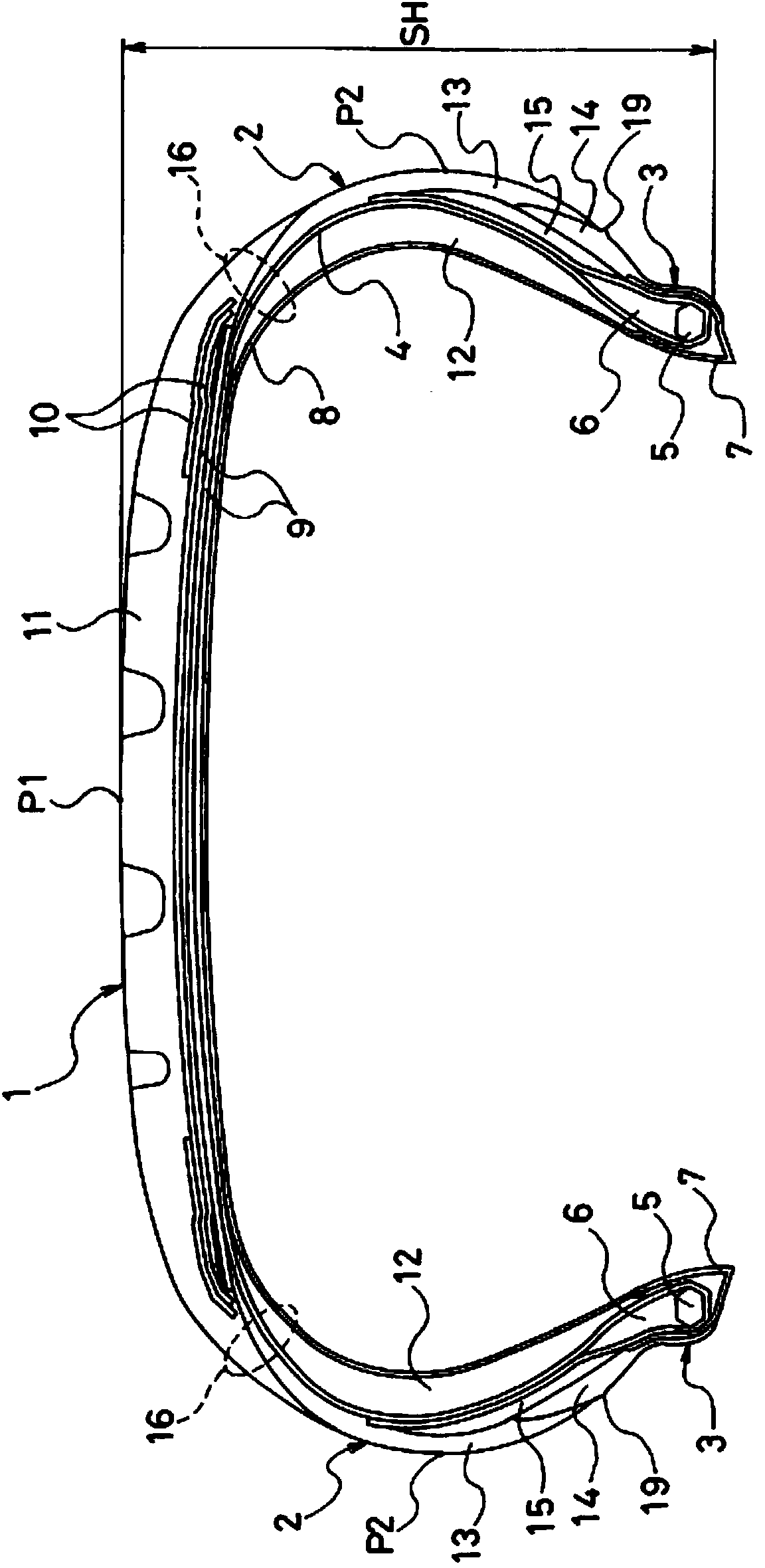

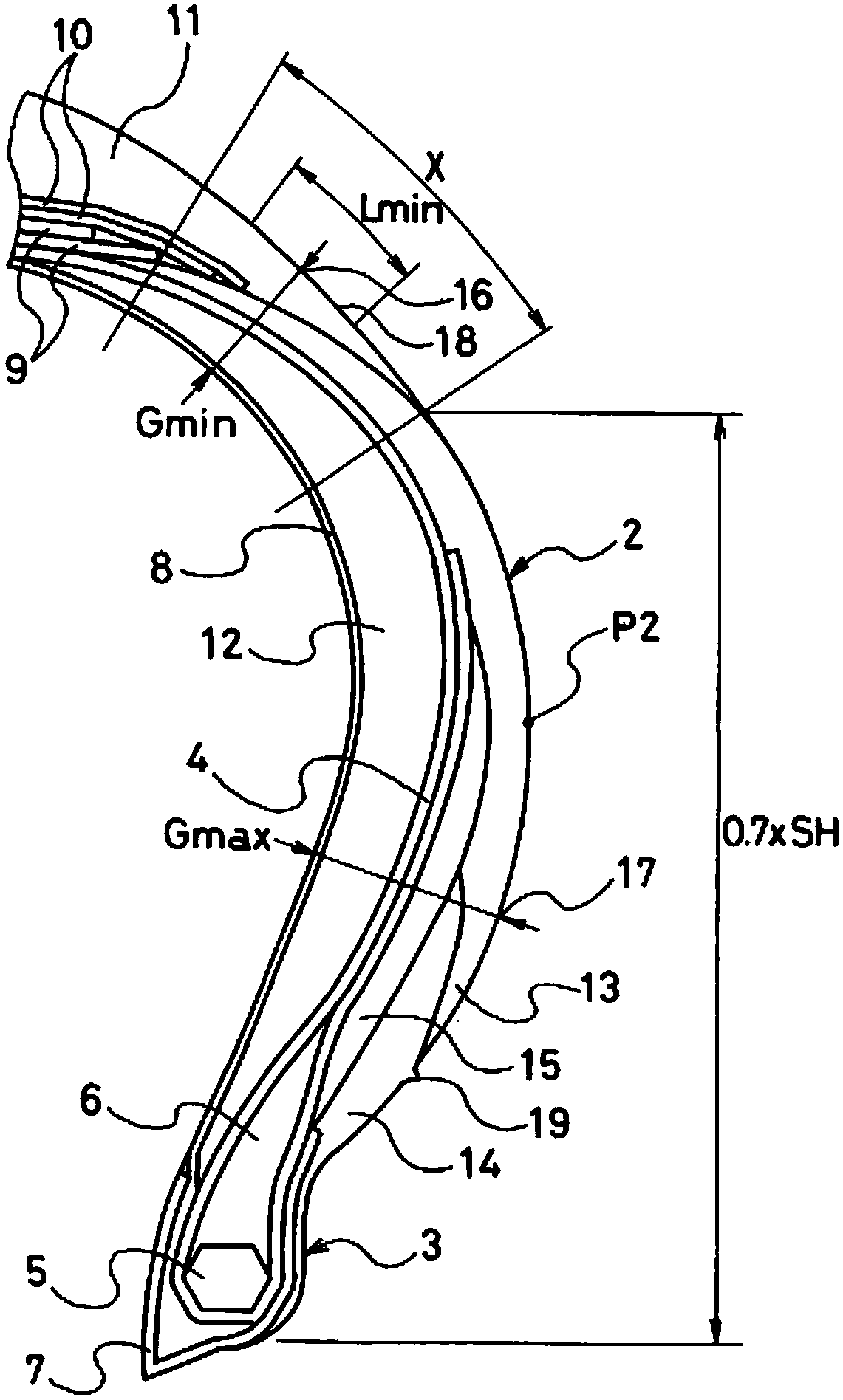

ActiveCN104321209AAvoid breakingIncreased durabilitySpecial tyresPneumatic tyre reinforcementsEngineeringRun-flat tire

Provided is a run-flat tire that achieves high levels of both run-flat durability and ride comfort, and minimizes weight increase. In a sidewall-reinforced run-flat tire, the minimum thickness section being positioned between the belt layer end section and the tire cross-sectional height (SH) 70% position, the relationship between the thickness (Gmin) of the minimum-thickness section and the thickness (Gmax) of the maximum thickness section (17) is defined as 0.5 × Gmax ≤ Gmin ≤ 0.8 × Gmax; the relationship between the length (Lmin) of the thin region and the tire cross-sectional height (SH) is defined as 0.18 × SH ≤ Lmin ≤ 0.26 × SH; the relationship between the weight (Wr) of the sidewall-reinforcement layer, the tire total weight (Wt), and the tire oblateness (R) is defined as 0.08 × Wt × (1 - 0.2 × (1 - R / 50)) ≤ Wr ≤ 0.18 × Wt × (1 - 0.2 × (1 - R / 50)); the relationship between the thickness (Ga) at the rim-check line of the outer-side rubber portion outward of the carcass layer, and the maximum thickness (Gb) thereof, is defined as 0.8 × Gb ≤ Ga ≤ 1.0 × Gb; and the relationship between the thickness (Gc) at the rim-check line of the inner-side rubber portion inward of the carcass layer and the thickness (Ga) is defined as 0.7 × Ga ≤ Gc ≤ 1.0 × Ga.

Owner:THE YOKOHAMA RUBBER CO LTD

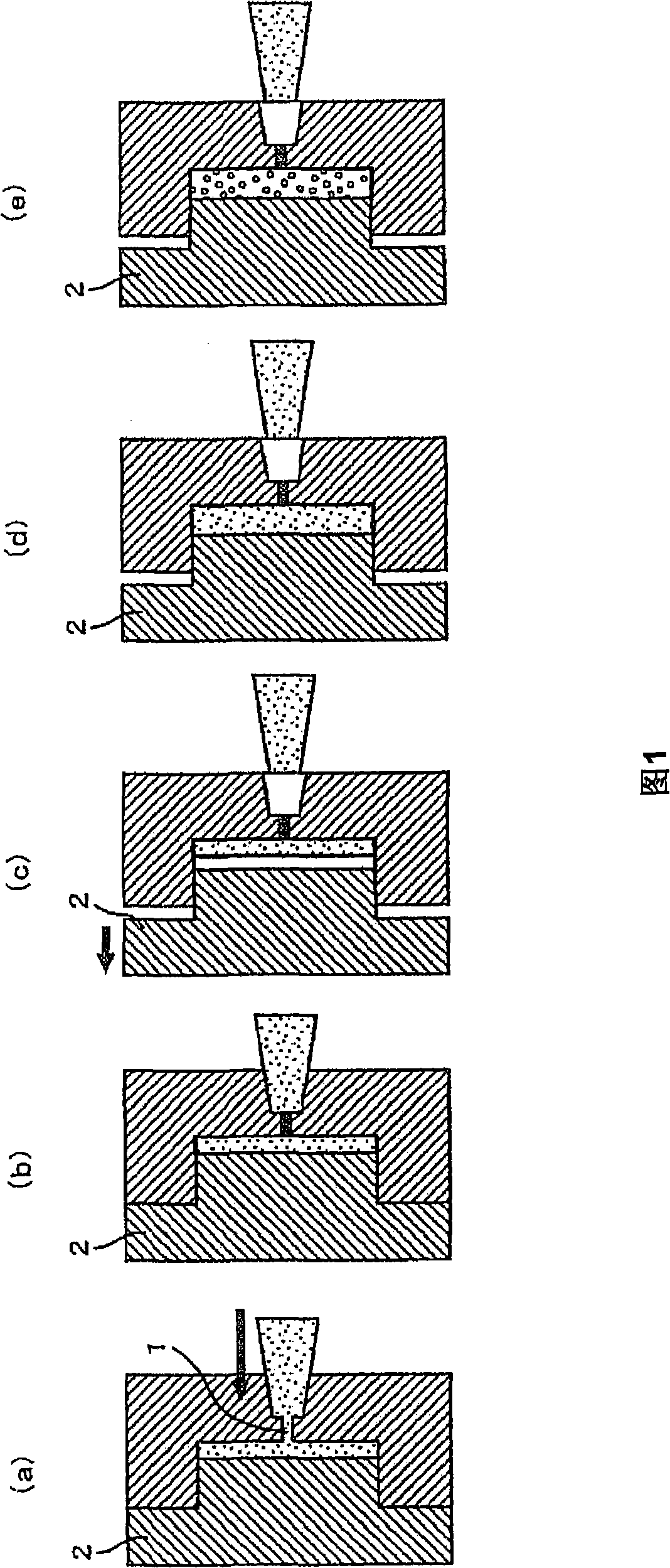

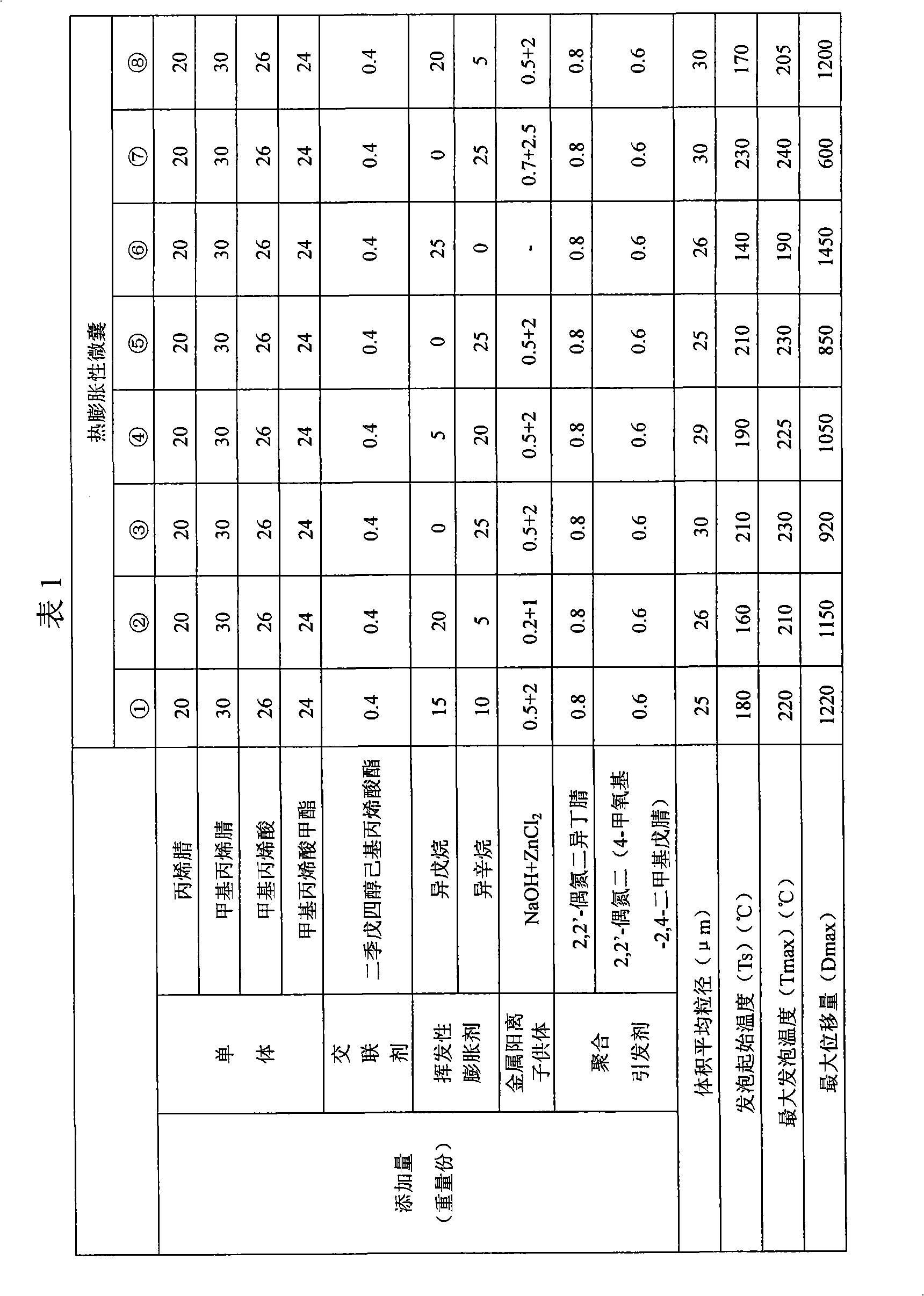

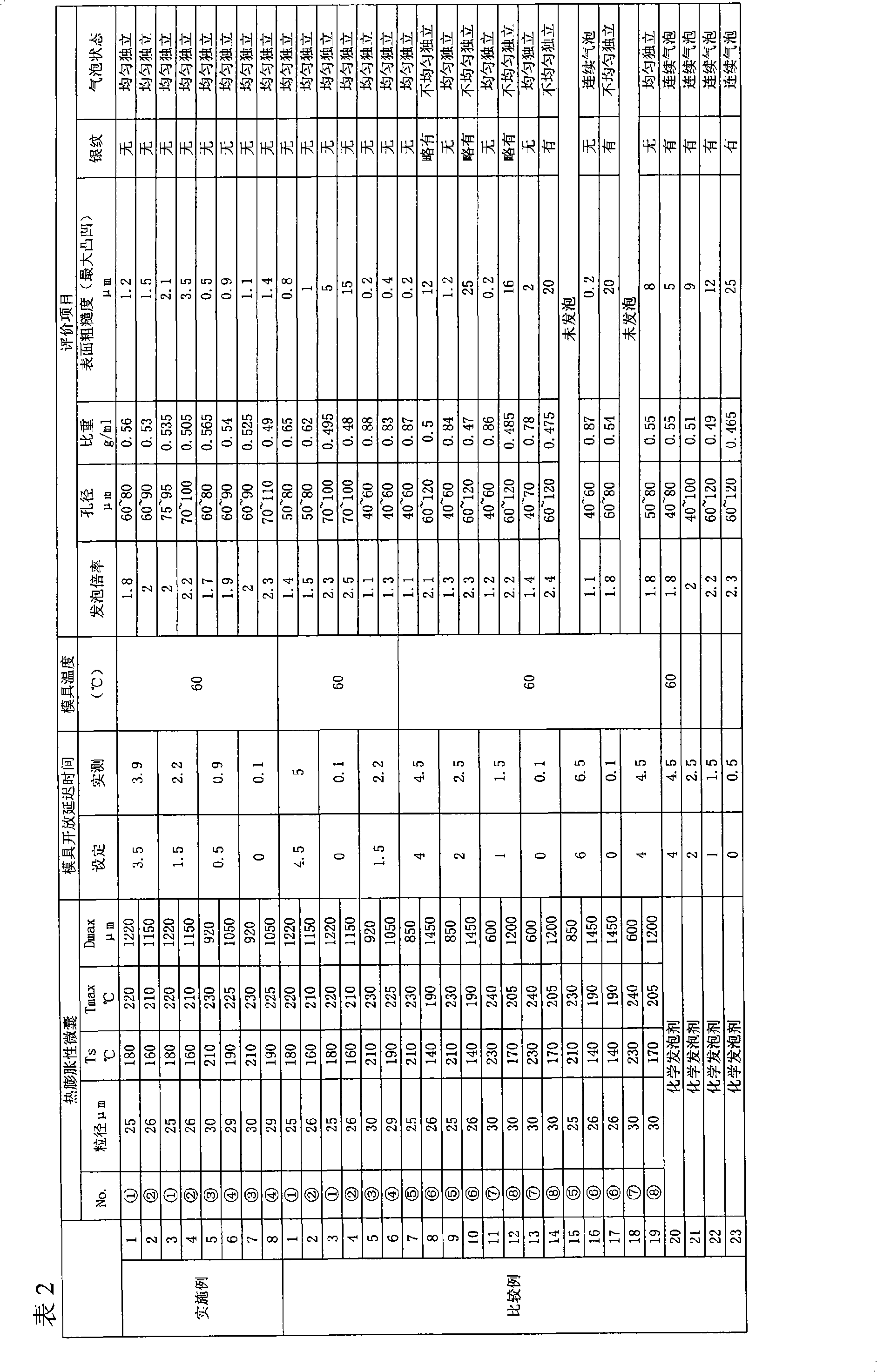

Molded foam article and method of producing molded foam article

It is intended to provide a molded foam article which has a high foaming ratio and a light weight and shows an excellent appearance with no surface coarsenss, and a method of producing a molded foam article whereby, in the case of using heat expandable microcapsules in injection molding, the heat expandable microcapsules can evenly expand to give a molded foam article having a high foaming ratio and an excellent appearance. A molded foam article having evenly distributed individual cells characterized in that the cell diameter is from 60 to 120 [mu]m, the specific gravity is 0.6 g / ml or less and the surface roughness is 4 [mu]m or less.

Owner:SEKISUI CHEM CO LTD

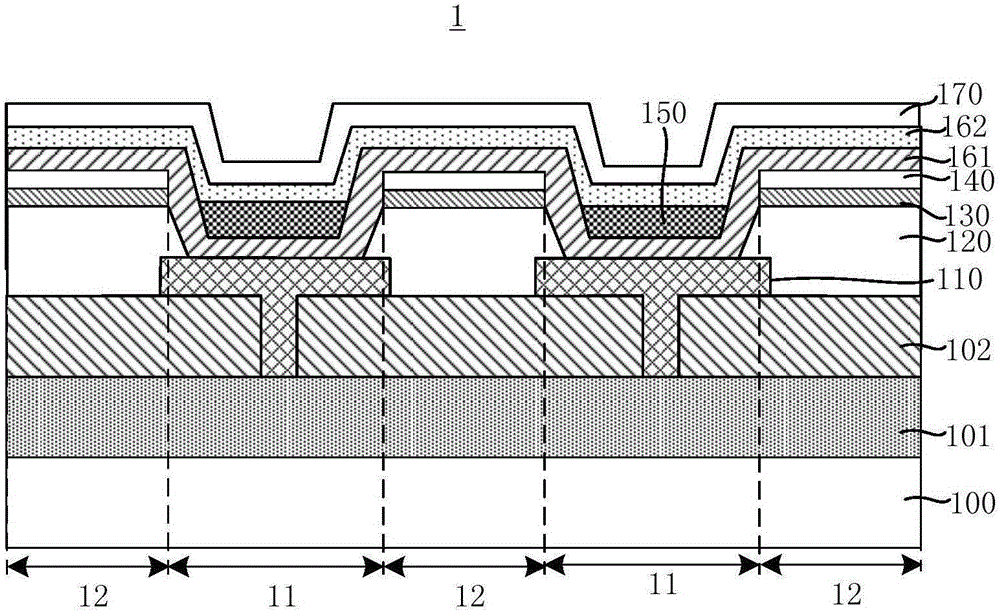

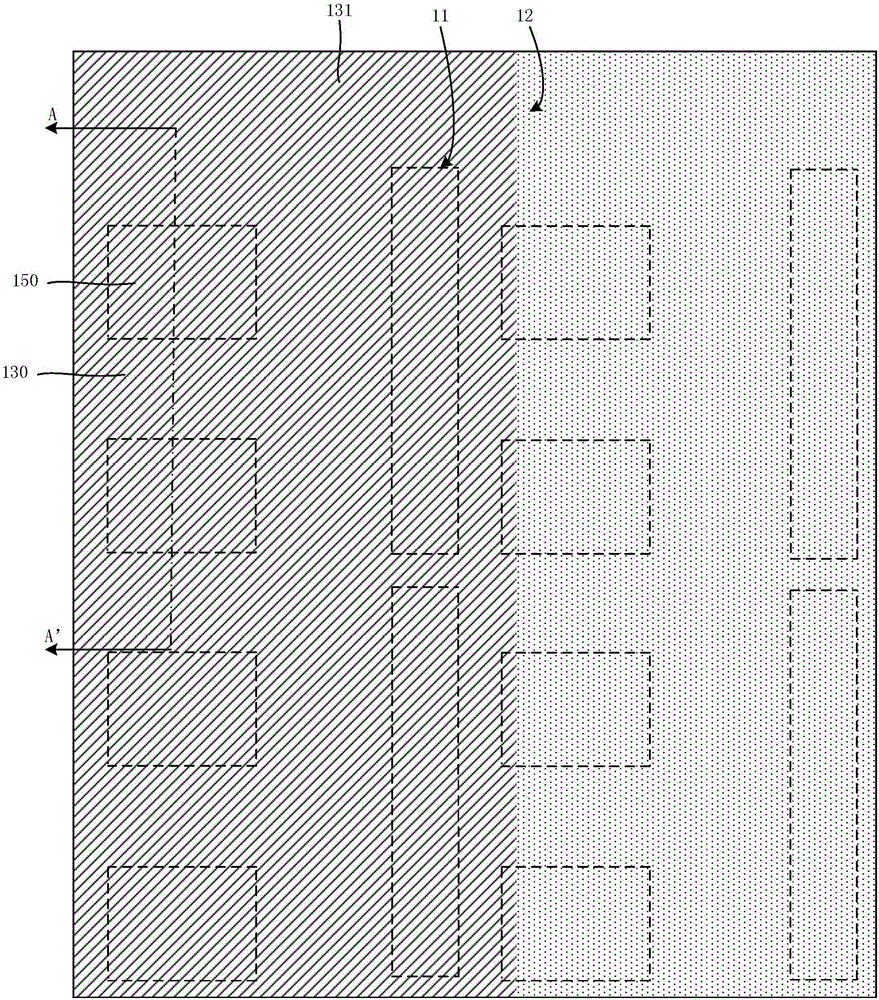

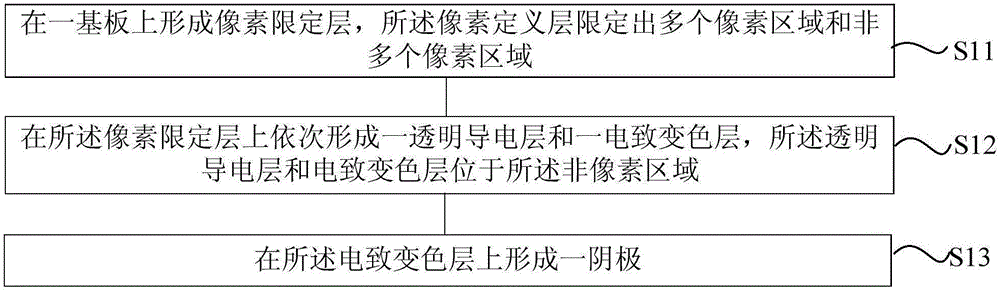

Display device and manufacturing method thereof

InactiveCN106384565AReduce complexityImprove lightnessNon-linear opticsIdentification meansDisplay deviceOptoelectronics

The invention discloses a display device, which comprises a substrate, a pixel limiting layer, a transparent conducting layer, an electrochromic layer and a cathode, wherein the pixel limiting layer is arranged on the substrate; multiple pixel areas and multiple non-pixel areas are limited by the pixel limiting layer; the transparent conducting layer is arranged on the pixel limiting layer, and is located in the non-pixel areas; the electrochromic layer is arranged on the transparent conducting layer and is located in the non-pixel areas; the cathode covers the electrochromic layer. The invention also discloses an electronic device comprising the display device and a manufacturing method of the display device. In the display device provided by the invention, through controlling the voltages of the transparent conducting layer and the cathode, the color or the transparence of the electrochromic layer is changed; thus, the display device is enabled to present different transparency or colors; moreover, the structure of the display device is simple; the realization of the lightening and the thinning of the display device is facilitated.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Method for manufacturing color filter ink, color filter ink, color filter, image display device, and electronic device

InactiveUS20090135349A1Increased durabilityImprove uniformityOrganic compound preparationOptical filtersSolventFine dispersion

A method for manufacturing a color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The method includes dispersing a dispersing agent in a solvent to obtain a dispersing-agent-dispersed liquid by agitating a mixture of the dispersing agent, a thermoplastic resin and the solvent, performing a fine dispersion treatment to obtain a pigment dispersed material by adding a pigment to the dispersing-agent-dispersed liquid and by adding inorganic beads to the dispersing-agent-dispersed liquid in multiple stages, and mixing the pigment dispersed material with a curable resin.

Owner:SEIKO EPSON CORP

Digital spray printing steam-cleaning-free process of disperse dye

ActiveCN102965988AImprove the authenticity rateExcellent color yieldDyeing processDisperse dyeTextile printer

The invention discloses a digital spray printing steam-cleaning-free process of disperse dyes. The process comprises the following steps of: preparing slurry; sizing a fabric; carrying out digital direct injection; and pressing at high temperature to obtain a finished product. By the digital spray printing steam-cleaning-free process disclosed by the invention, a steam cleaning process does not need to be carried out in the direct spray printing of the disperse dyes, the process that the transfer printing of the disperse dyes can be transferred to cloth only by virtue of paper serving as a medium can be changed, a large quantity of paper sheets can be saved; therefore, the process has a direct practical significance for the protection of forest trees.

Owner:绍兴柯桥滨海飞翔化工有限公司

Fiber reinforced polypropylene resin composition, molding material and prepreg

ActiveCN104066783AImprove interfacial adhesionExcellent mechanical propertiesCarbon fibresThin material handlingPolyolefinPolypropylene

An objective of the present invention is to obtain a molded article with excellent mechanical properties and water degradation resistance by using: a fiber reinforced polypropylene resin composition that contains a carbodiimide modified polyolefin (a), a polypropylene resin (b) and reinforced fiber (c), wherein the content of carbodiimide group in the resin component in the fiber reinforced polypropylene resin composition is 0.0005 to 140 mmol with respect to 100 g of a matrix resin component, and the reinforced fiber (c) is sized by a polyfunctional compound (s); and a molding material using the same.

Owner:TORAY IND INC

Composition for advertisement poster pigment, advertisement poster pigment and preparation method thereof

ActiveCN101100552AStrong coloring powerImprove lightnessNatural resin coatingsArtist's paintsGlycerolBrightness perception

A composite for pigment, pigment made from and its production are disclosed. The composite consists of peach glue 10-30 proportion, glycerol 4-15 proportion, water 60-85 proportion, ethylene glycol 4-10 proportion, filler 45-80 proportion, colorant 2-10 proportion and antiseptics 2-8 proportion. It's inodorous, has excellent coloring and cracking performances, brightness and friendly environment.

Owner:LOTUS STATIONERY

Comprehensive foamed concrete property-modifying additive, preparation method thereof and concrete

The invention discloses a comprehensive foamed concrete property-modifying additive, a preparation method thereof and concrete. The property-modifying additive comprises the following components in parts by weight: 1.8 parts of calcium stearate, 1.2 parts of dispersing agent NNO, 0.8 part of FDN superplasticizer, 1.2 parts of light calcium carbonate, 0.2 part of hydroxypropyl methylcellulose, 0.7 part of redispersible powder, 0.4 part of rosinate soap foaming powder (vegetable protein), 0.5 part of aluminum sulfate, 1.5 parts of sodium silicate, 0.2 part of sodium dodecyl benzene sulfonate and 0.5 part of sodium hexametaphosphate. A foamed cement (concrete) product prepared by using the comprehensive foamed concrete property-modifying additive disclosed by the invention has an excellent heat insulation property and is light in weight, low in flexible damping property and excellent in sound insulation property and water resistance.

Owner:FOSHAN SENKE NEW ENERGY DEV

Carbon/aluminum composite compound and inorganic compound coated with carbon/aluminum composite compound

InactiveCN101743194AImprove heat resistanceImprove lightnessSolid waste disposalCompound aHeat resistance

A method in which a novel composite compound excellent in heat resistance, lightweight property, flame retardancy, chemical resistance, and electrical conductivity can be obtained inexpensively and a substance which is harmful chemically or morphologically is converted into a harmless substance through a safe operation. The operation yields a structure which comprises the inorganic compound made harmless and the composite compound with which the surface of the inorganic compound is coated. Application of the method to a waste treatment can hence contribute to resource recycling. The compound is a carbon / aluminum composite compound obtained by distilling an aqueous dispersion containing poly(aluminum chloride) and a water-soluble organic substance to remove the water and then burning the residue at 300 DEG C or higher. The structure is one made of an inorganic compound coated with a carbon / aluminum composite compound and is obtained by impregnating inorganic compound particles with an aqueous solution containing poly(aluminum chloride) and a water-soluble organic substance and burning the resultant particles. Also provided is a method of waste treatment which comprises ripping off a waste containing an acicular inorganic compound while spraying an aqueous poly(aluminum chloride) solution thereover, subsequently infiltrating a water-soluble organic substance into the waste, and burning the mixture.

Owner:VAN

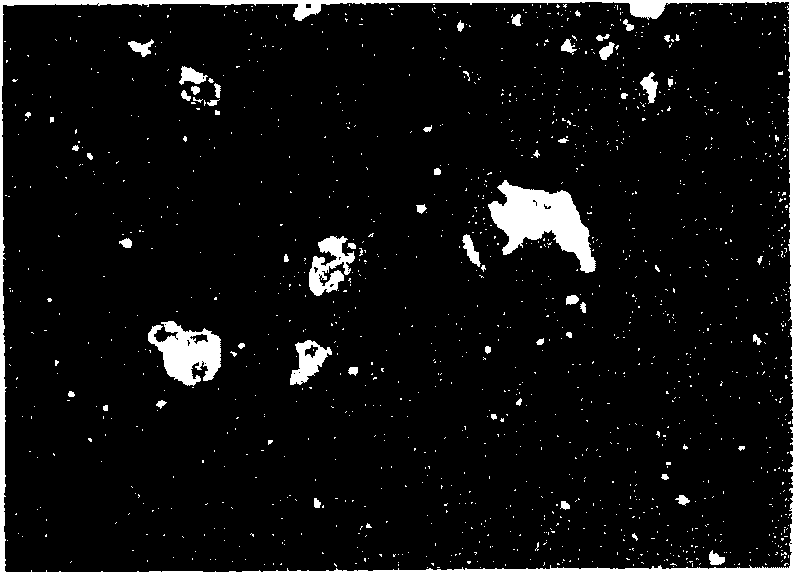

Production method of gold tailing water-permeable brick

ActiveCN105777065AHigh strengthLight weightCeramic shaping apparatusCeramic materials productionPre treatmentDrilling waste

The invention discloses a production method of a gold tailing water-permeable brick. The gold tailing water-permeable brick high in strength and good in water permeability is produced by: pre-calcining gold tailings, impregnating with petroleum drilling waste liquid, optimizing material composition and content for preparing the water-permeable brick, and adjusting physical and chemical properties of the water-permeable brick.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

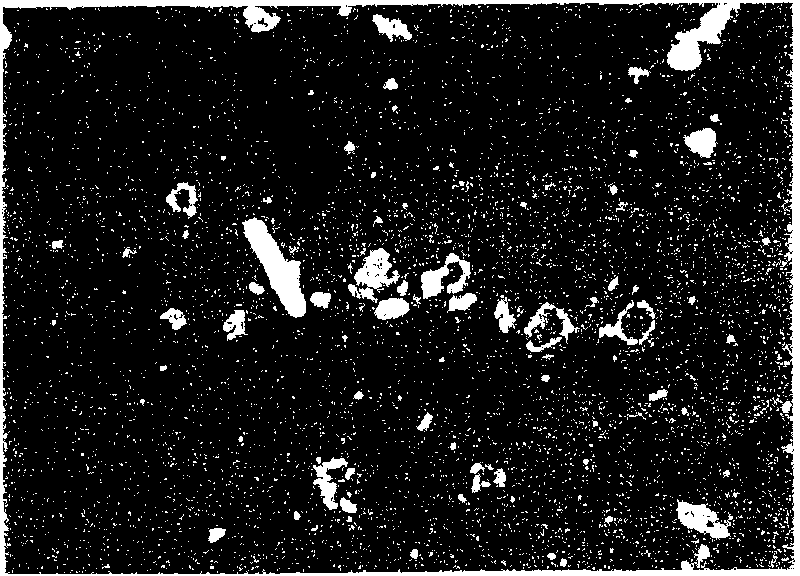

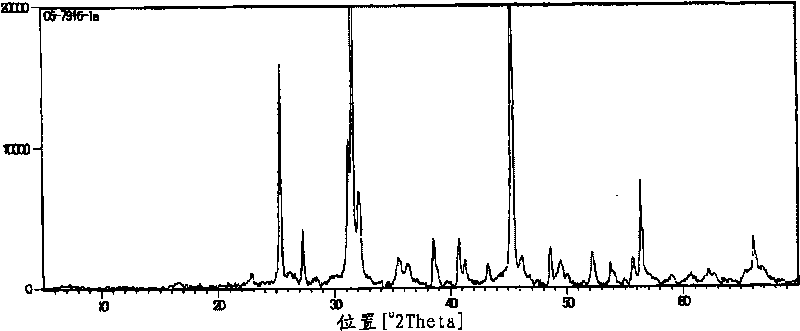

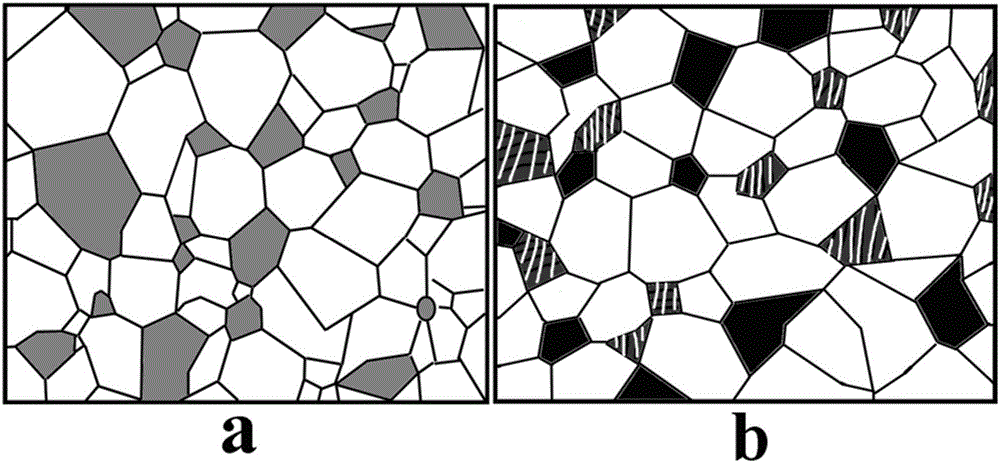

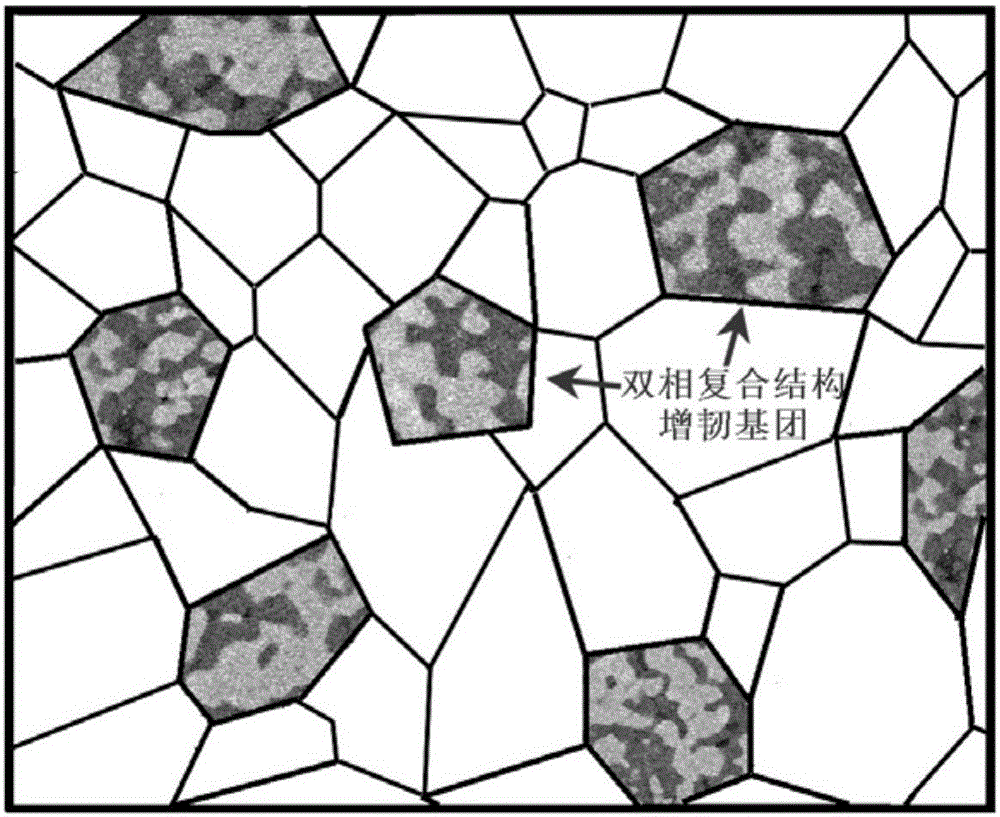

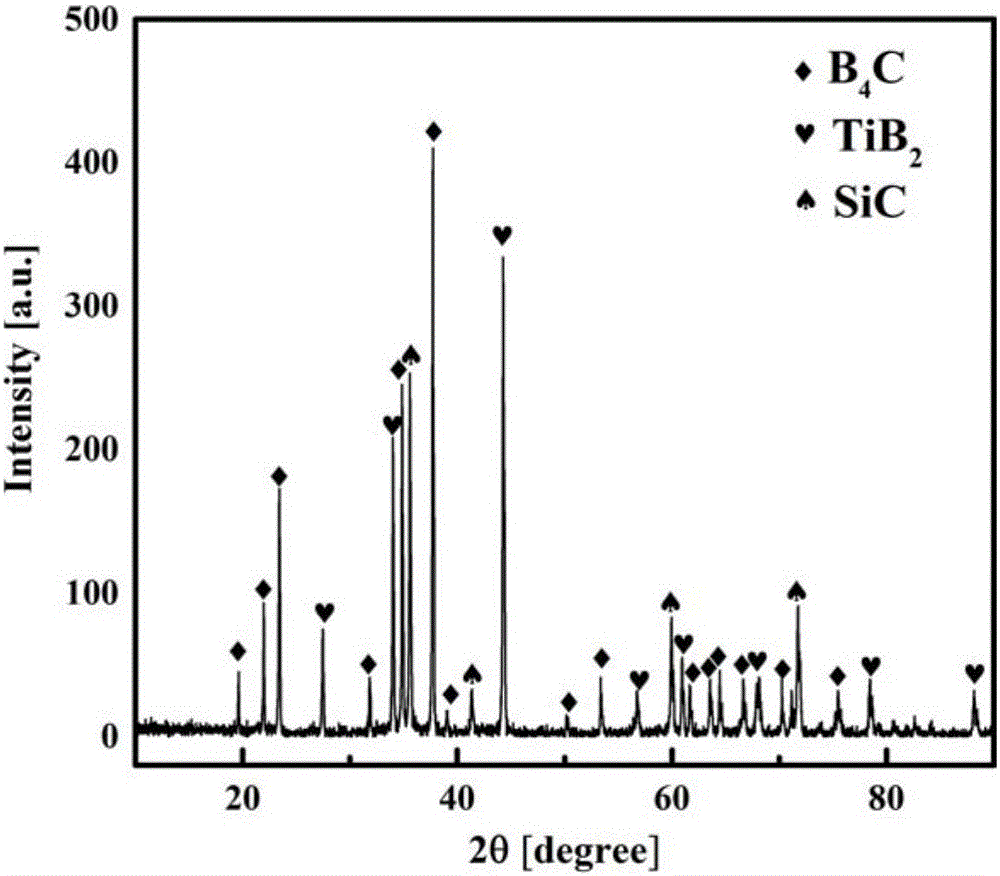

B4C composite ceramic with composite structure as toughening phase and preparation method of B4C composite ceramic

The invention relates to B4C composite ceramic with a composite structure as a toughening phase. With B4C as a matrix phase and the (TiB2-SiC) composite structure as the composite toughening phase, the B4C composite ceramic is prepared from, in percentage by weight, 70%-95% of the matrix phase and 5%-30% of (TiB2-SiC) composite groups serving as the toughening phase, wherein the mole ratio of TiB2 and SiC in the toughening phase is 2:3. According to the composite ceramic, B4C, TiC and Si serving as raw materials in the stoichiometric ratio are subjected to mechano-chemical treatment, then mixed with B4C matrix powder for the second time and finally sintered quickly at high pressure, and the B4C composite ceramic is prepared. According to the composite ceramic, the light and hard (TiB2-SiC) composite groups are taken as the toughening phase, the limit that a single phase or multiple independently distributed phases are taken as a toughening phase of current B4C composite ceramic is broken through, and accordingly, the fracture toughness of the B4C ceramic is substantially improved on the premise that the B4C material keeps the properties of lightness and hardness.

Owner:HEBEI UNIV OF ENG

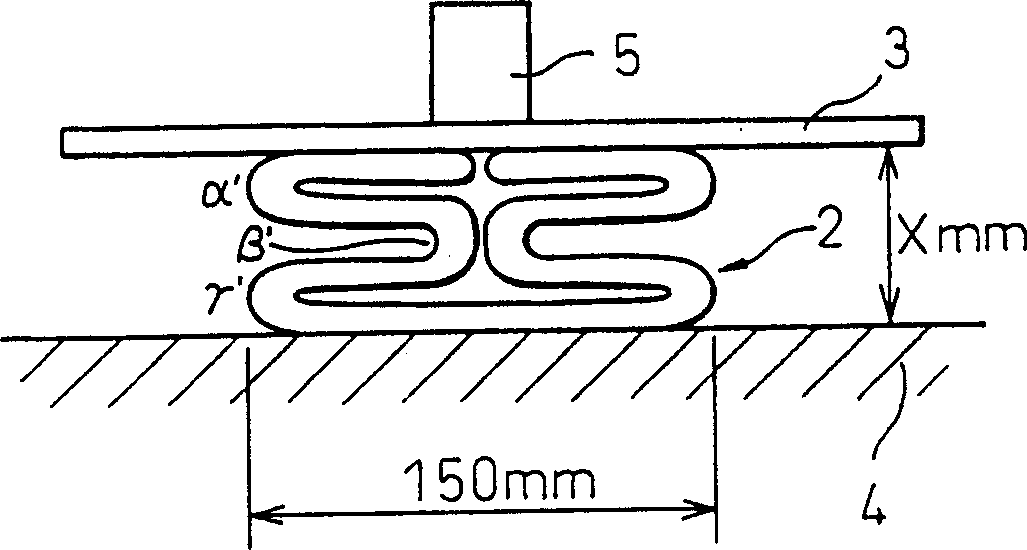

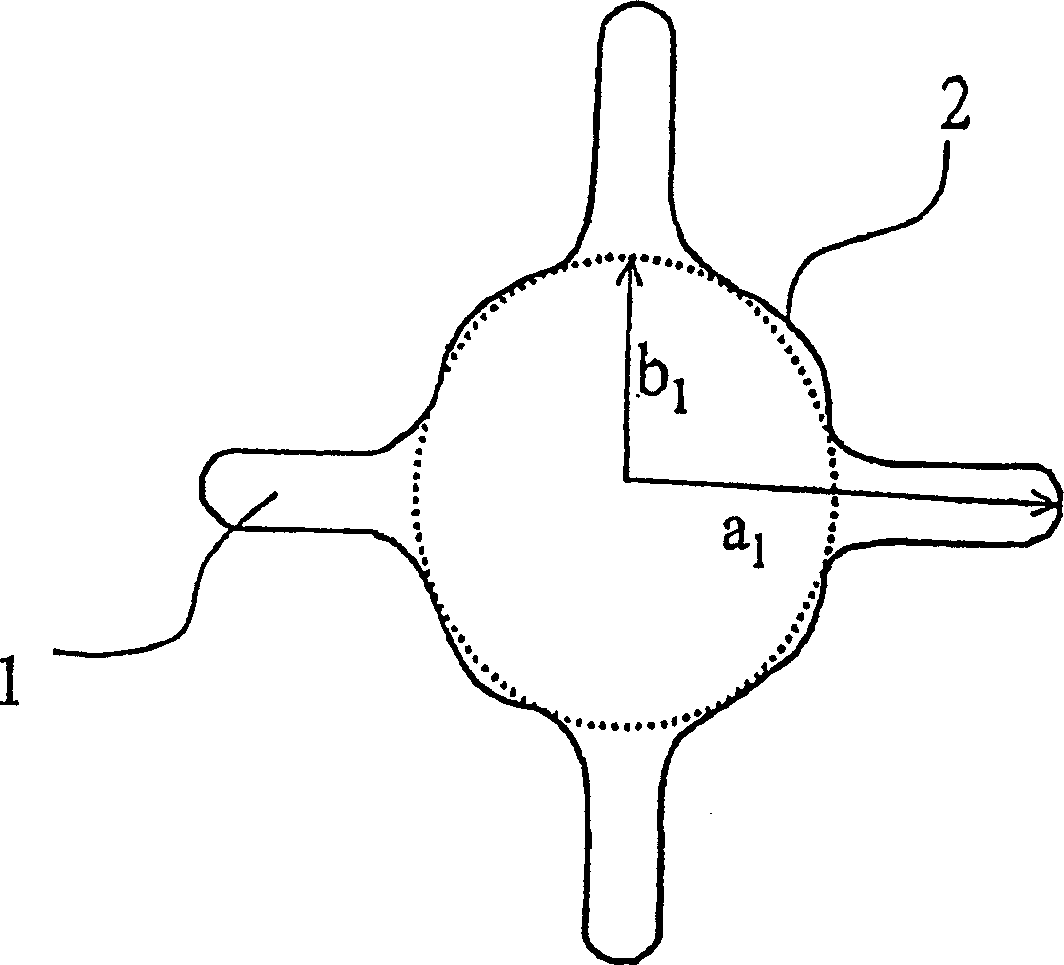

Silicone coating cloth and air bag

InactiveCN1518620AImprove lightnessGood flexibilityFibre treatmentPedestrian/occupant safety arrangementYarnDeployment time

The present invention provides a silicone coated fabric comprising a base woven fabric that is formed from a synthetic fiber weaving yarn that has a yarn size of from 100 to 270 dtex, and a weaving size expressed by a product calculated by multiplying the yarn size of a weaving yarn and a weave density (ends or picks / 2.54 cm) of from 10,000 to 25,000 (dtex.ends (or picks) / 2.54 cm) in both the warp direction and the weft direction, a silicone being applied to the woven fabric in an amount of from 5 to 25 g / m<2>, and having on one side a uniform silicone coating layer formeding part of the silicone mentioned above. The silicone coated fabric of the present invention is a lightweight coated fabric that shows improved heat resistance, improved flexibility and an improved low coefficient of friction as well as particularly improved burning resistance. The fabric can therefore be used for producing lightweight and compactly storable airbags that suppress bursting starting from a burnt-through-hole, and that shorten a deployment time.

Owner:ASAHI KASEI KK

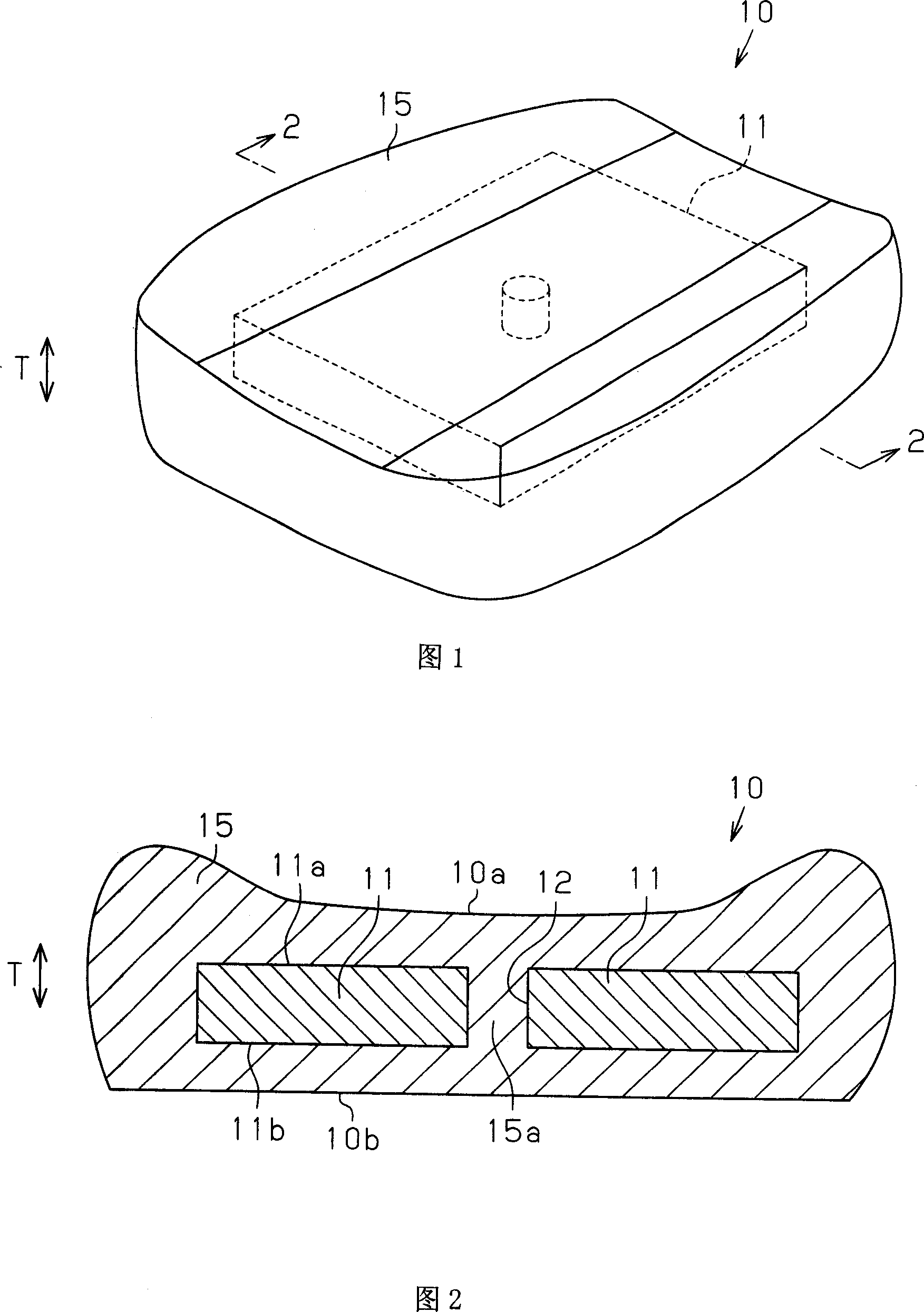

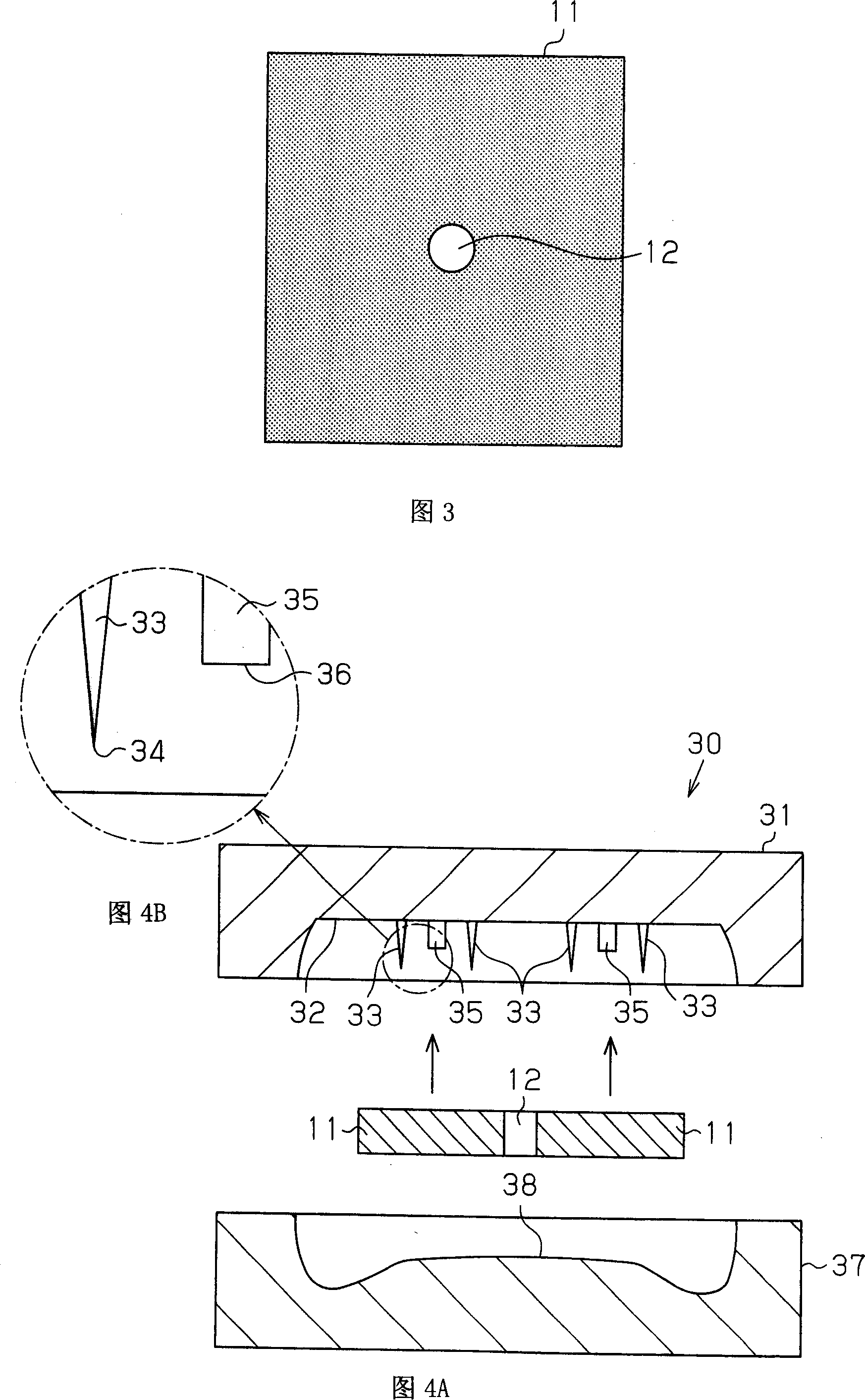

Cushion body and manufacturing method for a cushion body

InactiveCN101088435AImprove flame retardantImprove buffering effectUpholstery manufactureStuffed mattressesMelamine resinCushion

A cushion body is provided with a core material formed by a melamine resin foam body, and a surface layer material formed by a polyurethane resin foam body in which an expandable graphite is dispersed, and covering a periphery of the core material. A through hole extending along a thickness direction of the cushion body is formed at a predetermined position of the core material. The surface layer material fills the through hole, and the core material and the surface layer material are integrally formed. The cushion body increases a lightweight property of the cushion body by the core material formed by the melamine resin foam body, increases a fire retardant property of the cushion body by the expandable graphite, and increases cushioning and durability properties of the cushion body by the polyurethane resin foam body.

Owner:INOAC CORP

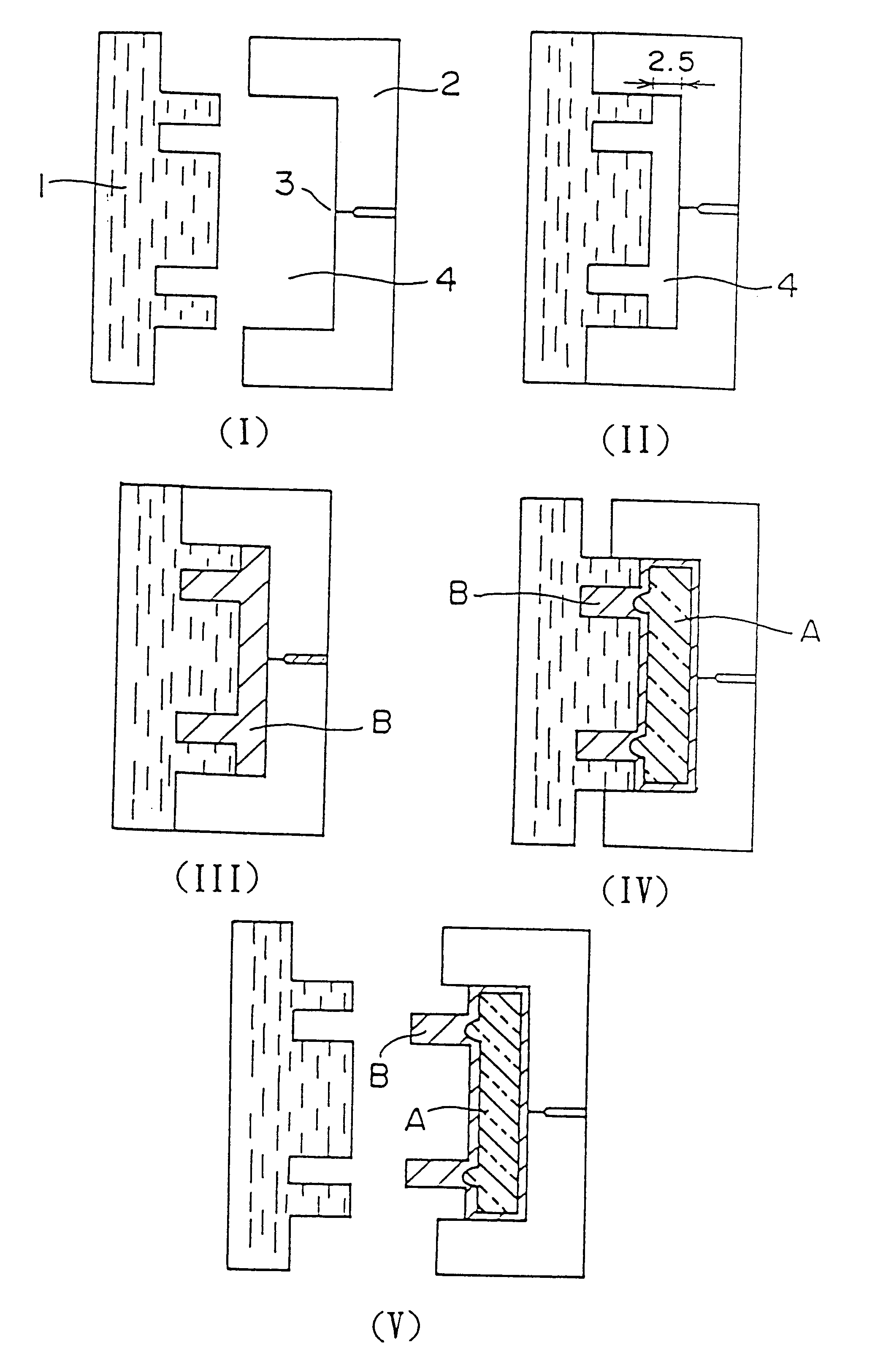

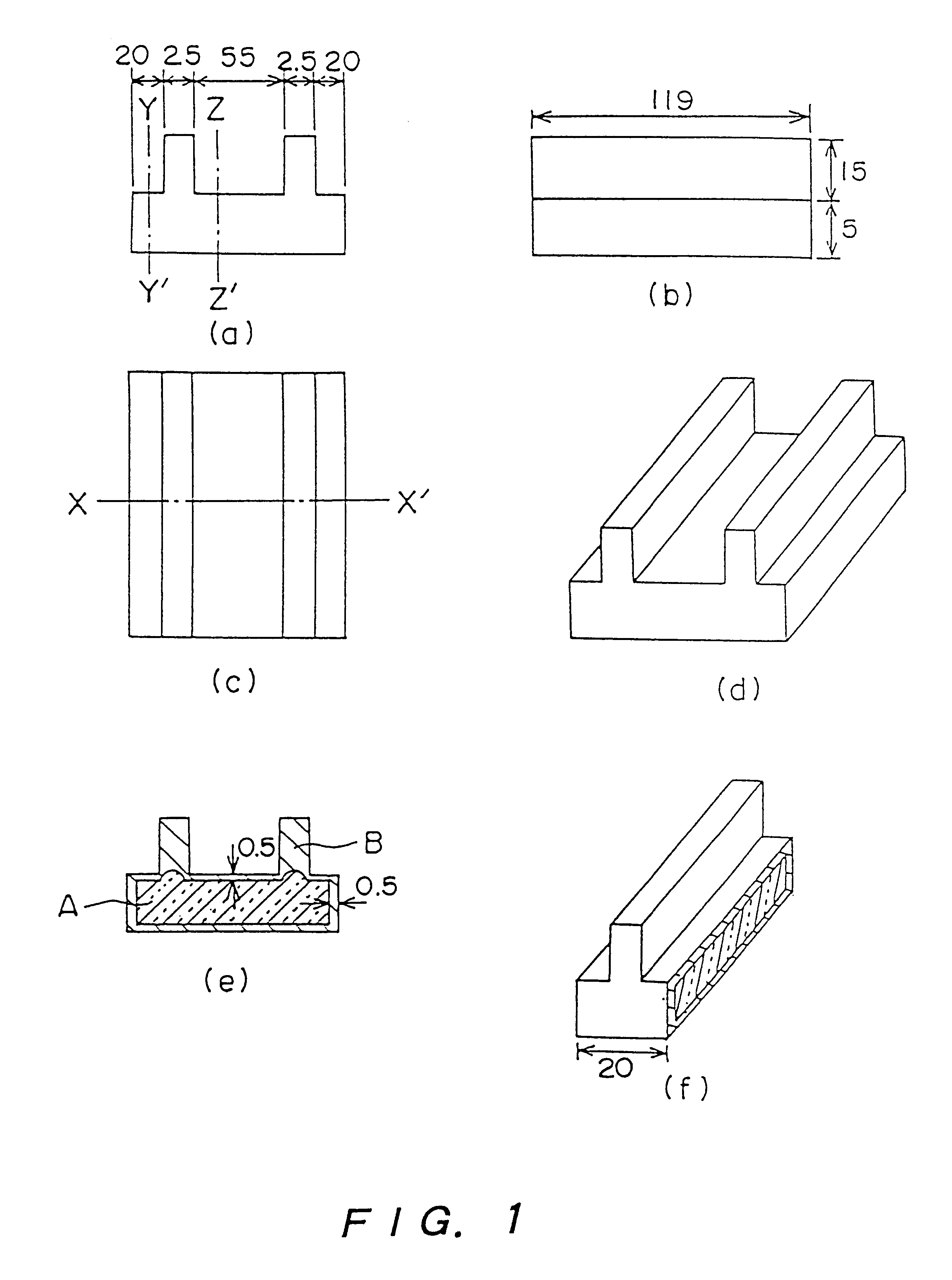

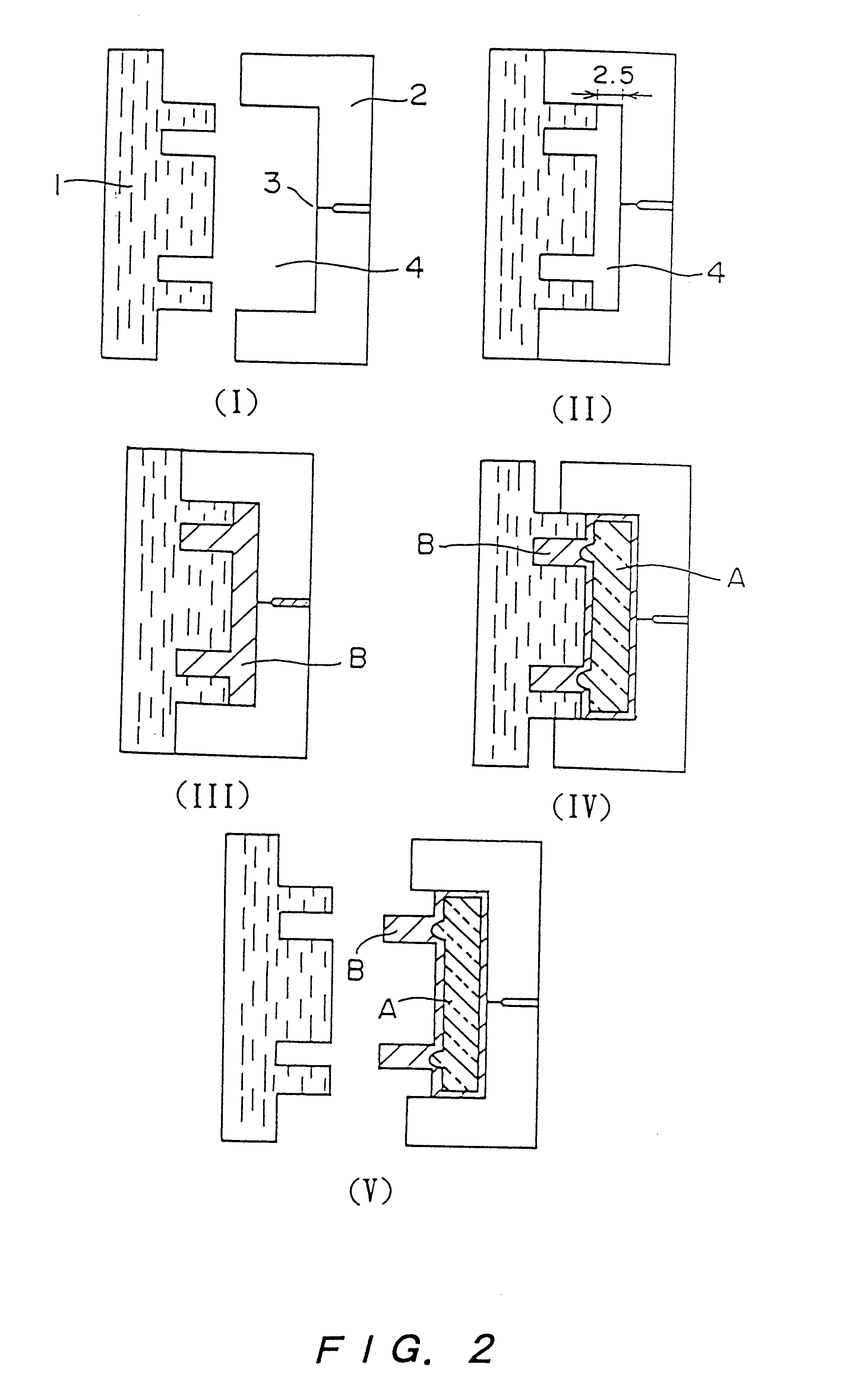

Method for producing molded article

InactiveUS6299807B1Improve rigidityIncrease heatLaminationLamination apparatusInternal layerSurface layer

An object is to provide a thermoplastic resin molded article concurrently having excellent heat insulating properties, rigidity, and lightness, and to provide a method for producing the same. A molded article made from a thermoplastic molding material comprises: a multilayer structure portion having a surface layer composed of a non-foamed type of said molding material and an internal layer composed of a foamed type of said molding material; and a portion composed of only a non-foamed type of said molding material. The molded article is produced by injecting and filling an expandable thermoplastic molding material which is melted in the heating cylinder that is adjusted to have the temperature of its tip part higher than that of its rear part, into a cavity having a 10 to 95% volume of the volume of the molded article, conducting a first cooling until the molding material becomes the condition that the surface layer contacted with the metal mold is solidified but the internal layer is melted, enlarging the volume of the cavity to the volume of the molded article to foam at least a part of the internal layer, and conducting a second cooling to take out the molded article.

Owner:JNC CORP

Polyester fibers having deformed section

InactiveCN1761779AStrong water absorptionImprove wear resistanceFilament/thread formingThin material handlingPolyesterFiber

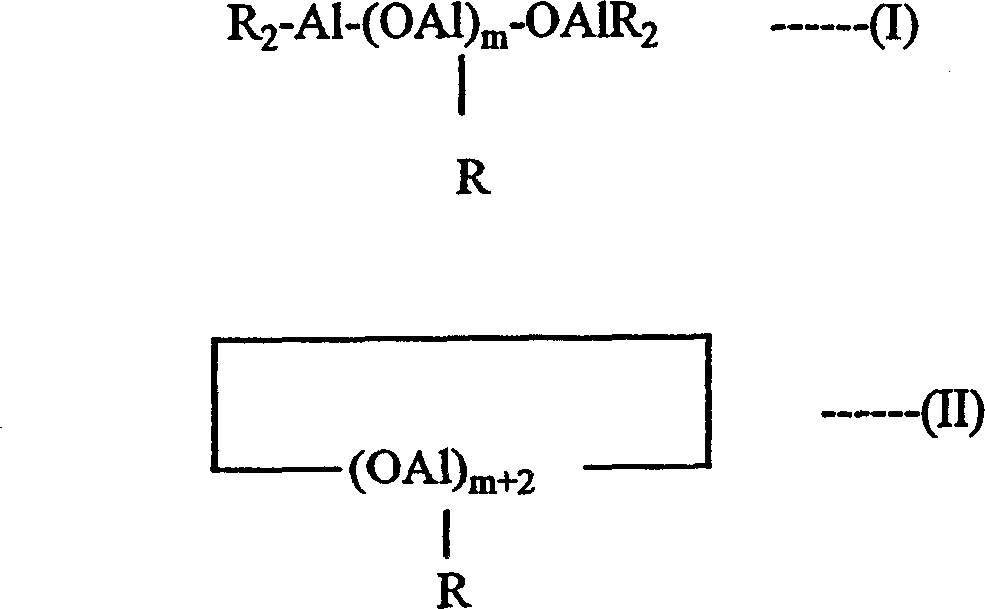

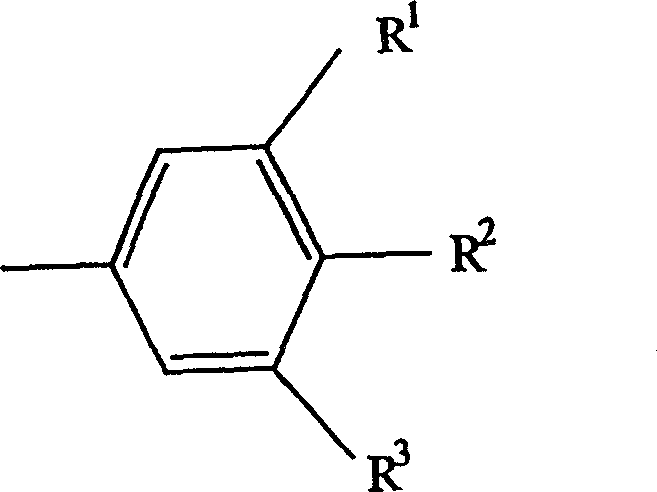

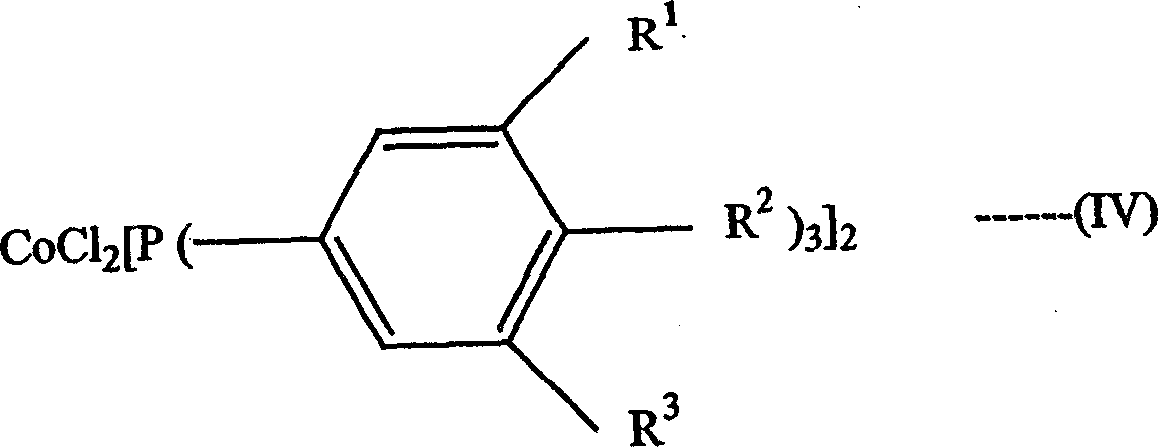

Polyester fibers having a deformed section are produced from a polyester polymer which is obtained by polycondensing an aromatic dicarboxylate ester in the presence of a catalyst containing a mixture of a Ti component (A) comprising at least one a titanium alkoxide or a reaction product thereof with a specific carboxylic acid or its anhydride with a P compound component (B) represented by the following general formula (III) and / or a reaction product of a Ti compound component (C) with a P compound component (D) represented by the following general formula (IV).

Owner:TEJIN FIBERS LTD

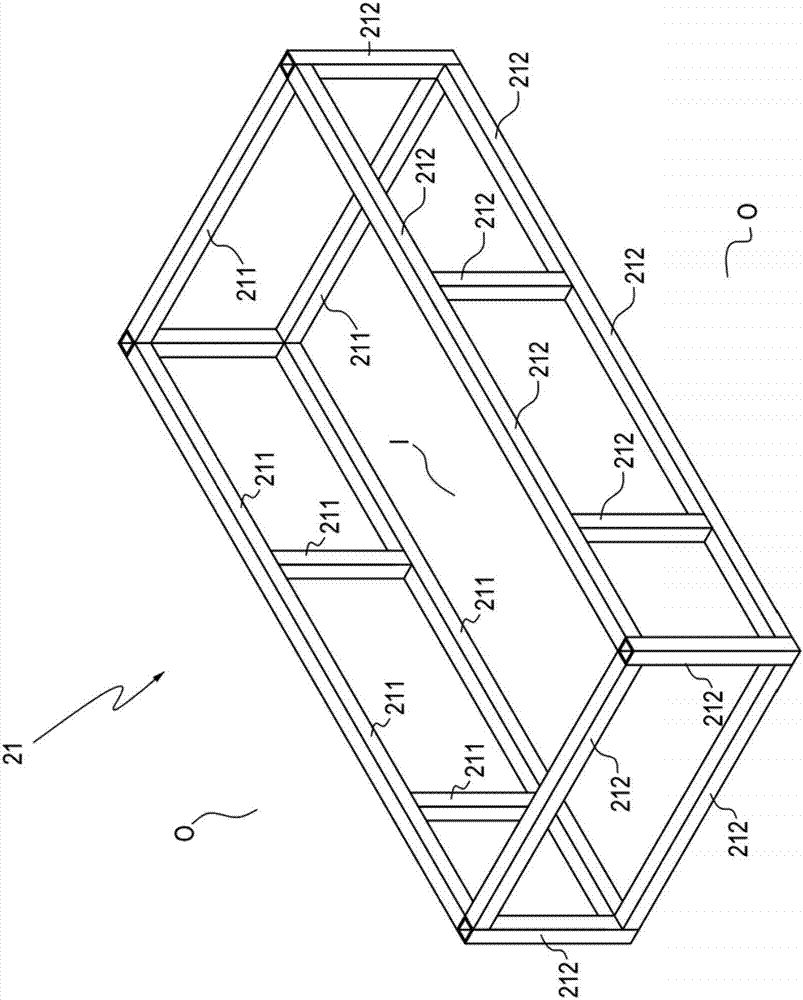

Electric vehicle battery box housing having heat dissipation and water exhaust structure

ActiveCN107887537AImprove lightnessImprove securitySecondary cellsCell component detailsElectric-vehicle batteryComputer module

The invention discloses an electric vehicle battery box housing having a heat dissipation and water exhaust structure and is suitable for an electric vehicle and used for accommodating a battery module. The electric vehicle battery box housing includes a frame, an inner layer box, an outer layer and a heat dissipation board. The frame includes an inner surface and an outer surface. The inner layerbox is connected to the inner surface of the frame with a plurality face boards and a box-shaped accommodation space is formed for accommodating the battery module. The inner side board of the box-shaped accommodation space is provided with high-position through holes. The outer layer box body is connected to the outer surface of the frame with a plurality of face boards and a box-shaped body isformed. The outer bottom board is provided with a plurality of penetrating water exhaust holes. The outer side board is provided with low-position through holes corresponding to the high-position through holes. The cover body is provided with penetrating air vent holes. The heat dissipation board is disposed below the outer bottom board of the outer layer box body. The heat dissipation board is provided with a water exhaust and venting channel corresponding to the water exhaust arranging zone of the outer bottom board.

Owner:METAL INDS RES & DEV CENT

Skin-core type composite fiber and production method thereof

ActiveCN103572399AImprove lightnessFilament/thread formingMonocomponent copolyesters artificial filamentPolyesterFiber

The invention discloses a skin-core type composite fiber and a production method thereof. Skin-core components of the composite fiber are through continuously along the length direction of the fiber. The weight ratio of the skin to the core is 40:60-80:20. The core component is an alkali-soluble modified polyester, and the skin component is a thermoplastic fiber forming polymer. In the cross section of the composite fiber, the core component is exposed on the skin component only in one position, and the arc length of the exposed part is 15-25% of the outer circumference of the composite fiber. The alkali minimization dissolution speed of the core component of the composite fiber is fast. The treated fiber maintains over 98% of strength and maintains a complete C-type section morphology, and therefore fabrics have good lightweight sense, heat insulating capability, a moisture absorbable function and a sweat releasing function.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com