Oil extended 1,2-polybutadiene and method of manufacturing polybutadiene, and composition and formed product thereof

A technology of polybutadiene and composition, applied in the field of new oil-extended 1, which can solve problems such as insufficient fluidity, long manufacturing time, and insufficient drug dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0230] Hereinafter, specific embodiments according to the present invention will be described.

[0231] The present invention is not limited to the following embodiments. It is possible to change arbitrarily without departing from the scope of the present invention. In addition, various measurements in the examples are based on the following methods, and "parts" means "parts by weight" unless otherwise specified.

[0232] The various determinations in the examples follow the following methods:

[0233] (1) 1,2-vinyl binding capacity

[0234] It is determined by infrared absorption spectroscopy (Morello method).

[0235] (2) Weight average molecular weight (Mw)

[0236] A gel permeation chromatograph (GPC) (Model 244 manufactured by Kota-Soo) was used. Mw is calculated in terms of polystyrene.

[0237] (3) Wear resistance

[0238] For Examples 1-5 and Comparative Example 1, the DIN abrasion amount (mm 3 ).

[0239] For Examples 21-27 and Comparative Examples 20-26, the mold tempera...

Embodiment 28-30

[0240] For Examples 28-30 and Comparative Examples 27-29, the Akulun abrasion method was used, and the abrasion measurement was carried out under the following conditions using an Akulun abrasion rotary machine.

[0241] Solid evaluation: 6Lbs, angle of 15 degrees, 1,000 times

[0242] Sponge evaluation: 2Lbs, angle of 15 degrees, 2,000 times

[0243] The abrasion resistance evaluation criteria of the Akulon abrasion method are as follows.

[0244] Solid evaluation (CC / 1,000 times): ⊚: less than 0.3, ◯: 0.3-0.49, △: 0.5-0.69, ×: 0.7 or more.

[0245] Sponge evaluation (CC / 2,000 times): ⊚: less than 0.4, ◯: 0.4-0.49, △: 0.5-0.69, ×: 0.7 or more.

[0246] (4) Melt flow rate (MFR) (processability)

[0247] It is implemented at a measurement temperature of 150°C in accordance with ASTM D 1238. The unit is g / 10 minutes. In terms of load, Examples 1-5 and Comparative Example 1 are 2.16 kg, Examples 12, 13, and Comparative Examples 5 and 6 are 5 kg, and Examples 16-18, 21-42, and Compara...

reference example 1

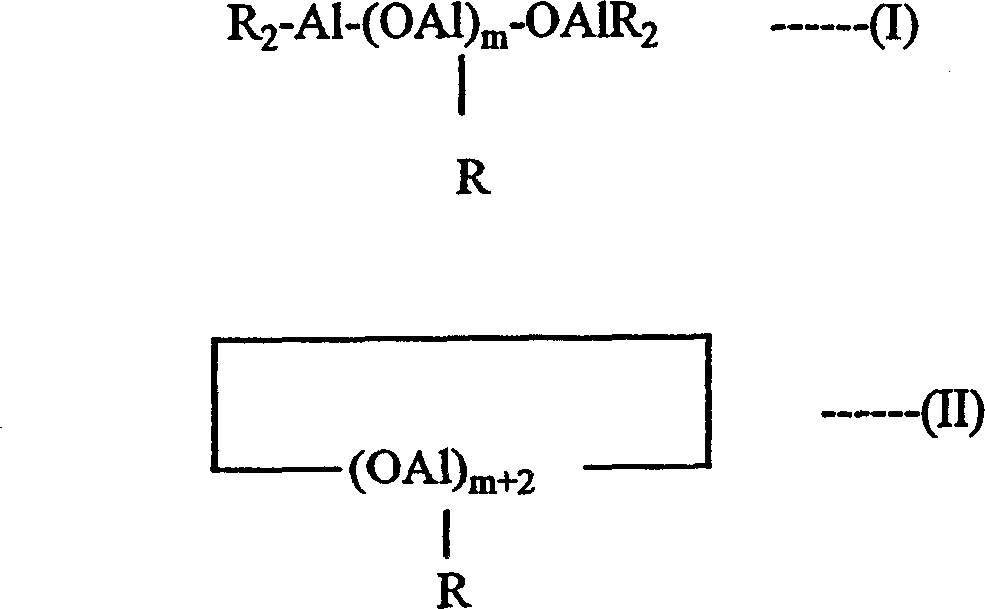

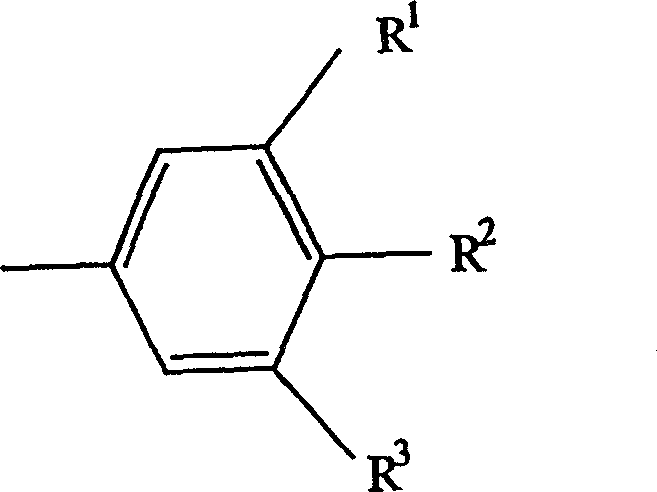

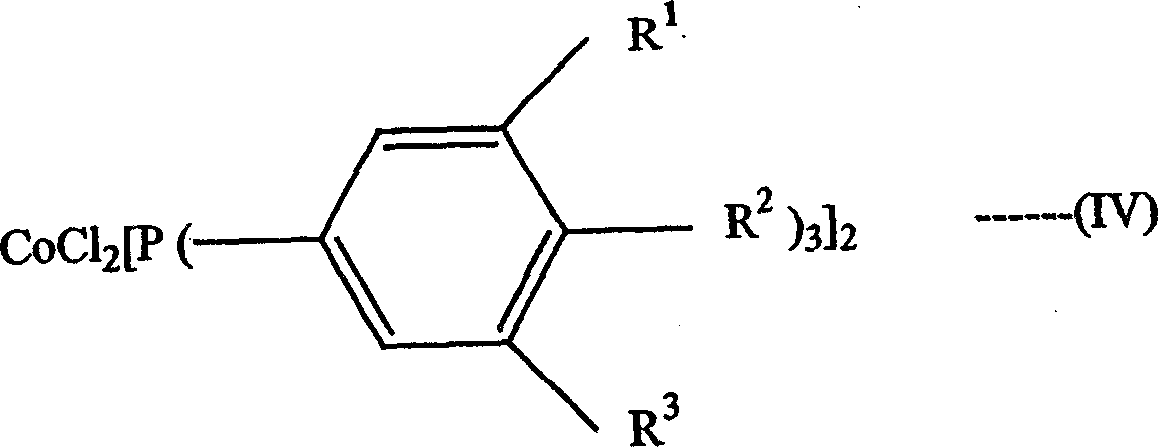

[0387] Reference example 1 (modulation of (a-1))

[0388] In a vertical reactor equipped with a stirrer with an internal volume of 20 L, 8,000 g of a cyclohexane / n-heptane (weight ratio 80:20) mixed solvent and 1,600 g of 1,3-butadiene were added, and the formazan was added with a syringe. Aluminoxane in toluene solution 6.58g (based on 1,3-butadiene / Al molar ratio, = 1,350), bis[tris(4-methylphenyl)phosphine]cobalt dichloride in dichloromethane 1.50g (1,3-butadiene / Co molar ratio, =180,000), the polymerization temperature was 45°C, and the polymerization started. After 120 minutes of reaction, the polymerization reaction was stopped by injecting a small amount of ethanol containing 2,6-di-tert-butyl-p-cresol as a reaction terminator. The yield of the obtained polymer (a-1) was 90% (polymer weight 1.44 kg), the Mw of the polymer (a-1) was about 400,000, and the 1,2-vinyl bond content was 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com