Patents

Literature

46results about How to "High cross-linking activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing epoxy cross-linking modified paper wet-strengthening agent

The invention discloses a method for producing an epoxy crosslinking modified paper humidity intensifier. The alkaline cured humidity intensifier polyamide polyamine epoxy chloropropane resin is the mainstream product at present, but the PAE which is not cross-linked and modified is poor in the crosslinking degree and molecular weight and has poor retaining performance, and the humidity-intensifying effect of the paper can not reach the production requirement, and can result in the increase of the adsorptive organic halide in the wastewater. The invention adopts the dibasic acid and polybasic amine as the raw material to produce the intermediate of polyamide polyamine; a certain amount of polyamide polyamine intermediate, epoxy and epoxy chloropropane react under certain temperature until the product reaches a certain viscosity, then acid is added to terminate the reaction and obtain the epoxy crosslinking modified paper humidity intensifier. The method can reduce the consumption of the epoxy chloropropane and decrease the content of organochlorine in the waste; the retaining rate of the product is greatly improved; the product provided by the invention can not only improve the wet strength of the paper but also can increase the physical properties of the paper, such as the folding strength, tensile strength and dry strength and the like.

Owner:SHAANXI UNIV OF SCI & TECH

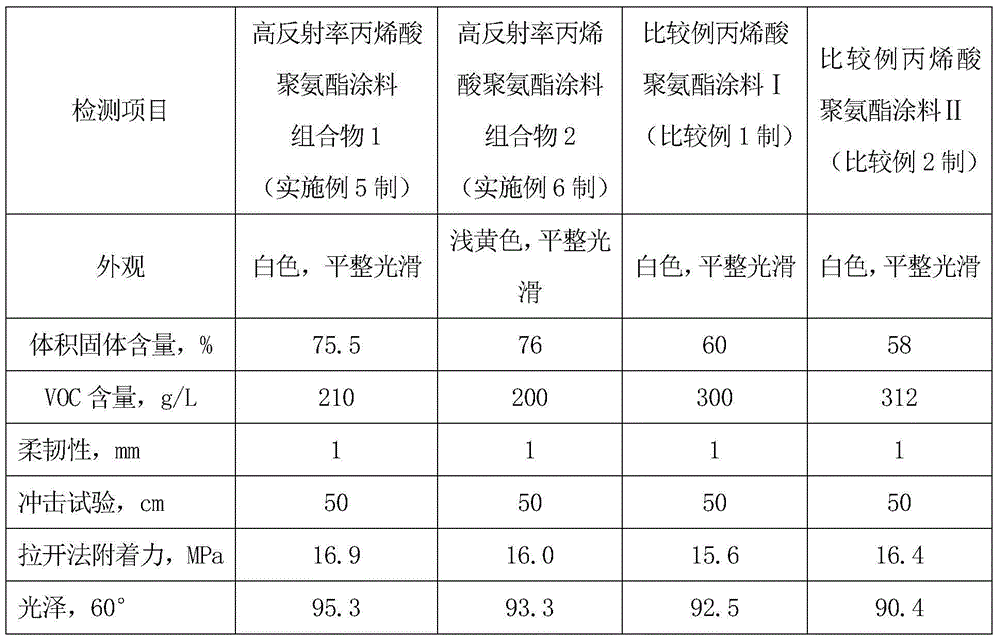

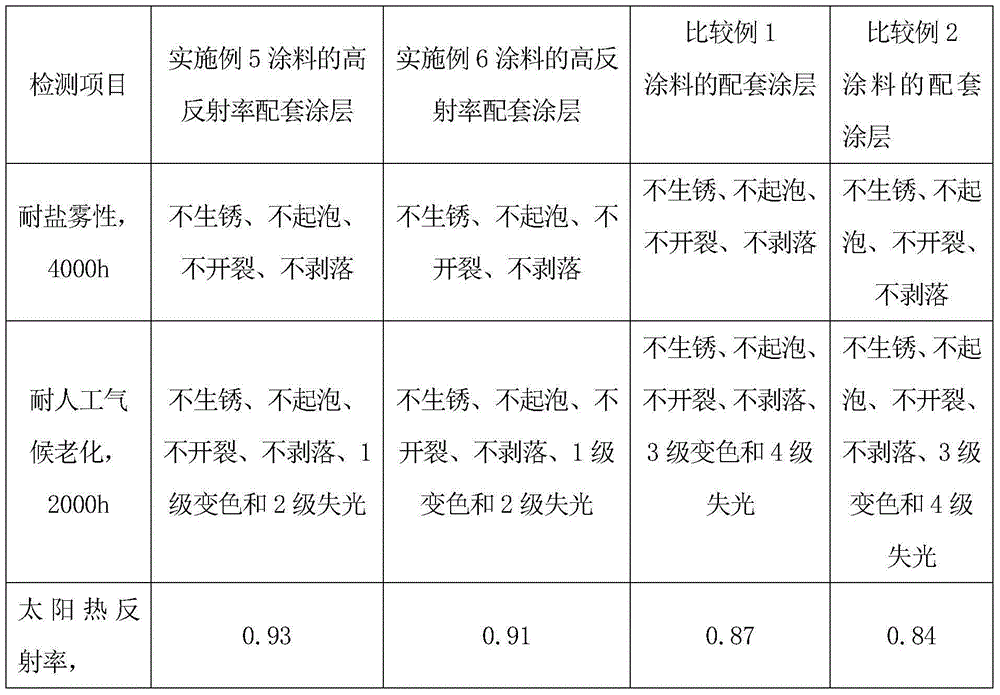

High-reflective acrylic polyurethane coating composition

ActiveCN104371531AHigh solid contentGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinIsophorone diisocyanate

The invention relates to a high-reflective acrylic polyurethane coating composition which comprises a component A and a component B in a mass part ratio of 20;3. The component A in 100 parts by mass comprises the following materials in part by mass: 30-50 parts of modified hydroxyl acrylic resin, 2-6 parts of auxiliaries, 35-45 parts of heat reflective pigments, 4-8 parts of aerogel and 10-15 parts of organic solvent. The component B in 100 parts by mass comprises the following materials in part by mass: 75-90 parts of polyisocyanate and 10-25 parts of organic solvent. The modified hydroxyl acrylic resin is obtained by cold-blending modified resin and hydroxyl acrylic resin in a mass part ratio of 1-3: 1; the solid content of the modified hydroxyl acrylic resin is greater than or equals to 75wt%; the particle size of heat reflective pigments ranges from 0.55 micron to 1.2 microns; the particle size of the aerogel ranges from 1 micron to 80 microns; the pore size of the aerogel ranges from 10 nanometers to 20 nanometers; and the heat conductivity coefficient of the aerogel is less than or equals to 0.015W / (m k). The polyisocyanate is one or more of HDI (hexamethylene diisocyanate) biuret, HDI trimer and IPDI (isophorone diisocyanate) trimer curing agents. The high-reflective acrylic polyurethane coating composition is high in reflective insulation quality; and the quantity of VOC (volatile organic compounds) of the high-reflective acrylic polyurethane coating component is low.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Method for preparing organosilicon modified paper sheet humidifying strong agent

InactiveCN101302731AImprove wet strengthImprove surface water resistanceReinforcing agents additionCross-linkEpoxy

The invention discloses a preparation method of a paper wet strengthening agent that is modified by organic silicon, which comprises the following steps: firstly combines the raw materials of dibasic acid and polyhydric amine into a polyamine intermediate compound of daiamid. A certain amount of the polyamine intermediate compound of daiamid, epoxy chloropropane and an organosilane coupling agent are taken to react under certain temperature so as to achieve certain viscosity, and the reaction is halted by adding acid, thus obtaining the paper wet strengthening agent that is modified by organic silicon. The preparation method of the paper wet strengthening agent that is modified by organic silicon can reduce the usage of the epoxy chloropropane and lower the organic chlorine content in discharged substances; the cross-linked product greatly increases molecular weight and active crosslinking points of molecular chain sections. The product of the paper wet strengthening agent that is modified by organic silicon achieves greatly raised retention degree, can improve not only the wet strength of paper but also the paper physical performance such as folding resistance, tensile strength and dry strength, etc., and the superficial water-proof performance of paper can be greatly raised if the paper wet strengthening agent is coated on the surface of paper.

Owner:SHAANXI UNIV OF SCI & TECH

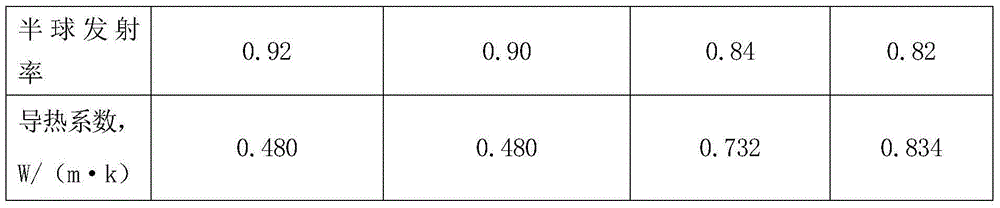

Low-smoke halogen-free flame-retardant silane crosslinked cable material capable of being crosslinked at room temperature and preparation method of cable material

InactiveCN104262883AReduce performanceLow smoke productionPlastic/resin/waxes insulatorsElastomerLinear low-density polyethylene

The invention relates to a low-smoke halogen-free flame-retardant silane crosslinked cable material capable of being crosslinked at the room temperature and a preparation method of the cable material. The method is characterized by comprising the steps as follows: firstly, a twin-screw mixing extruder is used for mixing polyolefin elastomers and linear low-density polyethylene with part of unsaturated silane and part of a grafting initiator respectively and extruding the mixtures into particles; then a high-speed mixer is used for mixing the two kinds of prepared particles with ethylene-vinyl acetate copolymer resin, functional polyolefin resin, a flame retardant, an antioxidant and a processing aid; and finally, the twin-screw mixing extruder is used for extruding the mixture into particles, so that the low-smoke halogen-free flame-retardant silane crosslinked cable material capable of being crosslinked at the room temperature is obtained. The cable material is high in silane grafting rate and high in crosslinking activity, crosslinking can be directly performed at the room temperature when the cable material is prepared into wires and cables, time-consuming and energy-consuming procedures such as water boiling, sauna and the like can be avoided, a crosslinking method is simple and easy to implement, and more than half of the crosslinking time can be saved even when a water boiling or steam sauna crosslinking method is adopted. The cable material is low in cost, high in production efficiency, easy to operate and free from structural limits when being used for producing the wires and the cables, and the product performance is stable and reliable after crosslinking.

Owner:WUXI JAKE PLASTIC

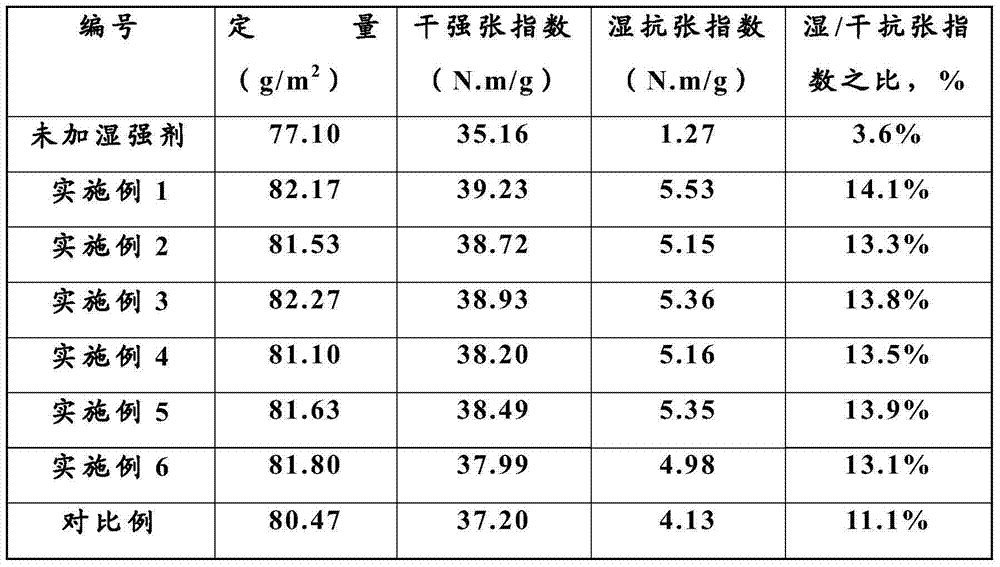

Wet strength agent, and preparation method and application of wet strength agent

ActiveCN104710579AGood effectHigh cross-linking activityReinforcing agents additionHydrogenPolyamide

The invention relates to a wet strength agent, and a preparation method and an application of the wet strength agent. The preparation method comprises the steps of allowing polycarboxylic acid and polyamine to react for 0.5-2h at 100-140 DEG C in the presence of a catalyst to form a polyamide polyamine prepolymer, adding dicarboxylic acid into the polyamide polyamine prepolymer for reaction for 4-10h at 150-190 DEG C to form a wet strength agent intermediate, adding a crosslinking monomer and an initiator at 30-50 DEG C for reaction for 0.5-1h at 50-60 DEG C to form a polymer, cooling the polymer to 30-35 DEG C, adding epoxy chloropropane, heating up to 60-80 DEG C for reaction for 2-6h, and adjusting pH (potential of hydrogen) of a reaction system to be 2-4 to form the wet strength agent. The wet strength agent has multiple branches, high molecular weight, balanced negative and positive charge distribution, high retention rate and high curing speed.

Owner:九洲生物技术(苏州)有限公司

Oil extended 1,2-polybutadiene and method of manufacturing polybutadiene, and composition and formed product thereof

InactiveCN1511176AExcellent formabilityHigh mechanical strengthSynthetic resin layered productsHeelsFoaming agentWear resistance

Disclosed are oil-extended 1,2-polybutadiene containing an extender oil in a specific amount based on 1, 2-polybutadiene and a production method thereof, and a composition further containing another (co)polymer, a foaming agent, a crosslinking agent, a softening agent and other additives. The resulting oil-extended 1,2-polybutadiene and the composition thereof has excellent functions characterizing conventional 1,2-polybutadiene and is further excellent in wear resistance, fluidity (processability), coloring properties (high distinctness of images), flexibility, attachability and the like, so that they can be applied to various formed articles, shoe sole materials and laminate having high performances.

Owner:JSR CORPORATIOON

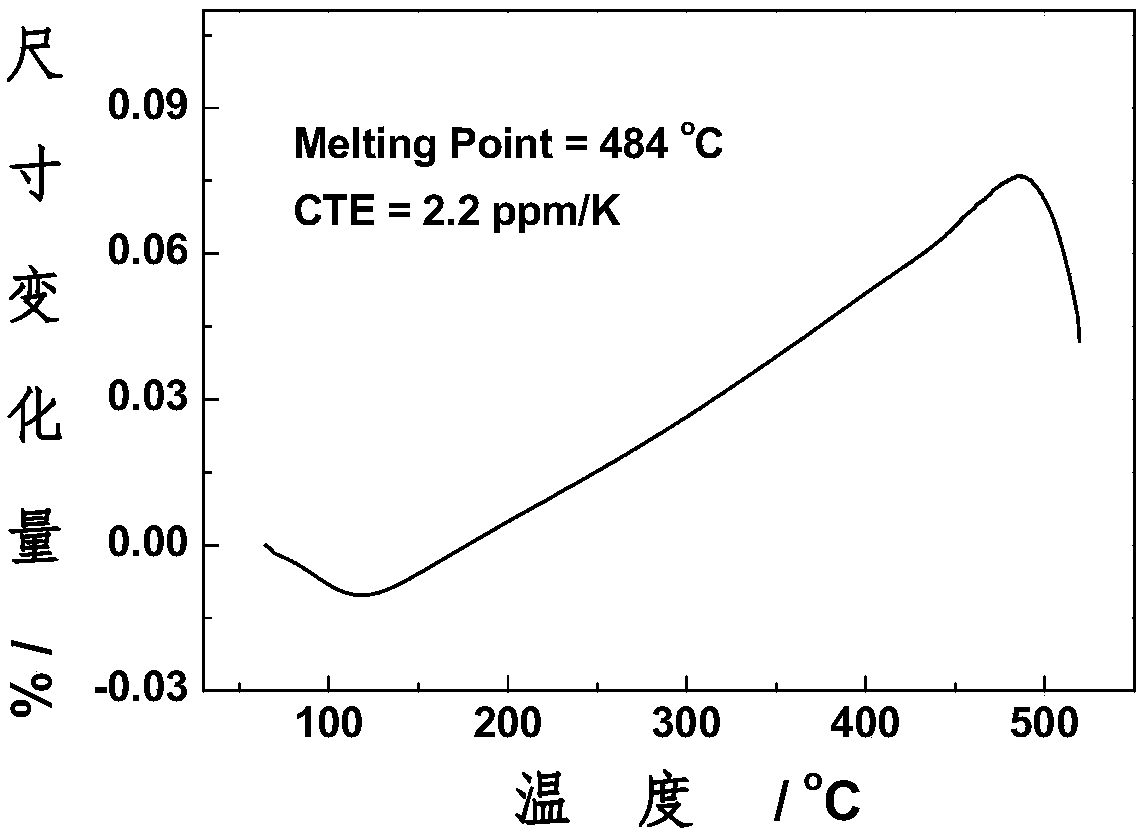

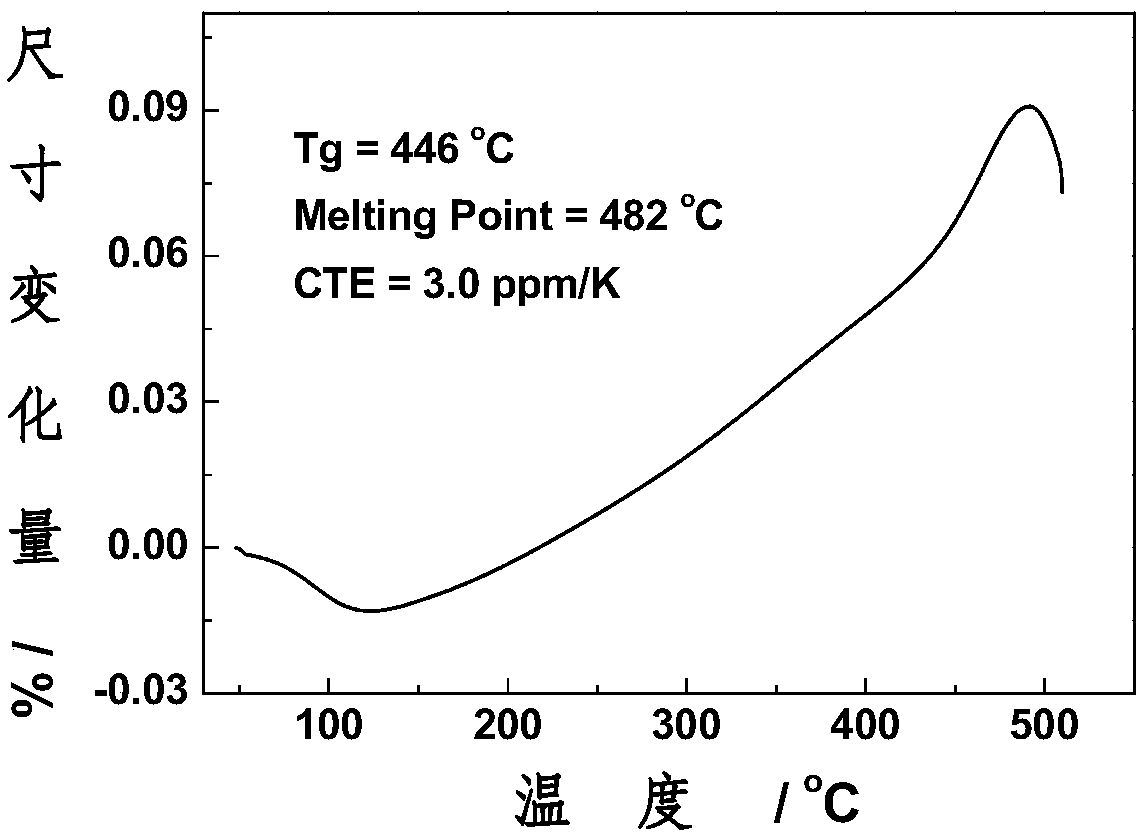

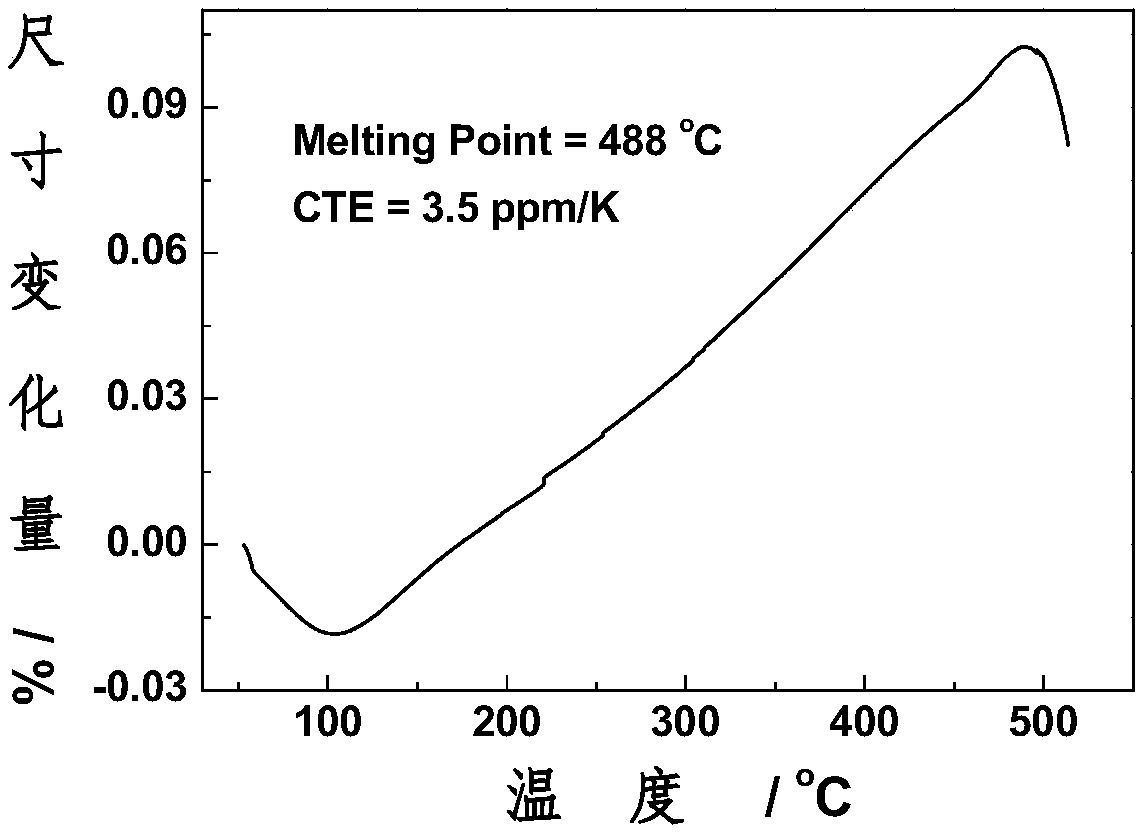

Thermosetting polyimide with high glass transition temperature and high heat resistance, and preparation method thereof

The invention discloses a thermosetting polyimide with a high glass transition temperature and a high heat resistance, and a preparation method thereof. An alkynyl anhydride compound is introduced into a PI molecular chain, and a crosslinking reaction of an alkynyl functional group is carried out to obtain the thermosetting polyimide having a network crosslinked structure. The polymerization process of a polyimide precursor and separation of an imidization process and a crosslinking process are controlled to make the network crosslinked structure of the polyimide tend to be complete. The thermosetting polyimide in the invention forms the network crosslinked structure, so the glass transition temperature is high, and even a significant glass transition process disappears; the heat resistance is improved; and the CTE is also kept close to that of the glass. The thermosetting polyimide with the high glass transition temperature and the high heat resistance in the invention keeps the performances of a film stable in the high-temperature processing process, meets the requirements of a flexible OLED panel product for a flexible substrate, and ensures the application in the OLED panel.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

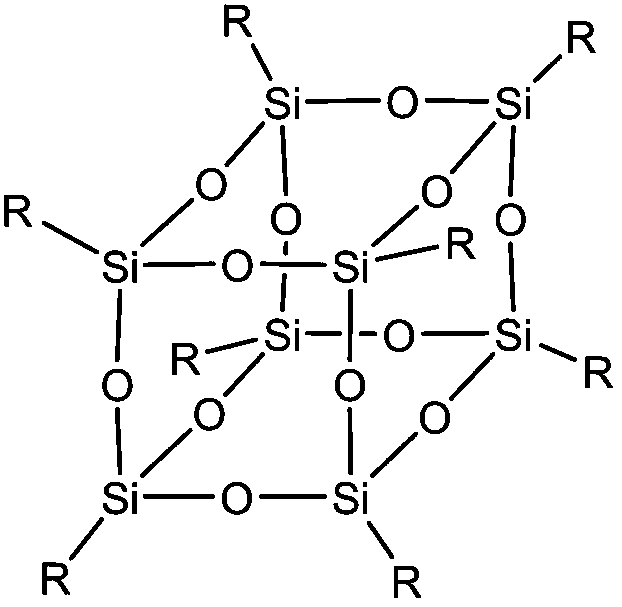

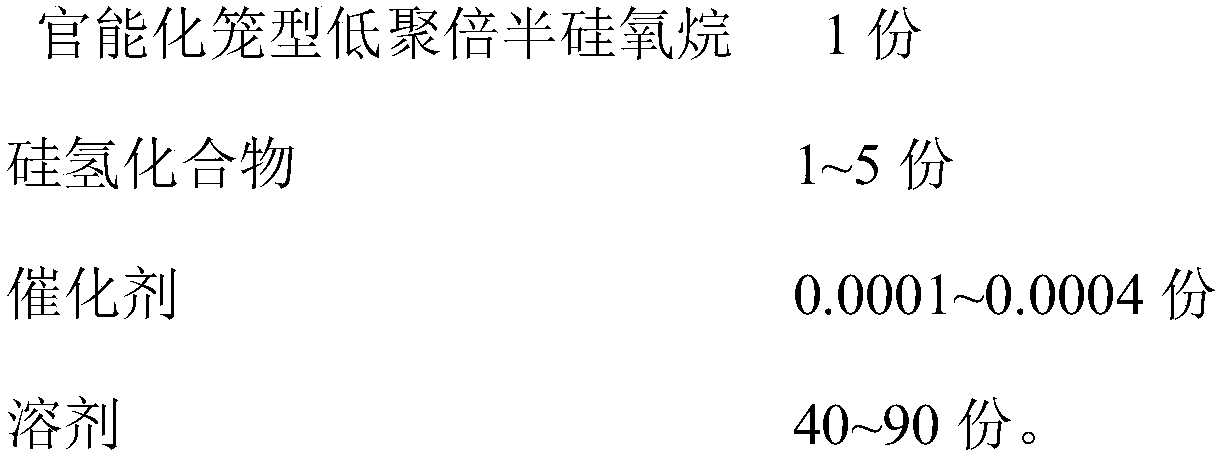

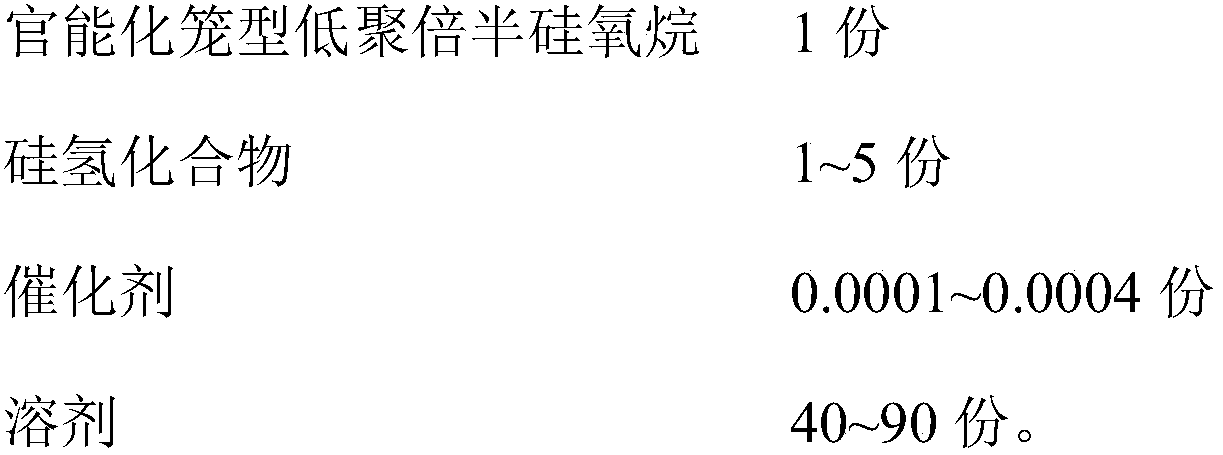

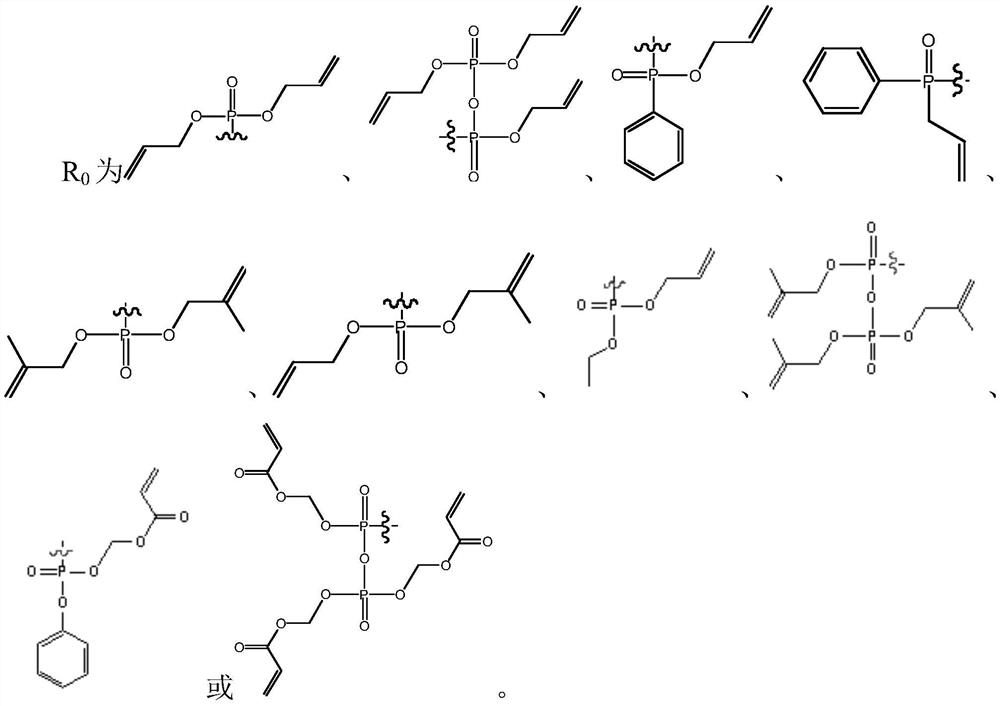

Organosilicon cross-linking agent containing cage oligomeric silsesquioxane structure and preparation method thereof

The invention relates to an organosilicon cross-linking agent containing a cage oligomeric silsesquioxane structure. The organosilicon cross-linking agent comprises, by weight, 1 part of functionalized cage oligomeric silsesquioxane, 1 to 1 5 parts of silicon hydride, 0.0001 to 0.0004 part of a catalyst and 40 to 90 parts of a solvent. A preparation method for the organosilicon cross-linking agentcontaining the cage oligomeric silsesquioxane structure comprises the synthesis of the cage oligomeric silsesquioxane-based organosilicon cross-linking agent. The organosilicon cross-linking agent ofthe invention contains phenyl groups, has high compatibility with phenyl silicone rubber, and can be used as both a reinforcing filler and a cross-linking agent; the cross-linking agent contains bothhydrosilyl groups and carbon-carbon double bonds, has high cross-linking activity, can form a three-dimensional cross-linking network with POSS as a core, and thus greatly improves the cross-linkingstructure of silicone rubber; and the cross-linking agent of the invention contains both a POSS structure and a benzene ring, and can significantly enhance the mechanical properties and thermal stability of silicone rubber.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Lubricating grease composition

The invention relates to a lubricating grease composition consisting of lubricating grease, liquid rubber and a peroxide crosslinking agent; the dropping point of the lubricating grease composition can be greatly increased in the using process, the lubricating grease composition is mainly used as long-life and high-dropping-point lubricating grease and an anti-rust and lubrication protective agent for steel wire ropes, and also can be used as a joint mixture for cement cracks of some buildings such as bridges and the like.

Owner:PETROCHINA CO LTD

Anti-tear silicone rubber compound and preparation method thereof

The invention discloses an anti-tear silicone rubber compound and a preparation method thereof, and belongs to the field of chemical industry. According to a silicone rubber base material for preparation, fluorine-containing siloxane is added in a mixed rubber base material, so that oil resistance of the silicone rubber is improved, and advantage combination of the silicone rubber and a mixed rubber additive are increased. Mixed rubber filler for preparation is prepared by taking white carbon black and nano carbon tubes as raw materials, so that temperature resistance of the rubber compound isimproved, and bonding performance between the rubber compound and a the silicone rubber matrix is improved. A cross-linking additive for preparation is prepared by taking lac and fumaric acid as rawmaterials, and has relatively good tear resistance and tensile strength. Aramid fiber short fibers and aramid fiber pulp are added, so that cross-linking activity in a mixing process is improved. According to the invention, the silicone rubber base material is added to improve oil resistance, and mixed fibers are added in the mixing process, so that various properties of the rubber compound are well combined. According to the invention, the problems of poor oil resistance and poor tear resistance of existing silicone rubber are solved.

Owner:黄广展

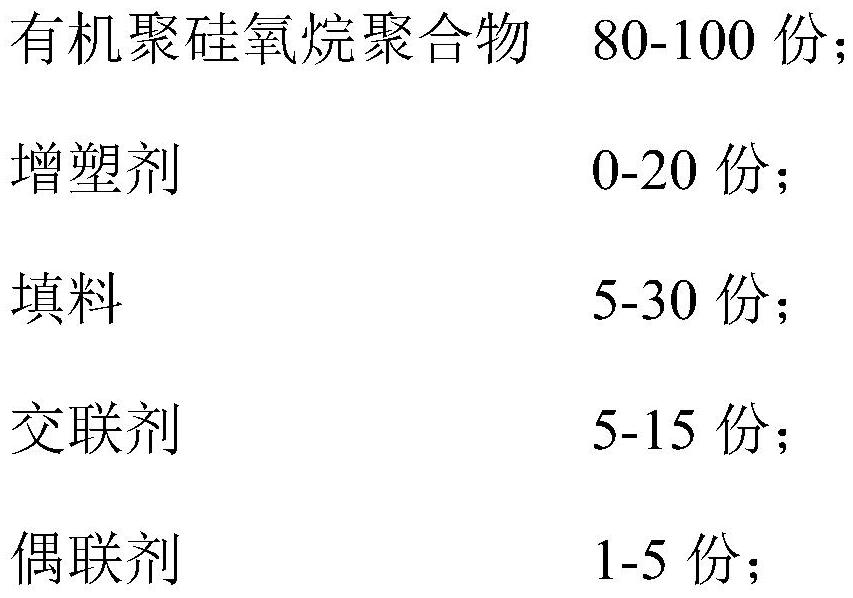

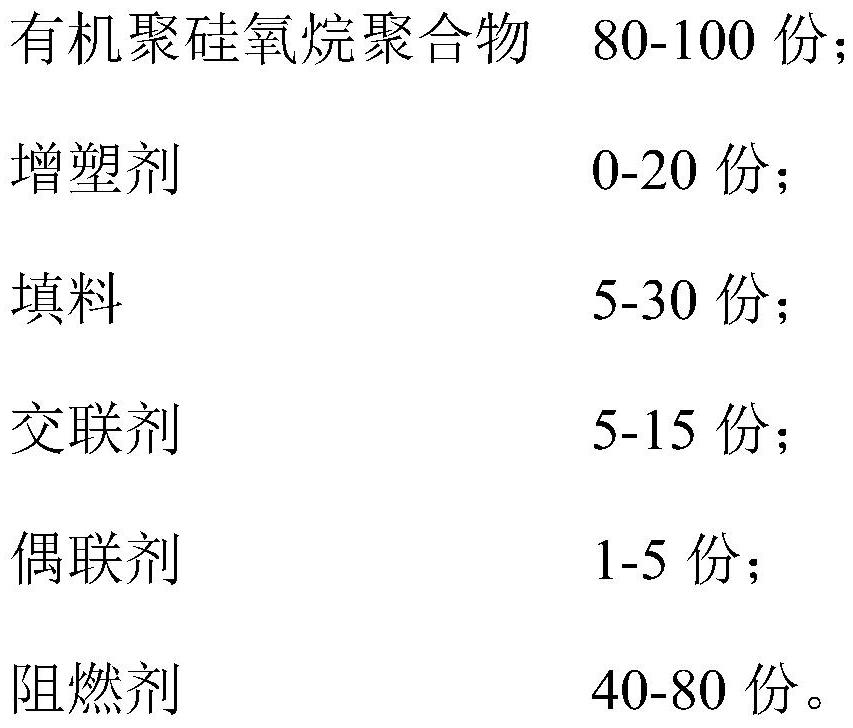

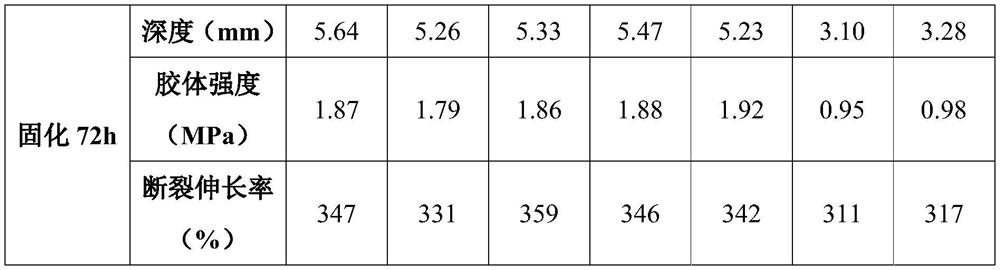

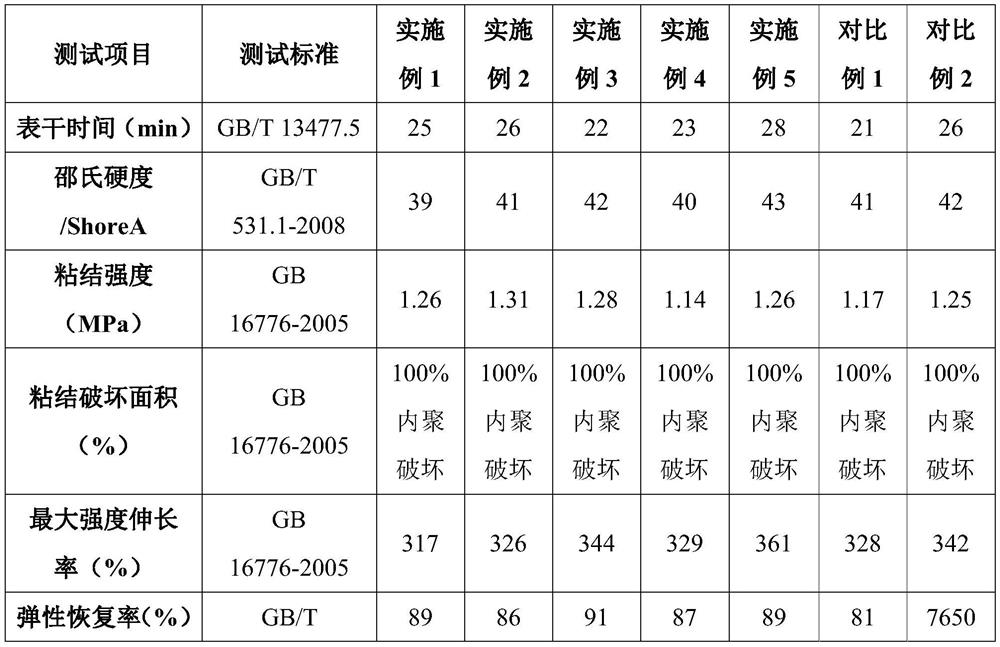

Deoximation type room temperature vulcanized silicone rubber and preparation method thereof

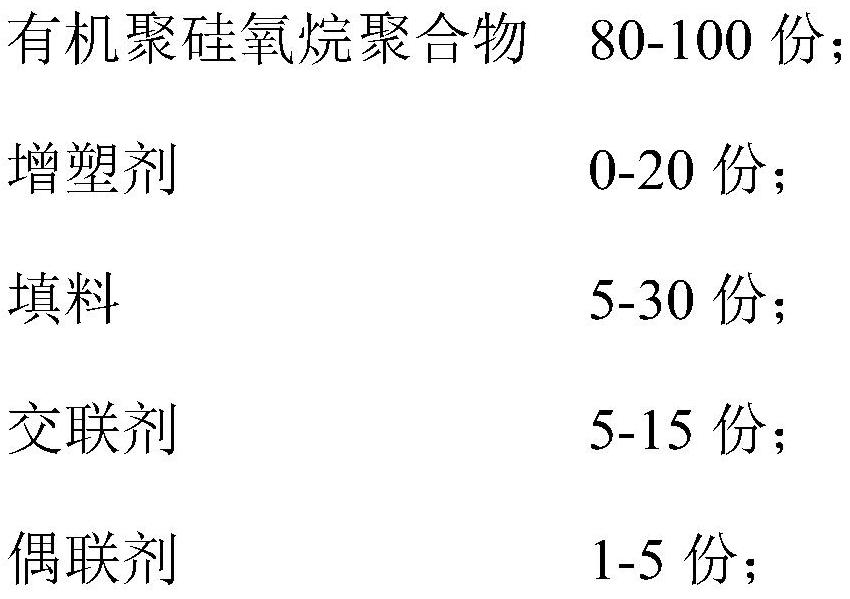

The invention relates to deoximation type room temperature vulcanized silicone rubber and a preparation method thereof, and relates to the technical field of high-molecular polymers. The deoximation type room temperature vulcanized silicone rubber is prepared from the following raw materials in parts by weight: 80 to 100 parts of an organic polysiloxane polymer; 0-20 parts of a plasticizer; 5-30 parts of a filler; 5-15 parts of a cross-linking agent; and 1-5 parts of a coupling agent. The preparation method of the cross-linking agent comprises the following steps: mixing silicate ester, diacetyl monoxime and a solvent, and carrying out heating reflux reaction. By treating the cross-linking agent, the activity of the cross-linking agent is improved, addition of organic tin or metal salt catalysts can be omitted, basically similar mechanical properties are achieved, meanwhile, the reversion phenomenon is avoided, and good mechanical strength and hardness can be kept in a heated closed environment.

Owner:GUANGZHOU BAIYUN CHEM IND

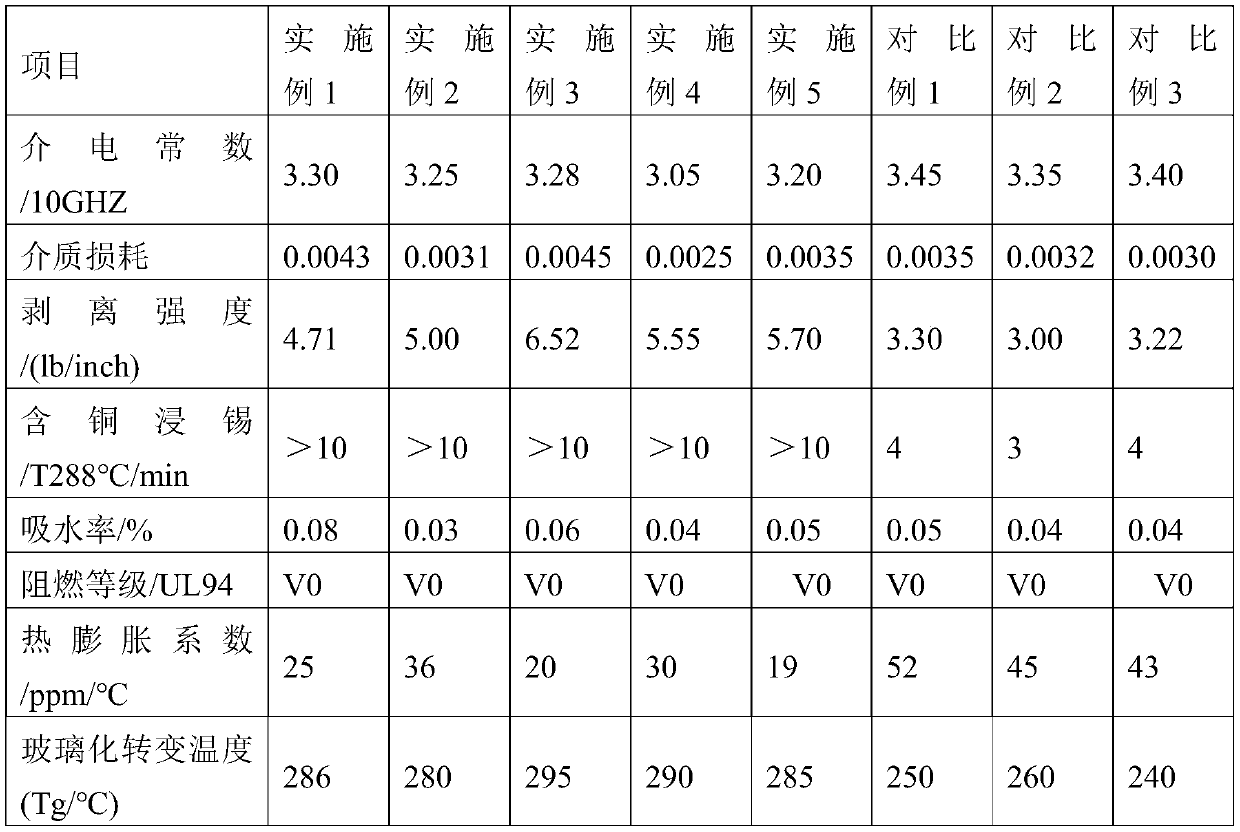

Multifunctional modified resin blended prepreg hydrocarbon composition, application thereof and method for preparing high-frequency and high-speed copper-clad plate by adopting prepreg hydrocarbon composition

ActiveCN111378243ALow dielectric constantSmall dielectric lossLamination ancillary operationsLaminationPolymer scienceButadiene Dioxide

The invention discloses a multifunctional modified resin blended prepreg hydrocarbon composition and an application thereof, and a method for preparing a high-frequency high-speed copper-clad plate byusing the prepreg hydrocarbon composition. The prepreg hydrocarbon composition comprises the following components: 20-60 parts of multifunctional modified resin; 25 to 65 parts of an inorganic filler; 10 to 50 parts of a flame retardant; 0.1 to 10 parts of an antioxidant; and 2-10 parts of a cross-linking agent. The multifunctional modified resin is one or more of a hydroxyl modified polybutadiene polymer, a hydroxyl modified polybutadiene-styrene copolymer, sulfydryl modified polybutadiene, polyether modified polybutadiene, an isoprene-styrene copolymer, a styrene-butadiene-styrene copolymerand a butadiene-acrylonitrile copolymer. The special multifunctional modified resin blended prepreg hydrocarbon composition for the high-frequency copper-clad plate provided by the invention has thecharacteristics of low dielectric constant, low dielectric loss, excellent heat resistance, good thermal mechanical properties, extremely low water absorption and stable performance.

Owner:无锡睿龙新材料科技有限公司

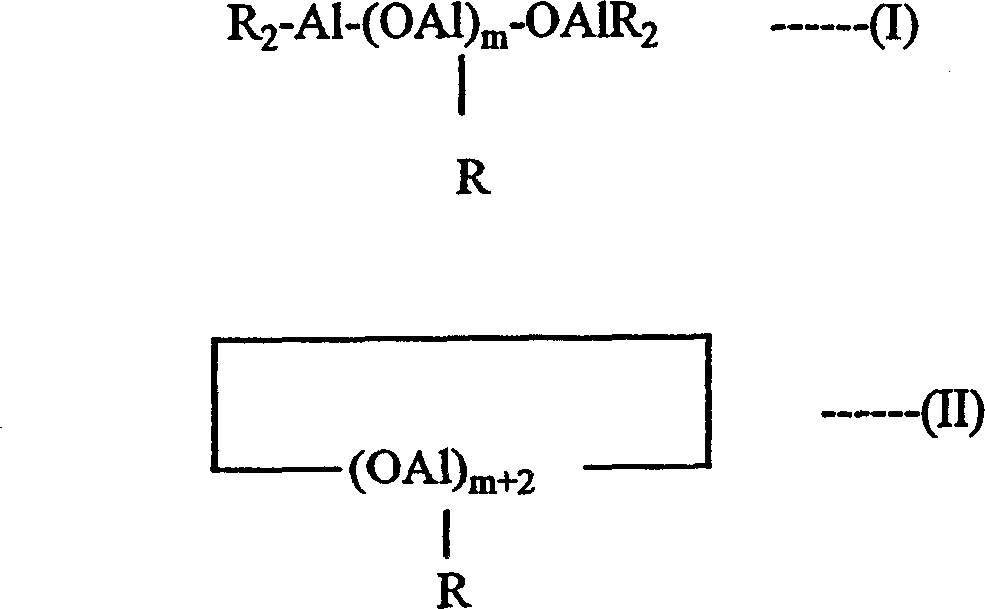

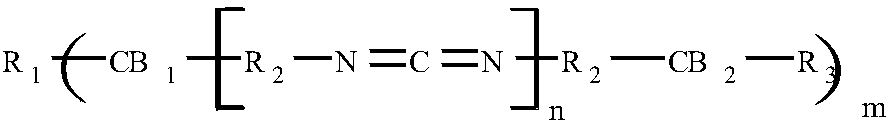

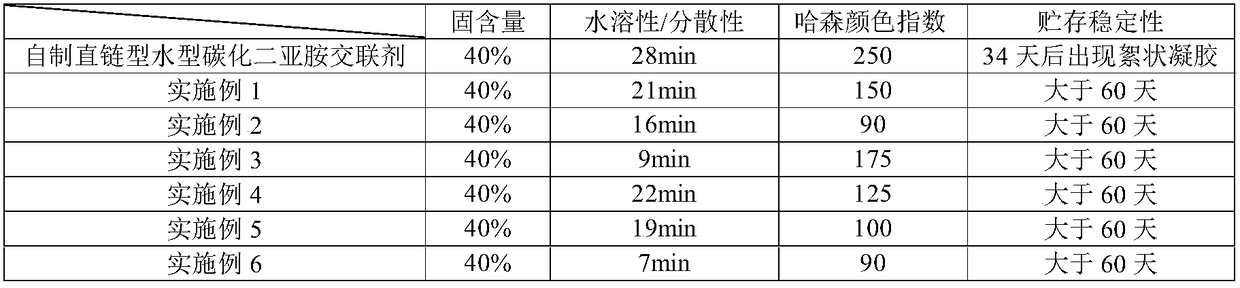

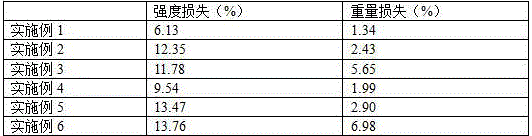

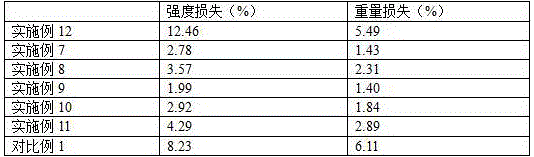

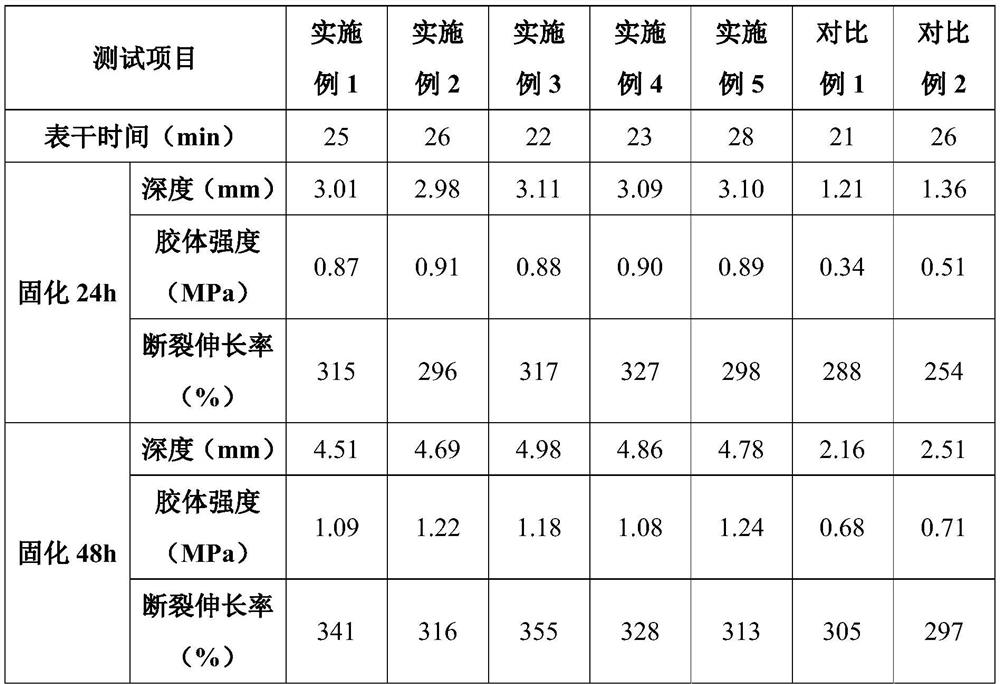

Branched aqueous carbodiimide type crosslinking agent and preparation method thereof

InactiveCN108863851ALow color change indexGood storage stabilityOrganic chemistryCross-linkSolubility

The invention relates to a branched aqueous carbodiimide type crosslinking agent and a preparation method thereof, and belongs to the technical field of polymer materials. The crosslinking agent has the structural formula as shown in the specification, wherein R1 is a polyfunctional compound group getting rid of an effective functional group reactive with isocyanate; R2 is a diisocyanate group getting rid of two isocyanato; R3 is a hydrophilic compound group getting rid of an effective functional group reactive with isocyanate; CB1 is a chemical bond formed by reacting an effective functionalgroup reactive with isocyanate on R1 with isocyanate; CB2 is a chemical bond formed by reacting an effective functional group reactive with isocyanate on R3 with isocyanate; m is an integer greater than 2; n is equal to 1-10. The cross-linking agent has good water solubility / dispersibility and low color change index, and can be used for crosslinking of aqueous coatings and hydrolysis resistance ofpolyester polymer materials. The preparation process is simple, the equipment requirements are not high, the cost is low, and thus the preparation method is suitable for industrial production.

Owner:四川创世新琰科技有限责任公司

Roadbase mixture prepared from construction waste resourcefully treated by dedicated soil stabilizer

ActiveCN106747120AHigh cross-linking activityTake advantage ofSolid waste managementSurface-active agentsMoisture

The invention relates to a roadbase mixture prepared from construction waste resourcefully treated by a dedicated soil stabilizer. The roadbase mixture is prepared from the materials of 93 to 98 weight parts of construction waste powder, 2 to 7 weight parts of cement and 0.01 to 0.1 weight part of soil stabilizer; the soil stabilizer is prepared from 100 weight parts of water, 1 to 15 weight parts of surface active agent and 0.1 to 10 weight parts of boric acid or borate. The roadbase mixture is further prepared from the material of water, and the use amount of the water is 1 to 4% more than the optimal moisture content of the roadbase mixture. The roadbase mixture disclosed by the invention has very good water stability.

Owner:包宗义

Glass surface long-acting anti-fog coating and preparation method thereof

ActiveCN111732890AImprove solubilityReduce viscosityOther chemical processesPolyether coatingsEpoxySilane compounds

The invention belongs to the technical field of glass functional coatings, and discloses a glass surface long-acting anti-fog coating and a preparation method thereof. The preparation method comprisesthe following steps: coating a pretreated glass substrate with a hydrophobic layer solution composed of a silane compound containing 2-4 alkoxy groups, hydrophobic silica sol, amino-terminated hyperbranched polysiloxane and a low-boiling-point alcohol solvent, and carrying out preheating treatment at 50-100 DEG C to evaporate the alcohol solvent so as to obtain a hydrophobic layer; and then spraying a hydrophilic layer solution containing aliphatic epoxy resin, hydrophilic silica sol, an additive and a diluent, and carrying out heating curing treatment at the temperature of 100-200 DEG C to obtain the long-acting anti-fog coating. Amino-terminated hyperbranched polysiloxane is adopted as a spreading agent of the hydrophobic layer solution and a cross-linking agent of the hydrophilic layerat the same time, and the curing effect, light transmittance and antifogging durability of the hydrophilic anti-fog coating are remarkably improved.

Owner:徐州市威固特种玻璃有限公司

High-temperature stable precoated sand

InactiveCN110586847AGood compatibilityImprove tensile propertiesFoundry mouldsFoundry coresLanthanumUltrasonic dispersion

The invention discloses high-temperature stable precoated sand, and belongs to the field of casting materials. Polylactic acid, lanthanum stearate and the like are used as raw materials, and are combined with subsequent nanoparticle effects for mutual connection to form space netty structures with nanometer microholes so as to improve the forming effect of the precoated sand. Three types of nanoparticles are used as nanomaterials for ultrasonic dispersion and acid mixing effects to improve the dispersion effect; and through adding of nanometer TiO2, a lot of plastic deformation energy can be absorbed when the external pressure effect is suffered, so that the softness of the prepared precoated sand is improved, the shell mold flexibility is improved, and the high-temperature pressure strength is improved. In the mixing process, through coaction between inorganic-organic components, compact air separation layers are formed in the precoated sand, and the influence on the internal of the precoated sand can be reduced when high-temperature effect is suffered. The high-temperature stable precoated sand solves the problems of easy unshelling and agglomeration of traditional precoated sandin the preparation process due to lower high-temperature pressure strength of the traditional precoated sand.

Owner:青铜峡市瑞通支撑剂有限公司

Silicone sealant with anti-bulging performance and preparation method thereof

InactiveCN113265221AExcellent anti-bulging performanceSolve the problem of easy drummingNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a silicone sealant with anti-bulging performance and a preparation method thereof. The silicone sealant comprises alpha, omega-dihydroxy polydimethylsiloxane, a reinforcing filler, a ketoxime type cross-linking agent, an amino silane-epoxy silane copolymer, a coupling agent and a catalyst, and the preparation method comprises the following steps: firstly, dehydrating the alpha, omega-dihydroxy polydimethylsiloxane and the reinforcing filler; and then mixing with the ketoxime type cross-linking agent, the amino silane-epoxy silane copolymer, the coupling agent and the catalyst, and stirring. The silicone sealant provided by the invention meets the requirements of 50-grade sealants in GB / T 14683-2017 Silicone Building Sealants, also has excellent anti-bulging performance, and can well solve the problem that the existing silicone sealant is easy to bulge when being used for aluminum veneer curtain wall joints and the problem that glue joints are easy to shrink and bulge when being used under the condition of large temperature difference.

Owner:广州绿腾新材料有限公司

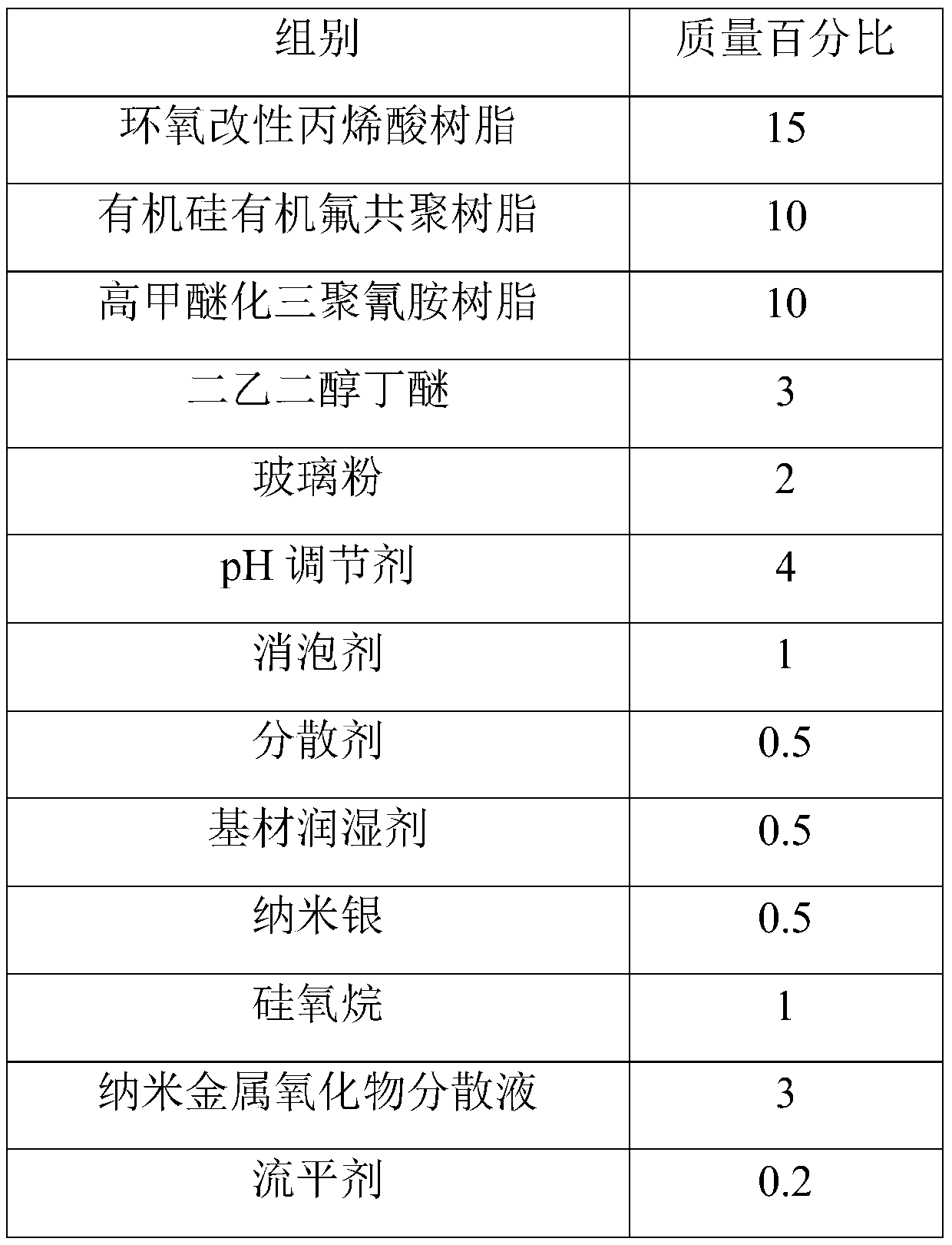

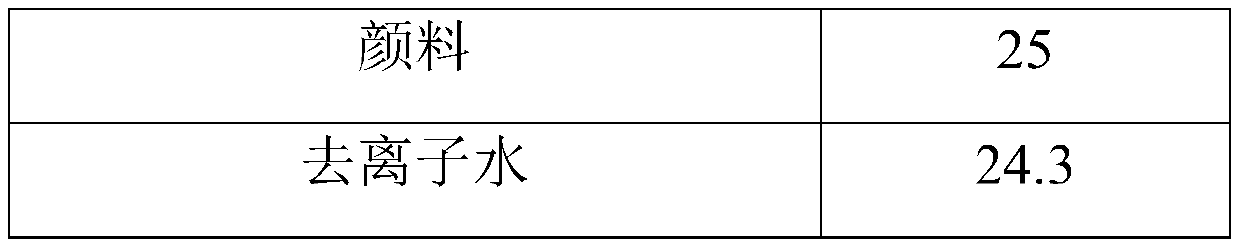

Water-based acrylic amino baking paint and preparation method thereof

InactiveCN110643240AOvercome defectsImprove adhesion strengthAntifouling/underwater paintsPaints with biocidesPolymer scienceWeather resistance

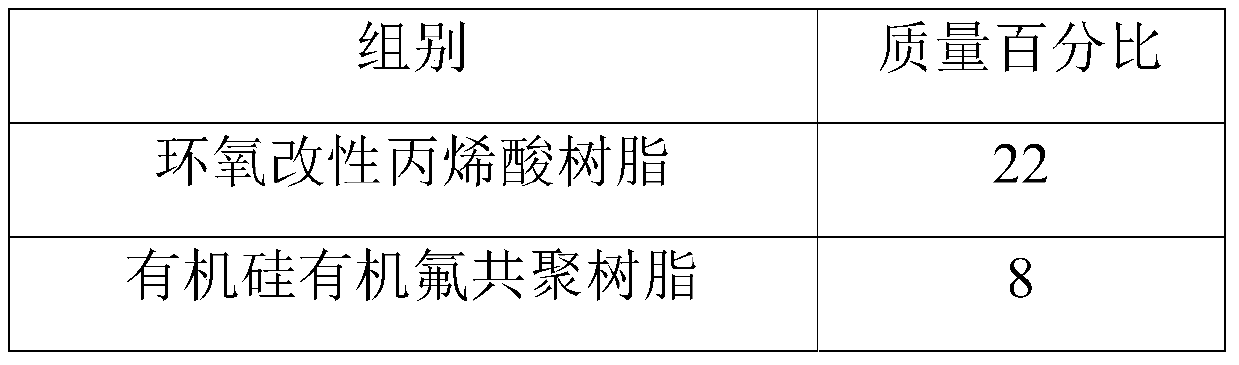

The invention relates to the technical field of coatings, and particularly discloses a water-based acrylic amino baking paint and a preparation method thereof. The water-based acrylic amino baking paint comprises, by mass, 15-30% of an epoxy modified acrylic resin, 5-10% of organic silicon and organic fluorine copolymer resin, 4-10% of high methylated melamine resin, 3-5% of a cosolvent, 2-4% of glass powder, 1-2% of a pH regulator, 0.5-1% of an antifoaming agent, 0.5-1.5% of a dispersant, 0.3-0.5% of a base material wetting agent, 0.5-1% of nano-silver, 1-2% of siloxane, 3-5% of a nanometer metal oxide dispersion, 0.2-0.4% of a leveling agent, 10-25% of a pigment, and the balance of deionized water. The water-based acrylic amino baking paint has the advantages of good wear resistance, strong adhesive force, good water resistance, good weather resistance, good impact resistance, and no sweat retention or bacteria breeding on the surface.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

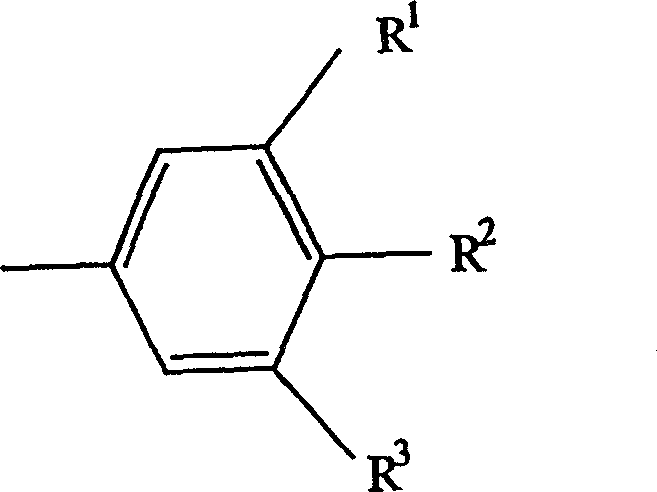

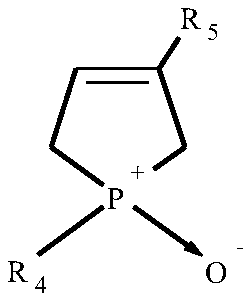

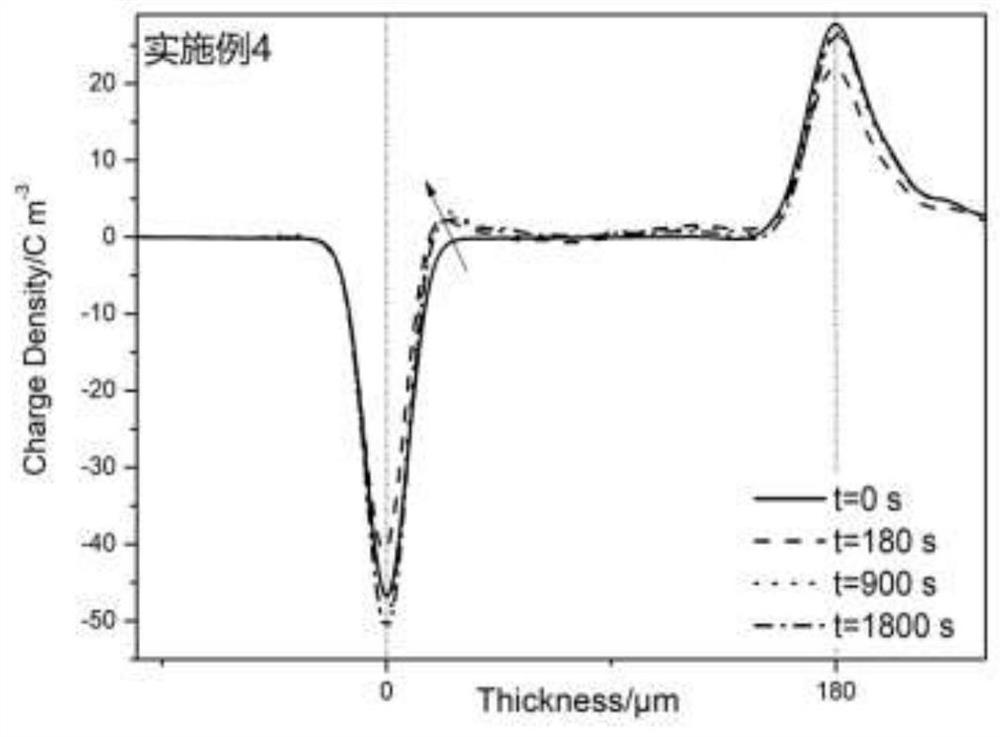

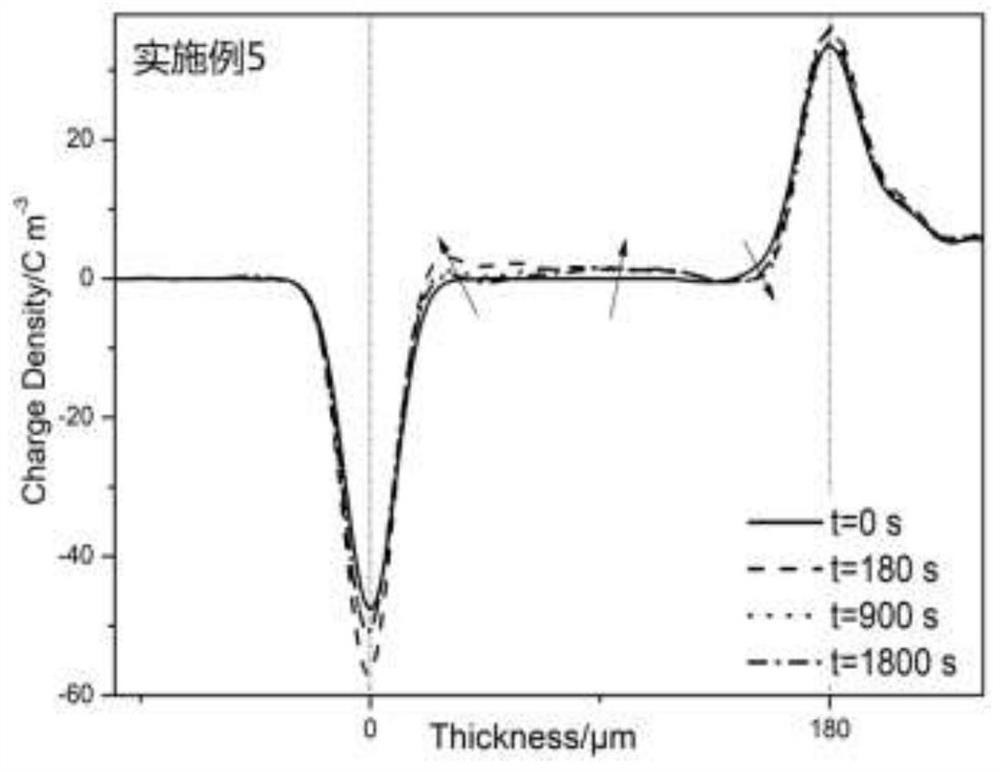

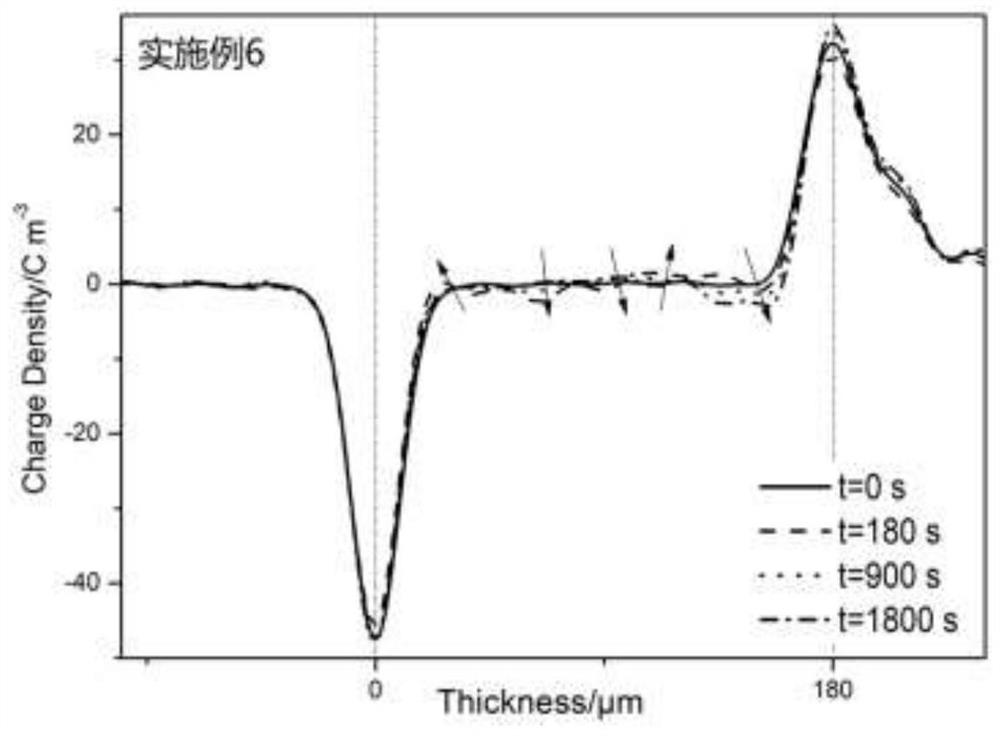

Voltage stabilizer for direct-current/alternating-current high-voltage cable insulation material and preparation method and application thereof

PendingCN113527122AImprove insulation performanceIncrease the degree of cross-linkingOrganic compound preparationCarboxylic acid esters preparationPolymer scienceEngineering

The invention provides a voltage stabilizer for a direct-current / alternating-current high-voltage cable insulation material and a preparation method and application thereof. The voltage stabilizer has a structure as shown in a formula 1, the high-voltage cable insulation material with the voltage stabilizer introduced not only has excellent thermal performance and mechanical performance, but also can remarkably improve the electrical performance, and the crosslinking degree of the cable insulation material can be remarkably improved by adding the voltage stabilizer, the problems of poor compatibility with a base material polyethylene and easy migration can be effectively solved, and the voltage stabilizer is a universal voltage stabilizer with a cross-linking effect.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

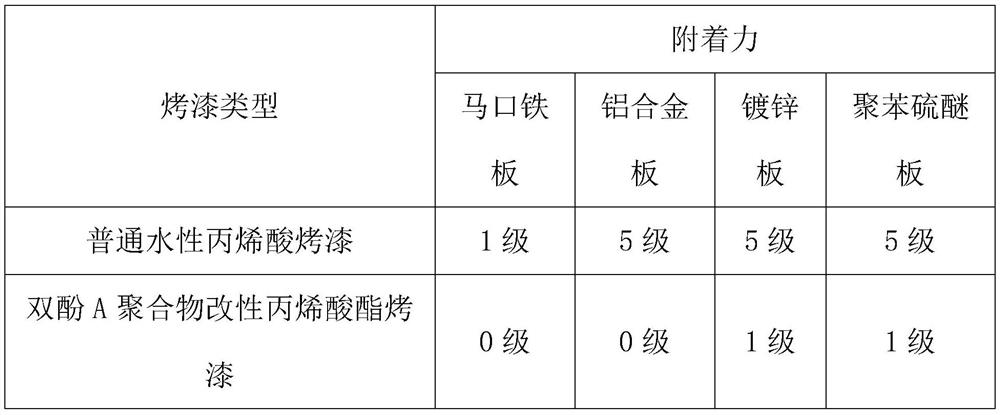

Bisphenol A polymer modified polyacrylate water-based baking varnish and preparation method thereof

The invention relates to a water-based primer, in particular to bisphenol A polymer modified polyacrylate water-based stoving varnish, and the varnish is prepared from the following raw materials in parts by weight: 55 parts of matrix resin, 5 parts of N-ethyl morpholine, 3 parts of carbon black, 0.3 part of BYK-190, 0.25 part of BYK-028, 0.2 part of BYK-348, 11 parts of cyan CYMEL 325 amino resin and 25.25 parts of purified water. The novel water-based stoving varnish provided by the invention not only has the performance and low price of the existing water-based acrylic stoving varnish, but also has better adhesive force on most of non-ferrous metals and part of non-metals.

Owner:泉州市三星精细化工有限公司

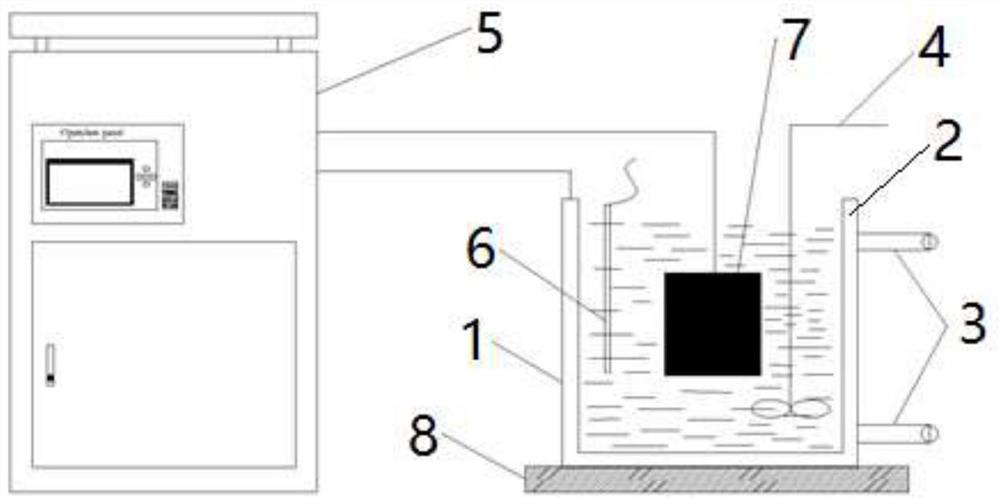

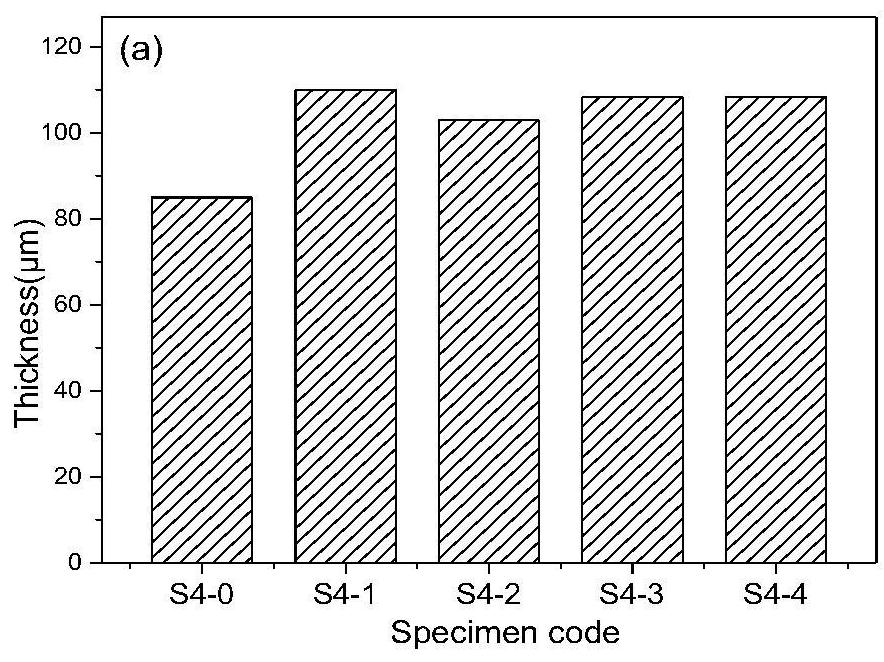

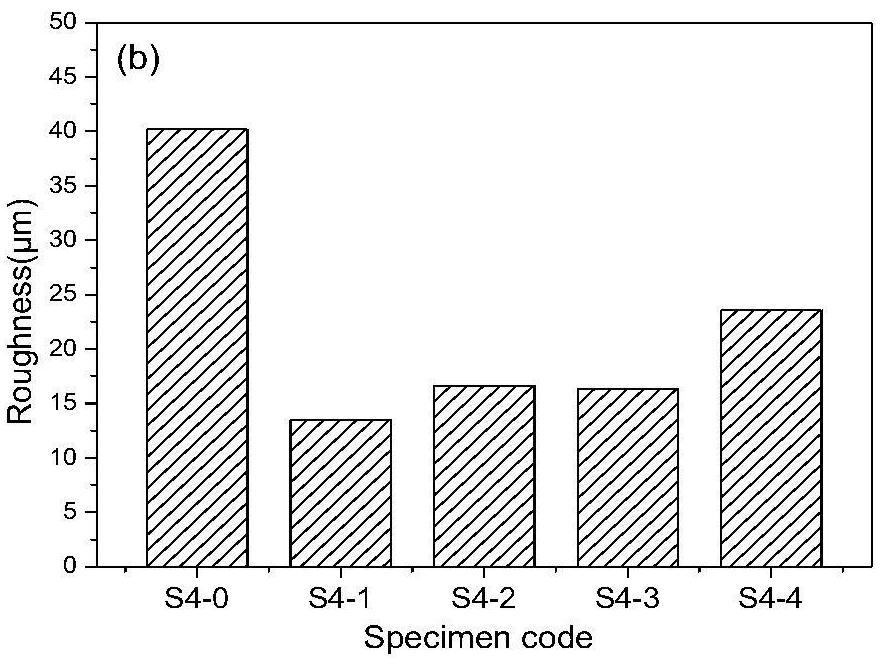

Method of Adding Zirconium Carbonate to Electrolyte to Improve Wear Resistance of Micro-arc Oxidation Film on Near-α Titanium Alloy

ActiveCN112030210BSmall diameterContribute to lossSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention discloses a method for adding zirconium carbonate to an electrolyte to improve the wear resistance of a near-alpha titanium alloy micro-arc oxidation film, comprising the following steps: (1) pretreatment of a near-alpha titanium alloy sample; (2) preparation of a micro-arc oxidation electrolyte ; (3) Micro-arc oxidation treatment. Zirconium carbonate is added to the electrolyte, and zirconium carbonate is gradually decomposed under the action of high temperature and high pressure of micro-arc oxidation to produce H 2 O.CO 2 and ZrO 2 , CO 2 The creation of more small discharge holes while the gas overflows helps the excess heat generated by the micro-arc oxidation to dissipate, and the growth rate of the micro-arc oxidation film layer increases; ZrO 2 It can enter the film layer by means of adsorption and engagement to fill the discharge holes and cracks, and disperse and distribute in the discharge holes and surface depressions to form effective filling, so that the diameter of the discharge holes is reduced, the roughness of the film layer is reduced, and the compactness is improved.

Owner:INNER MONGOLIA UNIV OF TECH

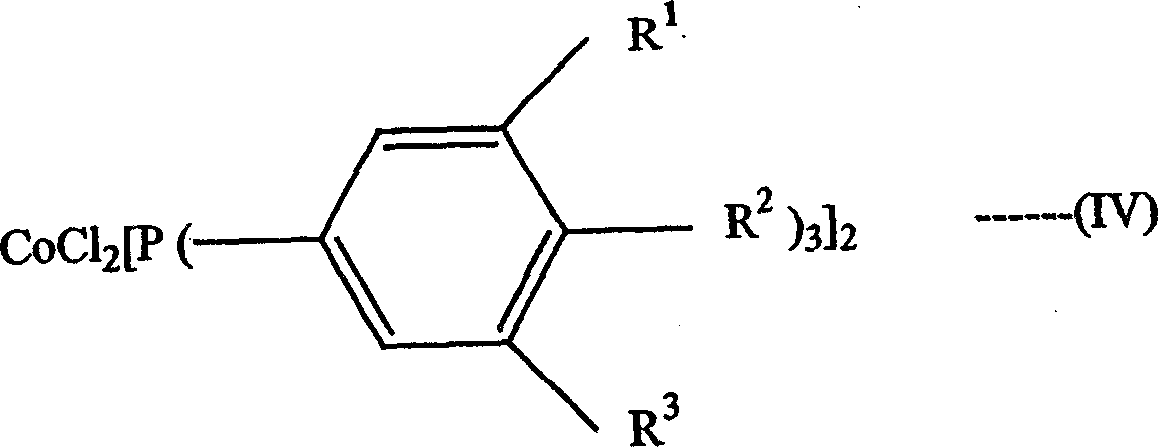

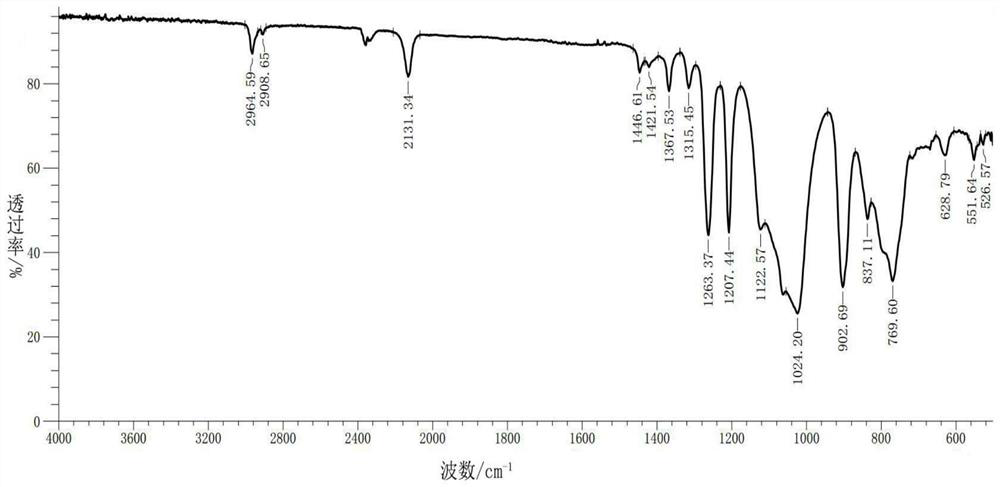

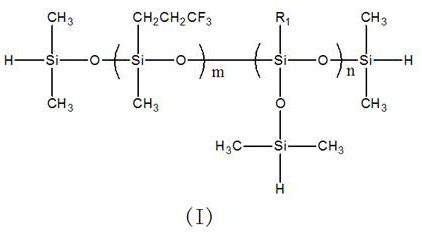

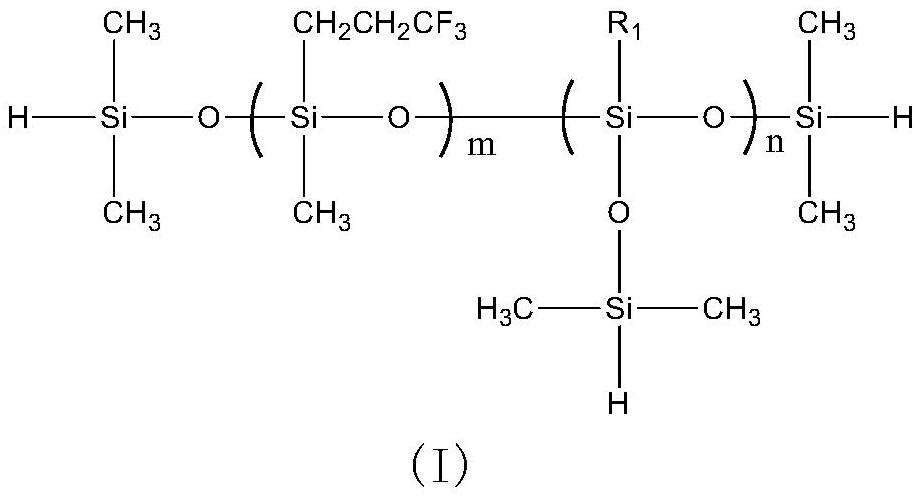

A kind of highly active hydrofluorosilicone oil crosslinking agent and preparation method thereof

Owner:威海新元新材料有限公司 +1

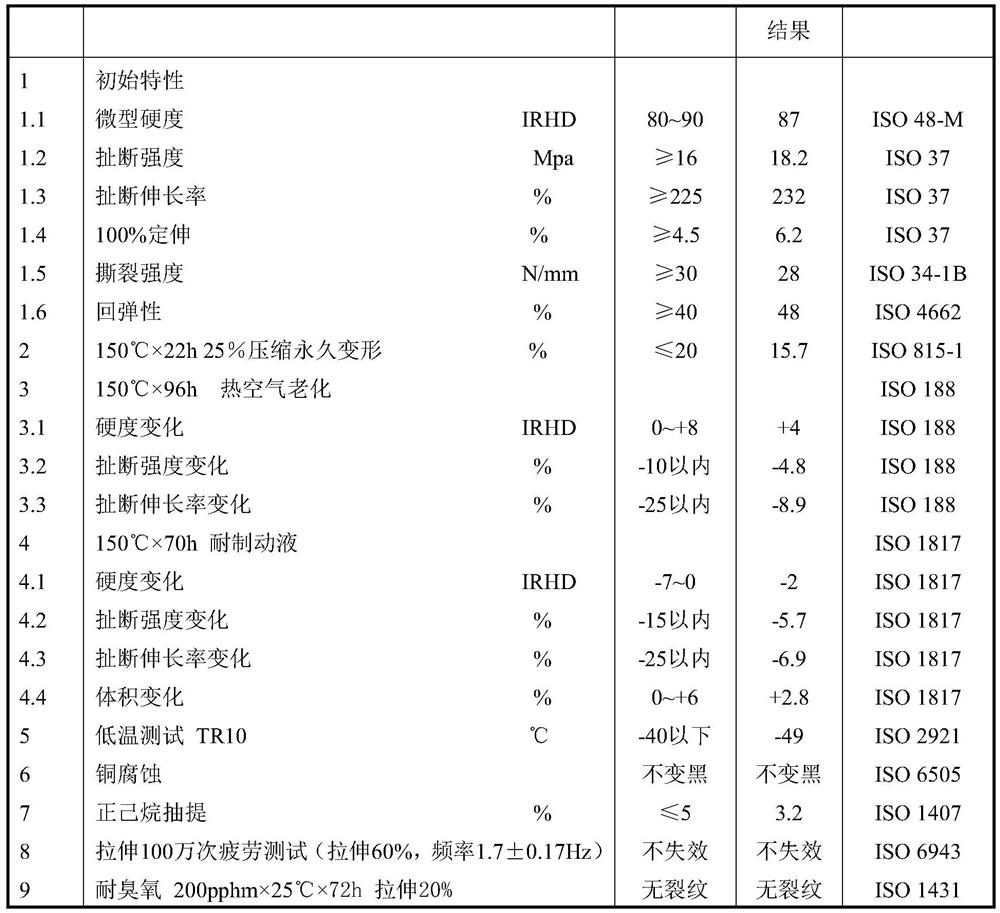

Air valve material for automobile electronic vehicle stability control system, and preparation method of air valve

The invention discloses an air valve material for an automobile electronic vehicle stability control system, and a preparation method of an air valve. The material comprises, by weight, 100 parts of ethylene propylene diene monomer, 5-10 parts of a thermoplastic elastomer, 3-5 parts of zinc oxide, 50-70 parts of furnace black, 5-15 parts of white carbon black, 1-3 parts of a processing aid, 1-2 parts of an anti-aging agent, 2.5-3.5 parts of a peroxide vulcanizing agent and 0.1-0.2 part of sulfur. The air valve material is good in compression set, good in flexibility, excellent in high and lowtemperature resistance, wear resistance and tear resistance, the preparation method is simple in process and high in production efficiency, and the obtained air valve is stable in performance, high in% of pass and long in service life, and can enhance the sealing performance and sensitivity of the automobile electronic vehicle stability control system.

Owner:DATWYLER SEALING TECH ANHUI

A kind of high temperature stable coated sand

InactiveCN110586847BGood compatibilityImprove tensile propertiesFoundry mouldsFoundry coresStearic acidNanoparti cles

The invention discloses high-temperature stable precoated sand, and belongs to the field of casting materials. Polylactic acid, lanthanum stearate and the like are used as raw materials, and are combined with subsequent nanoparticle effects for mutual connection to form space netty structures with nanometer microholes so as to improve the forming effect of the precoated sand. Three types of nanoparticles are used as nanomaterials for ultrasonic dispersion and acid mixing effects to improve the dispersion effect; and through adding of nanometer TiO2, a lot of plastic deformation energy can be absorbed when the external pressure effect is suffered, so that the softness of the prepared precoated sand is improved, the shell mold flexibility is improved, and the high-temperature pressure strength is improved. In the mixing process, through coaction between inorganic-organic components, compact air separation layers are formed in the precoated sand, and the influence on the internal of the precoated sand can be reduced when high-temperature effect is suffered. The high-temperature stable precoated sand solves the problems of easy unshelling and agglomeration of traditional precoated sandin the preparation process due to lower high-temperature pressure strength of the traditional precoated sand.

Owner:青铜峡市瑞通支撑剂有限公司

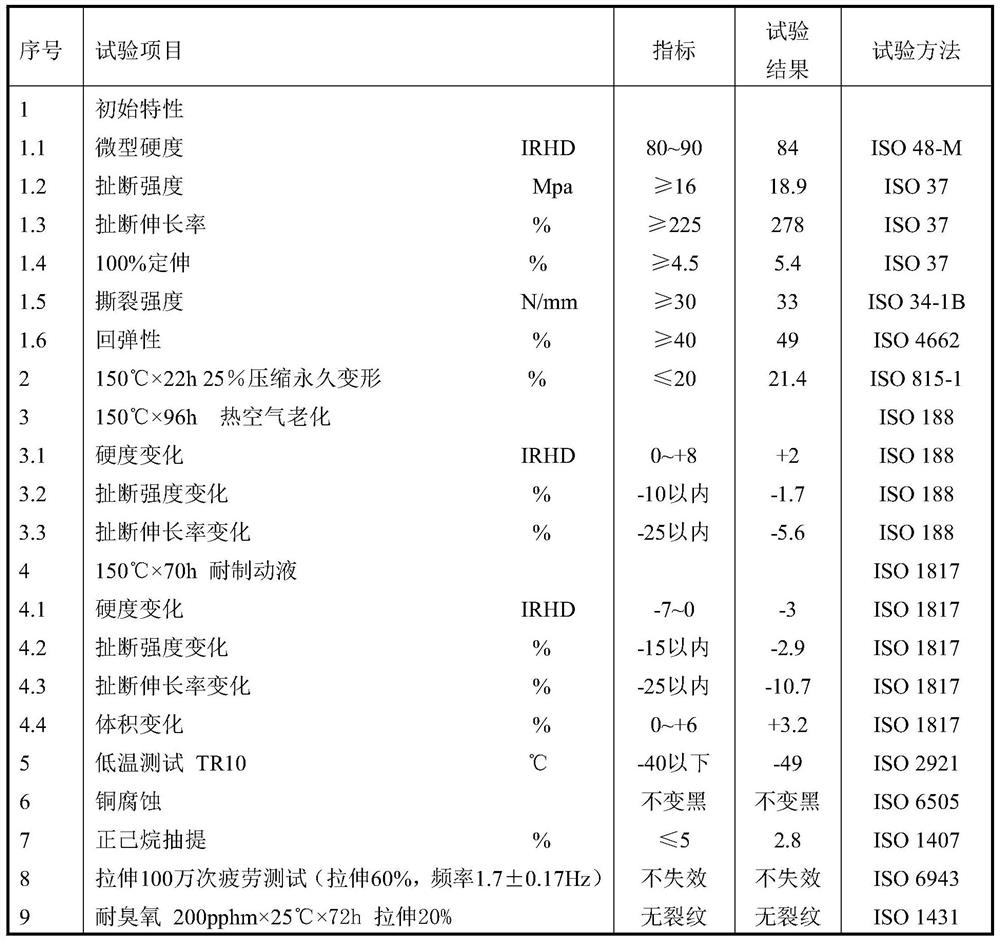

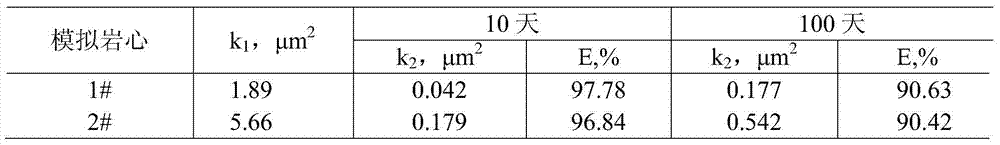

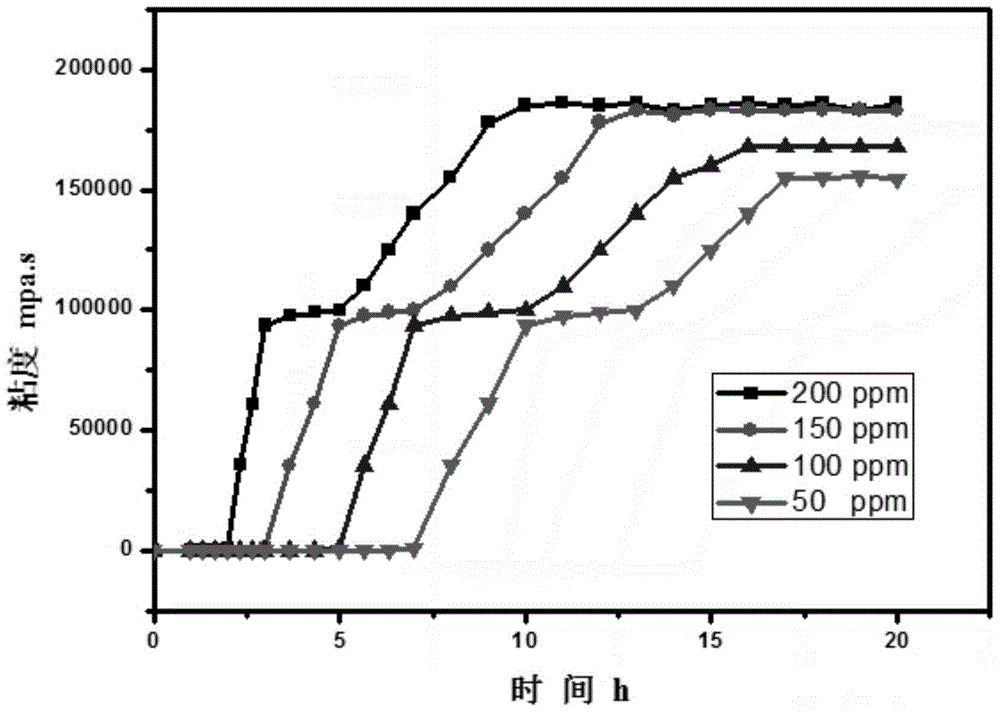

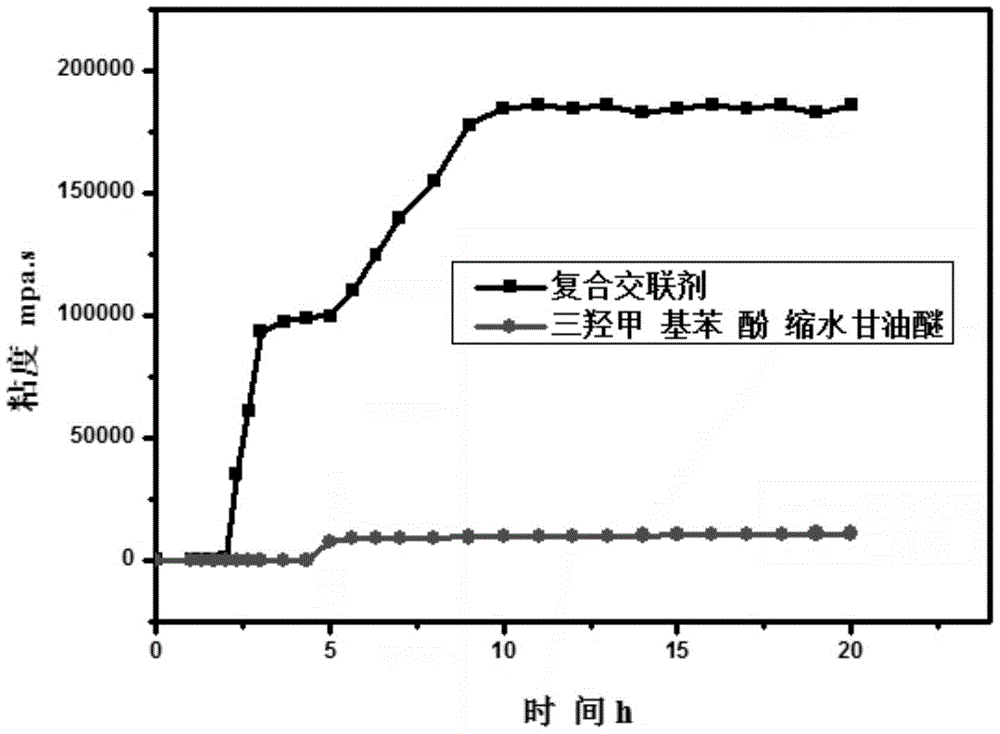

A temperature-resistant and salt-resistant jelly with low cross-linking agent dosage

The invention provides a temperature-resistant and salt-resistant jelly with a low cross-linking agent dosage. The mass percentage of the jelly is composed as follows: acrylamide / 2-acrylamide-2-methylpropanesulfonic acid copolymer 0.6%-1.2% , resorcinol 0.02%~0.04%, polyethyleneimine 0.02%~0.05%, paraformaldehyde 0.02%~0.04%, alkoxysilane 0.03%~0.1%, thiourea 0.2%~0.4%, balance It is water, the sum of each component is 100%, the salinity of the water is 22.4×104 mg / L, and the content of calcium and magnesium ions is 1.3×104 mg / L. The dosage of the jelly cross-linking agent provided by the invention is not more than 0.1%, and there is no phenomenon of gel breaking after aging for 100 days under the condition of 130° C., and the performance of temperature and salt resistance is excellent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of paper wet strength agent and preparation method thereof

InactiveCN103362032BSimple preparation processShort manufacturing timeReinforcing agents additionPaper/cardboardEpoxyDiethylenetriamine

The invention discloses a paper wet strength agent and a preparation method thereof. By weight, the paper wet strength agent comprises: 100 parts of adipic acid; 15-40 parts of diethylenetriamine; and 20-80 parts of an active diluent. The preparation method includes: (1) mixing the diethylenetriamine, the adipic acid and the active diluents in proportion, and subjecting the mixture to a polycondensation reaction so as to obtain a polyamide polyamine epoxy polymer; and (2) mixing the polyamide polyamine epoxy polymer with deionized water, adjusting the pH value and the solid content, thus obtaining the paper wet strength agent. The paper wet strength agent provided in the invention realizes zero discharge of organic chlorine and is environmentally friendly. The method disclosed in the invention has the advantages of simple operation and low cost, thus being suitable for industrialized production.

Owner:ZHEJIANG HEXIN TECH

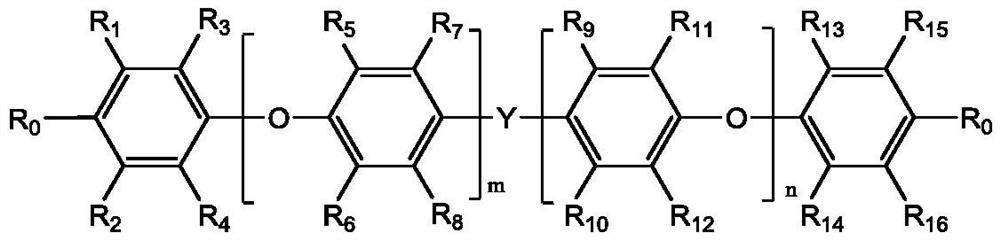

Modified polyphenyl ether resin, polyphenyl ether composite material, preparation method thereof and printed circuit board

PendingCN112708128AHigh glass transition temperatureHigh thermal decomposition temperaturePrinted circuit aspectsCircuit susbtrate materialsEndcappingPolymer science

The invention relates to modified polyphenyl ether resin, a polyphenyl ether composite material, a preparation method of the polyphenyl ether composite material and a printed circuit board. The modified polyphenyl ether resin has the structural characteristics shown in the specification. The modified polyphenyl ether resin adopts a phosphorus-containing group only containing one benzene ring or not containing one benzene ring as an end-capping group, and can be crosslinked to form a polyphenyl ether composite material with good flame retardancy and heat resistance, good mechanical properties, low dielectric constant and low dielectric loss.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

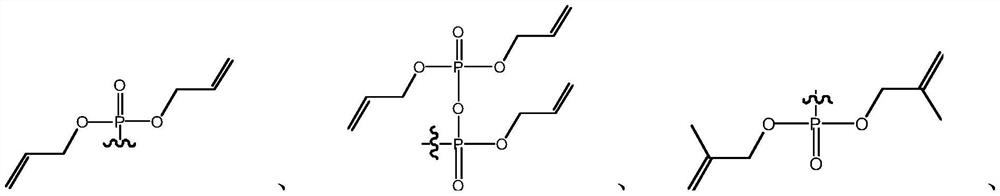

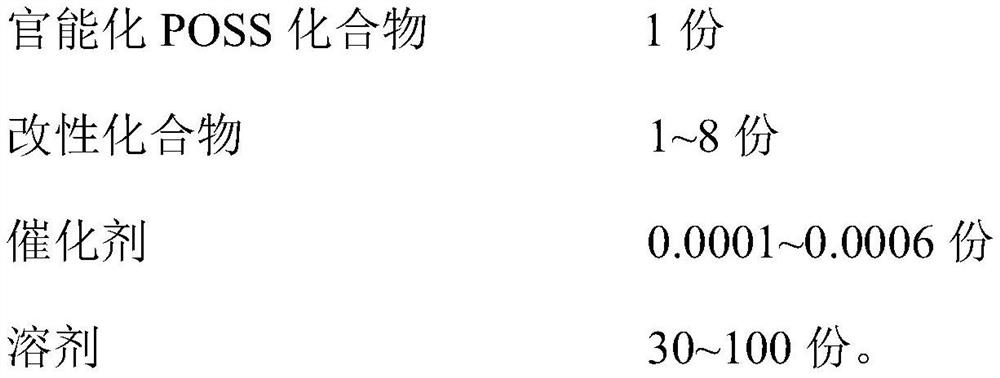

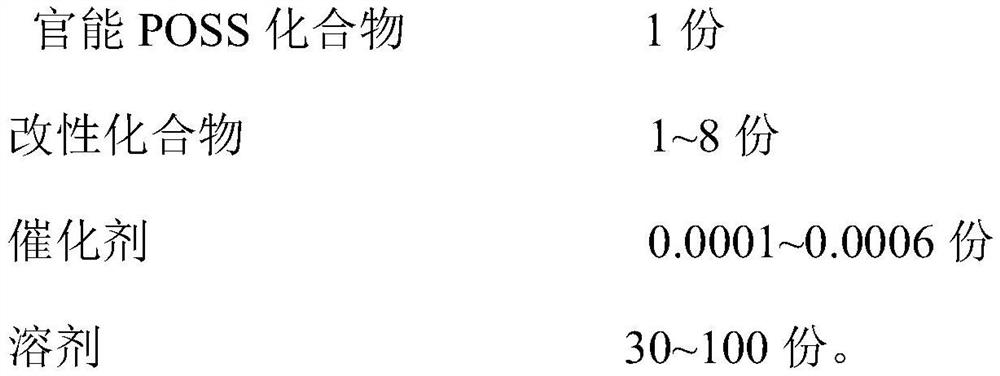

Polymer cross-linking agent based on polyhedral oligomeric silsesquioxane structure

PendingCN114437355AImprove physical and chemical propertiesImprove performanceSilicon organic compoundsPolymer scienceCross linker

The invention relates to a polyhedral oligomeric silsesquioxane (POSS) structure-based polymer cross-linking agent, which belongs to the field of polymer cross-linking agents and comprises the following components in parts by weight: 1 part of a functionalized POSS compound, 1-8 parts of a modified compound, 0.0001-0.0006 part of a catalyst and 30-100 parts of a solvent. The preparation method of the polymer cross-linking agent based on the polyhedral oligomeric silsesquioxane structure comprises the following steps: preparation of a functionalized POSS pre-reaction solution and synthesis of a POSS-based cross-linking agent. The cross-linking agent disclosed by the invention takes POSS as a core, contains active groups such as a silicon hydrogen group, a carbon-carbon double bond and an epoxy group, and can be used as a cross-linking or modifying agent of various polymer materials; the cross-linking agent is high in cross-linking activity, a POSS structure can be introduced into a polymer, a three-dimensional network with POSS as a cross-linking core is formed, and the comprehensive performance of a polymer material is remarkably improved; the preparation process is simple, the operation is convenient, the product is safe and environment-friendly, and the industrialization prospect is good.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

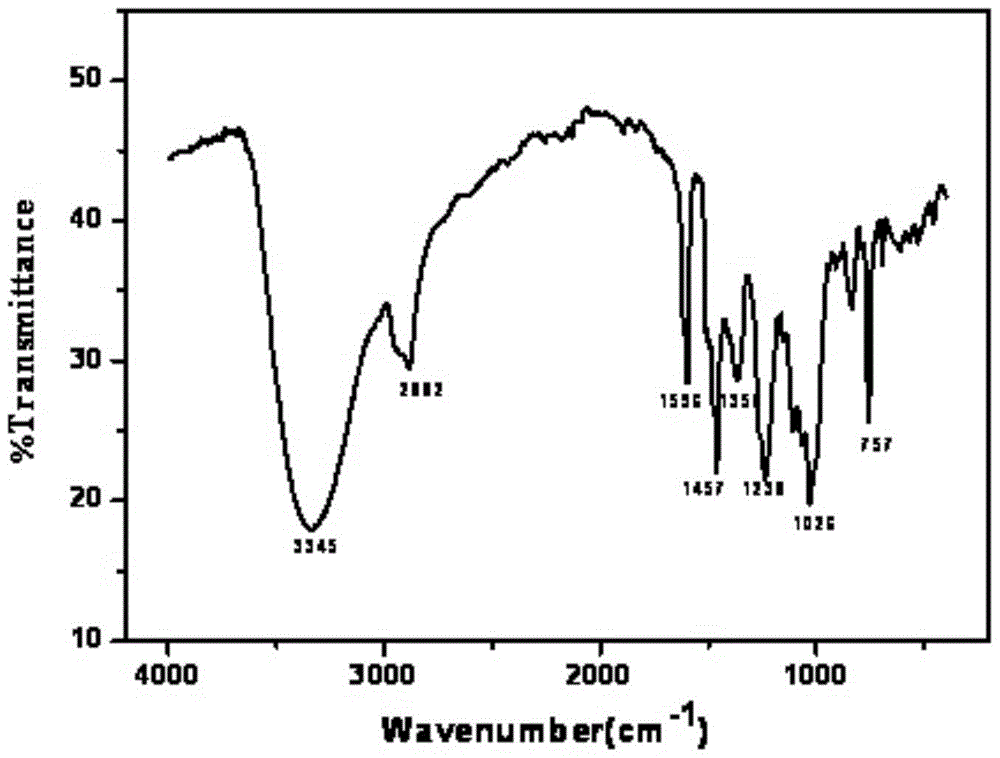

A kind of preparation method of crosslinking agent and crosslinking controllable high temperature resistant gel

InactiveCN103641798BGood water solubilityHigh cross-linking activityOrganic chemistryEthylenediamineTemperature resistance

The invention discloses a crosslinking agent and a preparation method of a crosslinking controllable high-temperature-resistant gel. The crosslinking agent is prepared through the synthetic steps of sequentially adding phenol and a formaldehyde solution into a reaction kettle in a weight ratio of 1:(3.0-3.1), uniformly stirring the obtained mixture, adding an ethylenediamine catalyst into the reaction kettle, and heating the obtained mixture in an oil bath at a temperature of 65-70 DEG C; in the process of reaction, detecting and observing the mixture by using the TLC (Thin-Layer Chromatography), and when trimethylol phenol is completely generated, sequentially adding hexadecyl trimethyl ammonium chloride, epichlorohydrin and a NaOH solution into the reaction kettle; heating the obtained product to 90 DEG C, and reacting for 2 hours. The gel is prepared from the following components in percentage by mass: (1) 0.2-0.7% of polyacrylamide; (2) 0.2-0.6% of a crosslinking agent, namely trimethylolpropane triglycidyl ether; (3) 50-200 ppm of a polyamine crosslinking promoter; (4) the balance of water. According to the invention, the crosslinking agent, namely trimethylolpropane triglycidyl ether, and the polyamine crosslinking promoter are introduced into a gel system for the first time, and the crosslinking promoter can effectively adjust the crosslinking time and promote the gel for further crosslinking so as to increase the strength of the gel, so that a gel which is controllable in crosslinking time, high in strength and high in temperature resistance is obtained.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Dibutyltin dilaurate catalyzes the method for synthesizing methoxyxime ketone silane

ActiveCN103833783BLight colorHigh cross-linking activityGroup 4/14 element organic compoundsPolymer scienceDibutyl tin dilaurate

The invention discloses a method for synthesizing methoxyssilane under catalysis of dibutyltin dilaurate, and relates to the cross-linking field. The method comprises the following steps of adding 1 part of tetramethoxysilane, 0.2-2.5 parts of diacetylmonoxime and 0.0005-0.005 part of dibutyltin dilaurate in parts by weight to a reaction kettle with a gaseous-phase extraction device, stirring for reacting for 3-7 hours under the condition that the temperature in the reaction kettle is in the range from 121 DEG C to 129 DEG C and then obtaining a product to be distilled, distilling the product to be distilled under the conditions of a temperature ranging from 100 DEG C to 120 DEG C and pressure ranging from -0.095 MPa to -0.098MPa, and then obtaining a methoxyssilane compound. According to the method, the dibutyltin dilaurate can be taken as a catalyst for molding silicone rubber by vulcanizing at the room temperature, and also can be left in the reaction products after the reaction is completed, and the reaction steps are quite simple; the tetramethoxysilane is taken as the raw material of the method so that the synthesis cost of the method is quite low.

Owner:湖北新蓝天新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com