Thermosetting polyimide with high glass transition temperature and high heat resistance, and preparation method thereof

A technology with high transition temperature and high vitrification, which is applied in the field of polymer materials to achieve the effects of small steric hindrance, good cross-linking effect, and increased glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

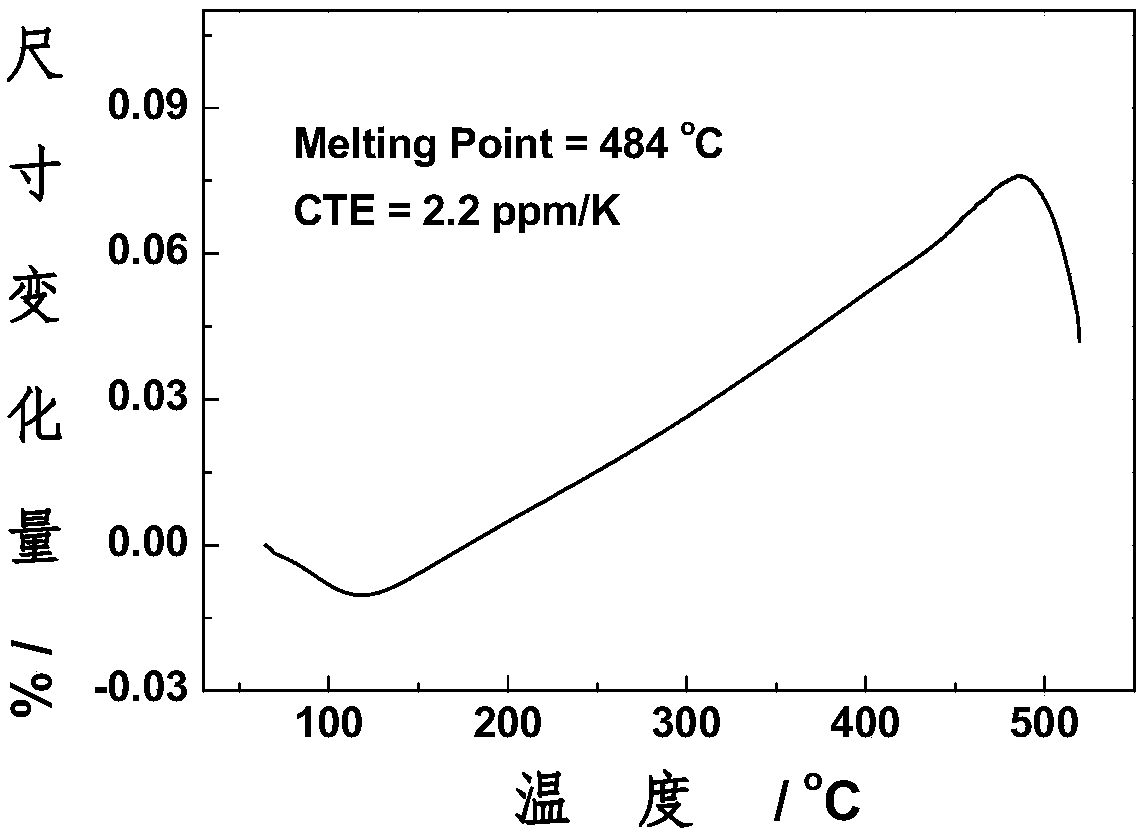

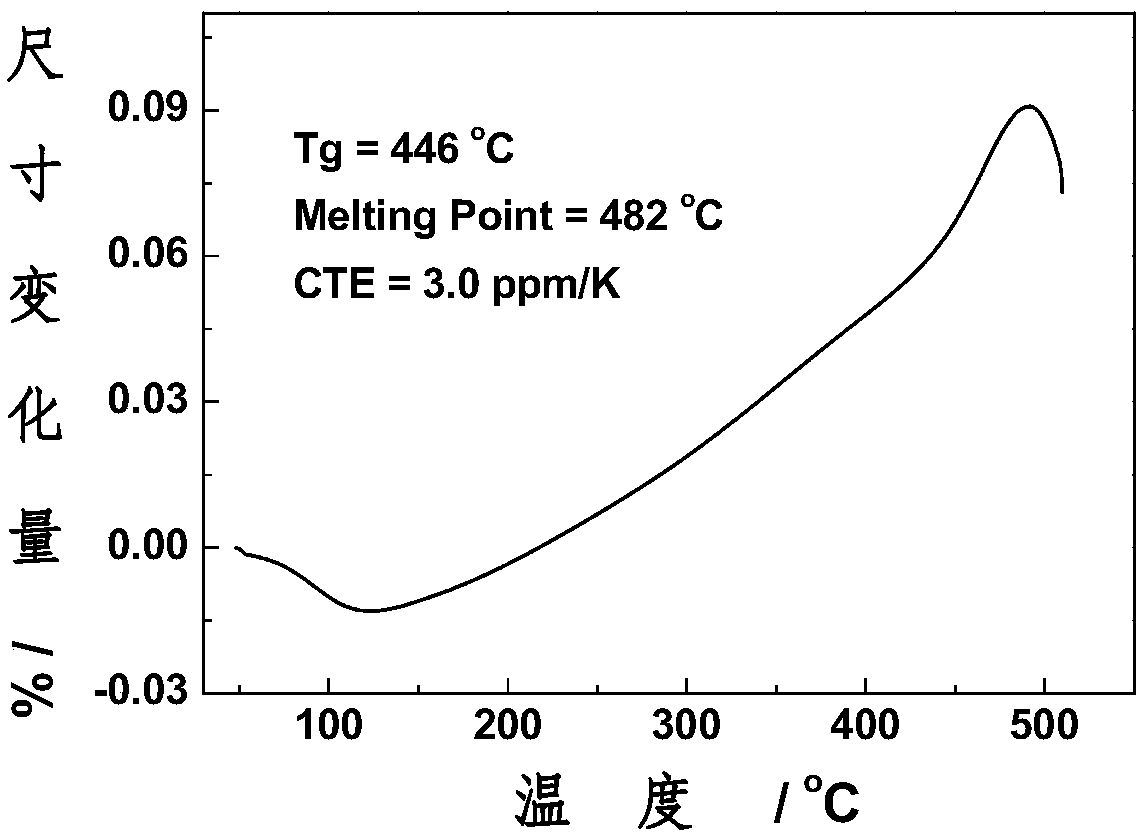

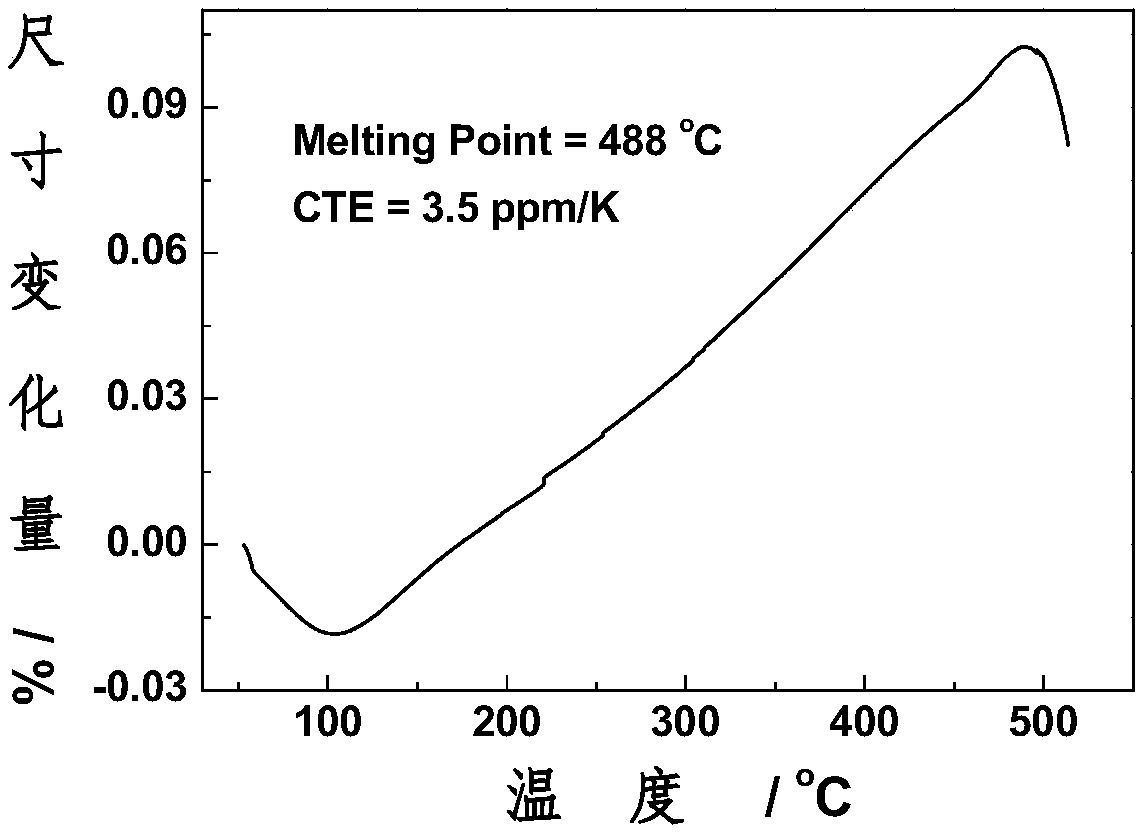

Image

Examples

Embodiment 1-20

[0057] [Polyimide A-T] was prepared according to the input amount of raw materials in Table 1 and the following experimental procedures:

[0058] Under a nitrogen atmosphere, in a 100mL three-necked flask, dissolve the quantitative aromatic diamine compounds shown in Table 1 in 40g of a strong polar solvent (such as NMP) while stirring, so that the mass of the aromatic diamine compounds The percentage is 5%-10%. Then add the quantitative 4,4'-(acetylene-1,2-diyl) diphthalic anhydride shown in Table 1, and add the quantitative aromatic tetracarboxylic dianhydride compounds shown in Table 1 three times at the same time. They are respectively 60%, 30%, and 10% of the total weight. During the process of stirring and adding, control the temperature of the solution at 60-80°C. Afterwards, it was stirred for 24-48h under a nitrogen atmosphere for amic acid reaction.

[0059] After the above reaction is completed, reduce the temperature of the reaction solution below 40°C. Afterwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com