Method for preparing alkoxymethyl furfural by catalyzing 5-hydroxymethylfurfural

A technology of alkoxymethylfurfural and hydroxymethylfurfural, which is used in the preparation of fuel or fuel additives, the preparation of functionalized graphene catalysts, and the preparation of alkoxymethylfurfural ethers, which can solve the problem of alkoxymethylfurfural Furfural difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

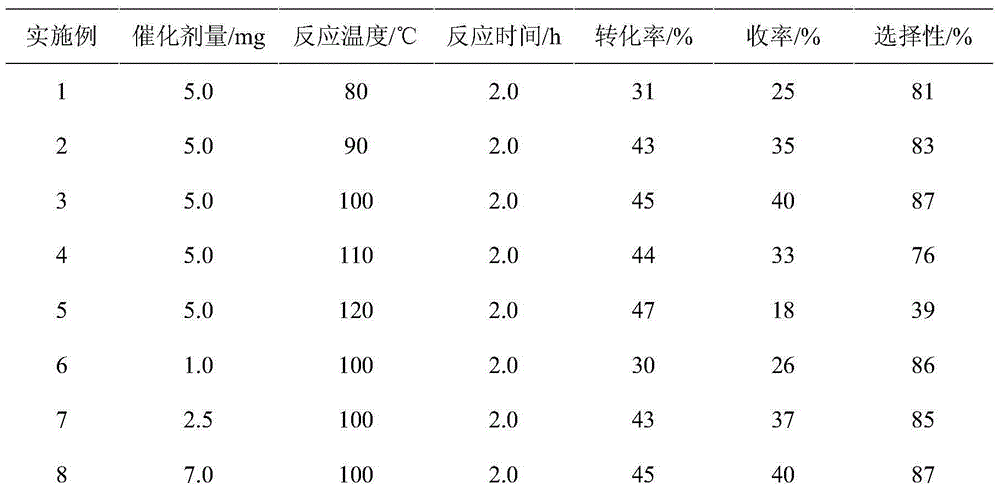

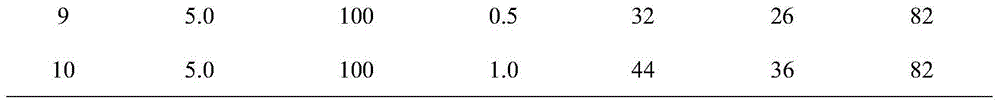

Examples

preparation example Construction

[0020] 1. Preparation of catalyst

[0021] 1. Graphene

[0022] The carrier of the functionalized graphene catalyst is graphene, which can be prepared by chemical methods, such as oxidative intercalation method combined with ultrasonic separation or thermal expansion method to prepare graphene oxide from flake graphite, and then prepare graphene oxide into graphite by a certain reduction method alkene. For the detailed synthesis method, see N.I. Kovtyukhova et al., the method adopted in (Chem. Mater., 1999, 11, 771–778). Of course, commercially available graphene can also be directly used.

[0023] 2. Sulfonated graphene

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com