Patents

Literature

383 results about "5-hydroxymethylfurfural" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201AAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

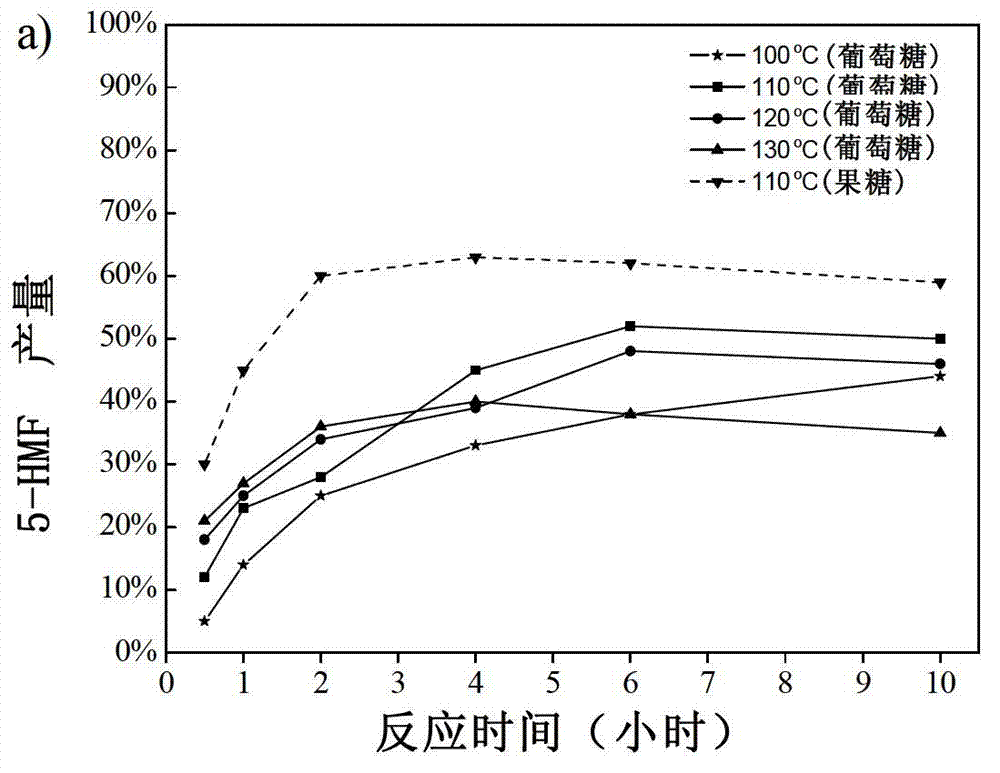

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

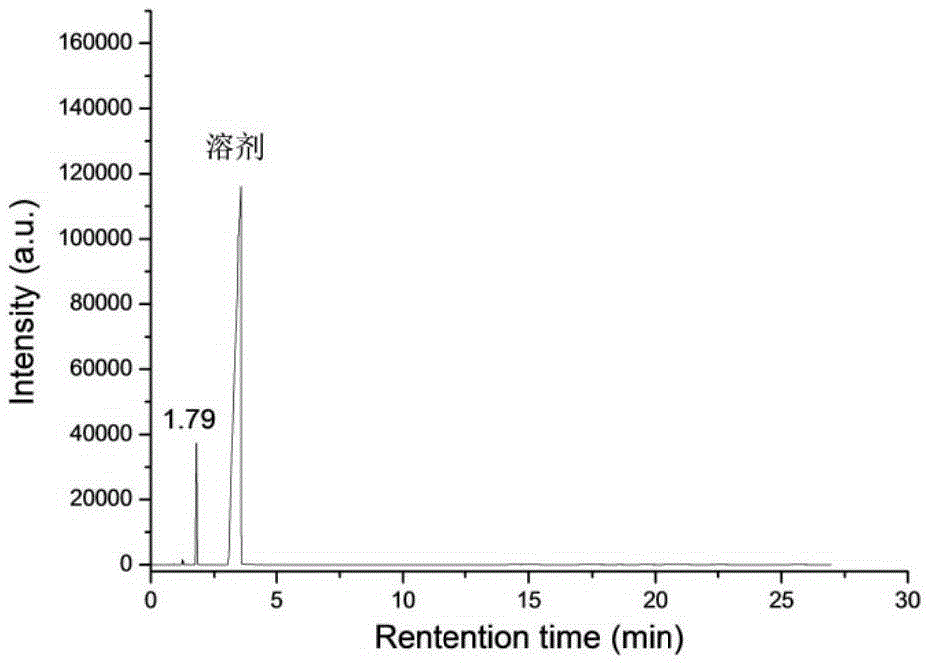

Method for preparing 2,5-diformylfuran by oxidizing 5-hydroxymethylfurfural

ActiveCN101987839AReduce dosageLow pricePhysical/chemical process catalystsOrganic chemistryOxygenHydroxymethylfurfural

The invention discloses a method for preparing 2,5-diformylfuran by selectively oxidizing 5-hydroxymethylfurfural in the presence of a catalyst. In the method, oxygen or air is used as an oxygen source, the catalyst is a composite catalyst system a composite catalyst system consisting of vanadium oxide and an auxiliary agent, and at the temperature of between 20 and 120 DEG C, the 5-hydroxymethylfurfural is selectively oxidized into the 2,5-diformylfuran. The method has high oxidation efficiency and high product yield; the catalyst is cheap and readily available; the reaction conditions are mild; the product is easy to separate and purify; and the purity of the product is over 99 percent. Therefore, the method has bright application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

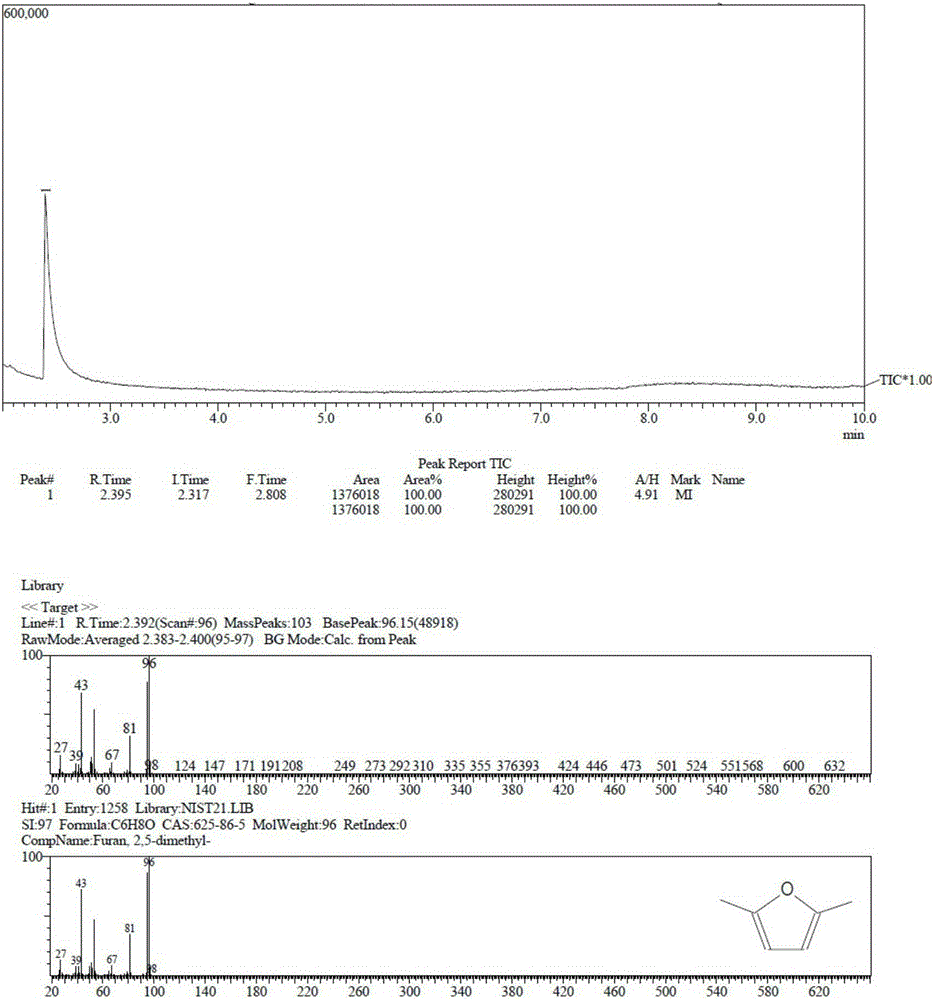

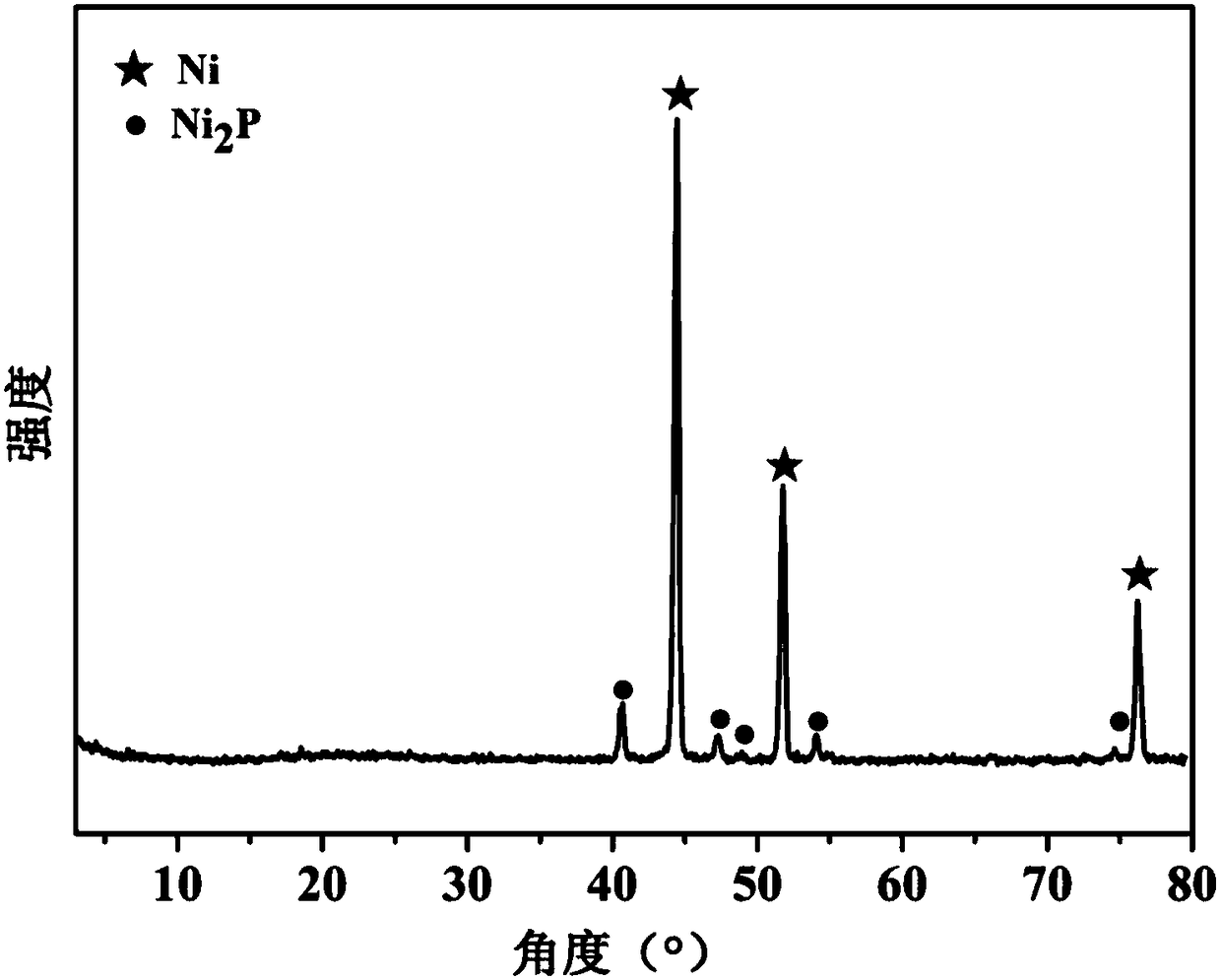

Catalyst for preparing 2,5-dimethylfuran through selective hydrogenolysis of 5-hydroxymethylfurfural and preparation method of catalyst

ActiveCN105251491ALow costPlay a protective roleOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCarbon layerHydroxymethylfurfural

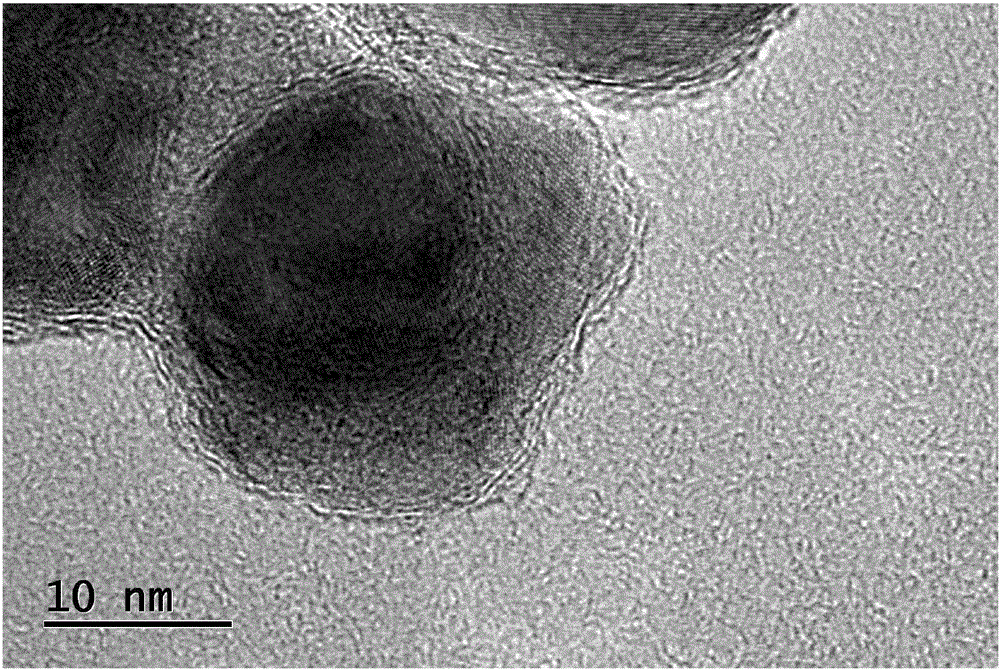

The invention discloses a catalyst for preparing 2,5-dimethylfuran through selective hydrogenolysis of 5-hydroxymethylfurfural and a preparation method of the catalyst. The catalyst consists of a catalyst carrier and carbon layer coated reactive metals, wherein the catalyst carrier comprises a carbon-based carrier, SiO2, TiO2 or Al2O3 and the like; and the reactive metals are selected from Co, Fe, Ni, Cu or Zn and other base metals. Compared with the conventional catalyst system, the catalyst disclosed by the invention has the advantages that (1) the reactive metal of the catalyst refers to a first transition metal, and the raw materials are cheap and readily available; (2) compared with a noble metal catalyst, the catalyst disclosed by the invention has extremely high activity and selectivity; and (3) the catalyst has magnetism and is easy to recycle.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Catalyst for synthesizing 5-hydroxymethylfurfural by hexose dehydration and method for synthesizing 5-hydroxymethylfurfural

InactiveCN101811066AEnables a clean synthesis processHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventHydroxymethylfurfural

The invention discloses a catalyst for synthesizing 5-hydroxymethylfurfural by hexose dehydration and a method for synthesizing the 5-hydroxymethylfurfural by using the catalyst. The catalyst consists of iron halide and ammonium halide, and the molar ratio of the iron halide to the ammonium halide is 0.1 to 10. The synthesizing method comprises the following steps: dissolving a reaction substrate into a solvent, adding the catalyst consisting of the iron halide and the ammonium halide into the solution, reacting the solution for 0.5 hour at the temperature of between 0 and 200 DEG C, distilling and condensing the solution, performing extraction, distilling the concentrate under reduced pressure, drying the distillate and collecting a product. The catalyst of the invention overcomes the defects that the catalyst in the prior art has large toxicity and the catalytic reaction needs a large amount of organic solvent and additive. The catalyst totally shows the characteristic of a homogeneous catalyst in the reaction process, and has high catalytic activity and high selectivity; and the using amount of the catalyst can be optimized to trace so as to facilitate the separation and purification of the reaction product. The catalyst has the advantages of simple reaction system, environment friendliness, low toxicity, low production cost and easy post treatment.

Owner:TIANJIN UNIV

Method for the synthesis of organic acid esters of 5-hydroxymethylfurfural and their use

Method for the manufacture of organic acid esters of 5-hydroxymethylfurfural by reacting a fructose or glucose-containing starting material with an organic acid or its anhydride in the presence of a catalytic or sub-stoechiometric amount of solid acid catalyst. The catalysts are heterogeneous and may be employed in a continuous flow fixed bed reactor. The esters can be applied as a fuel or fuel additive.

Owner:FURANIX TECH BV

Three-dimensional multi-level structure type high-dispersion nickel-based electro-catalytic material and preparation method thereof

ActiveCN108554413AAffects catalytic performanceUnique structural featuresCatalyst activation/preparationElectrolytic organic productionLevel structureIon exchange

The invention provides a three-dimensional multi-level structure type high-dispersion nickel-based electro-catalytic material and a preparation method thereof. The method takes foam nickel as a conducting matrix and a nickel source needed by reaction is provided; urea is used as a precipitating agent, ammonium fluoride is used as an etching agent and an NiAl-LDH / / NF precursor grows on the surfaceof a foam nickel framework structure in situ; negative ions including H2PO4<-> and B(OH)4<-> are introduced into hydrotalcite layers through an ion exchanging method; a hydrotalcite intermediate containing the negative ions is reduced at high temperature to obtain the three-dimensional multi-level structure type high-dispersion nickel-based electro-catalytic material; a chemical formula is NiY-Al2O3 / NF, wherein Y is one of P or B. The material is used for electro-catalytic oxygen evolution reaction under an alkaline condition; when the current density reaches 10mA.cm<-2>, the overpotential ofthe oxygen evolution reaction is 270 to 190mV. When the material is used for carrying out selective electro-catalytic oxidization reaction on 5-hydroxymethylfurfural under the alkaline condition, theconversion rate and the selectively reach 92 to 100 percent and 95 to 100 percent respectively, and the invention proves that the material is suitable for being used as the electro-catalytic material.

Owner:BEIJING UNIV OF CHEM TECH

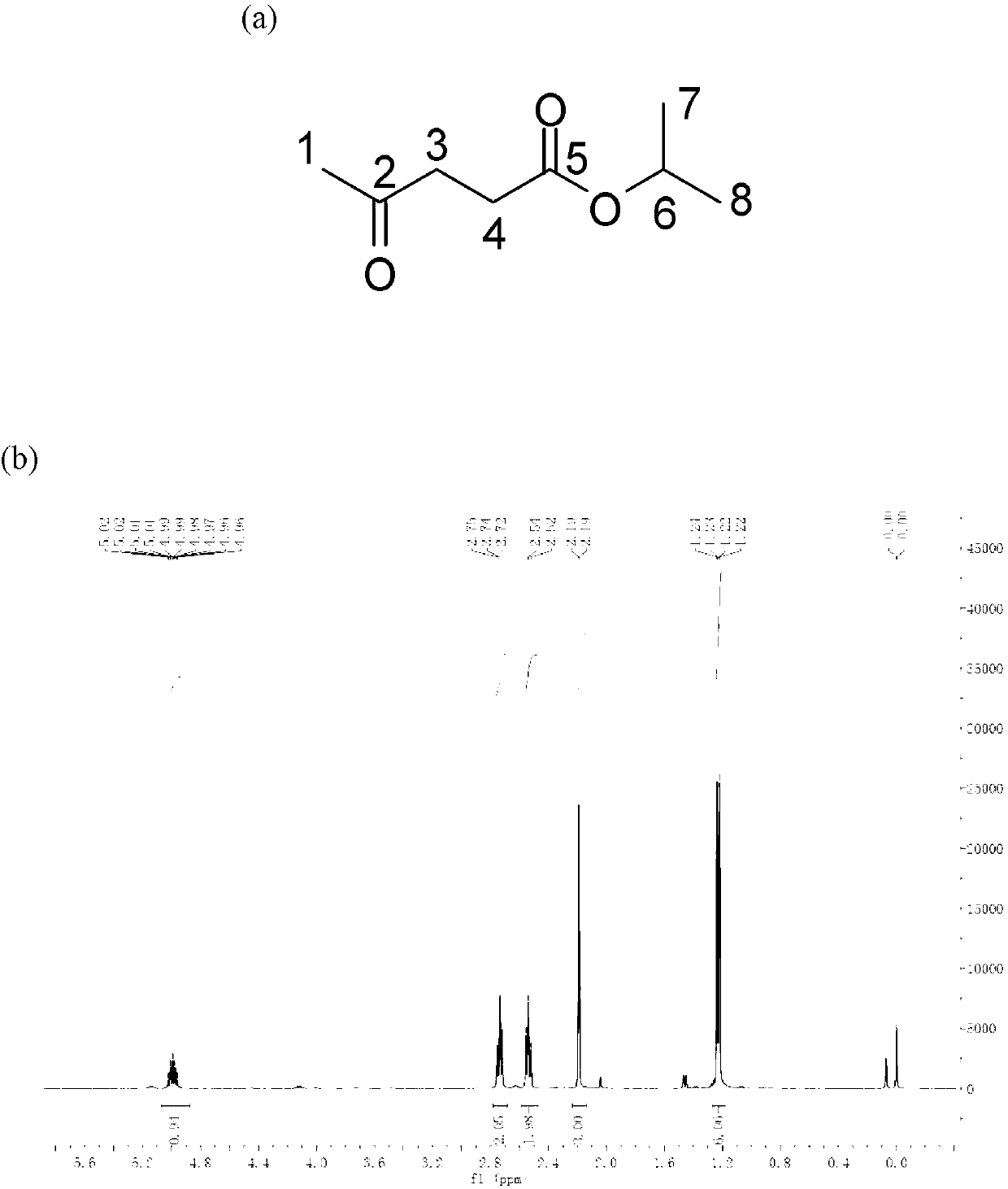

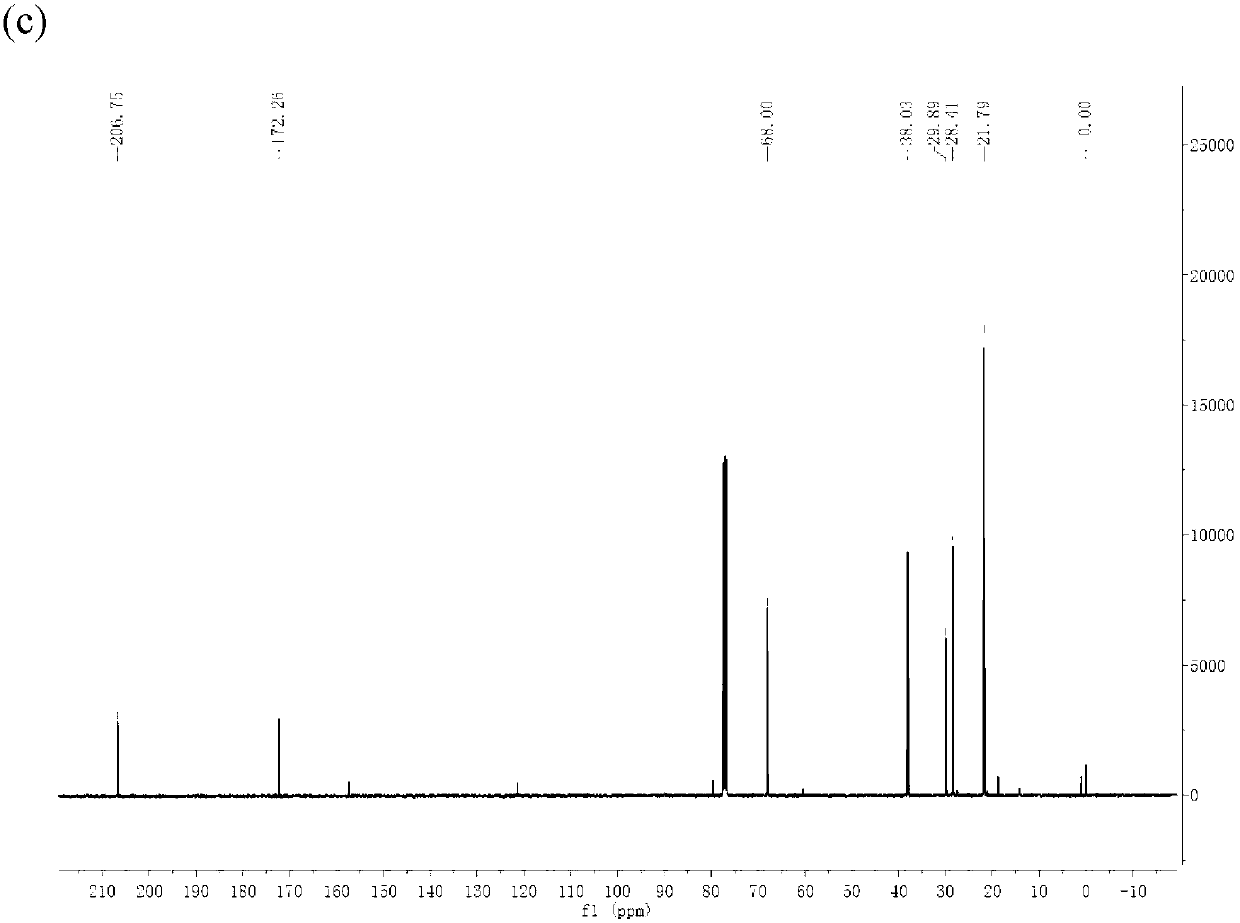

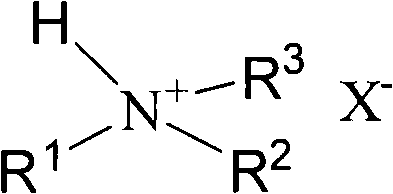

Method for preparing gamma-valerolactone with high selectivity under mild condition

The invention relates to a method for preparing gamma-valerolactone with high selectivity under the mild condition. The method comprises the following steps of: under the conditions of optimal room temperature and inert gas, with secondary alcohol as a hydrogen source and active Raney nickel as a catalyst, carrying out hydrogen transfer reaction on a levulinic acid ester compound to obtain the gamma-valerolactone. The invention particularly relates to a method of preparing gamma-valerolactone by a lignocellulose derivative with high selectivity under the mild condition, which comprises the following steps of: carrying out alcoholysis reaction on the lignocellulose derivative such as fructose, 5-hydroxymethylfurfural or furfuryl alcohol by a solid acid catalyst in the presence of an alcohol solvent at certain temperature, filtering solid acid, collecting liquid, and obtaining levulinic acid esters through reduced pressure distillation; and with the secondary alcohol as the hydrogen source, catalyzing the obtained esters by Raney Ni as a non-noble metal catalyst at the room temperature to obtain the gamma-valerolactone with high yield.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing 5-hydroxymethylfurfural

InactiveCN101906088AAvoid corrosionHigh selectivityOrganic chemistryRoom temperatureCatalytic effect

The invention discloses a method for preparing 5-hydroxymethylfurfural (HMF), which comprises the following steps of: mixing a biomass sugar source and an ammonium salt which can form a low eutectic mixture together with the biomass sugar source, reacting the mixture at the temperature of between 60 and 180 DEG C, and cooling the reaction product to room temperature after the reaction is finishedto obtain a target product. In order to ensure that the catalytic effect of the ammonium salt is not affected by temperature, a catalyst can be added to promote the reaction. The highest yield of themethod can reach 70 percent. The method has the advantages of high selectivity, mild condition, high reaction speed, low cost, simple process, environment friendliness, no need of catalyst, environment-friendly process and the like. The invention provides a new method for industrially producing the HMF from the biomass sugar.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +2

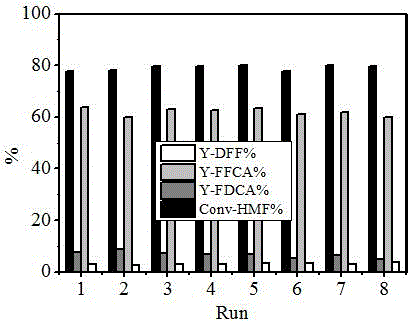

Method for preparing 2, 5-furandicarboxylic acid by conducting catalytic oxidation on 5-hydroxymethylfurfural

The invention relates to a method for preparing 2, 5-furandicarboxylic acid (FDCA) by conducting catalytic oxidation on a biomass derivative, namely 5-hydroxymethylfurfural (HMF) and belongs to the field of preparing renewable chemicals through synthesis of biomass and derivatives. The method comprises the steps that non-noble-metal, namely cerium-based composite oxide, is utilized as a catalyst; oxygen or air serves as an oxidizing agent; and effective catalytic oxidation is conducted on the 5-hydroxymethylfurfural for synthesizing the 2, 5-furandicarboxylic acid. The method is easy to operate and mild in condition; the yield of the 2, 5-furandicarboxylic acid can reach 86.7% at a maximum; in addition, the catalyst is easy to separate and recycle and good in reusability; and good industrialized application prospect is achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

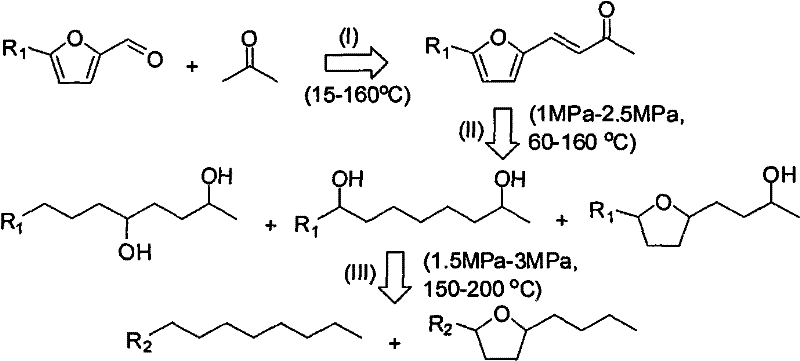

A new catalytic technique for the preparation of long-chain alkanes from biomass derivatives furfural or hmf

The invention relates to a new catalytic technology for preparing long-chain alkanes from biomass derivative furfural or 5-hydroxymethylfurfural (HMF), which can produce octane and nonane with high selectivity, as well as a small amount of tridecane and deca The pentane solves the problems of harsh conditions and low alkane selectivity in the process of preparing fuel from biomass derivatives. Using biomass derivatives furfural or HMF as raw materials, by designing new catalysts and new reaction pathways, an overall process and catalyst system for the preparation of long-chain alkanes from biomass derivatives furfural or HMF is proposed. The outstanding feature is that the reaction conditions are mild, Alkanes are more selective.

Owner:EAST CHINA UNIV OF SCI & TECH

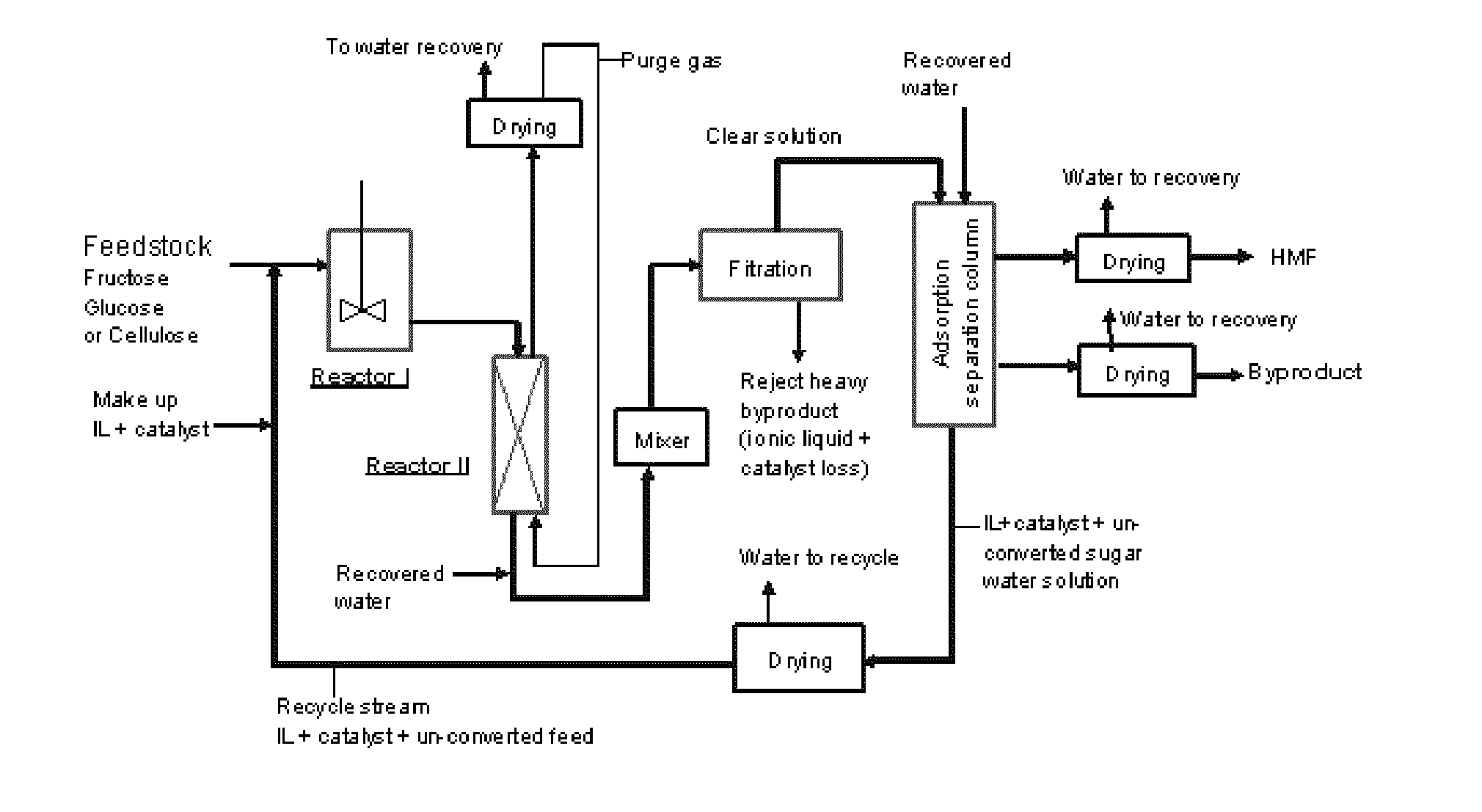

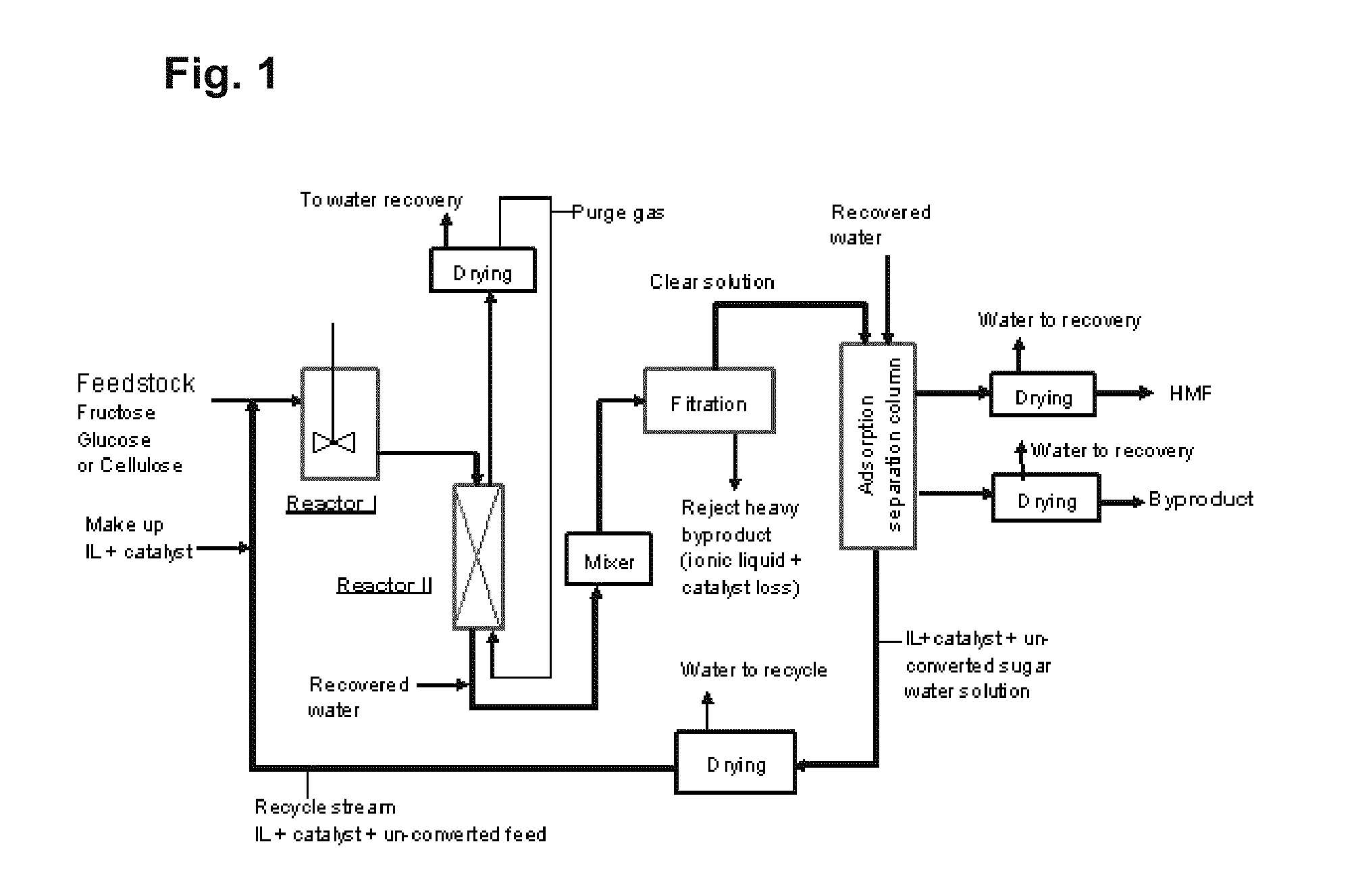

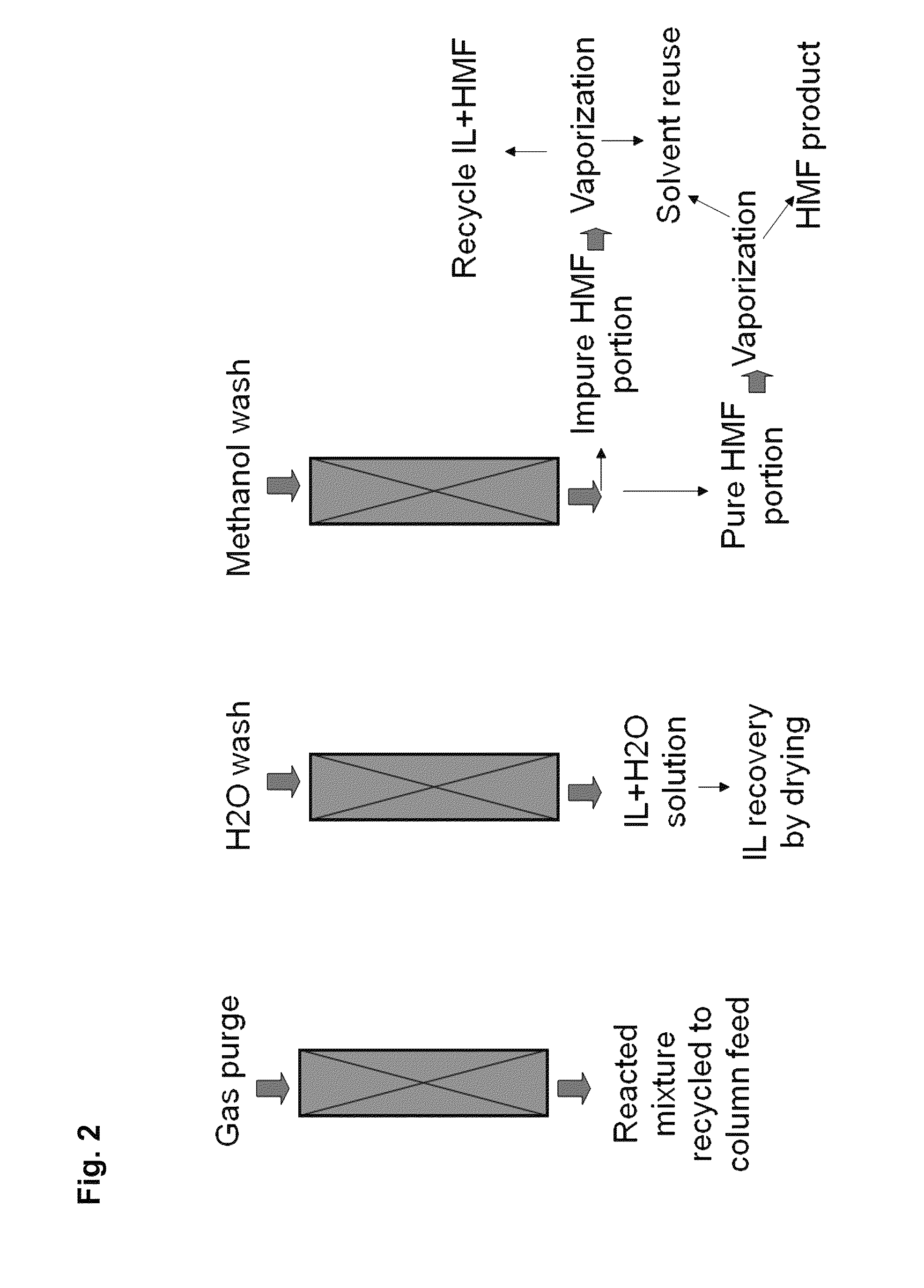

Adsorption separation processes for ionic liquid catalytic processes

Presently disclosed are methods and apparatus for separation of reaction products from reaction mixtures in an ionic liquid catalysis process, particularly in conversion of biomass, cellulose, and sugars into chemical intermediates such as 5-hydroxymethylfurfural (HMF). In one embodiment an ion exclusion adsorption mechanism is used for the separation process. The process comprises (i) mixing the ionic liquid-containing reaction mixture with de-ionized water, (ii) flowing the water solution mixture into an adsorption column, (iii) eluting the column with a water- and / or alcohol-based fluid, and (iv) collecting separated fractions at different elution times.

Owner:BATTELLE MEMORIAL INST

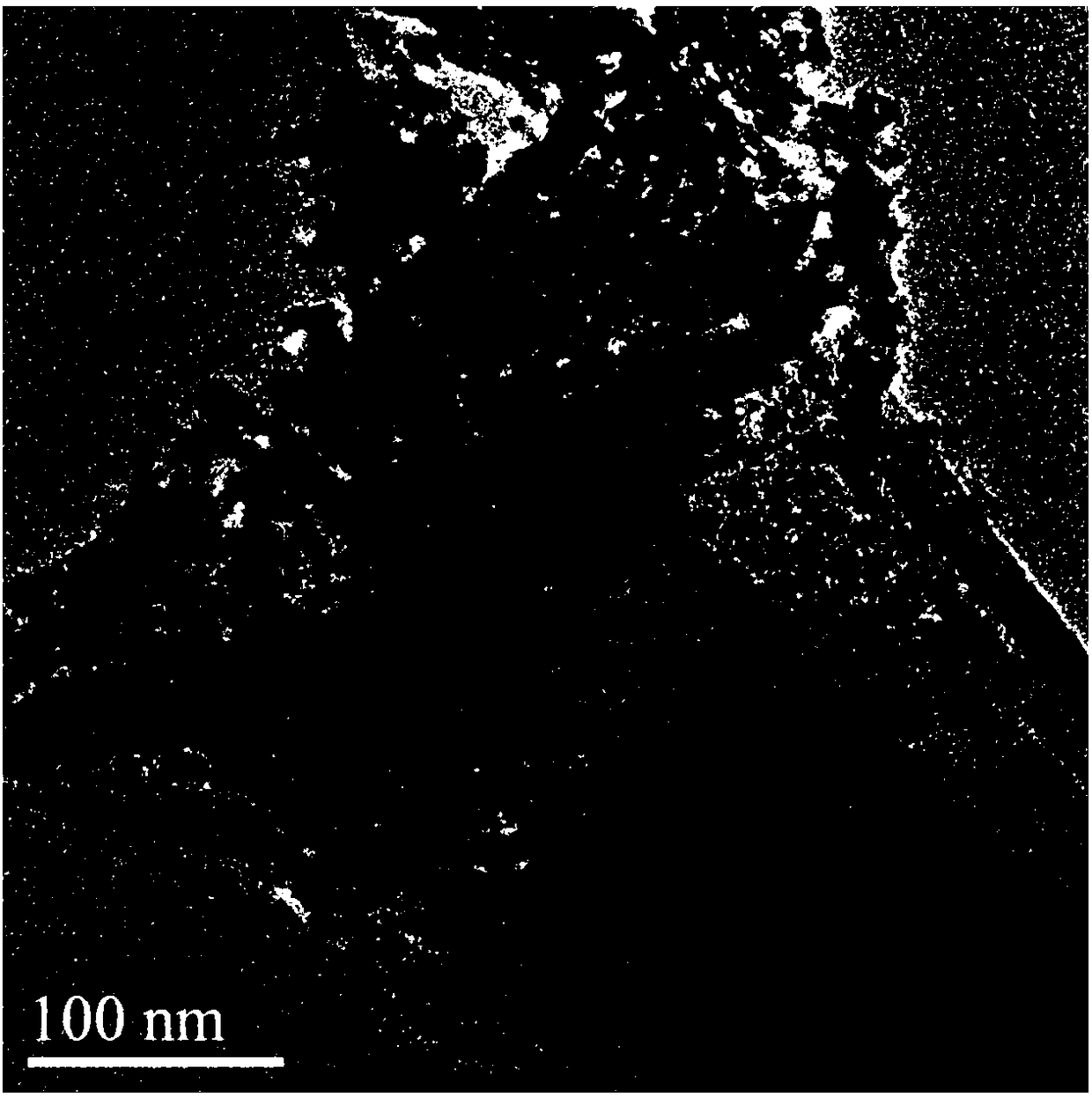

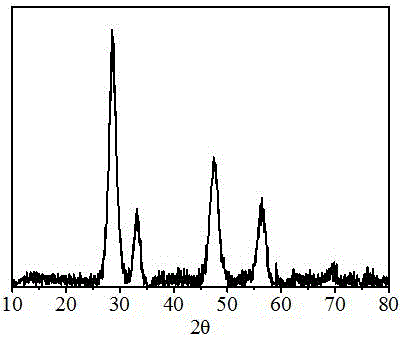

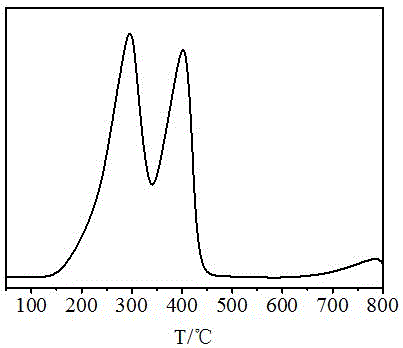

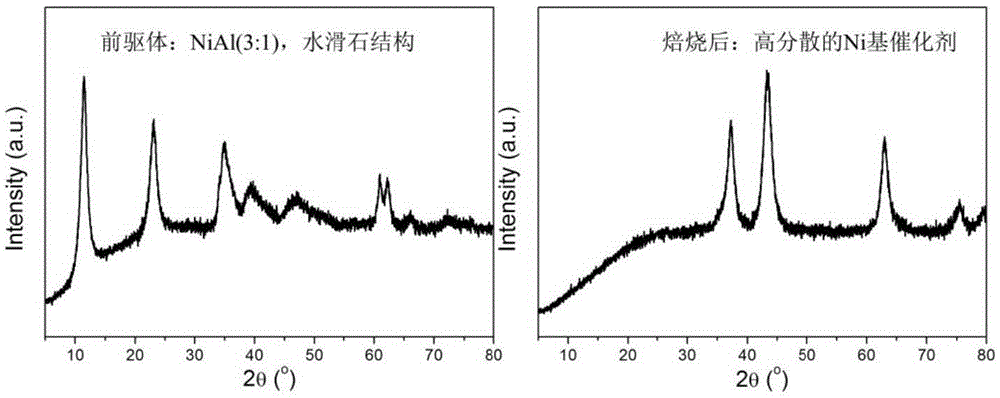

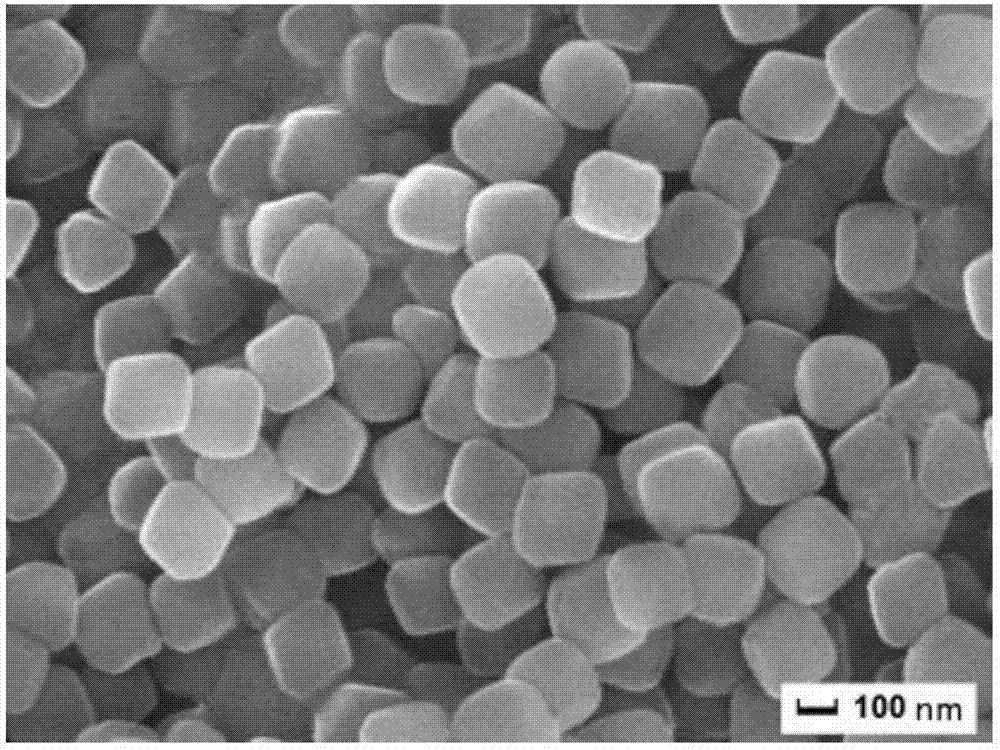

Nickel-based catalyst and its preparation method and use in 5-hydroxymethylfurfural hydrogenation

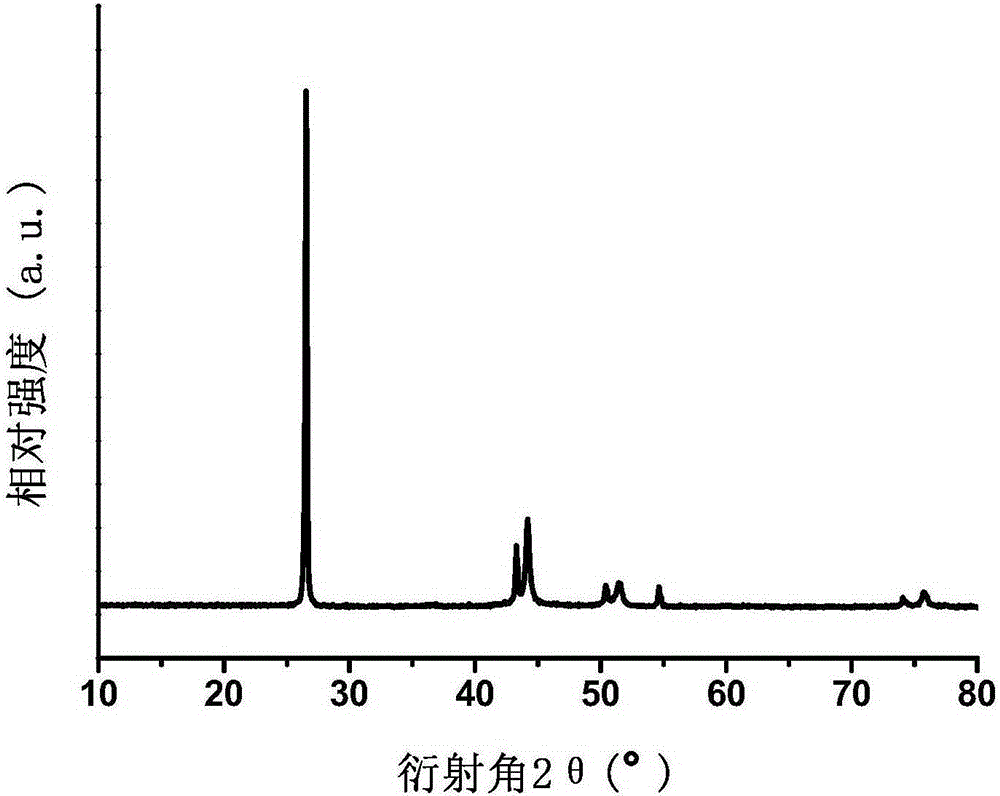

ActiveCN105289619AHigh activityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHydrotalciteEconomic benefits

The invention discloses a nickel-based catalyst and its preparation method and use in 5-hydroxymethylfurfural hydrogenation. The nickel-based catalyst has a general formula of NiAl or NiMAl, wherein M represents a metallic element selected from Zn, Mg and Mn, in NiAl, a mole ratio of Ni to Al is 1-3: 1, and in NiMAl, a mole ratio of Ni, M to Al is 1: 1: 1. Ni-based hydrotalcite as a precursor is roasted to form a high-dispersibility Ni-based catalyst with a high 5-hydroxymethylfurfural conversion rate (greater than 99%) and high 2, 5-dimethylfuran or 2, 5-dimethyltetrahydrofuran selectivity (greater than 95%). The nickel-based catalyst has the advantages of easily available raw materials, simple preparation method, operation convenience, low cost, repeatable utilization and latent economic benefits.

Owner:SYNFUELS CHINA TECH CO LTD

Method for preparing 5-hydroxymethylfurfural with fructose

InactiveCN102153527AHigh yieldMild reaction conditionsOrganic chemistryChemical recyclingLithium chlorideHeteropoly acid

The invention discloses a method for preparing 5-hydroxymethylfurfural with fructose. The method includes the following steps: taking N, N-dimethyl acetamide as solvent, lithium chloride as additive, fructose as a reaction material, and heteropoly acid loaded by titanium dioxide as a catalyst, reacting at the temperature of 80-150DEG C to generate 5-hydroxymethylfurfural. The method has the characteristics of few by-products, high yield, environment-friendly property, moderate reaction conditions, small corrosion to equipment, recyclability of catalyst, and the like, and has industrial prospect.

Owner:海宁市袁花镇工业投资有限公司

Preparation method for furan-2,5-dicarbaldehyde

The present invention discloses a preparation method for furan-2,5-dicarbaldehyde. According to the method, under mild reaction conditions, molecular oxygen is adopted as an oxidant, and 5-hydroxymethylfurfural is subjected to an oxidation reaction under a catalysis effect of a manganese oxide to obtain furan-2,5-dicarbaldehyde. The preparation method of the present invention has the following advantages that: the catalyst used in the present invention is cheap and easy to obtain; the reaction time is short, and characteristics of efficiency and energy saving are provided; the yield of the target product is up to 97%, and the amount of byproducts is low; air or oxygen is adopted as the oxygen source, such that the economic cost and the environmental cost are low; the product and the catalyst are easily separated, such that the post-treatment is simple; the catalyst is easily reused, the waste emission is low, and the green environmental protection characteristic is provided; and requirements on equipment are low, the equipment investment is low, and important application values are provided.

Owner:PEKING UNIV

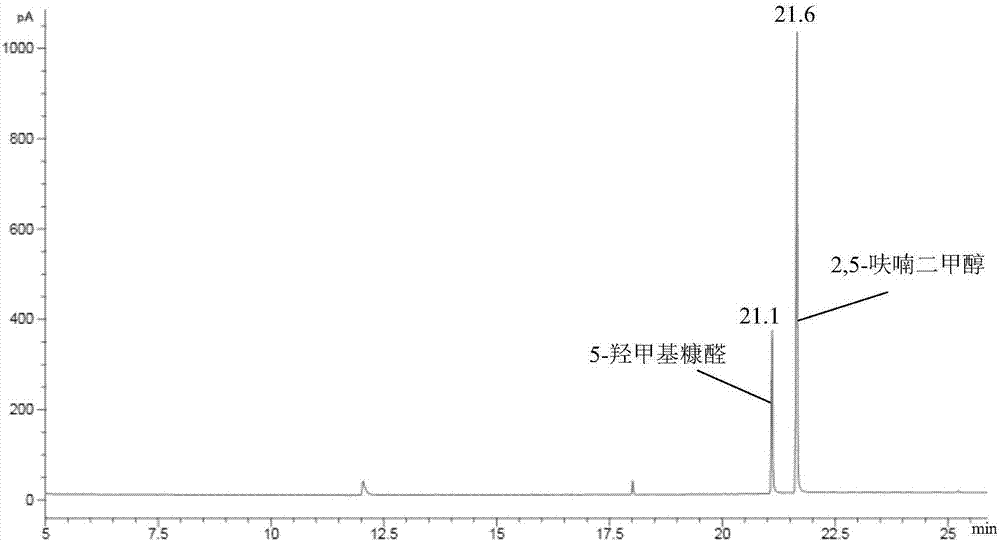

Method for synthesizing 2,5-furandimethanol by selective hydrogenation of 5-hydroxymethylfurfural

ActiveCN107442177AHigh acid-base strengthPolyacid-base siteOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholHydrogenation reaction

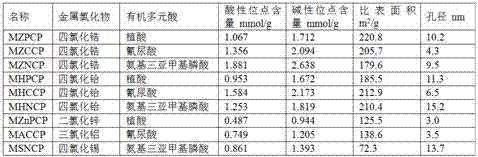

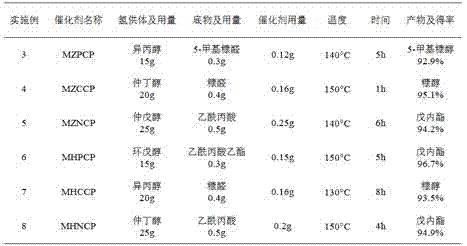

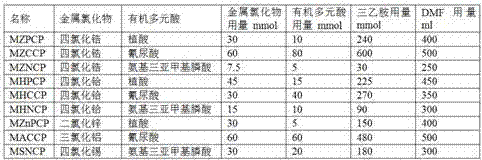

The invention discloses a method for synthesizing 2,5-dihydroxymethylfuran by selective hydrogenation of 5-hydroxymethylfurfural. The method is characterized in that a magnetic metal-organic coordination polymer is used as an acid and base bifunctional catalyst, low-price and easily-obtained low carbon alcohol is used as an in-situ hydrogen donor, and the 5-hydroxymethylfurfural is efficiently transformed into the 2,5-dihydroxymethylfuran by a selective transfer hydrogenation reaction under mild operation conditions and the maximum yield of the 2,5-dihydroxymethylfuran can be up to 98.6 percent. The magnetic metal organic coordination polymer used in the method disclosed by the invention has the advantages of relatively-high acid-base strength, more acid-base sites, relatively-large specific surface area and suitable pore size; in addition, the magnetic metal organic coordination polymer is simple in preparation process, is easy to separate and recover and shows excellent catalytic activity and catalytic stability. Furthermore, the low carbon alcohol is used as the in-situ hydrogen donor in the invention, so that the use of molecular hydrogen is avoided and the safety of the reaction process is improved; besides, the low carbon alcohol can be used as a reaction solvent and the introduction of exogenous substances is reduced, and thereby the production cost can be further reduced.

Owner:HUAIYIN TEACHERS COLLEGE

Preparation method and application of solid acid catalyst

InactiveCN102814189AEfficient conversionHigh selectivityOrganic chemistryMolecular sieve catalystsTetramethylammonium hydroxideSolid acid

The invention discloses a preparation method and application of a solid acid catalyst. The preparation method of the solid acid catalyst comprises the following steps: (1) mixing a silicon source, an alkali source, a metallic compound and a template, and carrying out hydrothermal reaction to obtain a reaction product 1; (2) filtering the reaction product 1 to obtain a solid, and drying at 60-120 DEG C for 12-36 hours to obtain a reaction product 2; and (3) calcining the reaction product 2 at 500-600 DEG C for 3-10 hours to obtain the solid acid catalyst. The silicon source is selected from hydrophilic nano silicon oxide, sodium silicate and tetraethyl orthosilicate; the alkali source is selected from tetramethylammonium hydroxide, alkali metal hydroxide and ammonia water; the metallic compound is selected from tin tetrachloride, zirconium sulfate, sodium silicate, chromic nitrate, nickel nitrate and tetrabutyl titanate; and the template is cetyl trimethyl ammonium bromide. The solid acid catalyst disclosed by the invention can be used for preparing 5-hydroxymethylfurfural.

Owner:UNIV OF SCI & TECH OF CHINA

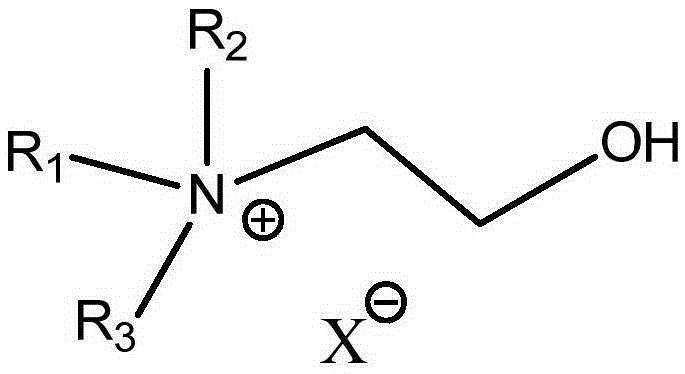

Method for preparing 5-hydroxymethylfurfural from fructose

InactiveCN104844543AEfficient preparationHigh yieldOrganic chemistryHydroxymethylfurfural5-hydroxymethylfurfural

The invention relates to 5-hydroxymethylfurfural, particularly a method for preparing 5-hydroxymethylfurfural from fructose. The method has the advantages of low cost, high yield, simple steps and environment friendliness. The method comprises the following steps: mixing fructose and choline chloride, adding hydrochloric acid as a catalyst, heating to react, and adding an organic extractant to extract the reaction mixture, thereby obtaining the product 5-hydroxymethylfurfural. By using the ultralow-concentration hydrochloric acid as the catalyst, the 5-hydroxymethylfurfural can be efficiently prepared in the fructose-choline chloride eutectic system, thereby being green and environment-friendly. By using the ultralow-concentration hydrochloric acid as the catalyst, the yield of the 5-hydroxymethylfurfural can reach 92%. The eutectic formed by the cheap choline chloride and fructose has favorable economical efficiency, thereby providing a novel idea for research of 5-hydroxymethylfurfural and downstream products thereof.

Owner:XIAMEN UNIV

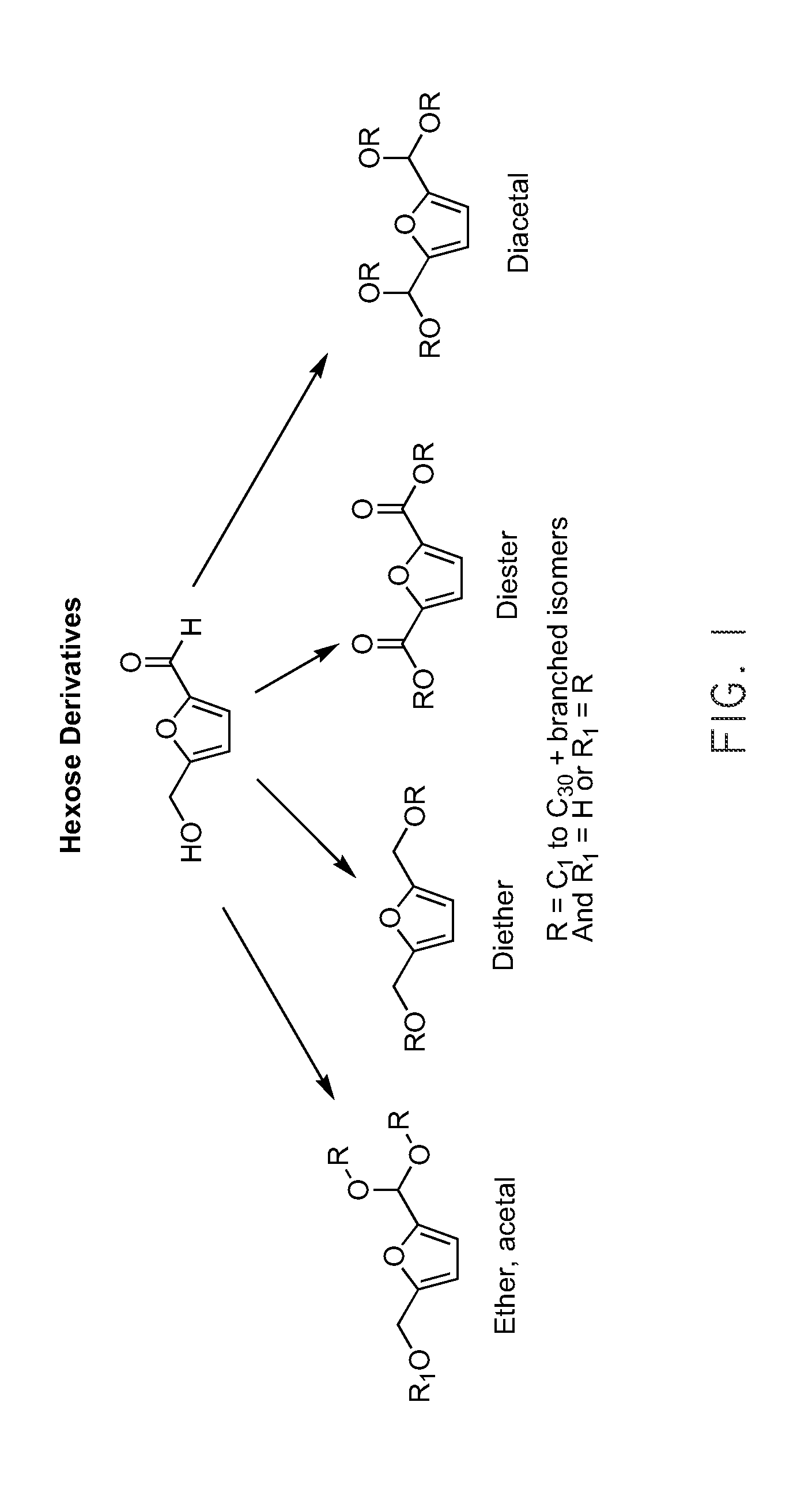

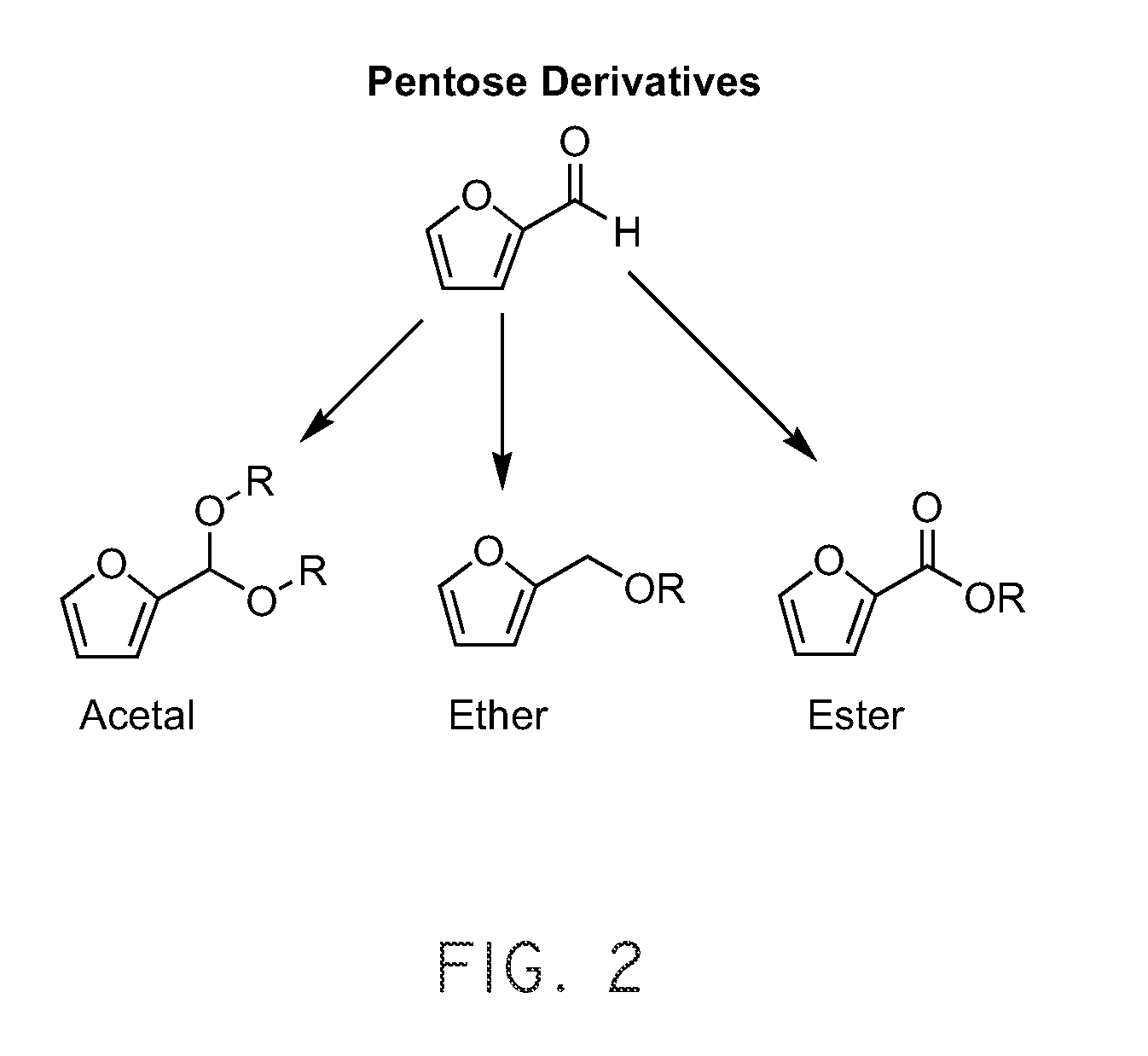

Hydroxymethylfurfural ethers from sugars and higher alcohols

Accordingly, the current invention provides a method for the manufacture of an ether of 5-hydroxymethylfurfural by reacting a hexose-containing starting material with a higher alcohol in the presence of an acid catalyst, and at a temperature in the range of from 125 to 250 degrees Centigrade.

Owner:FURANIX TECH BV

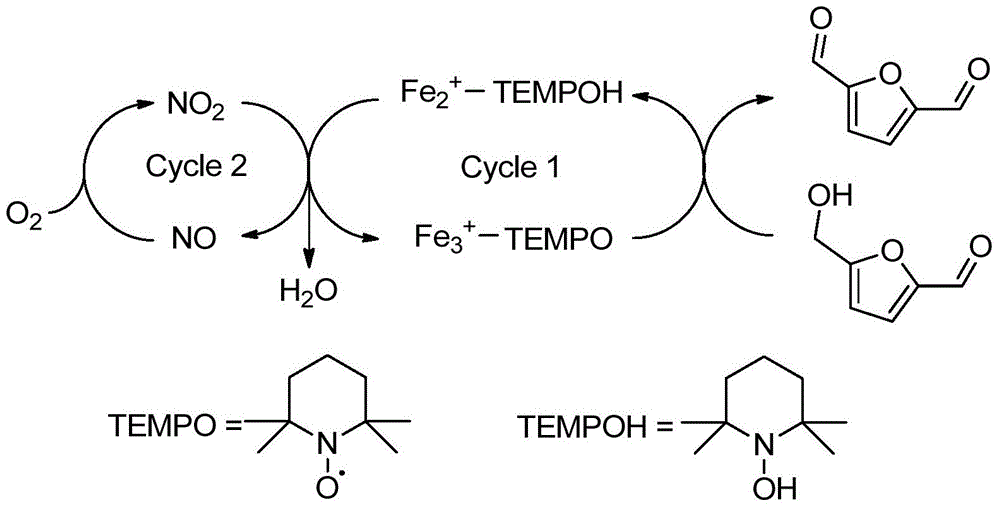

Method for preparing 2,5-diformylfuran

The invention discloses a method for preparing 2,5-diformulfuran. The method is characterized in that 5-hydroxymethylfurfural, a piperidine nitrogen oxide catalyst and a catalyst activating agent serve as raw materials, 5-hydroxymethylfurfural is added into an organic solvent, then the piperidine nitrogen oxide catalyst and the catalyst activating agent are added into the organic solvent, and raw material mixed liquor is formed; 5-hydroxymethylfurfural has an oxidation reaction under the catalyst action of the piperidine nitrogen oxide catalyst and the catalyst activating agent at the temperature of 10-100 DEG C for 1-24 hours with molecular oxygen as an oxidation agent, and the product of 2,5-diformulfuran is obtained. The catalyst used in the preparation method is low in price and easy to obtain, the reaction time is short, and the method is efficient and energy-saving; the yield of the target product reaches as high as 92%, and a few of by-products are produced; air serves as an oxygen source, and the economic and environment cost are low.

Owner:合肥利夫生物科技有限公司

Method for the synthesis of 5-hydroxymethylfurfural ethers and their use

Owner:FURANIX TECH BV

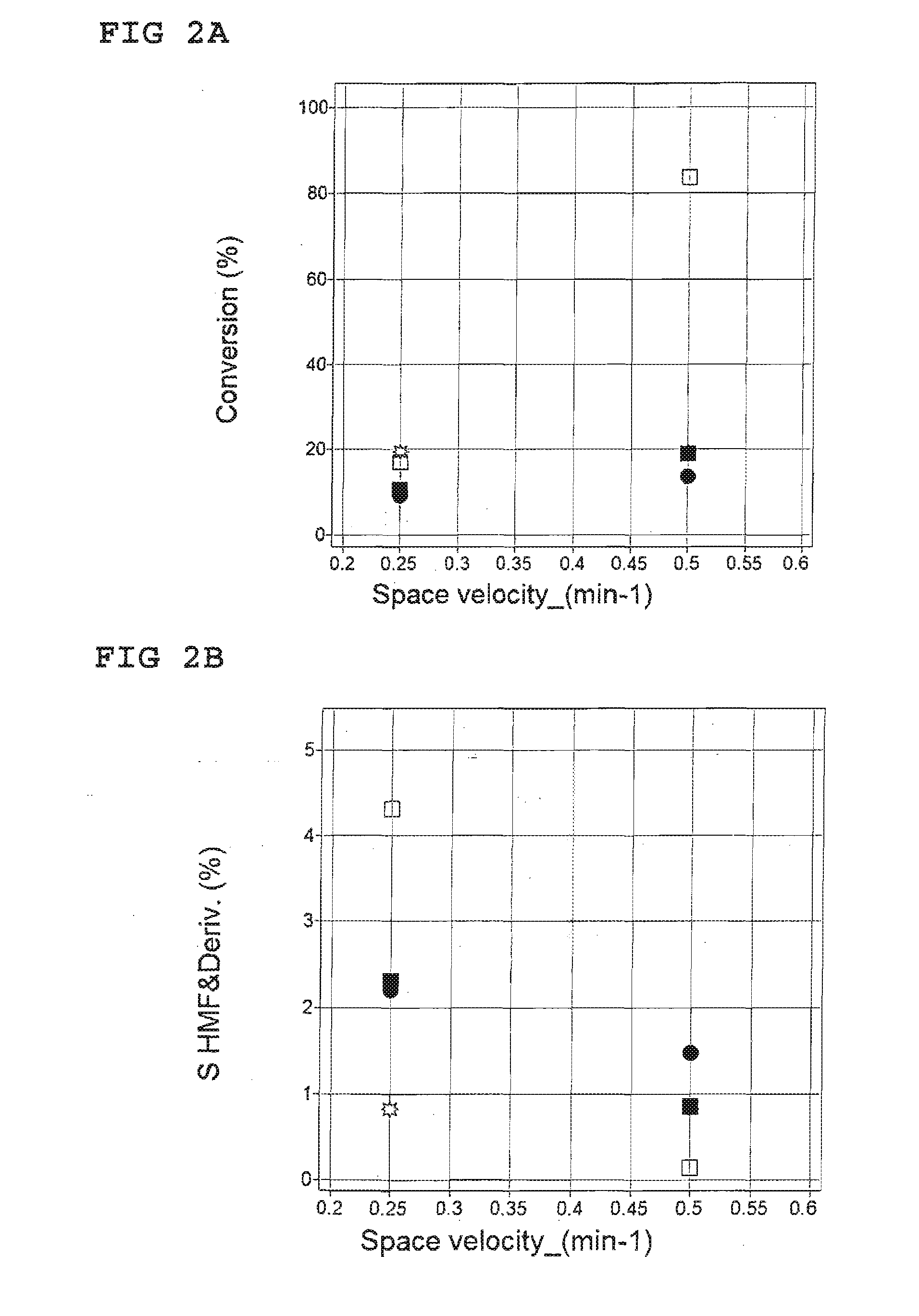

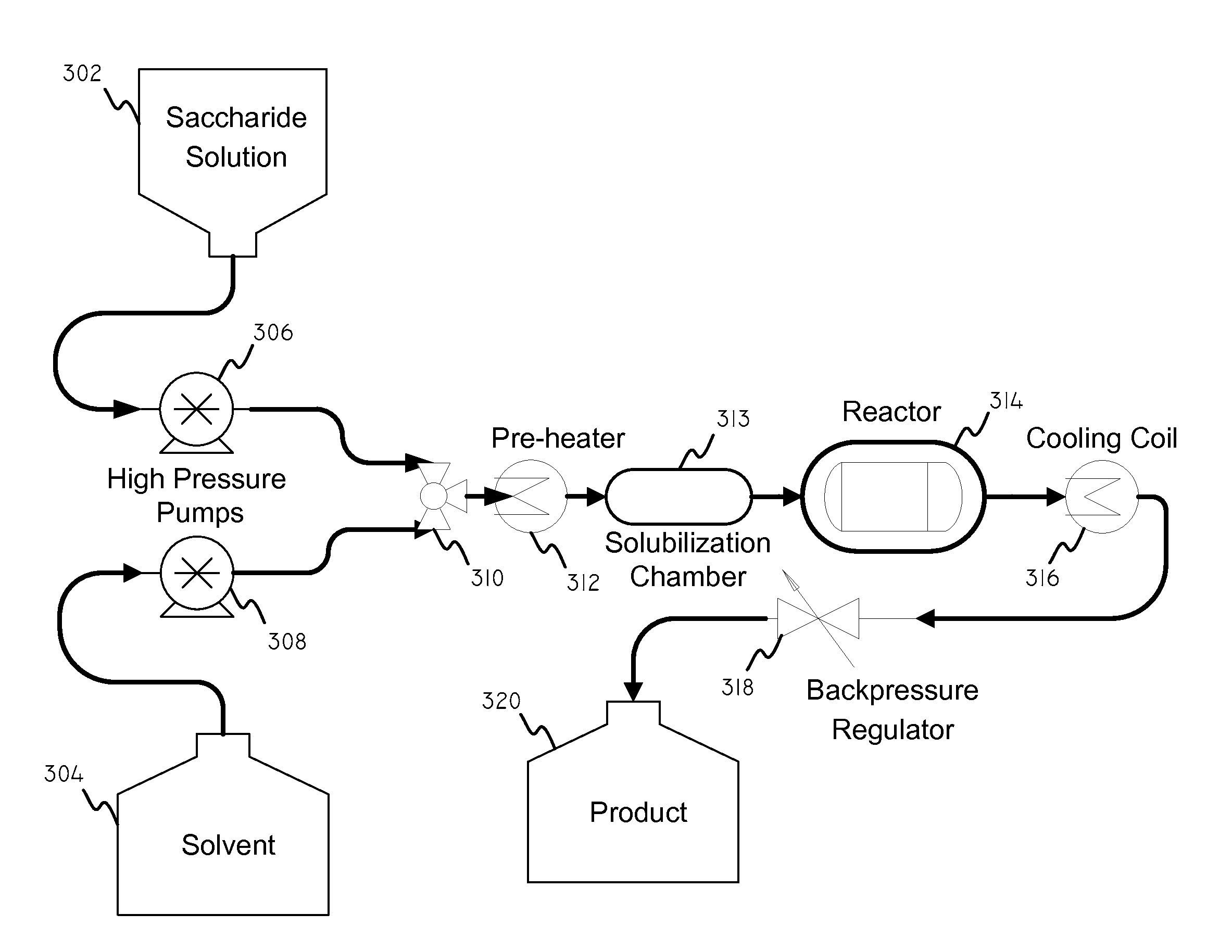

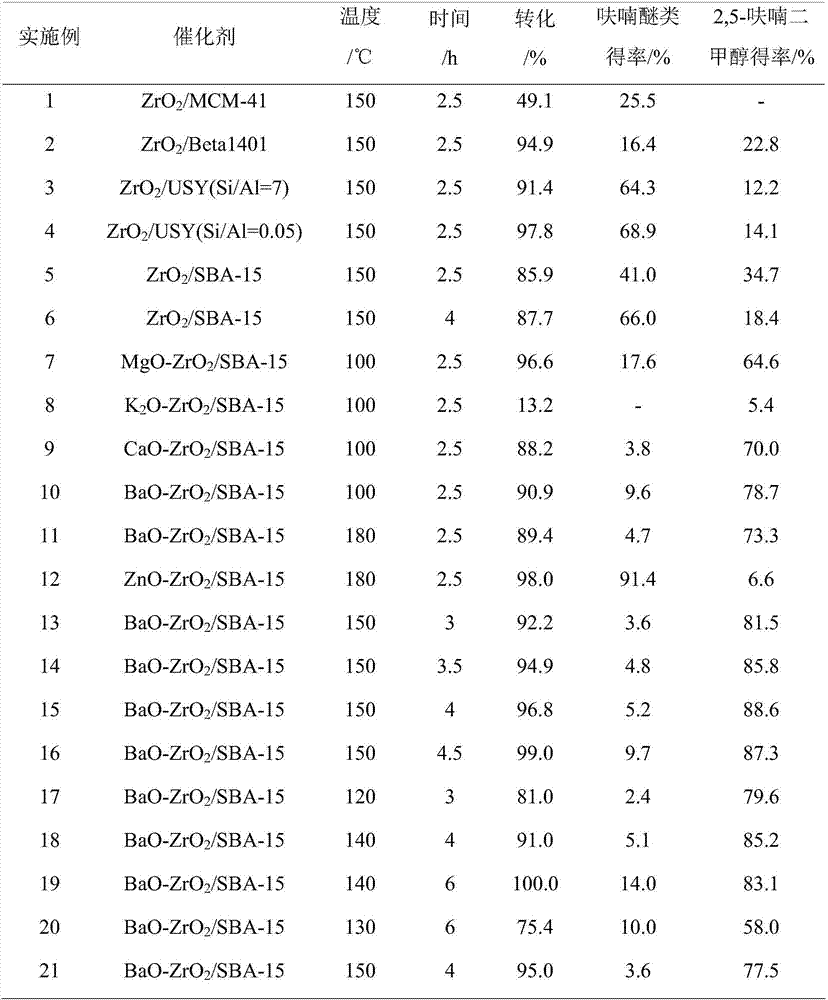

Systems and methods for producing fuels and fuel precursors from carbohydrates

The present invention relates to systems and methods for producing fuels and fuel precursors from carbohydrates. In an embodiment the invention includes a method of producing 5-hydroxymethylfurfural (HMF), including contacting a saccharide with a metal oxide catalyst at a temperature of greater than about 100 degrees Celsius. In an embodiment the invention includes a method of producing a biofuel including contacting a saccharide with a metal oxide catalyst at a temperature of greater than about 100 degrees Celsius. Other embodiments are also described herein.

Owner:SARTEC

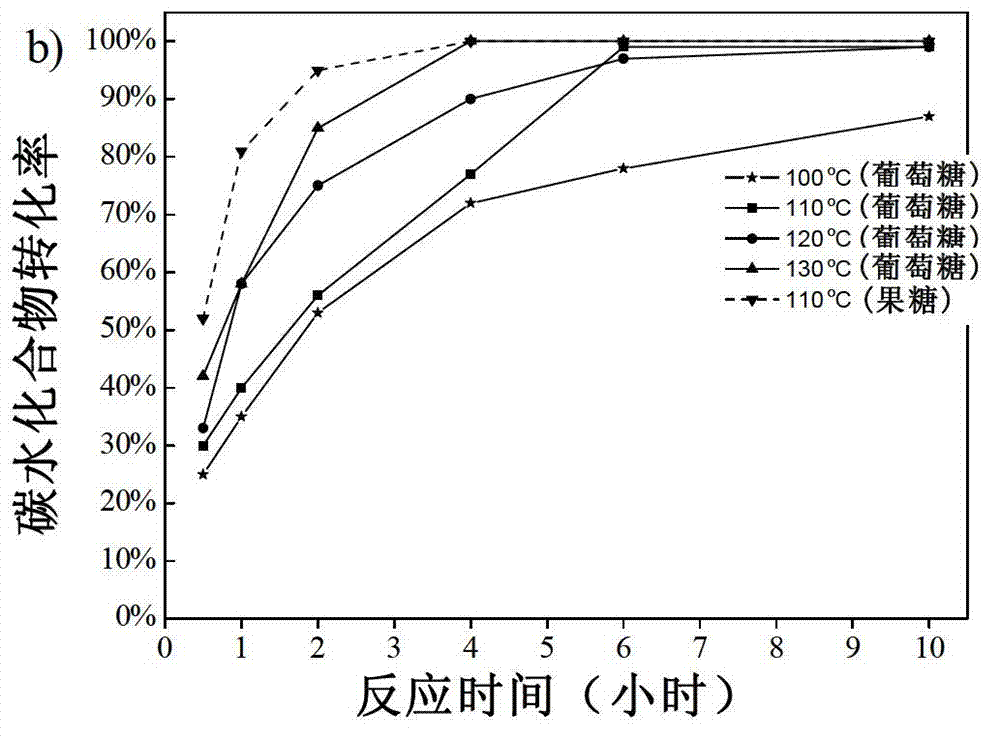

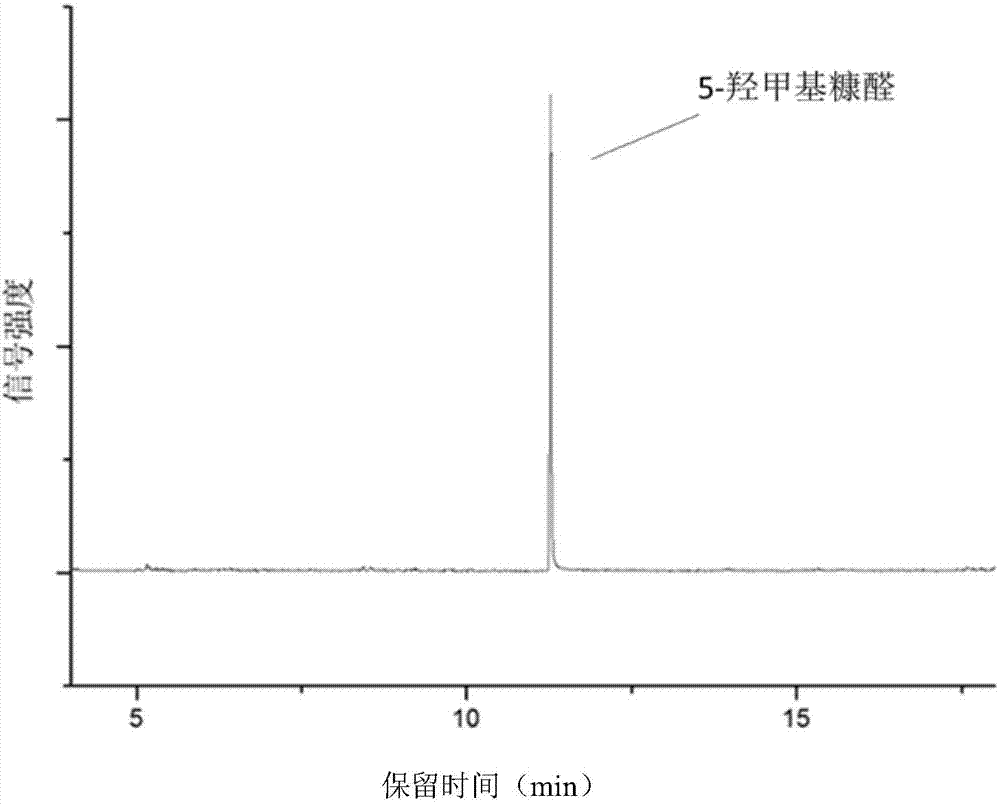

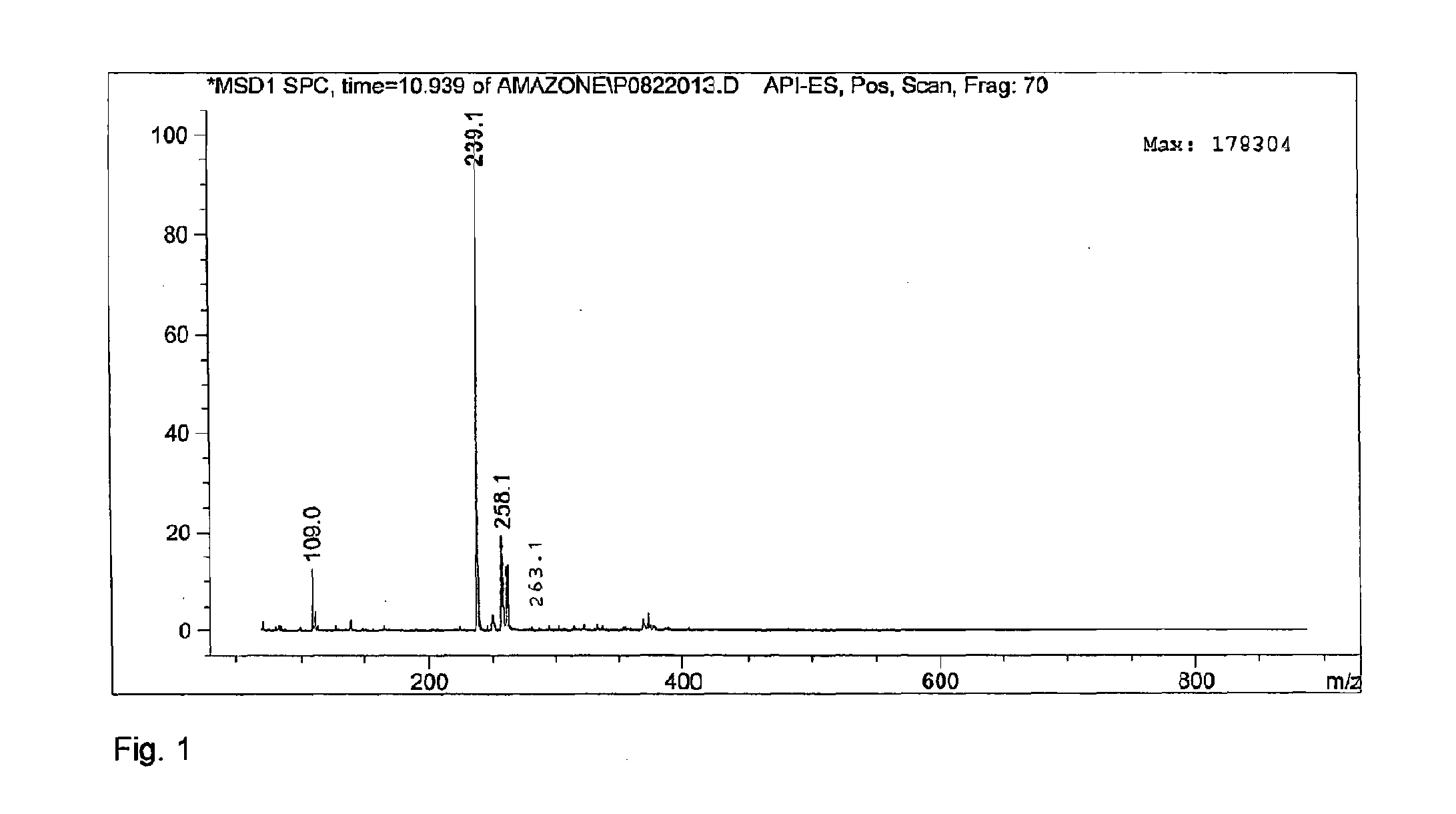

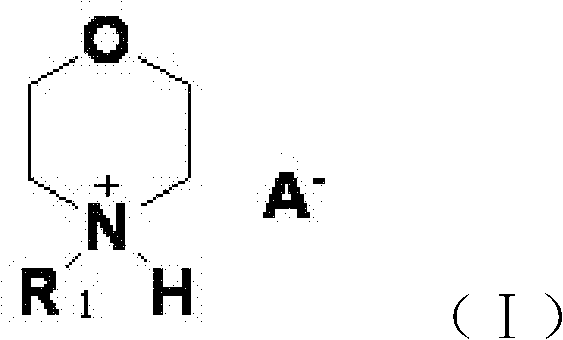

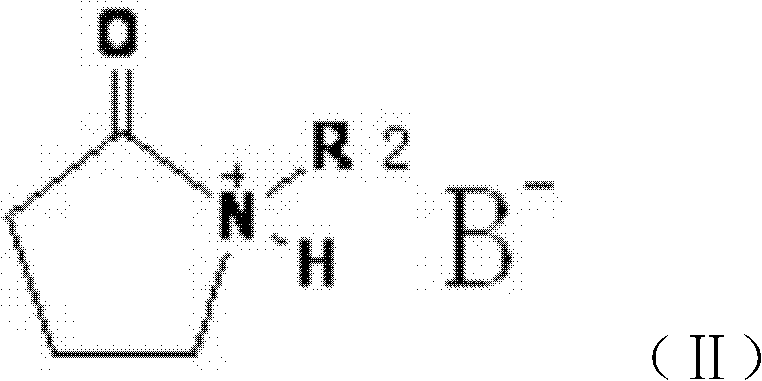

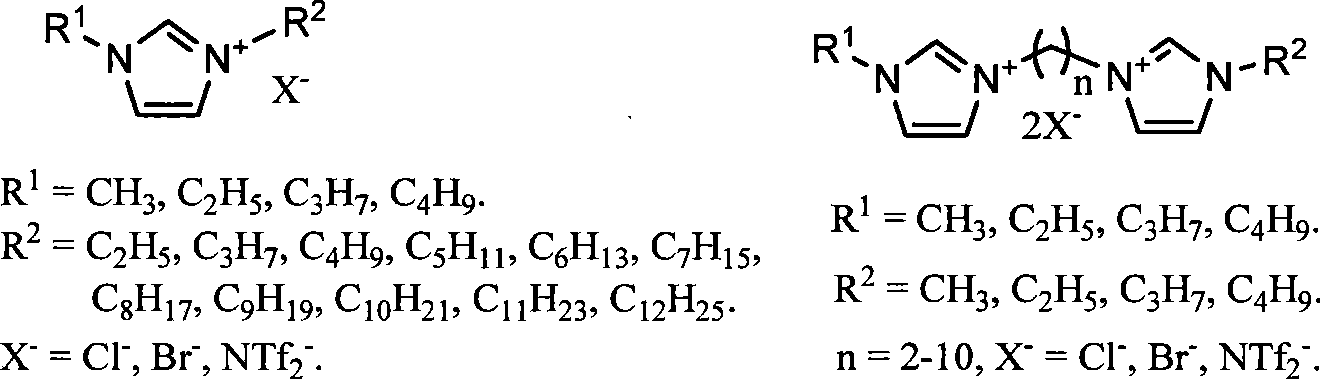

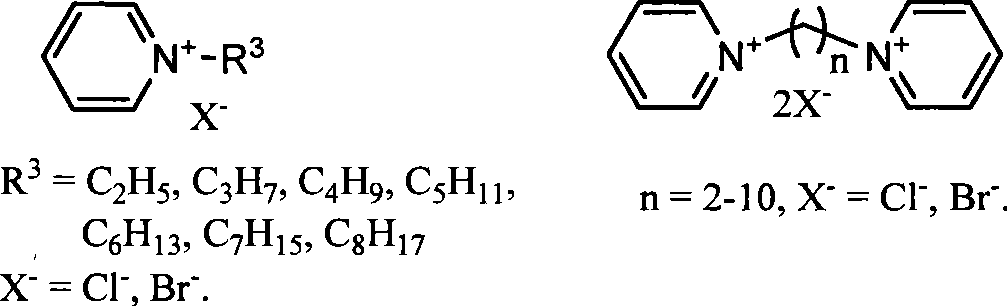

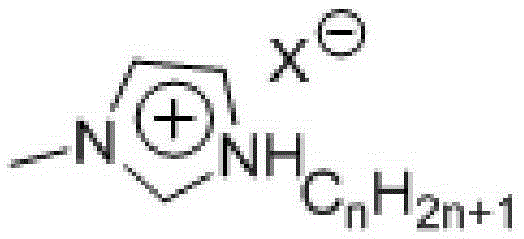

Method for generating 5-hydroxymethylfurfural by using ionic liquid catalysis

InactiveCN101812039AEasy to separateEasy to purifyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventHydroxymethylfurfural

The invention discloses a method for generating 5-hydroxymethylfurfural by using ionic liquid catalysis, which comprises the following steps: dissolving a reaction substrate into an organic solvent, and adding ionic liquid in an amount of 5 to 20 percent based on the total mole of the reaction substrate; and reacting the mixture for at least 2 hours at the temperature of between 70 and 120 DEG C under the protection of inert gas, namely neutralizing the reaction solution, and filtering, drying and distilling the reaction product to obtain the 5-hydroxymethylfurfural. The reaction system shows the characteristic of homogeneous reaction during catalytic dehydration, and has high catalytic activity and selectivity; and the using amount of a catalyst can be optimized to trace so as to improve the reaction conversion rate, reduce the use of other organic solvent and additive, reduce the cost and facilitate the separation and purification of the reaction product at the same time.

Owner:TIANJIN UNIV

Catalytic system for synthesizing 5-hydroxymethylfurfural by dehydration of sugar or polysaccharide

InactiveCN102212046AReduce processingRaw materials are cheap and easy to getOrganic chemistrySucroseSolvent

The invention relates to a catalytic system for synthesizing 5-hydroxymethylfurfural by dehydration of sugar or polysaccharide. The catalytic system consists of metal halide and halogenated ammonium, wherein the molar ratio of metal halide to halogenated ammonium is 0.1-10; and the catalytic system is used for synthesizing 5-hydroxymethylfurfural by dehydration of sugar or polysaccharide. The specific method comprises the following steps: dissolving the sugar or polysaccharide in a solvent; adding the mixture into the catalytic system so as to form a reaction system; and at the temperature of 0-200 DEG C and under atmosphere gas, carrying out magnetic stirring for dehydration reaction, wherein the reaction time is 30 seconds to 24 hours. The catalytic system has the advantages that the components of the catalytic system are different halogenated compounds, raw materials are available and cheap and cost is low, can catalyze the dehydration of sugar or polysaccharide so as to prepare 5-hydroxymethylfurfural with high efficiency and high selectivity and is environmentally-friendly, and the product is easy to process; in the whole process, different sugar or polysaccharide compounds are consumed, and cost is low, thereby meeting the technical economy requirement and having a good application prospect.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

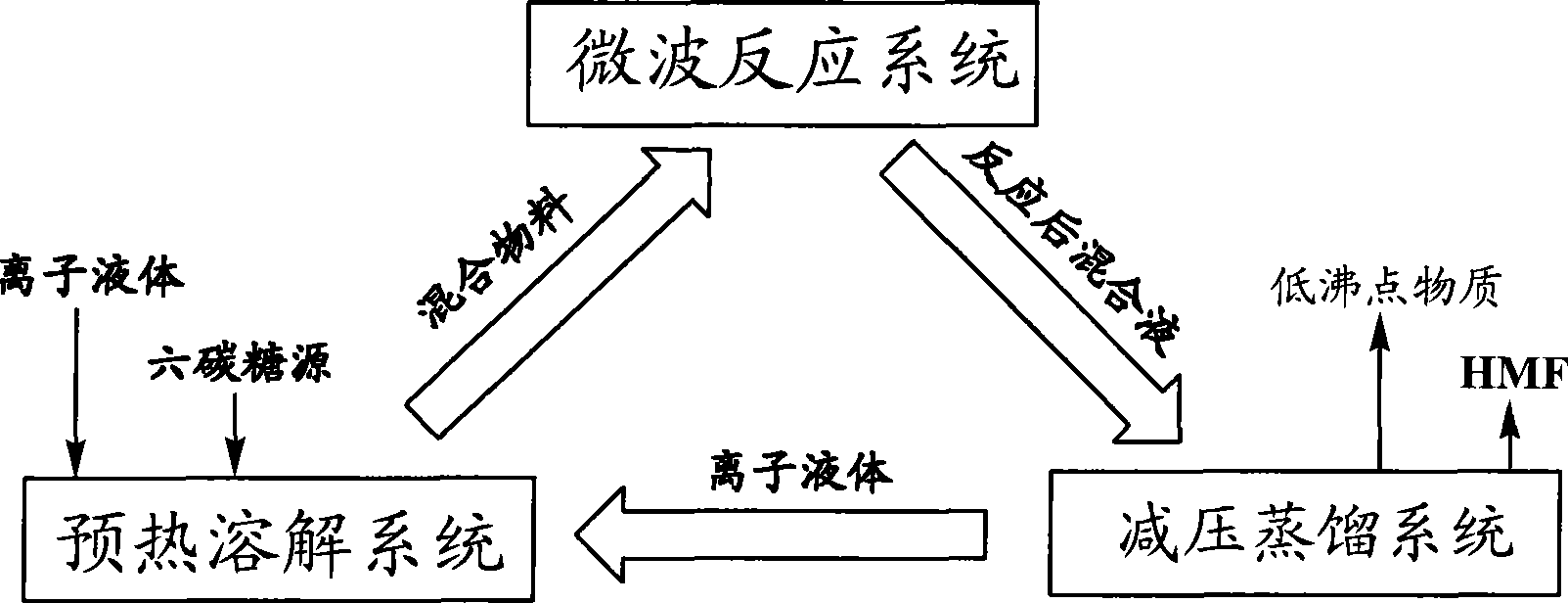

Method for preparing 5-hydroxymethyl-furfural by microwave promotion

ActiveCN101456851AReduce usageNo need to useOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlternative fuelsHydroxymethylfurfural

The invention relates to a continuous preparation method for 5-hydroxymethylfurfural (HMF) transformed by a biomass saccharine source under microwave radiation condition by using an ionic liquid as a reaction medium, in particular to a method for continuously preparing and separating HMF. The method comprises the following concrete steps: mixing the ionic liquid and hexose or hexose source biomass as a raw material substrate in a preheating and dissolving system, preheating and dissolving the mixture, feeding the mixture into a microwave reaction system to react for 30 seconds to 30 minutes under the microwave radiation condition so as to efficiently generate the HMF; then feeding the reaction mixture into a depressurizing and distilling system, and distilling the mixture under the condition that an operation temperature is not higher than 180 DEG C to obtain the HMF, wherein the separation yield is as high as 94 percent; and re-feeding the distilled remainder into a preheating system, adding the biomass saccharine source, and then repeating steps of reaction and separation, so as to achieve the aims of recycling of an ionic liquid catalyst system and continuous preparation of the HMF. The method has the advantages of no extra-added catalyst, high HMF selectivity, mild operation condition, quick reaction, reusability of the ionic liquid, low cost, simple process, environmental protection and continuous production, provides a new method for industrialized production of the HMF based on the biomass saccharine source, and opens up a new path for preparing common chemicals in a large scale and replacing fuels.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

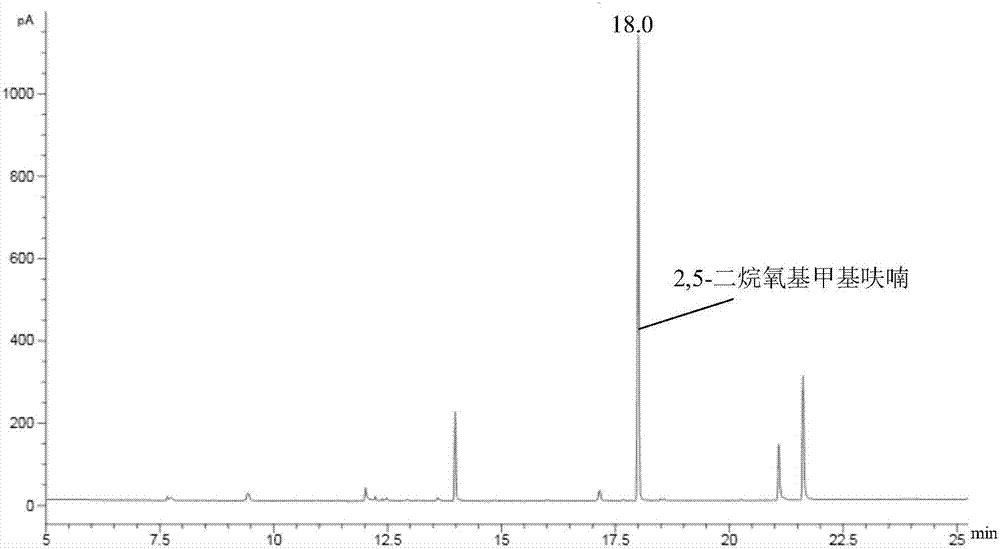

Synthetic method of 2,5-furan dimethanol and etherified product of 2,5-furan dimethanol

The invention discloses a synthetic method of 2,5-furan dimethanol and an etherified product of 2,5-furan dimethanol and relates to 2,5-furan dimethanol. The synthetic method comprises the following steps of: adding organic alcohol into a reaction substrate; putting the obtained mixture as a raw material in a high pressure reaction kettle; adding a certain amount of a molecular sieve supported catalyst; and performing a heating reaction to obtain 2,5-furan dimethanol and the etherified product of 2,5-furan dimethanol. By using alcohol as a hydrogen donor and a reaction substrate, no external hydrogen source does not needed. By adjusting the acid-base property of a catalyst through an active metal component, 2,5-furan dimethanol can be obtained by selectively catalyzing transfer hydrogenation of 5-hydroxymethylfurfural or 2,5-dialkoxyl methyl furan is obtained by further etherification. The catalyst is cheap and easily available and good in repeatability, no excessively hydrogenated product exists, and the whole reaction is hydrogenated in a hydrogen environment, and the synthetic method has relatively strong operating safety of industrial production and very good industrial application potential.

Owner:XIAMEN UNIV

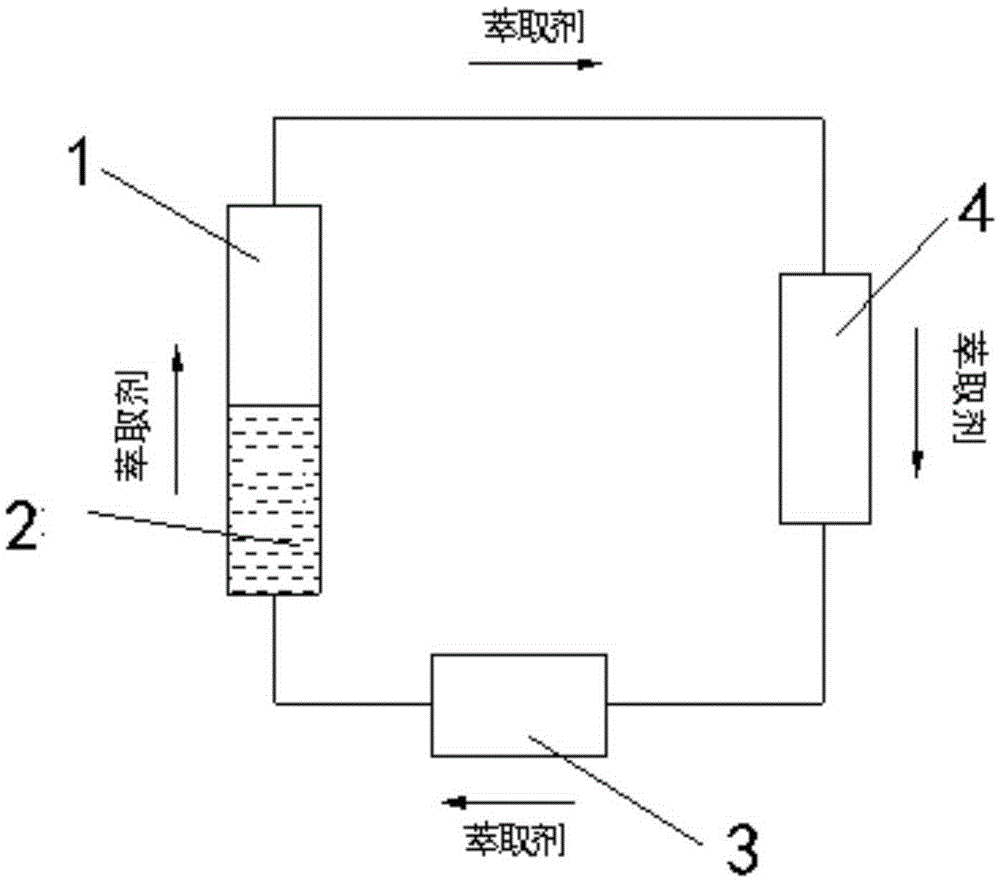

Method for realizing continuous synthesis of 5-hydroxymethylfurfural through continuous extraction

InactiveCN106810517ARealize online separationEfficient conversionOrganic chemistryHydroxymethylfurfuralProcess conditions

The invention discloses a method for realizing continuous synthesis of 5-hydroxymethylfurfural through continuous extraction. The method comprises the following steps: in a reaction system for generating the 5-hydroxymethylfurfural, continuously feeding an extracting agent and continuously extracting the 5-hydroxymethylfurfural generated in the reaction system; bringing the 5-hydroxymethylfurfural out of the reaction system to realize continuous production of the 5-hydroxymethylfurfural. A production process of the 5-hydroxymethylfurfural by utilizing glucose, provided by the invention, can realize large-scale production of the 5-hydroxymethylfurfural under a green and clean production process condition, and has wide application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

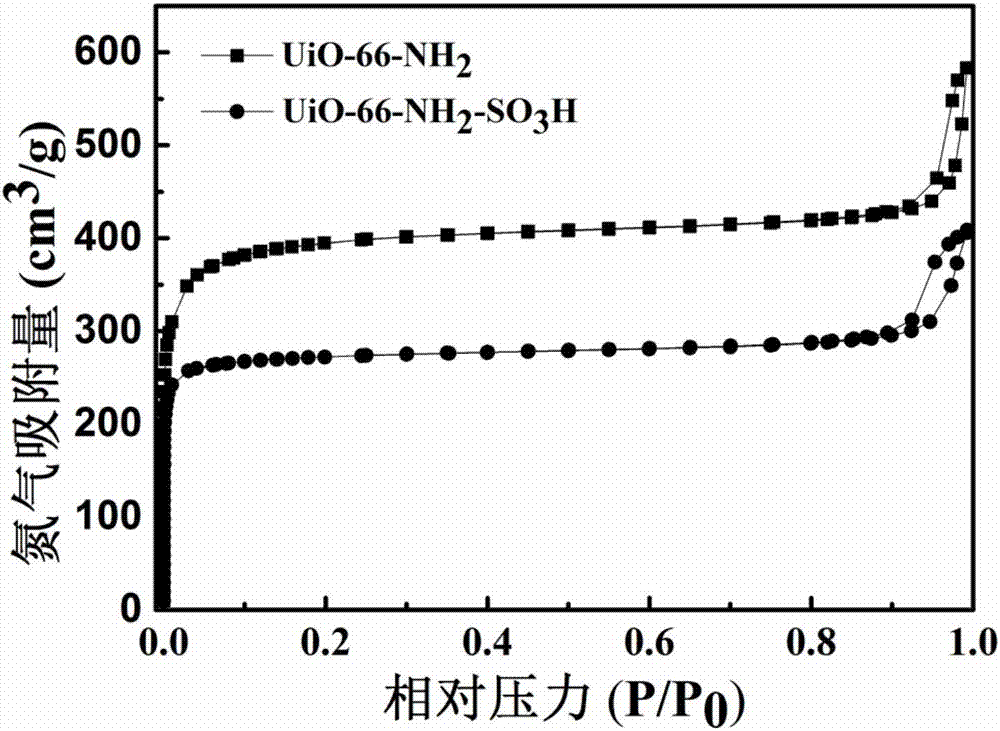

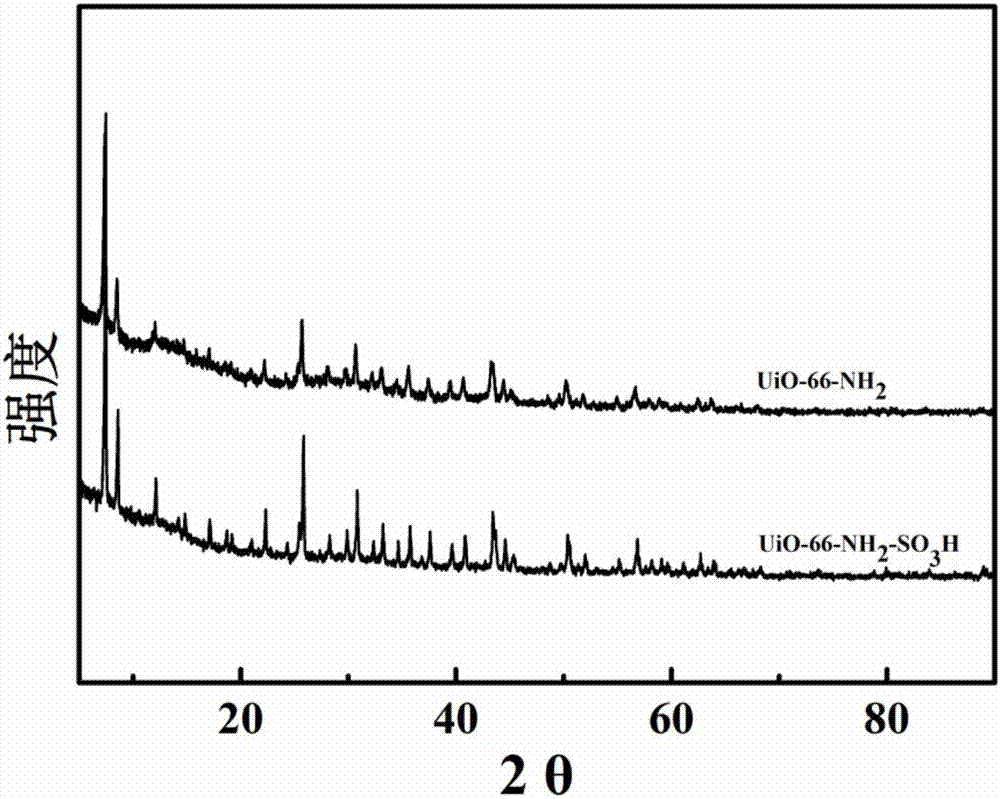

Acid-base bifunctional metal organic skeletal catalyst and preparation method and application thereof

InactiveCN107213915AShorten the timeFast preparationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsWater bathsFiltration

The invention provides an acid-base bifunctional metal organic skeletal catalyst and a preparation method and an application thereof. The preparation steps are as follows: zirconium salt and 2-aminaterephthalic acid are dissolved in weakly acidic solution, and the obtained mixed solution is uniformly dispersed under an ultrasonic condition, and reacts in water bath; after reaction, the product is filtered, collected and washed; after the washed product is immersed in low-boiling point solvent, filtration is carried out, vacuum drying is then carried out, and thereby a UiO-66-NH2 material is obtained; trichloromethane solution which contains 1,3-propane sultone is prepared, added with the prepared UiO-66-NH2 material and heated in water bath to react, and the prepared solid product is then centrifugally separated and washed by using Soxhlet extraction; the obtained solid material is put into a vacuum drying oven, and thereby the acid-base bifunctional metal organic skeletal catalyst is obtained. The process of preparing the product is simple, the preparation cost is low, the acid-base bifunctional metal organic skeletal catalyst is used in the preparation of 5-hydroxymethylfurfural by one-step catalysis of dextrose, the reaction progress is accelerated, and the reaction process is simplified.

Owner:JIANGSU UNIV

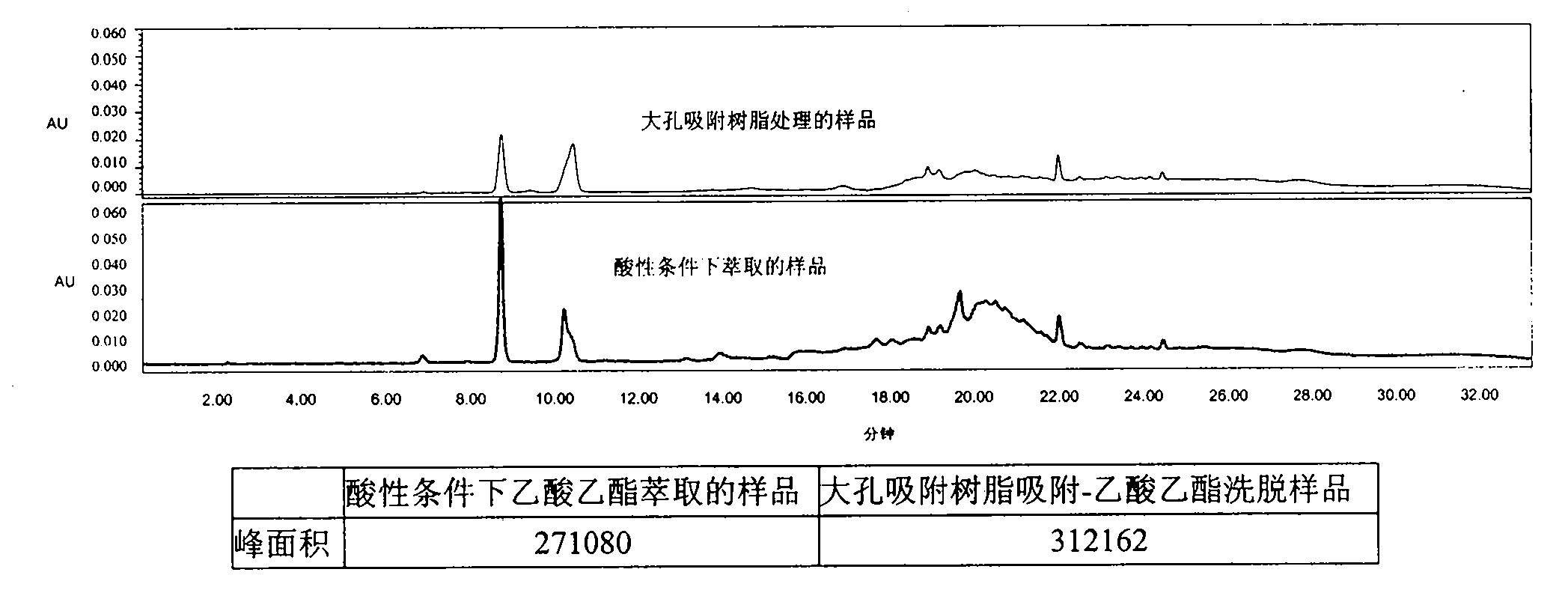

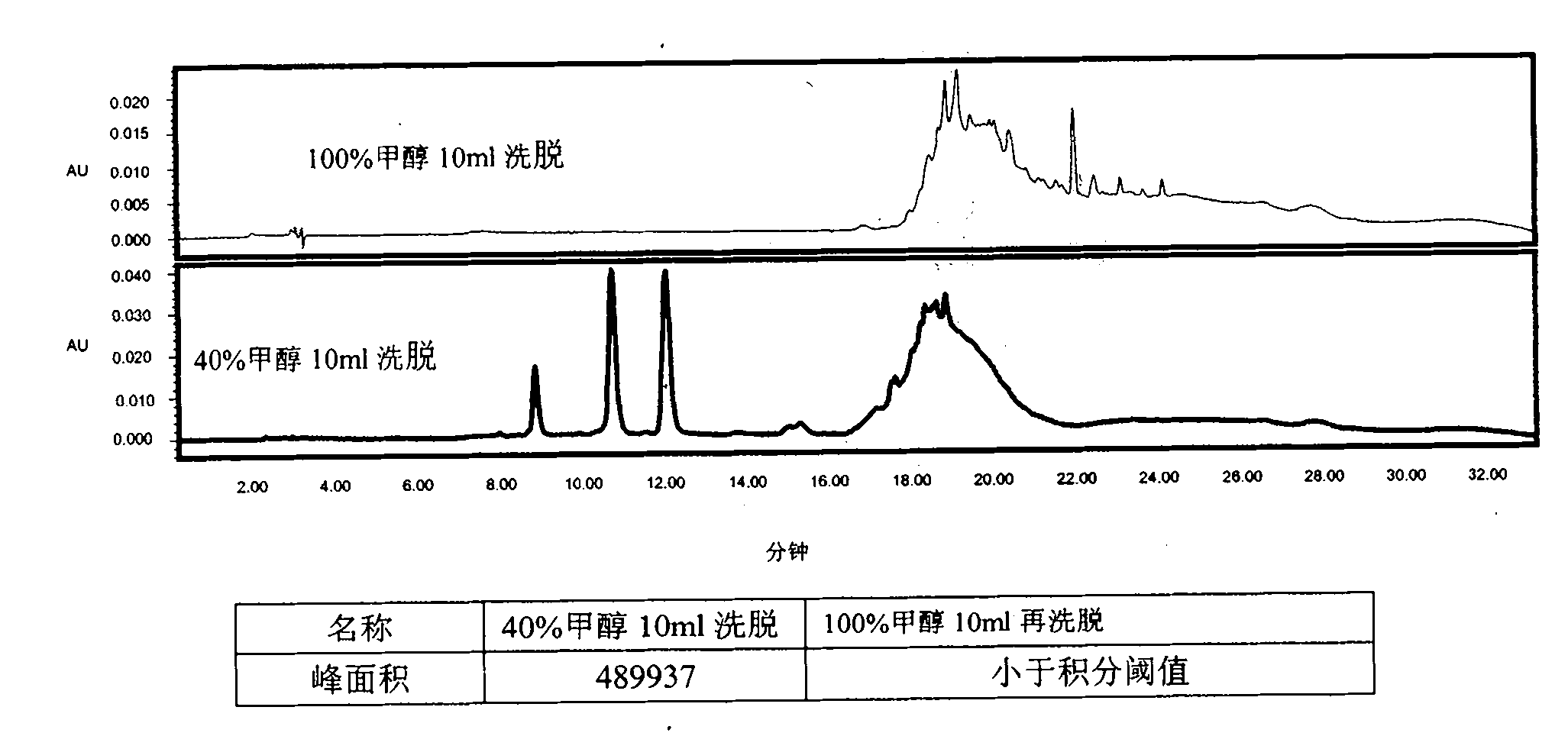

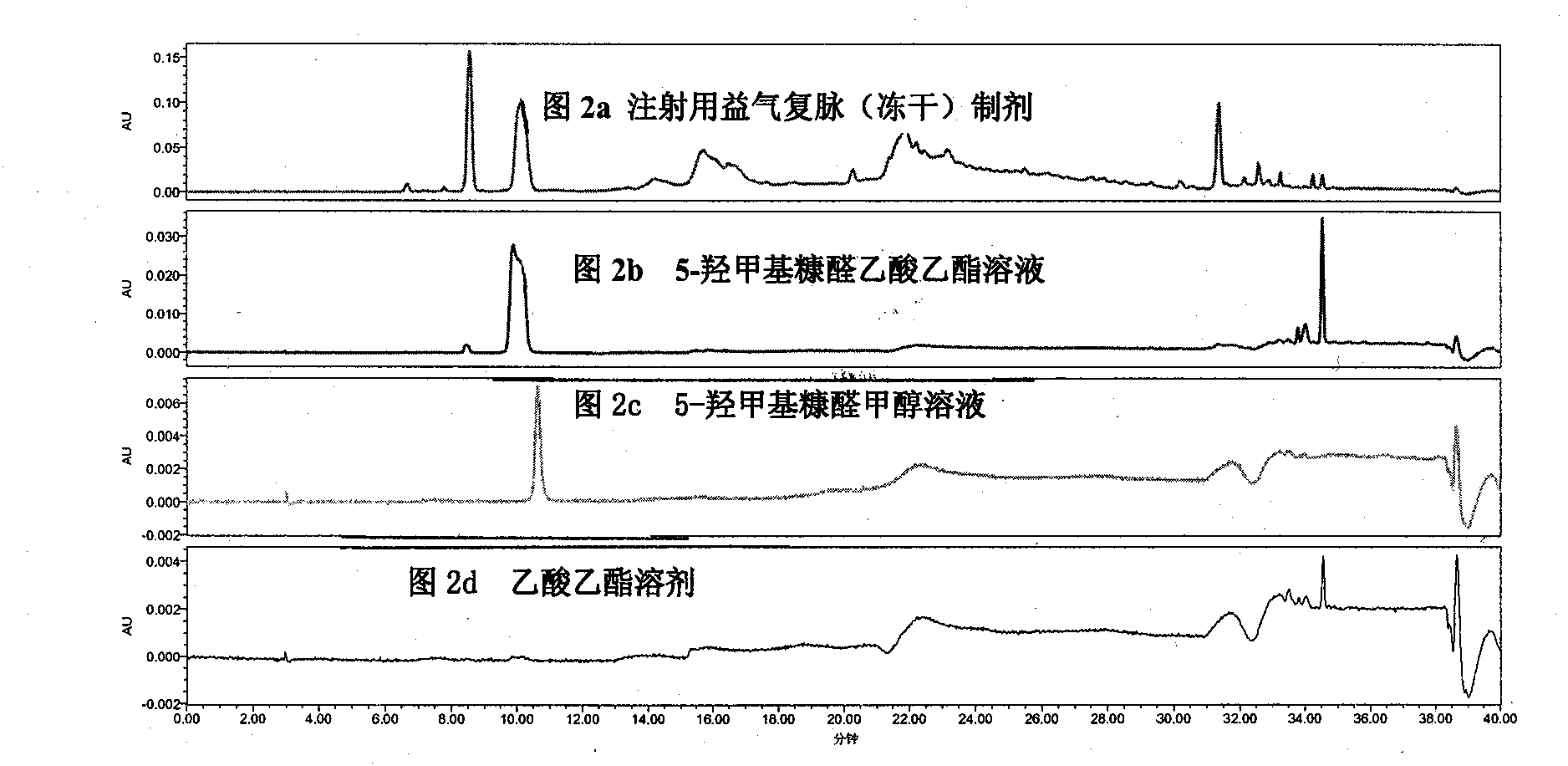

Measurement method of content of 5-hydroxymethylfurfural (5-HMF) in injection

ActiveCN102466658AThe method is simple and fastFast wayPowder deliveryComponent separationHydroxymethylfurfural5-hydroxymethylfurfural

The invention relates to a measurement method of content of 5-hydroxymethylfurfural (5-HMF) in an injection. The measurement method comprises the following steps of: (1) pre-processing the injection to obtain a sample solution; (2) preparing a 5-HMF reference solution; (3) measuring the sample solution and the reference solution by adopting a high performance liquid chromatography (HPLC); and (4) calculating the content of the 5-HMF in the sample solution, wherein the preprocessing step comprises the procedure of passing through macroporous adsorption resin.

Owner:TIANJIN TASLY ZHIJIAO PHARMA

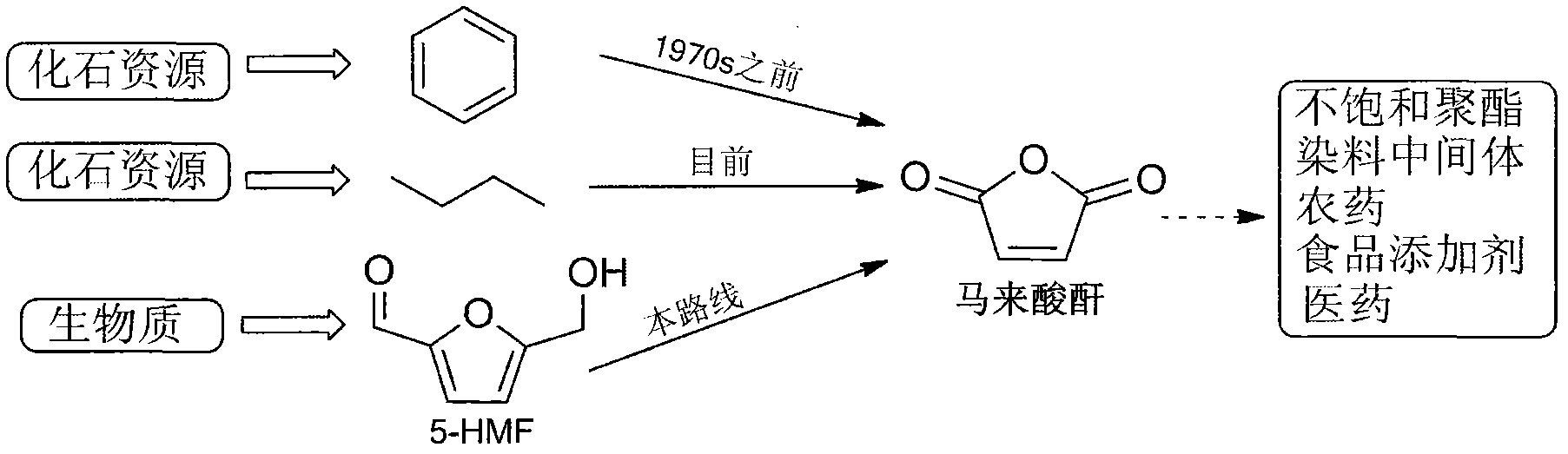

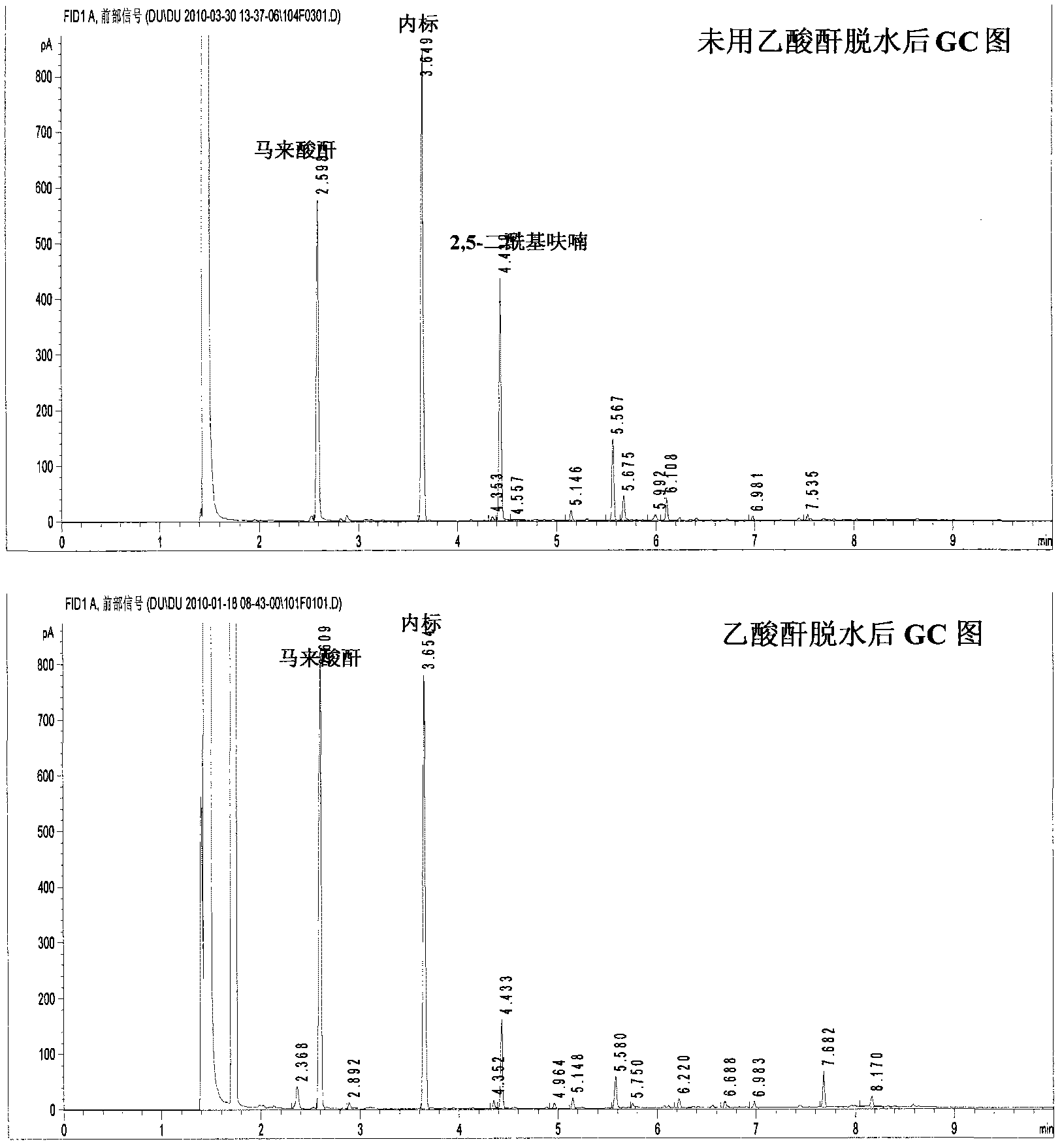

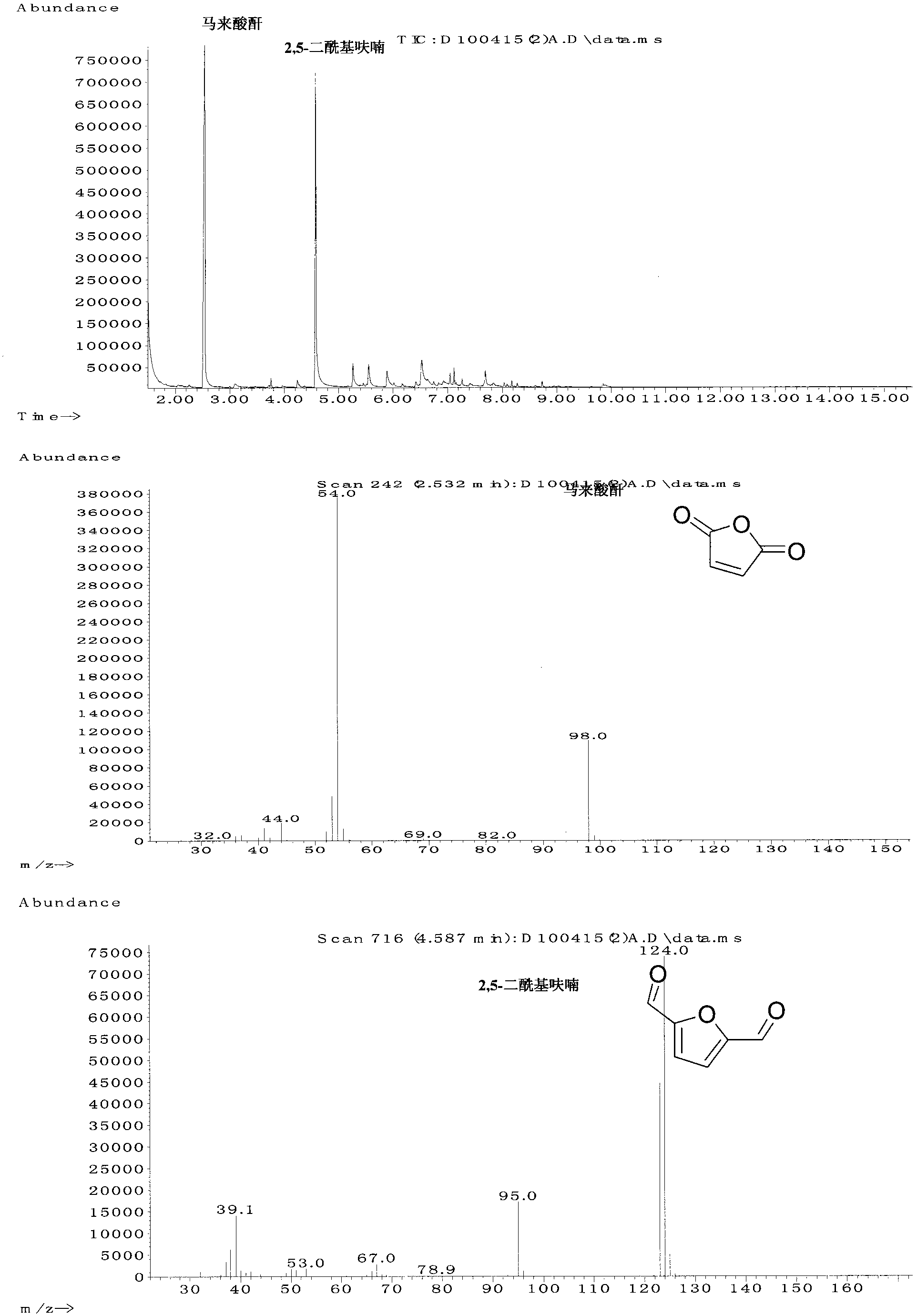

Method for preparing maleic anhydride by catalytic oxidation of 5-hydroxymethylfurfural

InactiveCN102372685AMild reaction conditionsReduce energy consumptionOrganic chemistryCatalytic oxidationOxygen

The invention relates to a new route for preparing maleic anhydride by catalytic oxidation of 5-hydroxymethylfurfural. According to the new route, air or oxygen is adopted as oxygen source; a vanadium oxide is adopted as a catalyst; the 5-hydroxymethylfurfural is subjected to selective oxidation at a temperature of 60-130 DEG C to obtain the maleic anhydride and the maleic acid. According to the method of the present invention, the biomass resources are adopted as the final raw material sources, the reaction conditions are mild, and the method has great development potential.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method and system for continuously synthesizing furandicarboxylic acid

The invention discloses a method for continuously synthesizing furandicarboxylic acid. The method comprises the following steps: (1) dissolving sugars into an organic solvent to prepare a sugar solution with the mass concentration of 5 percent to 50 percent; reacting at 60 to 140 DEG C for 0.5 to 12h under the action of a solid acid dehydration catalyst; (2) adding an alkaline water solution and an oxidant into effluent liquid of step (1); reacting for 2 to 12h under the action of a loading type oxidization catalyst and under the conditions of 60 to 110 DEG C and 0.1 to 1MPa; (3) evaporating the effluent liquid of step (2) to remove a solvent; then adding an acidifying agent and adjusting the pH (Potential of Hydrogen) to be less than 2; precipitating to obtain a furandicarboxylic acid crude product; filtering, washing and recrystallizing to obtain the furandicarboxylic acid. The invention further discloses a system for continuously synthesizing the furandicarboxylic acid. According tothe method disclosed by the invention, an intermediate 5-hydroxymethylfurfural does not need to be separated and purified and the furandicarboxylic acid is synthesized in a high-yield manner under moderate conditions; the method can be continuously operated and has an important application prospect.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com