Nickel-based catalyst and its preparation method and use in 5-hydroxymethylfurfural hydrogenation

A nickel-based catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as restricting development, and achieve easy operation and preparation methods. Simple, highly active and selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

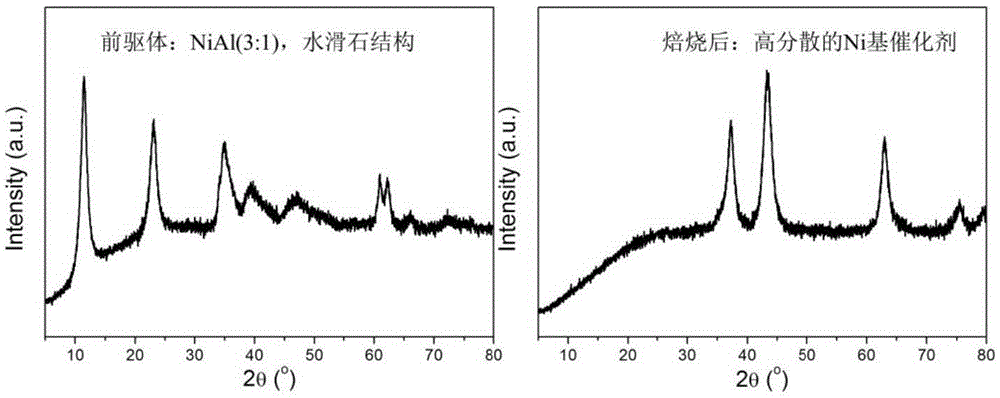

[0041] Example 1. Using hydrotalcite as a precursor to prepare NiAl(3:1) catalyst to catalyze the production of 2,5-dimethylfuran from 5-hydroxymethylfurfural

[0042] Preparation of NiAl(3:1) catalyst: weigh 109.0gNi(NO 3 ) 2 ·6H 2 O and 46.89gAl(NO 3 ) 3 9H 2 O is completely dissolved in 500ml of water; weigh 26.5gNa 2 CO 3and 70g NaOH were completely dissolved in 1L of water; the two mixtures were slowly added dropwise to 200ml mother liquor at the same time, vigorously stirred, and the pH was maintained at 10. After the addition, the obtained colloidal suspension was aged at 63°C for 18h; Washing with ionized water, drying, and roasting at 850°C for 4 hours, the intermediate product obtained is a highly dispersed NiAl (3:1) catalyst prepared from hydrotalcite as a precursor, and then the intermediate product is reduced in a hydrogen atmosphere, and the flow rate of hydrogen is 140ml / min, the heating rate from room temperature to the reduction reaction temperature o...

Embodiment 2

[0053] Example 2. Using hydrotalcite as a precursor to prepare a NiAl (3:1) catalyst to catalyze the production of 2,5-dimethyltetrahydrofuran from 5-hydroxymethylfurfural.

[0054] The preparation of NiAl (3:1) catalyst is the same as embodiment 1.

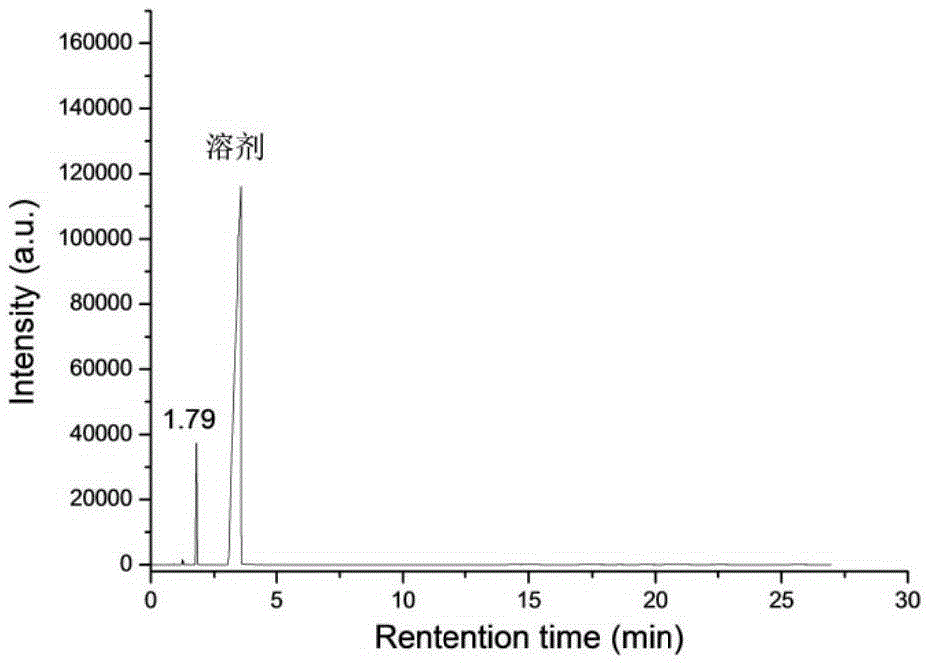

[0055] The experimental conditions are: the mass ratio of catalyst and raw material is 1:15, the reaction temperature is 180°C, the reaction pressure is 1.5MPa, and the reaction time is 20h. The product was analyzed by gas chromatography, the detector was FID, and the chromatographic column was J&WDB-WAX. The conversion rate and product selectivity were analyzed by the corrected area normalization method. The conversion rate of 5-hydroxymethylfurfural was about 100%, and the selectivity of 2,5-dimethyltetrahydrofuran furan was 97.4%, as shown in Table 1. Gas chromatographic results of the product after the reaction, such as Figure 4 .

[0056] Example 1 and Example 2 use the same catalyst NiAl (3:1), realize the selective mod...

Embodiment 3

[0060] Example 3. Using hydrotalcite as a precursor to prepare a NiAl (2:1) catalyst to catalyze the production of 2,5-dimethyltetrahydrofuran from 5-hydroxymethylfurfural.

[0061] Preparation of NiAl(2:1) catalyst: weigh 96.9gNi(NO 3 ) 2 ·6H 2 O and 62.52gAl(NO 3 ) 3 9H 2 O is completely dissolved in 500ml of water; weigh 26.5gNa 2 CO 3 and 70g NaOH were completely dissolved in 1L of water; the two mixtures were slowly added dropwise to 200ml mother liquor at the same time, vigorously stirred, and the pH was maintained at 10. After the addition, the obtained colloidal suspension was aged at 63°C for 18h; Washing with ion water, drying, and calcination at 600°C for 4 hours, the intermediate product is a highly dispersed NiAl(2:1) catalyst prepared with hydrotalcite as the precursor. Then reduce the intermediate product in a hydrogen atmosphere, the flow rate of hydrogen is 140ml / min, the heating rate from room temperature to the reduction reaction temperature of 250°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com